Page 1

Calibration Guide

Agilent Technologies

ESG Vector Signal Generator

This guide applies to signal generator models and associ ated serial number prefixes listed below.

Depending on your firmware revision, signal generator operation may vary from descriptions in this guide.

E4438C: US4146

Part N umber: E4400-90509

Printed in USA

March 2002

© Copyright 2001, 2002 Agilent Technologies, Inc.

Page 2

Notice

The material contained in this document is provided “as is”, and is subject to being changed, without notice,

in future editions.

Further, to the maximum extent permitted by applicable law, Agilent disclaims all warranties, either express

or implied with rega rd to this m anual and to any of the Agilent products to which it perta ins, including but

not limited to the implied warranties of merchantability and fitness for a particular purpose. Agilent shall

not be liable for errors or for incidental or co nseq ue nti a l damages in connect i on with the furni shi ng, use, or

performance of this document or any of the Agilent products to which it pertains. Should Agilent have a

written contra ct wit h the U se r and sh ou ld any o f the contr act terms conflict with these terms, the cont rac t

terms shall control.

F o r signal gener a tor warranty in formation, ref e r to the Installa tio n G uide or Service Guide.

Questions or Comments about our Documentation?

We welcome any questions or comments you may have about our documentation. Please email us at

sources_manuals@ am.exch.agilent.com.

ii

Page 3

Contents

1. Getting Started

Overview of Getting Started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Confirming Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Installing Service Support Software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

Uninstallin g Se rv ice Sup po rt Softwar e. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

Administration of Service Support Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

Software Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

Administering Service Support Software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

Running Service Support Software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-22

Starting the Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2 2

Identifying the DUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-23

Selecting Performance Tests, Adjustments, and Test Equipment . . . . . . . . . . . . . . . . . . .1-24

Defining the Location where Test Results are Saved . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-26

Running the Tests and Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-27

Reviewing the Test and Adjustment Results. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-28

Printing the Test and Adjustment Results. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-29

Exiting the Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-29

2. Required Equipment

3. Performance Tests

Overview of Performance Tests. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Running Performance Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

Printing Results of Performance Tests. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-8

Exiting this Service Support Software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

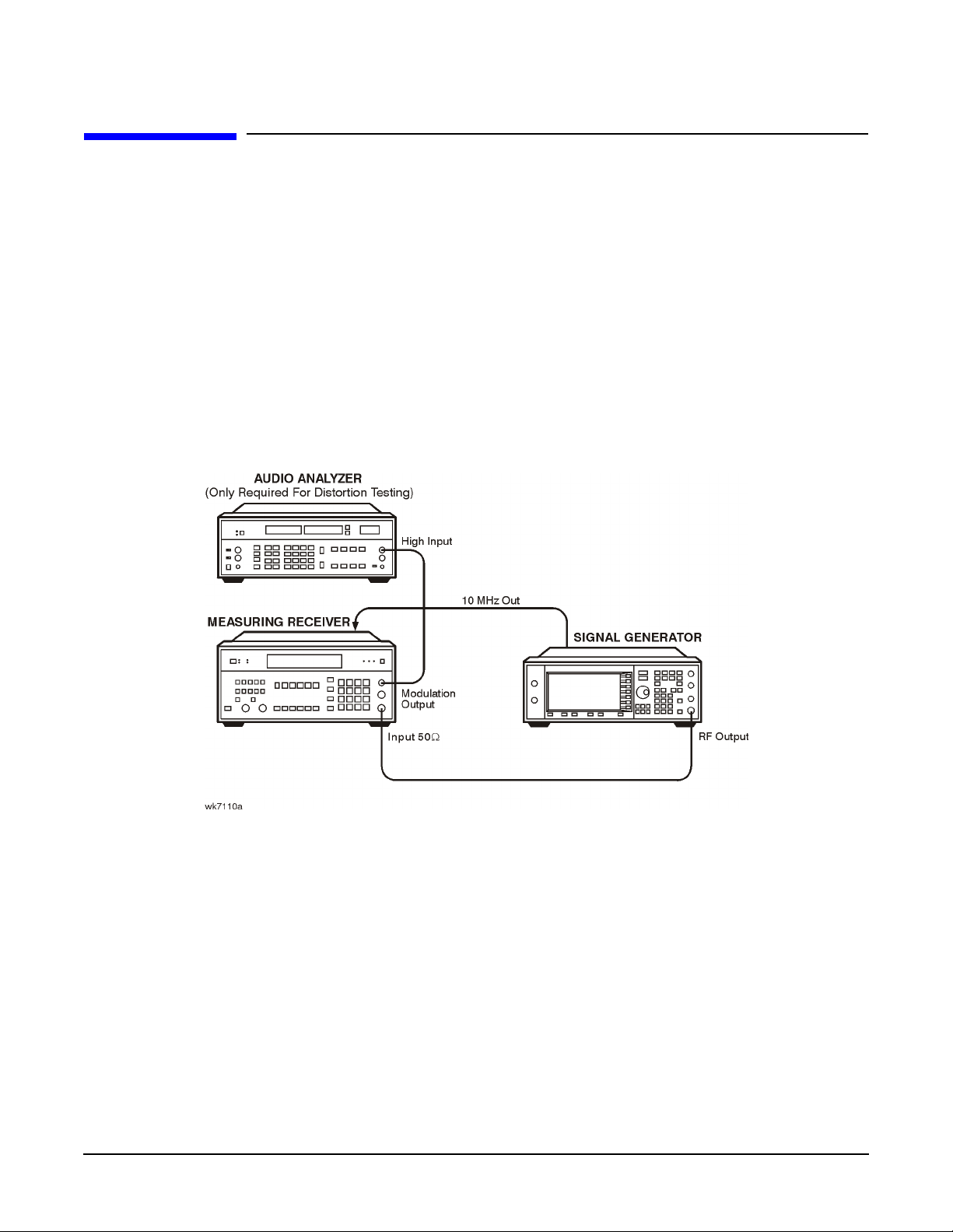

Internal FM Accuracy and Distortion. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-9

Recommended Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-9

Equipment Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-9

Internal A M Accuracy and Distortion. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-10

Recommended Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-10

Equipment Setups . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-10

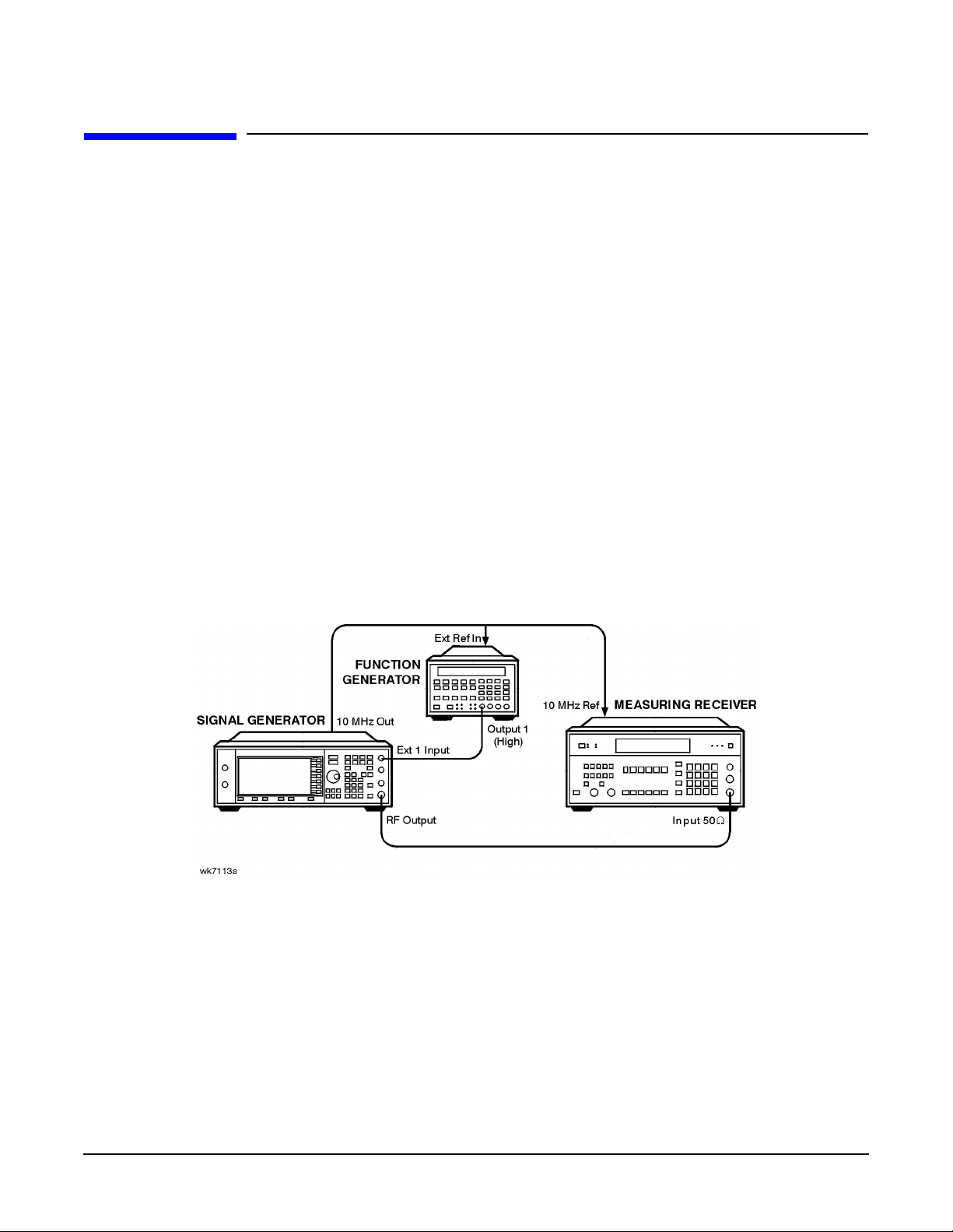

Phase Modulation Accuracy and Distortion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-12

Recommended Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-12

Equipment Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-12

FM Frequency Response . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-13

Recommended Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-13

Equipment Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-13

iii

Page 4

Contents

AM Frequency Response. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1 4

Recommended Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-14

Equipment Setups . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-14

Phase Modulation Frequency Response. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-16

Recommended Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-16

Equipment Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-16

DCFM Frequency Offset Relative to CW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-17

Recommended Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-17

Equipment Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-17

Residual FM

(Not Used with Option UNJ or Option 506) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

Recommended Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-18

Equipment Setups. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-18

Harmonic, Subharmonic, and Nonharmonic Spurious Signals . . . . . . . . . . . . . . . . . . . . . . . . 3-20

