Page 1

K

Service Source

Envelope Feeder

LaserWriter Pro 600/630 Envelope Feeder

LaserWriter 16/600 PS Envelope Feeder

Page 2

K

Service Source

Basics

Envelope Feeder

Page 3

Basics About This Manual - 1

About This Manual

This manual covers the Take

Apart, Additional Procedures, and Adjustments for

the sheet feeder. Refer to

the main printer manuals

for all other information.

Envelope Feeder

Page 4

Basics Compatibility - 2

Compatibility

The LaserWriter Pro 600/630 envelope feeder is

compatible only with the Pro 600/630 printer. However,

you may use the LaserWriter 16/600 PS envelope feeder

with either the Pro 600/630 or 16/600 printers.

You can tell the two feeders apart in three distinct ways:

1 By carefully inspecting the pickup rollers and shafts:

The LaserWriter Pro 600/630 model has a two-piece

roller/shaft construction. The LaserWriter 16/600 PS

model has a one-piece roller/shaft construction.

Page 5

Basics Compatibility - 3

2 By comparing controller board serial numbers: The

LaserWriter Pro 600/630 envelope feeder controller

board has the vendor number "RG5-0576" imprinted at

the end of the board. The LaserWriter 16/600 PS

envelope feeder controller board bears the number

"RG1-3437."

3 By comparing serial numbers: Numbers starting with

JXC00001 denote feeders for use only with the Pro

600/630. Numbers starting with LBK00001 denote

feeders for use on both generations of printer.

Page 6

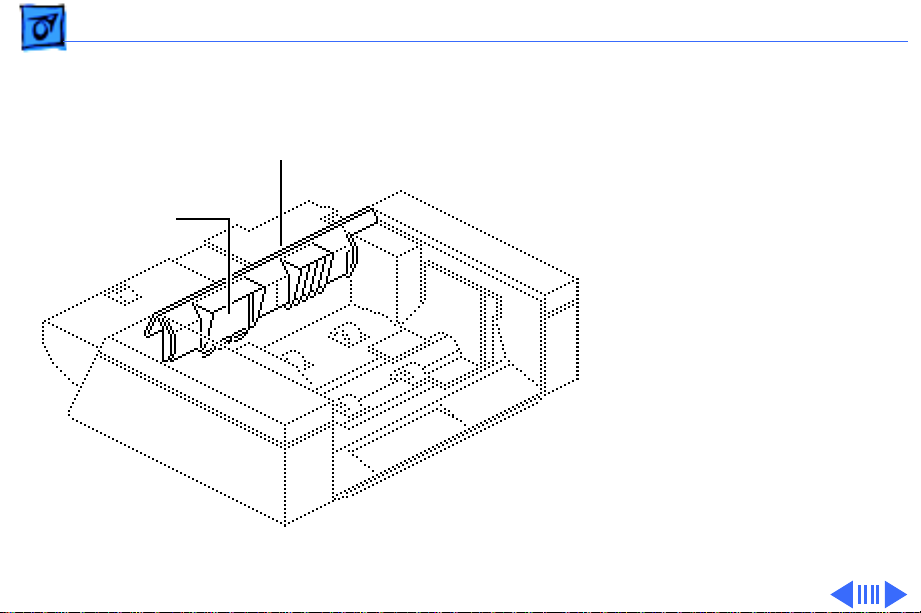

Basics Slip Torque Rollers - 4

Slip Torque

1/4" ±

Shaft

Roller or Gear

Rollers

Slip torque rollers and gears

are ratcheted torquelimiting gears that use

bearings instead of teeth to

govern rotation:

Page 7

Basics Slip Torque Rollers - 5

Primary Feed Roller:

This roller acts independently of the shaft when the roller is

rotated in reverse, thus permitting free removal of jams.

Separation Drive Assembly:

The gearing at the end of the separation assembly is

comprised of one passive gear and two slip torque gears.

This assembly results in counter-rotation of the separation

rollers, regardless of the drive direction of the gear train.

Pickup Roller Shafts:

The two gears that mesh with the transfer drive assembly

are slip torque gears.

Page 8

K

Service Source

T ak e Apart

Envelope Feeder

Page 9

Take Apart Envelope Weight - 1

Envelope Weight

No preliminary steps are

Envelope Weight

required before you begin

this procedure.

1 Pull one of the arms out

of the pin and lift out the

weight.

Page 10

Take Apart Left Cover - 2

Left Cover

Before you begin, remove

the envelope weight.

