Page 1

Mechanic’s

Tips

Allison Transmission

Division of General Motors Corporation

P.O. B ox 894 Indianapolis, Indiana 46206-0894

Printed in U.S.A. Copyright © 1995 General Motors Corp.

i

Page 2

IT IS YOUR RESPONSIBILITY to be completely familiar with the warnings and

cautions described in this handbook. It is, however, important to understand that these

warnings and cautions are not exhaustive. Allison Transmission could not possibly

know, evaluate, and advise the service trade of all conceivable ways in which service

might be done or of the possible hazardous consequences of each way. Consequently,

Allison Transmission has not undertaken any such broad evaluation. Accordingly,

ANYONE WHO USES A SERVICE PROCEDURE OR TOOL WHICH IS NOT

RECOMMENDED BY ALLISON TRANSMISSION MUST rst be thoroughly

satised that neither personal safety nor equipment safety will be jeopardized by the

service methods selected.

Proper service and repair is important to the safe, reliable operation of the equipment.

The service procedures recommended by Allison Transmission and described in this

handbook are effective methods for performing service operations. Some of these

service operations require the use of tools specially designed for the purpose. The

special tools should be used when and as recommended.

Three types of headings are used in this manual to attract your attention. These

warnings and cautions advise of specic methods or actions that can result in personal

injury, damage to the equipment, or cause the equipment to become unsafe.

WARNING: A warning is used when an operating procedure, practice,

etc., if not correctly followed, could result in personal injury or loss of life.

CAUTION: A caution is used when an operating procedure,

practice, etc., if not strictly observed, could result in damage to or

destruction of equipment.

NOTE:

A note is used when an operating procedure, practice, etc., is

essential to highlight.

ii

Page 3

Paragraph Description Page

1–1. Periodic Inspection and Care . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1–2. Importance of Proper Transmission Fluid Level . . . . . . . . . . . . 1

1–3. Transmission Fluid Check Procedures. . . . . . . . . . . . . . . . . . . . 2

1–4. Keeping Transmission Fluid Clean . . . . . . . . . . . . . . . . . . . . . . 5

1–5. Automatic Transmission Fluid Recommendations . . . . . . . . . . 5

1–6. Transmission Fluid and Filter Change Intervals . . . . . . . . . . . . 6

1–7. Fluid Temperatures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1–8. High-Efficiency, Main-Pressure External Filter Change. . . . . . 8

1–9. Transmission Fluid Contamination . . . . . . . . . . . . . . . . . . . . . . 8

1–10. Transmission Fluid and Filter Change Procedure . . . . . . . . . . . 9

1–11. Auxiliary Filter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1–12. Breather . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1–13. Transmission Stall Test and Neutral Cool-Down Check . . . . . . 10

2–1. Draining Transmission. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2–2. Disconnecting Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2–3. Uncoupling From Driveline, Engine, and Vehicle. . . . . . . . . . . 14

2–4. Removing the Transmission. . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2–5. Removing Input and Output Flanges or Yokes . . . . . . . . . . . . . 14

2–6. Rebuild, Overhaul Instructions . . . . . . . . . . . . . . . . . . . . . . . . . 15

3–1. Checking Input Components . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3–2. Installing Output Flange and Input Flange

(Remote-Mounted Transmission) . . . . . . . . . . . . . . . . . . . . . . . 16

3–3. Installing PTO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3–4. Installing Transmission Fill Tube and Seal . . . . . . . . . . . . . . . . 18

3–5. Checking Plugs, Openings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

iii

Page 4

Paragraph Description Page

4–1. Engine, Transmission Adaptation Requirements. . . . . . . . . . . . 19

4–2. Checking Flexplate Drive Assembly . . . . . . . . . . . . . . . . . . . . . 20

4–3. Checking Input Drive Components

(Remote-Mounted Transmissions). . . . . . . . . . . . . . . . . . . . . . . 20

4–4. Chassis and Driveline Inspection . . . . . . . . . . . . . . . . . . . . . . . . 22

4–5. Cooler, Filter, and Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4–6. Checking Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5–1. Handling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5–2. Mounting to Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5–3. Installing Transmission Mounting Components . . . . . . . . . . . . 28

5–4. Coupling to Driveline. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5–5. Coupling to Engine (Remote-Mounted Transmission) . . . . . . . 28

5–6. Connecting Input Retarder Control . . . . . . . . . . . . . . . . . . . . . . 29

5–7. Connecting Output Retarder Control . . . . . . . . . . . . . . . . . . . . . 29

5–8. Connecting Power Takeoff Controls . . . . . . . . . . . . . . . . . . . . . 29

5–9. Connecting Parking Brake Control . . . . . . . . . . . . . . . . . . . . . . 30

5–10. Connecting Cooler, Filter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

5–11. Installing Auxiliary Filter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

5–12. Connecting Speedometer Drive . . . . . . . . . . . . . . . . . . . . . . . . . 30

5–13. Installing Temperature and Pressure Sensors,

Connecting Electrical Components . . . . . . . . . . . . . . . . . . . . . . 32

5–14. Filling the Hydraulic System . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6–1. Installation Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

6–2. Road Test and Vehicle Operation Checklist . . . . . . . . . . . . . . . 35

7–1. Owner Assistance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

7–2. Service Literature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

iv

Page 5

This handbook is a mechanic’s reference for removing, installing, and maintaining

the HT, HTB, CL(B)T 700 Commercial Electronic Control Series Automatic

Transmissions. All features of the transmission and vehicle involved in installation

procedures are discussed. The information presented will help the mechanic to

remove, install, and maintain the transmission in a manner that assures satisfactory

operation and long service life. For additional detailed information, refer to HT, HTB

700 Electronic Control Series Service Manual SM2004EN or CL(B)T 700 Series

Service Manual SM1314EN and CL(B)T 755 Electronic Control Series Service

Manual Supplement SM1992EN. Troubleshooting the electronic control system is

presented in Troubleshooting Manual TS2712EN.

DEXRON® is a registered trademark of General Motor Corporation.

Loctite® is a registered trademark of the Loctite Corporation.

Teon® is a registered trademark of the DuPont Corporation.

Pro-Link® is a registered trademark of Micro Processor Systems, Inc.

