Page 1

DDEC IV APPLICAT

ION AND INSTALLATION MANUAL

5 DDEC FEATURES

Section Page

5.1 AIR COMPRESSOR CONTROL ............................................................. 5-3

5.2 ANTI-LOCK BRAKE SYSTEMS .............................................................. 5-9

5.3 CRUISE CONTROL ................................................................................ 5-13

5.4 CRUISE CONTROL FOR DRILLING/PUMPING APPLICATIONS WITH

OPTIONAL DUAL STATION CONTROL ................................................. 5-21

5.5 DIAGNOSTICS ........................................................................................ 5-23

5.6 EDM AND AIM ........................................................................................ 5-27

5.7 ELECTRONIC FIRE COMMANDER ....................................................... 5-31

5.8 ELECTRONIC SPEED SWITCH ............................................................. 5-35

5.9 ENGINE BRAKE CONTROLS ................................................................ 5-39

5.10 ENGINE PROTECTION .......................................................................... 5-45

5.11 ENGINE RATINGS .................................................................................. 5-57

5.12 ETHER START ........................................................................................ 5-61

5.13 EXTERNAL ENGINE SYNCHRONIZATION ........................................... 5-65

5.14 FAN CONTROL ....................................................................................... 5-69

5.15 FUEL ECONOMY INCENTIVE ............................................................... 5-83

5.16 GLOW PLUG CONTROLLER ................................................................. 5-85

5.17 HALF ENGINE IDLE ............................................................................... 5-89

5.18 IDLE SHUTDOWN TIMER AND VEHICLE POWER SHUTDOWN ........ 5-91

5.19 IRIS ......................................................................................................... 5-97

5.20 LOW GEAR TORQUE LIMITING ............................................................ 5-105

5.21 MAINTENANCE ALERT SYSTEM .......................................................... 5-107

5.22 MANAGEMENT INFORMATION PRODUCTS ........................................ 5-131

All information subjecttochangewithout notice. (Rev. (Rev. 3/02)) 5-1

7SA742 0203 Copyright © 2002 DETROIT DIESEL CORPORATION

Page 2

DDEC FEATURES

5.23 MARINE CONTROLS ............................................................................. 5-175

5.24 OPTIMIZED IDLE .................................................................................... 5-179

5.25 OPTIMUM LOAD SIGNAL ...................................................................... 5-185

5.26 OVERALL GOVERNOR GAIN ................................................................ 5-187

5.27 PASSMART ............................................................................................. 5-189

5.28 PASSWORDS ......................................................................................... 5-193

5.29 PRESSURE SENSOR GOVERNOR ...................................................... 5-197

5.30 PROGRESSIVE SHIFT ........................................................................... 5-203

5.31 PULSE TO VOLTAGE MODULE ............................................................. 5-209

5.32 TACHOMETER DRIVE ............................................................................ 5-213

5.33 THROTTLE CONTROL/GOVERNORS ................................................... 5-215

5.34 TRANSMISSION INTERFACE ................................................................ 5-233

5.35 TRANSMISSION RETARDER ................................................................ 5-253

5.36 VEHICLE SPEED LIMITING ................................................................... 5-255

5.37 VEHICLE SPEED SENSOR ANTI-TAMPERING .................................... 5-257

5-2 All information subject to change without notice. (Rev. (Rev. 3/02))

742 0203 Copyright © 20 02 DETROIT DIESEL CORPORATION

7SA

Page 3

DDEC IV APPLICATION AND INSTALLATION MANUAL

5.1 AIR COMPRESSOR CONTROL

Air Compressor C ontrolis an optional DDEC feature that allows DDEC to regulate engine speed

and load/unload a valve in order to maintain a requested compressor outlet air pressure for air

compressor applications.

The DDEC A ir Compressor Control Feature is available with the following software releases:

DDEC III - Release 4.0 (only)

DDEC IV - all software versions (Release 20.0 or later)

5.1.1 OPERATION

The ECM monitors the air outlet pressure while varying the engine speed and operating

load/unload a valve. The valve will be opened or closed. The desired operating pressure may be

varied by the operator, within limits preset by the OEM.

The ECM will activate the Air Compressor G overnor Controls when the digital input “Air

Compressor Load Switch” is gr ounded. Engine speed is governed based on the actual air

compressor outlet pressure versus the desired output pressure. The Air Compressor Pressure

Sensor provides a pressure signal to the ECM.

The engine response to various pressure conditions is listed in Table 5-1.

Pressure Set Point

Current outlet pressure is below the pressure set

point

Pressure in the system continues to increase and

a threshold pressure is exceeded

Current outlet pressure is above the pressure set

point

* The engine will continue to run at PTO maximumuntil the outlet pressure matches the sensor pressure.

† DDEC will open and close the loading valve as a function of pressure with hysteresis. When the pressure

reaches a programmable limit above the pressure set point the DDEC digital output will be grounded.

This output may be used to either open an air compressor vent or close the air inlet. Once the air

pressure has dropped to a lower programmable limit, the digital output will be open circuited which will

either close the vent

Engine speed increases as required up to PTO

maximum speed*

The air compressor solenoid digital output is

enabled† (opened)

Engine speed decreases as required down to the

minimum PTO speed.

Result

Table 5-1 Engine Operation with Air Compressor Controls

Each horsepower rating has an associated pressure range. Horsepower ratings are defined at time

of orde r entry. The minimum and maximum pressure setting for each of the horsepower curves is

set with the DDDL/DDR, Vehicle Ele ctronic Programming System (VEPS), or DRS. The initial

pressure set point is saved between ignition cycles.

Increase (Resume/Acceleration On)

Momentarily toggling and releasing the Increase Switch (grounding the "Resume/A

cceleration

On" digital input) increases set point pressure by 4% of the pressure range. Holding the switch in

the incr ease position (gr ounding the digital input), will increase the set point pressure at a rate of

two increments per second. Releasing the switch sets the compressor controls to

All information subject to change without notice. (Rev. (Rev. 3/02)) 5-3

7SA742

0203 Copyright © 2002 DETROIT DIESEL CORPORATION

the higher setting.

Page 4

DDEC FEATURES

Decrease (Set/Coast On)

Momentarily toggling and re leasing the decrease switch decr eases set point pressure by 4% of the

pressure range. See Figure 5-1. Holding the switch in the decrease position (grounding the digital

input), will decrease the set point pressure at a rate of two increments per second. Releasing the

switch sets the compressor controls to the lower setting.

Air Compressor Load Switch

Closing (grounding) the air compressor load switch digital input activates the air compressor

control system. See Figure 5-1. Opening the air compressor load switch digital input deactivates

the air compressor control system.

Air Compressor Solenoid

When the pressure reaches a programmable limit above the pressure set point the D DEC digital

output will be grounded. This output may be use d to either open an air compressor vent or close

the air inlet. Once the air pressure has dropped to a lower programmable limit, the digital output

will be open circuited which will either close the vent or open the air inlet.

Air Compressor Shutdown

DDEC will respond to a proprietary immediate engine shut down message sent over the SAE

J1587/J1708 data link by the Electronic Display Module (EDM). This feature requires both an

EDM and an Auxiliary Information Module (AIM); refer to section 5.6 for addition information

on EDM and AIM.

Multiple Pressure Ratings

The pressure ranges are linked to the engine ratings. A pressure range can be associated with

each rating. The maximum number of engine ratings and pressure ranges is three. Choosing the

rating, with the DDR/DDDL or rating switches will automatically select the associated pressure

range. The proper 6N4D group with multiple 6N4M groups must be specified. For additional

information, contact your DDC Applications Engineer.

5-4 All information subject to change without notice. (Rev. (Rev. 3/02))

742 0203 C opyright © 2002 DETROIT DIESEL CORPORATION

7SA

Page 5

DDEC IV APPLICATION AND INSTALLATION MANUAL

5.1.2 INSTALLATION

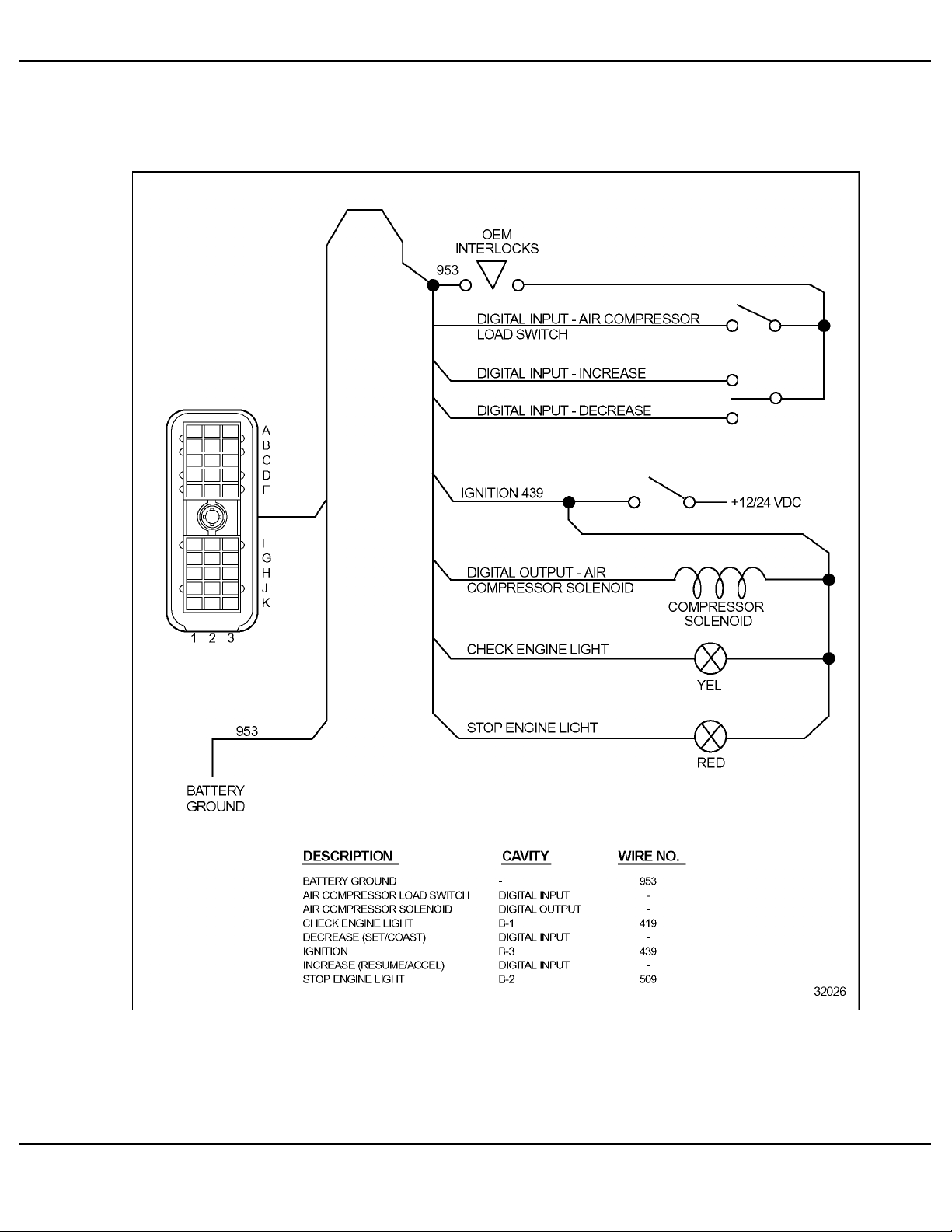

See Figure 5-1 for the Air Compressor Control Harness.

Figure 5-1 Air Compressor Control Harness

All information subject to change without notice. (Rev. (Rev. 3/02)) 5-5

7SA742

0203 Copyright © 2002 DETROIT DIESEL CORPORATION

Page 6

DDEC FEATURES

5.1.3 PROGRAMMING REQUIREMENTS AND FLEXIBILITY

Air Compressor Controls must be specified at the time of engine order or added to the ECM

calibration by Detroit Diesel Technical Service. An Application Code (6N4C) Group must be

selected that is configured for Air Compressor Control at order entry or by contacting Detroit

Diesel Technical Service.

