Page 1

User Guide

PIM Master™

Passive Intermodulation Analyzer

with Site Master™ Cable &

Antenna Analyzer (331) and

2-Port Options (703)

MW82119B

Anritsu Company

490 Jarvis Drive

Morgan Hill, CA 95037-2809

USA

http://www.anritsu.com

Part Number: 10580-00400

Published: February 2021

Copyright 2014, 2021 Anritsu Company

Revision: N

Page 2

Page 3

Table of Contents

Chapter 1—General Information

1-1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Related Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Document Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Contacting Anritsu for Sales and Service . . . . . . . . . . . . . . . . . . . . . . . 1-2

1-2 Instrument Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

PIM Master Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1-3 Instrument Care and Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . . 1-4

Connector Care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Connecting Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Test Cable from PIM Master to DUT . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Disconnecting Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Connector Saver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

ESD Caution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Battery Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

PIM Master Firmware Update . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

1-4 Calibration Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

1-5 Wireless Remote Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Chapter 2—PIM Master Overview

2-1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2-2 Turning On the PIM Master for the First Time . . . . . . . . . . . . . . . . . . . . . . 2-1

Calibration Due Date . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Calibration Reminder. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2-3 Front Panel Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

MW82119B PIM Master Front Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2-4 Front Panel Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2-5 Top Connector Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

2-6 Top Connector Panel -- Option 703 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

2-7 Side Panel Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

2-8 Measurement Display Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Front Panel Display Areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Main Menu Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Submenu Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

2-9 Secondary Function Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

2-10 Mode Selector Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

2-11 Menu Key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

MW82119B UG PN: 10580-00400 Rev. N Contents-1

Page 4

Table of Contents (Continued)

2-12 Touch Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

Graphical User Interface (GUI) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

2-13 Touch Screen Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

Calibrate Touch Screen Shortcut. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

Arrow Navigation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

2-14 Parameter Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

2-15 Symbols and Indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-27

2-16 Soft Carrying Case . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-28

2-17 Tilt Bail Stand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-31

Chapter 3—Quick Start Guide

3-1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3-2 Measurement Mode Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3-3 Cable & Antenna Analyzer Measurements (Option 331) . . . . . . . . . . . . . . 3-3

Select the Measurement Type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Set the Frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Set the Amplitude . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Turn on Markers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Single Limit Line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

DTF Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Calibrate with OSL Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

3-4 Passive Intermodulation (PIM) Measurements . . . . . . . . . . . . . . . . . . . . . . 3-8

Preparing for PIM Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Calibrating the PIM Analyzer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Verifying Residual PIM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Verifying the PIM Standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Verifying the PIM Test Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Checking for External Interference . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Making PIM Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

Measurement Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

Adding a Limit Line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

3-5 Setting Up Markers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

3-6 Saving Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

Chapter 4—File Management

4-1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4-2 Managing Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

File Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Contents-2 PN: 10580-00400 Rev. N MW82119B UG

Page 5

Table of Contents (Continued)

4-3 File Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Saving Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Save Dialog Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Quick Name Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Recalling Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Recall Dialog Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Copying Files. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Deleting Files. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Delete Dialog Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

4-4 File Menu Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

4-5 File Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

4-6 Save Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

4-7 Save Location Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

Select Save Location Dialog Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

Create Directory Dialog Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

4-8 Recall Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-17

Recall Dialog Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

4-9 Copy Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

Copy Dialog Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

4-10 Delete Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-21

Chapter 5—System Operation

5-1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5-2 System Menu Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

System Menu Map. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5-3 System Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

System Options Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Display Settings Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Brightness Settings Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Reset Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

5-4 Preset Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

5-5 Self Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Chapter 6—GPS (Option 31)

6-1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6-2 Setting Up GPS (Option 31) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Activating the GPS Feature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

MW82119B UG PN: 10580-00400 Rev. N Contents-3

Page 6

Table of Contents (Continued)

6-3 GPS Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

GPS Info . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Chapter 7—Anritsu Tool Box with LST

7-1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7-2 Anritsu Tool Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7-3 Install the Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7-4 Line Sweep Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Why use Line Sweep Tools? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Line Sweep Tools Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

Using Line Sweep Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

Markers and Limit Lines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

Marker Presets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

Naming Grid. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

Report Generator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

Appendix A—Other Documents

A-1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

PIM Master Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Related Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Appendix B—PIM Carrier Bands

B-1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-1

B-2 PIM Master Carrier Bands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-1

Appendix C—Wireless Remote Control

C-1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-1

C-2 Portable Router for Wireless Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-1

C-3 Configuring the PIM Master for Wireless Browser Control . . . . . . . . . . . . .C-2

Contents-4 PN: 10580-00400 Rev. N MW82119B UG

Page 7

Table of Contents (Continued)

C-4 Using a ZyXEL MWR102 Travel Router. . . . . . . . . . . . . . . . . . . . . . . . . . . C-2

Connecting the Router to the PIM Master . . . . . . . . . . . . . . . . . . . . . . . C-3

Configuring PIM Master for use with Router . . . . . . . . . . . . . . . . . . . . . C-4

C-5 Remote Control via a Browser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-6

Screen Capture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-7

List of Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-7

Using Anritsu Line Sweep Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-8

Saving Measurements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-9

Password Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-11

Instrument Name . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-12

Appendix D—Instrument Messages and Errors

D-1 Error Messages: Stop Current Measurements . . . . . . . . . . . . . . . . . . . . . .D-1

D-2 PIM Analyzer Warning Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-1

D-3 Operation Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-3

Appendix E—Instrument Care

E-1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-1

Appendix Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-1

E-2 Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-1

E-3 Battery Care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-2

E-4 Battery Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-3

E-5 PIM Master Firmware Update . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-6

Determining the Firmware Version . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-6

Downloading the Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-6

Updating with a USB Memory Device . . . . . . . . . . . . . . . . . . . . . . . . . . E-7

E-6 Adding Options with a License File. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-9

Appendix F—LAN and DHCP

F-1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-1

MW82119B UG PN: 10580-00400 Rev. N Contents-5

Page 8

Table of Contents (Continued)

F-2 Ethernet Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-1

LAN Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-1

Ethernet Config . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-3

Ethernet Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-4

F-3 DHCP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-5

Example 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-5

Example 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-6

F-4 ipconfig Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-6

F-5 Ping Tool. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-7

Appendix G—Glossary

G-1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .G-1

G-2 Glossary Terms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .G-1

Index

Contents-6 PN: 10580-00400 Rev. N MW82119B UG

Page 9

Chapter 1 — General Information

1-1 Introduction

The PIM Master MW82119B User Guide is one of the set of manuals that cover all of the

instrument’s functions and uses. The PIM Master with Site Master and 2-port LTE 700 MHz

(option 703) options is capable of performing a wide variety of Passive Intermodulation (PIM)

and Line Sweep measurements. This guide provides a quick-start section with a brief

overview of the available PIM, Line Sweep, and 2-port measurements. Please refer to the

measurement guides listed in Table 1-1, “Related Documentation” for more detailed

measurement instructions. This guide also provides a summary of the hardware and software

features of the PIM Master that are common to all measurement modes.

Throughout this user guide, screen images are provided as examples. The image

Note

Related Documentation

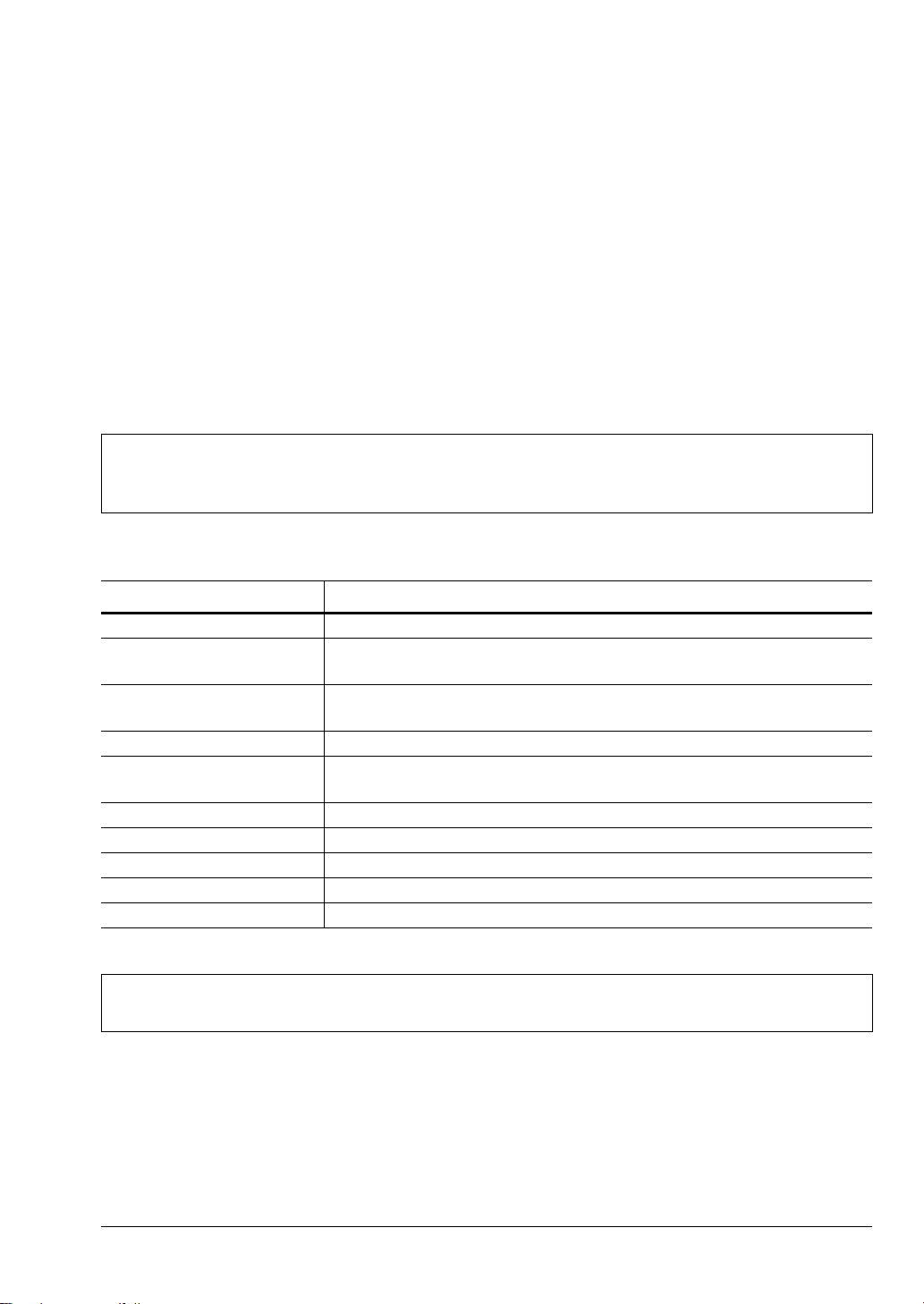

Document Part Number Description (Required Option)

10100-00065 Important Product Information, Compliance, and Safety Notices

10580-00240

10580-00241

11410-00824 PIM Master Product Brochure

11410-00821

10580-00402 Passive Intermodulation Analyzer Measurement Guide

10580-00403 PIM Master MW82119B Programming Manual

10580-00401 PIM Master MW82119B Maintenance Manual

11410-00784 Configuring the Anritsu PIM Master for Wireless Browser Control

10580-00252 Site Master User Guide

Table 1-1. Related Documentation

and measurement details on your instrument may differ from the examples in this

user guide.