Recommended Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-20

Equipment Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-20

Power Level Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-21

Recommended Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-21

Equipmen t Setup s

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-22

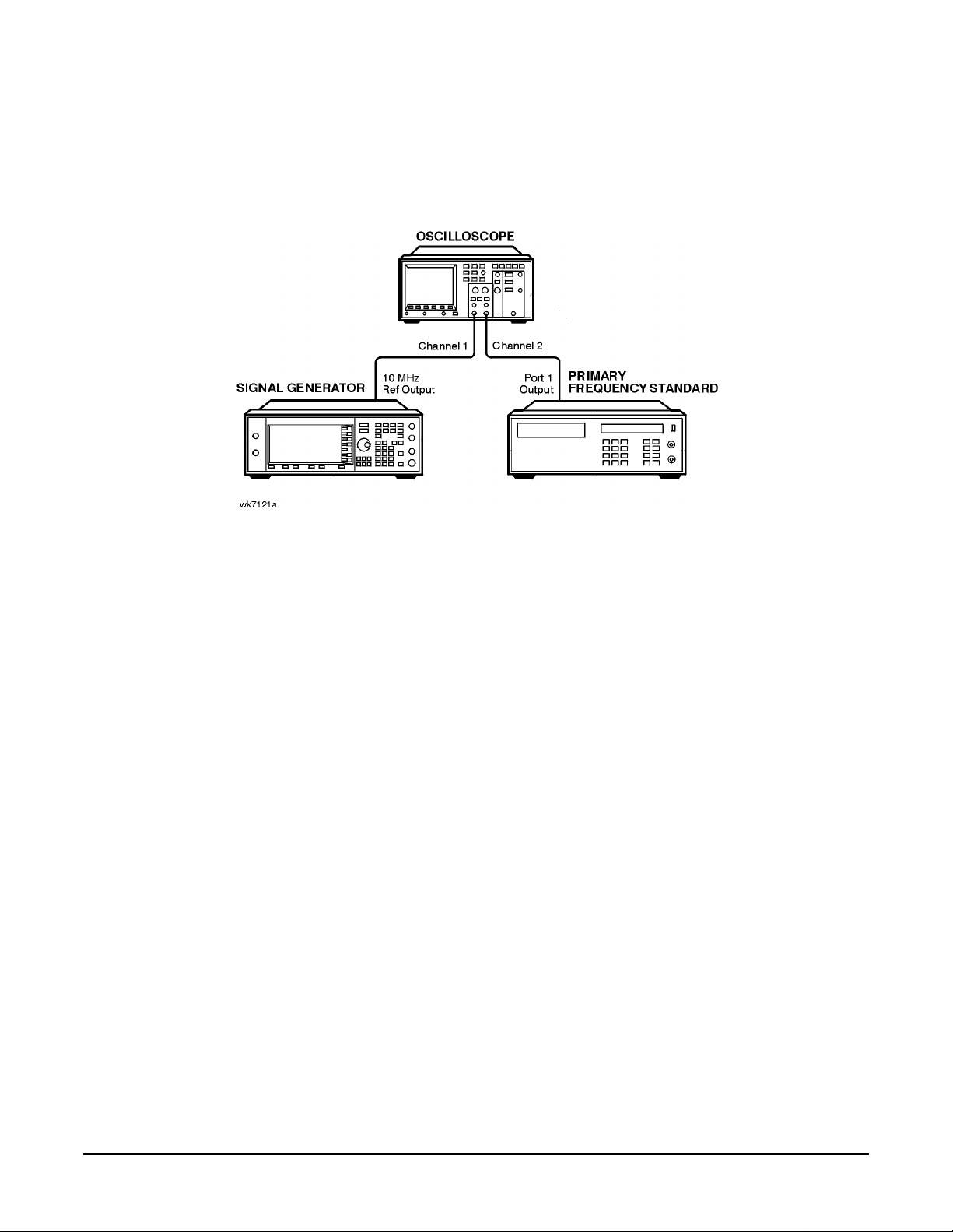

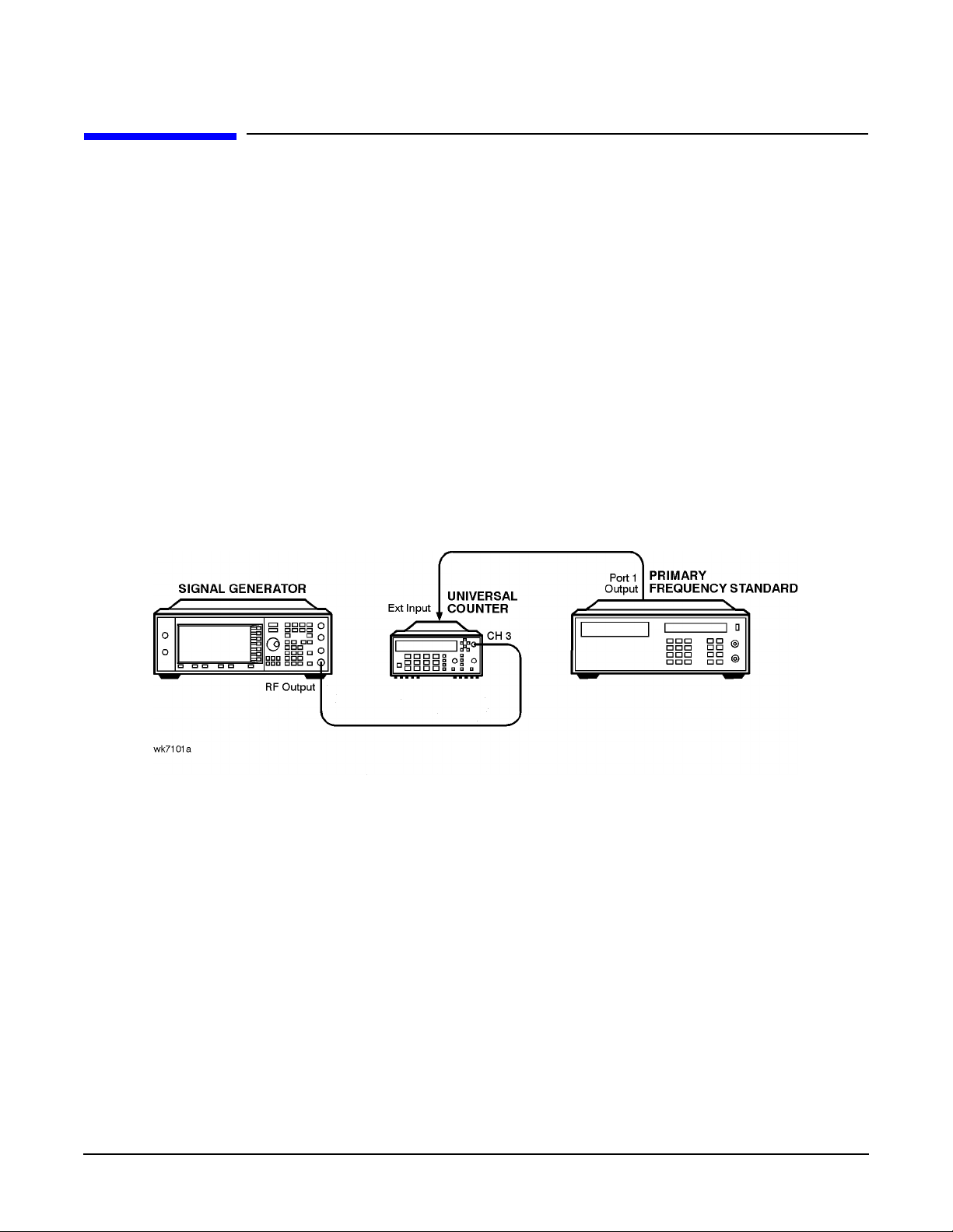

Tim ebase Aging Ra te

(Manual Test - Option U N J, Option 506, or Option 1E5 Only). . . . . . . . . . . . . . . . . . . . . . . . .3-24

Recommended Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-24

Equipment Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-25

Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-25

Digital Modulation Level Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-27

Recommended Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-27

Equipment Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-27

Internal Digital Modu latio n Qu ality

(Option 402 Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-28

Recommended Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-28

Equipment Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-28

Custom I/Q RF Modulation Quality

(Option 402 Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-29

Recommended Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-29

Equipment Setups. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-29

Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-30

Pulse Modulation On/Off Ratio. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-31

iv

Page 5

Contents

Recommended Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-31

Equipment Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-31

Burst Modulation On/Off Ratio. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-32

Recommended Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-32

Equipment Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-32

CDMA Adjacent Channel Power

(Not Used with Option UNB or Option 506). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-33

Recommended Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-33

Equipment Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-33

WCDMA Adjacent Channel Power

(Option 400) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3- 3 4

Recommended Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-34

Equipment Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-34

Phase Noise and Residual FM

(Manual Test - Option UNJ or Option 506 Only). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-35

Measuring Phase Noise. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-35

Measuring Residual FM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-38

Dual Arbitrary Waveform Generator Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-39

Recommended Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-39

Equipment Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-39

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3- 3 9

GSM Loopback BER Check

(Option 300 Only). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4 1

Recommended Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-41

Equipment Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-41

Performance Test Records . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-42

4. Adjustments

Overview of Adjustments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

Adjustment Relationships . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

Analog Bus ADC Calibration Related Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

Synthesizer Potentiometer Related Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

AM Accuracy Related Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

I/Q Modulation Accuracy Related Adjustments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

Burst Modulation Accuracy Related Adjustments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

FM Accuracy Related Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6

Power Level Range and Accuracy Related Adjustments. . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6

Internal Refer en ce Osc illator Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

v

Page 6

Contents

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Required Test Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Analog Bus ADC Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Required Test Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Pretune Calibration

(Option UNJ or Option 506 Only). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Required Test Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Internal Source Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1 0

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Required Test Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-10

VCO Bias Potentiometer Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Required Test Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-11

Lock Angle Potentiometer Ca libr atio n

(Not Used with Option UNJ or Option 506) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Required Test Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-12

KV versus Frequency Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

Required Test Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-13

Timebase DAC Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-14

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

Required Test Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-14

FM Scale DAC Offset Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-15

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

Required Test Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-15

vi

Page 7

Contents

FM Path Offset Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-16

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-16

Required Test Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-16

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4- 1 6

FM In-Band D AC Offset Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-17

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-17

Required Test Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-17

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4- 1 7

FM Inverting Amplifier Offset Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-18

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-18

Required Test Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-18

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4- 1 8

FM 1/2 Path Ratio Gain Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-19

Required Test Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-19

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4- 1 9

Modulation Source Relative Gain Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-20

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-20

Required Test Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-20

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4- 2 0

FM Out-of-Ba nd Calibration

(Not Used with Option UNJ or Option 506). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-21

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-21

Required Test Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-21

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4- 2 1

FM/PM Out-of-Band Calibratio n

(Option UNJ or Option 506 Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-22

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-22

Required Test Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-22

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4- 2 2

FM/PM YO Frequency Compensation Calibration

(Option UNJ or Option 506 Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-23

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-23

Required Test Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-23

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4- 2 3

DCFM Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-24

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-24

Required Test Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-24

vii

Page 8

Contents

Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-24

External Input Peak Detector Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-25

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-25

Required Test Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-25

Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-25

AM Audio Path Offset Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-26

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-26

Required Test Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-26

Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-26

Burst Modulator Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-27

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-27

Required Test Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-27

Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-27

Prelevel Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-28

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-28

Required Test Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-28

Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-28

VBLO Mixer Bias Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-29

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-29

Required Test Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-29

Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-29

Digital Gain Adjust Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-30

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-30

Required Test Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-30

Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-30

Bypass Gain Adjust Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-31

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-31

Required Test Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-31

Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-31

ALC Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-32

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-32

Required Test Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-33

Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-33

Power Level Accuracy, High Power Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-34

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-34

Required Test Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-34

Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-34

viii

Page 9

Contents

ALC Modulation Driver Bias Calibrat ion. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-35

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-35

Required Test Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-35

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4- 3 5

Power Le vel Ac curac y, Low Power Cal i bration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4- 3 6

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-36

Required Test Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-36

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4- 3 7

Power Search Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3 9

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-39

Required Test Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-39

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4- 3 9

AM Gain Calib ration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4- 4 0

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-40

Required Test Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-40

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4- 4 0

I/Q Ga i n/Offset /Quad ratu r e Calib ratio n. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4 1

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-41

Required Test Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-41

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4- 4 1

I/Q Impairment Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-42

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-42

Required Test Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-42

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4- 4 2

5. Contacting Agilent Technologies

Contacting Agilent Technologies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

ix

Page 10

Contents

x

Page 11

1 Gettin g Starte d

1-1

Page 12

Getting Started

Overview of Getting Star ted

Overview of Getting Started

Agilent’s service support software allows fast and accurate testing of the Agilent E4438C ESG vector signal

generator. Th is cha pt er describes how to install, configure, and run ser vic e supp ort so ftware so that yo u can

adjust and test an Agilent E4438C ESG vector signal gene rator to meet specifica tio ns.

How to Proceed

First, review the rest of this sectio n to le arn abou t inst alling, configuring, and running se rv ice sup po rt

softw ar e. Next, ref e r to “Re qui red Eq uipm ent ” to l earn abo ut h ard w are a nd sof tw are req ui reme nts, or becom e

familiar with “Performance Tests” or “Adjustments”. If you need assistance, refer to the section on

“Contactin g Agilent Technologies” on page 5-1.

To install, configure, and run this software, refer to and p erf o rm the step s in the following pro ced ur es:

1. “Confirmin g E quipment” on p age 1-3

2. “Installing Servic e Suppor t Sof tware” on p age 1-4

3. “Ad ministering S ervic e S upp ort Sof tware” o n page 1- 8

4. “Running Servic e Sup po rt Software” o n p age 1-22

1- 2

Page 13

Getting Started

Confirming Equipmen t

Confirming Equipment

• Confirm that you have the prope r te st equipmen t . (Refer t o Chapter 2 for a complete listing.) Let all the

test equipme nt and signal generator warm up in accord anc e wi th ins tru m e nt spe cific atio n s.

• Confirm that your co m puter has the following hardware and ope r atin g system:

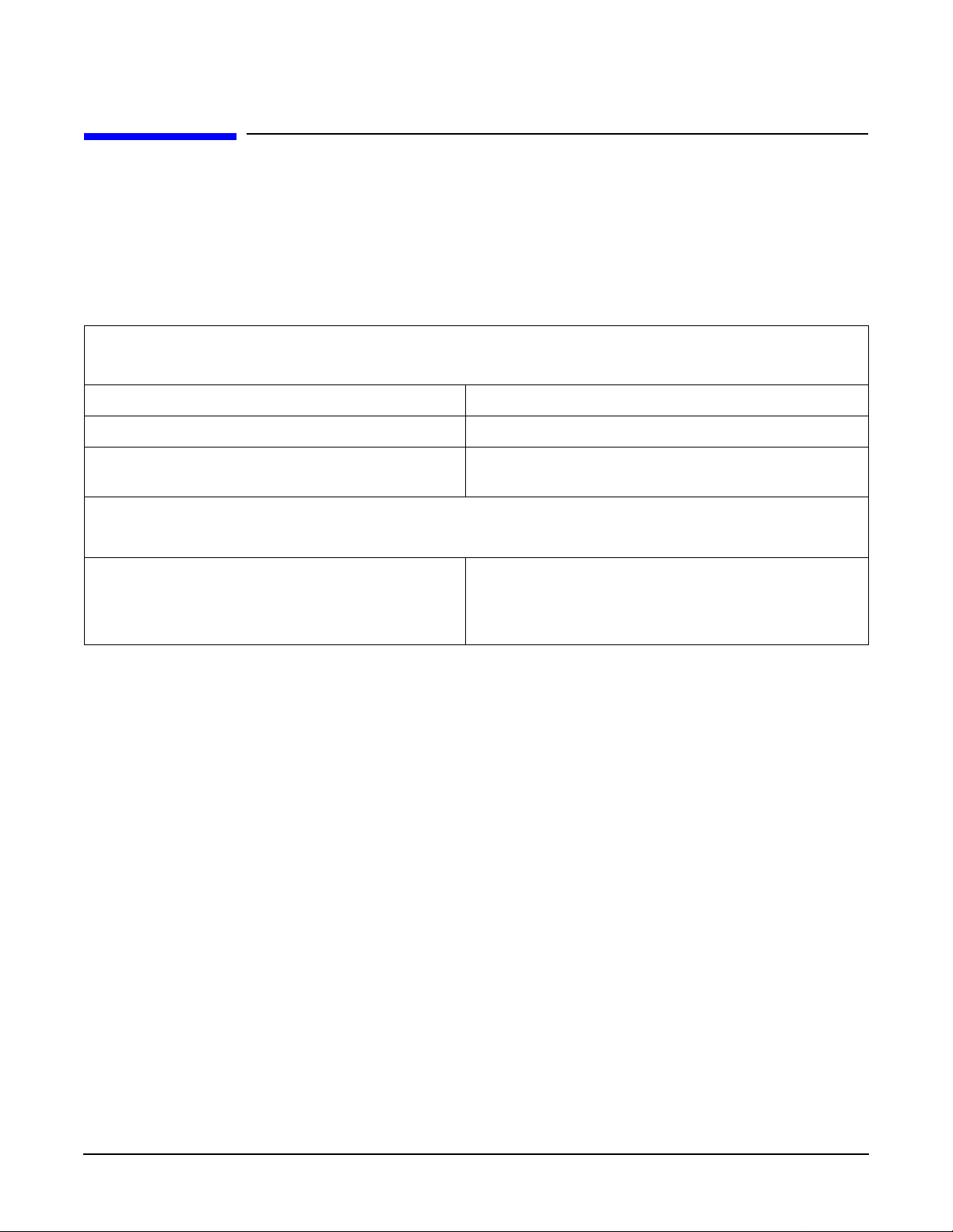

Tabl e 1-1 Computer Equipm ent

Hardware

Test System Controller IBM PC compatible

RAM Required 16 MB or more

GPIB Card Agilent 82341C/D or 82350A GPIB card

with Agilent SIC L Libraries installed and con figur e d

Operating System

IBM PC Operatin g System Windows 3.1,

Windows 95,

Windows 98,

Windows NT 4.0 computer with Ser vic e 5 or above

1-3

Page 14

Getting Started

Installing Ser vice Support Software

Installing Service Support Software

NOTE If you are installing service support software onto a computer which already has service

support software older than version A.03.00, the old version must be removed before installing

the new version.

To install service support software into a PC:

1. Insert “Disk 1” into the disk drive.

2. Display the Run dialog box:

• F or MS Windows 95 or Windows NT: Select the Start button, then select Run... from th e pop-up menu.

• For MS Windows version 3.x: Open the Program Manager, then select Run ... from the File drop-down

menu.

3. From the Run dialog box, type a:setup and se lect the OK button.

The Setup wind ow is d isp layed as it loads files for the installation.

Once these files ar e loade d, th e ESG Ser vic e Softwar e’s Welcome screen is displayed .

4. Continue with the setup by selecting the Next button.

5. The ESG Servic e Software’s Important Information windo w is d isplaye d. It con tain s info rmation that is

vital to installing and using the software. In addition, any new information may also be shown on this

screen. Stop and read th is information before continuing with the software installation!