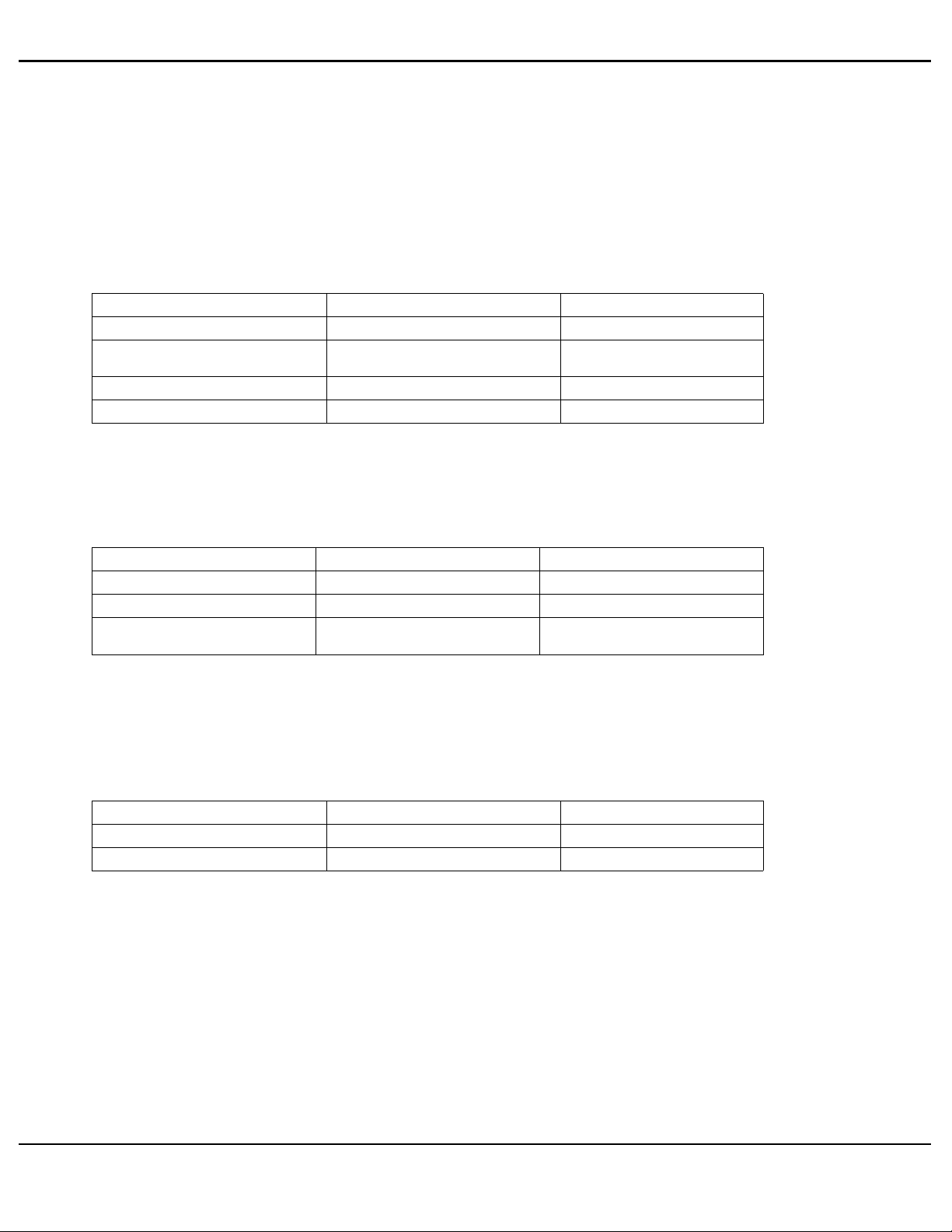

The digital outputs and inputs listed in Table 5-2 are required for Air Compressor Controls and

must be configured by order entry, VEPS, or the DRS.

Description Type Function Number

Set/Coast On (Decrease) Digital Input 20

Resume/Acceleration On

(Increase)

Air Compressor Load Switch Digital Input 35

Air Compressor Solenoid Digital Output 21

Table 5-2 Air Compressor Con trol Required Digital Inputs and Outputs

Digital Input 22

At order entry, the Application Code System (ACS) sets the default values for the parameters

listed in Table 5-3. These parameters may be modified using either VEPS or DRS.

Parameter Description

Air Compressor Integral Gain Integral Gain 0-128 RPM/(PSI x SEC)

Air Compressor ProportionalGain Proportional Gain 0-128 RPM/PSI

Air Compressor Pressure

Increment

Percent Pressure Increment

Choice/Display

0-50% (of fuel scale pressure

range)

Table 5-3 Air Compressor Control Parameters

Multiple pressure ratings can be selected with the use of ra ting switches. The proper 6N4D groups

with multiple 6N4M groups must be specified at engine order or by Detroit Diesel Technica l

Service. The digital inputs listed in Table 5-4 are required.

Description Type Function Number

Rating Switch #1 Digital Input 12

Rating Switch #2 Digital Input 13

Table 5-4 Multiple Pressure Ratings Required Digital Inputs

The VSG maximum and minimum RPM can be set with VEPS, DRS, DDR or DDDL as

listed in Table 5-5.

5-6 All information subject to change without notice. (Rev. (Rev. 3/02))

742 0203 C opyright © 2002 DETROIT DIESEL CORPORATION

7SA

Page 7

DDEC IV APPLICATION AND INSTALLATION MANUAL

Parameter Description

VSG Minimum RPM Sets the VSG minimum speed. Idle to VSG, Maximum RPM

VSG Maximum RPM Sets the VSG maximum speed. VSG Minimum RPM to (Rated Speed

Table 5-5 Variable Speed Gove

rnor Maximum and Minimum RPM

Choice/Display

+ LSG Droop)

The minimum and maximum pressure is set with the DDDL/DDR, DRS or VEPS as listed in

Table 5-6. There is a minimum and maximum pressure setting for each of the horsepower cur v es.

Parameter Description Range

Indicates the delta value above the current air

LOAD PSI

UNLOAD PSI

MAX RAT#1 PSI

MIN RAT#1 PSI

MAX RAT #2 PSI

MIN RAT#2 PSI

MAX RAT#3 PSI

MIN RAT #3 PSI

pressureset point thatwill initiate theair compressor

governor to reload the system.

Indicates the delta value above the current air

pressureset point thatwill initiate theair compressor

nor to unload the system.

gover

Indicates the maximum allowable air pressure set

point for engine rating #1

Indicates the minimum allowable air pressure set

point for engine rating #1.

Indicates the maximum allowable air pressure set

point for engine rating #2.

Indicates the minimum allowable air pressure set

point for engine rating #2.

Indicates the maximum allowable air pressure set

point for engine rating #3.

Indicates the minimum allowable air pressure set

point for engine rating #3.

0toUNLOADPSI

LOAD PSI to 31 PSI

MIN RAT#1 to 999 PSI

0toMAXRAT#1

MIN RAT#2 to 999 PSI

0toMAXRAT#2

MIN RAT#3 to 999 PSI

0toMAXRAT#3

Table 5-6 Air Compressor Parameters

5.1.4 INTERACTION WITH OTHER FEATURES

Air Compressor Control may not be used with Cruise Control or the Pressure Sensor Governor.

A proprietary immediate engine shut down message for immediate air compressor shutdown is

sent over the SAE J1587/J1708 data link by the EDM. This feature requires both an EDM and an

AIM; refer to section 5.6 for addition information on EDM and AI M.

All information subject to change without notice. (Rev. (Rev. 3/02)) 5-7

7SA742

0203 Copyright © 2002 DETROIT DIESEL CORPORATION

Page 8

DDEC FEATURES

THIS PAGE INTENTIONALLY LEFT BLANK

5-8 Allinformation subject to change without notice. (Rev. (Rev. 3/02))

742 0203 Co pyri ght © 2002 DETROIT DIESEL CORPORATION

7SA

Page 9

DDEC IV APPLICATION AND INSTALLATION MANUAL

5.2 ANTI-LOCK BRAKE SYSTEMS

Anti-lock Brake Systems (ABS) are electronic systems that monitor and control wheel speed

during braking. The systems are compatible with standard air brake systems. The system

monitors wheel speed at all times, and controls bra k ing during emergency situations. Vehicle

stability and control are impr oved by reducing wheel lock during braking.

5.2.1 OPERATION

The ECM transmits engine data via SAE J1587, SAE J1922, or SAE J1939. Anti-lock brake

systems monitor data on one or more of these communication links. In the event that an excessive

wheel spin is de tected, the ECM receives a message from the ABS requesting a 0% output torque

limit. The message is transmitted on SAE J1922 or SAE J1939.

SAE J1922 and SAE J1939 both implement the same message set. The difference being hardware

and performance. SAE J1922 transmits and rec eives data at 9.6 K baud while SAE J1939

transmits/receives data at 250 K baud. SAE J1939 has a much higher bit rate so messages reach

their de stination very quickly nearly eliminating the latency found with SAE J1922.

SAE J1922 is enabled on all DDEC IV ECMs. SAE J1939 is enabled on a ll DDEC IV ECMs

(Release 24.0 or later). ECMs prior to Release 24.0 must be configured if SAE J1939 is required.

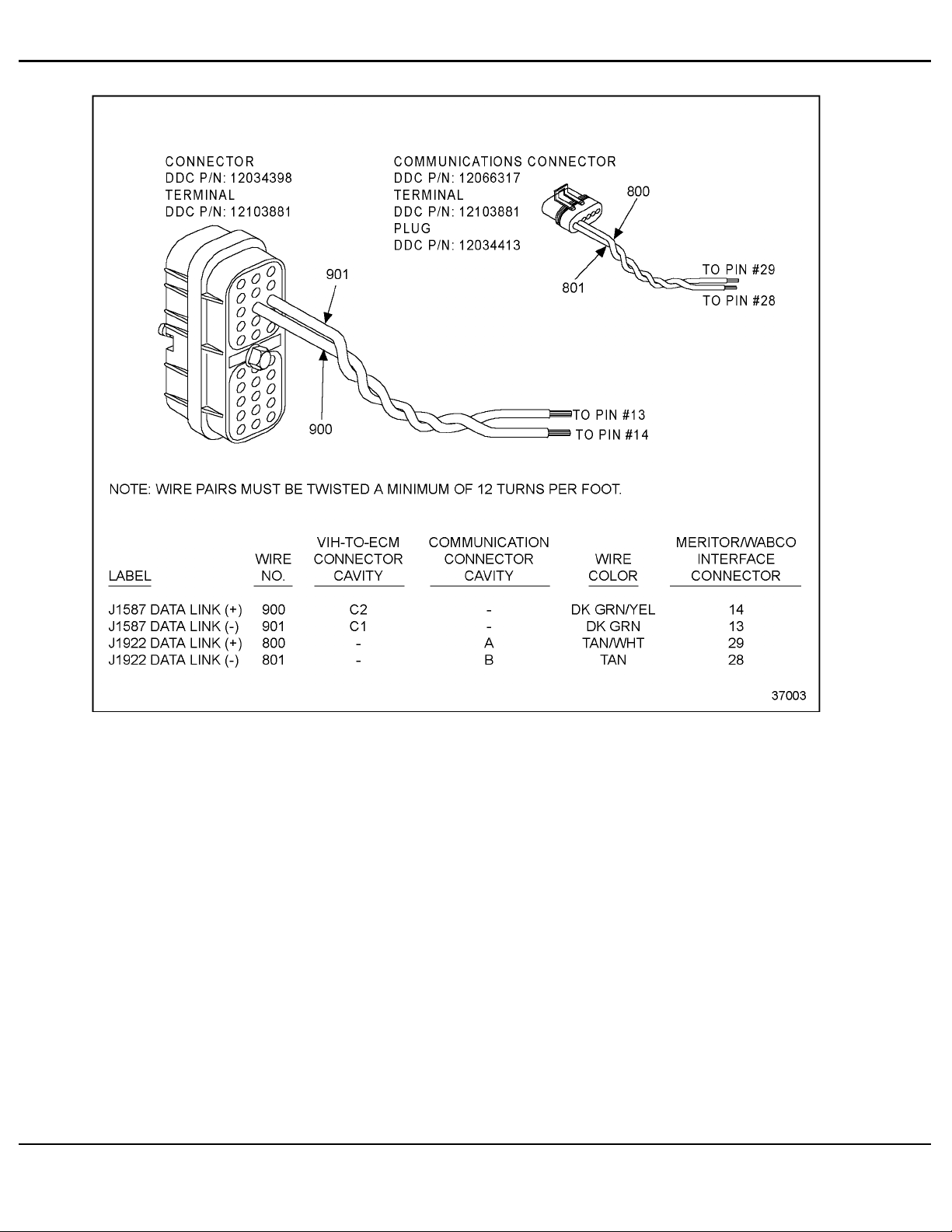

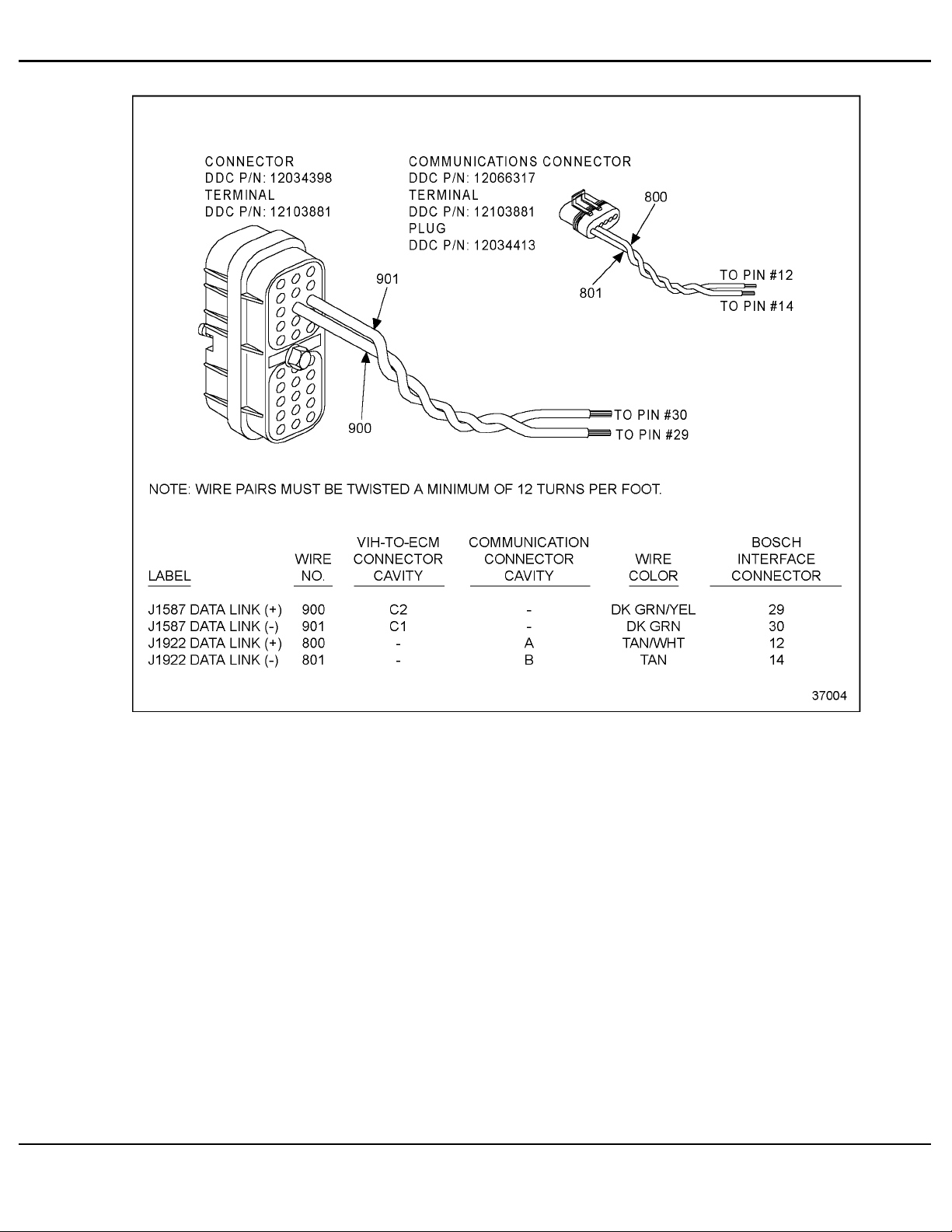

See F igure 5-2 and Figure 5-3 for interface with Meritor/WABCO and Bosch respectively.

