Page 1

Service Guide

Agilent Technologies

E4418B/ E4419B Power Meters

Agilent Technologies Part no. E4418-90059

Revision C

September 2003

Page 2

© Copyright 1998, 2003Agilent Technologies

All rights reserved. Reproduction, adaptation, or translation without prior written

permission is prohibited, except as allowed under the copyright laws.

Printed in the UK.

ii Agilent E4418B/E4419B Service Guide

Page 3

Legal Informat io n

Legal Information

Notice

Information contained in this document is subject to change without notice. Agile nt

Technologies makes no warranty of any kind with regard to this material, including,

but not limite d to, the implied warranties of mercha ntability and fitness for a

particula r purpose. Agilent T echnologies shall not be liable for errors contained

herein or for incidental or consequential damages in conn ection with the furnishings,

performance, or use of this material. No part of this document may be photocopi ed,

reproduced, or tr anslated to another language without the prior written consent of

Agilent Technologie s.

Certification

Agilent Technologies certifies that th is product met its published specifications a t the

time of shipment from the factory. Agilent Technologies further certifies that its

calibration measurements are traceable to the United States National Institute of

Standards and Technology, to the extent allowed by the Institute’s calibration facility,

and to the calib ration facilities of other International Standards Or ganization

members.

Warranty

This Agilent Technologies instrument pr oduct is war ranted a gainst de fe cts in ma teria l

and workmanship for a per iod of one ye ar f rom date of shipm ent. During the war ranty

period, Agile nt Technologies will at its opt ion , eith er repai r or repla ce produc ts whi ch

prove to be defective. For warranty service or repai r, this product must be returned to

a service facility designated by Agilent Technologies. Buyer shall prepay shipping

charges to Agilent T echn ologies and Agile nt T echnologi es shall pay shippi ng char ges,

duties, and taxes for products returned to Agilent Technologies from another country.

Agilent Technologies warrant s that its software and firmware designated by Agilent

Technologies for use with an instrument will execute its programming instructions

when properly ins talled on that instrument. Agil ent Technologies does not warrant

that the operation of the instrument, or firmware will be uninterrupted or error free.

Agilent E4418B/E4 419B S ervice Guide iii

Page 4

Legal Information

Limitation of Warranty

The foregoing warrant y sha ll not apply to defects resulting from improper or

inadequate maintenance by Buyer, Buyer-supplied software or interfacing,

unauthorize d modi fication or misuse, operation outside of the environmental

specifications for the product, or improper site preparation or maintenance. NO

OTHER WARRANTY IS EXPRESSED OR IMPLIED. AGILENT

TECHNOLOGIES SPECIFICALLY DISCLAIMS THE IMPLIED WARRANTIES

OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

Exclusive Remedies

THE REMEDIES PROVIDED HEREIN ARE BUYER’S SOLE AND E XCLUSIVE

REMEDIES. HP SHALL NOT BE LIABLE FOR ANY DIRECT, INDIRECT,

SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES, WHETHER

BASED ON CONTRACT, TORT, OR ANY OTHER LEGAL THEORY.

iv Agilent E4418B/E4419B Service Guide

Page 5

Equipment Operation

Equipment Operation

Warnings and Cautions

This guide uses warnings and cautions to denote hazards.

WARNING A warning calls attention to a procedure, practice or the like, which, if

not correctly performed or adhered to, could result in injury or the loss

of life. Do not proceed beyond a warning until the indicated conditions

are fully understood and met.

Caution A caution calls attention to a procedure, practice or the like which, if not

correctly perf orm ed or adhered to, could result in damage to or the

destruction of part or all of the equipment. Do not pr oce ed beyond a caution

until the indicated conditions are fully understood and met.

Personal Safety Considerations

WARNING This is a Safety Class I product (provided with a protective earthing

ground inco r p o ra t ed in the pow er co rd ). The main s p lu g sh a l l onl y be

inserted in a socket outlet provided with a protective earth co nt act. Any

interruptio n of the protective conductor, inside or outside the

instrument, is likely to make the instrument dangerous. Intentional

interrup t ion is prohibited .

If this instrument is not used as specified, the protection provided by the

equipment could be impaired. This instrument must be used in a normal

condition (in which all means of protection are intact) only.

No operator serviceable parts inside. Refer servicing to qualified

personnel. To prevent electrical shock, do not remove covers.

For continued protection against fire hazard, replace the line fuse(s)

only with fuses of the same type and rating (for example, normal blow ,

time delay, etc.). The use of other fuses or material is prohibited.

Agilent E4418B/E4 419B S ervice Guide v

Page 6

Equipment Operation

ISM

General Safety Considerations

WARNING Before this instr u m en t is s w i t ched on, ma k e su re it has been prop erly

grounded through the protective conductor of the ac power cable to a

socket outlet provided with protective earth contact.

Any interruption of the protective (grounding) conductor, inside or

outside the instrument, or disconnection of the protectiv e earth terminal

can result in personal inju ry.

Caution Any adjustments or service procedures that require operation of the

instrument with protective covers removed should be per formed only by

trained service personnel.

Markings

The CE mark shows that the product complies with all the

relevant European legal Directives (if accompanied by a

year, it signifies when the design was proven.

Group 1

Class A

vi Agilent E4418B/E4419B Service Guide

This is the symbol of an Indust rial Scientific and Medical

Group 1 Class A product.

The CSA mark is a registered trademark of the Canadian

Standards Association.

External Protective Earth Terminal.

While this is a Class I product, provided with a protectiv e

earthing conductor in a power cord, an external protective

earthing terminal has also been provided. This terminal is for

use where the ea rthing c annot be assured . At lea st an 18AWG

earthing conductor should be used in such an instance, to

ground the instrument to an assured earth terminal.

Page 7

Equipment Operation

IEC 1010-1 Compliance

This instrument has been designed and tested in accordance with IEC Publication

1010-1 +A1:1992 Safet y Requi rements for Electrical Equipment for Measur ement,

Control and L aborat ory Use and has be en suppl ied in a sa fe condi tion. The i nstruc tion

documentation contains information and warnings which must be followed by the

user to ensure safe operation and to maintain the instrument in a safe condition.

Statement of Compliance

This product has been designed and tested for compliance with IEC 60529 (1989)

Degrees of Protection Provided by Enclosures (IP Code). Leve l IPx 4 is attained if,

and only if, the carry ca s e (Agilent part number 34141A) is fitted.

User Environment

This product is desi gned for use in a sheltered environment (avoiding extreme

weather conditions) in accordance with Pollution De gree 3 defined in IEC 60664-1,

with the carry case ( Agilent part number 34141A) fitted over the inst rument.

The product is suitable for indoor use only, when this carry case is not fitted.

Installation Instructions

To avoid unnecessary over-temperature conditions, while this carry case is fitted do

not apply an ac mains suppl y volt age, only operat e your power mete r from the batt ery

pack.

Agilent E4418B/E4 419B S ervice Guide vii

Page 8

List of Related Publications

List of Rel ate d P ub li c ati on s

The Agilent E4418B and Agile ntE4419B User’s Guides are also available in the

following languages:

• English Langua ge Us er’s Guide - Standard

• German Language User’ s Guide - Option ABD

• Spanish Language Use r’s Guide - Option ABE

• French Language User’s Guide - Option ABF

• Italian Language User’s Guide - Option ABZ

• Japanese Language User’s Guide - Option ABJ

Agilent E4418B/E4419B Service Guide is available by ordering Option 915.

Agilent E4418B/E4419B CLIPs (Component Location and Information Pack) is

available by ordering E4418-90031.

viii Agilent E4418B/E4419B Service Guide

Page 9

Sales and Service Offi ces

Sales and Service Offices

For more information about Agilent Technologies test and measurement

products, applications, services, and for a current sales office listing, visit our

web site: http://www.agilent.com

You can also contact one of the following center s and ask for a test and

measurement sales representative.

Asia Pacific:

Agilent Te chnologies

19/F, Cityplaza One, 1111 King’s Road,

Taikoo Shing, Hong Kong, SAR

(tel) (852) 2599 7889

(fax) (852) 2506 9233

Japan:

Agilent Technologies Japan Ltd.

Measurement Assistance Center

9-1, Takakura-Cho, Hachioji-Shi

Yokyo, 192-8510

(tel) (81) 426 56 7832

(fax) (81) 426 56 7840

Australia/New Zealand:

Agilent Te chnologies Australia Pty Ltd

347 Burwood Highway

Forest Hill, Victoria 3131

(tel) 1-800 629 485 (Australia)

(fax) (61 3) 9272 0749

(tel) 0 800 738 378 (New Zealand)

(fax) (64 4) 802 6881

Canada:

Agilent Technologies Canada Inc.

