Page 1

TEST

IGNITION MODULE &

ENGINE SENSOR TESTER

HIGH

RANGE

RICH

Select

LOW

LOW,

POWER OFF

VOLTS

VOLTS

OHMS

FREQUENCY

FUNCTION

9V BATTERY TEST: 1) SET RANGE TO HIGH.

SIGNAL COMMON TRIGGER POWER 9V

2) SET FUNCTION TO OHMS. 3) DISCONNECT ALL LEADS.

O.K. IF TOPMOST TEST LIGHT IS ON. WEAK IF ANOTHER LIGHT IS ON.

®

LEAN

PULSE

CP9087

PROFESSIONAL

TM

Page 2

Vehicle

Service

Info

The following publishers have manuals containing diagnostic information for

electronic engine control and ignition systems. Contact the publishers for

availability and pricing, specifying the make, model and year of your vehicle.

Some manuals may be available at auto parts stores or your local public library.

Vehicle Service Manuals

Chilton Book Company

Chilton Way

Radnor, PA 19089

Haynes Publications

861 Lawrence Drive

Newbury Park, CA 91320

Vehicle Service

Manuals from General

Motors Corporation

Buick, Cadillac,

Chevrolet, GEO, GMC,

Oldsmobile & Pontiac

Helm Incorporated

Post Office Box 07130

Detroit, MI 48207

Saturn

Adistra Corporation

c/o Saturn Publications

101 Union Street

Post Office Box 1000

Plymouth, MI 48170

Cordura Publications

Mitchell Manuals, Inc.

Post Office Box 26260

San Diego, CA 92126

Suitable manuals have titles such as:

“Electronic Engine Controls”

“Fuel Injection and Feedback Carburetors”

“Fuel Injection and Electronic Engine Controls”

“Emissions Control Manual”

... or similar titles.

Vehicle Service

Manuals from Ford

Motor Company (Ford,

Motor’s Auto Repair Manual

Hearst Company

250 W. 55th Street

New York, NY 10019

Vehicle Service

Manuals from Toyota,

Honda, Nissan

Lincoln, Mercury)

Ford Publication Dept.

Helm Incorporated

Post Office Box 07150

Detroit, MI 48207

Vehicle Service

Manuals from Chrysler

Corporation

Chrysler Corporation

Dyment Distribution Service

Post Office Box 360450

Strongsville, OH 44136

Toyota Motor Corporation

Toyota Service Publications

750 W. Victoria Street

Compton, CA 90220-5538

Honda Motor Co., Ltd.

Helm Incorporated

Post Office Box 07280

Detroit, MI 48207

Nissan North America, Inc.

Dyment Distribution Service

c/o Nissan

20770 Westwood Drive

Strongsville, OH 44136

Page 3

Index

Section

1

2

3

4

Vehicle Service Information ...................... Inside front cover

Safety Precautions ............................................................... ii

Tester Basics............................................. 1-1

Testing Sensors ..........................................

• Troubleshooting Tips .......................................... 2-1

• Engine Coolant Temperature.............................. 2-2

• Inlet Air Temperature .......................................... 2-3

• Throttle Position (TP) .......................................... 2-6

• EGR Valve Position (EVP)................................ 2-14

• Oxygen .............................................................. 2-18

• Engine Knock .................................................... 2-26

• Manifold Absolute Pressure (MAP/BARO) ....... 2-28

• Mass Air Flow (MAF) ........................................ 2-34

• Vane Air Flow.................................................... 2-40

• Crankshaft/Camshaft Position .......................... 2-46

Magnetic Reluctance Type ......................... 2-49

Hall Effect or Optical Type .......................... 2-51

Testing Ignition Modules............................3-1

More Uses for the Sensor Probe ...............4-1

• "Circuit Tester" Voltage Check ........................... 4-1

• Continuity Checks ............................................... 4-2

• Diode Check........................................................ 4-4

2-1

i

Page 4

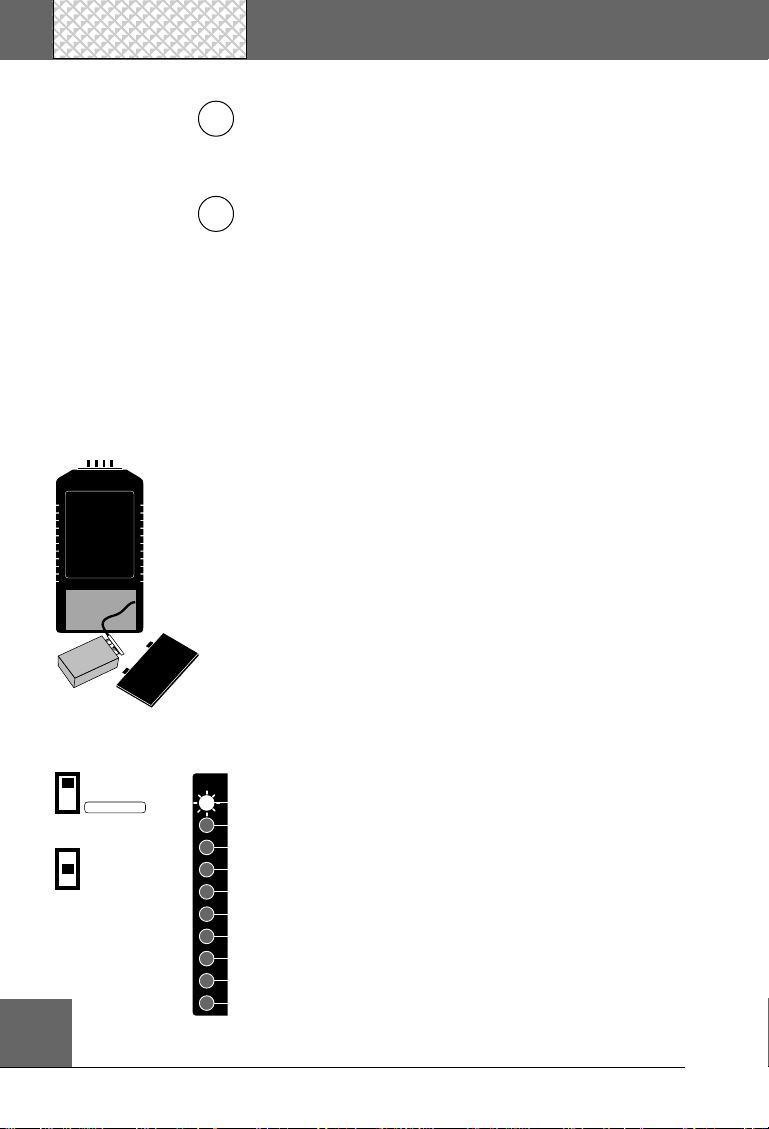

Safety

First

General Safety Guidelines to Follow When

Working on Vehicles

• Always wear approved eye protection

• Always operate the vehicle in a well-ventilated area. Do not inhale exhaust

gases – they are very poisonous!

• Always keep yourself, tools, and test equipment away from all moving or hot

engine parts.

• Always make sure the vehicle is in Park (automatic transmission) or Neutral

(manual transmission) and that the parking brake is firmly set. Block the drive

wheels.

• Never lay tools on vehicle battery. You may short the terminals together,

causing harm to yourself, the tools, or the battery.

• Never smoke or have open flames near vehicle. Vapors from fuel or charging

batteries are highly flammable and explosive.

• Never leave vehicle unattended while running tests.

• Always keep a fire extinguisher suitable for all types of fires handy.

• Always turn ignition key OFF when connecting or disconnecting electrical

components, unless otherwise instructed.

• Use shop rags to cover fuel line fittings when connecting or disconnecting fuel

lines. Avoid contact with fuel. Dispose of all rags properly.

• Clean up all fuel spills immediately.

• Keep away from engine cooling fan. On some vehicles, the fan may start up

unexpectedly.

• You must follow vehicle service manual cautions when working around the air

bag system. If the cautions are not followed, the air bag may open unexpectedly, resulting in personal injury. Note that the air bag can still open up several

minutes after the ignition key is turned OFF (or even if the battery is disconnected) because of a special energy reserve module.

• Always follow vehicle manufacturer’s warnings, cautions, and service procedures.

ii

6-3

Page 5

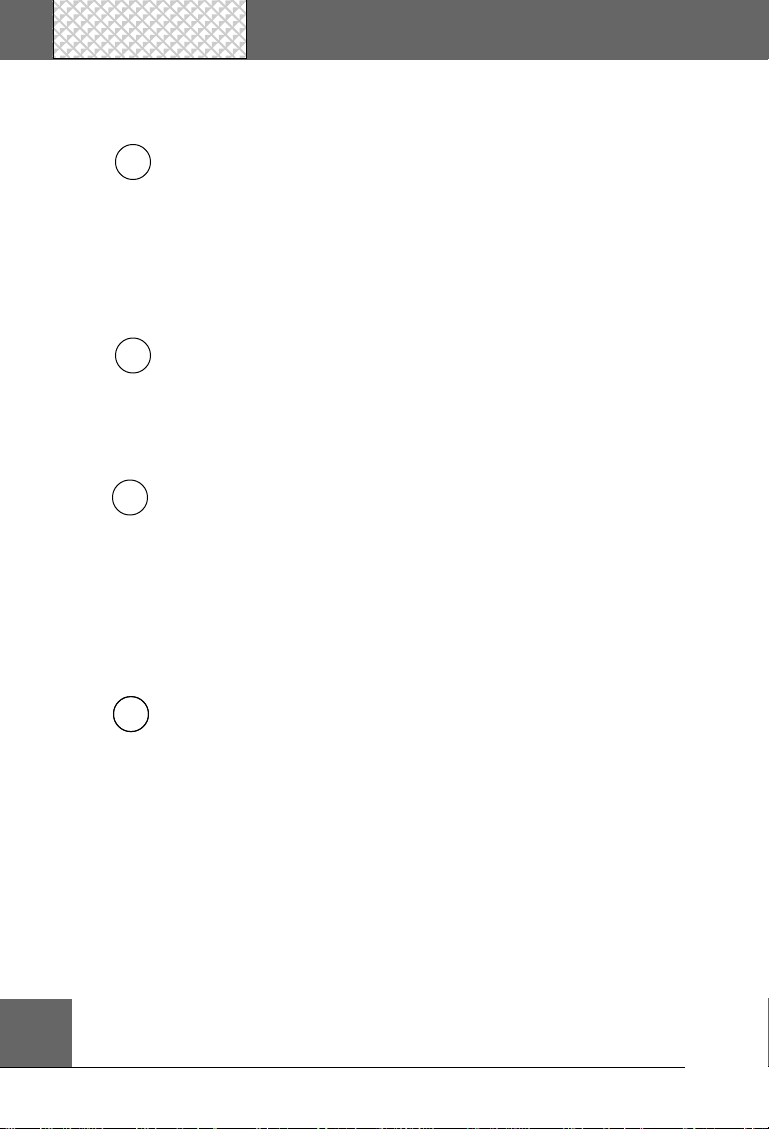

Section

Tester

1

— Description of Controls and Accessories

— Installing and Checking the 9 Volt Battery

Note: Detailed procedures for testing sensors and ignition modules are

located in Section 2 (sensors) and Section 3 (ignition modules).