All information subject to change without notice. (Rev. (Rev. 3/02)) 5-9

7SA742

0203 Copyright © 2002 DETROIT DIESEL CORPORATION

Page 10

DDEC FEATURES

Figure 5-2 Meritor/WABCO ABS/ATC Interface

5-10 All information subject to change without notice. (Rev. (Rev. 3/02))

742 0203 C opyright © 2002 DETROIT DIESEL CORPORATION

7SA

Page 11

DDEC IV APPLICATION AND INSTALLATION MANUAL

Figure 5-3 Bosch ABS/ATC Interface

All information subject to change without notice. (Rev. (Rev. 3/02)) 5-11

7SA742

0203 Copyright © 2002 DETROIT DIESEL CORPORATION

Page 12

DDEC FEATURES

THIS PAGE INTENTIONALLY LEFT BLANK

5-12 All information subject to change without notice. (Rev. (Rev. 3/02))

742 0203 Co pyri ght © 2002 DETROIT DIESEL CORPORATION

7SA

Page 13

DDEC IV APPLICATION AND INSTALLATION MANUAL

5.3 CRUISE CONTROL

Cruise Control is ava ilable with any DDEC engine. Cruise Control will operate in either Engine

or Vehicle Speed Mode and maintain a targeted speed (M PH or RPM) by increasing or decreasing

fueling. The targeted speed can be selected and adjusted with dash-mounted switches. Up to five

digital inputs are required (four for automatic transmission) for Cruise Control operation and a

digital output is optional (refer to section 4.1.1 for additional information on digital inputs). A

Vehicle Speed Sensor (VSS) is required for Vehicle Speed Cruise Control.

5.3.1 OPERATION

There are two types of Cruise Control: Engine Speed Cruise Control and Vehicle Speed Cruise

Control.

Engine Speed Cruise Control

Power is varied under Engine Speed Cruise Control to maintain constant engine speed. Vehicle

speed will vary depending on powertrain components. Engine Speed Cruise Control does not

need a VSS. Engine Speed Cruise Control cannot be used with automatic transmissions.

Vehicle Speed Cruise Control

Vehicle Speed Cruise is enabled when "Enable Cruise" and a Vehicle Speed Sensor (VSS) are

installed. Engine speed and power are varied under Vehicle Speed Cruise Control to maintain the

set vehicle speed. The maximum Cruise Control speed cannot exceed the programmed maximum

Vehicle Speed Limit (when programmed). The vehicle speed must be above 20 MPH and the

engine speed above 1,100 RPM (1,000 RPM for on-highway 1999 model year or later engines)

to set Cruise Control.

This type of Cruise Control is required when either of the following conditions exists:

Vehicle Speed Limiting -- Vehicle Speed Cruise Control is mandatory if the vehicle speed

limit is programmed and Cruise Control is desired. This will prevent the ECM from

fueling the engine at speeds greater than the vehicle speed limit.

Automatic Transmissions -- Vehicle Speed Cruise Control must be selected if the vehicle is

equipped with an automatic transmission. This will ensure proper transmission upshifts

while in Cruise Control. Refer to the transmission manufacturer's manual for more

information and see the Vehicle Interface Harness schematic.

Cruise c ontrol can be overridden at any time with the foot pedal if the vehicle is not operating at

the programmed Vehicle speed Limit.

Smart Cruise

The Eaton®Smart Cruise™ system will send a "he art beat" message on the SAE J1939 Data Link.

Manual C ruise Control and Smart Cruise will be disabled if the message is not received over the

data link or the message indicates that there is a failure in Smart Cruise. To regain manual control,

the driver must toggle the Cruise Master Switch twice within 10 seconds.

®

Eaton

All information subject to change without notice. (Rev. (Rev. 3/02)) 5-13

7SA742

and Smart Cruise™ trademarks of the Eaton Corporation.

0203 Copyright © 2002 DETROIT DIESEL CORPORATION

Page 14

DDEC FEATURES

This feature is available with Release 27.0 or later. Smart Cruise must be configured by VEPS

(Release 27.0 or later), WinVeps (Release 2.0 or later) or the DRS. F or additional information

on Smart Cruise, contact Eaton Corporation.

Cruise Enable

Cruise Control is enabled, but not active when the Cruise Control Enable digital input is switche d

to battery ground.

Set / Coast On

Set: Cruise Speed is set by momentarily contacting the switch to the ON position

(switching the digital input to battery ground). Cruise Control will become

active a nd maintain the engine or vehicle speed present at the time.

Coast: When Cruise Control is active, the Set/Coast input can

be used to reduce

power and speed by toggling the switch. Momentarily toggling a nd releasing

the Set/Coast switch will decrease the set point by 1 MPH increments for

Vehicle Speed Cruise Control and 25 RPM increments

for Engine Speed

Cruise Control. Holding the Set/Coast will decrease the set point by 1 MPH

per second (Vehicle Spee d CC) or 25 RPM per seconds (Engine Speed CC).

When released the Cruise Control set point will

be at the new speed.

Resume / Accel On

Resume: If Cruise Control has been disabled with the service brake or the clutch switch,

momentary contact to the ON position (switching the input to battery ground)

restores the previously set cruise speed.

Accel: When Cruise Control is active, the Resume/Accel input c an be used to increase

power and speed by toggling the switch. Momentarily toggling and releasing the

Resume/Accel switch will increase the set point by 1 MPH increments for Vehicle

Speed Cruise Control and 25 RPM increments for Engine Speed Cruise Control.

Holding the Resume/Accel will increase the set point by 1 MPH per second

(Vehicle Speed CC) or 25 RPM per seconds (Engine Speed CC). When released

the Cruise Control set point will be at the new speed.

5-14 All information subject to change without notice. (Rev. (Rev. 3/02))

742 0203 C opyright © 2002 DETROIT DIESEL CORPORATION

7SA

Page 15

DDEC IV APPLICATION AND INSTALLATION MANUAL

Clutch Released (Manual Transmissions)

This input indicates that the clutch is released and is used for suspending Cruise Control and

Auto Resume.

When the clutch is released, the input is at battery ground. Cruise Control is suspended if the

clutch is depressed once. If the clutch is depressed twice within three seconds, Cruise Control

is automatically resumed.

NOTE:

When engine brake is configured and auto resume is enabled, the first time the clutch

is depressed to suspend Cruise Control, the engine brakes will be delayed for three

seconds.

The digital input logic for the Clutch Switch disables Cruise Control in the unlikely event of a

broken clutch switch wire.

Service Brake Released (Automatic and Manual Transmissions)

This input indicates that the brake is released when switched to battery ground. If the bra ke is

activated, then the input is not grounded and Cruise Control is suspended. Cruise Control is

resumed by using the Resume/Accel Switch.

The input logic for the Brake Switch disables Cruise C ontrol in the unlikely event of a broken

brake switch wire.

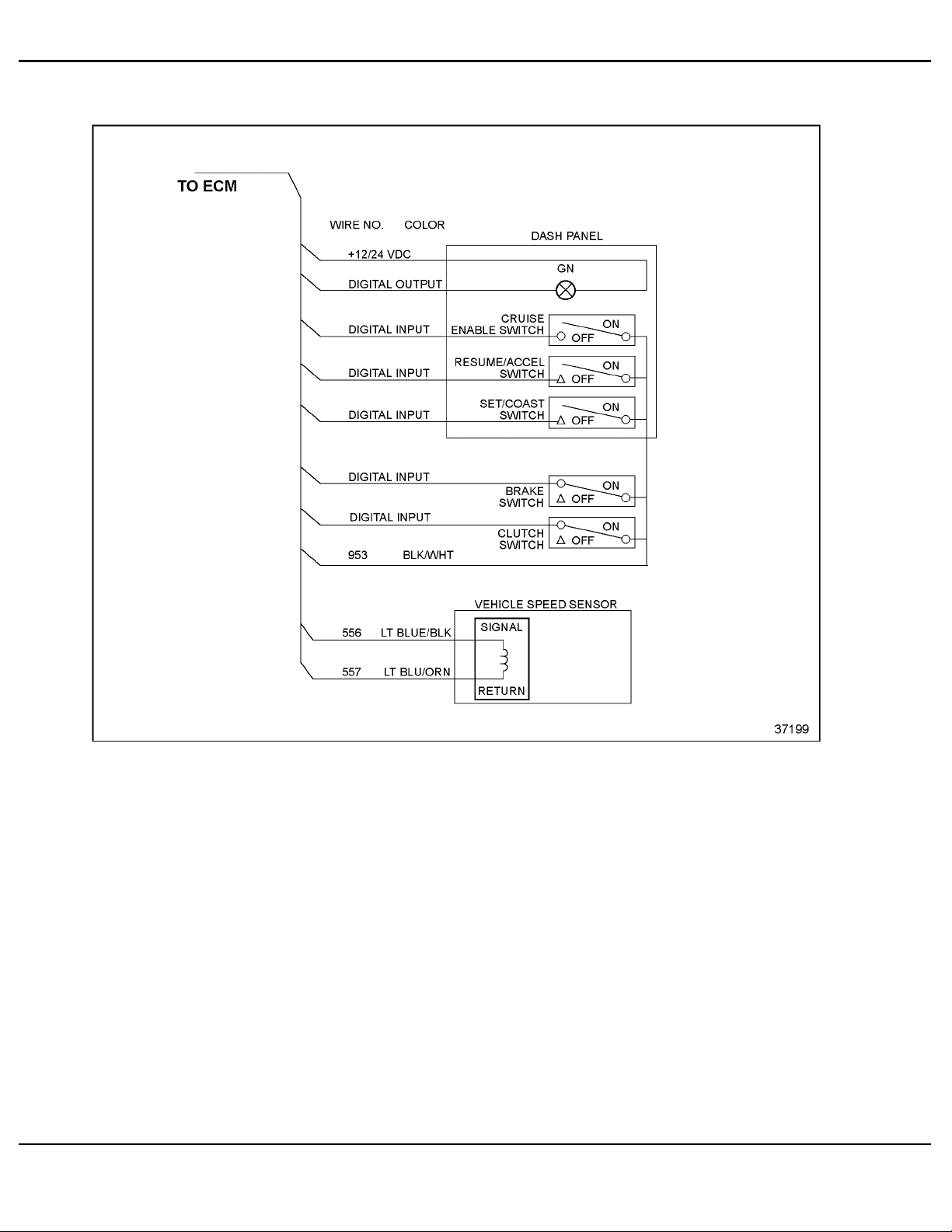

5.3.2 INSTALLATION

The following is a list of switches that are required for Cruise Control operation.

Cruise Enable Switch

Brake Switch

Clutch Switch -- optional for automatic transmissions

Set/Coast Switch

Resume/Accel Switch

Cruise Active Light -- optional

All information subject to change without notice. (Rev. (Rev. 3/02)) 5-15

7SA742

0203 Copyright © 2002 DETROIT DIESEL CORPORATION

Page 16

DDEC FEATURES

See Figure 5-4 for a diagram of the Cruise Control circuit.

Figure 5-4 Cruise Control Circuit

5-16 All information subject to change without notice. (Rev. (Rev. 3/02))

742 0203 C opyright © 2002 DETROIT DIESEL CORPORATION

7SA

Page 17

DDEC IV APPLICATION AND INSTALLATION MANUAL

5.3.3 PROGRAMMING REQUIREMENTS AND FLEXIBILITY

To configure an engine f or Cruise Control, the digital inputs, output and VSS settings listed in

Table 5-7 must be selected either with the Vehicle Electronic Programming System (VEPS), the

DDEC Reprogramming System (DRS) or on engine order entry. The required and optional

digital inputs and outputs are listed in Table 5-7.