6. Continue with the setup by selecting the Next button.

The Choose De stination Loca tion window is displaye d . The def ault location for ins tallin g the so ftware is

C:\HP_SV C \ESG_C. Use this as the software’s destination folder.

7. Continue with the setup by selecting the Next button.

The ESG Servic e Software’s Select Progr am Folder window is di splaye d . This in stallation procedu re will

install the service software icons into a program folder. You can enter a new folder name in the Program

Folders text field or select a folder from the Existing Folders field. It is recommended to use “ESG_C

Service Software” for the folder name.

NOTE This documentation re fers to the fold er name as “ES G_C Servi ce Soft w are.” If you use another

name for the folder, be aware of this difference.

8. Continue with the setup by selecting the Next button.

The ESG Service Software’s Start Copying Files window is displayed. This window shows the destination

directory and the folder name settings. To change these settings, select the Back button until the

appropriate window is displayed.

NOTE This is the last point that yo u can can ce l th e in stallation. If you select the Next button, the

installation p rocee d s un til the so ftware is co m ple te ly ins talle d .

9. Select the Next button to go ahe ad with the installation p rocess.

The graphic on the left of the sc reen shows the s tatus of each fil e as it i s copied to the dest ination dir ector y,

1- 4

Page 15

Getting Started

Installing Service Support Software

the status of each disk that is being copied, and the status of the overall memory of the destination. The

graphic in the center of the screen keeps you updated on the destinat i on folder, the fil es that are being

copied, a n d t h e pro gress of t he in s t a l l ation.

When the contents of the disk have been copied to their dest ination, you are not ified to insert each of the

next disks by the Setup Needs the Next Disk dialog box.

10. Ins ert the ne xt disk , as instr uc te d , and sele ct the OK button.

When the installation is complete, the Setup Complete window is displayed. You will be asked to select

whether you want to view the README file or the INFO file. (You a lready read the INFO file when you

started the installation.)

11. Select the README file and then select the Finish button.

The text editor will display the file. To close this file select the File pull do wn menu and then selec t Exit.

12. Select the Yes, I want to restart my computer now radio button. Ensure that the last disk has been

removed and then choose the Finish button to rest art MS Win d ows.

NOTE The MS Windows program must be restarted before you can use the software. When you select

restart, the computer reboots.

If you do not want to restart M S Windo ws at this time, select the No, I will restart my computer later

radio button. If you select restart, the computer reboots and you can start using the software.

1-5

Page 16

Getting Started

Uninstalling Service Support Software

Uninstalling Service Support Software

• MS Windows 95 or Windows NT:

1. Display the Control Panel program group

by pressing Start > Settin gs > C ontrol Panel.

2. Select the Add/Remove Programs icon.

3. From the Install/ U nin stall Tab in the Add/Remove Progra ms p rop erti es dialog box:

a. Select ESG_C, then selec t the Add/Remove button.

b. Select ESG Serv ice Sof tware, then select the Add/Remove button.

4. If the Details button is displayed, the program is removed but the path has not been removed. Click

the Details button and note the path. T hen click the OK button.

5. Display the M S Windows Explorer dialog box by selecting St art > Programs > Windows Explorer.

6. Select the path that you previously noted, and if you are not using these files for another purpose,

select Delete from the Files dro p- d own menu to delete the pat h.

• MS Windows versio n 3. x:

1. From the Program Manager, click on program group (Agilent Servi ce Suppor t w as the program’s

default title) to high light the program group name.

2. From the File drop-down menu, select Delete.

3. From the Fi le Manager, select the su bdirectory where the program is stored.

(The program ’s default subdirecto ry was hp_ sv c.)

4. From the File drop-down menu, select Delete.

1- 6

Page 17

Getting Started

Administration of Service Support Software

Administration of Service Support Software

The following se c tio n shows you how to ad mi nis te r and ru n the Service Support Software. The software’s

administra tive func tio ns allow for the addi tio n or re m oval o f all nec essary test equipme n t, sof twar e driv e rs,

and test procedures. This would in clude additional software drivers (as they are relea s ed) to extend the range

of tests and equipment supported by Servi ce Support Softw are test set, or maintenance relea se s of the

curren t d ri vers.

Soft ware Configuration

Follow the instructions below to configure the software to run in eithe r User Mode or Ad ministration Mode.

Start the software using the steps appropriate for the version of MS Windows th at is installed on your PC.

• For MS Windows version 3.x:

1. Open the Program Manager window.

2. O p en th e Agi l ent Se rvice S u ppor t program g roup.

3. Open the Agilent Service Software icon.

• For MS Windows 95 or Windows NT:

1. Select Start.

2. Select Agilent Serv ice Software for PCs.

3. Select Agile nt Serv ice So ftware.

The service support software has two configurations: User and Administration. The following sections explain

the difference between the two configurations.

Figure 1-1 The User Informatio n Window

User Configuration

Logging on in Use r Co nfiguration only allo w s a cces s to the instr um e nt ’s perform ance tests and adjustments.

Refer to “Starting the Sof tware” on p age 22.

1-7

Page 18

Getting Started

Administration of Service Suppor t Sof tw are

Administration Configuration

Logging on in Administration Configuration supports all administrative functions, including the addition of

new equipment and the installation of test procedures and device drivers.

Administering Service Support Software

1. Refer to the illus trat io n above and fill in the fi elds in the Us er Inf ormation window :

a. In the User Name field, type in the word Admin. (Case sensitive. )

b. In the Password fie ld , type in the word Falcon. (Case sensitive.)

2. Click OK. (Cance l closes the so ftware ap plicat io n. )

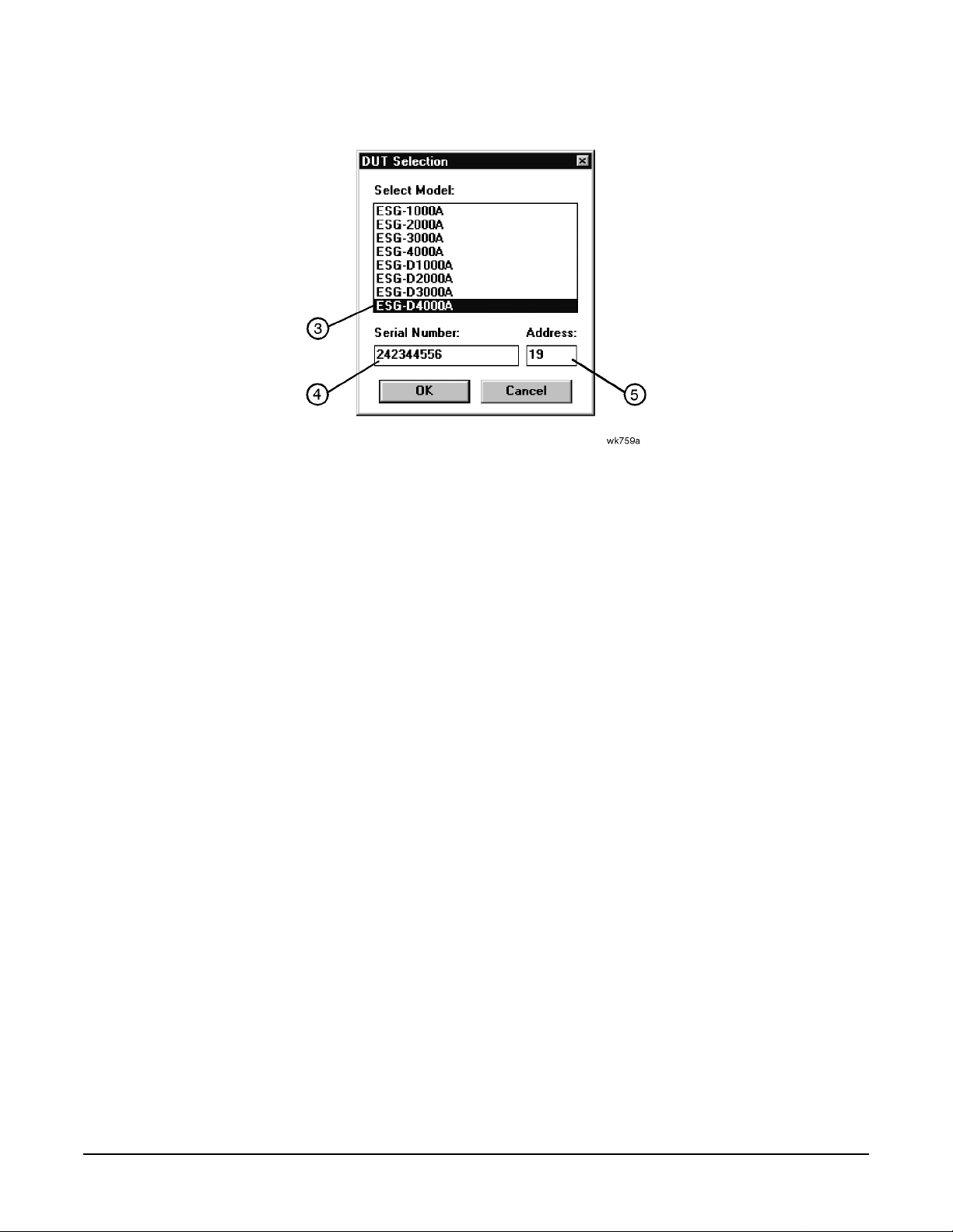

Identifying the Device Under Test (DUT)

When the DUT Selection dialog box is displayed:

1. Make sure that ESG_C is selected in the Select an Instrument Family list.

2. In the Select Model list, select the instrument model of the DUT to be adjusted or tested.

3. In the Serial Number box, enter the complete serial number of the DUT.

4. In the Address box, enter the two-digit GPIB address of the DUT. (To display the address on the signal

generator, press

1-8

Utility > GPIB/RS-232. The GPIB Address softkey shows the current add ress.)

Page 19

Getting Started

Administration of Service Support Software

5. Select the OK but ton.

6. The Select Test Equipment and Tests window appears on the display. Close this window.

Adding Test Equipment

Before any performance tests can be run, information regarding your specific test equipment must be entered

into the software’s database. This information includes the serial numbers, calibration dat es, GPIB address,

and traceabi lit y da t a for each individual compo nent . O n ly equipment which has been en t ere d i nto the system

will be available for the test equipment selection process during the test setup. To add test equipment, follow

the instruction s belo w:

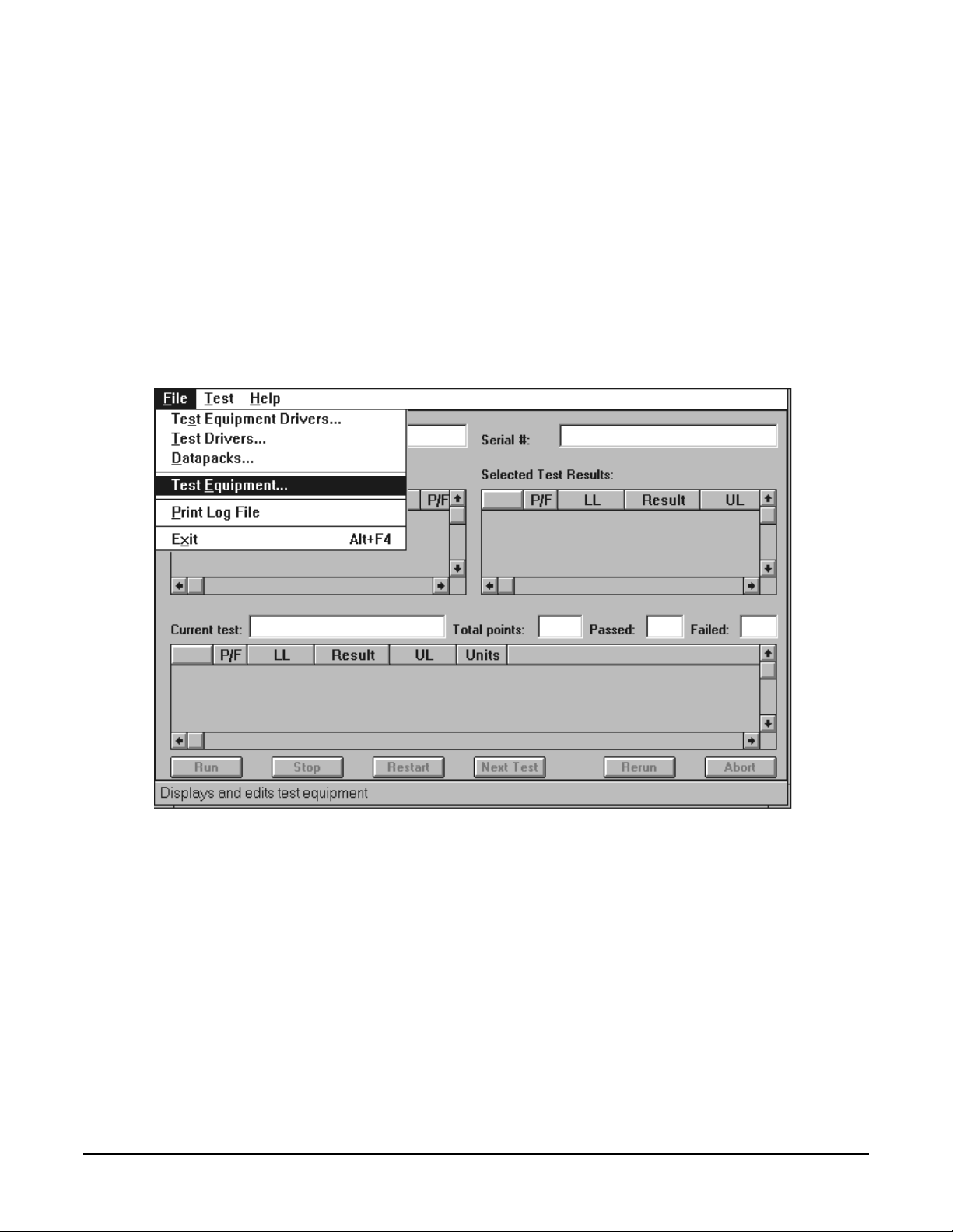

1. Refer to Figure 1-2. In the File drop-down menu, select Test Equipment.

Figure 1-2 Test Equipment in the File Drop-Down Menu

2. Refer to Figure 1-3. In the Test Equipment dialog box, select the Device Type for the new equipment you

are adding.

1-9

Page 20

Getting Started

Administration of Service Suppor t Sof tw are

Figure 1-3 Adding Test Equipment Using the Test Equipment Menu

3. Select the model of the device.

4. Click Add.

1-10

Page 21

Getting Started

Administration of Service Support Software

5. In the New Test Equipment window (refer to Figure 1-4), enter the follo win g p ara m et ers into th e

appropriate box:

Serial Number of the new equipment.

