Actron CP9135 Instructions Manual

OBD II

CP9135

AutoScanner

™

Performs diagnostics on OBD II

compliant vehicles 1994 and

newer

Instructions in English, Spanish, and French

Instrucciones en Inglés, Español, y Francés

Instructions en Anglais, Espagnol, et les Français

15825 Industrial Parkway

Cleveland Ohio 44135 USA (EUA)

Voltage: 16V

Tension de 16V

Tension: 16V

FULL ONE (1) YEAR LIMITED WARRANTY

Actron Manufacturing Company (“Actron”) warrants to the original purchaser that

product will be free from defects in materials and workmanship for a period of

this

(1) year from the date of original purchase. Any unit that fails within this period

one

be replaced or repaired at Actron’s discretion without charge. If you need to

will

product, please follow the instructions below. This warranty does not apply

return

damages (intentional or accidental), alterations or improper or unreasonable

to

use.

DISCLAIMER OF WARRANTY

ACTRON DISCLAIMS ALL EXPRESS WARRANTIES EXCEPT THOSE THAT

APPEAR

MERCHANTABILITY OF THE GOODS OR FITNESS OF THE GOODS FOR

OF

ANY

WARRANTY

PRODUCT

LIMITED

LONG

A SPECIFIC BUYER.)

TO

IN NO CASE SHALL ACTRON BE LIABLE FOR ANY SPECIAL, INCIDENTAL OR

CONSEQUENTIAL DAMAGES BASED UPON ANY LEGAL THEORY INCLUDING,

BUT NOT LIMITED TO, DAMAGES FOR LOST PROFITS AND/OR INJURY TO

PROPERTY.

OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THIS LIMITATION OR

EXCLUSION MAY NOT APPLY TO A SPECIFIC BUYER. THIS WARRANTY GIVES

YOU

WHICH VARY FROM STATE TO STATE.

ABOVE. FURTHER, ACTRON DISCLAIMS ANY IMPLIED WARRANTY

PURPOSE. (TO THE EXTENT ALLOWED BY LAW, ANY IMPLIED

OF MERCHANTABILITY OR OF FITNESS APPLICABLE TO ANY

IS SUBJECT TO ALL THE TERMS AND CONDITIONS OF THIS

WARRANTY. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW

AN IMPLIED WARRANTY LASTS, SO THIS LIMITATION MAY NOT APPLY

LIMITATION OF REMEDIES

SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION

SPECIFIC LEGAL RIGHTS, AND YOU MAY ALSO HAVE OTHER RIGHTS

information, illustrations and specifications contained in this manual are based

All

on the latest information available from industry sources at the time of publication.

No warranty (expressed or implied) can be made for its accuracy or completeness,

nor is any responsibility assumed by Actron or anyone connected with it for loss or

damages suffered through reliance on any information contained in this manual or

misuse of accompanying product. Actron reserves the right to make changes at any

time to this manual or accompanying product without obligation to notify any person

or organization of such changes.

TO USE YOUR WARRANTY

If you need to return the unit, please follow this procedure:

Actron Te ch Support at 1-(800)228-7667. Our Technical Service Representatives

1. Call

trained to assist you.

are

2. Proof

3. In

4. If

5. Print

6. You will be responsible for shipping charges in the event that your repair is not

of purchase is required for all warranty claims. For this reason we ask that you

your sales receipt.

retain

the event that product needs to be returned, you will be given a Return Material

Authorization

number.

possible, return the product in its original package with cables and accessories.

the RMA number and your return address on the outside of the package and

to the address provided by your Customer Service representative.

send

covered

by warranty.

OUT OF WARRANTY REPAIR

If you need product repaired after your warranty has expired, please call Te ch Support at

(800) 228-7667.

You will be advised of the cost of repair and any freight charges.

Table of Contents

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . SF-1

Section 1 - Quick Start

1.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2 Quick Start. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Section 2 - Tool Basics

2.1 Tool Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 2-1

2.1.1 Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.1.2 OBD II (J1962) Connector . . . . . . . . . . . . . . . . . . . . . . 2-2

2.1.3 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.2 Lists and Menus . . . . . . . . . . . . . . . . . . . . . . . . . . .. 2-2

2.3 Diagnostic Link Connector and Location . . . . . . . . .. 2-3

2.4 Diagnostic Trouble Codes (DTCs). . . . . . . . . . . . . .. 2-3

2.5 This Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 2-4

2.6 Vehicle Service Information. . . . . . . . . . . . . . . . . . .. 2-5

Section 3 - Using the Tool

3.1 AutoScanner Connection and Power-Up . . . . . . . . . 3-1

3.2 Read Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.3 Erase Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 3-3