Power Meter Measurement Guide

High-Accuracy Power Meter (Option 19)

Cable and Antenna Analyzer Measurement Guide

Cable and Antenna Analyzer (Option 331)

PIM Master Technical Data Sheet

Performance Specifications

Note

Read the Handheld Instruments Product Information, Compliance, and Safety Guide

(PN: 10100-00065) for important safety, legal, and regulatory notices before operating the

equipment. For additional information and literature covering your product, visit the product

page of your instrument and select the Library tab:

http://www.anritsu.com/en-US/test-measurement/products/mw82119B

MW82119B UG PN: 10580-00400 Rev. N 1-1

PIM is a measure of system linearity as compared to line sweeping, which is a

measure of system impedance. Both tests are critical to validate a cellular system.

Page 10

1-1 Introduction Chapter 1 — General Information

Document Conventions

Main menus and keypad buttons are shown in the user guide using a Serif Bold typeface.

Main menus are the buttons displayed at the bottom of the touchscreen. Submenus and

submenu buttons are displayed on the right side of the touchscreen display and shown in the

user guide using Serif Regular typeface.

Menu and button locations may be described in this document by their path:

Measurement > VSWR

The line above reads as “Press the Measurement main menu, then press the VSWR button."

Contacting Anritsu for Sales and Service

To contact Anritsu, please visit:

http://www.anritsu.com/contact-us

Here, you can find sales, customer service, and support contact information for your country

or region, provide online feedback, complete a “Talk to Anritsu” form to have your questions

answered, or obtain other services offered by Anritsu.

Updated product information can be found on the Anritsu web site:

http://www.anritsu.com/

Search for the product model number. The latest documentation is on the product page under

the Library tab.

Example URL for MW82119B:

http://www.anritsu.com/en-US/test-measurement/products/mw82119b

1-2 PN: 10580-00400 Rev. N MW82119B UG

Page 11

Chapter 1 — General Information 1-2 Instrument Description

1-2 Instrument Description

Anritsu developed the PIM Master, with Site Master and 2-Port LTE options, to fully

characterize the RF performance of transmission systems with a single test instrument.

Previously, two separate analyzers were required to measure Passive Intermodulation (PIM)

and impedance mismatches in RF transmission lines. With Site Master Option 331 installed,

the PIM Master can now perform both tests to ensure minimum signal degradation,

minimum noise generation, and maximum signal throughput. Capabilities with Option 331

installed include:

• PIM vs. TIME • Swept PIM

• Noise Floor • Distance-to-PIM

• Return Loss • VSWR

• Cable Loss • Distance-to-Fault (DTF)

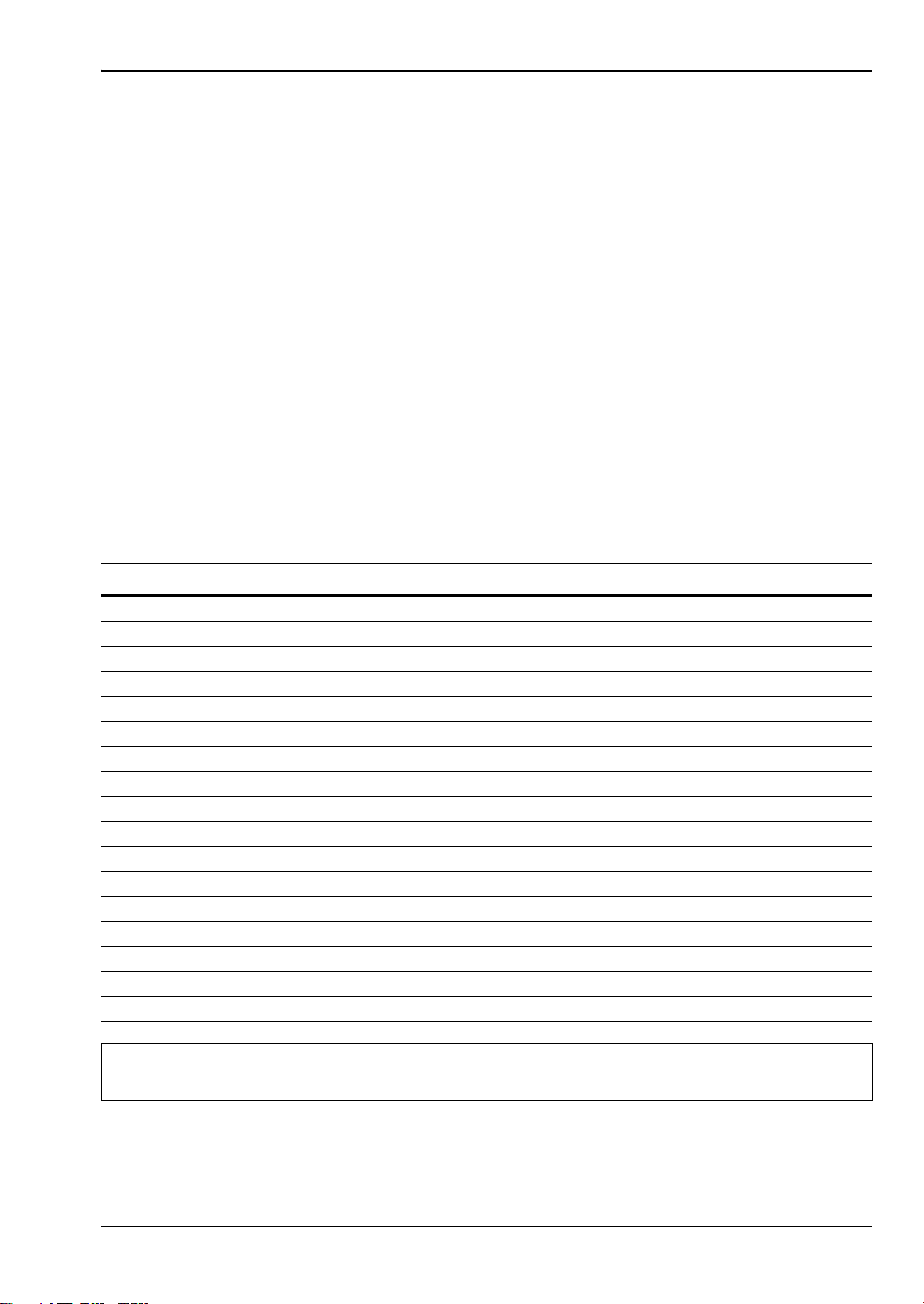

PIM Master Options

Table 1-2 lists the current available options. Refer to the Anritsu web site for the latest

information on available PIM Master options and frequency ranges.

Table 1-2. PIM Master Options

Note

Instrument Option Description

MW82119B-0600 LTE 600 MHz with 1900 MHz

MW82119B-0700 LTE 700 MHz

MW82119B-0701 APT 700 MHz

MW82119B-0703 2-Port LTE 700MHz

MW82119B-0800 LTE 800 MHz

MW82119B-0850 Cellular 850 MHz

MW82119B-0900 E-GSM 900 MHz

MW82119B-0902 E-GSM 900 MHz with IM2

MW82119B-0180 DCS 1800 MHz

MW82119B-0194 PCS/AWS 1900/2100 MHz

MW82119B-0210 UMTS 2100 MHz

MW82119B-0260 LTE 2600 MHz

MW82119B-0331 Site Master Cable and Antenna Analyzer

MW82119B-0031 GPS Receiver (requires antenna)

MW82119B-0019 High Accuracy Power Meter (requires sensor)

MW82119B-0098 Standard Calibration Certification

MW82119B-0099 Premium Calibration Certification

For ordering information and for option and accessory part numbers, refer to the

technical data sheet (listed in Appendix A).

MW82119B UG PN: 10580-00400 Rev. N 1-3

Page 12

1-3 Instrument Care and Preventive Maintenance Chapter 1 — General Information

1-3 Instrument Care and Preventive Maintenance

Site Master care and preventive maintenance consists of cleaning the unit and inspecting and

cleaning the RF connectors on the instrument and all accessories. Clean the Site Master with

a soft, lint-free cloth dampened with water or water and a mild cleaning solution.

Caution To avoid damaging the display or case, do not use solvents or abrasive cleaners.

Connector Care

Clean the RF connectors and center pins with a cotton swab dampened with denatured

alcohol. Visually inspect the connectors. The fingers of the N(f) connectors and the pins of the

N(m) connectors should be unbroken and uniform in appearance. If you are unsure whether

the connectors are undamaged, gauge the connectors to confirm that the dimensions are

correct. Visually inspect the test port cable(s). The test port cable should be uniform in

appearance, and not stretched, kinked, dented, or broken.

To prevent damage to your instrument, do not use pliers or a plain wrench to tighten the

Type-N connectors. The recommended torque is 12 lbf ·in to 15 lbf· in (1.36 N·m to 1.70 N·m).

Inadequate torque settings can affect measurement accuracy. Over-tightening connectors can

damage the cable, the connector, the instrument, or all of these items.

Visually inspect connectors for general wear, cleanliness, and for damage such as bent pins or

connector rings. Repair or replace damaged connectors immediately. Dirty connectors can

limit the accuracy of your measurements. Damaged connectors can harm the instrument.

Connection of cables carrying an electrostatic potential, excess power, or excess voltage can

damage the connector, the instrument, or both.

Connecting Procedure

1. Carefully align the connectors.

The male connector center pin must slip concentrically into the contact fingers of the

female connector.

2. Push connectors straight together. Do not twist or screw them together.

3. To tighten, turn the connector nut, not the connector body. Major damage can occur to

the center conductor and to the outer conductor if the connector body is twisted.

4. When you use a torque wrench, initially tighten by hand so that approximately 1/8 turn

or 45 degrees of rotation remains for the final tightening with the torque wrench.

Relieve any side pressure on the connection (such as from long or heavy cables) in order

to assure consistent torque. Use an open-end wrench to keep the connector body from

turning while tightening with the torque wrench.

Do not over-torque the connector.

1-4 PN: 10580-00400 Rev. N MW82119B UG

Page 13

Chapter 1 — General Information 1-3 Instrument Care and Preventive Maintenance

Test Cable from PIM Master to DUT

Remove O-rings from the test cable and be sure that the connectors are clean. If the DUT

connector has an O-ring, then use a torque wrench to tighten the connector.

When testing, cables are connected and disconnected many times. In order to

save wear on these test cables and RF adapters, Anritsu recommends removing

the O-rings. This allows getting a sufficiently tight connection without unnecessary

Note

stress on the connectors. In the field, O-rings are important to maintain connection

integrity over long time periods. Connections must be torqued to specifications in

order to ensure that they prevent water intrusion.

During your test, if the DUT connector has an o-ring, leave it in place and tighten

to the correct torque.

Disconnecting Procedure

1. If a wrench is needed, use an open-end wrench to keep the connector body from turning

while loosening with a second wrench.

2. Complete the disconnection by hand, turning only the connector nut.

3. Pull the connectors straight apart without twisting or bending.

Connector Saver

Anritsu recommends using an adapter on the intrument's 7/16 DIN female RF Out connector

to act as a connector saver. Typically, the instrument's connector has a useful life of 500

matings. A 7/16 DIN(f) to 7/16 DIN(m) and 50 Ω connector saver reduces wear on the

connector, and may stay on the instrument while it is in the soft case or transit case. One

connector saver is provided with your test instrument.

The recommended torque for attaching the connector saver to the instrument is 25 N · m

(~18 lbf · ft). Use a torque wrench to make the connection.

Replacement connector savers can be purchased from Anritsu. The part number is in your

Technical Data Sheet.

MW82119B UG PN: 10580-00400 Rev. N 1-5

Page 14

1-3 Instrument Care and Preventive Maintenance Chapter 1 — General Information

ESD Caution

The PIM Master, like other high-performance instruments, is susceptible to electrostatic

discharge (ESD) damage. Coaxial cables and antennas often build up a static charge, which

(if allowed to discharge by connecting directly to the PIM Master without first discharging the

static charge) may damage the PIM Master input circuitry.

