Page 1

MP1861A

56G/64Gbit/s MUX

Operation Manual

Second Edition

For safety and warning information, please read this

manual before attempting to use the equipment.

Additional safety and warning information is provided

in the MP1800A Signal Quality Analyzer Installation

Guide and the MT1810A 4 Slot Chassis Installation

Guide. Please also refer to one of these documents

before using the equipment.

Keep this manual with the equipment.

ANRITSU CORPORATION

Document No.: M-W3756AE-2.0

Page 2

Safety Symbols

To prevent the risk of personal injury or loss related to equipment malfunction, Anritsu Corporation uses the

following safety symbols to indicate safety-related information. Ensure that you clearly understand the meanings of

the symbols BEFORE using the equipment. Some or all of the following symbols may be used on all Anritsu

equipment. In addition, there may be other labels attached to products that are not shown in the diagrams in this

manual.

Symbols used in manual

DANGER

WARNING

CAUTION

This indicates a very dangerous procedure that could result in serious injury or

death if not performed properly.

This indicates a hazardous procedure that could result in serious injury or death if

not performed properly.

This indicates a hazardous procedure or danger that could result in light-to-severe

injury, or loss related to equipment malfunction, if proper precautions are not taken.

Safety Symbols Used on Equipment and in Manual

The following safety symbols are used inside or on the equipment near operation locations to provide information

about safety items and operation precautions. Ensure that you clearly understand the meanings of the symbols and

take the necessary precautions BEFORE using the equipment.

This indicates an obligatory safety precaution. The obligatory operation is

This indicates a warning or caution. The contents are indicated symbolically in or

This indicates a note. The contents are described in the box.

These indicate that the marked part should be recycled.

This indicates a prohibited operation. The prohibited operation is indicated

symbolically in or near the barred circle.

indicated symbolically in or near the circle.

near the triangle.

MP1861A 56G/64Gbit/s MUX

Operation Manual

15 May 2015 (First Edition)

10 July 2015 (Second Edition)

Copyright © 2015, ANRITSU CORPORATION.

All rights reserved. No part of this manual may be reproduced without the prior written permission of the

publisher.

The contents of this manual may be changed without prior notice.

Printed in Japan

ii

Page 3

For Safety

Electric Shock

Repair

WARNING

ALWAYS refer to the operation manual when working near locations

at which the alert mark shown on the left is attached. If the advice in

the operation manual is not followed, there is a risk of personal injury

or reduced equipment performance. The alert mark shown on the left

may also be used with other marks and descriptions to indicate other

dangers.

Overvoltage Category

This equipment complies with overvoltage category II defined in IEC

61010. DO NOT connect this equipment to the power supply of

overvoltage category III or IV.

To ensure that the equipment is grounded, always use the supplied

3-pin power cord, and insert the plug into an outlet with a ground

terminal. If power is supplied without grounding the equipment, there

is a risk of receiving a severe or fatal electric shock or causing

damage to the internal components.

Only qualified service personnel with a knowledge of electrical fire and

shock hazards should service this equipment. This equipment cannot

be repaired by the operator. DO NOT attempt to remove the

equipment covers or unit covers or to disassemble internal

components. There are high-voltage parts in this equipment

presenting a risk of severe injury or fatal electric shock to untrained

personnel. In addition, there is a risk of damage to precision

components.

iii

Page 4

For Safety

Calibration

Falling Over

WARNING

The performance-guarantee seal verifies the integrity of the equipment.

To ensure the continued integrity of the equipment, only Anritsu

service personnel, or service personnel of an Anritsu sales

representative, should break this seal to repair or calibrate the

equipment. Be careful not to break the seal by opening the

equipment or unit covers. If the performance-guarantee seal is

broken by you or a third party, the performance of the equipment

cannot be guaranteed.

This equipment should always be positioned in the correct manner. If

the cabinet is turned on its side, etc., it will be unstable and may be

damaged if it falls over as a result of receiving a slight mechanical

shock.

Always set up the equipment in a position where the power switch

can be reached without difficulty.

iv

Page 5

For Safety

CAUTION

Cleaning

Check Terminal

Use in a Residential

Environment

Use in Corrosive

Atmospheres

Always remove the main power cable from the power outlet before

cleaning dust around the power supply and fan.

Clean the power inlet regularly. If dust accumulates around the

power pins, there is a risk of fire.

Keep the cooling fan clean so that the ventilation holes are not

obstructed. If the ventilation is obstructed, the cabinet may

overheat and catch fire.

Never input a signal of more than the indicated value between the

measured terminal and ground. Input of an excessive signal may

damage the equipment.

This equipment is designed for an industrial environment.

In a residential environment, this equipment may cause radio

interference in which case the user may be required to take adequate

measures.

Exposure to corrosive gases such as hydrogen sulfide, sulfurous acid,

and hydrogen chloride will cause faults and failures.

Note that some organic solvents release corrosive gases.

solvents release corrosive gases.

v

Page 6

Equipment Certificate

Anritsu Corporation certifies that this equipment was tested before shipment

using calibrated measuring instruments with direct traceability to public

testing organizations recognized by national research laboratories, including

the National Institute of Advanced Industrial Science and Technology, and

the National Institute of Information and Communications Technology, and

was found to meet the published specifications.

Anritsu Warranty

Anritsu Corporation will repair this equipment free-of-charge if a malfunction

occurs within one year after shipment due to a manufacturing fault.

However, software fixes will be made in accordance with the separate

Software End-User License Agreement. Moreover, Anritsu Corporation will

deem this warranty void when:

The fault is outside the scope of the warranty conditions separately

described in the operation manual.

The fault is due to mishandling, misuse, or unauthorized modification or

repair of the equipment by the customer.

The fault is due to severe usage clearly exceeding normal usage.

The fault is due to improper or insufficient maintenance by the customer.

The fault is due to natural disaster, including fire, wind, flooding,

earthquake, lightning strike, or volcanic ash, etc.

The fault is due to damage caused by acts of destruction, including civil

disturbance, riot, or war, etc.

The fault is due to explosion, accident, or breakdown of any other

machinery, facility, or plant, etc.

The fault is due to use of non-specified peripheral or applied equipment

or parts, or consumables, etc.

The fault is due to use of a non-specified power supply or in a

non-specified installation location.

The fault is due to use in unusual environments

The fault is due to activities or ingress of living organisms, such as

insects, spiders, fungus, pollen, or seeds.

In addition, this warranty is valid only for the original equipment purchaser. It

is not transferable if the equipment is resold.

Anritsu Corporation shall assume no liability for injury or financial loss of the

customer due to the use of or a failure to be able to use this equipment.

(Note)

.

vi

Page 7

Note:

For the purpose of this Warranty, "unusual environments" means use:

In places of direct sunlight

In dusty places

Outdoors

In liquids, such as water, oil, or organic solvents, and medical fluids, or

places where these liquids may adhere

In salty air or in place chemically active gases (sulfur dioxide, hydrogen

sulfide, chlorine, ammonia, nitrogen dioxide, or hydrogen chloride etc.)

are present

In places where high-intensity static electric charges or electromagnetic

fields are present

In places where abnormal power voltages (high or low) or instantaneous

power failures occur

In places where condensation occurs

In the presence of lubricating oil mists

In places at an altitude of more than 2,000 m

In the presence of frequent vibration or mechanical shock, such as in

cars, ships, or airplanes

Anritsu Corporation Contact

In the event of this equipment malfunctions, contact an Anritsu Service and

Sales office. Contact information can be found on the last page of the printed

version of this manual, and is available in a separate file on the CD version.

vii

Page 8

r

Notes On Export Management

This product and its manuals may require an Export License/Approval by

the Government of the product's country of origin for re-export from you

country.

Before re-exporting the product or manuals, please contact us to confirm

whether they are export-controlled items or not.

When you dispose of export-controlled items, the products/manuals need

to be broken/shredded so as not to be unlawfully used for military purpose.

viii

Page 9

Crossed-out Wheeled Bin Symbol

Equipment marked with the Crossed-out Wheeled Bin Symbol complies with

council directive 2012/19/EC (the “WEEE Directive”) in European Union.

For Products placed on the EU market after August 13, 2005, please contact

your local Anritsu representative at the end of the product's useful life to

arrange disposal in accordance with your initial contract and the local law.

ix

Page 10

Software End-User License Agreement (EULA)

Please read this Software End-User License Agreement (hereafter this EULA) carefully before using

(includes executing, copying, registering, etc.) this software (includes programs, databases, scenarios,

etc., used to operate, set, etc., Anritsu electronic equipment). By reading this EULA and using this

software, you are agreeing to be bound by the terms of its contents and Anritsu Corporation (hereafter

Anritsu) hereby grants you the right to use this Software with the Anritsu-specified equipment

(hereafter Equipment) for the purposes set out in this EULA.

1. Grant of License and Limitations

1. Regardless of whether this Software was

purchased from or provided free-of-charge by

Anritsu, you agree not to rent, lease, lend, or

otherwise distribute this Software to third

parties and further agree not to disassemble,

recompile, reverse engineer, modify, or create

derivative works of this Software.

2. You may make one copy of this Software for

backup purposes only.

3. You are not permitted to reverse engineer

this software.

4. This EULA allows you to install one copy of

this Software on one piece of Equipment.

2. Disclaimers

To the extent not prohibited by law, in no

event shall Anritsu be liable for personal

injury, or any incidental, special, indirect or

consequential damages whatsoever,

including, without limitation, damages for

loss of profits, loss of data, business

interruption or any other commercial

damages or losses, arising out of or related

to your use or inability to use this Software.

3. Limitation of Liability

a. If a fault (bug) is discovered in this Software,

preventing operation as described in the

operation manual or specifications whether

or not the customer uses this software as

described in the manual, Anritsu shall at its

own discretion, fix the bug, or exchange the

software, or suggest a workaround,

free-of-charge. However, notwithstanding

the above, the following items shall be

excluded from repair and warranty.

i) If this Software is deemed to be used for

purposes not described in the operation

manual or specifications.

ii) If this Software is used in conjunction with

other non-Anritsu-approved software.

iii) Recovery of lost or damaged data.

iv) If this Software or the Equipment has been

modified, repaired, or otherwise altered

without Anritsu's prior approval.

v) For any other reasons out of Anritsu's direct

control and responsibility, such as but not

limited to, natural disasters, software virus

infections, etc.

b. Expenses incurred for transport, hotel, daily

allowance, etc., for on-site repairs by Anritsu

engineers necessitated by the above faults

shall be borne by you.

c. The warranty period for faults listed in

article 3a above covered by this EULA shall

be either 6 months from the date of purchase

of this Software or 30 days after the date of

repair, whichever is longer.

x

Page 11

4. Export Restrictions

You may not use or otherwise export or

re-export directly or indirectly this Software

except as authorized by Japanese and

United States law. In particular, this

software may not be exported or re-exported

(a) into any Japanese or US embargoed

countries or (b) to anyone on the Japanese or

US Treasury Department's list of Specially

Designated Nationals or the US Department

of Commerce Denied Persons List or Entity

List. By using this Software, you warrant

that you are not located in any such country

or on any such list. You also agree that you

will not use this Software for any purposes

prohibited by Japanese and US law,

including, without limitation, the

development, design and manufacture or

production of missiles or nuclear, chemical or

biological weapons of mass destruction.

