Page 1

15825 Industrial Parkway

Cleveland Ohio 44135 USA (EUA)

OBD II

AutoScanner

CP9135

™

Performs diagnostics on OBD II compliant vehicles 1994 and newer

Instructions in English, Spanish, and French

Instrucciones en Inglés, Español, y Francés

Instructions en Anglais, Espagnol, et les Français

Voltage: 16V

Tension: 16V

Tension de 16V

Page 2

FULL ONE (1) YEAR LIMITED WARRANTY

Actron Manufacturing Company (“Actron”) warrants to the original purchaser that

this

product will be free from defects in materials and workmanship for a period of

one

(1) year from the date of original purchase. Any unit that fails within this period

will

be replaced or repaired at Actron’s discretion without charge. If you need to

return

product, please follow the instructions below. This warranty does not apply

to

damages (intentional or accidental), alterations or improper or unreasonable

use.

ACTRON DISCLAIMS ALL EXPRESS WARRANTIES EXCEPT THOSE THAT

APPEAR

OF

ANY

WARRANTY

PRODUCT

LIMITED

LONG

TO

IN NO CASE SHALL ACTRON BE LIABLE FOR ANY SPECIAL, INCIDENTAL OR

CONSEQUENTIAL DAMAGES BASED UPON ANY LEGAL THEORY INCLUDING,

BUT NOT LIMITED TO, DAMAGES FOR LOST PROFITS AND/OR INJURY TO

PROPERTY.

OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THIS LIMITATION OR

EXCLUSION MAY NOT APPLY TO A SPECIFIC BUYER. THIS WARRANTY GIVES

YOU

WHICH VAR Y FROM STATE TO STATE.

All

on the latest information available from industry sources at the time of publication.

No warranty (expressed or implied) can be made for its accuracy or completeness,

nor is any responsibility assumed by Actron or anyone connected with it for loss or

damages suffered through reliance on any information contained in this manual or

misuse of accompanying product. Actron reserves the right to make changes at any

time to this manual or accompanying product without obligation to notify any person

or organization of such changes.

ABOVE. FURTHER, ACTRON DISCLAIMS ANY IMPLIED WARRANTY

MERCHANTABILITY OF THE GOODS OR FITNESS OF THE GOODS FOR

PURPOSE. (TO THE EXTENT ALLOWED BY LAW, ANY IMPLIED

IS SUBJECT TO ALL THE TERMS AND CONDITIONS OF THIS

WARRANTY. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW

AN IMPLIED WARRANTY LASTS, SO THIS LIMITATION MAY NOT APPLY

A SPECIFIC BUYER.)

SPECIFIC LEGAL RIGHTS, AND YOU MAY ALSO HAVE OTHER RIGHTS

information, illustrations and specifications contained in this manual are based

DISCLAIMER OF WARRANTY

OF MERCHANTABILITY OR OF FITNESS APPLICABLE TO ANY

LIMITATION OF REMEDIES

SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION

If you need to return the unit, please follow this procedure:

1. Call

Actron Te ch Support at 1-(800)228-7667. Our Technical Service Representatives

are

trained to assist you.

2. Proof

of purchase is required for all warranty claims. For this reason we ask that you

retain

your sales receipt.

3. In

the event that product needs to be returned, you will be given a Return Material

Authorization

possible, return the product in its original package with cables and accessories.

4. If

5. Print

send

6. You will be responsible for shipping charges in the event that your repair is not

covered

number.

the RMA number and your return address on the outside of the package and

to the address provided by your Customer Service representative.

by warranty.

OUT OF WARRANTY REPAIR

If you need product repaired after your warranty has expired, please call Te ch Support at

TO USE YOUR WARRANTY

(800) 228-7667.

You will be advised of the cost of repair and any freight charges.

Page 3

Table of Contents

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . SF-1

Section 1 - Quick Start

1.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2 Quick Start. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Section 2 - Tool Basics

2.1 Tool Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.1.1 Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 2-2

2.1.2 OBD II (J1962) Connector . . . . . . . . . . . . . . . . . . . . . . 2-2

2.1.3 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.2 Lists and Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.3 Diagnostic Link Connector and Location . . . . . . . . .. 2-3

2.4 Diagnostic Trouble Codes (DTCs). . . . . . . . . . . . . .. 2-3

2.5 This Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 2-4

2.6 Vehicle Service Information. . . . . . . . . . . . . . . . . . . . 2-5

Section 3 - Using the Tool

3.1 AutoScanner Connection and Power-Up . . . . . . . . . 3-1

3.2 Read Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.3 Erase Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 3-3

3.4 MIL Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 3-5

3.5 I/M Monitors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 3-5

3.6 Tool Setup/Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

3.6.1 Changing Display Contrast. . . . . . . . . . . . . . . . . . . . .. 3-7

3.6.2 Display Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

3.6.3 Keypad Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

3.6.4 Memory Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

3.6.5 Software Identification (SW ID) . . . . . . . . . . . . . . . . . . 3-8

Section 4 - Troubleshooting

4.1 Vehicle Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.2 AutoScanner Does Not Power Up: . . . . . . . . . . . . . . 4-2

4.3 Link Errors or Erroneous Data. . . . . . . . . . . . . . . . . . 4-3

4.4 Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Appendix A - Glossary

Appendix B - About OBD II

Page 4

Y

T

E

F

A

S

S

N

O

I

T

U

A

C

E

R

P

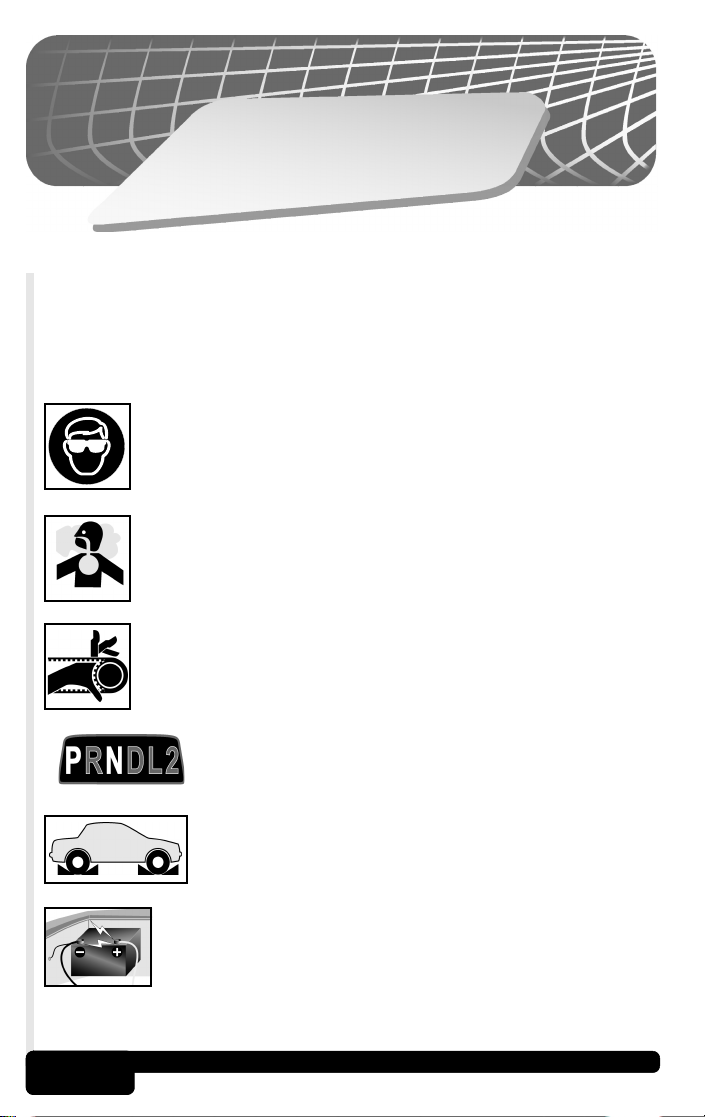

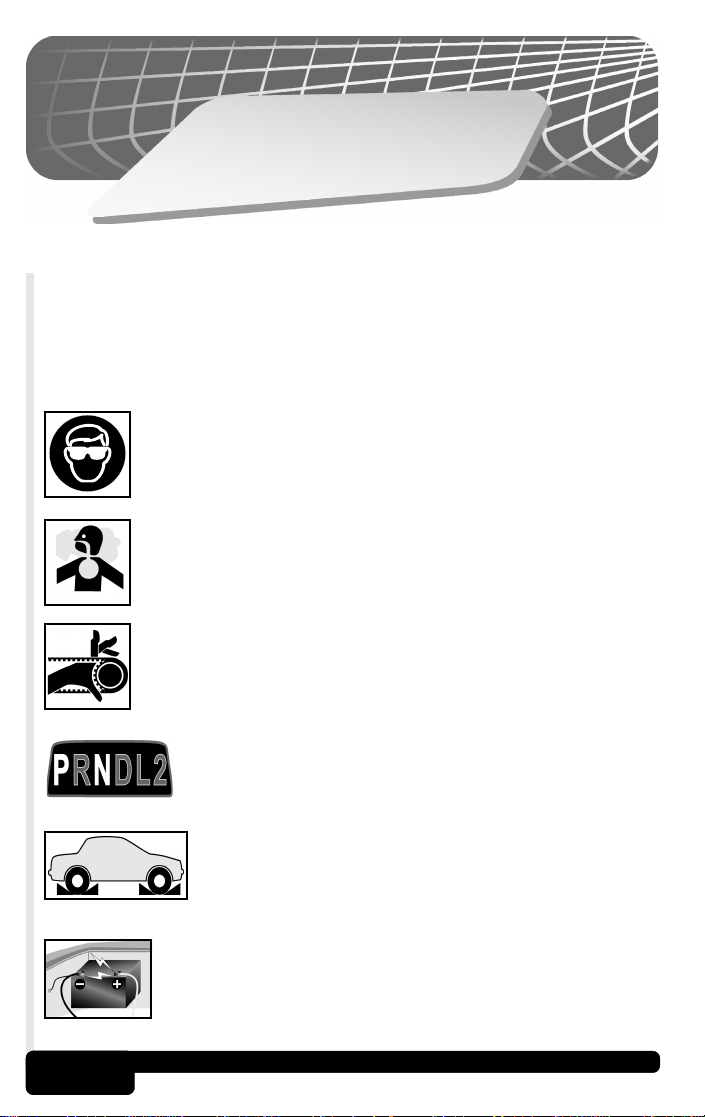

To prevent accidents that could possibly result in serious

injury and/or damage to vehicles and/or test equipment,

carefully follow all safety rules and test procedures when

working on vehicles.

Always wear ANSI approved eye protection.

Always operate the vehicle in a well-ventilated area. Do

not breath exhaust gases — they are very hazardous.

Always keep yourself, tools and test equipment away from

all moving or hot engine parts.

SF-1

Always make sure the vehicle is in Park (automatic

transmission) or Neutral (manual transmission).

Ensure the parking brake is firmly set.

Block the drive wheels.

Never leave vehicle unattended while testing.

Never lay tools on vehicle battery. You may short the

terminals together causing harm to yourself, the tools or

the battery.

Page 5

Always use caution when working around the ignition coil,

distributor cap, ignition wires, and spark plugs. These

components can produce High Voltage while the engine

is running.

Battery electrolyte is sulfuric-acid and is extremely caustic.

If contacted, rinse with water or neutralize with a mild base

(i.e. baking soda). If contacted in eyes, flush with water

and call a physician immediately.

Never smoke or have open flames near vehicle. Vapors

from gasoline and the battery during charge are highly

flammable and explosive.

Never use the AutoScannerTM if internal circuitry has been

exposed to any moisture. Internal shorts could cause fire

and damage to the tool.