GPIB Address of the new equipment. This address must be in the range of 0 through 31 and it should

not conflict with any other instrument address already present in the test setup.

NOTE The power sensor must be assigned GPIB address −1 (negative 1).

Cal Due Dat e the projected calibration due date of the new equipment.

Trace Number the calibration tracking nu m b er. This is the last required item.

Calibration Type (optional) is used only whe n spe cial ca libr atio n data is associated with the dev ice

being added, and on l y a s a functi on setup by the factory for equipment r eq uir i ng s pecific

calibration data. The only devic e s currently requiring th is feat ur e are po wer se n sors.

Table 1-2 is an example of the calibration information required to ensure accuracy for

measurements using the power sensor. This window is accessed for data entry by

selecting the wor d s CAL D ATA from the Ca libr atio n T ype field in the Edit or New Test

Equipmen t wind o w, Figure 1-4.

Table 1-2 An Example of Calibration Data for Power Sensors

Frequency (MHz)

0.1000 97.6

0.3000 98.9

1.0 99.1

3.0 99.4

NOTE If an Agilent E9304A power sensor is used, the power sensor calibration is automatically

loaded into the power meter and a calibration data table is not used.

Calibration

Factor (%)

1-11

Page 22

Getting Started

Administration of Service Suppor t Sof tw are

Figure1-4 Adding the Equipment Information Using the New Test Equipment Window

6. Click OK.

NOTE The serial number of the test equipment added will be displayed in the Equipment field of the

Test Equipment dialog box (Figure 1- 3 ).

Removing Test Equipment

Removal of test equipment is accomplished using the Test Equipment dialog box. Refer to Figure 1-5.

1. Select the Devic e Type of th e test eq ui pme n t to be remove d .

1-12

Page 23

Getting Started

Administration of Service Support Software

Figure 1-5 Removing an d Editi ng Test Equipme nt Using the Test Equipmen t Window

2. Select the model of the test equipment to be removed from the Models field.

3. Select the serial number of the test equipmen t to be removed from the Equipment field .

4. Click Remove.

5. Click Close.

Editing Test Equipment

Editing test equipment parameters is accomplished using the Test Equipment dialog box. Refer to Figure 1-5.

1. Select the Devic e Type of th e test eq ui pme n t to be edite d.

2. Select the model of the test equipment to be edited from the Models field.

3. Select the serial number of the test equipmen t to be edited.

4. Click Edit. The Edit Test Equipment window will appear. Change the field parameters as necessary.

5. Click OK to save the changes and clos e the wind ow.

6. Click Close in the Test Equipment window.

1-13

Page 24

Getting Started

Administration of Service Suppor t Sof tw are

Adding Device Drive rs

Follow these instructions to add test equipment device drivers to the program:

CAUTION This and the following procedures: Adding/Removing D evice (Test Equipment) Drivers,

Adding/Removing Test Drivers, and Adding/Removing Datapa cks are included for

informational purpos es. These procedures should only be used when instructions are provided

describing whi ch drivers or datapacks need replacement or removal.

1. Log into the sof tware no r m ally un til the Select Test Equipment and Tests window is disp laye d.

2. Click the Cance l bu tto n t o clos e t he Sel ect Test E q u i p men t a n d Tests w i ndow.

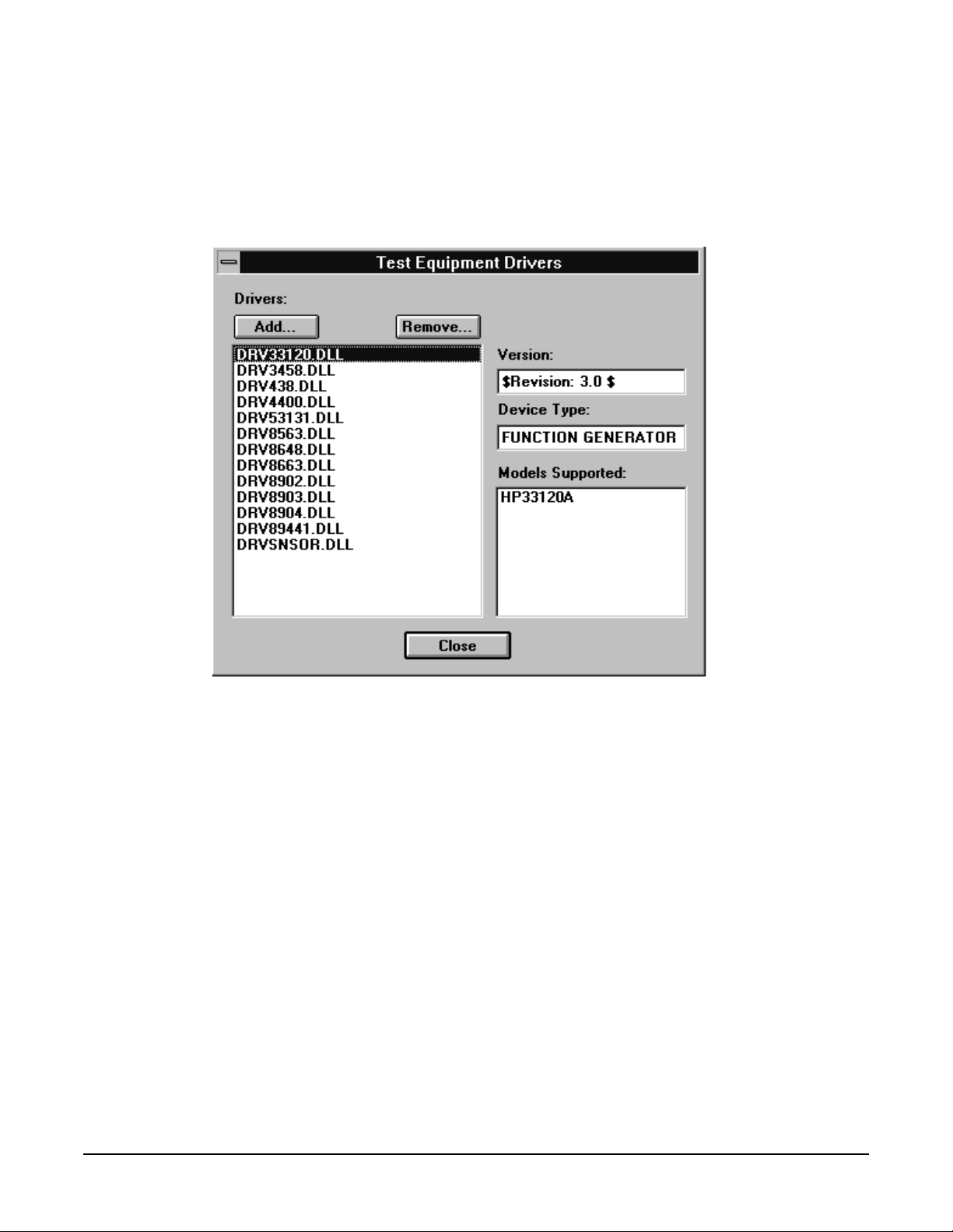

3. Refer to Figure 1-6. In the File drop-down menu, select Test Equipment Drivers.

Figure 1-6 Test Equipment Drivers in the File Drop-Down Menu

This selection allows for the addition or removal of software drivers for the test equipment being used to

verify the performance of the DUT.

4. To add a device driver to the existing list of test e quip me nt drivers, click the Add button (Figure 1-7).

1-14

Page 25

Administration of Service Support Software

Figure 1-7 Addin g a Device Drive r Using the Test Equi pment Drivers Window

Getting Started

5. Refer to Figure 1-8. Using the standard file search procedure, select the driver that you are adding and

click OK.

Figure 1-8 Using the Open Dialog Box to Se arch for a Device Driver Fi le to Add

The selected driv e r shou ld now be display ed in th e Test Equipment Driv er s dialo g box,

as seen in Figu re 1- 9.

1-15

Page 26

Getting Started

Administration of Service Suppor t Sof tw are

Removing Device Drivers

Removing device drivers is accomplished using the Test Equipment Drivers dialog box. Refer to Figure 1-9.

1. Select the driver (.dll) file to be remo v ed.

Figure 1-9 Remov ing a Device Driver Using the Test Equip ment Drivers Window

2. Ensure that th e infor m ation displayed in the Version, Device Type, and Models Su ppo r ted fields ref lec ts

the correct info rmation for the se lecte d d riv er b eing re mo ve d.

3. Click Remove.

4. Click Close.

Adding Test Drivers

Adding software dri ve rs is ac com p lish e d using the Test Drivers window.

1. Refer to Figure 1-10. In the File drop-down menu, select Test Drivers.

1-16

Page 27

Figure 1-10 Test Drivers in the File Drop-Down Menu

Getting Started

Administration of Service Support Software

2. Refer to Figure 1-11. To add a test driver to the existing list of test d riv ers, click Add.

Figure 1-11 Adding a Test Driver Using the Test Drivers Window

1-17

Page 28

Getting Started

Administration of Service Suppor t Sof tw are

3. Refer to Figure 1-12. Using th e sta ndard file search proce dur e, selec t the te st drive r that yo u are adding

and click OK.

Figure 1-1 2 Using the Open Dialog Box to Se arch for a Test Driver File to Add

The selected driv e r shou ld now be display ed in th e Test Drivers dialog box, as se en in Figure 1-11.

4. Click Close (Figure 1-11).

1-18

Page 29

Administration of Service Support Software

Removing Test Drivers

Removing test drivers is accomplished using the Test Drivers dialog box. Refer to Figure 1-13.

1. Select the driver (.dll) file to be removed.

Figure 1-13 Removing a Test Driver Using the Test Drivers Window

Getting Started

2. Ensure that th e infor m ation displayed in the Version, Required Devic es, and Tests Supported field s

reflects the correct information for the selected driver being removed.

3. Click Remove.

4. Click Close.

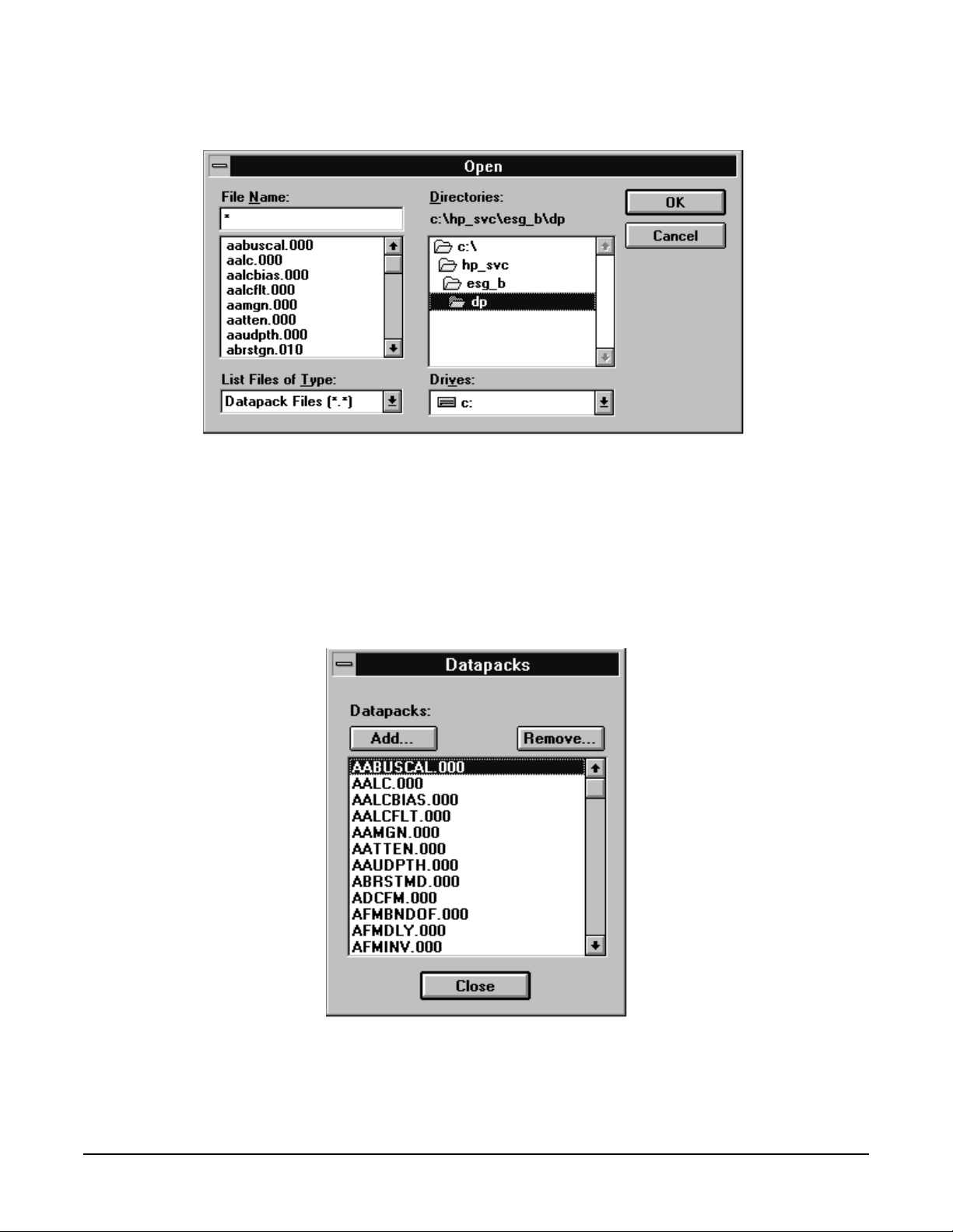

Adding Datapacks

Adding datapacks for test procedures is accompli shed usi ng the Datapacks di alog bo x.

1. Refer to Figure 1-14. In the File drop-down menu, select Datapacks.

1-19

Page 30

Getting Started

Administration of Service Suppor t Sof tw are

Figure 1-14 Datapacks in the File Drop-Down Menu

2. Refer to Figure 1-15. To add a datapack to the existing list of datapacks, click A dd.

Figure 1-15 Adding a Datapack Using the Datapacks Window

3. Refer to Figure 1-16. Using the sta nda r d file se arc h pro ced ur e, selec t the da tapa ck that you are adding

and click OK.

1-20

Page 31

Administration of Service Support Software

Figure 1-1 6 Using the Open Dialog Box to Se arch for a Datapack File to Add

The selected driv e r shou ld now be display ed in th e Da tap acks d ialo g box, as seen in F igu re 1-15.

4. Click Close (Figure 1-15).

Getting Started

Removing Datapac ks

Removing dat ap acks is accompl ishe d using the Datap ack s d ialo g bo x. Refe r to Figu re 1-17.

1. Select the datapack (.000) file to be removed.

Figure 1-17 Removing a Datapack Using the Datapacks Window

2. Click Remove.

3. Click Close.

1-21

Page 32

Getting Started

Running Service Supp ort Softw are

Running Service Support Software

Starting the Sof t wa re

1. Start the service support software using the steps appropriate for the version of MS Windows that is

installed on your PC.