Caution

Operators should exercise practices outlined within industry standards such as JEDEC-625

(EIA-625), MIL-HDBK-263, and MIL-STD-1686, which pertain to ESD and ESDS devices,

equipment, and practices. Because these apply to the PIM Master, Anritsu recommends that

any static charges that may be present be dissipated before connecting coaxial cables or

antennas to the PIM Master. This may be as simple as temporarily attaching a short or load

device to the cable or antenna prior to attaching to the PIM Master. It is important to

remember that the operator may also carry a static charge. Following the practices outlined

in the referenced standards will ensure a safe environment for both personnel and

equipment.

Operators must be aware of the potential for ESD damage and take all necessary

precautions.

Battery Information

The batteries that are supplied with the PIM Master may need charging before use. They can

be charged using either the AC-DC Adapter or the DC adapter. The batteries can also be

charged by using an external charger (refer to your Technical Data Sheet). Refer to

Section E-3 “Battery Care” on page E-2.

Use only Anritsu Company approved batteries, adapters, and chargers with this

instrument.

The batteries charge at a faster rate when the instrument is turned off. Charging

the batteries while the instrument is running requires a longer time to reach a full

charge.

Note

To prolong the useful battery life, the internal charging circuit monitors the battery

temperature. Normal charging occurs when the battery temperature is between

0 °C and 45 °C. Charging is paused if the internal battery temperature is beyond

this range.

Anritsu Company recommends removing the battery for long-term storage of the

instrument.

When using the Automotive Cigarette Lighter Adapter, always verify that the

Caution

The PIM Master batteries can be replaced without the use of tools. The battery compartment

access is on the bottom of the PIM Master. Refer to Section E-4 “Battery Replacement”

on page E-3.

1-6 PN: 10580-00400 Rev. N MW82119B UG

supply is rated for a minimum of 40 Watts at 12 VDC, and that the socket is clear

of any dirt or debris. If the adapter plug becomes hot to the touch during operation,

then discontinue use immediately.

Page 15

Chapter 1 — General Information 1-4 Calibration Requirements

PIM Master Firmware Update

Refer to Section E-5 “PIM Master Firmware Update” on page E-6 for firmware upgrade

procedures.

1-4 Calibration Requirements

Field-calibrate your PIM Master as required to achieve acceptable residual PIM. The

instrument provides calibration prompts to help you determine calibration status. Anritsu

recommends annual factory calibration and performance verification by local Anritsu

service centers. The Cable and Antenna Analyzer mode requires calibration standards for

OPEN, SHORT, and LOAD (OSL), which are sold separately.

Note

Anritsu recommends allowing the instrument to warm up to typical operation

temperature (approximately 15 minutes) before calibrating.

1-5 Wireless Remote Control

Browser-based control allows you to remotely control the PIM Master from any Wi-Fi enabled

device with web browser software (Chrome or Firefox preferred). This includes a wide range

of tablets and phones running Android or iOS operating systems as well as the traditional

Linux and Windows laptop and desktop computers.

Wi-Fi links are useful in the field, particularly when the PIM Master is on a tower, and you

are on the ground.

For wireless remote control, a Wi-Fi router must be connected to the PIM Master.

Refer to Appendix C, “Wireless Remote Control” for more details on using this capability to

enable wireless control.

MW82119B UG PN: 10580-00400 Rev. N 1-7

Page 16

1-5 Wireless Remote Control Chapter 1 — General Information

1-8 PN: 10580-00400 Rev. N MW82119B UG

Page 17

Chapter 2 — PIM Master Overview

2-1 Introduction

This chapter describes the MW82119B PIM Master. It also includes a brief description of

preventive maintenance, calibration requirements, and additional PIM Master documents.

The Anritsu PIM Master is capable of producing 80 Watts of RF power in the

cellular communications bands. Users must take precautions to minimize

exposure to these RF fields:

Always terminate the PIM output port of the test equipment into a load, a

loaded line, or a line that will radiate or absorb the energy before beginning

a PIM test.

Warning

Confirm that the PIM Master RF power is off after a PIM test.

Always confirm that the PIM RF power is off before disconnecting a coaxial

connection, otherwise RF burns may result. Immediate burns to fingers or

eyes can result from exposure to live connectors.

Ensure that all antennas under test are placed so that no personnel are

exposed to RF levels that exceed the maximum allowable exposure.

2-2 Turning On the PIM Master for the First Time

The Anritsu MW82119B PIM Master is capable of more than 3.0 hours of continuous

operation from a fully charged, field-replaceable battery (refer to Section E-4 “Battery

Replacement” on page E-3). The PIM Master can also be operated from a 12 VDC source

(which will also simultaneously charge the battery). This can be achieved with either the

Anritsu AC Adapter or Automotive 12 Volt Adapter. Both items are included as standard

accessories (refer to the list of accessories in the Technical Data Sheet for your specific

instrument, as listed in Appendix A).

When using the Automotive Adapter, always verify that the supply is rated for a

Caution

To turn on the MW82119B PIM Master, press the On/Off button on the front panel

(Figure 2-3 on page 2-4). The PIM Master takes approximately 40 seconds to complete

power-up and to load the application software. At the completion of this process, the

instrument is ready to be used.

Note

minimum of 60 Watts at 12 VDC and that the socket is clear of any dirt or debris. If

the adapter plug becomes hot to the touch during operation, then discontinue use

immediately.

Anritsu recommends that you turn on your PIM Master and let it warm up for

10 minutes before performing your first calibration.

MW82119B UG PN: 10580-00400 Rev. N 2-1

Page 18

2-2 Turning On the PIM Master for the First Time Chapter 2 — PIM Master Overview

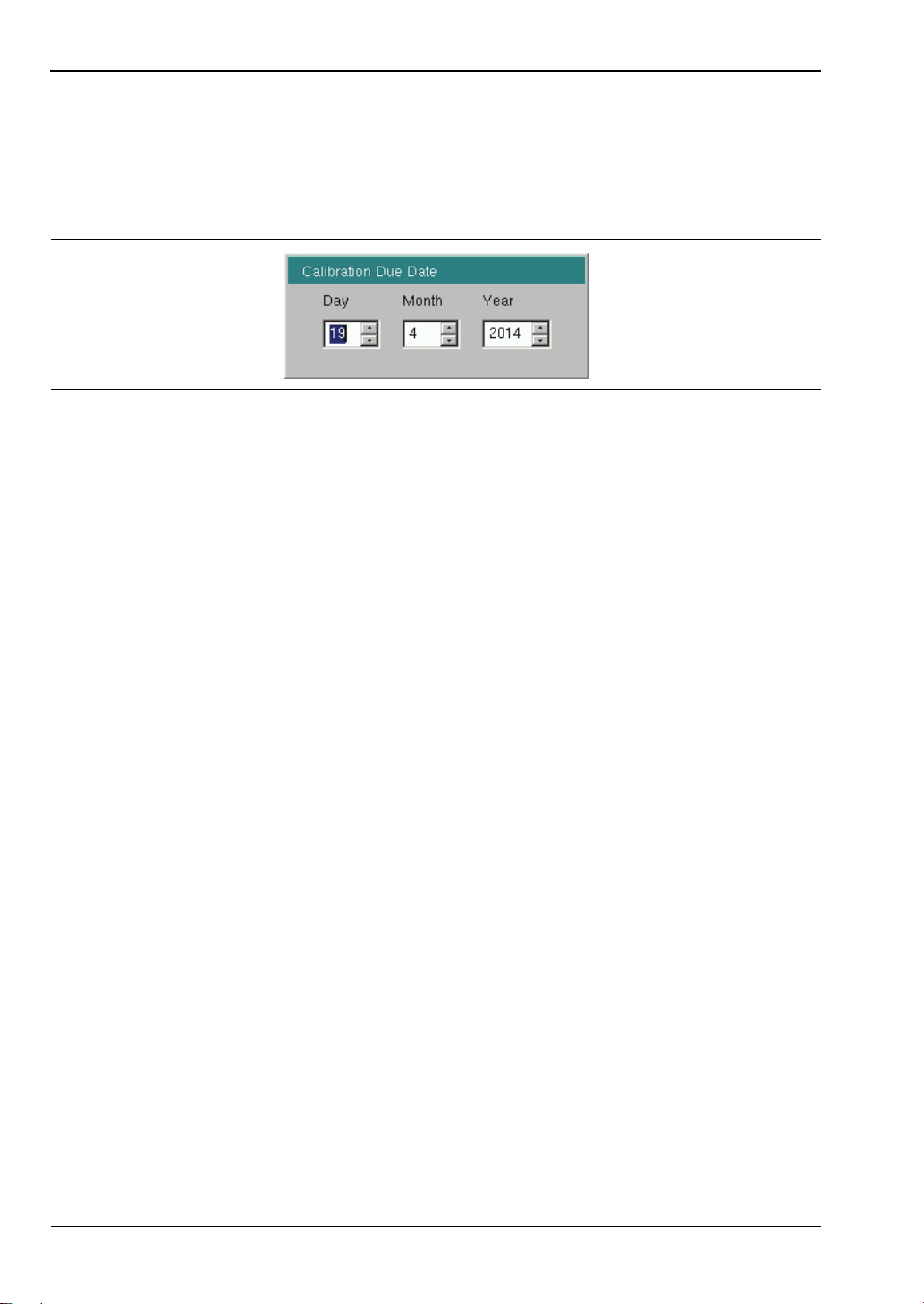

Calibration Due Date

On first use, or if the Calibration Reminder setting is greater than the due date, a menu is

displayed requesting that you enter the Calibration Due Date for this instrument. This date is

available on the calibration sticker that is provided with the instrument. Enter the correct

day, month, and year and then press Enter.

Figure 2-1. Calibration Due Date Dialog Box

The initial calibration due date is set to one year from the Factory Calibration Date, unless

you enter a different date.

