MG3641A/MG3642A

Synthesized Signal Generator

Operation Manual

13th Edition

For safety and warning information, please read this

manual before attempting to use the equipment.

Keep this manual with the equipment.

ANRITSU CORPORATION

Document No.: M-W1137AE-13.0

Safety Symbols

To prevent the risk of personal injury or loss related to equipment malfunction, Anritsu Corporation uses the following

safety symbols to indicate safety-related information. Ensure that you clearly understand the meanings of the

symbols BEFORE using the equipment. Some or all of the following symbols may be used on all Anritsu

equipment. In addition, there may be other labels attached to products that are not shown in the diagrams in this

manual.

Symbols used in manual

DANGER

WARNING

CAUTION

This indicates a very dangerous procedure that could result in serious injury or

death if not performed properly.

This indicates a hazardous procedure that could result in serious injury or death if

not performed properly.

This indicates a hazardous procedure or danger that could result in light-to-severe

injury, or loss related to equipment malfunction, if proper precautions are not taken.

Safety Symbols Used on Equipment and in Manual

The following safety symbols are used inside or on the equipment near operation locations to provide information

about safety items and operation precautions. Ensure that you clearly understand the meanings of the symbols

and take the necessary precautions BEFORE using the equipment.

This indicates a prohibited operation. The prohibited operation is indicated

symbolically in or near the barred circle.

This indicates an obligatory safety precaution. The obligatory operation is

indicated symbolically in or near the circle.

This indicates a warning or caution. The contents are indicated symbolically in or

near the triangle.

This indicates a note. The contents are described in the box.

These indicate that the marked part should be recycled.

MG3641A/MG3642A

Synthesized Signal Generator

Operation Manual

10 March 1997 (First Edition)

7 December 2007 (13th Edition)

Copyright © 1997-2007, ANRITSU CORPORATION.

All rights reserved. No part of this manual may be reproduced without the prior written permission of the

publisher.

The contents of this manual may be changed without prior notice.

Printed in Japan

ii

For Safety

WARNING

1. ALWAYS refer to the operation manual when working near locations

at which the alert mark shown on the left is attached. If the advice in

the operation manual is not followed there is a risk of personal injury

or reduced equipment performance. The alert mark shown on the

left may also be used with other marks and descriptions to indicate

other dangers.

2. IEC 61010 Standard

The IEC 61010 standard specifies four categories to ensure that an

instrument is used only at locations where it is safe to make

measurements. This instrument is designed for measurement

category I (CAT I). DO NOT use this instrument at locations

specified as category II, III, or IV as defined below.

Measurement category I (CAT I):

Secondary circuits of a device that is not directly connected to a

power outlet.

Measurement category II (CAT II):

Primary circuits of a device that is directly connected to a power outlet,

e.g., portable tools or home appliance.

Measurement category III (CAT III):

Primary circuits of a device (fixed equipment) to which power is

supplied directly from the distribution panel, and circuits running from

the distribution panel to power outlet.

Measurement category IV (CAT IV):

Building service-line entrance circuits, and circuits running from the

service-line entrance to the meter or primary circuit breaker

(distribution panel).

iii

For Safety

WARNING

Electric Shock

Repair

Calibration

3. To ensure that the instrument is earthed, always use the supplied 3-

pin power cord, and insert the plug into an outlet with an earth

terminal. If power is supplied without earthing the equipment, there

is a risk of receiving a severe or fatal electric shock or causing

damage to the internal components.

4. This equipment cannot be repaired by the operator. DO NOT attempt

to remove the equipment covers or unit covers or to disassemble

internal components. Only qualified service personnel with a

knowledge of electrical fire and shock hazards should service this

equipment. There are high-voltage parts in this equipment presenting

a risk of severe injury or fatal electric shock to untrained personnel. In

addition, there is a risk of damage to precision components.

5. The performance-guarantee seal verifies the integrity of the equipment.

To ensure the continued integrity of the equipment, only Anritsu service

personnel, or service personnel of an Anritsu sales representative,

should break this seal to repair or calibrate the equipment. If the

performance-guarantee seal is broken by you or a third party, the

performance of the equipment cannot be guaranteed.

Falling Over

6. This equipment should always be positioned in the correct manner.

If the cabinet is turned on its side, etc., it will be unstable and may be

damaged if it falls over as a result of receiving a slight mechanical

shock.

Always set up the equipment in a position where the power switch

can be reached without difficulty.

iv

Fuse Replacement

Cleaning

For Safety

CAUTION

1. Always remove the mains power cable from the power outlet before

replacing blown fuses. There is a risk of electric shock if fuses are

replaced with the power cable connected. Always use new fuses of

the type and rating specified on the rear panel of the instrument.

There is a risk of fire if a fuse of a different rating is used.

T5A indicates a time-lag fuse.

2. Keep the power supply and cooling fan free of dust.

Clean the power inlet regularly. If dust accumulates around the

•

power pins, there is a risk of fire.

Keep the cooling fan clean so that the ventilation holes are not

•

obstructed. If the ventilation is obstructed, the cabinet may

overheat and catch fire.

3. Use two or more people to lift and move this equipment, or use a

trolley. There is a risk of back injury, if this equipment is lifted by one

person.

v

For Safety

CAUTION

Replacing Memory

Back-up Battery

Use in a residential

environment

This equipment uses a Poly-carbomonofluoride lithium battery to backup

the memory. This battery must be replaced by service personnel when

it has reached the end of its useful life; contact the Anritsu sales section

or your nearest representative.

Note: The battery used in this equipment has a maximum useful life of

7 years. It should be replaced before this period has elapsed.

This instrument is designed for an industrial environment.

In a residential environment this instrument may cause radio interference

in which case the user may be required to take adequate measures.

vi

Equipment Certificate

Anritsu Corporation certifies that this equipment was tested before

shipment using calibrated measuring instruments with direct traceability

to public testing organizations recognized by national research

laboratories, including the National Institute of Advanced Industrial

Science and Technology, and the National Institute of Information and

Communications Technology, and was found to meet the published

specifications.

Anritsu Warranty

Anritsu Corporation will repair this equipment free-of-charge if a

malfunction occurs within one year after shipment due to a manufacturing

fault, under the condition that this warranty is void when:

The fault is outside the scope of the warranty conditions described in

•

the operation manual.

The fault is due to mishandling, misuse, or unauthorized modification

•

or repair of the equipment by the customer.

The fault is due to severe usage clearly exceeding normal usage.

•

The fault is due to improper or insufficient maintenance by the

•

customer.

The fault is due to natural disaster including fire, flooding, earthquake,

•

etc.

The fault is due to use of non-specified peripheral equipment,

•

peripheral parts, consumables, etc.

The fault is due to use of a non-specified power supply or in a non-

•

specified installation location.

In addition, this warranty is valid only for the original equipment

purchaser. It is not transferable if the equipment is resold.

Anritsu Corporation shall assume no liability for injury or financial loss of

the customer due to the use of or a failure to be able to use this equipment.

Anritsu Corporation Contact

In the event that this equipment malfunctions, contact an Anritsu Service

and Sales office. Contact information can be found on the last page of

the printed version of this manual, and is available in a separate file on

the CD version.

vii

Notes On Export Management

r

This product and its manuals may require an Export License/Approval by

the Government of the product's country of origin for re-export from you

country.

Before re-exporting the product or manuals, please contact us to confirm

whether they are export-controlled items or not.

When you dispose of export-controlled items, the products/manuals need

to be broken/shredded so as not to be unlawfully used for military purpose.

viii

Crossed-out Wheeled Bin Symbol

Equipment marked with the Crossed-out Wheeled Bin Symbol complies

with council directive 2002/96/EC (the “WEEE Directive”) in European

Union.

For Products placed on the EU market after August 13, 2005, please

contact your local Anritsu representative at the end of the product's

useful life to arrange disposal in accordance with your initial contract and

the local law.

ix

CE Conformity Marking

Anritsu affixes the CE conformity marking on the following product(s) in

accordance with the Council Directive 93/68/EEC to indicate that they

conform to the EMC and LVD directive of the European Union (EU).

CE marking

1. Product Model

Model: MG3641A/MG3642A Synthesezed Signal

Generator

2. Applied Directive

EMC: Directive 2004/108/EC

LVD: Directive 2006/95/EC

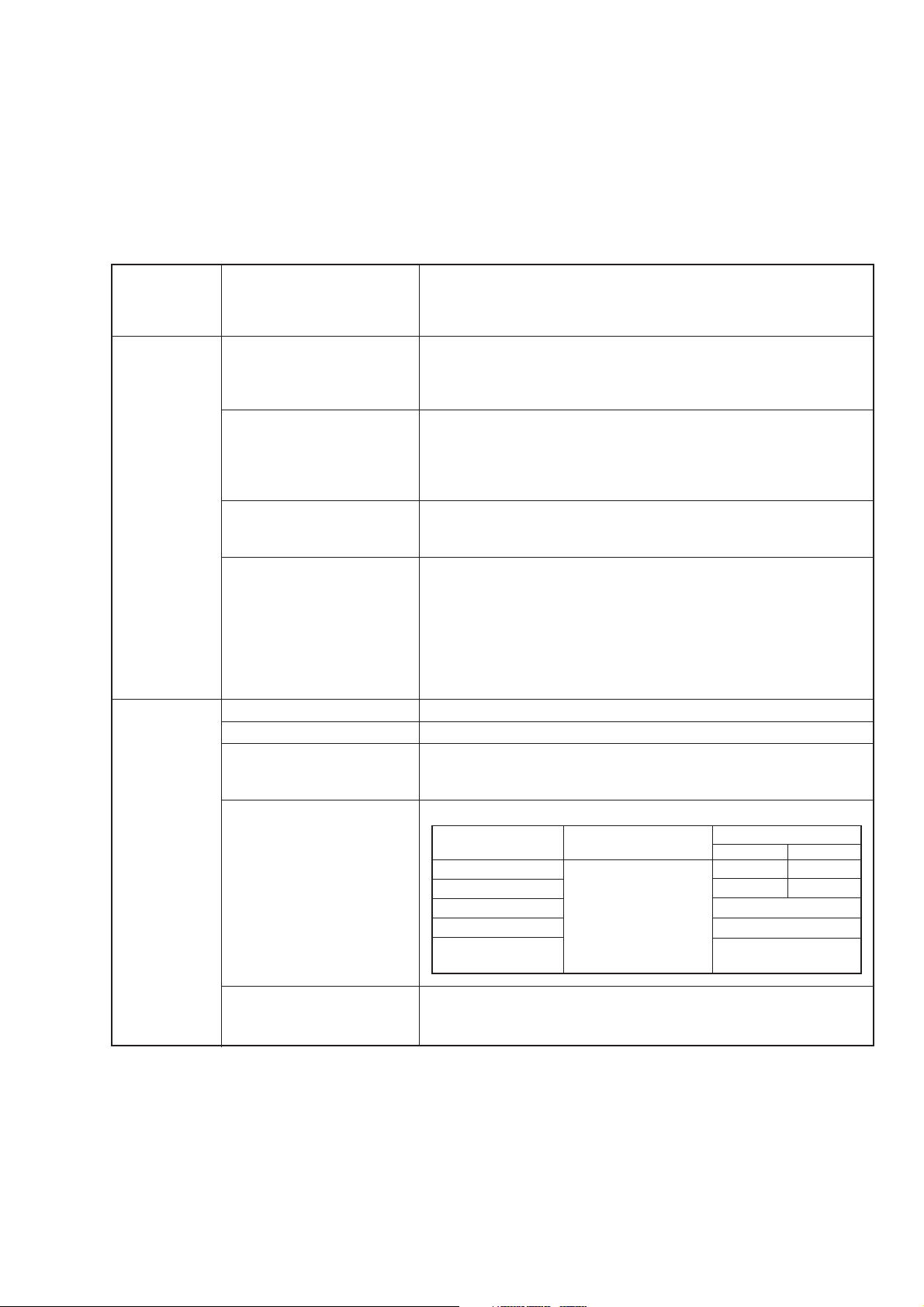

3. Applied Standards

EMC:Emission: EN 61326-1: 2006 (Class A)

•

Immunity:EN 61326-1: 2006 (Table 2)

IEC 61000-4-2 (ESD) B

IEC 61000-4-3 (EMF) A

IEC 61000-4-4 (Burst) B

IEC 61000-4-5 (Surge) B

IEC 61000-4-6 (CRF) A

IEC 61000-4-8 (RPFMF) A

IEC 61000-4-11 (V dip/short) B, C

*: Performance Criteria

A: During testing, normal performance within the

specification limits.

B: During testing, temporary degradation, or loss of

function or performance which is self-recovering.

C: During testing, temporary degradation, or loss of

function or performance which requires operator

intervention or system reset occurs.

Performance Criteria*

x

Harmonic current emissions:

EN 61000-3-2: 2006 (Class A equipment)

LVD: EN 61010-1: 2001 (Pollution Degree 2)

•

4. Authorized representative

Name: Loic Metais

European Quality Manager

ANRITSU S.A. France

Address, city: 16/18 Avenue du Québec SILIC 720 Zone de

Courtaboeuf

91951 Les Ulis Cedex

Country: France

xi

C-tick Conformity Marking

Anritsu affixes the C-tick mark on the following product(s) in accordance

with the regulation to indicate that they conform to the EMC framework

of Australia/New Zealand.

