A. O. Smith DEL-10 Installation Manual

MODELS DEN AND DEL

COMMERCIAL ELECTRIC WATER HEATERS

• Installation |

• Electrical |

• Wiring Diagrams |

• Replacement Parts |

• Operation |

• Maintenance |

• Leakage Checkpoints |

• Limited Warranty |

A DIVISION OF A. O. SMITH CORPORATION

McBee, South Carolina, USA

www.hotwater.com

CAUTION

CAUTION

TEXT PRINTED OR OUTLINED IN RED CONTAINS INFORMATION RELATIVE TO YOUR SAFETY.

PLEASE READ THOROUGHLY BEFORE INSTALLING AND USING THIS APPLIANCE.

PLACE THESE INSTRUCTIONS ADJACENT TO HEATER AND NOTIFY OWNER TO KEEP FOR FUTURE REFERENCE.

Printed 0607 |

195201-003 |

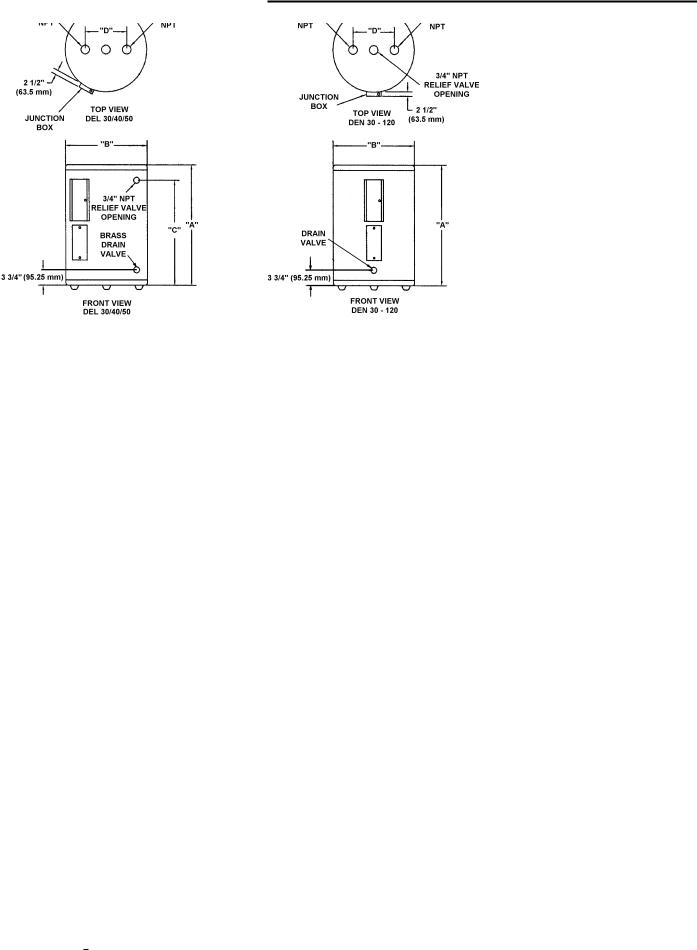

ROUGH-IN DIMENSIONS

ROUGH-IN DIMENSIONS

Models |

No. of |

Tank Capacity |

|

A |

|

B |

C |

|

D |

|

Shipping Weight. |

Approx |

|||||

|

|

|

|

|

|||||||||||||

Dimensions |

Elements |

US Gals. |

Litres |

inches |

|

mm |

inches |

|

mm |

inches |

|

mm |

inches |

mm |

Lbs. |

Kg. |

|

DEL-6 |

1 |

6 |

23 |

15 1/2 |

|

394 |

14 1/4 |

|

362 |

11 |

|

279 |

- |

- |

35 |

15.9 |

|

DEL-10 |

1 |

10 |

38 |

18 1/4 |

|

464 |

18 |

|

457 |

12 1/2 |

|

318 |

- |

- |

54 |

24.5 |

|

DEL-15 |

1 |

15 |

57 |

26 |

|

660 |

18 |

|

457 |

20 1/2 |

|

521 |

- |

- |

58 |

26.3 |

|

DEL-20 |

1 |

20 |

76 |

22 1/4 |

|

565 |

21 3/4 |

|

552 |

15 3/8 |

|

391 |

- |

- |

73 |

33.1 |

|

DEL-30 |

2 |

30 |

114 |

30 7/8 |

|

784 |

21 3/4 |

|

552 |

24 1/8 |

|

613 |

8 |

203 |

100 |

45.4 |

|

DEL-40 |

2 |

40 |

151 |

32 1/4 |

|

819 |

24 |

|

610 |

25 9/16 |

|

649 |

8 |

203 |

125 |

56.7 |

|

DEL-50 |

2 |

50 |

189 |

32 1/4 |

|

819 |

26 1/2 |

|

673 |

25 1/8 |

|

638 |

8 |

203 |

166 |

75.3 |

|

DEN-30 |

2 |

30 |

114 |

34 1/2 |

|

876 |

20 1/2 |

|

521 |

- |

|

- |

8 |

203 |

98 |

44.5 |

|

DEN-40 |

2 |

40 |

151 |

45 1/8 |

|

1146 |

20 1/2 |

|

521 |

- |

|

- |

8 |

203 |

113 |

51.3 |

|

DEN-52 |

2 |

50 |

189 |

54 7/8 |

|

1394 |

20 1/2 |

|

521 |

- |

|

- |

8 |

203 |

131 |

59.4 |

|

DEN-66 |

2 |

66 |

250 |

60 3/4 |

|

1543 |

21 3/4 |

|

552 |

- |

|

- |

8 |

203 |

176 |

79.8 |

|

DEN-80 |

2 |

80 |

303 |

59 3/8 |

|

1508 |

24 |

|

610 |

- |

|

- |

8 |

203 |

211 |

95.7 |

|

DEN-120 |

2 |

119 |

450 |

62 7/16 |

|

1586 |

29 3/8 |

|

746 |

- |

|

- |

8 |

203 |

326 |

