AEG-Electrolux EXE 460 User Manual

Instructions

for the use and installation of gas cookers

Notice d’emploi

pour l’installation et l’utilisation des cuisinieres à gaz

GB

F

ATTENTION

This owner’s manual is valid for the Country mentioned on the appliance.

Keep this manual close to hand and preserve it for any further consultation.

The packing components (plastic bags, foamed polystyrene, nails, etc...) are a source of potential risk; never leave them within the reach of children.

If you use the grill keep the oven door half-open and the grill deflector assembled as shown in the instructions booklet. The glass cover (only on some models), before lighting the over burners of the top and until their turning off, shall be in open position; it is important to avoid any contact with cookware during the cooking in order to save from a dangerous overheating.

Important

After the cooker use it is recommended to:

1)always check that the knobs are in the “ ” position.

” position.

2)close the cock of the gas cylinder (if you use liquefied gas) or the supply cock (in case of natural gas).

3)periodically check the wear of the hosepipe and replace it if necessary. Do not repair it.

IMPORTANT:

The appliance must be installed only by qualified and competent technicians in compliance with the national provisions in force. Any modification that should be necessary to the domestic system in order to install the appliance shall be carried out by qualified technicians only. The manufacturer declines all responsibility for any damage caused by the non-observance of the rules in force or due to an improper installation.

For any intervention please apply to an authorised aftersales servicing centre and ask for original spare parts.

REMARK: during and after the use, the glass of the oven door and accessible parts can be very hot; it is therefore necessary to keep children away from the appliance.

-Make sure that there is a regular air circulation around the gas appliance. A poor ventilation reduces the oxygen.

In case of doubts consult the installer.

-The forming of fat or other food can start a fire. Carefully mind the cooking with oils and fats.

-This appliance has been designed exclusively for the cooking of food. Any other use (e.g. environment hating) is considered improper and dangerous.

-Do not install the cooker near flammable material (e.g. curtains, tea towels, etc...)

-Never clog the holes on the bottom of the oven. Do not cover with aluminium sheets the oven walls, especially the lower side.

-Always close the cock of gas supply before any cleaning and maintenance operations.

-The oven parts in contact with food are made with materials in compliance with the provisions of Directive EEC 89/109 dated 21/12/88.

-The cooker complies with the European Directives as to gas EEC 90/395, EEC 93/88 and provisions EN 30-11 and EN 2-1.

-Before operating on the unit remove the plastic films.

MODELS SPECIFICATIONS

|

|

Fig. 1 |

2 |

|

|

a |

B |

|

|

|

|

1 |

|

|

a |

|

|

100 |

|

|

C1 |

2 |

|

|

a |

B |

|

C2 |

|

|

|

|

|

|

1 |

|

|

a |

|

|

100 |

|

|

C1 |

|

|

C2 |

COOKER DIMENSIONS |

|

80x50 |

80x50 |

90x60 |

90x60 |

AND CHARACTERISTICS |

|

with cylinder |

|

with cylinder |

|

|

|

compartment |

|

compartment |

|

|

|

|

|

|

|

Height of top |

a1 |

85 ± 2 cm |

85 ± 2 cm |

85 ± 2 cm |

85 ± 2 cm |

|

|

|

|

|

|

Depth |

c1 |

51 cm |

51 cm |

60 cm |

60 cm |

|

|

|

|

|

|

Width |

B |

80 cm |

80 cm |

90 cm |

90 cm |

|

|

|

|

|

|

Height of topof open lid |

a2 |

129 ± 2 cm |

132 ± 2 cm |

141 ± 2 cm |

141 ± 2 cm |

|

|

|

|

|

|

Depth with oven door open |

c2 |

88 cm |

90 cm |

98 cm |

104 cm |

|

|

|

|

|

|

Working capacity |

|

44 dm3 |

74 dm3 |

58 dm3 |

135 dm3 |

|

|

|

|

|

|

Class |

|

1 |

1 |

2 subclass 1 |

2 subclass 1 |

|

|

|

|

|

|

Burners |

|

Burners adaptable for operation with LPG - natural gas |

|||

|

|

|

|

|

|

Operating voltage |

|

|

220 Volt - 60 Hz |

|

|

|

|

|

|

|

|

INSTRUCTION FOR USE

COOK-TOP

|

gas supply closed |

|

maximum |

|

gas position |

|

|

|

minimum |

Fig. 2 |

gas position |

BURNERS USE

MANUAL LIGHTING OF THE COOK-TOP BURNERS

Put a lighted match to the burner, hold down and press the proper knob to the left up to the max  .

.

Turn the knob to the minimum position in order to reduce the flame  (small flame).

(small flame).

On the control panel next to each knob is drawn a flame schema where it is indicated the burner position to which the knob refers to. (fig. 2).

2 |

|

GB |

|

LIGHTING THE BURNERS OF THE COOK-TOP EQUIPPED WITH SAFETY THERMOCOUPLE

(automatic stop of gas supply in case of accidental flame putting out).

In case of lack of electricity light the burner with a match, following the instructions given in the previous paragraph. After lighting keep hold down the knob for about 10 seconds. The gas supply can be cut off by turning the knob clockwise on the position  (gas supply closed).

(gas supply closed).

ADVICE FOR SAVING ENERGY

Avoid using cookware of diameter too small as to the burner used, so that the flame does not flow out of the container. When it starts boiling low the flame to the minimum turning the knob to the left (fig. 3).

The use of burners depending on the cookware type shall be as follows:

Rapid burner |

R1 |

Cookware diameter 24/26 cm |

Rapid burner |

R2 |

Cookware diameter 20/22 cm |

Semi-rapid burner |

B |

Cookware diameter 16/18 cm |

|

|

|

Auxiliary burner |

A |

Cookware diameter 12/14 cm |

|

|

|

Extra-rapid burner |

Ø 130 |

Cookware diameter 24/26 cm |

Fish Kettle burner |

P |

Cookware diameter 26 oval |

|

|

35x13 cm |

Triple crown burner |

|

Cookware diameter 24/26 cm |

Kwali BK |

|

|

|

|

|

REMARKS

The gas cooker during its

operating produces heat and humidity in the room where it

is installed.