3.4 MIL Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 3-5

3.5 I/M Monitors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 3-5

3.6 Tool Setup/Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

3.6.1 Changing Display Contrast. . . . . . . . . . . . . . . . . . . . . . 3-7

3.6.2 Display Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 3-7

3.6.3 Keypad Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

3.6.4 Memory Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 3-8

3.6.5 Software Identification (SW ID) . . . . . . . . . . . . . . . . . . 3-8

Section 4 - Troubleshooting

4.1 Vehicle Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.2 AutoScanner Does Not Power Up: . . . . . . . . . . . . . . 4-2

4.3 Link Errors or Erroneous Data. . . . . . . . . . . . . . . . .. 4-3

4.4 Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Appendix A - Glossary

Appendix B - About OBD II

Y

U

T

ONS

I

T

FE

A

S

A

C

E

R

P

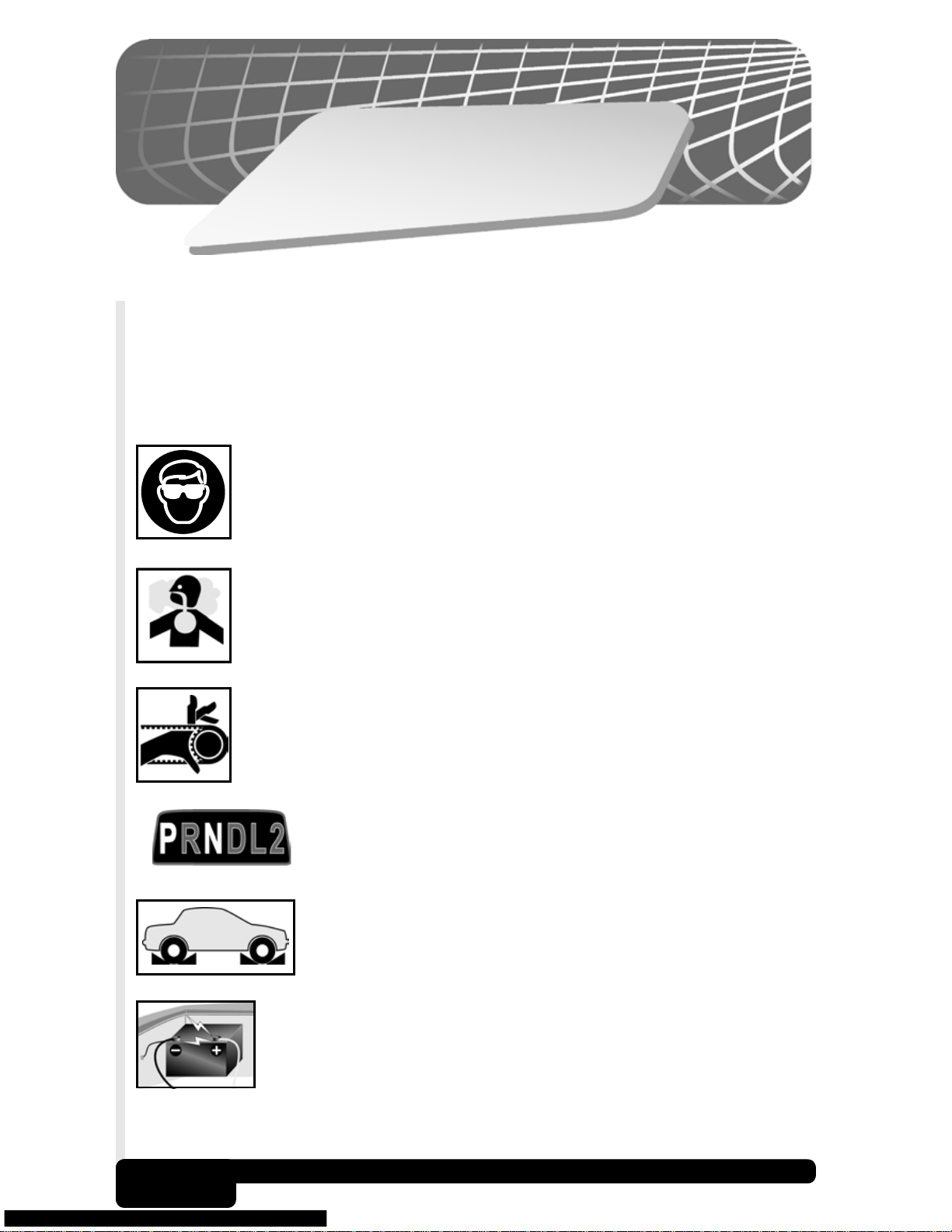

To prevent accidents that could possibly result in serious

injury and/or damage to vehicles and/or test equipment,

carefully follow all safety rules and test procedures when

working on vehicles.