C-tick marking

1. Product Model

Model: MG3641A/MG3642A Synthesezed Signal

Generator

2. Applied Standards

EMC:Emission: EN 61326-1: 2006 (Class A equipment)

xii

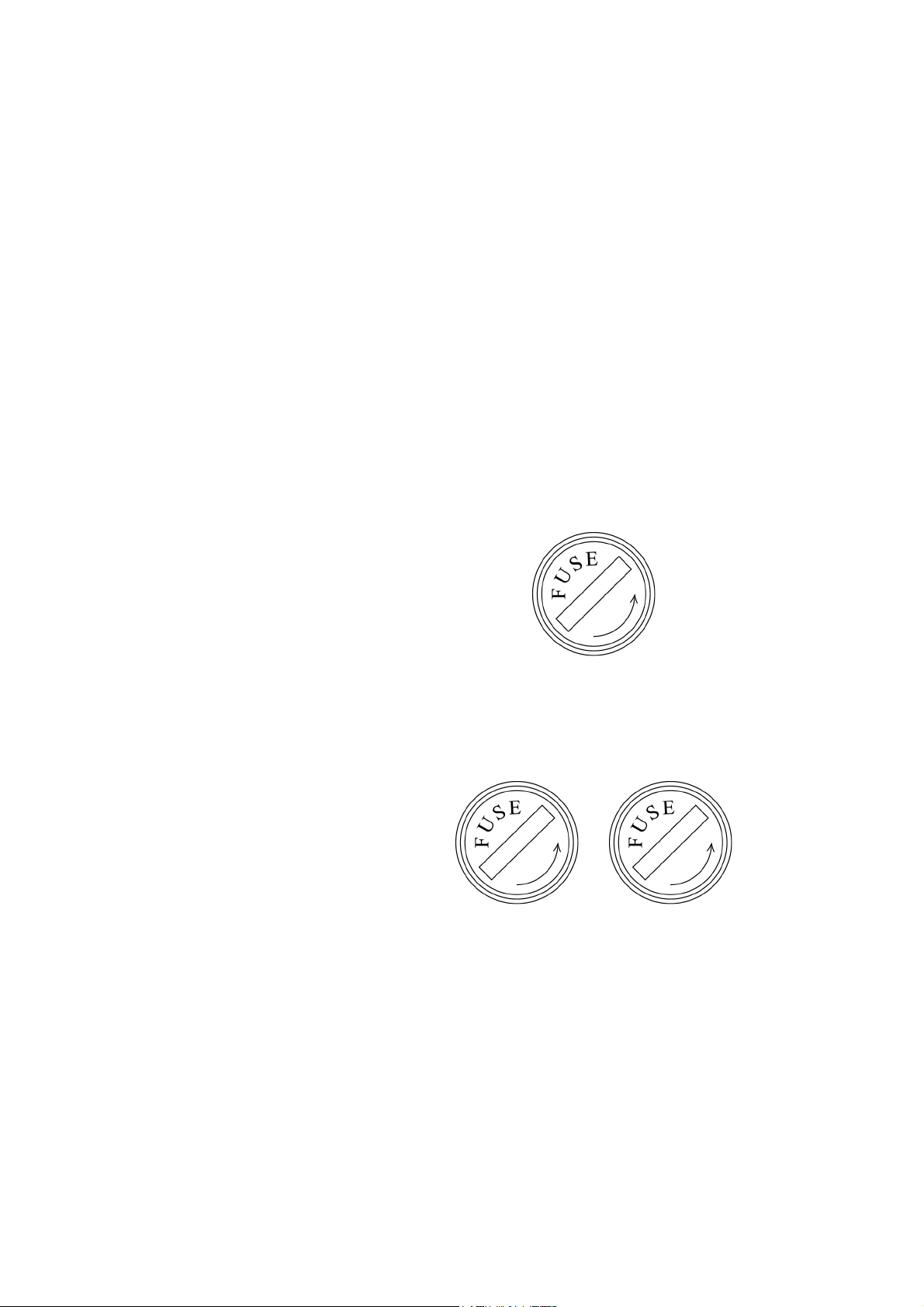

Power Line Fuse Protection

For safety, Anritsu products have either one or two fuses in the AC power

lines as requested by the customer when ordering.

Single fuse:

Double fuse:

Example 1: An example of the single fuse is shown below:

Example 2: An example of the double fuse is shown below:

A fuse is inserted in one of the AC power lines.

A fuse is inserted in each of the AC power lines.

Fuse Holder

Fuse Holders

xiii

xiv

TABLE OF CONTENTS

For Safety ................................................................................................................. iii

SECTION 1 GENERAL ............................................................................................. 1-1

1.1 Brief Description .............................................................................................................. 1-1

1.2 Operation Manual ............................................................................................................. 1-2

1.3 Composition of Devices ................................................................................................... 1-3

1.3.1 Standard Composition ...................................................................................... 1-3

1.3.2 Options ............................................................................................................. 1-4

1.4 Application Parts .............................................................................................................. 1-5

1.5 Specifications ................................................................................................................... 1-6

SECTION 2 PRECAUTION ....................................................................................... 2-1

2.1 Installation Precautions .................................................................................................... 2-1

2.1.1 Installation site environmental conditions ....................................................... 2-1

2.2 Safety Measures ................................................................................................................ 2-2

2.2.1 General power supply safety measures ............................................................ 2-2

2.2.2 Reverse power input to RF output connector ................................................... 2-2

2.3 Mounting the MG3641A/MG3642A in the Frame .......................................................... 2-3

2.4 Preparation Before Power-On .......................................................................................... 2-4

2.4.1 Connecting the Power Cord ............................................................................. 2-5

2.4.2 Fuse Replacement ............................................................................................ 2-6

SECTION 3 PANEL LAYOUT ................................................................................... 3-1

3.1 Panel Layout ..................................................................................................................... 3-1

3.1.1 Front panel layout ............................................................................................ 3-1

3.1.2 Rear panel layout ............................................................................................. 3-3

3.1.3 Panel layout diagram ........................................................................................ 3-4

SECTION 4 OPERATING INSTRUCTIONS ............................................................. 4-1

4.1 Turning Power On/Off ..................................................................................................... 4-1

4.1.1 Turning Power On ............................................................................................ 4-3

4.1.2 Turning Power Off ........................................................................................... 4-4

4.2 Explanation of Screens ..................................................................................................... 4-5

4.3 Initial Settings ................................................................................................................... 4-6

4.4 Setting the Frequency ....................................................................................................... 4-8

4.4.1 Setting the Frequency ....................................................................................... 4-8

4.4.2 Displaying the Frequency Relative Value ....................................................... 4-9

4.4.3 Frequency Offset ............................................................................................ 4-10

4.5 Setting the Output Level ................................................................................................. 4-11

4.5.1 Setting the Output Level ................................................................................ 4-11

4.5.2 Displaying the Output Level Relative Value ................................................. 4-12

4.5.3 Output Level Offset ....................................................................................... 4-13

I

4.5.4 Level Continuous Mode ................................................................................. 4-14

4.5.5 Switching the Output Signal On/Off .............................................................. 4-15

4.5.6 Special Functions Related to Level ................................................................ 4-16

4.6 Setting the Modulation ................................................................................................... 4-18

4.6.1 Outline of Modulation .................................................................................... 4-18

4.6.2 Setting the Modulation Function .................................................................... 4-19

4.6.3 Setting the Modulation Factor and Frequency Deviation .............................. 4-20

4.6.4 Setting Range of FM Frequency Deviation ................................................... 4-21

4.6.5 Polarity of Modulation Signal ........................................................................ 4-21

4.6.6 Pulse Modulation ........................................................................................... 4-22

4.7 Setting the Modulation Signal Source ............................................................................ 4-24

4.7.1 Internal Modulation Signal (Int1) .................................................................. 4-24

4.7.2 Internal Modulation Signals (Int2, Int3) ........................................................ 4-25

4.7.3 External Modulation Signals (Ext1, Ext2) ..................................................... 4-26

4.8 Setting the AF Output ..................................................................................................... 4-28

4.9 Memory Functions .......................................................................................................... 4-30

4.9.1 Outline of Memory Functions ........................................................................ 4-30

4.9.2 Storing in the Memory ................................................................................... 4-30

4.9.3 Recalling Memory Contents .......................................................................... 4-31

4.9.4 Clearing the Memory ..................................................................................... 4-33

4.9.5 Selecting the Memory Recall Mode ............................................................... 4-34

4.10 Sweep Functions ............................................................................................................. 4-35

4.10.1 Outline of Sweep Functions ........................................................................... 4-35

4.10.2 Setting and Executing the Sweep ................................................................... 4-36

4.10.3 Sweep Auxiliary Outputs ............................................................................... 4-39

4.11 Trigger Functions ........................................................................................................... 4-41

4.11.1 Outline of trigger function ............................................................................. 4-41

4.11.2 Registering the trigger program ..................................................................... 4-42

4.11.3 Executing the trigger program ....................................................................... 4-43

4.11.4 Checking the contents of the trigger program ................................................ 4-44

4.12 Miscellaneous Functions ................................................................................................ 4-45

4.12.1 Setting Display On/Off .................................................................................. 4-45

4.12.2 Setting Bell • Alarm On/Off ........................................................................... 4-46

4.12.3 Setting address and only mode of GPIB ........................................................ 4-47

4.12.4 Panel Lock ...................................................................................................... 4-48

4.13 Removing Reverse Power Protection (RPP) Circuit Operation ..................................... 4-49

4.14 Error Messages ............................................................................................................... 4-50

SECTION 5 MEASUREMENT .................................................................................. 5-1

5.1 Measurement of Sensitivity .............................................................................................. 5-1

5.1.1 Measuring 20 dB NQ sensitivity ...................................................................... 5-2

5.1.2 Measuring 12 dB SINAD sensitivity ............................................................... 5-3

II

5.2 Measuring the 1-signal Selectivity ................................................................................... 5-4

5.2.1 Measuring selectivity characteristics of the FM receiver in 20 dB

NQ method ....................................................................................................... 5-4

5.2.2 Measuring spurious response ........................................................................... 5-7

5.3 Measuring the 2-signal Sensitivity ................................................................................... 5-9

5.3.1 Measuring the sensitivity blocking of the FM receiver ................................... 5-9

5.3.2 Measuring the cross-modulation characteristics ............................................ 5-12

SECTION 6 GPIB...................................................................................................... 6-1

6.1 Outline of GPIB ................................................................................................................ 6-1

6.1.1 Overview .......................................................................................................... 6-1

6.1.2 GPIB functions ................................................................................................. 6-1

6.1.3 Setup example .................................................................................................. 6-2

6.1.4 Standard ........................................................................................................... 6-3

6.2 Device Message List ......................................................................................................... 6-4

6.2.1 Outline .............................................................................................................. 6-4

6.2.2 General Information On SCPI .......................................................................... 6-4

6.2.3 Command Structure ......................................................................................... 6-4

6.2.4 Writing Commands .......................................................................................... 6-5

6.2.5 Compounding Commands ................................................................................ 6-6

6.2.6 Parameter ......................................................................................................... 6-7

6.2.7 Unit ................................................................................................................... 6-7

6.2.8 Command Tree ................................................................................................. 6-8

6.3 Connecting the GPIB Cable ........................................................................................... 6-14

6.4 Device Message Format ................................................................................................. 6-15

6.4.1 Program message format ................................................................................ 6-15

6.4.2 Response message format .............................................................................. 6-18

6.5 Status Message ............................................................................................................... 6-20

6.5.1 Status register configuration .......................................................................... 6-20

6.5.2 IEEE488.2-based status register .................................................................... 6-21

6.5.3 SCPI standard status register .......................................................................... 6-22

6.5.4 Reading, writing, clearing, and resetting the status register .......................... 6-23

6.5.5 SCPI error messages ...................................................................................... 6-25

6.6 Initializing Device .......................................................................................................... 6-27

6.6.1 Bus initialization ............................................................................................ 6-27

6.6.2 Message initialization .................................................................................... 6-27

6.6.3 Device initialization ....................................................................................... 6-27

6.6.4 Device state at power-on ................................................................................ 6-27

6.7 Detailed Description of Commands ............................................................................... 6-28

6.7.1 Frequency subsystem ..................................................................................... 6-28

6.7.2 Output level subsystem .................................................................................. 6-32

6.7.3 AM subsystem ................................................................................................ 6-38

6.7.4 FM subsystem ................................................................................................ 6-39

6.7.5 PM subsystem ................................................................................................ 6-41

III

6.7.6 Modulation source subsystem ........................................................................ 6-42

6.7.7 MEMORY subsystem .................................................................................... 6-45

6.7.8 Display subsystem .......................................................................................... 6-47

6.7.9 System subsystem .......................................................................................... 6-48

6.7.10 Status subsystem ............................................................................................ 6-49

6.8 IEEE488.2 Common Command ..................................................................................... 6-51

6.9 Sample Program ............................................................................................................. 6-53

6.10 GPIB Command Interchange Function .......................................................................... 6-56

6.10.1 Outline ............................................................................................................ 6-56

6.10.2 Restrictions in MG3633Acommand interchange mode ................................. 6-57

6.10.3 Restrictions in MG3631A/32A command interchange mode ........................ 6-60

SECTION 7 PERFORMANCE TEST ........................................................................ 7-1

7.1 Performance Test Required .............................................................................................. 7-1

7.2 Performance Test Device List .......................................................................................... 7-2

7.3 Performance Test .............................................................................................................. 7-3

7.3.1 Output frequency .............................................................................................. 7-4

7.3.2 Output level frequency characteristics ............................................................. 7-5

7.3.3 Output level accuracy ....................................................................................... 7-6

7.3.4 FM deviation and FM distortion ...................................................................... 7-8

7.3.5 AM modulation factor and AM distortion ..................................................... 7-10

SECTION 8 CALIBRATION ...................................................................................... 8-1

8.1 Calibration Required ........................................................................................................ 8-1

8.2 Calibration Device List ..................................................................................................... 8-1

8.3 Calibration ........................................................................................................................ 8-2

SECTION 9 STORAGE AND TRANSPORTATION .................................................. 9-1

9.1 Daily Servicing and Preventive Maintenance .................................................................. 9-1

9.2 Storage Precautions .......................................................................................................... 9-1

9.2.1 Precautions before storage ............................................................................... 9-1

9.2.2 Recommended storage conditions ................................................................... 9-2

9.3 Repacking and Transportation .......................................................................................... 9-2

9.3.1 Repacking ......................................................................................................... 9-2

9.3.2 Transportation .................................................................................................. 9-2

APPENDIX A INITIAL FACTORY SETTINGS ............................................................. A-1

APPENDIX B FUNCTION-KEY TRANSITION ............................................................ B-1

APPENDIX C FRONT AND REAR PANEL LAYOUT ..................................................C-1

APPENDIX D INDEX ................................................................................................... D-1

APPENDIX E PERFORMANCE TEST RESULT SHEET ............................................ E-1

IV

.