Therefore the local needs a good airing; keep unclogged the opening of the natural ventilation and activate the airing mechanical device (extractor hood or electric fan).

In case of an intensive or long use of the appliance it is necessary additional airing, e.g. open a window or more effective ventilation increasing the power of the mechanical aspiration (if any).

If the appliance is equipped with cover in tempered glass, this can burst if overheated.

Turn off any burner before closing the cover.

The cooker with enamelled support grids are supplied with a small reduction grid which shall be used for heating cookware of small diameter, exclusively on the auxiliary burner.

In case of convex pots (wook-type) it is necessary to use on the Kwali triple-crown burner grid, the special reduction grid, while if you use normal cookware with flat bottom it is necessary to put on the grid a ring in order improve the burner functioning.

USING ELECTRIC PLATES

The electric heating plates can be put on by turning the proper knob on the control panel (fig. 4). A yellow light indicates its functioning. The cooker is equipped with the following plates:

Standard plate: Ø 110 P = 800 700 W

Ø145 P = 1000 W Rapid P = 1500W

Ø180 P = 1500 W Rapid P = 2000W

Every plate is controlled by a 7 positions selector (6 working position + 0). The highest position corresponds to the max power, while the position 1 is the minimum.

The right quantity of heat for cooking can be obtained by selecting intermediate positions.

|

6 |

|

1 |

|

|

|

|

5 |

|

|

2 |

|

|

4 |

3 |

|

|

|

Fig. 4

PRACTICAL ADVICE

During the first plate insertion and in order to eliminate any trace of residual humidity in the insulator, arrange for its drying by switching on the plate for 30 minutes in position 1 without cookware.

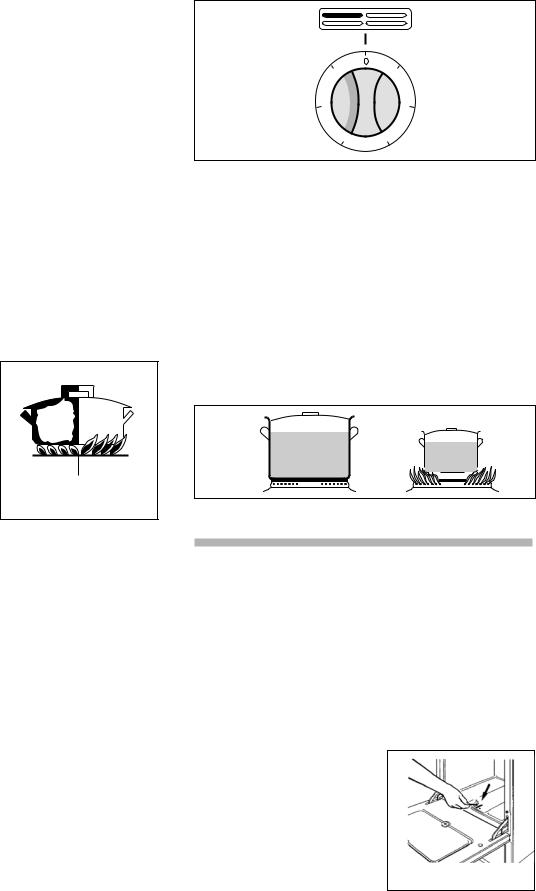

It is possible to save energy consumption by using cookware with flat and thick bottom (fig. 5). Never use cookware with diameter lower than the plate.

Do not forget the plates on without cookware or with empty vessels and make sure that the bottom of the cookware is perfectly dry.

For a good preservation, after the use the plate shall be lightly greased with a cloth soaked with oil so that the surface appears clean and shining.

YES |

NO |

Fig. 5

OVEN AND GRILL

USING THE GAS OVEN Manual lighting of the oven

Open the oven door. Put a flame to the proper holes present on the bottom of the oven (fig. 6), hold down and turn to the left the proper knob on the control panel marked by the  symbol up to the maximum position (big flame).

symbol up to the maximum position (big flame).

Once it is on, keep pressed the knob for about 10 seconds and make sure that the burner is lighted observing it by the hole (fig. 6). The flame can be reduced turning the knob up to the minimum position (small flame) and acting on the temperature selected.

Before introducing food it is recommended to heat the oven for 15 minutes at the maximum position. For the lighting of the oven burner equipped with thermostat, follow the above mentioned instructions, keeping in mind that the indicator of the

control knob shall be turned to

Fig. 6

the max. position (fig. 7).

GB |

|

3 |

|

|

|

|

|

The oven burners are provided |

|

|

|

|

|

with safety thermocouple |

|

|

|

|

|

(automatic stop of gas supply |

|

|

|

|

|

||

|

|

|

|

||

|

|

|

min |

in case of accidental flame |

|

|

|

|

putting out). |

||

|

|

|

150 |

||

|

|

|

Therefore keep pressed the |

||

|

|

|

|

||

|

|

|

175 |

knob for about 10 seconds. |

|

max |

|

|

If the burner is off, release |

||

285 |

|

|

205 |

||

235 |

the knob and wait for a |

||||

|

|

||||

|

|

|

|||

Fig. 7 |

|

|

|

minute before trying again |

|

|

|

|

with the lighting. |

||

|

|

|

|

||

|

|

|

|

||

In case of accidental burner put out, turn the knob in closed

position and wait for one minute before relighting it. REMARK

During and after the use, the glass of the oven door and accessible parts can be very hot, it is therefore necessary to keep children away from the appliance. The oven parts in contact with food are made with materials in compliance with the provisions of Directive EEC 89/109 dated 21/12/88.

INDICATIVE TABLE FOR USING THE OVEN

The data reported are purely as and indication: experience and personal taste will suggest you any variations for the best use of the appliance.