v

Page 6

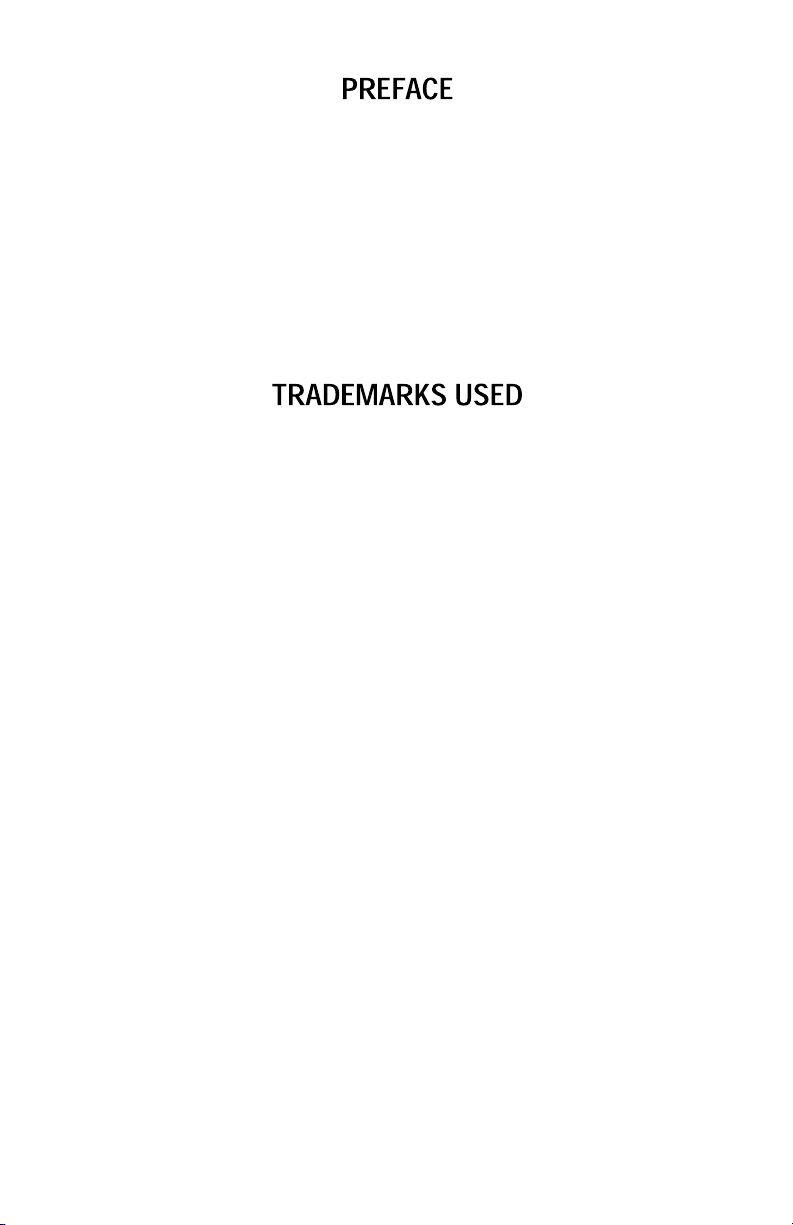

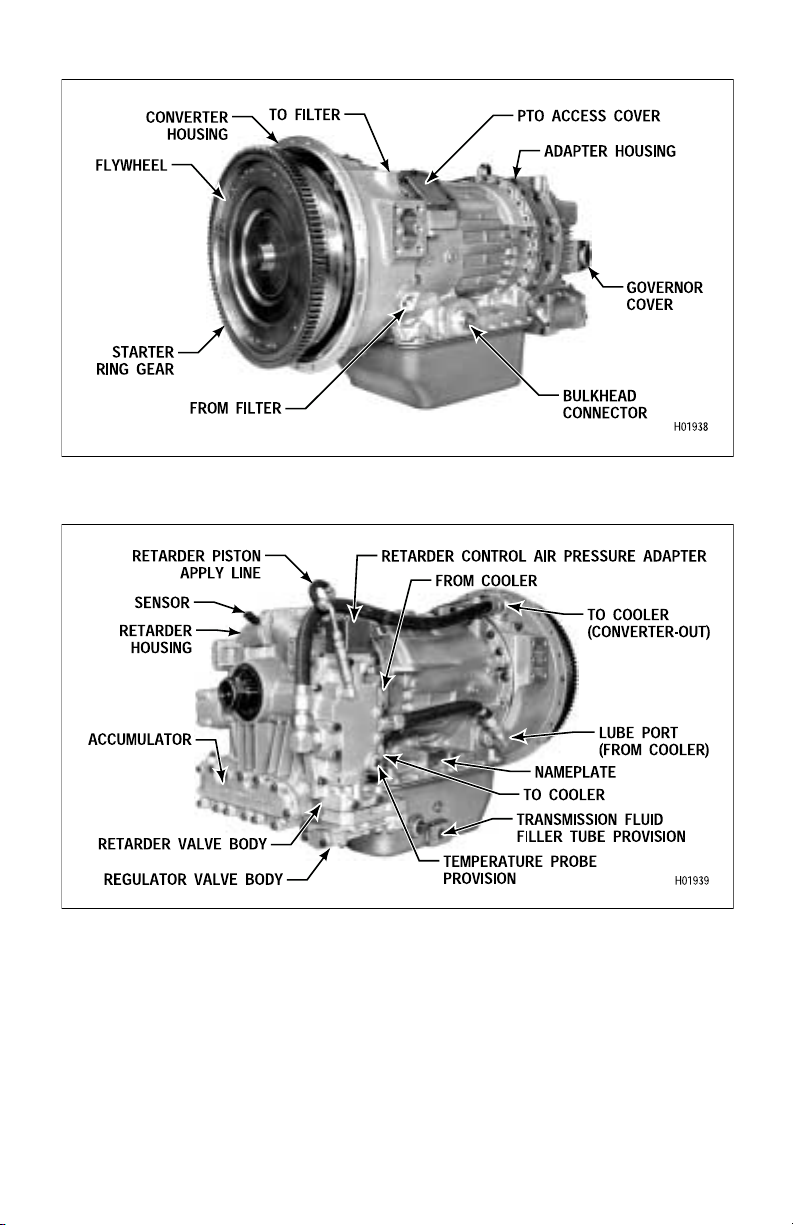

Model HT 741, 748 Transmission — Left-Rear View

Model HT 741, 748 Transmission — Right-Front View

vi

Page 7

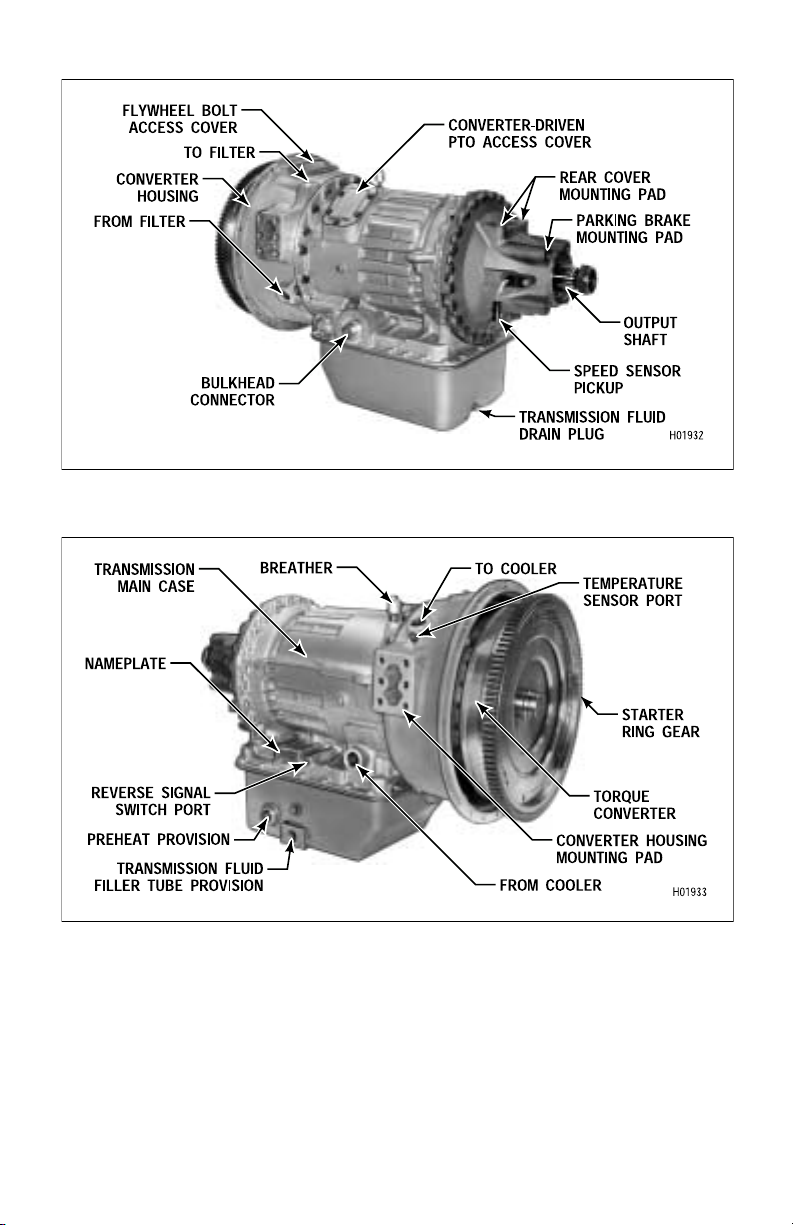

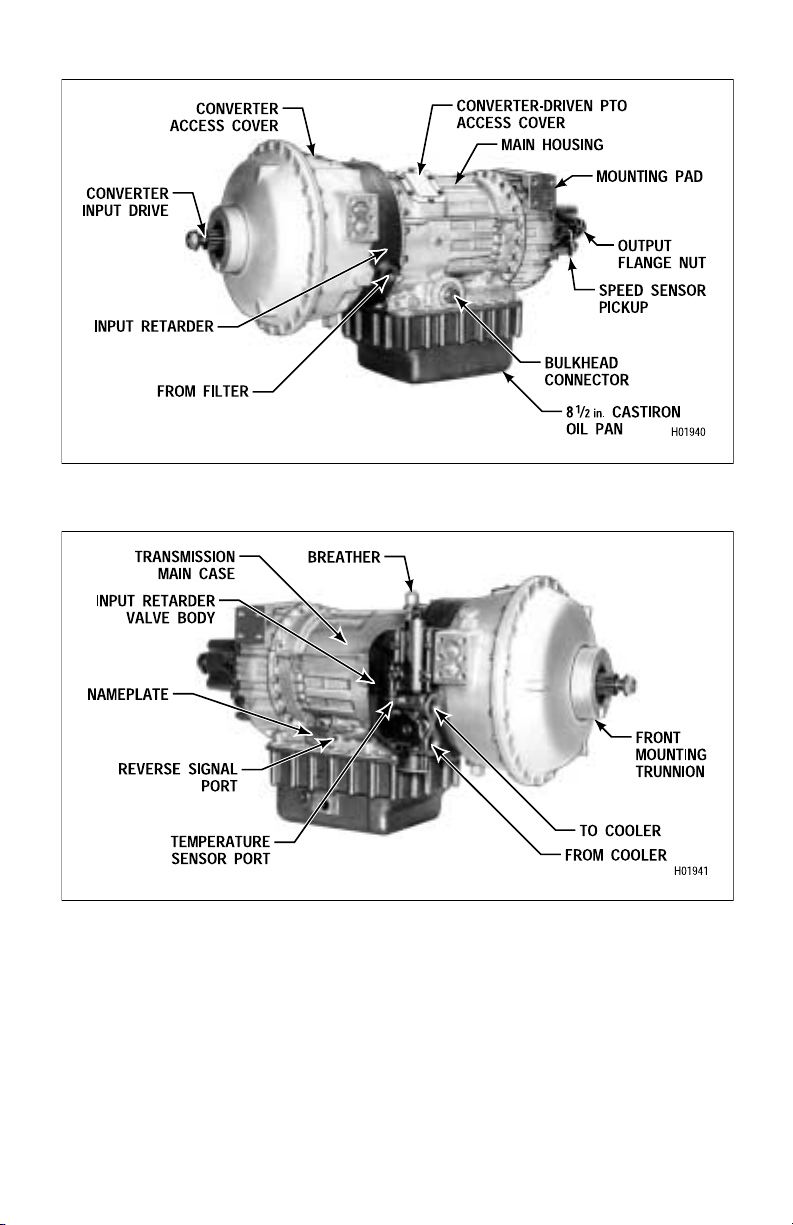

Model HT 755CR Transmission — Left-Rear View

Model HT 755CR Transmission — Right-Front View

vii

Page 8

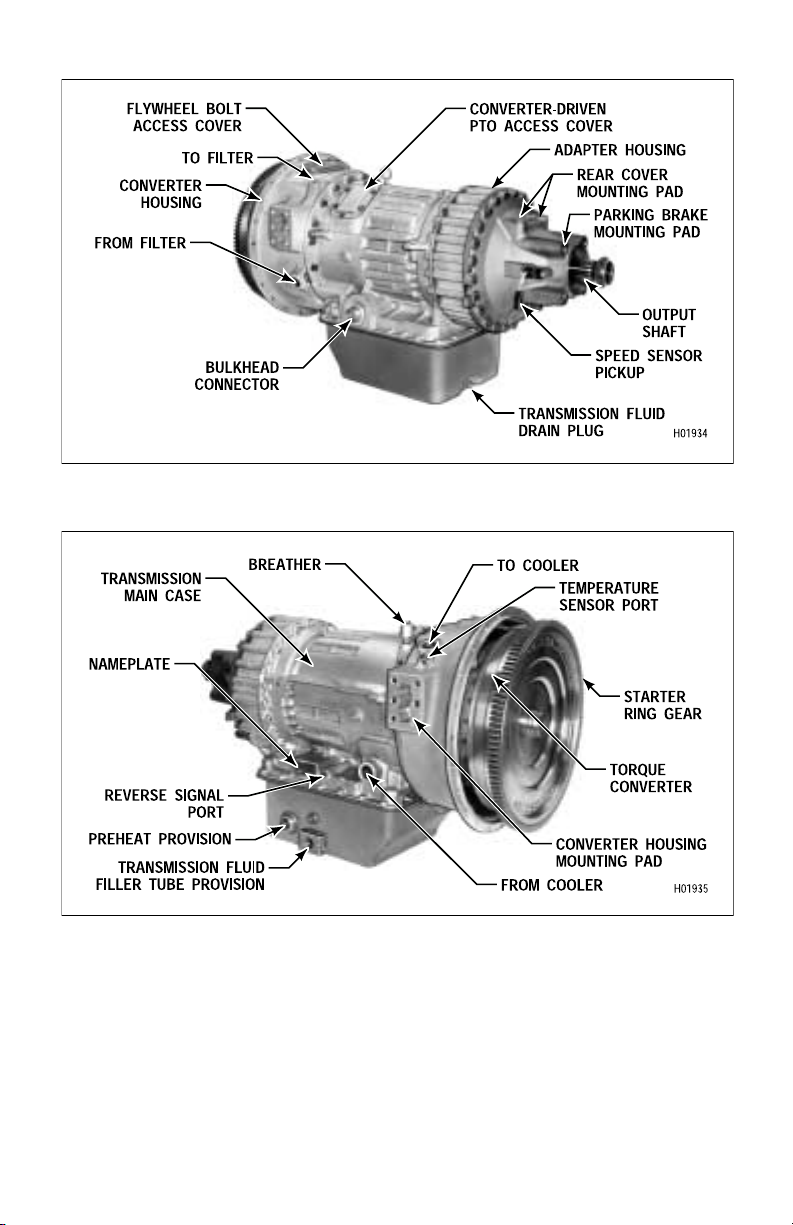

Model HT 755DR Transmission — Left-Rear View (With Input Retarder)

Model HT 755DR Transmission — Right-Front View (With Input Retarder)

viii

Page 9

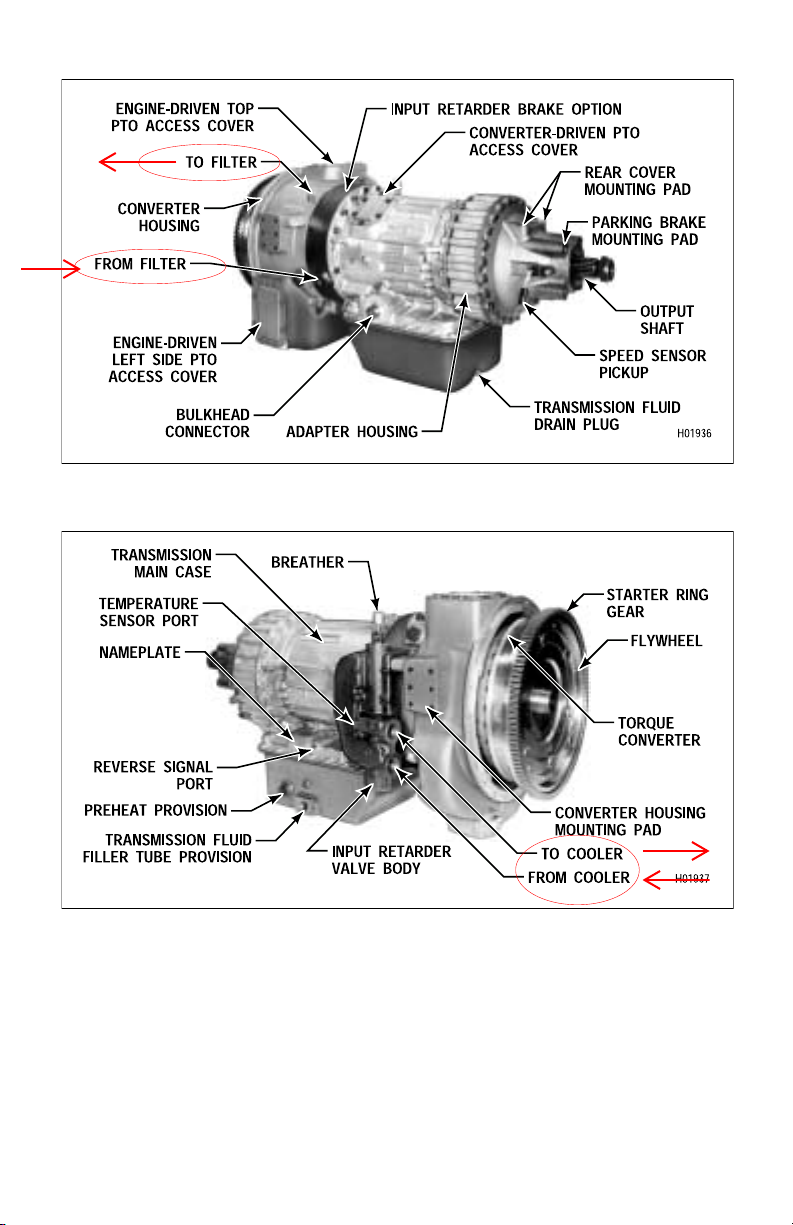

Model HTB 748 Transmission — Left-Front View (With Output Retarder)

Model HTB 748 Transmission — Right-Rear View (With Output Retarder)

ix

Page 10

Model CLBT 755 Transmission — Left-Front View

Model CLBT 755 Transmission — Right-Front View

x

Page 11

SECTION

I

Clean and inspect the exterior of the transmission at regular intervals. Severity of

service and operating conditions determine the frequency of these inspections.

Inspect the transmission for:

• loose bolts — transmission and mounting components

• uid leaks — repair immediately

• loose, dirty, or improperly adjusted throttle sensor linkage

• damaged or loose hoses

• worn, frayed, or improperly routed electrical harnesses

• worn or out-of-phase driveline U-joints and slip ttings

CAUTION: When welding on the vehicle:

• DO NOT WELD on the vehicle without disconnecting from

the ECU all control system wiring harness connectors.

• DO NOT WELD on the vehicle without disconnecting ECU

battery power and ground leads.

• DO NOT WELD on any control components.

• DO NOT CONNECT welding cables to any control components.

A label describing on-vehicle welding precautions is available from your authorized

Allison service dealer and should be installed in a conspicuous place. A vehicle used

in a vocation that requires frequent modications or repairs involving welding must

have an on-vehicle welding label.

Because the transmission uid cools, lubricates, and transmits hydraulic

power, it is important that the proper uid level be maintained at all times.