147.9 |

|

RECOVERY CAPACITIES

Element |

|

|

|

|

|

U.S. Gallons/Hr and Litres/Hr at TEMPERATURE RISE INDICATED |

|

|||||||||

Wattage |

INPUT |

F° |

36F° |

|

40F° |

|

54F° |

60F° |

72F° |

80F° |

90F° |

100F° |

108F° |

120F° |

|

126F° |

(Upper/Lower) |

KW |

C° |

20C° |

|

22.2C° |

|

30C° |

33.3C° |

40C° |

44.4C° |

50C° |

55.5C° |

60C° |

66.6C° |

|

70C° |

NON-SIMULATANEOUS OPERATION |

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

/1500 |

|

GPH |

17 |

15 |

|

11 |

10 |

8 |

8 |

7 |

6 |

6 |

5 |

|

5 |

|

|

1.5 |

LPH |

64 |

58 |

|

43 |

38 |

32 |

29 |

26 |

23 |

21 |

19 |

|

18 |

|

/2000 |

|

GPH |

23 |

20 |

|

15 |

14 |

11 |

10 |

9 |

8 |

8 |

7 |

|

6 |

|

|

2.0 |

LPH |

85 |

77 |

|

57 |

51 |

43 |

38 |

34 |

31 |

28 |

26 |

|

24 |

|

/2500 |

|

GPH |

28 |

25 |

|

19 |

17 |

14 |

13 |

11 |

10 |

9 |

8 |

|

8 |

|

|

2.5 |

LPH |

107 |

96 |

|

71 |

64 |

53 |

48 |

43 |

38 |

36 |

32 |

|

30 |

|

3000/3000 |

|

GPH |

34 |

30 |

|

23 |

20 |

17 |

15 |

14 |

12 |

11 |

10 |

|

10 |

|

|

3.0 |

LPH |

128 |

115 |

|

85 |

77 |

64 |

58 |

51 |

46 |

43 |

38 |

|

37 |

|

4000/4000 |

|

GPH |

45 |

41 |

|

30 |

27 |

23 |

20 |

18 |

16 |

15 |

14 |

|

13 |

|

|

4.0 |

LPH |

170 |

153 |

|

114 |

102 |

85 |

77 |

68 |

61 |

57 |

51 |

|

49 |

|

4500/4500 |

|

GPH |

51 |

46 |

|

34 |

30 |

25 |

23 |

20 |

18 |

17 |

15 |

|

14 |

|

|

4.5 |

LPH |

192 |

173 |

|

128 |

115 |

96 |

86 |

77 |

69 |

64 |

58 |

|

55 |

|

5000/5000 |

|

GPH |

56 |

51 |

|

38 |

34 |

28 |

25 |

23 |

20 |

19 |

17 |

|

16 |

|

|

5.0 |

LPH |

213 |

192 |

|

142 |

128 |

107 |

96 |

85 |

77 |

71 |

64 |

|

61 |

|

6000/6000 |

|

GPH |

68 |

61 |

|

45 |

41 |

34 |

30 |

27 |

24 |

23 |

20 |

|

19 |

|

|

6.0 |

LPH |

256 |

230 |

|

170 |

153 |

128 |

115 |

102 |

92 |

85 |

77 |

|

73 |

|

SIMULATANEOUS OPERATION |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

3000/3000 |

|

GPH |

68 |

|

61 |

|

45 |

41 |

34 |

30 |

27 |

24 |

23 |

20 |

|

19 |

|

6 |

LPH |

256 |

|

230 |

|

170 |

153 |

128 |

115 |

102 |

92 |

85 |

77 |

|

73 |

4000/4000 |

|

GPH |

90 |

|

81 |

|

60 |

54 |

45 |

41 |

36 |

32 |

30 |

27 |

|

26 |

|

8 |

LPH |

341 |

|

307 |

|

227 |

205 |

170 |

153 |