Left Cover

Page 11

Take Apart Left Cover - 3

Note:

Two hidden flex tabs

on the bottom and two posts

at the top attach the left

cover to the feeder.

1 Turn over the envelope

Bottom

feeder.

2 Using a small flat-blade

screwdriver, pry the

two hidden tabs in the

order shown and remove

the left cover.

Left Cover

Bottom

Page 12

Take Apart Right Cover - 4

Right Cover

Right Cover

Before you begin, remove

the envelope weight.

Page 13

Take Apart Right Cover - 5

Note:

Two hidden flex tabs

on the bottom and two posts

at the top attach the right

Bottom

cover to the feeder.

1 Turn over the envelope

feeder.

2 Using a small flat-blade

screwdriver, pry the

two hidden tabs in the

Right Cover

Bottom

order shown and remove

the right cover.

Page 14

Take Apart Front Cover - 6

Front Cover

Front Cover

Before you begin, remove

the following:

• Envelope weight

• Left cover

• Right cover

Note:

If you remove the

separation guide plate from

the front cover, you will

have to adjust the gap

between the separation guide

plate and the primary feed

roller. See "Separation

Guide Opening" in

Adjustments.

Page 15

Take Apart Front Cover - 7

Flex Tab

1 Remove the screw that

secures the grounding

cable that runs from the

front cover (not shown).

2

Note:

This graphic

shows the flex tab

connector at the left side

of the feed opening.

Release the two flex tab

connectors at each side of

the feed opening and pull

out the front cover.

Page 16

Take Apart Bottom Cover - 8

Bottom Cover

Before you begin, remove

the following:

• Envelope weight

• Left cover

• Right cover

1 Remove the four screws

and lift off the bottom

cover.

Bottom Cover

Page 17

Take Apart Motor - 9

Motor

Before you begin, remove

the following:

• Envelope weight

• Left cover

• Right cover

• Bottom cover

1 Disconnect cable J932

from the controller

board and remove the

cable from the retaining

channel in the feeder.

2 Remove the two screws

and lift the motor from

Motor

the feeder.

Page 18

Take Apart Sensing Arm - 10

Sensing Arm

Before you begin, remove

Sensing Arm

the following:

• Envelope weight

• Left cover

• Right cover

• Bottom cover

Page 19

Take Apart Sensing Arm - 11

1 Slide out the tray

extension, snap the

sensing arm out of the

Sensing Arm

collar grip, and lift the

arm out of the feeder.

Sensing Arm Spring

Replacement Note:

Be sure

to install the spring at the

end of the sensing arm as

shown in the diagram.

Confirm arm installation by

tripping the lever end of the

arm at the controller

board. The lever should

rotate freely through a 45°

arc.

Page 20

Take Apart Controller Board - 12

Controller Board

Before you begin, remove

Controller Board

the following:

• Envelope weight

• Left cover

• Right cover

• Bottom cover

Note:

See "Circuit Board

Diagrams" in Basics in the

LaserWriter Pro manual for

layout of board.

Page 21

Take Apart Controller Board - 13

1 Disconnect the two cables from the controller board.

2 Snap the sensing arm out of the collar grip and raise the

arm above the edge of the board.

3 Remove the screw in the bottom left corner of the board,

pull the board off the two positioning pins, and remove

the board from the feeder.

Page 22

Take Apart Printer Interface Cable - 14

Printer Interface

Printer Interface Cable

J136

Cable

Before you begin, remove

the following:

• Envelope weight

• Left cover

• Right cover

• Bottom cover

Page 23

Take Apart Printer Interface Cable - 15

1 Remove the two screws that secure the green ground

wire and the ferrite core to the mounting bracket.

Replacement Note:

is the 3/8 inch (100 mm) black washer-head screw.

2 Disconnect J931 from the controller board and free the

cable from the clamp.

3 Open the ferrite core and remove the cables from it.

4 Release the expansion posts behind the receptacle and

remove the interface cable from the feeder.

The screw securing the ferrite core

Page 24

Take Apart Pickup Rollers - 16

Pickup Rollers

Before you begin, remove

the following:

• Envelope weight

• Left cover

• Right cover

• Bottom cover

Rear Pickup Rollers

Forward Pickup Rollers

Page 25

Take Apart Pickup Rollers - 17

Note:

The removal procedure is identical for both the rear

and forward pickup rollers. The pickup rollers are

independent of the shafts and are available separately.

