ML2430A SERIES

POWER METER

OPERATION MANUAL

ANRITSU LTD (EMD)

RUTHERFORD CLOSE

STEVENAGE

HERTS

SG1 2EF

P/N: 10585-00001

REVISION: K

PRINTED: MARCH. 2000

COPYRIGHT 2000 ANRITSU

WARRANTY

The ANRITSU product(s) listed on the title page is (are) warranted against defects in materials and

workmanship for one year from the date of shipment.

ANRITSU's obligation covers repairing or replacing products which prove to be defective during the

warranty period. Buyers shall prepay transportation charges for equipment returned to ANRITSU for

warranty repairs. Obligation is limited to the original purchaser. ANRITSU is not liable for

consequential damages.

LIMITATION OF WARRANTY

The foregoing warranty does not apply to ANRITSU connectors that have failed due to normal

wear. Also, the warranty does not apply to defects resulting from improper or inadequate

maintenance by the Buyer, unauthorized modification or misuse, or operation outside of the

environmental specifications of the product. No other warranty is expressed or implied, and the

remedies provided herein are the Buyer's sole and exclusive remedies.

TRADEMARK ACKNOWLEDGMENTS

V Connector and K Connector are registered trademarks of ANRITSU Company.

HP 436A, HP 437B, HP 438A, Deskjet, and HP 340 Deskjet are registered trademarks of

Hewlett-Packard Company. Adobe Acrobat and Acrobat Reader are trademarks of Adobe Systems

Incorporated.

NOTICE

ANRITSU Company has prepared this manual for use by ANRITSU Company personnel and

customers as a guide for the proper installation, operation and maintenance of ANRITSU Company

equipment and computer programs. The drawings, specifications, and information contained herein

are the property of ANRITSU Company, and any unauthorized use or disclosure of these drawings,

specifications, and information is prohibited; they shall not be reproduced, copied, or used in whole

or in part as the basis for manufacture or sale of the equipment or software programs without the

prior written consent of ANRITSU Company.

Safety Symbols

To prevent the risk of personal injury or loss related to equipment malfunc

tion, ANRITSU Company uses the following symbols to indicate safetyrelated information. For your own safety, please read this information care

fully BEFORE operating the equipment.

Symbols used in manuals

DANGER

Indicates a very dangerous procedure that could result in serious injury or

death if not performed properly.

WARNING Indicates a hazardous procedure that could result in serious injury or

death if not performed properly.

CAUTION Indicates a hazardous procedure or danger that could result in light-to-

severe injury, or loss related to equipment malfunction, if proper precautions are not taken.

Safety Symbols Used on Equipment and in Manuals

(Some or all of the following five symbols may or may not be used on all ANRITSU equipment. In addition, there

may be other labels attached to products that are not shown in the diagrams in this manual.)

The following safety symbols are used inside or on the equipment near

operation locations to provide information about safety items and opera

tion precautions. Ensure that you clearly understand the meanings of the

symbols and take the necessary precautions BEFORE operating the

equipment.

-

-

-

This symbol indicates a prohibited operation. The prohibited operation is

indicated symbolically in or near the barred circle.

This symbol indicates a compulsory safety precaution. The required op

eration is indicated symbolically in or near the circle.

This symbol indicates warning or caution. The contents are indicated sym

bolically in or near the triangle.

This symbol indicates a note. The contents are described in the box.

These symbols indicate that the marked part should be recycled.

-

ML2430A OM SAFETY-1

-

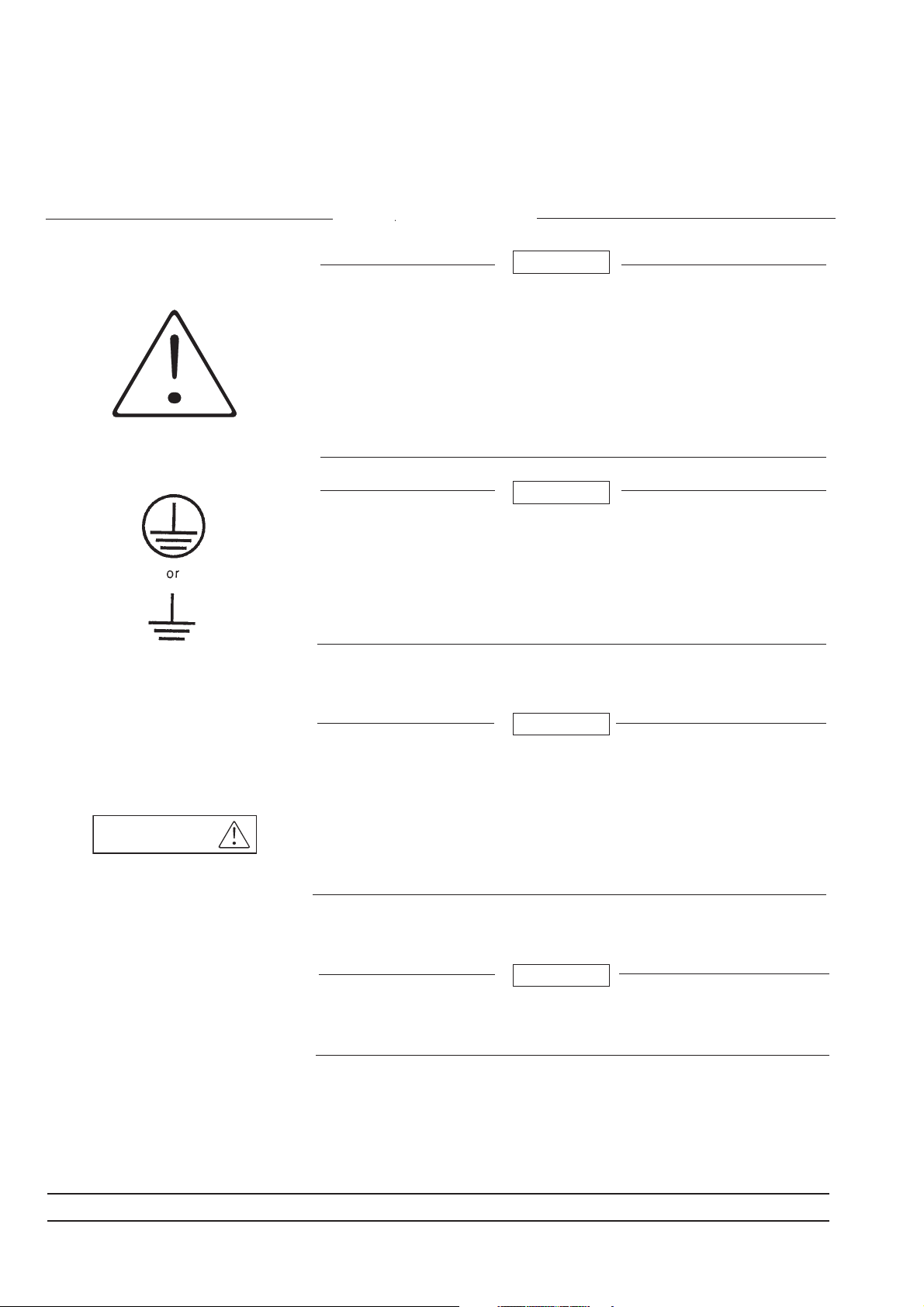

For Safety

WARNING

Always refer to the operation manual when working near locations at

which the alert mark, shown on the left, is attached. If the operation, etc.,

is performed without heeding the advice in the operation manual, there is

a risk of personal injury. In addition, the equipment performance may be

reduced.

Moreover, this alert mark is sometimes used with other marks and de

scriptions indicating other dangers.

WARNING

When supplying AC power to this equipment, connect the accessory 3-pin

power cord to a 3-pin grounded power outlet. If a grounded 3-pin outlet is

not available, use a conversion adapter and ground the green wire, or connect the frame ground on the rear panel of the equipment to ground. If

power is supplied without grounding the equipment, there is a risk of receiving a severe or fatal electric shock.

-

Repair

WARNING

WARNING

This equipment cannot be repaired by the operator. DO NOT attempt to re

move the equipment covers or to disassemble internal components. Only

qualified service technicians with a knowledge of electrical fire and shock

hazards should service this equipment. There are high-voltage parts in this

equipment presenting a risk of severe injury or fatal electric shock to un

trained personnel. In addition, there is a risk of damage to precision com

ponents.

WARNING

If this equipment is used in a manner not specified by the manufacturer,

the protection provided by the equipment may be impaired.

-

-

-

SAFETY-2 ML2430A OM

Table of Contents

Chapter 1 - General Information

1-1 Scope of This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1-2 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1-3 Related Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1-4 Identification Number . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1-5 Power Meter Models, Options, and Accessories . . . . . . . . . . . . . 1-2

1-6 Sensors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3/1-4

Chapter 2 - Installation

2-1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2-2 Initial Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2-3 Sensor Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2-4 Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2-5 Environmental Requirements. . . . . . . . . . . . . . . . . . . . . . . 2-3

2-6 Rack Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2-7 Battery Charging, Removal and Replacement . . . . . . . . . . . . . . 2-9

2-8 Storage and Shipment . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Chapter 3 - Connections

3-1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3-2 Front Panel Connectors . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3-3 Rear Panel Connectors. . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Chapter 4 - Front Panel Operation

4-1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4-2 Front Panel Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4-3 Power-on Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4-4 Sensor Menu4-5

4-5 Channel Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

4-6 Trigger Menu4-15

4-7 System Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

4-8 Cal/Zero Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-34

ML2430A OM i

Chapter 5 - Procedures

5-1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5-2 Power Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5-3 Zeroing the Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5-4 Sensor Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5-5 Sensor Zero/Cal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5-6 Performance Verification . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

5-7 Printer Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

5-8 GPIB Remote Operation . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

5-9 Serial Remote Operation . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

5-10 RS232 Modem Support . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

5-11 Profile Operation Mode . . . . . . . . . . . . . . . . . . . . . . . . 5-11

5-12 Source Sweep Mode. . . . . . . . . . . . . . . . . . . . . . . . . . 5-17

5-13 Power vs. Time Mode . . . . . . . . . . . . . . . . . . . . . . . . . 5-19

5-14 User Cal Factors . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-19

5-15 Optimizing Readings. . . . . . . . . . . . . . . . . . . . . . . . . . 5-21

5-16 Operator Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . 5-25

Chapter 6 - GPIB Operation

6-1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6-2 Typographic Conventions. . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6-3 Data I/O Formats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6-4 Query Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

6-5 GPIB PC Card Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

6-6 Using 488.1 GPIB . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

6-7 Using 488.2 GPIB . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

6-8 Service Request Status (SRQ) . . . . . . . . . . . . . . . . . . . . . . 6-9

6-9 Functional Groups. . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

6-10 ML24XXA Native Commands . . . . . . . . . . . . . . . . . . . . . 6-12

6-11 GPIB Emulation Modes . . . . . . . . . . . . . . . . . . . . . . . . 6-84

6-12 ML4803A Emulation Commands . . . . . . . . . . . . . . . . . . . 6-85

6-13 HP 436A Emulation Commands . . . . . . . . . . . . . . . . . . . . 6-96

6-14 HP 437B Emulation Commands . . . . . . . . . . . . . . . . . . . 6-101

6-15 HP 438A Emulation Commands . . . . . . . . . . . . . . . . . . . 6-118

6-16 Programming Examples . . . . . . . . . . . . . . . . . . . . . . . 6-129

ii ML2430A OM

Appendix A - Specifications

A-1 Introduction A-1

A-2 System Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

A-3 System Defaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-6

A-4 System Error Messages . . . . . . . . . . . . . . . . . . . . . . . . A-11

Appendix B - GPIB Quick Reference

B-1 Introduction B-1

B-2 ML24XXA Quick Reference . . . . . . . . . . . . . . . . . . . . . . . B-1

B-3 ML4803A Quick Reference . . . . . . . . . . . . . . . . . . . . . . . B-9

B-4 HP 436A Quick Reference . . . . . . . . . . . . . . . . . . . . . . . B-10

B-5 HP 437B Quick Reference . . . . . . . . . . . . . . . . . . . . . . . B-11

B-6 HP 438A Quick Reference . . . . . . . . . . . . . . . . . . . . . . . B-14

B-7 HP-IB Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-16

Appendix C - Menu Maps

C-1 Introduction C-1

C-2 Sensor Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

C-3 Channel Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-6

C-4 Trigger Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-8

C-5 System Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-9

C-6 Cal/Zero Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-15

Index

ML2430A OM iii/iv

Chapter 1

General Information

1-1

SCOPE OF THIS

MANUAL

This manual provides installation and operation information for the Model

ML2430A Series of ANRITSU Power Meters (Figure 1-1).

