Page 1

•

For safety and warning information, please read this

•

Additional safety and warning information is provided

•

st

MX269022A

LTE TDD Downlink Measurement

manual before attempting to use the equipment.

within the MS2690A/MS2691A/MS2692A Signal

Analyzer Operation Manual (Mainframe Operation),

MS2830A Signal Analyzer Operation Manual

(Mainframe Operation), or MS2850A Signal Analyzer

Operation Manual (Mainframe Operation). Please also

refer to this document before using the equipment.

Keep this manual with the equipment.

Software

Operation Manual

Operation

21

Edition

ANRITSU CORPORATION

Document No.: M-W3209AE-21.0

Page 2

Safety Symbols

To prevent the risk of personal injury or loss related to equipment malfunction, Anritsu Corporation uses the

following safety symbols to indicate safety-related information. Ensure that you clearly understand the meanings of

the symbols BEFORE using the equipment. Some or all of the following symbols may be used on all Anritsu

equipment. In addition, there may be other labels attached to products that are not shown in the diagrams in this

manual.

Symbols used in manual

DANGER

WARNING

CAUTION

This indicates a very dangerous procedure that could result in serious injury or

death if not performed properly.

This indicates a hazardous procedure that could result in serious injury or death if

not performed properly.

This indicates a hazardous procedure or danger that could result in light-to-severe

injury, or loss related to equipment malfunction, if proper precautions are not taken.

Safety Symbols Used on Equipment and in Manual

The following safety symbols are used inside or on the equipment near operation locations to provide information

about safety items and operation precautions. Ensure that you clearly understand the meanings of the symbols and

take the necessary precautions BEFORE using the equipment.

This indicates an obligatory safety precaution. The obligatory operation is

This indicates a warning or caution. The contents are indicated symbolically in or

This indicates a note. The contents are described in the box.

These indicate that the marked part should be recycled.

This indicates a prohibited operation. The prohibited operation is indicated

symbolically in or near the barred circle.

indicated symbolically in or near the circle.

near the triangle.

MX269022A

LTE TDD Downlink Measurement Software

Operation Manual Operation

15 May 2009 (First Edition)

31 October 2019 (21st Edition)

Copyright © 2009-2019, ANRITSU CORPORATION.

All rights reserved. No part of this manual may be reproduced without the prior written permission of the

publisher.

The contents of this manual may be changed without prior notice.

Printed in Japan

ii

Page 3

iii

Equipment Certificate

Anritsu Corporation guarantees that this equipment was inspected at

shipment and meets the published specifications.

Anritsu Warranty

During the warranty period, Anritsu Corporation will repair or exchange this

•

software free-of-charge if it proves defective when used as described in the

operation manual.

The warranty period is 6 months from the purchase date.

•

The warranty period after repair or exchange will remain 6 months from

•

the original purchase date, or 30 days from the date of repair or

exchange, depending on whichever is longer.

This warranty does not cover damage to this software caused by Acts of

•

God, natural disasters, and misuse or mishandling by the customer.

In addition, this warranty is valid only for the original equipment purchaser. It

is not transferable if the equipment is resold.

Anritsu Corporation shall assume no liability for injury or financial loss of the

customer due to the use of or a failure to be able to use this equipment.

Anritsu Corporation Contact

In the event of this equipment malfunctions, contact an Anritsu Service and

Sales office. Contact information can be found on the last page of the printed

version of this manual, and is available in a separate file on the PDF version.

Page 4

iv

This product and its manuals may require an Export License/Approval by

the Government of the product's country of origin for re-export from your

country.

Before re-exporting the product or manuals, please contact us to confirm

whet

When you dispose of export-controlled items, the products/manuals need

to be broken/shredded so as not to be unlawfully used for military purpose.

Notes On Export Management

her they are export-controlled items or not.

Page 5

v

Software End-User License Agreement (EULA)

Please read this Software End-User License Agreement (hereafter this EULA) carefully before using

(includes executing, copying, registering, etc.) this software (includes programs, databases, scenarios,

etc., used to operate, set, etc., Anritsu electronic equipment). By reading this EULA and using this

software, you are agreeing to be bound by the terms of its contents and Anritsu Corporation (hereafter

Anritsu) hereby grants you the right to use this Software with the Anritsu-specified equipment

(hereafter Equipment) for the purposes set out in this EULA.

1. Grant of License and Limitations

1. Regardless of whether this Software was

purchased from or provided free-of-charge by

Anritsu, you agree not to rent, lease, lend, or

otherwise distribute this Software to third

parties and further agree not to disassemble,

recompile, reverse engineer, modify, or

create derivative works of this Software.

2. You may make one copy of this Software for

backup purposes only.

3. You are not permitted to reverse engineer

this software.

4. This EULA allows you to install one copy of

this Software on one piece of Equipment.

2. Disclaimers

To the extent not prohibited by law, in no

event shall Anritsu be liable for personal

injury, or any incidental, special, indirect or

consequential damages whatsoever,

including, without limitation, damages for

loss of profits, loss of data, business

interruption or any other commercial

damages or losses, arising out of or related

to your use or inability to use this Software.

3. Limitation of Liability

a. If a fault (bug) is discovered in this Software,

preventing operation as described in the

operation manual or specifications whether

or not the customer uses this software as

described in the manual, Anritsu shall at its

own discretion, fix the bug, or exchange the

software, or suggest a workaround,

free-of-charge. However, notwithstanding

the above, the following items shall be

excluded from repair and warranty.

i) If this Software is deemed to be used for

purposes not described in the operation

manual or specifications.

ii) If this Software is used in conjunction with

other non-Anritsu-approved software.

iii) Recovery of lost or damaged data.

iv) If this Software or the Equipment has been

modified, repaired, or otherwise altered

without Anritsu's prior approval.

v} For any other reasons out of Anritsu's direct

control and responsibility, such as but not

limited to, natural disasters, software virus

infections, etc.

b. Expenses incurred for transport, hotel, daily

allowance, etc., for on-site repairs by Anritsu

engineers necessitated by the above faults

shall be borne by you.

c. The warranty period for faults listed in

article 3a above covered by this EULA shall

be either 6 months from the date of purchase

of this Software or 30 days after the date of

repair, whichever is longer.

Page 6

vi

4. Export Restrictions

You may not use or otherwise export or

re-export directly or indirectly this Software

except as authorized by Japanese and

United States law. In particular, this

software may not be exported or re-exported

(a) into any Japanese or US embargoed

countries or (b) to anyone on the Japanese or

US Treasury Department's list of Specially

Designated Nationals or the US Department

of Commerce Denied Persons List or Entity

List. By using this Software, you warrant

that you are not located in any such country

or on any such list. You also agree that you

will not use this Software for any purposes

prohibited by Japanese and US law,

including, without limitation, the

development, design and manufacture or

production of missiles or nuclear, chemical or

biological weapons of mass destruction.

5. Termination

Anritsu shall deem this EULA terminated if

you violate any conditions described herein.

This EULA shall also be terminated if the

conditions herein cannot be continued for

any good reason, such as violation of

copyrights, patents, or other laws and

ordinances.

6. Reparations

If Anritsu suffers any loss, financial or

otherwise, due to your violation of the terms

of this EULA, Anritsu shall have the right to

seek proportional damages from you.

7. Responsibility after Termination

Upon termination of this EULA in

accordance with item 5, you shall cease all

use of this Software immediately and shall

as directed by Anritsu either destroy or

return this Software and any backup copies,

full or partial, to Anritsu.

8. Dispute Resolution

If matters of dispute or items not covered by

this EULA arise, they shall be resolved by

negotiations in good faith between you and

Anritsu.

9. Court of Jurisdiction

This EULA shall be interpreted in

accordance with Japanese law and any

disputes that cannot be resolved by

negotiation described in Article 8 shall be

settled by the Japanese courts.

Page 7

vii

Only files that have been provided directly from Anritsu or generated

All other required files should be transferred by means of USB or

Do not download or install software that has not been specifically

y protection in

place.

Cautions against computer virus infection

• Copying files and data

using Anritsu equipment should be copied to the instrument.

CompactFlash media after undergoing a thorough virus check.

• Adding software

recommended or licensed by Anritsu.

• Network connections

Ensure that the network has sufficient anti-virus securit

Page 8

viii

Page 9

About This Manual

(

)

(

)

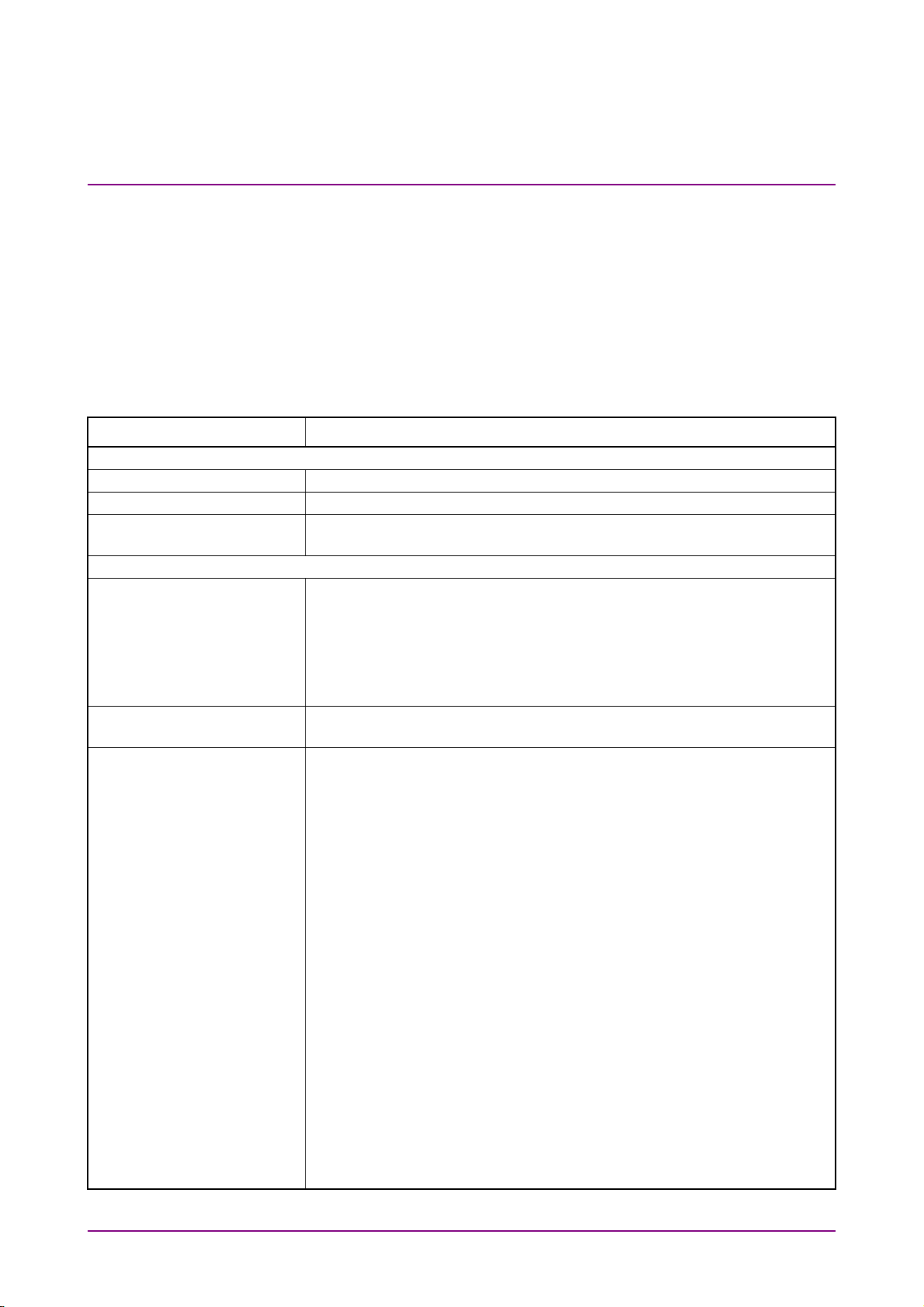

Composition of Operation Manuals

The operation manuals for the MX269022A LTE TDD Downlink

Measurement Software are comprised as shown in the figure below.