Because the envelope feeder draws from the bottom of a stack

of envelopes instead of from the top, the pickup rollers don't

operate against gravity and consequently don't look like

conventional pickup rollers. They do, however, perform the

same function.

1 Pull out the tray extension.

Page 26

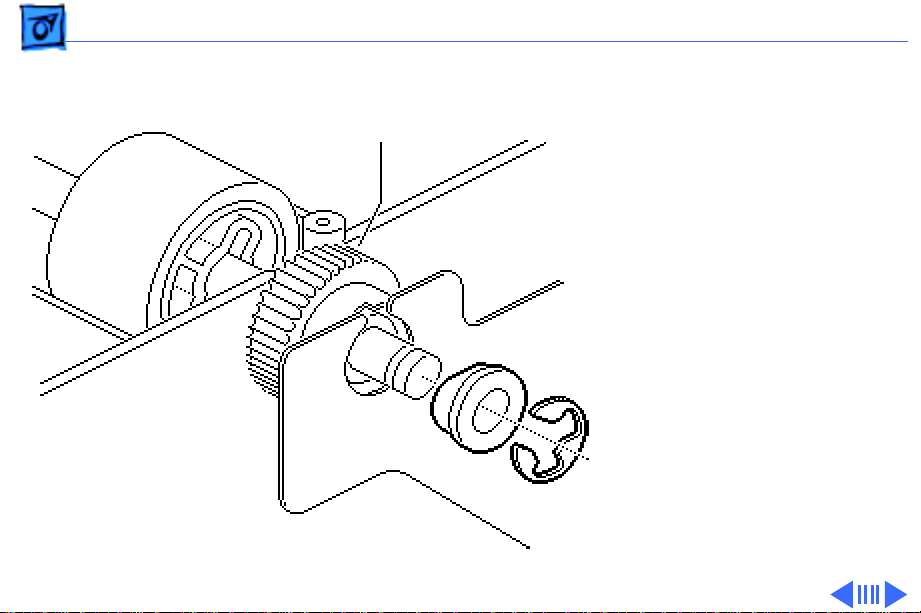

Take Apart Pickup Rollers - 18

2 Remove the E-ring from

Pickup Roller

Pickup Roller Gear

the end of the shaft and

slide the bushing from

the drive assembly plate

off the end of the shaft.

Bushing

E-Ring

Page 27

Take Apart Pickup Rollers - 19

1

2

3

Pickup Roller Gear

3 Raise the pickup roller

shaft slightly, push it

about 1/4 inch inward to

clear the bushing at the

opposite end, and remove

the shaft from the

feeder.

4 Slide the gear off the

shaft.

Note:

If you are removing

the leftmost pickup roller

from a LaserWriter Pro

600/630 envelope feeder,

remove the E-ring and

bushing on that end (not

shown here).

Page 28

Take Apart Pickup Rollers - 20

Note:

The LaserWriter 16/600 PS envelope feeder features

a one-piece pickup roller/shaft construction, so the step on

the previous page concludes the pickup roller topic. If you

are servicing a LaserWriter Pro 600/630 envelope feeder,

proceed to the steps on the following pages.

Page 29

Take Apart Pickup Rollers - 21

Note:

Steps 5 and 6 describe removal of a single roller. If

you want to remove the middle roller, repeat these steps.

5

Caution:

drops when the roller slides away.

Using your fingernails or a small jeweler's

screwdriver, release the two flex tabs, and slide the

roller off the dowel.

The dowel pin on the opposite side of the rollers

Page 30

Take Apart Pickup Rollers - 22

6 Slip the roller off the

end of the shaft, and

release the tabs at the

shaft grooves as

necessary.

Shaft Groove

Replacement Note:

The

smaller rollers and gear go

on the forward shaft and the

larger ones go on the rear.

Page 31

Take Apart Transfer Drive Assembly - 23

Transfer Drive Assembly

Before you begin, remove

the following:

• Envelope weight

• Left cover

• Right cover

• Bottom cover

• Motor

Note:

This assembly

receives rotational drive

directly from the motor and

transfers it to the pickup

and main feed shafts.

Transfer Drive Assembly

Page 32

Take Apart Transfer Drive Assembly - 24

1 Remove the E-rings and bushings at the end of the three

roller shafts.

2 Remove the three screws that secure the transfer drive

assembly to the feeder body.