POSITION |

OVEN |

FOOD |

COOKING |

|

OF THE |

TEMPERATURE |

TIME |

||

|

||||

OVEN GRID |

°C |

|

|

|

HIGH |

150 - 170°C |

Meringue - Sweets |

40 min. |

|

|

|

|||

Legumes - Flat bread |

45 min. |

|||

|

|

|||

MEDIUM |

180 - 200°C |

Soufflè - Puddings |

35 min. |

|

|

|

|

||

HIGH |

Pigeon - Pheasant |

65 min. |

||

|

||||

MEDIUM |

210 - 230°C |

Cakes - Short pastry |

30 min. |

|

HIGH |

Chicken - Veal |

80 min. |

||

|

||||

MEDIUM |

240 - 260°C |

Lamb - Pork |

60 min. |

|

Dentex - Lasagne |

90 min. |

|||

|

|

|||

MEDIUM |

270 - 280°C |

Pizza - Gratins |

30 min. |

|

|

|

|

||

LOW |

Bread - Fish |

50 min. |

||

|

USING THE GAS GRILL

Manual lighting of the grill burner

Open the oven door completely. Put a lighted match to the grill burner which is on the upper side of the oven (fig. 8). Press and turn to the right the oven knob up to the grill position (fig. 7). Check that the flames of the burner are regularly lighted on both sides.

Fig. 8 |

|

Fig. 9 |

Fig. 9/1 |

4 |

Using the turnspit

(available on some models)

The turnspit is operated by turning the oven knob to encounter the symbol  together with the grill.

together with the grill.

First of all, place the food on the spit, using the two special forks to hold it in place. Take care to distribute the weight evenly, to prevent unnecessary strain on the motor (fig. 9/1). Then place the end of the spit in the motor hole, and the opposite end on its special support. Unscrew and remove the plastic handle and turn on the grill. The oven burners are provided with safety thermocouple (automatic stop of gas supply in case of accidental flame putting out). Therefore keep pressed the knob for about 10 seconds.

If the burner is off, release the knob and wait for a minute before trying again with the lighting.

In case of accidental burner put out, turn the knob in closed position and wait for one minute before relighting it.

ATTENTION

During the use of the grill the door of the oven shall be opened. It is besides necessary to insert the grill deflector - D- as shown in fig. 9. Put the tongues in the slots F or P placed on the upper front side of the oven. Then fix the deflector pressing it downwards.

This prevents an overheating of the control panel available in some models it's possible to grill with the oven door closed, in this case read the allegate instruction “cool door sistem”.

ATTENTION

During the grill functioning, the accessible parts can be hot. Keep the children at a safe distance.

COOL DOOR SYSTEM

During use of the grill burner on its own or simultaneously with the oven burner, the oven door must be SHUT.

This prevents overtheating of the control panel.

CAUTION: Check that the gas pressure at the cooker inlet is

as required: LPG: |

280-300 mm H2O |

Natural Gas: |

180-200 mm H2O |

Pressure different from those indicated may cause the appliance to overheat dangerously.

COOKING WITH THE GRILL

Before introducing the dishes, let the radiant plate grow redhot, and then arrange the dishes on the grid and position the dripping-pan on the immediately lower guides for the dripping collection. The oven parts in contact with food are made with materials in compliance with the provisions of Directive EEC 89/109 dated 21/12/88.

USING THE ELECTRIC OVEN

The electric oven is heated by a lower resistor placed on the bottom of the oven and by an upper resistor placed on the top. The electric thermostat automatically connects and disconnects the resistors in order to keep the desired temperature. Turning the knob on the control panel marked by the symbol  (fig. 10) it is possible to regulate the oven at the selected temperature from 50° and 260° C. The knob can be turned beyond its position if you want to activate or the lower resistor, or the upper resistor, or the grill resistor. Before introducing the food it is advisable to heat the oven for 2 minutes at max. temperature.

(fig. 10) it is possible to regulate the oven at the selected temperature from 50° and 260° C. The knob can be turned beyond its position if you want to activate or the lower resistor, or the upper resistor, or the grill resistor. Before introducing the food it is advisable to heat the oven for 2 minutes at max. temperature.

Once the food is put in the oven, turn the knob on the desired temperature.

Oven knob positions (fig. 10):

-The symbol  (light oven ON; it’s on with any function)

(light oven ON; it’s on with any function)

-The values of different temperatures 60-110-160-220-240

-Max

-the symbol  (lower resistor

(lower resistor

|

connection only) |

|

|

|

- the symbol |

(upper resistor |

|

|

|

|

connection only) |

|

|

|

- the symbol |

(grill resistor |

60 |

|

|

|

connection only) |

|

|

|

|

|

|

|

|

- the symbol |

(grill resistor + |

011 |

|

max |

|

rotisserie) |

60 |

240 |

|

A red indicator light signals the |

|

|||

1 |

200 |

|

||

|

|

|

|

|

connection of one of the electric |

Fig. 10 |

|

|

|

component. |

|

|

|

|

GB

ATTENTION

-During the functioning the oven door is hot. It is recommended to keep children at safe distance. To prevent the contact with the oven door, it is available an additional safety device. It is recommended to assemble this device in case of presence of young children. Ask for this device to the servicing centre with relative instructions for its assembling.

The use of detergents, abrasive powders or paste, can damage the surfaces.

It is recommended to clean immediately any lemon spots, vinegar and acid substances, in order to preserve the enamel brightness.

The grids and burners can be taken away and easily washed in warm water and soda.

OVEN

It is advisable to clean the oven periodically. While it is still warm clean with a cloth soaked with warm water and detergent, followed by a careful rinsing and drying.

The bottom of the oven can be easily extracted and washed in the washbasin together with dripping-pan and gridiron shelf.

IMPORTANT:

Check the wear of the gas hosepipe connecting the cooker to the cylinder and replace it in case of anomalies. It is recommended to change it yearly; in any case within the date impressed on the hose.

The replacement of spare parts and maintenance operations shall be carried out by qualified personnel only.