5150 Spectrum Way,

Mississauga, Ontario

L4W 5G1

(tel) 1 877 894 4414

Agilent E4418B/E4 419B S ervice Guide ix

Page 10

Sales and Service Offices

Europe:

Agilent Te chnologies

Test & Measurement

European Marketing Organization

P. O. Box 999

1180 AZ Amstelvee n

The Netherlands

(tel) (31 20) 547 9999

Latin America:

Agilent Te chnologies

Latin American Region Headquarters

5200 Blue Lagoon Drive, Suite #950

Miami, Florida 33126

U.S.A.

(tel) (305) 267 4245

(fax) (305) 267 4286

United States:

Agilent Te chnologies

Test and Measurement Call Center

P. O. Box 4026

Englewood, CO 80155-4026

(tel) 1 800 452 488

In any correspondence or telephone conversations, refer to the power sensor

by its model nu mber and f ull s erial n umber. With t his i nformation, the Agi le nt

T echnologies representative can quickl y determine whether your unit is still

within its warranty peri od.

x Agilent E4418B/E4419B Service Guide

Page 11

Sales and Service Offi ces

Returning Your Power Meter for Service

Use the information in this section if you need to return your power meter to Agilent

Technologies.

Package the Power Meter for Sh ipment

Use the foll owing steps to package the power meter for shipment to Agilent

Technologies for service:

1. Fill in a blue ser vice tag (available at the end of this guide) and attach it to

the power meter. Please be as specific as possible about the nature of the

problem. Send a copy of any or all of the following information:

n A n y erro r mes s ag es that appeared on th e p ow er m et er dis p l ay.

n Any information on the performance of the power meter.

Caution Power meter damage can result from using packaging materials other than

those specified. Never use styrene pellets in any shape as packaging

materials. They do not adequately cushion the power meter or prevent it

from shifting in the carton. Styrene pellets cause power meter damage by

generating static electricity and by lodging in the rear panel.

2. Use the original packaging materials or a strong shipping con tainer that is

made of double-wall ed, corrugated cardboard with 159 kg (350 lb) burstin g

strength. The carton must be both large enough and strong en ough to

accommodate the power meter and allow at least 3 to 4 inches on all sides of

the power meter for packing material.

3. Surround the power meter with at least 3 to 4 inches of packing material, or

enough to prevent the powe r meter from moving in the carton. If packing

foam is not available, t he best alternative is SD-240 Air Cap

TM

from Seal ed

Air Corporation (Commerce, CA 90001). Air Cap looks like a plastic sheet

covered with 1-1/4 inch air filled bubbles. Use the pink Air Cap to reduce

static electricity. Wr ap the power meter several times in the material to both

protect the power meter and prevent it from moving in the carton.

4. Seal the shipping container securely with strong nylon adhesive tape.

5. Mark the shipping container “FRAGILE, HANDLE WITH CARE” to

ensure careful handling.

6. Retain copies of all shipping papers.

Agilent E4418B/E4 419B S ervice Guide xi

Page 12

About this Guide

About this Guide

Chapter 1: Specifications

This chapter li st s the power meter’s specifications and describes how to interpret

these sp ecifica ti o n s .

Chapter 2: Performance Test s

This chapter contains procedures which allow you to tes t the power meter’s electrical

performance to it’s specifications.

Chapter 3: Adjustments

This chapter conta ins checks and adjustments that ensure proper performance of the

power meter.

Chapter 4: Theory of Operation

This chapter describes how each of the power meter’s individual assemblies operate.

Chapter 5: Replaceable Parts

This chapter detai ls the power meter’s replaceable parts. It also explains how to

assemble and dis assemble the power meter.

Chapter 6: Trou blesho oting

This chapter con tains troubleshooting flow charts designed to isolate faults in the

Rmt I/O, GP-IB and RS232/422 interface ports.

Appendix A: “Measurement Uncertainty Analysis – Instrument Accuracy Test”

Appendix B: “Measurement Uncertainty Analysis – Power Refere nce Level Test”

xii Agilent E4418B/E4419B Service Guide

Page 13

Tab le of Contents

Specifications....................................................................................... 1

Introduction ................................................................................... 1-2

Power Meter Speci fications.......... ............ ............ ....................... .1-3

Meter....................................................................................... 1-3

Accuracy.................................................................................. 1-4

1 mW Power Reference .......... ........................ ............ ............1-5

Power Meter Supplemen t a l Char a ct eristics ............................... 1-6

Measurement Speed............................................................... 1-6

Zero Drift of Sensor s ................. ....................... ...................... 1-6

Measurement Noise................................................................ 1-7

Settling Time....... ............ ........................ ............ ................... 1-9

Power Sensor Speci f i ca t i o ns....... ............ ............ ................... 1-12

Battery Option 001 Operat ional Cha rac teris tics .... .................... 1-13

General Characteristics............................................... ................. 1-14

Rear Panel Connectors......... ............ ........... ........................ ... 1-14

Environmental Characteristics........................................ ........... .1-15

General Condition s........................... ....................... ............ ... 1-15

Operating Environment......................................................... 1-15

Storage Conditions ................................................................. 1-15

General.......................................................................................... 1-16

Dimensions ............................................................................. 1-16

Weight..................................................................................... 1-16

Safety ......................................................................................1-16

Remote Programming ............................................................1-17

Non-Volatile Me mory.................... ........................ ............ ..... 1-17

Page

Performance Tests.............................................................................. 1

Introduction ................................................................................... 2-2

Equipment Required .............................................................. 2-3

Performance Test Record....................................................... 2-4

Performance Tests..................................................................2-4

Calibration Cycle....................................................................2-4

Test Procedures ...................................................................... 2-4

Zero Test............ ....................... ............ ........................ ............ ..... 2-5

Specification ........................................................................... 2-5

Description.............................................................................. 2-5

Agilent E4418B/E4 419B Service Guide Contents-1

Page 14

Equipment .............................................................................. 2-5

Test Setup ............................................................................... 2-5

Procedure................................................................................2-6

Instrument Acc ur a cy Te st....................... ............ ........... ..............2-7

Specification........................................................................... 2-7

Description.............................................................................. 2-7

Test Procedure 1..................................................................... 2-7

Equipment .............................................................................. 2-7

Test Setup ............................................................................... 2-8

Procedure................................................................................2-8

Test Procedure 2..................................................................... 2-11

Equipment .............................................................................. 2-11

Test Setup ............................................................................... 2-11

Procedure................................................................................2-12

Power Reference Lev el Te st ......... ............ ............ ....................... 2-15

Description.............................................................................. 2-15

Equipment .............................................................................. 2-17

Test Setup ............................................................................... 2-17

Procedure................................................................................2-17

Agilent E-Series Power Sensor Interface Test............................ 2-19

Procedure................................................................................2-19

Agilent E-Series Power Sensor Funct ional Test......................... 2-20

Description.............................................................................. 2-20

Equipment .............................................................................. 2-20

Procedure................................................................................2-20

Performance Test Record..............................................................2-23

Adjustments.......................................................................................... 1

Introduction ................................................................................... 3-2

Safety Considerations ............................................................ 3-2

Equipment Required .............................................................. 3-3

Post-Repair Adju s tments........ ........................ ....................... 3-3

Power Reference Oscillator Frequency Adjustment ................... 3-4

Description.............................................................................. 3-4

Equipment .............................................................................. 3-4

Procedure................................................................................3-4

Power Reference Oscillator Level Adjustment............................ 3-6

Description.............................................................................. 3-6

Equipment .............................................................................. 3-8

Procedure................................................................................3-8

Measurement Uncertainty..................................................... 3-10

Display Brightn es s and Contrast Adjustment....... ..................... 3-11

Introduction ............................................................................ 3-11

Contents-2 Agilent E4418B/E4419B Service Guide

Page 15

Procedure................................................................................ 3-11

Theory of Operation........................................................................... 1

Introduction ................................................................................... 4-2

A1 Power Supply/Battery Charger ...................... ........................4-3

A2 Processor Assembly...................................... ........................ ... 4-4

A3 Front Panel Assembly...... ............ ........................ ................... 4-7

A4 Comms Assembly ........ ............ ........................ ....................... .4-8

A5 Daughter Assembly......................................... ....................... .4-9

A6 Measurement Assembl y.......... ........................ ....................... .4-10

A8 Rechargeable Battery Ass emb l y............................................. 4-12

Replaceable Parts............................................................................... 1

Introduction ................................................................................... 5-2

Assembly Part Numbers ............................................................... 5-3

Power Supply Assembl y Typ es............................... ............ ... 5-5

Front Panel Connector Repair.....................................................5-6

Firmware Upgrades.......... ............ ........................ ............ ............5-7

Downloading Firmware.......................................................... 5-7