2-2 PN: 10580-00400 Rev. N MW82119B UG

Page 19

Chapter 2 — PIM Master Overview 2-3 Front Panel Overview

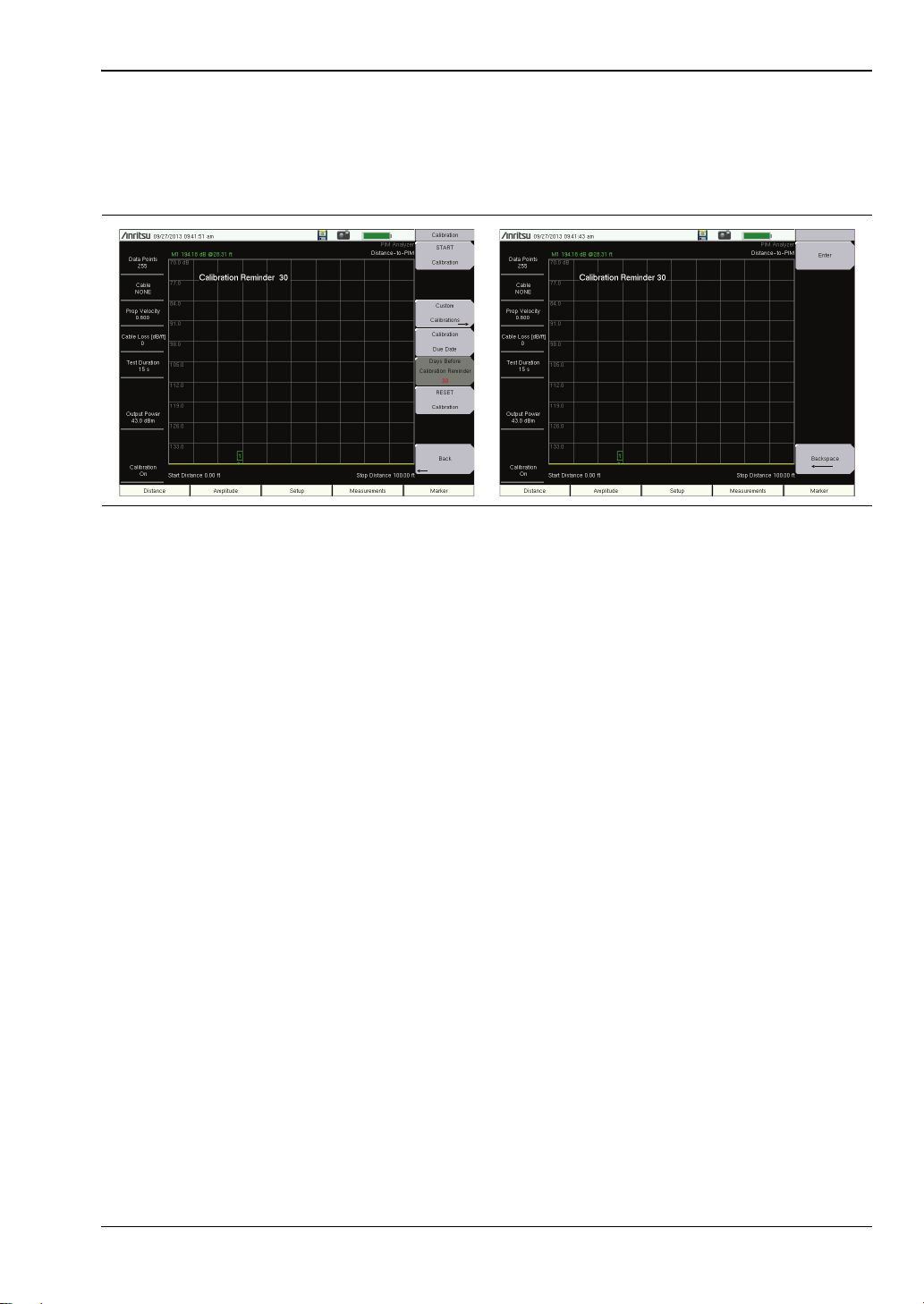

Calibration Reminder

You can set a reminder of the due date by pressing the Days Before Calibration Reminder

submenu key and entering a number with the number keypad. Complete the entry by

pressing the Enter submenu key or the instrument Enter key.

Figure 2-2. Days Before Calibration Reminder

2-3 Front Panel Overview

The PIM Master menu-driven interface is easy to use and requires little training. The

PIM Master uses a touch screen and keypad for data input. The five bottom menu keys and

eight submenu keys on the right side are touch screen keys. The menu and submenu keys will

vary depending upon the selected mode of operation, refer to “Mode Selector Menu”

on page 2-20.

Number keys 1 through 9 are dual purpose, depending upon the current mode of operation.

The dual-purpose keys are labeled with a number on the key itself with the alternate function

printed in blue above each of the keys. Use the blue Shift key to access the functions printed

on the panel. The Escape key, used for aborting data entry, is the button located above

number key 8. The four Arrow keys and the keypad can be used to change the value of an

active parameter.

MW82119B UG PN: 10580-00400 Rev. N 2-3

Page 20

2-3 Front Panel Overview Chapter 2 — PIM Master Overview

2

1

3

MW82119B PIM Master Front Panel

Figure 2-3. MW82119B PIM Master Front Panel

1. On/Off Button (and Battery and Power LEDs)

2. Number Keypad

3. Measurement Display (a Touch Screen)

2-4 PN: 10580-00400 Rev. N MW82119B UG

Page 21

Chapter 2 — PIM Master Overview 2-4 Front Panel Keys

1

4

2

5

7

6

3

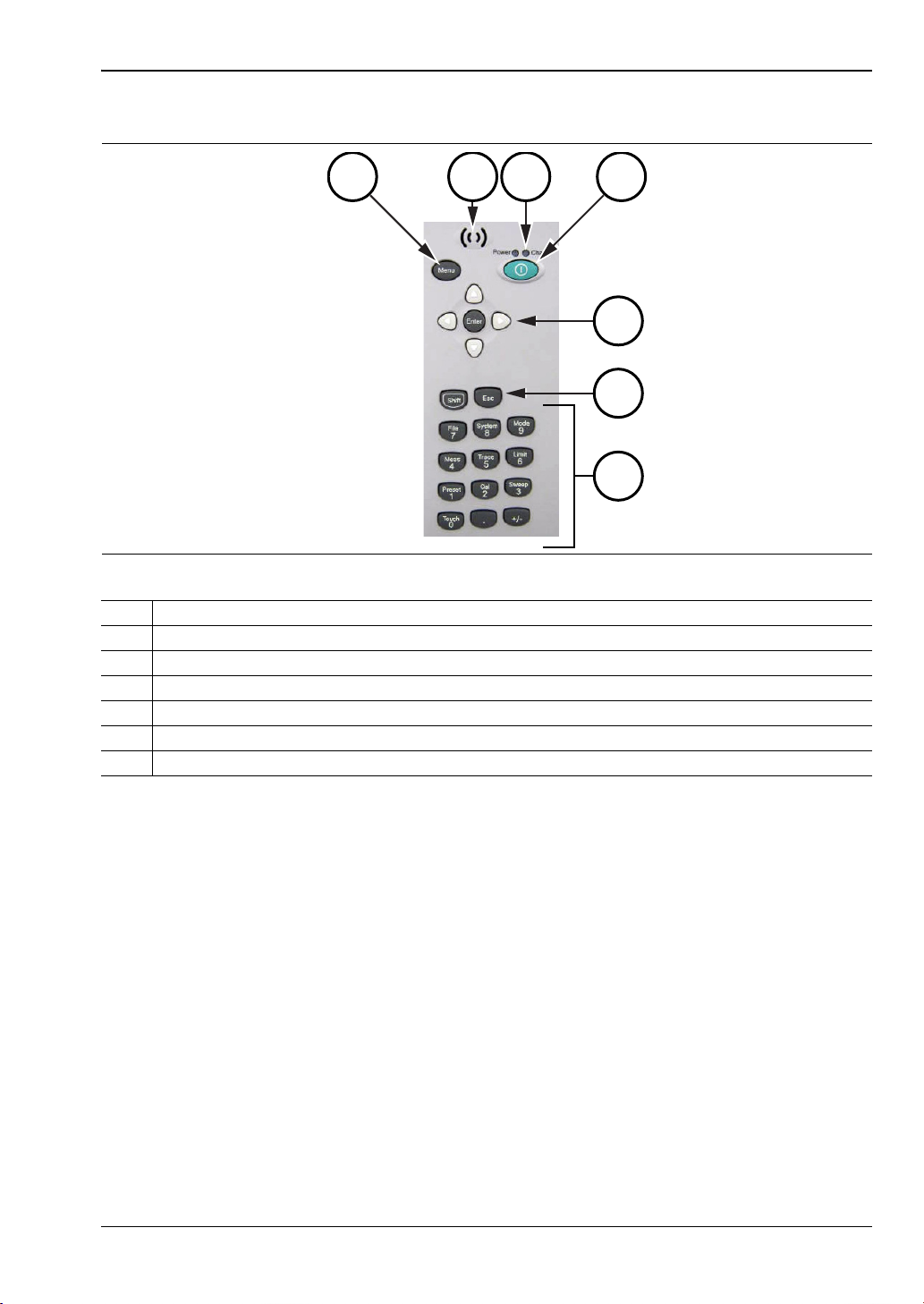

2-4 Front Panel Keys

Figure 2-4. Front Panel Layout

1. Menu Key

2. Speaker Grill

3. LED Indicators for Battery Charge and Power

4. On/Off Button

5. Arrow Keys and Enter Key in center

6. Shift Key and Escape Key

7. Number Keypad

The terms button and hard key refer to all of the buttons on the instrument face. These keys

perform as follows:

Menu Key

(item 1 in Figure 2-4)

Press the Menu key to display the Menu Key Screen, a grid of shortcut icons for installed

measurement modes and user-selected menus and setup files.

MW82119B UG PN: 10580-00400 Rev. N 2-5

Page 22

2-4 Front Panel Keys Chapter 2 — PIM Master Overview

On/Off Button

(item 4 in Figure 2-4)

Press this button to turn on power to the PIM Master. Press and hold this button to turn off

power.

Arrow Keys

(item 5 in Figure 2-4)

The four Arrow keys are used to scroll up, down, left, or right. The Arrow keys can often be

used (depending upon measurement selection) to change a value or to change a selection from

a list. In some measurements, the Left/Right arrow keys change values by different

increments than the Up/Down arrow keys. The Arrow keys are also used to move markers.

Enter Key

(item 5 in Figure 2-4)

Press this key to finalize data input.

Shift Key

(item 6 in Figure 2-4)

Press the Shift key and then press a number key to open the menu that is indicated in text

above the key number. When the Shift key is active, its icon is displayed at the top-right of the

measurement display area between the battery charge indicator and the submenu key labels.

Figure 2-5. Shift Key Icon

Esc Key

(item 6 in Figure 2-4)

Press this key to cancel any setting that is currently being made.

LED Indicators (above the On/Off Button)

(item 3 in Figure 2-4)

Battery Charge LED (Green)

The Battery Charge LED flashes if the battery is charging, and remains on steady when the

battery is fully charged.

Power LED (Green)

The Power LED remains on when the PIM Master is on.

2-6 PN: 10580-00400 Rev. N MW82119B UG

Page 23

Chapter 2 — PIM Master Overview 2-4 Front Panel Keys

Number Keypad

(item 7 in Figure 2-4)

Press these keys to directly input numbers. Number keys are also used to open menus when

used with the “Shift Key”. For example, press Shift and Touch (0) to initiate Touch Screen

Calibration.

+/– Key

(item 7 in Figure 2-4)

Press this key to change the sign of numbers that are entered with the number keys.

