Apple Laserwriter Ii Service Manual

K Service Source

LaserWriter II

LaserWriter II SC, LaserWriter II NT, LaserWriter II NTX, LaserWriter IIf, LaserWriter IIg

K Service Source

Basics

LaserWriter II

Basics |

Product Information - 1 |

|

|

Product Information

The printers covered in this manual are

• LaserWriter II SC

• LaserWriter II NT

• LaserWriter II NTX

• LaserWriter IIf

• LaserWriter IIg

Compatibility:

Except for I/O boards components, all parts are compatible among the five models. Refer to Illustrated Parts and Take Apart chapters for more information. Refer to “Print Engine Check” in Flowcharts for Troubleshooting information.

Basics |

Startup Test Page - 2 |

|

|

Startup Test Page

LaserWriter II printers generate a startup test page approximately 2 – 3 minutes after you switch on the printer.

Except for the IISC, the startup test page also shows unit-specific configuration information. The following pages describe each element of the startup test page.

Basics |

|

Startup Test Page - 3 |

|

|

|

|

|

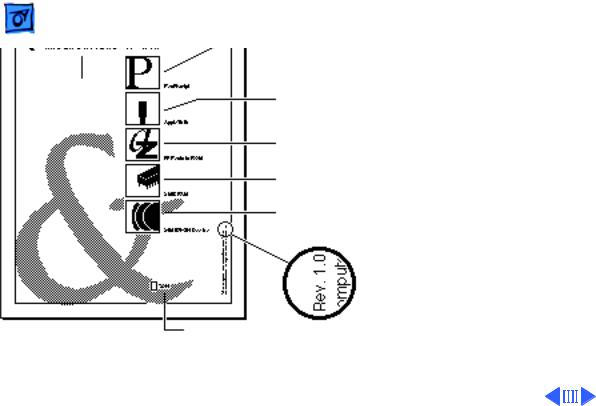

II NT/NTX Startup Test Page |

|

Printer |

|

|

Name |

Configuration |

|

|

|

|

|

PostScript, Diablo 630, or Hewlett Packard |

|

|

LaserJet Plus™ emulation (NTX only) |

I/O Board |

|

Communication Protocol |

Type |

|

RS-232 serial or AppleTalk

Fonts in ROM

Installed RAM

Size of hard drive, if connected, and number of fonts it contains (NTX only)

Version of ROM installed

Number of pages the I/O board has produced

Basics |

Startup Test Page - 4 |

|

|

Printer

IIf Startup Test Page

Name

I/O Board

Type

Communication parameters and printer control language selected for an individual printer port

Version of ROM installed

Fonts in ROM

Installed RAM

FinePrint feature enabled

Number of pages the I/O board has produced

Basics |

Startup Test Page - 5 |

|

|

Printer

IIg Startup Test Page

Name

I/O Board

Type

Communication parameters and printer control language selected for an individual printer port

Version of ROM installed

Fonts in ROM

Installed RAM

FinePrint feature enabled

Number of pages the I/O board has produced

Basics |

Startup Test Page - 6 |

|

|

|

IISC Startup Test Page |

The LaserWriter IISC test page consists only of vertical lines. The printer will generate a test page only if its SCSI address has been set to 7 prior to powering up.

Note: Be sure to set the SCSI address back before you resume printing.

Basics |

Service Test Page - 7 |

|

|

Service Test Page

The service test page is generated by the DC controller board and serves to confirm print engine operation. To generate this test page, remove the bottom panel cap located at the rear of the printer. Insert a screwdriver or similar dowel-shaped tool through the quarter inch diameter opening and press the service test page button.

Basics |

Preventive Maintenance - 8 |

|

|

Preventive Maintenance

Before performing any preventive maintenance, be sure to do the following:

1Check the page count on the startup test. If the I/O board has been replaced or upgraded, check the repair log label affixed to the bottom of the printer or consult with the customer to determine page count.

2Power off and unplug the printer.

3Allow the fuser assembly rollers to cool.

4Prepare your work area for electrostatic discharge prevention.

5Spread a drop cloth under the work area to protect the floor from grease and spilled toner.