MS2690A/MS2691A/MS2692A Signal Analyzer Operation Manual

Main Frame Operation

Or

MS2690A/MS2691A/MS2692A and MS2830A/MS2840A/MS2850A

Signal Analyzer Operation Manual (Main Frame Remote Control)

MS2830A Signal Analyzer Operation Manual

Main Frame Operation

MS2850A Signal Analyzer Operation Manual

(Main Frame Operation)

MX269022A LTE TDD Downlink Measurement Software

Operation Manual (Operat i on)

MX269022A LTE TDD Downlink Measurement Software

Operation Manual (Remote Control)

I

Page 10

Signal Analyzer Operation Manual (Mainframe Operation)

Signal Analyzer Operation Manual (Mainframe Remote Control)

These manuals describe basic operating methods, maintenance

procedures, common functions, and common remote control of the signal

analyzer mainframe.

LTE TDD Downlink Measurement Software Operation Manual

(Operation) <This document>

This manual describes basic operating methods, and functions of the LTE

TDD Downlink Measurement Software. As for signal analyzer

hardware and its basic functions and operation outline, refer to

MS2690A/MS2691A/MS2692A Signal Analyzer Operation Manual

(Mainframe Operation), MS2830A Signal Analyzer Operation Manual

(Mainframe Operation),

(Mainframe Operation)

or

MS2850A Signal Analyzer Operation Manual

.

LTE TDD Downlink Measurement Software Operation Manual (Re mote

Control)

This manual describes remote control of the LTE TDD Downlink

Measurement Software. As for signal analyzer application’s basic remote

control functions and its definitions of common commands, refer to

MS2690A/MS2691A/MS2692A and MS2830A/MS2840A/MS2850A Signal

Analyzer Operation Manual (Mainframe Remote Control)

.

Convention Used in This Manual

Throughout this document, the use of MS269xA Series is assumed unless

otherwise specified. If using MS2830A or MS2850A, change MS269xA to

read MS2830A, MS2850A.

In this document,

indicates a panel key.

II

Page 11

Table of Contents

1

About This Manual........................................ I

Chapter 1 Overview .................................... 1-1

1.1 Product Overview ...................................................... 1-2

1.2 Product Configuration ................................................ 1-3

1.3 Specifications ............................................................. 1-4

Chapter 2 Preparation ................................ 2-1

2.1 Part Names ................................................................ 2-2

2.2 Signal Path Setup ...................................................... 2-14

2.3 Application Startup and Selection .............................. 2-15

2.4 Initialization and Calibration ....................................... 2-16

2

3

4

5

Chapter 3 Measurement ............................ 3-1

3.1 Basic Operation ....................................................... 3-6

3.2 Setting Frequency and Level ................................... 3-12

3.3 Setting Trigger ......................................................... 3-15

3.4 Common Settings .................................................... 3-17

3.5 Setting Modulation Analysis ..................................... 3-23

3.6 Modulation Analysis Measurement and Results ...... 3-47

3.7 Power vs Time Setting ............................................. 3-71

3.8 Measurement and Result for Power vs Time .......... 3-84

3.9 MIMO Summary Settings ......................................... 3-91

3.10 MIMO Summary Measurement Results .................. 3-93

3.11 Setting Batch Measurement .................................... 3-95

3.12 Batch Measurement Results .................................... 3-131

3.13 Spectrum Measurement .......................................... 3-133

6

Index

III

Page 12

Chapter 4 Digitizing and Replaying .......... 4-1

4.1 Digitize function.......................................................... 4-2

4.2 Replay Function ......................................................... 4-8

Chapter 5 Performance Test ..................... 5-1

5.1 Overview of Performance Test .................................. 5-2

5.2 Performance Test Items ............................................ 5-3

Chapter 6 Other Functions ........................ 6-1

6.1 Selecting Other Functions ......................................... 6-2

6.2 Setting Title ................................................................ 6-2

6.3 Erasing Warmup Message ........................................ 6-2

Index .......................................................... Index-1

IV.

Page 13

Chapter 1 Overview

This chapter provides an overview of the MX269022A LTE TDD

Measurement Software and describes the product configuration.

1

Product Overview ...................................................... 1-2

1.1

1.2 Product Configuration ................................................ 1-3

1.2.1 Standard configuration .................................. 1-3

1.2.2 Option ............................................................ 1-3

1.2.3 Applicable parts ............................................. 1-3

1.3 Specifications ............................................................. 1-4

Overview

1-1

Page 14

Chapter 1 Overview

1.1 Product Overview

MS269x Series, MS2830A, or MS2850A Signal Analyzer enables

high-speed, high-accuracy, and simple measurements of transmission

characteristics of base stations and mobile stations for various mobile

communications types. The MS2690A/MS2691A/MS2692A, MS2830A or

MS2850A is equipped with high-performance signal analyzer and

spectrum analyzer functions as standard, with optional measurement

software allowing modulation analysis functionality supporting various

digital modulation modes.

The MX269022A LTE TDD Downlink Measurement Software

(hereinafter referred to as MX269022A) is a software option for

measuring the RF characteristics of LTE TDD (Frame structure type 2)

downlink signal specified by 3GPP, TS36.211 V8.6.0 (2009-03) Physical

Channels and Modulation (Release 8).

The MX269022A provides the following measurement features.

Modulation accuracy measurement

Carrier frequency measurement

Transmitter power measurement

MS2830A-005/105 and MS2830A-006/106 is required to use the

MX269022A on MS2830A.

1-2

Page 15

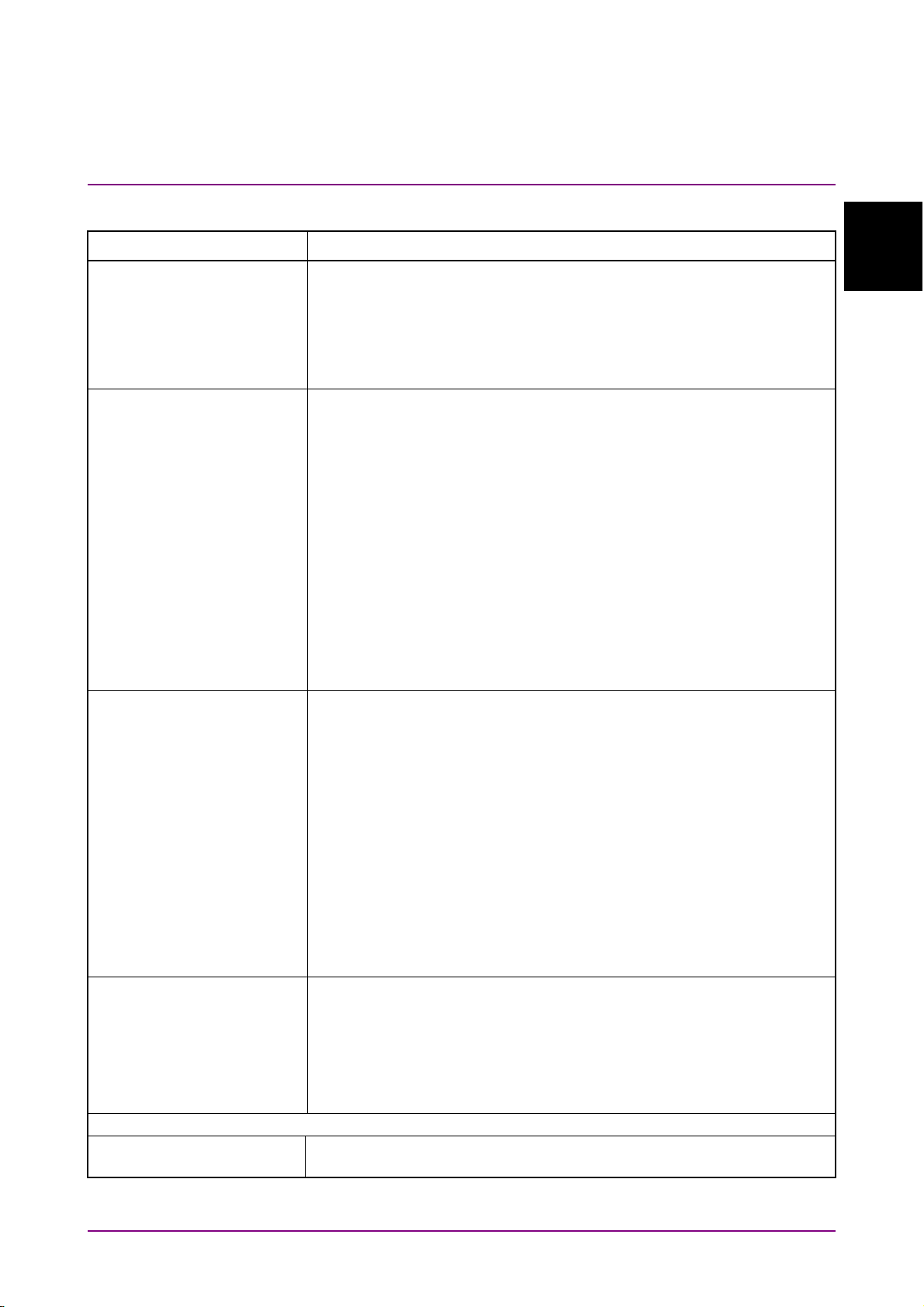

1.2 Product Configuration

1.2.1 Standard configuration

Table 1.2.1-1 lists the standard configuration of the MX269022A.

Table 1.2.1-1 Standard configuration

1.2 Product Configuration

1

Overview

Item

Application MX269022A

Accessory ― Installation CD-ROM 1

Model

Name/Symbol

Product Name Q’ty Remarks

LTE TDD Downlink

Measurement Software

1

Application software,

operation manual CD-ROM

1.2.2 Option

Tables 1.2.2-1 list the option for the MX269022A. This is sold separately.

Table 1.2.2-1 Option

Option No. Product Name Remarks

MX269022A-001

LTE-Advanced TDD Downlink Measurement

Software

Only for MS269xA,

MS2830A, MS2850A

1.2.3 Applicable parts

Table 1.2.3-1 lists the applicable parts for the MX269022A.

Table 1.2.3-1 Applicable parts

Model

Name/Symbol

W3209AE

W3210AE

Product Name Remarks

MX269022A LTE TDD Downlink

Measurement Software Operation

Manual (Operation)

MX269022A LTE TDD Downlink

Measurement Software Operation

Manual (Remote Control)

English,

printed version

English,

printed version

1-3

Page 16

Chapter 1 Overview

1.3 Specifications

Table 1.3-1 shows the specifications for the MX269022A.

When MS2830A, MS2850A is used, this software’s specification is

specified by the condition below, unless otherwise noted.

Attenuator Mode: Mechanical Atten Only

Table 1.3-1 Specifications

Item Specification

Common Specifications

Channel bandwidth 1.4, 3, 5, 10, 15, 20 MHz

Target signal LTE TDD Downlink

Capture time

Modulation/Frequency Measurement

Measurement frequency

ranges

Measurement level range

Carrier frequency accuracy

Capture Time = Auto : 5 frame

Capture Time = Manual : 5 to 150 frame

MS269x Series: 600 to 4000 MHz

MS2830A-041/043/044/045:

600 to 4000 MHz

MS2830A-040: 600 to 3600 MHz

MS2850A: 600 to 4000 MHz (Analysis bandwidth ≤ 31.25 MHz)

800 to 4000 MHz (Analysis bandwidth > 31.25 MHz)

15 to +30 dBm (at Pre-Amp Off, or Pre-Amp not installed.)