MW82119B UG PN: 10580-00400 Rev. N 2-7

Page 24

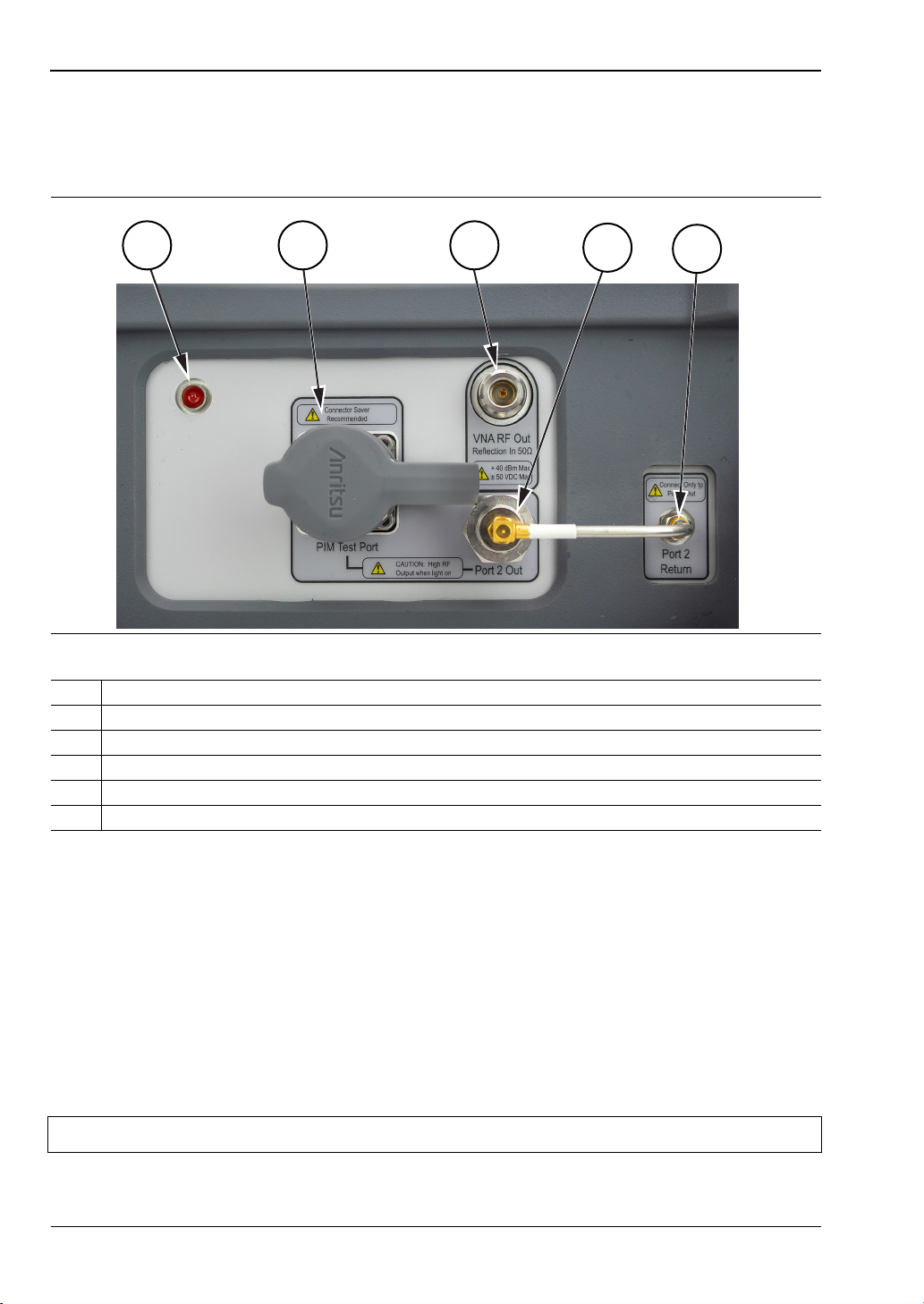

2-5 Top Connector Panel Chapter 2 — PIM Master Overview

1

3

2

54

2-5 Top Connector Panel

The top connector panel includes the test port connectors and the Radio Frequency On light.

Figure 2-6. PIM Master Top Panel Layout

1. Indicator Light for RF On (Red)

2. PIM Test Connector, 7/16 DIN, female, 50 Ω

3. VNA RF Out Connector, Type-N, female, 50 ohms (Option 331)

4. IM2 In Connector, Type-N, female, 50 ohms (Option 902)

5. Strap Bracket (shown without strap), 2x

PIM Radio Frequency ON Light (item 1 in Figure 2-6)

This red indicator is illuminated when PIM RF output power is On.

PIM Test Connector (item 2 in Figure 2-6)

Type 7/16 DIN(f), 50 test port connector that is used to perform PIM versus Time, Swept

PIM, Noise Floor, and Distance-to-PIM (DTP) measurements.

To prevent damage to your instrument, do not use pliers or a plain wrench to tighten the DIN

connector. Do not over-tighten the connector. The recommended torque is 25 N ·m (~18 lbf·ft).

To prevent rotation, secure the PIM test connector or the recommended connector saver with

a wrench when attaching a test lead.

Refer to “Connector Saver” on page 1-5.

2-8 PN: 10580-00400 Rev. N MW82119B UG

Page 25

Chapter 2 — PIM Master Overview 2-5 Top Connector Panel

VNA RF Out Connector (item 3 in Figure 2-6)

VNA RF Out Connector, Type-N, female, 50 ohms (Option 331). This test port is available

only on instruments with Site Master Option 331. It is used to perform Return Loss, VSWR,

Cable Loss, and Distance-to-Fault (DTF) measurements. Hand tighten this connection. Do

not use a wrench.

IM2 In Connector (item 4 in Figure 2-6)

IM2 In Connector, Type-N, female, 50 ohms (Option 902). This test port is available only with

frequency Option 902. It is used to receive second order intermodulation products. Hand

tighten this connection. Do not use a wrench.

Strap Bracket (item 5 in Figure 2-6)

The Strap Brackets hold the Handle Strap and can accommodate a Carabiner. Note that each

bracket is secured to the PIM Master with 2 screws. The handle is sewn to the brackets, but is

not shown in the figure in order to reveal the bracket design. See Figure 2-23 on page 2-30 for

the complete bracket, mounted and in use.

MW82119B UG PN: 10580-00400 Rev. N 2-9

Page 26

2-6 Top Connector Panel -- Option 703 Chapter 2 — PIM Master Overview

5

3

2

1

4

2-6 Top Connector Panel -- Option 703

The 2-port top connector panel includes the base features from Figure 2-6 plus those for the

2-port.

Figure 2-7. PIM Master Top Panel Layout: 2-Port

1. Indicator Light for RF On (Red)

2. PIM Test Connector, 7/16 DIN, female, 50 Ω

3. VNA RF Out Connector, Type-N, female, 50 Ω (Option 331)

4. Port 2 Out Connector, 4.3-10, female, 50 Ω (Option 703)

5. Port 2 Return Connector, Type SMA, female, 50 Ω (Option 703)

6. Strap Bracket (not shown), 2x

Port 2 Out Connector (item 4 in Figure 2-7)

VNA RF Out Connector, 4.3-10, female, 50 ohms (Option 703). This test port is available only

on instruments with 2-Port LTE Option 703. It is used to perform Return Loss, VSWR, Cable

Loss, and Distance-to-Fault (DTF) measurements. Hand tighten this connection. Do not use a

wrench.

Port 2 Return Connector (item 5 in Figure 2-7)

Port 2 Return Connector, SMA, female, 50 ohms (Option 703). This test port is available only

on instruments with 2-Port LTE Option 703. Hand tighten this connection. Do not use a

wrench.

Note Use care to use all wrenches in such a way that the rigid cable is not impacted.

2-10 PN: 10580-00400 Rev. N MW82119B UG

Page 27

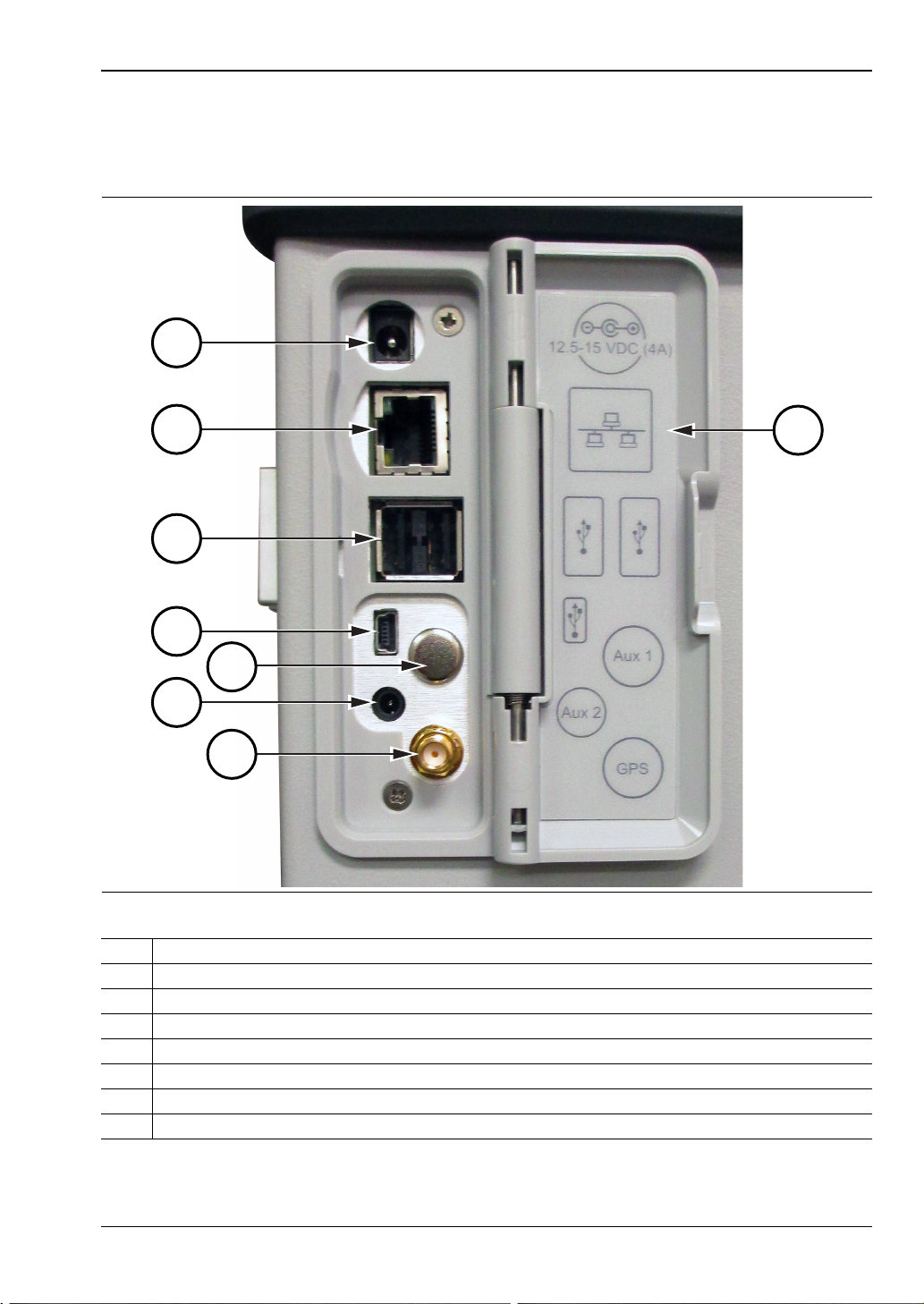

Chapter 2 — PIM Master Overview 2-7 Side Panel Connectors

7

5

1

3

2

4

6

8

2-7 Side Panel Connectors

The side connector panel includes connectors for External Power, Ethernet/LAN, USB

interface, and GPS.

Figure 2-8. PIM Master Side Panel Overview

1. External Power

2. LAN Connection, RJ45

3. USB Interface, Type A

4. USB Interface, 5-pin mini-B

5. Auxiliary 1 (factory use only)

6. Auxiliary 2 (factory use only)

7. GPS Connector, SMA female (with Option 31)

8. Legend (icons identify connection types)

MW82119B UG PN: 10580-00400 Rev. N 2-11

Page 28

2-7 Side Panel Connectors Chapter 2 — PIM Master Overview

External Power (item 1 in Figure 2-8)

This 2.1 mm by 5.5 mm barrel connector is used to power the unit and for battery charging.

Input is 12 VDC to 15 VDC at up to 5.0 A.

When using the AC-DC Adapter, always use a three-wire power cable that is

Warning

connected to a three-wire power line outlet. If power is supplied without grounding

the equipment in this manner, then the user is at risk of receiving a severe or fatal

electric shock.

LAN Connection (item 2 in Figure 2-8)

The RJ45 connector is used to connect the PIM Master to a local area network. Integrated

into this connector are two LEDs. The amber LED shows the presence of a 10 Mbit/s LAN

connection when on, and a 100 Mbit/s LAN connection when off. The green LED flashes to

show that LAN traffic is present. For additional information about the LAN connection,

Ethernet connection, and DHCP, refer to Appendix F, “LAN and DHCP”.