SECTION 1 GENERAL

SECTION 1

GENERAL

1.1 Brief Description

The MG3641A/MG3642A is a synthesized signal generator capable of outputing highly accurate, highly pure signals

over a broad frequency range.

The extremely excellent spurious characteristics and leakage characteristics offer to make the signal generator most

suitable to evaluate sensitivity characteristics and interference characteristics, which comprise the basic performance

of radio equipment.

Meanwhile, the signal generator can also be used to test communication systems operating with a variety of modulation

methods, such as a pager system, since it provides diverse modulation functions and frequency modulation with good

carrier frequency stability.

Its output level can be corrected over the entire frequency range. Because the signal generator allows to select high

level outputs and high resolutions, it can also serve to test various high frequency components.

The generator displays its basic functions, such as frequency, output level, and memory addresses, on a 7-segment

display unit. For those functions which require to have many parameters set, such as modulation, sweep function,

etc., it adopts the multimenu display. Moreover, the generator boasts of an outstanding operability, since it comes

equipped with a dedicated rotary knob and step keys for setting output levels.

1-1

SECTION 1 GENERAL

1.2 Operation Manual

This operation manual contains 9 sections and 5 appendixes. The format and outline of each section is described

below.

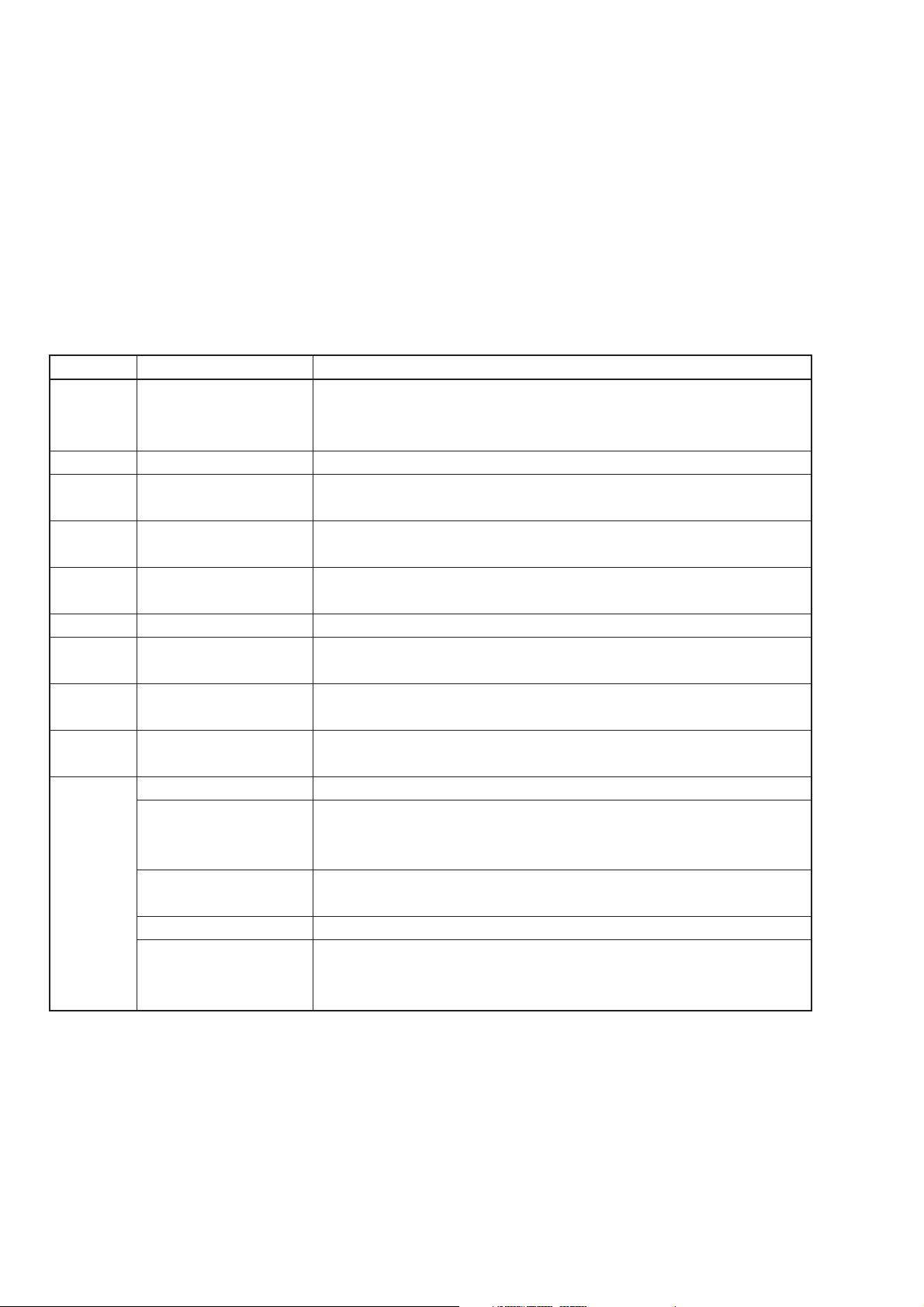

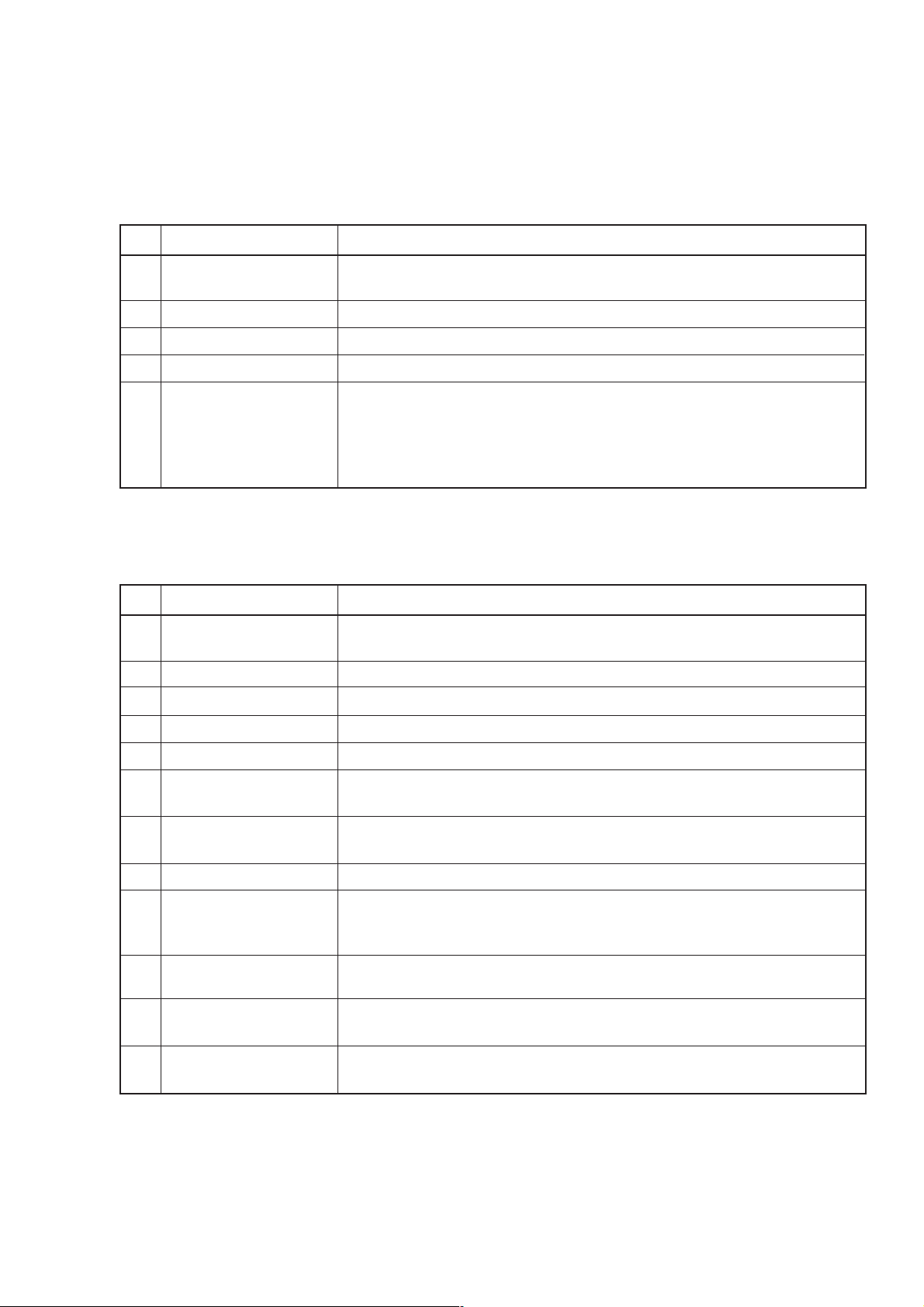

Table 1-1

Section Title Contents

1 GENERAL

2 PRECAUTION

3 PANEL LAYOUT

4 OPERATING

INSTRUCTIONS

5 MEASUREMENT

6 GPIB

7 PERFORMANCE TEST

8 CALIBRATION

9 STORAGE AND

TRANSPORTATION

APPENDIX A INITIALSETTINGS

B FUNCTION KEY

TRANSITION

DIAGRAM

C FRONT AND REAR

PANEL LAYOUT

D INDEX

E PERFORMANCE

TEST RESULT

SHEET

Description of the MG3641A/MG3642A (standard configuration,

specifications), optional accessories and peripheral equipment, and outline of

operation manual.

Operations to be performed before powering-up the MG3641A/MG3642A

Layout, function and method of preparative operation of components such as

keys, connectors, knobs, and indicators on both the front and rear panels.

Details of manual operation (local operation) of the front and rear panels. (Except

for remote control by GPIB)

Explains how to measure the sensitivity and selectivity, giving typical

examples using the signal generator

Remote-control operational procedure and description of device messages

Description of the measuring unit and performance test required to test the

performance of this device

Description of the calibration as the preventive maintenance to prevent the

performance from reducing.

Daily maintenance, long period storage, re-packing and transportation

1-2

1.3 Composition of Devices

The composition of standard accessories to the MG3641A/MG3642A will be explained in this section.

1.3.1 Standard Composition

The table below shows the standard composition of devices for the MG3641A/MG3642A.

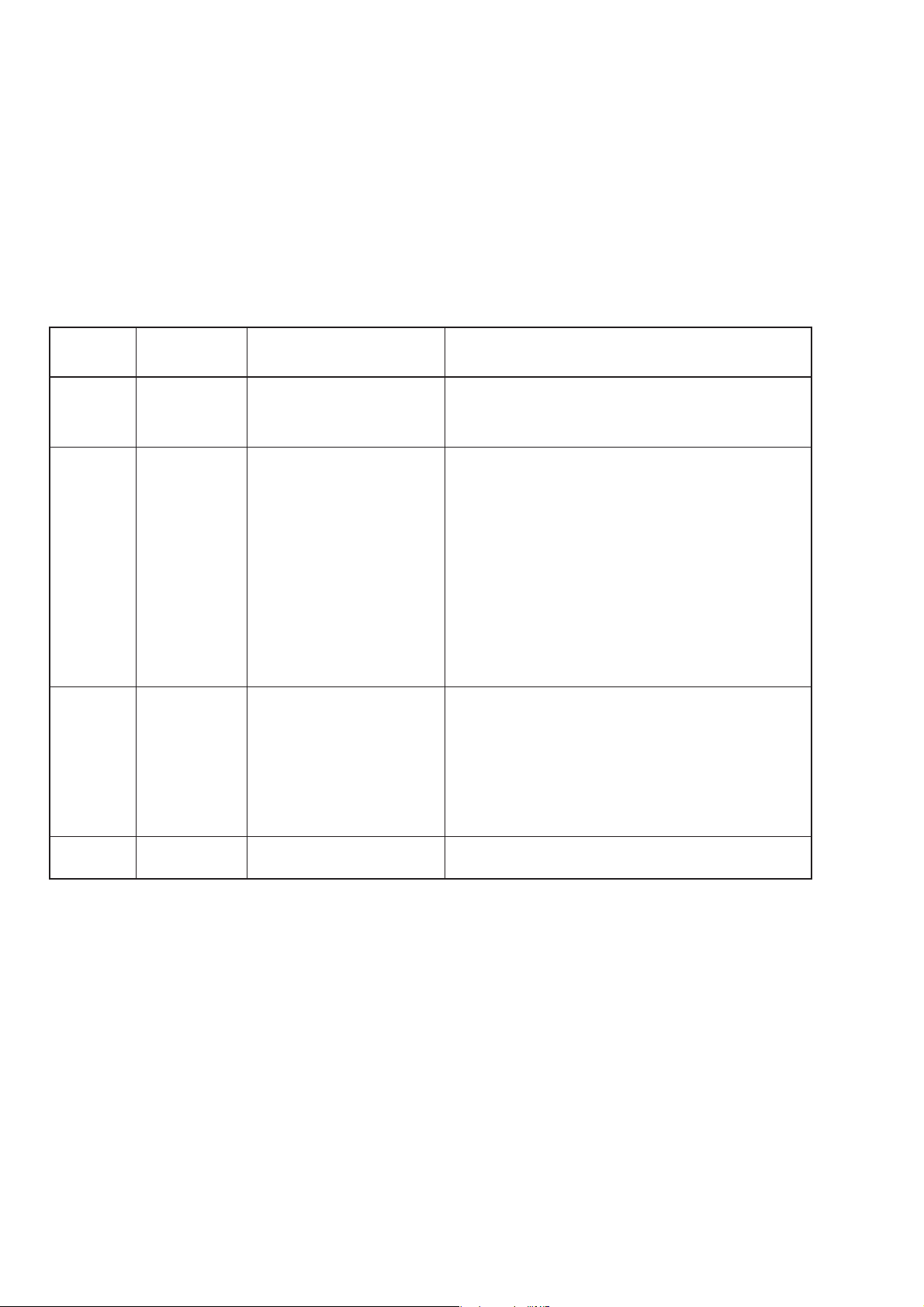

Table 1-2. Standard Composition of Devices

Item Model/Symbol Product Name Q'ty Remarks

Main unit MG3641A/

MG3642A

Accessories Power cord 1 Length: approx. 2.6 m

B0325 GPIB shield cap 1

F0013 Fuse 1

or

F0012

W1137AE Operation manual 1 English version

W1137BE Service manual 1 English version

Synthesized signal generator 1

Two of 5 A (T5 A 250 V) for 100 VAC system

or

Two of 3.15 A (T3.15 A 250 V), for 200 VAC

system

SECTION 1 GENERAL

1-3

SECTION 1 GENERAL

1.3.2 Options

The table below lists options for the MG3641A/MG3642A.