136 |

123 |

114 |

102 |

|

97 |

4500/4500 |

|

GPH |

101 |

|

91 |

|

68 |

61 |

51 |

46 |

41 |

36 |

34 |

30 |

|

29 |

|

9 |

LPH |

384 |

|

345 |

|

256 |

230 |

192 |

173 |

153 |

138 |

128 |

115 |

|

110 |

5000/5000 |

|

GPH |

113 |

|

101 |

|

75 |

68 |

56 |

51 |

45 |

41 |

38 |

34 |

|

32 |

|

10 |

LPH |

426 |

|

384 |

|

284 |

256 |

213 |

192 |

170 |

153 |

142 |

128 |

|

122 |

6000/6000 |

|

GPH |

135 |

|

122 |

|

90 |

81 |

68 |

61 |

54 |

49 |

45 |

41 |

|

39 |

|

12 |

LPH |

511 |

|

460 |

|

341 |

307 |

256 |

230 |

205 |

184 |

170 |

153 |

|

146 |

Recovery capacities at 100° F rise equal: for non-simultaneous element operation = 4.1 gal. x KW of one element; for simultaneous element operation = 4.1 gal. x 2/3 KW of both elements. For other rises multiply element KW as previously explained by 410 and divide by temperature rise. Full load current for single phase = total watts : voltage.

FOREWORD

Thank you for buying this energy efficient water heater from State. We appreciate your confidence in our products. Detailed installation diagrams are in this manual. These diagrams will serve to provide the installer with a reference for the materials and method of piping suggested. IT IS NECESSARY THAT ALL WATER PIPING AND THE ELECTRICAL WIRING BE INSTALLED AND CONNECTED AS SHOWN IN THE DIAGRAMS.

In addition to these instructions, the water heater must be installed in accordance with local codes and the authority having jurisdiction.

GENERAL SAFETY INSTRUCTIONS

BE SURE TO TURN OFF POWER WHEN WORKING ON OR NEAR THE ELECTRICAL SYSTEM OF THE HEATER. NEVER TOUCH ELECTRICAL COMPONENTS WITH WET HANDS OR WHEN STANDING IN WATER. WHEN REPLACING FUSES ALWAYS USE THE CORRECT SIZE FOR THE CIRCUIT.

The principal components of the heater are identified on page 6. The model and rating plate on page 5 interprets certain markings into useful information. Both of these references should be used to identify the heater, its components and optional equipment.

.

WARNING

FOR CALIFORNIA INSTALLATION THIS WATER HEATER MUST BE BRACED, ANCHORED, OR STRAPPED TO AVOID FALLING OR MOVING DURING AN EARTHQUAKE. SEE INSTRUCTIONS FOR CORRECT INSTALLATION AND PROCEDURES. INSTRUCTIONS MAY BE OBTAINED FROM YOUR LOCAL DEALER, WHOLESALER, PUBLIC UTILITIES OR CALIFORNIA’S OFFICE OF STATEARCHITECT, 400 P STREET, SACRAMENTO, CALIFORNIA 95814.