Assembly and Disassembly Guidelines ....................................... 5-8

Removing the Power Meter Cover.........................................5-8

Removing the A1 Power Supply Assembly........................... 5-9

Removing the A2 Processor Assembly...................................5-10

Removing the A4 Comms Assembly...................................... 5-11

Removing the A5 Daughter or A6 Measurement Assemblies5-12

Removing the A7 Fan Assembly ............................................ 5-13

Removing the Power Meter RAM Battery (BT1).................. 5-14

Removing the A3 Front Panel Assembly............................... 5-15

Replacing the Front Panel Power Reference Cable Assembly.5-18

Replacing the Rear Panel Power Sensor Cable Assemblies

(Options 002 and 003) ............................................................ 5-19

Replacing the Rear Panel Power Reference Cable Assembly

(Option 003) . ........................................................................... 5-21

Replacing the Rear Panel Recorder Output Cable Assembly.5-22

Replacing The Chassis Assembly ......................................... .5-23

Troubleshooting.................................................................................. 1

Introduction ................................................................................... 6-2

Suggested Diagnost ic Equipment...... ............ ....................... .6-2

Measur ement Unc ertainty Analysis Instrument Accuracy Test1

Measurement Introduction........................................................... A-2

Uncertainties..........................................................................A-3

Define the Measurand............ ........................ ............ ............A-3

Agilent E4418B/E4419B Service Guide Con tents-3

Page 16

Define the Measurement Equati on.............. ........... ..............A-3

Sensitivit y Coeffi cients Ci:............. ............ ............................A-8

Combined Standard Uncer tai nty uc(y): ................................A-9

Expanded Uncertaint y kuc(y):.......... ............ ....................... ..A-9

Measur ement Unc ertaint y Analysis Power Re ference Level Test1

Measurement Introduction........................................................... B-2

Define the Measuran d...... ........................ ........................ ......B-2

Define the Measurement Equati on.............. ........... ..............B-2

Uncertainty Equation ............................................................B-4

Voltage Measurement s Uncertainty ......... ............ ................B-4

Mismatch ................................................................................B-5

Calibration factor ...................................................................B-7

Sensor Calibration Factor Drift.............................................B-7

Resistance...............................................................................B-8

Repeatability..................................... ......................................B- 8

Sensitivit y Coeffi cients (Ci) ................................... ................B-10

Combined Standard Uncer tai nty (uc(y)).................... ...........B-12

Expanded Uncertaint y............................... ........................ ....B-12

Contents-4 Agilent E4418B/E4419B Service Guide

Page 17

1

Specifications

Page 18

Specifications

Introduction

Introduction

This chapter details the power meter’s specificatio n s a nd supp le m ental

characteristics.

Specifications descri be the warranted perfo rma nc e and apply afte r a 30

minute warm-up . The se specifications are valid over the power meter’ s

operating and environmental range unless otherwise stated and after

performing a zero and calibration.

Supplement al char act eristics, which are shown in italics, are inten d ed to

provide infor m ation useful in applyin g the power meter by givi ng ty pi cal,

but non-warranted performance parameters. These characteristics are

shown in italics or denoted as “typical”, “nominal” or “approximate”.

For information on measurement uncertainty calculations, refer to Agilent

Application Note 64-1A, “Fundam e nt als of RF and Micro wave Power

Measurements”, Literature Number 5965-6630.

1-2 Agilent E4418B/E4419B Service Guide

Page 19

Specifications

Power Meter Specifications

Power Meter Specifications

Meter

Frequency R ange

100 kHz to 110 GH z, power sensor dependent

Power Range

-70 dBm to +44 dBm (100 pW to 25 W), power sensor dependent

Power Sensors

Compatible with all Agile nt 8480 serie s pow e r sensors and

Agilen t E-series powe r s e nsors.

Singl e Sensor Dynamic Range

90 dB maximum (Agilent E-series power sensors)

50 dB maximum (Agilent 8480 series power sensors)

Display Units

Absolute: Watts or dBm

Relative: Percent or dB

Display Resolution

Selectable resolution of:

1.0, 0.1, 0.01 and 0.001 dB in logar ith mic mo de, or

1, 2, 3 and 4 significant digits in linear mode

Default Resolution

0.01 dB in logarithmic mode

3 digits in linear mo de

Agilent E4418B/E4419B Service Guide 1-3

Page 20

Specifications

Powe r Me te r S p ecifications

Accuracy

Instrumentation

Absolute: ±0.02 dB (Logarithmic) or ±0.5% (Linear). (Refer to the power

sensor linearity specification in your power sensor manual to assess

overall system accu racy.)

Relative: ±0.04 dB (Logarithmic) or ±1 .0% (Linear). (Refer to the power

sensor linearity specification in your power sensor manual to assess

overall system accu racy.)

Zero Set (digital settabi li ty of zero) : Power sensor dependent (refer to

Table 1-1). For Agilent E-series power sensors, this specification applies

when zeroing is performed with the sensor input disconnected from the

POWER REF.

Table 1-1: Zero Set Specifications

Power Sensor Zero Set

Agilent 8481A ±50 nW

Agilent 8481B ±50 µW

Agilent 8481D ±20pW

Agilent 8481H ±5 µW

Agilent 8482A ±50 nW

Agilent 8482B ±50 µW

Agilent 8482H ±5 µW

Agilent 8483A ±50 nW

Agilent 8485A ±50 nW

Agilent 8485D ±20 pW

Agilent R8486A ±50 nW

Agilent R8486D ±30pW

Agilent Q8486A ±50 nW

Agilent Q8486D ±30 pW

Agilent V8486A ±200 nW

Agilent W8486A ±200 nW

Agilent 8487A ±50 nW

Agilent 8487D ±20 pW

Agilent E4412A ±50 pW

Agilent E4413A ±50 pW

1-4 Agilent E4418B/E4419B Service Guide

Page 21

Specifications

Power Meter Specifications

1 mW Power Reference

1

• Power Out p ut: 1.00 mW (0.0 dBm).

• Accur acy: (for two ye a rs )

±0.9% (0 to 55 ºC).

±0.6% (25±10 ºC).

±0.5% (23±3 ºC).

• Frequency: 50 MHz nomi na l .

•SWR

2

: 1.06 maximum (1.08 maximum for

option 003).

• Connector Type: Type N (f), 50 ohms.

1. National met rology institutes of member states of the Metre Convention,

such as the National Institute of Standards and Technology in the USA, are

signator ies to the Comi t é Inte r na tio nal de s Poids et Me su res Mutual

Recognition Arrangem ent. Further information is available from the Bureau

Interna tio na l de s Poids e t Me su re s, at ht tp :/ /w ww.bipm.fr/

2. This SWR specification is only warranted for the E4418B and the E4419B

Power Meters with serial prefix GB4331xxxx and above. Prior to this prefix

the values shown are sup plemental characteristics.

Agilent E4418B/E4419B Service Guide 1-5

Page 22

Specifications

Power Meter Supplemental Characteristics

Power Meter Supplemental Characteristics

Measurement Speed

Over the GP-IB, three mea s urement sp ee d modes are a v ai l a bl e as shown ,

along wit h th e t yp ical maxi m um measurem ent speed fo r ea ch mo de:

• Normal: 20 readings/sec ond

• x2: 40 readi ngs/second

• Fast: 20 0 rea d i ngs/secon d, for Agilen t E-s eries powe r se nsors onl y

Maximum measurement speed is obtained using binary output in free run

trigger m o de.

Zero Drift of Sensors

Power sensor dependent (refer to Table 1-3).

1-6 Agilent E4418B/E4419B Service Guide

Page 23

Specifications

Power Meter Supplemental Character istics

Measurement Noise

Power sensor dependent (refer to Table 1-2 and Table 1-3).

Averaging effects on measurement nois e. Averaging over 1 to 1024

readings is available for redu cin g noise. Table 1-3 provides the

measurement noise for a particular power sensor with the number of

averages set to 16 for normal mode and 32 for x2 mode. Use the “Noise

Multiplier” for the appropriate mode (normal or x2) and number of

averages to determi ne the tot al measurement noise value.