Always keep a fire extinguisher suitable for

gasoline/electrical/chemical fires readily available.

• When performing road tests, never operate the tool while driving

the vehicle. Always have one person drive the vehicle and an

assistant operate the AutoScanner

TM

.

• Always turn ignition key OFF when connecting or disconnecting

electrical components, unless otherwise instructed.

• Some vehicles are equipped with safety air bags. You MUST follow

vehicle service manual cautions when working around the air bag

components or wiring. If the cautions are not followed, the air bag

may open up unexpectedly, resulting in personal injury. Note that

the air bag can still open up several minutes after the ignition key is

off (or even if the vehicle’s battery is disconnected) because of a

special energy reserve module.

• Always follow vehicle manufacturer’s warnings, cautions and

service procedures.

SF-2

Page 6

1

n

o

i

t

c

e

S

t

r

a

t

S

k

ic

u

Q

1.1 Introduction

Congratulations!

You've purchased an automotive scanner that can unlock the fault

code information stored in the on-board computer(s) of your car or

light truck. This information gives you the power to identify and repair

problems that may arise with the operation of your vehicle's engine.

Cars and trucks cannot completely diagnose their problems, and no

scanner available can tell you with pinpoint accuracy what is wrong

with the vehicle.

Once you have retrieved the diagnostic information from the computer,

you have taken the first step in finding and fixing the problem. Now it

is time to continue with the rest of the diagnostic process.

Important points to remember:

• Diagnostic Trouble Codes (DTCs) warn us of a symptom or

problem with a particular engine system, not a specific part.

• The computer can only report DTCs based on what its sensors

are telling it.

• Sometimes, sensors appear to be bad when in fact, they are not.

- A poor connection, broken wire or short circuit may be preventing

the sensor signal from reaching the computer.

- A malfunction in one system may cause a sensor in another

system to report a value that is too high or too low.

• We recommend the use of a vehicle specific service manual to

assist you with the diagnostic process.

• Some of the vehicle computer's sensors and actuators can be

pretty expensive; it is best to make sure they are defective prior

to replacing them!

1-1

Quick Start

Page 7

The next step in the diagnostic process is to test systems and parts

that are suspected to be defective. This testing process may include:

• Sensors

• Fuel injection system

Even when working on modern, computer-controlled vehicles there is

no substitute for good old-fashioned troubleshooting.

Once you have isolated and repaired the failed problem(s), you can

use your AutoScanner to clear the codes from the computer's memory.

This will also turn off your Malfunction Indicator Lamp (MIL), or Check

Engine Light, and may reset all Inspection/Maintenance (I/M) monitor

statuses to “Not Ready”.

The following Quick Start section will help you begin to use your OBD II

AutoScanner right away. Subsequent sections of this manual contain

more detailed information to help you get the most out of your scanner.

If you have questions not covered in the manual, please call our

Technical Support line at 1-800-228-7667 (8:00 - 6:00 EST Monday Friday), or send an email to tech_support@actron.com.

• Ignition system

• Vacuum & Pressure systems

1.2 Quick Start

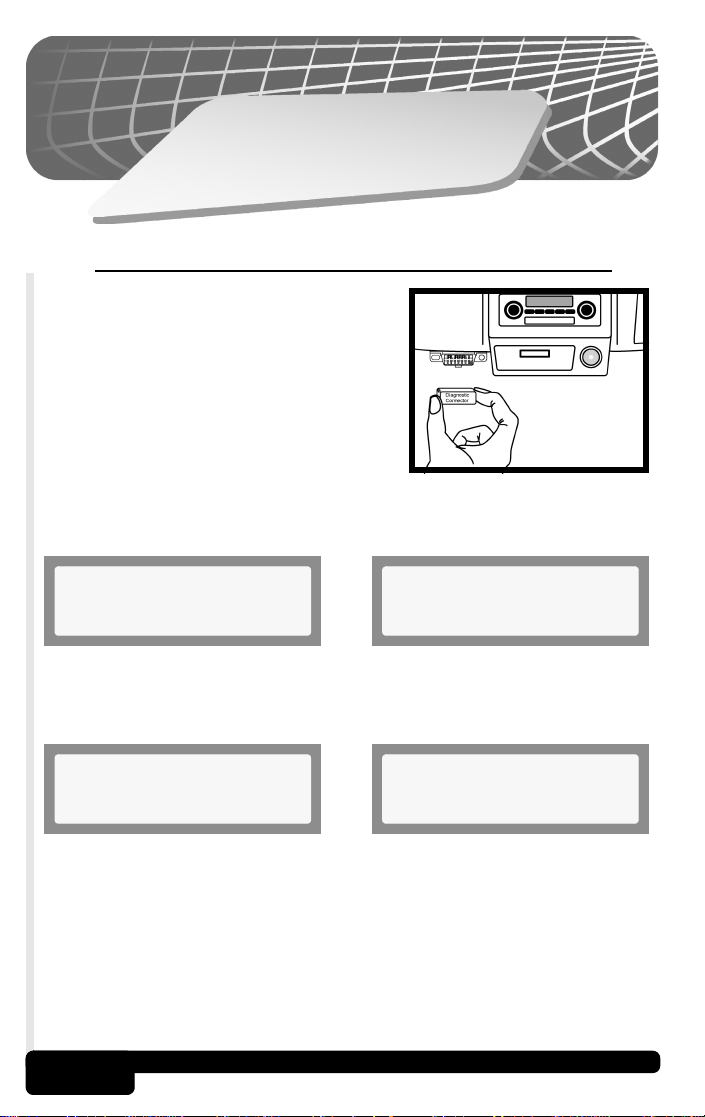

Connect the OBD II AutoScanner to the vehicle’s Data Link Connector

(DLC) which is normally located under the dash on the driver’s side.

Once the connection is made, the tool will turn on, boot, and then

display the Main Menu. If the display is hard to read, adjust the contrast

using the Tool Setup/Test function.

All AutoScanner functions can be performed with the Key On-Engine

Off (KOEO). The ERASE function cannot be done with the Key

On-Engine Running (KOER).

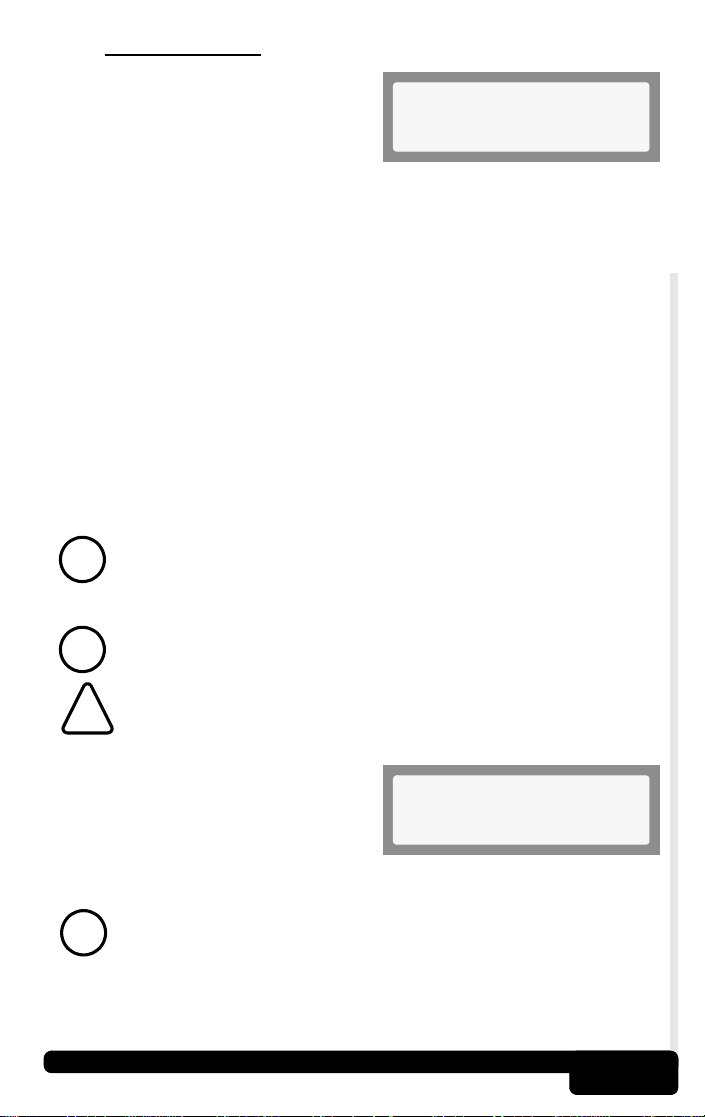

To retrieve Diagnostic Trouble Codes

(DTCs), press the READ key on the

AutoScanner. This function can be

performed with the KOEO or KOER.

Main Menu

1)Read Codes [

If DTCs are present, they will appear on the display. Use the ▲ or ▼

keys to view the codes. The definition will continuously scroll to the left if

it is longer than the display (20 characters). To freeze the scrolling message,

press and hold the ENTER key. When done, press the BACK key to return

to the Main Menu.

CAUTION! Avoid Cooling Fan! It May Turn On During Test.

!

Quick Start

1-2

Page 8

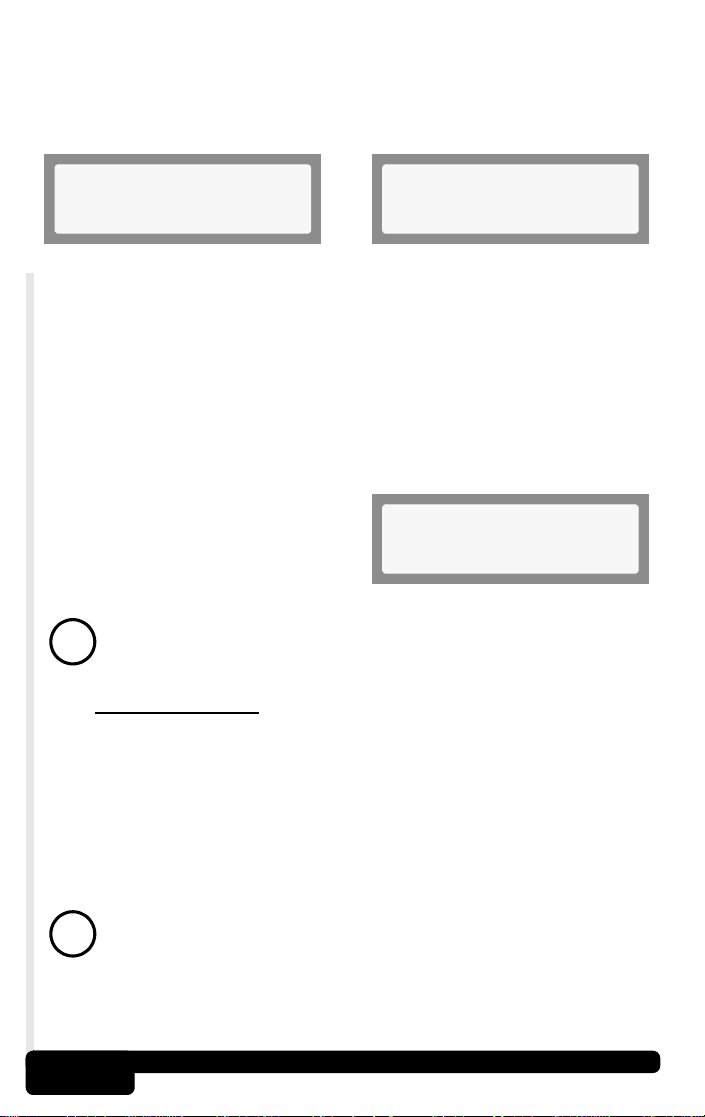

To erase DTCs, press the ERASE

key on the AutoScanner. This

function must be performed with the

KOEO - Do not START engine.