• For MS Windows 95:

a. Select Start.

b. Select Agilent Service Support for PC’s.

c. Select Agilent Service Software.

• For MS Windows version 3.x:

a. Open the Program Manager window.

b. Open the Agilent Service Support program gr oup .

c. Select the Agilent Service Suppo rt icon .

2. Once the User Information dialog box is displ a y ed, enter the user name and the password.

a. In the User Name box, enter User. (Case sensitive.)

b. In the Password box, enter User. (Cas e sensitive.)

c. Click OK.

1-22

Page 33

Identifying the DUT

When the DUT Selection dialog box is displayed,

1. Make sure that ESG_C is selected in the Selec t An Instrument Family list.

Getting Started

Running Service Support Software

2. In the Select Model list, select the signal generator model of the DUT to be adjusted or tested.

3. In the Serial Number box, enter the complete serial number of the DUT.

4. In the Address box, enter the two-digit GPIB address of the DUT. (To display the address on the signal

generator, press

5. Select the OK but ton.

Utility > GPIB/RS-232. The GPIB Address softkey shows the current add ress.)

1-23

Page 34

Getting Started

Running Service Supp ort Softw are

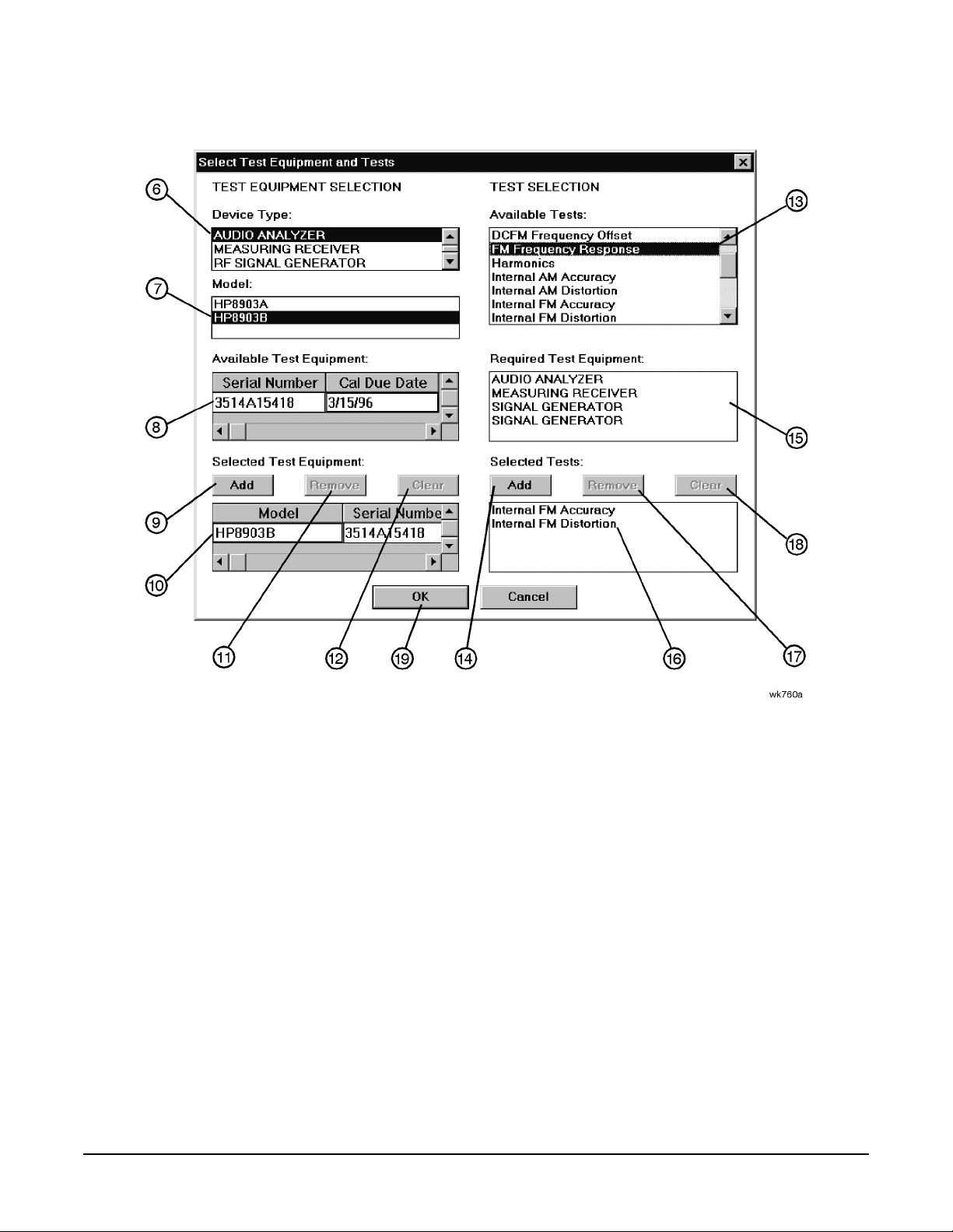

Selecting Performance Tests, Adjustments, and Test Equipment

When the Select Test Equipmen t a nd Tests window is d isplaye d ,

1. Se l e ct either the Perfor mance Tests radio button to display the list o f auto m ate d per f orm ance tests or

the Adjustments radio button to d isplay the list o f auto m ate d ad justments.

2. From the list of perfo r m anc e tests or adjustmen ts, sele ct the te sts or adjustm ents that will be performed

on the DUT. Select a test name by clicking on it (the DCFM Frequency Offset Relative to CW test will be

selected for th e sec tions following). The sele ct ed te st wi ll be hig hlig hted.

Select all of the performance tests or adjustments by selecting the Select All button. Unselec t all of the

sele c ted tests o r adjustmen ts by choosing the Unselec t button.

As each test or adjustment is selec t ed, the te st eq uipment required to perform the test or adjustment is

listed in the Required Test Equipment box. As each test or adjustment is removed from the list, the test

equipment required to perform the test or adjus tme nt is removed from the li st. Onl y the test equipme nt

for the highlighted tests is displayed in the list.

3. Once the test is highlighted, iden tify all te st e qui p m en t listed in the Re quir e d Test Equipmen t box . To

identify test equipment:

a. Select the type of device from the Device Type list.

b. Select the model number from the Model list for the device.

c. Select the device’s serial numbe r from the A v a i labl e Test Equipment list.

d. Select the Add button to add the de vic e to the list in th e Selec ted Test Equipment box .

The following buttons are ava ilab l e for t he Select ed Test Equipment box:

Add Copies the tests and adjustments highlighted in the Available Test Equipment box to

the Selected Test Equipment box.

Remove Removes the highlighted test equipment from the Selected Test Equipment box.

Clear Removes all of the test equipment from the Selected Test Equipment box.

1-24

Page 35

Getting Started

Running Service Support Software

NOTE If necessary, the test equipment GPIB address can be changed after it is added to the Selected

Test Equipment box. Change the GPIB address by pressing the right arrow on the keyboard

until the GPIB ad d ress se lection in the Select ed Test Equipm e nt box is se le ct ed. (Th e GPI B

address is s elected when it has a dark box around the selection.) Then, type the new GPIB

address and press Enter to change the address.

e. Repeat the previous steps for each test equipment instrument.

4. Once the tes t equipment has been i denti fi ed, select the Add bu tton locat ed above the Selec ted T es ts box to

add each of the highlighted performance tes ts or adju stmen t s. The tests or adjustments that were

highlighted are now displayed in the list in the Selected Tests box.

The followin g butt on s are available for the Selected Tests box:

Add Copies the t ests and adjustments highlighted in the list of tests and adjustments to the

Selected Tests box.

Remove Removes the highlighted tests and ad ju stm e n ts fro m the Se lecte d Tests box.

Clear Removes all of the tests and adjustments from the Se le cted Tests box.

5. If the appropriate tests or adjustments are listed in the Selected Tests box and the appropriate test

equipme nt is listed in th e Sele ct ed Test Equipm e nt box, se le ct th e OK button.

1-25

Page 36

Getting Started

Running Service Supp ort Softw are

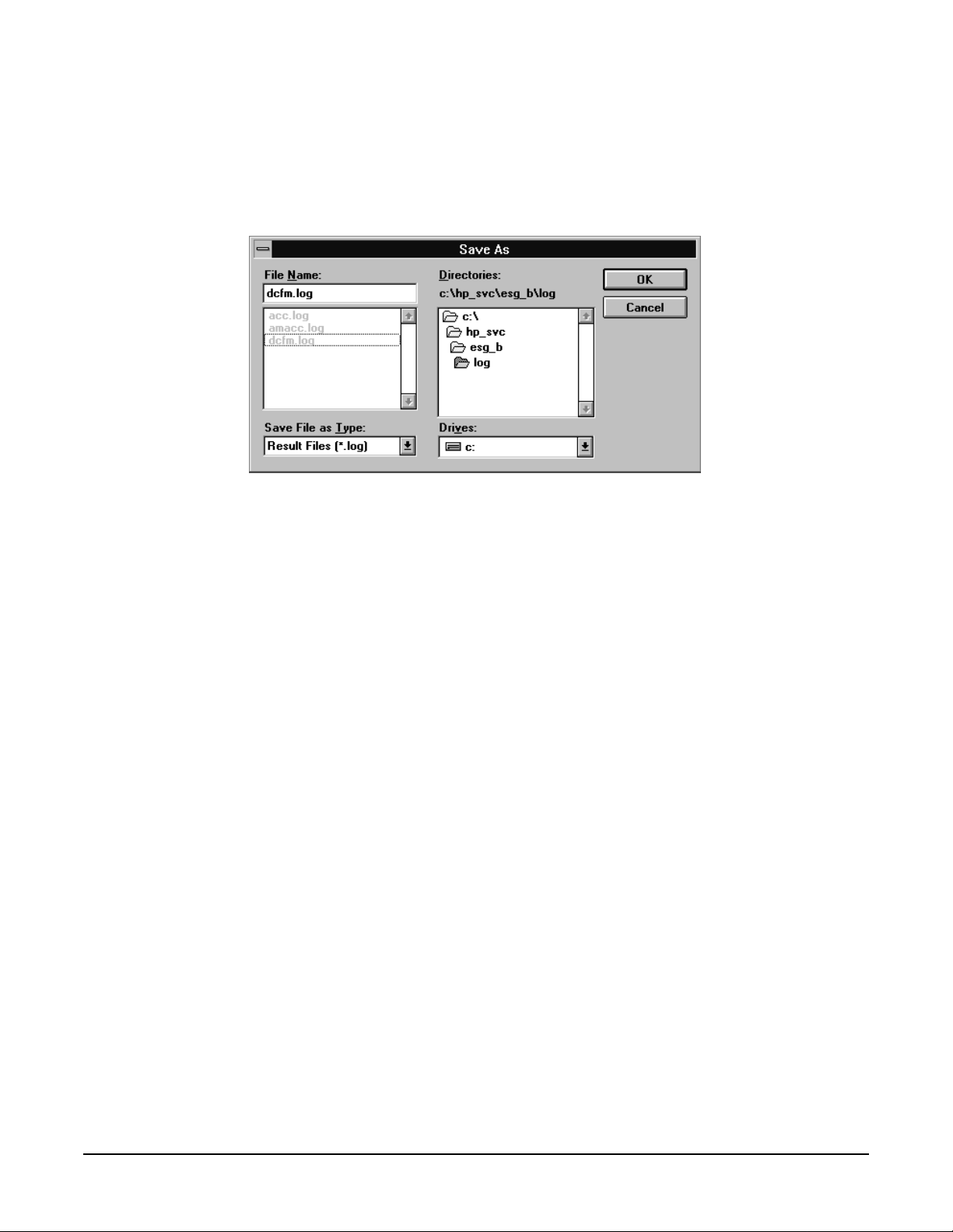

Defining the Location where Test Results are Saved

1. When the Save As dialog box is displayed, select the File Name box and enter the file name into which you

would like to save the test results.

The results file name suffix is.log. The results are saved automatically to the.log file. You may select the

directory into wh ich yo u wou ld like to sav e the file by cha ngin g the drive and folder in this window. This

file is a text file and can be viewed using many text editors. Notepad, a standard accessory in MS

Windows, is an example of a text edito r that can be used to view text files.

2. Once you have selected the drive, folder, and assigned a file name, select the OK button to save these

settings for when the tests are comp le te.

1-26

Page 37

Running the Tests and Adjustments

Once the Agilent Service Support Software window is displayed:

Getting Started

Running Service Support Software

1. Select the Run button to star t the auto m ated tests or adjustm ents displayed in the Se lecte d Tests box.

The software ste p s thr o ug h the te sts o r adjustments se que n tially.

2. Follow the instruction s disp laye d on the PC.

A description for each automated performance test or adjustment can be

found in Chapter 3, “Performance Tests,” and Chapter 4, “Adjustments.”

1-27

Page 38

Getting Started

Running Service Supp ort Softw are

Reviewing the Test and Adjustment Results

Once the tests have finished runnin g, you will want to revie w th e results of the tests. The Agilent Se rv ice

Support Software window displ ays the DUT model number and serial number, the selected tests , the re sul ts

of the selected test , and th e cu rre nt te st in for m atio n. Six buttons, which are us ed to control the testin g, are

also displayed.

The Selected Tests box displays the nam e of the se le cted te sts, the p ass/ fail status (P/F) of each test that has

been run, the total number of points that each test checks, and the number of points that passed and failed for

each test. The pass/fai l statu s indicates a failure if any point in that te st fails.

The Selected Test Results bo x shows the results of the te st that is highlighte d in the Se lecte d Tests box. The

Selected Test Results box shows the pass/fail status (P/F), the lower limits (LL), the measured value (Result),

the upper limits (UL), and the measured units (for example, kHz, mV , or dBm) for each test point checked by

the performan ce te sts and some ad ju stm e nts. “** ” indicates values no t disp laye d by the adjustments.

The Current test box shows the results of the test that is currently running. The Current test box shows the

pass/fail status (P /F) , the lowe r limi ts (LL) , the measu red valu e (Resu lt), th e uppe r limi ts (UL) , and the

measured units (for example, kHz, mV, or dBm) for each test point checked by the performan ce tests and

some adjustments. “**” indicates values not displayed by the adjustments.

The following buttons are also displayed on the Agilent Service Support Software window. These buttons are

used to control the testing. Only the buttons that are appropriate are active. For example, if the test is already

in progress, the Run button would not be active.

Run Start running the highlighted test when initially starting the testing. Also used to start

testing at the same point where the test was stopped.

Stop Stop the test that is cu rren tly run ning. The test stops after mak ing the next measur e m ent.

Restart Rerun a test that was running when the testing was stopped. This restarts the test from the

beginning.