Table 1-3. Options

Option

No.

01 MG3641A/ Reference Crystal Oscillator

Model number/

Order number

MG3642A-01

Name

Frequency: 10 MHz

Aging rate: 5×10

Temperature caracteristics: ±5×10–9 (at 0 to 50°C)

11 MG3641A/ Pulse ON/OFF ratio: >80 dB

MG3642A-11

modulator

Rise time/fall time: <100 ns

Minimum pulse width: <500 ns

Pulse repetition frequency: DC to 1 MHz

Maximum delay time: <100 ns

Overshoot/ringing: <20 %

Video feed through: <20 %

Pulse modulation signal: External, BNC connector on

21 MG3641A/

MG3642A-21

AF synthesizer

Frequency : 0.01 Hz to 400 kHz (sine wave)

: 0.01 Hz to 50 kHz

Resolution : 0.01 Hz

Wave form: sine wave, triangular wave, square wave,

sawtooth wave

Frequency accuracy: Equal to the accuracy of the refere-

22

MG3641A/

FSK encoder

2-level FSK, 4-level FSK

MG3642A-22

–10

/day

the rear panel, 50 Ω/600 Ω,

TTL(Positive logic)

(triangular, square, sawtooth wave)

nce oscillator.

1-4

SECTION 1 GENERAL

1.4 Application Parts

The table below lists application parts for the MG3641A/MG3642A, which are all optional purchase items.

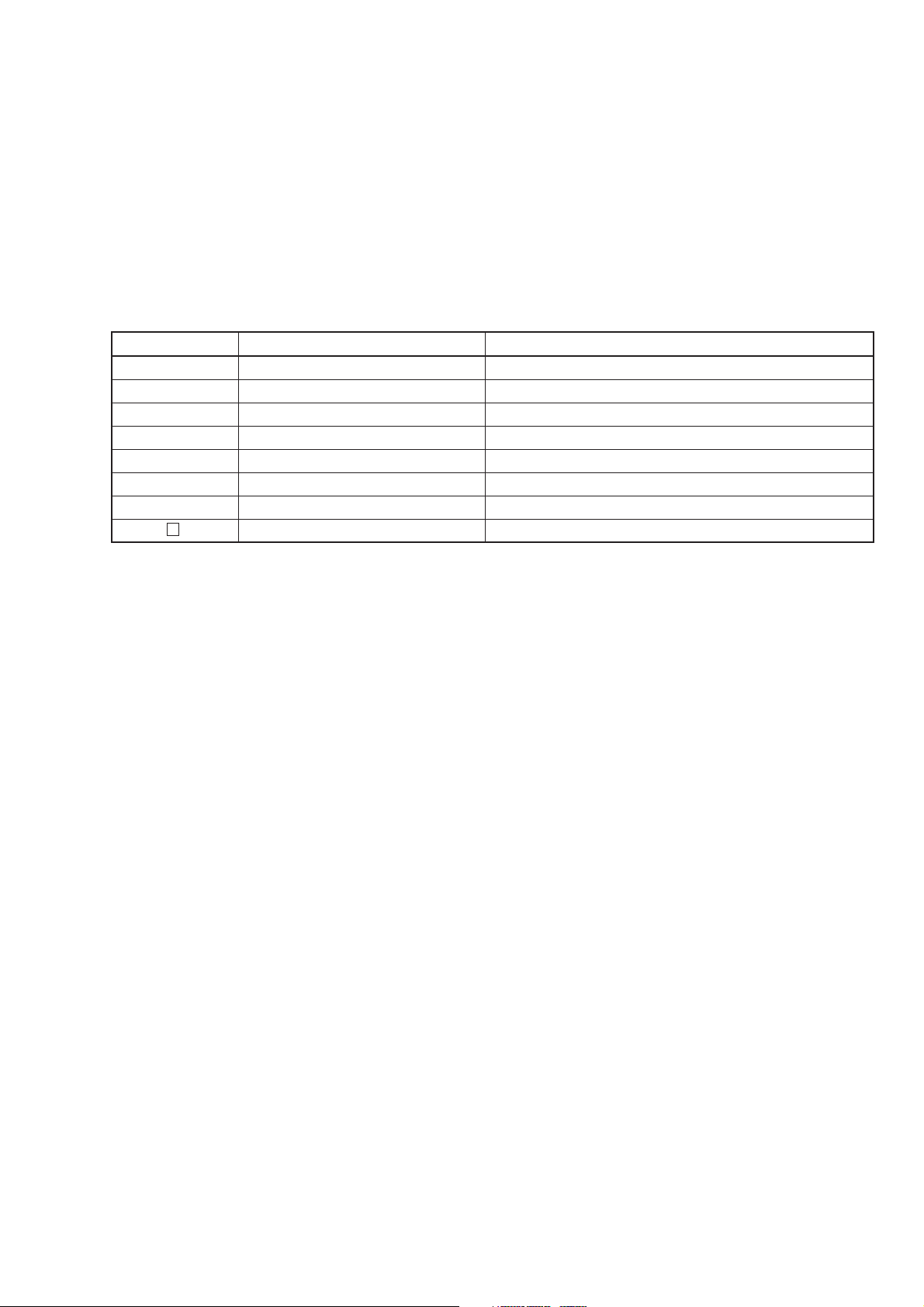

Table 1-4. Application Parts

Model/Symbol Product Name Remarks

J0576B Coaxial cord N-P•5D-2W•N-P, 1 m

J1027A Coaxial cord BNC-P•RG58A/U•BNC-P, 1 m

J0007 GPIB cable 408JE-101, 1 m

J0008 GPIB cable 408JE-102, 2 m

MP51A Pad Conversion from 75 Ω system to 50 Ω system

MP52A Pad Conversion from 50 Ω system to 75 Ω system

MA1612A Four-port junction pad 5 to 3000 MHz, 50 Ω

MP721 Fixed attenuator DC to 12.4 GHz, 3, 6, 10, 20, 30, 40, 50, 60 dB

1-5

SECTION 1 GENERAL

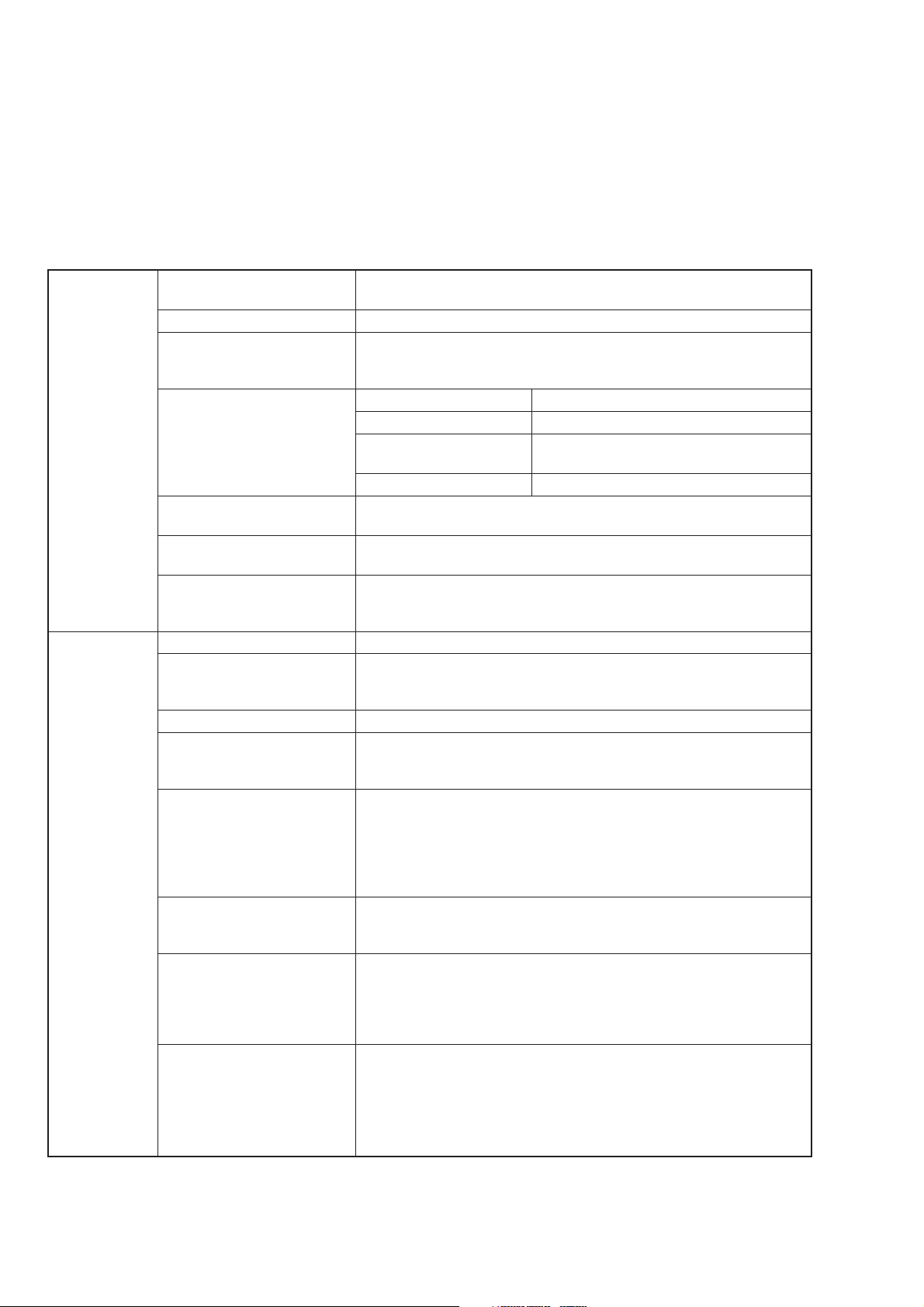

1.5 Specifications

Carrier Range 125 kHz to 1040 MHz: MG3641A

Frequency

Resolution 0.01 Hz

Accuracy Dependent on the accuracy of the reference oscillator.

Internal reference Frequency 10 MHz

oscillator

*1

External reference input 5/10 MHz, ±10 ppm, ≥0.7 Vp–p/50 Ω (AC coupling)

Buffer output 10 MHz, TTL level (DC coupling)

Switching time Response time from last command, till the preset frequency ±0.1 ppm

Output level Range –143 to +17 dBm (Permissible setting range: –143 to +23 dBm)

Unit dBm, dBµ, V, mV, µV

Resolution 0.01dB

Frequency response With reference to 0 dBm

Accuracy With pulse modulation off

Impedance 50 Ω, type N connector

Switching time Response time from last command, till the final level ±0.5 dB is

Special setting mode Level continuous mode:

*1 Available up to 5×10

*2 Only with Pulse Modulator(Opt. 11) installed

125 kHz to 2080 MHz: MG3642A

In the FM modulation,

Accuracy of reference frequency ±(0.3 % of FM deviation setting +5 Hz)

Aging rate ±5×10–9/day

Startup characteristics 1×10–7/10 min. (reference after 24-hour

operation)

Temperature stability ±3×10–8 (0 to 50°C)

BNC connector on the rear panel

BNC connector on the rear panel

is obtained, under external control:

<40 ms

(Switching between terminated-voltage display and open-voltage

display is possible for dBµ, V, mV and µV)

±0.5 dB

±1.0 dB (With pulse modulation on)

*2

±1 dB (≤+17 dBm, ≥–127 dBm)

±3 dB (<–127 dBm)

With pulse modulation on

*2

±1 dB (≤+12 dBm, ≥–127 dBm)

±3 dB (<–127 dBm)

VSWR: <1.5 (≤–3 dBm)

<2.5 (>–3 dBm)

obtained, under external control:

<50 ms (Normal mode)

<100 ms (Level safety mode)

<10 ms (continuous mode)

Level can be varied over a range of the set value ±10 dB, without

interruptions of the output

Level safety mode:

Level is narrowed to prevent spike-like signals from appearing when

the mechanical attenuator is working.