30 to +10 dBm (at Pre-Amp On)

After CAL execution at 18 to 28ºC

For a signal of EVM = 1%

When Downlink 10 Subframe is the measurement target

MS269x series:

(accuracy of reference frequency carrier frequency + 3 Hz)

(Excluding the Batch Measurement when MS269xA-004/104 is

installed)

MS2830A:

(accuracy of reference frequency carrier frequency + 3.5 Hz)

(When the center frequency is from 600 MHz to 2700 MHz and

MS2830A-078/178 is not installed)

(accuracy of reference frequency carrier frequency + 8.0 Hz)

(When the center frequency is from 2700 MHz to 4000 MHz and

MS2830A-078/178 is not installed)

(accuracy of reference frequency carrier frequency + 4.0 Hz)

(In the CC of the center frequency when the center frequency is

from 600 MHz to 2700 MHz and MS2830A-078/178 is installed)

(At the input level of –4 dBm when MS2830A-045 is installed)

(accuracy of reference frequency carrier frequency + 8.0 Hz)

(In the CC of the center frequency when the center frequency is

from 2700 MHz to 4000 MHz and MS2830A-078/178 is installed)

(And when MS2830A-045 is installed, at the input level of –4 dBm)

1-4

Page 17

Table 1.3-1 Specifications (Cont’d)

1.3 Specifications

Item Specification

MS2850A:

(accuracy of reference frequency carrier frequency + 4.0 Hz)

Carrier frequency accuracy

Residual EVM

Transmitter power accuracy

Waveform display

Adjacent Channel Power Measurement

Measurement method

(Center frequency 600 to 2700 MHz (Analysis bandwidth ≤ 31.25 MHz))

(Center frequency 800 to 2700 MHz (Analysis bandwidth > 31.25 MHz))

(accuracy of reference frequency carrier frequency + 8.0 Hz)

(Center frequency 2700 to 4000 MHz)

After CAL execution at 18 to 28C

When Downlink 10 Subframe is the measurement target

MS269x series: 1.0% (rms)

(When MS269xA-078/178 is not installed.

When MS269xA-004/104 is installed, excluding the Batch

Measurement.)

< 1.3% (rms)

(When MS269xA-078/178 is installed, in the CC of the center frequency. )

MS2830A:

(When MS2830A-078/178 is not installed. At the input level of –4 dBm

when MX2830A-045 is installed)

1.3% (rms)

(When MS2830A-078/178 is installed, in the CC of the center frequency.

At the input level of –4 dBm when MX2830A-045 is installed)

MS2850A:

After CAL execution at 18 to 28ºC, input attenuator ≥ 10 dB,

The signal measured is within the measurement level range and less

than or equal to Input Level.

MS269x series:

0.6 dB (at Pre-Amp Off, or Pre-Amp not installed.)

1.1 dB (at Pre-Amp On)

(When MS269xA-004/104 is installed, excluding the Batch

Measurement. )

MS2830A:

0.6 dB (at Pre-Amp Off, or Pre-Amp not installed.)

MS2850A:

0.6 dB (at Pre-Amp Off, or Pre-Amp not installed.)

1.1 dB (at Pre-Amp On)

The transmitter power accuracy is obtained by an RSS (root summed

square) error of the absolute amplitude accuracy and in-band

frequency characteristics.

Provides functions for displaying waveforms below.

Constellation

EVM vs Subcarrier

EVM vs Symbol

Power vs Resource Block

EVM vs Resource Block

Spectral Flatness

Executes the adjacent channel power measurement function of the

Spectrum Analyzer or Signal Analyzer.

1.3% (rms)

1.3% (rms)

1

Overview

1-5

Page 18

Chapter 1 Overview

Table 1.3-1 Specifications (Cont’d)

Item Specification

Occupied Bandwidth Measurement

Measurement method

Executes the occupied bandwidth measurement function of the Spectrum

Analyzer or Signal Analyzer.

Channel Power Measurement

Measurement method

Executes the channel power measurement function of the Spectrum

Analyzer or Signal Analyzer.

Spectrum Emission Mask Measurement

Measurement method

Executes the spectrum emission mask measurement function of the

Spectrum Analyzer.

Digitize function

Function overview

Outputs acquired waveform data to the internal storage device or to

external storage device.

Format: I, Q (32 bit floating point binary format)

Level: If 0 dBm is input, the following is assumed:

Waveform data

22

= 1

QI

Level accuracy:

Same as absolute amplitude accuracy and in-band frequency

characteristics of signal analyzer.

Replay Function

Analyzes each trace from the saved waveform data.

Function overview

Format: I, Q (32 bit floating point binary format)

Sampling rate: 50 MHz

Power vs Time

Function overview

Provides measurements for Transmitter OFF Power, Time Mask, and

Transmitter Transient Period.

121.4 dB (nominal) *

1, *2, *3

*1: This is the value when Channel bandwidth is 5 MHz.

For the other channel bandwidth, the following formula can be

Dynamic range

used.

10log

10

( Channel bandwidth / 5.0 MHz ) dB

*2: Wide Dynamic Range = On, Noise Correction = On

*3: Applied to only MS269x series

MIMO Summary

Function overview Inputs multiple MIMO signals and measures timing differences.

1-6.

Page 19

Chapter 2

This chapter describes the preparations required for using the

application you are using. Refer to the

Signal Analyzer Operation Manual (Mainframe Operation),

Signal Analyzer Operation Manual (Mainframe Operation)

Signal Analyzer Operation Manual (Mainframe Operation)

features not included in this manual.

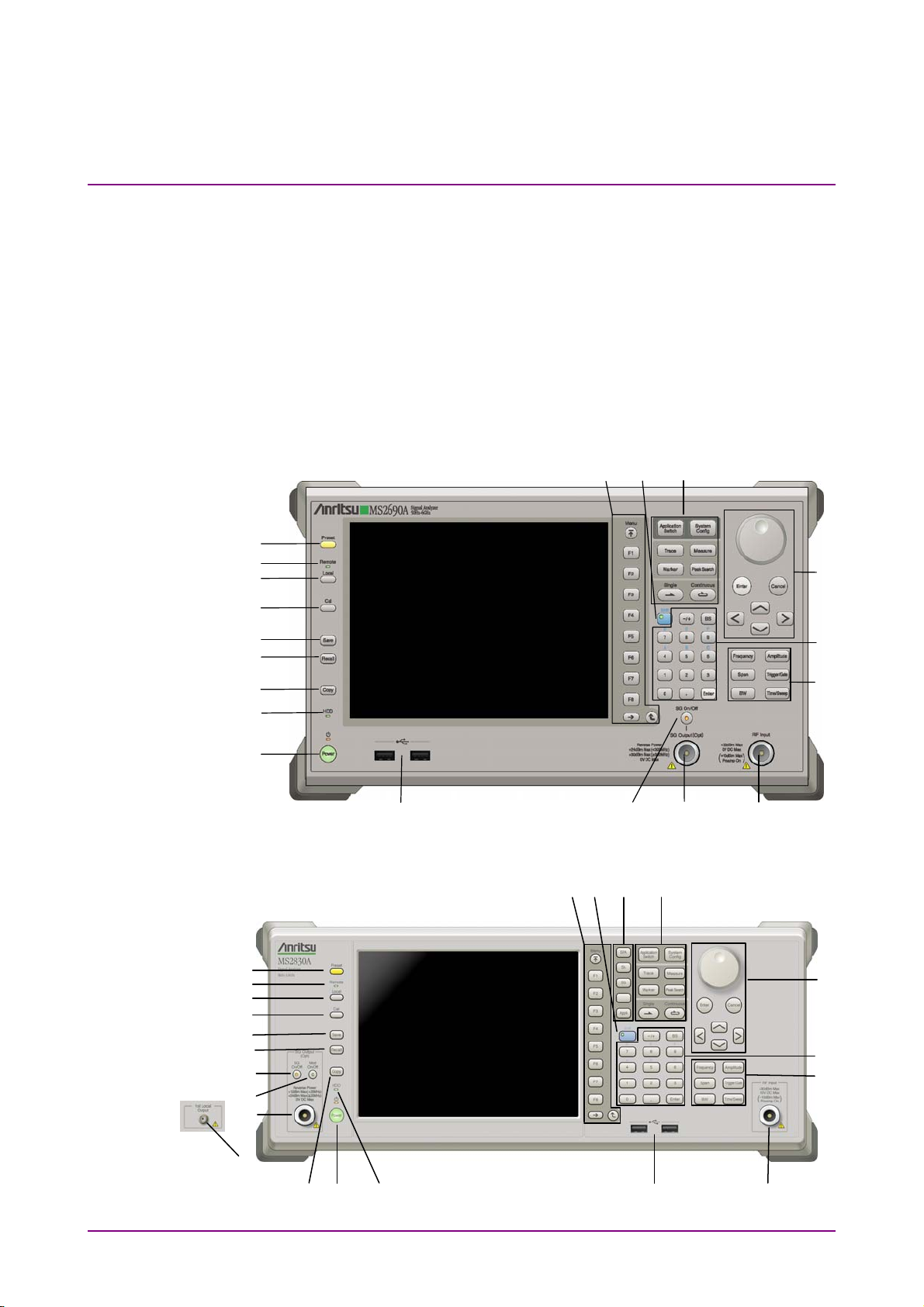

Part Names ................................................................... 2-2

2.1

2.1.1 Front panel ....................................................... 2-2

2.1.2 Rear panel ........................................................ 2-9

2.2 Signal Path Setup ....................................................... 2-14

2.3 Application Startup and Selection ............................... 2-15

2.3.1 Launching application ..................................... 2-15

2.3.2 Selecting application....................................... 2-15

2.4 Initialization and Calibration ........................................ 2-16

2.4.1 Initialization ..................................................... 2-16

2.4.2 Calibration ...................................................... 2-16

MS2690A/MS2691A/MS2692A

Preparation

MS2830A

or

MS2850A

for common

2

Preparation

2-1

Page 20

Chapter 2 Preparation

2.1 Part Names

This section describes the panel keys for operating the instrument and

connectors used to connect external devices. For general points of caution,

refer to the

Manual (Mainframe Operation), MS2830A Signal Analyzer Operation

Manual (Mainframe Operation)

Manual (Mainframe Operation)

2.1.1 Front panel

This section describes the front-panel keys and connectors.

9

8

7

MS2690A/MS2691A/MS2692A Signal Analyzer Operation

or

MS2850A Signal Analyzer Operation

.

10

14

12

13

6

5

4

3

2

1

19

17

18

16

15

11

Figure 2.1.1-1 MS269x series front panel

9

8

7

6

5

4

17

20

18

10 21 12 14

13

15

11

2-2

22

3 21

19 16

Figure 2.1.1-2 MS2830A/MS2850A front panel (MS2830A Example)