Caution: Never use an ammonia-based cleaner on the

Basics Preventive Maintenance - 9

LaserWriter II. These cleaners can discolor the plastic.

Caution: Before servicing the fuser rollers, make sure that the printer has been off at least 5 minutes to allow the fuser assembly to cool.

The service provider should clean the following items every 12 months or during each service call.

|

|

Service Point |

Tool/Solvent |

|

|

Primary corona wire |

Cleaning brush supplied with |

|

printer |

|

|

Transfer corona wire |

Cotton swab and isopropyl |

|

alcohol |

|

|

Transfer guide |

Cloth dampened with water |

|

|

Fuser rollers |

Fuser cleaning pad |

|

|

Basics |

Preventive Maintenance - 10 |

||||

|

|

|

|

||

|

|

|

|

||

|

Service Point |

Tool/Solvent |

|

||

|

|

|

|

||

|

Exterior case |

Cloth dampened with water |

|

||

|

|

|

|

||

|

Separation claws |

Cloth dampened with alcohol |

|

||

|

|

|

|

||

|

Paper guide |

Cloth dampened with alcohol |

|

||

|

|

|

|

||

|

Lower delivery guide |

Cloth dampened with alcohol |

|

||

|

|

|

|

||

|

Feeder guide |

Cloth dampened with water |

|

||

|

|

|

|

||

|

Registration rollers |

Cloth dampened with water |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Basics Parts Replacement Schedule - 11

Basics Parts Replacement Schedule - 11

Parts Replacement Schedule

Perform the following tasks every 50,000 prints:

• Replace the ozone filter

• Check upper and lower fan operation.

Replace the following parts every 100,000 prints:

• Fuser assembly

• Transfer guide assembly

• Preconditioning exposure assembly

• Paper feed roller assembly

• Transfer corona assembly

The LaserWriter II refurbishment kit (P/N 652-0597) contains one each of the parts listed above.

K Service Source

Specifications

LaserWriter II

Specifications |

General - 2 |

|

|

|

|

Engine

Printing Method

Optical System

Resolution

Imaging Languages

Supported

General

Canon SX engine

Electrophotography using single-component, dry toner

Semiconductor laser and a rotating six-faced prism scanning mirror

300 dpi

SC: QuickDraw

NT: PostScript and a subset of the Diablo 630 printer NTX/NTX-J: PostScript, a subset of the Diablo 630 printer, and a

subset of the Hewlett-Packard LaserJet Plus

Specifications |

General - 3 |

|||

|

|

|

||

|

f/g: PostScript Level 1 and 2 and HP LaserJet IIP (HP PCL4) |

|||

|

Note: NTX-J does not support emulation mode. |

|||

|

|

|

|

|

|

|

|

|

|

Specifications |

Intro Dates - 4 |

|

|

|

|

Intro Dates

SC, NT, and NTX

IIf and IIg

July 1990

October 1991

Specifications Logic Board - 5

Specifications Logic Board - 5

|

Logic Board |

CPU |

SC: Motorola 68000 microprocessor (7.45 MHz) |

|

NT: Motorola 68000 microprocessor (11.16 MHz) |

|

NTX/NTX-J: Motorola 68020 microprocessor (16.67 MHz) |

|

f: Motorola 68030 microprocessor (20.0 MHz) |

|

g: Motorola 68030 microprocessor (25.0 MHz) |

DRAM |

SC: 1 MB |

|

NT: 2 MB |

|

NTX: 2 MB, expandable to 12 MB |

|

NTX-J: 4 MB, expandable to 12 MB |

|

f: 2 MB/5MB, expandable to 32 MB |

|

g: 5 MB/8MB, expandable to 32 MB |

|

Specifications |

Logic Board - 6 |

|||

|

|

|

|

||

ROM |

SC: 16 KB |

||||

|

|

NT: 1 MB |

|||

|

|

NTX/NTX-J: 1 MB, expandable to 8 MB on expansion board |

|||

|

|

f: 2 MB standard; ROM expansion slot provided |

|||

|

|

g: 2 MB standard; ROM expansion slot provided |

|||

I/O |

SC: SCSI, Apple Desktop Bus (ADB) |

||||

|

|

NT: RS-232/422, LocalTalk, ADB |

|||

|

|

NTX/NTX-J: RS-232/422, LocalTalk, SCSI, ADB |

|||

|

|

f: RS-232/422; LocalTalk; SCSI |

|||

|

|

g: RS-232/422; LocalTalk; SCSI; Ethernet |

|||

|

|

|

|

|

|

|

|

|

|

|

|

Specifications |

Performance - 7 |

|

|

|

|

Performance

Printing Speed

8 pages per minute (all paper sizes except legal)

7 pages per minute (legal size)

Note: Actual performance depends on the application.

