Page 1

Getting Started Guide

PSA Series Spectrum Analyzers

This manual provides documentation for the following instruments:

E4440A (3 Hz - 26.5 GHz)

E4443A (3 Hz - 6.7 GHz)

E4445A (3 Hz - 13.2 GHz)

E4446A (3 Hz - 44 GHz)

E4447A (3 Hz - 42.98 GHz)

E4448A (3 Hz - 50 GHz)

Manufacturing Part Number: E4440-90284

Supersedes: E4440-90274

Printed in USA

March 2006

© Copyright 2001-2006 Agilent Technologies, Inc.

Page 2

Notice

The information contained in this document is subject to change

without notice.

Agilent Technologies makes no warranty of any kind with regard to this

material, including but not limited to, the implied warranties of

merchantability and fitness for a particular purpose. Agilent

Technologies shall not be liable for errors contained herein or for

incidental or consequential damages in connection with the furnishing,

performance, or use of this material.

The following safety symbols are used throughout this manual.

Familiarize yourself with the symbols and their meaning before

operating this analyzer.

WAR NING Warning denotes a hazard. It calls attention to a procedure

which, if not correctly performed or adhered to, could result in

injury or loss of life. Do not proceed beyond a warning note

until the indicated conditions are fully understood and met.

CAUTION Caution denotes a hazard. It calls attention to a procedure that, if not

correctly performed or adhered to, could result in damage to or

destruction of the analyzer. Do not proceed beyond a caution sign until

the indicated conditions are fully understood and met.

NOTE Note calls out special information for the user’s attention. It provides

operational information or additional instructions of which the user

should be aware.

Additional Information

For the latest information about this analyzer, including firmware

upgrades, application information, and product information, see the

following URL:

http://www.agilent.com/find/psa/

2

Page 3

Contents

1. Installation and Setup

Initial Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Turning on the Analyzer for the First Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Firmware Revision . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Running Internal Alignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Printer Setup and Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Protecting Against Electrostatic Discharge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2. Front and Rear Panel Features

Front Panel Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Rear-Panel Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Key Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Front and Rear Panel Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Table of Contents

3. Making a Basic Measurement

Using the Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Presetting the Spectrum Analyzer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Viewing a Signal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

4. Viewing Catalogs and Saving Files

File Menu Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Saving a File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Using the Alpha Editor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

5. Options and Accessories

Ordering Options and Accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

6. In Case of Difficulty

Types of Spectrum Analyzer Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Before Calling Agilent Technologies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Returning an Analyzer for Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

3

Page 4

Contents

Table of Contents

4

Page 5

Installation and Setup

1 Installation and Setup

5

Page 6

Installation and Setup

This chapter provides the following information that you may need

when you first receive your spectrum analyzer:

• “Initial Inspection” on page 7

• “Power Requirements” on page 9

• “Turning on the Analyzer for the First Time” on page 13

• “Printer Setup and Operation” on page 18

• “Protecting Against Electrostatic Discharge” on page 21

• “Running Internal Alignments” on page 17

• “Safety Information” on page 22

Agilent

Technologies

Performance

Installation and Setup

Spectrum

Analyzer (PSA)

6 Chapter 1

Page 7

Installation and Setup

Initial Inspection

Initial Inspection

Inspect the shipping container and the cushioning material for signs of

stress. Retain the shipping materials for future use, as you may wish to

ship the analyzer to another location or to Agilent Technologies for

service. Verify that the contents of the shipping container are complete.

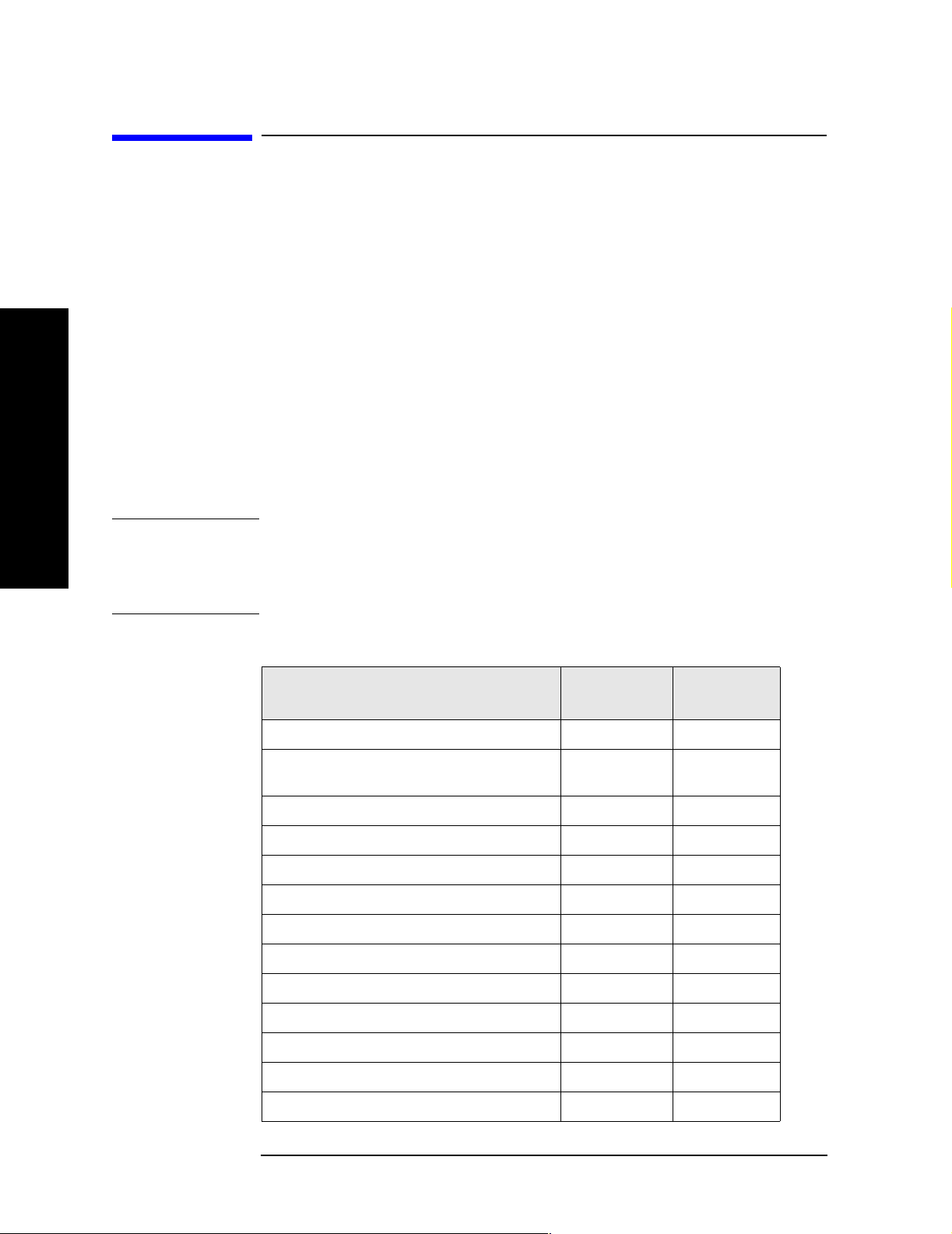

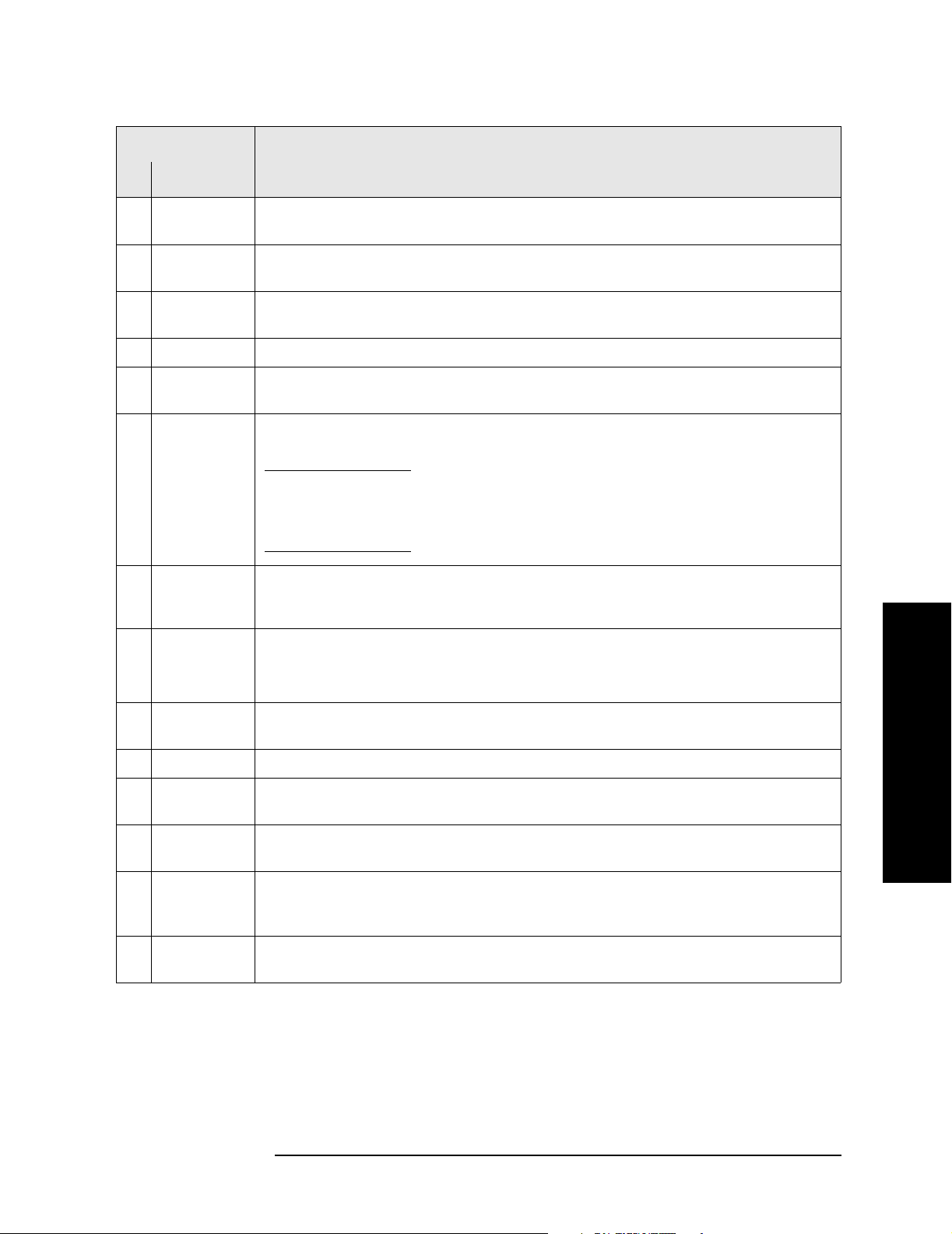

The following table lists the items shipped with the analyzer.

Item Description

Accessories

IntuiLink Toolbar software, CD-ROM Provides a set of connectivity tools that enable you to easily

move data from your analyzer to your PC.

Power Cable (See Table 1-2 on page 11) Connection for power source

USB Cable (Option 111 only) Connects PSA USB to USB on a PC, part number 8121-1074

Adapter (E4446A, E4447A, and E4448A

only)

Adapter (E4446A, E4447A, and E4448A

only)

Agilent Automation-Ready CD Assists in quickly and properly connecting instruments to

Standard Documentation Set

Getting Started Guide Covers unpacking and setting up the analyzer, analyzer

User’s/Programmer’s Guide Describes analyzer features in detail, including front-panel

2.4 mm(f) to K(f) front panel connector adapter, part number

1250-2187

2.4 mm(f) to 2.4 mm(f) front panel connector adapter, part

number 1250-2188

your PC, part number E2094-60003. Includes: Agilent IO

Libraries Suite, Agilent VEE Pro, T&M Tool Kit, and Agilent

IO Hardware information.

features, and how to make a basic measurement. Includes

information on options and accessories, and what to do if you

have a problem.

key descriptions, basic spectrum analyzer programming

information, and SCPI command descriptions.