5. Termination

Anritsu shall deem this EULA terminated if

you violate any conditions described herein.

This EULA shall also be terminated if the

conditions herein cannot be continued for

any good reason, such as violation of

copyrights, patents, or other laws and

ordinances.

6. Reparations

If Anritsu suffers any loss, financial or

otherwise, due to your violation of the terms

of this EULA, Anritsu shall have the right to

seek proportional damages from you.

7. Responsibility after Termination

Upon termination of this EULA in

accordance with item 5, you shall cease all

use of this Software immediately and shall

as directed by Anritsu either destroy or

return this Software and any backup copies,

full or partial, to Anritsu.

8. Dispute Resolution

If matters of dispute or items not covered by

this EULA arise, they shall be resolved by

negotiations in good faith between you and

Anritsu.

9. Court of Jurisdiction

This EULA shall be interpreted in

accordance with Japanese law and any

disputes that cannot be resolved by

negotiation described in Article 8 shall be

settled by the Japanese courts.

xi

Page 12

A

Cautions Against Computer Virus Infection

Copying files and data

Only files that have been provided directly from Anritsu or generated

using Anritsu equipment should be copied to the instrument.

ll other required files should be transferred by means of USB or

CompactFlash media after undergoing a thorough virus check.

Adding software

Do not download or install software that has not been specifically

recommended or licensed by Anritsu.

Network connections

Ensure that the network has sufficient anti-virus security protection in

place.

xii

Page 13

r

Protection Against Computer Virus Infections

Prior to the software installation

Before installing this software or any other software recommended o

approved by Anritsu, run a virus scan on your computer, including

removable media (e.g. USB memory stick and CF memory card) you

want to connect to your computer.

When using this software and connecting with the measuring instrument

Copying files and data

On your computer, do not save any copies other than the following:

Files and data provided by Anritsu

Files created by this software

Files specified in this document

Before copying these files and/or data, run a virus scan, including

removable media (e.g. USB memory stick and CF memory card).

Connecting to network

Connect your computer to the network that provides adequate

protection against computer viruses.

Cautions on Proper Operation of Software

This software may not operate normally if any of the following operations

are performed on your computer:

Simultaneously running any software other than that recommended or

approved by Anritsu

Closing the lid (Laptop computer)

Turning on the screen saver function

Turning on the battery-power saving function (Laptop computer)

For how to turn off the functions, refer to the operation manual that came

with your computer.

xiii

Page 14

CE Conformity Marking

Anritsu affixes the CE Conformity marking on the following product(s) in

accordance with the Council Directive 93/68/EEC to indicate that they

conform to the EMC and LVD directive of the European Union (EU).

CE marking

1. Product Model

Model: MP1861A 56G/64Gbit/s MUX

2. Applied Directive and Standards

EMC: Directive 2004/108/EC

LVD: Directive 2006/95/EC

3. Applied Standards

EMC: Emission: EN 61326-1: 2013 (Class A)

Immunity: EN 61326-1: 2013 (Table 2)

IEC 61000-4-2 (ESD) B

IEC 61000-4-3 (EMF) A

IEC 61000-4-4 (Burst) B

IEC 61000-4-5 (Surge) B

IEC 61000-4-6 (CRF) A

IEC 61000-4-8 (RPFMF) A

IEC 61000-4-11 (V dip/short) B, C

*: Performance Criteria

A: The equipment shall continue to operate as intended

during and after the test. No degradation of

performance or loss of function is allowed below a

performance level specified by the manufacturer, when

the equipment is used as intended. The performance

level may be replaced by a permissible loss of

performance. If the minimum performance level or the

permissible performance loss is not specified by the

manufacturer, either of these may be derived from the

product description and documentation and what the

user may reasonably expect from the equipment if used

as intended.

Performance Criteria*

xiv

Page 15

B: The equipment shall continue to operate as intended

after the test. No degradation of performance or loss of

function is allowed below a performance level specified

by the manufacturer, when the equipment is used as

intended. The performance level may be replaced by a

permissible loss of performance. During the test,

degradation of performance is however allowed. No

change of actual operating state or stored data is

allowed. If the minimum performance level or the

permissible performance loss is not specified by the

manufacturer, either of these may be derived from the

product description and documentation and what the

user may reasonably expect from the equipment if used

as intended.

C: Temporary loss of function is allowed, provided the

function is self-recoverable or can be restored by the

operation of the controls.

Harmonic current emissions:

EN 61000-3-2: 2006 +A1:2009 A2:2009

(Class A equipment)

No limits apply to this equipment with an active input power

under 75 W.

LVD: EN 61010-1: 2010 (Pollution Degree 2)

4. Authorized representative

Name: Murray Coleman

Head of Customer Service EMEA

ANRITSU EMEA Ltd.

Address, city: 200 Capability Green, Luton

Bedfordshire, LU1 3LU

Country: United Kingdom

xv

Page 16

C-Tick Conformity Marking

Anritsu affixes the C-Tick mark on the following product(s) in accordance

with the regulation to indicate that they conform to the EMC framework of

Australia/New Zealand.

C-Tick marking

1. Product Model

Model: MP1861A 56G/64Gbit/s MUX

2. Applied Standards

EMC: Emission: EN 61326-1: 2013 (Class A equipment)

xvi

Page 17

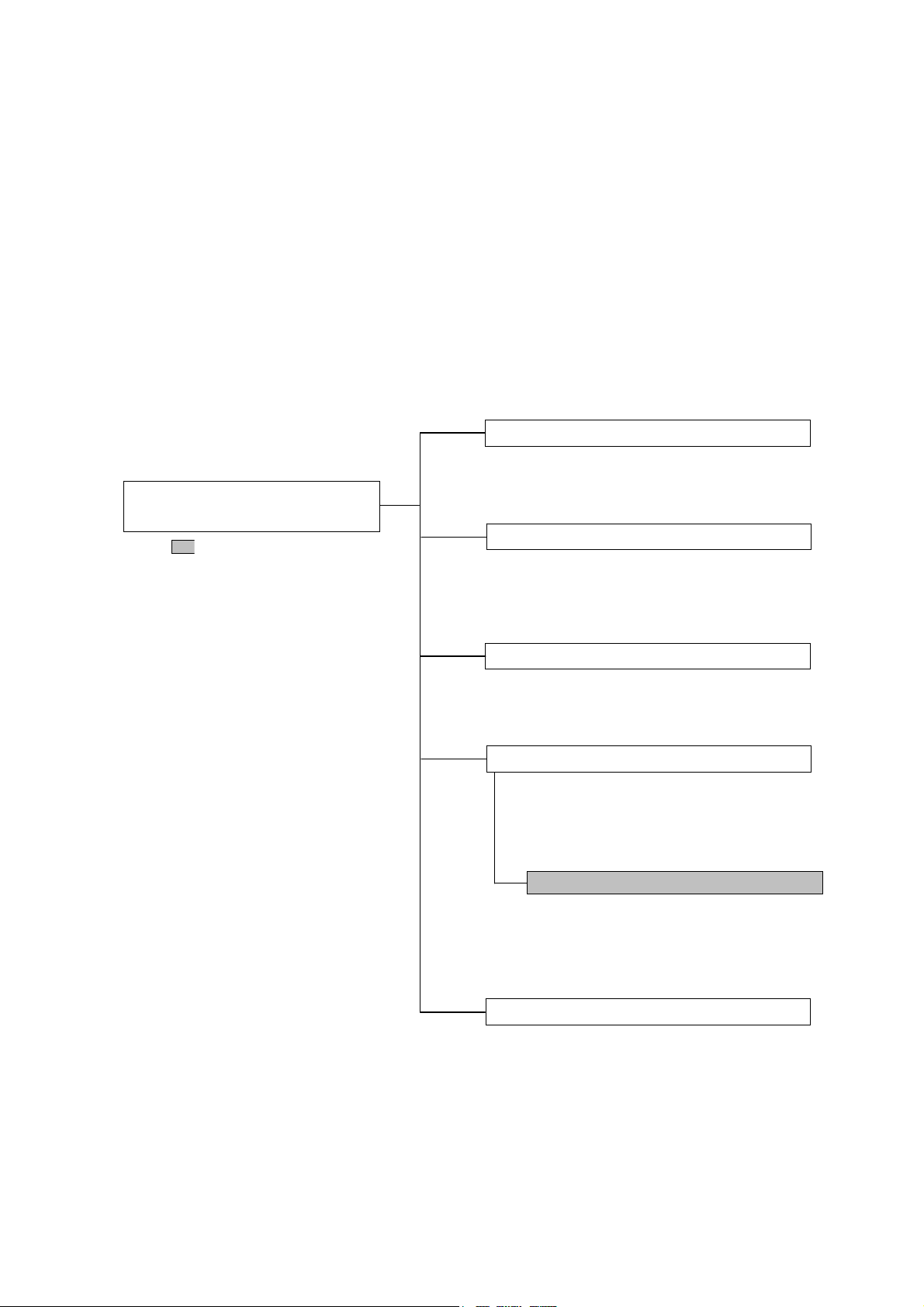

Configuration of Signal Quality

Analyzer Series Operation Manual

indicates this document.

About This Manual

A testing system combining an MP1800A Signal Quality Analyzer or

MT1810A 4 Slot Chassis mainframe, module(s), and control software is

called a Signal Quality Analyzer Series. The operation manuals of the

Signal Quality Analyzer Series consist of separate documents for the

installation guide, the mainframe, remote control operation, module(s),

and control software, as shown below.

Installation Guide

Installation guide from module installation

to the start of use. The Installation Guide

varies depending on the mainframe used.

Mainframe Operation Manual

Describes basic operations of the

mainframe. The Mainframe Operation

Manual varies depending on the mainframe

used.

Remote Control Operation Manual

Describes remote control using the GPIB

interface and LAN interface.

Module Operation Manual

Operation manual for the module. The

Module Operation Manual varies

depending on the module(s) used.

MP1861A 56G/64Gbit/s MUX

Describes how the

as well as how to operate and maintain it.

Control Software Operation Manual

Operation manual of the software that

controls the Signal Quality Analyzer Series.