Note: In addition to clearing DTCs, the Erase Codes function may

reset the status of the I/M System Monitors to “Not Ready.”

!

If DTCs are found, the tool will display the quantity and ask the user

“Erase Codes? (Y/N).” Pressing the NO key will display the message

“Cancelled, Erase Not Performed.” Pressing the YES key will display

a scrolling message on the bottom line. Press the BACK key to return

to the Main Menu.

“Hard” codes are codes that can be removed only by repairing

the faults that they cause; therefore, hard codes will remain in

!

the computer’s memory until the condition is repaired.

The MIL Status function displays the status of the computer module

that commanded the MIL to turn on. If the MIL Status is ON and the

MIL is not illuminated with the engine running, then a problem exists

in the MIL circuit.

Select the MIL Status function and

press the ENTER key. The MIL

Status of the computer will display

on the AutoScanner. Press the

BACK key to return to the Main

Menu.

Main Menu

2)Erase Codes

Main Menu

3)MIL Status

The I/M (Inspection and Maintenance) Monitors function displays the

state of the vehicle’s OBD II Monitors. Monitors test the operation of

emission related systems or components and detect out-of-range

values. The vehicle may have to be operated under certain driving

conditions to initiate a monitor.

Select I/M Monitors from the Main

Menu and press the ENTER key.

Use the

the list. Note the Monitors present

and their status. When done, press

the BACK key to return to the Main Menu

Detailed instructions are provided in Section 3 and OBD II background

information is provided in Appendix B.

▲ or ▼ keys to scroll through

Main Menu

4)I/M Monitors

.

Quick Start

1-3

Page 9

S

s

a

B

l

o

o

T

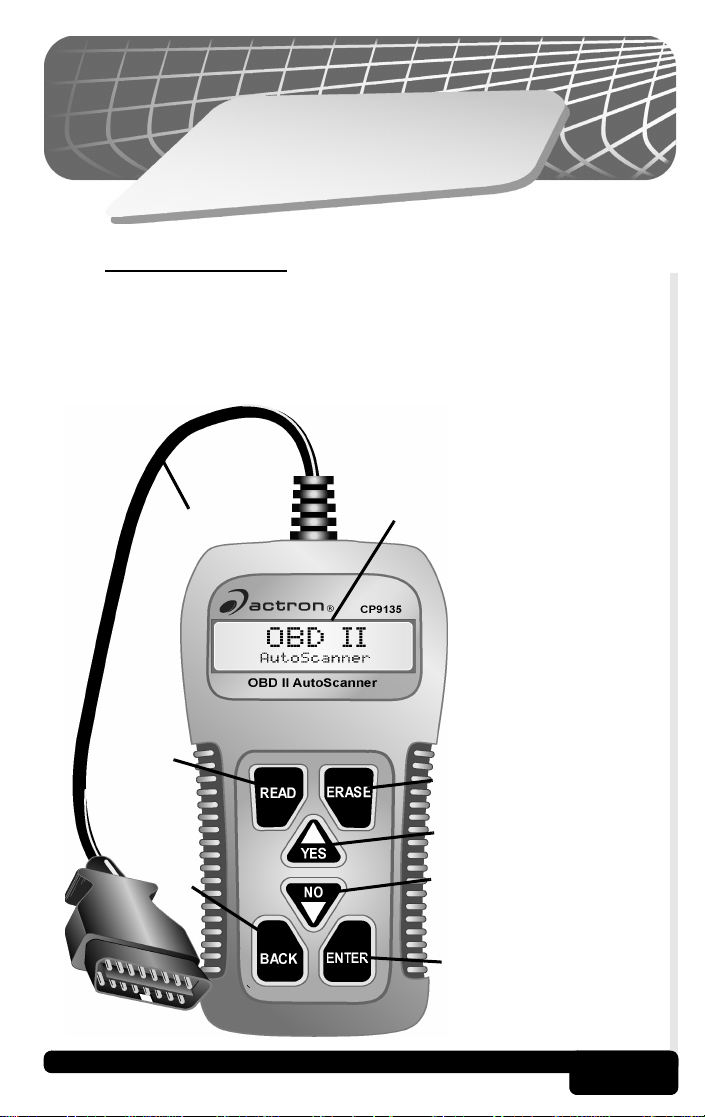

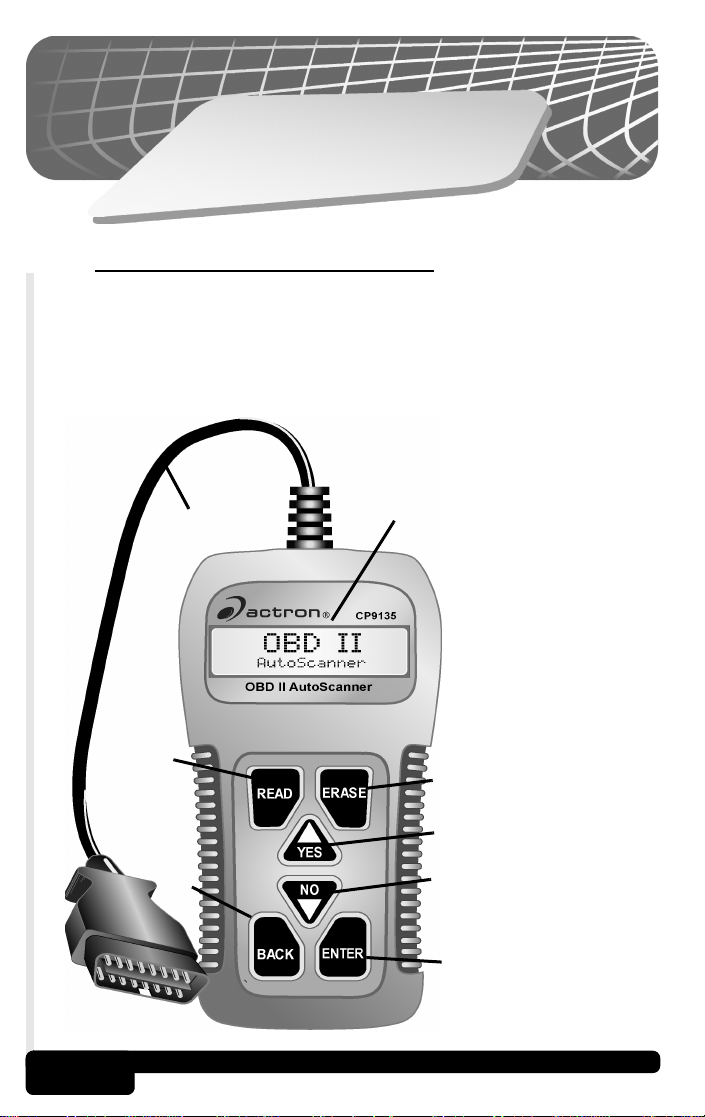

2.1 Tool Features

The

OBD II AutoScanner

service industry to help diagnose vehicles and assist in troubleshooting

procedures. The AutoScanner will perform OBD II functions on

compliant vehicles 1994 and newer. No batteries are needed; power is

provided from the vehicle’s data link connector (DLC)

B

was developed by experts in the automotive

c

ic

s

.

BOBD II connector &

cable with strain-relief.

CTwo-line LCD display.

DREAD key - performs

the Read Codes

function.

EERASE key - performs

the Erase Codes

function.

FV YES key - to scroll

up and answer YES.

GW NO key - to scroll

down and answer NO.

HBACK key - go to the

previous screen or

level.

IENTER key- selects

displayed items.

2

n

o

i

t

c

e

D

E

Too l Ba si cs

H

F

G

I

2-1

Page 10

2.1.1

The AutoScanner uses a two-line liquid crystal display (LCD). The top

line contains 10 characters to show function headings, numbers and

user prompts. The bottom line contains 20 characters to display

selections and code information. Messages longer than the lines will

scroll continuously across the display from right to left. Display

contrast adjustment is accessed from the Tool Setup/Test menu.

Display

2.1.2

Connects the AutoScanner to the vehicle for power and

communication. The AutoScanner will automatically communicate

with the vehicle using a protocol built into the software

After initiating a function, the

AutoScanner will link with the

vehicle.

2.1.3

Do not use solvents such as alcohol to clean the keypad or display.

Use a mild nonabrasive detergent and a soft cotton cloth. Do not soak

the keypad as water might find its way inside the tool.

2.2

The AutoScanner is designed for ease

in navigation and operation. All menu

and lists operate the same way. Five

functions are selectable by the user. The

Read Codes

can be run using the keys identified in

Section 2.1-Tool Features

Use the

ENTER

item. An arrow icon will be displayed

on the right of the bottom line to

indicate the scrolling direction

available; up (

To return to previous screens, press the

OBD II (J1962) Connector

Cleaning

Lists and Menus

and

Erase Codes

▲

or ▼ keys to scroll and the

key to select the function or

]

), down ([) or both ().

function

.

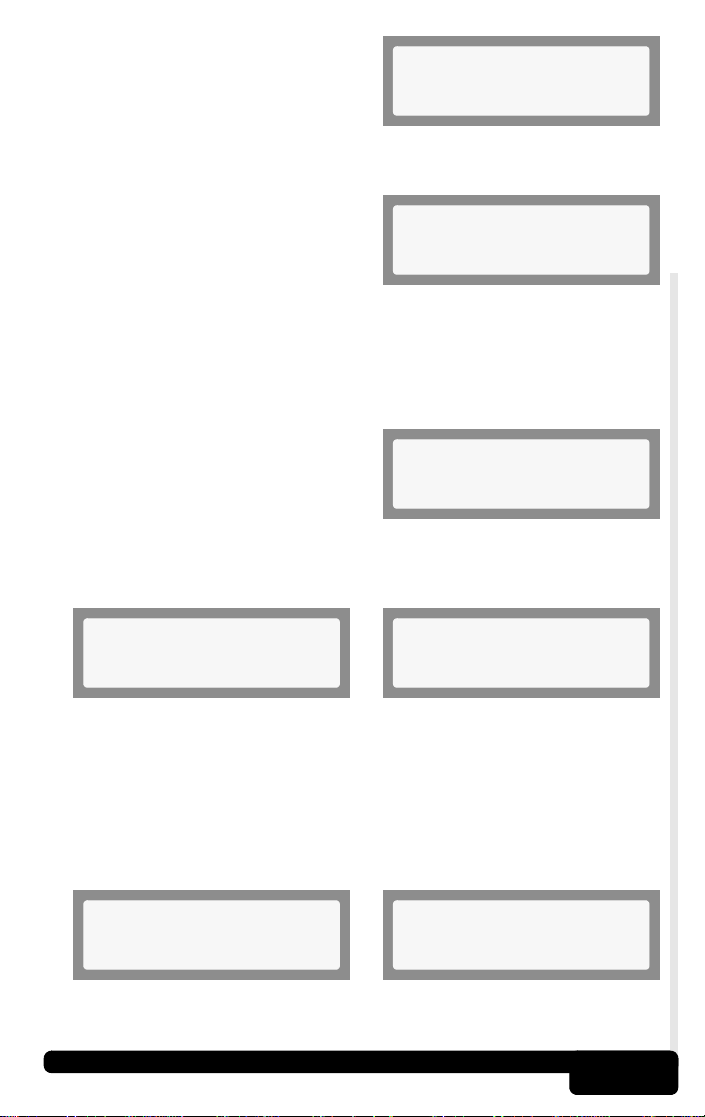

Linking

* Please Wait *

1)Read Codes

2)Erase Codes

3)MIL Status

4)I/M Monitors

5)Tool Setup/Test

1)Adjust Contrast

2)Display Test

3)Keypad Test

4)Memory Test

5)SW ID

Main Menu

1)Read Codes [

BACK

key.