Figure 1-1. ML2430A Series Power Meters

1-2

1-3

INTRODUCTION

RELATED

MANUALS

This chapter provides information to familiarize the user with the basic

ML2430A Series Power Meter. Included is information about the equip

ment identification number, models, options, and sensors.

This manual is one of a two manual set consisting of this Operation Man

ual, and the

10585-00003).

These manuals are available on CD ROM as Adobe Acrobat™ (*.pdf)

files. The files can be viewed using Acrobat Reader™, a freeware pro

gram provided on the CD ROM. For price and availability, contact the

nearest Anritsu Customer Service Center or visit our web site at:

www.global.anritsu.com.

ML2430A Series Maintenance Manual

(Anritsu part number

-

-

-

ML2430A OM 1-1

IDENTIFICATION NUMBER GENERAL

INFORMATION

1-4

1-5

IDENTIFICATION

NUMBER

POWER METER

MODELS, OPTIONS, AND

ACCESSORIES

The ML2430A Series ID number is affixed to the rear panel (see Figure

3-2). Please use the complete ID number when ordering parts or corre

sponding with the Anritsu Customer Service department.

The ML2430A Series Power Meter is available with either one or two sen

sor inputs, and is delivered with a 1.5m sensor cable (ML2400A-20) for

each input. Model numbers, options, and accessories are listed below.

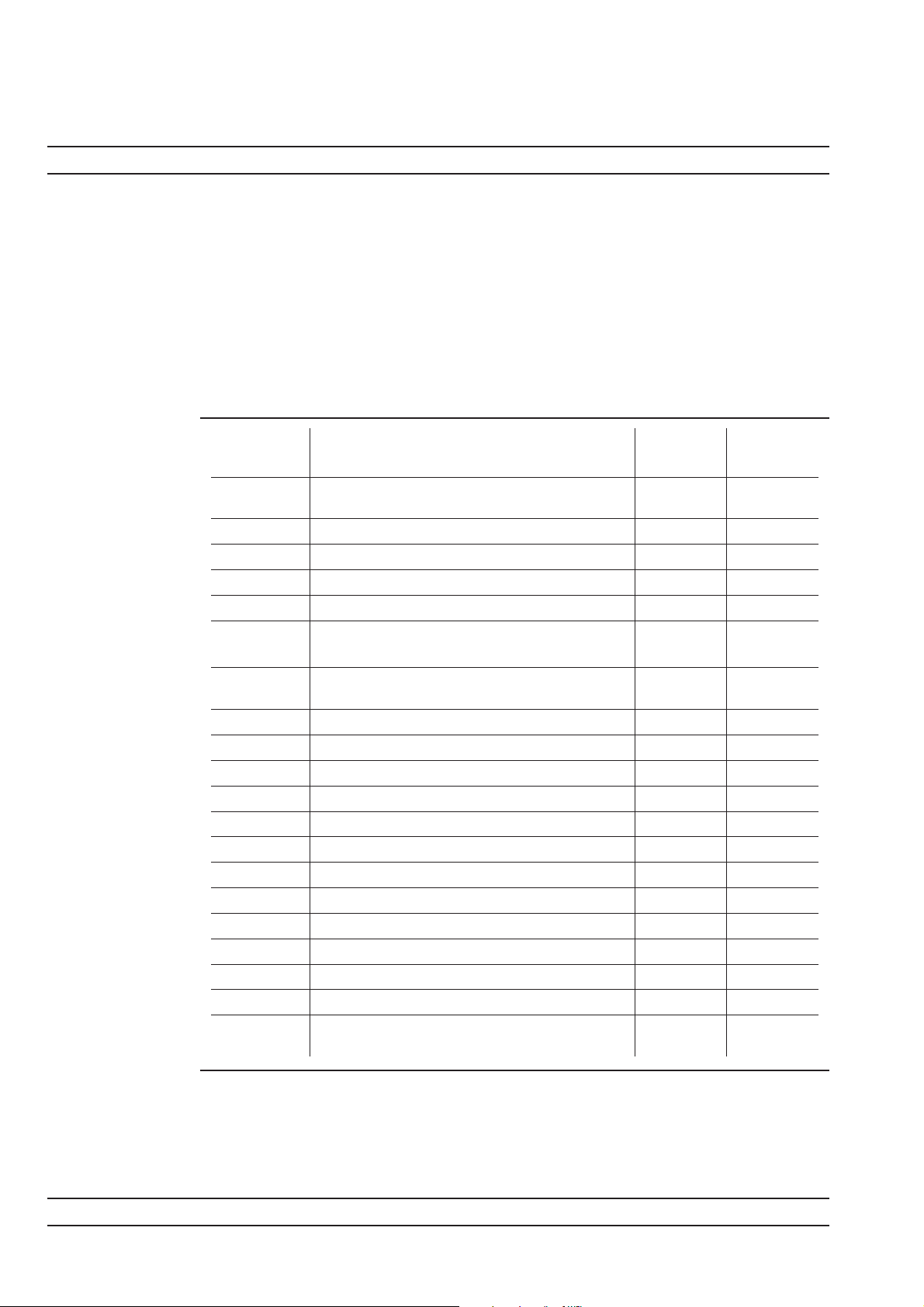

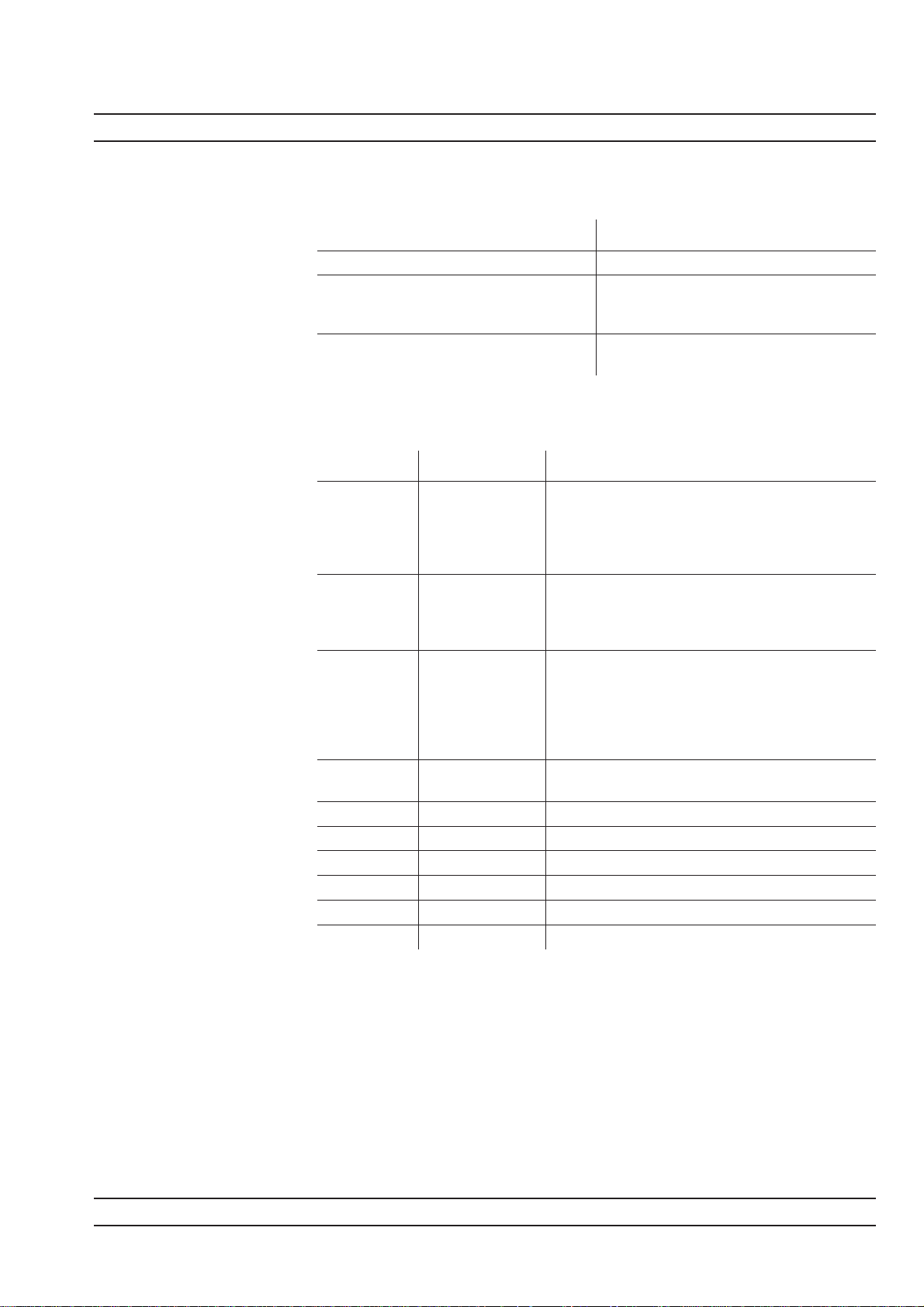

Models

Model No.

ML2437A Single Channel

ML2438A Dual Channel

Options

Model No.

ML2400A-01 Rack Mount, single unit

ML2400A-03 Rack Mount, side-by-side

ML2400A-05 Front Bail Handle

ML2400A-06 Rear Panel Mounted Input A

ML2400A-07 Rear Panel Mounted Input A & Reference

ML2400A-08 Rear Panel Mounted Inputs A, B, & Reference

ML2400A-09 Rear Panel Mounted Inputs A & B

Number of Sensor Channels

Option

(Options -01 thru -05 are mutually exclusive.)

(Options -06 thru -09 are mutually exclusive.)

-

-

ML2400A-11 3000 mA-h, NiMH Battery

ML2400A-12 Front Panel Cover

(Can not be used with rack mounted units.)

ML2400A-13 External Battery Charger

Accessories

Part No.

760-206 Hard Sided Transit Case

D41310 Soft Sided Carry Case with shoulder strap

ML2419A Range Calibrator

B41323 Serial Interface Cable

MA2418A 50 MHz, 0 dBm Reference Source

Item

1-2 ML2430A OM

GENERAL SENSORS

INFORMATION

1-6

SENSORS

The following sensors, sensor options, and sensor accessories are avail

able for use with the ML2430A Series Power Meters:

Power Sensors (–70 to + 20 dBm)

Model No.

MA2468A 10 MHz – 6 GHz

MA2469B 10 MHz – 18 GHz

MA2472A 10 MHz – 18 GHz

MA2473A 10 MHz – 32 GHz

MA2474A 10 MHz – 40 GHz

MA2475A 10 MHz – 50 GHz

Thermal Sensors (–30 to + 20 dBm)

Model No.

MA2421A 100 KHz to 18 GHz

MA2422A/B 10 MHz – 18 GHz

MA2423A/B 10 MHz – 32 GHz

MA2424A/B 10 MHz – 40 GHz

MA2425A/B 10 MHz – 50 GHz

High Accuracy Sensors (–64 to +20 dBm)

Model No.