For example, for an Agilent 8481D power sensor in normal mode with the

number of averages set to 4, the measurement noise is equal to:

(<45 pW x 2.75) = <124 pW

Table 1-2: Noise Multiplier

Number of

Averages

Noise Multiplier

(Normal Mode)

Noise Multiplier

(x2 mode)

12481632641282565121024

5.5 3.89 2.75 1.94 1.0 0.85 0.61 0.49 0.34 0.24 0.17

6.5 4.6 3.25 2.3 1.63 1.0 0.72 0.57 0.41 0.29 0.2

Agilent E4418B/E4419B Service Guide 1-7

Page 24

Specifications

Power Meter Supplemental Characteristics

Table 1-3: Power Sensor Specifications±

1

Power Sensor Zero Drift

Meas uremen t Noise

Agilent 8481A <±10 nW <110 nW

Agilent 8481B <±10 µW <110 µW

Agilent 8481D <±4pW <45 pW

Agilent 8481H <±1 µW <10µW

Agilent 8482A <±10 nW <110 nW

Agilent 8482B <±10 µW <110 µW

Agilent 8482H <±1 µW <10µW

Agilent 8483A <±10 nW <110 nW

Agilent 8485A <±10 nW <110 nW

Agilent 8485D <±4pW <45 pW

Agilent R8486A <±10 nW <110 nW

Agilent R8486D <±6pW <65 pW

Agilent Q8486A <±10 nW <110 nW

Agilent Q8486D <±6pW <65 pW

2

Agilent W8486A <±40 nW <450 nW

Agilent 8487A <±10 nW <110 nW

Agilent 8487D <±4pW <45 pW

Agilent E4412A <± 15 pW <70 pW

Agilent E4413A <± 15 pW <70 pW

1. Within 1 hour after zero set, at a constant te mperature, after a 24 hour

warm-up of the power meter.

2. The number of av erages at 16 (for normal m ode) and 32 (for x2 mode), at

a constant temperature, measu red over a 1 minute interval and 2 standard

deviations. For Agilent E-series power sensors the measurement noise is

measured within t h e low range. Refer to t he relevant power sensor manual

for furthe r in formation.

1-8 Agilent E4418B/E4419B Service Guide

Page 25

Power Meter Supplemental Character istics

Settling Time

0 to 99% settled readings over the GP-IB.

For Agilent 8480 series power sensors

Manual filter, 10 dB decreasing power step:

Table 1-4: Settling Time

Specifications

Number of

Averages

Settling Time (s)

(Normal Mode)

Response Time (s)

(x2 mode)

Normal Mode x2 Mode

Maximum dBm

Maximum dBm

Maximum dBm

150 ms

Typical

Settling

Settling

Settling

Times

Times

Times

200 ms

500 ms

12481632641282565121024

0.15 0.2 0.3 0.5 1.1 1.9 3.4 6.6 13 27 57

0.15 0.18 0.22 0.35 0.55 1.1 1.9 3.5 6.9 14.5 33

Auto filter, def a ul t res o lu t ion, 10 dB decreasing powe r st ep,

normal and x2 speed modes:

Maximum dBm

20 dB

20 dB

20 dB

10 dB

10 dB

10 dB

10 dB

10 dB

10 dB

Power

Power

Power

Sensor

Sensor

Sensor

Dynamic

Dynamic

Dynamic

Range

Range

Range

Typical

Settling

Settling

Settling

Times

Times

Times

150 ms

180 m s

350 m s

20 dB

20 dB

20 dB

10 dB

10 dB

10 dB

10 dB

10 dB

10 dB

Power

Power

Power

Sensor

Sensor

Sensor

Dynamic

Dynamic

Dynamic

Range

Range

Range

6.6 s

Minimum dBm

Minimum dBm

Minimum dBm

10 dB

10 dB

10 dB

3.5 s

Minimum dBm

10 dB

10 dB

10 dB

Agilent E4418B/E4419B Service Guide 1-9

Page 26

Specifications

Power Meter Supplemental Characteristics

For Agilent E-series power sensors

Number of

Averages

Settling Time (s)

(Normal Mode)

Response Time (s)

(x2 mode)

In FA ST m o de, within the range -50 dBm to +17 dBm, for a 10 dB

decreasing power step, the settling time is 10 ms

and 20 ms

1

When a decreasing power step crosses the power sensor’s auto-range

1

for the Agilent E4419B

1

for the Agilent E4418B

switch po in t , a dd 25 ms. Refer to th e re l ev a nt power sensor manual for

further information.

F o r Agilent E-series p ower sensors i n normal and x2 speed mode s, manua l

filter, 10 dB decreasing p o wer step:

Table 1-5: Settling Time

12481632641282565121024

0.07 0.12 0.21 0.4 1 1.8 3.3 6.5 13 27 57

0.04 0.07 0.12 0.21 0.4 1 1.8 3.4 6.8 14.2 32

1-10 Agilent E4418B/E4419B Service Guide

Page 27

Power Meter Supplemental Character istics

c

Auto filter, def a ul t res o lu t ion, 10 dB decreasing powe r st ep,

normal and x2 speed modes:

Normal Mode x2 Mode

Specifications

Typical

Settling

Times

Maximum dBm

70 ms

120 ms

400 m s

6.5 s

Minimum dBm

60 dB

10 dB

10 dB

10 dB

Power

Sensor

Dynamic

Range

Typical

Settling

Times

Maximum dBm

40 ms

70 ms

210 ms

3.4 s

60 dB

10 dB

10 dB

10 dB

Minimum dBm

Power

Sensor

Dynami

Range

Agilent E4418B/E4419B Service Guide 1-11

Page 28

Specifications

Power Meter Supplemental Characteristics

Power Sensor Specifications

Definitions

Zero Set

In any power meas ur ement, the power meter must initially be set to zero

with no power applied to the power senso r. Zero setting is accomplished

within the power meter by digitally correcting for residual offsets.

Zero Drift

This parame ter is also called lo ng term stability and is the chan ge in the

power meter indication over a long time (usually one hour) for a constant

input power at a constant temperature , after a defined war m-u p interv al.

Measurement Noise

This paramete r is also kn o wn as sh or t term stability and is specified as

the change in the po wer m ete r in di cation over a short time interval

(usually one minute) for a co nstant inp ut power at a co nstant

temperature.

1-12 Agilent E4418B/E4419B Service Guide

Page 29

Specifications

Battery Option 001 Operational Characteristics

Battery Option 001 Operational Characteristics

The following information describes characteristic performance based at a

temperature of 25

product performance that is useful in the applicati on of the product, but is

not covered by the product warranty.

Typical Operating Time

Up to 2 hours with LED backlight on; up to 3 hou rs with LED backligh t

off.

Charge Time

< 2 hours to charge fully from an empty state: 50 minutes charging

enables 1 hour of operation with L ED backlight ON; 35 minutes charging

enables 1 hour of operation with th e LED backlight OFF. Power meter is

operational whilst charging.

Service Life

°C unless otherwise note d. Ch aracte ri stics describe

To 70% of initial capacity at 25

cycles.

Chemistry

Nickel Metal Hydride.

Weight

1 kg.

°C: approximately 450 charge/discharge

Agilent E4418B/E4419B Service Guide 1-13

Page 30

Specifications

General Characteristics

General Characteristics

Rear Panel Connectors

Recorder Output(s)

Analog 0-1 Volt, 1 kΩ output impedance, BNC connector

GP-IB

Allows communication with an external GP-IB controller.

RS-232/422

Allows communication with an external RS-232 or RS422 controller. Male

Plug 9 position D-subminiature connector.

Remote Input/Output

A TTL log ic le ve l i s out put whe n the m ea sure men t e xce eds a p red et er mine d

limit. TTL inputs are provided to initiate zero and calibration cycles.

RJ-45 se ri es shielde d m o dular jack ass em b l y.

TTL output: high = 4.8 V max; low = 0.2 V max

TTL input: high = 3.5 V min, 5 V max; low = 1 V max, -0.3 V min

Ground

Binding post, accepts 4 mm plug or bare-wire connection

Line Power

• Input Voltage Range: 85 to 264 Vac, automatic selection

• Input Frequency Ra nge: 50 to 440 Hz

• Power Requirement: approximately 50 VA (14 Watts)

1-14 Agilent E4418B/E4419B Service Guide

Page 31

Specifications

Environmental Characteristics

Environmental Characteristics

General Conditions

Comp lies with th e requirem ents of th e E M C D i rective 8 9 /3 3 6/EEC. This

includes Generic Immunity Standard EN 50082-1: 1992 and Radiated

Interference Standard EN 55011:1991/CISPR11:1990, Group 1 - Class A.

Operating Environment

Temperature

0ºC to 55ºC

Maximum Humidity

95% at 40ºC (non-condensing)

Minimum Humidity

15% at 40ºC (non-condensing)

Maximum Altitude

3,000 meters (9,840 feet)

Storage Conditions

Storage Temperature

-20ºC to +70ºC

Non-Operating Maximum Humidity

90% at 65ºC (non-condensing)

Non-Operating Maximum Altitude

15,240 meters (50,000 feet)

Agilent E4418B/E4419B Service Guide 1-15

Page 32

Specifications

General

General

Dimensions

The following dimensions exclude front and rear panel protrusions:

212.6 mm W x 88.5 mm H x 348.3 mm D (8.5 in x 3.5 in x 13.7 in)

Weight

Net

Agilent E4418B, 4.0 kg (8.8 lb) - 5.0 kg (11.0 lb) with option 001

Agilent E4419B, 4.1 kg (9.0 lb) - 5.1 kg (11.2 lb) with option 001

Shipping

Agilent E4418B, 7.9 kg (17.4 lb) - 8.9 kg (19.6 lb) with option 001

Agilent E4419B, 8.0 kg (17.6 ib) - 9.0 kg (19.8 lb) with option 001

Safety

Conforms to the following Product Specifications:

• EN61010-1: 1993/IEC 1010-1:1990+A1/CSA C22.2 No.