Next Test Quit running the current test and give it a Fail status. Then, continue testing with the next

test.

Rerun Restart the test ing at the beginning of the first test.

Abort Q uit testing. Abort all tests.

1-28

Page 39

Getting Started

Running Service Support Software

Printing the T est and Adjustment Results

Once the tests are comple te, a dial og box is displ ayed th at ask s if you want to prin t the lo g file.

The log file is the file in whic h the te st ( or ad jus tm e nt) re su lts ar e st ore d . Select the Yes bu tton to p rin t the

test results using the printe r connected to LPT1. Cho osing the No butto n allow s yo u to ex it the pro gr am

without printin g the te st results.

There are two other methods of printing the test resu l ts.

The first method is sele cti ng the Print Log File selec tio n fro m the File d rop -d ow n m enu. The software asked

you to define the computer path and file name when the tests were performed. The default directory is the

“log” subdirectory of the destination directory where you installed the software. (C:\HP_SVC\ESG_C\ was

the default destination directory.)

The second alternative method of printing is opening the fil e in a text editor and printing the file in the text

editor.

Exiting the Software

Exit the software by selecting Exit from the file drop-down menu.

Pressing Alt-F4 on the keyboard is an alternate method of exiting the software.

1-29

Page 40

Getting Started

Running Service Supp ort Softw are

1-30

Page 41

2 Required Equipment

2-1

Page 42

Required Equipment

This section lists the test eq uipmen t needed to run perfor manc e test s and adjust ments, any critical

specification requirements, and recommended model numbers. The computer and all test equipment are

connected to the device under test (DUT) using GPIB.

CAUTIO N In all test equipment configu ra tio ns, cables and adapter s ne ed to be properly to rq ued .

Exceeding recommended torque values may cause damage to a cable or adapter and may cause

inaccurate test results.

Connector Type Torque Value

APC 3.5 Use an Agilent 8710-1765 at 8-lb inch when

connecting APC 3.5 (m) to APC 3.5 (f).

SMA Use an Agilent 8710-1765 at 8-lb inch when

connecting APC 3.5 (m) to SMA (f).

Use an Agilent 8710-1582 at 5-lb inch when

connecting SMA (m) to APC 3.5 (f).

Type-N Type-N connectors may be connected finger tight. If a

torque wrench is used, Agilent 8710-1766 at 12-lb inch

is recommended.

NOTE

• All test equipment requires a 30 minute warm-up period to ensure accurate performance.

• Models for each Test Equipment category are given in order of preference. Alter nate or

substitute models are listed after the preferred model, but should be considered as a lower

priority.

• It is recommended that all am plif iers be placed in e nclos ures. This should help reduce the

effect of signals radiating into adjacen t equ ip m e nt. It is also reco m m e n ded that amplifiers

are not physically positioned close to equipment that can radiate low-level RF signals.

2- 2

Page 43

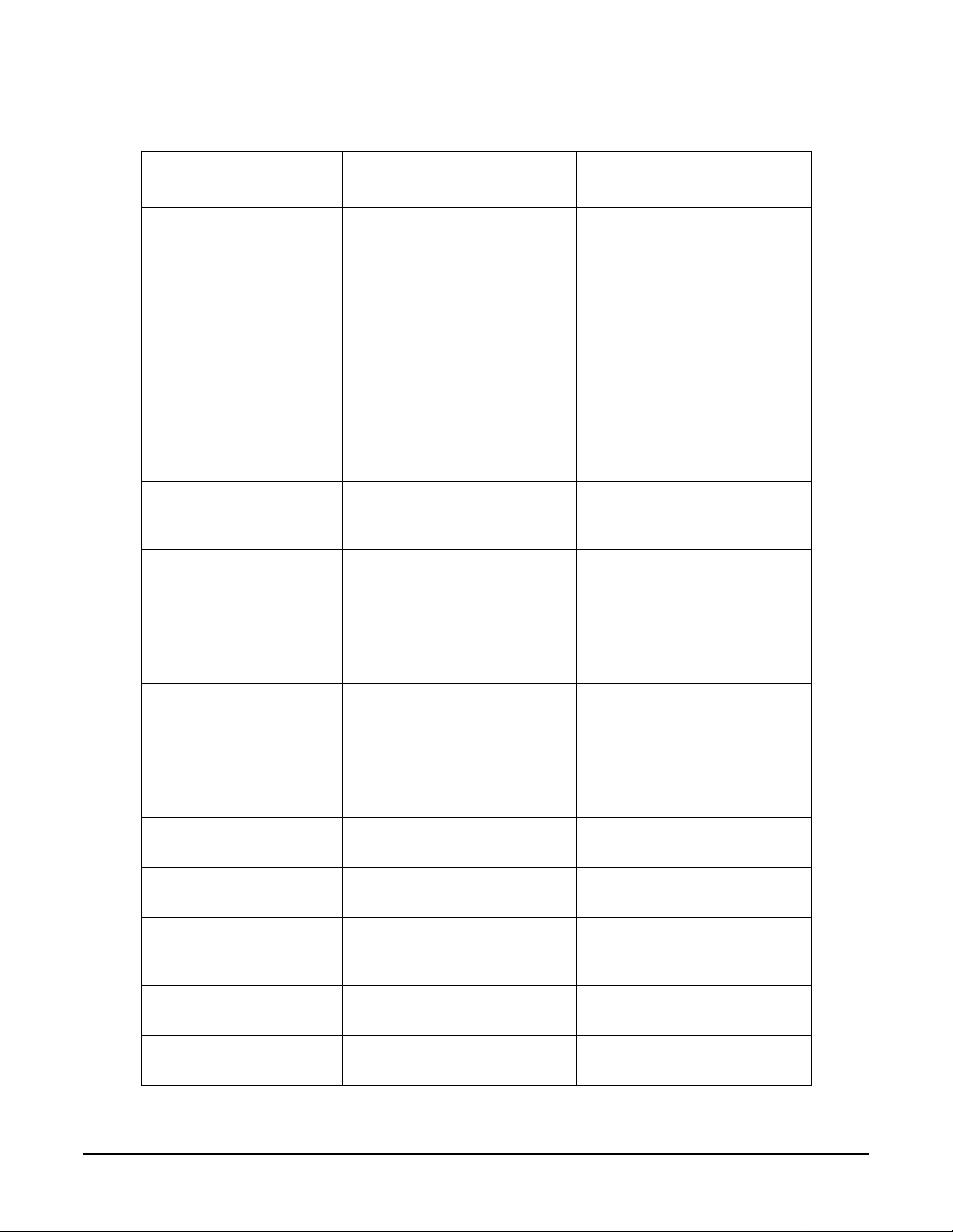

Table 2-1 Required Equipment

Required Equipment

Test Equipment Preferred Model

or Alternate Model

Power Meter Agilent E4418B E-Series

power meter,

or Agilent E4419A/B E-Series

power m e t e r

Pow er Se ns or,

Input: Type-N (m)

Spectrum Analyzer,

Input: Type-N (f)

Agilent E9304A E-Series

power sensor

The Agilent 8482A power

sensor can be used in place of

the Agilent E9304A E-Series

power sensor in some

performance tests and some

adjustments.

Agilent 8563/64/65EC

Option 001 and K35

spectrum ana lyz e r

Critical Spec ifications

The power me ter and the

signal generato r n eed to be

plugged into the same ac

power circuit. The power

meter also need s to be

conn e cted to the signal

generator wi th a m inim u m

length (18") GPIB cable.

9 kHz to 6 GHz,

−70 to +20 dBm

100 kHz to 4.2 GHz,

−30 to +20 dBm

This power sen sor is no t an

alternate model because some

performance tes ts can not use

the Agilent 8482A power

sensor.

9 kHz to 6 GHz

or Input: 2.4 mm (m)

Option 001

Output: APC 3.5 (f)

Option 007

Output: APC 3.5 (f)

Option K35

Input: SMA (f),

Output: SMA (f)

WCDMA Test Set,

RF Input: Type-N (f),

LO Input: SMA (f),

IF Output: SMA (f)

or Agilent 8563/64/65E

Option 001, 007, and K35

spectrum ana lyz e r

Option 001 adds a Second IF

Output

Option 007 adds digitized fast

time domain sweep; this

functionality has been

incorporated int o the

Agilent 8563/64/65EC

spectrum ana lyz e r.

Option K35 is required only

when adjusting “WCDMA

Adjacent Channel Power

(Option 400)” on page 3-34

Agilent Option K35 WCDMA

test set

2-3

Page 44

Required Equipment

Table 2-1 Required Equipment

Test Equipment Preferred Model

or Alternate Model

Function Gen erato r,

Output: BNC (f)

Function Gen erato r,

Output: BNC (f)

Frequency C o unter,

Channel 1: BNC (f)

Channel 2: BNC (f)

Channel 3: Type-N (f)

Frequency Stan d ard ,

Output: BNC (f)

Vector Signal An alyze r,

Input: Type-N (f)

Output: BNC (f)

Agilent 8904A function

generator

Agilent 33120A function

generator

Option 001 is required only

when testing “Digital

Modulation Level Accu rac y”

on pa g e 3 - 27.

Agilent 53132A Option 050

freq uency counter

Option 050

adds Channel 3 (5 GHz)

Use a 10 MHz house

standard. (For example, an

Agilent 5071A primary

frequency standard or

equivalent can be used.)

Agilent 89441A vector sign al

analyzer with Optio ns AYA,

AYH, AY 7, AY9, B7A, and

UFG or UTH.

Critical Spec ifications

Two Required

The frequency counter must

be plugged into the ac power

line for at least 24 hours

before testing begins .

2- 4

Option AYA adds vector

modulation analysis.

Option AYH adds digital

video modulation analysis.

Option AY7 adds second

10 MHz input channel.

Option AY9 adds extended

time capture memory

to 1 MSample.

Option B7A adds EDGE to

the vector modulation

analysis that is added by

Option AYA.

Option UFG adds ex te nde d

RAM and additional I/O.

Option UTH adds extended

RAM and additional I/O.

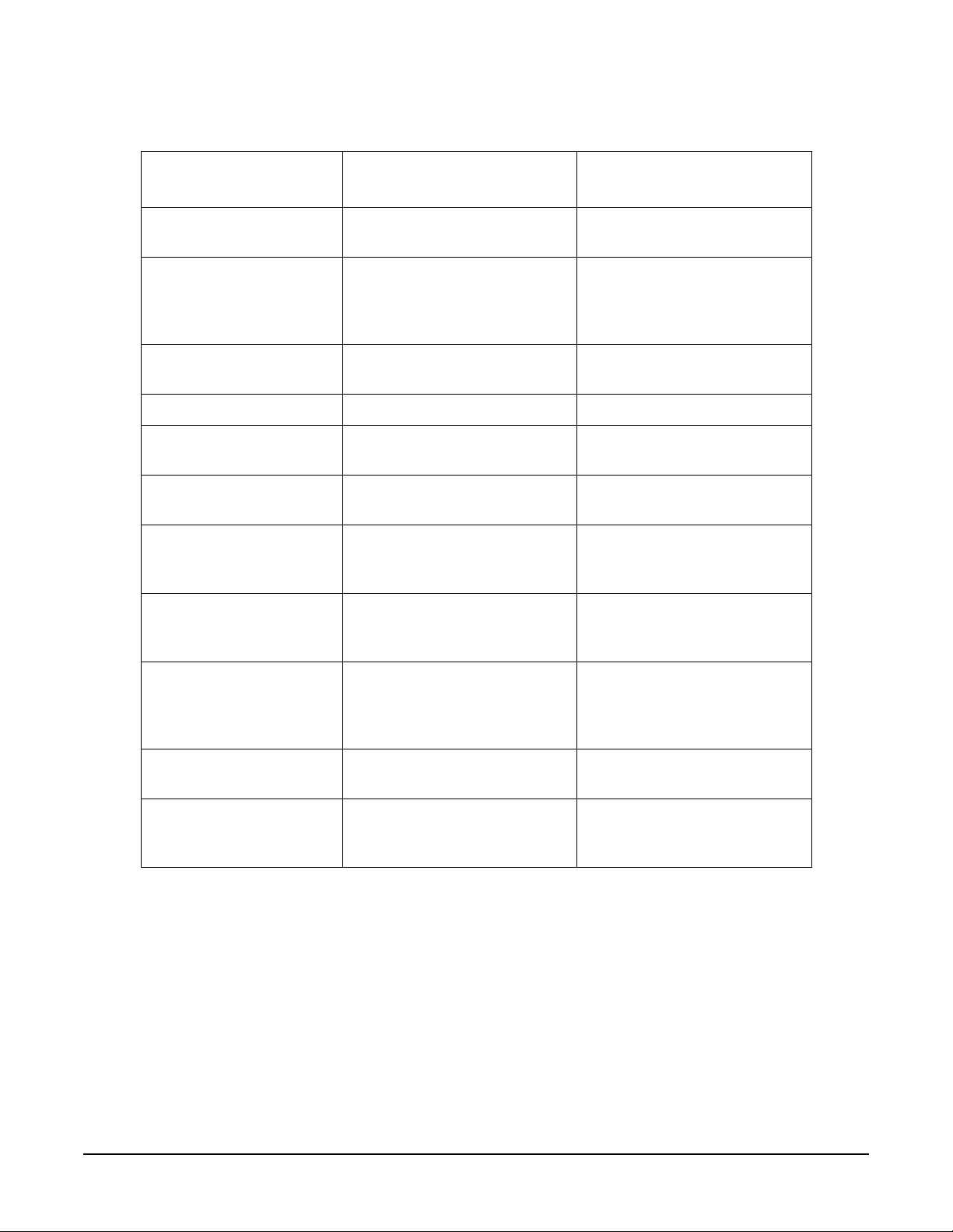

Page 45

Table 2-1 Required Equipment

Required Equipment

Test Equipment Preferred Model

or Alternate Model

Baseband Generator Agilent E4438C

ESG vector sign al gene r ato r

with Option 001 or 002,

or

Agilent E4430B thru E4437B

ESG-D Series sign al

generator wit h Op tion U N 8

Digital Multimete r,

Input: Dual Banana Plug

Digital Oscillosco p e,

Input: BNC (f)

Measuring Receiver,

Input: Type-N (f)

Audio Analyzer,

Input: BNC (f)

Agilent 3458A Option 002

digital multimeter

Option 002 adds a High

Stability Timebase

Agilent 54610B

digital oscilloscope

Agilent 8902A

measuring receiver

Agilent 8903B audio analyzer

with Options 010 and 051

or Options 011 and 050

Critical Spec ifications

20 Hz to 100 kHz

Power Supply Use any generi c power s upply

capable of supplying +15 Vdc

@ 300 mA.