MA2442A 10 MHz – 18 GHz

MA2444A 10 MHz – 40 GHz

MA2445A 10 MHz – 50 GHz

Range

(–60 to +20 dBm, nominal bw 1.2 MHz)

Range

Range

-

Universal Power Sensor

Model No.

MA2481A 10 MHz – 6 GHz

MA2480/01 Add Fast CW

Sensor Options

MA2400A-10 Extra Cal Factor Freq., 0.01 – 40 GHz

Range

ML2430A OM 1-3

SENSORS GENERAL

INFORMATION

SensorAccessories

ML2400A-20 1.5m SensorCable

ML2400A-21 0.3m SensorCable

ML2400A-22 3m Sensor Cable

ML2400A-23 5m Sensor Cable

ML2400A-24 10m Sensor Cable

ML2400A-25 30m Sensor Cable

ML2400A-26 50m Sensor Cable

NOTE

Theuseofsensorca

blesgreaterthan10

metersinlengthisnot

recommendedwhen

measuringpulsesof

lessthan10ms.

-

ML2400A-27 100m Sensor Cable

ML2400A-29 Bulkhead Adapter

ML2400A-30 Extra Operation Manual ML2437/38A

ML2400A-33 Printer

MA2499B Anritsu SensorAdapter

MA2497A HP Sensor Adapter

1N75C 5WLimiter, 0.01 – 3GHz,Nm-f, 75W

1N50C 5W Limiter, 0.01 – 18GHz,Nm-f, 50W

1K50A 5W Limiter, 0.01 – 20GHz, Km-f, 50W

1K50B 3W Limiter, 0.01 – 26GHz, Km-f, 50W

42N75-20 5 WattAttenuator,Nm-f, 75W

42N50-20 5 WattAttenuator,Nm-f, 50W

42N50-30 50 WattAttenuator,Nm-f, 50W

42KC-20 5 WattAttenuator, Km-f, 50W

1-4 ML2430AOM

Chapter 2

Installation

2-1

2-2

2-3

2-4

INTRODUCTION

INITIAL

INSPECTION

SENSOR

HANDLING

POWER

REQUIREMENTS

This chapter provides information for the initial inspection and preparation

for use of the ML2430A Series Power Meter. Shipping and storage infor

mation is also included.

Inspect the shipping container for damage. If the container or cushioning

material is damaged, retain until the contents of the shipment have been

checked against the packing list and the instrument has been checked for

mechanical and electrical operation.

If the power meter is damaged mechanically, notify your local sales repre

sentative or Anritsu Customer Service Center. If either the shipping con

tainer is damaged or the cushioning material shows signs of stress, notify

the carrier as well as Anritsu. Retain the shipping materials for the carrier's inspection.

The sensors are enclosed in a polycarbonate case to help prevent damage. The sensor connectors, however, are exposed and are a critical part

of the microwave instrument. Refer to the MA24XXA Series Power Sensor

manual (10585-00004) for detailed information on proper connector care.

The ML2430A Series Power Meter can be operated from either AC line

power, external DC power, or from the optional internal battery. The

ML2430A Series Power Meter is intended as an Installation (Overvoltage)

Category II, Insulation Category I device.

-

-

-

At power-on, the power meter will perform a brief power-on self test

(POST). If a POST error occurs, information and available options will be

displayed on the screen (See Chapter 4, page 4-3). If the POST is suc

cessful, the instrument will load the last used configuration, unless Secure

mode has been selected (see Chapter 4, page 4-34, or Chapter 6, page

6-68).

AC Line Power

DC Power

The ML2430A Series Power Meter can operate on AC

input power of 85-264V, 50-440 Hz, 40 VA maximum.

The Power Meter automatically configures itself for the

voltage applied. The AC line input is protected by an

internal fuse.

The ML2430A Series Power Meter can also operate

from a nominal external 12-24 VDC input in the ab

sence of AC line power. DC line power is protected by

-

-

ML2430A OM 2-1

POWER REQUIREMENTS INSTALLATION

a fuse mounted inside the unit, on the main board. A

grounding terminal is provided on the rear panel to

ground the unit during operation from a DC supply.

Battery Power

The ML2430A Series Power Meter can be operated

using the optional internal battery pack. During battery

operation, an icon will be displayed on measurement

screens indicating the state of charge. When the

remaining capacity reaches less than 10%, the icon

will flash, indicating that charging will soon be required.

When running from battery power, an estimate of

typical-use running time remaining can be viewed

using the System menu (see Chapter 4, Front Panel

Operation). Note that, due to power consumption con

siderations, GPIB and serial remote operation are not

available when the power meter is running from the

battery.

The AUTO POWER OFF feature is also available

through the System menu, and can be used to

automatically switch the unit to standby after a specified period of inactivity to save battery power. The

timer can be set for 10 to 240 minutes, and any key

press will restart the timer. This same feature will automatically switch the unit to standby when the battery is

fully discharged in order to minimize the risk of overdischarge.

NOTE

The ML2430A Series Power Meter uses a

high-capacity Ni-MH battery (option ML2400A-

11). Over-discharge can result in a permanent

loss of battery capacity of as much as 20%. If

the unit is to be stored for an extended period

(longer than one week), remove the optional

battery pack so as to preclude over-discharge.

-

For optimum battery life, store the battery pack

at –20 to +50° C (–4 to +122° F) for short periods and

–20 to +35° C (–4 to +95° F) for long term storage.

The ML2430A Series Power Meter will operate from

AC or DC main power with this battery removed. This

battery is not used for the retention of nonvolatile

memory functions. Refer to Section 2-7, Battery

Charging, Removal and Replacement, for further infor

mation.

2-2 ML2430A OM

-

INSTALLATION ENVIRONMENTAL REQUIREMENTS

2-5

ENVIRONMENTAL

REQUIREMENTS

Fuses

Grounding

The ML2430A Series Power Meter is designed to operate within the temperature range of 0 to 50° C (32 to 122° F) with a maximum humidity of

90% at 40° C (104° F), non-condensing. Full accuracy is specified at 5 to

35° C (23 to 95° F).

Although not recommended, operation in temperatures to –20° C

(–4° F) is possible. At these temperatures, however, the liquid crystal display may exhibit excessively slow response. The soft sided carry case

(part number D41310) and optional front panel cover (option ML2400A-

12) can be used to help retain internally generated heat and may improve

response.

The ML2430A Series Power Meter AC and DC input

lines are protected by internally mounted fuses. These

fuses should only be changed by qualified service per

sonnel. Replace only with fuses of the same type and

rating (AC fuse is 2A, 250V, slow-blow; DC fuse is 3A,

125V, slow-blow).

The ML2430A Series Power Meter must be properly

grounded. Failure to ground the instrument could be

hazardous to operating personnel. The meter is sup

plied with a three-conductor power cord. The instru

ment is properly grounded during AC line operation

when the plug is connected to a properly installed

three-prong receptacle. A grounding terminal is pro

vided on the rear panel to ground the unit during op

eration from a DC supply.

-

-

-

-

-

2-6

RACK MOUNTING

ML2400A-01 Rack

Mount Installation

The ML2430A Series Power Meter can be ordered with rack mounting

hardware that allows the unit to be mounted into a standard 19-inch

equipment rack. There are two rack mount option kits available:

q

The ML2400A-01 Rack Mount option allows the installation of a sin

gle ML2430A in either the left or right side rack position.

q

The ML2400A-03 Rack Mount option allows side-by-side mounting

of two ML2430A Power Meters.

The Power Meter itself must be ordered from the factory as a rack

mount-ready unit. As such, it will be fitted with rack mount top and bottom

cases. These cases have extra mounting holes so that the rack mount kits

can be installed. Instructions for installing the rack mount kits follow.

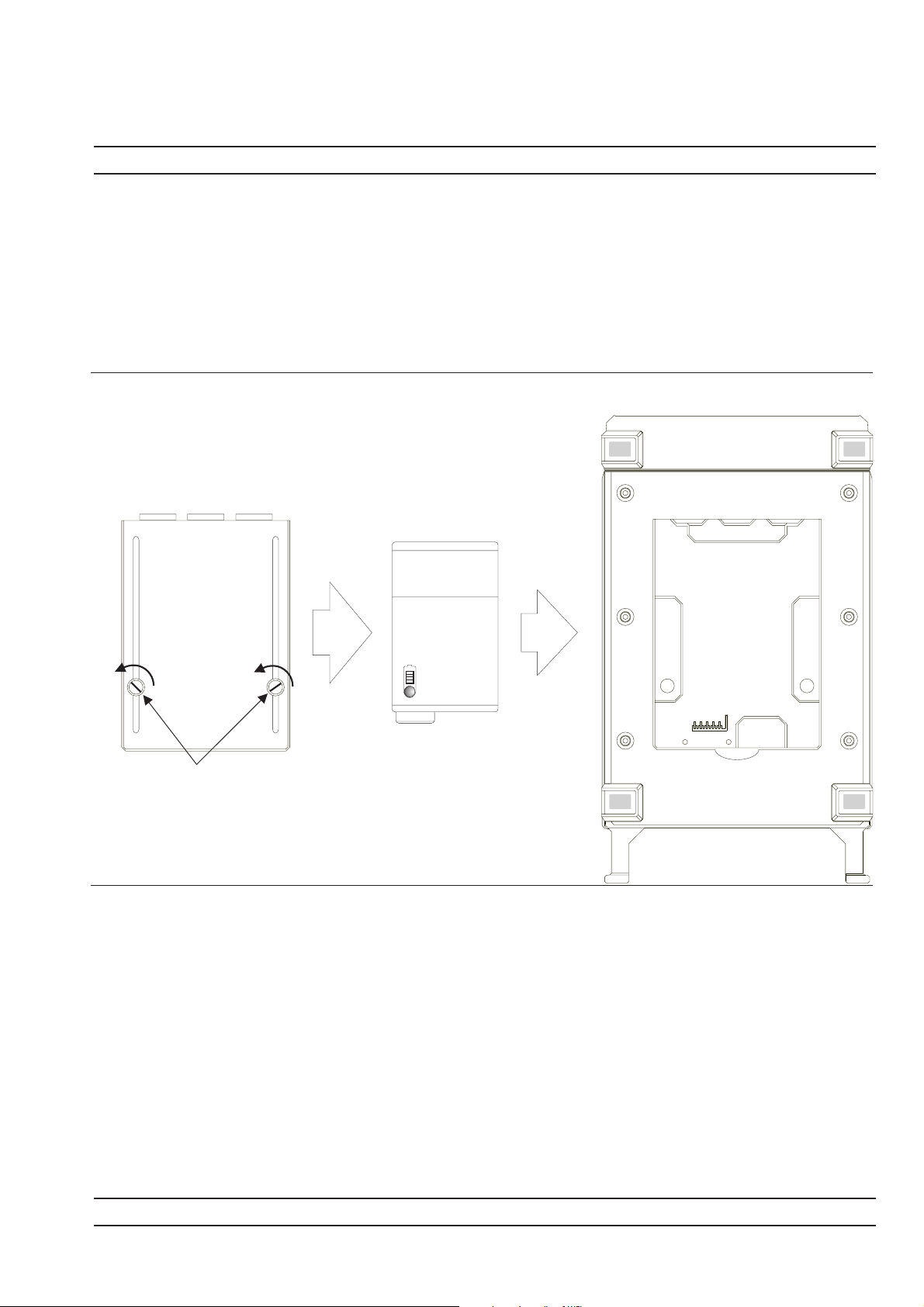

This section describes the assembly procedure for fitting a single ML2430A

Power Meter (PM) unit into an instrument rack. The PM must be fitted with rack

mount top and bottom covers before the rack mount kit can be fitted. The proce

dure involves fitting the support bracket to the PM. The PM can then be loaded

and secured in the rack position desired.