1010-1:1993

• EN60825-1: 1994/IEC 825-1: 1993 Class 1

• Low Voltage Directive 72/23/EEC

1-16 Agilent E4418B/E4419B Service Guide

Page 33

Specifications

General

Remote Programming

Interface

GP-IB interface operates to IEEE 488.2. RS-232 and RS-422 interfaces are

supplied as stand ar d.

Comman d Language

SCPI stan d ar d in terface comman ds.

Agilent E4418B is HP 437B code compatibl e.

HP E4419B is HP 438A code compatible

Agilent E4418B/E4419B GP-IB Compatibility

SH1, AH1, T6, TE0, L4, LE0, SR1, RL1, PP1, DC1, DT1, C0

Non-Volatile Memory

Battery

Lithium Polycarbon Monoflouride, approximate lifetime 5 years at 25ºC.

Agilent E4418B/E4419B Service Guide 1-17

Page 34

Specifications

General

1-18 Agilent E4418B/E4419B Service Guide

Page 35

2

Performance Tests

Page 36

Per formance Tests

Introduction

Introduction

The procedures in this chapt er test the power met er’s electrical

performance using the specifications in Chapter 1 as the performance

standards. All tests can be performed without access to the interior of the

power meter. A simpler operational test is inc lude d in “ Se lf Test” of the

User’s Guide.

Note For valid performance tests, the follo win g cond itions must be met:

a. The power meter and test e quipm ent must have a 30 minute

warm-up for all specific ations.

b. The line voltage for the power meter must be 85 to 264 Vac and

the line frequency must be 50 to 440 Hz.

c. The ambient temperature must be 00 to 550C.

2-2 Agilent E4418B/E4419B Service Guide

Page 37

Performance Tests

Introduction

Equipment Required

Table 2-1 lists all the equipment required for the adjustments and

performance tests. If substitutions must be made, the equipment used

must meet the critic al sp e cific atio ns.

Table 2-1: Required Equipment

Equipment

Required

Model Number Critical Specification Usage

Digital Multimeter Agilent 3458A Range 0 to 20 V

Resolution 0.01 V

DC Calibrator Datron 4000A

or

Fluke 5720A

Range Calibrator

Agilent 11683A

or

Agilent 11683A

Opt H01

Option H01 is essential for

accurate verification. (See

analysis in

Standard 11683A can be used

for indicati on on l y.

Appendix A). The

Frequency Counter Agilent 53132A Range 10 Hz to 50 MHz

Resolution 1 Hz

Power Meter Agilent 432A Range 1 mW

Transfer Accuracy 0.2%

Thermistor Mount Agilent 478A Opt H75/H76

or

Agilent 8478B Opt H01

SWR<1.05 at 50 MHz

Accuracy ±0.2% at 50 M Hz.

Power Sensor Agilent E-series power

sensor

1

P and A

P

P

P and A

P and A

P and A

P

30 dB Attenuator Agilent 11708A

or

Agilent 8491A Option 030

Power Sensor

Cable

1. P = Performance Tests, A = Adjustments

Agilent 11730A

or

Agilent

E9288A

Agilent E4418B/E4419B Service Guide 2-3

P

P and A

Page 38

Per formance Tests

Introduction

Performance Test Record

Results of the performance tests may be tabulated in Table 2-7,

“Performance Test Record,” on page 2-23. The Performance Test Record

lists all of the performance test specifications and the acceptable limits for

each specification. If performance test results are recorded during an

incoming inspection of the power meter, they can be used for comparison

during periodic maintenance. The test results may also prove useful in

verifying proper adjustments after repairs are made.

Performance Tests

The performance tests given in this chapter are suitable for incoming

inspection or preventive maintenance. During any performance test, all

shields and connecti ng hardware must be in place.

The tests are designed to verify published power meter specifications.

Perform t he tes ts in the order give n and record the dat a in Ta ble 2-7 on

page 2-23 and/or in the data spaces provided at the end of each procedure.

Calibration Cycle

This power meter requires periodic verification of performance to ensure

that it is operating within specified tolerances. The performance tests

described in t his ch apter s hould be perf ormed once every t wo yea rs. Under

conditions of heavy usa ge or seve re oper ating environments, the tests

should be more frequent. Adjustments that may be required are described

in Chapter 3.

Test Procedures

It is assumed that the per so n p erfo rm in g the following tests un d e rst and s

how to operate the specified test eq uipmen t . Equi pment se tti ngs, other

than those for the power meter, are stated in general terms. It is assumed

that the person will select the proper cables, adapters, and probes

required for test setups illustrated in this chapter.

2-4 Agilent E4418B/E4419B Service Guide

Page 39

Zero Tes t

Specification

Electric al Charac te ristics Perform ance Lim its

Performance Tests

Zero Test

Accuracy: Zero set (Digital settability of zero) ±0.0764 µW

1. This performance limit is determined by the zero set specification of the powe r

sensor used in the measur ement plus the measurement noise. The rang e

calibrator ha s a zero s et specification of

noise specification is 110 nW at 16 averages. At 512 av erages a noise multiplier of

0.24 is required, gi vi ng a measurement noise specification of 0.0264 µW

(0.24x512).

±0.05 µW . The calibrator measurement

1

Description

After the power meter is initially calibrated and zeroed, the change in the

digital readout is m onitored. This test als o takes d rift and noise into

accoun t , si nce d rif t , no is e a nd z e ro re a d ings canno t be s eparated.

Equipment

Range Calibrator .................................. Agilent 11683A

Power Sensor Cable .............................Agilent 11730A

Test Setup

Power M e t e r

Range

Calibrator

CHANNEL A

Agilent 11730A

POWER

METER

Figure 2-1: Zero Test Setup

Agilent E4418B/E4419B Service Guide 2-5

Page 40

Per formance Tests

Preset

dBm/W

System

Zero

Zero Test

Procedure

The following procedure should be performed for the Zero Test.

Note The procedure deta i l s the key pres se s required on the

Agilent E4418B. For the Agilent E4419B the equivalent key

presses should be performed on both chan nels.

1. Connect the equipment as shown in Figure 2-1.

2. Swi t ch the power m e t e r o n.

3. Press then .

Local

4. Press , for a reading in watts.

5. Set th e range calibrator as follows:

RANGE............................................3 µW

POLARITY......................................NORMAL

FUNCTION.....................................STANDBY

LINE................................................ON

Confirm

W

Note When switching the rang e ca libra to r to S TANDB Y, allow enough

time for the range calibrator to settle to its zero value before

attempting to zero the power meter . This settling would appear on

the power meter display as downward drift. When the drift has

reached minimum , (typ ica lly le ss th an 60 se cond s), the range

calibrator is settled.

6. On the power meter press ,

Filter Filter On Mode Man Length

, , , , and set the filter

Inputs

length to 512 in the pop up window then press .

7. On the power meter press , . Wait approximately 10

Cal

Input Settings

Enter

Zero

More

, ,

seconds for the wait symbol to disappear.

8. Wait 30 seconds then verify that the power mete r’s reading is

within ±0.05 µW. Record the re a d i ng.

Table 2-2: Zero Test Results

Channel B

Min

Channel A

Actual Re s ul t

Actual Result

(Agilent E4419B

Max

Only)

-76.40 nW ________________ ________________ +76.40 nW

2-6 Agilent E4418B/E4419B Service Guide

Page 41

Instrument Accuracy Test

Instrument Accuracy Test

Specification

Electric al Characteristics Performance L imits

Performance Tests

Accuracy ±0.5% or ±0.02 dB

1. This performance limit does not include the corresponding sensor power

linearity speci fication.

1

Description

The power meter accuracy is verified for variou s power inpu t s. There are

two different methods described here that can be used to perform this test,

although one of these methods has a relatively high measurement

uncertainty values associated with it.

Test Procedure 1

Note The measurement uncertainty of this test procedure is relatively

high at power levels of 30uW and below, as it uses a stan dard

11683A Range Calibrator. As such, this test procedure should be

used for indication only.

Equipment

Range Calibrator...................................Agilent 11683A

Power S ens or Cable...............................Agilent 11730A

Agilent E4418B/E4419B Service Guide 2-7

Page 42

Per formance Tests

Preset

dBm/W

Instrument Accuracy Test

Test Setup

Pow er Meter

Range

Calibrator

CHANNEL A

Agilent 11730A

Figure 2-2: Instrument Accu ra cy Test Setup

Procedure

The following procedu re should be perf ormed for the Instr ument Accurac y

Test.