Description Type Function Number

Service Brake Released Digital Input 17

Set/Coast Digital Input 20

Resume/Accel Digital Input 22

Cruise Control Enable Digital Input 23

Clutch Released

(required for manual transmissions)

Cruise Control Active Light

(optional for Cruise Control)

Table 5-7 Cruise Control Related Digital Input and Output Signals

Digital Input 18

Digital Output 11

AVeh

icle Speed Sensor must be configured for Vehicle Speed Cruise Control.

Refer to section 3.14.25, "Vehicle Speed Sensor," for additional inf ormation.

If Eaton Smart Cruise is installed on the ve hicle, the feature as listed in Table 5-8 must be

abledbyVEPSorDRS.

en

Parameter Description

Adaptive Cruise Control

(Smart Cruise)

Enables or disables the Smart Cruise Control feature. YES, NO

Choice

Table 5-8 Smart Cruise Parameter

The Cruise Control parameters listed in Table 5-9 can be set by order entry, DDR, DDDL, the

DRS, or VEPS.

All information subject to change without notice. (Rev. (Rev. 3/02)) 5-17

7SA742

0203 Copyright © 2002 DETROIT DIESEL CORPORATION

Page 18

DDEC FEATURES

Parameter Description Range

CRUISE CONTROL

MIN CRUISE SPEED Sets the maximum cruise speed in MPH or KPH.

MAX CRUISE MPH or KPH Sets the maximum cruise speed in MPH or KPH.

AUTO RESUME

CRUISE SWITCH VSG

INITIAL VSG SET SPEED Sets the cruise switch VSG initial set speed.

RPM INCREMENT Sets the cruise switched VSG RPM increment. 1to255RPM

CRUISE/ENGINE BRAKE

FEATURE

CRUISE/ENGINE BRAKE

ACTIVATION SPEED

ENG BRAKE INCREMENT

MPH or KPH

MAX OVERSPEED LIMIT

MAX SPEED NO FUEL

Enables or disables the vehicle speed Cruise

Control feature.

20 MPH to MAX

MIN CRUZ to Vehicle

Speed Limit or 127 mph

Enables or disables the automatic Cruise Control

set speed resume feature.

Enables or disables the cruise switch VSG set

speed feature.

VSG MIN RPM to

VSG MAX RPM

Enables or disables the feature that allows the

engine brake to be used while on Cruise Control

if the vehicle exceeds the cruise set speed.

Sets the additional speed before the engine

brake is applied to slow down the vehicle. The

engine brake is activated at low level unless the

operator has turned off the engine brakes with

the dash board switches.

Sets the additional incremental speed that must

be reached before the engine brake will activate

the medium and/or high level of retardation.

Sets the vehicle speed above which a diagnostic

code will be logged if the driver fuels the engine

andexceedsthislimit.Enteringa0willdisable

this option.

Sets the vehicle speed above which a diagnostic

code will be logged if the vehicle reaches this

speed without fueling the engine. Entering a 0

will disable this option.

YES, NO

CRUZ SPD

if VSL = NO

YES, NO

YES, NO

YES, NO

0to10MPH

1to5MPH

0to127MPH

0to127MPH

Table 5-9 Cruise Control Parameters

5.3.4 DIAGNOSTICS

Two faults (SID 216 FMI 14 and PID 86 FMI 14) will be logged simultaneously if Smart Cruise

is enabled and the data is not being received, the received data is ba d or the Smart Cruise unit has

been removed.

If these faults are received in addition to an SAE J1939 Data Link failure (SID 231 FMI 12) , then

the problem is with the SAE J1939 Data Link itself.

5-18 All information subject to change without notice. (Rev. (Rev. 3/02))

742 0203 C opyright © 2002 DETROIT DIESEL CORPORATION

7SA

Page 19

DDEC IV APPLICATION AND INSTALLATION MANUAL

5.3.5 INTERACTION WITH OTHER FEATURES

The Cruise Control logic i s also used with the DDEC Pressure Sensor Governor in fire trucks.

Both systems cannot be configured on the same engine. Refe r to section 5.29 for more

information on the Pressure Sensor Governor. DDEC can be configured to allow the engine

brakes to a ctivate during Cruise Control operation.

NOTE:

Cruise Control maximum speed cannot exceed the vehicle speed limit.

All information subject to change without notice. (Rev. (Rev. 3/02)) 5-19

7SA742

0203 Copyright © 2002 DETROIT DIESEL CORPORATION

Page 20

DDEC FEATURES

THIS PAGE INTENTIONALLY LEFT BLANK

5-20 All information subject to change without notice. (Rev. (Rev. 3/02))

742 0203 Co pyri ght © 2002 DETROIT DIESEL CORPORATION

7SA

Page 21

DDEC IV APPLICATION AND INSTALLATION MANUAL

5.4 CRUISE CONTROL FOR DRILLIN G/PUMPING

APPLICATIONS WITH OPTIO NAL DUAL STATION

CONTROL

Cruise control for drilling/pumping applications is an optional DDEC feature that allows the

setting of a targeted engine speed and a easy return to the targeted speed from idle.

For example, petroleum mud pumps are used to supply fluid to a drilling bit when a well is being

drilled. The operator will carefully adjust engine speed until he/she achieves the desired pumping

rate. The optimum speed will vary from job to job. The operator will continue until a new section

of drilling pipe must be added. At that point, the engine must be brought back to idle and the

transmission or clutch disengaged while new pipe is threaded in place. The operator can then

bring the engine back up to operating speed and continue the drilling and pumping operation.

5.4.1 OPERATION

This feature allows the operator to set an engine speed during the drilling and pumping process,

drop to idle speed, and then return to the original speed. Returning to the original set speed is

desirable since it has been carefully dialed in by the operator and is ideal for the particular job.

The Engine Speed Cruise Control feature would work to provide the desired engine set speed for

the pumping operation, but it is not configured to resume speed from engine idle.

This process operates as follows:

1. Start the engine, idle, and warm up.

2. Engage the ALT_MIN_VSG Switch - engine goes to ALT_MIN_VSG speed (e.g. 650

rpm).

3. Engage the Cruise Enable Switch.

4. Adjust the hand throttle to the desired speed, e.g. 1700 rpm.

5. Engage set/coast - sets speed to the desired speed, 1700 rpm.

6. Adjust the hand throttle back to idle position.

7. When the need to add pipe arises, engage the brake switch. The engine drops to 650 r pm.

8. When ready to continue, engage Resume/Accel and the spee d returns to 1700 rpm.

All information subject to change without notice. (Rev. (Rev. 3/02)) 5-21

7SA742

0203 Copyright © 2002 DETROIT DIESEL CORPORATION

Page 22

DDEC FEATURES

5.4.2 PROGRAMMING REQUIREMENTS & FLEXIBILITY

The hardware and software configuration include the proper 6N4C group for VSG engine

governing such as 06N04C0720 a nd customer selectable parameters.

The customer selectable parameters settings are listed in Table 5-10.

Parameter Description

Cruise Control Enable Enables the engine speed cruise control feature. YES

Alternate Minimum VSG Sets the Alternate Minimum VSG speed

(set above the idle speed)

Setting

650 RPM

Table 5-10 Customer Selectable Parameters

The digital inputs listed in Table 5-11 must be programme d.

Description Type Function Number

Cruise Enable Digital Input 23

Set/Coast Digital Input 20

Resume/Accel Digital Input 22

Service Brake Digital Input 17

Alt Min VSG Digital Input 16

Table 5-11 Digital Inputs

5.4.3 DUAL STATION CONTROLS

This feature will also work with dual control stations. The operator has the capability of starting

the engine at Station 1 mounted near the engine, follow the operation procedure above, and while

at the desired operating speed, switch to throttle Station 2 and adjust engine speed remotely, if

desired. The operator could then switch back to Station 1 when pipe was to be added.

For dual station controls, the digital inputs listed in Table 5-10 are required in addition to the

digital inputs listed in Table 5-12.

Description Type Function Number

VSG Station Change Digital Input 33

VSG Station Change C omplement Digital Input 34

Table 5-12 Additional Dual Station Control Digital Inputs

For additional installation information on VSG Dual Station Controls, refer to section, 4.31

"Throttle Controls/Governors".

5-22 All information subject to change without notice. (Rev. (Rev. 3/02))

742 0203 C opyright © 2002 DETROIT DIESEL CORPORATION

7SA

Page 23

DDEC IV APPLICATION AND INSTALLATION MANUAL

5.5 DIAGNOSTICS

Diagnostics is a standard feature of the DDEC system. The purpose of this feature is to provide

information for problem identification and problem solving in the form of a code. The ECM

continuously performs self diagnostic checks and monitors the other system components.

Information for problem identification and problem solving is enhanced by the detection of faults,

retention of fault codes and separation of active from inactive codes.

5.5.1 OPERATION

The e ngine-mounted ECM includes control logic to provide overall engine management. System

diagnostic checks are made at ignition on and continue throughout all engine operating modes.

Sensors provide information to the ECM regarding various engine and vehicle performance

characteristics. The information is used to regulate engine and vehicle per forma nce, provide

diagnostic information, and activate the engine protection system.

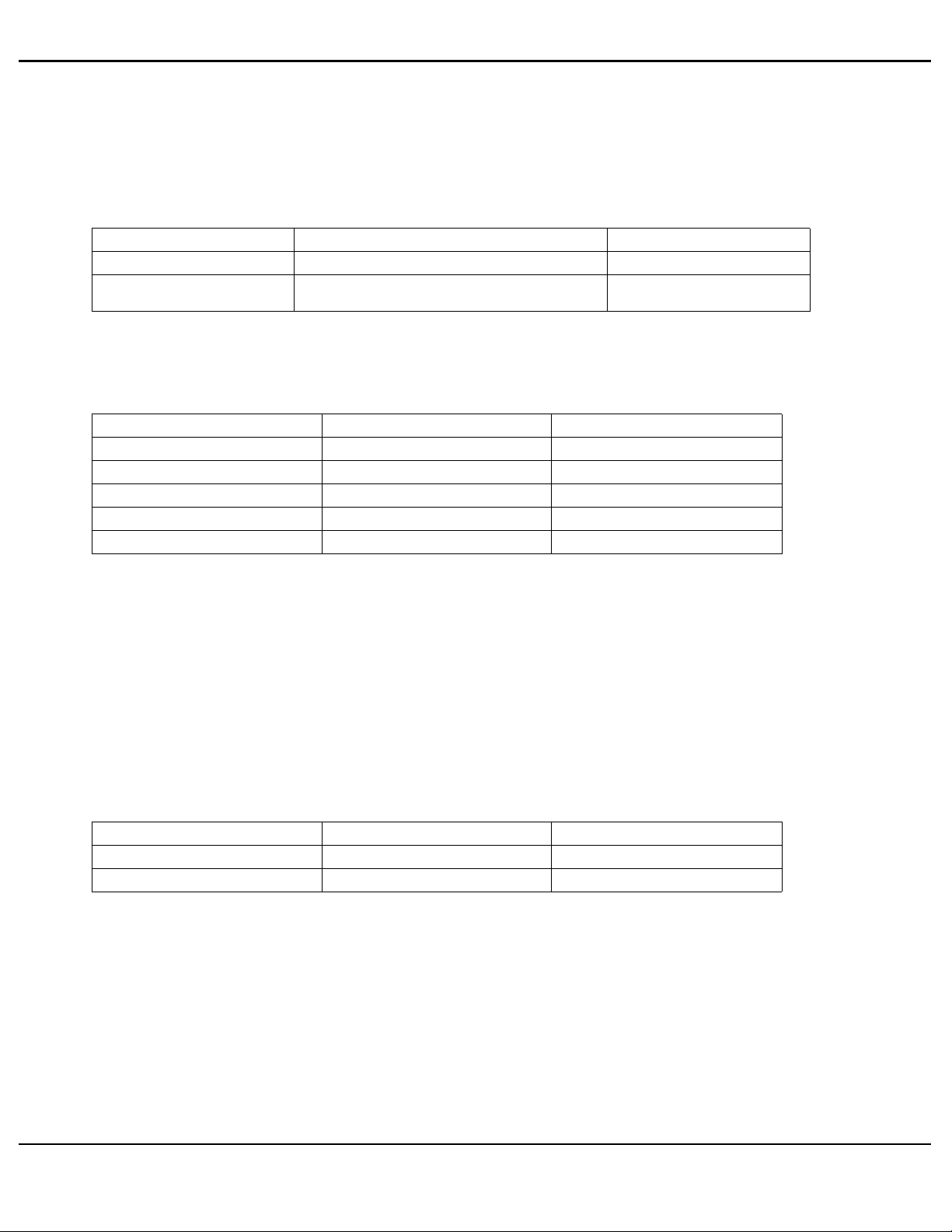

Instrument panel warning lights (see Figure 5-5), the Check Engine Light (CEL) and the Stop

Engine Light (SEL), warn the engine operator. The CEL is an amber light and the SEL is a

red light.