-10

/day with Reference Crystal Oscillator(Opt.01)

1-6

Specifications (continued)

SECTION 1 GENERAL

Output level

Interference radiation When measured with 50 Ω-terminated voltage using a two-loop

distortion

antenna of 25 mm in diameter at 25 mm away from the case:

<0.1 µV (At the output frequency)

<1 µV (Over the frequency range, at multimenu display OFF)

Signal Purity Spurious In CW mode and with reference to ≤+7 dBm:

Harmonics: <–30 dBc

Non-harmonics: <–100 dBc (≥15 kHz offset)

Those related to power: <–40 dBc (<15 kHz offset)

SSB phase noise In CW mode and with reference to 20 kHz offset:

<–140 dBc/Hz (≥10 MHz, <256 MHz)

<–136 dBc/Hz (≥256 MHz, <512 MHz)

<–130 dBc/Hz (≥512 MHz, ≤1040 MHz)

<–124 dBc/Hz (>1040 MHz, MG3642A)

Residual AM With reference to ≥500 kHz, CW mode, +7 dBm and in a 50 Hz to 15

kHz demodulation band:

<–80 dBc

Residual FM In CW mode and in a 300 Hz to 3 kHz demodulation band:

<4 Hzrms (≥10 MHz, <512 MHz)

<8 Hzrms (≥512 MHz, ≤1040 MHz)

<16 Hzrms (>1040 MHz, MG3642A)

In CW mode and in a 50 Hz to 15 kHz demodulation band:

<5 Hzrms (≥10 MHz, <512 MHz)

<10 Hzrms (≥512 MHz, ≤1040 MHz)

<20 Hzrms (>1040 MHz, MG3642A)

Amplitude Range 0 to 100 %

modulation

Resolution 0.1 %

Accuracy With reference to ≥0.4 MHz, ≤+7 dBm, AM≤90 %, Source=Int1 1

kHz, and in a 300 Hz to 3 kHz demodulation band:

±(5 % of set value +2 %)

Modulation frequency In ≤+7 dBm and ±1 dB Bandwidth:

response

Carrier frequency Lower limit frequency Upper limit frequency

≥

0.4 MHz, <0.5 MHz 2 kHz 1 kHz

≥

0.5 MHz, <2 MHz DC (Ext DC couple) 10 kHz 5 kHz

≥

2 MHz, <32 MHz 20 Hz (Ext AC couple) 20 kHz

≥

32 MHz, <64 MHz 50 kHz

≥

64 MHz 50 kHz

100 kHz (3 dB Bandwith)

AM = 30 % AM = 90 %

Distortion

With reference to ≥0.4 MHz, ≤+7 dBm, Source = Int1 1 kHz:

<–40 dB (AM = 30 %)

<–30 dB (AM = 90 %)

1-7

SECTION 1 GENERAL

Specifications (continued)

Amplitude Incidental FM With reference to ≥0.4 MHz, ≤+7 dBm, AM≤30 %, Source=Int1 1 kHz,

modulation

Modulation signal source Any one out of the internal modulation signal sources (Int1, Int2,

Modulation signal polarity Can be switched between positive and negative.

Frequency Range 0 to 125 Hz (≥125 kHz, <250 kHz)

modulation 0 to 250 Hz (≥250 kHz, <500 kHz)

Resolution 1 Hz (0 to 4.000 kHz deviation)

Accuracy With reference to ≥0.4 MHz, Source=Int1 1 kHz, and in a 300 Hz to

Modulation frequency In a ±1 dB bandwidth

response DC (Ext DC couple) or 20 Hz (Ext AC couple) to 20 kHz (≥0.4 MHz, <10 MHz)

Distortion With reference to ≥16 MHz:

Incidental AM With reference to ≥64 MHz, ≤+7 dBm, FM 100 kHz deviation,

External modulation group With reference to ≥10 MHz, Source=Ext DC coupling, and modulation

delay rate ≤100 kHz:

Modulation signal source Any one out of the internal modulation signal sources (Int1, Int2,

Modulation signal polarity Can be switched between positive and negative independently for

and in a 300 Hz to 3 kHz demodulation band:

<200 Hzpeak

Int3) and external modulation inputs (Ext1, Ext2) can be selected.

0 to 500 Hz (≥500 kHz, <1 MHz)

0 to 1 kHz (≥1 MHz, <2 MHz)

0 to 2 kHz (≥2 MHz, <4 MHz)

0 to 4 kHz (≥4 MHz, <8 MHz)

0 to 10 kHz (≥8 MHz, <16 MHz)

0 to 25.6 kHz (≥16 MHz, <32 MHz)

0 to 51.2 kHz (≥32 MHz, <64 MHz)

0 to 102 kHz (≥64 MHz, <128 MHz)

0 to 256 kHz (≥128 MHz, <256 MHz)

0 to 512 kHz (≥256 MHz, <512 MHz)

0 to 1024 kHz (≥512 MHz, ≤1040 MHz)

0 to 2048 kHz (>1040 MHz, MG3642A)

10 Hz (4.010 to 10.000 kHz deviation)

25 Hz (10.025 to 25.600 kHz deviation)

50 Hz (25.65 to 51.20 kHz deviation)

100 Hz (51.30 to 102.00 kHz deviation)

250 Hz (102.25 to 256.00 kHz deviation)

500 Hz (256.5 to 512.0 kHz deviation)

1 kHz (513 to 1024 kHz deviation)

1 kHz (1025 to 2048 kHz deviation, MG3642A)

3 kHz demodulation band:

±(5 % of set value +10 Hz) (≥0.4 MHz, <512 MHz)

±(5 % of set value +20 Hz) (≥512 MHz, ≤1040 MHz)

±(5 % of set value +40 Hz) (>1040 MHz, MG3642A)

DC (Ext DC couple) or 20 Hz (Ext AC couple) to 100 kHz (≥10 MHz)

–40 dB (FM=3.5 kHz deviation, and Source=Int1 1 kHz),

–45 dB (FM=22.5 kHz deviation, and Source=Int1 1 kHz)

Source=Int1 1 kHz, and in a 300 Hz to 3 kHz demodulation band:

<1 %peak

<30 µs

Int3) and external modulation inputs (Ext1, Ext2) can be selected for

each of FM1 and FM2.

FM1 and FM2.

1-8

SECTION 1 GENERAL

Specifications (continued)

Pulse See specifications of options.

modulation

Modulation Internal modulation (Int1) Frequency: 400 Hz/1 kHz (Switched over)

signal source

Internal modulation See specifications of options.

(Int2, Int3)

External modulation Optimum input level: Approx. 2 Vp–p

(Ext1, Ext2) Input impedance: 600 Ω, BNC connector on the front panel

AF Output Output signal source Any one out of the internal modulation signal sources (Int1, Int2,

Output level 0 to 4 Vp–p

Output level resolution 1 mVp–p

Output level accuracy In Source=Int1 1 kHz:

Impedance 600 Ω, BNC connector on the front panel

Simultaneous Simultaneous modulation, AM depth and FM deviation can be set

modulation independently for all combinations, except for a combination of AM

Sweep function Sweep parameter Frequency, Output level, and Memory

Sweep pattern Frequency sweep (Start/Stop): Liner (Stepsize specified, number

Sweep mode Auto, Single, Manual

Sweep time Setting range 1 ms to 600 s/point, Resolution 10 µs/point

Auxiliary outputs X-Output : BNC connector on the rear panel

Frequency accuracy: Equal to the accuracy of the reference oscillator.

Coupling: Switchable between AC/DC

Int3) and external modulation inputs (Ext1, Ext2) can be selected.

±(5% of set value + 2 mVp-p)

and pulse modulation.

of points specified)

Log (1 % specified)

Frequency sweep (Center/Span): Liner (Stepsize specified, number

of points specified)

Level sweep (Start/Stop): dB (Stepsize specified, number of points

specified)

Sweep in continuous mode (max. 20 dB width)

Level sweep (Center/Span): dB (Stepsize specified, number of points

specified)

Sweep in continuous mode (max. 20 dB width)

Memory sweep (Start/Stop)

(Actual sweep time depends on the sweep parameter switching times,

frequency, and output level.)

Staircase sawtooth wave worm

Start point of sweep: 0 V

Stop point of sweep: +10 V

Z-Output : BNC connector on the rear panel

TTL level

When sweeping: H-level

Blanking-Output : BNC connector on the rear panel

TTL level

When switched: L-level

Marker-Output : BNC connector on the rear panel

TTL level

When marker matches: H-level

1-9

SECTION 1 GENERAL

Specifications (continued)

Other functions Relative value display Carrier frequency and output level

Offset display Carrier frequency and output level

Memory 1000 panel setting conditions can be stored and recalled.

Recall mode: All panel settings, Frequency only, Frequency and Level.

Trigger function An external trigger signal (input from the BNC connector on the rear

panel, TTL level) can be used to execute a pre-programmed operation

sequence (except for operation of the power switch, Preset key, Local

key, and rotary knob).

Max. number of sequence steps of trigger program: 20 steps

Backup When switched on, the generator restores the same setting conditions

that existed immediately before it was last powered off.

However, the following are not restored:

• Data which was in the middle of entry

• Remote status

• Data which was in the middle of GPIB transfer

• Operating status of RPP

GPIB Can control all functions, except for pre-programmed operations

controlled by the trigger function, and operation of the power switch,

Local key, rotary knob, and knob resolution set keys.

Interface: SH1, AH1, T5, L3, TE0, SR1, RL1, PP0, DC1, DT1, C0,

E2

Reverse power Maximum reverse input 50 W (≤1040 MHz), 25 W (1040 to 2080 MHz, MG3642A only)

protection power ±50 Vac

General Power Voltage: *Vac (Up to max. 250 V)

Frequency: 47.5 to 63 Hz, 380 to 420 Hz

Capacity: 200 VAmax

Environmental performance Working temperature range: 0 to 50°C

Storage temperature range: –30 to 71°C

Conducted disturbance: EN 61326-1: 2006 (Class A)

Radiated disturbance: EN 61326-1: 2006 (Class A)

Harmonic Current Emission: EN 61000-3-2: 2006 (Class A)

Electrostatic Discharge: EN 61326-1: 2006 (Table 2)

Electromagnetic Field Immunity: EN 61326-1: 2006 (Table 2)

Fast Transient / Burst: EN 61326-1: 2006 (Table 2)

Surge: EN 61326-1: 2006 (Table 2)

Conducted RF: EN 61326-1: 2006 (Table 2)

Power Frequency Magnetic Field: EN 61326-1: 2006 (Table 2)

Voltage Dips / Short Interruptions: EN 61326-1: 2006 (Table 2)

Dimensions and mass 177 H×320 W×451 Dmm, ≤20 kg

* Please specify a nominal voltage in the range from 100 and 240 V when ordering the product.

1-10

1-10

SECTION 1 GENERAL

<Option>

■Option 01 (Reference crystal oscillator)

●Frequency 10MHz

●Aging rate 5×10

●Temperaturecharacteristics ±5×10

-10

/day

-9

(0 to 50°C)

■ Option 11 (Pulse modulator)

●Frequency 0.125 to 2080MHz

●On/Off ratio >80dB

●Rise/Fall time <100ns

●Min. pulse width <500ns

●Pulse repetition frequency DC to 1MHz

●Max. delay time <100ns

●Overshoot/ringing <20%

●Video feed through <20%

●Pulse modulation signal External, rear-panel BNC connector, 50/600 Ω, TTL (positive logic)

■Option 21 (AF synthesizer)

●Frequency 0.01Hz to 400kHz (sine wave)

0.01Hz to 50kHz (triangular wave, square wave, sawtooth wave)

●Resolution 0.01Hz

●Waveform Sine, triangular, square, sawtooth

●Frequency accuracy Same as reference oscillator

■Option 22 (FSK encoder)

●Frequency shift amount: Shifts frequency depending on data state, as below.

(Data21, Data20)=(0, 0): -FM deviation set value

(Data21, Data20)=(0, 1): -FM deviation set value/3

(Data21, Data20)=(1, 0): +FM deviation set value

(Data21, Data20)=(1, 1): +FM deviation set value/3

●Setting frequency: Set frequency for data input in the following timing.

Free: Shift frequency at data input.

Rise Trig: Shift frequency at rising edge of external clock.

Fall Trig: Shift frequency at falling edge of external clock.

●Baseband filter: Following filters can be used to pass signal.

Filter type: 10th-order Besser filter

Cutoff frequency: 100Hz to 30kHz(-3dB)

Set resolution: Upper 2 digits

●FM deviation accuracy: Same as that of MG3641A/MG3642A, with restriction of no baseband filter (by-passed)

●External modulation signal input

Data20: Rear-panel BNC connector (Int Mod Cont 2)

TTL level, pull-down

Data21: Rear-panel BNC connector (Int Mod Cont 1)

TTL level, pull-down

●External clock signal input

Ext Clock: Rear-panel BNC connector (Int Mod Cont 3)

TTL level, pull-up

1-11

SECTION 1 GENERAL

(Blank)

1-12.

SECTION 2 PRECAUTION

;

;

SECTION 2

PRECAUTION

This section describes the preparatory work which must be performed before using the MG3641A/MG3642A Synthesized

Signal Generator and the precautions relating to (1) installation and (2) power supply. For GPIB cable connection, address

setting, etc, see Section 6.

2.1 Installation Precautions

This paragraph describes the MG3641A/MG3642A Synthesized Signal Generator installation precautions and

mechanical assembly procedure for mounting the MG3641A/MG3642A in a rack.

2.1.1 Installation site environmental conditions

(1) Location to avoid

The MG3641A/MG3642A operates normally at ambient temperatures of 0° to 50°C.

However, for best performance, do not use or store it in locations where:

• It may be subjected to strong vibrations

• It may be exposed to extreme humidity or dust

• It may be exposed to direct sunlight

• It may be exposed to explosive gases

To maintain stable measurement for a long time, in addition to meeting the conditions listed above, the MG3641A/

MG3642A should be used at stable room temperatures and where the AC line voltage fluctuations are small.

CAUTION :

(2) Fan clearance

If the MG3641A/MG3642A is used at room temperature after being used or stored at a low temperature

for a long time, condensation may occur inside the instrument which could cause short circuiting. Always

ensure that the MG3641A/MG3642A is thoroughly dry before turning on the power.

To prevent excessive temperature increase inside the MG3641A/MG3642A, a cooling fan is mounted on the rear

panel. Leave a space of at least 10 cm between the rear panel and walls, peripheral devices, obstructions, etc. so

that air flow is not obstructed. Do not use the MG3641A/MG3642A on its side.

10cm

Do not use the MG3641A/

MG3642A in this orientation

Fig. 2-1. Clearance for Fan

2-1

SECTION 2 PRECAUTION

To protect circuits from an abnormal rise in the internal temperature, the MG3641A/MG3642A has a built-in

thermal protector. When the thermal protector operates, the MG3641A/MG3642A enters stand-by status (the stby

lamp lights).

If the thermal protector starts operating, check conditions surrounding the device and, after lowering the temperature

sufficiently, reset switch ●● | on the rear panel. If the thermal protector enters operation repeatedly, the fan may be

broken. In this case, have it repaired.