Duty Cycle

Minimum Life

Expectancy

Major Service

Interval

No limit in pages per month

300,000 pages

100,000 copies

|

Specifications |

|

Performance - 8 |

|

|

|

|

|

|

Printable Area |

All measurements are in inches: |

|||

|

|

SC |

|

|

|

|

US Letter : 8.00 by 10.60 |

||

|

|

Legal: 6.72 by 12.50 |

||

|

|

A4: |

8.00 by 11.27 |

|

|

|

B5: |

6.67 by 9.43 |

|

|

|

#10 Envelopes: 3.84 by 9.10 |

||

|

|

NT, NTX, and NTX-J |

||

|

|

US Letter : 8.00 by 10.78 |

||

|

|

Legal: 8.00 by 13.78 |

||

|

|

A4: |

7.79 by 11.08 |

|

|

|

B5: |

6.45 by 9.76 |

|

|

|

#10 Envelopes: 3.84 by 9.10 |

||

Specifications Performance - 9

IIf

US Letter : 8.11 by 10.79

Legal: 8.00 by 10.78 (Maximum printable area with 2 MB of RAM. Prints up to 8.00 x 13.78 with 5 MB of RAM. Prints up to 8.00 x 13.78 using PhotoGrade with 8 MB of RAM.)

A4: 7.89 by 11.44

B5: 6.72 by 9.81

#10 Envelopes: 3.84 by 9.10

IIg

US Letter : 8.11 by 10.79

Legal: 8.11 by 13.79 (Legal-size documents require 8 MB of

RAM to print with PhotoGrade.)

A4: 7.89 by 11.44

B5: 6.72 by 9.81

#10 Envelopes: 3.84 by 9.10

Specifications |

Paper - 10 |

|

|

|

|

Paper

Paper Weights

Cassette feed:16-24 lb., single-sheet, photocopy bond

Manual feed:16-36 lb., letterhead and colored stock, standardweight transparency material, envelopes, and labels

Cassette Sizes

US letter standard; legal, A4, B5, and envelope cassettes optional

Cassette:200 sheets |

Manual: single sheets |

|

Envelope cassette:15 envelopes |

|

|

Face-down tray:100 sheets |

Face-up tray:20 sheets |

|

Capacity In

Use manual feed for letterhead, colored stock, standard-weight transparency material, and labels.

Specifications |

Built-In Fonts - 11 |

|

|

|

|

SC

NT, NTX, NTX-J

IIf, IIg

Built-In Fonts

Times, Helvetica, Courier, and Symbol

Times, Helvetica, Helvetica Narrow, Courier, Symbol, Palatino, ITC Avant Garde, ITC Bookman, New Century Schoolbook, ITC Zapf Chancery, and ITC Zapf Dingbats

Times, Helvetica, Helvetica Narrow, Courier, Symbol, Palatino, ITC Avant Garde, ITC Bookman, New Century Schoolbook, ITC Zapf Chancery, ITC Zapf Dingbats, and Emulator.

Note: Built-in fonts can be expanded using an optional font expansion board. All LaserWriter II printers support TrueType when using LaserWriter driver 6.1 or greater.