Figure 5-5 Typical Diagnostic Request/SEO Switch and Warning Lights

All information subject to change without notice. (Rev. (Rev. 3/02)) 5-23

7SA742

0203 Copyright © 2002 DETROIT DIESEL CORPORATION

Page 24

DDEC FEATURES

The C EL is illuminated and a code is stored if an electronic system fault occurs. This indicates

the pr oblem should be diagnosed as soon as possible. The ECM illuminates the CEL and SEL

and stores a malfunction code if a potentially engine damaging fault is detected. Th ese codes

can be accessed in one of four ways:

Using the Diagnostic Data Reader (DDR)

Flashing the CEL and SEL with the Diagnostic Request Switch (may be combined with

Stop Engine Override switch, see Figure 5-5)

Using the Detroit Diesel Diagnostic Link™ (DDDL) PC software package

By ProDriver®, Electronic Fire Commander™, Electronic Display Module (EDM), or

other display

There are two types of diagnostic codes:

An active code - a fault present at the time when checking for codes

An inactive code - a fault which has previously occurred; inactive codes are logged into

the ECM and time stamped with the following information:

First occurrence of each diagnostic code in engine hours

Last occurrence of each diagnostic code in engine hours

Total time in seconds that the diagnostic code was active

5-24 All information subject to change without notice. (Rev. (Rev. 3/02))

742 0203 C opyright © 2002 DETROIT DIESEL CORPORATION

7SA

Page 25

DDEC IV APPLICATION AND INSTALLATION MANUAL

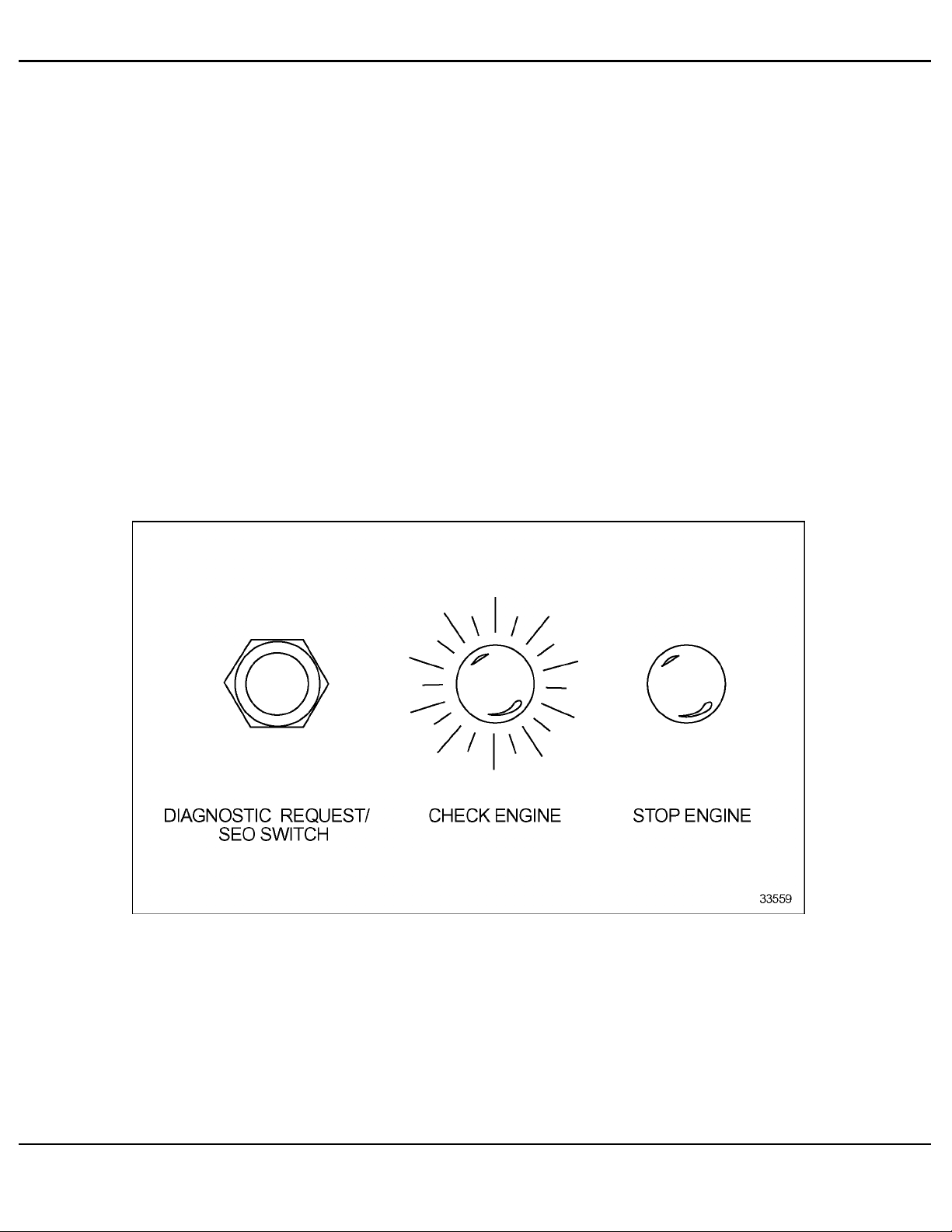

Diagnostic Request Switch

The Diagnostic Request Switch is used to activate the CEL/SEL to flash codes. Active codes are

flashed on the SEL and inactive codes are flashed on the CEL (see Figure 5-6). Inactive c odes are

flashed in numeric al order, a ctive codes are flashed in the order received, most recent to least

recent. The Diagnostic Request Switch can also be used as the Stop Engine Override (SEO)

Switch. The codes are flashed out of the ECM connected to the switch.

Figure 5-6 Flash Codes

NOTE:

For multi-ECM installations, the Diagnostic Request Switch and SEO are combined on

the master ECM. All receiver ECMs have a separate Diagnostic Request Switch.

The Diagnostic Request Switch is used to flash codes in the following circumstances:

The engine is not running a nd ignition is ON

The engine is idling

In both circumstances, activating and holding the Diagnostic Request Switch will flash out the

diagnostic codes.

All information subject to change without notice. (Rev. (Rev. 3/02)) 5-25

7SA742

0203 Copyright © 2002 DETROIT DIESEL CORPORATION

Page 26

DDEC FEATURES

Diagnostic Request Switch/Stop Engine Override

If no separate Diagnostic Request Switch is configured, the SEO Switch serves as both a

Diagnostic Request Sw itch and an SEO Switch.

The Diagnostic Request/Stop Engine Override Switch is used to flash codes in the following

circumstances:

The engine is not running and ignition is on

The engine is idling

In both circumstances, activating and releasing the switch will flash out the diagnostic codes;

activating and releasing the switch a second time will stop the ECM from flashing the diagnostic

codes. Codes will also cease flashing if the engine is no longer at idle. The codes are flashed out

of the ECM connected to the switch.

NOTE:

For multi-ECM installations, the Diagnostic Request Switch and SEO Switch are

combined on the master ECM. All receiver ECMs have a separate Diagnostic Request

Switch.

5.5.2 DEFINITIONS AND ABBREVIATIONS

Parameter Identification Character (PID): A PID is a single byte character used in SAE J1587

messages to identify the data byte(s) that follow. PIDs in the range 0-127 identify single byte

data, 128-191 identify double byte data, and 192-253 identify data of varying length.

Subsystem Identification Character (SID): A SID is a single byte cha racter used to identify

field-repairable or replaceable subsystems for which failures can be detected or isolated. SIDs are

used in conjunction with SAE standard diagnostic codes defined in SAE J1587 within PID 194.

Failure Mode Identifier (FMI): The FMI describes the type of failure detected in the subsystem

and identified by the PID or SID. The FMI and either the PID or SID combine to form a given

diagnostic code defined in SAE J1587 within PID 194.

Flashing Codes: Provides a two digit number (see Figure 5-6). This code may cover several

specific faults. It is provided to advise the operator of the general severity of the fault so the

operator can decide if engine operation can continue without damaging the engine.

Refer to Appendix A for a list of codes, the code number when flashed, the SAE J1587 number

and a description of each code.

5-26 All information subject to change without notice. (Rev. (Rev. 3/02))

742 0203 C opyright © 2002 DETROIT DIESEL CORPORATION

7SA

Page 27

DDEC IV APPLICATION AND INSTALLATION MANUAL

5.6 EDM AND AIM

The Construction and Industrial Electronic Display Module (EDM) and Auxiliary Information

Module (AIM) are the two components which comprise the Detroit Diesel Construction and

Industrial Electronic Display system for engine and equipment parameters.

5.6.1 OPERATION

The EDM (see Figure 5-7) m ay be used alone to display engine parameters or in conjunction with

the AIM to display additional equipment parameters. AIM cannot be used without the EDM.

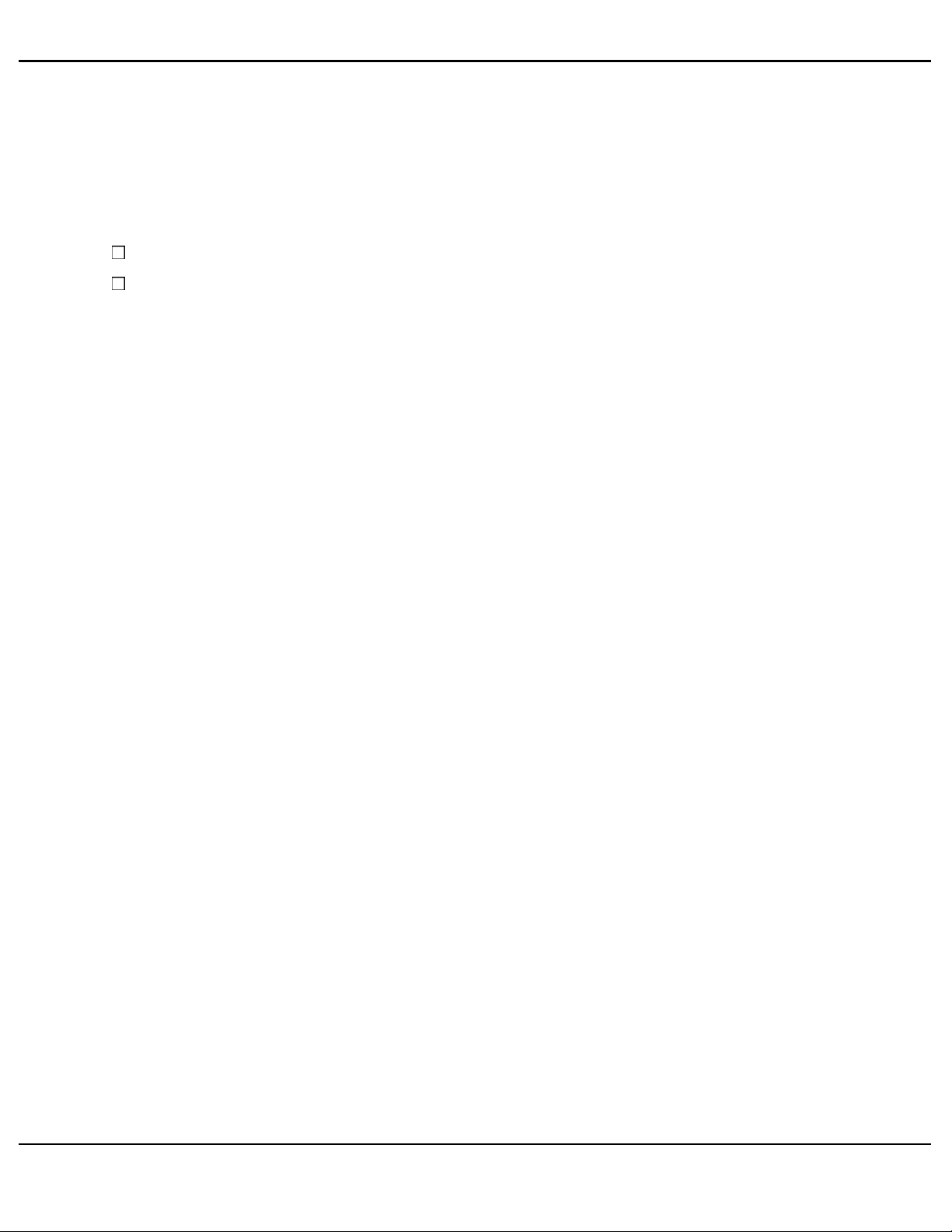

Figure 5-7 Electronic Display Module

The EDM will display the following parameters at all times if the sensor is installed on the

equipment:

Engine RPM

Engine Coolant or Oil Temperature

(Oil Temperature only when coolant temperature is unavailable from the ECM)

Engine Oil Pressure

ECM Battery Voltage or Auxiliary Current (Requires AIM) - (Battery Voltage display)

Vehicle Speed or Auxiliary Pump Pressure or Engine Load

Equipment Temperature or Pressure (Requires AIM)

Equipment Temperature or Pressures (Requires AIM) or Engine Turbo Boost Pressure

Fuel Level (Requires AIM)