USB Interface – Type A (item 3 in Figure 2-8)

This interface has two connectors for flash drive and USB Power Sensor. The MW82119B

PIM Master can also be a USB Host and allow various USB Flash Memory devices to be

connected to the instrument for storing measurements, setups, files, and firmware upgrades.

Either USB connection can be used with a USB power sensor (but only one power sensor at a

time).

USB Interface – Type Mini-B (item 4 in Figure 2-8)

The USB 2.0 interface can be used to connect the MW82119B PIM Master directly to a PC for

data transfer. The first time the PIM Master is connected to a PC, the normal USB device

detection by the computer operating system will take place. Drivers are available for

Windows XP (or later).

Note

For proper detection, Line Sweep Tools should be installed on the PC prior to

connecting the PIM Master to the USB port.

GPS Antenna Connector (Option 31) (item 7 in Figure 2-8)

The GPS antenna connection on the PIM Master is type SMA(F). Selectable +3 VDC or

+5 VDC antenna power.

To prevent damage to your instrument, do not use pliers or a plain wrench to tighten the

SMA connector. Do not overtighten the connector. The recommended torque is 8 lbf·in

(0.9 N·m or 90 N·cm).

2-12 PN: 10580-00400 Rev. N MW82119B UG

Page 29

Chapter 2 — PIM Master Overview 2-8 Measurement Display Overview

Date/Time GPS Battery Indicator

Measurement Title Area

Main Graph Area

Submenu

Keys

Main Menu Keys

Numerical Measurement Result Area

Instrument

Settings

Summary

2-8 Measurement Display Overview

Throughout this manual, typical measurement displays are shown for the basic measurement

modes of the PIM Master. Note that the images shown in this manual may be different from

any images that are displayed on your PIM Master.

Front Panel Display Areas

Figure 2-9. Front Panel Overview

MW82119B UG PN: 10580-00400 Rev. N 2-13

Page 30

2-8 Measurement Display Overview Chapter 2 — PIM Master Overview

Main Menu Keys

The PIM Master menu-driven interface is easy to use and requires little training. The five

Main Menu keys are located below the measurement display. These five keys are used to

display the function-specific menus in the active menu (submenu labels). These Main Menu

keys vary in function based on the selected mode of operation (Shift, Mode (9)) or

measurement type within a mode. Refer to “Mode Selector Menu” on page 2-20 for more

information on changing the instrument mode. Table 2-1 lists from left to right the Main

Menu Key labels for each mode of instrument operation.

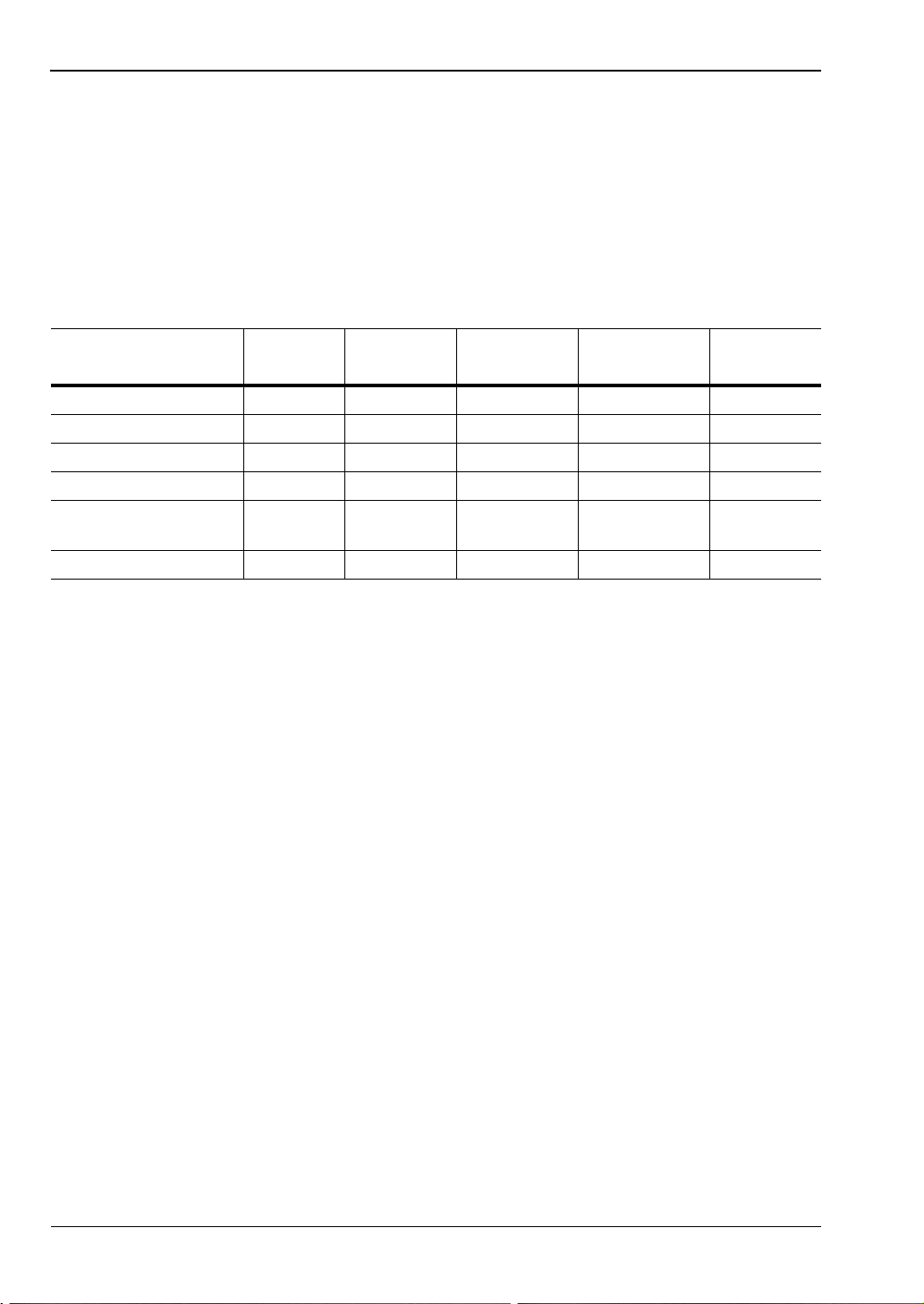

Tab le 2-1. Mode-Dependent Main Menu Keys Located at Bottom of Measurement Display

Mode/Measurement

Type Key 1 Key 2 Key 3 Key 4 Key 5

PIM vs. Time Freq Amplitude Setup Measurements Marker

Noise Floor Freq Amplitude Setup Measurements Marker

DTP Distance Amplitude Setup Measurements Marker

Swept PIM Freq Amplitude Setup Measurements Marker

High Accuracy

Power Meter

Cable & Antenna Freq/Dist Amplitude Sweep/Setup Measurements Marker

a

Amplitude Average Zero/Cal Limit

a.If High Accuracy Power Meter (option 19) is installed.

Submenu Keys

The eight submenu keys are located to the right of the measurement display. They change

function depending upon the current mode and current menu selection. The current submenu

title is shown at the top of the active function block (submenu key labels). For an example,

refer to item 6 in Figure 2-10 on page 2-15.

2-14 PN: 10580-00400 Rev. N MW82119B UG

Page 31

Chapter 2 — PIM Master Overview 2-8 Measurement Display Overview

1

3

710

9

2

5

4

6

8

Front Panel Layout, PIM vs. Time

The following three figures are provided to identify display components in different

measurement modes. The image and measurement details shown on your instrument may

differ from the examples in this user guide.

2-

Figure 2-10. Front Panel Layout with PIM vs. Time Display

1. Real Time Clock (followed by GPS Coordinates if Option 31 is installed)

2. Main Graph Area or Sweep Window or Measurement Grid

3. Limit Line (Green line, set from Limit menu)

4. Battery Status Icon

5. Instrument Mode and Measurement Title

6. Submenu Keys or Active Function Block

7. PIM Summary Table

8. Pass/Fail Indicator (set from Limit menu)

9. Main Menu Keys

10. Instrument Settings Summary

MW82119B UG PN: 10580-00400 Rev. N 2-15

Page 32

2-8 Measurement Display Overview Chapter 2 — PIM Master Overview

11

10

1

3

6

5

4

7

2

89

Front Panel Layout, Distance-to-PIM

Figure 2-11. Front Panel Layout with Distance-to-PIM Display

1. Real Time Clock (followed by GPS Coordinates if Option 31 is installed)

2. Reference Limit Line (blue line, set from Limit menu)

3. Main Graph Area or Sweep Window or Measurement Grid

4. Marker on Distance-to-PIM Measurement Trace

5. Battery Status Icon

6. Instrument Mode and Measurement Title

7. Submenu Keys or Active Function Block

8. Progress Indicator

9. Marker Table (set to Large)

10. Main Menu Keys

11. Instrument Settings Summary

2-16 PN: 10580-00400 Rev. N MW82119B UG

Page 33

Chapter 2 — PIM Master Overview 2-8 Measurement Display Overview

1

3

711

10

2

5

4

6

13

9

8

12

Front Panel Layout, Swept PIM

Figure 2-12. Front Panel Layout with Swept PIM Display

1. Real Time Clock (followed by GPS Coordinates if Option 31 is installed)

2. Main Graph Area or Sweep Window or Measurement Grid

3. Swept PIM Measurement Trace (green trace and yellow trace)

4. Battery Status Icon

5. Instrument Mode and Measurement Title

6. Submenu Keys or Active Function Block

7. PIM Summary Table

8. Limit Line (green)

9. Progress Indicator

10. Main Menu Keys

11. Instrument Settings Summary

12. Pass/Fail indicator

13. Marker and marker data automatically displayed

The yellow trace is created by holding F1 fixed and sweeping F2. The green trace is

created by holding F2 fixed and sweeping F1. The PIM Summary Table displays the

frequencies that are used to generate each sweep. In this display, the green trace

(Sweep #2) is visible only in the first few MHz of the sweep. Note that the PIM

Summary Table displays the Sweep numbers in yellow and green.

MW82119B UG PN: 10580-00400 Rev. N 2-17

Page 34

2-8 Measurement Display Overview Chapter 2 — PIM Master Overview

1

3

710

9

2

5

4

6

8

11

Front Panel Layout, C&AA (Option 331)

Figure 2-13. Front Panel Layout with Return Loss Display

1. Real Time Clock (followed by GPS Coordinates if Option 31 is installed)

2. Main Graph Area or Sweep Window or Measurement Grid

3. Limit Line (green)

4. Battery Status Icon

5. Instrument Mode and Measurement Title

6. Submenu Keys or Active Function Block

7. Marker Table

8. Return Loss Measurement Trace

9. Main Menu Keys

10. Instrument Settings Summary

11. Marker and marker data automatically displayed for active Marker [M2]

2-18 PN: 10580-00400 Rev. N MW82119B UG

Page 35

Chapter 2 — PIM Master Overview 2-9 Secondary Function Menus

2-9 Secondary Function Menus

Pressing the Shift key and then a number key selects the menu function that is printed above

the key number (Figure 2-14).

Figure 2-14. Keypad and Secondary Function Menus

Not all Secondary Function Menus are active in various operation Modes. If any one of these

menus is available in a specific instrument Mode of operation, then it can be called from the

number keypad. It may also be available from a main menu key or a submenu key.

The 10 Secondary Function Menus are:

0 Touch Screen Calibration (and Arrow Navigation)

1Preset

2Calibration

3 Sweep

4 Measurements

5 Trace

6Limit

7File

8System

9MODE

MW82119B UG PN: 10580-00400 Rev. N 2-19

Page 36

2-10 Mode Selector Menu Chapter 2 — PIM Master Overview

2-10 Mode Selector Menu

To access the functions under the Mode menu, select the Shift key, then the Mode (9) key.