Specifications |

Environmental - 12 |

|

|

|

|

Environmental

Temperature

Humidity

Operating: 50–90.5°F (10–33°C)

Storage:38–95° F (3–35°C)

Operating: 20-80% relative humidity Storage: 10-80% relative humidity

Printing: Under 60 dB(A)

Standby: Under 50 dB(A)

Specifications |

Electrical - 13 |

|

|

|

|

Line Voltage

Power Consumption

Electrical

US/Japan:100-115 V, 50-60 Hz

Europe/Australia:220-240 V, 50 Hz

Standby:

170 W (average)

Operating:

900 W maximum (115 V)

780 W maximum (220 V)

880 W maximum (240 V)

|

Specifications |

Physical - 14 |

|||

|

|

|

|

||

|

|

Physical |

|||

Dimensions |

Width: 20 in. (51 cm) |

||||

|

|

Depth: 18.9 in. (48 cm) |

|||

|

|

Height: 8.5 in. (21.6 cm) |

|||

Weight |

46 lb. (21 kg) |

||||

|

|

|

|

|

|

|

|

|

|

|

|

K Service Source

Troubleshooting

LaserWriter II

Troubleshooting |

IIf/IIg Diagnostic/ - 1 |

|

|

|

|

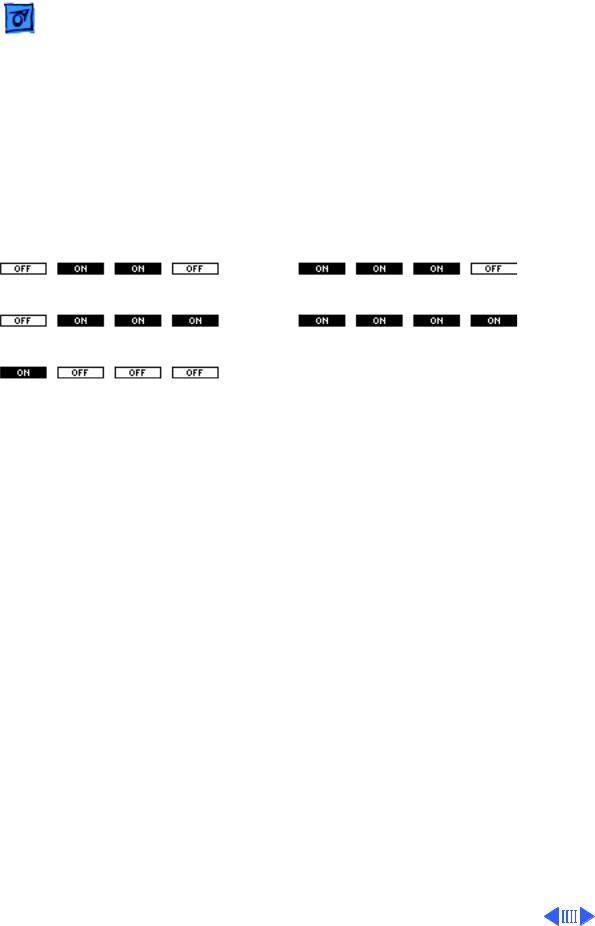

IIf/IIg Diagnostic

Set the rotary switch on the back of the printer to 4 and connect the LaserWriter II Test Connector to the DB-25 serial port (or simply jumper pins 4 and 22). Switch on the printer. Under normal conditions, LEDs should flash during startup, and then fix on the “diagnostic executing” configuration for about 2 minutes. If no error is found, all LEDs flash and a page prints. If the LEDs indicate an error, go to the appropriate topic in Flowcharts.

(Diagnostic Executing) |

(No Error Found) |

Fuser Assembly Error |

Replace SIMM #2 |

Laser/Scanner Error |

Replace SIMM #3 |

I/O Controller Board Error |

Replace SIMM #4 |

Replace ROM #1 |

Replace SIMM #5 |

Replace ROM #2 |

Replace SIMM #6 |

Replace ROM #3 |

Replace SIMM #7 |

Replace ROM #4 |

Replace SIMM #8 |

Replace SIMM #1 |

|

After running this diagnostic, switch off the printer, remove the Test Connector, and reset the rotary switch to its original setting.

Troubleshooting |

Capacitor Discharge - 2 |

|

|

Capacitor Discharge

When there is a failure of the fusing system, the DC controller board shuts off current to the fuser roller heater and charges capacitor C211 to prevent overheating. If there is a failure of the fusing system, you must turn the power off for about 30 minutes or manually discharge the capacitor before switching power back on.

C211

DC Controller Board

Loading...

Loading...