3 Lift the transfer drive assembly from the feeder.

Page 33

Take Apart Separation Drive Assembly - 25

Separation Drive

Separation Drive Assembly

Assembly

Before you begin, remove

the following:

• Envelope weight

• Left cover

• Right cover

• Bottom cover

• Controller board

Page 34

Take Apart Separation Drive Assembly - 26

Note:

The separation drive assembly receives rotational

drive through the primary feed shaft. The assembly then

transfers drive through three variable action gears to the

separation assembly and secondary feed roller.

Page 35

Take Apart Separation Drive Assembly - 27

1 Remove the E-rings and bushings at the end of the three

roller shafts and the two screws that secure the drive

assembly to the feeder body.

2 Pull the assembly away from the feeder body.

Note:

Stop here if you are removing the roller shaft or

roller gear.

3 If you are replacing either of the two gears within the

assembly, you can release the gear's tab and slide it off

the spindle now.

4 If you are replacing a defective separation drive

assembly, remove the two screws securing the ground

and the ferrite core and detach the assembly from the

feeder.

Replacement Note:

integrity at this point before completing feeder reassembly.

It is a good idea to confirm drive train

Page 36

Take Apart Separation Drive Assembly - 28

Place your fingertips on the primary feed roller and rotate

it counter to paper flow. All gears and rollers within the

envelope feeder should rotate freely. (The motor must be

removed from the transfer drive assembly to decrease the

torque.) If the rollers do not rotate, make sure that all

gears and shafts are seated correctly.

Page 37

Take Apart Primary Feed Roller - 29

Primary Feed Roller

Primary Feed Roller

Before you begin, remove

the following:

• Envelope weight

• Left cover

• Right cover

• Bottom cover

• Controller board

• Separation drive

assembly

Page 38

Take Apart Primary Feed Roller - 30

Note:

The primary feed roller is the 2-inch wide roller

visible at the bottom of the three-pronged paper guide. The

primary feed shaft is responsible for tranferring drive

across the width of the feeder to the separation drive

assembly.

Page 39

Take Apart Primary Feed Roller - 31

1 Slide the primary feed shaft about an inch away from the

motor side of the feeder and let the gear at that end drop

free.

2 Raise the shaft a short distance and slide the shaft back

and out the motor side of the feeder. Catch the gear on the

opposite end as it falls off the shaft.

Page 40

Take Apart Primary Feed Roller - 32

3

Note:

The primary feed roller has a pinless connection

(see "Slip Torque Rollers" in Basics). The roller is

secured laterally by small tabs that snag the groove in

the metal shaft.

Hold the shaft upright with the roller on the high end.

4 Using your fingernails, release the two small tabs and

slide the roller off the shaft.

Page 41

Take Apart Secondary Feed Roller - 33

Secondary Feed Roller

Before you begin, remove

Secondary Feed Roller

the following:

• Envelope weight

• Left cover

• Right cover

• Bottom cover

• Controller board

• Separation drive

assembly

Note:

Due to the solid shaft/

roller design, rollers cannot

be ordered separately.

Page 42

Take Apart Secondary Feed Roller - 34

1 Remove the E-ring and bushing at the end of the shaft

near the motor and slide the shaft out of the positioning

hole.

2 Raise the shaft a short distance and slide the shaft back

and out the motor side of the feeder. Catch the gear on the

opposite end as it falls off the shaft.