The AutoScanner may ask a question which requires a YES or NO

response from the user. Press either the

condition arises.

Tool Basics

YES

key or NO key when the

2-2

Page 11

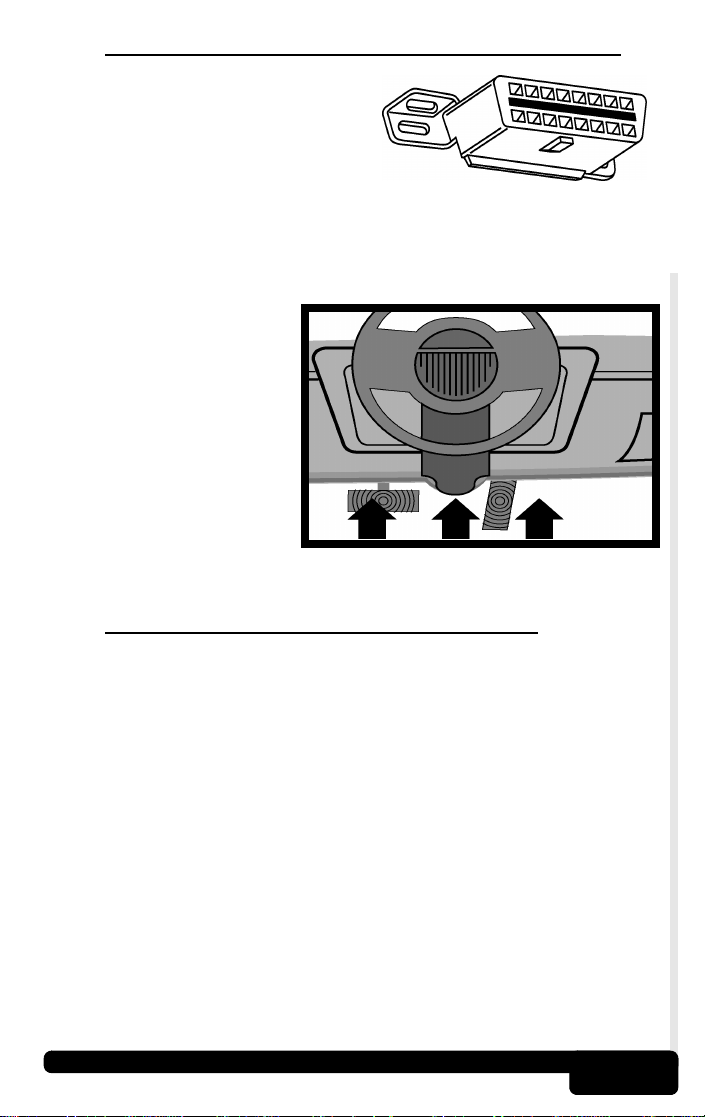

2.3

Diagnostic Link Connector and Location

The AutoScanner communicates with

the vehicle’s computer modules via a

Diagnostic Link Connector (DLC).

OBD II regulations define the physical

and electrical specification for the DLC.

Certain pins in the connector are dedicated for power

and ground. The DLC is also referred to as a J1962 connector. The term

J1962 is taken from a physical and electrical specification number

assigned by SAE (Society of Automotive Engineers). The standard

ensures that all vehicles with OBD II systems use the same connector.

The J1962 specification

defines the location of the

DLC in the vehicle. The DLC

should be located under the

dashboard on the driver side

of the vehicle. If the DLC is

not located under the

dashboard as stated, a

decal describing its location

should be attached to the

dashboard in the area the

DLC should have been

located.

2.4 Diagnostic Trouble Codes (DTCs)

Diagnostic Trouble Codes (DTCs) consist of a three-digit code preceded

by an alphanumeric designator. When the on-board computer recognizes

and identifies a problem, a DTC for that fault is stored in memory. These

codes are intended to help the user determine the root cause of a problem.

The format and type of DTCs is summarized on the next page.

J2012 is a standard for all DTCs established by the Society of Automotive

Engineers (SAE). Codes and the definitions assigned by this specification

are known as Generic (or Global) OBD II codes. OBD II requires

compliance of this standard, and has made it a standard for all cars, light

trucks, APVs, MPVs, and SUVs sold in the U.S. from Model Year 1996

and newer. Codes not reserved by the SAE are reserved for the

manufacturer and referred as Manufacturer Specific.

Periodically, new DTCs are developed and approved by the SAE. Upon

approval of the new codes, the AutoScanner’s software will be updated.

There is no established time period that updates are made to the database.

Too l Ba si cs

2-3

Page 12

For more information regarding DTC updates, please call our Technical

Support line at

send an email to

1-800-228-7667

tech_support@actron.com.

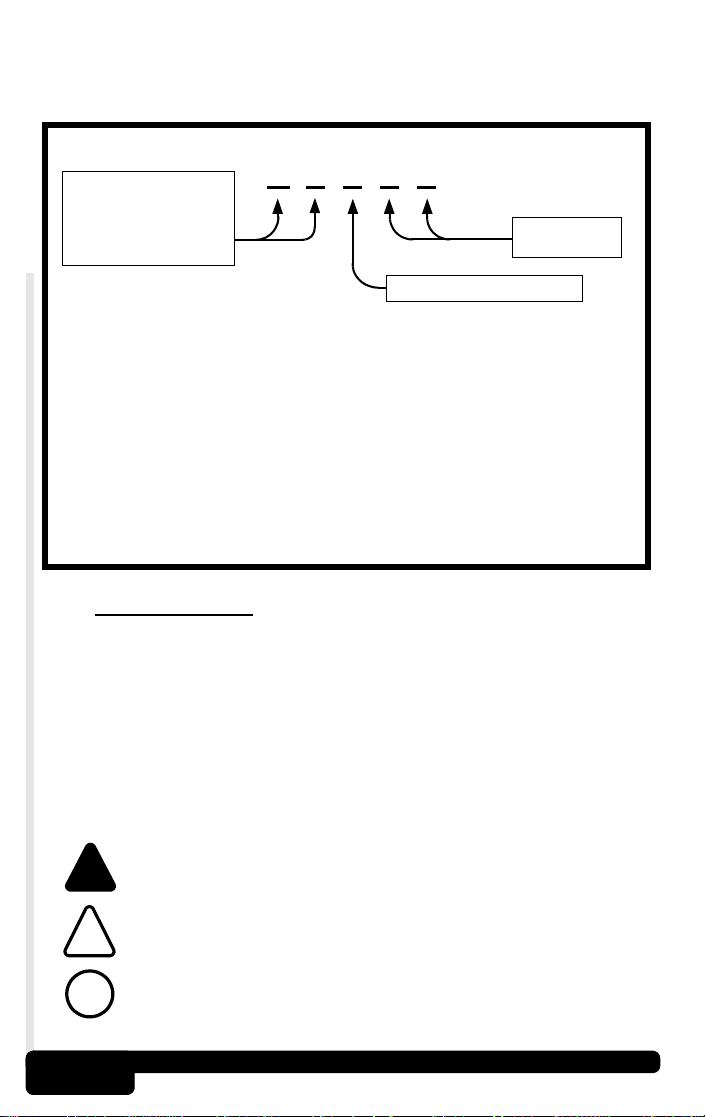

SAE J2012 OBD II DTC Recommended Standard

(8:00 - 6:00 EST Monday - Friday), or

Bx - Body

Cx

- Chassis

Px

- Powertrain

- Network Comm.

Ux

x

= 0, 1, 2 or 3

Example:

P0101 –Mass or Volume Air Flow Circuit

Powertrain Codes

P0xxx

P1xxx

P2xxx

P30xx-P33xx

P34xx-P39xx

Chassis

C0xxx

C1xxx

C2xxx

C3xxx

Range/Performance Problem

- Generic (SAE)

- Manufacturer Specific

- Generic (SAE)

- Manufacturer Specific

- Generic (SAE)

Codes

- Generic (SAE)

- Manufacturer Specific

- Manufacturer Specific

- Generic (SAE)

P 0 1 0 1

Vehicle Specific System

Body

Codes

- Generic (SAE)

B0xxx

- Manufacturer Specific

B1xxx

- Manufacturer Specific

B2xxx

- Generic (SAE)

B3xxx

Network

- Generic (SAE)

U0xxx

- Manufacturer Specific

U1xxx

- Manufacturer Specific

U2xxx

U3xxx

- Generic (SAE)

Specific Fault

Designation

Communication Codes

2.5 This Manual

This manual provides step-by-step procedures to operate the OBD II

AutoScanner. Specific diagnostics for the vehicle may be found in

applicable service manuals listed in Section 2.6. Information about

OBD II can be found in Appendix B - OBD II Background.

Warnings, Cautions and Notes

These are identified with the following symbols. Please read and

understand the Safety Precautions and adhere to them while testing

the vehicle.

!

!

!

2-4

The Warning symbol identifies hazards that may cause

serious harm and injury.

The Caution symbol alerts the operator of potential

noncritical harm or damage to equipment.

This symbol identifies special information.

Tool Basics

Page 13

2.6 Vehicle Service Information

Vehicle service manuals containing additional diagnostic information

are available at most auto parts stores or the local library. If unable to

locate them at those locations, write the below listed publishers for

availability and pricing. Please be sure to specify the make, model and

year of vehicle.

Vehicle Service Manuals

Chrysler, Plymouth, Dodge,

Jeep, Eagle:

Dyment Distribution Service

Publications

12200 Alameda Drive

Strongsville, OH 44136

www.techauthority.daimlerchrysler.com

Ford, Lincoln & Mercury:

Ford Publication Department

Helm Incorporated

P.O. Box 07150

Detroit, MI 48207

www.helminc.com

Cadillac, Chevrolet,

Buick,

GEO, GMC, Oldsmobile,

Pontiac;

Honda, Isuzu, Suzuki,

Acura,

Kia, Hyundai & Saab:

Helm Incorporated

P.O. Box 07130

Detroit, MI 48207

www.helminc.com

Saturn:

Adistra Corporation

c/o Saturn Publications

101 Union St.

P.O. Box 1000

Plymouth, MI 48170

Chilton Book Company

Chilton Way

Radnor, PA 19089

www.edmunds.com/edweb/Chilton

Mitchell Manuals, Inc.

Cordura Publications

P.O. Box 26260

San Diego, CA 92126

www.mitchellrepair.com

Haynes Publications Inc.

861 Lawrence Drive

Newbury Park, CA 91320

www.haynes.com

Haynes Publications Inc.

1299 Bridgestone Parkway

LaVergne, TN 37086

www.haynes.com

JENDHAM, Inc.

13230 Evening Creek Drive,

Suite #202

San Diego, CA 92128

www.jendham.com

Motor’s Auto Repair Manual

Hearst Company

250 W. 55th Street

New York, NY 10019

Suitable manuals have titles such as:

- “Electronic Engine Controls”

- “Fuel Injection and Electronic Engine Controls”

- “Emissions Control Manual”

... or similar titles

Too l Ba si cs

2-5

Page 14

3

n

o

i

t

c

e

S

l

o

o

T

e

h

t

g

n

i

s

U

3.1 AutoScanner Connection and Power-Up

Locate the DLC. If not found, refer to

Section 2.3.

The AutoScanner will not harm the

vehicle.

Remove the protective cap and connect

the AutoScanner’s 16-pin J1962

connector. The AutoScanner will

immediately power-up.

The AutoScanner displays its name for a brief period and then begins

“Loading Software.”

OBD II

Auto Scanner Loading Software.........

If the

▲ key is pressed and held while software is loading, the

Software ID will display until the key is released, and then the Main

Menu will display.

Main Menu

Software ID: 392A

When the Main Menu displays, the AutoScanner is ready to use.