If the uid level is too low, the torque converter and clutches will not

receive an adequate supply of transmission uid, and the transmission

will overheat. If the uid level is too high, the uid aerates — causing the transmission

to shift erratically and overheat. Fluid may be expelled through the breather or

dipstick tube when the uid level is too high.

1

Page 12

A severely low uid level causes the Allison Transmission Electronic Control to do

two things automatically —

• Turn on the CHECK TRANS light

• Prevent upshifting into the highest range

When the uid level is corrected, the transmission will return to normal operation.

Do not use the Electronic Control to replace regular uid level checks. Check the

level at the intervals specied in your vehicle service instructions.

WARNING: Take the following precautions so that unexpected,

possible sudden vehicle movement is avoided. Whenever it becomes

necessary to leave the vehicle, even momentarily, while the engine is

running, place the transmission shift selector in Neutral, set the parking brake and/or emergency brakes and chock the wheels.

a. Fluid Check Procedure.

Clean all dirt from around the end of the ll tube before removing the

dipstick. Do not allow the dirt or any foreign matter to enter the

transmission. Dirt or foreign matter may cause undue wear of the

transmission parts, make valves stick, and clog passages. Check the

uid level, manually, using the following procedure and record the level in your

maintenance log. To perform the uid level check, the engine must be running at

idle speed and the transmission must be in N (Neutral).

Add transmission uid to the transmission through the ll tube opening. Be sure to

use proper transmission uid and uid containers as discussed in Sections 1–4 and

1–5. Refer to Table 1–1 for approximate transmission uid capacity.

Table 1–1. Transmission Fluid Capacity

Application U.S. Quarts Liters

41⁄2 inch (114 mm) oil pan 34 32

6 inch (152 mm) oil pan 30 28.5

7 inch (178 mm) oil pan 30 28.5

81⁄2 inch (215 mm) oil pan 43 41

NOTE: Does not include external circuits.