Use the directional Arrow keys to highlight the selection, and press the Enter key to select.

The list of modes that appears in this menu will vary depending upon the options that are

installed and activated in your instrument. Figure 2-15 is an example of the Mode menu.

Your instrument may not show the same list.

Figure 2-15. Mode Selector Menu

2-20 PN: 10580-00400 Rev. N MW82119B UG

Page 37

Chapter 2 — PIM Master Overview 2-11 Menu Key

2-11 Menu Key

Press the Menu key to display the Menu Key Screen, a grid of icons for installed

measurement modes and shortcuts to user-selected menus and setup files.

Figure 2-16 shows the Menu key screen without any user shortcuts. Touch one of the icons in

the top two rows to change modes. The icons that are shown here are preinstalled and cannot

be moved or deleted. The display of the Menu screen will vary depending on instrument

model, firmware version, and installed options. The image in Figure 2-16 may differ from the

menu on your instrument.

Figure 2-16. Menu Key Screen, Icons for Installed Measurements

Note

MW82119B UG PN: 10580-00400 Rev. N 2-21

The High Accuracy Power Meter icon is present only if Option 19 is installed.

See Appendix A, “Other Documents” for information about this publication.

Page 38

2-11 Menu Key Chapter 2 — PIM Master Overview

Figure 2-17 shows the Menu key screen with shortcut icons for features of the installed

measurement modes and additional user-defined shortcuts to menus and setup functions.

Press and hold down any key for a few seconds to add a shortcut to this screen. For example,

to create a shortcut for PIM versus Time measurements, open the PIM Master Measurements

menu and hold down on the PIM vs. Time submenu key for a few seconds. The PIM Master

displays a grid (occupied locations show their shortcut), then select the location for the

shortcut. The display of the Menu screen will vary depending on instrument model, firmware

version, and installed options. The image in Figure 2-17 may differ from the menu on your

instrument.

Figure 2-17. Menu Key Screen, Icons for Installed Measurements and Shortcuts

User-defined shortcuts stay in memory until deleted. To delete or move a shortcut button,

press the Menu key, then press and hold the shortcut for approximately three seconds. The

Customize Button dialog box opens to allow a button to be deleted or moved. Press Esc to exit

the Menu shortcut display.

The Master Reset will delete all user-created shortcut icons from the Menu screen.

Refer to the “Reset Menu” on page 5-7 for additional information.

Note

To retain shortcuts during a firmware update, select the "Save & restore user data"

option shown in Figure E-5 on page E-8.

2-22 PN: 10580-00400 Rev. N MW82119B UG

Page 39

Chapter 2 — PIM Master Overview 2-11 Menu Key

Help for the Menu shortcut screen is available by pressing the question mark icon in the

lower-right corner of the display.

Figure 2-18. Menu Help

MW82119B UG PN: 10580-00400 Rev. N 2-23

Page 40

2-12 Touch Screen Chapter 2 — PIM Master Overview

2-12 Touch Screen

The touch screen and keypad are used for data entry. The sweep window and surrounding

screen areas provide measurement information (see Figure 2-9, “Front Panel Overview”

on page 2-13).

Graphical User Interface (GUI)

The measurement display, or sweep window, provides measurement trace data. Above the

grid and trace data, additional measurement data are displayed, and the analyzer mode is

shown in the top-right corner. The lower area of the grid may be reduced in size to display an

optional data window, such as a table of measurement data or marker data. To the left of the

grid and trace data is the instrument settings summary; below the grid are the five main

menu touch keys; to the right are the submenu touch keys. For a list of the main menu keys

in different instrument modes, refer to “Main Menu Keys” on page 2-14.

The five main menu touch keys and (up to) eight submenu touch keys are available in all

analyzer Modes, providing control of measurement settings. In addition, you can touch other

areas of the display screen to perform tasks that are also available from the menu keys.

For example:

• If you touch the Scale setting on the left side of the display (Instrument Settings

Summary), then the Amplitude menu is displayed, and the Scale submenu key is

active. Scale is displayed in PIM vs. Time and Swept PIM measurements.

• If you touch Data Points (Instrument Settings Summary), then the DTP Parameters

setup window is displayed, and the Data Points parameter is selected (Distance-to-PIM

measurements.

• If you touch Cable (Instrument Settings Summary), then the Cable List is displayed

(Distance-to-PIM measurements).

• If you place a marker on the screen, then you can touch the measurement trace to

relocate the marker.

• If you touch the file type list box in one of the file management dialog boxes, then you

can open the Filetype drop-down list to select a file type.

Main Menu Touch Screen Keys

The main menu key functions change to match specific instrument Mode settings. The main

menu keys generate function-specific submenus. The measurement modes are selected by

pressing the Shift key and then the Mode (9) key. For more details about the Mode menu,

refer to “Mode Selector Menu” on page 2-20.

Submenu Touch Screen Keys

The submenu touch keys are located in the active function block (submenu key labels) along

the right edge of the display. The submenu labels change as instrument measurement and

parameter settings change. The current submenu title is shown at the top of the submenu key

block. An example of the keys is shown in Figure 2-10 on page 2-15. Additional details are

described in Section 2-8 “Measurement Display Overview” on page 2-13.

2-24 PN: 10580-00400 Rev. N MW82119B UG

Page 41

Chapter 2 — PIM Master Overview 2-13 Touch Screen Calibration

2-13 Touch Screen Calibration

The Calibrate Touch Screen submenu key is in the “System Menu” on page 5-3. When pressed,

the touch screen calibration message box is displayed with instructions for calibration.

Calibration optimizes the response of touch input. You touch targets in sequence as they are

displayed on the touch screen. This requires less than one minute.

Calibration is recommended if your touch inputs do not correspond to the appropriate

locations on the screen. After the information box is displayed, press Enter to begin

calibration, or press Esc to cancel.

You can also press 1 to use arrow navigation.

Calibrate Touch Screen Shortcut

You can access touch screen calibration by pressing Shift then Touch (0). This displays the

touch screen calibration message box. Press Enter to begin calibration, or press Esc to cancel.

This shortcut can be used if your touch inputs do not correspond to the appropriate locations

on the screen to such an extent that you cannot access the Calibrate Touch Screen submenu

key.

Arrow Navigation

If the touch screen is not functioning, you can use Arrow Navigation to simulate pressing the

touch screen main menu keys and submenu keys. From the touch screen calibration message

box, press 1 to use arrow navigation. This displays the arrow navigation message box. Press 1

again to enter the arrow navigation mode, or press Esc to cancel. Note that entering arrow

navigation mode disables the touch function of the touch screen.

In arrow navigation mode, a red selection box surrounds a key (see Figure 2-19 on page 2-26

in which the Carrier F1 submenu key is selected). To move the red selection box, use the

Arrow keys above the number keypad (see Figure 2-14 on page 2-19). Then press the Menu

key to activate the selected touch screen key. Note that only the main menu keys and

submenu keys can be activated by using Arrow Navigation. When using the File management

menus for Copy, Recall, and Delete, however, you can press the +/– key to change focus of the

arrow navigation from the menu keys to the lists in the dialog box and back to the menu keys.

Arrow navigation places a green selection box around the Source or Destination file group

(depending on the selection toggled in the Scroll submenu key). You can then use the arrow

keys to navigate and select files. This feature does not move the arrow navigation selection

box into any other areas of the touch screen.

To save a measurement in arrow navigation mode, press Shift then File (7). Use the Arrow

keys to move the red selection box to the Save Measurement As submenu key. This submenu

key must be used because the arrow navigation mode cannot be used to change data in popup

windows in the measurement display. Filenames are determined by the current setting of the

Save Measurement As submenu key. Refer to “Save Measurement As” on page 4-12.

You can save a JPEG image of the current display screen by pressing three keys, Shift, then

Decimal, then +/–. The JEPG image shows screen data, but does not contain the additional

measurement information that accompanies a saved measurement in a *.pim measurement

file.

MW82119B UG PN: 10580-00400 Rev. N 2-25

Page 42

2-14 Parameter Setting Chapter 2 — PIM Master Overview

To return to normal touch entry mode, reboot the instrument (turn power Off and then On). If

your touch screen has been damaged, then refer to Section 1-2 “Instrument Description”

on page 1-3.

Figure 2-19. Arrow Navigation Mode

2-14 Parameter Setting

Pop-up list boxes or edit boxes are used to provide selection lists and selection editors. Scroll

through a list of items or parameters with the Arrow keys or by using the touch screen. Select

numerical values by scrolling with the Arrow keys or by entering the digits directly from the

number keypad. These list boxes and edit boxes frequently display a range of possible values

or limits for possible values.

Finalize the input by pressing the Enter key. At any time before finalizing the input, press the

escape (Esc) key to abort the change and retain the previously existing setting.

2-26 PN: 10580-00400 Rev. N MW82119B UG

Page 43

Chapter 2 — PIM Master Overview 2-15 Symbols and Indicators

Shift

2-15 Symbols and Indicators

The following symbols, icons, and indicators convey the instrument status or condition on the

display. The colors shown here are in the standard or default display mode.

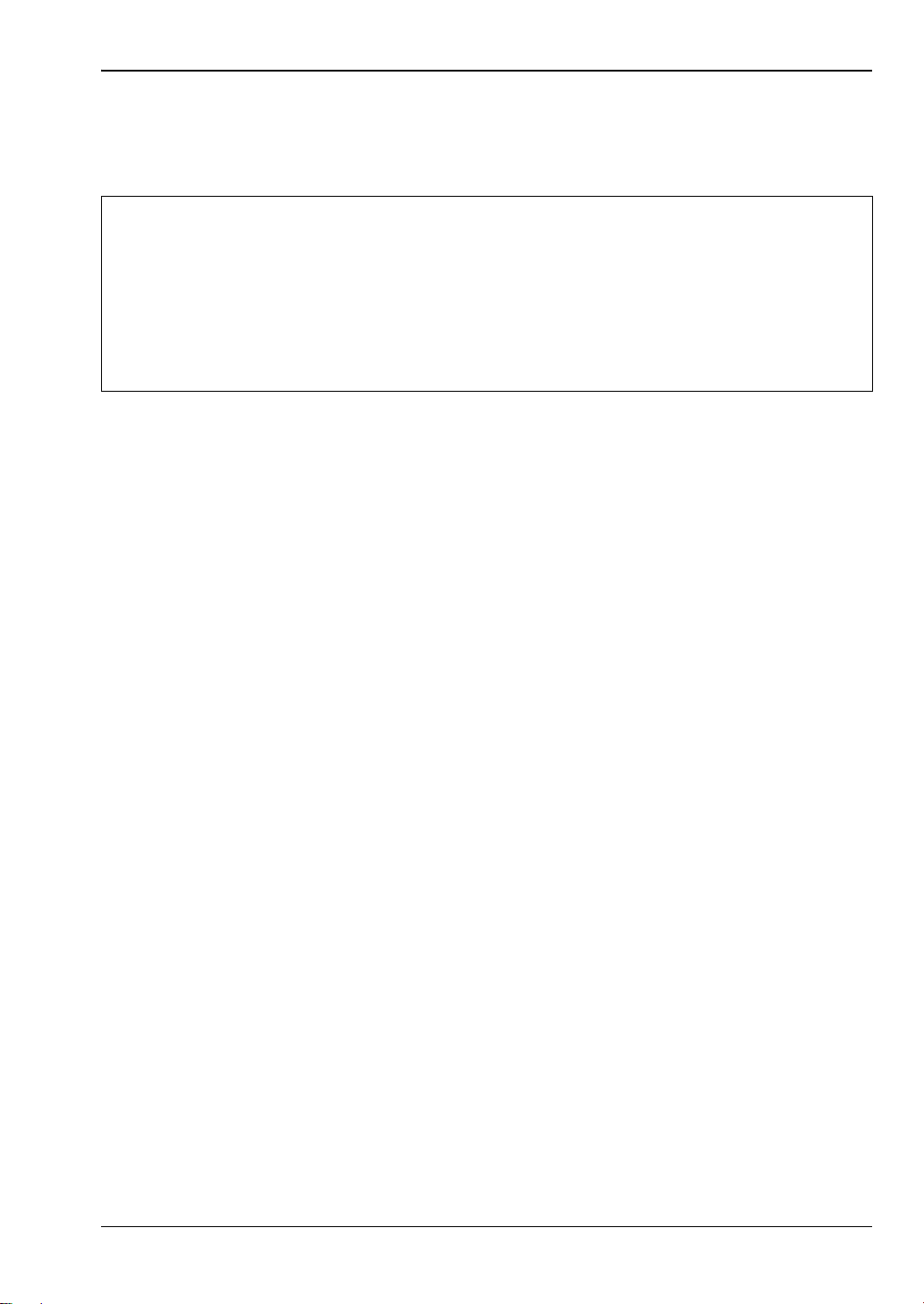

Table 2-2. Symbols and Icons

Symbol Description

Green: Battery is 30 % to 100 % charged

Yellow: Battery is 10 % to 30 % charged

Red: Battery 0 % to 10 % charged

Green with Black Plug body: Battery is fully charged and

external power is applied

Lightning Bolt: Battery is being charged (any color symbol)