-

ML2430A OM 2-3

-

RACK MOUNTING INSTALLATION

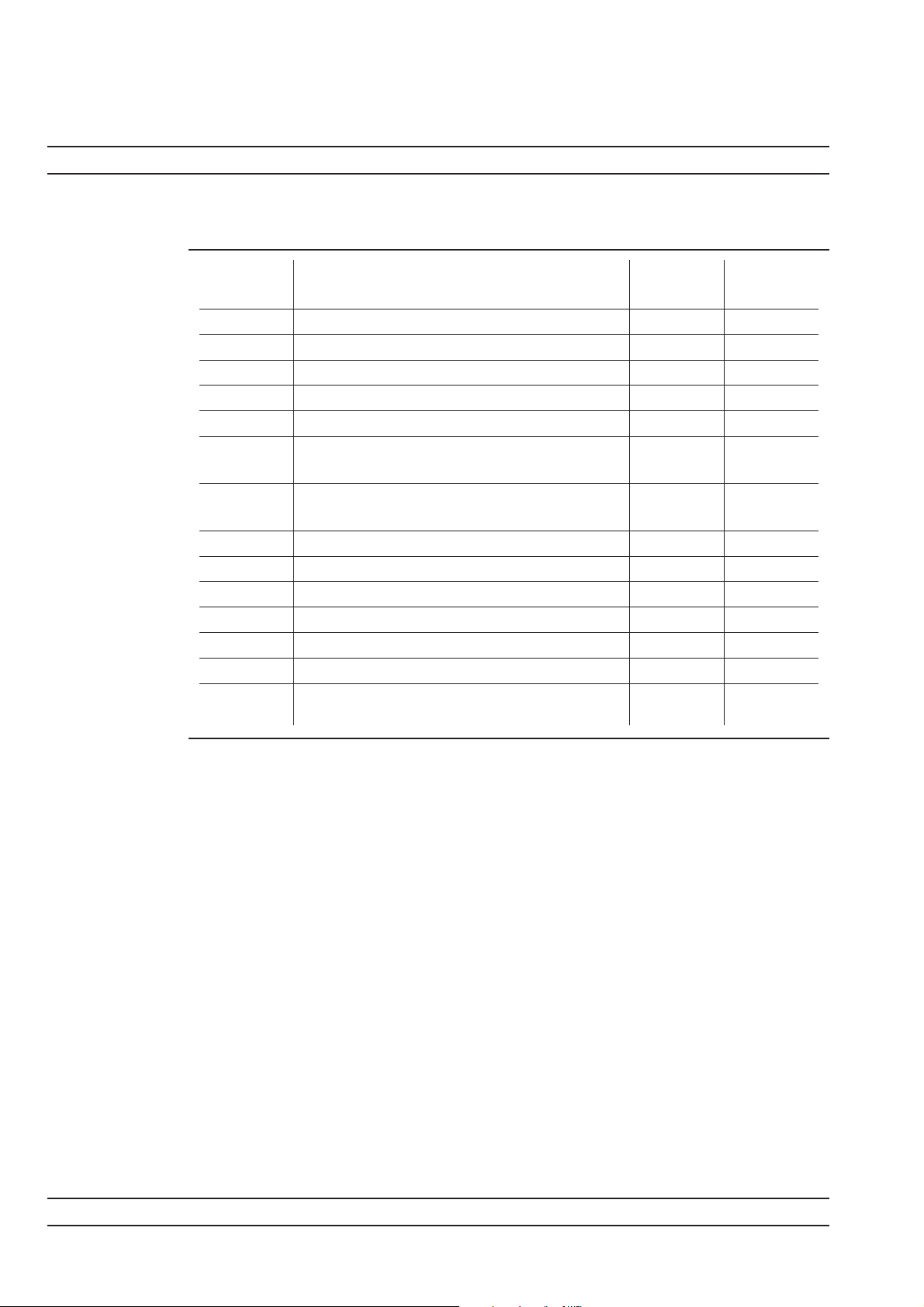

The required parts and tools are listed below:

Quantity

(each)

2

4

8

4

4

8

6

6

1

1

1

1

1

1

Description

HANDLE, PULL, CHASSIS, PLASTIC, HARDWARE

SPEED NUT

6-32, SST, WASHER, FLAT

M4, 8.00 MM, PHH, SCREW, FLAT HEAD

DECORATIVE SCREW

M3X8, POS, SST, PATCHLOCK, SCREW, METRIC,

PAN HEAD

M3X5, POS, SST, PATCHLOCK, SCREW, METRIC,

PAN HEAD

SNAP RIVET, PLASTIC

RACK MOUNT, SIDE, BRACKET

REAR SUPPORT, BRACKET, RACK MOUNT

RACK MOUNT, SUPPORT, BRACKET

BRACKET SUPPORT, BASE PANEL

FRONT FACE PLATE

POWER METER FITTED WITH RACK MOUNT TOP

AND BOTTOM COVERS

Anritsu Part

Number

783-1055

790-319

900-345

900-795

900-821

905-68 .4lbf.in

905-72 .4lbf.in

788-575

C37276

C41449

D41473

49361

49362

ML2430A

Max. Torque

[45cN m]

[45cN m]

Setting

Table 2-1 ML2430A-01 Rack Mount Kit Parts List

Tools Required: Small Phillips screw driver

Large Phillips screw driver

Small Phillips torque screw driver 10cNm to 120cNm

Assembly drawing “ML2400A/01 RACK MOUNTED LEFT

OR RIGHT OPTION”

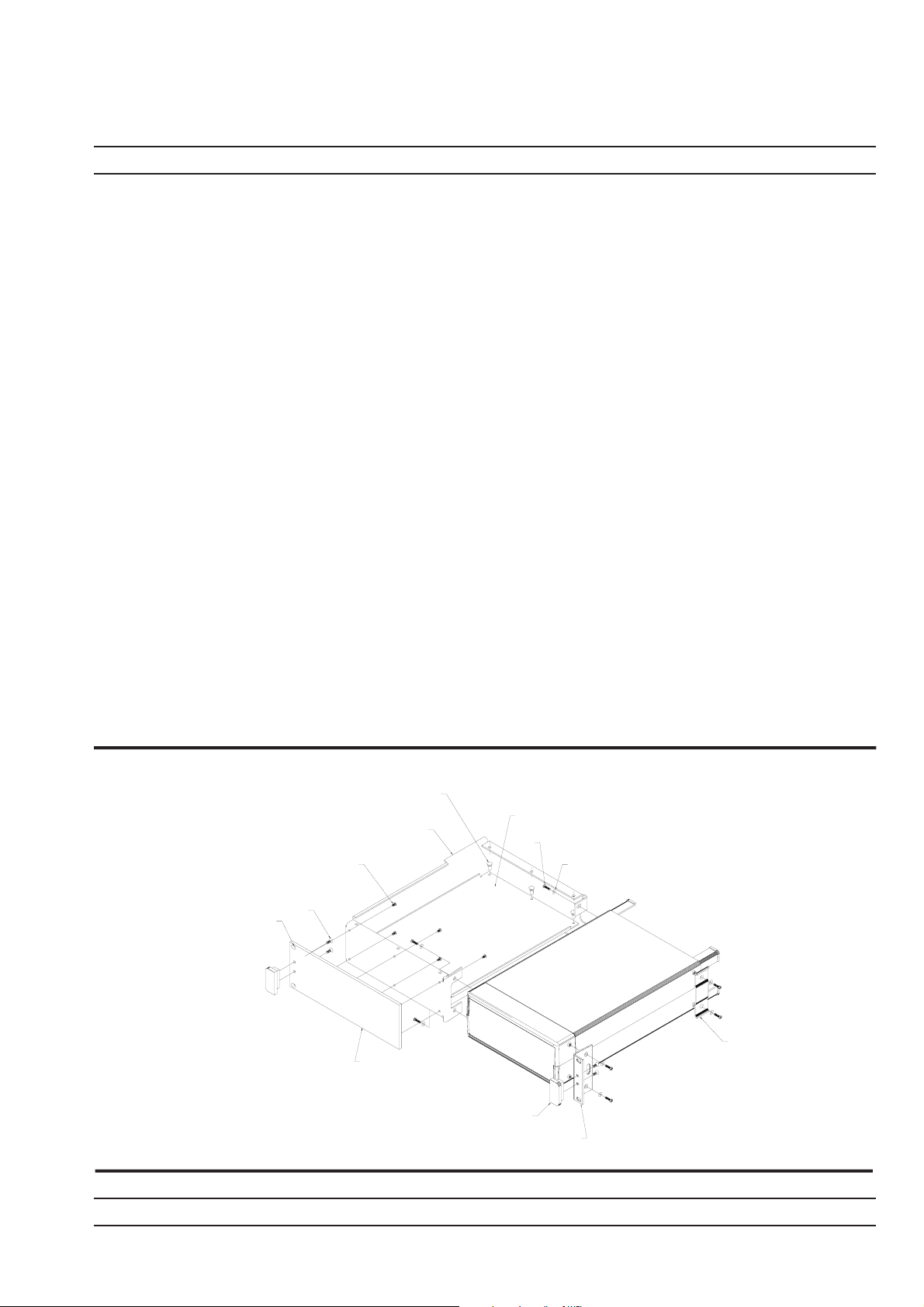

Assembly Procedure 1. Confirm the correct tools are available and the parts listed above are present. Re

fer to diagram on page 2-5 throughout this procedure.

2. Fit the two handles 783-1055 to front plate 49362 and the front rack bracket

C37376 using 4 screws 900-795.

3. Lay the large support bracket D41473 next to the Power Meter as per the assem

bly drawing. Note if the PM needs to be mounted on the left hand side of the rack,

simply lay the bracket on the PM’s right side. i.e. a mirror image of the assembly

drawing.

4.

-

-

2-4 ML2430A OM

INSTALLATION RACKMOUNTING

Locate the support bracket on the four PM case pillars.Secure with 4 screws

905-68 and 4 washers 900-345.(See max.torque settings page 2-4.)

5.Locate the front rack mounting bracket C37276 at the front of the PM on the other

side to the large support bracket with two screws 905-68 and two washers

900-345.(See max.torque settings page 2-4).

6.Locate the rear bracket C41449 at the back of the PM on the other side to the

large support bracket with two screws 905-68 and two washers 900-345.See

maximum torque settings above.Locate the rear bracket C41449 at the back of

the PM on the other side to the large support bracket with two screws 905-68 and

two washers 900-345.(See max.torque settings page 2-4).

7.Fit the front plate 49362 with 6 screws 905-72.(See max.torque settings page

2-4).

8.Position the base panel 49361 as shown in the drawing, and secure with 6 snap

rivets 788-575.

9.Fit the four speed nut 790-319 to the rack in the correct place to allow mounting

of the PM in the rack.

NOTE:

FITCOMPLETED

ASSEMBLYTORACKUSING

DECORATIVESCREW900-821

X4ANDSPEEDNUT790-319

X4IN4CORNER

POSITIONSASSHOWN

10.Slide the PM into the rack and secure with 4 decorative screws 900-821.

788-575

X6

SNAPRIVET

PRESSDOWNCENTER

900-795

X4

PINUSINGAFLATEDGE

041473

SUPPORT

BRACKET

905-72

X6

SCREW

49362

FRONTPLATE

49361

BASEPANEL

905-68

X8

900-345

X8

C41449

RACKMOUNT

BRACKET

REARSUPPORT

783-1055

HANDLE

X2

C37276

RACKMOUNT

SIDEBRACKET

ML2430AOM 2-5

RACK MOUNTING INSTALLATION

ML2400A-03 Rack

Mount Installation

This section describes the assembly procedure for fitting two ML2430A Power

Meters (PM) into a instrument rack. The PM’s must be fitted with rack mount top

and bottom covers for the rack mount kit to be fitted. The procedure involves fit

ting support brackets, two front handles, and two rear support brackets, one to

each PM. The two PM,s which are locked together can then be loaded and se

cured in the rack position desired. This assembly procedure also provides assem

bly instructions for fitting a ML2430A to a HP34401A Multimeter and a MF2412A

Microwave Frequency Counter.