2

Page 13

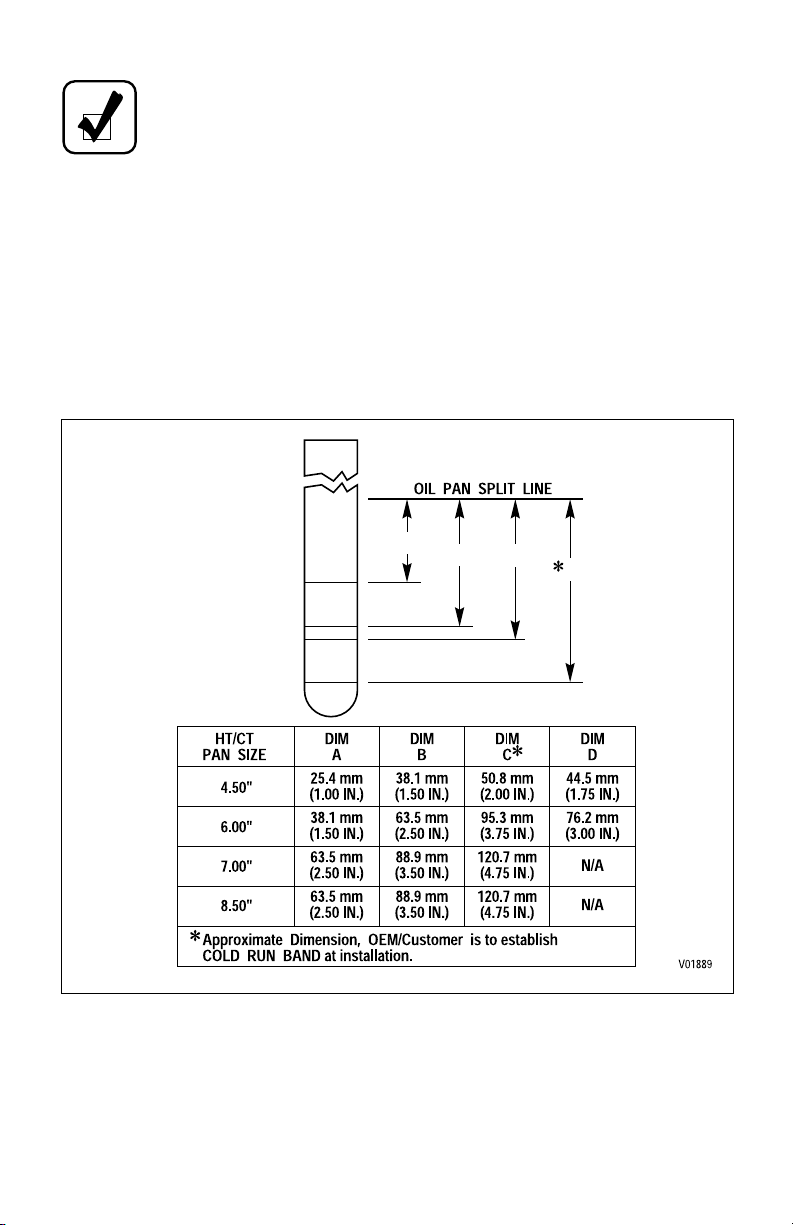

b. Cold Check.

NOTE:

The purpose of the Cold Check is to determine if the transmission

has enough fluid to be safely operated until a hot check can be

made.

• Park the vehicle on a level surface. Apply the parking brake, and chock the

wheels.

CAUTION: The uid level rises as uid temperature increases.

DO NOT ll above the “COLD RUN” band if the transmission uid is

below normal operating temperatures.

• Run the engine for at least one minute. Shift to D (Drive) and then to

R (Reverse) to clear the hydraulic circuits of air. Then shift to N (Neutral) and

allow the engine to idle (500–800 rpm).

• Insert the dipstick into the tube and remove. Check the uid level reading.

Repeat the check procedure to verify the reading.

• If the uid level is within the “COLD RUN” band, the transmission may be

operated until the uid is hot enough to perform a “HOT RUN” check. If the

uid level is not within the “COLD RUN” band, add or drain as necessary to

bring it to the middle of the “COLD RUN” band.

• Perform a hot check as soon as the normal operating temperature of

160–200°F (71–93°C) is reached.

c. Hot Check.

CAUTION: The transmission uid must be hot to ensure an accurate

check. The uid level rises as temperature increases.

• Operate the transmission in D (Drive) until normal operating temperature is

reached:

160–200°F (71–93°C) sump temperature

180–220°F (82–104°C) converter-out temperature

• Park the vehicle on a level surface and shift to N (Neutral). Apply the parking

brake, and chock the wheels. Allow the engine to idle.

• With the engine running, remove the dipstick from the tube and wipe it clean.

• Insert the dipstick into the tube and remove. Check uid level reading. Repeat

the check procedure to verify the reading.

3

Page 14

NOTE:

Safe operating level is within the “HOT RUN” band on the

dipstick, Figure 1–1.

• If the uid level is not within the “HOT RUN” band, add or drain as necessary

to bring the uid level to within the “HOT RUN” band.

d. Consistency of Readings.

• Always check the uid level at least twice and with the engine running.

Consistency is important to maintain accuracy of the reading. If inconsistent

reading persists, check the transmission breather to be sure it is clean and

unclogged.

A

B

D

C

HOT

RUN

RUN

COLD

Figure 1–1. Typical Dipstick Markings

4

Page 15

CAUTION: Containers or llers that have been used for any antifreeze or engine coolant solution must not be used for the transmission uid. Antifreeze and coolant solutions contain ethylene glycol

which, if introduced into the transmission, can cause the clutch plates

to fail.

Transmission uid must be handled in clean containers, llers, etc., to prevent

foreign material from entering the transmission. Clean around the ller tube before

removing the dipstick. Lay the dipstick in a clean place while lling the

transmission.

• Hydraulic uids (oils) used in the transmission are important inuences on

transmission performance, reliability and durability. DEXRON®-III uid is

recommended for light-duty applications. Type C-4 uids are recommended

for severe-duty applications.

• Some DEXRON®-III uids are also qualied as Type C-4 uids. To ensure the

uid is qualied for use in Allison transmissions, check for a DEXRON®-III or

C-4 uid license, or approval numbers on the container, or consult the lubricant

manufacturer. Consult your Allison Transmission dealer or distributor before

using other uid types; uid types such as Type F, and universal farm uids may

or may not be properly qualied for use in your Allison transmission.

CAUTION: Disregarding minimum uid temperature limits can

result in transmission malfunction or reduced transmission life.

• When choosing the optimum viscosity grade of uid to use, duty cycle,

preheat capabilities, and/or geographical location must be taken into

consideration. Table 1–2 lists the minimum uid temperatures at which the

transmission may be safely operated. Preheat with auxiliary heating

equipment or by running the vehicle with the transmission in N (Neutral) for a

minimum of 20 minutes before attempting range operation.

5

Page 16

Table 1–2. Operating Temperature Requirements for Transmission Fluid

Ambient Temperature Below

Viscosity Grade

DEXRON®-III

Which Preheat Is Required

Fahrenheit

–17 –27

Celsius

SAE 10W –4 –20

SAE 15W-40 5 –15

SAE 30 32 0

SAE 40 50 10

Ref. 13-TR-90.

a. Frequency.

Transmission uid and lter change frequency is determined by severity of

transmission service and by the lter equipment installed. Table 1–3 is a

general guide. More frequent changes may be required when operating

conditions create high levels of contamination or overheating.

Table 1–3. Transmission Fluid and Filter Change Intervals

Internal Sump

Fluid Change Interval

and Governor

Filter

50,000 miles (80 000 km)

or 12 months or 1200

hours*

* Whichever occurs rst.

** An Allison high efciency lter may be used until the change lter light indicates it is

contaminated or until it has been in use for three years, whichever occurs rst. No mileage

restrictions apply.

b. Abnormal Conditions. Transmission uid must be changed whenever there

At overhaul After rst 5000 miles (8 000 km) and

Standard Main Pressure

External Filter**

at each 25,000 miles (40 000 km) or

6 months or 600 hours, thereafter*

is evidence of dirt or a high temperature condition. A high temperature condition is

indicated by the transmission uid being discolored or having a strong odor, or by

uid analysis. Local conditions, severity of operation, or duty cycle require more or

less frequent uid or lter change intervals.

6

Page 17

c. Fluid Analysis. Transmission protection and uid change intervals can be

optimized by monitoring uid oxidation according to the tests and limits shown in the

Table 1–4. Consult your telephone directory for uid analysis rms. To ensure consistent

and accurate uid analysis, select only one uid analysis rm. Refer to

the latest edition of GN2055EN, Technician’s Guide for Automatic Transmission Fluids.

Table 1–4. Fluid Oxidation Measurement Limits

Measurement Limit

Viscosity ±25% change from new uid

Carbonyl absorbance +0.3 A*/0.1 mm change from new uid

Total acid number +3.0 change from new uid

Solids 2% by volume maximum

* Note: A = Absorbance units.

• If the sensor is located in the converter housing or input retarder valve, the

critical temperatures are listed in the converter-out column. If the sensor is

located in some other area, refer to the vehicle manual for the critical

temperatures. If the maximum uid temperature is reached, follow this

procedure:

— Stop the vehicle and shift the transmission into N (Neutral) and

operate the engine at 1500 rpm to reduce the transmission uid

temperature.

— If the transmission uid does not cool in approximately 30 seconds,

or if it continues to overheat after operation is continued, stop the

vehicle and engine and locate the problem.

Table 1–5. Fluid Temperatures

Condition Converter-Out

Converter Operation — CLBT 700 Series

— HT 700 Series

275˚F (135˚C) max

300˚F (149˚C) max

Retarder Operation — Intermittent 330˚F (166˚C) max

Lockup Operation 250˚F (121˚C) max

Normal Operation 180–220˚F (82–105˚C)

7

Page 18

Allison high-efciency external lters, which have a change lter indicator, do not

need to be changed when the transmission uid is changed unless restriction is

indicated. There is no mileage limitation with the use of Allison high-efciency lters.

An Allison high-efciency external lter element must be changed if the engine

and transmission are at operating temperature (over 160°F; 71°C) and the Change

Filter light is illuminated for any length of time or the element has not been

changed for three years, whichever occurs rst.

a. Examine At Fluid Change. At each transmission uid change, examine the uid

that is drained for evidence of dirt or water. A normal amount of condensation will

emulsify in the uid during operation of the transmission. However, if there is evidence of water, check the cooler (heat exchanger) for leakage between the water and

uid areas. Fluid in the water side of the cooler (heat exchanger) is another sign of

leakage. This, however, may indicate leakage from the engine oil system.

b. Metal Particles.

CAUTION: If excessive metal contamination has occurred, replace

the cooler and all bearings within the transmission.