All information subject to change without notice. (Rev. (Rev. 3/02)) 5-27

7SA742

0203 Copyright © 2002 DETROIT DIESEL CORPORATION

Page 28

DDEC FEATURES

Check and Stop Indicators

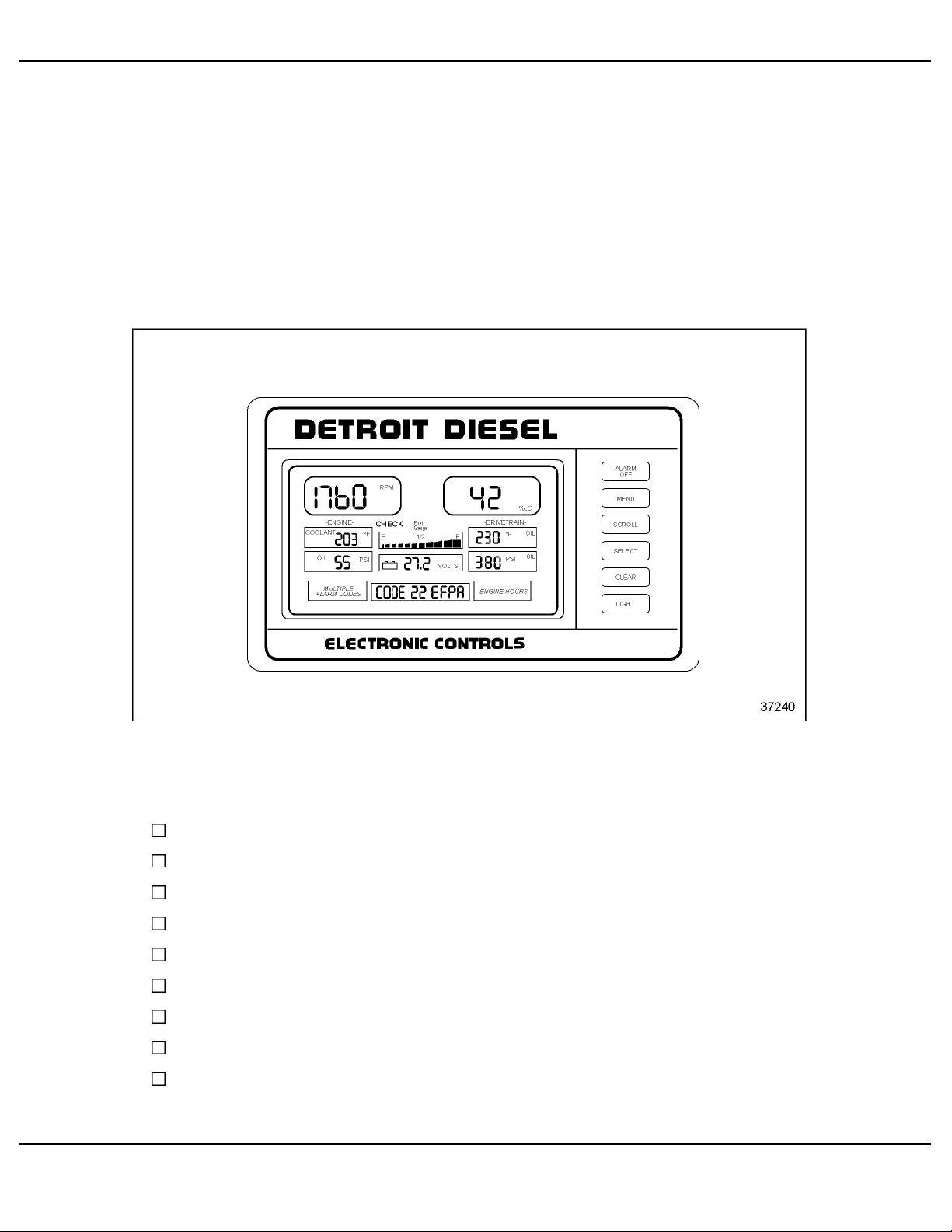

The AI M (see Figure 5-8) is used in conjunction with the EDM to display additional equipment

parameters.

Figure 5-8 Auxiliary Interfa

ce Module

5.6.2 INSTALLATION

For information on installing the Construction and Industrial EDM and AIM refer to the

Construction & Industrial EDM and AIM Installation and Troubleshooting manual ( 7SA801).

5.6.3 PROGRAMMING REQUIREMENTS AND FLEXIBILITY

Refer to Const

(7SA801).

5-28 All information subject to change without notice. (Rev. (Rev. 3/02))

ruction & Industrial EDM and AIM Installation and Troubleshooting manual

742 0203 C opyright © 2002 DETROIT DIESEL CORPORATION

7SA

Page 29

DDEC IV APPLICATION AND INSTALLATION MANUAL

5.6.4 INTERACTION WITH OTHER FEATURES

DDEC installations equipped with both the EDM and AIM may initiate engine shutdowns based

on equipment parameters. The shutdown option include the standard 30 second shutdown as well

as an option for an immediate engine shutdown.

5.6.5 DIAGNOSTICS

Refer to the Construction & Industrial EDM and AIM Installation and Troubleshooting manual

(7SA801).

All information subject to change without notice. (Rev. (Rev. 3/02)) 5-29

7SA742

0203 Copyright © 2002 DETROIT DIESEL CORPORATION

Page 30

DDEC FEATURES

THIS PAGE INTENTIONALLY LEFT BLANK

5-30 All information subject to change without notice. (Rev. (Rev. 3/02))

742 0203 Co pyri ght © 2002 DETROIT DIESEL CORPORATION

7SA

Page 31

DDEC IV APPLICATION AND INSTALLATION MANUAL

5.7 ELECTRONIC FIRE COMMANDER

The Detroit Diesel Electronic Fire Commander™ (EFC) is designed to support DDEC III and

DDEC IV engines in the fire fighting and emergency services market. I t combines the DDEC

Pressure Sensor Governor (PSG), a system monitor, and a pump panel display for vital engine

operating parameters into one co mpa ct, durable package (see Figure 5-9).

EFC replaces the PSG switches, as well as many pump panel gauges as it provides complete

control and monitoring of both DDEC III and DDEC IV systems on the fire truck.

Figure 5-9 Electronic Fire Commander Pump Panel Display

RPM, Oil Pressure, Oil or Coolant Temperature, and ECM Voltage are displayed continuously in

the Engine Data section of the EFC.

Messages and any known diagnostic code accompanying a Check Engine or Stop Engine

condition will be displayed on the Information Center message display. The external alarm output

will also be activated. The EFC displays the PSG status in the Information Center whenever the

OEM interlocks are met. The r eal time of day will also be displayed. The EFC logs the time that

the pump is engaged and that time can be displayed using the Information Center.

All information subject to change without notice. (Rev. (Rev. 3/02)) 5-31

7SA742

0203 Copyright © 2002 DETROIT DIESEL CORPORATION

Page 32

DDEC FEATURES

5.7.1 OPERATION

The Electronic Fire Commander has two modes of operation:

RPM Mode (engine speed)

Pressure Mode (water pump pressure, psi)

RPM M ode controls engine speed to a desired RPM and Pressure Mode controls engine speed to

maintain a desired discharge manifold pressure.

The operating modes are selectable and may be change d by pr essing the MODE button providing

the appropriate interlocks have been met. The engine will continue to run at the same speed when

the mode switch is toggled between the RPM and Pressure modes.

The maximum pres et pressure for EFC is 200 psi.

5.7.2 INSTALLATION

The Electronic Fire Commander Harness schematic shows the minimum requirements for the

PSG to operate (see Figure 5-10). Additional functions and interlocks may be used. Refer to the

Electronic Fire Commander Installation and Troubleshooting manual (6SE476).

EFC may be powered from a 12/24 V supply.

5.7.3 ORDERING EFC

The hardware listed in Table 5-13 is needed for Pressure Governor installation with EFC. The

6N4C group must be specified at engine order entry or through Detroit Diesel Technical Service.

Component

Electronic Fire Commander 23519655

Pressure Sensor 23520795

Electronic Fire Commander Harness (see

Figure 5-10)

OEM Interlocks OEM Supplied

Table 5-13 Electronic Fire Commander and Pressure Sensor

Hardware available from the DDC Parts Distribution Center for installation of Electronic Fire

Commander (EFC) is listed in Table 5-13 as a complete kit. The 6N4C group must be specified at

engine order entry or through Detroit Diesel Technical Service.

Component

Electronic Fire Commander Kit

(contains Electronic Fire Commander and the pressure sensor)

Part Number

OEM Supplied

Part Number

23520139

Table 5-14 Electronic Fire Commander Kit

5-32 All information subject to change without notice. (Rev. (Rev. 3/02))

742 0203 C opyright © 2002 DETROIT DIESEL CORPORATION

7SA

Page 33

DDEC IV APPLICATION AND INSTALLATION MANUAL

Figure 5-10 Electronic Fire Commander Harness

All information subject to change without notice. (Rev. (Rev. 3/02)) 5-33

7SA742

0203 Copyright © 2002 DETROIT DIESEL CORPORATION

Page 34

DDEC FEATURES

5.7.4 PROGRAMMING REQUIREMENTS AND FLEXIBILITY

The digital inputs listed in Table 5-15 are required for use with EFC and can be configured at

order entry, by VEPS, or DRS. Refer to section 4.1, "Digital Inputs," for additional information.

Description Function Number

Pressure/RPM Mode 8 523 H1

PSG Enable 24 543 G2

Resume/Accel On

(increase)

Set/Coast On (decrease) 20 541 J1

* DDC circuit numbers and port assignments shown are default settings but can differ from application

to application.

22 545 G3

Circuit Number*

VIH-to-ECM

Connector Assignment*

Table 5-15 Required Digital Inputs for E FC

The digital outputs required for use with EFC are listed in Table 5-16 and can be configured at

order entry, by VEPS, or DRS. Refer to section 4.2, "Digital Outputs," for additional information.

Description Function Number

PSG Active 5 499

Cruise Active 11 565

* DDC circuit numbers and port assignments shown are default settings but can differ from application

to application.

Circu

it Number*

Conne

Pigtail off the Engine Sensor

ctor Assignment*

VIH-to-ECM Connector

avity F3

-C

Harness - Cavity Y3

Table 5-16 Required Digital Outputs for EFC

The correct 6N4C group must be specified at engine orde r entry or through Detroit Diesel

Technical Service. More information is available in the manual Electronic Fire Commander

Installation and Troubleshooting (6SE476).

5-34 All information subject to change without notice. (Rev. (Rev. 3/02))

742 0203 C opyright © 2002 DETROIT DIESEL CORPORATION

7SA

Page 35

DDEC IV APPLICATION AND INSTALLATION MANUAL

5.8 ELECTRONIC SPEED SWITCH

The Electronic Speed Switch (ESSE-2) is a two channel electronic speed switch typically used in

generator set applications. Two channels can be used f or crank (starter motor) disconnect and

overspeed protection, or for underspeed and overspeed warnings.

5.8.1 OPERATION

The switches on the cover of ESSE-2 are used for two conditions: no power and power applied

with no signal present. When the engine reache s proper speed during cranking, Switch 1 will

close causing the cranking motor to be disconnected. Switch 2 closes during an overspeed

condition causing the engine to cease operation. by removing power from the fuel solenoid.

The setpoint for switch closing is determined by the two se tpoint potentiometers.

There are four reset options available for resetting the speed switch: electrical latch, manual reset,

automatic reset and adjustable reset.

Electrical Latch

After the setpoint has been r eac hed, the switch will close and remain closed even if the input

signal frequency has been lowered to 0 Hz. The only way to reset the unit is to remove power

This switch is typically used for overspeed protection.

Manual Reset

The ESSE-2 is supplied with a reset button. The unit will be reset by pressing the reset button.

Automatic Reset

The switch automatically resets if the frequency of the input signal is lowered to 85 ± 5% of the

setpoint. This switch is typically used for crank disconnect.

Adjustable (Automatic) Reset

The switch will automatically reset at the frequency determine d by the setting of the supplied

reset potentiometer. The reset can be selected anywhere be tween 25% and 95% by adjusting the

potentiometer.

5.8.2 INSTALLATION

Four mounting holes are provided on the ESSE-2 case. Mount the unit in a location where

vibration effects are minimized. Two conductor shielded cable should be used to connect

the signal source, Mini-Gen, mag pickup, to ESSE-2. Single conductor shielded cable is

recommended for alternator or ignition signal sources. The shield should be connected to ground

only at one end. The shield is connected to Terminal 2 for the Mini-Gen or mag pickup connection

and to Terminal 5 for the alternator connection.

All information subject to change without notice. (Rev. (Rev. 3/02)) 5-35

7SA742

0203 Copyright © 2002 DETROIT DIESEL CORPORATION

Page 36

DDEC FEATURES

Fuses or circuit br eakers should be c onnec ted in series with the load to protect ESSE-2. The fuse

should be a 10 Amp slow blow. The circuit breaker should be rated at 10 Amps. If load currents

in e xcess of 10 Amps are expected, interface relays should be used. See Figure 5-11.

Figure 5-11 Electronic Speed Switch Installation

5-36 All information subject to change without notice. (Rev. (Rev. 3/02))

742 0203 C opyright © 2002 DETROIT DIESEL CORPORATION

7SA

Page 37

DDEC IV APPLICATION AND INSTALLATION MANUAL

The pin definition for the connector, current, and wire gage are listed in Table 5-17.

Current

Under 5 Amps 1-2, 7-12 16 AWG

5 - 10 Amps 1-2, 7-12 14 AWG

--

Terminals

3-6 18 - 20 AWG

Wire Gauge

Table 5-17 Wire Gauge for ESSE-2

The electrical input voltage options for ESSE-2 are listed in Table 5-18.