The required parts and tools are listed below:

Quantity

(each)

2

4

16

4

4

16

4

4

2

2

4

1

1

1

1

2

1

1

2

2

Description

HANDLE, PULL, CHASSIS, PLASTIC,

HARDWARE

SPEED NUT

WASHER, 6-32UNC, OVERSIZE

M4, 8.00 MM, PHH, SCREW, FLAT HEAD

DECORATIVE SCREW

M3X8, POS, SST, PATCHLOCK, SCREW, METRIC, PAN HEAD

M3X6, POS, SST, PATCHLOCK, SCREW, METRIC, FLAT HEAD

WASHER, M4 SPLIT.

M4X12MM, SCREW, PAN HD

M3.5X8MM, SCREW, PAN HD

M4X10MM, SCREW, FLT HD

RACK MOUNT, SIDE BRACKET

RACK MOUNT, CENTRE, FRT, BRACKET

SPACER PLATE

RACK MOUNT, CENTER, FRONT, BRACKET

RACK MOUNT, SIDE, BRACKET

RACK MOUNT, CENTER, BRACKET

RACK MOUNT, CENTER, BRACKET

REAR SUPPORT, BRACKET, RACK MOUNT

POWER METER FITTED WITH RACK MOUNT

TOP

Anritsu Part

Number

783-1055

790-319

900-345

900-795

900-821

905-68 .4lbf.in

905-69

900-807

900-806

905-103

905-63

49415

49413

49439

C37275

C37276

C37277

C37279

C41449

Max. Torque

-

-

-

Setting

[45cN m]

Table 2-2 ML2430A-03 Rack Mount Kit Parts List

2-6 ML2430A OM

INSTALLATION RACKMOUNTING

ToolsRequired: 1 Small Phillips screw driver

1 Large Phillips screw driver

1 Small Phillips torque screw driver 10cNm to 120cNm.

1 Assembly drawing “ML2400/03 SIDE BY SIDE OPTION”

Assembly Procedure 1.Confirm the correct tools are available and the parts listed above are present.Re

fer to diagram on page 2-8throughout this procedure.

2.On the two sides of the power meter to be joined together, fit the two rear brack

ets 49413, C37279, and two front brackets C37275, C37277 using 8 screws

905-68 and 8 washers 900-345.(See max.torque settings page 2-6).

3.Slide the two PM units together and secure using 4 counter sink screws 905-69.

4.Fit the two handles 783-1055 to the front rack brackets using 4 screws 900-795.

5.Locate the two front rack brackets C37276 and 49415 at the front of each of the

PM’s, one on each side with four screws 905-68 and four washers 900-345.See

max, torque setting above.

6.Locate the two rear rack brackets C41449 at the back of each of the PM’s one on

each side with four screws 905-68 and four washers 900-345.(See max.torque

settings page 2-6).

7.Fit the four speed nuts 790-319 to the rack in the correct place to allow mounting

of the two PM’s in the rack.

8.Slide the instruments into the rack and secure with the four decorative screws

(900-821) provided.

-

-

ML2430AOM 2-7

RACK MOUNTING INSTALLATION

49415

RACKMOUNT SIDE

BRACKET ( MULTI-F IT) .

USE THIS BRACKET

WHEN FITTING A

HP34401A

905-63

x2

NOTE:

FI T C OMPLETED

ASSEMBLY TO RACK USI NG

DECO RATI VE SCREW 900- 821

X4 AN D SPEED NUT 790- 319

X4 IN 4 CORNER

POSI TIO NS AS SH OWN

905-68

x16

900-795

x4

C37275

RACKMOUNT

BRACKET

CENTER FRONT

905-69

905-63 x 4

USE THESE FIXING S WHEN

FI TTING A HP 34401A TO A

ML2430A O R MF 2412A

x4

C37277

RACKMOUNT

BRACKET

CENTER INNER

FRONT

900-345

x16

49439 X2

SPACER PLATE

USE O N A HP 34401A

ONLY, IN 2 POSITIONS

WHEN FITTING TO A

ML2430A O R MF 2412A.

USE ALSO WITH SIDE

BRACKET 49415

C37279

RACKMOUNT BRACKET

CENTER INNER REAR

783-1055

HANDLE

X2

49413

RACKMOUNT BRACKET

CENTER REAR

C37276

RACKMOUNT SIDE

BRACKET

900-807 X2

900-806 X2

USE THESE F IXIN GS

WHEN FI TTIN G A MF2412A

COU NTER T O A ML2430A

POWER METER

900-103 X2

900-807 X2

USE THESE F IXIN GS W HEN

FI TTING A HP34401A

MULTIMET ER TO A ML2430A

POWER METER

C41449

RACKMOUNT BRACKET

REAR SUPPO RT

X2

USE THESE BR ACKETS

WHEN FI TTIN G A ML2430A

TO ANO THER ML2430A

POWER METER.

The procedure for fitting a ML2430A to a HP34401A Multimeter is as fol

-

lows:

1. Fit to the ML2430A Power Meter front brackets C37276, C37275 and

rear bracket C41449 using 6 screws 905-68 and 6 washers 900-345. Do

not tighten fully at this stage, only enough to allow the bracket to slide to

its maximum position.

2. Fit the center rear bracket 49413 using 2 screws 905-63. (See max.

torque settings page 2-6).

3. Fit to the HP34401A spacer plate 49439 in 2 positions with front brack

ets C37277 and 49415 using 4 screws 905-63. (See max. torque settings

page 2-6).

4. Offer up the HP34401A to the ML2430A unit ensuring the front bracket

fixing holes ofboth units are in line. Slide the center rear bracket 49413

forward till it makes contact with the rear face of the HP34401A.

5. Gently remove the HP34401A unit and tighten the 49413 bracket fixings

in its new position. (See max. torque settings page 2-6).

-

2-8 ML2430A OM

BATTERY CHARGING, REMOVAL AND REPLACEMENT INSTALLATION

2-7

OPEN

BATTERY

CHARGING,

REMOVAL AND

REPLACEMENT

BATTERY

COVER

OPEN

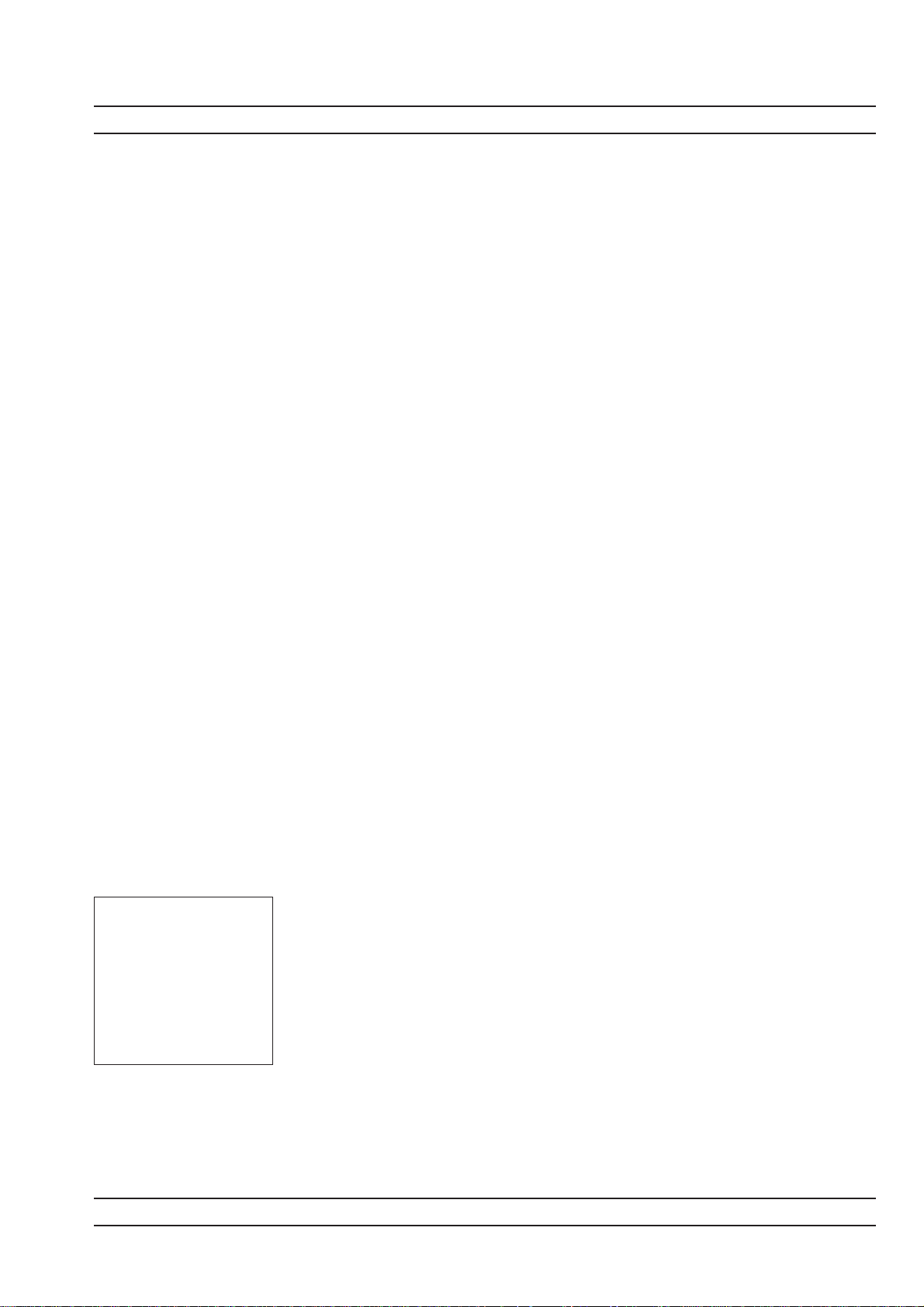

The optional ML2430A Series Power Meter battery is a 12 Volt, 3000

mA-h nickel-metal hydride (Ni-MH) multi-cell pack, located in a compart

ment on the bottom of the housing. The compartment cover is secured by

fractional turn fasteners, as shown in Figure 2-1. Rotate the fasteners ap

proximately ¼-turn counterclockwise to release the cover.

NOTE

-

ML2430A

BATTERY

-

BATTERY

COVER

FASTENERS

NOTE: Do not lubricate the battery cover fasteners.

Figure 2-1. Model ML2430A Series Battery Compartment

The battery is shipped with a partial charge only, and

should be fully charged before use.

The battery can be completely charged in about two hours with the power

meter in standby mode by selecting CHARGE from the System menu

(page 4-30). This selection is available only when the instrument is being

powered by AC line power or external DC power greater than 21 volts.

Note that the instrument will shut down during the charging cycle, and re

start automatically when the charging is completed. A series of 10 beeps

signals completion of the charge cycle.

The external battery charger (option ML2400A-13) can completely charge

the battery in 2.5 hours.

ML2430A OM 2-9

-

INSTALLATION BATTERY CHARGING, REMOVAL AND REPLACEMENT

CAUTION

To avoid excessive heat build

•

up, always remove the

ML2430A from the optional

soft sided carrying case

(D41310) before selecting fast

charging.