INSULATION BLANKETS

Insulation blankets available to the general public for external use on electric water heaters are not approved for use on your State water heater. The purpose of an insulation blanket is to reduce the standby heat loss encountered with storage tank water heaters. Your State water heater meets or exceeds the National Appliance Energy Act standards with respect to insulation and standby loss requirements, making an insulation blanket unnecessary.

WARNING

WARNING

Should you choose to apply an insulation blanket to this heater, youshouldfollowtheseinstructions(Seepage5foridentificationof components mentioned below). Failure to follow these instructions can result in fire, serious personal injury or death.

•Do not cover the temperature & pressure relief valve.

•Do not cover the instruction manual. Keep it on the side of the water heater or nearby for future reference.

•Do obtain new labels from State Water Heaters for placement on the blanket directly over the existing labels.

EXTENDED NON-USE PERIODS

CAUTION

CAUTION

HYDROGEN GAS CAN BE PRODUCED IN A HOT WATER SYSTEM SERVED BYTHIS HEATER THAT HAS NOT BEEN USED FOR A LONG PERIOD OF TIME (GENERALLY TWO WEEKS OR MORE). HYDROGEN GAS IS EXTREMELY FLAMMABLE. To

reduce the risk of injury under these conditions, it is recommended that the hot water faucet be opened for several minutes at a nearby kitchen sink before using any electrical appliance connected to the hot water system. If hydrogen is present, there will probably be an unusual sound such as air escaping through the pipe as the water begins to flow. THERE SHOULD BE NO SMOKING OR OPEN FLAME NEAR THE FAUCET AT THE TIME IT IS OPENED.

CAUTION

CAUTION

AN ELECTRICAL GROUND IS REQUIRED TO REDUCE RISK OF ELECTRIC SHOCK OR POSSIBLE ELECTROCUTION. THE GROUND SCREW AT THE JUNCTION BOX IS FOR BONDING THE HEATER TO A GROUNDED SERVICE ENTRANCE CONDUCTOR,AGROUNDED SERVICE ENTRANCE RACEWAY, OR AN EARTH GROUNDING ELECTRODE CONDUCTOR.

WARNING

WARNING

FAILURE TO FOLLOW THESE INSTRUCTIONS CAN RESULT IN SERIOUS PERSONAL INJURY OR DEATH.

REQUIRED ABILITY

INSTALLATION OR SERVICE OF THIS WATER HEATER REQUIRES ABILITY EQUIVALENT TO THAT OF A LICENSED TRADESMAN IN THE FIELD INVOLVED. PLUMBING AND ELECTRICAL WORK ARE REQUIRED.

GENERAL

The installation must conform to these instructions, the local code authority having jurisdiction, and the requirements of the power company. In the absence of code requirements follow the current edition of NFPA-70, The National Electrical Code which may be ordered from: National Fire Protection Association, 1 Batterymarch Park, Quincy, MA 02269.

LOCATION

The water heater should be located as close as possible to/or centralized to the water piping system. The water heater should be located in an area not subject to freezing temperatures.

The heater should be located in an area where leakage of the tank or connections will not result in damage to the area adjacent to the heater or to lower floors of the structure.

When such locations cannot be avoided, a suitable drain pan should be installed under the heater.

Such pans should be at least two inches deep, have a minimum length and width of at least two inches greater than the diameter of the heater and should be piped to an adequate drain.

Drain pans suitable for these heaters are available from your distributor or A.O. Smith Water Heater Parts Fulfillment, 125

Southeast Parkway, Franklin, TN 37068.

Water heater life depends upon water quality, water pressure and the environment in which the water heater is installed. Water heaters are sometimes installed in locations where leakage may result in property damage, even with the use of a drain pan piped to a drain. However, unanticipated damage can be reduced or prevented by a leak detector or water shut-off device used in conjunction with a piped drain pan. These devices are available from some plumbing supply wholesalers and retailers, and detect and react to leakage in various ways:

•Sensors mounted in the drain pan that trigger an alarm or turn off the incoming water to the water heater when leakage is detected.

•Sensors mounted in the drain pan that turn off the water supply to the entire home when water is detected in the drain pan.

•Water supply shut-off devices that activate based on the water pressure differential between the cold water and how water pipes connected to the water heater.