Refer to Section 3.6 - Tool Setup/Test and Section 4 -

Troubleshooting if problems occur.

More information about OBD II can be found in Appendix B - OBD II

Background.

1)Read Codes [

Using the Tool

3-1

Page 15

3.2 Read Codes

The Read Codes function retrieves

Diagnostic Trouble Codes (DTCs)

from the vehicle’s computer modules.

This function can be performed with

the KOEO or KOER.

There are two types of codes, Malfunction Indicator Lamp (MIL) codes

and Pending codes. An icon (

are Pending codes.

MIL Codes: These codes cause the computer to illuminate the MIL

when an emission related or driveability fault occurs. The MIL is also

known as the "service engine soon" or "check engine lamp”. The

computer will illuminate the MIL when the engine is running and

remain in the vehicle’s memory until the fault is repaired.

Pending Codes: These codes are also referred as “continuous

monitor” and “maturing codes”. An intermittent fault will cause the

computer to store a code in memory. If the fault does not occur within

40 warm-up cycles, the code will be cleared from memory. If the

fault occurs a specific number of times, the code will mature into a

DTC and the MIL will turn on.

Changing any part without first isolating the circuit or system may

result in the replacement of good components.

!

) will be displayed next to DTCs that

Main Menu

1)Read Codes [

Before performing this function, read and understand the Safety

Precautions and Section 2 - Tool Basics.

!

CAUTION! Avoid Cooling Fan! It May Turn On During Test.

!

Press the READ key to initiate the

Read Codes function. The

AutoScanner will retrieve the DTCs

stored in the vehicle’s computer

module(s). This function can also be

run by selecting Read Codes from the Main Menu.

If a Link Error message displays, make sure the OBD II

connector is securely attached, and the ignition key is ON. Cycle

!

the ignition key to OFF for 10 seconds, then ON. This may be

required to reset the computer. If required, select “Yes” to try

again. If the problem still exists, refer to Section 4:

Troubleshooting.

Using the Tool

Reading

* Data From Vehicle *

3-2

Page 16

If one DTC is retrieved, the AutoScanner will display the DTC number

and type (MIL or pending) on the top line, and the definition on the

bottom. If more than one DTC is present, the top line will also display

the code index (n/x), i.e. 1 of 3. This and the DTC number will alternate

on the display while the bottom line shows the definition.

P0452

EVAP Emission Cont [

If the definition is longer than the display, it will continuously scroll to

the left. To freeze the scrolling message, press and hold the ENTER

key. Use the

BACK key to return to the Main Menu.

• Definitions for Generic (or Global) DTCs will be displayed on the

bottom line. These definitions can be found in the vehicle’ service

manual (refer to Section 2.6 - Vehicle Service Information or

on the enclosed product CD).

If no DTCs are present, the message

“PASS, No Codes Returned” will

display. Press the BACK key to

return to the Main Menu.

!

▲ or ▼ keys to view each DTC. When done, press the

Do not disconnect the AutoScanner until codes have been

recorded. When power is removed, the AutoScanner’s memory

is cleared.

1 of 3

ion Control System [

PASS

No Codes Returned

3.3 Erase Codes

The Erase Codes function deletes the DTCs from the vehicle’s

computer memory. Perform this function only after the systems have

been checked completely and DTCs have been documented. This

function should be performed with KOEO - Do not START engine.

After servicing the vehicle, delete the stored DTCs and verify no codes

have been reset. If DTCs return, the problem has not been corrected

or other faults are present.

In addition to clearing DTCs, the Erase Codes function resets

the status of the I/M System Monitors to “Not Ready.”

!

3-3

Using the Tool

Page 17

To Erase Codes, press the ERASE

key. This function can also be run by

selecting Erase Codes from the Main

Menu.

Before erasing codes, the AutoScanner will perform the Read Codes

function and display the number of DTCs stored in the vehicle’s

computer memory.

CAUTION! Avoid Cooling Fan! It May Turn On During Test.

!

If no DTCs are present, then press

ENTER to return to the Main Menu.

If DTCs are found, the tool will

display the quantity and ask the user

“Erase Codes? (Y/N).” Pressing the

NO key will display the message

“Cancelled, Erase Not Performed.”

Press the BACK key to return to the Main Menu.

Pressing the YES key will display a

scrolling message on the bottom

line. Turn key On, engine Off and

then press the ENTER key.

Main Menu

2)Erase Codes

No Codes

Press ENTER To Exit

5 Codes

Erase Codes? (Y/N)

Verify Engine Off, Key

The AutoScanner will perform Read Codes again to check the number

of DTCs erased.

If all DTCs have been erased, a

message “No Codes Remain (Press

ENTER)” will scroll across the

bottom line.

If DTCs still exist, the number will be displayed. The faults must be

repaired to remove these DTCs. Press ENTER to return to the Main

Menu.

“Hard” codes are codes that can be removed only by repairing

the faults that they cause; therefore, hard codes will remain in

!

the computer’s memory until the condition is repaired.

Using the Tool

ERASE DONE

No Codes Remain (Pres

3-4

Page 18

3.4 MIL Status

The MIL (Malfunction Indicator Lamp) Status function displays the

state of the computer module that commanded the MIL to turn on. A

request is sent to the computer module(s) to state whether they are

commanding the MIL to turn ON. If the MIL Status is ON and the MIL

is not illuminated with the engine running, then a problem exists in the

MIL circuit. Refer to “Diagnostic Circuit Check” in the service repair

manual.

Some manufacturers will turn the MIL Off if a certain number of

drive cycles occur without the same fault being detected. The

!

DTCs related to a MIL are erased from the computer’s memory

after 40 warm-up cycles if the same fault is not detected.

Select the MIL Status function and

press the ENTER key.

The MIL Status will display on the

top line and a scrolling message on

the bottom indicating if the MIL lamp

should be ON or OFF.

Main Menu

3)MIL Status

MIL - ON

MIL Lamp Should be On

When done, press the BACK key to return to the Main Men

u.

3.5 I/M Monitors

The I/M (Inspection and Maintenance) Monitors function displays the

state of the vehicle’s OBD II Monitors. Monitors test the operation of

emission related systems or components and detect out-of-range

values. The vehicle may have to be operated under certain driving

conditions to initiate a monitor.

Using the Tool

3-5

Page 19

Currently, there are eleven OBD II Monitors defined and required by

C

($0E)

the U.S. Environmental Protection Agency (EPA), but not all monitors

are supported by all vehicles. The OBD II monitors and their

abbreviation are listed below.

Abbreviation

Misfire ..................... Misfire

Fuel Sys ................... Fuel System

Comprehens ............. Comprehensive Components

Catalyst................... Catalyst

Heated Cat .............. Heated Catalyst

Evap Sys ................... Evaporative System

Sec Air ...................... Secondary AIR

A/C Refrig .............. Air Conditioning Refrigerant

O2 Sensor................. Oxygen Sensor

HO2 Sensor .............. Oxygen Heater Sensor

EGR Sys ...................... Exhaust Gas Recirculation System

Select I/M Monitors from the Main

Menu and press the ENTER key.

The top line will display the I/M

Monitor and the second line will

display its status. Use the

keys to scroll through the monitors.

• A status of “Ready” means that the required driving conditions

for that monitor have been meet and it passed.

• A status of “Not Ready” means that the required driving

conditions for that monitor have not been met or it did not pass.

• A status of “Not Applicable (N/A)” means the vehicle does not

support that monitor.

Note the Monitors present and their status. When done, press the

BACK key to return to the Main Menu

Definition

omprehens

Comprehens($1F)

Main Menu

Comprehens($D1)

4)I/M Monitors

▲ or ▼

Fuel Sys

Ready

.

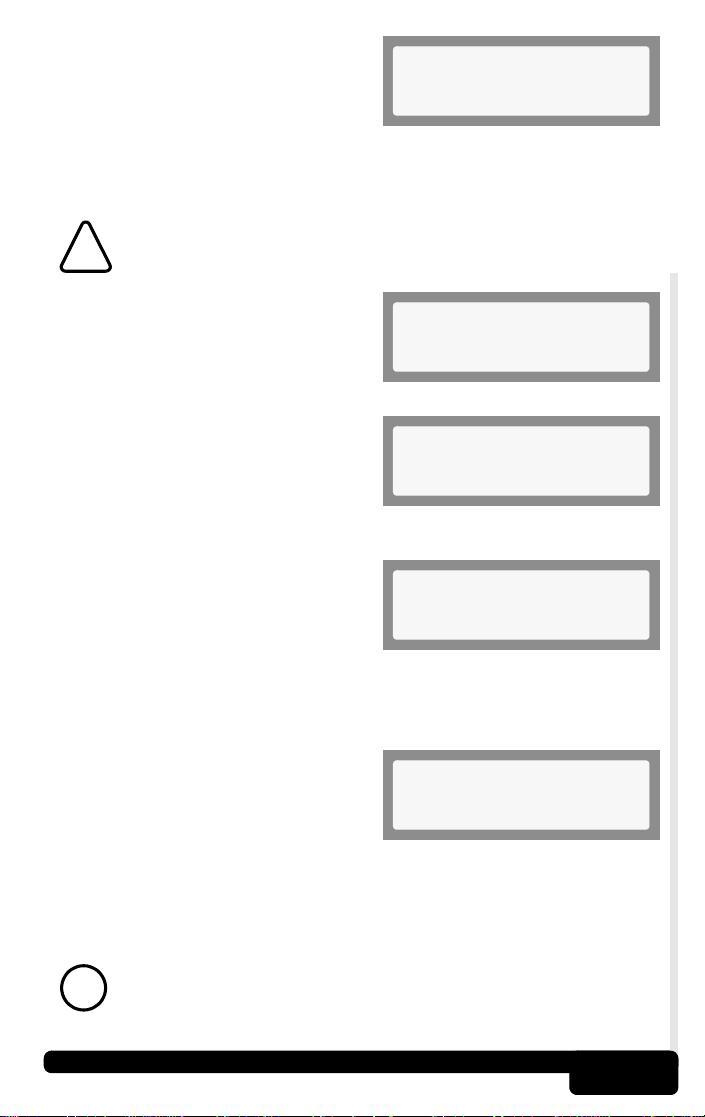

3.6 Tool Setup/Test

The Tool Setup/Test functions allow

the user to adjust the display’s

contrast and perform self-tests.

Using the Tool

Main Menu

5)Tool Setup/Test ]

3-6

Page 20

3.6.1 Changing Display Contrast

The contrast is displayed as a percent value ranging from 100% to

5% and can be changed by 5% intervals .

In the Tool Setup/Test menu, the

first function is Adjust Contrast.

Press the ENTER key and then use

the

▲ or ▼ keys to increase or

decrease the contrast. Holding

down the

steps. When done, press the ENTER key to return to the Tool

Setup/Test menu.

Contrast settings are not saved after the tool is turned OFF. Contrast

is reset to the manufacturers setting when powered-up.

!

This is a self-test to inspect the AutoScanner’s LCD display. The

test will turn every pixel black.

Select Display Test from the Tool

Setup/Test menu and press

ENTER.

The display will toggle between the two following screens every

3 seconds. Look for missing spots in the solid black characters.

When done, press the BACK key to return to the Tool Setup/Test

menu.

▲ or ▼ keys changes the contrast in that direction in 5%

To quickly change the contrast after powering the AutoScanner,

press the ▼ key four (4) times and then the ENTER key twice.

3.6.2 Display Test

][ Change

90% ENTER When Done

Tool Setup

2)Display Test

LCD Test

Press BACK To Quit

3.6.3 Keypad Test

The Keypad Test is used to check the functionality of the

AutoScanner’s Keypad.

Select Keypad Test from the Tool

Setup/Test menu and press the

ENTER key.