CAUTION

• The ML2430A battery pack

can leak, explode, or catch on

fire if it is opened, disassembled, or exposed to fire or

very high temperatures. No

attempt should be made to

open, repair, or modify the

battery package.

For optimal battery life, the battery should be fully discharged before re

charging. Repeated partial charge/discharge cycles can result in a loss of

battery capacity, recoverable by applying several “conditioning” (full

charge/discharge) cycles. If the power meter determines that a battery

conditioning cycle is required, a message stating this requirement will be

displayed on the front panel, and will remain until the battery is fully condi

tioned or replaced. A number of complete conditioning cycles may be nec

essary to fully condition a battery.

The ideal battery temperature ranges are:

Discharging: –20 to +50° C (–4 to +122° F)

q

Charging: +10 to +45° C (+50 to +113° F)

q

Note that charging will be inhibited if the temperature falls outside these

limits.

To remove the battery, first disconnect any AC or DC input line power.

Open the battery compartment as illustrated and remove the battery. Replace the battery only with an identical battery or an equivalent as

recommended by an Anritsu Service Center. Ensure that the battery is

correctly connected and that the battery compartment cover is securely

fastened.

Note that the battery is an optional component that is not used for the retention of nonvolatile memory functions, and is not required for the Power

Meter to operate from either AC or DC line sources. Serial and GPIB remote operation, however, are not available when the power meter is

running from battery power.

-

-

-

•

When a battery pack has

reached the end of its func

tional life, it should be re

turned to the nearest Anritsu

Service Center for proper re

cycling or disposal. Do not

treat a used battery as normal

waste.

-

-

-

2-10 ML2430A OM

INSTALLATION STORAGE AND SHIPMENT

2-8

STORAGE AND

SHIPMENT

Preparation for

Storage

Environmental

Requirements

Preparation for

Shipment

The following paragraphs describe preparing the power meter for storage and

shipment.

Preparing the power meter for storage consists of cleaning the unit and packing it

with moisture-absorbing desiccant crystals. Whenever the unit is to be stored for

an extended period (longer than one week), it is advisable to remove the optional

battery pack. Refer to Section 2-7, “Battery Charging, Removal and Replace

ment,” for instructions.

Store the unit in a temperature controlled environment that is maintained be

tween –40 and +70° C

(–40 to +156° F), with a maximum humidity of 90% at 40° C (104° F), noncondensing. For optimum battery life, store the battery pack at –20 to +50° C (–4

to +122° F) for short periods and –20 to +35° C (–4 to +95° F) for long term

storage.

To provide maximum protection against damage in transit, the power meter

should be repackaged in the original shipping container. If this container is no

longer available and the power meter is being returned to Anritsu for repair, advise Anritsu Customer Service Center; they will send a new shipping container

free of charge. In the event neither of these two options is possible, follow the

packaging instructions below.

Use a

Suitable

Container

Obtain a corrugated cardboard carton with a 275-pound test

strength. This carton should have inside dimensions of no less than

six inches larger than the instrument dimensions to allow for

cushioning.

-

-

Protect the

Instrume nt

Cushion the

Instrume nt

Seal the

Container

Address the Con

tainer

Wrap the instrument to protect the finish.

Cushion the instrument on all sides by tightly packing dunnage or

urethane foam between the carton and the instrument. Provide at

least three inches of dunnage on all sides.

Seal the carton using either shipping tape or an industrial stapler.

-

If the instrument is being returned to Anritsu for service, mark the

address of the appropriate Anritsu service center (Table 2-1), the

Return Materials Authorization (RMA) number, and your return ad

dress on the carton in a prominent location.

-

ML2430A OM 2-11

STORAGE AND SHIPMENT INSTALLATION

Table 2-3. ANRITSU Service Centers

UNITED STATES

ANRITSU SALES COMPANY

685 Jarvis Drive

Morgan Hill, CA 95037-2809

Telephone: (408) 776-8300

FAX: (408) 776-1744

ANRITSU SALES COMPANY

10 Kingsbridge Road

Fairfield, NJ 07004

Telephone: (201) 227-8999

FAX: (201) 575-0092

AUSTRALIA

ANRITSU PTY. LTD.

Unit 3, 170 Foster Road

Mt Waverley, VIC 3149

Australia

Telephone: 03--9558--8177

FAX: 03--9558--8255

BRAZIL

ANRITSU ELETRONICA LTD

Praia de Botafogo 440, Sala 2401

CEP 22250-040

Rio de Janeiro, RJ, Brasil

Telephone: 021-527-6922

FAX: 021-53-71-456

CANADA

ANRITSU INSTRUMENTS LTD.

215 Stafford Road, Unit 102

Nepean, Ontario K2H 9C1

Telephone: (613) 828-4090

FAX: (613) 828-5400

CHINA

ANRITSU BEIJING SERVICE CENTER

416W Beijing Fortune Building

5 Dong San Huan Bei Lu

Chao Yang Qu, Beijing 1000004, China

Telephone: 011861065909237

FAX: 011861065909236

FRANCE

ANRITSU S.A

9 Avenue du Quebec

Zone de Courtaboeuf

91951 Les Ulis Cedex

Telephone: 016-44-66-546

FAX: 016-44-61-065

GERMANY

ANRITSU GmbH

Grafenberger Allee 54-56

D-40237 Dusseldorf, Germany

Telephone: 0211-67-97-60

FAX: 0211-68-33-53

INDIA

MEERA AGENCIES (P) LTD.

Head Office

A-23 Hauz Khas

New Delhi 110 016

Telephone: 011-685-3959

FAX: 011-686-6720

ISRAEL

TECH-CENT, LTD

Haarad Street No. 7

Ramat Haahayal

Tel Aviv 69701

Telephone: 03-64-78-563

FAX: 03-64-78-334

ITALY

ANRITSU Sp.A

Roma Office

Via E. Vittorini, 129

00144 Roma EUR

Telephone: 06-50-22-666

FAX: 06-50-22-4252

JAPAN

ANRITSU CORPORATION

1800 Onna Atsugi-shi

Kanagawa-Prf. 243 Japan

Telephone: 0462-23-1111

FAX: 0462-25-8379

KOREA

ANRITSU KOREA

#901 Daeo building 26-5

Yeoido Dong, Youngdeungpo

Seoul, Korea 150010

Telephone: 02-782-7156

FAX: 02-782-4590

SINGAPORE

ANRITSU (SINGAPORE)

PTE LTD

3 Shenton Way

#24-03 Shenton House

Singapore 068805

Telephone: 226-5206

FAX: 226-5207

SOUTH AFRICA

ETESCSA

1st Floor Montrose Place

Waterfall Park

Becker Road

Midrand, South Africa

Telephone: 011-315-1366

FAX: 011-315-2175

SWEDEN

ANRITSU AB

Box 247

S-127 25 Skarholmen

Telephone: 08-74-05-840

FAX: 08-71-09-960

TAIWAN

ANRITSU CO., LTD.

8F, No. 96, Section 3

Chien Kuo N. Road

Taipei, Taiwan, R.O.C.

Telephone: 02-515-6050

FAX: 02-509-5519

UNITED KINGDOM

ANRITSU EUROPE LTD.

200 Capability Green

Luton, Bedfordshire

LU1 3LU, England

Telephone: 015-82-41-88-53

FAX: 015-82-31-303

2-12/2-12 ML2430A

Chapter 3

Connections

3-1

3-2

INTRODUCTION

FRONT PANEL

CONNECTORS

This chapter describes physical connections to the power meter on both

the front and rear panels.

The front panel connectors are illustrated in Figure 3-1. Detailed descrip

tions of each connector follow.

Calibrator

Connector

Sensor A

Connector

Sensor B

Connector

(ML2438A only)

-

Figure 3-1. Model ML2430A Series Power Meter Front Panel Connectors

Calibrator

0.0 dBm Reference

ML2430A OM 3-1

This connector is a precision female N-Type, 50 Ohm connector that provides a

precision, traceable 0.0 dBm, 50 MHz reference signal for absolute calibration of

the sensors. The calibration signal can be turned on or off through the Cal/Zero

menus (see Chapter 4, Front Panel Operation). Use only compatible 50 Ohm NType connectors.

REAR PANEL CONNECTORS CONNECTIONS

Sensor A

Connector

Sensor B

Connector

(ML2438A only)

An optional rear panel Calibrator connector is offered as an alternative (see Fig

ure 3-2). If the rear panel connector option is installed, the front panel connector

is not installed. Refer to Chapter 5, Procedures, for information on using the Cali

brator output.

This connector is a 12-pin circular precision connector to be used in conjunction

with power sensor cables. An optional rear panel Channel A connector is offered

as an alternative (see Figure 3-2). If the rear panel connector option is installed,

the front panel connector is not installed.

This connector is a 12-pin circular precision connector to be used in conjunction

with power sensor cables. An optional rear panel Channel B connector is offered

as an alternative (see Figure 3-2). If the rear panel connector option is installed,

the front panel connector is not installed.

NOTE

Only MA2400A Series sensors can be connected directly

to the ML2430A Series Power Meters. MA4700A and

MA4600A Series sensors require the MA2499A or

MA2499B Anritsu Sensor Adapter. MP-Series (10-pin)

sensors require an MA4001A or MA4002B adapter and

an MA2499B.

-

-

3-3

REAR PANEL

CONNECTORS

The Rear Panel connectors are illustrated and described in Figure 3-2.

.

3-2 ML2430A OM

OPERATION REAR PANEL CONNECTORS

GPIB/ IEEE488 Connector

Standard General Purpose Inter

face Bus connector used to con

nect through GPIB to other test

equipment and a host computer.

The ML2430A Series is compatible

with IEEE-488.1 requirements.

Refer to Chapter 6, GPIBProgram

ming for information on using

GPIB.

RS232 Serial Connector

Serial control and data output commands are

entered using the same format as the GPIB interface. Refer to Section 5-9 for more information on using Serial Remote Operation. Allows

communication with an Anritsu 68/69000-series

synthesizer in Source Sweep mode. Also allows

service access for software upgrades, etc. The

hardware handshake lines RTS and CTS are

used to control the flow of data.

Sensor Connectors

-

-

-

Parallel Printer Port

Provides an interface to a stan

dard parallel printer. Compatible

printers include the Canon BJC80,

HP 340 Deskjet, and most other

300 and 500 Series HP Deskjet

printers.

ID Number Label

The ML2430A Series ID

number is affixed to the rear

-

panel here. Please use the

complete ID number when

ordering parts or corre

sponding with the Anritsu

Customer Service depart

ment.

-

-

85-264 VAC, 47-440 Hz, 40 VA maximum. The Power Meter automati

cally configures itself for the voltage applied. Connecting AC power here

will turn the instrument on. Subsequently, the instrument can be switched

between the ON state and the STANDBY state using the front panel

ON/OFF button. The optional battery can be fast charged when AC input

voltage is applied through this connector and all other Power Meter func

tions are off.

AC Main Power Input

-

-

Chassis Ground

Used as a convenient earth ground

reference when DC line power is

applied and an optional safety

ground when operating from battery

power.

DC Power Supply Input

Used for 12-24 VDC input in the absence of AC

line power. The optional battery can be fast

charged when the DC input voltage is greater

than or equal to 21V and all other functions are

off. Fast charge must be selected from the Sys-

tem menu. The external DC Power Supply input

line is protected by an internal fuse

Alternate Sensor input connec

tors for Channels A and B. If the

rear panel optional connectors

are installed, the front panel

connectors are not installed.

Calibrator Connector

Alternate Calibrator output con

nector. If this rear panel connector

option is installed, the front panel

connector is not installed. Refer to

Chapter 5, Procedures, for infor

mation on using the Reference

Calibrator output.