Page 21

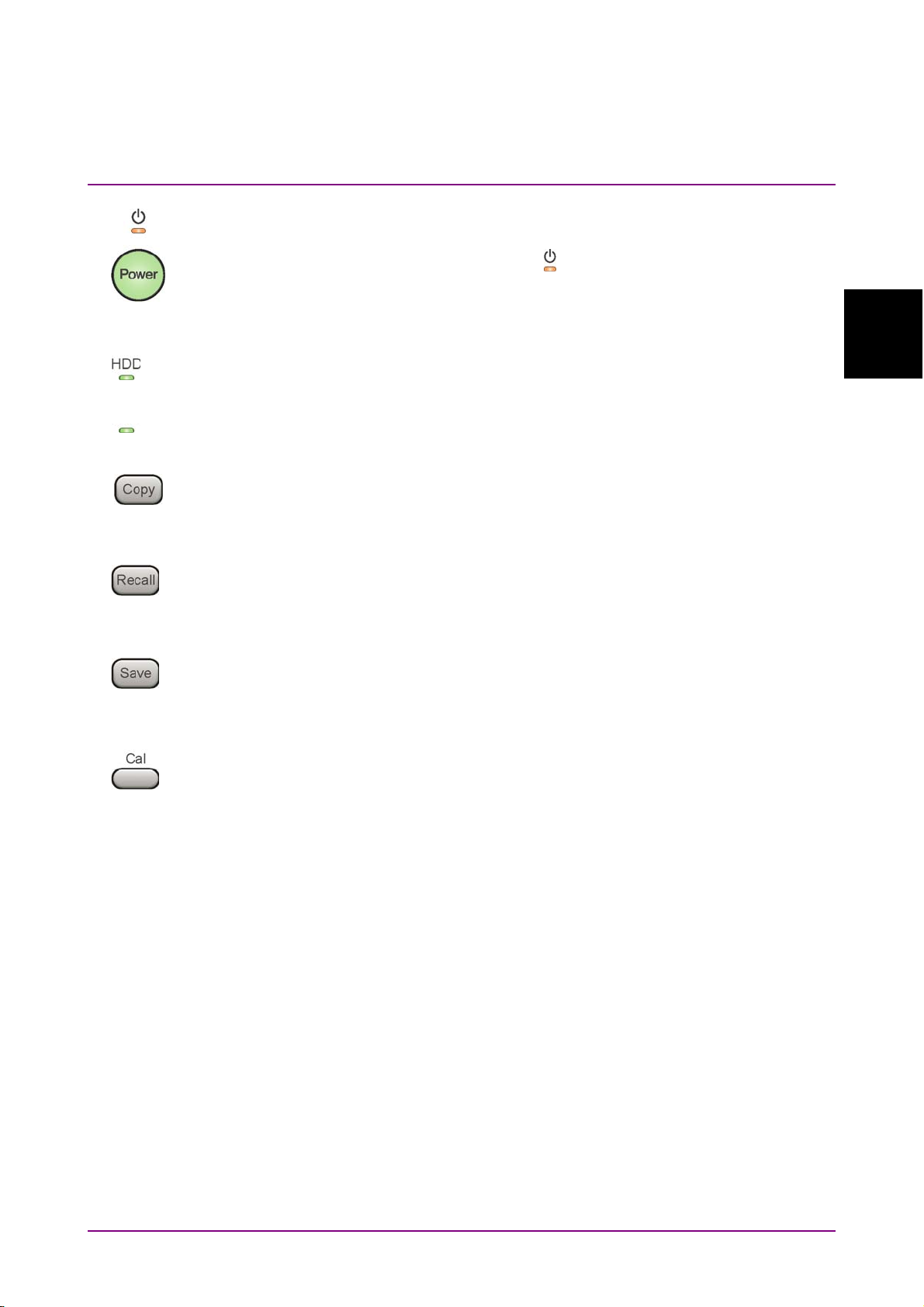

2.1 Part Names

1

2

SSD

SSD access lamp (MS2850A)

3

4

5

6

Power Switch

Press to switch between the standby state (AC power supplied) and

power-on state. The Power lamp

Power On. Press the power switch for about 2 seconds.

Hard disk access lamp (MS269x series, MS2830A)

Lights up when the internal hard disk is accessed.

Lights up when the internal SSD is accessed .

Copy key

Press to capture display screen and save to file.

Recall key

Press to recall parameter file.

Save key

Press to save parameter file.

Cal key

Press to display the Calibration menu.

lights orange at Standby and green at

Preparation

2

2-3

Page 22

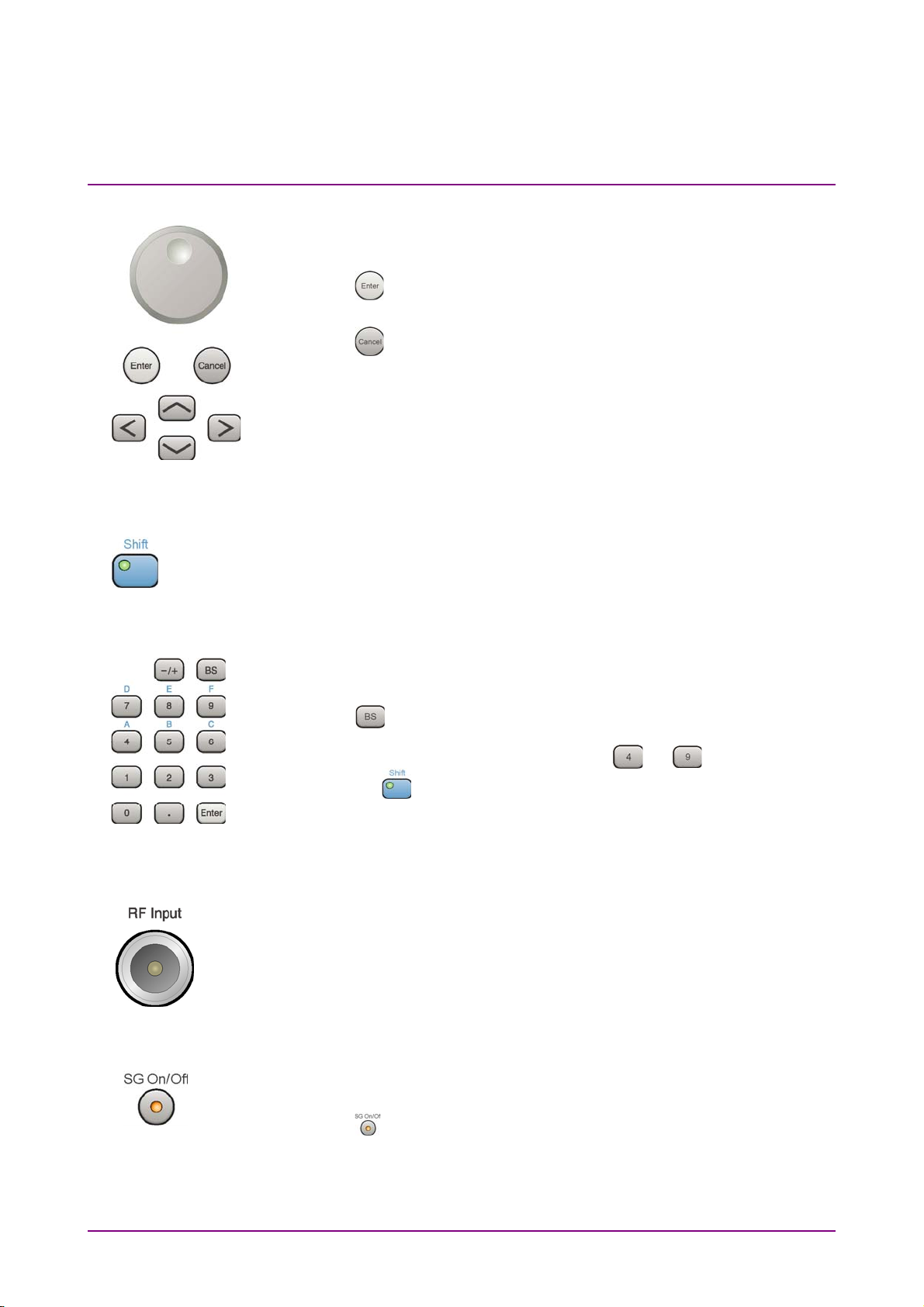

Chapter 2 Preparation

7

8

9

10

Local key

Press to return to local operation from remote control via GPIB, Ethernet,

or USB (B), and enable panel settings.

Remote lamp

Lights when in remote-control state.

Preset key

Resets parameters to initial settings.

Function keys

Selects or configures function menu displayed on the right of the screen.

The function menu is provided in multiple pages and layers.

Press

is displayed at the bottom of the function menu, as in “1 of 2”.

Sub-menus may be displayed when a function menu is pressed. Press

to go back to the previous menu. Press

to fetch next function menu page. The current page number

to go back to the top menu.

2-4

Page 23

2.1 Part Names

11

12

Main function keys 1

Press to set or execute main functions.

Executable functions vary with the current application. When nothing

happens with the press, it indicates that the application in use does not

support the key.

Press to set frequency parameters.

Press to set level parameters.

No function is assigned to this key.

Press to set trigger parameters.

No function is assigned to this key.

Press to set measurement item parameters.

Main function keys 2

Press to set or execute main functions.

Executable functions vary with the current application. When nothing

happens with the press, it indicates that the application in use does not

support the key.

2

Preparation

Press to switch application.

Press to display Configuration screen.

Press to set the trace items or to switch the operation window.

Press to set measurement item parameters.

Use when switching graph marker operation.

Press to set parameters related to the peak search function.

Press to start single measurement.

Press to start continuous measurements.

2-5

Page 24

Chapter 2 Preparation

13

14

15

Rotary knob/Cursor key/Enter key/Cancel key

The rotary knob and cursor keys select display items or change settings.

Press

Press

Shift key

Operates keys with functions in blue characters on panel. Press the Shift

key so the key lamp is green and then press the target key.

Numeric keypad

Enters numbers on parameter setup screens.

to set the entered or selected data.

to cancel input or selected data.

16

17

Press

[A] to [F] can be entered by pressing keys

key lamp

RF Input connector

Inputs RF signal. This is an N type input connector.

For the MS2830A with the MS2830A-045 and the MS2850A, a K type

input connector is installed.

RF Output Control key (when MS269xA-0 20/120, MS2830A-020/120/021/121

is installed)

Press

Signal Generator option is installed. The RF output control key lamp

lights orange when the RF signal output is set to On.

This cannot be installed on the MS2830A with the MS2830A-044/045, or

on the MS2850A.

to delete the last entered digit or character.

to while the Shift

is green.

to switch on/off the modulation of RF signal when the Vector

2-6

Page 25

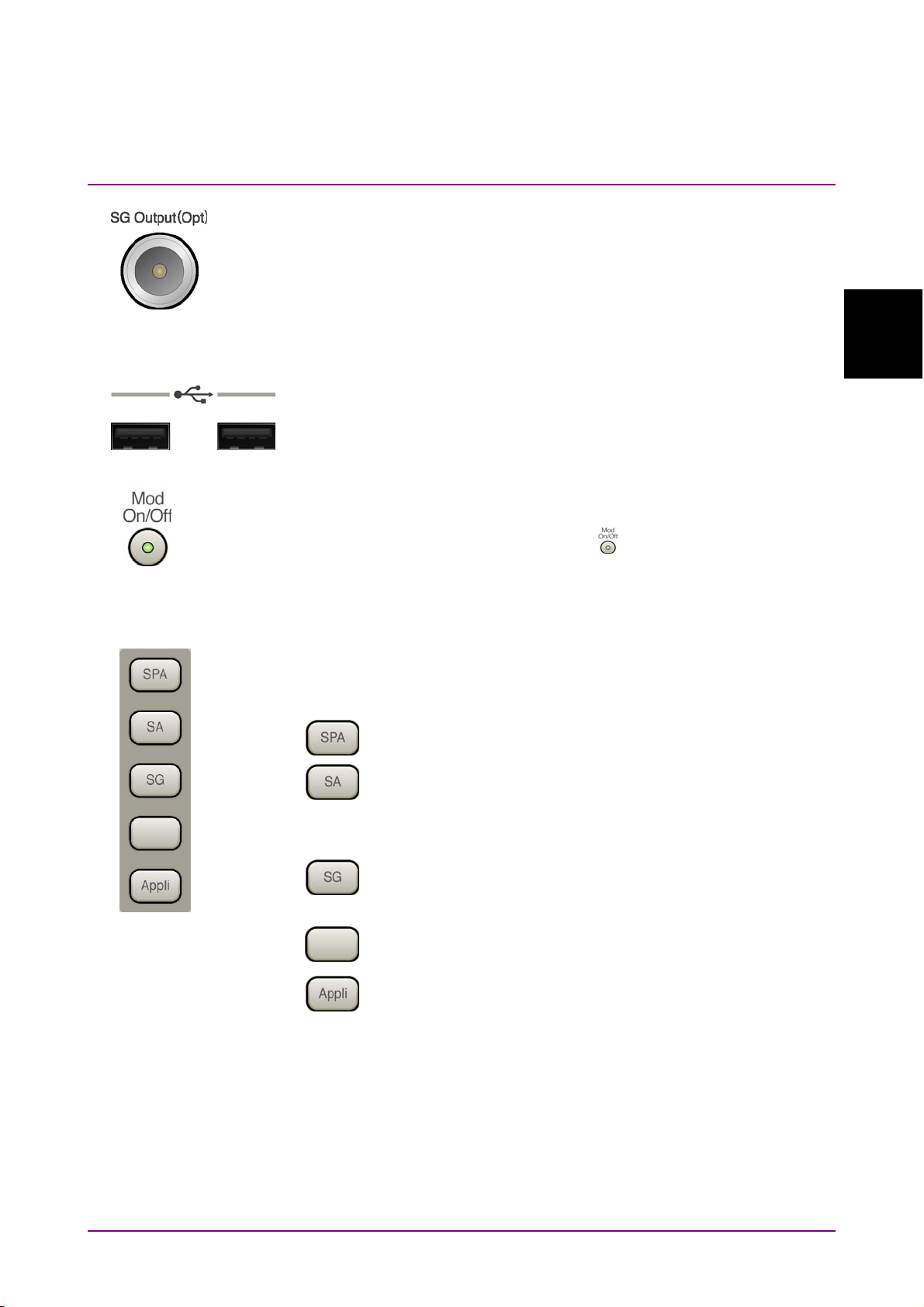

2.1 Part Names

18

19

20

21

RF Output connector (when MS269xA-020/120, MS2830A-020/120/021/121

installed)

Outputs RF signal, when the Vector Signal Generator option is installed.