Note The procedure deta i l s the key pres se s required on the

Agilent E4418B. For the Agilent E4419B the equivalent key

presses should be performed on both chan nels.

1. Connect the equipment as shown in Figur e 2-2.

2. Swi t ch the power m e t e r o n.

3. Press then .

Local

4. Press , for a reading in watts.

5. Set th e range calibrator as follows:

RANGE........................ .................... 3 µW

POLARITY...................................... NORMAL

FUNCTION.....................................STANDBY

LINE ............................................... ON

Confirm

W

POWER

METER

2-8 Agilent E4418B/E4419B Service Guide

Page 43

Performance Tests

System

Zero

Instrument Accuracy Test

Note When switching the rang e ca libr ato r to S TANDB Y, allow enough

time for the range calibrator to settle to its zero value before

attempting to zero the power meter . This settling would appear on

the power meter display as downward drift. When the drift has

reached minimum , (typ ica lly le ss th an 60 se cond s), the range

calibrator is settled.

6. On the power meter press ,

Filter Filter On Mode Man Length

, , , , and set the filter

Inputs

length to 512 in the pop up win d ow then p ress .

7. On the power meter press , . Wait approximately 10

Cal

Input Settings

Enter

Zero

More

, ,

seconds for the wait symbol to disappear. V erify that the display

reads 0 ±0.05 µW.

8. Set the range calibrator’s FUNCTION switch to CALIBRATE.

9. Set th e ra nge calibrator ’s RANGE sw it ch to 1 mW.

10. Press to calibrate the power meter.

Cal

11. Set the range calibrator’s RANGE switch to the positions shown in

Table 2-3 on page 2-10. For each setting, verify that the power

meter’s reading is within the limits shown.

Agilent E4418B/E4419B Service Guide 2-9

Page 44

Per formance Tests

Instrument Accuracy Test

Table 2-3: Instru m e nt Accuracy Results (For Indication Only)

Range

Calibrator

Setting

Min

1

Channel A

Actual Results

Channel B

Actual Results

(Agilent E4419

B only)

Max

1

3 µW3.100 µW _______________ _______________ 3.230 µW

10 µW9.900 µW _______________ _______________ 10.10 µW

30 µW 31.40 µW _______________ _______________ 31.80 µW

100 µW 99.50 µW _______________ _______________ 100.5 µW

300 µW 314. 00 µW _______________ _______________ 318.00 µW

1 mW 0.995 mW _______________ _______________ 1.005 mW

3 mW 3.141 mW _______________ _______________ 3.171 mW

10 mW 9.984 mW _______________ _ ______________ 10.08 mW

30 mW 31.63 mW _______________ _______________ 3 1.94 mW

100 mW 100.9 mW _______________ _______________ 101.8 mW

1. These performance limits are determined by the zero set specification of the power sensor

used in the measurement plus the measurement noise.

Note The nominal outputs for the 3µW, 30 µW, 300 µW, 3 mW, 10 mW,

30 m W and, 100 mW settings are 3.16 µW, 31.6 µW, 316 µW,

3.156 mW, 10.03 mW, 31.78 mW, and 101.3 mW respectively.

Note It is not neces sary to ch ec k instrument accur acy in dBm . T he

power meter uses the same internal circuitry to measure power

and mathematically converts watts to dBm .

2-10 Agilent E4418B/E4419B Service Guide

Page 45

Performance Tests

Instrument Accuracy Test

Test Procedure 2

Note This test procedure makes use of a 11683A Range Calibrator fitted

with option H01. The measurement uncer t a i nty of this test

procedure is significantly lower than the previously described

method (refer to Appendix A f or a des cr i pt i on of the mea s ur ement

uncertainty analysis). As such, this test procedure should be used

to ensure the power meter meets it's published specification.

Equipment

• Range Calibrator: Agilent 11683A Option H01

• Power Sensor Cable: Agilent 11730A

• DC Range Calibrator: Datron 4000A

Test Setup

DC Calibrator

Power Meter

CHANNEL A

Power sensor cable

Range

Calibrator

Figure 2-3: Instrum ent Ac curacy (Average Path) Test Setup

Agilent E4418B/E4419B Service Guide 2-11

Page 46

Per formance Tests

Preset

dBm/W

Meas

n

Instrument Accuracy Test

Procedure

The following procedu re should be perf ormed for the Instr ument Accurac y

Test.

Note The procedure deta i l s the key pres se s required on the

Agilent E4418B. For the Agilent E4419B the equivalent key

presses should be performed on both chan nels.

1. Connect the equipment as shown in Figur e 2-3.

2. Unplug the range calibrator's power cord. Due to a ground loop

design problem with th e 1168 3A option H01 ra nge cali brat or, it

will not operate properly unl ess gr ound lo ops are elimi nat ed. The

instrument will continue to operat e with no pow er appl ie d, and

disconnecting the power cord eliminates the problem.

WARNI NG There is a small risk of mild electrical shock from the

chassis of the 11683A option H01 range calibrator unless

the power meter is connected.

3. Figure 2-3 shows the HI/LO outputs of the DC calibrator

connected to the DC reference input of the range calibrator.

Ensure that the Guard and LO output of the DC calibrator are

floating, and are not connected to the earth ground.

4. Swi t ch the power m e t e r o n.

5. Press then .

Local

6. Press , for a reading in watts.

7. Press on the power meter, and set the value

Setup

Confirm

W

Resolutio

to 4.

8. Set th e range calibrator as follows:

• RANGE: 100 mW

• POLARITY: NORMAL

•FUNCTION: STANDBY

• REF SWITCH: EXT

•LINE: OFF

2-12 Agilent E4418B/E4419B Service Guide

Page 47

Performance Tests

System

Zero

Instrument Accuracy Test

Note When switching the rang e ca libr ato r to S TANDB Y, allow enough

time for the range calibrator to settle to its zero value before

attempting to zero the power meter . This settling would appear on

the power meter display as downward drift. When the drift has

reached minimum , (typ ica lly le ss th an 60 se cond s), the range

calibrator is settled.

9. Set the DC calibrator as follow s:

• SET VALUE: 0 (ZERO)

• FUNCTION: DC

• OUTPUT: OFF

10. On the power meter press ,

Filter Filter On Mode Man Length

, , , , and set the filter

Inputs

length to 512 in the pop up win d ow then p ress .

11. On the power meter press , . Wait approximately 10

Cal

Input Settings

Enter

Zero

More

, ,

seconds for the wait symbol to disappear. V erify that the display

reads 0 ±0.05 µW.

12. Set the DC cali brator output to 144.93mV, and set the output

switch to '+'.

13. Press to calibrate the power meter.

Cal

Agilent E4418B/E4419B Service Guide 2-13

Page 48

Per formance Tests

Instrument Accuracy Test

14. Set the DC calibrator output to the values shown in Table 2-4. For

each setting, set the filte r length of the power mete r to the

corresponding value, and veri f y that the power me ter reading is

within the limits sho wn. Refer to step 10 for details o n how to

setup the filter len gth

.

Table 2-4: Instrument Accuracy Results

DC

Calibrator

Setting

458.31uV 3.1623 uW 256 0.028 uW 3.0977uW 3.2269uW

1.4493mV 10uW 256 0.027 uW 9.904 uW 10.096uW

4.5831mV 31.6228uW 256 0.027 uW 31.428uW 31.819uW

14.493mV 100uW 64 0.073 uW 99.49uW 100.51uW

45.831mV 316.2278uW 64 0.104 uW 314.72uW 317.74uW

144.93mV 1mW 16 0.2 uW 0.9954mW 1.0047mW

459.12mV 3.1623mW 16 0.9 uW 3.1477mW 3.1769mW

1.4588V 10mW 16 1.6 uW 9.954mW 10.046mW

4.6872V 31.6228mW 16 4.8 uW 31.477mW 31.769mW

15.588V 100mW 16 18.5 uW 99.54mW 100.46mW

Effective

Power

Applied

Power

Meter

Filter

Setting

Meas

Unc

Lower

Limit

Ch A

Result

Ch B

Result

Upper

Limit

Note The test limits shown in th is table d o not tak e into acc o unt the

correspo nding measure m e nt uncertaint y va lu e s.

2-14 Agilent E4418B/E4419B Service Guide

Page 49

Po wer Reference Level Test

Performance Tests

Power Reference Level Test

Electrical

Characteristics

Power reference 1 mW Internal 50 MHz oscillator

Power refere nce

accura cy setting

Power refere nce

accura cy after

2 years

Performance

Limits

facto ry set to ±0 .4% tr acea ble to

National Phy sica l Labora tory

(NPL), UK.