Metal particles in the transmission uid or on the magnetic drain plug (except for

the minute particles normally trapped in the lter) indicate damage has occurred in

the transmission. When these particles are found in the sump, the transmission must

be disassembled and closely inspected to nd the source. Metal contamination will

require complete disassembly of the transmission and cleaning of all internal and

external circuits, cooler, and all other areas where the particles could lodge. During

the repair of a major internal failure of a transmission, it should be dismantled into

as many serviceable detail parts as possible and thoroughly cleaned. Do not

disassemble the unit just to the problem area.

c. Coolant Leakage.

• The presence of ethylene glycol coolant in the transmission uid is

detrimental to the reliability and durability of the internal components.

Ethylene glycol has a deteriorating effect on friction-faced clutch plates and

nonmetallic components (seals, gasket, etc.) and on highly loaded steel parts,

such as bearings and gears, due to reduced lubricity of the uid.

8

Page 19

d. If the presence of ethylene glycol in the uid is suspected, immediately perform

a verication test. A Gly-Tek test kit is available and is a quick and easy method to

determine the presence of glycol. If glycol is found, disassemble and inspect the

transmission, and remove all traces of coolant and varnish deposits resulting from

coolant contamination. Replace all seals, gaskets, and friction-faced clutch plates.

Repair or replace the cooler prior to installation of the new or rebuilt transmission.

NOTE:

Do not drain the transmission fluid if only filters are being

replaced.

a. Drain Fluid.

• Drain the uid when the transmission is at operating temperature —

160–200°F (71–93°C). Hot uid ows quicker and drains thoroughly.

• Remove the drain plug from the oil pan and allow the uid to drain into

a suitable container.

• Examine the uid as described in the Section 1–8.

b. Replace Filters.

• Refer to the latest edition of the HT 700 Series Service Manual SM2004EN

for complete procedures for replacement of the lter.

• Remove the oil pan, and replace the old lter with the new one.

c. Rell Transmission. The amount of rell uid is less than the amount used

for the initial ll. Fluid remains in the external circuits and transmission cavities

after draining the transmission. After rell, check the uid level using the procedure

described in Section 1–3.

• If a condition occurs that introduces debris into the transmission hydraulic

system, a complete cleanup of the cooler and lines is required.

• Because repeated cleaning and ushing may not remove all debris, install an

auxiliary lter in the cooler-out circuit (models without an output retarder), or

in the lubrication circuit (models with an output retarder). This

recommendation applies whether the transmission is overhauled or replaced

by a new or rebuilt unit.

• If any doubt exists about the cleanup of the cooler, replace the cooler.

9

Page 20

• The auxiliary lter must have at least a 40-micron lter element or ner and a

maximum lter pressure drop of 2 psi (14 kPa) at 15 gpm (57 liters/minute) at

180˚F (82˚C). The maximum external circuit pressure drop must not exceed

30 psi (207 kPa) at 15 gpm (57 liters/minute) at operating temperature, in

D (Drive) at full throttle stall.

• The following auxiliary lters are recommended:

Table 1–6. Auxiliary Filter Recommendations

Filter Assembly Filter Element

Allison 29510921* Allison 29510918*

AC PM 13-16 PF 897

AC PM 16-1 PF141

FX 11583 HF6520

Fram HP 1-1 HP 1 or AC HD 222

Purolator OF-15C-1 OF-2C-1

Purolator 20-10 PER-20

* High-efciency lter and element are available from your authorized Allison distributor.

Ref: SIL 12-TR-93 (latest revision)

a. Location and Purpose. The breather is located on top of the transmission hous-

ing. The breather prevents air pressure buildup within the transmission and its passage must be kept clean and open.

b. Maintenance. The amount of dust and dirt encountered will determine the fre-

quency of breather cleaning. Use care when cleaning the transmission. DO NOT

SPRAY STEAM, WATER, OR CLEANING SOLUTION DIRECTLY AT THE

BREATHER. Spraying steam, water, or cleaning solution directly at the breather

can force the water or cleaning solution into the transmission.

c. Replacement. Always use a wrench of the proper size to remove or replace the

breather. Pliers or a pipe wrench can crush or damage the stem and produce metal chips

which could enter the transmission. Tighten the breather to 9–12 lb ft (12–16 N·m).

WARNING: When conducting a transmission stall test, the vehicle

must be prevented from moving. Apply the parking brake and service

brakes and block the vehicle securely. Warn personnel to keep clear of

the vehicle and its travel path. Failure to do so can cause serious injury.

10

Page 21

a. Purpose.

The stall test provides a method for determining if the malfunction

is in the engine or in the transmission when a vehicle is not performing

satisfactorily.

The neutral cool-down check utilizes the two-minute cooling period on the stall test

to gather transmission uid temperature data for troubleshooting reference.

b. Transmission Stall Test Procedure. The engine stall point (rpm) under load

is compared to the engine manufacturer’s specied rpm for the stall test.

NOTE:

The engine manufacturer’s test data must be available for the

stall test. This data can be obtained from the engine

manufacturer, or from your equipment dealer or distributor.

• Connect a tachometer of known accuracy to the engine and install a

temperature probe into the converter-out (to cooler) line. Bring the

transmission to the normal operating temperature 160–200°F (71–93°C).

CAUTION: Do not attempt to stall test any transmission in reverse

range. Do not attempt to stall test the 755DR Series transmission in

rst (low) gear. The torque produced in that gear can damage the

vehicle driveline.

• On the 755 Series transmissions, shift the selector to D (Drive) range or utilize

the optional stall check feature. On the 741 or 748 Series, shift to any forward

range.

CAUTION: Never maintain the stall condition for more than 30

seconds at any one time because of the rapid rise in transmission uid

temperature. Do not let the converter-out temperature exceed 300°F

(149°C). Do not rely on converter-out temperature to limit stall

duration. During stall conditions, internal temperatures rise much

faster than converter-out temperature. If the stall test is repeated, do

not let the engine overheat.

• With the vehicle blocked, parking brake and service brake applied, hold the

engine at wide-open throttle. When the converter-out temperature reaches

a minimum of 255°F (124°C), record the engine speed.

• Reduce engine speed to idle and shift to N (Neutral).

11

Page 22

c. Neutral Cool-Down Check Procedure. The neutral cool-down check determines

if the transmission uid cools following an engine load condition. Perform this check

immediately after the engine speed has been recorded in the stall test.

• Record the converter-out temperature.

• With the transmission remaining in Neutral, run the engine at 1200–1500 rpm

for two minutes to cool the transmission uid.

• At the end of two minutes, record the converter-out temperature.

d. Results.

NOTE:

Environmental conditions, such as ambient temperature, altitude,

engine accessory loss variations, etc., affect the power input to the

converter. Under such conditions, a stall speed deviation within

±150 rpm of specication can be accepted as within normal range.

If engine stall speed is more than 150 rpm below the stall speed specied by the

engine manufacturer, an engine problem is indicated, such as need for tune-up.

If engine stall speed is more than 150 rpm above specication, a transmission

problem is indicated, such as slipping clutches, cavitation, or torque converter

failure. Refer to Section 2–6 for the applicable service manual number.

An extremely low stall speed, such as 33 percent of the specied engine stall rpm,

during which the engine does not smoke, could indicate a freewheeling stator.

If the engine stall speed conforms to specication, but the transmission uid

overheats, refer to the cool-down check. If the transmission uid does not cool

during the two-minute cool-down check, a stuck stator can be indicated.

If the engine stall speed conforms to specication and the cool-down check shows

that transmission uid cools properly, refer to Troubleshooting Manual TS2712EN.

12

Page 23

SECTION

II

Drain the transmission uid before the transmission is removed from the vehicle.

• Remove the drain plug from the oil pan. Examine the drained transmission

uid for evidence of contamination (see Section 1–9). Reinstall the drain

plug.

• Remove transmission uid ll tube if it interferes with transmission removal.

NOTE:

A signicant amount of transmission uid may drain from the

hydraulic lines when they are disconnected from the transmission.

• Disconnect all other hydraulic lines from the transmission. Remove the lines

from the vehicle if they will interfere with the transmission removal. Plug all

hose openings to keep dirt from entering the hydraulic system.

• Disconnect or completely remove the electronic controls. If controls are not

removed from the transmission, position them so they do not interfere with

transmission removal.

• Disconnect the electronic control chassis harness from the transmission main

connector and from the speed sensor connector (Figure 2–1).

• If an external pressure switch for a reverse signal is used, disconnect vehicle

harness from switch.

• Disconnect the speedometer drive cable, if used.

• Disconnect the air supply line at the output retarder control valve (if output

retarder is used).

• Disconnect the input retarder control linkage (if input retarder is used).

13

Page 24

Figure 2–1. Disconnect Locations

• Disconnect the vehicle driveline from the transmission output

ange. Position the disconnected shaft to avoid interference when

removing the transmission.

• If transmission mounts support the rear of the engine, place a jack or

other support under the engine.

• Support the transmission securely on a hoist, jack, or other suitable removal

equipment.

• Remove all bolts, nuts, washers, spacers, and supports that attach the

transmission to the vehicle and to the engine (reference Figure 4–1).

• Move the transmission away from the engine until it is completely

clear of the engine. If used, remove the adapter ring and/or gasket.

• Raise or lower the transmission as necessary to remove it from the

vehicle.

When replacing the transmission, it may be necessary to transfer input and output

anges or yokes to the replacement transmission. If the anges or yokes are retained

by a large self-locking nut, follow specic procedures below for removal of the nut.

14

Page 25

CAUTION: The use of an impact wrench for removing the input or

output nut requires a means to hold the ange. Failure to hold the

ange can cause internal damage to the transmission.

• Before removing the self-locking nut, check to see if there are any notches cut

into the wrenching ats. If there are ve notches, remove the nut and throw it

away.

• If there are less than ve notches or none at all, remove dirt and burrs from the

shaft thread. Then loosen the nut until there is about 1⁄16 inch gap between the

nut and ange.

• Check the running torque as the nut is being removed. The rst time the nut is

removed (no notches), running torque must be at least 400 lb in. (45 N·m).