MP1861A

is configured

I

Page 18

Table of Contents

For Safety .................................................... iii

About This Manual........................................ I

Chapter 1 Overview ........................................... 1-1

1.1 Product Overview ......................................................... 1-2

1.2 Product Composition .................................................... 1-3

1.3 Specifications ................................................................ 1-6

Chapter 2 Before Use ........................................ 2-1

2.1 Preparation Before Use ................................................ 2-2

2.2 Getting Started with MX180000A ............................... 2-10

2.3 Other Usage Methods ................................................. 2-19

2.4 Preventing Damage .................................................... 2-24

Chapter 3 Panel Layout and Connectors ........ 3-1

3.1 Panel Layout ................................................................. 3-2

3.2 Inter-Module Connection .............................................. 3-5

Chapter 4 Window Operations ......................... 4-1

4.1 Configuration of Operation Screen ............................... 4-2

4.2 Configuration of the Operation Window ........................ 4-3

4.3 Setting Output Interface ................................................ 4-4

4.4 Operating the Linked Module ...................................... 4-13

4.5 Multi Channel Functions ............................................. 4-15

II

Chapter 5 Use Examples ................................... 5-1

5.1 Achieving Error-Free Data Transmission ..................... 5-2

5.2 Measuring Optical Transceiver Module ........................ 5-4

5.3 Testing Jitter Tolerance ................................................ 5-6

Page 19

1

Chapter 6 Performance Test ............................. 6-1

6.1 Overview ....................................................................... 6-2

6.2 Devices Required for Performance Tests ..................... 6-3

6.3 Performance Test Items ............................................... 6-4

Chapter 7 Remote Commands ......................... 7-1

7.1 Status Commands ........................................................ 7-2

7.2 Common Commands .................................................... 7-5

7.3 64G MUX Commands ................................................. 7-15

Chapter 8 Maintenance ..................................... 8-1

8.1 Daily Maintenance ........................................................ 8-2

8.2 Cautions on Storage ..................................................... 8-2

8.3 Transportation ............................................................... 8-3

8.4 Calibration ..................................................................... 8-3

8.5 Disposal ........................................................................ 8-4

Chapter 9 Troubleshooting ............................... 9-1

9.1 Problems That May Occur When Starting MP1861A ... 9-2

9.2 Problems That May Occur During Output Waveform

Observation ................................................................... 9-3

9.3 Problems That May Occur During Error Rate

Measurement ................................................................ 9-4

2

3

4

5

6

7

8

9

III

Appendix

Page 20

Appendix A List of Initial Settings .................. A-1

Appendix B Setting Restrictions ................. B-1

Appendix C Performance Test Record Sheet C-1

Appendix D Fault Diagnosis Tool ................... D-1

Appendix E Sequence Examples ..................... E-1

IV.

Page 21

Chapter 1

This chapter provides an overview of the MP1861A 56G/64Gbit/s MUX

(MP1861A hereafter).

Product Overview ......................................................... 1-2

1.1

1.2 Product Composition .................................................... 1-3

1.2.1 Standard composition ....................................... 1-3

1.2.2 Options ............................................................. 1-4

1.2.3 Application parts ............................................... 1-5

1.3 Specifications ................................................................ 1-6

1.3.1 Specifications for MP1861A ............................. 1-6

Overview

1

Overview

1-1

Page 22

Chapter 1 Overview

1.1 Product Overview

The MP1861A is a plug-in module that can be built into a Signal Quality

Analyzer main frame. This equipment 2:1 multiplexes the output signal

of the MU183020A 32 Gbit/s and MU181021A 32 Gbit/s 4ch PPG

(hereafter MU18302xA) to generate 8 to 64.2 Gbit/s PRBS, DATA and

Zero-Substitution patterns.

Various option configurations are available for the MP1861A. This

module is therefore useful for research, development, and production of

various types of digital communication equipment, modules, and devices.

Features of the MP1861A:

Operating rates: 8 to 56.2 Gbit/s (64.2 Gbit/s using additional options)

Multiplexes input data signal to 2:1

High-quality output signal waveform

Flexible for functional expansion in the future, by installing additional

options.

Controlled by MX180000A Signal Quality Analyzer Control Software

(hereafter MX180000A) when either MP1800A or controller PC

connected

1-2

Page 23

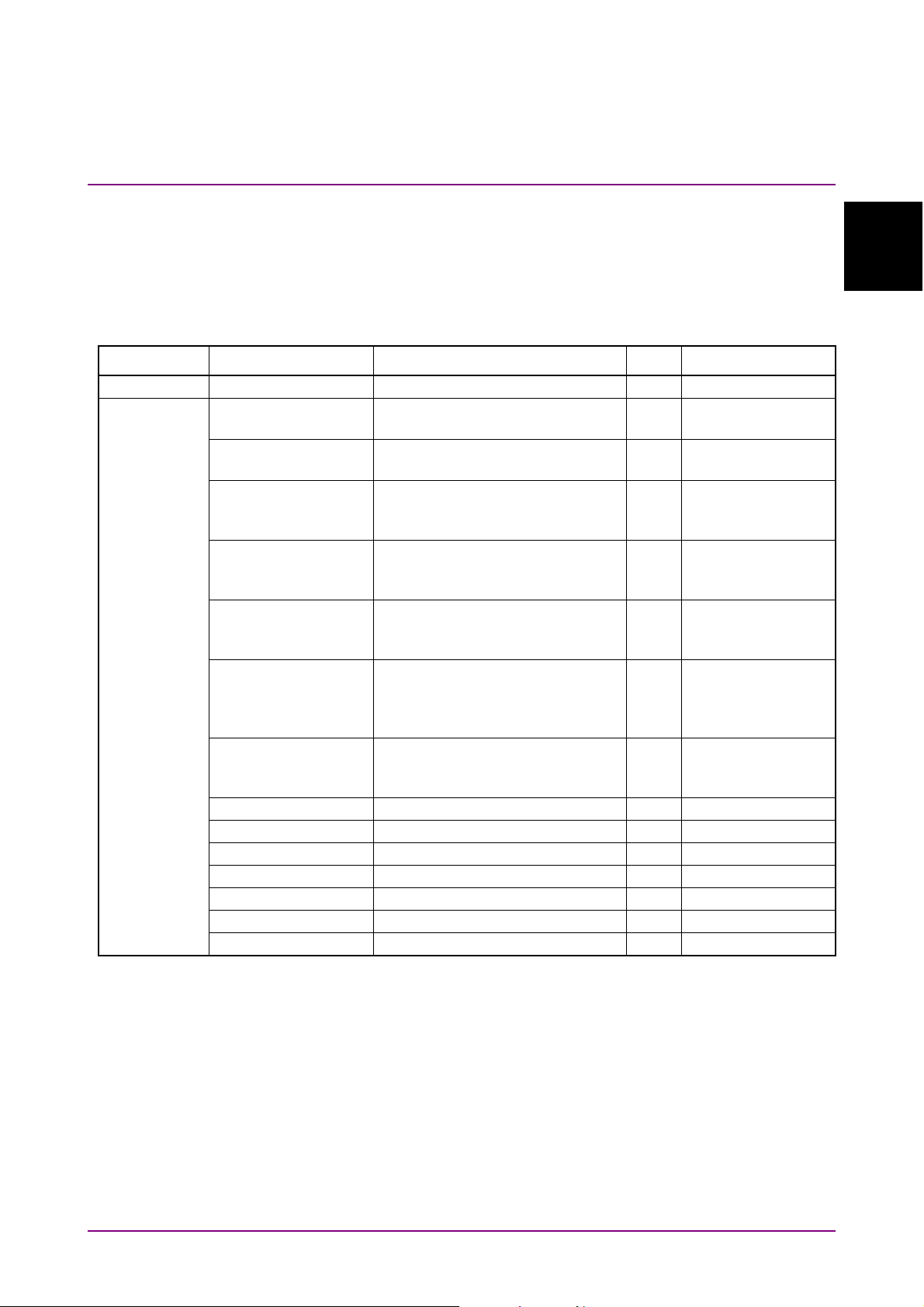

1.2 Product Composition

1.2 Product Composition

1.2.1 Standard composition

Table 1.2.1-1 shows the standard composition of the MP1861A.

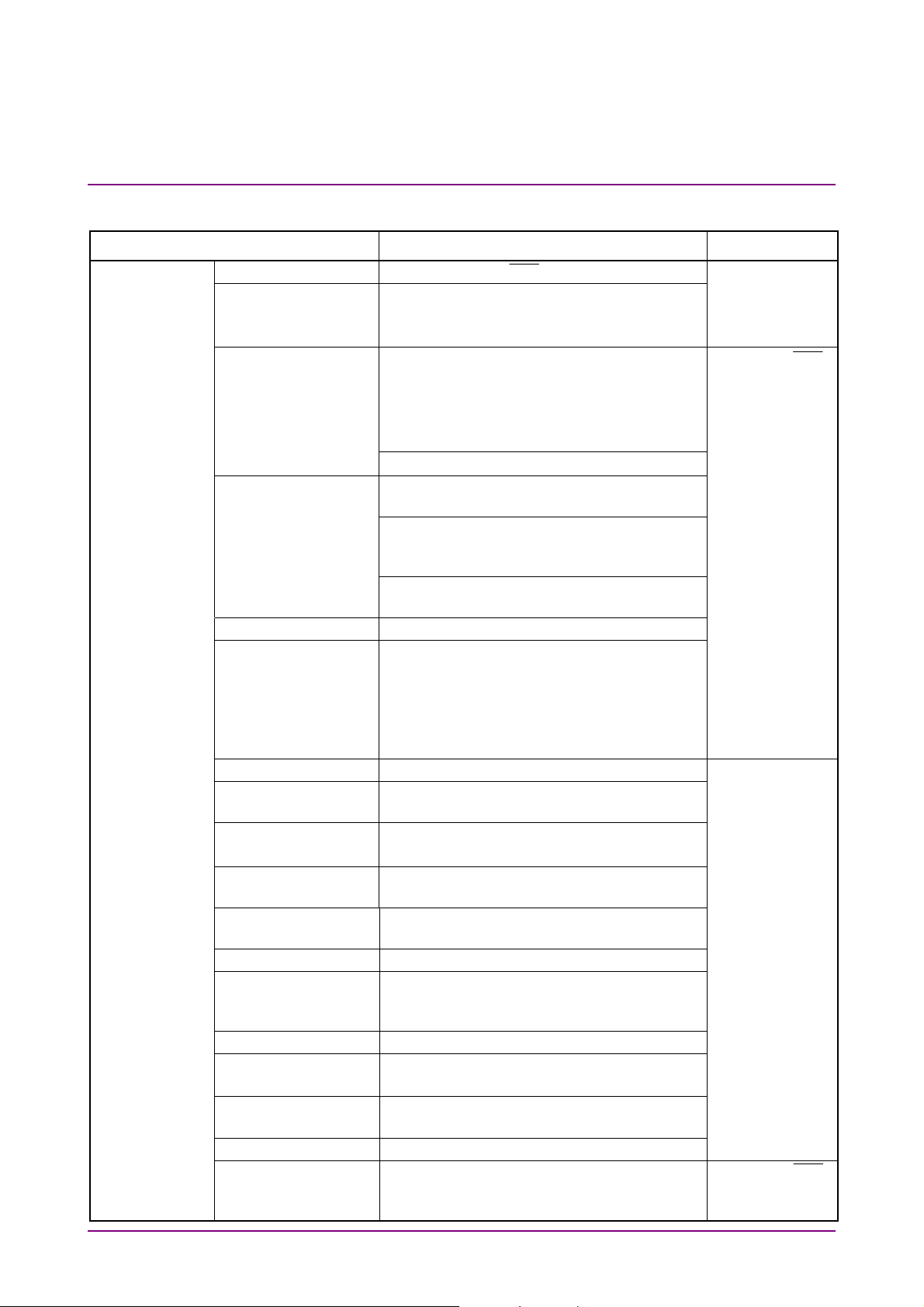

Table 1.2.1-1 Standard composition for MP1861A

Item Model Product name Q’ty Remarks

Main frame MP1861A 56G/64Gbit/s MUX 1

Accessory J1658A Coaxial skew match pair cable

(1.3 m, K connector)