Installation and Setup

Measurement Guide Provides details on how to measure various signals, and how

to use catalogs and files.

Specifications Guide Documents specifications, safety, and regulatory information.

Instrument Messages and Functional Tests Includes instrument messages (and suggestions for

troubleshooting them), and manual functional tests.

Programming Conversion Guide Describes SCPI programming command compatibility for

8590, 8560, 8566, ESA/PSA series analyzers.

Documentation CD-ROM Includes the documents in the standard set (listed above).

You can view and print the information as needed. See the

CD-ROM jacket for installation information.

Chapter 1 7

Page 8

Installation and Setup

Initial Inspection

NOTE If you purchased one or more optional measurement personalities, the

related guides for the options you ordered are included.

Service documentation is not included in the standard documentation

set. See “Options” on page 65 for information on ordering.

If There Is a Problem

If the shipping materials are damaged or the contents of the container

are incomplete:

• Contact the nearest Agilent Technologies office to arrange for repair

or replacement (see “Contacting Agilent Technologies” on page 80).

You will not need to wait for a claim settlement.

• Keep the shipping materials for the carrier’s inspection.

• If you must return an analyzer to Agilent Technologies, use the

Installation and Setup

original (or comparable) shipping materials (see “Returning an

Analyzer for Service” on page 81).

8 Chapter 1

Page 9

Installation and Setup

Power Requirements

Power Requirements

The only physical installation of your Agilent spectrum analyzer is a

connection to a power source.

Line voltage does not need to be selected.

This analyzer does not contain customer serviceable fuses.

WAR NING Failure to ground the analyzer properly can result in personal

injury. Before turning on the analyzer, you must connect its

protective earth terminals to the protective conductor of the

main power cable. Insert the main power cable plug into a

socket outlet that has a protective earth contact only. DO NOT

defeat the earth-grounding protection by using an extension

cable, power cable, or autotransformer without a protective

ground conductor.

Installation and Setup

If you are using an autotransformer, make sure its common

terminal is connected to the protective earth contact of the

power source outlet socket.

This is a Safety Class 1 Product (provided with a protective

earthing ground incorporated in the power cord). The mains

plug shall only be inserted in a socket outlet provided with a

protective earth contact. Any interruption of the protective

conductor inside or outside of the product is likely to make the

product dangerous. Intentional interruption is prohibited.

WAR NING To prevent electrical shock, disconnect the Agilent

Technologies spectrum analyzer from mains before cleaning.

Use a dry cloth or one slightly dampened with water to clean

the external case parts. Do not attempt to clean internally.

CAUTION VENTILATION REQUIREMENTS: When installing the product in a

cabinet, the convection into and out of the product must not be

restricted. The ambient temperature (outside the cabinet) must be less

than the maximum operating temperature of the product by 4°C for

every 100 watts dissipated in the cabinet. If the total power dissipated

in the cabinet is greater than 800 watts, then forced convection must be

used.

This analyzer has autoranging line voltage input. Be sure the supply

voltage is within the specified range.

NOTE For detailed analyzer specifications, see the Specifications guide.

Chapter 1 9

Page 10

Installation and Setup

Power Requirements

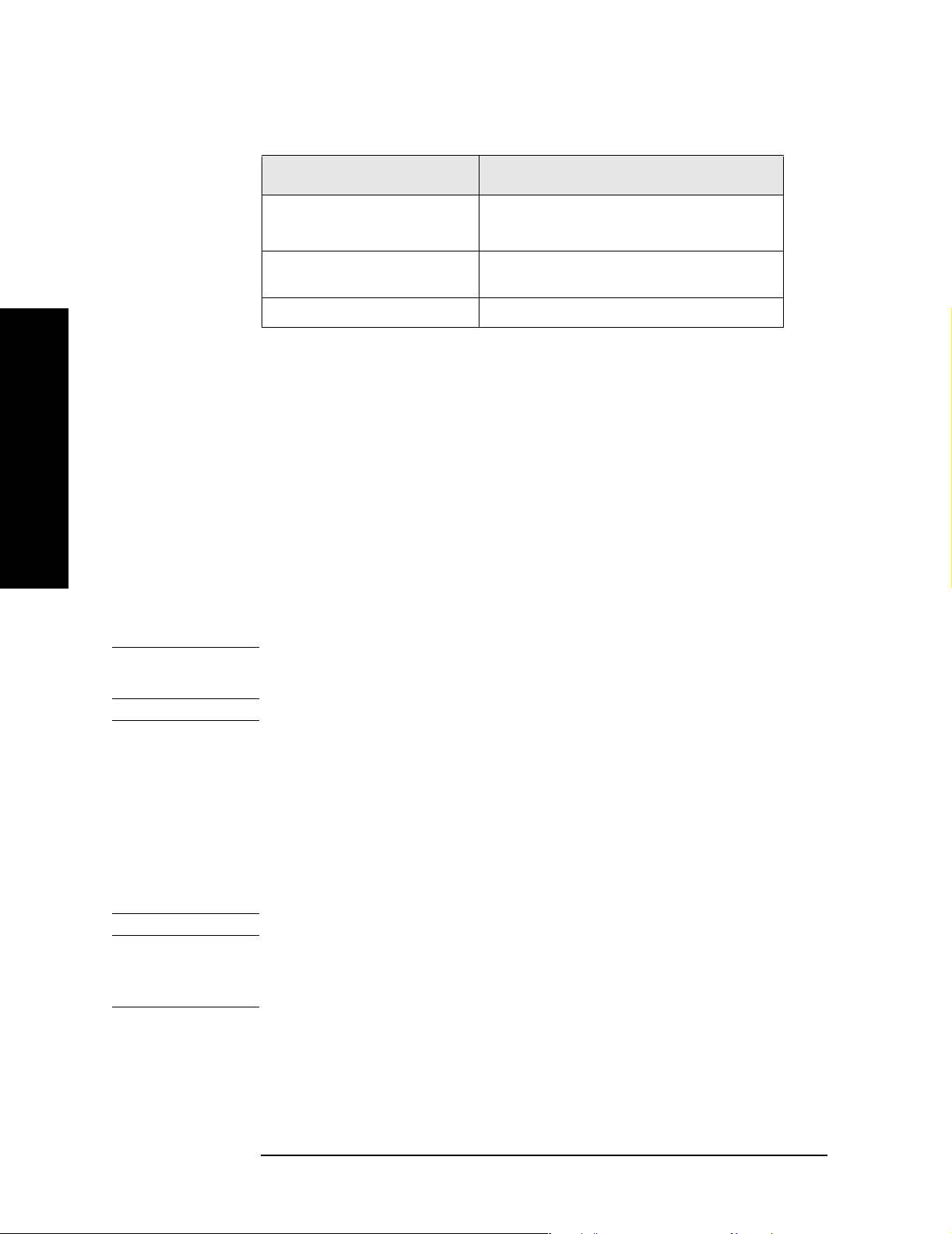

Table 1-1 Power Requirements

Description

Voltage, Frequency 100 to 120 Vrms, 50/60/400 Hz

220 to 240 Vrms, 50/60 Hz

Power Consumption, On Base Fully Loaded

< 260 W < 450 W

Power Consumption, Standby < 20 W

Specification

1

1. For greater detail, refer to the Specifications Guide.

AC Power Cord

The analyzer is equipped with a three-wire power cord, in accordance

with international safety standards. This cable grounds the analyzer

cabinet when connected to an appropriate power line outlet. The cable

appropriate to the original shipping location is included with the

Installation and Setup

analyzer.

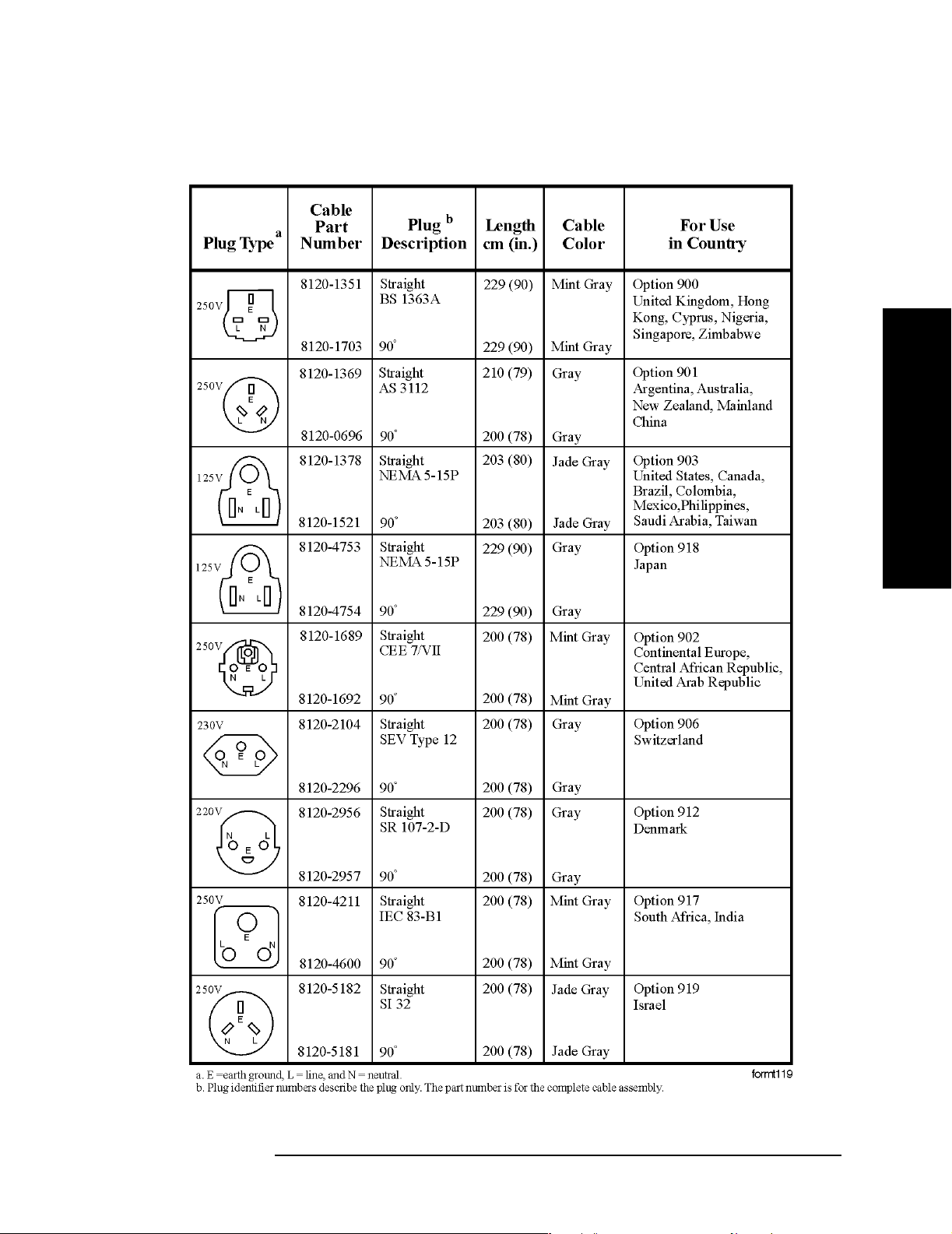

Various AC power cables are available that are unique to specific

geographic areas. You can order additional AC power cables for use in

different areas. AC Power Cords, on page 11 lists the available AC

power cables, illustrates the plug configurations, and identifies the

geographic area in which each cable is appropriate.