RANGE

Switch

Basics

Controls power to the Tester and selects measure-

1

ment range sensitivity (as required by various

sensor tests).

• POWER OFF - No power supplied to either the

tester or RED test lead.

• LOW - Tester powered up for use. Voltage from

9 volt battery supplied to RED test lead. Selects

range for measuring low levels of voltage,

resistance or frequency.

• HIGH - Tester powered up for use. Voltage from

9 volt battery supplied to RED test lead. Selects

range for measuring higher levels of voltage,

resistance or frequency.

2

FUNCTION

Switch

Selects the type of signal being measured (for

conducting sensor and ignition module tests). Different

kinds of signals are used by various sensors.

• VOLTS - Measures voltages. This function is used

to test most sensors.

• OHMS - Measures resistance. Also used for

checking continuity and testing diodes (see section

4). Mostly used for testing temperature sensors.

• FREQUENCY - Measures frequency signals.

(Peak signal voltage must be at least 3 volts

to register.) Some MAP and MAF sensors

send a frequency signal. This function is

also used to test ignition modules.

1-1

Page 6

Section 1

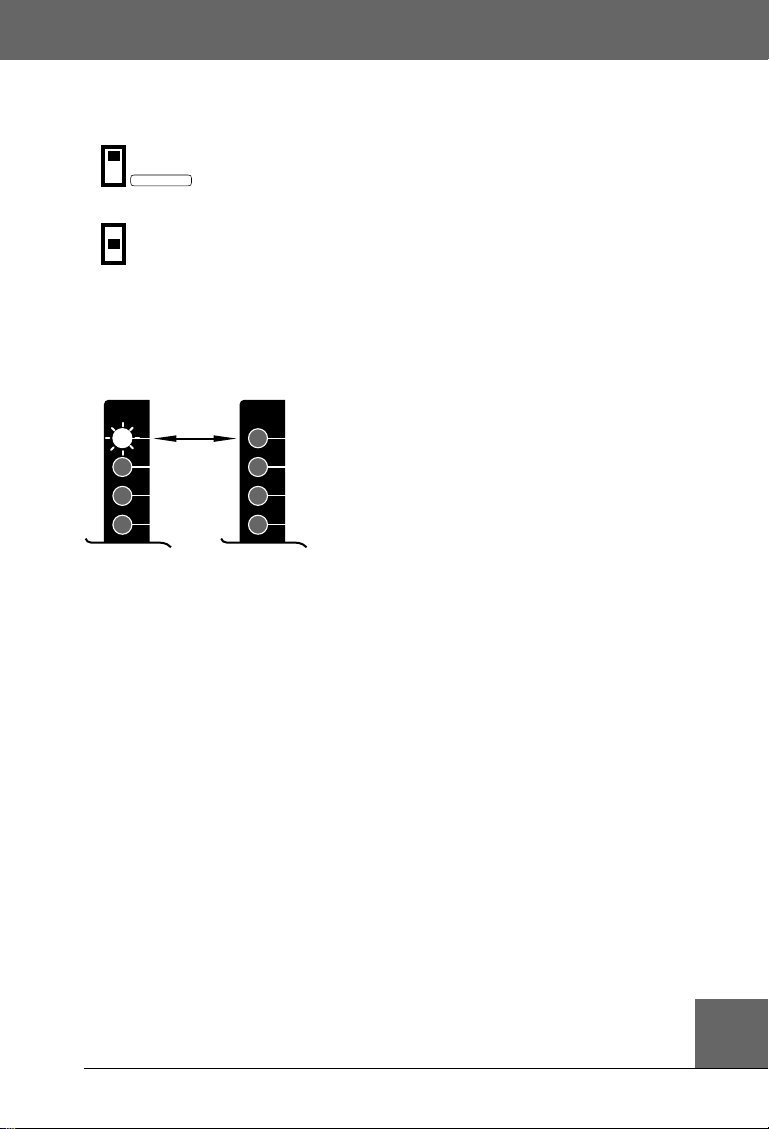

A single TEST light turns on to show the level of a measured signal

3

(voltage, resistance or frequency). When signal values are low, the

TEST

Lights

PULSE

Light

RICH/

LEAN

Lights

TEST light is off or near the bottom of the column. The TEST light

moves higher up the column as the signal level increases.

Sensor tests involve working the sensor and watching the TEST

light move up, down or flash. Note that the motion of the light is

more important than its actual position.

Used when testing ignition modules. The PULSE light will flash

4

if the module is good.

Note that the PULSE light will also be on (or flash) whenever

frequency signals are being measured - this is normal.

These lights are active when the tester switches are set to LOW

5

VOLTS only.

• LEAN (green): ON for voltages between 0.1 and 0.59 volts.

• RICH (red): ON for voltages above 0.6 volts.

The RICH/LEAN lights work along with the TEST lights and are

helpful when testing oxygen sensors. The RICH/LEAN lights may be

ignored when testing other sensors using the LOW VOLTS range.

1-2

6

6

Test

Leads

Two or more of these are used for the various tests and checks.

Yellow - The SIGNAL lead. Signals probed by this lead cause

the TEST lights to react. Usually connected to a sensor or

ignition module output circuit during testing.

Black - The COMMON lead. Used as a circuit ground or signal

reference point for all tests and checks. This lead is always

used.

Green - The TRIGGER lead. Used when testing ignition

modules. Sends a signal to “fire” the module. Usually connected

to the module crankshaft/camshaft input circuit.

Red - The 9V power lead. This lead is connected to the 9 volt

battery inside the tester whenever the RANGE switch is in the

LOW or HIGH positions. Ignition modules and some sensors

require this power for testing.

Page 7

IGNITION MODULE &

IGNITION MODULE &

ENGINE SENSOR TESTER

ENGINE SENSOR TESTER

TEST

Tester Bas ics

6

1

2

4

7

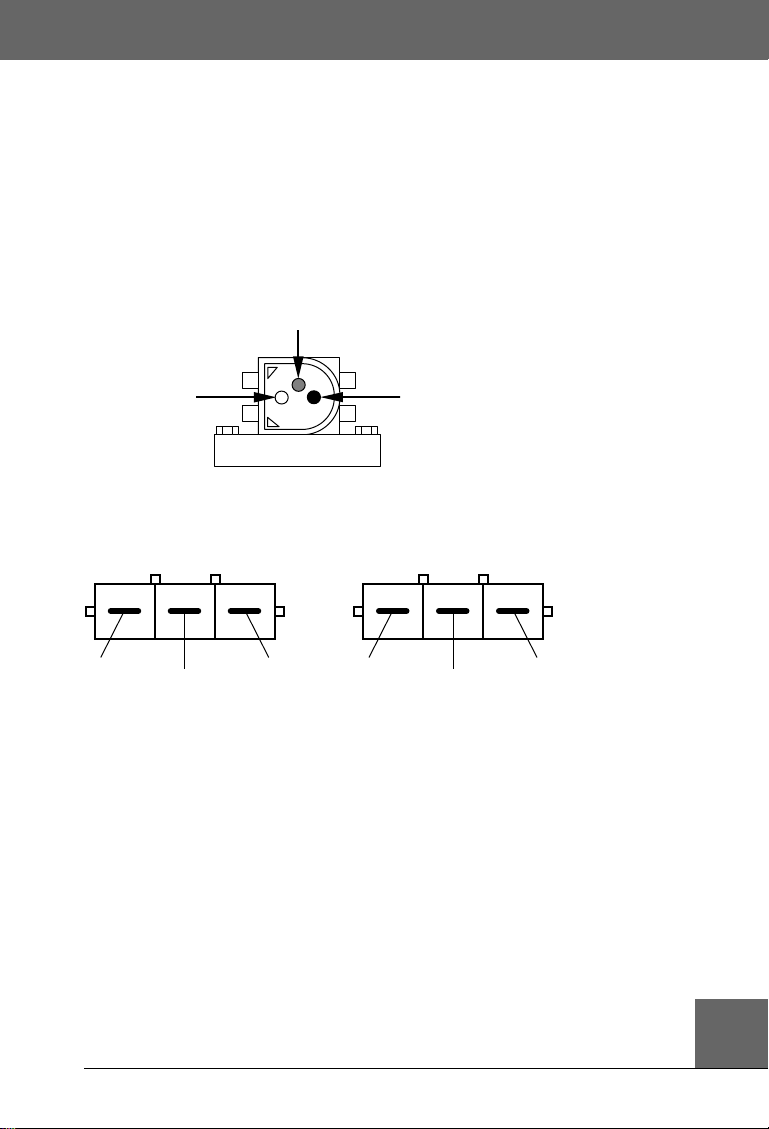

Backprobe

Adapter

To Sensor

3

5

RANGE

FUNCTION

HIGH

LOW

POWER OFF

VOLTS

OHMS

FREQUENCY

Select

LOW,

VOLTS

PULSE

RICH

LEAN

7

SIGNAL COMMON TRIGGER POWER 9V

9V BATTERY TEST: 1) SET RANGE TO HIGH.

2) SET FUNCTION TO OHMS. 3) DISCONNECT ALL LEADS.

O.K. IF TOPMOST TEST LIGHT IS ON. WEAK IF ANOTHER LIGHT IS ON.

8

9

Allows test lead to probe sensor circuits when the sensor is

connected to vehicle wiring harness.

• Slide the “scooped” end of adapter next to circuit wire

entering rear of connector.

• Continue pushing adapter until it touches terminal inside

connector. (Slightly twisting adapter while pushing may

ease entry)

• Grasp open end of adapter with test lead clip. Keep

pushing on adapter to maintain circuit contact.

To Computer

Caution: The “scooped” end of the

adapter will break if you bend it.