J1652A Coaxial cable

(0.5 m, K connector)

J1654A U Link Cable B 1 Delayed Clock

J1363A Protection cap 2 Data

41V-6 Precision fixed attenuator 6 dB 2 Data

J1632A Terminator 4 Clock Output1/2

J1341A Open 3 External Clock

J1655A Semi-rigid Cable (0.2 m, V) 1

J1475A USB cable 1

Z1312A AC Adapter 1

G0342A ESD Discharger 1

Power cord 2.6 m 1

Z0897A MP1800A Manual CD 1 CD-ROM version

Z0918A MX180000A Software CD 1 CD-ROM version

1

Overview

1 Data Input1/2

1 External Clock

Input

Output to Mux

Clock Input

Output/XData

Output

Output/XData

Output

1/2 Clock

OutputBuffered

Clock Output

Input

Data Input1/2

1-3

Page 24

A

Chapter 1 Overview

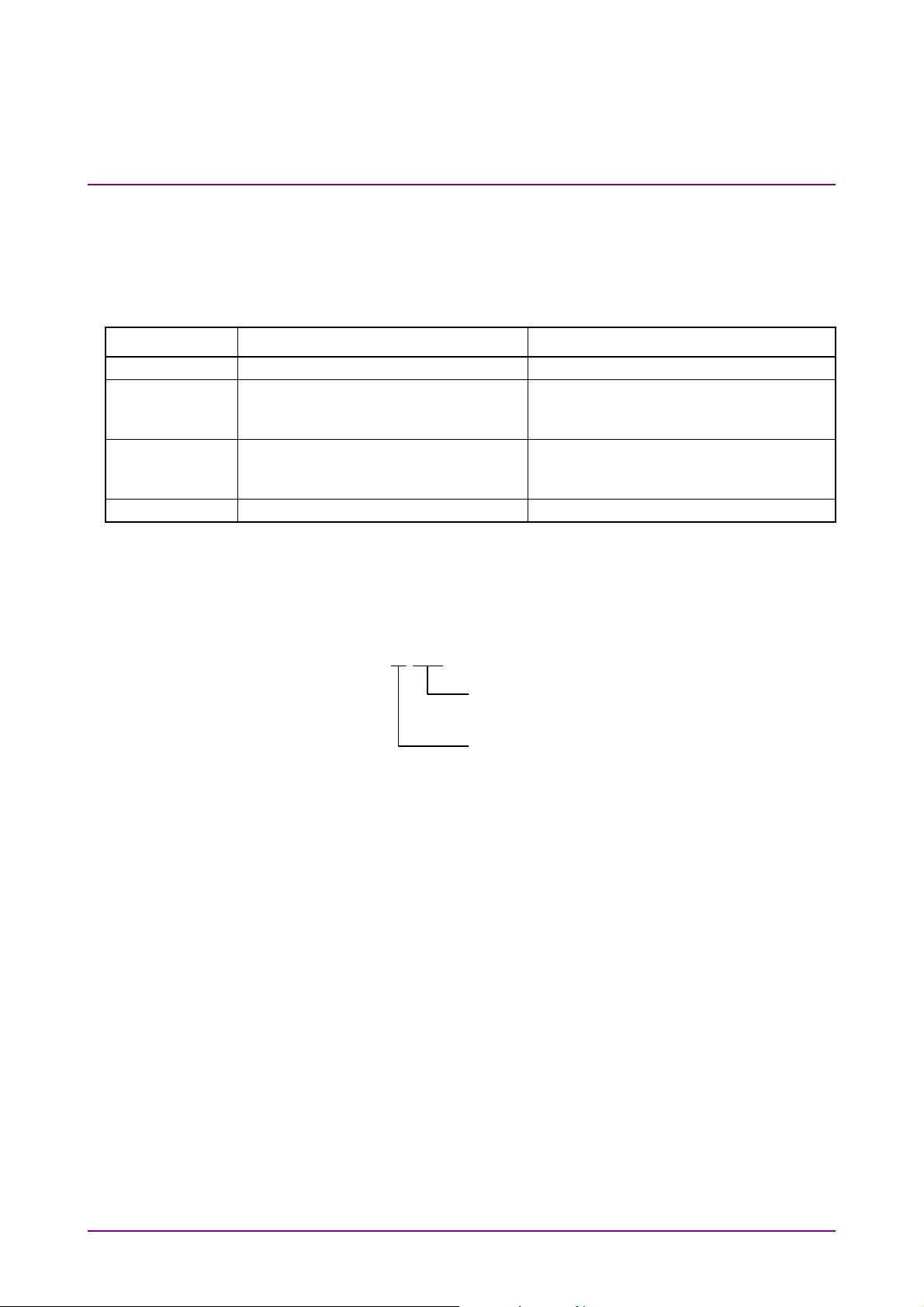

1.2.2 Options

Table 1.2.2-1 shows the options for the MP1861A. All options are sold

separately.

Table 1.2.2-1 Options for MP1861A

Model name Product name Remarks

MP1861A-x01 64 Gbit/s Extension

MP1861A-x11 Variable Data Output (0.5 to 2.5 Vp-p) Mandatory option

Cannot be installed together with

MP1861A-x13.

MP1861A-x13 Variable Data Output (0.5 to 3.5 Vp-p) Mandatory options

Cannot be installed together with

MP1861A-x11.

MP1861A-x30 Variable Data Delay

Option name format is as follows:

MP1861A- x x x

Indicates function.

This value is recognized by the mainframe.

nritsu management number.

This value is not recognized by the mainframe.

1-4

Page 25

1.2.3 Application parts

Table 1.2.3-1 shows the application parts for the MP1861A. All

application parts are sold separately.

1.2 Product Composition

1

Table 1.2.3-1 Application parts

Model Product name Remarks

J1600A Skew match pair cable

(0.2 m, V connector)

J1656A Coaxial cable set

(MP1861A-MP1862A)

J1646A Passive Equalizer 6dB (V connector)

Z0306A Wrist strap

J1678A ESD Protection Adapter-K K connector

J1679A ESD Protection Adapter-V V connector

Cable for measurement

Two (a pair) for jitter tolerance

measurement

Overview

1-5

Page 26

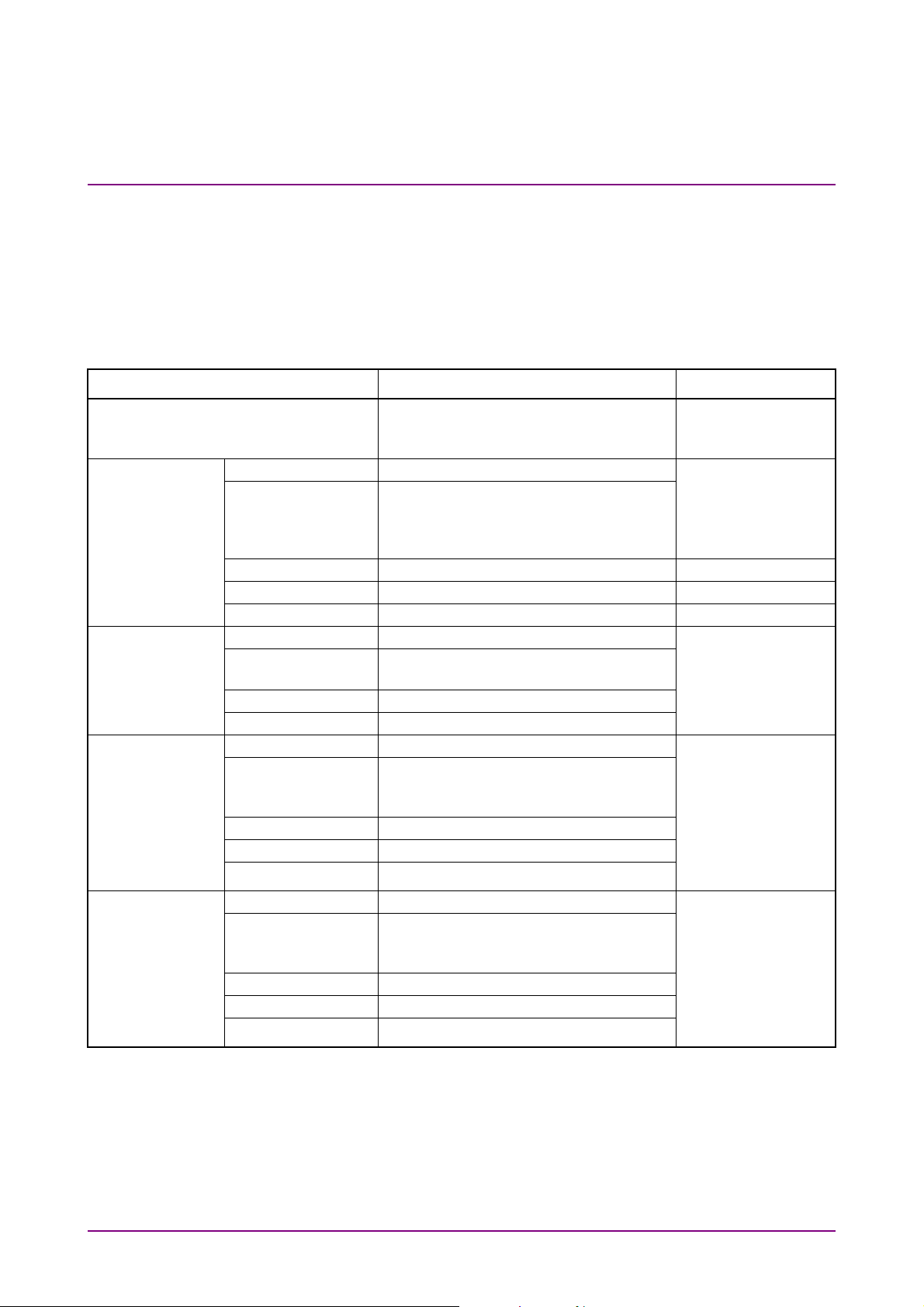

Chapter 1 Overview

1.3 Specifications

1.3.1 Specifications for MP1861A

The input/output specification value is defined assuming that a sampling

oscilloscope range with 70 GHz is used.