Figure 3-2. ML2430A Series Rear Panel

-

Output 2

Output 1

Multi-purpose BNC connector is user

configurable for Modulation Output

-

-

(TTL), Analog Output 1 (volts/units),

or Limits Pass/fail (TTL). Supports

pass/fail testing for channels 1 and 2.

Also configurable to output a

real-time measurement signal from

sensor input A, suitable for leveling

purposes.

Multi purpose BNC connec

tor is user configurable for

Analog Output 2 (volts/units),

Blanking Zero (TTL), or Lim

its Pass/Fail (TTL). Supports

pass/fail testing for channels

1 and 2. Also configurable to

output a real-time measure

ment signal from sensor in

put B, suitable for leveling

purposes.

-

Input 1, Digital

-

Multi purpose BNC con

nector is user configur

able for Blanking Input

(used to ARM measure

-

ments in triggering

-

modes) or TTL Trigger

Input.

Input 2, Analog

Multi-purpose BNC connector used for Volts per GHz connection. Supports 0 to

-

-

-

+20V nominal input voltage with software selectable scaling. V/GHz is used for

automatic CAL FACTOR correction by applying an external voltage, scaled to fre

quency. The correct calibration factor for this frequency is automatically interpo

lated and applied when in V/GHz calibration factor mode. Different scaling may be

applied to sensor A or B allowing for measurement of frequency translation de

vices. Available simultaneously with channel A and/or B data, the data rate is as set

on the channel. The default data rate is 20 ms in DEFAULT measurement mode

(with the default settling time of 0.1%), and programmable in PROFILE operation

mode and CUSTOM measurement mode.

-

-

-

ML2430A OM 3-3/3-4

Chapter 4

Front Panel Operation

4-1

4-2

INTRODUCTION

FRONT PANEL CONTROLS

The ML2430A Series Power Meter is controlled from the front panel using the

five main menu keys; Sensor, Channel, Trigger, System, and Cal/Zero. This

chapter explains the power-on procedure and the features and functions of each

of the menus. Also refer to Appendix C for quick reference Menu Maps.

The front panel controls are shown and described in Figure 4-1. The following

sections provide more detailed explanations of the Menus and soft keys.

NOTE

Where appropriate, related GPIB commands are listed in brackets

under the menu selection. Refer to Chapter 6, GPIB Operation, for information on using GPIB commands.

NOTE

This manual is written for instruments fitted with software 3.00 or

above.

ML2430A OM 4-1

FRONT PANEL CONTROLS OPERATION

Graphic LCD with Backlight

The LCD display settings are configured in the

System menus. The backlight canbe turned on or

off, or time delayed, as required to suit ambient

conditions and battery drain. The backlight is

controlled through the System menuswhen oper

ating from the internal battery.

Numeric Keypad

Provides the means for entering

numeric data in the appropriate

menus as required for system

configuration or calibration.

Soft Keys

Soft keys select submenus, toggle selections,

control cursor position, and allow data entry. A

flashing cursor indicates when numbers can be

-

entered using the numeric keypad. Refer to the

following sections of this chapter for detailed in

formation on using the soft keys.

-

Power On /Off

Switches the power meter from STANDBY to ON, or ON to

STANDBY. Note that whenever AC power is applied, the power

meter defaults to the ON state. Subsequently, the instrument

can be switched between the ON state and the STANDBY state

using this front panel Power On /Off key.

When External or Internal (battery) DC power is first applied to

the instrument (no AC present) the power meter defaults to the

STANDBY state. It can then be switched to the ON state using

the front panel Power On /Off key.

Figure 4-1. ML2430A Series Front Panel Controls

The clear (CLR) key performs various functions depending on when it is

pressed. For example, when editing an entry in a menu, pressing the CLR key

clears the digits. If in a menu screen, pressing the CLR key returns to the pre

vious menu level.

If the limits FAIL indicator HOLD audible alarm is sounding, pressing the CLR

key stops the alarm. The FAIL indication is not affected by the clear key, and

can only be cleared by turning fail hold off.

If the GPIB box is on the screen and the system is not in a menu screen, and

the system is in local mode (menus available), and no GPIB operations are

pending, then pressing the CLR key clears the GPIB box off the screen.

Clear Key

Menu Keys

-

When pressed, the first level submenus

appear on the display directly above the

soft key for that menu function. Refer to

the following sections of this chapter for

detailed information on using the menu

keys.

4-2 ML2430A OM

OPERATION POWER-ON PROCEDURE

4-3

POWER-ON

PROCEDURE

At power-on, the power meter performs a brief power-on self test (POST).

After the POST, the instrument loads the last used configuration and dis

play settings. If a POST error occurs, information and available options

will be displayed on the screen.

The following tests are performed during the power-on self test, and also

when the GPIB *TST? command is sent:

Table 4-1 Power-on Self Test

TEST SEQUENCE POSSIBLE STATUS

Flash EPROM code checksum Pass or Fail

Flash EPROM personality data checksum Pass or Fail

Flash EPROM calibration data checksum Pass or Fail

Volatile RAM tests Pass or Fail

Non-volatile RAM checksums Pass, Fail

WARNING - Software version

changed - all non-vol stores reset

Current store failed - current store

reset

Saved store(s) failed - failed store

status changed to not saved

WARNING - Secure mode clear

memory - all non-vol stores reset

Display Pass or Fail

Keyboard Pass or Fail

During the power-on self test, only failures and warnings will be displayed

on the front panel. If all tests pass successfully, no self test information is

displayed.

Failure and warning messages that can be displayed on the front panel

are:

Flash code csum

Personality csumVolatile RAM

Cal data csum

Non-Vol RAM

Software version - this is only a warning

Current Setup

Saved Setups

Secure - Mem clear - this is only a warning

Display

Keyboard

DSP error # - followed by a 4-digit hexadecimal error code

ML2430A OM 4-3

POWER-ON PROCEDURE OPERATION

If any error, other than a DSP error, is encountered, the text:

“Press ANY key to continue”

will be displayed at the bottom of the screen. If only warnings are

encountered, nothing will be displayed at the bottom of the screen, and

the unit will continue to initialize.

If a DSP error occurs, the text:

"Restart unit. If error persists, con-tact Service Center."

is displayed and the unit will halt the self test. Make note of the hexadeci

mal error code displayed and contact your nearest Anritsu Service Center

(see Chapter 2, Table 2-1).

Self test error messages are also available over the GPIB, as a self test

status string (see STERR command, page 6-74).

-

4-4 ML2430A OM

OPERATION SENSORMENU

4-4

TheMODEselectionis

notavailableinProfile

orSourceSweep

modes.

SENSOR MENU

Setup Selects the data acquisition controls for the sensor.The followingsubmenusare

NOTE

The Sensor menu has controls for sensor data processing.

NOTE

When editing an entry in a menu, pressing theCLRkey

clears the digits.If in a menu screen, pressing theCLRkey

returns to the previous menu level.

displayed.

SENSOR

OPTION

MODE

[SENMM]

Model ML2438A (dual channel) only.Select the sensor to be con

figured.Toggles between Channel A and Channel B for all sub

menu functions.

Only displayed if a Universal Power Sensor with Option 01 is con

nected to selected input channel.This key selects between True

RMS sensor operation (for WCDMA measurements) and Fast CW

(for TDMA/Pulse measurements).

Select either Default, Modulated Average, or Custom.

Default is the sensor mode setting following system preset.It is the

ML2430A Series simplest operating mode.Measurement speed is

automatically adjusted according to sensor response times and the

user-adjustable Settling %.Triggering controls, except for GPIB trigger, are disabled when the sensor mode is set to Default.This is intended to simplify basic power measurement by avoiding the

necessity of specific trigger settings.

-

-

-

Modulated Average mode is used to stabilize the front panel digital

NOTE

Whenmeasuringmod

ulatedsignalswithadi

odesensor,ensure

ModulatedAverageis

selectedormeasure

menterrorsmayresult.

-

-

-

readout.It is a specialized sensor mode for either MA2440A or

MA2470A Series power sensors.These sensors are fast enough to

demodulate the amplitude modulation of many RF test signals.The

Mod Average sensor mode is unnecessary for thermal power

sensors.

The Custom sensor mode permits the highest measurement rates.

Trigger controls are available with this sensor mode.Trigger Delay

(the time between the ML2430A Series receipt of a valid trigger

event and the start of sample integration) and Gate Width (the du

ration of sample integration) controls are located in the Trigger

menus.

When using universal power sensors only default mode is avail

able unless OPTION is set to Fast CW.Fast CW can only be se

lected for sensors supplied with option 01.

-

-

-

ML2430AOM 4-5

SENSOR MENU OPERATION

NOTE

The HOLD selection is

not available when

System/Setup/mode is

set to Source Sweep.

In this mode, AUTO

ranging is used.

HOLD

[RGH]

Allows the operating range of the selected sensor to be set to the

desired range. Select a Range Hold value of 1 to 5, or Auto. When

in Auto, the range changes to take the best measurement automati

cally. Auto is the default setting following system preset.

Typical Range Hold values for diode sensors are:

Range 1 above approximately –12 dBm

Range 2 –10 to –27 dBm

Range 3 –25 to –42 dBm

Range 4 –40 to –57 dBm

Range 5 below –55 dBm

-

NOTE

SETTLE% affects

GPIB speed. Consider

this when optimizing

GPIB performance.

Calfactor Allows entry of the calibration correction factor. The calibration factor compen-

NOTE

Frequency or V/GHz are pre

ferred methods as the sen

sors have internal linearity

correction which varies with

frequency.

SETTLE %

[SENSTL]

Settle % per reading is available when the sensor mode is set to

Default. The settling time allows some control over the tradeoff between speed and the extent to which a measurement has settled to

its final value. A 1% settling value relates to approximately 0.04 dB,

0.5% relates to 0.02 dB and 0.25% to 0.01 dB. The default value after a system preset is 0.1%, or about 0.004 dB. Increasing the Settle percent to 1% or more will substantially increase measurement

speed.

sates for mismatch losses and effective efficiency over the frequency range of the

power sensor.

SENSOR

Model ML2438A (dual channel) only. Select the sensor to be con

figured. Toggles between Sensor A and Sensor B for all submenu

functions.

SOURCE

[CFSRC

CFVAL]

Three selections are available, Frequency, Manual, and V/GHz.

Frequency

In this mode, correction data is read from the EEPROM in the sen

sor and applied automatically to the measurement based on the us

-

-

er’s input frequency. The EEPROM correction data value nearest to

the entered frequency is used to calculate the correction applied to

the signal.

-

-

-

4-6 ML2430A OM

OPERATION SENSOR MENU

For greater accuracy, calibration factors are interpolated for settings

that are between the calibration factor data provided in the sensor

NOTE

When the MA2499B Anritsu

Sensor Adapter or the

MA2497A HP Sensor Adapter

are used, the input frequency

should be set to 50 MHz irre

spective of the measurement

frequency. Linearity correc

tion factors are not applied

when the adapters are being

used.

NOTE

You will see a live update of the Current Cal

Factor only if that sensor is being used on a

channel. For example:

If you are editing the

Cal Factor Frequency

on Sensor B, but you

only have channel 1 set

to A and channel 2 off,

you will not see the

"Current Cal Factor"

being updated.

NOTE

User defined Cal Fac

tor tables are available

for applications where

user-supplied calibra

tion points are re

-

quired. Additional cal

factor frequencies can

be entered in a user ta

ble and used in con

-

junction with the factory

table.

-

-

FREQ

[CFFRQ]

USE TABLE

[CFUSEL

CFUTBL

CFUUSE

CFUVLD]

EEPROM. For example, if calibration factors exist for 1 and 2 GHz,

then the calibration factor applied for 1.5 GHz will be a value mid

-

way between the two.

Sensor linearity adjustments for temperature are also interpolated;

If the correction factor for 1.5 GHz at 25° C is 1 dB, and for 35° C is

1.1 dB, then at 30° C a value of 1.05 dB will be used.