Input Voltage

Option

Max. Operating

Current

Max. Standby

Current

Relay Contact

Ratings

Power Supply

Transient

Protection

Reverse Polarity

Protection

0.1 to 10 Amps - 28 VDC Resistive Load 0.1 to 4 Amps - 75 VDC Resistive Load

0.1 to 8 Amps - 28 VDC Inductive Load 0.1 to 3 Amps - 75 VDC Inductive Load

900 VDC for 100 microseconds

8-40VDC 40 - 80 VDC

At 40 V: 250 MA At 80 V: 115 MA

At 24 V: 220 MA At 64 V: 100 MA

At 12 V: 200 MA At 40 V: 50 MA

At 40 V: 70 MA At 80 V: 75 MA

At 40 V: 45 MA At 64 V: 60 MA

At 40 V: 30 MA At 40 V: 50 MA

900 VDC for 100 microseconds

Exponential Decay

140 VDC for 1 milliseconds

Exponential Decay

110 VDC for 0.45 seconds

Exponential Decay

1000 VDC 1000 VDC

Exponential Decay

140 VDC for 1 milliseconds

Exponential Decay

110 VDC for 0.45 seconds

Exponential Decay

Table 5-18 ESSE-2 Electrical Input Voltage O ptions

All information subject to change without notice. (Rev. (Rev. 3/02)) 5-37

7SA742

0203 Copyright © 2002 DETROIT DIESEL CORPORATION

Page 38

DDEC FEATURES

THIS PAGE INTENTIONALLY LEFT BLANK

5-38 All information subject to change without notice. (Rev. (Rev. 3/02))

742 0203 Co pyri ght © 2002 DETROIT DIESEL CORPORATION

7SA

Page 39

DDEC IV APPLICATION AND INSTALLATION MANUAL

5.9 ENGINE BRAKE CONTROLS

The Engine Brake option converts a power-producing diesel engine into a power-absorbing air

compressor. This is accomplished by opening the cylinder exhaust valves near the top of the

normal compression stroke and releasing the compressed cylinder charge to exhaust. The release

of the compressed air to atmospheric pressure prevents the return of energy to the engine piston

on the expansion stroke, the effect being a net energy loss. Fueling is cut off when this occurs.

5.9.1 OPERATION

A dash mounted On/Off Switch is used to enable the Engine Brake option. DDEC IV will directly

control the engine brake solenoids using an intensity switch to select two, four or six cylinders

to produce low, medium, or high braking power on a Series 60. For Series 71/92, the intensity

switch is used to select left bank or left and right bank cylinders to produce low or high brak ing

power for 6V and 8V engines. Inline 6-71 engines use an intensity switch to select the front three

or all cylinders to produce low or high braking power. The engine brakes are engaged every time

the f oot pedal is brought back to the idle position and Cruise Control is not active.

The following are six options for Engine Brake:

Cruise Control with Engine Brake

Engine Brake Disable

Engine Brake Active

Engine Fan Braking

Clutch Released Input

Service Brake Control of Engine Brakes

Min. MPH for Engine Brakes

Cruise Control with Engine Brake

The Engine Brake option can also provide Engine Brake capability when the vehicle is in Cruise

Control. For example, if the vehicle is going down hill in Cruise Control while the engine brake is

selected, the ECM will control the amount of Engine Brake with respect to the Cruise Control set

speed. The level of Engine Brake (low, medium, high) selected with the dash switches will be the

maximum amount of engine bra king the ECM allows. Cruise Control with Engine Brake can

be set with DDDL/DDR, VEPS, and DRS.

Engine Brake Disable

The Engine Brake Disable option uses a digital input which is switched to ground whenever a

vehicle system, such as a traction control device, does not allow engine braking to occur. This

option is required for most automatic transmissions.

All information subject to change without notice. (Rev. (Rev. 3/02)) 5-39

7SA742

0203 Copyright © 2002 DETROIT DIESEL CORPORATION

Page 40

DDEC FEATURES

Engine Brake Active

The Engine Brake Active option uses a digital output that can be used to drive an Engine Brake

Active Light. This output is switched to battery ground whenever the engine brake is active.

Engine Fan Braking

The Engine Fan Bra k ing option turns on the cooling fan when the engine brake level is high and

DDEC fan control is enabled. This creates about 20 to 40 hp additional engine braking power

depending on the size of the cooling fan. This option is selected at the time of engine order or set

by DDDL/DD R, VEPS or DRS. For additional information, refer to section 5.14, "Fan Controls."

Clutch Released Input

The C lutch Released digital input will prevent the engine brakes from being turned on when the

clutch is pressed. This input is required for use with manual transmissions. Refer to section 4.1,

"Digital Inputs," for additional information.

Service Brake Control of Engine Brakes

This option will allow the dash-mounted engine brake switch to be set to the ON position but

not engage the engine brakes until the service brake pedal is pre ssed. A digital input must be

programmed for service brake. Refer to section 4.1, Digital Inputs for additional information.

VEPS, DDR/DDDL or DRS can set this function. This feature is available with Release 5.0 or

later.

Min MPH for Engine Brakes

This option will disable the engine brakes until a minimum vehicle speed is re ached. This

parameter can be configured by VE PS, DRS, or DDR/DDDL. A Vehicle Speed Sensor is required.

Refer to section 3.14.25, "Vehicle Speed Sensor," for additional information.

5.9.2 INSTALLATION

See Figure 5-12 for a schematic of the internal engine brake for the DDEC III/IV ECM and

see Figure 5-13 for a schematic of the internal engine brake for the DDE C III/IV ECM World

Transmission interface.

5-40 All information subject to change without notice. (Rev. (Rev. 3/02))

742 0203 C opyright © 2002 DETROIT DIESEL CORPORATION

7SA

Page 41

DDEC IV APPLICATION AND INSTALLATION MANUAL

Figure 5-12 Internal Engine Brake for DDEC III/IV ECM

All information subject to change without notice. (Rev. (Rev. 3/02)) 5-41

7SA742

0203 Copyright © 2002 DETROIT DIESEL CORPORATION

Page 42

DDEC FEATURES

Figure 5-13 Internal E ngine Brake for DDEC III/IV ECM World Trans Interface

5-42 All information subject to change without notice. (Rev. (Rev. 3/02))

742 0203 C opyright © 2002 DETROIT DIESEL CORPORATION

7SA

Page 43

DDEC IV APPLICATION AND INSTALLATION MANUAL

5.9.3 PROGRAMMING REQUIREMENTS AND FLEXIBILITY

Engine Brake must be specified at the time of engine order or by contacting Detroit Diesel

Technical Service. This enables the two digital outputs required.

The digital inputs listed in Table 5-19 must be configured by order entry, VEPS, DRS:

Description Function Number

Engine Brake Low 1

Engine Brake Medium 2

Engine Brake Disable

(required for most automatic transmissions)

Clutch Switch

(required for manual transmissions)

Table 5-19 Required Digital Inputs for Engine Brake Controls

The par ameters listed in Table 5-20 can be set by order entry, VEPS, DDDL/DDR or DRS for the

Cruise C

ontrol Engine Brake option.

26

18

Parameter Description

CRUISE CONTROL ENGINE

BRAKE

CRUISE ENGINE BRAKE

ACTIVATION SPEED

ENGINE BRAKE INCREMENT

Enables or disables the feature that

allows the engine brake to be used while

on cruise control if the vehicle exceeds

the cruise set speed.

Sets the delta speed that the engine

brake should be applied to slow the

vehicle while in cruise control.

Sets the additional incremental speedthat

must be reached before the engine brake

will activate the medium and/or high level

of retardation.

Choice / Display

YES, NO

1to10MPH

1to5MPH

Table 5-20 Cruise Control Engine Brake Parameters

The optional digital output listed in Table 5-21 can be configured by order entry, VEPS or DRS. It

can be used to drive an Engine Brake Active Light.

Description Type Function Number

Engine Brake Active Digital Output 16

Table 5-21 Optional Digital Output for Engine Brakes

All information subject to change without notice. (Rev. (Rev. 3/02)) 5-43

7SA742

0203 Copyright © 2002 DETROIT DIESEL CORPORATION

Page 44

DDEC FEATURES

The Engine Fan Braking option as listed in Table 5-22 can be configured at the time of engine

order, VEPS, DDR, DDDL or DRS.

Parameter Description

Provides additional engine braking

by activating the DDEC controlled

DYNAMIC BRAKING

fan whenever the engine brakes

areactiveinhigh. Thisfunction

requires both DDEC engine brake

controls and DDEC fan controls.

Choice/Display

YES, NO

Table 5-22 Optional Fan Braking for Engine Brakes

The para meter listed in Table 5-23 can be set by order entry, VEPS, DDDL/DDR or DRS for the

Service Brake Control of the Engine Brakes option.

Parameter Description

SERVICE BRAKE ENABLE

When this function is enabled, an input

from the service brake is required in order

to activate the engine brake.

Choice / Display

YES, NO

Table 5-23 Service Brake Control of Engine Brakes Parameter

The parameter listed in Table 5-24 can be configured by order entry, VEPS, DDR, and DDDL

for the Minimum Vehicle Speed for engine braking to occur.

Parameter Description

ENGINE BRAKE MIN MPH

The minimum vehicle speed

required before engine braking will

occur.

Choice/Display

0-40 MPH

Table 5-24 Minimum MPH for Engine Brakes Option

5.9.4 INTERACTION WITH OTHER FEATURES

DDEC will respond to requests from other vehicle systems via SAE J1939 data link or SAE

J1922 data link to disable the engine brakes.

5-44 All information subject to change without notice. (Rev. (Rev. 3/02))

742 0203 C opyright © 2002 DETROIT DIESEL CORPORATION

7SA

Page 45

DDEC IV APPLICATION AND INSTALLATION MANUAL

5.10 ENGINE PROTECTION

The DDEC engine protection system monitors all engine sensors and electronic components, and

recognizes s ystem malfunctions. If a critical fault is detected, the Check Engine Light (CEL) and

Stop Engine Light (SEL) illuminate. The malfunction codes are logged into the ECM's m e mory.

The standard parameters which are monitored for engine protection are:

Low coolant level

High coolant temperature

Low oil pressure

High oil temperature

The additional parameters for Series 4000 and Series 2000 which are monitored for engine

protection are:

Low coolant pressure

High crankcase pressure

High intercooler temperature

Low intercooler coolant pressure

Auxiliary digital input(s)

5.10.1 OPERATION

Engine protection is a vital part of ECM programming and software. The ECM monitors

coolant level, various pressures and temperatures, and compares these parameters against the

allowable limits to de term ine when a critical fault is reached. The CEL is illuminated and a code

logged if there is an electronic system fault. This indicates the problem should be diagnosed as

soon as possible. The ECM illuminates the CEL and SEL and stores a malfunction code if a

potentially engine damaging fault is detected. Once a critical fault is reached, the CEL and SEL

are illuminated a nd a 30 second timer starts a countdown to the desired level of protection.

Temperature and pressure limits are established in the engine's calibration and may differ slightly

from one engine model to another.

Engine protection consists of different protection levels:

Warning Only

Rampdown

Shutdown

All information subject to change without notice. (Rev. (Rev. 3/02)) 5-45

7SA742

0203 Copyright © 2002 DETROIT DIESEL CORPORATION

Page 46

DDEC FEATURES

Warning Only

The CEL and S EL will illuminate if a fault is detected. There is no power and/or speed reduction

when "Warning Only" is selected. The resulting engine protection is at the discretion of the

engine operator.

NOTE:

The operator has the responsibility to take action to avoid engine damage.

Some applications require two sets of warning lights for different control stations. The wiring

for two sets of lights is in Chapter 3, refer to section 3.16.4.

NOTE:

A diagnostic switch is not required but applications using one, must have a separate

diagnostic switch for each ECM on the engine.

The Diagnostic Request switch is used to activate the CEL and SEL to flash codes.

Rampdown

The CELand SEL will illuminate if a fault is detected. The ECM reduces torque and/or speed

over a 30 second period after the SEL illuminates. The initial torque/speed, which is used for

reduction, is the operating torque or speed prior to the SEL fault condition. See Figure 5-14.

Figure 5-14 Rampdown

A Stop Engine Override (SEO)/Diagnostic Request switch is required when this engine protection

option is selected. The SEO options are available to prevent engine shutdown at the operator's

discretion.

5-46 All information subject to change without notice. (Rev. (Rev. 3/02))

742 0203 C opyright © 2002 DETROIT DIESEL CORPORATION

7SA

Page 47

DDEC IV APPLICATION AND INSTALLATION MANUAL

Shutdown

This option operates in the same manner a s rampdown, exc ept the engine shuts down 30 seconds

after the SEL is illuminated ( see Figure 5-15). (The initial torque and/or speed which is used f or

reduction, is the torque and/or speed w hich occurred immediately prior to the fault condition.) The

Stop Engine Override options are available to preventengine shutdown atthe operator's discretion.

Figure 5-15 Engine Shutdown

A SEO/Diagnostic Request Switch is required when this engine protection option is selected.

Refer to section 5.10.3. The SEO options are available to prevent engine shutdown at the

operator's discretion.

5.10.2 ENGINE OVERTEMPERATURE PROTECTION

Engine Overtemperature Protection (EOP) is additional logic programmed into the ECM and used

in conjunction with standard temperature protection. When EOP is part of the engine calibration,

engine torque and/or speed is reduced as a function of temperature. The CEL illuminates and a

fault code is logged when the EOP calibrated temperature is reached. If the temperature does

not decrease as torque/speed is reduced, the SEL will illuminate when a still higher temperature

is reached.

The subsequent action taken by the ECM depends on customer selection of one of the following:

Warning only (see Figure 5-16)

30 second rampdown (see Figure 5-17)

Shutdown (see Figure 5-18)

Torque reduction is based on the average torque/speed in use prior to the fault condition.

All information subject to change without notice. (Rev. (Rev. 3/02)) 5-47

7SA742

0203 Copyright © 2002 DETROIT DIESEL CORPORATION

Page 48

DDEC FEATURES

Figure 5-16 Engine Overtemperature Protection and Warning Only

EOP can be disabled when

Warning Only is selected for engine protection (Rel ease 22.00 or later

only). This feature is based on the engine series as listed in Table 5-25.