Always wear ANSI approved eye protection.

Always operate the vehicle in a well-ventilated area. Do

n

ot breath exhaust gases — they are very hazardous.

Always keep yourself, tools and test e

all moving or hot engine parts.

Always make sure the vehicle is in Park (

transmission) or Neutral (manual transmission).

Ensure the parking brake is firmly set.

Block the drive wheels.

Never leave vehicle unattended while testing.

Never lay tools on vehicle battery. You may short the

terminals together causing harm to yourself, the tools or

quipment away from

automatic

SF-1

e battery.

th

Always use caution when working around the ignition coil,

distributor cap, ignition wires, a

components can produce High Voltage while the engine

is running.

Battery electrolyte is sulfuric-acid and is extremely caustic.

If contacted, rinse with water or neutralize with a mild base

i.e. baking soda). If contacted in eyes, flush with water

(

and call a physician immediately.

Never smoke or have open flames near vehicle. Vapors

from gasoline and the battery during charge are highly

mable and explosive.

flam

Never use the AutoScanner

exposed to any moisture. Internal shorts could cause fire

and damage to the tool.

nd spark plugs. These

TM

if internal circuitry has been

Always keep a fire exting

gasoline/electrical/chemical fires readily available.

• Whe

• Always turn ignition key OFF when connecting or disconnecting

• Some vehicles are equipped with safety air bags. You MUST follow

n performing road tests, never operate the tool while driving

the vehicle. Always have one person drive the vehicle and an

assistant operate the AutoScanner

electrical components, unless otherwise instructed.

vehicle service manual cautions when working around the air bag

components or wiring. If the cautions are not followed, the air bag

may open up unexpectedly, resulting in personal injury. Note that

the air bag can still open up several minutes after the ignition key is

off (or even if the vehicle’s battery is disconnected) because of a

special energy reserve module.

uisher suitable for

TM

.

• Always follow vehicle manufacturer’s warnings, cautions and

service procedures.

SF-2

1

n

o

ti

ec

S

t

r

a

t

S

uic

Q

1.1 Introduction

Congratulations!

You've purchased an automotive scanner that can unlock the fault

code information stored in the on-board computer(s) of your car or

light truck. This information gives you the power to identify and repair

problems that may arise with the operation of your vehicle's engine.

Cars and trucks cannot completely diagnose their problems, and no

scanner available can tell you with pinpoint accuracy what is wrong

with the vehicle.

Once you have retrieved the diagnostic information from the computer,

you have taken the first step in finding and fixing the problem. Now it

is time to continue with the rest of the diagnostic process.

k

Important points to remember:

• Diagnostic Trouble Codes (DTCs) warn us of a symptom or

problem with a particular engine system, not a specific part.

• The computer can only report DTCs based on what its sensors

are telling it.

• Sometimes, sensors appear to be bad when in fact, they are not.

- A poor connection, broken wire or short circuit may be preventing

the sensor signal from reaching the computer.

- A malfunction in one system may cause a sensor in another

syste

• We recommend the use of a vehicle specific service manual to

assist you with the diagnostic process.

• Some of the vehicle computer's sensors and actuators can be

pretty expensive; it is best to make sure they are defective prior

to replacing them!

m to report a value that is too high or too low.

1-1

Quick Start

The next step in the diagnostic process is to test systems and parts

that are suspected to be defective. This testing process may include:

• Sensors

• Fuel injection system

Even when working on modern, computer-controlled vehicles there is

no substitute for good old-fashioned troubleshooting.

Once you have isolated and repaired the failed problem(s), you can

use your AutoScanner to clear the codes from the computer's memory.

This will also turn off your Malfunction Indicator Lamp (MIL), or Check

Engine Light, and may reset all Inspection/Maintenance (I/M) monitor

statuses to “Not Ready”.

The following Quick Start section will help you begin to use your OBD II

AutoScanner right away. Subsequent sections of this manual contain

more detailed information to help you get the most out of your scanner.

If you have questions not covered in the manual, please call our

Technical Support line at 1-800-228-7667 (8:00 - 6:00 EST Monday Friday), or send an email to tech_support@actron.com.

• Ignition system

• Vacuum & Pressure systems

1.2 Quick Start

Connect the OBD II AutoScanner to the vehicle’s Data Link Connector

(DLC) which is normally located under the dash on the driver’s side.

Once the connection is made, the tool will turn on, boot, and then

display the Main Menu. If the display is hard to read, adjust the contrast

using the Tool Setup/Test function.