Table 1.3.1-1 Specifications for MP1861A

Item Specifications Remarks

Operating Bit Rate 8 to 56.2 Gbit/s

8 to 64.2 Gbit/s (when MP1861A-x01

installed)

External Clock

Input

Data Input Number of Input 2 (Data Input 1, Data Input 2) From MU18302xA

1/2 Clock Output Number of Output 1 (1/2 Clk Output) To be terminated

Clock Output Number of Output 2 (Clk Output1, Clk Output2) Output frequency:

Number of Input 1 (Ext Clk Input) From the

Frequency 4 to 28.1 GHz

4 to 32.1 GHz (when MP1861A-x01

installed)

Input Amplitude 0.3 to 1.0 Vp-p

Termination 50

Connector K (f.)

Level 0/–0.7 V (H:–0.15 to +0.05, L: –0.85 to

Termination 50

Connector K (f.)

Frequency 2 to 14.05 GHz

Output Amplitude 0.3 to 1.0 Vp-p

Termination 50

Connector SMA(f.)

Frequency 4 to 28.1 GHz

Output Amplitude 0.4 to 1.0 Vp-p

Termination 50

Connector K (f.)

/AC

–0.55)

/GND

2 to 16.05 GHz (when MP1861A-x01

installed)

/AC

4 to 32.1 GHz (when MP1861A-x01

installed)

/AC

MU18302xA Clock

Output connector

(Full rate Clock

Output setting)

Data Output

into 50 when not

in use.

Output frequency:

Half of the

frequency input to

the Ext Clk Input

connector.

The same as the

frequency input to

the Ext Clk Input

connector.

To the MP1862A

Ext. Clock Input

connector or DUT

1-6

Page 27

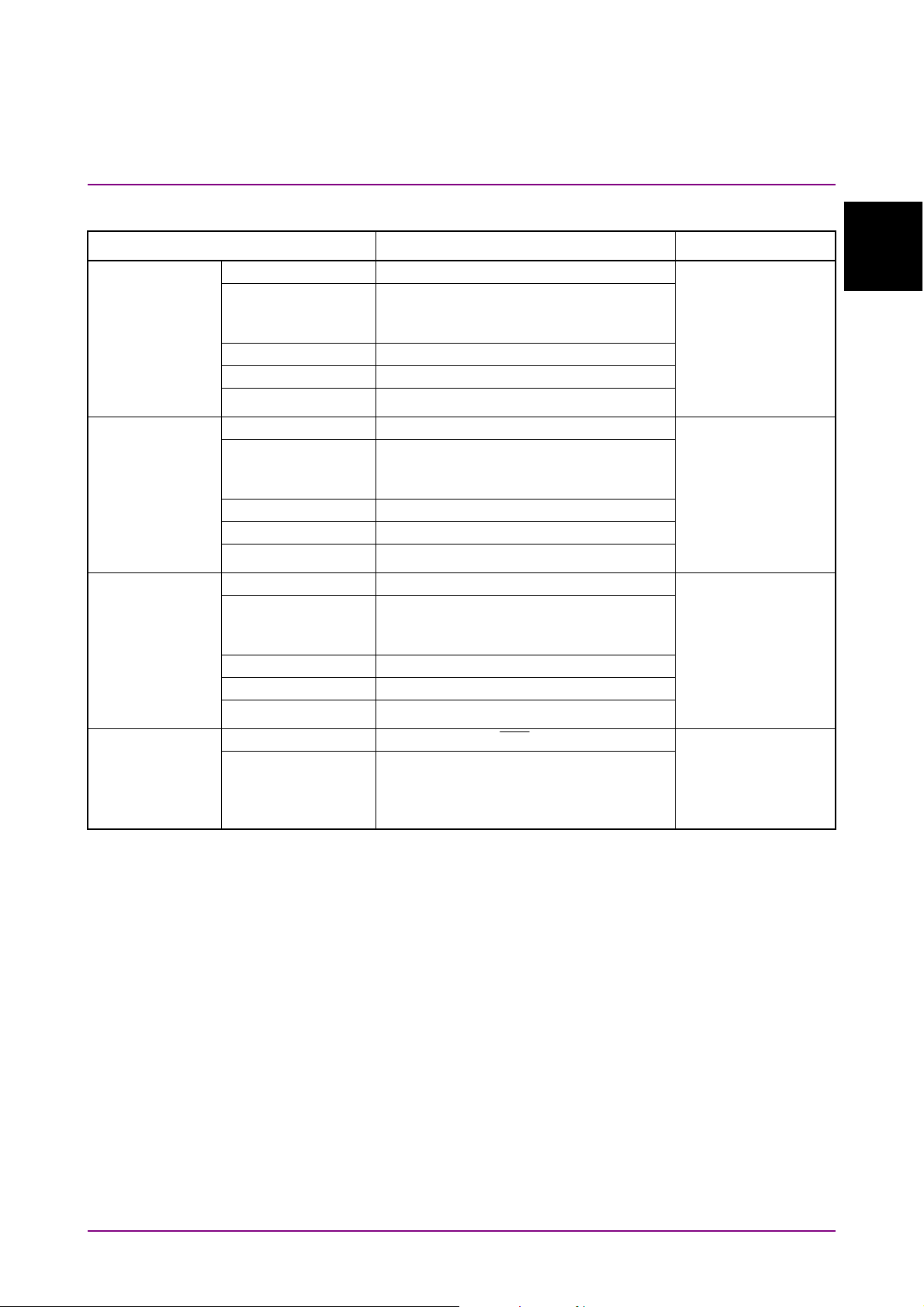

Table 1.3.1-1 Specifications for MP1861A (Cont’d)

1.3 Specifications

Buffered Clock

Output

Delayed Clock

Output

MUX Clock

Input

Data Output*1

MP1861A-x11

(Variable Data

Output (0.5 to

2.5 Vp-p))

Item Specifications Remarks

Number of Output 1 (Buffered Clk Output) To be terminated

Frequency 4 to 28.1 GHz

4 to 32.1 GHz (when MP1861A-x01

installed)

Output Amplitude 0.2 to 1.0 Vp-p

Termination 50

Connector K (f.)

Number of Output 1 (Delayed Clk Output) To be connected to

Frequency 4 to 28.1 GHz

Output Amplitude 0.2 to 1.0 Vp-p

Termination 50

Connector K (f.)

Number of Input 1 (MUX Clk Input) To be connected to

Frequency 4 to 28.1 GHz

Input Amplitude 0.2 to 1.0 Vp-p

Termination 50

Connector K (f.)

Number of Output 2 (Data Output/

Bit Rate 8 to 56.2 Gbit/s

/AC

4 to 32.1 GHz (when MP1861A-x01

installed)

/AC

4 to 32.1 GHz (when MP1861A-x01

installed)

/AC

Output)

Data

8 to 64.2 Gbit/s (when MP1861A-x01

installed)

into 50 when not

in use.

Output frequency:

The same as the

frequency input to

the Ext Clk Input

connector.

the Mux Clk Input

connector.

Output frequency:

The same as the

frequency input to

the Ext Clk Input

connector.

the Delayed Clk

Output connector.

Input frequency:

The same as the

frequency input to

the Ext Clk Input

connector.

1

Overview

*1: Defined under the following test pattern conditions:

• PRBS2^31–1

• Mark Ratio1/2

1-7

Page 28

Chapter 1 Overview

Item Specifications Remarks

Data Output*1

Amplitude*

MP1861A-x11

(Variable Data

Output (0.5 to

2.5 Vp-p))

(Continued)

Offset –2.0 to +3.3 Voh /1 mV Step

Defined Interface NECL, SCFL, NCML, PCML, LVPECL

Cross Point 45% to 55% / 0.1% Step (≤56.2 Gbit/s)

Tr/Tf*2, *3 Typ.8 ps (20 to 80%)*4,*5

Half Period Jitter –20 to 20/1 Step

Jitter (RMS)*2, *3 Typ. 450 fs, ≤550 fs*4,*7

Random Jitter

(RMS)

Waveform

Distortion

(0-peak)*

ON•OFF Can be switched ON/OFF

Termination Can be switched between AC and DC, 50

Connector V (f.)

Offset reference Can be switched between Voh, Vth and

Data/XData

Tracking

Level Guard Yes

Table 1.3.1-1 Specifications for MP1861A (Cont’d)

2, *3

0.5 to 2.5 Vp-p/2 mV Step

0.5 to 2.5 Vp-p/2 mV Step (≤56.2 Gbit/s) *

1.0 to 2.5 Vp-p/2 mV Step (>56.2 Gbit/s)

The range of 0.5 to 0.998 V is not

guaranteed but can be set.

*5

Accuracy: 50 mV 17% of Amplitude*4,*5

Min. –4.0 Vol

Accuracy:

65 mV 10% of Offset (Vth)

(Amplitude Accuracy/2)

Current Limit:

Sourcing 100 mA/Sinking 100 mA

“Overload” is displayed in the following

cases because the cross point of 50 %

cannot be guaranteed.

• >56.2 Gbit/s

• When MP1861A-x01 is installed

With monitor display in units of UI.

Typ. 650 fs *

5,*7

Typ. 200 fs *4,*7

4,*5,*6

2,*3

Typ. 25 mV 10% of Amplitude *

/GND, –2 V, + 1.3 V (when DC selected)

Vol

Yes

Data and

5

can be set

separately.

Data

1-8

External ATT

Factor

*2: Defined based on the condition the cross point is 50%.

Yes Data and

Data

can be set

separately.

Page 29

1.3 Specifications

*3: Defined based on the following observation conditions:

• The coaxial cable (J1655A) is used

• The sampling oscilloscope band is 70 GHz.

1

*4: At a bit rate of 56.2 Gbit/s

*5: At a bit rate of 64.2 Gbit/s (with MP1861A-x01 installed)

*6: At an output amplitude of 2.5 Vp-p

*7: The specified value applies when using an oscilloscope with residual

jitter of less than 200 fs (RMS).

Overview

1-9

Page 30

Chapter 1 Overview

Item Specifications Remarks

Table 1.3.1-1 Specifications for MP1861A (Cont’d)

Data Output*1

(Cont’d)

MP1861A-x13

(Variable

Data Output

(0.5 to

3.5 Vp-p))

Number of Output 2 (Data Output /

Output)

Data

Bit Rate 8 to 56.2 Gbit/s

8 to 64.2 Gbit/s (when MP1861A-x01

installed)

*5

Data and

can be set

separately.

Data

Amplitude*2, *3 0.5 to 3.5 Vp-p/2 mV Step

0.5 to 3.5 Vp-p/2 mV Step (≤56.2 Gbit/s)

1.0 to 3.5 Vp-p/2 mV Step (>56.2 Gbit/s)

The range of 0.5 to 0.998 V is not

5

guaranteed but can be set.*

Accuracy: 50 mV 17% of Amplitude*3

Offset –2.0 to + 3.3 Voh/1 mV Step

Min. –4.0 Vol

Accuracy:

65 mV 10% of Offset (Vth)

(Amplitude Accuracy/2)

Current Limit:

Sourcing 100 mA/Sinking 100 mA

Defined Interface NECL, SCFL, NCML, PCML, LVPECL

Cross Point 45 to 55% /0.1% Step (≤56.2 Gbit/s)

“Overload” is displayed in the following

cases because the cross point of 50 %

cannot be guaranteed.