1-3

Page 8

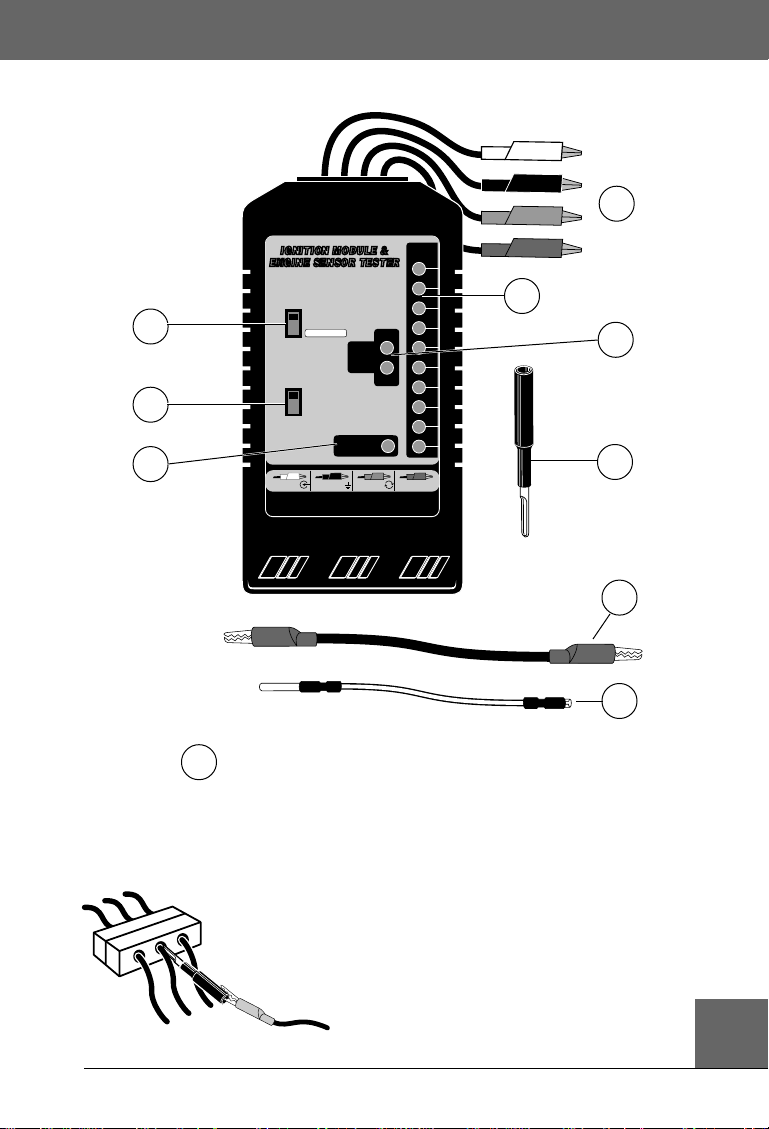

Section 1

8

Jumper Lead

9

Connector

Pin Adapters

Tester Basics

Used when checking some ignition modules. Makes

extra connections as required for testing.

Used for easier attachment of test leads to certain

sensor or wiring connector pins.

• Push one end of the adapter onto the desired

connector pin.

• Grasp the other end with the test lead clip.

9V

RANGE

FUNCTION

HIGH

LOW

POWER OFF

VOLTS

OHMS

FREQUENCY

Sensor

Tester

Power

TEST

A 9-volt transistor radio battery must be installed to

power the unit. Use an alkaline battery (conventional

batteries are too weak for ignition module testing).

Installing the Battery

1. Hold the tester face down with both hands.

2. Using both thumbs, firmly press downwards and

outwards on the battery compartment door at the

bottom of the tester.

3. Slide the battery compartment door away from the

tester to remove.

4. Attach battery to connector and install inside

compartment.

5. Replace battery door. Slide door inwards until it

snaps closed.

Checking the Battery

1. Make sure none of the test leads are connected

together or touching anything.

2. Set RANGE switch to HIGH.

3. Set FUNCTION switch to OHMS.

4. Battery is good if the top TEST light is ON. If any light

below the top TEST light is ON, the battery is too

weak for reliable testing and should be replaced.

TIP: To extend battery life, always switch to POWER

OFF when not making a measurement. This is safe to

do even if the tester is connected to a circuit.

1-4

Page 9

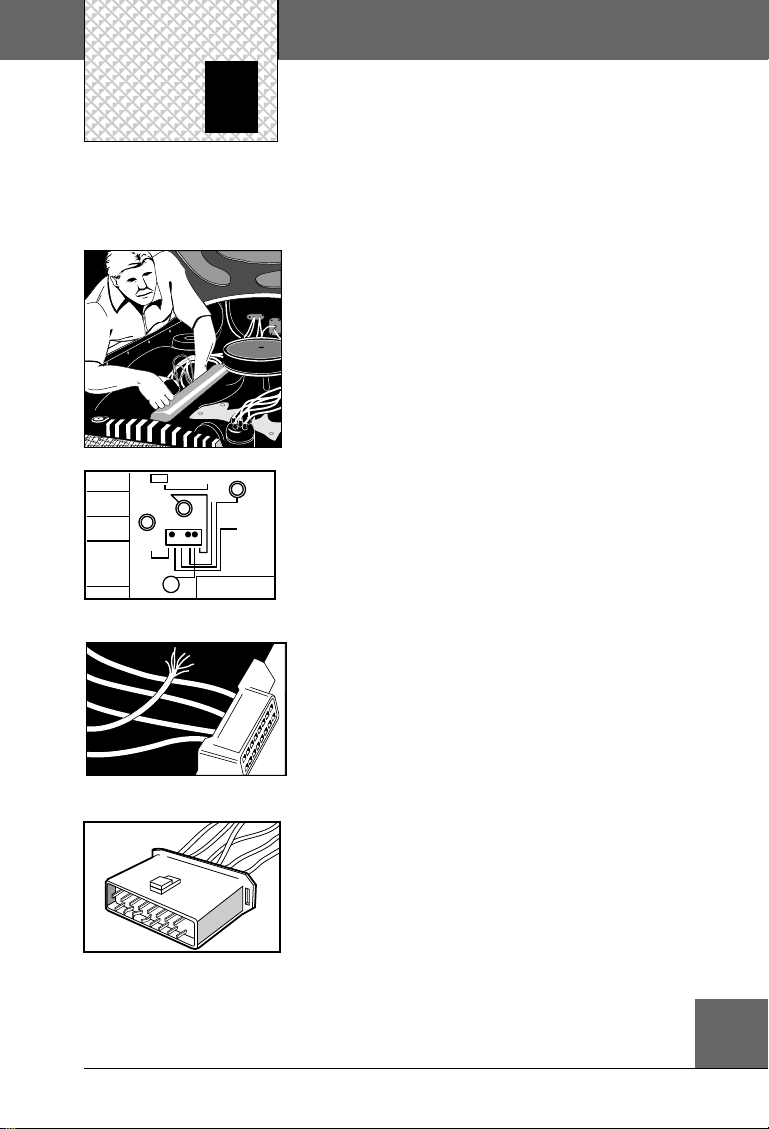

Section 2

Section

2

T roubleshooting

Tips

HVAC

YST

CE BOOSTER

G GAP

U.S.A.

M

CRUISE

EGR

VAC

REG

EGR

VAC

REG

BRAKE BOOSTER

FUEL

PRESS

REG.

TO TRANS

MODE

FRONT

OF CAR

12RA C8

6DLC24

Testing Sensors

Save yourself time! Always begin with a thorough

visual and “hands-on” inspection. You can often

find the cause of many problems by just looking.

• Has the vehicle been serviced recently?

Sometimes things get reconnected in the wrong

place, or not at all.

• Don’t take shortcuts. Inspect hoses and wiring

which may be difficult to see due to location.

• Inspect the air cleaner and ductwork for defects.

• Check sensors and actuators for damage.

• Inspect all vacuum hoses for:

– Correct routing. Refer to vehicle service

manual, or Vehicle Emission Control Information

(VECI) decal located in the engine compartment.

– Pinches and kinks.

– Splits, cuts or breaks.

• Inspect wiring for:

– Contact with sharp edges (this happens often).

– Contact with hot surfaces, such as exhaust

manifolds.

– Pinched, burned or chafed insulation.

– Proper routing and connections.

5AAC28

• Check electrical connectors for:

– Corrosion on pins.

– Bent or damaged pins.

– Contacts not properly seated in housing.

– Bad wire crimps to terminals.