Each additional time the nut is removed (one to four notches), running torque

must be at least 300 lb in. (34 N·m). Discard the nut if it does not meet the

running torque limit.

Refer to the latest edition of the following Service Manuals for rebuild or overhaul

of the transmission:

— HT, HTB 700 Electronic Control Series Service Manual SM2004EN

— CL(B)T 700 Series Service Manual SM1314EN, with CL(B)T 755

Electronic Control Series Service Manual Supplement SM1992EN

15

Page 26

SECTION

III

a. Bolt Holes. Check all bolt holes on the front of the ywheel/converter/explate

adapter. The threads must be undamaged, and the holes must be free of any chips or

foreign materials.

b. Pilot Boss. Check the pilot boss (at center of ywheel) for damage or raised

metal which could prevent bolt free entry into the ex disk hub (adapter).

c. Starter Ring Gear. Check the starter ring gear for excessive wear or damage.

d. Transmission Mounting Flange. Check the transmission mounting ange for

raised metal, dirt, or pieces of gasket material.

e. Transmission-To-Engine Mounting Flange. Inspect the transmission-to-engine

mounting ange for raised metal, burrs, or pieces of gasket material. Also inspect

the threaded holes for damaged threads.

a. Output Oil Seal. Check the output ange rear oil seal and input front ange oil

seal for leaks or damage. Replacement instructions are in the HT, HTB 700 Electronic Control Series Service Manual SM2004EN, and CL(B)T Series Service Manual SM1314EN with CL(B)T 755 Electronic Control Series Service Manual

Supplement SM1992EN. Lubricate the oil seals with high-temperature grease or

transmission uid.

b. Check Yoke. Inspect each ange or yoke for damage or wear. The oil seal con-

tact surface must be smooth and regular to prevent transmission uid leaking past

the seal. Rotate the ange during installation to avoid seal lip damage.

c. Installing the Parking Brake. Install the parking brake assembly on the parking

brake mounting pads on the transmission, and tighten the bolts to the vehicle manufacturer specications.

d. Installing Output Yoke. Install the rear output yoke on the rear output shaft.

16

Page 27

Access to the PTO mounting pads and the space available to maneuver the

transmission determine whether the PTO should be installed before or after the

transmission is installed.

CAUTION: DO NOT use cork or other soft gaskets to install the

PTO. Use only the shims/gaskets listed in the appropriate parts

catalog of your transmission model.

NOTE:

DO NOT use sealing compounds — they are usually incompatible

with automatic transmission fluid.

a. Install Guide Pins — Included in the PTO Installation Kit. Determine the re-

quired position of the guide pins in relation to the mounted position of the PTO. The

guide pins must align with the two blind holes in the PTO. Install two headless guide

pins into the converter-housing PTO pad. Tighten the pins.

b. Determine the Backlash and Proper Gasket/Shim. You might have a turbine-

driven PTO or an engine-driven PTO.

• For the turbine-driven PTO, the prescribed backlash between the drive gear

(in the transmission) and the driven gear (in the PTO) is 0.018–0.024 inch

(0.46–0.60 mm) prior to S/N 32404, and 0.006–0.029 inch (0.16–0.73 mm)

after S/N 32403 models.

• For the engine-driven PTO, the prescribed backlash is 0.006–0.029 inch

(0.16–0.73 mm).

• Refer to the latest edition of Service Manual SM2004EN for the description

of the method to determine the backlash. Establish proper backlash by

selecting proper thickness of shims (gaskets).

c. Mount the PTO. Mount the PTO on the guide pins, meshing the PTO driven

gear with the PTO drive gear. Retain the PTO by installing a bolt in the top bolt hole.

Install the remaining bolts. Tighten the bolts to 51–61 N.m (38–45 lb ft).

CAUTION: PTO units using transmission main pressure to engage

the PTO driven gear must have a positive main pressure shut-off at the

solenoid valve when the PTO is not engaged.

17

Page 28

a. Inspection. Inspect the ll tube for proper vent location and vent hole diameter;

a vent hole should be located on the underside of the tube and just below the seal of

the dipstick, and the diameter should measure 0.060–0.080 inch (1.6–2.0 mm).

b. Location. The ller tube may be mounted on either the left or the right side. The

unused ll tube provision must have an expansion plug installed in the ll tube

opening.

CAUTION: Install the ll tube brackets with the correct length bolt.

Too long a bolt may cause cracks and leaks in the main housing. Refer

to the appropriate HTB 700 Series Parts Catalog PC1965EN or CLT

700 Series Parts Catalog PC1993EN.

c. Installation. Install the ll tube into the main housing. Insert the ll tube

through the seal. Align the tube bracket with its bolt location. Install the ll tube

bolts and tighten to 14–18 lb ft (19–24 N·m).

Check carefully at all sides of the transmission for loose or missing hydraulic

pressure check plugs.

• The 1⁄8 inch pipe plugs should be tightened to 48–60 lb in. (5.5–6.7 N·m).

• Check the four openings into which the cooler and lter lines connect, for

cleanliness. Remove any closures or obstructions.

• Check the drain plug for tightness. The drain plug must be tightened to 15–20

lb ft (21–27 N·m).

• Check the main electrical connector in the transmission housing for

cleanliness.

18

Page 29

SECTION

IV

You must ensure that a new transmission installation can be adapted to the vehicle’s

engine. The explained measurements in this section ensure correct transmission-toengine adaptation. Refer to Figures 4–1, 4–2, and 4–3.

a. Measuring Equipment. Refer to the following list for the required measuring

equipment.

• 24.0 inches (600 mm) precision caliper

• 2–4 inches (50–100 mm) telescoping gauge

• 1–3 inches (25–76 mm) outside micrometer

• 0–6 inches (0–150 mm) depth micrometer

• Dial indicator and mounting attachments — base, posts, and clamps

b. Flywheel Housing Pilot Bore Diameter. The ywheel housing pilot bore diame-

ter must measure from 20.125–20.130 inches (511.18–511.30 mm).

c. Flywheel Housing Bore Runout. Flywheel housing bore runout cannot exceed

0.020 inch (0.51 mm) TIR.

d. Flywheel Housing Face Squareness. The ywheel housing face cannot be

out-of-square more than 0.020 inch (0.51 mm) TIR.

e. Crankshaft Hub Pilot or Adapter Diameter. The crankshaft hub pilot or hub

adapter pilot diameter must measure between 2.437–2.439 inches (61.90–61.95 mm).

f. Crankshaft Hub Pilot or Adapter Squareness. The crankshaft hub or hub adapt-

er cannot be out-of-square more than 0.005 inch (0.13 mm) TIR.

g. Crankshaft Hub Pilot or Adapter Eccentricity. The crank shaft hub pilot or the

hub adapter cannot be out-of-square more than 0.005 inch (0.13 mm) TIR.

h. Flexplate Bolt Hole Flatness. Flexplate atness in the area of the bolt holes is not

a measurement required for HT and CT 700 Series explates.

i. Torque Converter Axial Location. Refer to Figure 4–2. Using a depth gauge,

measure from the torque converter housing to the torque converter’s explate adapter

mounting face. The torque converter axial location should measure 3.592–3.413 inches

(91.24–86.69 mm).

19

Page 30

a. Flexplate Inspection. Inspect the explate for cracks, wear, distortion, and elon-

gated bolt holes. Replace a damaged part.

b. Engine Crankshaft End Play. Ensure that the crankshaft end play is within the

engine manufacturer’s specications.

c. Flexplate Assembly Installation. Install the explate onto the engine crankshaft

hub using the bolts and torque values specied for that engine.

• Inspect shaft condition. The shaft must not be dented or bent. Welds must be

sound.

• Remove any accumulation of grease and dirt.

• Inspect universal joints, yokes, coupling anges, and slip-joint splines for

wear or damage.

• Lubricate universal joints and slip-joints using the vehicle manufacturer’s

recommended lubricants.

NOTE:

Misindexing of driveline can cause failure of the transmission.

Figure 4–1. Typical Method Of Coupling Transmission To Engine

20

Page 31

Figure 4–2. Converter Axial Location Measurement

Figure 4–3. Arrangement of Adaptation Components

21

Page 32

Inspect the chassis and driveline components for the following conditions, and

correct them as appropriate.

• Transmission mounts — broken or worn-out

• Bolts and other hardware — damaged, missing, or incorrect

• Isolators (rubber mounts) — damaged or missing

• Driveline angles — runout, balance, or offsets which do not conform to the

manufacturer’s recommendations

• Driveline yoke slip joints:

— freedom of movement

— damaged or worn-out

— correctly lubricated

— correctly indexed

• Driveline midship or hanger bearings — damaged or misaligned

• Universal joints:

— freedom of movement

— damaged or worn-out

— correctly lubricated

— correctly indexed

• Vehicle differential backlash — manufacturer’s specication

• Universal joint coupling — alignment and differential damage

• Cross-frame members and rear support members — condition and location

• PTO driven equipment shafts and couplings — damaged or misaligned

• Auxiliary transmission:

— shaft alignment

— alignment of yoke or ange

— backlash

— uid leaks

a. Inspection. Perform the following and correct any faulty conditions:

• Transmission uid cooler and related coolant lines:

— Check for contamination — clean and ush as necessary

— Inspect for deterioration

— Inspect for faulty connectors or kinks

— Clean and ush transmission uid cooler, both coolant and oil sides.

Pressure check both sides using a 40 psi (276 kPa) air supply.