Tool Setup

3)Keypad Test

3-7

Using the Tool

Page 21

Each time you press a key, its name

should appear on the display. For

example, if you press the

key, the screen will display

“UP / YES.” If key’s name does not

display, then the key is not working. Press the other keys to verify

proper operation.

Check the BACK key last. When

the BACK key is pressed, the

AutoScanner will return to the Tool

Setup/Test menu. If you are not

returned to this menu, then the

BACK key is not working.

3.6.4 Memory Test

If the AutoScanner has trouble performing functions, the Memory

Test should be performed.

From the Tool Setup/Test menu,

select the Memory Test option and

press ENTER to begin.

As the memory is tested, its address is displayed on the bottom line.

After the memory test is done, either a “TEST PASS” or “TEST FAIL”

message is displayed.

▲ /YES

ROM Test

Testing Addr a500

UP / YES

Press Any Key

BACK

Leaving Keypad Test

Tool Setup

4)Memory Test ]

TEST PASS

Press Any Key

Press any key to return to the Tool Setup/Test menu.

3.6.5 Software Identification (SW ID)

The Software Identification is needed when contacting customer

support. Note this in the manual for reference.

From the Tool Setup/Test menu, select the SW ID option and press

ENTER. Note this in the manual for reference.

Tool Setup

5)SW ID ]

Press any key to return to the Tool Setup/Test menu.

Using the Tool

SW ID: 47H5

Press Any Key

3-8

Page 22

4

n

o

i

t

c

e

S

g

n

i

t

o

o

h

s

e

l

b

u

o

r

T

4.1 Vehicle Inspection

Many problems can be found by performing a visual and “hands-on”

under-the-hood inspection before starting any diagnostic procedure.

• Has the vehicle been serviced recently?

Sometimes things are reconnected in the

wrong place, or not at all.

• Do not take shortcuts. Inspect hoses and

wiring which may be difficult to see because

of location (under air cleaner housing,

alternators and similar components).

• Inspect the air cleaner and ductwork for

defects.

• Check sensors and actuators for

damage.

• Inspect all vacuum hoses for:

- Correct routing. Refer to vehicle

service manual, or Vehicle Emission

Control Information (VECI) decal

located in the engine compartment.

- Pinches and kinks.

- Splits, cuts or breaks.

• Inspect electrical wiring for:

- Damaged insulation caused by sharp

objects (a common problem) or by hot

surfaces such as engine and exhaust

manifold.

- Corroded and broken wires.

4-1

Troubleshooting

Page 23

• Carefully inspect electrical connectors for:

- Corrosion or foreign debris on pins.

- Bent or damaged pins.

- Recessed contacts not seated properly

in housing.

- Bad wire crimps to terminals.

Connector problems are common in vehicles. Inspect carefully.

Some connectors use a special grease, called dielectric grease,

!

on the contacts to prevent corrosion. Do not remove. If required,

apply more grease to the connector. The grease can be obtained

from a dealership or auto parts store.

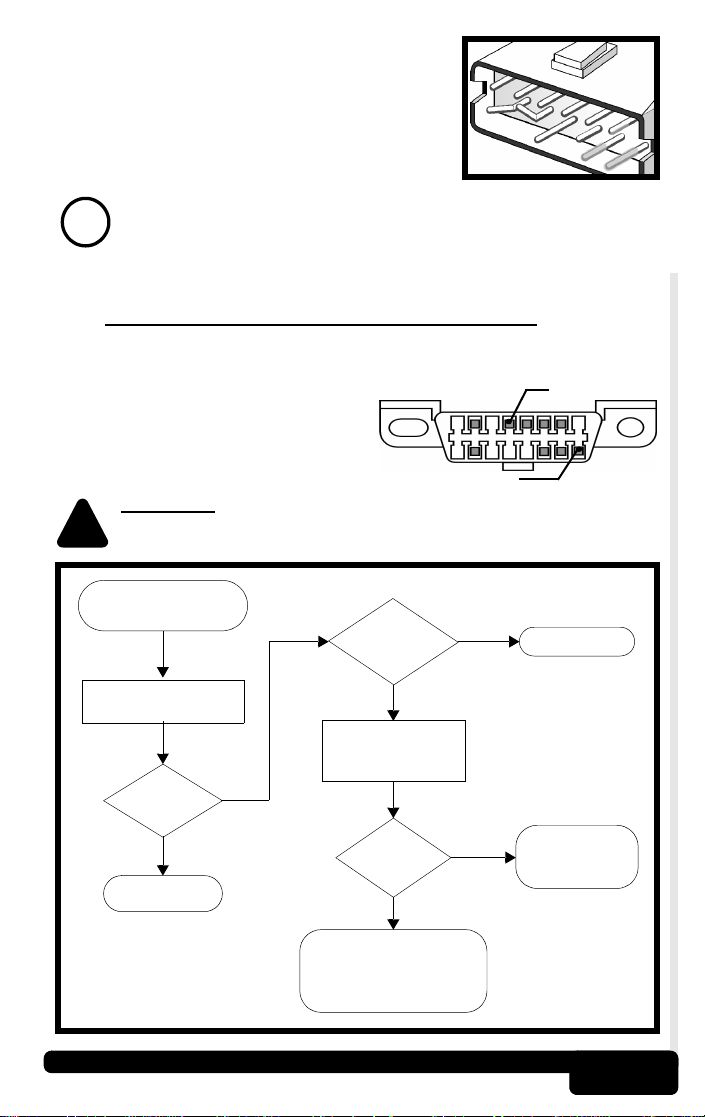

4.2 AutoScanner Does Not Power Up

• Make sure the AutoScanner’s DLC is connected correctly to the

vehicle’s DLC. Verify the pins are clean and fully seated in the DLC.

4

(GND)

• The AutoScanner requires a

minimum of 8 volts between pin

16 (BAT+) and pin 4 (GND) to

power up. Use the flowchart

provided below to troubleshoot.

WARNING! Never Lay Tools On Vehicle Battery. You May Short

The Terminals Together Causing Harm To Yourself, The Tools

!

Or The Battery.

AutoScanner will not

power up.

Is

battery

charged?

PIN 16 (BAT+)

fully

NO

PIN

Charge battery.

Measure Voltage

between Pins 16 and 4.

Above 8V?

YES

Contact Actron.

Troubleshooting

Measure resistance

between Pin 4 and

NO

Open exists in power

circuit. Check for a blown

fuse or an open wire. Refer

to a service manual.

YES

frame ground.

less than

5

ohms?

YES

NO

Repair Ground

circuit.

Refer to a

service manual.

4-2

Page 24

4.3 Link Errors or Erroneous Data

A Link Error occurs if the vehicle’s

computer(s) stops communicating

with the AutoScanner. When this

happens, the AutoScanner prompts

the user to try again. Press the YES

key to try again or the NO key to return to the Main Menu.

If the AutoScanner displays Link Errors when attempting to read or

erase codes, check the following:

• Verify ignition key is ON - not in the

ACCESSORIES position.

• Make sure the AutoScanner’s cable is

securely connected to the vehicle’s DLC.

• Examine the DLC closely and check for

cracked or recessed pins, or for any

substance that could prevent a good

electrical connection.

•Verify that the vehicle you are testing is an OBD II compliant

vehicle. Just because it has the OBD II J1962 DLC does not

mean the vehicle is OBD II compliant. Inspect the vehicle’s

VECI decal for a statement of OBD II compliance.

• Test for continuity between the DLC wiring and the computer. In

an extreme case there may be a broken wire.

• With the KOEO, check the vehicle for blown fuses . The computer

and DLC usually use separate fuses. If the fuse for the computer

fuse is blown, it cannot transmit data. The fuses may be located

on the fuse block in the passenger compartment.

• Make sure the computer has a good ground. If the computer has

a ground directly to the case, clean the connection and apply a

conductive (dielectric) grease to the mating surfaces.

• With the KOEO, verify the battery voltage is at least 10.5V; the

minimum voltage to power the computer.

• As a last resort, the computer may be defective. Refer to the

vehicle service manual to diagnose the computer.

Link Error

Try Again?

4.4 Technical Support

If the AutoScanner is not working correctly after the checks and

corrections above, contact technical support personnel at

1-800-228-7667 (8:00 - 6:00 EST Monday - Friday), or send an email

to tech_support@actron.com. Be prepared to provide the

AutoScanner’s Software ID.

Troubleshooting

4-3

Page 25

A

G

p

l

pe

o

s

s

n

a

d

ry

A

x

i

A/C:

Air Conditioning.

A/F:

Air/Fuel ratio. The proportion of air and

fuel delivered to the cylinder for

combustion. For example, an A/F ratio

of 14:1 denotes 14 times as much air

as fuel in the mixture. A typical ideal

A/F ratio is 14.7:1.

AC Clutch Relay:

The PCM uses this relay to energize

the A/C clutch, turning the A/C system

on or off.

AC Pressure Sensor:

Measures air conditioning refrigerant

pressure and sends a voltage signal to

the PCM.

AC Pressure Switch:

A mechanical switch connected to the

A/C refrigerant line. The switch is

activated (sending a signal to the PCM)

when the A/C refrigerant pressure

becomes too low.

Actuator:

Actuators such as relays, solenoids,

and motors allow the PCM to control

the operation of vehicle systems.

Air Injection Reaction (AIR) System:

An emission control system operated

by the PCM. During cold starts, an air

pump injects outside air into the

exhaust manifold to help burn hot

exhaust gases. This reduces pollution

and speeds warm-up of oxygen

sensors and catalytic converters. After

the engine is warm, the air will either

be “dumped” back to the atmosphere

(or into the air cleaner assembly) or

sent to the catalytic converter.

Bank 1:

The standard way of referring to the

bank of cylinders containing cylinder

#1. In-line engines have only one bank

of cylinders. Most commonly used to

identify the location of oxygen sensors.

See O2S, Sensor 1, Sensor 2.

Bank 2:

The standard way of referring to the

bank of cylinders opposite cylinder #1.

Found on V-6, V-8, V-10, etc. and

horizontally opposed engines. Most

commonly used to identify the location

of oxygen sensors. See O2S, Sensor

1,

Sensor 2.

BARO:

Barometric Pressure Sensor.

See MAP Sensor.

Boost Control Solenoid:

A solenoid that is energized by the

PCM, in order to control supercharger

boost pressure.

Brake Switch Signal:

An input signal to the PCM indicating

that the brake pedal is being pressed.

This signal is typically used to

disengage Cruise Control systems and

Torque Converter Clutch (TCC)

solenoids. See also TCC.

CAM:

Camshaft Position Sensor. Sends a

frequency signal to the PCM in order to

synchronize fuel injector and spark plug

firing.

CARB:

California Air Resources Board.

Governing body for emissions control in

California.

Glossary

A-1

Page 26

CKP REF:

Crankshaft Position Reference.

CKP:

Crankshaft Position. See CPS.

Closed Loop (C/L):

A feedback system that uses the O2

sensor(s) to monitor the results of

combustion. Based on the signal(s)

from the O2 sensor(s), the PCM

modifies the air/fuel mixture to maintain

optimum performance with lowest

emissions. In closed loop mode, the

PCM can “fine tune” control of a

system to achieve an exact result.

CO:

Carbon Monoxide

Continuous Memory Codes:

See Pending Codes.

CPS:

Crankshaft Position Sensor. Sends a

frequency signal to the PCM. It is used

to reference fuel injector operation and

synchronize spark plug firing on

distributorless ignition systems (DIS).

CTS:

Coolant Temperature Sensor. A

resistance sensor that sends a voltage

signal to the PCM indicating the

temperature of the coolant. This signal

tells the PCM whether the engine is

“cold” or “warm”.