All AutoScanner functions can be performed with the Key On-Engine

Off (KOEO). The ERASE function cannot be done with the Key

On-Engine Running (KOER).

To retrieve Diagnostic Trouble Codes

(DTCs), press the READ key on the

AutoScanner. This function can be

performed with the KOEO or KOER.

If DTCs are present, they will appear on the display. Use the ▲ or ▼

keys to view the codes. The definition will continuously scroll to the left if

it is longer than the display (20 characters). To freeze the scrolling message,

press and hold the ENTER key. When done, press the BACK key to return

to the Main Menu.

Main Menu

1)Read Codes ]

CAUTION! Avoid Cooling Fan! It May Turn On During Test.

!

Quick Start

1-2

To erase DTCs, press the ERASE

key on the AutoScanner. This

function must be performed with the

KOEO - Do not START engine.

Note: In addition to clearing DTCs, the Erase Codes function may

reset the status of the I/M System Monitors to “Not Ready.”

!

If DTCs are found, the tool will display the quantity and ask the user

“Erase Codes? (Y/N).” Pressing the NO key will display the message

“Cancelled, Erase Not Performed.” Pressing the YES key will display

a scrolling message on the bottom line. Press the BACK key to return

to the Main Menu.

“Hard” codes are codes that can be removed only by repairing

!

The MIL Status function displays the status of the computer module

that commanded the MIL to turn on. If the MIL Status is ON and the

MIL is not illuminated with the engine running, then a problem exists

in the MIL circuit.

the faults that they cause; therefore, hard codes will remain in

the computer’s memory until the condition is repaired.

Main Menu

2)Erase Codes

Select the MIL Status function and

press the ENTER key. The MIL

Status of the computer will display

on the AutoScanner. Press the

BACK key to return to the Main

Menu.

The I/M (Inspection and Maintenance) Monitors function displays the

state of the vehicle’s OBD II Monitors. Monitors test the operation of

emission related systems or components and detect out-of-range

values. The vehicle may have to be operated under certain driving

conditions to initiate a monitor.

Select I/M Monitors from the Main

Menu and press the ENTER key.

Use the

the list. Note the Monitors present

and their status. When done, press

the BACK key to return to the Main Menu

▲ or ▼ keys to scroll through

Main Menu

3)MIL Status

Main Menu

4)I/M Monitors

.

Detailed instructions are provided in Section 3 and OBD II background

information is provided in Appendix B.

Quick Start

1-3

s

c

ic

s

.