NOTE The front panel switch is a standby switch only; it is not a LINE switch

(power disconnecting device).

WAR NING Install the product so that the detachable power cord is readily

identifiable and easily reached by the operator. The detachable

power cord is the product disconnecting device. It disconnects

the mains circuits from the mains supply before other parts of

the product. The front panel switch is only a standby switch

and is not a LINE switch. Alternatively, an externally installed

switch or circuit breaker (which is readily identifiable and is

easily reached by the operator) may be used as a disconnecting

device.

CAUTION Always use the three-prong AC power cord supplied with this product.

Failure to ensure adequate earth grounding by not using this cord can

cause product damage.

10 Chapter 1

Page 11

Table 1-2 AC Power Cords

Installation and Setup

Power Requirements

Installation and Setup

Chapter 1 11

Page 12

Installation and Setup

Power Requirements

Battery Information

The analyzer uses a Lithium Polycarbon Monofloride battery to power

the analyzer clock. The battery is located on the CPU board.

You can order the service documentation for Agilent spectrum

analyzers through your Agilent Sales and Service office. The

documentation is described under “Options” on page 65.

NOTE If the analyzer’s clock does not keep time when powered off, the

problem is the battery. See “Returning an Analyzer for Service” on

page 81.

WAR NING Danger of explosion if battery is incorrectly replaced. Replace

only with the same or equivalent type recommended. Discard

used batteries according to the manufacturer’s instructions.

Installation and Setup

12 Chapter 1

Page 13

Installation and Setup

Turning on the Analyzer for the First Time

Turning on the Analyzer for the First Time

❏ Plug in the power cord.

WAR NING If this product is to be energized via an external auto

transformer for voltage reduction, make sure that its common

terminal is connected to a neutral (earthed pole) of the power

supply.

CAUTION The analyzer is shipped with a a transportation disk inserted in the

disk drive to prevent damage to the disk drive during

transportation. This transportation disk, or a blank floppy disk,

should be inserted in the disk drive whenever transporting the

analyzer.

Do not leave a disk in the front-panel disk drive while turning the

analyzer on. Also, ensure that the transportation disk is removed

from the drive.

NOTE Do not connect anything else to the analyzer yet.

❏ Press the power switch (located in the lower left-hand corner of the

analyzer’s front panel) to turn the analyzer on. See “Front Panel

Overview” on page 24.

NOTE The instrument requires >2 minutes to power-on.

Information

Screen

An information screen appears during the initialization process. The

information screen contains the analyzer product number and a URL

for accessing product support information on the World Wide Web. See

“Additional Information” on page 2.

Installation and Setup

NOTE The information screen displays for approximately 10 seconds before

the initialization process is complete.

Record the firmware revision and serial number, and keep it for

reference. If you should ever need to call Agilent Technologies for

service or with any questions regarding your analyzer, it will be helpful

to have this information readily available. You can also obtain the

firmware revision and serial number by pressing

System.

Chapter 1 13

System, More, Show

Page 14

Installation and Setup

Turning on the Analyzer for the First Time

❏ If using LAN, set the IP address of the analyzer to an appropriate

number for your network; one that the network recognizes, but that

is not yet in use. (Consult your local IT group):

— Press System, Config I/O, and note the IP address.

— If the current address is not appropriate, press IP Address and use

the keypad to change it.

— Connect the LAN cable to the LAN connector located on the rear

panel of your analyzer (see “Rear-Panel Features” on page 29).

— Cycle the analyzer power.

NOTE It is necessary to cycle the power to the analyzer after plugging in the

LAN for the analyzer to recognize the network.

❏ Allow the spectrum analyzer to warm-up for 30 minutes before

making a calibrated measurement. To meet its specifications, the

analyzer must meet operating temperature conditions.

Installation and Setup

NOTE It is normal to hear clicking when the Auto Alignment function is on.

See “Running Internal Alignments” on page 17 for more information.

Why Aren’t All the Personality Options Loaded in Memory?

Many measurement personality options are available for use with this

instrument. If the option is loaded in the instrument, you must also

have a license key entered, to use it.

Some versions of instrument hardware may not have enough memory

to accommodate all the options that you have ordered. If this is the case

you will need to swap the applications in/out of memory, as needed. It

may also be possible to upgrade your hardware to have more memory.

Contact your local sales/service office.

If Option 117 is Loaded in Memory

If you ordered Option 117, the Secure Memory Erase option was loaded

into the memory of your instrument and licensed at the factory but not

enabled. DO NOT enable this option until you have fully configured

your instrument (set the

removed options and licenses, and configured the power-up state you

desire). After the security mode is enabled, the main Flash memory

becomes read-only, rather than read/write memory. This makes it

impossible to add or remove personalities or their license keys, or

otherwise change the instrument’s configuration, unless you do a

System, Security, Secure Erase All procedure. This procedure will render

the instrument inoperable. You will then need to run the upgrade

System, Config I/O settings as needed, added or

14 Chapter 1

Page 15

Installation and Setup

Turning on the Analyzer for the First Time

procedure (on the Agilent Web site) to reinstall the firmware and

completely reconfigure your instrument. Refer to “Managing Security”

in Chapter 4 of the “User’s and Programmer’s Reference, Volume 1.”

When you are totally satisfied with the configuration of your PSA

analyzer, enable the Secure Memory Erase option by pressing

Security, Security, Enabled

. The security mode will then be enabled the

System,

next time the analyzer’s power is cycled.

Using an External Reference

1. To use an external frequency reference, connect it to the

EXT REF IN connector on the rear panel (see “Rear-Panel

Features” on page 29).

2. Enter the frequency of the external reference into the analyzer:

a. Press System, Reference, Freq Ref

b. Select the Ext function.

c. Use the keypad to enter the frequency of the external frequency

reference.

Installation and Setup

Chapter 1 15

Page 16

Installation and Setup

Firmware Revision

Firmware Revision

To view the firmware revision of your analyzer, press System, More,

Show System. If you call Agilent Technologies regarding your analyzer,

it is helpful to have this revision and the analyzer serial number

available.

TIP You can get automatic electronic notification of new firmware releases

and other product updates/information by subscribing to the Agilent

Technologies Test & Measurement E-Mail Notification Service for the

PSA and ESA Series at http://www.agilent.com/find/notifyme

Installation and Setup

16 Chapter 1

Page 17

Installation and Setup

Running Internal Alignments

Running Internal Alignments

Each time the analyzer is powered on, the internal alignment routine

runs automatically.

The analyzer was shipped from the factory with the Alignments mode

set to Auto. This setting enables the alignment routine to run

automatically either every 24 hours, or when the internal analyzer

temperature changes ±3°C.

NOTE When the Alignment routine runs, you will hear the attenuator settings

changing, which generates noise. This is not an indication of trouble.

Manually Performing an Alignment

If

Auto Align, Off is selected, refer to the Specifications guide for the

conditions required to maintain calibration.

NOTE For detailed information regarding the alignment routine (including

how to run alignments, and how the analyzer can alert you when

alignments are required) refer to the User’s guide for your analyzer.

Installation and Setup

Chapter 1 17

Page 18

Installation and Setup

Printer Setup and Operation

Printer Setup and Operation

A printer can be connected to your analyzer if it is equipped with an

external I/O interface. Supported printers accept Hewlett-Packard

Printer Control Language Level 3 (PCL3) or 5 (PCL5). Refer to the

documentation or specifications supplied with your printer, or contact

the manufacturer to identify your printer’s language.

Equipment

• IEEE 1284 compliant printer cable.

• Supported and tested printers are listed below. Note that there are

many PCL3/5 printers that may work with your analyzer, however,

they have not been tested.

— PCL3 printers include most HP DeskJet printers.

— PCL5 printers include most HP LaserJet printers.

Installation and Setup

NOTE The following printers are not compatible with your analyzer.

• HP Deskjet 720C, 722C, 820C and 1600C

• Epson MX-80, FX-85, Stylus, and LQ-570

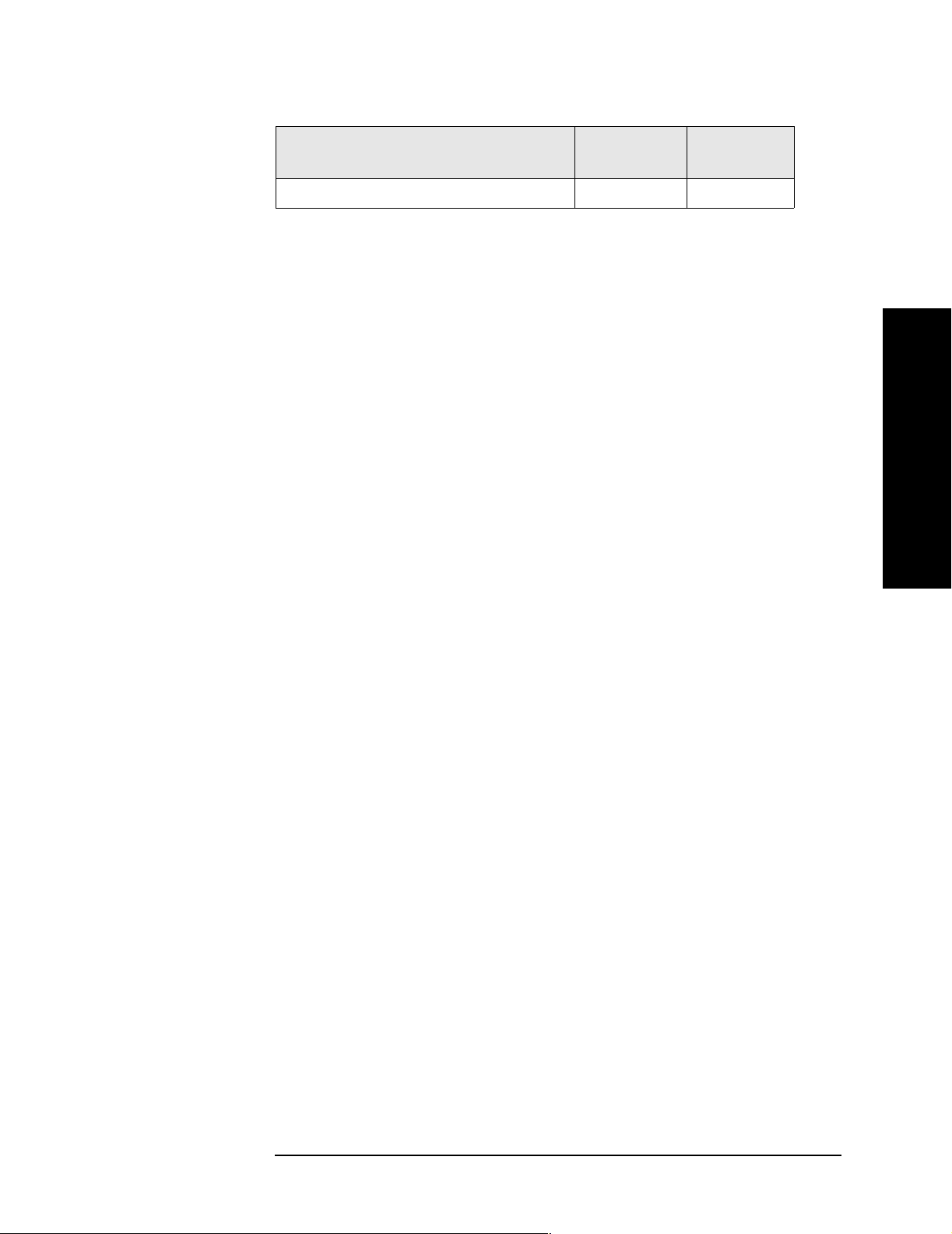

Printer Models Language

Type

HP DeskJet 310, 320, 350C, 400L PCL3 yes

HP DeskJet 500C, 550C, 600, 660C, 672C,

680C, 682C, 690C, 693C

HP DeskJet 840C, 850C, 870C, 890C, 895C PCL3 yes

HP DeskJet 935C, 970C, 990C PCL3 yes

HP DeskJet 1120C, 1150C PCL3 yes

HP Inkjet 2000C PCL 3 yes

HP LaserJet 4L, 4P, 4 Plus PCL3/5 no

HP LaserJet 5L, 5M, 5N, 5P, 5SI PCL3/5 no

PCL3 yes

Color

Capable

HP LaserJet 6L, 6MP, 6P PCL5 no

HP LaserJet 2100 Series, PCL3/5 no

HP LaserJet 4050N PCL3/5 yes

HP LaserJet 5000GN PCL3/5 yes

HP Professional Series 2500CM PCL3 yes

18 Chapter 1

Page 19

Installation and Setup

Printer Setup and Operation

Printer Models Language

Type

HP Professional Series 2500CM PCL3 yes

Color

Capable

Installation and Setup

Chapter 1 19

Page 20

Installation and Setup

Printer Setup and Operation

Interconnection and Setup

1. Turn off the printer and the analyzer.

2. Using an IEEE 1284 compliant parallel printer cable, connect the

printer to the analyzer parallel I/O interface connector on the rear

panel (see “Rear-Panel Features” on page 29).