•Devices that will turn off the gas supply to a gas water heater while at the same time shutting off its water supply.

CLEARANCES

Aminimum clearance of 4” must be allowed for access to replaceable parts such as thermostats, drain valve and relief valve.

Adequate clearance for servicing this appliance should be considered before installation, such as changing the anodes, etc.

FLOOD WARNING

FLOOD WARNING

IF THE HEATER BECOMES IMMERSED IN WATER UP TO OR ABOVE THE LEVEL OF THE BOTTOM OF THE ELEMENT DOORS, THE HEATER SHOULD BE EXAMINED BY A COMPETENT SERVICE PERSON BEFORE IT IS PLACED IN OPERATION.

CHEMICAL VAPOR CORROSION

Water heater corrosion and component failure can be caused by the heating and breakdown of airborne chemical vapors. Spray can propellants, cleaning solvents, refrigerator and air conditioning refrigerants, swimming pool chemicals, calcium and sodium chloride, waxes, and process chemicals are typical compounds which are potentially corrosive. These materials are corrosive at very low concentration levels with little or no odor to reveal their presence. Products of this sort should not be stored near the heater.

ELECTRICAL (GENERAL)

Check the heater model and rating plate information against the characteristics of the branch circuit electrical supply. DO NOT CONNECT THE HEATER TO AN IMPROPER SOURCE OF ELECTRICITY. Contact the heater supplier for conversion information if necessary.

Voltage applied to the heater should not vary more than +5% to -10% of the model and rating plate marking for satisfactory operation.

DO NOT ENERGIZE THE BRANCH CIRCUIT FOR ANY REASON BEFORE THE HEATER TANK IS FILLED WITH WATER. DOING SO WILL CAUSE THE HEATING ELEMENTS TO BURN OUT.

The factory wiring is attached to a terminal block within the external junction box unit. The branch circuit is connected to the terminal block within this junction box. The water heater should be connected to a separate, grounded, branch circuit with overcurrent protection and disconnect switch. The water heater should be grounded in accordance with national and local codes.

BRANCH CIRCUIT

The branch circuit wire size should be established through reference to the current edition of NFPA-70, the National Electrical Code or other locally approved source in conjunction with the heater amperage rating. For convenience, portions of the wire size tables from the Code are reproduced here. The branch circuit should be sized at 125 percent of the heater rating and further increase wire size as necessary to compensate for voltage drop in long runs.

CALCULATING

AMPERAGE/OVERCURRENT PROTECTION

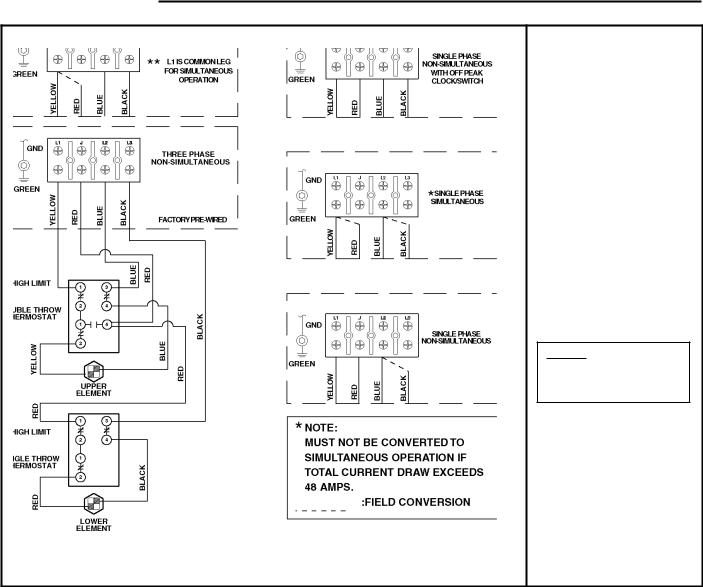

The heaters come from the factory in two configurations:

1.Two wire C-2 circuit for single element heater equipped with a high limit control, single phase power input.

2.Four wire A-8 circuit for dual element heater equipped with two high limit controls, single phase or three phase power input.

The heater with dual elements is factory wired for connection to a three wire, three-phase delta branch circuit, non-simultaneous operation. In addition a ground conductor is required.