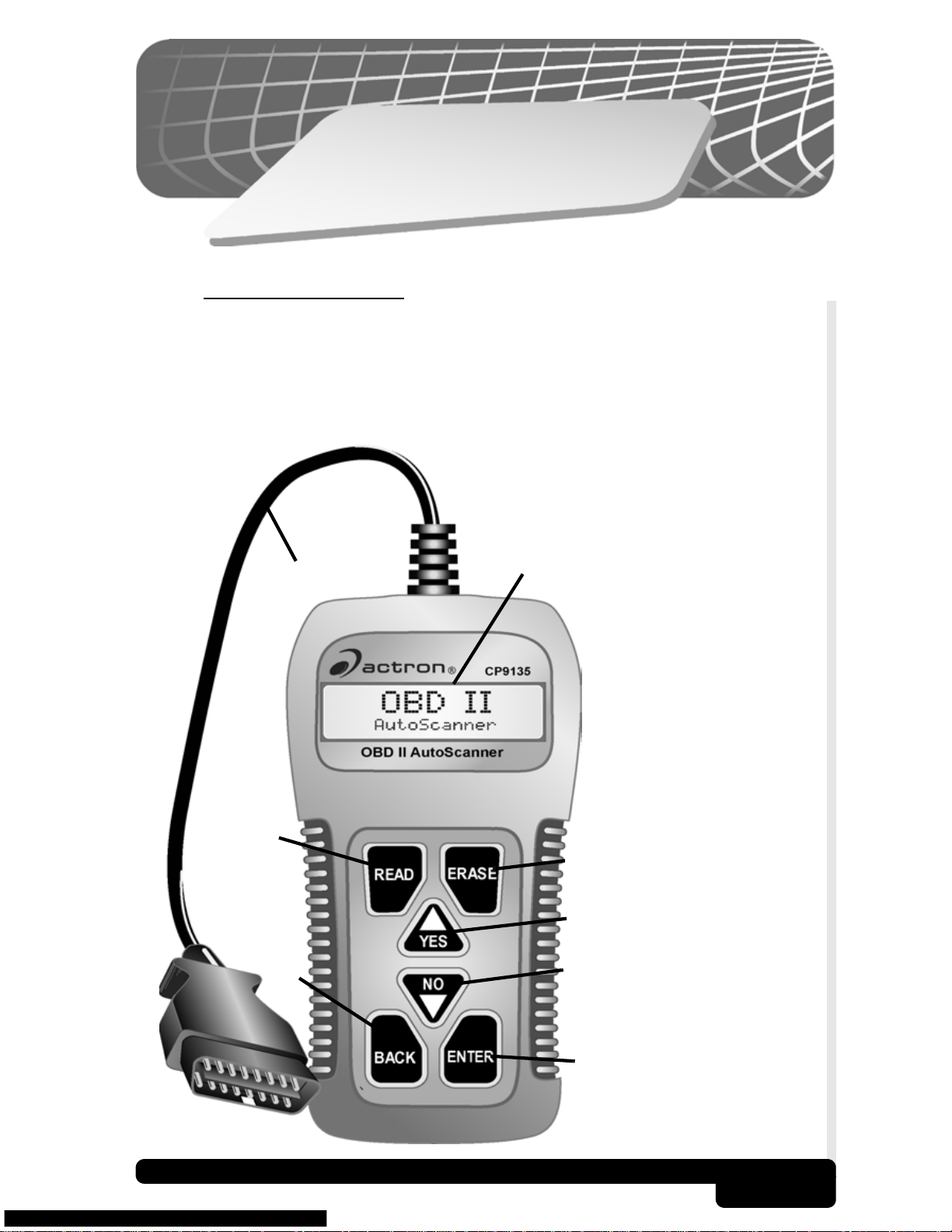

BOBD II connector &

cable with strain-relief.

CTwo-line LCD display.

DREAD key - performs

the Read Codes

function.

EERASE key - performs

the Erase Codes

function.

FV YES key - to scroll

up and answer YES.

GW NO key - to scroll

down and answer NO.

HBACK key - go to the

previous screen or

level.

IENTER key- selects

displayed items.

2

n

o

ti

ec

S

a

B

l

To

2.1 Tool Features

The

OBD II AutoScanner

service industry to help diagnose vehicles and assist in troubleshooting

procedures. The AutoScanner will perform OBD II functions on

compliant vehicles 1994 and newer. No batteries are needed; power is

provided from the vehicle’s data link connector (DLC)

o

was developed by experts in the automotive

B

D

E

Too l Basi cs

H

F

G

I

2-1

2.1.1

The AutoScanner uses a two-line liquid crystal display (LCD). The top

line contains 10 characters to show function headings, numbers and

user prompts. The bottom line contains 20 characters to display

selections and code information. Messages longer than the lines will

scroll continuously across the display from right to left. Display

contrast adjustment is accessed from the Tool Setup/Test menu.

Display

2.1.2

Connects the AutoScanner to the vehicle for power and

communication. The AutoScanner will automatically communicate

with the vehicle using a protocol built into the software

After initiating a function, the

AutoScanner will link with the

vehicle.

2.1.3

Do not use solvents such as alcohol to clean the keypad or display.

Use a mild nonabrasive detergent and a soft cotton cloth. Do not soak

the keypad as water might find its way inside the tool.

2.2

The AutoScanner is designed for ease

in navigation and operation. All menu

and lists operate the same way. Five

functions are selectable by the user. The

Read Codes

can be run using the keys identified in

Section 2.1-Tool Features

Lists and Menus

OBD II (J1962) Connector

Linking

* Please Wait *

Cleaning

and

Erase Codes

function

.