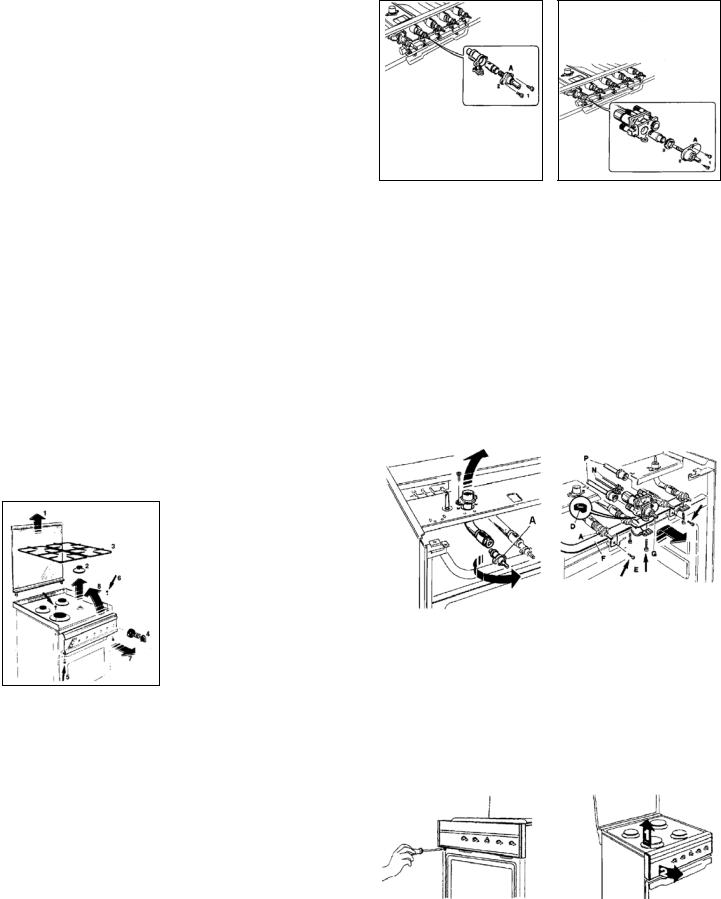

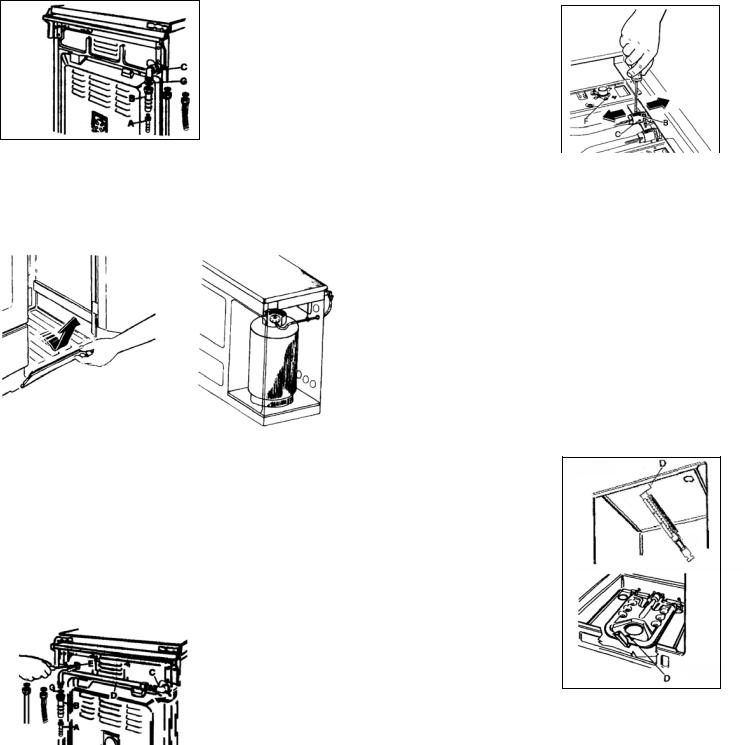

If it is necessary to intervene on gas door placed under the cook-top (thermostat valves, injectors, etc....) unscrew the two screws fixing the top on the back and after taking away the top support grids and burners, lift it by turning it on back pins. Follow the sequence indicated in fig. 11. To disassemble the cooker, proceed in the reverse order.

SPARE PARTS

REPLACEMENT

For special spare parts replacement it is necessary: To apply to the SUPPLIER

o r AU T H O R I Z E D AFTER S A L E S S E R V I C I N G CENTRE.

Provide with the indications reported on the DATA PLATE. It is placed on the

lower side of the chafing dish or on the back of the cooker.

With all data and technical documentations of the cooker, the technician will be able to supply with the requested parts and start the repairing of his competence.

Always ask for original spare parts.

GREASING THE THERMOSTAT VALVES

In case a cock is blocked or stiff during the turning, it is necessary to change the grease as follows:

-Close the on-off valve of the gas system or cylinder.

-Unscrew the screws fixing the cook-top (fig. 11)

-Take away the burners caps, caps and support grids

-Lift up the cook-top

-Unscrew the screws of the control panel and remove it.

-Unscrew both screws fixing the cover ( A fig. 12 - 12/a)

-Extract the plug of the cock.

-Clean accurately both the plug and its seat

-Sprinkle the plug with a thin coat of special grease, insert it in its seat and rotate it few times.

-Re-extract the plug and eliminate the grease in excess, checking that the gas holes are not clogged.

-Reassemble any parts carefully following the reverse orders.

Fig. 12A

Fig. 12

COCKS AND THERMOSTAT REPLACEMENT

Replace the cock (or thermostat) as follows:

-close the gas supply valve;

-take away the control panel

-disassemble the burners as shown in fig. 13

-unscrew the check nut “P” of the connection inclines of the oven burner and grill (see fig. 11); in case of cookers with safety thermocouple it is necessary to unscrew the N nut in order to remove the thermostat and cocks.

-Take away the fixing support and unscrew the E screws

-Remove partially the F incline

-Unscrew the E screws in order to remove the A cock and G thermostat, change D gasket every time you replace a cock in order to ensure a perfect seal between the body and incline F.

Fig. 13 |

|

Fig. 14 |

|

|

|

After having dismounted the knobs it is possible to remove the control panel by unscrewing the left lower visible part as shown in the picture; acting upwards remove the left terminal and extract the control panel. Then extract the control panel of the right terminal which is fixed to the cooker.

Turn the above mentioned terminal to outside and lift up the cook-top (fig. 15-fig. 15/b).

Fig. 15 |

|

Fig. 15/B |

|

|

|

GB |

|

5 |

|

||

|

USE OF ACCESSORIES

Timer

Your range can be fitted with this accessory that you can wind by rotating the corresponding knob clockwise by one complete turn and set the pointer to the desired cooking time (expressed in minutes) by rotating the knob counterclockwise.

The set time running out will be signaled by a bell.

Electric timer

Your range can be fitted with this accessory acting both as a clock and as a timer as well. To set hour push and rotate the small knob counterclockwise. To set minutes rotate the small knob counter clockwise without pushing it.