This is an N type output connector.

This cannot be installed on the MS2830A with the MS2830A-044/045, or

on the MS2850A

USB connector (type A)

Connect the accessory USB keyboard, mouse or USB memory.

Modulation control key (when MS2830A-020/120/021/121 installed)

Press to switch on/off the modulation of RF signal when the Vector Signal

Generator option is installed. The lamp

in the modulation On state.

This cannot be installed on the MS2830A with the MS2830A-044/045, or

on the MS2850A.

Application key (MS2830A, MS2850A)

Press to switch between applications.

Press to display the Spectrum Analyzer main screen.

Press to display the Signal Analyzer main screen, when

MS2830A-005/105/007/006/106/009/109/077/078 or MS2850A

are installed.

Press to display the Signal Generator main screen, when Vector

Signal Generator option is installed. (MS2830A only)

This is a blank key. Not used. (MS2830A only)

Displays the main screen of the application that is selected

using the Application Switch (Auto), or displays that of the

pre-selected application (Manual).

For details, refer to 3.5.4 “Changing application layout” in

on the key lights up in green

MS2830A Signal Analyzer Operation Manual (Mainframe

Operation) or MS2850A Signal Analyzer Operation Manual

(Mainframe Operation)

.

Preparation

2

2-7

Page 26

Chapter 2 Preparation

1st Local Output connector (MS2830A, MS2850A)

22

This is installed with the MS2830A-044/045, or MS2850A.

Supplies local signal and bias current to the external mixer, and receives

the IF signal with its frequency converted.

2-8

Page 27

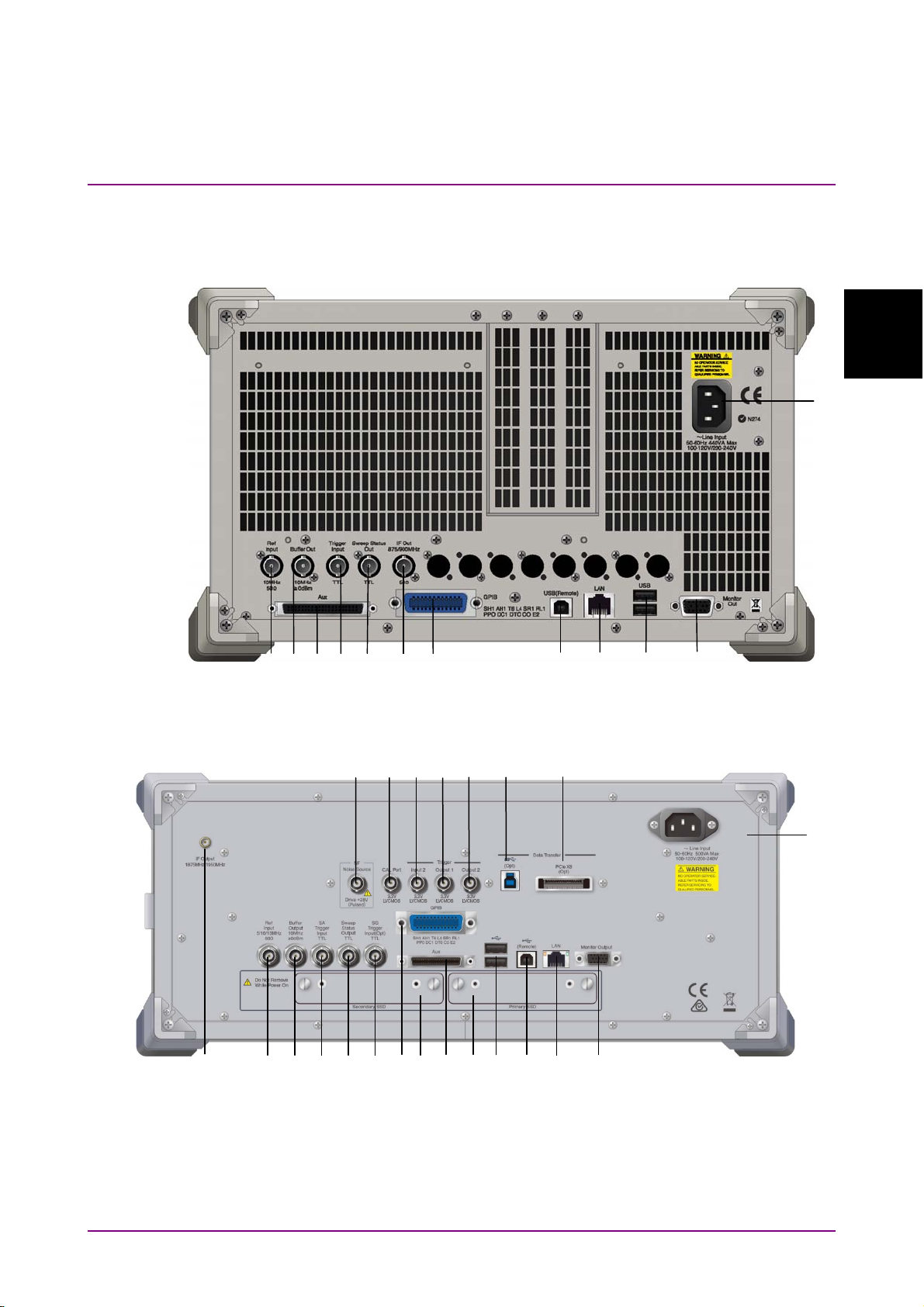

2.1.2 Rear panel

2.1 Part Names

This section describes the rear-panel connectors.

2

Preparation

12

1

2 6 3 4 5

Figure 2.1.2-1 MS269x series rear panel

18 19

Figure 2.1.2-2 MS2830A/MS2850A rear panel (MS2850A Example)

7

20 21

22 23 24

8 9 10

981067144 13 2 1 16 1517

11

11

12

2-9

Page 28

Chapter 2 Preparation

1

2

3

4

5

6

7

GP-IB

Ref Input connector (reference frequency signal input connector)

Inputs external reference frequency signal. It is for inputting reference

frequency signals with higher accuracy than the instrument’s internal

reference signal, or for synchronizing the frequency of the

MS2690A/MS2691A/MS2692A or MS2830A, MS2850A to that of other

equipment. The following frequencies are supported:

MS269x series: 10 MHz/13 MHz

MS2830A, MS2850A: 5 MHz/10 MHz/13 MHz

Buffer Out connector (reference frequency signal output connector)

Outputs the internal reference frequency signal (10 MHz). It is for

synchronizing frequencies between other equipment and the

MS2690A/MS2691A/MS2692A or MS2830A, MS2850A.

Trigger Input connector (MS269x series only)

Inputs trigger signal from external device.

Sweep Status Out connector

Outputs signal when internal measurement is performed or

measurement data is obtained.

IF Out connector (MS269x series only)

Not used.

AUX connector

Not used.

GPIB connector

For external control via GPIB.

2-10

Page 29

2.1 Part Names

8

9

10

11

12

Monitor Out

USB connector (type B)

For external control via USB.

Ethernet connector

Connects PC or Ethernet network.

USB connector (type A)

Used to connect a USB keyboard or mouse or the USB memory supplied.

Monitor Out connector

Connects external display.

AC inlet

Supplies power.

Preparation

2

13

14

15 HDD

16 HDD(Opt)

or

Primary HDD/SSD

or

Secondary HDD/SSD

SA Trigger Input connector (MS2830A, MS2850A)

This is a BNC connector for inputting external trigger signal (TTL) for

SPA and SA applications.

SG Trigger Input connector (MS2830A)

This is a BNC connector for inputting external trigger signal (TTL) for

Vector Signal Generator option.

HDD slot (MS2830A)

SSD slot (MS2850A)

HDD slot for Option (MS2830A)

SSD slot (MS2850A)

This is a standard HDD slot.

This is a standard SSD slot.

This is a HDD slot for the options.

This is a SSD slot for the options.

2-11

Page 30

Chapter 2 Preparation

17

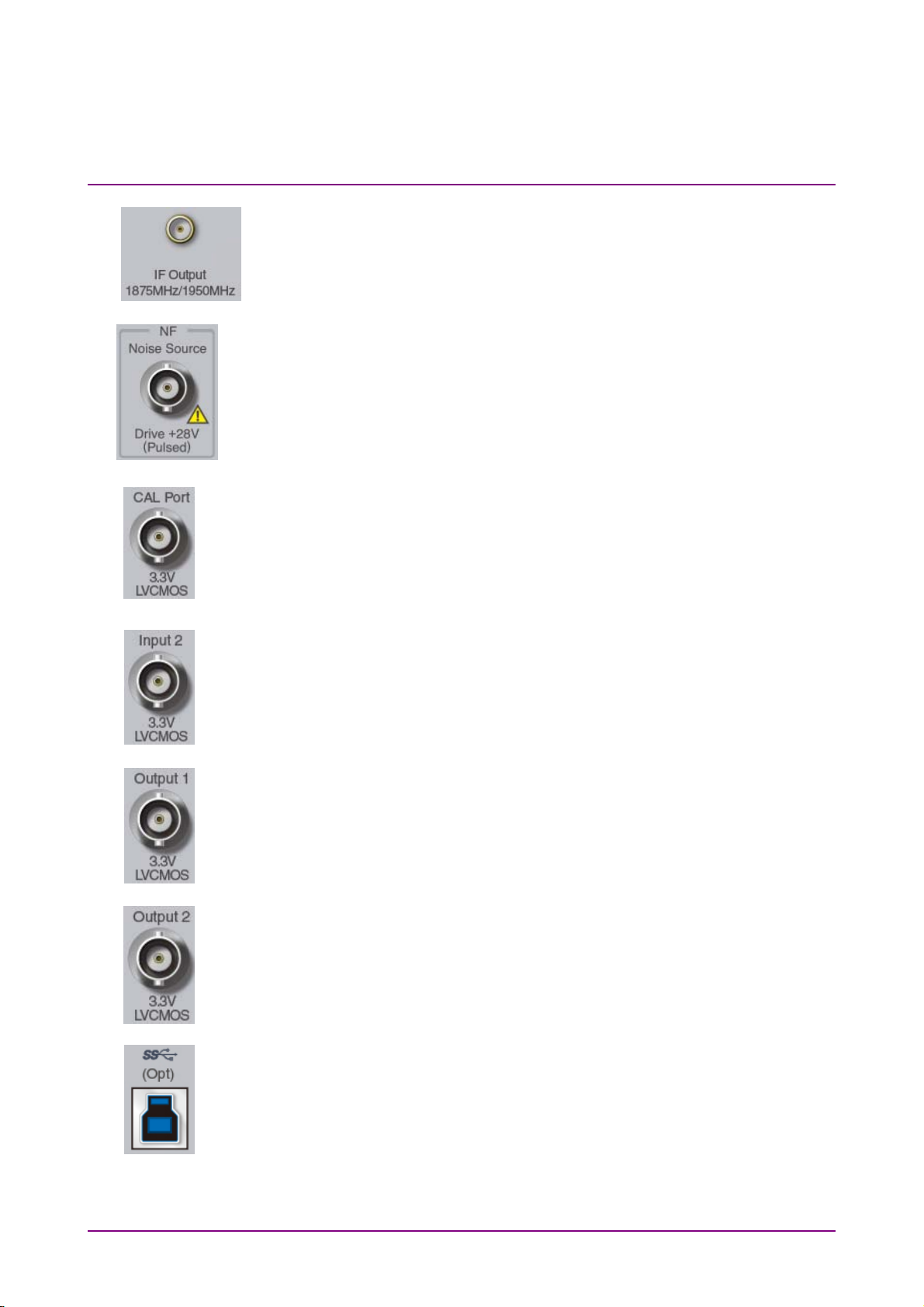

Noise Source connector

18

CAL Port connector (Future extensions) (MS2850A)

19

Trigger Input 2 connector (MS2850A)

20

Trigger Output 1 connector (MS2850A)

21

Trigger Output 2 connector (MS2850A)

22

USB 3.0 connector (MS2850A)

23

IF output connector (MS2830A, MS2850A)

This is installed with the MS2830A-044/045 or on the MS2850A.