±0.1% Guardban ded Test Line Limits.

±0.5%

(23 ±3

o

C)

Worst case power me ter

accuracy, taking into account

the possibilit y of oscil lato r drift

and operation at 55 degree s.

Conditions

Description

This test verifies the power level accuracy of the internal 50 MHz

osci ll ator—also cal led the power reference oscillator. The power reference

oscillator output is factory adjusted to 1 mW ±0.4%. This accuracy

includes a performance limit of 0.1% and a system measurement

uncertainty figure of 0.3% (traceable to the National Physical Laboratory

(NPL), UK). Refer to Appendix B for the measurement uncertainty of the

system.

Note The setting of the oscillator output accuracy is determined from the

system measurement uncertainty plus any chosen test line limit.

For example, if a test line limit of 1 mW ±0.2% was chosen while

maintaining a system measur ement uncer t a int y of ±0.3%, the overall

accuracy of the test setup for the 1 mW power out put be com es

0.3% + 0.2%, giving a setting accuracy of 0.5%.

Agilent E4418B/E4419B Service Guide 2-15

Page 50

Per formance Tests

Power Reference Level Test

If an equivalent measurement system is employ ed f or post-factory test,

the power reference oscillator output can again be set to 1 mW ±0.4%. This

setting is sufficient to ensure that the power reference oscillator meets the

accuracy specification of ±0.5% after 2 years. This specification includes

the ±0.4% settin g and also tak es into acc o un t othe r facto r s that will

contribute to determining the accuracy after 2 years. The complete

breakdown of the ±0.5% specific atio n is as fo llo ws:

• Test line limit: 0.1%.

• System uncertainty: 0.3%.

• 2 year oscillator drift: 0.04% .

• Delta environment: <0.06%.

The same equipment used to measure the accuracy of t he power reference

oscillator can also be used to set it to the post-factory accuracy of ±0.4%

(for further information re f e r t o chap t e r 3, Adjust m e nts).

The following procedure ensures maximum accuracy in measuring power

reference oscillator output using Agilent test instruments of known

capability. Signal acqu isition criteria may vary if alternative test

instr umen t s ar e us ed. In s u ch ca se s re f er to the man uf act ur er’s guide li ne s

for furthe r i nf o r m a ti o n.

The test is performed using Equatio n 2-4:

Equation 2-4: Power Level Provided By The Reference Oscillator

2

2

V

–+

1

P

meas

2V

compV1V0

---------------------------------------------------------------------------------- -=

4R Calibratio

–()V

0

nFactor()

The components of this equation are defined as foll ows:

is the voltage measured between V

•V

0

comp

and V

with no powe r

RF

applied and after the Agilent 432A has been zeroed.

•V

is the voltage measured between V

1

comp

and V

with power applied.

RF

This power is approx im ately 1 m W.

•V

is the voltage between th e Agilent 432A V

comp

connector and

comp

chassis ground with power applied.

• R is the resistance of the mount resistor in the Agilent 432A power

meter. For fu rther information re f e r to A p pe ndix A.

• Calibration Factor is the value of the thermistor mount at 50 MHz

2-16 Agilent E4418B/E4419B Service Guide

Page 51

Power Reference Level Test

Equipment

• Test power mete r: Agilent 432A .

• Thermistor moun t: Agil ent 478A opt ion H75 or H76.

• Digital voltmeter (DVM): Agilent 3458A.

Test Setup

Performance Tests

Pow er Meter

Te st Powe r Mete r

Power

ref

Digital Voltmeter

V

RF

Vcomp

Thermistor

mount

Figure 2-4: Power Reference Level Test Setup

Procedure

Use the following procedure to perfo rm the power reference level test:

Note The procedure detail s the key presses required on the

Agilent E4418B. For the Agilent E4419B the equivale nt key presse s

should be performed on both channels.

1. Set the DVM to me asu re resistance:

Connect the DVM betw e en the V

Agilent 432A and pin 1 on the thermistor mou nt end of the sen sor cab le .

V erify that no power is applied to the Agilent 432A.

2. Round off the DVM reading to two decimal places and note this valu e

as the internal bridge resistance (R) of the Agilent 432A

(approximately 200 Ω).

•R ____________Ω

3. Connect the equipment as shown in Figure 2-4, ensuring that the DVM

input leads are isolated from chassis ground.

connector on th e rear pa ne l of the

RF

+ input

-input

Note Ensure that the Agile nt 432A and the power meter under test ha ve

been powered on for at least 30 minutes be fo re mov ing to step 4.

Agilent E4418B/E4419B Service Guide 2-17

Page 52

Per formance Tests

Preset

n

Power Reference Level Test

4. Preset the power meter:

Press , then on the power m e ter.

Local

Confirm

Set the Agilent4 32A RANGE switch to Coarse Zero. Adjust the front

panel Coarse Zero control to obtain a zero meter indication.

5. Zero the Agilent 432A test power me te r:

•Fine zero the Agilen t 432A on the most sensit ive ran ge.

•Set the RANGE switch to 1 mW.

6. Set the DVM to measure m icr ovo lts.

7. Connect the p ositive and negative input leads to the V

comp

and VRF

connectors respectively, on the rear panel of the test power meter.

8. Observe the reading on the DVM. If less than 400 µV, proceed to the

next step. If 400 µV or greater, press and hold the test power meter

Fine Zero switch and adjust the Coarse Zero control so that the DVM

indicates 200 µV or less. Release the Fine Zero switch and proceed to

the next step.

9. Round the DVM reading to two decimal places.

Record t h i s re a d i n g a s V

___________

•V

0

.

0

10.Turn the po wer refe re nce on:

Press , .

Zero

Cal

Power Ref O

11.Round the DVM reading to two decimal places.

Record t h i s re a d i n g a s V

___________

•V

1

12.Disconnect the DVM negative input lead from the V

.

1

connector on the

RF

Agilent 432A. Reconnect it to the Agilent 432A chassis ground.

13.Obs erve the DVM read ing. Record the readin g as V

•V

__________

comp

comp

.

14.C alc ulat e th e Power Referen ce Osc illato r power usin g eq uatio n 2-4.

15.Verify that P

is within the limits shown in Table 2-5 and record the

meas

reading in the table.

Table 2-5: Power Reference Level Test Result

Min Max Actual Result

0.999 mW 1.001 mW ________________

2-18 Agilent E4418B/E4419B Service Guide

Page 53

Performance Tests

Agilent E-Series Power Sensor Interface Test

Agilent E-Series Power Sensor Interface Test

The Agilent E-series power sensors have their sensor calib ration tables

stored in EEPROM which enables the frequency and calibrati on factor

data to be downloa ded automatically by the p o wer m e ter. The frequency

and calibration factor data have checksums which are compared with the

data downloaded by the powe r mete r. For the Agilent E4419B dual

channel p o w e r m e ter, this test shoul d b e perf o rmed on both chann els.

Procedure

1. When there is no power sensor connected to the Channel A input

the message “No Sensor” (“No Sensor ChA” on the

Agilent E4419B) appears on the measurem ent window.

2. Connect the A gilent E-series power sensor to the power meter’s

Channel A input. The message “Reading Sensor ChA” appears.

When all the data is downloaded this message disappears and a

reading is displayed on the measurement window. If the download

fails, a war ning message and error flag are displayed on the front

panel. Also, SCPI error message “-310, System Error” is

generated.

3. For the Agilent E4419B repeat these steps for Channel B.

Agilent E4418B/E4419B Service Guide 2-19

Page 54

Per formance Tests

Agilent E-Series Power Sensor Functional Test

Agilent E-Series Power Sensor Functional Test

Description

This test verifie s that the mete r /sen so r com bin atio n can make RF

measurements.

The Agilent E-series power sensors operate over a 90 dB dynamic range

(-70 to +20 dBm). However, since there is an amplifier in these power

sensors, the voltages presented to the power sensor connector are always

within the range of voltages available from the Agilent 11683A range

calibrator.

Equipment

Power Sensor Cable...............................Agilent 11730A

Reference Attenuator............................Agilent 11708A

Agilen t E-series powe r s e nsor

Procedure

T o complet e th e Functi onal Test the following procedu re should be

performed.

Note The procedure deta i l s the key pres se s required on the

Agilent E4418B. For the Agilent E4419B the equivalent key

presses should be performed on both chan nels.

1. Connect the equipment as shown in Figur e 2-5.

Powe r Meter

Figure 2-5: Sensor Functional Test Setup

2-20 Agilent E4418B/E4419B Service Guide

Agilent E-Series

Power Sensor

POWER

REF

CHANNEL A

Agilent 11730A

Page 55

Performance Tests

Preset

Zero

Zero

Zero

System

Agilent E-Series Power Sensor Functional Test

2. Press then .

Local

3. On the power meter press , . Wait approxima t el y

Confirm

Cal

Zero

10 seconds for the wait symbol to disappear. Verify that the

display reads 0 ±50 pW.