2-1

Page 10

Section 2

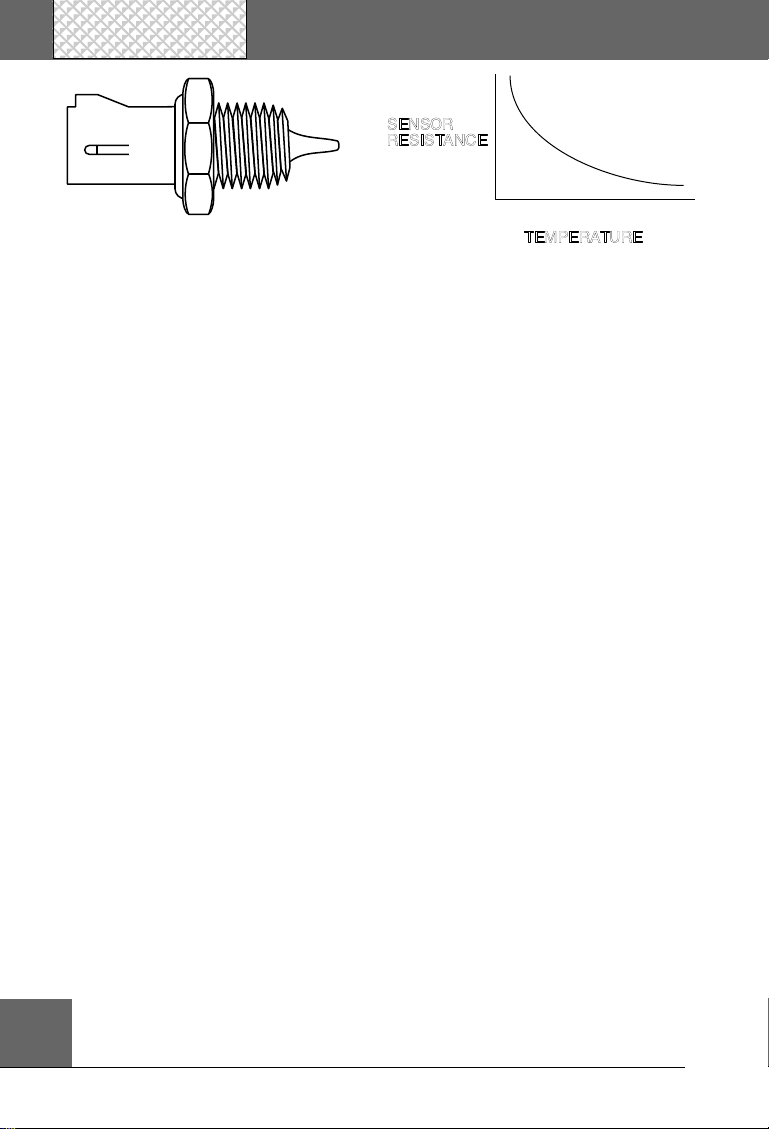

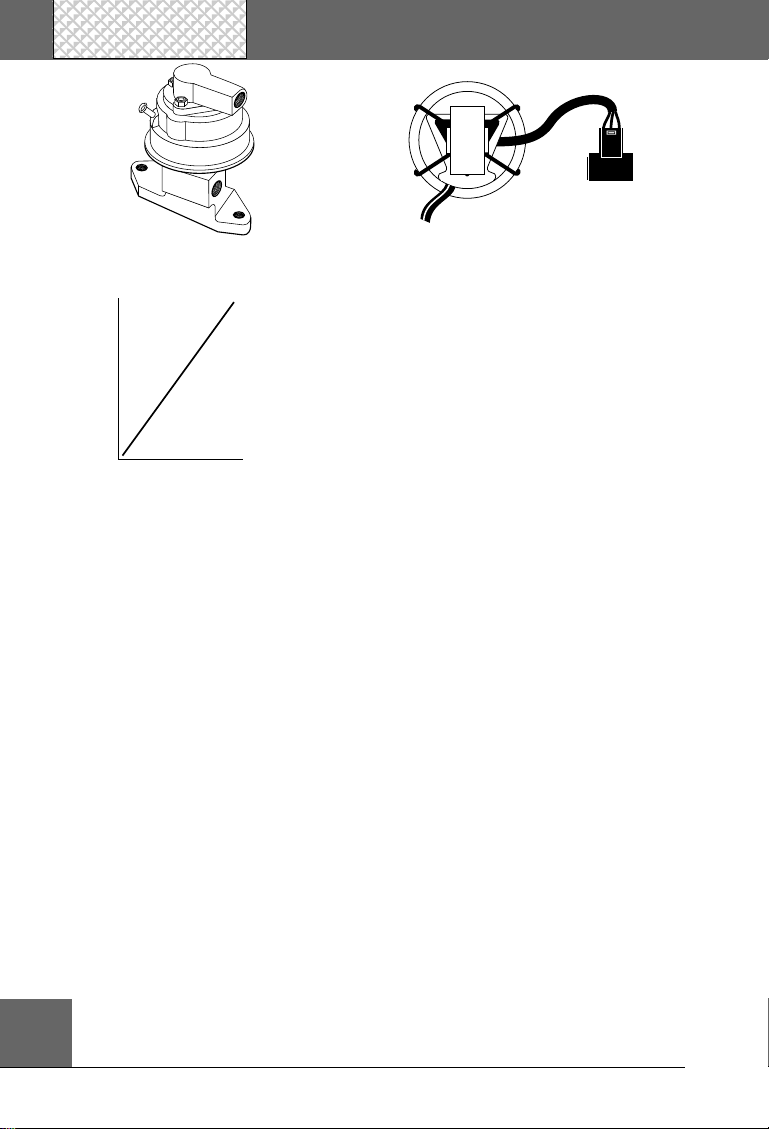

Typical Engine Coolant

Temperature Sensor

Engine TEMPERA TURE

HIGH

SENSOR

RESISTANCE

LOW

Cold Hot

TEMPERATURE

What is It?

How is It

Used?

Location

When to Test

The engine temperature sensor is a thermistor - a

resister whose resistance changes with temperature. The hotter the sensor gets, the lower the

resistance becomes. The thermistor is mounted

inside the tip of a threaded metal housing. This is a

2-wire sensor. (Exception: some Chrysler engines

have a dual sensor with three wires.)

The computer needs to know engine temperature

so it can modify air/fuel ratios, spark advance, idle

speed, and emission device operation (such as an

EGR valve).

The sensor is usually threaded into the engine

block, lower intake manifold, or cylinder head to

provide direct contact with coolant.

• Related trouble codes sent by computer.

• Driveability problems such as hard starting,

rough idle, stalling, hesitation, stumble, surging,

knocking (pinging), poor fuel economy, or black

exhaust smoke.

2-2

What to

Inspect

Sensor operation (see test on page 2-4). Poor

connections at sensor or computer. Faulty sensor

wiring (open or short circuits). Heavy deposits on

sensor tip which can cause poor response.

Leakage into sensor housing. Engine running too

hot (problems with antifreeze, thermostat, water

pump, fan, belts, low engine oil).

Page 11

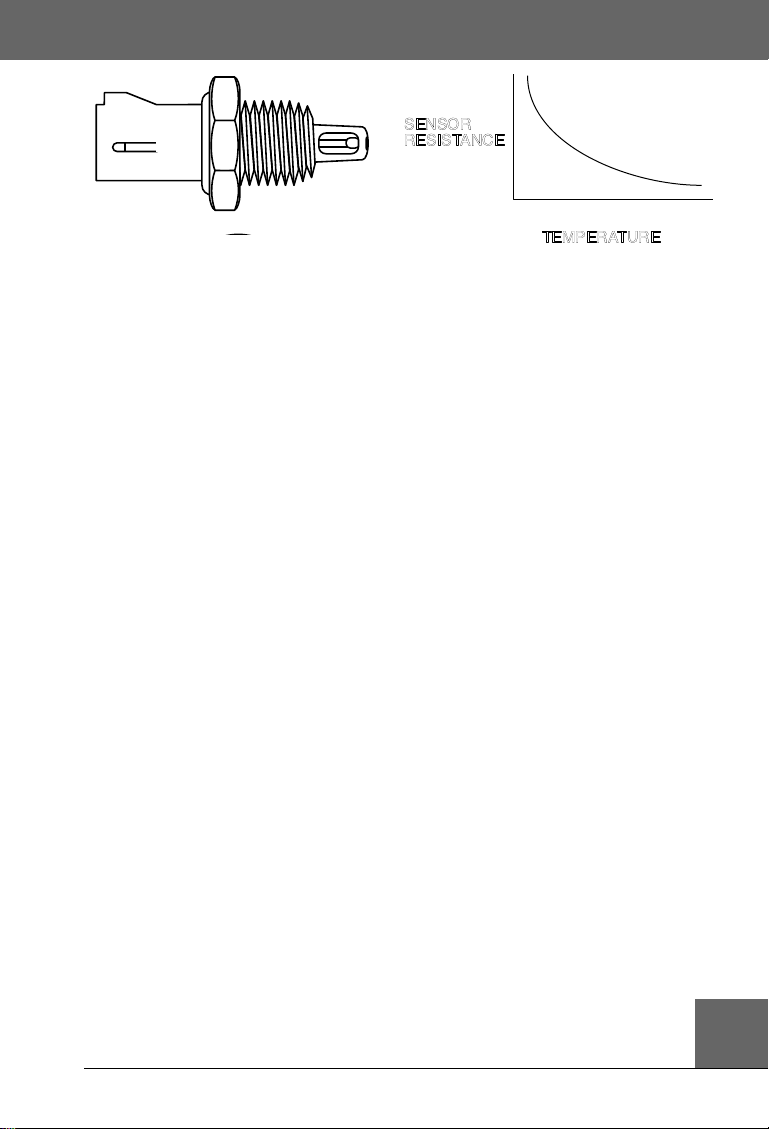

Air TEMPERA TURE

HIGH

SENSOR

RESISTANCE

LOW

Typical Air Temperature Sensor

What is It? The air temperature sensor is a thermistor - a

resister whose resistance changes with temperature.

The hotter the sensor gets, the lower the resistance

becomes. The thermistor is mounted inside the tip of

a threaded metal housing. This is a 2-wire sensor.

Cold Hot

TEMPERATURE

How is It

Used?

The computer needs to know air temperature to

calculate the amount of air entering the engine.

Then, the computer can provide the proper air/fuel

mixture for the desired operating condition.

Location The sensor is threaded into the intake manifold,

throttle body, rear of air cleaner assembly or

elsewhere along the path of air entering the

engine. Sometimes this sensor is built into a vane

airflow meter or mass airflow sensor assembly.

One connector handles both the air flow and

temperature sensor circuits.

When to Test

What to

Inspect

• Related trouble codes sent by computer.

• Driveability problems such as hard starting,

rough idle, stalling, hesitation, stumble, surging,

poor fuel economy, or black exhaust smoke.

Sensor operation (see test on page 2-4). Poor

connections at sensor or computer. Faulty sensor

wiring (open or short circuits). Heavy deposits on

sensor tip which can cause poor response.

Restricted or blocked air passageways.

Engine running too hot (problems with

antifreeze, thermostat, water pump, fan, belts,

low engine oil).

2-3

Page 12

Section 2

Testing Sensor s

Temperature Sensor Test Procedure

Use this procedure for testing all engine coolant or inlet air temperature sensors.

Exceptions:

• Certain Toyota, Nissan and Ford engines using vane airflow sensors have the

air temperature sensor built into the vane airflow assembly. Refer to page 2-40

for testing.

• GM 1988 2.8L Mass Airflow Sensor (5 pin only) also has a built-in air temperature sensor. Use same test procedure as for vane airflow temperature sensor.

Refer to page 2-34 for testing.

Sensor may be tested on or off vehicle.

Warning: On-car testing involves running engine. Observe all safety precautions

(see page ii). Work in well ventilated area.

1) Verify ignition key is OFF.

Allow engine to cool to outside temperature before testing.

2) Check Tester battery

Refer to page 1-4. Set RANGE switch to POWER OFF

when done.

2-4

3) Disconnect wiring harness from sensor - Inspect for

damage.

Some vehicles use a metal snap ring to secure wiring

harness to sensor. Remove this snap ring before disconnecting wiring harness.

4) Off-Car testing only: Remove sensor.

Be careful of coolant spillage from mounting hole if

removing engine temperature sensor.

5) Connect test leads.

• YELLOW to

• BLACK to remaining sensor pin.

Yellow

either sensor pin.

Black

Page 13

RANGE

FUNCTION

HIGH

LOW

POWER OFF

VOLTS

OHMS

FREQUENCY

Engine Air TEMPERA TURE

6) Verify test clips make good contact and do not touch each

other.

Make sure red and green test clips are not touching anything.

7) Set RANGE switch to HIGH.

8) Set FUNCTION switch to OHMS.

9) Note TEST light position on tester.

If the sensor is good, the light will move downwards as the

sensor heats up.

10) On-Car test only: Disconnect test leads and reconnect

sensor to vehicle wiring harness.

11) Heat sensor tip thoroughly.

On-Car test: Start engine and idle at 2000 RPM until upper

radiator hose is hot.

Off-Car test:

– Dip sensor tip into boiling water, OR...

– (metal sensor housing) Heat tip with flame from candle or

cigarette lighter OR...

– (plastic sensor housing) Heat tip with hair dryer.

12) On-Car test only: Turn ignition key OFF. Disconnect

vehicle wiring harness from sensor and reconnect test

leads as before.

13) Observe TEST light position for test results.

• Good Sensor - TEST light moved downwards below original

position. (TEST light may go off if sensor is very hot - this is

OK.) The TEST light will move upwards as the sensor cools

off. Range of TEST light movement varies with sensor type

and temperature change.