Monitor output of the internal IF signal.

Supply (+28 V) of the Noise Source Drive.

This is available when the Option 017/117 is installed.

Input the trigger signal (3.3 V LVCMOS) for SPA and SA applications.

Output the trigger signal (3.3 V LVCMOS).

Output the trigger signal (3.3 V LVCMOS).

This is available when the MS2850A-054/154 is installed.

2-12

Page 31

PCIe X8 connector (MS2850A)

24

This is available when the MS2850A-053/153 is installed.

2.1 Part Names

2

Preparation

2-13

Page 32

Chapter 2 Preparation

2.2 Signal Path Setup

As shown in Figure 2.2-1, connect the instrument and the DUT using an

RF cable, so that the signal to be tested is input to the RF Input

connector. To prevent an excessive level signal from being input, do not

input the signal before setting the input level using this application.

RF Input

DUT

Figure 2.2-1 Signal path setup example

Set the reference signal and/or trigger signal paths from external sources,

as required.

Trigger signal (TTL)

Reference frequency signal

2-14

Figure 2.2-2 External signal input

Page 33

2.3 Application Startup and Selection

2.3 Application Startup and Selection

To use this application, it is necessary to load (start up) and select the

application.

2.3.1 Launching application

The application startup procedure is described below.

Note:

The XXX indicates the application name currently in use.

<Procedure>

1. Press

2. Press

Switch Registration screen.

3. Press

in the Unloaded Applications list.

If “XXX” is displayed in the Loaded Applications list, this means

that the application is already loaded.

If “XXX” appears in neither the Loaded Applications nor Unloaded

Applications list, this means that the application has not been

installed.

4. Press

Loaded Applications list, this means that the application is already

loaded.

2

Preparation

to display the Configuration screen.

(Application Switch Settings) to display the Application

(Load Application Select), and move the cursor to “XXX”

(Set) to load the application. If “XXX” is displayed in the

2.3.2 Selecting application

The selection procedure is described below.

<Procedure>

1. Press

2. Press the menu function key displaying “XXX”.

The application can also be selected with mouse, by clicking “XXX” on the

task bar.

to display the Application Switch menu.

2-15

Page 34

Chapter 2 Preparation

2.4 Initialization and Calibration

This section describes the parameter settings and the preparations

required before starting measurement.

2.4.1 Initialization

After selecting this application, first perform initialization. Initialization

returns the settable parameters to their default value in order to clear

the measurement status and measurement results.

Note:

When another software application is switched to or this

application is unloaded (ended), the application keeps the

parameter settings at that time. The parameter values that were

last set will be applied when this application is selected next time.

2.4.2 Calibration

The initialization procedure is as follows.

<Procedure>

1. Press

2. Press

Perform calibration before performing measurement. Calibration sets the

level accuracy frequency characteristics for the input level to flat, and

adjusts level accuracy deviation caused by internal temperature

fluctuations. Calibration should be performed when first performing

measurement after turning on power, or if beginning measurement when

there is a difference in ambient temperature from the last time

calibration was performed.

<Procedure>

1. Press

2. Press

For details on calibration functionality only executable with this

instrument, refer to the

Operation Manual (Mainframe Operation),

Operation Manual (Mainframe Operation)

Operation Manual (Mainframe Operation)

to display the Preset function menu.

(Preset).

to display the Application Cal function menu.

(SIGANA All).

MS2690A/MS2691A/MS2692A Signal Analyzer

MS2830A Signal Analyzer

or

MS2850A Signal Analyzer

.

2-16.

Page 35

Chapter 3 Measurement

3-1

Measurement

This chapter describes the measurement functions and parameters of the

MX269022A, together with descriptions of how to set them.