Timer with cooking end function

Your range can be fitted with this double functional accessory: it can show the cooking time that has already passed and automatically turn off the oven. You can set the desired cooking time by rotating the timer knob clockwise by one complete turn and set the pointer to the desired cooking time (expressed in minute); when this time has passed the acoustic warning signal switches on and contemporaneously the automatic cooking end device starts.

As far as the oven connection modes are concerned please refer to the handbook specific paragraphs.

If you desire to use the oven without the timer function you should turn the knob to the symbol

(manuel).

(manuel).

N.B. When the knob pointer is set to “0” position, oven cannot work.

Electric clock supplied with cooking end device

Range can be fitted with this double functional accessory: it consists of a clock able to turn off oven automatically when the set cooking time has run out.

To set hour push and rotate the small knob counterclockwise. To set minutes rotate the small knob counterclockwise without pushing it. When the set time has run out the acoustic warning signal starts to inform that oven is off.

Turn the knob to the symbol  to stop it.

to stop it.

If you desire to use oven without setting a cooking time you should rotate the knob pointer counterclockwise to the symbol

(manuel).

(manuel).

N.B. When the knob pointer is set to “0” position and to symbol, oven cannot work.

Electronic programmer

Your range can be fitted with this accessory whose main functions are:

-Clock (to be set with push buttons 2 and 3).

-Timer (to be set with push button 1).

-Cooking time (to be set with push button 2).

-Cooking end time (to be set with push button 3).

-Manual working (to be set with push button 4).

-Regulation of times “backward” (to be set with push button 5).

-Regulation of times “forward” (to be set with push button 6).

The digital display “D” (see pict. 4 at the end of this handbook) shows the hour, the cooking time and the cooking end time.

Time setting

After the electric connection or a lack of current, on the display the “AUTO” e “0.00” signals will flash at the same time. Push and release contemporaneously push buttons 2 and 3 and start setting the current hour by pushing either button 4 or 5 within 4 seconds. Once the setting is over no symbol will be on.

Timer

Push button 1 and select your cooking time by means of either button 4 or 5.

The symbol will lit up.

symbol will lit up.

When the set time has run out, the acoustic warning signal starts and the symbol will flash. After the bell disconnection that symbol will disappear.

symbol will flash. After the bell disconnection that symbol will disappear.

Half-automatic working mode (cooking time)

By pushing button 2 and setting the cooking time by means of button 5, both the “AUTO” and the symbol will lit up. When the set time has run out, the symbol will switch off while the “AUTO” symbol flashes and the acoustic warning signal starts.

Half-automatic working mode (end of cooking time)

By pushing button 3 and setting the end of cooking time by means of button 5, both the “AUTO” and the symbols will lit up. When the set time has run out, the symbol will switch off while the “AUTO” symbol flashes and the acoustic warning signal starts.

Automatic working mode (postponed cooking start time)

First you should set your cooking time (both the “AUTO” and the  symbols will lit up) and then the cooking end time, the

symbols will lit up) and then the cooking end time, the

symbol will switch off as previously stated.

symbol will switch off as previously stated.

The

symbol will lit up again when the oven starts baking. When cooking time has run out, the

symbol will lit up again when the oven starts baking. When cooking time has run out, the

symbol will switch off while the ”AUTO” symbols flashes and the acoustic warning signal starts.

symbol will switch off while the ”AUTO” symbols flashes and the acoustic warning signal starts.

Manual working

Manual working is possible only after having cleared the automatic program by pushing button 3. The “AUTO” symbol disappears and no other symbols lit up.

Acoustic warning signal

The acoustic warning signal starts at the end of a program and lasts about two minutes. To interrupt it you should push one of the function buttons.

Program start and check

Program starts after about 4 seconds from the setting. It is possible to check the set program at any time by pushing the corresponding button.

Correction and cancellation of program

It is possible to correct the set program at any time by first pushing the relative programming button and then buttons 4 or 5. It is possible to cancel a program by changing the set time to “0.00”. By cancelling the working time you will automatically cancel the working end time and vice versa. Oven automatically switches off while the “AUTO” symbol flashes. Push button 3 to set the programmer to manual working mode.Time cannot be corrected when the automatic working program is on.

FEED CABLES TYPES |

TYPE OF |

INPUT |

AND SECTION |

CABLE |

220 V~ |

TOTAL GAS |

H05 RR-F |

3x0,75 mm2 |

MIXED UP TO 660 W |

H05 RR-F |

3x1 mm2 |

MIXED UP TO 1320 W |

H05 RR-F |

3x1,5 mm2 |

MIXED UP TO 2200 W |

H05 RR-F |

3x2,5 mm2 |

MIXED UP TO 3520 W |

H05 RR-F |

3x4 mm2 |

6 |

|

GB |

|

||

|

TECHNICAL INFORMATION FOR THE INSTALLATION

The installation and regulations shall be carried out by qualified technicians only. After removing external packaging and inside packing of movable parts, make sure of the integrity of the appliance. In case of doubts do not use the appliance and turn to qualified technicians.

Never leave packing components (carton, bags, foamed polystyrene, nails.....) within the reach of children as they represent potential dangers.

ASSEMBLY OF ADJUSTABLE LEVELLING FEET

Remove the packaging of the cooker. Assemble the feet which are in the accessories kit, fitting them in the proper fixed seats placed on the four corners of the cooker.

(fig. 16 – fig. 16/a). Align or level the cooker with other furniture by adjusting the foot.