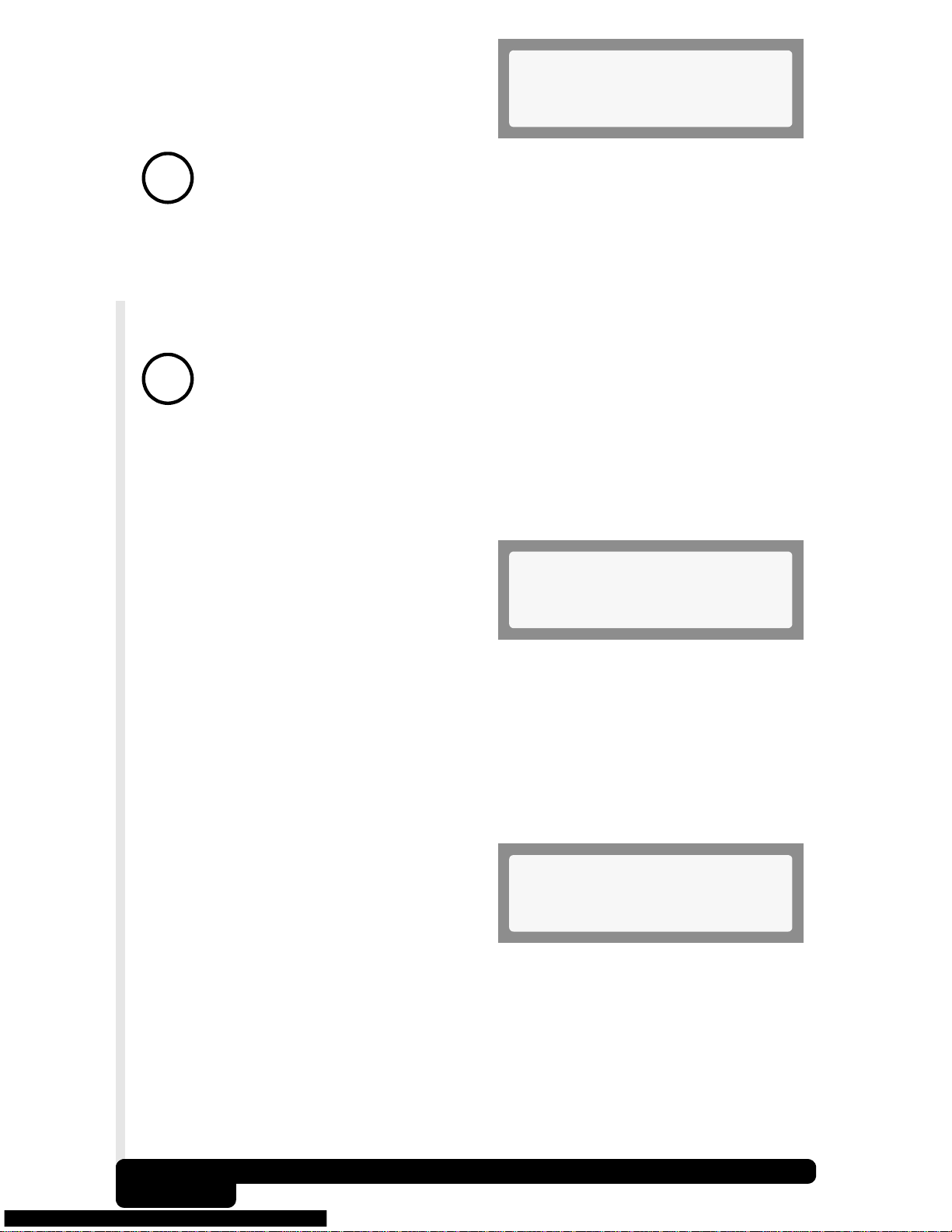

1)Read Codes

2)Erase Codes

3)MIL Status

4)I/M Monitors

5)Tool Setup/Test

1)Adjust Contrast

2)Display Test

3)Keypad Test

4)Memory Test

5)SW ID

▲

Use the

ENTER

item. An arrow icon will be displayed

on the right of the bottom line to

indicate the scrolling direction

available; up (

To return to previous screens, press the

or ▼ keys to scroll and the

key to select the function or

\

), down (]) or both ().

Tool Basics

2-2

Main Menu

1)Read Codes ]

BACK

key.

The AutoScanner may ask a question which requires a YES or NO

response from the user. Press either the

condition arises.