Page 43

K

Service Source

Exploded V ie w

Envelope Feeder

Page 44

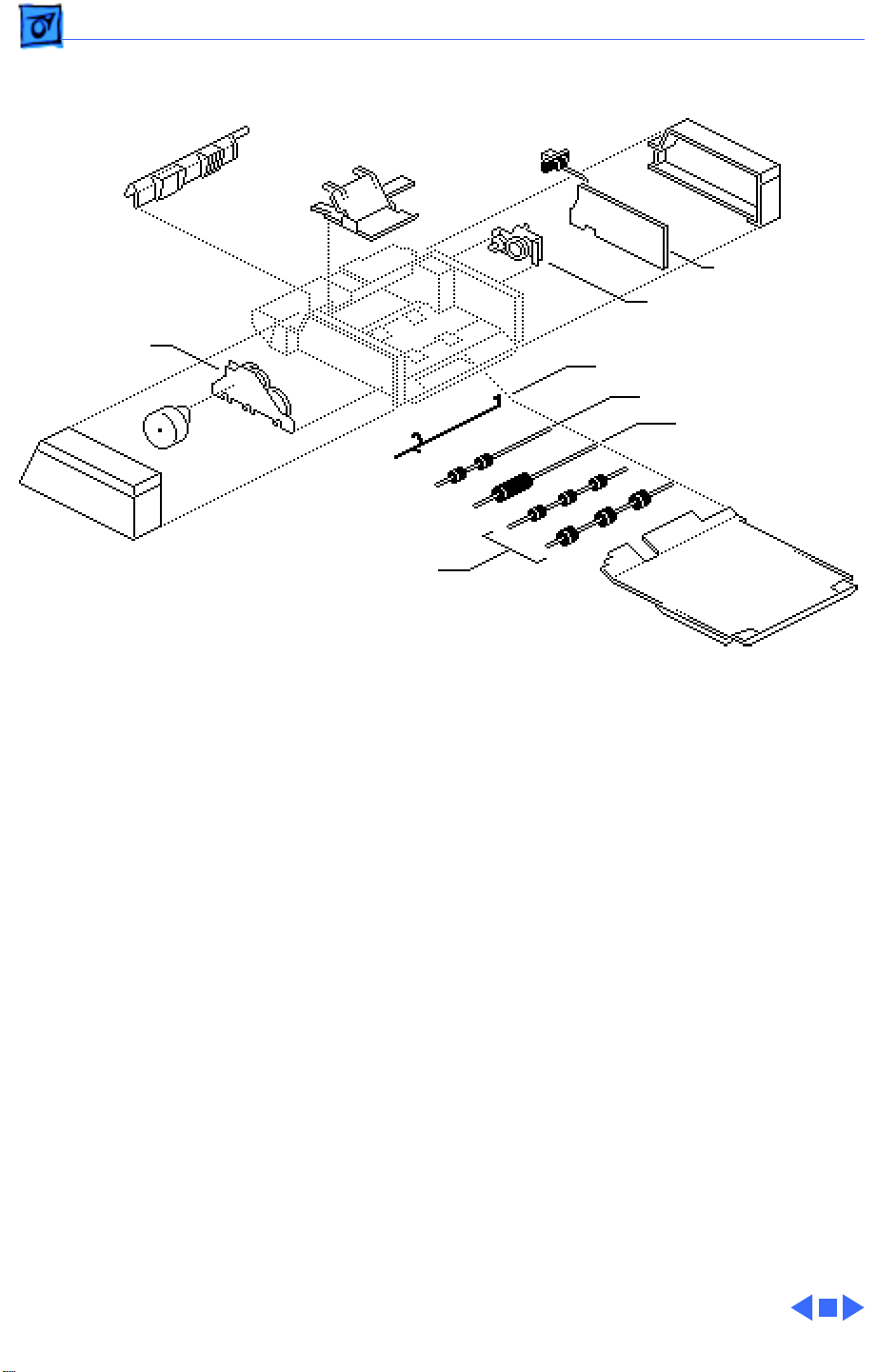

Exploded View 1

Exploded View

Front Cover

Transfer Drive

Assembly

Left Cover

Motor

Envelope

Weight

Pickup Rollers

Printer

Interface

Cable

Right Cover

Controller Board

Separation Drive

Assembly

Sensing Arm

Secondary Feed Roller

Primary Feed Roller

Bottom Cover

Page 45

K

Service Source

Additional Procedures

Envelope Feeder

Page 46

Additional Procedures Expansion Post Connectors - 1

Expansion Post Connectors

Note:

This printer has

several cable receptacles

that are secured to the

Cross Section

Fin

Expansion Post

Connector

Fin

printer by finned post

connectors. The fins expand

when you insert the

connector, but once the

connector is installed it can

be difficult to remove.

Listed on the next page are

some removal tools that you

can try.

Page 47

Additional Procedures Expansion Post Connectors - 2

• Fingers

• Small bent-nose pliers

• Grip-rings forced around the post in collar fashion

• 5 mm nut driver

Page 48

K

Service Source

Adjustments

Envelope Feeder

Page 49

Adjustments Separation Guide Opening - 1

Separation Guide

Separation Guide

Opening

Front Cover

Opening

Note:

If you have removed

the separation guide plate

from the front cover, you

must adjust the gap between

the separation guide plate

and the primary feed roller.

Page 50

Adjustments Separation Guide Opening - 2

1 Loosen the screw that

secures the guide plate to

the front cover.

2 Insert a 1 mm and 0.5

mm thickness gauge

Separation

Guide Plate

between the guide plate

and the primary feed

roller.

3 Tighten the screw.

Thickness Gauges

1.5 mm

Primary Feed Roller

Loading...

Loading...