• Bad Sensor - TEST light position did not change during test.

14) Testing is complete.

Set RANGE switch to POWER OFF and remove all test

leads.

2-5

Page 14

Section 2

TYPICAL THROTTLE POSITION SENSORS

Testing Sensor s

HIGH

2-6

What

is It?

Throttle Position Sensor

The throttle position sensor is a

potentiometer - a type of variable

resistor (similar to a dashboard

dimmer control). These sensors come

in a wide variety of styles - some with

connectors at the end of a short wire

“pigtail”. The computer supplies power

and ground to the sensor. The sensor has an element which is

turned (rotary type) or pushed (linear type). When the sensor is

mounted on the engine, the element is linked to the throttle so

they move together. The sensor sends a voltage signal back to

the computer indicating element (and thus throttle) position. The

voltage signal increases when the throttle opens and operates

the sensor element. Throttle position sensors on Asian vehicles

may also include one or two throttle position switches.

SIGNAL

VOLTAGE

LOW

ROTATION

MAX.MIN.

Throttle Position Switch

This is one or two switches usually built into a single housing

(often resembling a throttle position sensor). Movement of the

throttle linkage operates the throttle switches. The switches are

wired to the computer. The computer usually supplies an

ground connection to one side of each switch.

• The idle position switch is closed (or open - depends upon

vehicle) when the throttle is resting. The switch operates

when the throttle is opened (by any amount) and no longer in

the idle position.

Page 15

THROTTLE POSITION Sensor/Switch

• Sometimes a second switch is used to signal a wide

open throttle condition. This switch is normally open (or

closed - depends upon vehicle) when the throttle is at

idle or just partially open. The switch operates when the

throttle is opened beyond a certain point. (The amount of

throttle opening required to operate the switch varies

with vehicle.)

How it is

used?

Location

When to

Test

What to

Inspect

The computer uses throttle position to determine engine

operating condition: idle (closed throttle), cruise (part

throttle), or hard acceleration (wide open throttle). The

computer can then properly control air/fuel mixtures, spark

advance, idle speed, and lock-up torque converters.

Fuel injected engines: Rotary type sensor - usually

mounted to outside of throttle body and linked to throttle

shaft.

Computer controlled carburetor engines: Linear (sliding)

type - usually mounted inside carburetor (GM) or outside

carburetor (Ford).

• Related trouble codes sent by computer.

• Driveability problems such as hard starting, rough idle,

stalling, hesitation, stumble, surging, knocking (pinging),

poor fuel economy, backfiring, no torque converter lock-up.

Sensor operation (see test on page 2-10) or switch

operation (see test on page 2-12). Poor connections at

sensor or computer. Sensor position adjustment. Faulty

sensor wiring (open or short circuits). Binding throttle shaft

or linkage. If used: “Cruise Control” linkage problems, idle

speed control motor, vacuum hose connected to throttle

positioner, choke, or cam systems affecting throttle

position.

2-7

Page 16

Section 2

Testing Sensor s

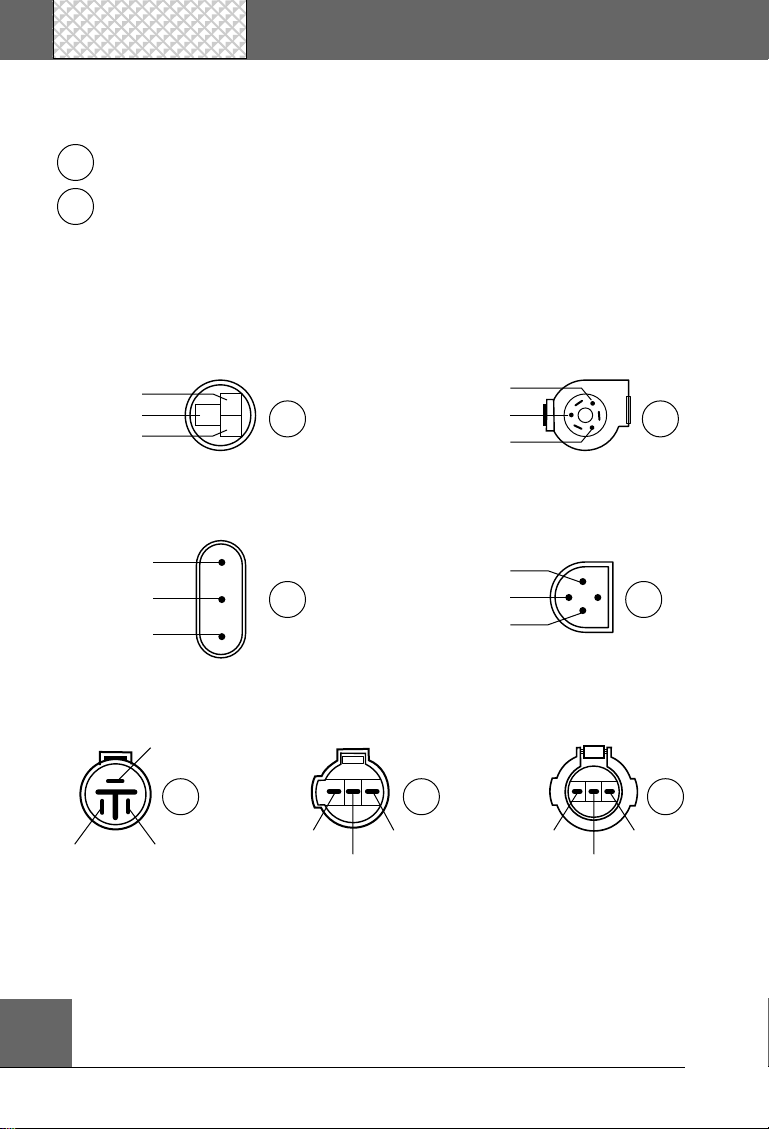

Throttle Position Sensor Connectors

= Test A, page 2-10

A

= Test B, page 2-12

B

Note: If the Red and Black test lead hook-ups are reversed,

the TEST light will move in the opposite direction during Test A.

This does not affect the accuracy of the test or harm the sensor.

GM FORD

Red

Yellow

Black

GM, FORD, CHRYSLER, HONDA

Black

Yellow

Red

Some sensors require more than one test.

Black

A

A

Yellow

Red

Yellow

Red

Black

A

FORD

A

2-8

HONDA

Yellow

RedBlack

Refer to vehicle service manual for connectors

not shown. Hook up as follows:

• Red test lead to sensor power pin

• Yellow test lead to sensor signal pin

• Black test lead to sensor ground pin

HONDA

RedBlack

Yellow

HONDA

AA A

RedBlack

Yellow

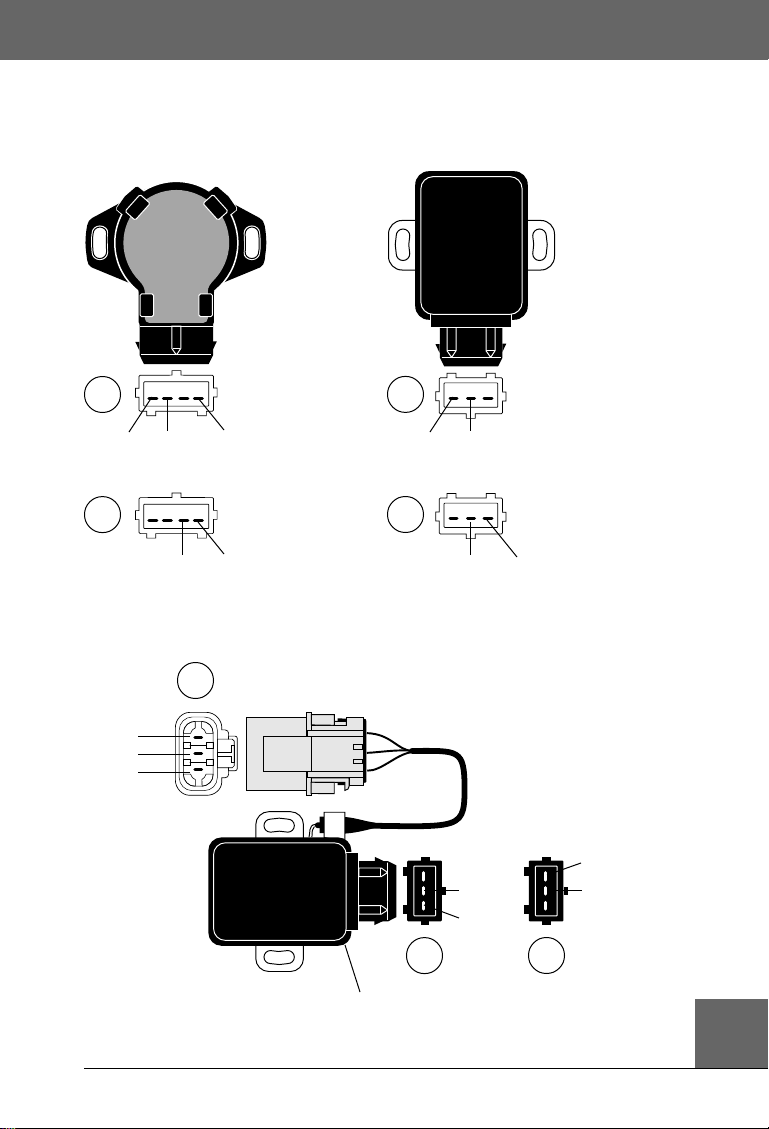

Page 17

THROTTLE POSITION Sensor/Switch

A

B

TOYOTA

A

TOYOTA/NISSAN

B

BlackYellowRed

BlackYellow

Yellow Black

B

Black Yellow

Not used on some

vehicles. Perform this

test only if vehicle

mating connector has

3 wires.

Red

Yellow

Black

Some sensors have

cable attached here.

Testing is identical.

Black

Yellow

B B

Yellow

Black

Not used on some

vehicles. Perform

this test only if

vehicle mating

connector

has 3 wires.

2-9

Page 18

Section 2

Testing Sensor s

TEST A - Throttle Position Sensor

Important: If more than one hook-up is shown, it means more than one test is

required to check all parts of the sensor. Do all tests shown for your sensor.

The letter next to the hook-up refers to the test procedure.

Sensor may be tested on or off vehicle. (Exception: On-car test only for most

Honda - sensor permanently attached to throttle body.)

Warning: Observe all safety precautions (see page ii) if testing sensor on

vehicle.

1) Verify ignition key is OFF.

2) Check Tester battery

Refer to page 1-4. Set RANGE switch to POWER OFF when

done.

3) Disconnect wiring harness from sensor - Inspect for

damage.