Low Frequency LNA,

Input: BNC (f)

Output: BNC (f)

High Freque nc y L N A ,

Input: APC 3.5 (f)

Output: APC 3.5 (f)

Advance Control Components

W50ATC low frequen cy

low-noise amplifie r (LNA )

Advance Control Components

20 Meridian Road

Eatontown, NJ 07724

Phone: (732) 460-0212

FAX: (516) 460-0214

MITEQ Inc.

AFS3-00010300-18-5P-4 high

frequency low noise amplifier

(LNA)

MITEQ Inc.

100 Davids Drive

Hauppauge, NY. 11788

Phone: (516) 436-7400

FAX: (516) 436-7430

+15 Vdc @ 300 mA

Frequency R ange:

100 kHz to 500 MHz

(The LNA is only use d up to

10 MHz.)

Gain: 50 dB

Noise Figure: 1.85 dB

1 dB compression minimum:

+5 dBm

Frequency R ange:

50 MHz to 3 GHz (Only used

up to 2 GHz)

Gain: >56 dB (Total gain with

two amplifiers cascaded)

Noise Figure: 1.8 dB

1 dB compression minimum:

+10 dBm

2-5

Page 46

Required Equipment

Table 2-1 Required Equipment

Test Equipment Preferred Model

or Alternate Model

Phase Noise System,

Input: APC 3.5 (m)

Reference Source,

Output: Type-N (f)

Mixer (0.5 to 9 GHz),

Connectors: SMA (f)

Agilent E5502B Option 001

phase noise syste m with

Option 401

or Option 402 added

Option 401 adds an

Agilent 8662A

high-performance RF signal

generator

Option 402 adds an

Agilent 8663A

high-performance RF signal

generator

Agilent 8662A/8663A

high-performance RF signal

generator

MD/MDC-164 Mixer

M/A COM INC.

DIV of AMP INC.

1011 Pawtucket Blv.

Lowell, MA 01853

Phone: (800) 366-2266

Critical Spec ifications

Only required for

Options UNJ and 506.

0.5 to 9 GHz

Mixer (1.0 to 2.8 GHz),

Connectors: SMA (f)

10 dB Attenuator,

Type-N (f) to (m)

20 dB Attenuator,

Type-N (f) to (m)

Step Attenuator,

Input: Type-N (f)

Output: Type-N (f)

Step Attenuator Driver Agilent 11713A

Step Attenuator Driver

Cable

MD/MDC-174 Mixer

M/A COM INC.

DIV of AMP INC.

1011 Pawtucket Blv.

Lowell, MA 01853

Phone: (800) 366-2266

Agilent 8491A/B Option 010

fixed attenuator

Agilent 8491A/B Option 020

fixed attenuator

Agilent 8495G programmable

step attenuator

step attenuator driver

Agilent 8120-2703

step attenuator driver cable

1.0 to 2.8 GHz

10 dB, dc to 6 GHz

20 dB, dc to 6 GHz

0 to 70 dB

2- 6

Page 47

Table 2-1 Required Equipment

Required Equipment

Test Equipment Preferred Model

or Alternate Model

Cable,

APC 3.5 (m) to (m)

Cable,

BNC (m) to (m)

Cable,

Type-N (m) to (m)

Adapter,

BNC Tee (m) (f) (f)

Adapter,

BNC (f) to BNC (f)

Adapter,

BNC (f)

to Dual Banana

Adapter,

BNC (f)

to Type-N (m)

Agilent 8120-4921

APC 3.5 (m) to (m) c abl e

Agilent 8120-1840

BNC (m) to (m) cable

or Agilent 10503A

BNC (m) to (m) cable

Agilent 11500A

Type-N (m) to (m) cable

Agilent E9625A

BNC Tee (m) (f) (f) adapter

Agilent 1250-0080

BNC (f) to BNC (f) adapter

Agilent E9637A

BNC (f) to dual banana

adapter

Agilent 1250-0780

BNC (f) to Type-N (m)

adapter

Critical Spec ifications

1 meter cable length

48 inch cable length

Adapter,

BNC (f) to SMA (m)

Adapter,

BNC (m) to SMA (f)

Adapter,

BNC (m)

to Mini-Grabbers

Agilent 1250-1200

BNC (f) to SMA (m) adapter

or Agilent E9631A

BNC (f) to SMA (m) adapter

Agilent 1250-2015

BNC (m) to SMA (f) adapter

Agilent 8120-2337

BNC (m) to mini-grabbers

adapter

2-7

Page 48

Required Equipment

Table 2-1 Required Equipment

Test Equipment Preferred Model

or Alternate Model

Adapter,

APC 3.5 (m) to (m)

Adapter,

APC 3.5 (f) to (f)

Adapter,

APC 3.5 (m)

to Type-N (m)

Adapter,

APC 3.5 (f)

to Type-N (m)

Adapter,

APC 3.5 (f)

to Type-N (f)

Digital Test Card Agilent E4400-60073

Agilent 1250-1748

APC 3.5 (m) to (m) adapter

Agilent 1250-1749

APC 3.5 (f) to (f) adapter

Agilent 1250-1743

APC 3.5 (m) to Type-N (m)

adapter

Agilent 1250-1744

APC 3.5 (f) to Type-N (m)

adapter

Agilent 1250-1745

APC 3.5 (f) to Type-N (f)