YES

key or

NO

key when the

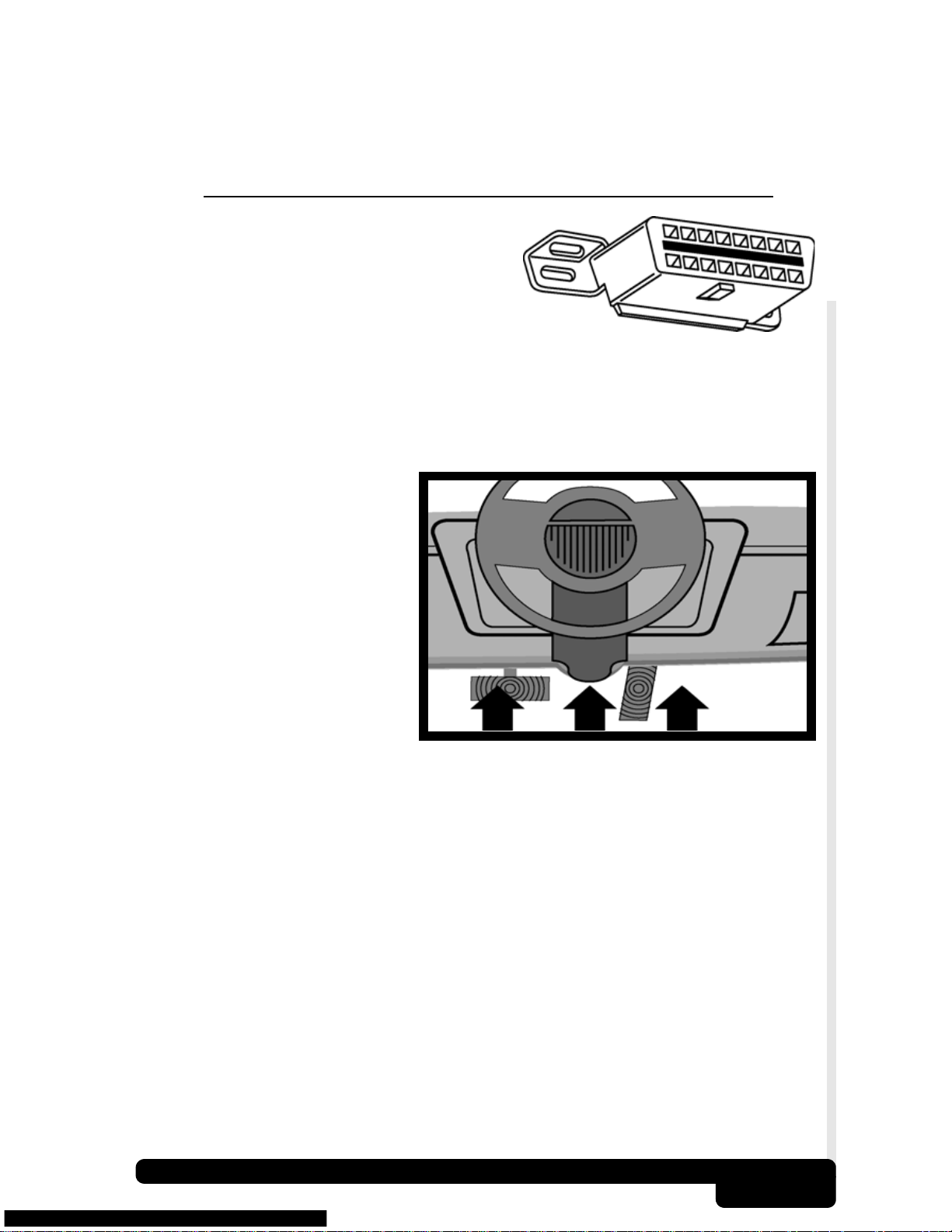

2.3

The AutoScanner communicates with

the vehicle’s computer modules via a

Diagnostic Link Connector (DLC).

OBD II regulations define the physical

and electrical specification for the DLC. Certain

pins in the connector are dedicated for power and

ground. The DLC is also referred to as a J1962 connector. The term J1962

is taken from a physical and electrical specification number assigned by

SAE (Society of Automotive Engineers). The standard ensures that all

vehicles with OBD II systems use the same connector.

The J1962 specification

defines the location of the

DLC in the vehicle. The DLC

should be located under the

dashboard on the driver side

of the vehicle. If the DLC is

not located under the

dashboard as stated, a

decal describing its location

should be attached to the

dashboard in the area the

DLC should have been

located.