Data Link Connector (DLC):

The interface port between the

vehicle’s on-board computer and a

diagnostic tool. Vehicles with OBD II

use a 16-pin connector located in the

passenger compartment.

Data Stream:

The actual data communications sent

from the vehicle’s PCM to the data

connector.

DEPS:

Digital Engine Position Sensor.

Detonation:

See Knock.

DTC:

Diagnostic Trouble Code. Indicates a

malfunction flagged by the vehicle’s

computer.

DI/DIS:

Direct Ignition/Distributorless Ignition

System. A system that produces the

ignition spark without the use of a

distributor.

Duty Cycle:

A term applied to signals that switch

between “on” and “off”. Duty cycle is

the percentage of time the signal is

“on”. For example, if the signal is “on”

only one fourth of the time, then the

duty cycle is 25%. The PCM uses duty

cycle type signals to maintain precise

control of an actuator.

ECT:

Engine Coolant Temperature sensor.

See CTS.

EFI:

Electronic Fuel Injection. Any system

where a computer controls fuel delivery

to the engine by using fuel injectors.

EGR:

Exhaust Gas Recirculation. The PCM

uses the EGR system to recirculate

exhaust gases back into the intake

manifold to reduce emissions. EGR

Recirculation is used only during warm

engine cruise conditions. EGR flow at

other times can cause stalling or no

starts.

EPA:

Environmental Protection Agency.

ESC:

Electronic Spark Control. An ignition

system function that warns the PCM

when “knock” is detected. The PCM will

then retard spark timing to eliminate the

knocking condition.

EST:

Electronic Spark Timing. An ignition

system that allows the PCM to control

spark advance timing. The PCM

determines optimum spark timing from

sensor information

—

engine speed,

A-2

Glossary

Page 27

throttle position, coolant temperature,

engine load, vehicle speed, Park/Neutral

switch position, and knock

sensorcondition

EVAP:

Evaporative Emissions System.

Hall Effect Sensor:

Any of a type of sensor utilizing a

permanent magnet and a transistorized

Hall Effect switch. Hall Effect type

sensors may be used to measure

speed and position of the crankshaft or

camshaft — for spark timing and fuel

injector control.

HO2S:

Heated Oxygen Sensor. See O2S.

IAC:

Idle Air Control. A device mounted on

the throttle body which adjusts the

amount of air bypassing a closed

throttle so that the PCM can control idle

speed.

ICM:

Ignition Control Module.

I/M:

Inspection and Maintenance.

ISC:

Idle Speed Control. A small electric

motor mounted on the throttle body and

controlled by the PCM. The PCM can

control idle speed by commanding the

ISC to adjust its position.

Knock:

Uncontrolled ignition of the air/fuel

mixture in the cylinder. Also referred to

as detonation or ping. Knock indicates

extreme cylinder pressures or

“hotspots” which are causing the

air/fuel mixture to detonate prematurely.

Knock Sensor (KS):

Used to detect engine detonation or

“knock.” The sensor contains a

piezoelectric element and is threaded

into the engine block. Special

construction makes the element

sensitive only to engine vibrations

associated with detonation.

KOEO:

Key On, Engine Off.

.

KOER:

Key On, Engine Running.

LCD:

Liquid Crystal Display.

LT:

Long Te rm fuel trim.

M/T:

Manual transmission or manual

transaxle.

MAF:

Mass Air Flow Sensor. Measures the

amount and density of air entering the

engine and sends a frequency or

voltage signal to the PCM. The PCM

uses this signal in its fuel delivery

calculations.

MAP:

Manifold Absolute Pressure Sensor.

Measures intake manifold vacuum or

pressure and sends a frequency or

voltage signal (depending on sensor

type)

to the PCM. This gives the PCM

information on engine load for control

of fuel delivery, spark advance, and

EGR flow.

MAT:

Manifold Air Temperature sensor . A

resistance sensor in the intake

manifold that sends a voltage signal to

the PCM indicating the temperature of

the incoming air. The PCM uses this

signal for fuel delivery calculations.

MIL:

Malfunction Indicator Lamp. The MIL is

most commonly known as the Check

Engine Light. Also labeled Service

Engine Soon, Power Loss or Power

Limited.

Monitor:

A test performed by the on-board

computer to verify proper operation of

emission related systems or

components.

MPFI or MFI:

Multi-Port Fuel Injection. MPFI is a fuel

injection system using one (or more)

injector(s) for each cylinder. The

injectors are mounted in the intake

manifold, and fired in groups rather

than individually.

Glossary

A-3

Page 28

NOx:

Oxides of Nitrogen. A pollutant. The

EGR system injects exhaust gases into

the intake manifold to reduce these

gases at the tailpipe.

O2S:

Oxygen Sensor. Generates a voltage of

0.6 to 1.1 volts when the exhaust gas is

rich (low oxygen content). The voltage

changes to 0.4 volts or less when the

exhaust gas is lean (high oxygen

content). This sensor only operates

after it reaches a temperature of

approximately 349°C (660°F). O2

sensors are usually found both

upstream and downstream of the

catalytic converter. The PCM uses

these sensors to fine tune the air-fuel

ratio and to monitor the efficiency of the

catalytic converter. See Bank 1, Bank

2, Sensor 1, Sensor 2.

ODM:

Output Device Monitor.

OBD II:

On-Board Diagnostics, Second

Generation. OBD II is a U.S.

Government-mandated standard

requiring all cars and light trucks to

have a common data connector,

connector location, communication

protocol, DTCs and code definitions.

OBD II first appeared on vehicles in

late 1994, and is required to be present

on all cars sold in the US after January

1, 1996.

Open Loop (O/L):

A control system mode that does not

monitor the output to verify if the

desired results were achieved. A fuel

delivery system will usually operate in

open loop mode during cold engine

warm-up because the oxygen sensors

are not yet ready to send a signal.

Without the oxygen sensor signal, the

computer cannot check the actual

results of combustion.

P/N:

Park/Neutral Switch. This switch tells

the PCM when the gear shift lever is in

the Park or Neutral position. When in

Park or Neutral, the PCM will operate

the engine in an “idle” mode.

PCM:

Powertrain Control Module. The

“brains” of the engine control system

housed in a metal box with a number of

sensors and actuators connected via a

wiring harness. Its job is to control fuel

delivery, idle speed, spark advance

timing, and emission systems. The

PCM receives information from

sensors, then energizes various

actuators to control the engine. The

PCM is also known as the ECM

(Engine Control Module).

PROM:

Programmable Read-Only Memory.

The PROM contains programming

information the PCM needs to operate

a specific vehicle model/engine

combination.

Pending Codes:

Also referred to as Continuous Memory

codes and Maturing Diagnostic Trouble

codes. These codes are set when

intermittent faults occur while driving. If

the fault does not occur after a certain

number of drive cycles, the code is

erased from memory.

Purge Solenoid:

Controls the flow of fuel vapors from

the carbon canister to the intake

manifold. The canister collects vapors

evaporating from the fuel tank,

preventing them from escaping to the

atmosphere and causing pollution.

During warm engine cruise conditions,

the PCM energizes the Purge Solenoid

so the trapped vapors are drawn into

the engine and burned.

Reluctance Sensor:

A type of sensor typically used to

measure crankshaft or camshaft Speed

and/or position, driveshaft speed, and

wheel speed

ROM:

Read-Only Memory. Permanent

programming information stored inside

the PCM, containing the information the

PCM needs to operate a specific

vehicle model/engine combination.

SAE:

Society of Automotive Engineers.

A-4

Glossary

Page 29

Sensor:

Any device that reports information to

the PCM. The job of the sensor is to

convert a parameter such as engine

temperature into an electrical signal

that the PCM can understand.

Sensor 1:

A standard term used to identify the

location of oxygen sensors. Sensor 1 is

located upstream of the catalytic

converter. See O2S, Bank 1, Bank 2.

Sensor 2:

A standard term used to identify the

location of oxygen sensors. Sensor 2 is

located downstream of the catalytic

converter. See O2S, Bank 1, Bank 2.

SFI or SEFI:

Sequential Fuel Injection or Sequential

Electronic Fuel Injection. A fuel

injection system that uses one or more

injectors for each cylinder. The injectors

are mounted in the intake manifold, and

are fired individually.

ST:

Short Te rm fuel trim.

TBI:

Throttle Body Injection. A fuel injection

system having one or more injectors

mounted in a centrally located throttle

body, as opposed to positioning the

injectors close to an intake valve port.

TBI is also called Central Fuel Injection

(CFI) in some vehicles.

TDC:

To p Dead Center. When a piston is at

its uppermost position in the cylinder.

Throttle Body:

A device which performs the same

function as a carburetor in a fuel injection

system. On a throttle body injection (TBI)

system, the throttle body is both the air

door and the location of the fuel injectors.

On port fuel injection systems (PFI, MPFI,

SFI, etc.) the throttle body is simply an air

door. Fuel is not added until the injectors

at each intake port are activated. In each

case, the throttle body is attached to the

accelerator pedal.

Glossary

TPS:

Throttle Position Sensor.

Potentiometer-type sensor connected to

the throttle shaft. Its voltage signal

output increases as the throttle is

opened. The PCM uses this signal to

control many systems such as idle

speed, spark advance, fuel delivery,

etc.

TTS:

Transmission Temperature Sensor. A

resistance sensor mounted in the

transmission housing in contact with

the transmission fluid. It sends a

voltage signal to the PCM indicating the

temperature of the transmission.

VECI:

Vehic le Emission Control Information. A

decal located in the engine

compartment containing information

about the emission control systems

found on the vehicle. The VECI is the

authoritative source for determining

whether a vehicle is OBD II compliant.

VIN:

Vehic le Identification Number. This is

the factory-assigned vehicle serial

number. This number is stamped on a

number of locations throughout the

vehicle, but the most prominent

location is on top of the dashboard on

the driver’s side, visible from outside

the car. The VIN includes information

about the car, including where it was

built, body and engine codes, options,

and a sequential build number.

VSS:

Vehicle Speed Sensor. Sends a

frequency signal to the PCM. The

frequency increases as the vehicle moves

faster to give the PCM vehicle speed

information used to determine shift points,

engine load, and cruise control functions.

WOT:

Wide-Open Throttle. The vehicle

operating condition brought about when

the throttle is completely (or nearly) open.

The PCM will typically deliver extra fuel to

the engine and de-energize the A/C

compressor at this time for acceleration

purposes. The PCM uses a switch or the

Throttle Position Sensor to identify the

WOT condition.

A-5

Page 30

B

x

i

d

n

pe

p

A

I

I

D

B

O

t

u

o

b

A

OBD II

In 1994, manufacturers began equipping vehicles with a new class of computer

technology which puts more processing power in the vehicle than ever before. It

is called On-Board Diagnostics, Second Generation (OBD II) and offers increased

system monitoring and diagnostic information. Beginning January 1, 1996,

vehicles sold in the U.S. are required to be OBD II compliant. However, a few

vehicles were exempt since no changes were made to the engine. Most domestic

manufacturers began using this system on some vehicles beginning as early as

1994.

OBD II systems are designed to meet or exceed standards and regulations to

improve air quality. These standards and regulations are primarily set forth by the

Environmental Protection Agency (EPA) Clean Air Act of 1990. Most of the

standards and regulations were developed by the California Air Resources Board

(CARB). OBD II systems are unique in that they possess the capability of

monitoring the performance of emission related systems and their components;

to detect hard and intermittent faults that may cause a vehicle to pollute.

This new system stores a large library of general trouble codes along with

manufacturer-specific codes, some of which can be accessed with the tool. These

codes cover:

B-Codes . . . . . . . Body Systems

C-Codes . . . . . Chassis Systems

Now, basic terms are standardized and all generic (global) codes share a common

format and terminology established by the manufacturers and the Society of

Automotive Engineers (SAE).