3. Turn on the analyzer and printer.

4. On the front panel, press Print Setup, then press the Printer Setup

menu key.

5. Select the printer language and color capability appropriate for your

printer. See table above this section for a list of some compatible

printers.

Testing Printer Operation

When you have completed the printer setup for the analyzer, press the

front panel

Installation and Setup

successful, a printout of the analyzer display will be printed. If the

Print key. If the printer is ready and the printer setup was

printer is not ready, the message “Printer not responding” appears

at the bottom of the screen.

NOTE There may be some small discrepancies in the color mapping of the

analyzer display to your color printer. Due to differences in display and

printer technologies, the default display colors do not map exactly to the

printer colors. For example trace 1 is yellow on your analyzer display

while it maps to green on your printer.

20 Chapter 1

Page 21

Installation and Setup

Protecting Against Electrostatic Discharge

Protecting Against Electrostatic Discharge

Electrostatic discharge (ESD) can damage or destroy electronic

components (the possibility of unseen damage caused by ESD is present

whenever components are transported, stored, or used).

Test Equipment and ESD

To help reduce ESD damage that can occur while using test equipment:

• Before connecting any coaxial cable to an analyzer connector for the

first time each day, momentarily short the center and outer

conductors of the cable together.

• Personnel should be grounded with a 1 MΩ resistor-isolated

wrist-strap before touching the center pin of any connector and

before removing any assembly from the analyzer.

• Be sure that all instruments are properly earth-grounded to prevent

build-up of static charge.

WAR NING Do not use these first three techniques when working on

circuitry with a voltage potential greater than 500 volts.

• Perform work on all components or assemblies at a static-safe

workstation.

• Keep static-generating materials at least one meter away from all

components.

• Store or transport components in static-shielding containers.

• Always handle printed circuit board assemblies by the edges. This

reduces the possibility of ESD damage to components and prevent

contamination of exposed plating.

Installation and Setup

For information on ordering static-safe accessories, see “Accessories” on

page 71.

Additional Information about ESD

For more information about ESD and how to prevent ESD damage,

contact the Electrostatic Discharge Association (http://www.esda.org).

The ESD standards developed by this agency are sanctioned by the

American National Standards Institute (ANSI).

Chapter 1 21

Page 22

Installation and Setup

Safety Information

Safety Information

WAR NING This is a Safety Class 1 Product (provided with a protective

earthing ground incorporated in the power cord). The mains

plug shall be inserted only in a socket outlet provided with a

protective earth contact. Any interruption of the protective

conductor inside or outside of the product is likely to make the

product dangerous. Intentional interruption is prohibited.

If this product is not used as specified, the protection provided

by the equipment could be impaired. This product must be used

in a normal condition (in which all means for protection are

intact) only.

Installation and Setup

22 Chapter 1

Page 23

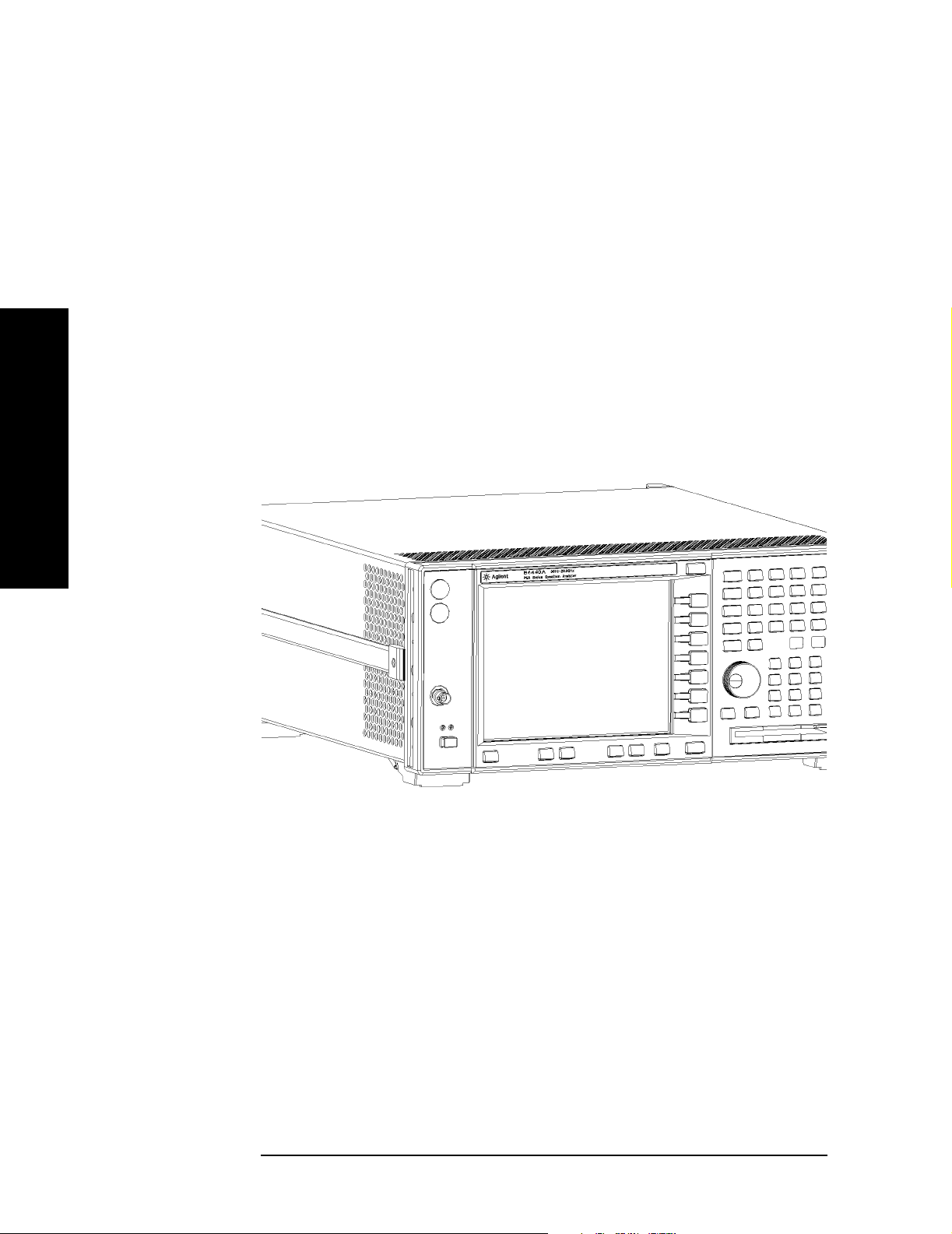

2 Front and Rear Panel Features

This chapter gives you an overview of the front and rear panels of your

analyzer. For details on analyzer keys and remote programming, refer

to the User’s and Programmer’s Reference. For connector specifications

(including input/output levels), see the Specifications guide.

Front and Rear Panel Features

23

Page 24

Front and Rear Panel Features

Front Panel Overview

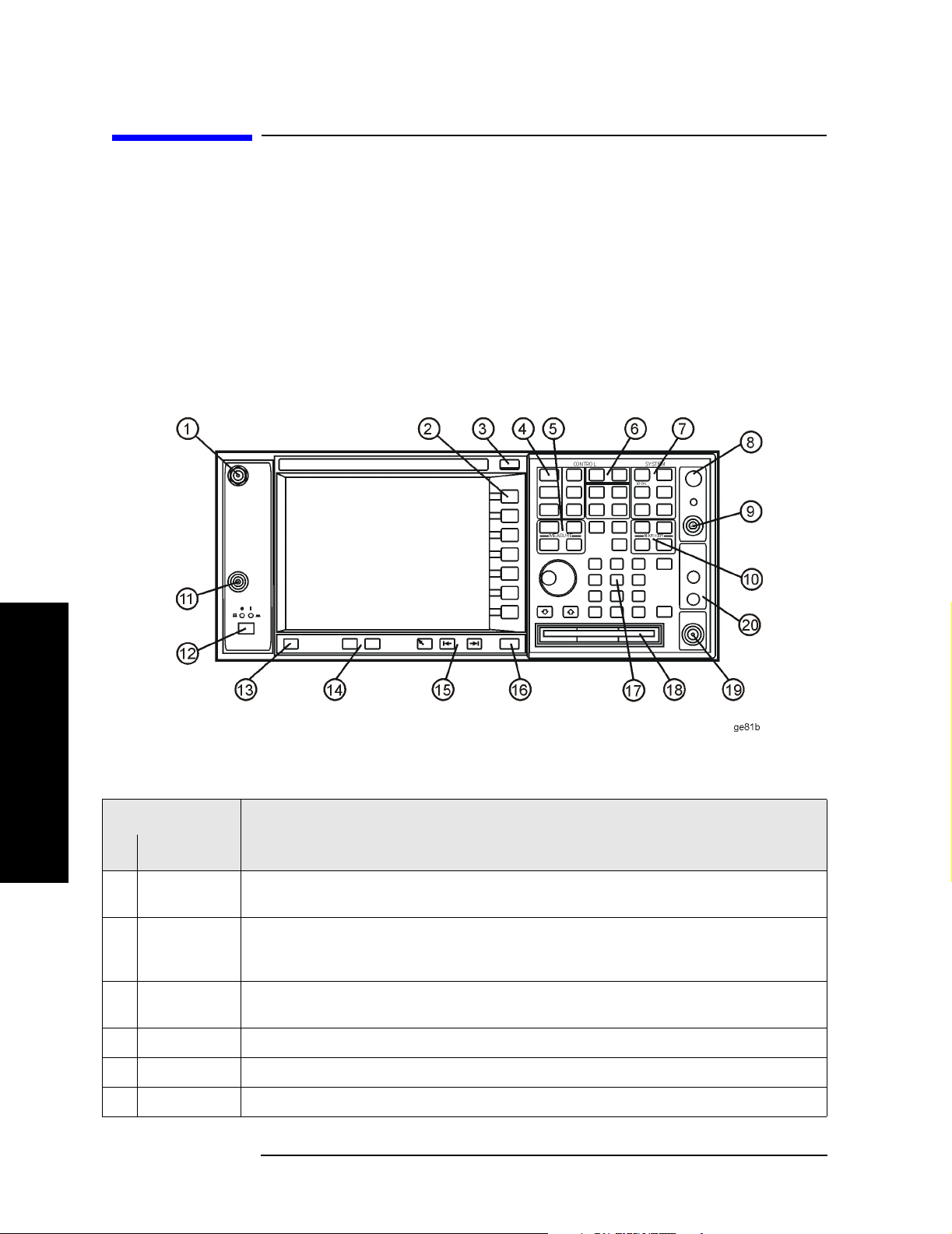

Front Panel Overview

This section provides information on the analyzer’s front panel,

including:

• Front Panel Connectors and Keys, see below

• “Display Annotations” on page 26

Front-Panel Connectors and Keys

Item

Description

Front and Rear Panel Features

# Name

1

AUDIO I NPU T High-impedance input for audio signal path (Option 107). Maximum input: 7 Vrms,

20 Vdc

Softkeys Menu labels identifying the current function of each softkey appear to the left of each

2

key. Softkey menus dependent on the active menu. Also see “Using Menu Keys” on page

37.