Fig. 16 |

|

Fig. 16/A |

|

|

|

REMARKS FOR THE INSTALLATION

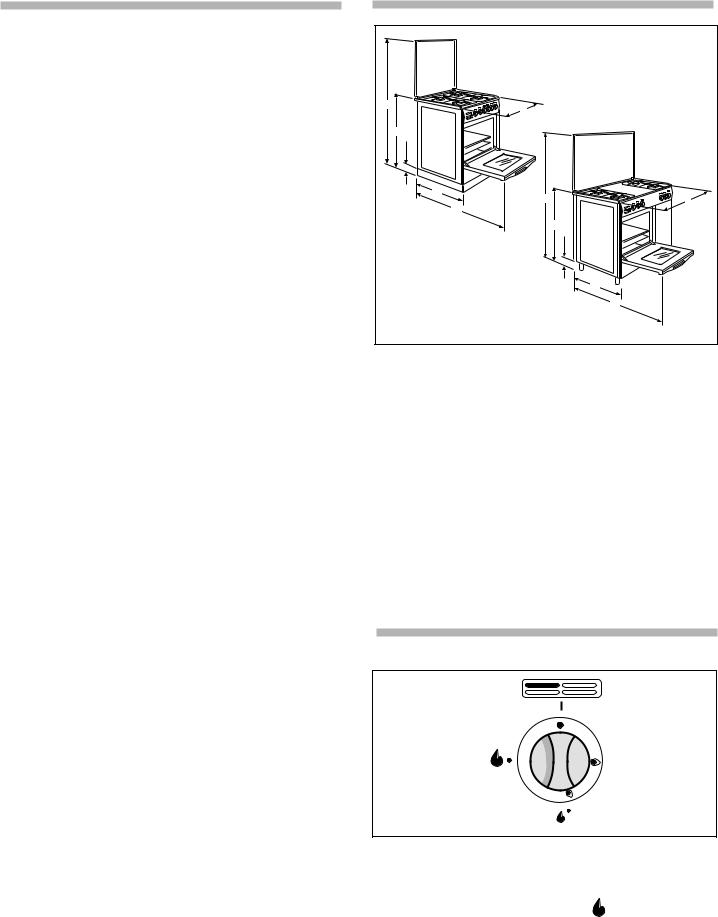

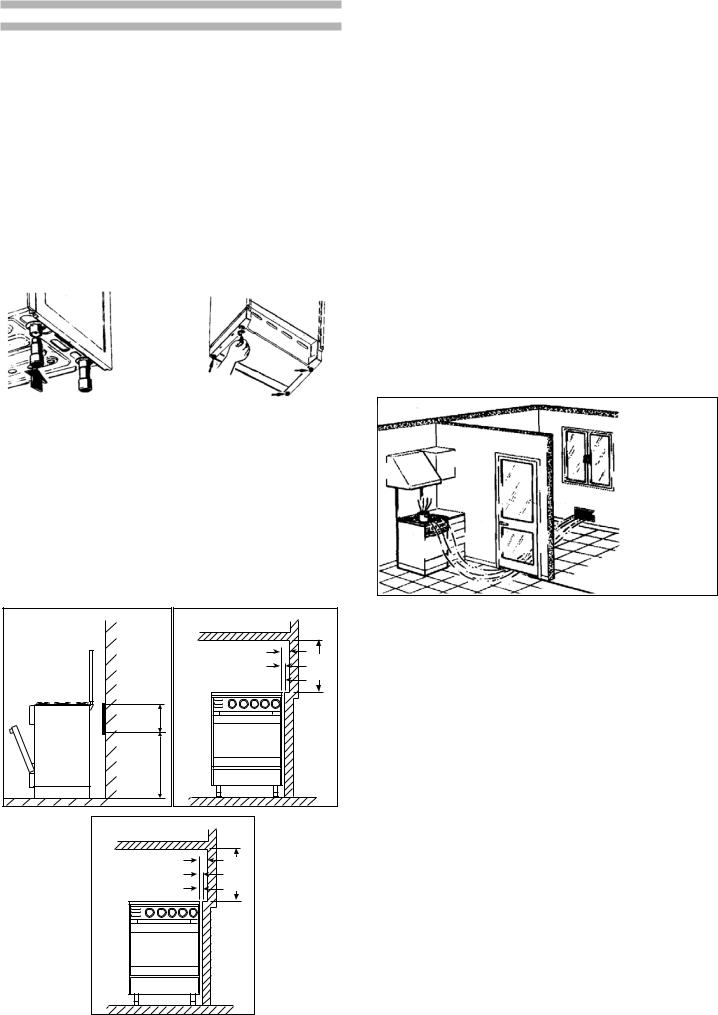

The installation shall be carried out in compliance with the national rules in force. Install the appliance in a well-aired room. Check that the flux of the gas meter and the diameter of the ducts have enough capacity for all the appliances and that the connectors are water-tightness. The gas cookers belong to Class I and therefore they shall not be put closer to furniture. The walls next to the cooker shall be resistant to a temperature of 75° C. (fig. 17) or covered with insulating material. The cooker shall be installed at a distance of 20 mm from the walls and the cook-top 650 mm from the suspended wall unit (fig. 17/a). The gas cookers belong to class II can be lean agains the walls ( fig.17/b )

Fig. 17 |

25 cm |

60 cm |

Fig. 17/A |

|

|

50 Min |

Min |

|

20 Min |

||

650 |

||

|

Fig. 17/b

50 mm Min |

Min |

|

|

5 mm Min |

650 mm |

CLASS II under Class I |

TypeY

Dimensions shown apply to BOTH sides of the appliance

Applies to base &wall units (if fitted)

ROOMS VENTILATION

Attention: this appliance can be installed and used only in constantly ventilated rooms according to the national rules in force. The right functioning of the cooker is ensured by the installation in a constantly ventilated room. The flow of air for a regular gas combustion and ventilation shall not be less than 20 m3. The natural influx of air shall be directly from the outside through openings on the wall of the room with a cross section of at least 100 cm2. These openings shall be made in a way that can’t be clogged. It is allowed the indirect airing through the extraction of air from adjacent rooms (fig. 18) in compliance with the national regulations in force.

ATTENTION:

The section of the ventilation opening of a cooker with burners not fitted with safety thermocouple should be at least 200 cm2.

POSITIONING

The gas cookers shall discharge smokes and gases from combustion by means of hoods connected to chimneypots, flues or directly outside. In absence of a hood it is permitted the use of a ventilator installed on a window or on a wall to the outside, which shall be operate simultaneously with the appliance on condition that the national rules in force are complied with.

Wider opening between door and floor

Fig. 18

CONNECTION TO THE GAS SYSTEM

Important: the installation shall be made according to the national rules in force. Install the appliance in a well-ventilated room; check that the capacity of the gas meter and the hosepipes diameter are enough to supply power to all appliances connected. Do not forget to install, upwards the appliance, a gas cock of at least 1/2”, visible and reachable.