Manual Set

Allows manual correction of sensor data either as a percentage or

a fixed dB value. An input frequency is also required to allow the

correct linearity correction factors to be applied.

V/GHz

Most modern synthesized sources have a rear panel BNC connec

tor which outputs a voltage proportional to the synthesized frequency. The V/GHz is supplied to the rear panel input connector of

the ML2430A Series. The SETUP submenu has controls for customizing the voltage and frequency relationship.

When the Cal Factor source is set to Frequency or manual, enter

the input signal frequency in GHz or MHz. The correct sensor calibration factor is automatically interpolated and applied to the displayed power reading.

Defines which calibration factor table is to be used. Can be set to

Factory, table number 1-10, or Factory + table number. The maxi

mum number of tables available is displayed on the screen, and is

never greater than 10. If a selected table has not been used before,

the user will be prompted to CLEAR or PRESET the table, or can

cel the selection. If a table is CLEARED, all entries are cleared ex

-

cept for a single entry of 100% @ 50 MHz. If a table is PRESET the factory defined calibration factor table is copied into the speci

fied user calibration factor table. The CLEARED or PRESET table

is saved directly to the sensor. PRESET clears the ID string, while

CLEAR leaves the ID string as currently set.

The number of tables available is defined by the frequency range of

the sensor and the amount of factory calibration data stored.

Delete

Deletes the currently displayed table number.

-

ML2430A OM 4-7

SENSOR MENU OPERATION

Factory

Selects the Factory calibration factor table. Pressing Factory and

NOTE

Whichever set, or sets,

of cal factors are used,

the linearity and tem

perature correction re

mains active at all

times. Ensure the

power meter is pro

grammed with the fre

quency of the signal

being measured.

-

-

-

-

%/dB

[CFUNITS]

the +/- key on the numeric keypad allows selection of a userdefined table in addition to the factory table. This allows full factory

calibration to be active, and allows adjustments or corrections to be

entered in the user-defined table. If user table 1 was selected, the

menu would show ‘Factory+1’ and the Status box on the readout

display would show a warning ‘*’ sign on the Cal Factor line (bottom

text line in the box) to show that non-standard calibration is being

applied (CAL *F or CAL *V).

Enter

Confirms the selection.

Toggles the Current Cal factor display format from percentage to

dB, and back.

NOTE

Manual Cal Factor

method only.

EDIT

[CFUADD

CFUSAV

CFUCT

CFUPT

CFULD

CFURD

CFUID]

FACTOR

[CFCAL]

CAL

ADJUST

[CFADJ]

Edit any of the available user calibration factor tables in the sensor.

Options available are CLEAR or PRESET the table, enter a new table identity string, change or delete existing frequency/cal factor

data pairs, or enter new frequency/cal factor data pairs. All frequency/cal factor data pairs can have both frequency and calibration factor value modified, except for the data pair at 50 MHz, which

can only have its cal factor value changed. All frequency/cal factor

data pairs can be deleted, but there must always be one data pair

remaining. If there is a data pair at 50 MHz, this will be the data pair

that will remain.

The user must ensure that the maximum number of cal factor data

pairs entered into a table is not exceeded. Sensors with a maxi

mum frequency of up to 40 GHz will hold 90 pairs, while sensors

with a maximum frequency of 50 GHz will hold 110 pairs.

Once all changes have been made, the SAVE soft key saves the

changed data to the sensor. If any user cal factor data is changed

and not saved, any attempt to exit the cal factor menu or select a

new table will result in a prompt to discard or save the changes.

When the Cal Factor Source is set to Manual, the operator is ex

-

pected to enter the calibration factor value in dB or % terms.

Sets a calibration factor to be used when performing a 0 dBm cali

bration and the calibration factor source is set to 'Manual.' This

value is the only factor applied when performing a 0 dBm reference

calibration. If the sensor calibration factor source is set to V/GHz or

Frequency, the sensor internal EEPROM correction value at 50

MHz is used.

4-8 ML2430A OM

OPERATION SENSOR MENU

Averaging Sensor data averaging. The available soft keys depend upon the operating mode

NOTE

Automatic averaging

also applies an algorithm to enhance settling at low power levels

(e.g.,signal sources).

SETUP

[CVSTF

CVSPF

CVSTV

CVSPV]

Sets up the Start and Stop frequencies and voltages when Source

is set to V/GHz. This tells the ML2430A how to determine the fre

quency of the swept signal based on the applied rear panel voltage.

selected.

In Readout and Power vs. Time modes, the following soft keys appear:

SENSOR

Model ML2438A (dual channel) only. Select sensor A or B, in Power

vs. Time or Readout modes.

MODE

[AVG

AVGM]

Select OFF, AUTO, MOVING or REPEAT, in Power vs. Time or

Readout modes.

AUTOMATIC averaging uses a MOVING type of average and in

creases the amount of averaging as the noise level increases. The

display updates at approximately 100 ms intervals, however the

data is available at the full rate. The display is slowed down to prevent jitter and allow the user to follow the update.

MOVING average allows the user to manually select the amount of

averaging regardless of the signal level. The display is continually

updated while averaging.

-

-

NUMBER

[AVG

AVGM]

When selected, the following soft key becomes available:

Sweep averaging number (1 to 512).

ML2430A OM 4-9

SENSOR MENU OPERATION

REPEAT averaging also allows the user to manually select the

NOTE

GPIB trigger com

mands automatically

apply REPEAT averag

ing after TR2 com

mands to ensure ‘old’

samples are excluded

from the measurement.

However, the user

should be aware that

due to the high speed

of the meter, other in

struments in the ATE

system may not be set

tled.

-

-

-

-

-

LOW

LEVEL

[AVGLL]

amount of averaging regardless of the signal level, however the dis

play is updated only when the NUMBER of readings specified have

been taken (1-512).

NOTE

Due to the nature of this method of operation, if the power

level changes between updates, the display update will not

reflect the true input power for one measurement only.

When a channel is set to a ratio, e.g., A–B or A/B etc., the

repeat method described above only operates if all sensors

are set to the REPEAT mode.

Select OFF, LOW, MEDIUM, or HIGH, Low Level Averaging, in

Power vs. Time or Readout modes. Sets the low level averaging

window for the sensor. At resolution settings of 0.01 and 0.001 dB,

digital readouts may flicker due to the high reading rate of the

power meter. Low level averaging applies a low pass filter to postaverage data readings to achieve a more stable front panel display

without slowing down the response of the meter to larger changes

in level. The three windows for LOW, MEDIUM and HIGH low level

averaging are ± 0.01, 0.02, and 0.05 dB.

-

For example: When a LOW setting of low level averaging is applied

while stepping from 0 dBm to –1 dBm, the meter displays the final

reading within 0.01 dB with no delay. The final settling of 0.01 dB

will settle over a short subsequent period of time, leading to a stable high resolution readout.

With a HIGH setting of low level averaging, the settling window is

increased (up to approximately 0.05 dB) and the settling time is

longer.

With low level averaging OFF, the meter displays the final reading

instantly with no further settling observed. Any jitter due to noise is

reflected in the displayed reading, which may be inconvenient for

high resolution readings.

In Profile and Source sweep modes, the following soft keys appear:

STATE

[GRSWS]

Graph averaging state, ON or OFF. When set to ON, the following

additional soft keys appear:

A NUMBER

B NUMBER (ML2438A only)

[GRSWP]

[GRSWP]

Sweep averaging number (1 to 512).

4-10 ML2430A OM

OPERATION SENSOR MENU

RESET

Sweep average reset. If the graph sweep averaging state is ON,

this key resets the data points and restarts the sweep to sweep

mode.

Offset Allows an offset, in dB, to be applied to sensor data for the selected sensor.

NOTE

Use Fixed or Table to

compensate for a fixed

attenuator on a sensor

for measuring higher

power levels. A better

method is to apply a

Fixed cal factor in the

User tables as this is

then taken into account

in the Zero/Cal pro

cess.

CURSOR

[GRSWR]

Between cursor averaging ON or OFF. When ON, a digital readout

of the average power between the two cursors is displayed in the

readout area of the PROFILE display.

SENSOR

Model ML2438A (dual channel) only. Used to select the sensor to

be configured. Toggles between Channel A and Channel B for all

submenu functions.

TYPE

[OFFTYP]

Selects the type of offset to be applied:

Off

No offset applied.

Fixed

A fixed dB offset VALUE is applied to the sensor data.

Table

The tables are a set of frequency-against-dB offsets. The offset

value used from the table depends on the setting of the frequency

correction source. If the source is FREQUENCY, the entered frequency is used to calculate the offset from the table. If the fre

quency correction source is V/GHz, the frequency value calculated

from the supplied ramp input is used to calculate the offset from the

table.

-

If the frequency does not match any frequency in the table, interpo

-

lation is used to calculate the correct offset.

NOTE

If the frequency is greater than the maximum frequency in

the table, the offset value from the maximum table fre

quency is used. If the frequency is less than the minimum

frequency in the table, the offset from the minimum table

frequency is used.

VALUE

[OFFFIX

OFFVAL]

Enter the offset value (dB) when Offset TYPE is set to Fixed. Valid

range is –99.99 to +99.99.

ML2430A OM 4-11

SENSOR MENU OPERATION

TABLE

[OFFTBL

OFFTBR

OFFTBU

OFFVAL]

Select the offset table number (1-5) when Offset TYPE is set to Ta

ble. When a table is selected, additional soft keys become

available:

EDIT

This will bring up all of the selected offset table’s entries, with their

associated frequencies and offsets. Select an entry and enter the

frequency and offset using the keypad.

CLEAR

[OFFCLR]

When an offset table is selected, CLEAR will set all of the table’s

elements to zero.

Duty cycle Applies a duty cycle to the selected sensor. An offset will be applied based on the

entered value.

SENSOR

Model ML2438A (dual channel) only. Used to select the sensor to

be configured. Toggles between sensor A and sensor B for all submenu functions.

STATE

[DUTYS]

ON or OFF

-

Rng Hold

[RGH]

NOTE

Rng Hold is not available

when System|Setup|mode

is set to Source Sweep. In

this mode, AUTO ranging is

DUTY

[DUTYS]

Delete, Enter, or Cancel. An offset will be applied based on the entered value. For example, specifying a duty cycle of 50% will alter

the displayed readings by approximately +3.01 dB.

This function will toggle the sensor between holding the present operating range

and Auto Ranging. Auto Ranging automatically selects the best range to take the

measurement.

If either sensor is auto ranging, this key will force both sensors to hold their pres

ent operating ranges. If either sensor is held within an operation range, this key

will force both sensors to Auto Range.

-

4-12 ML2430A OM

OPERATION CHANNEL MENU

4-5

CHANNEL MENU

Setup The setup menu allows the user to set up the configuration of the display chan

The Channel menu controls the operation of a display channel. There are two

display channels, Channel 1 and Channel 2. Channel 1 appears at the top of the

readout display and channel 2 at the bottom. If a channel input configuration is

turned off, the remaining channel appears in the center of the screen.

NOTE

When editing an entry in a menu, pressing the CLR key

clears the digits. If in a menu screen, pressing the CLR key

returns to the previous menu level.

The Channel submenus are as follows:

-

nels. The setup parameters are:

CHANNEL

INPUT

[CHCFG]

Selects the channel to be configured. Toggles between Channel 1

and Channel 2.

This is the sensor, combination of sensors, or rear panel BNC input

that is used to calculate the measured and processed value for this

channel. For the Model ML2437A (single input) power meter, the

available options are A, External Volts, or OFF. For the ML2438A

(dual input) power meter, the options are A, B,

A – B, B – A, A/B, B/A, External Volts, or OFF.

NOTE