Diagnostic Link Connector and Location

Too l Basi cs

2-3

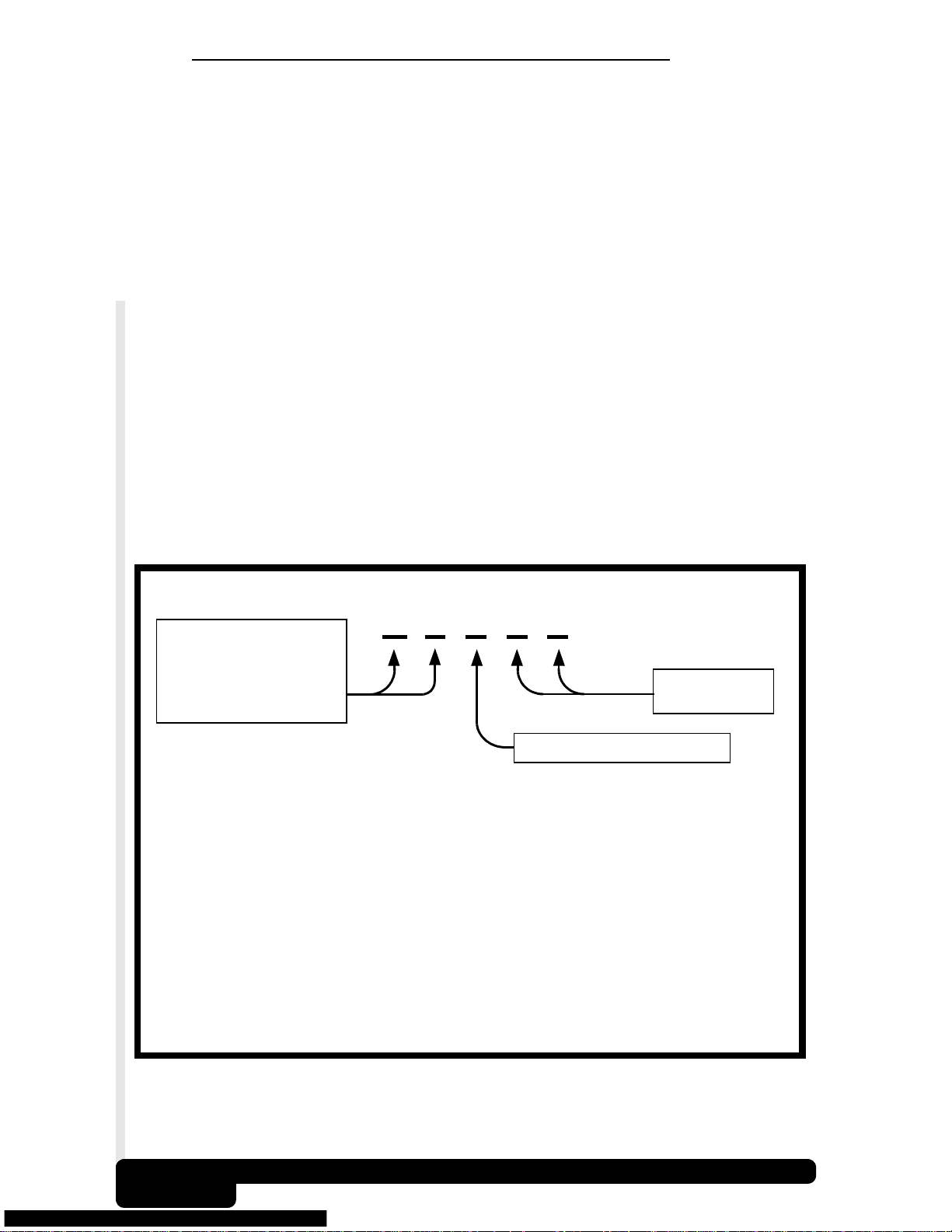

2.4 Diagnostic Trouble Codes (DTCs)

Diagnostic Trouble Codes (DTCs) consist of a three-digit code preceded

by an alphanumeric designator. When the on-board computer recognizes

and identifies a problem, a DTC for that fault is stored in memory. These

codes are intended to help the user determine the root cause of a problem.

The format and type of DTCs is summarized on the next page.

J2012 is a standard for all DTCs established by the Society of Automotive

Engineers (SAE). Codes and the definitions assigned by this specification

are known as Generic (or Global) OBD II codes. OBD II requires

compliance of this standard, and has made it a standard for all cars, light

trucks, APVs, MPVs, and SUVs sold in the U.S. from Model Year 1996

and newer. Codes not reserved by the SAE are reserved for the

manufacturer and referred as Manufacturer Specific.

Periodically, new DTCs are developed and approved by the SAE. Upon

approval of the new codes, the AutoScanner’s software will be updated.

There is no established time period that updates are made to the database.

For more information regarding DTC updates, please call our Technical

Support line at

send an email to

1-800-228-7667

(8:00 - 6:00 EST Monday - Friday), or

tech_support@actron.com.

SAE J2012 OBD II DTC Recommended Standard

Bx - Body

Cx - Chassis

- Powertrain

Px

Ux - Network Comm.

x = 0, 1, 2 or 3

Example:

P0101 –Mass or Volume Air Flow Circuit

Powertrain Codes

P0xxx

P1xxx

P2xxx

P30xx-P33xx

P34xx-P39xx

Chassis

C0xxx

C1xxx

C2xxx

C3xxx

Range/Performance Problem

- Generic (SAE)

- Manufacturer Specific

- Generic (SAE)

- Manufacturer Specific

- Generic (SAE)

Codes

- Generic (SAE)

- Manufacturer Specific

- Manufacturer Specific

- Generic (SAE)

P 0 1 0 1

Vehicle Specific System

Body

Codes

B0xxx

B1xxx

B2xxx

B3xxx

Network

U0xxx

U1xxx

U2xxx

U3xxx

- Generic (SAE)

- Manufacturer Specific

- Manufacturer Specific

- Generic (SAE)

Communication Codes

- Generic (SAE)

- Manufacturer Specific

- Manufacturer Specific

- Generic (SAE)

Specific Fault

Designation

2-4

Tool Basics

Loading...

Loading...