Some vehicles use a metal snap ring to secure wiring harness

to sensor. Remove this snap ring before disconnecting wiring

harness.

2-10

4) Off-Car testing only: Remove sensor.

IMPORTANT: Many throttle position sensors require special

adjustment when reinstalled. Refer to vehicle service manual

for adjustment procedure. A good sensor will not perform

properly if incorrectly adjusted.

5) Connect test leads.

Connect TEST leads according to diagram A in the component drawing.

6) Verify test clips make good contact and do not touch

each other.

Make sure unused clips are not touching anything.

Page 19

THROTTLE POSITION Sensor/Switch

7) Honda only: 1988-92 Civic and CRX

– Remove vacuum hose from dashpot diaphragm.

– Apply 20 in. Hg to the dashpot diaphragm using a hand

vacuum pump.

– The dashpot diaphragm is part of the throttle body

assembly. It is used to control cold engine fast idle and

throttle closure speed so engine will not stall.

8) Set RANGE switch to HIGH.

9) Set FUNCTION switch to VOLTS.

10) Operate sensor - Watch TEST light for results.

(Note: TEST light may be on or off before sensor is

operated.)

On-Car test: Slowly move throttle linkage back and forth from

idle to wide open position.

Off-Car test: Slowly rotate sensor element back and forth

from end to end.

RANGE

FUNCTION

HIGH

LOW

POWER OFF

VOLTS

OHMS

FREQUENCY

• Good Sensor

- TEST light smoothly moves up or down as

sensor is operated. (The TEST light may go off if it moves

to the bottom of the column - this is O.K.) Range of TEST

light movement varies with sensor type and vehicle

mounting.

• Bad Sensor

- TEST light position does not change during

test OR light movement is erratic, showing a sudden jump

or dip during smooth sensor operation.

11) Testing is complete.

Set RANGE switch to POWER OFF and remove all test

leads.

2-11

Page 20

Section 2

Testing Sensor s

TEST B - Throttle Position Switch

Important: If more than one hook-up is shown, it means more than one test is

required to check all parts of the switch. Do all tests shown for your switch. The

letter next to the hook-up refers to the test procedure.

Switch may be tested on or off vehicle.

Warning: Observe all safety precautions (see page ii) if testing sensor on

vehicle.

1) Verify ignition key is OFF.

2) Check Tester battery

Refer to page 1-4. Set RANGE switch to POWER OFF when

done.

3) Disconnect wiring harness from switch - Inspect for

damage.

Some vehicles use a metal snap ring to secure wiring

harness to switch. Remove this snap ring before disconnecting wiring harness.

2-12

4) Off-Car testing only: Remove switch.

IMPORTANT: Many throttle position switches require special

adjustment when reinstalled. Refer to vehicle service manual

for adjustment procedure. A good switch will not perform

properly if incorrectly adjusted.

5) Connect test leads.

Connect TEST leads according to diagram B in the component drawing.

6) Verify test clips make good contact and do not touch

each other.

Make sure unused clips are not touching anything.

Page 21

THROTTLE POSITION Sensor/Switch

HIGH

LOW

RANGE

FUNCTION

POWER OFF

VOLTS

OHMS

FREQUENCY

7) Set RANGE switch to HIGH.

8) Set FUNCTION switch to OHMS.

9) Operate sensor - Watch TEST light for results.

On-Car test: Slowly move throttle linkage back and forth

from idle to wide open position.

Off-Car test: Slowly rotate sensor element back and forth

from end to end.

TEST TEST

• Good Switch

- TEST light switches between

being ON at top of column and OFF

• Bad Switch

- TEST light always ON at top of

column or always OFF.

10) Testing is complete.

Set RANGE switch to POWER OFF and

remove all test leads.

2-13

Page 22

Section 2

Testing Sensor s

FORD

EGR Valve

HONDA

EGR Valve

What is it? This sensor is a potentiometer - a type of variable

HIGH

SENSOR

VOLTAGE

LOW

VALVE OPENING

resistor (similar to a dashboard light dimmer

control). The computer supplies power and ground

to the sensor. the sensor has a shaft which is

pushed. When the sensor is mounted on the EGR

valve, the shaft gets pushed as the valve opens.

The sensor sends out a voltage signal indicating

the amount of valve opening (“lift”). The voltage

signal gets larger the more the valve is opened.

MAX.MIN.

How it is

Location Attached to the top of the EGR valve.

When to Test

2-14

used?

What to

Inspect

The computer is programmed to provide optimum

EGR flow during idle, cruise, and hard acceleration

operating conditions. The computer uses the

sensor signal to calculate actual EGR flow. Then

the computer can modify the EGR valve opening

as required.

• Related trouble codes sent by computer.

• Driveability problems such as hesitation,

stumble, surging, poor fuel economy, erratic

acceleration, knocking (pinging), no torque

converter lock-up.

Sensor operation (see page 2-15). Poor connections at the sensor or computer. Damaged or

sticking EGR valve. Worn or broken vacuum

hoses, vacuum connectors. Damaged vacuum

reservoir, canister. Problems with control solenoids

supplying operating vacuum to open EGR valve.

Page 23

EGR Valv e Pos ition/Lift Sensors

EGR Valve Position Sensor Test Procedure

Sensor may be tested on or off vehicle.

Warning: Observe all safety precautions (see page ii) if testing sensor on

vehicle.

1) Verify ignition key is OFF.

2) Check Tester battery

Refer to page 1-4. Set RANGE switch to POWER

OFF when done.

3) Disconnect wiring harness from sensor - Inspect

for damage.

Some vehicles use a metal snap ring to secure

wiring harness to sensor. Remove this snap ring

before disconnecting wiring harness.

4) Off-Car testing only: Remove sensor.

Note: Some sensors are permanently attached to

the EGR valve and cannot be removed.

RANGE

FUNCTION

HIGH

LOW

POWER OFF

VOLTS

OHMS

FREQUENCY

5) Connect test leads according to diagram.

6) Verify test clips make good contact and do not

touch each other.

Make sure unused clips are not touching anything.

7) Set RANGE switch to HIGH.

8) Set FUNCTION switch to VOLTS.

9) Operate sensor - Watch TEST light for results.

(Note: TEST light may be on or off before sensor is

operated.)

On-Car test:

– Remove vacuum control hose from EGR valve.

– Connect hand vacuum pump to EGR valve.

– Gradually apply vacuum to slowly open valve.

2-15

Page 24

Section 2

Off-Car test: Slowly push sensor element back and forth

from end to end.

• Good Sensor

sensor is operated. (The TEST light may go off if it moves

to the bottom of the column - this is O.K.) Range of TEST

light movement varies with sensor type and vehicle

mounting.

• Bad Sensor

test OR light movement is erratic, showing a sudden jump

or dip during smooth sensor operation.

10) Testing is complete.

Set RANGE switch to POWER OFF and remove all test

leads.

Testing Sensor s

- TEST light smoothly moves up or down as

- TEST light position does not change during

2-16

Page 25

EGR Valv e Pos ition/Lift Sensors

Sensor Connectors

Note: If the Red and Black test lead hook-ups are reversed,

the TEST light will move in the opposite direction during the

test. This does not affect the accuracy of the test or harm

the sensor.

Black

FORD

RedYellow

Black

HONDA – #2HONDA – #1

Yellow

Red

Refer to vehicle service manual for connectors

not shown. Hook up as follows:

• Red test lead to sensor power pin

• Yellow test lead to sensor signal pin

• Black test lead to sensor ground pin

Yellow Red

Black

Honda uses two

sensor types. Try

hook-up #1 first.

If good test

results are not

obtained, retest

using hook-up #2

before judging

sensor.

2-17

Page 26

Section 2

Testing Sensor s

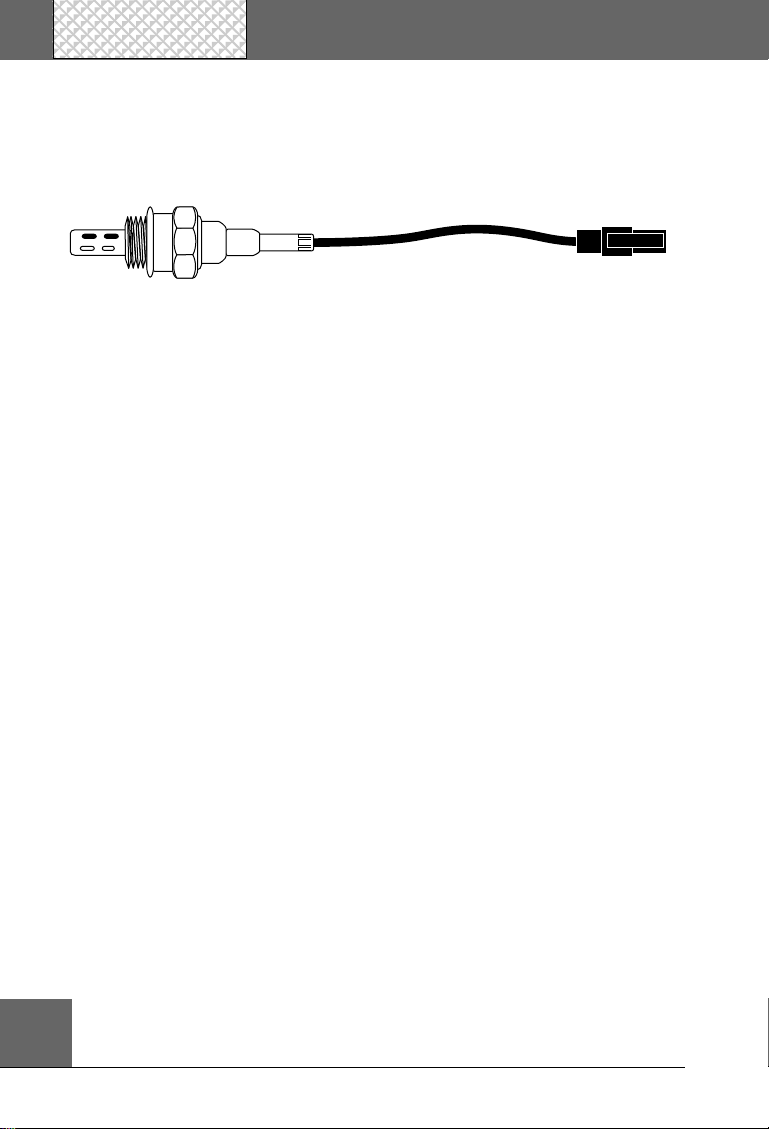

Typical Oxygen Sensor

What is It? The oxygen sensor is a zirconium dioxide ceramic

mounted in the tip of a threaded metal housing.

The tip is perforated to protect the sensing element

but still allow exhaust gases to pass through.

The sensor produces a voltage signal based on the

amount of oxygen it contacts. A low voltage

indicates a lean exhaust (too much oxygen). A

higher voltage signals a rich exhaust (not enough

oxygen).