ESC Key Exits any function without modifying the current parameters. Also blanks the active

3

function annotation and aborts the power-on alignments.

4

Control Keys Set parameters used for making measurements in the current measurement mode.

5

Measure Keys Select and set up specific measurements within the current application.

Mode Keys Select measurement mode and mode parameters.

6

24 Chapter 2

Page 25

Front and Rear Panel Features

Front Panel Overview

Item

Description

# Name

7 System Keys Access features used with all analyzer modes and affect the state of the entire spectrum

analyzer.

8 Vol. Control/

Earphones

9

PROBE PWR Supplies power for external high frequency probes and accessories (see “Accessories” on

Not currently implemented.

page 71).

10

Marker Keys Enable markers to obtain specific information about the displayed measurement.

EXT TRIGGER

11

INPUT

12

POWER

ON/OFF

Enables you to externally trigger measurements.

Turns the analyzer on. A green light indicates power on. A yellow light indicates

standby mode.

NOTE The front-panel switch is a standby switch, not a LINE switch

(disconnecting device); the analyzer continues to draw power

even when the line switch is in standby. Use the detachable

power cord to disconnect the analyzer from the mains supply.

Help Key Press the Help key, then any other key to get a short description of that key and the

13

associated SCPI command. The next key you press will remove the help window from

the display.

Window Keys Next Window: On displays with multiple windows, changes the highlighted window that

14

is currently active.

Zoom: Zooms in on the highlighted window.

Front and Rear Panel Features

15

Navigation

Keys

16

Return Key Exits the current menu and returns to the previous menu.

Data Controls Change the numeric value of an active function. Entries appear in the active function

17

Move cursor between fields on the display.

area of the display. Also see “Entering Data” on page 37.

Floppy

18

Disk Drive

19

RF Input Input for an external signal. Make sure that the total power of all signals at the

Accepts a 3.5 inch 1.44 MB floppy disk.

analyzer input does not exceed +30 dBm (1 watt). The E4446A, E4447A, and E4448A

input connector is 2.4 mm.

20 IF Input, 1st

LO Output

Allows connections for external mixing (Option AYZ)

Chapter 2 25

Page 26

Front and Rear Panel Features

Front Panel Overview

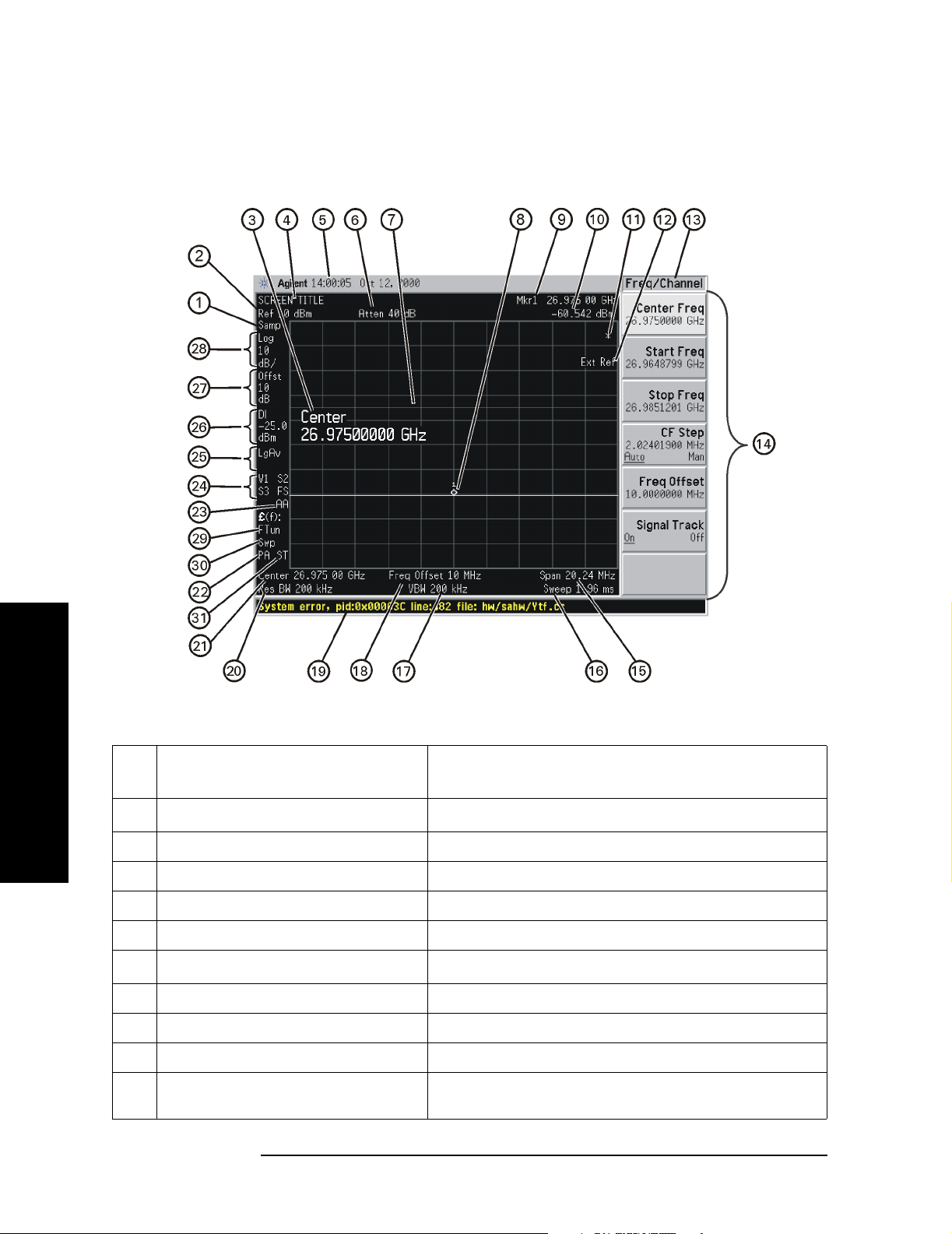

Display Annotations

Ite

m

1

Detector type

Front and Rear Panel Features

2 Reference level Amplitude, Ref Level

3 Active function block Refer to the description of the activated function.

4 Screen title

5 Time and date display System, Time/Date

6

RF attenuation

7 Display line Display, Display Line

8Marker Marker

9 Active marker Marker

10 Active marker frequency and

amplitude

Description Associated Function Keys

1

a

Det/Demod, Detector

Display, Title

Amplitude, Attenuation

Marker

26 Chapter 2

Page 27

Front and Rear Panel Features

Front Panel Overview

Ite

Description Associated Function Keys

m

11 Data invalid indicator Asterisk (*) means some or all trace data may not match

annotation due to possible analyzer setting changes.

12 Status message area Displays status messages (see “Types of Spectrum

Analyzer Messages” on page 77).

13 Key menu title Dependent on menu selection.

14 Softkey menu Softkey labels

15 Frequency span or stop frequency

16

Sweep time

17

Video bandwidth

a

a

Span or Frequency, Stop Freq

Sweep, Sweep Time

BW, Video BW

18 Frequency offset Frequency, Freq Offset

19 Display status line Displays informational and error messages (see “Types of

Spectrum Analyzer Messages” on page 77).

20

Resolution bandwidth

a

BW, Res BW

21 Center frequency or start frequency Frequency, Center Freq or Start Freq

22 Internal preamp Amplitude, Int Preamp

23 Auto alignment routine status System, Alignments, Auto align

(If auto alignment is off, no indicator appears)

AA: auto alignment of all

analyzer parameters.

24 Trigger or Tra ce

Tri g or Trace/Avg

Trigger & sweep modes:

F: free-run trigger

X: external (front) trigger

R: external (rear) trigger

L: line trigger

V: video trigger

C: continuous sweep

S: single sweep

25

Average

a

Trace/Avg, Average: The

number shown indicates

current average number.

26 Display line annotation

Display, Display Line

27 Amplitude offset Amplitude, Ref Lvl Offst

Front and Rear Panel Features

AL: analyzer alerts you

when alignment is

needed.

Trac e mo des :

W: clear-write

S: store blank

m: minimum hold

M: maximum hold

V: view

1: trace 1

2: trace 2

3: trace 3

VAvg: voltage average

LgAv: log power average

PAvg power average

28 Amplitude scale Amplitude, Scale Type or Amplitude, Scale/Div

Chapter 2 27

Page 28

Front and Rear Panel Features

Front Panel Overview

Ite

m

29

Phase noise optimization

30

Sweep type

31 Signal track

Could also be CP (Continuous Peak)

Description Associated Function Keys

a

a

Auto Couple, PhNoise Opt

Phase noise can be optimized for:

f<50k: frequencies less than 50 kHz from carrier.

f>50k: frequencies greater than 50 kHz from carrier.

FTun: LO for fast tuning.

Sweep, Sweep Type

Frequency, Signal Track

Peak Search

, Continuous Pk

1. This function can be auto-coupled. A pound (#) symbol in front of this annotation

indicates an uncoupled function.

Front and Rear Panel Features

28 Chapter 2

Page 29

Rear-Panel Features

Front and Rear Panel Features

Rear-Panel Features

Item Description

# Name

1 NOISE SOURCE

DRIVE OUT

+28 V (PULSED)

2 PRESEL TUNE

OUT

3

10 MHz OUT

(SWITCHED)

EXT REF IN Input for a 1 to 30 MHz external frequency reference signal.

4

5

321.4 MHz IF

Out

6

TRIGGER 1 OUT A trigger output used to synchronize other test equipment with the analyzer. Trigger

Provides 28 V to drive a noise source. Used on Option 219 Noise Figure personality.

Outputs tuning voltage for preselected harmonic mixer.

A switched output of the analyzer’s internal 10 MHz frequency reference signal used

to lock the frequency reference of other test equipment to the analyzer.

Provides 321.4 MHz IF output. Not available on E4447A.

1 is the High=Sweeping (HSWP) signal.

7

TRIGGER 2 IN Allows external triggering of measurements.

8

VIDEO OUT Provides a y-axis video out signal. Note that this signal is not available when gating

is being used. (Option 124)

9

21.4 MHz IF OUT Provides 21.4 MHz IF output. (Option HB2) Not available on E4447A.

Front and Rear Panel Features

10

USB Port Provides USB interface (Option 111). USB device side I/O only.

Chapter 2 29

Page 30

Front and Rear Panel Features

Rear-Panel Features

Item Description

# Name

11 KYBD Enables connection of an external PS-2 keyboard using a 6-pin mini-DIN connector.

Always turn off power before plugging in keyboard.

This feature not fully implemented. Currently used only for firmware upgrades.

12 Line power

input

13

GPIB Allows the connection of a General Purpose Interface Bus (GPIB, IEEE 488.1) cable,

The AC power connection. Also see “Power Requirements” on page 5.

which enables remote analyzer operation.

14

LAN A TCP/IP Interface.

Also see “Turning on the Analyzer for the First Time” on page 11 for information on

setting the IP address.

For information on using the analyzer remotely, refer to the User’s/Programmer’s

Guide.

TRIGGER 2 OUT A trigger output used to synchronize other test equipment with the analyzer.

15

Reserved for future applications.

16

PARALLEL Supports remote printing (Printing is supported only from the parallel port).