• >56.2 Gbit/s

• When MP1861A-x01 is installed

Tr/Tf*2,*3 Typ.8 ps (20 to 80%)*4,*5

Half Period Jitter –20 to 20/1 Step

With monitor display in units of UI.

Jitter (RMS)*2,*3 Typ. 450 fs, ≤550 fs*4, *

7

Typ. 650 fs, *5, *7

Random Jitter

Typ. 200fs *4, *7

(RMS)

Waveform Distortion

2,*3

(0-peak) *

Typ. 25 mV 10% of Amplitude *

4,*5,*6

ON/OFF Can be switched ON/OFF

Termination Can be switched between AC and DC,

50 /GND, –2 V, + 1.3 V (when DC

selected)

Connector V (f.)

Offset reference Can be switched between Voh, Vth and Vol

1-10

Data/XData

Yes

Tracking

Level Guard Yes

External ATT

Yes Data and

Factor

can be set

separately.

Data

Page 31

Table 1.3.1-1 Specifications for MP1861A (Cont'd)

1.3 Specifications

Jitter tolerance

1,*4,*5

*

Item Specifications Remarks

When interacting

with MU181500B+

MU18302xA

This item is defined under the following

conditions:

• Bit rate:

1

Overview

56.2 Gbit/s

64.2 Gbit/s (With MP1861A-x01 installed)

• Pattern: PRBS2^31–1

• Temperature: 20 to 30°C

• Loopback connection with MP1862A

The following shall be applied simultaneously

by using MU181500B:

• SSC with a 5300 ppm amplitude

• RJ of 0.3 UI

Modulation frequency:

56.2 Gbit/s: Up to 250 MHz

64.2 Gbit/s: Up to 150 MHz

2000

20dB/decade

15

10

Variable Data

Delay

Jitter Amplitude [UIp-p]

Modulation Frequency [MHz]

Variable phase

–64000 to +64000 mUI/ 4 mUI Step With

range

Phase setting

error

Typ. 50 mUIp-p (≤56.2 Gbit/s) *

Typ. ±150 mUIp-p (>56.2Gbit/s, (when

MP1861A-x01 installed)) *

8

8

mUI-ps conversion Available

Calibration Available (When jitter modulation is off)

Relative 0 Available

Jitter Input Available

*8: The values are specified, assuming an oscilloscope with a linearity of

less than 200 fs will be used.

MP1861A-x30

installed

1-11

Page 32

Chapter 1 Overview

Table 1.3.1-1 Specifications for MP1861A (Cont'd)

Item Specifications Remarks

Control interface USB 2.0 or 1.1 Type B ×1

Channel setting Can be selected from CH1 to CH4.

Power (AC

adapter)

Power consumption DC 19 V, 4 A

Dimensions

(Excluding protrusions)

Mass 5.0 kg or less

Environmental

Performance

Input voltage AC 100 to 240 V *9

Input frequency 50 to 60 Hz

Output power DC 19 V, 7.9 A (Max)

90.9 mm(H), 120 mm (W), 140 mm (D)

Operation

Temperature

Storage

Temperature

*9: Operating voltage: within the range of +10% to –15% from the rated

+ 15 to + 35C (ambient temperature of

equipment)

–20 to +60C

voltage

1-12.

Page 33

2-1

Before Use

Chapter 2 Before Use

This chapter describes preparation required before using MP1861A.

Preparation Before Use ................................................ 2-2

2.1

2.1.1 Environmental Conditions of Installation Site ... 2-2

2.1.2 Clearance from Fan .......................................... 2-2

2.1.3 Power Connection ............................................ 2-3

2.1.4 Usage Patterns of MP1861A ............................ 2-4

2.2 Getting Started with MX180000A ............................... 2-10

2.2.1 Installing MX180000A..................................... 2-10

2.2.2 Starting MX180000A ...................................... 2-15

2.2.3 Exiting MX180000A ........................................ 2-16

2.2.4 Messages that are displayed when

connecting/disconnecting the USB cable ....... 2-17

2.3 Other Usage Methods ................................................. 2-19

2.3.1 Checking Installed Software Version .............. 2-19

2.3.2 Updating Software .......................................... 2-21

2.3.3 Initializing Settings .......................................... 2-23

2.4 Preventing Damage .................................................... 2-24

2

Page 34

Chapter 2 Before Use

2-2

10 cm

10 cm

2.1 Preparation Before Use

This section explains the installation position of the mainframe and how

to turn on the power.

2.1.1 Environmental Conditions of Installation Site

The MP1861A operates in the temperature range from 15 to 35°C. Avoid

using it under any of the following environment conditions that may

cause failure.

•

Strong vibrations

•

High humidity or dust

•

Direct sunlight

•

Chemically active gases

•

Substantial temperature changes

Note:

Condensation may form inside of the MP1861A if it is moved to a

warm location after operating for a long time in a cool location. In

such a case, be sure to wait until the MP1861A becomes completely

dry before turning on the power. Doing so with condensation

present may cause a short circuit and damage the MP1861A.

2.1.2 Clearance from Fan

A cooling fan is provided on the side of the MP1861A. Install the

MP1861A at least 10 cm away from walls, peripheral devices, or the like

to prevent blockage of ventilation. Insufficient ventilation may cause the

internal temperature to rise, resulting in failure.

Figure 2.1.2-1 Clearance from fan

Page 35

2.1 Preparation Before Use

2-3

Before Use

2.1.3 Power Connection

This section describes the procedures for supplying power.

Use a supplied AC adapter. If AC adapter other than the supplied one is

used, the MP1861A may be damaged.

Connect the shielded connector from the AC adapter to the rear panel

connector of the MP1861A. Refer to Figure 2.1.3-1.

Figure 2.1.3-1 Rear Panel of MP1861A

Insert the power plug into an outlet, and connect the other end to the

power inlet on the rear panel. To ensure that the instrument is earthed,

always use the supplied 3-pin power cord, and insert the plug into an

outlet with an earth terminal.

2

WARNING

If the power cord is connected without grounding

MP1861A, there is a risk of receiving a fatal electric shock.

In addition, the peripheral devices connected to MP1861A

may be damaged.

When connecting to the power supply, DO NOT connect to

an outlet without a ground terminal. Also, avoid using

electrical equipment such as an extension cord or a

transformer.

Page 36

Chapter 2 Before Use

2-4

MP1800A with MX180000A

MP186xA

USB

Power

Data OutputData Output

Clock Output1/2 Clock Output

0.7Vp-p 0.7Vp-p

0.5-3.5Vp-p

On

USB Connection

2.1.4 Usage Patterns of MP1861A

This section describes the two ways to control MP1861A and how to

connect to MP1800A or control PC.

MP1861A is controlled via the MX180000A installed to MP1800A or

control PC. When connecting MP1861A to MP1800A (control PC), use the

standard accessory USB cable.

(1) Connecting MP1800A:

Connect the USB connector (type A) to the front panel or rear panel

of MP1800A, and then connect the USB connector (type B) to

MP1861A.

Figure 2.1.4-1 Connecting to MP1800A

To connect two MP1861As to MP1800A, connect them to the USB

connectors (type A) on MP1800A’s front panel.

MP1861As may not be able to function properly if one of them is

connected to the USB connector on MP1800’s rear panel. To connect

more than two MP1861As, connect a USB hub to the front or rear

panel of MP1800A, and then connect each of MP1861As to MP1800A

via the USB hub.

Page 37

2.1 Preparation Before Use

2-5

Before Use

Figure 2.1.4-2 Connecting Multiple MP186xAs to MP1800A

2

Page 38

Chapter 2 Before Use

2-6

MP1825B

USB

MP186xA

Control PC with MX180000A

(2) Connecting to control PC:

Connect the USB connector (type A) to PC, and then connect the

USB connector (type B) to the MP1861A.

Figure 2.1.4-3 Connecting to Control PC

Note the following when connecting two MP186xAs to control PC:

For PC with multiple USB connectors, connect to the USB

•

connector with the same USB controller, as shown below.

It may not function normally if connecting to the connector with

different USB controller.

If the number of USB connectors on the Control PC is not

•

enough, use a USB hub.

Note:

Anritsu is not responsible for the proper functioning of all USB

hubs.

Page 39

2.1 Preparation Before Use

2-7

Before Use

MP186xA

MP186xA

Control PC with MX180000A

Control PC with MX180000A

USB connector

with

controller

USB

USB connector

with

the same

controller

USB connector

of the same

controller

MP186xA

Control PC with MX180000A

USB Hub

USB

different

2

Figure 2.1.4-4 Connecting Control PC to Two MP186xAs

Figure 2.1.4-5 Connecting Control PC Using A USB Hub

Using other USB devices

Refer to the following for how to use commercially available USB devices

when MP1861A is in use.

Connect the USB device before starting the MP1800A; do not connect or

disconnect USB devices while using the MX180000A Control Software.

In addition, only read measurement data using a USB device after

exiting the MX180000A Control Software (closing selector screen).

Page 40

Chapter 2 Before Use

2-8

Compatibility

IBM-PC or compatible PC

OS

Windows XP Version 2002 Service Pack 2

Hard Disk

Required free disk space for installing the software

package: At least 200 MB

CPU Pentium4 processer and 1.6 GHz or higher

Memory ≥ 512 MB

Monitor resolution 800 × 600 dots or more

Display color ≥ 256 colors

CD-ROM driver Required when installing the software package

USB Interface USB 2.0 or USB 1.1

Use a PC that meets or exceeds the following specifications.

Table 2.1.4-1 Required Specifications for Control PC (For Windows XP)

Item Specifications

Page 41

2.1 Preparation Before Use

2-9

Before Use

Compatibility

IBM-PC or compatible PC

CPU

OS

Windows 7 Professional/Enterprise/Ultimate

Memory

32-bit: 1 GB RAM

64-bit: 2 GB RAM

CD-ROM driver

Required when installing the software package

Hard Disk

Required free disk space for installing the software

package: At least 200 MB

USB Interface

10 BASE-T or 100 BASE-TX

Table 2.1.4-2 Required Specifications for Control PC (For Windows 7)

Item Specifications

1 GHz or faster 32-bit (x86) or 64-bit (x64) processor

2

Monitor resolution 800 × 600 dots or more

Display color ≥ 256 colors

The MP1861A will not operate normally when performing the following

operations and functions on the PC while the MX180000A is operating.

(1) Running another application at same time

(2) Closing lid of laptop PC

(3) Running screen saver

(4) Running battery save function

Read the PC instruction manual to switch off the screen saver and

battery save functions described in items (3) and (4) above.

Note:

Operation is not assured even with PCs meeting the specifications

outlined in Table 2.1.4-1 or Table 2.1.4-2.

Page 42

Chapter 2 Before Use

2-10

Yes

Yes

Continue Anyway

2.2 Getting Started with MX180000A

This section explains how to install the software and how to start and

exit MX180000A.