2-18

How it is

used?

Location

The sensor must be very hot to operate: 349(C

(660(F). Many have 2-wire heating elements builtin to quicken the warm-up time.

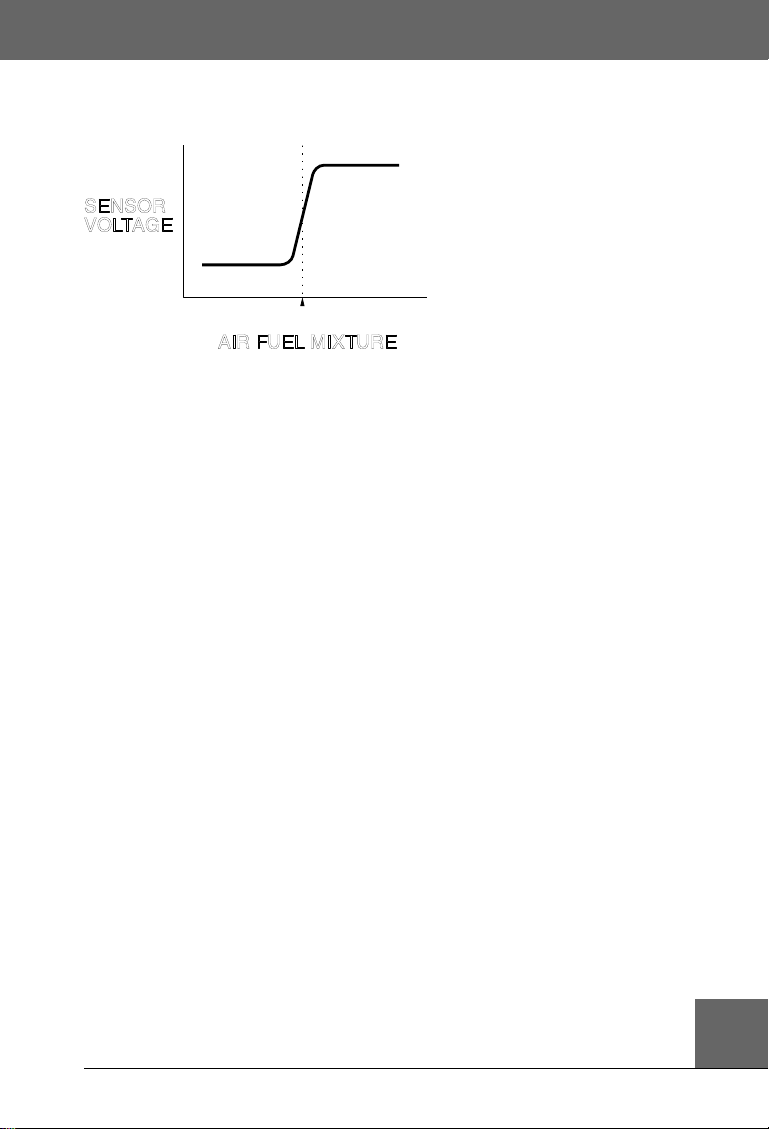

The computer uses this sensor to calculate

optimum air/fuel mixture for low emissions and

good fuel economy. If the sensor indicates a rich

exhaust (not enough oxygen because of too much

fuel), the computer will compensate by reducing

fuel delivery. If the computer receives a lean signal

(too much oxygen because of too little fuel), it will

increase fuel delivery. NOTE: Some vehicles use

more than one oxygen sensor.

The sensor is threaded into the exhaust manifold to

give it direct contact with the exhaust gases.

Page 27

OXYGEN

HIGH

SENSOR

VOLTAGE

LOW

Lean OPTIMUM Rich

AIR FUEL MIXTURE

When to Test • Related trouble codes sent by computer.

• Driveability problems such as rough running,

hesitation, stumble, poor fuel economy, poor

performance, black exhaust smoke.

Inspection

IMPORTANT:

Sensor operation (see page 2-21). Poor connections at the sensor or computer.

This sensor often fails because of contamination

from fuel, oil additives, gasket sealer or an overly

rich running engine. Factors which can make a rich

running engine include: ignition system problems

(coil, distributor cap, rotor, spark plugs, wires), fuel

contaminated by engine oil, emission devices

(carbon canister, EGR valve, PCV valve, air

injection system), manifold leaks, air filter, fuel

pressure and engine not at normal operating

temperature.

Some engines (usually off-road applications)

use a titania-type oxygen sensor. This sensor

resembles the common zirconium type, but has

an open-ended tip. The titania sensor changes

resistance when it operates. This tester is

not designed to test the titania type

sensor.

2-19

Page 28

Section 2

Testing Sensor s

Sensor Types

1-Wire: Single wire goes to sensor SIGNAL.

Sensor housing is connected to sensor GROUND.

2-Wire: One wire goes to sensor SIGNAL. Second

wire goes to sensor GROUND. Refer to vehicle

service manual for wire identification. (Sensor wire

is often black.)

3-Wire: Two wires (often the same color) go to the

sensor heating element. Third wire (different color

from the others) goes to sensor SIGNAL. Sensor

housing is connected to sensor GROUND.

4-Wire: Two wires (often the same color) go to the

sensor heating element. Third wire goes to sensor

SIGNAL. Fourth wire goes to sensor GROUND.

Refer to vehicle service manual for wire identification. (Signal wire is often black.)

2-20

Page 29

OXYGEN

Heating Element Test

• Do this test if sensor has a heating element (3 or 4 wire connector).

• If sensor has 1 or 2 wire connector, do not do this test. Go directly to On-Car

Test (page 2-22).

Warning: Observe all safety precautions (see page ii) if testing sensor on vehicle.

1) Verify ignition key is OFF.

2) Check Tester battery

Refer to page 1-4. Set RANGE switch to POWER OFF when done.

3) Disconnect wiring harness from sensor - Inspect for damage.

Some vehicles use a metal snap ring to secure wiring harness to

sensor. Remove this snap ring before disconnecting wiring

harness.

4) Connect test leads.

• YELLOW to either sensor HEATER pin.

• BLACK to remaining sensor HEATER pin.

RANGE

FUNCTION

HIGH

LOW

POWER OFF

VOLTS

OHMS

FREQUENCY

TEST

5) Verify test clips make good contact and do not touch each

other.

Make sure unused clips are not touching anything.

6) Set RANGE switch to HIGH.

7) Set FUNCTION switch to OHMS.

8) Observe TEST light for test results.

• Good Heater:

• Bad Heater:

TEST light OFF (low resistance).

TEST light ON in any position (resistance too

high, or open circuit).

9) Heating Element test is complete.

• Set RANGE switch to POWER OFF and remove all test leads.

• Go to On-Car Test.

2-21

Page 30

Section 2

Testing Sensor s

On-Car Test

Important: Reliable testing of the oxygen sensor while on-vehicle is very

difficult because test conditions cannot be well controlled. If the sensor

responds during on-car testing, then it is probably good and no other

testing is necessary. If the sensor does not seem to respond when tested

on-car, remove it and perform the off-car test before deciding whether or

not the sensor is bad.

Warning: This test involves running the engine. Observe all safety precautions

(see page ii). Work in well-ventilated area.

1) Verify ignition key is OFF.

2) Check Tester battery

Refer to page 1-4. Set RANGE switch to POWER OFF

when done.

3) Connect test leads.

• YELLOW to sensor SIGNAL circuit.

• BLACK to good vehicle GROUND.

– Keep sensor connected to vehicle wiring and use

backprobe adapter to contact sensor SIGNAL circuit if

possible.

– If you cannot use backprobe, disconnect sensor

connector and connect YELLOW test lead directly to

sensor SIGNAL pin. Note: Most computer systems will

store a trouble code in memory (and turn on the “Check

Engine” light) if engine is run with sensor disconnected.

Ignore or erase the code after testing. Refer to Vehicle

Service Manual.

2-22

RANGE

FUNCTION

HIGH

LOW

POWER OFF

VOLTS

OHMS

FREQUENCY

4) Verify test clips make good contact.

Make sure unused clips are not touching anything.

5) Set RANGE switch to LOW.

6) Set FUNCTION switch to VOLTS.

7) Start engine - Idle until hot.

Run engine until upper radiator hose is hot and

pressurized.

Page 31

RICH

LEAN

OXYGEN

8) Observe RICH/LEAN lights during fast idle.

• The TEST light column also indicates sensor voltage,

but it is easier to check operation by watching the RICH/

LEAN lights.)

• Maintain throttle partially open (2000 RPM idle).

– IF the RICH/LEAN lights flash back and forth every 3

seconds or less...

THEN the sensor is good and no further testing is

necessary. Go to step 10.

– IF it takes longer than 3 seconds for the RICH/LEAN

lights to switch back and forth...

THEN the sensor may be degraded. Go to step 10,

then do the Off-Car test on page 2-24

– IF the RICH/LEAN lights do not flash back and forth...

THEN go to step 9.

9) Observe RICH / LEAN lights during throttle changes.

• Quickly move throttle from idle to partially open (2000

RPM) position then back to idle. (This attempts to create

a momentary rich or lean engine operating condition.)

Repeat this throttle action several times while observing

the RICH/LEAN lights.

RICH

LEAN

– IF the RICH/LEAN lights switch within 3 seconds of the

throttle action...

THEN the sensor is good and no further testing is

necessary. Go to step 10.

– IF it takes longer than 3 seconds for the RICH/LEAN

lights to switch...

THEN the sensor may be degraded. Go to step 10. Do

the Off-Car test on page 2-24

– IF the RICH/LEAN lights do not flash back and forth...

THEN go to step 10. Do the Off-Car test on page 2-24.

10) On-Car test is complete - Turn ignition key OFF.

• Set RANGE switch to POWER OFF and remove all test

leads.

• If the RICH / LEAN lights did not flash, or flashed

too slowly, in steps 8 or 9, then do the Off-Car test

on page 2-24.

2-23

Page 32

Section 2

Testing Sensor s

Off-Car Test

Warning: This test involves use of an open flame from a propane torch.

Observe all safety precautions for torch operation. Do not use near flammable

material or gases.

1) Verify ignition key is OFF.

2) Check Tester battery

Refer to page 1-4. Set RANGE switch to POWER

OFF when done.

3) Disconnect wiring harness from sensor - Inspect

for damage.

Some vehicles use a metal snap ring to secure wiring

harness to sensor. Remove this snap ring before

disconnecting wiring harness.

4) Remove sensor.

5) Firmly grasp sensor with a pair of locking pliers.

2-24

RANGE

FUNCTION

HIGH

LOW

POWER OFF

VOLTS

OHMS

FREQUENCY

6) Connect test leads

• YELLOW to sensor SIGNAL pin.