Element connection is for non-simultaneous operation. This means only one element at a time operates. The wiring diagram, on page 5, shows the heater may be field converted to simultaneous element operation by moving the red wire on “J” terminal to L1. It is then possible for both elements to operate at once as determined by the thermostats. Regardless of element connection the heater operates in an “unbalanced” fashion.

The heater may be field converted to single-phase operation by moving the wire on L3 of the terminal block to L2. L3 is not used, see page 5.

The heater, now in single-phase non-simultaneous operation, may be field-converted to single phase simultaneous operation by moving the red wire on terminal “J” to L1, see page 5.

This is an example of calculating heater amperage for both types of element operation. From this, the branch circuit conductor and overcurrent protection sizing can be established.

The example is of a three-phase 240 volt unit with two, 6 kw elements. The notations are for units field converted to single-phase. Check the heater model and rating plate for actual specifications and substitute those values in the following.

Non-simultaneous: |

Simultaneous: |

||||

(as factory wired) |

(Field conversion) |

||||

|

|

|

|

|

|

3000 |

: |

240 = 12.5 amps* |

3000 |

: |

240 = 12.5 amps* |

|

|

|

12.5 x 1.73 = 21.6 amps |

||

|

|

|

|

|

|

*NOTE: as a single-phase |

*NOTE: as a single-phase |

||||

non-simultaneous unit. |

simultaneous unit the |

||||

|

|

|

total is: |

||

|

|

|

12.5 x 2 = 25 amps |

||

|

|

|

|

|

|

The rating of the overcurrent protection should be computed on the basis of 125 percent of the total connected load amperage. Where the standard ratings and settings do not correspond with this computation, the next higher standard rating or setting should be selected.

Portion of Table 310-16 (NFPA-70) follows:

Allowable Ampacities of Insulated Copper Conductors. Not more than three conductors in Raceway or Cable or Direct Burial (Based on Ambient Temperature of 30° C, 86° F).

These ampacities relate only to conductors described in Table 310-13 in Code.

For ambient temperatures over 30° C (86° F), see Correction Factors, Note 13 in Code.

For ambient temperatures over 30° C (86° F), see Correction Factors, Note 13 in Code.

Size |

Temperature Rating of Conductor |

|

|

See Table 310-13 in Code |

|

AMG |

60° C |

75° C |

MCM |

(140° F) |

(167° F) |

|

TYPES: |

TYPES: |

|

RUW |

RH, RHW, RUH, |

|

(14-2), |

(14-2), THW |

|

T, TW, |

THWN, XHHW, |

|

UF |

USE |

18 |

- - - |

- - - |

16 |

- - - |

- - - |

14 |

15 |

15 |

12 |

20 |

20 |

10 |

30 |

30 |

8 |

40 |

45 |

6 |

55 |

65 |

4 |

70 |

85 |

3 |

80 |

100 |

|

|

|

Portion of Table 310-18 follows:

Allowable Ampacities of Insulated Aluminum and Copper -Clad Aluminum Conductors.

Not more than three conductors in Raceway or Cable or Direct Burial (Based on Ambient Temperature of 30° C, 86° F. These ampacities relate only to conductors described in Table 310-13 in Code.

For ambient temperatures over 30° C (86° F), see Correction Factors, Note 13 in Code.

Size |

Temperature Rating of Conductor |

||

|

See Table 310-13 in Code |

|

|

AMG |

60° C |

|

75° C |

MCM |

(140° F) |

|

(167° F) |

|

|

|

|

|

TYPES: |

|

TYPES: |

|

RUW |

|

RH, RHW, RUH, |

|

(12-2), |

|

(12-2), THW |

|

T, TW, |

|

THWN, XHHW, |

|

UF |

|

USE |

12 |

15 |

|

15 |

10 |

25 |

|

25 |

8 |

30 |

|

40 |

6 |

40 |

|

50 |

4 |

55 |

|

65 |

3 |

65 |

|

75 |

2 |

75 |

|

90 |

1 |

85 |

|

100 |

WIRING DIAGRAMS

A-8 CIRCUIT FOR DUAL ELEMENT HEATER

C-2 CIRCUIT

FOR SINGLE

ELEMENT HEATERS

EQUIPPED WITH HIGH

LIMIT CONTROL

FACTORY WIRED

---------- FIELD WIRING

† WHITE FOR 120V & 277V

Loading...

Loading...