Before connecting the appliance check the data reported on the plate placed inside the chafing dish door or on the back of the cooker reporting the type of gas, pressure and capacity of the cooker.

Connection to canalized gas system: the cooker shall be connected as indicated (fig. 19), by using:

- non-flexible steel metal pipe, copper pipe, flexible stainless steel hosepipe, rubber flexible hosepipe, the hosepipes. Shall be in compliance with the national rules in force. In case of natural gas the supply pipe shall be put on the big tubeholder (B) after screwing and taking away the reduction unit (A) (liquefied gas tubeholder) (fig. 19.)

CONNECTION TO LIQUEFIED GAS-CYLINDER SPACE

The cookers with support for cylinders are regulated for being used with LPG.

The support cylinder space is 620 mm high and 325 mm wide and can contain standard cylinders of 10 kg.

GB |

|

7 |

|

||

|

Provide the cylinder with a gas pressure reducer.

By a hosepipe of 8 mm. connect it to the reducer A, screwed on the cylinder support B (fig. 19) of the cooker ready for the connection, arranging then the cylinder in the special space (fig. 20).

IMPORTANT: follow these guidelines:

1)The flexible hosepipe shall be from 400 mm up to 800 mm. long and conform to the standards.

2)The cylinder support of the reducer shall be faced to the right side of the cylinder support space.

3)The hosepipe connection to the reducer/cooker cylinder

suppor ts shall be carried out as indicated in fig. 20, i.e.: entering the suppor t place upright and coming out from the cooker by the special back hole. For the fastening operation use clamps conform to the standards.

4)Arrange the cylinder in the special space not in contact with the oven wall.

5)During the cylinder change, do not remove the tube from its crossing.

6)Before inserting the cylinder take away the plastic base as shown in fig. 21.

Fig. 20 |

|

Fig. 21 |

|

|

|

IMPORTANT:

The hosepipe shall not present narrowing and be far from heat sources, especially the back of the oven. After the connection, check that the pipes are properly sealed, using a soapy water solution on the joints. The flexible hosepipe shall never cross from one side of the appliance to the other and be visible. In the need of a connection on the opposite side of the one provided, ask the manufacturer (see the address in the overleaf)

for additional metal hosepipe D (fig. 20-22). |

|

||

The additional pipe can be assembled as follows: |

|

||

|

a) r e m o v e |

t h e |

|

|

|||

|

tubeholder of fig. 19 |

||

|

and turn the “cross” |

||

|

coupling C fig. 22. |

||

|

b) Screw the |

metal |

|

|

pipe to the coupling |

||

|

putting in the seal |

||

|

G and fix it on the |

||

Fig. 22 |

back of the cooker |

||

by the screw E. |

|||

|

|||

|

|||

c) Assemble the tubeholder on the other end of the pipe putting in the seal G.

Carry out the connection by a proper pipe in conformity with the regulations making sure that it is perfectly put on the tubeholder and tightened by a proper fixing clamp.

Remark: the gas supply connector of the appliance is a threaded male 1/2” for round gas pipe and conforms to UNI-ISO 228-1.

The flexible hosepipe shall be replaced within the date indicated on the pipe.

Attention: the installer must ascertain that the national provisions in force have been complied with.

The manufacturer declines all responsibility for the nonobservance of the above mentioned regulations.

ADAPTING THE COOKER TO DIFFERENT TYPES OF GAS

In order to adapt the cooker |

fig. 23 |

|

to a gas different from the one |

|

|

for which it has been designed, |

|

|

it is necessary to change the |

|

|

burners nozzles, to regulate |

|

|

the air and the minimum. |

|

|

Before starting with this |

|

|

operation make sure that the |

|

|

gas cock has been closed. |

|

|

|

|

|

1°) NOZZLES REPLACEMENT |

|

|

a - Cook-top burners

Remove the support grids, the burners and burner caps of the cook-top. Unscrew the side front screws and back (if any), remove the knobs and the control panel so that the cook-top is free; lift it up (consult maintenance chapter fig.11). Disassemble the Venturi pipes, unscrewing the screws F (fig. 13). From the nozzles-holder tag (supplied with) chose the proper injector for any burner and type of gas, following the indications reported.

By means of a 7 mm socket wrench replace (unscrewing) the nozzles on the valves. With the cook-top lifted up, assemble the burners and the burner caps. Regulate the primary air and the minimum as indicated in chapter 2 and 3. Once the regulations has been carried out as described in the following paragraphs, seal the regulation elements and replace the old label on the appliance with the one reporting the new type of gas.

b - Oven burners

Remove the oven accessories, the lower plate and unscrew the back screw D, fixing the burner to the bottom of the oven, in order to take it away and enter the injector (fig. 24) By means of the socket wrench of 7 mm. unscrew the injector.

Once the proper injector has been assembled, remount the burner of the oven.

GRILL

OVEN

Fig. 24

c - Grill burner

It is possible to enter the injector taking away the burner fixed on the top of the oven by the front screw D (fig. 24). Change the injector in the same way as per the oven and reassemble the grill.

It is recommended to put the replaced injector in the proper accessory kit and preserve them.

WARNING

Check that the gas pressure at the entry of the appliance is the correct one.

8 |

|

GB |

|

||

|

L.P.G. 30 mbar Natural gas 20 mbar

2°) REGULATION OF THE AIR OF BURNERS

The air regulation is very important for a good combustion and best performance of the burners with a consequent save of energy.

If the flame is not uniform around the burner it means that there is excess of air; if it presents yellow points there is black of air.

A well-regulated flame shall be not so luminous and light blue. For the regulation act on the rings (fig. 23) in order to obtain the opening stated in the following table.

Type of burner |

L.P.G. 30 mbar |

G31-37 mbar |

G20-20 mbar |

|

|

|

(25-35 mbar) |

|

G25-25 mbar |

Rapid |

R1 |

18 mm |

16 mm |

11 mm |

Rapid |

R2 |

16 mm |

14 mm |

13,5 mm |

Semi-rapid |

B |

6 mm |

5 mm |

3,5 mm |

Auxiliairy |

A |

5 mm |

3,5 mm |

1 mm |

Fish cattle |

|

|

|

|

ø 130 Kwali |

|

18 mm |

16 mm |

11 mm |

BURNERS OF THE COOK-TOP

Unscrew the B screw and let the ring C slides (fig. 23) so that it opens or closes the air passage until getting a correct flame, uniform and blue.