17

70 MHZ IF OUT Provides 70 MHz IF output (Option H70). Not available on E4447A.

Other IF output options may occupy this rear-panel location.

18 MONITOR Allows connection of an external VGA monitor.

19

RS-232 Allows connection of a PC, printer, or modem.

This feature is not fully implemented.

20

HNQ IN

H7L IN

H70 IN

These features are only available when special options are installed.

Requires a BNC jumper cable from the rear-panel “321.4 MHz IF Out” to one of

these inputs, depending on the option. Not available on E4447A.

Front and Rear Panel Features

30 Chapter 2

Page 31

Front and Rear Panel Features

Key Overview

Key Overview

The keys labeled FREQUENCY Channel, System, and Marker are all

examples of front-panel keys. The front-panel keys are dark gray, light

gray, green, or white in color. Front-panel keys that are white perform

an immediate action rather than bringing up a menu. The only green

key is the

all front panel keys and their related menu keys can be found in user’s

guide for your analyzer). Pressing most of the dark or light gray

front-panel keys accesses menus of functions that are displayed along

the right side of the display. These are called menu keys.

Menu keys list functions other than those accessed directly by the front

panel keys. To activate a menu key function, press the key immediately

to the right of the annotation on the screen. The menu keys that are

displayed depend on which front-panel key is pressed and which menu

level is enabled.

If a menu key function’s value can be changed, it is called an active

function. The function label of the active function is highlighted after

that key has been selected. For example, press

calls up the menu of related amplitude functions. Note the function

labeled

highlighted.

indicating that it is the active amplitude function and can now be

changed using any of the data entry controls.

Preset key, which performs an analyzer reset (A summary of

AMPLITUDE Y Scale. This

Ref Level (the default selected key in the Amplitude menu) is

Ref Level also appears in the active function block,

Front and Rear Panel Features

A menu key with On and Off in its label can be used to turn the menu

key’s function on or off. To turn the function on, press the menu key so

that On is underlined. To turn the function off, press the menu key so

that Off is underlined. In the manual, when On should be underlined, it

will be indicated as

Function (On).

A function with Auto and Man in the label can either be auto-coupled or

have its value manually changed. The value of the function can be

changed manually using the numeric keypad, knob, or step keys. To

auto-couple a function, press the menu key so that Auto is underlined.

In some key menus, one key label will always be highlighted to show

which key has been selected. For example, when you press

Marker, you

will access a menu of keys in which some of the keys are grouped

together by a blue bar on the left side of the menu. The

which is the

Marker menu default key, will be highlighted. When you

press another key within the blue bar region, such as

Normal key,

Delta, the

highlight will move to that key to show it has been selected.

Chapter 2 31

Page 32

Front and Rear Panel Features

Key Overview

In other key menus, one key label will always be highlighted to show

which key has been selected but the menu is immediately exited when a

selection is made. For example, when you press the

the

Print Setup menu), it will bring up its own menu of keys. The Portrait

Orientation key (on

key, which is the Orientation menu default key, will be highlighted.

When you press the

to show it has been selected and the screen will return to the

Landscape key, the highlight will move to that key

Print Setup

menu.

The arrow keys located below the analyzer display (sometimes referred

to as Tab keys) can be used to navigate within tables, for example the

Limit-Line table. These keys are used to move between rows. The

Left-arrow key moves up, while the right-arrow key moves down. While

navigating through the table, the cursor (inverse video highlight) stays

in the same column. Navigating left or right in the table is

accomplished by choosing the desired field using the front-panel keys.

Front and Rear Panel Features

32 Chapter 2

Page 33

Front and Rear Panel Features

Front and Rear Panel Symbols

Front and Rear Panel Symbols

This symbol is used to indicate power ON (green LED).

This symbol is used to indicate power STANDBY mode

(yellow LED).

This symbol is used to indicate the ON position of the

power button.

This symbol is used to indicate the OFF position of the

power button.

This symbol indicates the input power required is AC.

The instruction documentation symbol. The product is

marked with this symbol when it is necessary for the

user to refer to instructions in the documentation.

The CE mark is a registered trademark of the

European Community.

The C-Tick mark is a registered trademark of the

Australian Spectrum Management Agency.

This is a marking of an Industrial Scientific and

Medical Group 1 Class A product, and to indicate

product compliance with the Canadian

Interference-Causing Equipment Standard (ICES-001).

The CSA mark is a registered trademark of the

Canadian Standards Association.

This product complies with the WEEE Directive

(2002/96/EC) marking requirements. The affixed label

indicates that you must not discard this electrical/

electronic product in domestic household waste.

Product Category: With reference to the equipment types

in the WEEE Directive Annex I, this product is classed

as a “Monitoring and Control instrumentation” product.

Front and Rear Panel Features

Do not dispose in domestic household waste.

To return unwanted products, contact your local

Agilent office, or see

http://www.agilent.com/environment/product/ for

Chapter 2 33

Page 34

Front and Rear Panel Features

Front and Rear Panel Symbols

more information.

Front and Rear Panel Features

34 Chapter 2

Page 35

3 Making a Basic Measurement

This chapter provides information on basic analyzer operation. For

more information on making measurements, see the measurement

guide for your analyzer.

Making a Basic Measurement

35

Page 36

Making a Basic Measurement

This chapter is divided into the following sections:

• “Using the Front Panel” on page 37

• “Presetting the Spectrum Analyzer” on page 39

• “Viewing a Signal” on page 40

CAUTION Ensure that the total power of all signals at the analyzer RF input does

not exceed +33 dBm (2 watts).

Basic Assumption

The material in this chapter is presented with the assumption that you

understand the front and rear panel layout, and display annotations of

your analyzer. If you do not, refer to “Front and Rear Panel Features”

on page 23.

NOTE The display examples in this book are made using various analyzer

models, you may see some variations depending upon your analyzer.

Making a Basic Measurement

36 Chapter 3

Page 37

Making a Basic Measurement

Using the Front Panel

Using the Front Panel

Entering Data

When setting measurement parameters, there are several ways to enter

or modify the value of the active function:

Knob Increments or decrements the current value.

Arrow Keys Increments or decrements the current value.

Numeric

Keypad

Unit Softkeys Terminate a value that requires a unit-of-measurement.

Enter Key Terminates an entry when either no unit of measure is needed,

Enters a specific value. Then press the desired terminator

(either a unit softkey, or the

or you want to use the default unit.

Enter key).

Using Menu Keys

Menu Keys (which appear along the right side of the display) provide

access to many analyzer functions. Here are examples of menu key

types:

Toggle Allows you to activate/deactivate states.

Exampl

e:

Submenu Displays a new menu of softkeys.

Exampl

e:

Choice Allows you to make a selection from a list of values.

Signal Track

On Off

Catalog

Toggles the selection (underlined choice)

each time you press the key.

A submenu key allows you to view a new

menu of softkeys related to the submenu

key category.

Exampl

e:

Adjust Highlights the softkey and sets the active function.

Exampl

es:

Y Axis Units

dBm

CF Step

13.2550000 GHz

A choice key displays the currently

selected submenu choice, in this example,

dBm. When the choice is made, the

submenu automatically returns.

Press this type of key and enter a value.

Chapter 3 37

Making a Basic Measurement

Page 38

Making a Basic Measurement

Using the Front Panel

Attenuation

10.00 dB

Auto Man

The default for softkeys with an

automatic (Auto) or manual (Man) choice

is automatic. After you enter a value, the

selection changes to manual. You can also

press the softkey twice to change to

manual.

Making a Basic Measurement

38 Chapter 3

Page 39

Making a Basic Measurement

Presetting the Spectrum Analyzer

Presetting the Spectrum Analyzer

Preset provides a known starting point for making measurements. The

analyzer has three types of preset:

Factory Preset Restores the analyzer to its factory-defined state.

User Preset Restores the analyzer to a user-defined state.

Mode Preset This type of preset restores the currently selected mode

to a known state.

For details, see the User’s/Programmer’s manual.

When

triggers a factory preset. When

Preset displays the softkeys Factory Preset, User Preset, and Mode Preset

(if applicable); you then select the preset you want. If

to

Preset Type is set to Factory, pressing the green Preset key

Preset Type is set to User, pressing

Preset Type is set

Mode, but a personality is not installed, pressing Preset triggers a

factory preset.

Creating a User Preset

If you constantly use settings which are not the factory defaults, use the

following steps to create a user-defined preset:

1. Set analyzer parameters as desired.

2. Press System, Power On/Preset, Save User Preset to set the current

parameters as the user preset state.

3. Press Preset to select User in the same softkey menu to enable user

preset as an option.

Disabling User Preset

Go to the Power On/Preset menu (press

select a

Preset Type of Factory or Mode.

System, Power On/Preset) and

Chapter 3 39

Making a Basic Measurement

Page 40

Making a Basic Measurement

Viewing a Signal

Viewing a Signal

1. Press Preset. If the softkeys Factory Preset and User Preset appear,

select

2. Press System, Reference, then note the 10 MHz Out setting. If Off is

active (underlined), press the softkey to toggle the reference on.

3. Connect the analyzer’s rear panel 10 MHz OUT (SWITCHED) to the

front-panel input.

Setting Reference Level and Center Frequency

NOTE The display examples in this section are made using various analyzer

models, you may see some variations depending upon your analyzer.

4. Set the reference level to 10 dBm: Press AMPLITUDE, 10, dBm.

5. Set the center frequency to 30 MHz: Press FREQUENCY, Center

Freq

Factory Preset.

, 30, MHz.

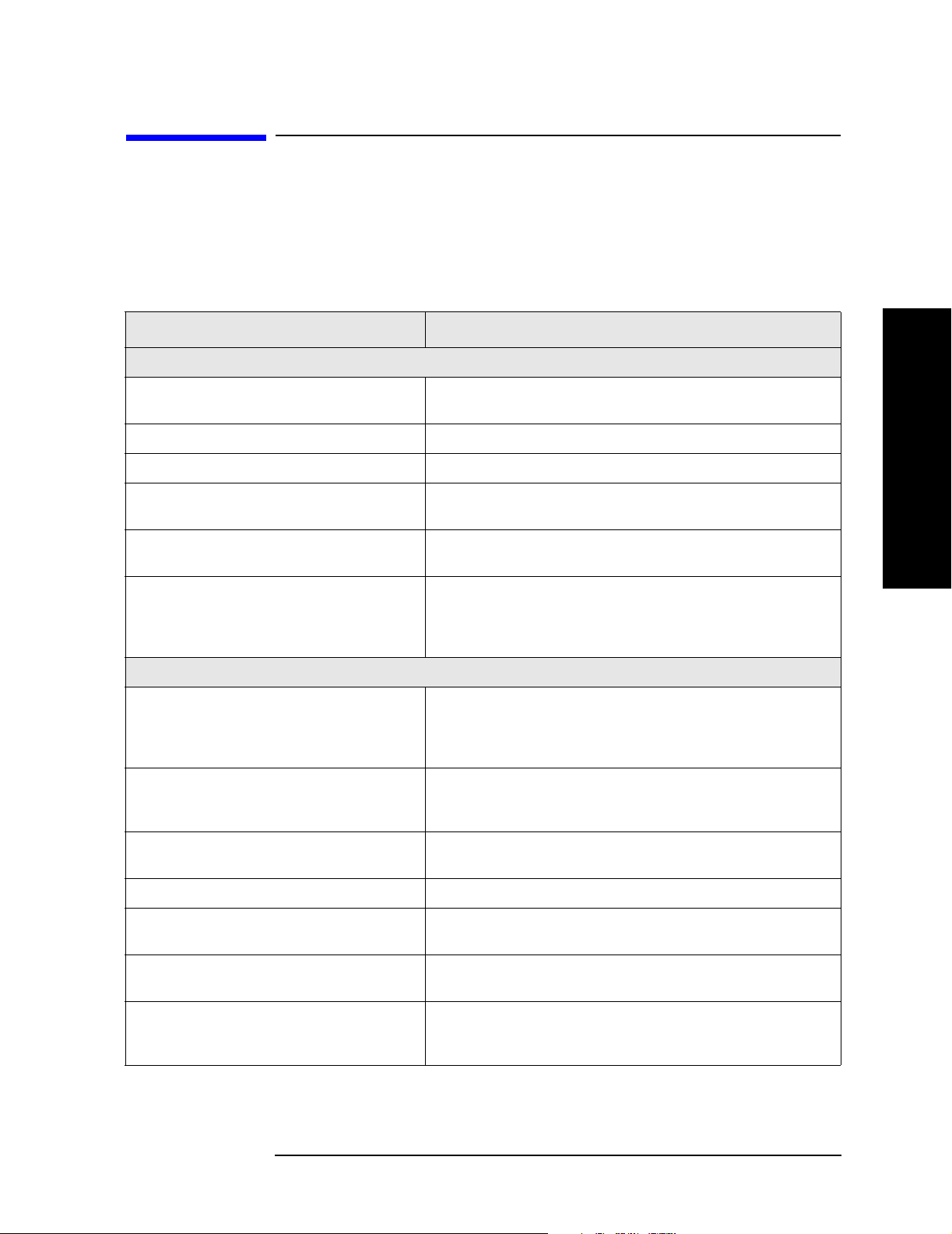

The 10 MHz reference signal spectrum appears on the display, as

shown in Figure 3-1.