adapter

digital test card

Critical Spec ifications

2- 8

Page 49

3 Performance Tests

3-1

Page 50

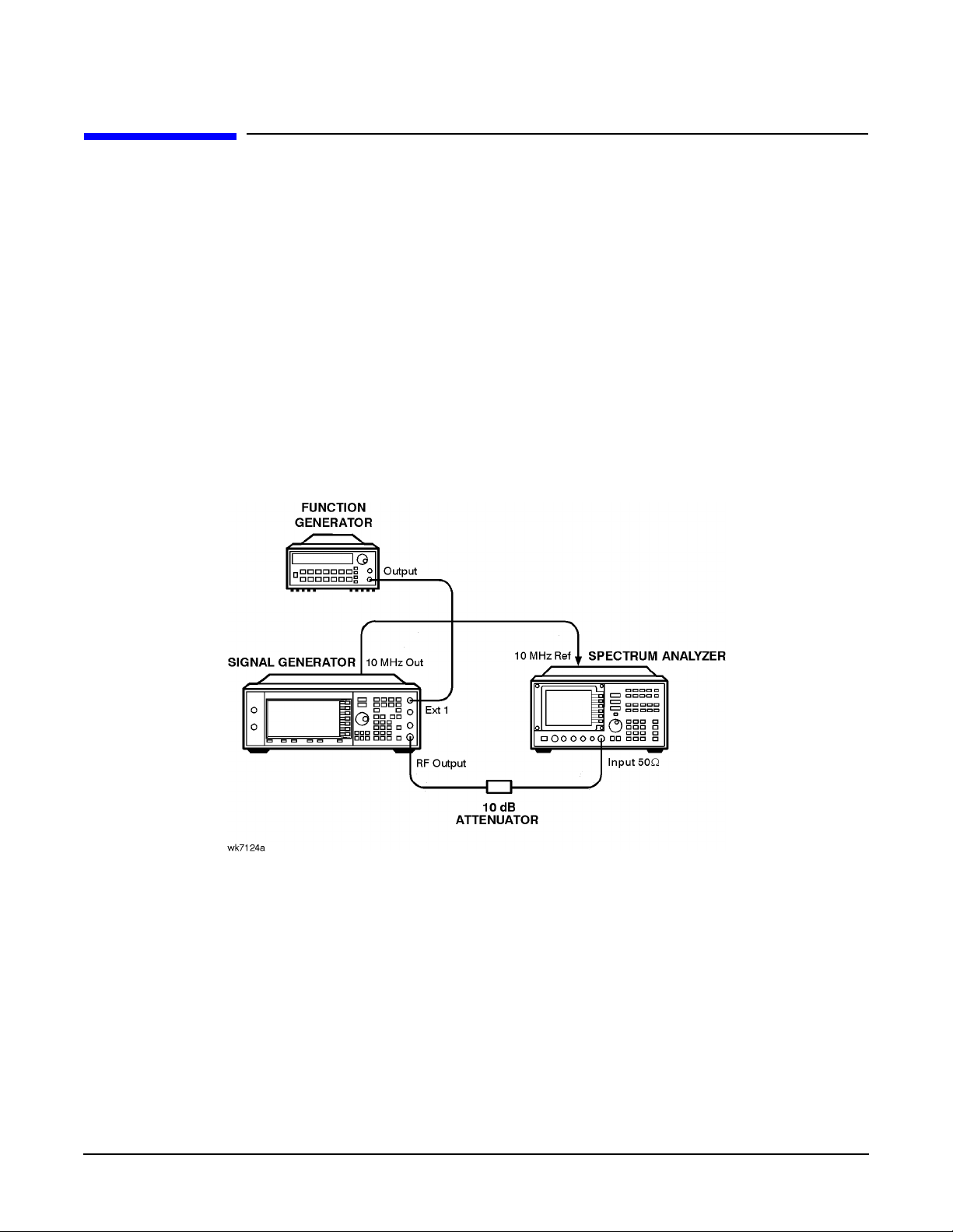

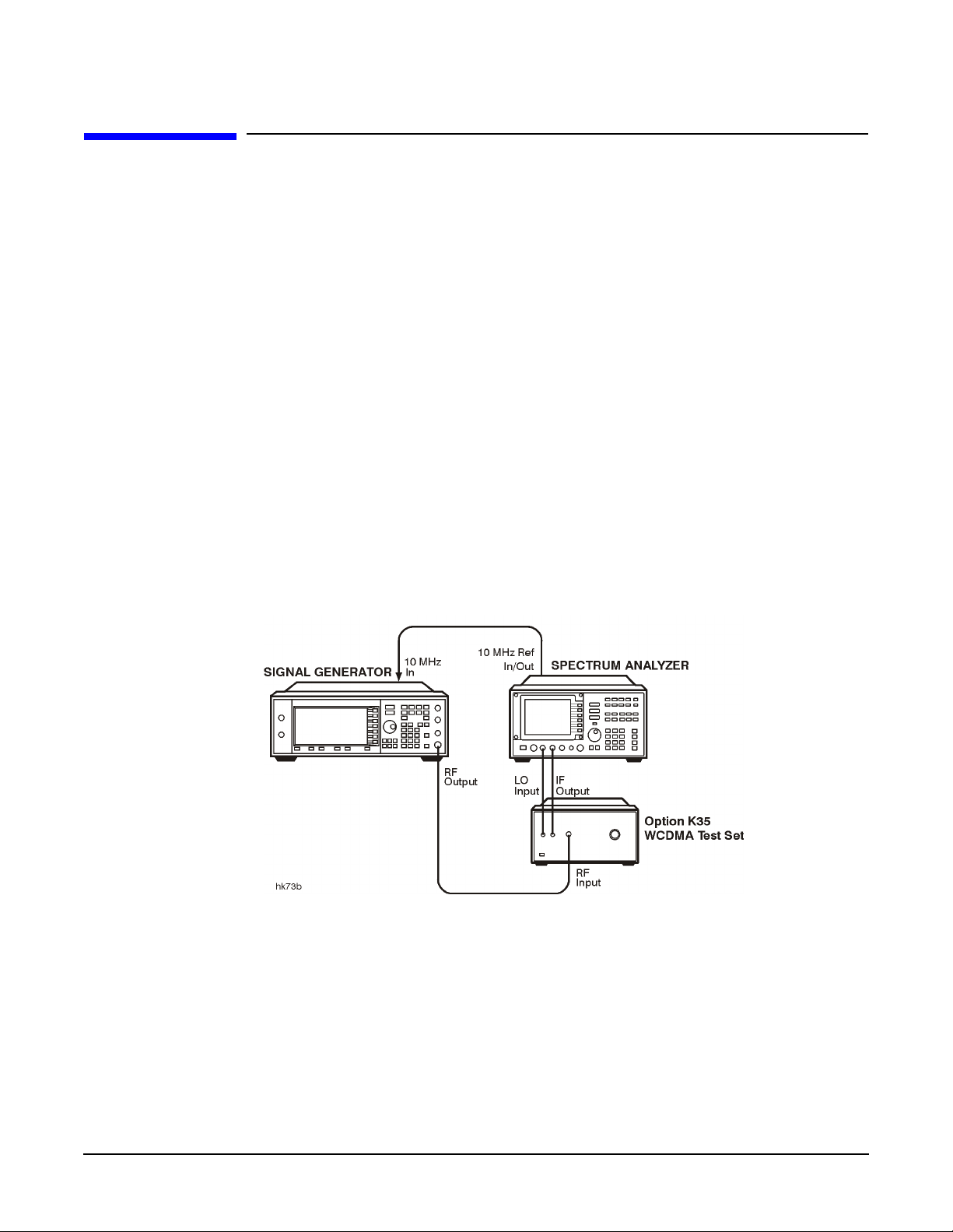

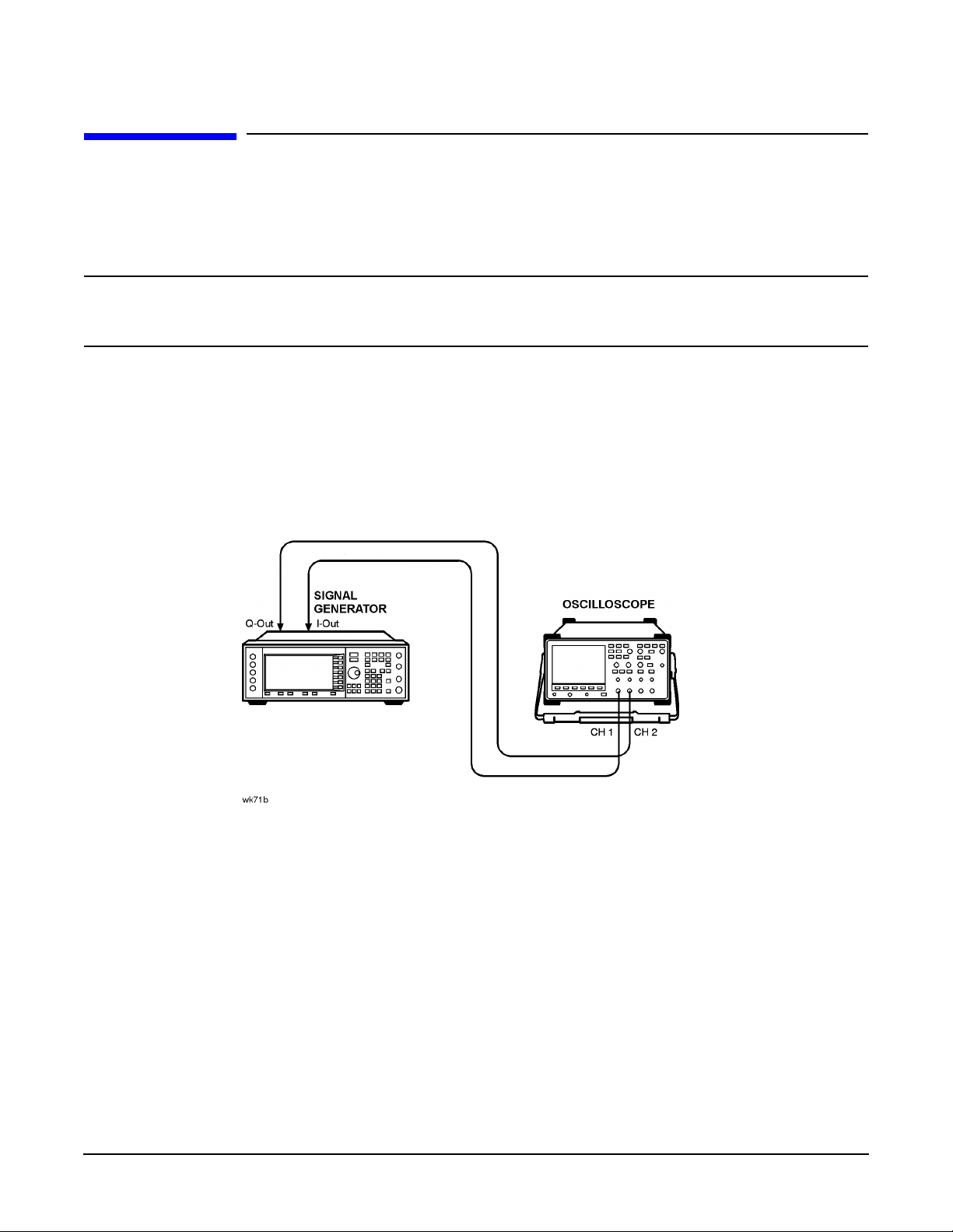

Performance Tests

Overview of Performance T ests

Overvi ew of Performance Tests

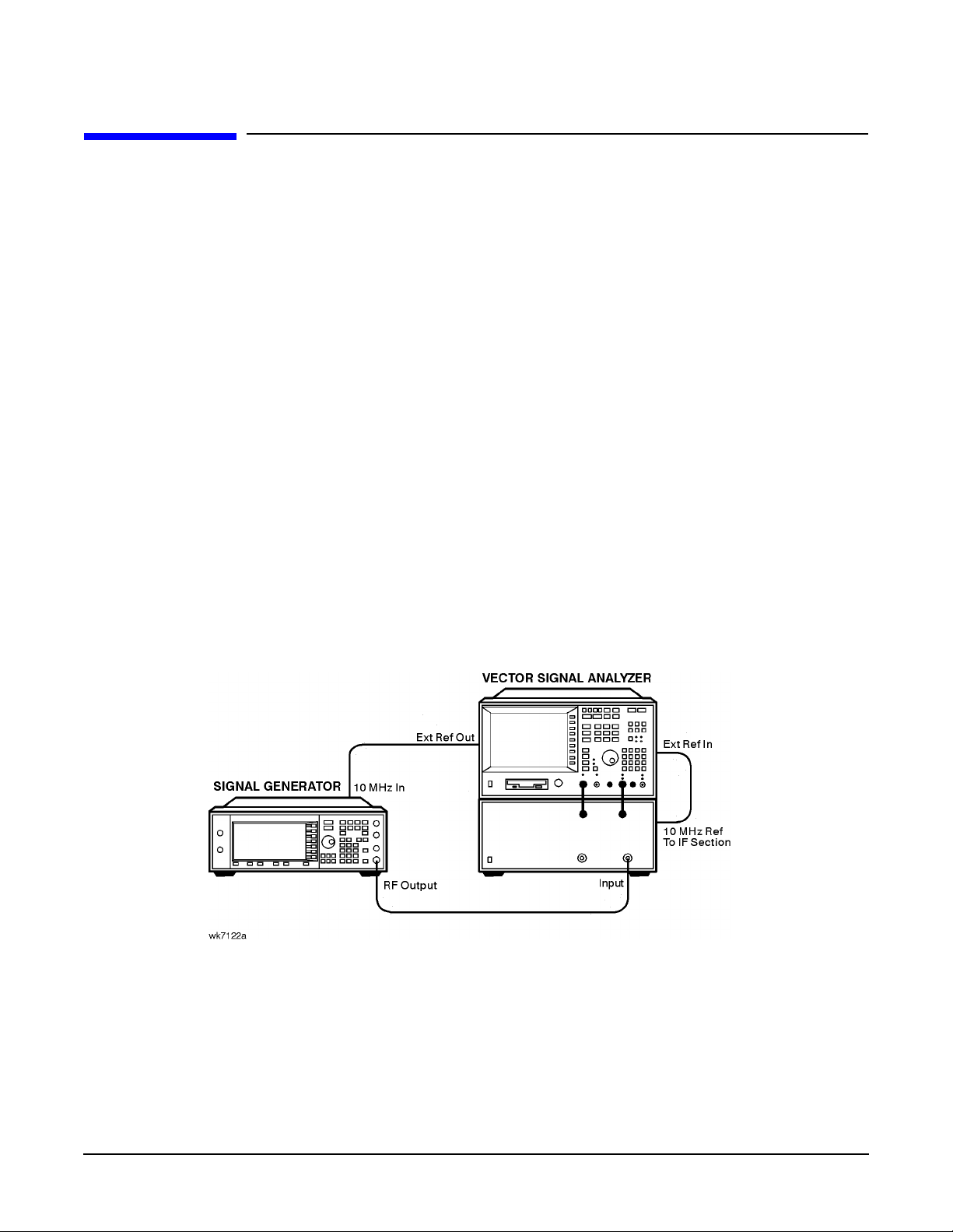

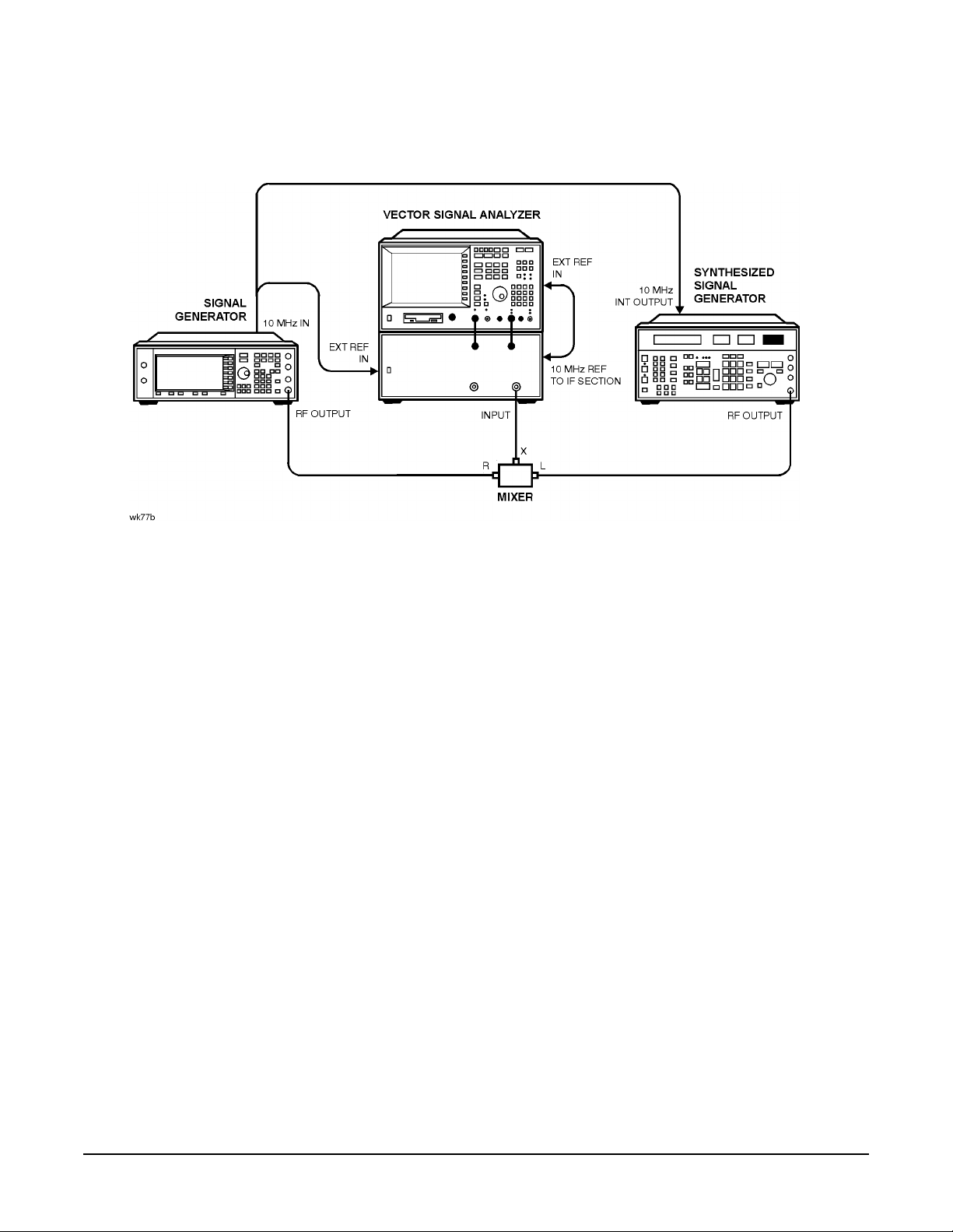

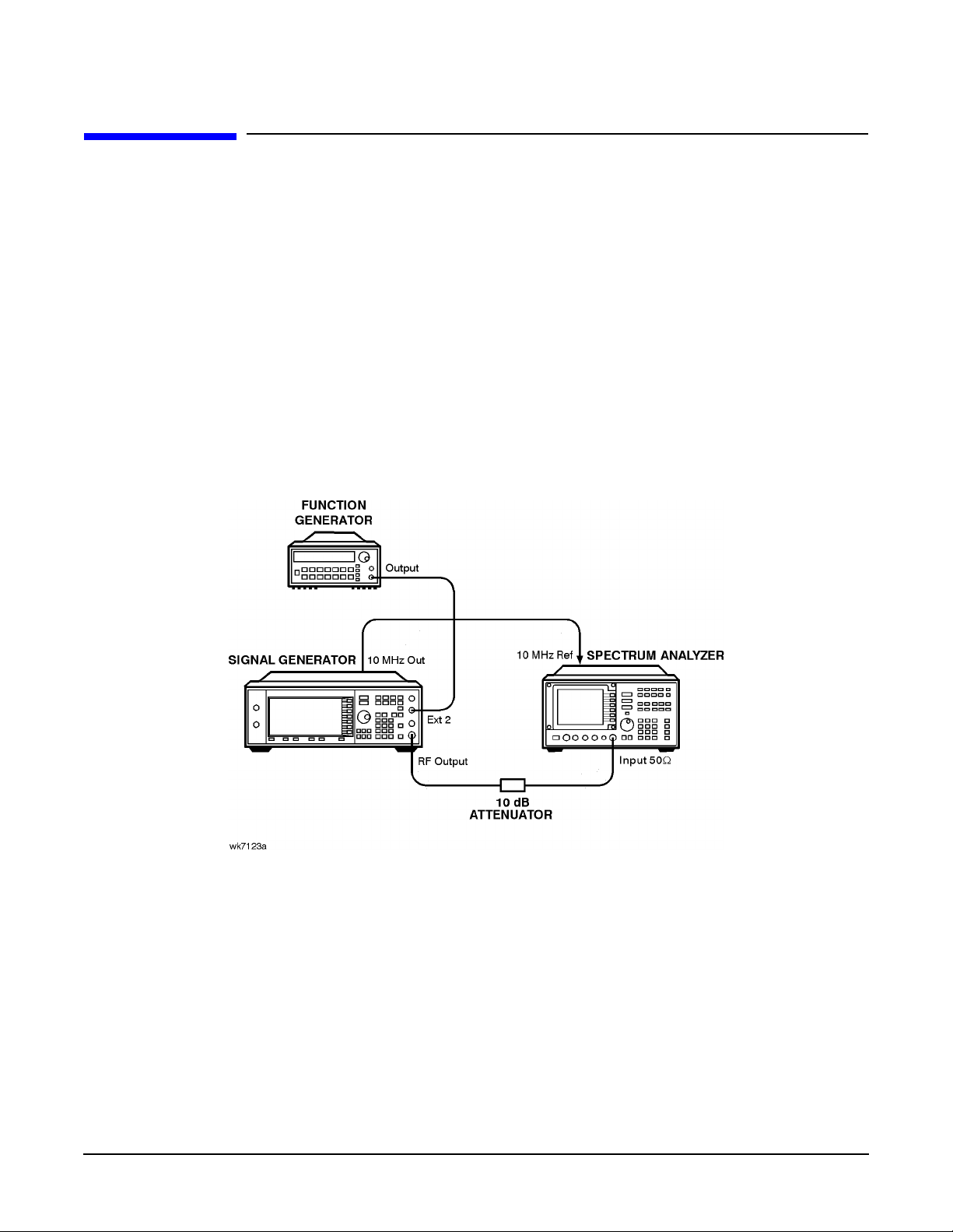

In this chapter you will learn about all available performance tests as well as how to run the Service Support

Software to test and verify the performance of the Agilent E4438C ESG vector signal generator. These

performance tests verify that the signal generator meets specifications. Chapter 1, “Getting Started,”

expla ins how to set up the Se rvice Support Sof tware for a particular set of test instruments and interfaced

components in a test environment.

Recommended Calibration Cycle

This inst rument r equires periodic ve ri fi c a ti o n o f performa nc e. U nd e r n o rm al use and env i ro nmenta l

conditions, the instrument sho u ld be calibrat ed every two ye ars. Normal use is de fined as about 2,0 00 hour s

of use per year.

Performance Test Records

Unless stated differently, the Service Supp ort So ftware f or the A gilent E4438C ESG vec to r sign al gene r ato r

can print a test reco rd that con tain s the results of the automate d per for ma n ce te sts. A perfo rmance test

record (located at the end of this chapter) can be photocopi ed for use when performing eac h of the two manual

performance tests for this product.

Recommended Test Equipment

The recommended test equipment table, located in Chapter 2, “Required Equipment,” on page 2-1 is the

complete list of equipment required to perform the procedures in this chapter. Test equipment is also listed

with each test and is shown in the test setup. However, to avo id clutter in the figur es, the cont rolle r req uir ed

to run the Service Supp o rt Sof tware is no t shown in the test setu p for each auto ma ted tes t. The controller

must be connected via GPIB to all of the test equipment in the currently selected automated tests. For

performance tes t s , other equipment can be substituted for the recommended models if it meets or exceeds the

critical specifications listed in Chapter 2, “Required Equipment,” on page 2-1 For the adjustment procedures,