A.O. Smith BTL-120, BTL-154, BTL-180, BTL-199, BTL-250A User Manual

...

Ultra-Low NOx

Commercial Gas Water Heaters

MASTER-FIT® ULTRA-LOW NOx

COMMERCIAL GAS WATER HEATERS

FAN ASSISTED COMBUSTION

•The blower is built into the low NOx burner assembly

•Complies with California SCAQMD Rule 1146.2 and other air quality management districts with similar NOx emission requirements of 14 ng/J or 20 ppm

AIR-FLAPPER

•A stainless steel air flapper is used inside the premix system to replace externally mounted flue damper to minimize the standby heat loss and to minimize the overall heater height

METAL VENTING

•Rated Category I Appliance. Uses standard double wall type “B” vent

•Can be commonly vented with other Category I appliances

•Vent connects directly to the vent connector outlet

•An excellent choice for retrofit and upgrade installations

•When common venting multiple BTL water heaters into a common vent system, follow the common vent tables in the current edition of the National Fuel Gas Code book for Category 1, Fan assisted heaters.

FOAM INSULATION

• Saves fuel, helps reduce standby heat loss

JACKET

•Heavy gauge steel finished with a baked enamel finish over a bonderized undercoat

EASY CLEANING

• Handhole cleanout allows access for easy cleaning

FULLY TESTED FOR SAFETY AND PERFORMANCE

•Design certified by the Underwriters Laboratory for 180°F hot water service

•Meets rigid requirements of the National Sanitation Foundation when equipped with optional leg kit

•Certified for use on combustible flooring

INTERMITTENT IGNITION DEVICE

•Eliminates standing pilot

•Provides flame failure response in less than one second

•Spark ignitor and power ON/OFF switch

WATER CONNECTIONS

•For ease of installation, all BTL’s feature water connections on the top, front, and back

•“The Eliminator” inlet water connection eliminates harmful scale buildup, extending the life of the product

•The front inlet connection must be used for the Eliminator benefits

GLASSLINED TANK

•Permaglas® Ultracoat is the proprietary ceramic coating developed by A. 0. Smith’s ceramic engineers specifically for the heater

•Glassing is applied after the complete tank has been assembled to give a seamless barrier against hot water corrosion

INSTALLED COST SAVINGS

•The BTL uses a smaller vent diameter than a natural draft water heater which saves on installation cost

FULLY AUTOMATIC DIGITAL CONTROLS WITH SAFETY SHUTOFF

•Accurate, dependable control system

•Manual reset gas shutoff device for added safety

EASY TO INSTALL

•Completely factory-assembled

•Only gas, water, vent and electric connections need to be made. Provided with drain valve

ANODES

• CoreGuard™ long-life, stainless steel core anode rods

PLUG KITS

•Pipe nipples and caps are included to plug unused water connections

APPROVAL RATINGS AND

CERTIFICATION

•All models meet ANSI Z21.10.3 - CSA 4.3 standards and the thermal efficiency and standby loss requirements of the U.S. Department of Energy and current edition of ASHRAE/IES 90.1

3-YEAR LIMITED TANK / 1-YEAR LIMITED PARTS WARRANTY

•For complete warranty information, consult written warranty or go to howater.com.

MODELS

BTL-120 THRU BTL-400(A)

SERIES 200

ON SELECT MODELS

© December 2015 A. O. Smith Corporation. All rights reserved. |

Page 1 of 4 |

www.hotwater.com | 800-527-1953 Toll-Free USA | A. O. Smith Corporation | 500 Tennessee Waltz Parkway | Ashland City, TN 37015 |