Red Plug body: External power is applied, and no battery is

installed, or battery has lost communications with the instrument

Storage Icon: Image of a 3.5 inch floppy disk drive, shortcut to the

Save Menu

Camera Icon: Saves a JPEG image of the current screen display

Shift Key Icon: This icon is displayed between the battery symbol

and the submenu keys after the Shift key has been pressed, and

until another key is pressed.

GPS Icon: This icon is displayed right after the date and time

when GPS is available. For additional details, refer to

Chapter 6, “GPS (Option 31)”.

Power Button with Power LED and Charge LED: This is a

physical button with LED indicators. It is located near the number

keypad.

The battery symbol above the display indicates the charge remaining in the battery. The

colored section inside the symbol changes size and color with the charge level. The Battery

Charge LED (adjacent to the On/Off button) flashes when the battery is charging, and

remains on steady when the battery is fully charged.

Use only Anritsu-approved batteries, adapters, and chargers with this instrument.

Caution

Anritsu Company recommends removing the battery for long-term storage of the

instrument.

Touch the storage icon to open the touch screen keyboard for saving measurements, setups,

limit lines, or screen display JPEG files (see Figure 4-1, “Save Dialog Box” on page 4-4).

MW82119B UG PN: 10580-00400 Rev. N 2-27

Page 44

2-16 Soft Carrying Case Chapter 2 — PIM Master Overview

2-16 Soft Carrying Case

The PIM Master can be operated while in the soft carrying case by opening the front flap

(secured by two zippers).

Figure 2-20. Case Open to Operate the PIM Master

The case is padded on all sides and contains protective inserts in the front and back panels.

An additional flap at the top of the rear panel can be folded over the PIM Master top

connector panel for additional protection.

2-28 PN: 10580-00400 Rev. N MW82119B UG

Page 45

Chapter 2 — PIM Master Overview 2-16 Soft Carrying Case

To install the instrument into the soft carrying case:

1. The Back panel of the case is secured with two zippers that start at the bottom of each

side. Fully close the front panel of the case to help support the shape of the case while

you are inserting the PIM Master into the back.

2. Place the soft carrying case face down on a stable surface, with the front panel fully

closed and laying flat.

3. Open the zippered back of the case.

4. Insert the instrument face down into the case, taking care that the connectors are

properly situated in the case top opening. Refer to the tilting of the instrument as

shown in Figure 2-21. Note that the instrument in this figure may differ from your

model. The method of insertion remains the same.

Figure 2-21. Putting PIM Master into Soft Case

5. Close the back panel and secure with one or both zippers to securely enclose the

PIM Master.

6. Two pairs of additional straps cross over the top of the PIM Master (inside the strap

brackets) to keep the soft case closed securely around the instrument. These straps

have hook-and-loop fasteners. See Figure 2-23 on page 2-30.

7. An additional flap (sewn to the back cover) with a protective insert can be folded over

the center of the top connector panel. It attaches to the front of the case by

hook-and-loop fasteners. This flap is shown closed in Figure 2-22 on page 2-30.

MW82119B UG PN: 10580-00400 Rev. N 2-29

Page 46

2-16 Soft Carrying Case Chapter 2 — PIM Master Overview

A side flap provides access to the side panel. Inside and below the panel is a pocket to hold a

wireless router. The router connecting cables can be enclosed by the side flap.

Figure 2-22. Access to Side Panel

Figure 2-23. Instrument Enclosed in the Soft Carrying Case

2-30 PN: 10580-00400 Rev. N MW82119B UG

Page 47

Chapter 2 — PIM Master Overview 2-17 Tilt Bail Stand

2-17 Tilt Bail Stand

A tilt bail is attached to the back of the PIM Master for desktop operation. To deploy the tilt

bail, pull the bottom of the tilt bail away from the back of the instrument. To store the tilt

bail, push the bottom of the bail towards the back of the instrument until it attaches to the

PIM Master.

Figure 2-24. Tilt Bail Extended

MW82119B UG PN: 10580-00400 Rev. N 2-31

Page 48

2-17 Tilt Bail Stand Chapter 2 — PIM Master Overview

2-32 PN: 10580-00400 Rev. N MW82119B UG

Page 49

Chapter 3 — Quick Start Guide

The Anritsu PIM Master is capable of producing 80 Watts of RF power in the

cellular communications bands. Users must take precautions to minimize

exposure to these RF fields:

Always terminate the PIM output port of the test equipment into a load, a

loaded line, or a line that will radiate or absorb the energy before beginning

a PIM test.

Warning

3-1 Introduction

This chapter describes the basic setup and use of the PIM Master for performing Line Sweep

(cable and antenna analysis, or CAA) and PIM measurements (Option 331). Tasks common to

all PIM measurements are also introduced here.

Confirm that the PIM Master RF power is off after a PIM test.

Always confirm that the PIM RF power is off before disconnecting a coaxial

connection, otherwise RF burns may result. Immediate burns to fingers or

eyes can result from exposure to live connectors.

Ensure that all antennas under test are placed so that no personnel are

exposed to RF levels that exceed the maximum allowable exposure.

MW82119B UG PN: 10580-00400 Rev. N 3-1

Page 50

3-2 Measurement Mode Selection Chapter 3 — Quick Start Guide

3-2 Measurement Mode Selection

Press the Menu key and use the touch screen to select the appropriate measurement icon.

Figure 3-1. Menu Screen with Icons for Installed Measurement Modes

Note The display of the Menu screen will vary depending on installed options.

3-2 PN: 10580-00400 Rev. N MW82119B UG

Page 51

Chapter 3 — Quick Start Guide 3-3 Cable & Antenna Analyzer Measurements (Option 331)

Measurement 2/2

Smith Chart

1-Port Phase

Back

Measurement 1/2

More

Return Loss

Cable Loss

DTF

Return Loss

DTF VSWR

VSWR

Display Format

Single Dual

Active Display

Top Bottom

Cable Loss

And

DTF-RL

3-3 Cable & Antenna Analyzer Measurements (Option 331)

Set the instrument to Cable & Antenna Analyzer mode (refer to Section 3-2 “Measurement

Mode Selection” or “Menu Key” on page 2-21). This section is a brief introduction to cable and

antenna analysis. For more details, refer to the Cable and Antenna Analyzer Measurement

Guide that is listed in Appendix A.

Select the Measurement Type

Press the Measurement main menu key and select the appropriate measurement.

Figure 3-2. C&AA Measurement Menus

Set the Frequency

MW82119B UG PN: 10580-00400 Rev. N 3-3

1. Press the Freq/Dist main menu key.

2. Press the Start Freq submenu key and use the keypad or the arrow keys to enter the

start frequency.

3. Press the Stop Freq submenu key and use the keypad or the arrow keys to enter the stop

frequency.

Page 52

3-3 Cable & Antenna Analyzer Measurements (Option 331) Chapter 3 — Quick Start Guide

Set the Amplitude

1. Press the Amplitude main menu key.

2. Press the To p submenu key and use the keypad or the arrow keys to edit the top scale

value. Press Enter to set.

3. Press the Bottom submenu key and use the keypad or the arrow keys to edit the bottom

scale value. Press Enter to set.

Note

For Amplitude in Smith Chart measurements, refer to “Smith Chart” on page 2-23

of the Cable & Antenna Measurement Guide listed in Appendix A.

Turn on Markers

1. Press the Marker main menu key.

2. Press the Marker 1 2 3 4 5 6 submenu key and select the marker number 1 button using

the touch screen. The underlined number on the Marker submenu key indicates the

active marker.

3. Use the arrow keys or the keypad to move the marker. The current value for the

selected marker is shown above the upper-left corner of the graph. It is also possible to

drag the marker using the touch screen.

4. Delta Markers are available for each of the six reference markers. For the selected

marker, Toggle the Delta On/Off submenu key to turn on the Delta marker.

Peak/Valley Auto Markers

When making Return Loss and VSWR measurements, the Peak/Valley Auto feature can be

used to automatically turn on Marker 1 to peak, Marker 2 to valley, and display M1 and M2

in the Marker Table. This feature is not available for DTF measurements.

1. Press the Marker main menu key.

2. Press the Peak/Valley Auto key.

3-4 PN: 10580-00400 Rev. N MW82119B UG

Page 53

Chapter 3 — Quick Start Guide 3-3 Cable & Antenna Analyzer Measurements (Option 331)

Single Limit Line

1. Press Shift and then Limit (6) to enter the Limit menu.

2. Press the Limit On/Off key to turn on the Limit.

3. Press Single Limit and then use the numeric keypad or the arrow keys to change the

limit value and then press Enter.

Note

4. Press the Limit Alarm key to turn on or off the Limit Alarm.

Refer to the Cable & Antenna Measurement Guide listed in Appendix A for

creating multi-segment limit lines.

Figure 3-3. Single Limit Lines

MW82119B UG PN: 10580-00400 Rev. N 3-5

Page 54

3-3 Cable & Antenna Analyzer Measurements (Option 331) Chapter 3 — Quick Start Guide

DTF Setup

1. Press the Measurements main menu key and select DTF Return Loss or DTF VSWR.

2. Press the Freq/Dist main menu key.

3. Press the Units submenu key and select m to display distance in meters or ft to display

distance in feet.

4. Press DTF Aid and use the touch screen, or arrow keys to navigate through all the DTF

parameters.

a. Set Start Distance and Stop Distance. Stop Distance needs to be smaller than

Dmax.

b. Enter the Start and Stop frequencies.

c. Press Cable, select the appropriate cable from the cable list and press Enter.

d. Press Continue.

Figure 3-4. DTF Aid

5. Press Shift then Calibrate (2) to calibrate the instrument. Refer to “Calibrate with OSL

Calibration” on page 3-7 for additional information.

6. Press the Marker main menu key and set the appropriate markers.

7. Press Shift and Limit (6) to enter and set the appropriate limit lines.

8. Press Shift and File (7) to save the measurement. Refer to Chapter 4, “File

Management” for details.

3-6 PN: 10580-00400 Rev. N MW82119B UG

Page 55