2.2.1 Installing MX180000A

Note the following procedure when installing software for the MP1861A

in the MP1800A or remote PC.

The following examples show the case when the software is installed in

the MP1800A. For the general software installation procedures, refer to

the

MP1800A Installation Guide (W2747AE)

Guide (W2748AE)

(1) When the general procedures are followed by the installer, the

confirmation dialog is displayed. Press

.

or

MT1810A Installation

to start installation.

Figure 2.2.1-1 Confirmation Dialog of USB Driver Installation (1)

(2) For Windows 7, a confirmation dialog box is displayed to ask if you

want to install Anritsu Corporation Universal Serial BUS Controller.

Click

to continue installation.

Click

to continue installation.

Page 43

2.2 Getting Started with MX180000A

2-11

Before Use

Continue Anyway

Finish

(3) For Windows XP, when the screen shown in Figure 2.2.1-2 is

displayed, click

to continue.

2

Figure 2.2.1-2 Confirmation Dialog of USB Driver Installation (2)

Note:

The screen as shown in Figure 2.2.1-1 may not be displayed on the

front page. If software installations take a long time, check that

the screen as shown in Figure 2.2.1-1 is hidden at the back of the

other screen.

(4) The following window is displayed when the installation completes

normally. Click

to end the installation procedure.

Figure 2.2.1-3 Completing Installation

Page 44

Chapter 2 Before Use

2-12

No, not this time

Next

Install the software automatically

Next

When the MP1861A is connected to the MP1800A or remote PC after

software installation, install the driver using the following procedures.

The following example show when the MP1861A is connected to the

MP1800A.

(1) Connect the MP1800A and MP1861A using an USB cable.

For Windows 7, the driver is installed automatically.

For Windows XP, perform the step 2 to 5 to install the driver.

(2) The Found New Hardware Wizard screen is displayed to confirm

windows update. Select

and press

.

(3) Select

Figure 2.2.1-4 Confirmation of Windows Update

Figure 2.2.1-5 Software Installation

and press

.

Page 45

2.2 Getting Started with MX180000A

2-13

Before Use

Continue Anyway

Finish

(4) Figure 2.2.1-6 is displayed when the hardware is found.

Press

to continue the installation procedures.

2

(5) Click

Figure 2.2.1-6 Hardware Installation

to end the installation procedure.

Figure 2.2.1-7 Completing Installation

Page 46

Chapter 2 Before Use

2-14

Start

Add/Remove Programs

Anritsu USB Device Driver

Remove

If the installed driver is no longer needed, uninstall it as follows.

(1) Select

Panel.

(2) Double-click

(3) Select

start the uninstallation.

menu →Control Panel

Figure 2.2.1-8 Removing USB Driver

, and then open the Control

in the Control Panel.

from the list and click

to

Page 47

2.2 Getting Started with MX180000A

2-15

Before Use

2.2.2 Starting MX180000A

When connecting to MP1800A:

(1) Connect the MP1861A and MP1800A as explained in Section 2.1.4.

(2) Connect the AC adapter to the MP1861A and set the power switch to

ON.

The LED lights green while power is on.

(3) When the MP1800A is turned on, Windows boots and the

MX180000A starts automatically. Select [Main application] on the

selector screen.

(4) The MP1861A control screen is displayed.

When connecting to control PC:

2

(1) Connect the MP1861A and control PC as explained in Section 2.1.4.

(2) Connect the AC adapter to the MP1861A and set the power switch to

ON.

The LED lights green while power is on.

(3) Start the MX180000A controller PC and select Main application on

the selector screen.

(4) The MP1861A control screen is displayed.

Figure 2.2.2-1 Selector Screen

Page 48

Chapter 2 Before Use

2-16

Main application

Exit

OFF

2.2.3 Exiting MX180000A

When connecting to MP1800A:

(1) Press and hold the power switch on the MP1800A front panel or

click the Shut down button on the selector screen. After the

application are shut down, the MP18000A Power lamp goes off, and

then the Standby LED lights up.

(2) Set the MP1861A power switch to OFF.

The LED lights orange, indicating the standby status.

When connecting to control PC:

(1) Close

(2) Press

(3) Set the MP1861A power switch to

Notes:

on the selector screen to close the window.

The LED lights orange, indicating the standby status.

To cut the power without following the above procedure, press

•

the MP1861A power switch for more than 10 seconds to enter

the standby status.

Do not disconnect the power cord and AC adapter without first

•

turning off the MP1861A as described above, otherwise the

MP1861A may be damaged.

to display the selector screen.

.

Page 49

2.2 Getting Started with MX180000A

2-17

Before Use

2.2.4 Messages that are displayed when connecting/disconnecting the

USB cable

This section describes the messages that are displayed when the USB

cable is connected to or disconnected from MP1861A.

When disconnecting the USB connection of this equipment for some

unexpected reason, follow the procedure described below to minimize the

impact on running applications. However, all the USB disconnection

cannot be assured by this operation. Normally, follow the startup and

shutdown procedures described in sections 2.2.2 and 2.2.3, respectively.

When USB connection disconnected while application running:

(1) The following dialog screen is displayed when the USB connection is

disconnected.

Figure 2.2.4-1 USB Disconnected

(2) The buttons for calling screens are disabled and the screen goes

blank. The Data Output and Clock Output are set forcibly to OFF.

2

(3) The MP1800A module connected to this equipment can still be used.

When USB device connected while application running:

(1) The following USB connection dialog is displayed.

Figure 2.2.4-2 USB Connection Message

Page 50

Chapter 2 Before Use

2-18

(2) If there is a backup file (saved when previous application terminated

when connection made), each setting is restored. Each setting is

restored when reconnecting previously connected equipment that

has been disconnected.

(3) The button for calling screens is enabled and the screen is displayed

for use. The Data Output and Clock Output are OFF.

When USB connection disconnected while using Setup utility:

(1) No warning is issued at the instant of disconnection.

(2) If processing is executed when the equipment is already

disconnected, a message indicating that the equipment is not

connected is displayed.

Figure 2.2.4-3 USB Disconnection Message

while Setup Utility in Use

(3) The MP1800A module connected to this equipment can still be used.

When USB device connected while using Setup utility:

(1) When a connection is made while using the Setup utility, the

equipment is not recognized.

(2) Restart from the selector screen after setting the power OFF and ON

and running the Setup utility once more.

CAUTION

If the connection between MP1861A, MP1800A and

controller PC is broken during downloading with the Setup

utility, MP1861A may no longer operate normally. NEVER

break the connection during downloading.

Page 51

2.3 Other Usage Methods

2-19

Before Use

2.3 Other Usage Methods

Help

Versi on

Help

Setup utility

Login

User

Version

This section explains how to check the installed software version,

perform software updates, and initialize the settings.

For how to operate the MX180000A, refer to the

Quality Analyzer Control Software Operation Manual

2.3.1 Checking Installed Software Version

Check the installed software version using the

Application menu bar or the Setup utility.

Select

following screen opens to display the currently installed software version.

from the

item at the Main Application menu bar. The

MX180000A Signal

.

item at the Main

2

Figure 2.3.1-1 Version Display Screen

Objects displayed with yellow highlighting on the Version Display screen

have a version other than the installed version. In this case, update the

installed software as described in section 2.3.2. If the installed software

versions are mismatched, operation may not be normal.

The Setup utility is selected by choosing

screen displayed when the MX180000A is started; log-in using

.

Click the

below opens to display the version information.

tab to display the software version. The screen shown

from the selector

–

Page 52

Chapter 2 Before Use

2-20

Figure 2.3.1-2 Version Display Screen

Objects displayed with yellow highlighting on the Version Display screen

have a version other than the installed version. In this case, update the

installed software as described in section 2.3.2. If the installed software

versions are mismatched, operation may not be normal.

Page 53

2.3 Other Usage Methods

2-21

Before Use

2.3.2 Updating Software

Download

Load

Load

The equipment software can be updated from the Setup utility screen.

When installing a new software version, there may sometimes be a

mismatch with already installed software and operation is not assured.

To solve the problem of mismatched installed software versions, start the

Setup utility and click the

the downloaded file display field. Put checkmarks in the boxes opposite

the files to be upgraded and click the

When download is completed normally, the installed software can be

upgraded.

Normally, the installed software is upgraded to the latest version when

the

button is clicked.

tab to display the download files in

button to start the download.

2

Figure 2.3.2-1 Download Screen

Page 54

Chapter 2 Before Use

2-22

[1]

This displays files that can be downloaded

checkmarks in the boxes and download the new files.

[2]

These are checkboxes for files to download. When it is necessary to download

versions), the checkbox is marked automatically.

[3]

This executes download using the MX180000A SQA control software installer.

differences, the files are downloaded.

[4]

This displays the download slot number and file name.

[5]

This displays the download status.

[6]

This suspends downloading.

[7]

This quits the setup utility.

No. Function and Usage

Table 2.3.2-1 Download Screen

Versions displayed in the New column are versions of object files offered by the

MX180000A SQA control software.

Versions displayed in the Current column are the versions of software already

installed in the equipment.

If there is a mismatch between versions in New and Current, place

the latest version (because there are differences between the New and Current

The versions of files saved to the internal hard disk are compared with

versions to be downloaded for each module in this equipment, and if there are

Notes:

If the Current version is not displayed and there is no

•

checkmark in the checkbox, put a checkmark in the checkbox

and execute download.

Downloading the FPGA as described below takes about 10

•

minutes per file. The power must be toggled OFF and ON to

enable the update. Set the power to OFF as described in section

2.2.3.

xx in the filename MP186xA_MUX_Opt_Delay_xx_xx_xx.FPGA

indicates the version.

CAUTION

If the connection between MP1861A, MP1800A and

controller PC is broken during downloading with the Setup

utility, MP1861A may no longer operate normally. NEVER

break the connection during downloading.

Page 55

2.3 Other Usage Methods

2-23

Before Use

2.3.3 Initializing Settings

Initialize

Help

Execute

Click

to initialize the equipment to the factory defaults. In addition, the

equipment settings can be returned to the factory defaults using the

Setup utility; start the utility and click the

in the File menu of the MX180000A SQA control software

tab.

2

Figure 2.3.3-1 Initializing Settings

When

initialized to the factory default settings.

in the Initialize group box is clicked, the equipment is

Page 56

Chapter 2 Before Use

2-24

•

•

•

•

•

•

•

•

2.4 Preventing Damage

Be sure to observe the rating ranges when connecting input and output

of the MP1861A. Otherwise, the MP1861A may be damaged.

Do not apply a voltage exceeding the rated voltage of

MP1861A. Excessively high input voltage can damage

the circuit.

When output is used at the 50 Ω/GND terminator, never

feed any current or input signals to the output.

As an antistatic measure, make sure the other devices

(including experimental circuits) to be connected with

ground wires before connecting the I/O connectors.

CAUTION

The outer conductor and core of the coaxial cable may

become charged as a capacitor. Use any metal to

discharge the outer conductor and core before use.

Never open the MP1861A. If you open it and the

MP1861A has failed or sufficient performance cannot

be obtained, we may decline to repair the MP1861A.