AOSCG10503 |

Ultra-Low NOx

Commercial Gas Water Heaters

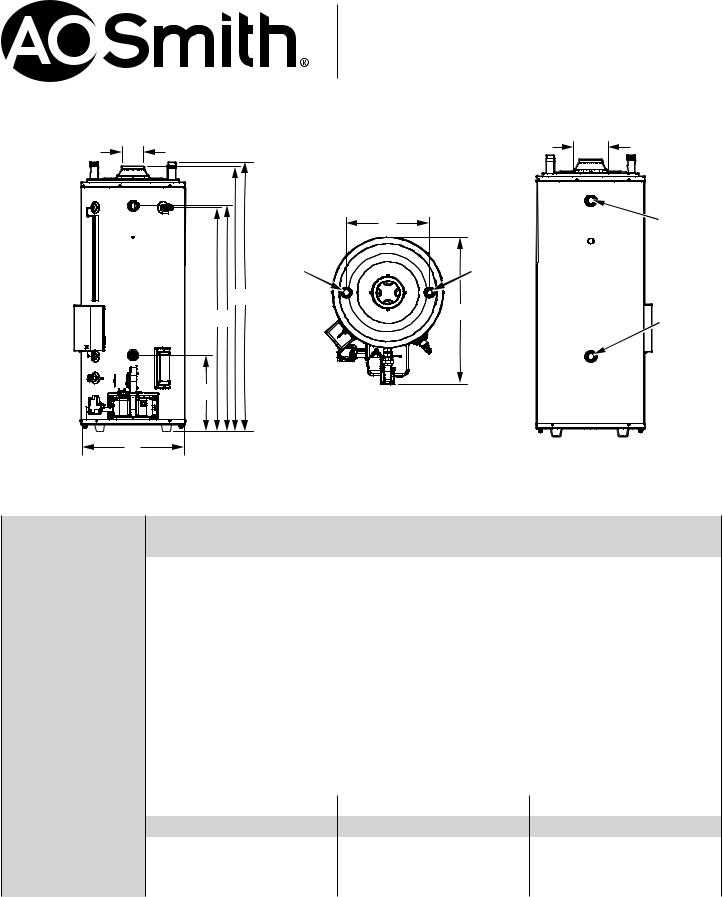

ROUGH IN DIMENSIONS: MASTER-FIT BTL-120 through BTL-400(A)

I

|

F |

TOP OUTLET |

TOP INLET |

1 1/2 NPT |

|

|

1 1/2 NPT |

A C |

|

D H |

B |

|

G

E

E

TOP VIEW

M |

K |

L |

J |

|

FRONT VIEW |

BACK VIEW |

DIMENSIONS

Model Dimension |

BTL-120, 154, 180, 198 |

BTL-199, 250(A), 275(A) |

BTL-310(A), 366(A), 400(A) |

||||

|

|

|

|

|

|

|

|

Inches |

cm |

Inches |

|

cm |

Inches |

cm |

|

|

|

||||||

|

|

|

|

|

|

|

|

A |

63-3/4 |

161.93 |

71-3/4 |

|

182.25 |

71-3/4 |

182.25 |

|

|

|

|

|

|

|

|

B |

37 |

93.98 |

37 |

|

93.98 |

37 |

93.98 |

|

|

|

|

|

|

|

|

C |

65 |

165.1 |

73 |

|

185.42 |

73 |

185.42 |

|

|

|

|

|

|

|

|

D |

52-3/4 |

133.99 |

60-3/4 |

|

154.31 |

60-3/4 |

154.31 |

|

|

|

|

|

|

|

|

E |

20-3/4 |

52.71 |

20-1/2 |

|

52.07 |

20-1/2 |

52.07 |

|

|

|

|

|

|

|

|

F |

21 |

53.34 |

21 |

|

53.34 |

21 |

53.34 |

|

|

|

|

|

|

|

|

G |

|

|

|

3/4 NPT |

|

|

|

|

|

|

|

|

|

|

|

H |

53 |

134.62 |

61 |

|

154.94 |

61 |

154.94 |

|

|

|

|

|

|

|

|

I |

6 |

15.24 |

6 |

|

15.24 |

6 |

15.24 |

|

|

|

|

|

|

|

|

J |

27-3/4 |

70.49 |

27-3/4 |

|

70.49 |

27-3/4 |

70.49 |

|

|

|

|

|

|

|

|

K |

|

|

|

1-1/2 NPT |

|

|

|

|

|

|

|

|

|

|

|

L |

|

|

|

1-1/2 NPT |

|

|

|

|

|

|

|

|

|

|

|

M |

N/A |

N/A |

8 |

|

20.3 |

8 |

20.3 |

|

|

|

|

|

|

|

|

Approx. Shipping Weight |

|

BTL-120, 154, 180, 198 |

BTL-199, 250(A), 275(A) |

BTL-310(A), 366(A), 400(A) |

||||

|

|

|

|

|

|

|

|

|

|

lbs. |

kg |

lbs. |

|

kg |

lbs. |

kg |

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

Standard |

605 |

174 |

665 |

|

301 |

740 |

335 |

|

|

|

|

|

|

|

|

|

|

ASME |

N/A |

N/A |

715 |

|

324 |

790 |

358 |

|

|

|

|

|

|

|

|

||

Dimensions and specifications subject to change without notice in accordance with our policy of continuous product improvement |

|

|

|

|||||

All models rated at 80% thermal efficiency |

|

|

|

|

|

|

|

|

“A” after the model number designates ASME construction. |

|

|

|

|

|

|

||

BTL models not available in LP gas. |

|

|

|

|

|

|

|

|

© December 2015 A. O. Smith Corporation. All rights reserved. |

|

|

|

|

|

Page 2 of 4 |

||

www.hotwater.com | 800-527-1953 Toll-Free USA | A. O. Smith Corporation | 500 Tennessee Waltz Parkway | Ashland City, TN 37015 |

|

AOSCG10503 |

||||||

Loading...

Loading...