22

Page 33

• Hydraulic lines:

— Check for contamination — clean and ush as necessary

— Inspect for deterioration

— Inspect for faulty connectors, or kinks

b. After Overhaul. A complete cleanup of the transmission system after an over-

haul cannot be assumed. Repeated cleaning and ushing may not remove all debris

from the transmission uid cooler system. Replace the transmission “from cooler”

(lube) lter after 5000 miles (8000 km). Rell the transmission to the correct uid

level — refer to Paragraph 1–4.

a. Inspection. Inspect the following control components and correct any faulty

conditions:

• Shift selector:

— proper operation

— proper electrical connection

— proper harness routing

• Speedometer drive cable:

— wear

— damage

— kinks

— lubrication

— proper routing

• Cab and chassis wiring harness:

— proper connections

— frayed insulation

— wiring damage

• Throttle sensor components:

— freedom of movement

— improper routing

— bellows damage

— improper or loose cable mounting

• Throttle sensor adjustment:

— accuracy

• Parking brake controls:

— cracks

— bends

— damaged threads

— clevis pins

— worn-out rod ends

23

Page 34

• Hydraulic retarder control:

— damage

— wear

— frayed cable

— worn-out rod ends

— cotter pins

— lubrication

— proper operation

• PTO control:

— damage

— wear

— improper operation

— lubrication

• Temperature gauge:

— capillary tube damage (if used)

— sensor damage

• Fluid pressure gauge tubing:

— damage

— kinks

— improper routing

b. Throttle Position Sensor (TPS) Adjustment — When properly installed by the

equipment manufacturer, the TPS should not need adjustment. If TPS adjustment is

necessary, conrm that it has been installed to ATD specications. The TPS is selfcalibrating, and therefore has no optimum close throttle or full throttle count value.

Idle count should be 50 or higher and full throttle should be 200 or lower. As long as

the counts are in the 50 and 200 range, with a difference of 85 to 130 counts between

closed and full throttle, the TPS is set correctly. Refer to Figure 4–4.

c. Hitch-Pin Throttle Position Sensor Installation. Refer to Figure 4–5.

• Install the throttle sensor body as follows:

— Clamp cable end, using clamp and shims

— Secure the sensor body, using the mounting holes provided.

— Install a heat shield if any part of the throttle sensor is near the exhaust

manifold, turbocharger, or any other heat source.

• Adjust the Hitch-Pin throttle sensor as follows:

— The engine fuel lever must be at the closed throttle position.

— Install the hitch-pin cable end of the sensor to the engine fuel lever

with brackets so that at the idle position, the cable end is 0.44–0.67

inch (11–17 mm) from its fully retracted position, and at wide open

throttle position, the cable end is 0.60–0.90 inch (15–22.9 mm) from

the idle position.

24

Page 35

Figure 4–4. Throttle Position Determination Diagram

— Check the stroke distance of the throttle sensor, from closed to wide

open. Stroke distance must be from 0.60–0.90 inch (15–22.9 mm).

— Recheck for zero clearance at the fuel lever. Make sure that the

0.60–0.90 inch (15–22.9 mm) dimension has not changed.

— Design throttle sensor linkage brackets and levers to nominal dimensions

so that the system stays within tolerance band throughout its operating life.

d. Slip-Link Throttle Sensor Installation. Refer to Figure 4–6.

• Loosen 1⁄4–20 nuts A and B enough to let the threaded shaft move to its fully

retracted position.

• Make sure the engine fuel lever is at the closed throttle position.

• Tighten nut A against the slip-link until the threaded shaft moves 0.44–0.66

inch (11.2–16.7 mm) from its retracted position. Check to be sure there is zero

clearance between the drive pin on the fuel lever and the end of the slot in the

slip-link. Then tighten nut B securely against the slip-link.

• Recheck for zero clearance at the fuel lever. Then recheck the 0.44–0.66 inch

(11.2–16.7 mm) dimension to ensure that it has not changed.

• Move the throttle from closed to wide open to check the stroke distance of the

throttle sensor. The stroke distance must be within the range of 0.63–0.86 inch

(16.0–21.8 mm).

25

Page 36

Figure 4–5. Hitch-Pin Throttle Sensor Installation Diagram

Figure 4–6. Slip-Link Throttle Sensor Installation Diagram

26

Page 37

SECTION

V

a. Preventing Damage. Carefully handle the transmission to prevent damage to

components in the installation path.

b. Control of Transmission Movements. Use a hoist or transmission jack that al-

lows precise control of transmission movement during installation.

• Align one of the explate’s bolt holes in the explate with the access

opening at the front of the engine ywheel housing.

• Install a headless guide bolt into one of the explate bolt holes in the

ywheel (Figure 4–1). Align the guide bolt with the explate hole at

the access opening.

• Lubricate the center pilot boss with molybdenum disulde grease.

• Push the transmission toward the engine while guiding the pilot boss on the

ywheel into the explate hub (adapter), and the guide bolt into the hole in

the explate.

• Seat the transmission squarely against the engine ywheel housing. No force

is required — if interference is encountered, move the transmission away

from the engine and investigate the cause.

• Align the bolt holes in the converter housing with those in the engine ywheel

housing. Install all of the bolts, nger tight, that retain the transmission to the

engine.

CAUTION: The converter housing must be ush against the engine

ywheel housing before tightening any bolts. Do not use the bolts to

seat the housing.

• Tighten four bolts at 90 degree intervals around the converter housing bolt

circle. Then tighten the remaining bolts. Use the torque recommended by the

vehicle or engine manufacturer.

27

Page 38

• Remove the guide bolt through the access opening in the engine ywheel

housing. Replace it with a 1⁄2–20 x 1 inch self-locking bolt. Tighten the bolt

nger tight at this time.

NOTE:

Do not tighten any ywheel bolts until all of the bolts have been

installed and tightened nger tight.

• Rotate the engine drive shaft enough to install the eleven remaining 1⁄2–20 x 1

inch self-locking bolts into the ywheel, nger tight. When all bolts including

twelve 1⁄2–20 x 3⁄4 inch self-locking bolts are in place, tighten them to 96–115

lb ft (131–155 N·m).

• Install the ywheel housing access cover.

• Install all bolts, washers, spacers, isolators, brackets, and supports required to

support the transmission in the vehicle frame.

CAUTION: Use the type and grade of mounting bolts recommended

by the vehicle manufacturer.

• Tighten the bolts to the torque recommended by the vehicle manufacturer.

• Couple the driveline companion ange or universal joint yoke to the ange or

yoke on the transmission. Use the bolts and torque recommended by the

vehicle manufacturer.

• Check the universal joint angularity (all joints in driveline) to determine if

they are within the specications of the vehicle manufacturer.

• Install (if removed) the input drive shaft components that connect the engine

and transmission.

• Couple the ange or yoke to the ange or yoke at the front of the

transmission. Use the bolts and torque recommended by the vehicle

manufacturer.

• Check the transmission to engine alignment against the vehicle

manufacturer’s specications.

28

Page 39

• Place the operator’s control at the OFF (disengaged) position.

• Check the input retarder control valve. The valve is spring-loaded to retract

into the valve body when the retarder is OFF. Lift the valve upward, to the ON

position, to check for the full travel of 1.5 inches (38 mm) from OFF to ON

position.

• Release the valve, permitting the spring to retract the valve. Be sure the valve

is fully retracted.

• Adjust the linkage so that rod end or clevis registers with the pin hole in the

retarder valve. Connect the linkage to the retarder valve and check the

operation of the valve. The valve must be fully extended when the operator’s

control is at ON.

• The valve must be fully retracted when the control is at OFF.

NOTE:

Failure to ensure a full off stroke will result in low vehicle power and

transmission overheating. Failure to ensure a full on stroke will

result in less than rated retarder performance.

The output retarder (when used) is connected to the vehicle braking system by an air

supply line.

• Connect the air supply hose tting to the retarder control valve. Tighten the

tting to 7–10 lb ft (10–13 N·m).

• If not previously installed, mount the PTO on the transmission. Refer to

Paragraph 3–3 for instructions.

• Connect controls to the PTO. Check for proper operation of the controls.

• Check cable or linkage rod routing. Kinks, sharp bends, and close proximity

of the cable to exhaust pipes or manifold must be avoided. Rods or linkage

must not rub or interfere with adjacent parts.

CAUTION: PTOs using main transmission oil pressure to apply the

PTO must have main pressure dead-headed at the PTO control valve

when not in use.

• Couple the PTO output to its driven equipment. Check couplings or universal

joints for proper assembly and alignment.

29

Page 40

• Connect and properly adjust the parking brake linkage.

• Adjust the brake shoe-to-drum clearance as specied by the manufacturer.

Figure 5–1 shows typical cooler and lter line locations.

• Be sure that the hydraulic lines are of the proper size and type recommended.

Use new O-ring seals where required.

• Secure the ller tube bracket(s) as required.

• Connect the hydraulic lines to the transmission and to the cooler and external

lter, checking to see that the lines are clean and unobstructed.

• Tighten the line ttings at the transmission to the torque values shown on

Figure 5–1.

• Check for sharp bends, kinks, twists and for contact with components that will

chafe or collapse the oil lines.

• Check to ensure that the hydraulic lines are not in close proximity to

manifolds or exhaust pipes. Excessive heat will hasten the deterioration of

hydraulic lines.

It is recommended that an auxiliary lter be installed in the cooler-circuit following

cleanup. The auxiliary lter must have a 40 micron (max) lter element and a

maximum lter pressure drop of 2 psi (13 kPa) at 15 gpm (57 liters/minute)

at 180º F (82º C). The maximum cooler circuit pressure drop must not exceed

30 psi (206 kPa) at 15 gpm (57 liters/minute) at operating temperature and full

throttle stall.

• Install the auxiliary lter.

NOTE:

An electronic speed signal is provided by the ECU to operate an

electronic speedometer. The mechanical speedometer driven gear

assembly is required only if the vehicle is equipped with a

mechanical speedometer.

30

Page 41

TRANSMISSIONS WITHOUT RETARDER

VIEW A

TRANSMISSIONS WITH INPUT RETARDER

VIEW B

VIEW C

TRANSMISSIONS WITH OUTPUT RETARDER

Figure 5–1. Torque Values of Typical Filter and Cooler Lines

31

Page 42

• Install the speedometer driven gear assembly into the transmission

(if required). Tighten the gear assembly in the transmission rear cover to

45–50 lb ft (62–67 N·m). If no speedometer drive is provided, be sure the plug

is installed to close the hole in the housing (torque is same as for gear

assembly).