Basics of Computer-Controlled Vehicles

This section explains the engine computer control system, the types of sensors

and how the computer controls engine fuel delivery, idle speed and timing.

Additional information may be found in technical support books at your local library

or auto parts store. The more you know about the computer system, the better

you can diagnose vehicle computer problems.

Computer

regulations for lower emissions levels and improved fuel economy. This began in

the early 1980’s when basic mechanical systems were no longer able to accurately

control key engine parameters. A computer could be programmed to control the

engine under various operating conditions, making the engine more reliable. While

these early systems were very limited in the scope of their control, providing only

10 to 14 trouble codes, they did help guide the vehicle repair process.

Today,

efficient than ever before.

U-Codes . Network Communications

P-Codes . . . . . . Powertrain Systems

controls were originally installed on vehicles to meet federal government

computer controls have made cars and trucks faster, cleaner, and more

B-1

About OBD II

Page 31

What does the computer control

The main control areas of the vehicle computer are fuel delivery, idle speed,

spark advance, and emission controls. Some on-board computers may also

control the transmission, brakes, and suspension systems as well.

What has not changed

A computer-controlled engine is very similar to the older, non-computerized

engine. It is still an internal combustion engine with pistons, spark plugs,

valves, and camshaft(s). The ignition, charging, starting, and exhaust systems

are very similar as well. You test and repair these systems just as before.

The technical manuals for these components show you how to perform the

tests. Additionally, compression gauges, vacuum pumps, engine analyzers,

and timing lights will continue to be useful.

The engine computer control system

The vehicle’s on-board computer is the “heart” of the system. It is sealed in

an enclosure and connected to the rest of the engine by a wiring harness.

The computer is located, in most cases, in the passenger compartment,

behind the dashboard or in the “kick panel” position, although some

manufacturers locate the computer control module in the engine compartment

area. Most computers can withstand a lot of vibration and are built to live in

a rugged environment.

computer is programmed by the manufacturer. The program is a complex

The

list of lookup tables and instructions telling the computer how to control the

engine based on various driving conditions. To do its job, the computer uses

sensors to know what is happening and then provides instructions back to a

network of switches and actuators throughout the vehicle.

Sensors (computer inputs)

Sensors are devices which measure operating conditions and translate them

into signals the computer can understand. Some examples of sensors:

thermistors (for temperature readings), potentiometers (like a throttle position

sensor), and signal generators (such as an 02 sensor).

Relays and actuators

Relays and Actuators are electric devices energized by the computer to

perform a specific function. A relay is an electromagnetic device (or switch)

for remote or automatic control that is actuated by the computer or another

device. Actuators might include solenoids (such as fuel injector valves) and

small motors (such as the Idle Speed Control). Not all of the computer’s

outgoing signals are routed to relays and actuators. Sometimes information

is sent to other system computers like transmission, brakes, ignition modules,

and trip computers. These signals are also called “outputs.”

How the Computer Controls Fuel Delivery

Engine operation and emissions performance depend upon precise fuel

delivery and ignition control. Early computer systems controlled fuel by

electronically adjusting the carburetor metering and jet systems. Soon,

however, this was replaced by the more precise fuel delivery of fuel injection.

an electronically carbureted system, the computer simply controls fuel flow

In

based on how far the throttle is opened by the driver. The computer “knows”

how much air can flow through the carburetor at various throttle openings,

and adds the appropriate amount of fuel to the mixture at the carburetor.

Fuel injection is some what more sophisticated in the way it delivers fuel. The

computer still adds an appropriate amount of fuel to the entering air, but now

About OBD II

B-2

Page 32

it uses fuel injectors (either in a throttle body or at each intake port). Fuel

injectors are far more precise than carburetor jets, and create a much finer

fuel “mist” for better combustion and increased efficiency. In addition, most

fuel injection systems have ways of measuring exactly how much air is

entering the engine, and can calculate the proper air/fuel ratio using lookup

tables. Computers no longer have to “estimate” how much air the engine is

using.

many modern systems, the computer also uses information provided by

In

sensors to give it an idea of how well it is doing its job, and how to do it better.

Sensors can tell the computer how warm the engine is, how rich or lean the

fuel mixture is, and whether accessories (like the air conditioner) are running.

This feedback information allows the computer to “fine tune” the air/fuel

mixture, keeping the engine operating at its peak.

What the computer needs to know

• Engine operating condition. Sensors used are: coolant temperature,

throttle position, manifold pressure (vacuum), air flow and RPM.

intake. Sensors used are: mass air flow, manifold absolute pressure,

• Air

manifold air temperature and RPM.

• Air/fuel mixture status. Sensors used are: oxygen sensor(s).

Open and closed loop modes

Open or closed loop operation refers to the way the computer is deciding how

much fuel to add to the air entering the engine. During cold start and other low

temperature situations, the computer operates in open loop mode. This means

that it is relying on a set of internal calculations and data tables to decide how

much fuel to add to the incoming air. It uses sensors such as the coolant

temperature sensor (CTS), the throttle position sensor (TPS), and the manifold

absolute pressure sensor (MAP) to determine optimum mixtures. The important

difference here is that it does not check to see if the mixtures are correct, leaving

the computer adjustment loop open

closed loop mode, the computer still decides how much fuel to add by using

In

the sensors listed above, and by looking up the appropriate numbers on a data

table. However, it now checks itself to determine whether the fuel mixture is

correct. It is able to check itself by using the information provided by the oxygen

sensor(s) (O2S) in the exhaust manifold. The O2S will tell the computer if the

engine is running rich or lean, and the computer can take steps to correct the

situation. In this way, the computer closes the adjustment loop by checking itself

and making necessary corrections. It should be noted that the O2S must be at a

very high operating temperature (650°F) before they begin sending information

to the computer. This is why open loop mode is necessary—to give the O2 sensors

time to warm up to operating temperature.

long as the engine and O2 and Coolant Temperature Sensors are at operating

As

temperature, the computer can operate in the closed loop mode. Closed loop

mode constantly corrects to obtain an air/fuel mixture at the ideal 14.7:1. But in

stop and go cycles, the O2 sensor may in fact cool down enough that the computer

will need to rely on a set of internal parameters and go into open loop mode again.

This may happen during extended periods of idling. Many newer vehicles now

use heated O2 (HO2S) sensors to prevent this condition.

In many vehicles, the computer controls other systems related to open and closed

loop modes, including idle speed, electronic spark control, exhaust gas

recirculation, and transmission torque converter clutches. In open loop

some of these systems will be adjusted to speed the warming of the engine and

get the computer into closed loop mode as quickly as possible.

.

mode,

About OBD II

B-3

Page 33

About Diagnostic Trouble Codes (DTCs)

Engine computers can find problems

The computer systems in today’s vehicles do more than control engine

operations—they can help you find problems, too! Special testing abilities are

permanently programmed into the computer by engineers. These tests check

the components connected to the computer which are used for (typically):

fuel delivery, idle speed control, spark timing, emission systems, and

transmission shifting. Mechanics have used these tests for years. Now you

can do the same thing by using your OBD II AutoScanner!

Engine computers perform special tests

The engine computer runs the special tests, depending on the manufacturer,

engine, model year, etc. There is no “universal” test that is the same for all

vehicles. The tests examine INPUTS (electrical signals going INTO the

computer) and OUTPUTS (electrical signals coming OUT of the computer),

as well as internal calculations made by the computer. Input signals which

have “incorrect” values, or output circuits which do not operate properly are

noted by the test program and the results are stored in the computer’s

memory. These tests are important. The computer cannot control the engine

properly if it has incorrect input information or faulty output circuits.

Code numbers reveal malfunctions

Malfunctions are stored by using code numbers, usually called “diagnostic

trouble codes” or “DTCs.” For example, a code P0122 might mean “throttle

position sensor signal voltage is too low.” Generic code meanings are a part

of your OBD II AutoScanner’s software. Manufacturer specific DTCs will

require the use of a vehicle service manual. See page 2-5 for more information

on ordering service manuals or on the enclosed product CD.

Read trouble codes

To find the cause of the problem yourself, you need to perform special tests

called “diagnostics.” These procedures are in the vehicle’s service manual.

There are many possible causes for any problem. For example, suppose you

turned on a wall switch in your home and the ceiling light did not turn on. Is

it the bulb, light socket, wiring, or wall switch? Maybe there is no power coming

into the house! As you can see, there are many possible causes. The

diagnostics written for servicing a particular trouble code take into account

all the possibilities. If you follow these procedures, you should be able to find

the problem causing the code and fix it yourself.

the OBD II AutoScanner is fast and easy. Trouble codes give you

Using

valuable knowledge - whether you go for professional service or do it yourself.

Now that you know what trouble codes are and where they come from, you

are well on your way to fixing today’s computer-controlled vehicles! Once you

have read the DTCs, you can either:

•Have

•Repair

With

in the vehicle, helping to pinpoint the system where there may be a problem.

your vehicle professionally serviced, or

the vehicle yourself using the diagnostic trouble codes to help

locate the source of the problem.

the OBD II AutoScanner, you can also monitor the operation of systems

About OBD II

B-4

Page 34

About the Malfunction Indicator Lamp (MIL)

All OBD II compliant vehicles have a “Malfunction Indicator Lamp” or MIL. In

the past, the MIL has been referred to as a “Check Engine” or “Service Engine

Soon” light.

Normal operation

The engine computer turns the MIL ON and OFF as needed. This dashboard

message is either amber or red, and maybe labeled with “Check Engine”,

“Service Engine Soon”, “Service Engine Now”, or marked with a small engine

picture or diagram

The MIL is normally OFF when the engine is RUNNING.

NOTE: The MIL will turn on when the ignition key is in ON position, but

Problem spotted

If the MIL does not come on during this test, you may have an electrical

problem which needs repair. Refer to the “Diagnostic Circuit Check” steps of

your vehicle service manual.

Current problem

When the MIL remains ON after the engine is RUNNING, the computer sees

a problem that does not go away (known as a “current” failure). The light will

stay on as long as the problem is present and a trouble code is stored in the

computer’s memory. Use the OBD II AutoScanner at the earliest convenient

time to obtain codes.

Intermittent problem

When

the computer saw a problem, but the problem went away (known as an

“intermittent” failure). Though the MIL went OFF because the problem went

away, the code stays in memory. Use the OBD II AutoScanner at the earliest

convenient time to obtain codes.

NOTE: The computer will automatically erase these codes after

Poorly running engine, no MIL

Most likely, this condition is not due to computer system failures, but reading

codes can still be useful as part of a basic troubleshooting procedure. Check

wiring and bulb for “Check Engine” light failures. Refer to vehicle service

manual for additional diagnostic information.

On

The vehicle may not run any differently, but the OBD II system is designed

to note very small changes in the engine’s operation which could lead to

emissions damage or failure.

the engine is OFF prior to starting the vehicle. This is a normal

test of all the dashboard message lights.

the MIL comes ON and then goes OFF while the engine is RUNNING,

repeated restarts if the problem does not return.

OBD II vehicles, the MIL also signals an emissions-control related failure.

B-5

About OBD II

Page 35

Cleveland Ohio 44135 USA (EUA)

OBD II

AutoScanner

C P 913 5

™

Permet la réalisation de diagnostics

sur les véhicules fabriqués depuis

1994, conformes avec l'OBD II

Instructions in English, Spanish and French

Instrucciones en inglés, español y franceses

Instructions en anglais, espagnol et français

Voltage: 16V

Tension 16V

Tension de 16V

Page 36

Actron Manufacturing Company ("Actron") garantit à l'acheteur d'origine que ce pro-

GARANTIE LIMITÉE D'UN (1) AN