NOTE The display examples in this book are made using various analyzer

models, you may see some variations depending upon your analyzer.

Making a Basic Measurement

40 Chapter 3

Page 41

Making a Basic Measurement

Viewing a Signal

Figure 3-1 10 MHz Internal Reference Signal and Associated Spectrum

10 MHz Peak

Setting Frequency Span

6. Set the frequency span to 50 MHz: Press SPAN, 5, 0, MHz.

This displays the signal as shown in Figure 3-2.

Making a Basic Measurement

Chapter 3 41

Page 42

Making a Basic Measurement

Viewing a Signal

Figure 3-2 Span Changed to 50 MHz

10 MHz Peak

Reading Frequency & Amplitude

7. Place a marker (labeled 1) on the 10 MHz peak, as shown

in Figure 3-3.

Press

Peak Search.

Note that the frequency and amplitude of the marker appear both in

the active function block, and in the upper-right corner of the screen.

You can use the knob, the arrow keys, or the softkeys in the Peak

Search menu to move the marker. Pressing

Esc removes the value

from the display.

8. If you have moved the marker, return it to the peak of the 10 MHz

signal.

Changing Reference Level

9. Press AMPLITUDE, and note that reference level (Ref Level) is now

the active function. Press

Marker ➞, Mkr ➞ Ref Lvl.

Note that changing the reference level changes the amplitude value

of the top graticule line.

Figure 3-4 shows the relationship between center frequency and

reference level. The box represents the analyzer display. Changing

the center frequency changes the horizontal placement of the signal

on the display. Changing the reference level changes the vertical

placement of the signal on the display. Increasing the span increases

the frequency range that appears horizontally across the display.

Making a Basic Measurement

42 Chapter 3

Page 43

Figure 3-3 A Marker on the 10 MHz Peak

Making a Basic Measurement

Viewing a Signal

Marker AnnotationActive function block

Figure 3-4 Relationship Between Frequency and Amplitude

Making a Basic Measurement

Chapter 3 43

Page 44

Making a Basic Measurement

Viewing a Signal

Improving Frequency Accuracy

10. While not all of the zeros following the decimal in the active function

block are significant, the numbers after the decimal in the marker

annotation (upper-right corner of screen) are significant. To increase

the accuracy of the frequency reading in the marker annotation, turn

on the frequency count function.

a. Press Mkr Fctn.

• The Marker Fctn softkeys appear.

b. Press Marker Count.

• The Marker Count softkeys appear.

Note softkey

Marker Count On Off. If Off is underlined, press the

softkey to toggle marker count on.

As shown in Figure 3-5 and Figure 3-6:

• The marker annotation changes from Mkr1 to Cntr1.

• The displayed resolution in the marker annotation improves.

NOTE When you use the frequency count function, if the ratio of the resolution

bandwidth to the span is less than 0.002, the following message

appears on the display: Freq Count: Reduce Span/RBW ratio

This indicates that the resolution bandwidth is too narrow.

11. Press Marker ➞, Mkr ➞ CF to move the 10 MHz peak to the center of the

display

.

Valid Marker Count Range

12. Move the marker down the skirt of the 10 MHz peak. Note that

although the readout in the active function changes, as long as the

marker is at least 26 dB above the noise, the counted value

(upper-right corner of display) does not change (see Figure 3-6). For

an accurate count, the marker does not have to be at the exact peak.

NOTE Marker count functions properly only on CW signals or discrete peaks.

For a valid reading, the marker must be ≥26 dB above the noise.

13. Press BW/Avg, Res BW, then enter a new value. This action makes

the resolution bandwidth the active function and allows you to

experiment with different resolution bandwidth (RBW) values.

14. Press Marker, Off to turn the marker off.

NOTE After properly setting the analyzer to display your signal, you can save

the settings as either a user preset (press

Making a Basic Measurement

44 Chapter 3

System, Power On/Preset, Save

Page 45

User Preset), or a file (see “Saving a File” on page 53).

Figure 3-5 Increasing Marker Frequency Accuracy

Frequency Count

increases accuracy

Making a Basic Measurement

Viewing a Signal

Chapter 3 45

Making a Basic Measurement

Page 46

Making a Basic Measurement

Viewing a Signal

Figure 3-6 Using Marker Counter

Making a Basic Measurement

46 Chapter 3

Page 47

t\

Viewing Catalogs and Saving Files

4 Viewing Catalogs and Saving

Files

47

Page 48

Viewing Catalogs and Saving Files

The analyzer stores and retrieves data similarly to the way that a

personal computer (PC) does: both have internal storage and a floppy

disk drive. While a PC has an internal drive, the analyzer’s internal

storage is nonvolatile (flash) memory, which acts as an internal drive.

As with a PC, both the internal storage and the floppy disk drive have

directory and sub-directory capability.

Viewing Catalogs and Saving Files

This chapter tells you how to:

• locate catalogs and view files, on page 49.

• save a file, on page 53.

For more information on catalogs and files, see the

Measurement/Programming Examples.

48 Chapter 4

Page 49

Viewing Catalogs and Saving Files

File Menu Functions

File Menu Functions

This chapter describes how to use the functions located under the

front-panel

that of personal computers (PCs). Like PCs, these analyzers include an

internal storage drive and a floppy disk drive, both of which have

directory and sub-directory capability.

You will learn how to do all of the following:

• locate and view files in the catalog

• save a file

• load a file

• rename a file

• copy a file

• delete a file

File key. Data storage and retrieval are handled similarly to

t\

Viewing Catalogs and Saving Files

NOTE The display examples in this book are made using various analyzer

models, you may see some variations depending upon your analyzer.

Locating and viewing files in the catalog

Techniques for locating files and directories are consistent throughout

the various file menu functions. Although this section provides specific

information about navigation in the catalog, you may wish to refer back

to this section when performing other operations of the file menu.

NOTE Trace files are not bitmap files. Files saved as Trace cannot be imported

into other applications or converted. If you require the use of other

applications, for example Microsoft® Word or Microsoft® Excel, be sure

to save your files as .gif or .wmf formats using

Comma separated value (csv) files can also be imported into Microsoft®

Excel.

Screen for your file Type.

Chapter 4 49

Page 50

Viewing Catalogs and Saving Files

Viewing Catalogs and Saving Files

File Menu Functions

Press File, Catalog to bring up a screen display as shown in Figure 4-1.

Figure 4-1 Catalog Menu

NOTE Use the front-panel Step Keys or Knob and the Dir Up or Dir Select keys

to move up and down within the directory information box.

1. The entry fields show the parameters for the files viewed. Entry

fields that are being modified or are modifiable are indicated by

highlighting (inverse video). Each file menu function has its own

unique set of entry fields pertaining to that function. Below are the

fields listed under the catalog key:

a. Name: field states the filename.

b. Show Type: field displays the type of files viewed.

c. Path: field displays the drive and directory location of the files.

2. The directory information box displays the drives, directories, and/or

files currently described in the entry fields. Highlighting a row of

information selects that location and updates the entry fields. There

are four column headings in this area of the display. They are

described as follows:

a. Name: column states the drive ([-A-] or [-C-]) if at the top level

50 Chapter 4

Page 51

Viewing Catalogs and Saving Files

File Menu Functions

on the drive, directory name, or filename.

b. Type: column displays the extension of the filename, for example,

.STA or .TRC. Directories are displayed as DIR and drives have

nothing listed under Type:. They are only designated by the

Name: column ([-A-] or [-C-]).

c. Size: column displays the size of the file in bytes.

d. Modified: column displays the date and time the last change

occurred.

3. The softkey menu has four options:

a. Typ e: allows you to choose the type of file you wish to view. (You

may view all types by using the

All key under Type. )

t\

Viewing Catalogs and Saving Files

b. Sort

: Under the Sort key, you can sort by any of the four columns

and you can choose up (ascending) or down (descending).

c. Dir Up: moves you up one directory level. If you are already at the

top level, this key moves you up to the drive level, displaying the

available disk drives.

d. Dir Select: moves you down into the highlighted directory or up

into the next level (directory or drive) if the “. .” under the Name:

column is highlighted.

NOTE Navigation keys: Use the front-panel Step Keys or Knob and the Dir Up

or Dir Select keys to move around in the directory information box.

4. The drive space line shows the number of bytes used on the drive

and the number of bytes still free on the drive.

Creating a directory

Directories and sub-directories can be created on both the A: floppy disk

and the internal C: drive. This allows maximum flexibility in

organizing files. For this example, we will create a directory on the C:

drive.

1. Press File, More 1 of 2, Create Dir. Your screen should look similar to

Figure 4-1, except the entry fields will be Dir Name: and Path: and

the Heading will read: Directories.

2. Navigate through the file system until the Path: field displays C:\.

(Use the Step Keys, Knob, Dir Up, and/or Dir Select keys.)

3. Press Name and enter the name, “START” using the Alpha Editor.

(The numeric keypad is also available for the filename.) Press

Enter

(hardkey) when the Dir Name: field contains this directory title.

(Use the

4. Press Create Dir Now to execute the operation. The message:

Chapter 4 51

Bk Sp hardkey on the front panel to make corrections.)

Page 52

Viewing Catalogs and Saving Files

Viewing Catalogs and Saving Files

File Menu Functions

Creating Directory appears on the screen. Then the status bar

displays: Directory C:\START created.

5. To make a sub- d irect o ry, scroll down to the START directory you just

created and press

Dir Select. The Path: field should now read:

C:\START\. Repeat Steps 3 and 4 above, using a new name. The

status bar now should read: Directory C:\START\new name

created.

52 Chapter 4

Page 53

Viewing Catalogs and Saving Files

Saving a File

Saving a File

You can save files (setups, states, traces, limits, corrections,

measurement results, or screens) to a floppy disk (A:\), or the internal

drive (C:\). In this example you will save a trace to the internal C:

drive.

NOTE Trace files are not bitmap files. Files saved as Trace cannot be imported

into other applications or converted. If you require the use of other

applications, for example Microsoft® Word or Microsoft® Excel, be sure

to save your files as .gif or .wmf formats using Screen for your file Type.

Step 1. Set up the analyzer trace

t\

Viewing Catalogs and Saving Files

1. Perform a factory preset by pressing Preset, Factory Preset (if

present).

2. Turn on the internal 50 MHz alignment signal of the analyzer as

follows:

• Press Input/Output, Input Port, Amptd Ref.