3.1 Basic Operation ............................................................ 3-6

3.1.1 Screen layout .................................................... 3-6

3.1.2 Types of Measurement Function ...................... 3-9

3.1.3 Performing Measurement ............................... 3-10

3.1.4 Measurement Signals and Troubleshooting

Errors .............................................................. 3-11

3.2 Setting Frequency and Level ...................................... 3-12

3.2.1 Carrier Frequency ........................................... 3-12

3.2.2 Input Level ...................................................... 3-12

3.2.3 Offset .............................................................. 3-13

3.2.4 Pre-Amp ......................................................... 3-14

3.2.5 Auto Range ..................................................... 3-14

3.3 Setting Trigger ............................................................ 3-15

3.3.1 Trigger Switch ................................................. 3-15

3.3.2 Trigger Source ................................................ 3-15

3.3.3 Trigger Slope .................................................. 3-16

3.3.4 Trigger Delay .................................................. 3-16

3.3.5 Frame Sync Setup .......................................... 3-16

3.4 Common Settings ....................................................... 3-17

3.4.1 Channel Bandwidth ........................................ 3-17

3.4.2 Test Model ...................................................... 3-17

3.4.3 Test Model Version ......................................... 3-17

3.4.4 Uplink-downlink Configuration ........................ 3-18

3.4.5 Special Subframe Configuration ..................... 3-19

3.4.6 Synchronization Mode .................................... 3-20

3.4.7 Cell ID ............................................................. 3-20

3.4.8 Reference Signal Boosting ............................. 3-21

3.4.9 Number of Antenna Ports ............................... 3-21

3.4.10 Antenna Port ................................................... 3-22

3.5 Setting Modulation Analysis ........................................ 3-23

3.5.1 Starting Subframe Number ............................. 3-23

3.5.2 Measurement Interval ..................................... 3-25

3.5.3 PDSCH Modulation Scheme .......................... 3-26

3.5.4 Total EVM & Constellation Composite ........... 3-27

3.5.5 EVM Window Length ...................................... 3-28

3.5.6 PBCH - On / Off .............................................. 3-29

3.5.7 PBCH - Power Auto/Manual

3.5.8 PBCH - Power Boosting ................................. 3-30

3.5.9 Precautions at Power Auto Setting ................. 3-31

3.5.10 P-SS - On/Off ................................................. 3-31

........................... 3-30

3

Page 36

Chapter 3 Measurement

3-2

3.5.11 P-SS - Power Auto / Manual .......................... 3-32

3.5.12 P-SS - Power Boosting ................................... 3-32

3.5.13 S-SS - On/Off ................................................. 3-32

3.5.14 S-SS - Power Auto/Manual ............................ 3-33

3.5.15 S-SS - Power Boosting ................................... 3-33

3.5.16 PDCCH - On / Off ........................................... 3-33

3.5.17 PDCCH - Power Auto / Manual ...................... 3-34

3.5.18 PDCCH - Power Boosting .............................. 3-34

3.5.19 PCFICH - On/Off ............................................ 3-34

3.5.20 PCFICH - Power Auto / Manual ..................... 3-35

3.5.21 PCFICH - Power Boosting .............................. 3-35

3.5.22 PHICH - On / Off ............................................. 3-36

3.5.23 PHICH - Power Auto / Manual ........................ 3-37

3.5.24 PHICH - Power Boosting ................................ 3-37

3.5.25 PDSCH - Power Auto / Manual ...................... 3-38

3.5.26 PDSCH - Power Boosting............................... 3-38

3.5.27 PHICH - TDD m_i=1(E-TM) On/Off ................ 3-39

3.5.28 PHICH - Ng ..................................................... 3-39

3.5.29 PHICH - Duration ............................................ 3-39

3.5.30 Number of PDCCH Symbols - Auto/Manual... 3-40

3.5.31 Number of PDCCH Symbols .......................... 3-41

3.5.32 PDCCH Mapping ............................................ 3-41

3.5.33 PDCCH Format .............................................. 3-42

3.5.34 Number of PDCCHs ....................................... 3-43

3.5.35 Channel Estimation ........................................ 3-43

3.5.36 DwPTS............................................................ 3-43

3.5.37 PDSCH EVM Calculation ............................... 3-44

3.5.38 Test Model Starting Frame Type .................... 3-44

3.5.39 Measurement Filter Type................................ 3-45

3.5.40 Extended Freq Lock Range ............................ 3-45

3.5.41 Operating Detail Settings Dialog .................... 3-45

3.5.42 Analysis Frame Position ................................

3.5.43 Analysis Offset Time ....................................... 3-46

3.6 Modulation Analysis Measurement and Results ......... 3-47

3.6.1 Setting Storage Mode/Count .......................... 3-48

3.6.2 Trace Mode .................................................... 3-49

3.6.3 Frame Offset ................................................... 3-50

3.6.4 Main Numeric Results .................................... 3-51

3.6.5 Setting EVM Display Units and Scale ............ 3-51

3.6.6 Constellation ................................................... 3-52

3.6.7 EVM vs Subcarrier .......................................... 3-53

3.6.8 EVM vs Symbol .............................................. 3-55

3.6.9 Spectral Flatness ............................................ 3-57

3.6.10 PDSCH Constellation ..................................... 3-59

. 3-46

Page 37

Chapter 3 Measurement

3-3

Measurement

3.6.11 Subframe Number .......................................... 3-59

3.6.12 Resource Block Number................................. 3-60

3.6.13 Power vs RB ................................................... 3-61

3.6.14 EVM vs RB ..................................................... 3-62

3.6.15 Marker............................................................. 3-63

3.6.16 Summary ........................................................ 3-66

3.6.17 Test Model Summary ..................................... 3-69

3.7 Power vs Time Setting ................................................ 3-71

3.7.1 Wide Dynamic Range ..................................... 3-72

3.7.2 Noise Correction ............................................. 3-73

3.7.3 Pre-Amp Mode ............................................... 3-73

3.7.4 Channel bandwidth ......................................... 3-74

3.7.5 Setting smoothing (Smoothing) ...................... 3-74

3.7.6 Select Mask .................................................... 3-75

3.7.7 Mask Setup ..................................................... 3-75

3.7.8 Frame Sync .................................................... 3-80

3.7.9 Limiter Mode ................................................... 3-81

3.8 Measurement and Result for Power vs Time ............. 3-84

3.8.1 Averaging (Storage) ....................................... 3-86

3.8.2 Main Numeric Results .................................... 3-87

3.8.3 Marker............................................................. 3-89

3.9 MIMO Summary Settings ............................................ 3-91

3.9.1 Number of Antenna Ports ............................... 3-91

3.9.2 Antenna Port ................................................... 3-91

3.9.3 Active Antenna Threshold .............................. 3-92

3.10 MIMO Summary Measurement Results ..................... 3-93

3.10.1 Numeric Results ............................................. 3-94

3.11 Setting Batch Measurement ....................................... 3-95

3.11.1 Common Settings : Storage Mode ................. 3-95

3.11.2 Common Settings : Storage Count ................. 3-95

3.11.3 Common Settings : Storage Mode for

Unwanted Emissions ...................................... 3-95

3.11.4 Common Settings : Storage Count for

Unwanted Emissions ...................................... 3-96

3.11.5 Common Settings : Starting Subframe

Number ........................................................... 3-96

3.11.6 Common Settings : Measurement Interval ..... 3-97

3.11.7 Common Settings : Starting OFDM Symbol

Number ........................................................... 3-97

3.11.8 Common Settings : Measurement Interval for

3.11.9 Common Settings : Modulation Analysis ........ 3-98

3.11.10 Common Settings : OBW ............................. 3-99

3.11.11 Common Settings : ACLR ............................ 3-99

Unwanted Emissions ...................................... 3-98

3

Page 38

Chapter 3 Measurement

3-4

3.11.12 Common Settings : OBUE

(Operating Band Unwanted Emissions) ....... 3-99

3.11.13 Band Settings : Measurement Item ........... 3-100

3.11.14 Band Settings : Carrier Frequency ............ 3-101

3.11.15 Band Settings : Input Level ........................ 3-101

3.11.16 Band Settings : Pre-Amp ........................... 3-102

3.11.17 Band Settings : Level Offset ...................... 3-102

3.11.18 Band Settings : Offset Value ...................... 3-102

3.11.19 Band Settings : Contiguous Mode ............. 3-103

3.11.20 Band Settings : OBUE Standard ................ 3-103

3.11.21 Band Settings : OBUE Standard Additional3-104

3.11.22 CC Settings : Measurement Item ............... 3-104

3.11.23 CC Settings : Frequency Band .................. 3-105

3.11.24 CC Settings : Frequency Offset ................. 3-105

3.11.25 CC Settings : Channel Bandwidth ............. 3-106

3.11.26 CC Settings : Test Model ........................... 3-106

3.11.27 CC Settings :

Test Model Starting Frame Type ............... 3-107

3.11.28 CC Settings :

Uplink-downlink Configuration ................. 3-107

3.11.29 CC Settings :

Special Subframe Configuration ................ 3-108

3.11.30 CC Settings : Synchronization Mode ......... 3-108

3.11.31 CC Settings : Cell ID .................................. 3-109

3.11.32 CC Settings : CRS Power Boosting ........... 3-109

3.11.33 CC Settings :

CRS Number of Antenna Ports .................. 3-110

3.11.34 CC Settings :

CSI-RS Number of Antenna Ports ............. 3-110

3.11.35 CC Settings : CRS Antenna Port ............... 3-111

3.11.36 CC Settings : CSI-RS Antenna Port .......... 3-111

3.11.37 CC Settings : PDSCH Modulation Scheme 3-112

3.11.38 CC Settings : EVM Window Length ........... 3-112

3.11.39 CC Settings : Channel Estimation ............. 3-113

3.11.40 CC Settings : DwPTS ................................. 3-113

3.11.41 CC Settings :

DwPTS for Unwanted Emissions ............... 3-113

3.11.42 CC Settings : Measurement Filter Type ..... 3-114

3.11.43 CC Settings : PBCH On/Off ....................... 3-114

3.11.44 CC Settings : PBCH Power Auto/Manual .. 3-115

3.11.45 CC Settings : PBCH Power Boosting ........ 3-115

3.11.46 CC Settings : P-SS On/Off ......................... 3-116

3.11.47 CC Settings : P-SS Power Auto/Manual .... 3-116

3.11.48 CC Settings : P-SS Power Boosting .......... 3-

117

Page 39

Chapter 3 Measurement

3-5

Measurement

3.11.49 CC Settings : S-SS On/Off ......................... 3-117

3.11.50 CC Settings : S-SS Power Auto/Manual .... 3-118

3.11.51 CC Settings : S-SS Power Boosting .......... 3-118

3.11.52 CC Settings : PDCCH On/Off .................... 3-119

3.11.53 CC Settings : PDCCH Power Auto/Manual 3-119

3.11.54 CC Settings : PDCCH Power Boosting ...... 3-120

3.11.55 CC Settings : PCFICH On/Off .................... 3-120

3.11.56 CC Settings : PCFICH Power Auto/Manual3-121

3.11.57 CC Settings : PCFICH Power Boosting ..... 3-121

3.11.58 CC Settings : PHICH On/Off ...................... 3-122

3.11.59 CC Settings : PHICH Power Auto/Manual . 3-122

3.11.60 CC Settings : PHICH Power Boosting ....... 3-123

3.11.61 CC Settings : PDSCH Power Auto/Manual 3-123

3.11.62 CC Settings : PDSCH Power Boosting ...... 3-124

3.11.63 CC Settings : PHICH - Ng .......................... 3-124

3.11.64 CC Settings : PHICH Duration ................... 3-125

3.11.65 CC Settings : Number of PDCCH Symbols -

Auto/Manual ............................................... 3-125

3.11.66 CC Settings : Number of PDCCH Symbols

for Subframe 1 and 6 ................................. 3-126

3.11.67 CC Settings : Number of PDCCH Symbols 3-126

3.11.68 CC Settings : PDCCH Mapping ................. 3-127

3.11.69 CC Settings : PDCCH Format ................... 3-127

3.11.70 CC Settings : Number of PDCCHs ............ 3-128

3.11.71 CC Settings : CSI-RS On/Off ..................... 3-128

3.11.72 CC Settings : CSI-RS Configuration .......... 3-129

3.11.73 CC Settings : CSI-RS Periodicity T ............ 3-129

3.11.74 CC Settings : CSI-RS Subframe Offset ..... 3-130

3.12 Batch Measurement Results ..................................... 3-131

3.12.1 Measurement results .................................... 3-131

3.13 Spectrum Measurement ........................................... 3-133

3.13.1 Measurement results .................................... 3-135

3.13.2 Advanced Settings ........................................ 3-136

3

Page 40

Chapter 3 Measurement

3-6

3.1 Basic Operation

3.1.1 Screen layout

This section describes the screen layout of the MX269022A.

Figure 3.1.1-1 Screen Appearance (Modulation Analysis)

1. Title

This displays the title of the application. The title can be changed.

6.2 Setting Title

2. Measurement Parameter

This displays the settings of the main parameters.

Carrier Freq.

Modulation

(Displayed when Test Model set to Off)

Test Model

Channel Bandwidth

Input Level

ATT

Internal attenuator setting (automatic)

Input signal carrier frequency setting

PDSCH modulation method setting

Test model setting

(Displayed when Test Model not set to

Off)

Channel bandwidth setting

Average power setting while input

signal transmission on

Page 41

3.1 Basic Operation

3-7

Measurement

Offset

Trigger

Delay

3. Measurement Status

This displays the measurement results of status and storage status.

performing measurement is too large for the settings. When Level

Over is displayed, either increase the Input Level value or decrease

the level of the input signal and measure again.

"Measuring" indicates that measurement is in progress.

the input signal has failed. Measurement results are not displayed

on the screen when this happens. When the signal abnormal is

displayed, check the status of the input signal and the correct

settings for this application.

Trigger signal type setting

Trigger delay setting

Reference Signal

Reference Signal detection method

indicates that the level of the signal input for

Level offset setting (displayed at Offset

On)

(displayed at Trigger Switch On)

(displayed at Trigger Switch On)

3.2.2 Input Level

3.1.3 Performing Measurement

indicates that frame synchronization with

3

3.1.4 Measurement Signals and Troubleshooting Errors

The storage status is indicated at the right side of the measurement

status field. It is not displayed when Storage Mode is set to Off. The

numeric value at the right side of

setting and the numeric value at the left side indicates the

completed measurement count.

4. Constellation

This field displays the symbol constellation for the specified range.

The marker positions and I and Q Coordinates for the marker

positions are displayed on the left side of the constellation screen.

The constellation is displayed when Modulation Analysis is selected.

5. Numeric Results/Graph (Upper)

This displays the measurement results for the currently selected

Measure function and Trace Mode.

"/"

indicates the Storage Count

Page 42

Chapter 3 Measurement

3-8

6. Graph/Numeric Results (Lower)

This displays the measurement results for the currently selected

Measure Function and Trace Mode. The Trace Mode contents are

displayed when Modulation Analysis is selected.

7. Reference Frequency Signal

This indicates that type and status of the detected reference

frequency signal.

Ref.Int

8. Pre-amplifier Setting

9. Correction Setting

Internal reference frequency signal/lock status

Ref.Ext

Ref.Int Unlock

Ref.Ext Unlock

This indicates a pre-amplifier settings status.

Pre-Amp On

Pre-Amp Off

This is displayed when the Correction function is On.

External reference frequency signal/lock status

Internal reference frequency signal/unlock

status

External reference frequency signal/unlock

status

Preamplifier On

Preamplifier Off or not installed

3.2.4 Pre-Amp

Refer to the

MS2690A/MS2691A/MS2692A Signal Analyzer

Operation Manual (Mainframe ,Operation), MS2830A Signal

Analyzer Operation Manual (Mainframe Operation), or MS2850A

Signal Analyzer Operation Manual (Mainframe ,Operation)

10. Message

The indicates the cause of the Signal Abnormal display.

"Synchronizing signal cannot be detected" indicates that

synchronization with the input signal was lost.

11. Function Menu

This indicates the functions that can be executed by the relevant

function keys.

3.1.4 Measurement Signals and Troubleshooting Errors

.

Page 43

3.1 Basic Operation

3-9

Measurement

3.1.2 Types of Measurement Function

This application has the following measurement functions.

(1) Modulation Analysis

Measures the modulation accuracy such as frequency error, EVM,

etc.

(2) Power vs Time

Measures the time fluctuations of power of the obtained measured

signal.

(3) ACP (FFT)

Recalls the ACP function of the Signal Analyzer function. This

function is only enabled when Channel Bandwidth is set to 1.4, 3,

and 5 MHz.

(4) ACP (Swept)

3

Recalls the ACP function of the Spectrum Analyzer function.

(5) Channel Power (FFT)

Calls Signal Analyzer function and Channel Power function

(6) Channel Power (Swept)

Recalls the Channel Power function of the Spectrum Analyzer

function.

(7) OBW (FFT)

Recalls the OBW function of the Signal Analyzer function.

(8) OBW (Swept)

Recalls the OBW function of the Spectrum Analyzer function.

(9) Spectrum Emission Mask (Swept)

Recalls the spectrum emission mask function of the Spectrum

Analyzer function.

Page 44

Chapter 3 Measurement

3-10

3.1.3 Performing Measurement

There are two measurement modes: single and continuous. Measurement

is performed once in the single measurement mode, and continuously in

the continuous measurement mode.

Single Measurement

After capturing an input signal based upon the settings of Capture Time,

the selected measurement items are measured only for the measurement

count (Storage Count) before measurement is stopped.

Continuous Measurement

1. Press

2. Press

After capturing an input signal based upon the settings of Capture Time,

the selected measurement items are continuously measured for the

measurement count (Storage Count).

1. Press

2. Press

Notes:

The two measurement modes are not available when the Replay

•

function is executed. For the Replay function, analysis starts

when the IQ data file is specified.

The continuous measurement cannot be performed at the

•

Power vs Time Measurement. The measurement mode is

switched forcefully from the continuous measurement to the

single measurement.

to select the measurement function.

.

to select the measurement function.

.

4.1.1 Loading IQ Data

4.2 Replay Function

Page 45

3.1 Basic Operation

3-11

Measurement

3.1.4 Measurement Signals and Troubleshooting Errors

Wireless standard

3GPP TS36.211 V8.6.0 (2009-03)

Multiplex method

TDD

Frame length (1

frame)

Channel Bandwidth

1.4 / 3 / 5 / 10 / 15 / 20 MHz

Cyclic prefix (CP)

Normal cyclic prefix

Uplink-downlink

0 to 6

(DL Subframe included in subframe)

Special subframe

0 to 8

(DwPTS included)

PDSCH (required), PBCH, PCFICH, PDCCH,

PHICH

Reference signal (required), Synchronization

signal

Test Model

E-TM1.1 / 1.2 / 2 / 2a / 3.1 / 3.1a / 3.2 / 3.3

Table 3.1.4-1 lists the minimum requirements for measuring with the

MX269022A. To measure with this application, check that the input

signal satisfies the conditions listed in Table 3.1.4-1 and that the

application settings match these conditions.