Engine Series Enabled/Disabled

Series 50, Series 60 Will not be disabled with Warning Only

Series 71, Series 92, Series 149 Will not be disabled with W arning Only

Series 2000 Will not be disabled with W arning Only

Series 4000 Will be disabled with Warning Only

Table 5-25 Warning Only Disabled

5-48 All information subject to change without notice. (Rev. (Rev. 3/02))

742 0203 C opyright © 2002 DETROIT DIESEL CORPORATION

7SA

Page 49

DDEC IV APPLICATION AND INSTALLATION MANUAL

Figure 5-17 Engine Overtemperature Protection and Rampdown

All information subject to change without notice. (Rev. (Rev. 3/02)) 5-49

7SA742

0203 Copyright © 2002 DETROIT DIESEL CORPORATION

Page 50

DDEC FEATURES

Figure 5-18 Engine Overtemperature Protection and Shutdown

Some 1999 Model Year Ser

ies 60 engines and later (DDEC Release 26.0 or later) h ave additional

logic to start the ove rtemperature torque reduction logic earlier without alerting the driver.

Engine torque and/or speed is reduced as a function of temperature. A code will be logged and

torque reduction

will begin when the first EOP calibrated temperature is reached. The CEL

will illuminate and a fault code is logged when the second higher temperature limit is reached.

If the temperature does not reduce as torque/speed is reduced, the SEL will illuminate when a

still higher te

5-50 All information subject to change without notice. (Rev. (Rev. 3/02))

mperature is reached.

742 0203 C opyright © 2002 DETROIT DIESEL CORPORATION

7SA

Page 51

DDEC IV APPLICATION AND INSTALLATION MANUAL

The subsequent action taken by the ECM is the 30 second rampdown (see Figure 5-19) or

shutdown (see Figure 5-20) depending on the customer selection. Torque reduction is based on

the average torque/speed in use pr ior to the fault condition.

Figure 5-19 Series 60 1999 Mode

l Year Engine Overtemperature Protection

and Rampdown

All information subject to change without notice. (Rev. (Rev. 3/02)) 5-51

7SA742

0203 Copyright © 2002 DETROIT DIESEL CORPORATION

Page 52

DDEC FEATURES

Figure 5-20 Series 60 1999 Model Year Engine Overtemperature Protection

and Shutdown

5-52 All information subject to change without notice. (Rev. (Rev. 3/02))

742 0203 C opyright © 2002 DETROIT DIESEL CORPORATION

7SA

Page 53

DDEC IV APPLICATION AND INSTALLATION MANUAL

5.10.3 ENGINE PROTECTION SWITCHES

The SEO/Diagnostic Request switch can be combined. A separate Diagnostic Request switch is

an option.

NOTE:

EOP is active even if engine protection is configured for Warning only for the Series

60, Series 50, and Series 2000 engines.

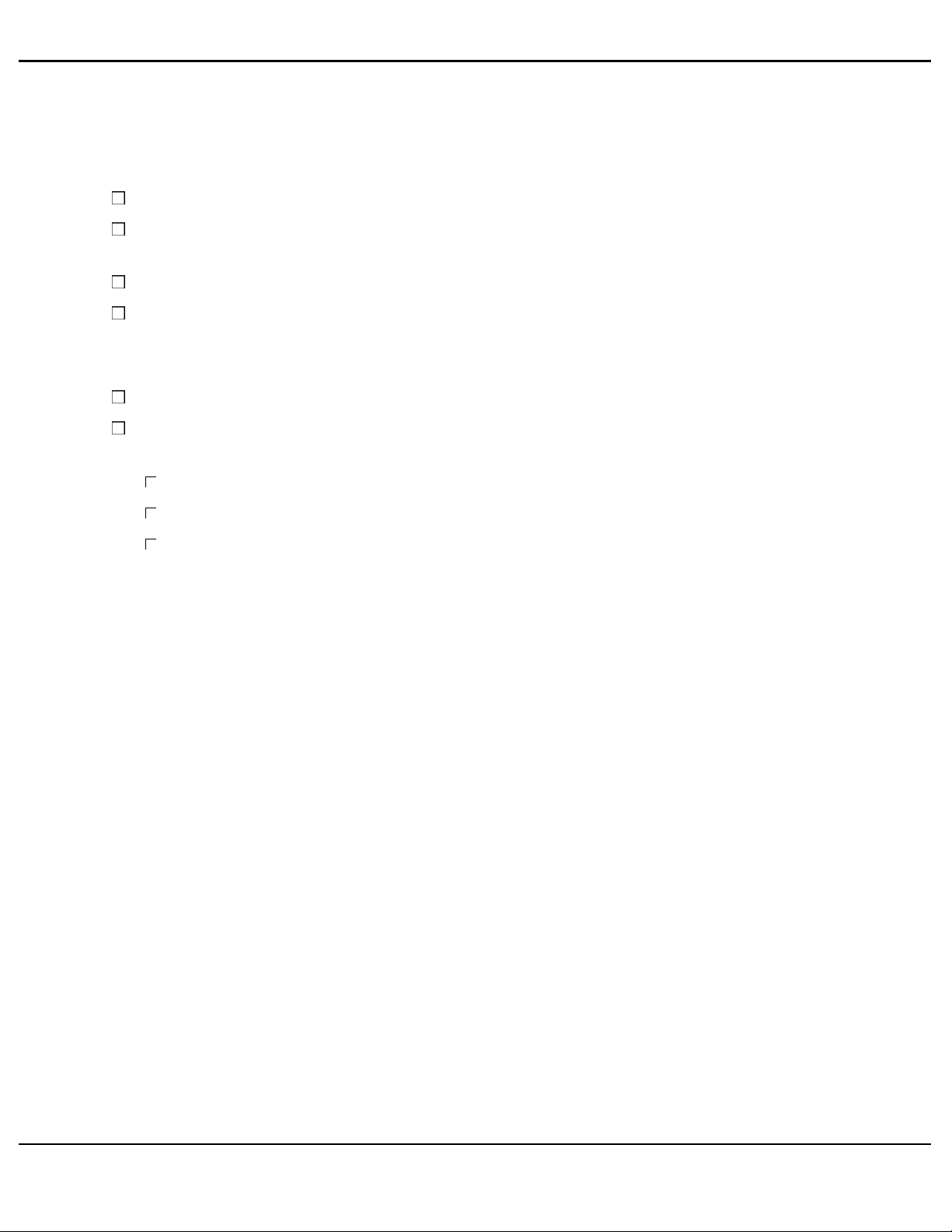

Diagnostic Request Switch

The Diagnostic Request switch is used to activate the CEL and SEL to flash codes (see

Figure 5-21). The SEL will flash the active codes and the CEL will flash the inactive codes.

Refertosection4.1.3.

Figure 5-21 Typical SEO Switch, Diagnostic Request Switch and Warning

Lights

The Diagnostic Request switch is used to flash codes when:

The engine is not running and ignition is on

The engine is idling and not in an "engine protection" condition

Activating and releasing the switch will flash out the diagnostic codes for either condition.

Activating and releasing the switch a second time will stop the ECM from flashing the diagnostic

codes. Codes will also cease flashing if the engine is no longer at idle.

The codes are flashed out of the ECM c onnected to the switch. For multi-ECM installations,

the Diagnostic Request Switch and SEO switchare combined on the master ECM. All receiver

ECMs use a separate Diagnostic Request Switch.

All information subject to change without notice. (Rev. (Rev. 3/02)) 5-53

7SA742

0203 Copyright © 2002 DETROIT DIESEL CORPORATION

Page 54

DDEC FEATURES

5.10.4 STOP ENGINE OVERRIDE OPTIONS

Two types of stop engine overrides are available, Momentary Override and Continuous

Override. Continuous Override has two options. These types are dependent upon spec ific

engine applications. The ECM will record the num ber of times the override is activated after

a fault occurs.

Momentary Override - An SEO switch is used to over ride the shutdown sequence . This override

resets the 30 second shutdown timer, restoring power to the level when the SEL was illuminated.

The switch must be recycled a fter five sec onds to obtain a subsequent override. See Figure 5-22.

NOTE:

The operator has the responsibility to take action to avoid engine damage.

Figure 5-22 Engine Overtemperature Protection and Shutdown Protection with

Stop Engine Override

5-54 All information subject to change without notice. (Rev. (Rev. 3/02))

742 0203 C opyright © 2002 DETROIT DIESEL CORPORATION

7SA

Page 55

DDEC IV APPLICATION AND INSTALLATION MANUAL

Continuous Override, Option 2- This option is used when the vehicle needs full power during a

shutdown sequence . Full torque capability is maintained as long as the override switch is pressed.

This is intended for Coach applications only.

Continuous Override, Option 2- This option is used for a one time continuous override of the

shutdown sequence. This is primarily used in construction and industrial applications. The engine

protection system is disabled until the ignition key is cycled. See Figure 5-23.

Figure 5-23 Engine Overtempe

rature Protection and Shutdown Protection with

Continuous Override, Option 1

5.10.5 INSTALLATION

Some a pplication require two sets of warning lights (CEL and SEL) at different control stations

(refer to sect

All information subject to change without notice. (Rev. (Rev. 3/02)) 5-55

7SA742

ion 3.16.4).

0203 Copyright © 2002 DETROIT DIESEL CORPORATION

Page 56

DDEC FEATURES

5.10.6 PROGRAMMING FLEXIBILITY

All E CM s are programmed with pressure, temperature, and level protection limits. The level of

protection can be any of the three engine protection features (Warning, Rampdown, or Shutdown)

for each parameter monitored by the ECM. These can be set at time of order entry or with any

of the available service tools, VEPS, DRS, DDR, or DDDL.

The DDEC engine protec tion system monitors all engine sensors and electronic components, and

recognizes system malfunctions. The choices listed in Table 5-26 are available for reprogramming

Engine Protection.

Parameter

RECEIVER 1 OIL

TEMPERATURE

OIL PRESSURE

CRANKCASE PRESSURE

COOLANT PRESSURE

RECEIVER 1 COOLANT

PRESSURE

OIL LEVEL

COOLANT LEVEL

AUXILIARY SHUTDOWN #1

RECEIVER 1 AUXILIARY

SHUTDOWN #1

AUXILIARY SHUTDOWN #2

Definition

Determines the type of engine protection with high

oil temperature on the Receiver ECM #1

Determines the type of engine protection with low

oil pressure. N/A will be displayed if the sensor is

not present.

Determines the type of engine protection with high

crankcase pressure. N/A will be displayed if the

sensor is not present.

Determines the type of engine protection

coolant pressure. N/A will be displayed if the sensor

is not present.

Determines the type of engine protection with low

coolant pressure on the Receiver EC M #1

Determines the type of engine protection with low

oil level. N/A will be displayed if the sensor is not

present.

Determines the type of engine protection with low

coolant level. N/A will be displayed if the sensor

is not present.

Determinesthetypeofengineprotectionwith

an active auxiliary switch #1 input. N/A will be

displayed if auxiliary switch #1 has not been

configured as a switch input.

Determines the type of engine protection with an

active auxiliary switch #1 INPUT on the Receiver

ECM #1

Determinesthetypeofengineprotectionwith

an active auxiliary switch #2 input. N/A will be

displayed if auxiliary switch #2 has not been

configured as a switch input.

with low

Range

N/A; WARN,

RAMP,SHTDWN

N/A; WARN,

RAMP,SHTDWN

N/A; WARN,

RAMP,SHTDWN

N/A; WARN,

RAMP,SHTDWN

N/A; WARN,

RAMP,SHTDWN

N/A; WARN,

RAMP,SHTDWN

N/A; WARN,

RAMP,SHTDWN

N/A; WARN,

RAMP,SHTDWN

N/A; WARN,

RAMP,SHTDWN

N/A; WARN,

RAMP,SHTDWN

Table 5-26 Engine Protection

5.10.7 INTERACTION WITH OTHER FEATURES

Cruise Control operation, Optimized Idle, and PSG are disabled when the SEL is illum inated.

For Applications with LSG and VSG, the governor will revert to the primary governor when

Engine Protection is enabled.

5-56 All information subject to change without notice. (Rev. (Rev. 3/02))

742 0203 C opyright © 2002 DETROIT DIESEL CORPORATION

7SA

Page 57

DDEC IV APPLICATION AND INSTALLATION MANUAL

5.11 ENGINE RATINGS

Engine ratings are designated by horsepower rating and engine speed. For on-highway

applications, three independent engine ratings and an additional dependent rating (cruise power)

are provided. For construction and industrial applications, up to three independent ratings are

provided. Although multiple ratings are stored in the ECM, only one rating is in operation at

any time.

5.11.1 OPERATION

The engine rating may be selected with the DDR, DDDL or OEM supplied rating switches.

Detroit Diesel's method of designating engine ratings is listed in Table 5-27.

Example #1 Example #2

430 bhp @ 2100 RPM Rating #0 470 bhp @ 2100 RPM Rating #0

400 bhp @ 2100 RPM Rating #1 470 bhp @ 1800 RPM Rating #1

370 bhp @ 2100 RPM Rating #2 430 bhp @ 1800 RPM Rating #2

370/430 bhp @ 2100 RPM Rating #3 430/370 bhp @ 1800 RPM Rating #3

Table 5-27 Examples of Engine Ratings

Detroit Diesel can provide additional security to prevent the ECM rating selection from being

modified with the DDR or DDDL. The additional security is not available with the use of rating