3°) MINIMUM REGULATION

Regulation of the minimum of the burners of cook-top and of the oven without thermostat: Turn a burner at a time to maximum position. Remove the knob, turn the cock to the left to the MIN. position and by the screw inside the shaft regulate the minimum until getting a small but uniform flame even with sharp passages from minimum to maximum, with burner cold. For cock with valves the regulation screw H is on the side of the rod (fig. 25). Regulation of the minimum of oven burner with thermostat. Remove the bottom plate of the oven, light the burner at maximum (oven knob on max. position), close the oven door and wait for 10 minutes. Take the knob away and unscrew the minimum screw placed on the cock/thermostat. Reassemble the knob and turn it to the MIN position. Take away the knob and reassemble the minimum screw H until getting a small flame but uniform even with sharp passages from minimum to maximum and with fast closing of the door. (fig. 26) The regulations shall be carried out only with natural gas burners while with liquefied gas burners they shall be blocked.

Fig. 25 |

|

Fig. 26 |

|

|

|

BEFORE CALLING

THE AFTER-SALES

SERVICING CENTRE

If the appliance does not function correctly, before turning to after-sales servicing centre check the following:

The gas flux is not regular.

Make sure that:

-the holes of the burners are not clogged

-in the cylinder there is still enough gas

-the pressure regulator is functioning

-the valve of the cylinder is completely open

There is smell of gas in the room

Make sure that:

-a cock is not open

-the gas supply pipe is well positioned or in good condition, remember to replace it once per year.

Do not search a lack of gas with a match; check the seal by soapy water.

The oven or the grill do not heat

Make sure that the oven knob is ON Cooking times too long

Check that the temperature set is the most suitable for the food to be cooked.

The oven sends out smokes

It is recommended to clean it after any use. During meat cooking it is possible the forming of fat splashes that, if not cleaned, could case smoke and smell to the following cooking (see the paragraph regarding the cleaning). If after the above mentioned check the appliance does not function turn to the nearest servicing centre, supplying any data relative to the appliance model and serial number.

HOB BURNER |

|

|

|

-WMAX |

-WMIN |

L.P.G. 30 mbar |

NATURAL GAS |

|||

|

|

|

25-35 mbar |

20 mbar |

||||||

|

|

|

|

|

Nominal thermalcapacity |

Nominal thermalcapacity |

40,40 Mj/Kg. |

37,78 Mj/Kg. |

||

|

|

|

|

|

Injectorsize mm1/110ø |

gr/h |

Injectorsize mm1/110ø |

gr/h |

||

|

|

|

|

|

|

|

(13,76kWh/Kg) |

(11,10kWh/m3) |

||

|

|

|

|

|

|

|

|

|

|

|

Rapid burner |

|

R1 |

L.H.F. |

|

3100 |

700 |

85 |

225 |

125 |

290 |

|

|

|

|

|

|

|

|

|

|

|

Rapid burner |

|

R2 |

R.H.R. |

|

2750 |

650 |

80 |

199 |

120 |

261 |

|

or |

|

||||||||

|

L.H.F. |

|

||||||||

Semi-rapid burner |

B |

L.H.R. |

|

1650 |

350 |

62 |

119 |

90 |

157 |

|

|

|

|

|

|

|

|

|

|

|

|

Auxiliary burner |

A |

R.H.F. |

|

930 |

290 |

48 |

68 |

68 |

89 |

|

|

|

|

|

|

|

|

|

|

|

|

Fish burner Ø 130 / P |

Central |

|

3600 |

800 |

92 |

260 |

140 |

343 |

||

|

|

|

|

|

|

|

|

|

|

|

Kwali burner |

|

BK |

Central |

|

4000 |

1040 |

95 |

290 |

145 |

380 |

|

or |

|

||||||||

|

|

|

R.H.F. |

|

|

|

|

|

|

|

|

|

OVEN AND GRILL BURNER |

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

COOKERS: |

|

Oven |

|

|

2450 |

950 |

72x |

167 |

100Y |

219 |

with tap |

|

|||||||||

80x50 |

|

Oven |

|

|

3100 |

950 |

85 |

225 |

114Y |

295 |

with thermostat |

|

|||||||||

with cylinder |

|

|

|

|

|

|

|

|

|

|

|

Grill |

|

|

|

|

|

|

|

|

|

compartment |

|

|

|

2000 |

- |

70 |

145 |

102Z |

190 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Oven |

|

|

4500 |

1040 |

105 |

290 |

150 |

380 |

80x50 |

with thermostat |

|

||||||||

|

Grill |

|

|

3400 |

- |

90 |

247 |

135 |

290 |

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

Oven |

|

|

5000 |

1600 |

110 |

305 |

165 |

400 |

90x60 |

with thermostat |

|

||||||||

|

Grill |

|

|

3200 |

- |

90 |

230 |

135 |

323 |

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

Oven |

|

|

2900 |

1040 |

84 |

211 |

12 |

276 |

90x60 |

with tap |

|

||||||||

|

|

|

|

|

|

|

||||

|

Oven |

|

|

|

|

|

|

|

|

|

with cylinder |

|

|

|

3300 |

1040 |

90 |

240 |

133 |

314 |

|

with thermostat |

|

|||||||||

compartment |

|

Grill |

|

|

2000 |

- |

70 |

145 |

105 |

190 |

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

90x60 |

|

Oven |

|

|

5000 |

1600 |

110 |

305 |

165 |

400 |

with thermostat |

|

|||||||||

grill with door |

|

|

|

|

|

|

|

|

|

|

|

Grill |

|

|

|

|

|

|

|

|

|

closed |

|

|

|

3000 |

- |

88 |

218 |

129 |

285 |

|

GAS CONNECTION |

|

|

L.P.G. 30 mbar |

NATURAL |

||||||

THERMAL CAPACITIES DETERMINED WITH THE HIGH HEATING VALUE OF THE GAS AT 15°C-1013mbar

GB |

|

9 |

|

||

|

Loading...

Loading...