Table 3.1.4-1 Measurement Signals (minimum conditions)

Item Value

10 ms = 10 subframes

configuration

3

configuration

Physical channels

Physical signals

Note:

This application is for frame synchronizing the Reference or

Synchronization signals (determined by Synchronization Mode

settings) included in 10 Downlink subframes (5 frames max.).

If Signal Abnormal is displayed, consider the following possible causes.

Check the input signal parameter settings and try to measure again.

(1) The Carrier Frequency Settings do not match the input signal

carrier frequency.

(2) The input level is too low for the Input Level setting.

(3) The Synchronization Mode is set to Synchronization Signal but there

is no Synchronization Signal in the input signal.

(4) The Synchronization Mode is set to Reference Signal but the set Cell

ID is different from the input signal.

Page 46

Chapter 3 Measurement

3-12

3.2 Setting Frequency and Level

3.2.1 Carrier Frequency

This sets the carrier frequency of the input signal.

You cannot set Carrier Frequency when the Replay function is executed.

3.2.2 Input Level

4.2 Replay Function

Procedure

> (Frequency) > (Carrier Frequency)

or

Range 300 MHz to the upper limit of the main unit

(MS2830A-078, MS2850A)

100 MHz to the upper limit of the main unit

(MS269xA, MS2830A other than above.)

100 MHz to the upper limit of the main unit

Minimum resolution 1 Hz

Default 2110 MHz

This sets the average power (rms) in the input signal transmission-on

period. The difference between the average power and the peak power

(crest factor) with this application is 14 dB. When calling the signal

analyzer or spectrum analyzer ACP, Channel Power, OB W, and SEM

measurement functions from this application, set Input Level +14 dB as

Reference Level.

You cannot set Input Level when the Replay function is executed.

4.2 Replay Function

Procedure

> (Amplitude) > (Input Level)

or

Range With Pre-Amp On or Pre-Amp Mode On at Power vs Time

measurement:

(–80.00 + Offset Value) to (10.00 + Offset Value) dBm

With Pre-Amp Off:

(–60.00 + Offset Value) to (30.00 + Offset Value) dBm

Minimum resolution: 0.01 dB

Default

10.00 dBm

–

Page 47

3.2 Setting Frequency and Level

3-13

Measurement

3.2.3 Offset

DUT

40 dBm Output

Attenuator

30 dB

MS2690A/MS2691A/MS2692A,

MS2830A, or MS2850A

Input Level 40 dBm

Offset On

Offset Value 30 dB

10 dBm

Offset

This adds the displayed offset to the Input Level setting. Input the

increase or decrease in the level due to devices such as cables,

attenuators, amplifiers, etc., between this equipment and the

measurement target as the level offset and set the same input level as

the output level at the antenna of the DUT.

3

Figure 3.2.3-1 Setting Input Level and Level Offset

Procedure

> (Amplitude) > (Offset)

Offset Value

Options On, Off

Default Off

Note:

Offset is set automatically to on when setting Offset Value.

Procedure

> (Amplitude) > (Offset Value)

Range

Minimum resolution: 0.01 dB

Default 0.00 dB

Note:

The correction set at the System Config. screen is used irrespective

of the Offset Value.

99.99 to +99.99 dB

–

3.1.1 Screen layout

Page 48

Chapter 3 Measurement

3-14

3.2.4 Pre-Amp

The MS2690A/MS2691A/MS2692A-008/108 6 GHz Preamplifier,

MS2830A-008/108 Preamplifier, or MS2850A-068/168 Preamplifier

(hereinafter referred to as “Option 008”) is installed in this instrument.

The level sensitivity can be increased by setting this pre-amp to On.

You ca n not set Pre-Amp when the Replay function is executed.

3.2.5 Auto Range

4.2 Replay Function

Procedure

> (Amplitude) > (Pre-Amp)

Options On, Off

Default Off

Notes:

If opt-008 is not installed, the Pre-Amp menu is not displayed.

•

When Wide Dynamic Range is On at Power vs Time

•

measurement, the Pre-Amp menu is displayed in gray and the

function is disabled.

This function adjusts input level according to input signal.

You cannot set Auto Range when the Replay function is executed.

4.2 Replay Function

You cannot set Auto Range when Limiter Mode is On.

Procedure

> (Amplitude) > (Auto Range)

3.7.9 Limiter Mode

Page 49

3.3 Setting Trigger

3-15

Measurement

3.3 Setting Trigger

The trigger signal determining the measurement start timing may be

either the external input signal from the Trigger Input connector on the

back panel or an internal signal generated from the optional Vector

Signal Generator. Using this application, a header-timing signal with a

10-ms frame interval is input.

You cannot set Trigger when the Replay function is executed.

4.2 Replay Function

3

3.3.1 Trigger Switch

This enables/disables the trigger function.

Procedure

> (Trigger) > (Trigger Switch)

or

Options On (Enabled), Off (Disabled)

Default Off

3.3.2 Trigger Source

This sets the trigger signal type.

Procedure

or

Options

External*

External 2*

SG Marker Starts measurement by the timing of internal

Frame*

Frame Sync Setup*

*1: External 1 is displayed only for MS2850A.

*2: External 2 is selectable only for MS2850A.

*3: Frame is selectable only for MS2850A.

*4: Frame Sync Setup is selectable only for MS2850A.

Default External

> (Trigger Switch)

> (Trigger) > (Trigger Source)

> (Trigger Source)

1

Measurement starts with external trigger signal input.

2

Measurement starts with external trigger 2

signal input.

Vector Signal Generator option.

3

Starts measurement by the timing of

equipment-internal trigger.

4

Sets the Frame Trigger starting source if

Trigger Source is set to Frame. Frame Sync

Setup function menu is displayed.

Refer to 3.3.5 “Frame Sync Setup“

Page 50

Chapter 3 Measurement

3-16

3.3.3 Trigger Slope

3.3.4 Trigger Delay

This sets the trigger polarity.

Procedure

> (Trigger) > (Trigger Slope)

or

Options

Rise Synchronizes with rising edge of the trigger.

Fall Synchronizes with falling edge of the trigger.

Default Rise

This sets the difference between the trigger signal detection timing and

the measurement start timing.

Procedure

or

> (Trigger Slope)

> (Trigger) > (Trigger Delay)

> (Trigger Delay)

Range When the Measure is Modulation Analysis or

Minimum resolution: 20 ns

Default 0 s

3.3.5 Frame Sync Setup

Sets the Frame Trigger starting source if Trigger Source is set to Frame.

Procedure

or

Options

Frame Trigger Period Sets the generation period for the frame

Frame Sync Offset Sets the offset time from when a trigger

MIMO Summary.

–2 s to + 2 s

When the Measure is Batch Measurement.

0.5 to + 0.5 s

−

> (Trigger) > (Trigger Source) > (Frame Sync Setup)

>

(Trigger Source) > (Frame Sync Setup)

trigger signal. 10 ms fixed

signal (the equipment-internal trigger

signal, Wide IF Video signal, or external

trigger signal) is generated until a trigger

actually occurs. 0 s fixed

Page 51

3.4 Common Settings

3-17

Measurement

3.4 Common Settings

This section explains the shade parameters used by all measurement

functions of this application. These parameters are mainly referenced for

performing synchronization processing related to the input signal.

3.4.1 Channel Bandwidth

This sets the channel width.

Procedure

> (Common Setting) > (Channel Bandwidth)

or

Options 1.4 MHz, 3 MHz, 5 MHz, 10 MHz, 15 MHz, 20 MHz

Default 5 MHz

>

(Modulation Analysis) > (Channel Bandwidth)

3

3.4.2 Test Model

When the input signal is an E-UTRA Test Model (Test Model hereafter)

defined by 3GPP TS36.141, Test Model is set. When Test Model is set, the

parameters defined by Test Model are fixed. If there is no Test Model, Off

is set.

Procedure

or

Options Off, E-TM1.1, E-TM1.2, E-TM2, E-TM2a, E-TM3.1,

Default Off

3.4.3 Test Model Version

This sets the version of 3GPP TS36.141 when the input signal is an

E-UTRA Test Model (Test Model hereafter) defined by 3GPP TS36.141.

Procedure

> (Common Setting) > (Test Model)

>

(Modulation Analysis) > (Detail Settings)

E-TM3.1a, E-TM3.2, E-TM3.3

>

(Modulation Analysis) > (Detail Settings)

Options 3GPP TS36.141 V8.2.0 (2009-03),

Default 3GPP TS36.141 V8.3.0 (2009-05)

3GPP TS36.141 V8.3.0 (2009-05)

Page 52

Chapter 3 Measurement

3-18

3.4.4 Uplink-downlink Configuration

This sets the position of the Downlink subframe in the frame.

Table 3.4.4-1 shows the relation between the Uplink-downlink

Configuration and subframe type.

Table 3.4.4-1 Relation between Uplink-downlink Configuration and

Subframe Type

Uplink-downlink

Configuration

0 D S U U U D S U U U

1 D S U U D D S U U D

2 D S U D D D S U D D

3 D S U U U D D D D D

4 D S U U D D D D D D

5 D S U D D D D D D D

6 D S U U U D S U U D

D

: Downlink subframe

U

: Uplink subframe

S

: Special subframe (DwPTS + GP + UpPTS)

This can be set when Test Model is Off. The setting is fixed to 3 when

Test Model is not Off.

Procedure

Subframe number

0 1 2 3 4 5 6 7 8 9

> (Common Setting)

>

(Uplink-downlink Configuration)

Range 0 to 6

Default 3

Page 53

3.4 Common Settings

3-19

Measurement

3.4.5 Special Subframe Configuration

6592×Ts

19760×Ts

21952×Ts

24144×Ts

26366×Ts

6592×Ts

19760×Ts

21952×Ts

24144×Ts

This sets the configuration of the special subframe.

The special subframe is composed of three parts: the DwPTS (Downlink

part of the special subframe), the GP (Guard Period),and the UpPTS

(Uplink part of the special subframe). The length of the DwPTS and

UpPTS are determined by the Special Subframe Configuration as shown

in Table 3.4.5-1.

Table 3.4.5-1 Special Subframe Configuration

Special Subframe

Configuration

0

1

2

3

4

5

6

7

8

This can be set when Test Model is Off. It is fixed to 8 when Test Model is

not Off.

Procedure

> (Common Setting)

DwPTS UpPTS

2192×Ts

4384×Ts

3

>

(Special Subframe Configuration)

Range 0 to 8

Default 8

Page 54

Chapter 3 Measurement

3-20

3.4.6 Synchronization Mode

This sets the type of physical signal used for synchronization processing

with the input signal. When Reference Signal is selected, Cell ID must

also be set correctly.

This can be set when Test Model is Off. It is fixed to Synchronization

Signal when Test Model is not Off.

Procedure

> (Common Setting)> (Synchronization Mode)

or

> (Modulation Analysis) > (Detail Settings)

Options Reference Signal, Synchronization Signal

Default Synchronization Signal

3.4.7 Cell ID

3.4.7 Cell ID

This sets the Cell ID.

It is used to create the Reference Signal for synchronization and for

defining the physical channel depending on the Cell ID value. This

parameter is only enabled when Synchronization Mode is set to

Reference Signal.

3.4.6 Synchronization Mode

Procedure

> (Common Setting) > (Reference Signal)

>

(Cell ID)

or

> (Modulation Analysis) > (Detail Settings)

Range 0 to 503

Default 0

Page 55

3.4 Common Settings

3-21

Measurement

3.4.8 Reference Signal Boosting

This sets the Reference Signal Boosting level.

This application uses the power value for the specified Reference Signal

plus the value specified by this parameter as the reference level for each

physical channel and the physical signal (0 dB).

Physical Channel / Physical Signal Reference Level

It can be set when Test Model is Off. It is fixed to 0.000 dB when Tes t

Model is not Off.

Procedure

> (Common Setting) > (Reference Signal)

= Reference Signal Power - Reference Signal Boosting

Level

3

>

(Power Boosting)

or

>

Range

Default 0.000 dB

–

3.4.9 Number of Antenna Ports