2.2 Safety Measures

This section explains the safety measures required in any case to prevent the operator from being endangered and

avoid device damage and serious system-down.

2.2.1 General power supply safety measures

CAUTION

Before power-on : Be sure to ground the MG3641A/MG3642A. If the power is turned on without the

protective grounding, it may result in an electric shock causing death or injury.

Also be sure to check the AC line voltage. Applying an abnormal power exceeding

the determined value to the device may damage the device and cause fire.

During power supply : To maintain the MG3641A/MG3642A, the operator may have to check and adjust the

internal units while opening its cover during power supply. The internal units contain

some high-voltage dangerous parts. If the operator touches them carelessly, it may

result in an electric shock that affects a person's life and injury. For maintenance of

this device, contact qualified service personnel.

2.2.2 Reverse power input to RF output connector

The MG3641A/MG3642A has a reverse power protector in the output unit to protect the internal circuits from a

reverse input overpower. The reverse power protector can protect the following power:

• ±50 Vdc

• 50 W (Up to 1040 MHz)

• 25 W (1040 to 2080 MHz, MG3642A)

CAUTION

The reverse power protector uses a mechanical switch. If a reverse power is applied frequently, the contact is

consumed. To use this protector, take maximum care not to apply a reverse power. Also never release the

reverse power protector as a reverse power remains applied, or a fault will occur in the reverse power protector.

The impedance of the RF output connector is opened during operation of the reverse power circuit. Be careful

to avoid damage due to a mismatched transmitter, etc.

2-2

SECTION 2 PRECAUTION

2.3 Mounting the MG3641A/MG3642A in the Frame

An optional rack mount kit is required to mount the MG3641A/MG3642A in the frame. For the mounting method,

refer to the illustration appended to the rack mount kit.

2-3

SECTION 2 PRECAUTION

2.4 Preparation Before Power-On

The MG3641A/MG3642A normally operates by connecting the power having the voltage range +10 % to –15 % for

the specified nominal voltage 100 to 240 Vac. However, the safety measures are required to avoid the following

before the AC power is supplied:

• Accident resulting in injury or death caused by electric shock

• Internal unit damage by abnormal voltage

• Trouble by earth current

To protect the user's safety and call a user's attention, WARNING and CAUTION are indicated on the rear panel as

follows:

WARNING CAUTION

NO OPERATOR SERVICE- FOR CONTINUED FIRE

ABLE PARTS INSIDE. PROTECTION. REPLACE

REFER SERVICING TO ONLY WITH SPECIFIED

QUALIFIED PERSONNEL. TYPE AND RATED FUSE.

Warning

This measuring instrument that is a precision electronic

device has some dangerous parts. The user cannot

repair this device, so do not disassemble this device.

For services of this device, contact your qualified

service personnel.

The user must therefore take the safety measures described in the following pages.

Caution

Use a specified type and rated contents when replacing

a fuse. Using an illegal fuse may result in a fire.

2-4

SECTION 2 PRECAUTION

2.4.1 Connecting the Power Cord

Check that the " ● | " switch on the rear panel is turned off (switched to the (O) side).

Insert the power plug into an outlet, and connect the other end to the power inlet on the rear panel. To ensure that the

instrument is grounded, always use the supplied 3-pin power cord, and insert the plug into an outlet with a ground

terminal.

WARNING

If the power cord is connected without the instrument grounded, there is a risk of receiving a fatal electric

shock. In addition, the peripheral devices connected to the instrument may be damaged.

When connecting to the power supply, DO NOT connect to an outlet without a ground terminal. Also, avoid

using electrical equipment such as an extension cord or a transformer.

CAUTION

If an emergency arises causing the instrument to fail or malfunction, disconnect the instrument from the power

supply by either turning off the " ● | " switch on the rear panel (switch to the (O) side), or by pulling out the

power cord or the power inlet.

When installing the instrument, place the instrument so that an operator may easily operate the " ● | " switch.

If the instrument is mounted in a rack, a power switch for the rack or a circuit breaker may be used for power

disconnection.

It should be noted that, the "Stby/On" switch on the front panel of the instrument is a standby switch, and

cannot be used to cut the main power.

2-5

SECTION 2 PRECAUTION

2.4.2 Fuse Replacement

The MG3641A/MG3642A is supplied with two 5 A or 3.15 A fuses shown in Table 1-2. The fuses are to be loaded

inside the fuse holders shown in Figure 2-2.

If a fuse blows, locate the fault and correct the cause before replacing.

CAUTION

If a fuse is replaced with the power turned on, there may be an electric shock hazard. Before replacing a fuse,

turn off the POWER switch and unplug the power cord from the AC outlet.

If the power is turned on without the protective grounding, there may be an electric shock hazard. When the

AC power voltage is unsuitable, the internal equipment may be damaged by an abnormal power.

Before turning on the power again after replacing a fuse, perform either protective grounding measures described

in Section 2.4.1 and check that the AC line voltage is suitable.

CAUTION

If there are no spare fuses, check that the replacement you obtain is of the same type, rated voltage and current

as the original.

If the fuse is not of the same type, it may not fit the holder, contact may be poor, or the fusing time may be too

long.

If the rated voltage and current of the replacement fuse are too high and trouble recurs, the new fuse may not

blow and the instrument could catch fire.

Take these safety measures before replacing a fuse in the following procedure:

STEP PROCEDURE

1. Set the POWER switch to OFF and unplug the power cord from the AC outlet.

2. Turn the fuse-holder cap (see Figure 2-2) counterclockwise and remove the cap together with the fuse.

3. Remove the blown fuse from the fuse cap and replace it with a spare fuse. (Direction arbitrary)

4. Refit the cap and clockwise turn it with a standard screwdriver until it will turn no further.

2-6

.

SECTION 3 PANEL LAYOUT

SECTION 3

PANEL LAYOUT

3.1 Panel Layout

This section explains the keys, switches, display, and connectors on the front and rear panels of the MG3641A/

MG3642A synthesized signal generator.

3.1.1 Front panel layout

This paragraph outlines the switches and connectors arranged on the front panel.

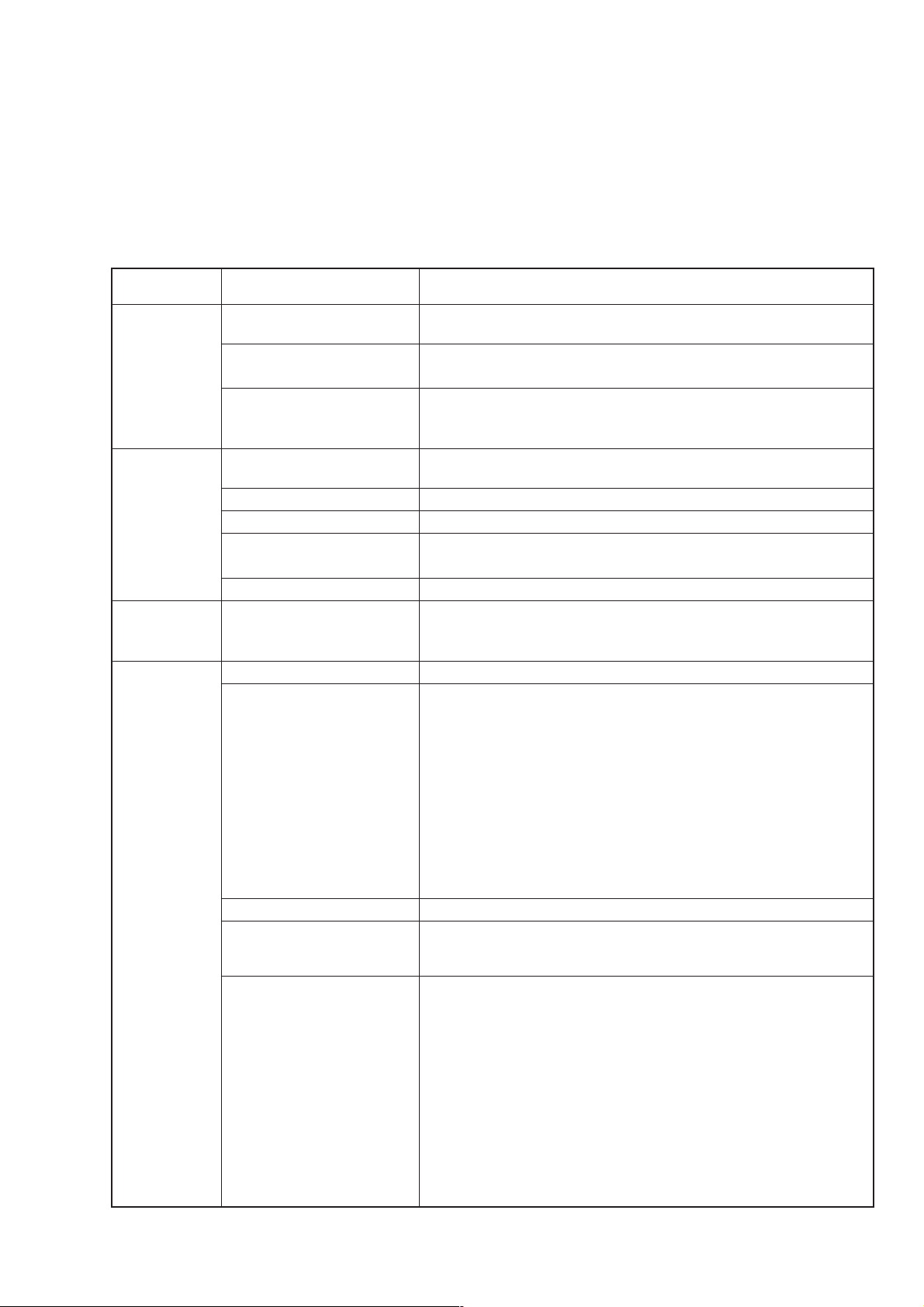

No

1

2

3

4

5

6

7

8

9

10

11

12

Name, display

[F1], [F2], [F3], [F4],

and [F5] keys

Multi-menu display

[More] key

Uncal lamp

CW and Mod lamp

Memory display

Frequency display

Output level display

F-Ofs and L-Ofs lamps

EMF lamp

Cont lamp

[Rel Freq] and

[Rel Level] keys

Description

Used to select and execute the functions corresponding to the key menus displayed

on the multi-menu display.

Displays the operation and state of the modulation, sweep, etc.

Displays the next page of the multi-menu on the same layer when the current menu

has multiple pages

Lights for the incorrect setting or abnormal operation. Error contents are displayed

in the error message area of the multi-menu display.

Displays the current modulation state. The CW lamp lights on without modulation;

the Mod lamp lights on with modulation.

Displays the memory address in the memory mode.

Displays the carrier frequency.

Displays the output level.

The F-Ofs lamp lights on when the frequency is in offset mode. The L-Ofs lamp

lights on when the output level is in offset mode.

The EMF lamp lights on together with the unit lamp when the output level display

indicates the open voltage.

Lights on in the output-level continuous mode.

Display the frequency or level in the relative value, respectively. Pressing either

key switches to the respective relative display assuming the current frequency or

output level as reference value 0. The key lamp then lights on.

When either key is pressed in the relative display mode, its lamp goes off and the

display returns to the ordinary frequency or output level value.

If either key is pressed following the Shift key in the relative or offset display mode,

the currently output true frequency or output level is displayed, respectively.

Output Level Step

13

[^] and [∨] key

Steps up or down the output level. Pressing the ∨ key following the Shift key

switches to the output level continuous mode. Pressing the ^ key following the

Shift key releases the continuous mode.

3-1

SECTION 3 PANEL LAYOUT

No

14

15

16

17

18

19

20

Name, display

Output Level Rotary

Knob, Resolution [<] and

[>] keys

RF Output connector

[RF Off/On] key

Entry [GHz/wdBm],

[MHz/dB

and [Hz/µV] keys

Entry, [0] through [9], [–/

+], and [BS] keys

Entry [Shift] key

Entry [Frequency],

[Level], [Modulation],

and [Memory] keys

µ

], [kHz/mV],

Description

Specifies the rotary knob for varying the output level and its resolution.

When the > key is pressed following the Shift key, the resolution of the rotary knob

matches the step size of the step key, and the knob can be set up and down with an

arbitrary level step size.

Outputs the MG3641A/MG3642A output signal with impedance 50 Ω.

Turns on or off a signal from the RF output connector. In the off mode, the key

lamp lights on.

When the reverse power protector operates by applying a reverse power, if this key

is pressed following the Shift key, the device returns to the ordinary state.

A unit key used to enter each parameter with a numeric value using the ten keys and

decide the numeric value. Select a unit according to each input parameter and press

an appropriate one.

Ten keys used to enter each parameter with a numeric value and backspace key

used to erase an erroneously entered digit.

To operate a key displayed in blue characters on the panel, first press this key (its

lamp lights on), then press the required key.

Header keys used to select the ten keys, step keys in the edit zone, or rotary knob

function.

Pressing one of four keys turns on its lamp and validates a value entered using the

ten keys as a parameter.

One lamp indicating the edit zone function then lights on and the step key and

rotary knob function are selected.

However, the Level key has the output level step key and rotary knob, and the edit

zone function is not modified.

Pressing the Frequency or Level key following the Shift key places each step key

into the step size entry state. Then, use the ten keys and unit key to set a value.

Pressing the Modulation key following the Shift key sets the memory set mode that

enables to store and clear memory contents.

3-2

21

AF output connector

22

Edit Step [^] and [∨]

keys

23

Edit Rotary Knob

Resolution [<] and

[>] key

24

Mod Input Ext1 and Ext2

connectors

25

Edit Frequency,

Modulation, and Memory

lamps

Outputs a signal of the modulation signal source with impedance 600 Ω.

Steps up or down the parameter specified with the Entry key or on the multi-menu

display.

Specifies the rotary knob for varying the parameter specified with the Entry key or

on the multi-menu display and its resolution.