• Install the speedometer drive cable onto the driven gear assembly. Tighten the

nut to 52 lb inch (6 N·m). Avoid kinks or sharp bends in the cable assembly.

Bends must have a minimum radius of 6 inches (150 mm). No more than one

90° bend is allowed.

• Connect the electronic control chassis harness to the transmission main

connector and to the speed sensor connector. Be sure the main connector is

turned until a positive snap is felt.

• Install temperature probe (capillary tube and bulb, or thermocouple), if so

equipped, into the converter housing or hydraulic retarder valve.

— If equipped with capillary tube and bulb, tighten the 1⁄2 inch pipe thread

adapter sufciently to prevent leakage.

— Install the bulb into the adapter and tighten the nut into the adapter.

— Check the capillary tube for interference with other parts that might chafe

or damage the tube. Long tubes may require clips or brackets for support.

— If equipped with electrical temperature sensor, install thermocouple and

connect electrical leads.

• Install and connect other electrical components such as heaters, winterization

equipment, and pressure sensors.

• Install the pressure gauge tube, or line, if so equipped.

• If a reverse pressure switch is mounted on the transmission at the reverse

pressure port, make the appropriate connection.

• Check that all unused hydraulic openings are plugged.

• Select the transmission uid.

• Fill the transmission with the required amount of uid (refer to

Section 1–9).

• Run the engine for about one minute and check the transmission uid level

(refer to Section 1–3).

32

Page 43

Use this list after transmission installation. As items are checked, mark

them off this list.

• Torque Values

Flexplate bolts — 96–115 lb ft (131–155 N·m)

Transmission-to-engine bolts*

Transmission-to-frame or mounting bolts*

Input ange nut — 450–550 lb ft (611–745 N·m)

Output ange nut — 600–800 lb ft (814–1084 N·m)

Companion ange or universal joint bolts*

Speedometer cable nut — 52 lb in. (6 N·m)

Speedometer body — 45–50 lb ft (62–67 N·m)

Hydraulic lines-to-transmission — 40–50 lb ft (55–67 N·m) max

Cooler lines to and from retarder — 50–59 lb ft (68–79 N·m)

Drain plug — 15–20 lb ft (20–27 N·m)

Speed sensor bolt — 20–23 lb ft (28–31 N·m)

PTO mounting bolts* (if PTO used)

Reverse signal switch to transmission, if so equipped

48–60 lb in. (5.5–6.7 N·m)

Parking brake bolts to transmission — 117–140 lb ft (159–189 N·m)

Center bolt external lter — 75 lb in. (8.5 N·m)

• Cooler Fluid Lines and Air Hose

No Leaks

Connection Tightness

Correct Routing

SECTION

VI

* Tighten to vehicle manufacturer’s recommendation

33

Page 44

• Throttle Position Sensor

Proper Adjustment

Correct routing of cable and harness

• Parking Brake

Proper clearance

Adjustment for full application

Check for full release

• Input Retarder

Adjustment for full open, closed

Ease of operation

• Driveline

Proper indexing of universal and slip-joints

Proper drive shaft angles

Driveline backlash

Lubricated universals and slip-joints

• Hydraulic System

Recommended uid

Proper uid level in transmission

Proper calibration of the dipstick

Properly vented ller tube

Proper ller tube and oil pan connection

Clean and free of obstruction breather

Transmission uid leak

• Instruments and Electrical Equipment

Proper wiring and electrical connections

Instruments, gauges, and light work correctly

Shift selector display is on and DO NOT SHIFT light is off

Fluid temperature gauge is working correctly

• Power Takeoff

Proper control connection and operation

Correctly coupled to driven equipment

Properly connected and routed lubrication line — if used

34

Page 45

NOTE:

Refer to HT/CT Transmission Operator’s Handbook for operating

instructions.

a. Driveability. Drive-away checks are performed to verify proper transmission and

support equipment installation and operation. The following steps outline driveaway check procedures:

• Check Fluid — ll the transmission with the appropriate uid.

• Start the Vehicle — check for proper system response during start-up.

— Turn on the vehicle master/ignition switch.

— The DO NOT SHIFT light should come on.

— Start the engine.

— The DO NOT SHIFT light should go off.

• Clear Trouble Codes — during installation, it is common for “false” codes to

be stored in the electronic control’s ECU. These codes must be cleared prior

to road testing the vehicle.

• Road Test the Vehicle — allow the electronic control time to “converge”

shifts.

• Check for Proper Operation — check all components for proper mounting and

operation, and check for transmission uid leaks at gasket surfaces, lines, and

hoses.

• Re-check for Trouble Codes — use the Pro-Link® or Diagnostic Data Reader

(DDR) to determine if codes were set during the road test. Connect the ProLink® or DDR to the ECU through the Diagnostic Data Link (DDL).

• Troubleshoot — if codes exist after the road test, problems must be found and

corrected. Refer to the latest edition of HT/CT Troubleshooting Manual

TS2712EN.

b. Service and Maintenance. Refer to the latest edition of the HT 700 Series

Electronic Control Service Manual for detailed transmission service and maintenance instructions. Refer to the latest edition of the HT 700 Series Electronic

Control Troubleshooting Manual for detailed electronic control system troubleshooting. Refer to Section 7–2 for the latest publication number.

35

Page 46

c. Road Test Checklist. Complete the following checklist.

• Neutral Start Circuit

Starts only in neutral

• Instruments

DO NOT SHIFT light and CHECK TRANS light

Transmission uid pressure gauge — if used

Speedometer

Temperature gauge — if used

Reverse warning system — if used

• Transmission Fluid

Fluid level meet specications — cold, neutral, level

No leaks

Warm-up and check uid level — hot, neutral, level

• No-Load Governed Engine Speed

No-load governed speed of engine

Adjust governor as necessary — refer to the manufacturer’s specications

for the engine-transmission being tested.

• PTO

PTO operation — refer to HT 700 Series Operator’s Manual or to the

vehicle manufacturer’s specic instructions.

• Shift Sequence

Transmission upshifts and downshifts smoothly through all ranges

• Other Checks

Stall test

Shift quality

• Comments

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

36

Page 47

SECTION

VII

The satisfaction and good will of the owners of Allison transmissions are of primary

concern to Allison Transmission Division (ATD), its distributors, and their dealers.

As an owner of an Allison transmission, you have service locations throughout the

world that are eager to meet your parts and service needs with:

• Expert service by trained personnel

• Emergency service 24 hours a day in many areas

• Complete parts support

• Sales teams to help determine your transmission requirements

• Product information and literature

Normally, any situation that arises in connection with the sale, operation, or service

of your transmission will be handled by the distributor or dealer in your area (check

the telephone directory for the Allison Transmission service outlet nearest you).

Reference the Sales and Service Directory (SA2229EN) for the current listing of

Allison Transmission authorized distributor and service dealers.

We recognize, however, that despite the best intentions of everyone concerned,

misunderstandings may occur. To further assure your complete satisfaction, we have

developed the following three-step procedure to be followed in the event a problem

has not been handled satisfactorily.

Step One — Discuss the problem with a member of management from

the distributorship or dealership. Frequently, complaints are the result of a

breakdown in communication and can quickly be resolved by a member of

management. If you have already discussed the problem with the Sales or Service

Manager, contact the General Manager. All ATD dealers are associated with an ATD

distributor. If the problem originates with a dealer, explain the matter to a

management member of the distributorship with whom the dealer has his service

agreement. The dealer will provide his ATD distributor’s name, address, and

telephone number on request.

37

Page 48

Step Two — When it appears the problem cannot be resolved readily at the

distributor level without additional assistance, contact the Allison Transmission

Regional Ofce responsible for the local distributor. You will be assisted by a

member of the Regional Service Manager’s staff, depending on the nature of your

problem.

For prompt assistance, please have the following information available.

• Name and location of authorized distributor or dealer

• Type and make of equipment

• Transmission model number, serial number, and assembly number (if

equipped with electronic controls, also provide the ECU assembly number)

• Transmission delivery date and accumulated miles and/or hours of operation

• Nature of problem

• Chronological summary of unit’s history

Step Three — If you contacted a regional ofce and you are still not satised,

present the entire matter to the Home Ofce by writing to the following address

or calling the phone number below:

Manager, Warranty Administration — PF9

Allison Transmission

P.O. Box 894

Indianapolis, Indiana 46206–0894

Phone: (317) 242–3538

The inclusion of all pertinent information will assist the Home Ofce in expediting

the matter. If an additional review by the Home Ofce of all the facts involved

indicates that some further action can be taken, the Regional Ofce will be advised.

When contacting the Regional or Home Ofce, please keep in mind that ultimately

the problem will likely be resolved at the distributorship or dealership utilizing their

facilities, equipment, and personnel. Therefore, it is suggested the above steps be

followed in sequence when experiencing a problem.

Your purchase of an Allison Transmission product is greatly appreciated, and it is

our sincere desire to assure complete satisfaction.

38

Page 49

Additional service literature is available. This service literature provides

fully illustrated instructions for the operation, maintenance, service,

overhaul, and parts support of your transmission. To ensure that you get

maximum performance and service life from your unit, see your dealer or

distributor for the following publications. Check the telephone directory for the

Allison Transmission service outlet nearest you.

Table 7–1. Service Literature

Publication HTB 700 Series CLT, CLBT 700 Series

Service Manual SM2004EN

SM1992EN*

Parts Catalog PC1965EN PC1993EN

Troubleshooting Manual TS2712EN TS2712EN

Operator’s Manual OM1957EN OM1957EN

Technician’s Guide GN2009EN****

GN2033EN***

GN2055EN**

* Electronic Control Service Manual Supplement

** Automatic Transmission Fluid

*** HT/CLBT Series Inspection/Analysis

**** HTB Series Hydraulic Output Retarder Inspection/Analysis

SM1314EN

SM1992EN*

GN2055EN**

GN2033EN***

39

Page 50

Loading...

Loading...