3. Set the center frequency to 50 MHz by pressing press FREQUENCY,

Center Freq, 50, MHz.

4. Set the span to 75 MHz by pressing SPAN, Span, 75, MHz. The

reference signal will appear on the display.

5. View trace 1 and put it into maximum hold by pressing View/Trace,

Max Hold. (Trace 1 should already by underlined, but if not, press

Trace 1 2 3 until 1 is underlined and then press Max Hold.) Your

analyzer display should look similar to Figure 4-3.

Chapter 4 53

Page 54

Viewing Catalogs and Saving Files

Viewing Catalogs and Saving Files

Saving a File

Figure 4-2 Viewing Trace 1

6. Activate trace 2 and put it into minimum hold by pressing Trace (2),

Min Hold. Your analyzer display should look similar to Figure 4-4.

Figure 4-3 Viewing Traces 1 and 2

7. Activate trace 3 by pressing Trace (3), Clear Write. Your analyzer

display should look similar to Figure 4-5.

54 Chapter 4

Page 55

Figure 4-4 Viewing Traces 1, 2, and 3

t\

Viewing Catalogs and Saving Files

Viewing Catalogs and Saving Files

Saving a File

Step 2. Save the file

1. To access the Save menu, press, File, Save.

2. Select the type of file you want to save. In this example you are

saving a trace; press

NOTE Trace files are not bitmap files. Files saved as Trace cannot be imported

into other applications or converted. If you require the use of other

applications, for example Microsoft® Word or Microsoft® Excel, be

sure to save your files as .gif or .wmf formats using

file

Type. Comma separated value (csv) files can also be imported

into Microsoft® Excel.

3. Select the trace you wish to save (1, 2, 3, or all traces). In this

example you will save trace 3; press

4. Select the format you wish to use for saving the trace, either trace

plus state (

Trac e + S tate ) or comma separated value (CSV). In this

example you will save as trace plus state; press

5. Enter a filename by pressing Name. The Alpha Editor appears. For

this example you will name the file, “TEST1”. (The numeric keypad

is also available for the filename.) Note that the file extension is

always set by the system and for this file type the extension is TRC.

You must now press the

menu.

Type, Tra ce.

Screen for your

Source (softkey), Trace 3.

Format, Trace + State.

Enter (hardkey) to get back to the Save

Chapter 4 55

Page 56

Viewing Catalogs and Saving Files

Viewing Catalogs and Saving Files

Saving a File

NOTE You need to use a filename that does not already exist in the current

directory. The filename is limited to eight characters, alpha (A-Z) or

numeric (0-9) in any combination. The analyzer will not allow you to

overwrite an existing file. If you select a filename that already

exists, the status bar will display the message: File already

exists. If you do not choose a filename, the analyzer will

automatically generate a name based on the type of file you are

saving (Setup: SETUP, State: STATE, Trace: TRACE, Limits: LIMIT,

Corrections: COREC, Screen: SCREN). It also generates a three digit

integer (starting at 000 and extending through 999, remembering

the previously saved value through a power cycle) which it adds to

the name, for example: TRACE056.TRC. Also note that this three digit

integer increments upon each attempted save until a unique

filename is created, without regard to the success of the save.

6. The destination for the saved file is shown in the Path: field. In this

example, you will select the path as C:\START\. If the correct

location is not listed in the Path: field, change directories as follows:

a. Press Dir Up or Dir Select and use the step keys or knob, to

highlight the desired destination directory.

b. Press Dir Select and confirm your choice displayed in the Path:

field.

7. Press Save Now or Save (hardkey) to save the file to the C:\Start\

location. The message Saving Now is displayed during this

operation. For this example, the status line displays:

C:\START\TEST1.TRC file saved.

NOTE When saving to drive (A:), never remove the floppy disk during the save

operation. To do so could corrupt all data on the floppy disk.

56 Chapter 4

Page 57

Viewing Catalogs and Saving Files

Saving a File

Loading a file

1. Reset the analyzer by pressing Preset, Factory Preset (if present).

2. To access the Load menu, press File, Load.

3. Select the type of file you want to load (setup, state, trace, limits, or

corrections). In this example you are loading a trace file; press

Trac e

.

NOTE Not all file types can be loaded back into the analyzer. For example,

Screen files and CSV (comma separated value) files cannot be

loaded. CSV and Screen files are designed for use with a PC.

4. Select the directory where your file is located. In this example, select

the C:\START\ directory. (Use the front-panel step keys, knob,

and/or

Dir Select keys to locate the directory.)

Type,

Dir Up,

t\

Viewing Catalogs and Saving Files

5. Select the file you want to load into the analyzer by moving the

cursor with the front-panel knob to highlight the file name. In this

example the file is TEST1.TRC. Select the trace into which you wish

to load the file. In this example, load it into Trace 2. (

Trace 2).

6. Press Load Now to load the specified file. Your display should look

similar to Figure 4-6. The status bar reads: C:\START\TEST1.TRC

file loaded.

Figure 4-5 File Loaded

Destination,

Chapter 4 57

Page 58

Viewing Catalogs and Saving Files

Viewing Catalogs and Saving Files

Saving a File

NOTE You should notice that the trace you saved, in this example trace 3, is

loaded to trace 2. If you wish to verify this condition, remove the

signal input. Press

Input/Output, Input Port, Amptd Ref (Off).

Note that when a trace is loaded, it is placed in view mode. To see

that trace 2 is in view mode, blank traces 1 and 3 by pressing

View/Trace, Trace 1, Blank, Trace 3, Blank. Then press Trace 2. Notice

that trace 2 is the only trace displayed in view mode (the view key is

selected, and the trace is not sweeping). Your display should look

similar to Figure 4-7.

Figure 4-6 Verifying Trace 1

CAUTION When operating in dc coupled mode, ensure protection of the input

mixer by limiting the input level to 0 Vdc and +30 dBm.

NOTE When loading Limits files, be sure you have selected the appropriate

X Axis Units: frequency or time (

Units

). If you are in time X-Axis Units, and you load frequency limits,

Display, Limits, Properties, X Axis

all current limit line data will be erased and the analyzer will switch

to the frequency domain. The reverse of the this situation also holds

true.

58 Chapter 4

Page 59

Viewing Catalogs and Saving Files

Saving a File

Renaming a File

1. To acce ss the Rename menu, press File, Rename.

2. Select the type of file you want to rename (setup, state, trace, limits,

screens, or corrections). In this example you are renaming a trace

file; press

3. Select the drive and directory where your file is located. In this

example, choose drive C:\START.

4. Select the file you want to rename. In this example, choose the file

TEST1.TRC.

5. Press Name to open the Alpha Editor menu. For this example,

rename the file to RENAME using the Alpha Editor softkeys. (The

Name: field is limited to eight characters.) Your display should look

similar to Figure 4-8.

Type, Tr ace.

t\

Viewing Catalogs and Saving Files

6. Press Enter, Rename Now: your file is now renamed and visible within

the directory displayed on your analyzer. The status line displays the

message: C:\START\TEST1.TRC file renamed to

C:\START\RENAME.TRC.

Figure 4-7 Renaming a File

Chapter 4 59

Page 60

Viewing Catalogs and Saving Files

Viewing Catalogs and Saving Files

Saving a File

Copying a File

1. To access the Copy menu, press File, Copy. This menu function brings

up 2 directory boxes as described by the From: and To: fields located

directly above the boxes. Refer to Figure 4-9.

Figure 4-8 Copy Menu

2. Put a formatted floppy in the A: drive.

3. Select the type of file you want to copy (setup, state, trace, limits,

screens, or corrections). In this example you are copying a trace file

from the C: drive to the A: drive; press,

4. Press Dir (in the key menu) to underline From:. Notice the From:

Type, Tr ace.

field (just above the top directory box) highlights the location from

which you will be copying. Using the navigation keys (

select

, step keys, or front panel knob), locate the C:\START\

Dir Up, Direct

directory.

5. Scroll to highlight the file displayed in the directory box from which

you wish to copy. In this example, you will need to highlight the file

RENAME.

6. Press Dir (in the key menu) to underline To:. The To: field (just

above the bottom directory box) is highlighting the location to which

you will be copying. Using the navigation keys as described above,

highlight the A:\ drive.

NOTE When pressing Dir (To), the file chosen in the From: location is no longer

highlighted, however the Name: field above the From directory box

60 Chapter 4

Page 61

Viewing Catalogs and Saving Files

Saving a File

displays the chosen file; in this example: RENAME.TRC.

NOTE Highlighting a filename in the To: directory box has no significance.

The file cannot be placed inside another file.

7. Press Copy Now to execute the operation. The message: “Copying

file” is displayed during the copying process. Upon completion, the

status bar reads: “C:\START\RENAME.TRC file copied”. You have

now copied the file RENAME from the C: drive to the A: drive.

Deleting a File

1. To access the Delete menu, press File, Delete.

2. Select the type of file you want to delete (setup, state, trace, limits,

screens, or corrections). In this example, you are deleting a trace file;

press

Typ e, Trace.

t\

Viewing Catalogs and Saving Files

3. Select the drive and directory where the file you wish to delete is

located. In this example, choose C:\START\. Use the navigation keys

Dir Up, Dir Select, step keys, front panel knob) to highlight this

(

location in the Path: field. (Refer to “Locating and viewing files in

the catalog” on page 49 for more instructions.)

4. Select the file you want to delete. In this example, choose the file

RENAME.TRC. Move the cursor with the navigation keys to highlight

the file name.

5. Press Delete Now. The message: Deleting file pops up on the

display during the operation. Upon completion, the status bar reads:

C:\START\RENAME.TRC file deleted. Your file is now deleted and

is no longer visible in the directory displayed on your analyzer.

Chapter 4 61

Page 62

Viewing Catalogs and Saving Files

Viewing Catalogs and Saving Files

Using the Alpha Editor

Using the Alpha Editor

The Alpha Editor enables you to select letters to enter a name for a file

or directory (

1. Use the More keys to display the softkey that lists the character you

want. Each softkey has several characters on it.

2. When you press a softkey, its characters are displayed on individual

softkeys.

3. Select the one you want.

4. Digits are entered using the front panel numeric key pad.

File, Rename, for example).

62 Chapter 4

Page 63

Options and Accessories

5 Options and Accessories

This chapter lists options and accessories available for your analyzer.

63

Page 64

Options and Accessories

Ordering Options and Accessories

Ordering Options and Accessories

Options and accessories help you configure the analyzer for your

specific applications, and enable you to use the analyzer.

Options (see page 65)

Unless specified otherwise, all options are available when you order a

spectrum analyzer; some options are also available as kits that you can

order and install after you receive the analyzer. Order kits through your

local Agilent Sales and Service Office.

For the latest information on Agilent Spectrum Analyzer options and

upgrade kits, visit the following Internet URL:

http://www.agilent.com/find/sa_upgrades

Options and Accessories

Accessories (see page 71)

Order accessories through your local Agilent Sales and Service Office.

64 Chapter 5

Page 65

Options

Options and Accessories

Options

Option

Number

0B0

0B1

0BW

1CM

1CN Front Handle Kit Available as P/N 5063-9228.

1CP

1CR

1DS

Manual Set on CD-ROM

Only

Additional Manual Set An additional set of the standard documentation shipped with

Service Documentation The Service guide describes assembly-level troubleshooting

Rack Mount Kit Includes rack mount flanges and hardware. Used to rack mount

Rack Mount Kit with

Handles

Rack Slide Kit Available as P/N E4406-60115. Rack slides allow the analyzer

Preamplifier An internal preamplifier assembly. Not required when Option

Name Description

The documentation CD-ROM contains the standard

documentation set as well as Adobe Acrobat Reader with

Search.

the analyzer. See “Initial Inspection” on page 7 for information

about the standard documentation set.

procedures, provides a parts list, and documents post-repair

procedures.

analyzers without front handles (available as P/N 5063-9215).