When the > key is pressed following the Shift key, the resolution of the rotary knob

matches the step size of the step key, and the knob can be set up and down with an

arbitrary level step size.

(This function is valid only at setting of a frequency.)

An external modulation signal input connector.

The appropriate input level is 2 Vp-p. If the input signal level is lower than that

value, the “▲” lamp lights on; otherwise, the “▼” lamp lights on to notify that the

input signal level is not appropriate.

Indicate the parameter for which the rotary knob and step key in the edit zone are

valid currently.

All the lamps go off when a parameter is selected on the multi-menu display.

SECTION 3 PANEL LAYOUT

No

26

27

28

29

30

Name, display

[Stby/On] switch

[Local] key

Remote lamp

[Preset] key

[Display] key

3.1.2 Rear panel layout

This paragraph outlines the switches and connectors arranged on the rear panel.

No

31

32

Name, display

Cooling fan

Freq Adj trimmer

Description

Switches the standby mode to the on mode and vice versa. The Stby lamp lights on

in the standby mode; the On lamp lights in the on mode.

Returns to the local mode after remote control.

Lights on at remote control.

Initializes the mode set on the panel.

Turns off the multi-menu display to suppress the undesired radiation. Pressing this

key following the Shift key enables to turn off all the displays excluding the On

lamp and external modulation level indicators “▲” and “▼”.

To turn on the multi-menu display again, perform the same procedure as the turnoff procedure.

Description

Exhausts the heat generated inside the MG3641A/MG3642A to the outside. Do

not leave anything to obstruct the air flow around the fan.

Fine-adjusts the frequency of the internal base oscillator .

33

GPIB connector

34

●● | switch

35

AC power inlet

36

FG terminal

37

Trig Input connector

38

Sweep Out connectors

39

Int Mod Cont 1, 2, 3

connectors

40

Pulse Mod Input

connector

10 MHz Buff Out

41

connector

42

5 MHz/10 MHz Ref In

connector

Used in GPIB remote control mode.

Turns on or off all the power to the MG3641A/MG3642A.

Inlet for AC power supply to the MG3641A/MG3642A.

Grounds the frame to the ground potential. This terminal must be grounded for

safety.

When the trigger function is used, this connector is used to input the trigger

signal.

Outputs an auxiliary sweep signal.

When an internal modulation source option that needs to be controlled externally

is mounted, one of these connectors is used to input the control signal.

The function depends on the type of option mounted.

Inputs a pulse modulation signal. (Pulse Modulator is optional.)

Outputs a signal of the frequency synchronized to the reference signal in the

MG3641A/MG3642A.

Inputs the reference signal to synchronize the MG3641A/MG3642A with an

external reference signal.

3-3

SECTION 3 PANEL LAYOUT

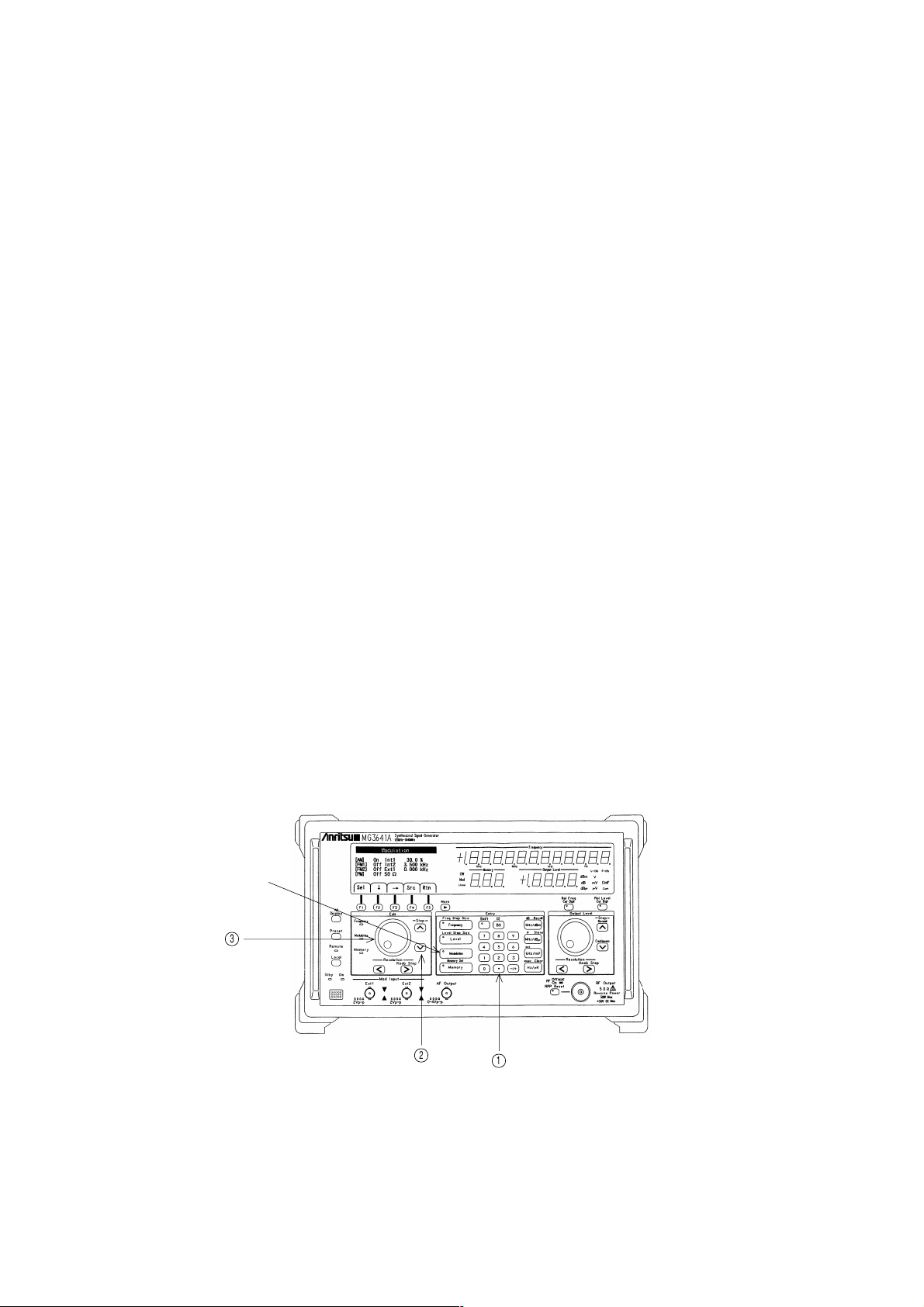

3.1.3 Panel layout diagram

Figures 3-1 and 3-2 show the front and rear panel diagrams, respectively.

The numbers in the diagrams correspond to those in the paragraphs 3.1.1 and 3.1.2.

12345678 9

10

11

30

29

28

27

26

16171825 24 23 22 21 20 19

Fig. 3-1. Front Panel

31 32 33 34

12

13

14

15

35

3-4

36

3738394042 41

Fig. 3-2. Rear Panel

.

SECTION 4 OPERATING INSTRUCTIONS

Stby On

Stby/On

MG3641A/MG3642A Rear panel

O| switch

MG3641A/MG3642A Front Panel

Frame ground terminal: To prevent electric

shock, connect

this terminal to

ground potential.

Stby On

Stby/On

SECTION 4

OPERATING INSTRUCTIONS

4.1 Turning Power On/Off

The MG3641A/MG3642A comes provided with two power switches, namely, the "Stby/On" switch on the front

panel and the " " switch on the rear panel.

Turning power on without grounding protection could lead to a bodily injury due to electric shocks.

Where a three-pole (2-pole for grounding type) current outlet is not available, make sure you connect the frame

ground terminal (FG) located on the rear panel or the ground terminal of the accessory power cord to the

ground potential, before you supply power to the MG3641A/MG3642A.

DANGER

4-1

SECTION 4 OPERATING INSTRUCTIONS

WARNING

In case the AC line voltage fed to the unit is not an appropriate one, the interior of the signal generator may be

damaged because of abnormal voltages. Before switching on the MG3641A/MG3642A, check to make sure

that the AC line voltage meets the specified value.

In normal operation of this signal generator, leave the " " switch of the rear panel permanently set in the " "

position, with the accessory power cord plugged into the AC inlet and the current outlet, and control the on/off

operations of the signal generator only by the "Stby/On" switch located on the front panel.

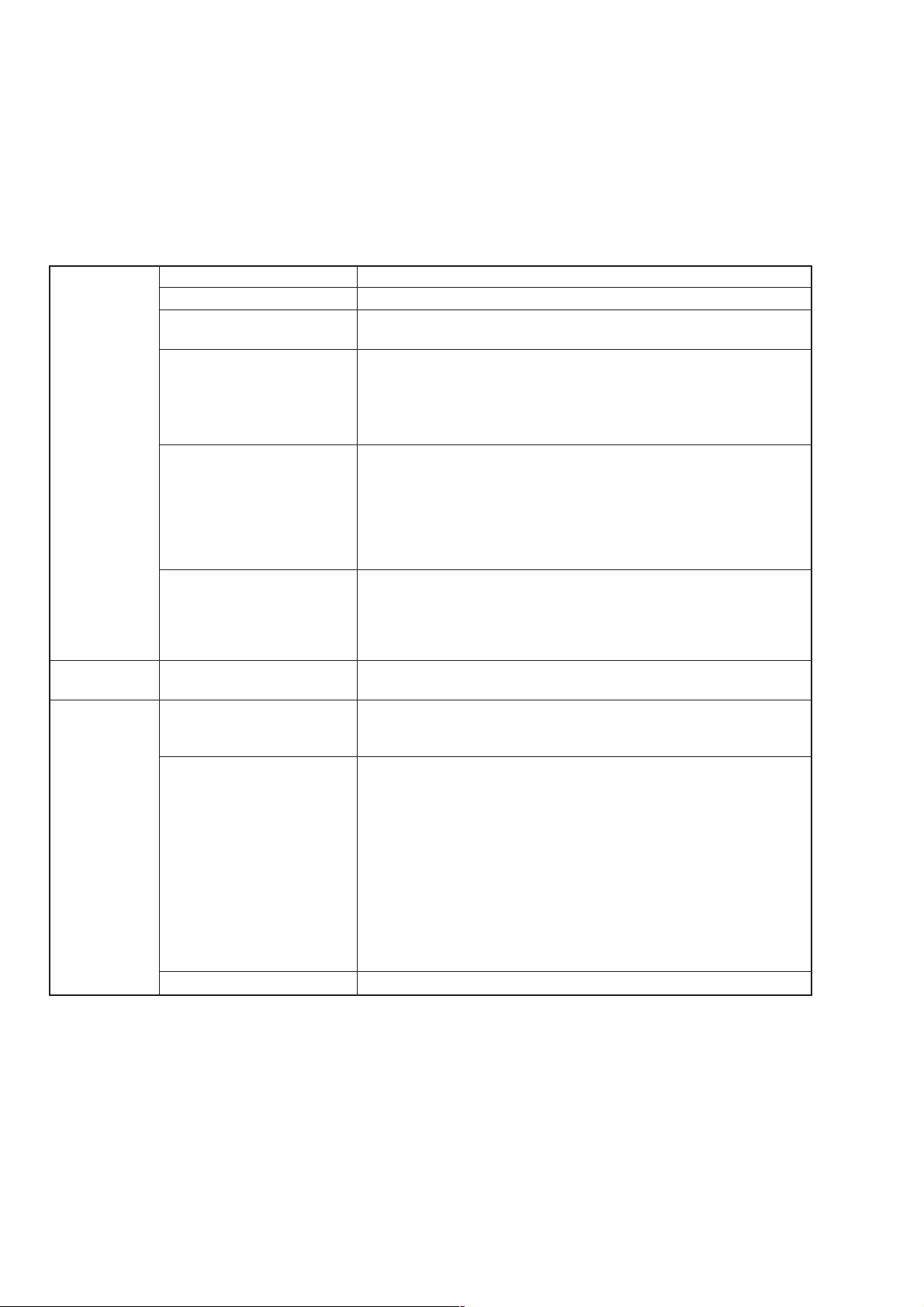

Table 4-1. Indications of Power Indicator Lamps and Power Statuses

Status of power switch Status of power indicator lamp

" " swich "Stby/On" switch "Stby" (Green) "On" (Orange)

Stby Unlit Unlit

Stby Lit Unlit

On Unlit Lit

4-2

4.1.1 Turning Power On

The procedure to be followed from preheating the internal reference oscillator, till operating the signal generator,

will be explained below.

STEP PROCEDURE

SECTION 4 OPERATING INSTRUCTIONS

1. Connect the FG terminal located on the rear panel to

ground.

2. Place the " " switch on the rear

panel in the " " (Off) position.

3. Plug the jack of the power cord into the AC power

inlet on the rear panel.

4. Insert the plug of the power cord into the AC current

outlet.

5. Turn on the " " switch on the rear panel.

• If you use a 3-pole power cord fitted with a ground

terminal, you do not have to do this grounding

connection.

• When this button is pressed and remains depressed, it

is in the " " (On) position. To turn it off, bring the

button up by pressing it again. When the button is

turned off, the AC power is cut off, even if the power

button on the front panel is set in the On position.

• Push in the jack of the power cord securely, till the

clearance is reduced to 1 to 2 mm.

• The "Stby" lamp of the power

switch on the front panel lights up.

• The preheating of the internal

reference oscillator begins. To

operate this signal generator after

it has been exposed in a low-

temperature ambient, preheat it for

at least 24 hours.

Stby On

6. Press the "Stby/On" switch on the front panel to turn

it on.

Note :

If neither of the power indicator lamps comes on, check the following points:

1. Is the power cord coupled correctly to the current outlet and the power plug?

2. Is the specified fuse installed correctly in the fuse-holder?

3. Is the supply voltage a correct one?

• The "On" lamp of the power switch

on the front panel lights up, while

the "Stby" lamp goes out.

• The power will be supplied to all

the circuits of the MG3641A/

MG3642A, which gets ready for

operation.