The MP1861A has many important circuits and parts

including hybrid ICs. These parts are extremely

sensitive to static electric charges, so never open the

case of the MP1861A.

The hybrid ICs used in the MP1861A are sealed in

airtight containers; never open them. If you open it and

the MP1861A has failed or sufficient performance

cannot be obtained, we may decline to repair the

MP1861A.

To protect the MP1861A from e being damaged by

static electricity, be sure to observe the following:

• Spread a conductive sheet on a workbench.

• Wear a wrist strap connected to the conductive

sheet or the frame ground of MP1861A

Page 57

2.4 Preventing Damage

2-25

Before Use

•

•

•

CAUTION

When connecting an external device such as a Bias-T

to the output connectors of this equipment (PPG or

MUX), if the output signal includes any DC voltage,

variations in the output of the DC power supply or load

may change the level of the output signal, risking

damage to the internal circuits. Note the following

precautions when using this equipment:

Do not connect or disconnect any external devices

while DC voltage is impressed.

Only switch DC power sources ON and OFF when all

equipment connections have been completed.

<Recommended procedure>

Measurement Preparation 1:

1. Connect all equipment.

2. Set the DC power supply output to ON.

3. Set the equipment output to ON and complete

measurement.

Measurement Preparation 2:

1. Set the equipment output to OFF.

2. Set the DC power supply output to OFF.

3. Disconnect the equipment, or change the DUT

connections.

Since even unforeseen fluctuations in DC voltage and

load (open or short circuits at the equipment output

side and changes caused by using a high-frequency

probe, etc.) can damage the DUT and equipment, we

recommend connecting a 50–ohm resistance in series

with the DC terminal of the Bias-T to prevent risk of

damage.

2

Page 58

Chapter 2 Before Use

2-26.

MP1861A

DUT

DC

50Ω

Bias-T

Coaxial cable

Coaxial cable

Set output ON/OFF after

To protect DUT and PPG

Do not connect/disconnect while DC

power

voltage impressed.

Figure. 2.4-1 Bias-T Connection Example

completing connections.

Page 59

Chapter 3

This chapter describes the panels and connectors of MP1861A.

3.1

3.2 Inter-Module Connection .............................................. 3-5

Panel Layout and Connectors

Panel Layout ................................................................. 3-2

3.1.1 MP1861A Front Panel ...................................... 3-2

3.1.2 MP1861A Rear Panel ....................................... 3-3

3.2.1 1ch TRx connection .......................................... 3-7

3.2.2 2ch Tx connection .......................................... 3-10

3

Panel Layout and Connectors

3-1

Page 60

Chapter 3 Panel Layout and Connectors

3.1 Panel Layout

This section describes the components located on the front and rear

panels of MP1861A.

3.1.1 MP1861A Front Panel

[2]

[3]

[1]

[6]

Figure 3.1.1-1 MP1861A (Option-x13) Front Panel

Table 3.1.1-1 MP1861A Front Panel Name and Function

No. Name Description

[1] Data Output connector

Output connector

Data

[2] Clock Output 1 connector

Clock Output 2 connector

[3] USB Connection LED Displays status of connection between MP1861A and MP1800A

[4] Power Switch

[5] Channel number indicators

(LEDs)

[6] Frame ground To which connects a wrist strap for antistatic measures before

Output for 2:1 multiplexed differential data signal

Supports various interfaces by selecting option

Output for Clock signal for MP1862A

or control PC

The LED is lit when the MP1861A can be controlled.

Switches from ON to Standby

When AC adapter and power code are connected, the switch

LED lights orange in the Standby status and green at ON.

The lamp of the set channel number illuminates.

1: Blue, 2: Pink, 3: Purple, 4: Orange

Set the channel number with the Channel Setting switch on the

rear panel of MP1861A.

using MP1861A.

Always wear the wrist strap when using MP1861A.

[4]

[5]

3-2

Page 61

3.1.2 MP1861A Rear Panel

3.1 Panel Layout

[7]

[2]

[10]

[1]

[5]

Figure 3.1.2-1 MP1861A Rear Panel

Table 3.1.2-1 MP1861A Rear Panel Name and Function

No. Name Description

[1] Data Input 1 connector

Data Input 2 connector

[2] Ext. Clock Input connector Connector for inputting the clock signal used as reference for

[3] Delayed Clock Output

connector

[4] Buffered Clock Output

connector

[5] 1/2 Clock Output connector Connector for outputting the frequency clock signal that is half of

[6] Mux Clock Input connector Connector for inputting the same frequency clock as the clock

[7] DC Input connector Connector for connecting AC adapter supplied as standard

[8] USB port Used for connecting MP1800A or controller PC to this equipment

Inputs for data signals from dual MU18302xA

Multiplexes signal to Data Output

equipment operation

Connector for outputting the same frequency clock as the clock

that is input to the Ext. Clock Input connector. Connect to the

MUX Clock Input connector using the supplied J1654A U-link

cable B.

Connector for outputting the same frequency clock as the clock

that is input to the Ext. Clock Input connector. Terminate into

50 when not in use.

the frequency clock input to the Ext. Clock Input connector.

Terminate into 50 when not in use.

that is input to the Ext. Clock Input connector. Connect to the

Delayed Clock Output connector using the supplied J1654A

U-link cable B.

accessory. Do not use non-Anritsu AC adapters, otherwise there

is a risk of damage to the equipment.

Do NOT connect anything other than the MP1800A or controller

PC.

[8]

[4]

[9]

[6]

[3]

3

Panel Layout and Connectors

3-3

Page 62

Chapter 3 Panel Layout and Connectors

Table 3.1.2-1 MP1861A Rear Panel Name and Function (Cont’d)

No. Name Description

[9] Channel Setting switch Sets the channel number of MP1861A.

Channel Number Switch Setting

1 0,0,0

2 1,0,0

3 0,1,0

4 1,1,0

Make sure the power to MP1861A has been shut off before

changing the channel switch settings. The new channel number

setting is enabled when powering on the next time.

[10] Frame ground Connector for wrist strap to discharge static electricity

Always wear a wrist strap when using this equipment.

3-4

Page 63

3.2 Inter-Module Connection

This section describes precautions to follow when handling the

equipment. Prevent the equipment from being damaged by static

electricity.

Do not apply a voltage exceeding the rated voltage of

MP1861A. Excessively high input voltage can damage

the circuit.

As an antistatic measure, make sure the other devices

(including experimental circuits) to be connected with

ground wires before connecting the I/O connectors.

3.2 Inter-Module Connection

WARNING

3

Panel Layout and Connectors

Be sure to discharge static electricity from the outer

conductors and cores of the coaxial cables by touching

them with any metal object before connecting the

coaxial cables.

To protect the MP1861A from e being damaged by

static electricity, be sure to observe the following:

• Spread a conductive sheet on a workbench.

• Wear a wrist strap connected to the conductive

sheet or the frame ground of MP1861A.

Do not apply excessive force to connectors when

removing the cables from MP1861A. Excessive force

can degrade the characteristics or cause failures.

Be sure to use a torque wrench when

connecting/disconnecting the cables. (Recommended

torque: 0.9 N-M)

3-5

Page 64

Chapter 3 Panel Layout and Connectors

Avoid inputting the signal exceeding the maximum input

level of MP1861A when connecting the Data Output

connector of MU183020A/MU183021A to the Data Input1

and 2 connectors of MP1861A.

Maximum input level of the Data Input1 and 2 connectors

of MP1861A: 0/–0.7 V (Vth = –0.35V)

Maximum data output level:

• MU183020A-x13/x23, MU183021A-x13: 3.50 Vp-p

• MU183020A-x12/x22, MU183021A-x12: 2.50 Vp-p

The Data Input connector of MP1861A can be damaged if

the signal exceeding the maximum input level is input.

CAUTION

3-6

Page 65

3.2.1 1ch TRx connection

This section describes a connection example using one MP1861A and one

MP1862A 56G/64G DEMUX (hereafter, MP1862A). According to the

following procedure, connect the equipment as shown in Figure 3.2.1-1.

[Equipment configuration]

MP1861A (this module)

MP1862A

MP1800A

MU183020A-x22/x23+x31

MU183040B

MU181500B

MU181000A

DUT (Device under test)

3.2 Inter-Module Connection

3

Panel Layout and Connectors

3-7

Page 66

Chapter 3 Panel Layout and Connectors

[Procedure]

1. Connect the Clock Output connector of MU181000A and the Ext.

Clock Input connector of MU181500B by using the J1624A coaxial

cable that comes with MU181000A.

2. Connect the Jittered Clock Output connector of MU181500B and the

Ext. Clock Input connector of MU183020A by using the J1624A

coaxial cable that comes with MU181500B.

3. Connect the Data Input1/2 connectors on the rear panel of MP1861A

and the Data Output1/2 connectors of MU183020A respectively by

using coaxial cables. The coaxial cables must be one of the following:

• J1658A coaxial skew match pair cable that comes with MP1861A

• Coaxial cables that are of the same length

4. Connect the Clock Output connector of MU183020A and the Ext.

Clock Input connector on the rear panel of MP1861A by using the

J1652A coaxial cable that comes with MP1861A.

5. Connect the Buffered Clock Output and MUX Clock Input

connectors that are on the rear panel of MP1861A, by using the

J1653A cable that comes with MP1861A. If the MP1861A-x30

Variable Data Delay is installed to MP1861A, connect the Delayed

Clock Output and MUX Clock Input connectors that are on the rear

panel of MP1861A, by using the J1654A cable that comes with

MP1861A.

6. Connect the Data Output and

panel of MP1861A to the DUT by using coaxial cables.

7. Connect the Clock Output connector on the front panel of MP1861A

and the Ext. Clock Input connector on the front panel of MP1862A

by using a coaxial cable.

8. Connect the DUT and the Data Input and

on the front panel of MP1862A by using coaxial cables.

9. Connect the Delayed Clock Output and DEMUX Clock Input

connectors on the rear panel of MP1862A by using the J1654A cable

that comes with MP1862A.

10. Connect the Data Output1/2 connectors on the rear panel of

MP1862A and the Data Input1/2 connectors of MU183040B

respectively by using coaxial cables. The coaxial cables must be one

of the following:

• J1657A coaxial cables that come with MP1862A

• Coaxial cables that are of the same length

Output connectors on the front

Data

Input connectors

Data

3-8

11. Connect the 1/2 Clock Output connector on the rear panel of

MP1862A and the Ext. Clock Input connector of MU183040B by

using the J1668A coaxial cable that comes with MP1862A.

Page 67

A

3.2 Inter-Module Connection

MU181000

MU183020A

MU183040B

MU181500B

1

33

2

3

Panel Layout and Connectors

4

5

6 6

7

DUT

8

9

10

11

Figure 3.2.1-1 1ch TRx Connection Example

8

3-9

Page 68

Chapter 3 Panel Layout and Connectors

3.2.2 2ch Tx connection

This section describes a connection example using two MP1861As and

two MU183020As.