4. Press to calibr ate the p ow er m ete r.

Cal

5. Turn the pow e r referenc e on by pressi ng

■ , on the Agilent E4418B.

■ , , , on the

Power Ref Off On

Cal

More

Cal

Cal

Power Ref Off On

Agilent E4419B.

6. Connect the 30 dB attenuator as shown in Figure 2-6.

Power M e t e r

Agilent E-Series

Pow er Sens or

Agilent 11708A

30 dB ATTENUATOR

CHANNEL A

HP 11730A

Figure 2-6: Sensor Function al Test Setup with Attenuator

7. Press , , and select to “LOWER”.

Inputs

Input Settings Range

This s witch es to th e power sensor’s l ow rang e.

8. Verify that the display reads -30 dBm ±1 dB. Rec o rd the read i ng.

9. Press and set to “UPPER”. This switches to the power

Range

sensor’s upper range.

10. Verify that the display reads -30 dBm ±1 dB. Record t he re a d i ng.

11. Press and set to “LOWER”.

Range

12. Disconn e ct th e 30 dB attenuato r and rec onnect as shown in

Figure 2-5.

13. Verify that an overload error is displayed on the status line at the

top of the power meter’s display.

14. Press and set to “UPPER”.

Range

15. Verify that the display reads 0 dBm ±1 dB. Record the reading.

Agilent E4418B/E4419B Service Guide 2-21

Page 56

Per formance Tests

Agilent E-Series Power Sensor Functional Test

Table 2-6: Functional Test Result

Test

ChannelA

Overload Error

Low Range, 30 dB pad

Upper Range, 30 dB pad

Low Rang e, no pad

High Range, no pad

Channel B

Overload Error

(Agilent E4419B

Only)

2-22 Agilent E4418B/E4419B Service Guide

Page 57

Performance Test Record

Performance Test Record

Model Agilent E4418B/E4419B Power Meter

Tested by ___________________________________________

Serial Number ________ _______________________________

Date _______________

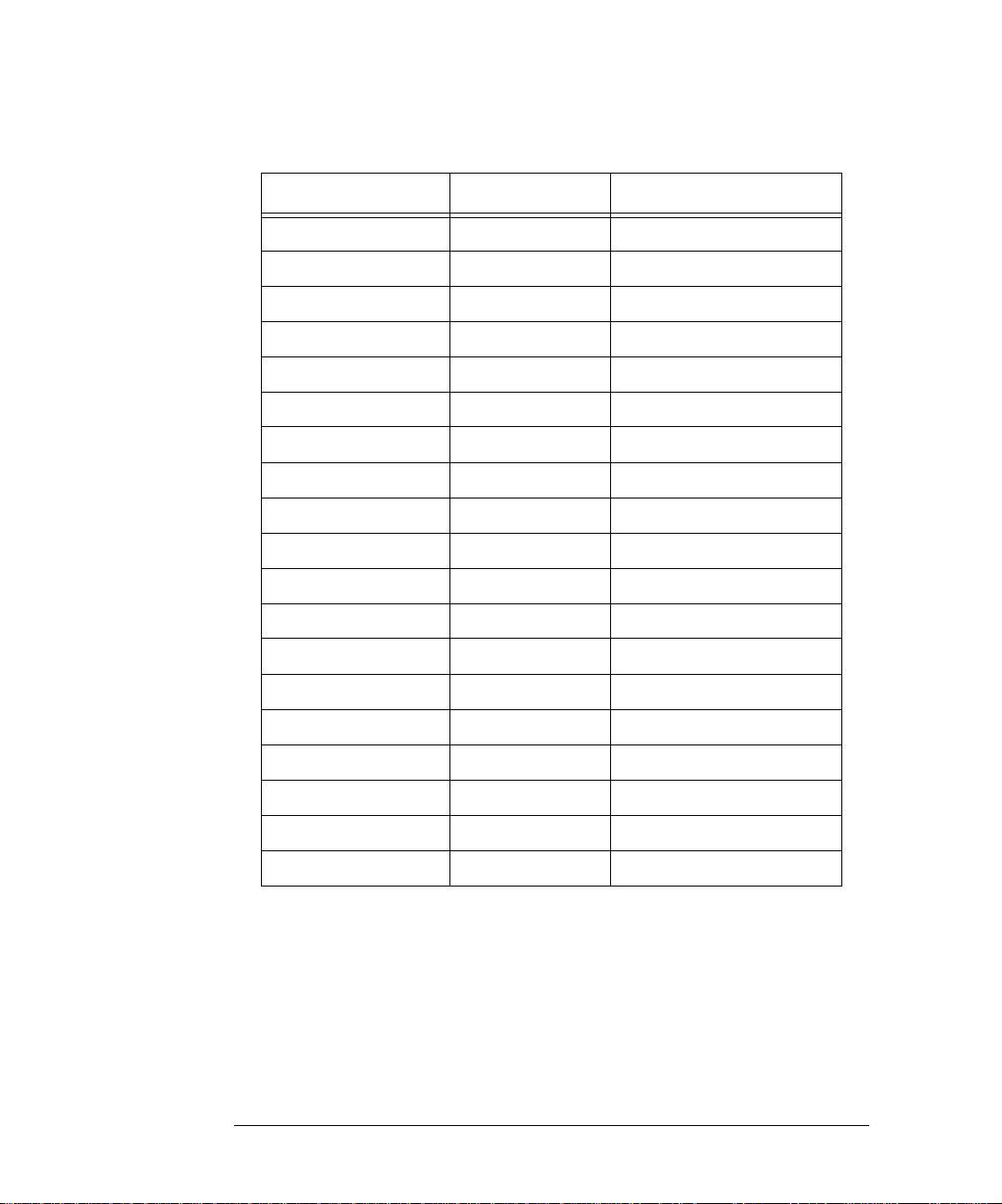

Table 2-7: Performance Test Record

Performance Tests

Test

Zero Test −76.40 nW +76.40 nW

Instrument Accuracy

3.1623 µW

10 µW

31.6228 µW

100 µW

316.227 µW

1 mW

3.1623 mW

10 mW

31.6228 mW

100 m W

Power Reference

P

meas

Interface Test Pass/Fail ___________ ___________ Pass/Fail

Functional Test

Low Range, 30 dBm pad

Low Range, 30 dBm pad

Low Range, no pad

Upper Range, no pad

Min

Result

3.0977 µW

9.904 µW

31.428 µW

99.49 µW

314.72 µW

0.9954 mW

3.1477 mW

9.954mW

31.477 mW

99.54mW

0.999 mW ___________ ___________ 1.001 mW

Pass/Fail

Pass/Fail

Pass/Fail

Pass/Fail

Channel A

Actual

Result

___________

___________

___________

___________

___________

___________

___________

___________

___________

___________

___________

___________

___________

___________

Channel B

Actual

Result

___________

___________

___________

___________

___________

___________

___________

___________

___________

___________

___________

___________

___________

___________

Max

Result

3.2269 µW

10.096 µW

31.819 µW

100.51µW

317.74 µW

1.0047 mW

3.1769 mW

10.046 mW

31.769 mW

100.46 mW

Pass/Fail

Pass/Fail

Pass/Fail

Pass/Fail

Agilent E4418B/E4419B Service Guide 2-23

Page 58

Per formance Tests

Performance Test Record

Test

Output Standing Wave

Ratio Test

1. This test is not channel relat ed.

2. For instruments with the 50MHz 1mW output (power ref) connector mounted on the

front panel .

For instruments with the 50MHz 1mW output (power ref) connector mounted on the rear

3.

panel. This applies to models E4416A and E4417A with option 003 fitted.

1

Min

Result

N/A

Channel A

Actual

Result

___________ ___________

Channel B

Actual

Result

Result

1.06

1.08

Max

1, 2

1, 3

2-24 Agilent E4418B/E4419B Service Guide

Page 59

3

Adjustments

Page 60

Adjustments

Introduction

Introduction

This chapter descr ibe s adjustments and che cks which ensure prope r

performance of the power meter. Adjustments are not normally required

on any fixed periodic basis , a nd normal l y are perf ormed only af ter a

performance test has indicated that some parameters are out of

specification . Performanc e tests should be complete d after any rep air s

that may have altered the characte r istic s of th e po wer m e ter. The test

results will make it pos sible to determine if adjustments are required.

Allow 30 minutes for the power meter to warm up, and then remove the

cover, for access to the test and adjustment points.

T o determine which performan ce tests and adjustments to perform after a

repair, see “Post -Repa i r Adjustments”, on page 3-3.

Safety Considerations

This warni ng must b e fol l owe d for your protection and to avoid damage to

the equipment being used.