Stby On

4-3

SECTION 4 OPERATING INSTRUCTIONS

4.1.2 Turning Power Off

To turn the power off, follow the same procedure detailed in Item 4.1.1 inversely.

4-4

SECTION 4 OPERATING INSTRUCTIONS

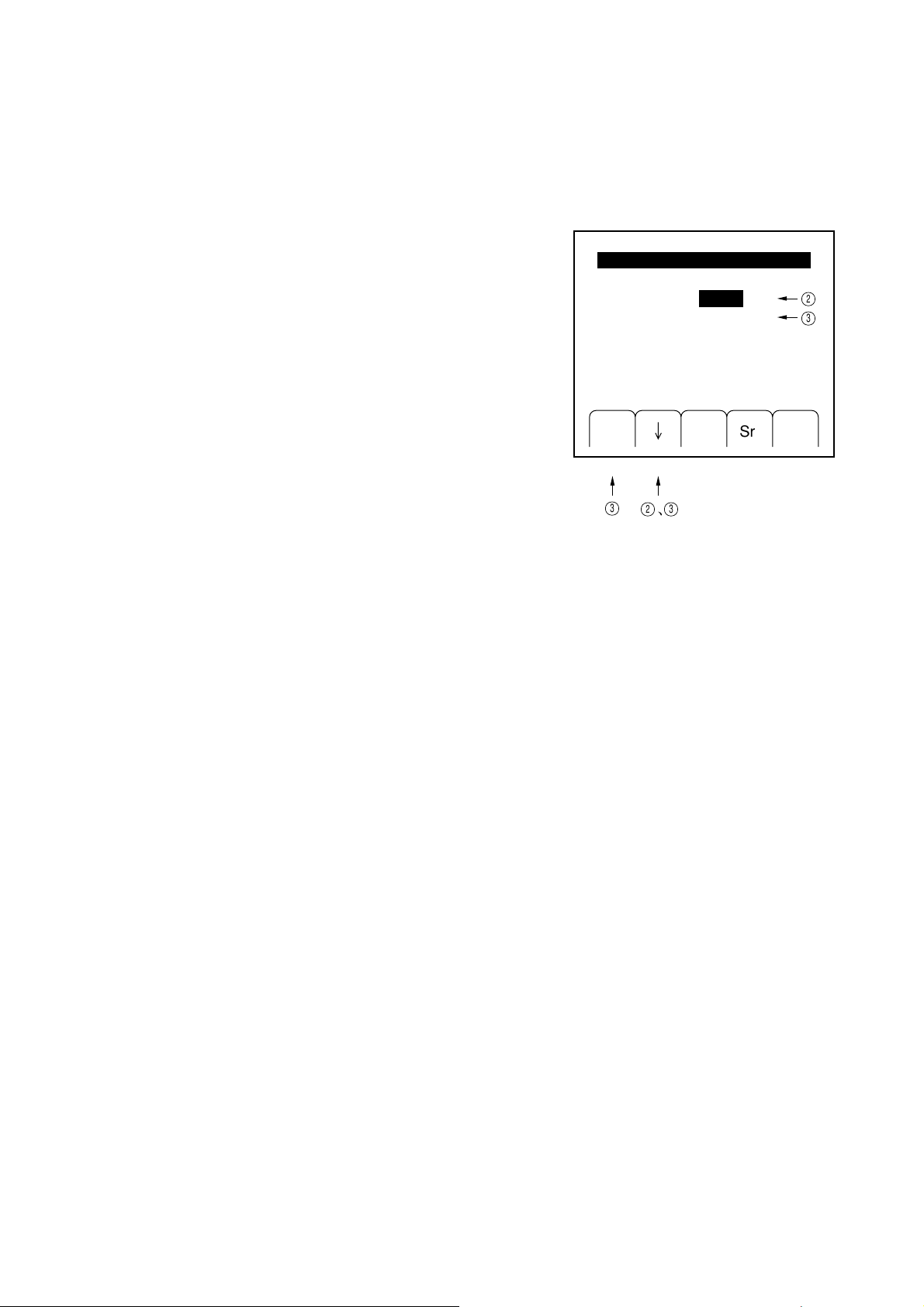

4.2 Explanation of Screens

This signal generator is equipped with a multi-menu display for indicating statuses and setting operations, except for

the major items, such as frequency, output level, memory, etc.

(1) Screen Layout

Displays the menu currently

open.

Modulation

Area for status display and

setting operations.

A parameter can be set or a

status selected at the location

where the characters are

highlighted.

[AM]

[FM1]

[FM2]

[PM]

OffInt1

OffInt1

OffInt1

600Ω

Off

0.0

0

0

%

Hz

Hz

Sel Rtn

Error message area. Indicates

details of an operation error or

other errors.

Function keys corresponding

to the key menu shown on the

display

(2) Functions of Function Keys

The function keys have the following operational functions:

Sel .................. Used when the currently highlighted parameter is a selection item. Each press to this key displays

selection items successively.

↓, → ............... Keys to select a parameter to be set.

By pressing these keys, you move the highlighted item in the direction of arrows.

Src .................. A key to move to the menu of the next layer. (“Src” indicates a menu name.)

Rtn .................. Return key to go back to the menu of the immediately higher layer.

F2F1 F4F3 F5

Key to turn the page when a

menu of the same layer goes

over to multiple pages.

Src

More

▼

4-5

SECTION 4 OPERATING INSTRUCTIONS

1

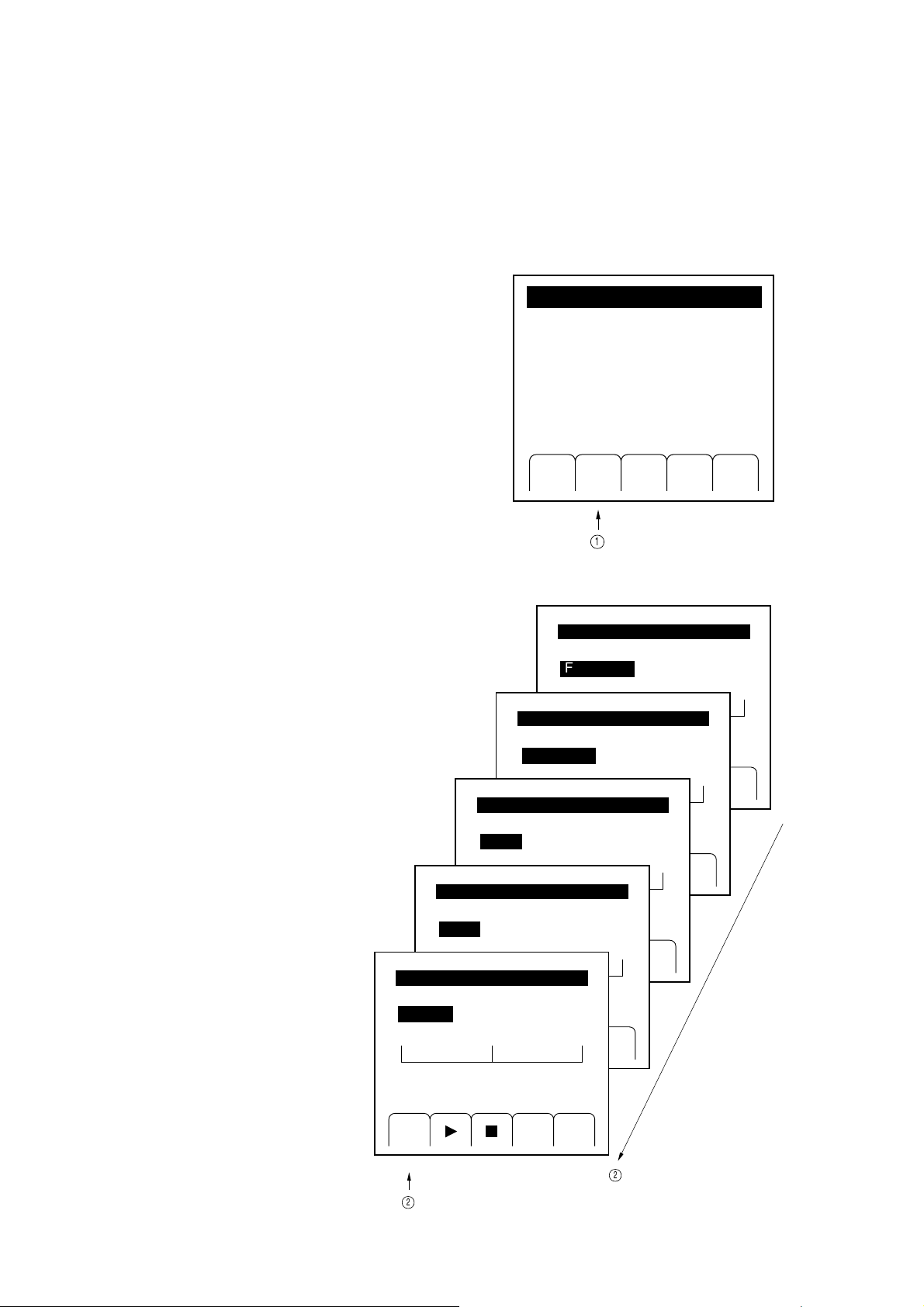

4.3 Initial Settings

You can return the panel settings of the MG3641A/MG3642A to the initial setting conditions by pressing the [Preset]

key.

The term "Initial Settings" as used herein refers to the conditions under which the signal generator was shipped out of

the factory (Appendix A). However, if you alter the contents of the preset memory, you will be able to restore your

desired initial conditions from any current panel settings.

MG3641A/MG3642A front panel

[Preset] key

To alter the preset memory contents, first set up conditions you want to use as initial settings, and then follow the

procedure detailed below:

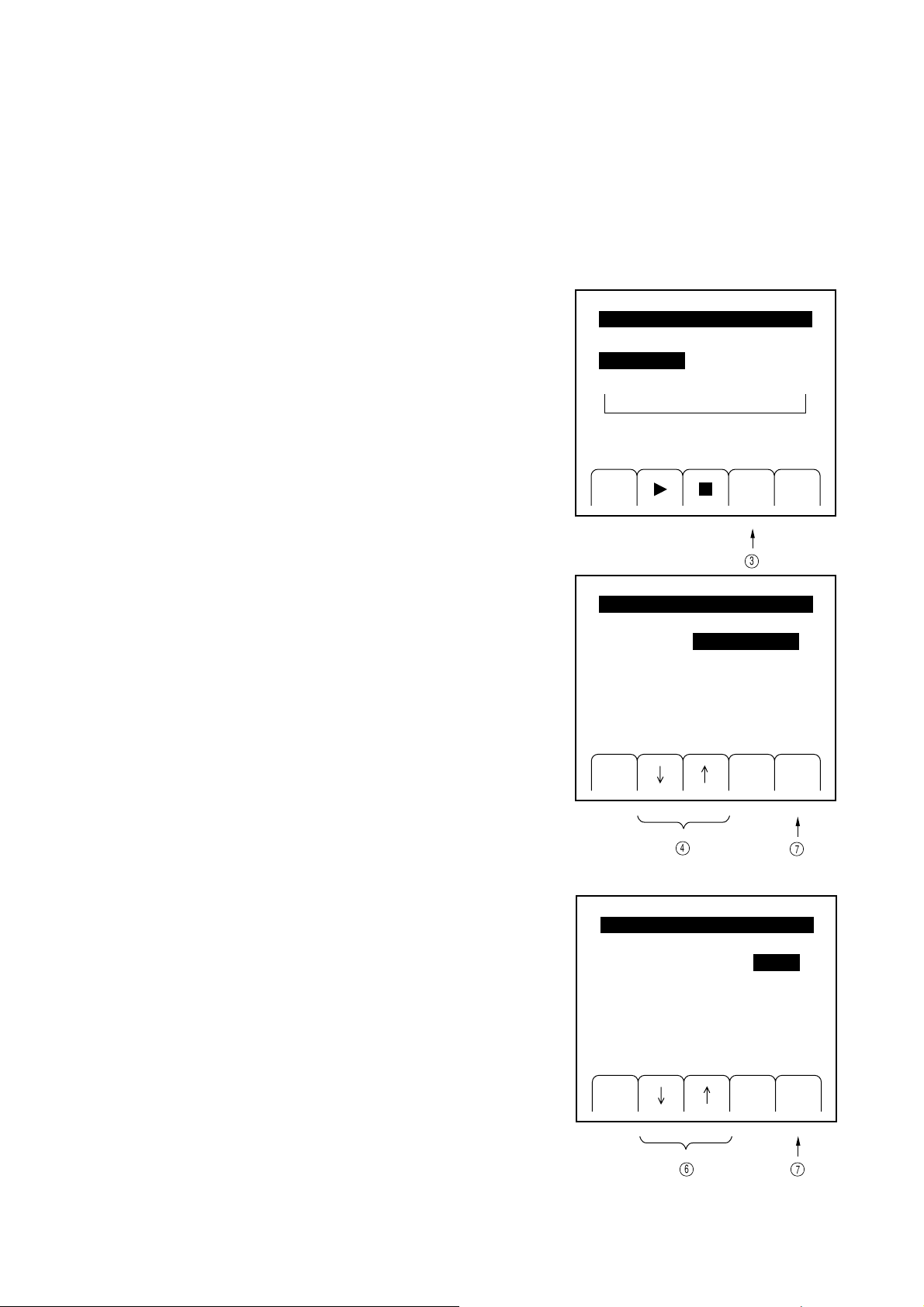

(1) Press the "Sys" [F3] key in the top menu to open the

"System (1)" menu.

MainMenu(2/2)

Chk

SysGPIB Opt Trig

4-6

SECTION 4 OPERATING INSTRUCTIONS

3

(2) Select "Initial memory set" by pressing the " ↓ " [F2]

key or " ↑ " [F3] key (the characters are highlighted).

(3) As you press the "Sel" [F1] key, the current panel

settings will be written to the preset memory.

Factoryinitiarize

Initialmemoryset

Initialmemoryclear

[Bell]

[Alarm]

System(1/2)

Off

On

Sel Rtn

2