• BLACK to sensor GROUND.

7) Verify test clips make good contact and do not

touch each other.

Make sure unused clips are not touching anything.

8) Set RANGE switch to LOW.

9) Set FUNCTION switch to VOLTS.

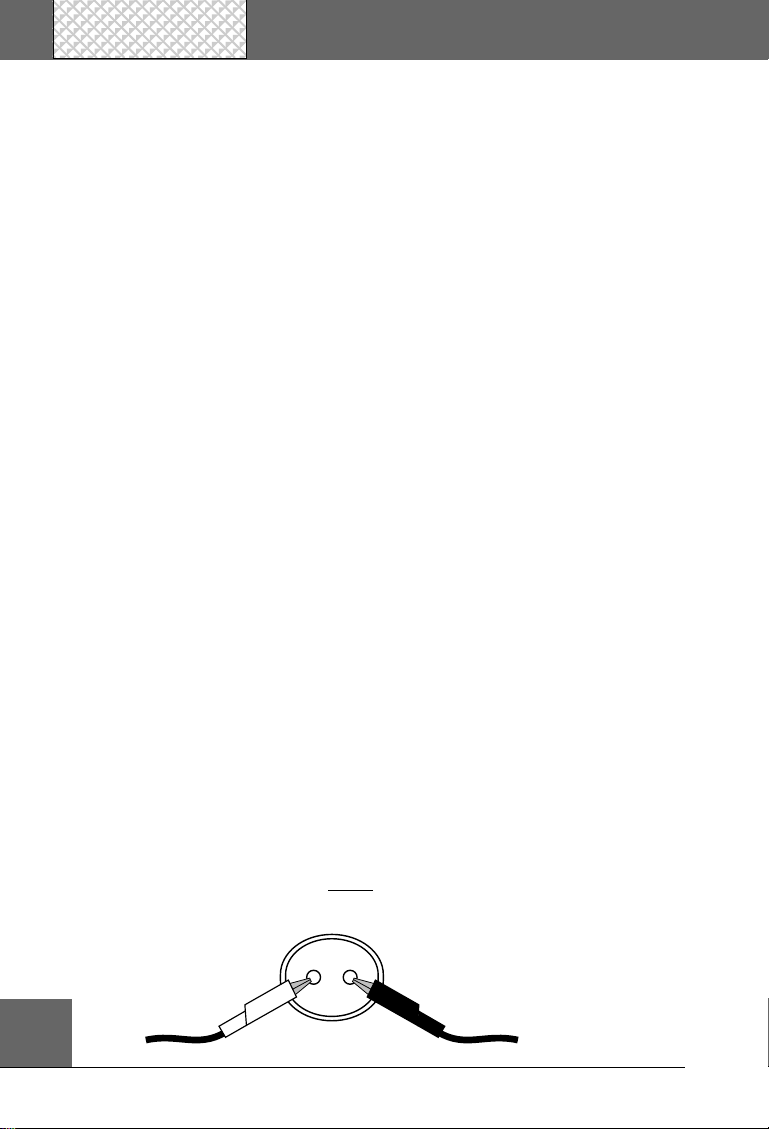

10) Light torch - Heat sensor tip - Observe RICH/

LEAN lights.

• Thoroughly heat sensor tip until tip is as hot as

possible, but not “glowing”. See Fig. 1.

• The sensor tip must be very hot to operate! (349(C,

660(F)

• The LEAN or RICH light should be ON. If both lights

are off, the sensor is defective.

Page 33

OXYGEN

11) Observe RICH/LEAN lights while operating

sensor.

• After sensor tip is hot. move the flame until the

sensor tip is completely surrounded by the flame.

This keeps oxygen away from the tip. See Fig. 2.

– Good Sensor:

seconds indicating a “rich” (low oxygen) condition.

– Bad Sensor:

seconds to turn on, or does not turn on at all.

• Move flame so oxygen can reach sensor tip.

(Keep sensor tip hot with flame.) See Fig. 1.

– Good Sensor:

seconds indicating a “lean” (high oxygen) condition.

– Bad Sensor:

seconds to turn on, or does not turn on at all.

12) Repeat step 11 a few times to verify results.

13) Testing is complete.

Extinguish flame, set RANGE switch to POWER

OFF, let sensor cool and remove test leads.

IMPORTANT: Special anti-seize compound must be

applied to sensor housing threads before reinstallation.

Refer to vehicle service manual for proper type.

RICH light turns ON within 3

RICH light takes longer than 3

LEAN light turns ON within 3

LEAN light takes longer than 3

RICH

LEAN

Fig. 1 Fig. 2

RICH

LEAN

2-25

Page 34

Section 2

Yellow

Black

Testing Sensor s

What is It? The knock sensor is a piece of piezoelectric

material mounted in a metal housing. The sensor

acts like a microphone - it changes vibrations into a

small AC voltage signal. The sensor usually has a

one wire or two wire connector.

Yellow

Black

How it is

used?

The computer (or other spark timing controller) is

designed to recognize sensor signals caused by

engine knock vibrations. Then, spark timing is

retarded to eliminate the damaging knock condition

Location Usually threaded into (or bolted on) the engine

block, intake manifold or exhaust manifold. Often

near the cylinder heads.

When to Test • Related trouble codes sent by computer.

• Knocking during cruise or hard acceleration (not

enough spark retard), hesitation, poor performance and fuel economy (excess spark retard).

What to

Inspect

2-26

Sensor operation (see test on page 2-27). Poor

connections at sensor or computer. Faulty sensor

wiring (open or short circuits). Spark timing. Bad

fuel quality.

Page 35

Engine KNOCK

Knock Sensor Test Procedure

Sensor may be tested on or off vehicle.

Warning: Observe all safety precautions (see page ii) if testing sensor on vehicle.

1) Verify ignition key is OFF.

2) Check Tester battery (refer to page 1-4).

3) Disconnect wiring harness from sensor - Inspect for

damage.

4) Connect test leads to sensor.

One-wire connector:

• YELLOW test lead to signal pin (top of sensor).

• BLACK test lead to body of sensor (off-car) or nearby

ground (on-car).

Two-wire connector:

• YELLOW test lead to either sensor pin.

• BLACK test lead to remaining sensor pin.

5) Set RANGE switch to LOW.

6) Set FUNCTION switch to VOLTS.

7) Operate sensor - Watch TEST light for results.

(Note: Ignore any RICH/LEAN light flashes.)

On-car test: Lightly tap surface near sensor using a

socket extension (or similar tool) and a light hammer.

Do not tap directly on sensor!

Off-car test: Grasp sensor firmly. Gently tap sensor tip

with a light hammer.

RANGE

FUNCTION

TEST

HIGH

LOW

POWER OFF

VOLTS

OHMS

FREQUENCY

– Good sensor:

TEST lights flash upward from the

bottom of the TEST light column during a tap. (Only a

few lights may flash. This is O.K.) Range of TEST light

movement varies with sensor type and tapping force.

– Bad sensor:

TEST lights do not flash during a tap.

8) Testing is complete.

2-27

Page 36

Section 2

GM/CHRYSLER

Testing Sensor s

FORD

TOYOTA/HONDA

Manifold Absolute Pressure (MAP) Sensor

Barometric Pressure (BARO) Sens

2-28

What is It?

How it is

used?

This sensor is an electronic module which sends a

signal to the computer indicating atmospheric

pressure and/or engine vacuum. Depending upon

sensor type, the signal may be a dc voltage or a

frequency. More pressure (less vacuum) makes the

sensor signal increase (higher voltage or frequency). The computer supplies power and ground

to the sensor.

The computer needs to know air pressure both

outside and inside the manifold to properly adjust

the air/fuel mixture and ignition timing for varying

engine load and altitude conditions. On turbocharged engines, the computer also uses the

sensor to monitor boost pressure and operate the

wastegate accordingly.

Page 37

Manifold Absolute Pressur e MAP/B ARO

Location

When to Test

Harness

Connectors

for MAP

Sensor

(Mating side of

connector shown.)

The sensor is mounted either on the bulkhead, air

cleaner, throttle body or elsewhere in the engine

compartment. A vacuum hose connects the sensor

to a strong source of manifold vacuum. (Some new

MAP sensor types may be directly mounted to the

manifold, eliminating the vacuum hose connection.)

The BARO sensors are vented to the atmosphere there is no vacuum hose attached.

Some Honda engines locate the MAP sensor inside

a control box containing several vacuum hoses and

solenoids.

• Related trouble codes sent by computer.

• No start, hard starting, stalling, rough idle,

hesitation, stumble, surging, poor fuel economy,

black exhaust smoke, knocking, backfiring,

catalytic converter overheating or no torque

converter lock-up.

GM/CHRYSLER

Power

MAP Signal

Ground

FORDVehicle

MAP Signal

Ground

Power

HONDA

Ground Power

Signal

Refer to vehicle service manual for connectors not shown.

Ground

Signal

TOYOTA

GroundPower

Signal

Power

2-29

Page 38

Section 2

Testing Sensor s

Manifold Absolute Pressure (MAP) Sensor

Test Procedure

Testing is done on-vehicle.

Warning: This test involves running the engine. Observe all safety

precautions (see page ii). Work in well-ventilated area.

1) Verify ignition key is OFF.

2) Check Tester battery

Refer to page 1-4. Set RANGE switch to POWER

OFF when done.

3) Connect test leads.

Yellow

Keep sensor connected to vehicle wiring.

• YELLOW to sensor SIGNAL circuit. Use

backprobe adapter.

• BLACK to good vehicle GROUND.

2-30

Backprobe

4) Verify test clips make good contact.

Make sure unused clips are not touching anything.

5) Set switches:

• RANGE on HIGH.

• FUNCTION on VOLTS.

Exception:

Ford vehicles with frequency type sensor (see

diagram).

– RANGE on LOW.

– FUNCTION on FREQUENCY.

6) Turn ignition key ON but DO NOT START

ENGINE.

7) Note TEST light position on tester.

• If the sensor is good, the light will move

downwards when vacuum is applied.

Page 39

Manifold Absolute Pressur e MAP/B ARO

• Note: If the TEST light is OFF a problem

exists. Go to step 9 and continue testing to find

cause.

8) Operate sensor - Watch TEST light for

results.

(Note: Ignore any PULSE light action.)

Non-Turbo Engines only: Start engine and let

idle.

Turbo Engines only: Attach hand vacuum

pump to sensor vacuum port. Apply 18 in.

vacuum. (More than 25 in. vacuum may damage

sensor.)

Good Sensor

– TEST light moves downward during engine idle

or when vacuum applied. (The TEST light may

go off if it moves to the bottom of the column this is O.K.)

– Range of TEST light movement varies with

sensor type and applied vacuum.

– Note: if test results are O.K. but a computer

trouble code indicates a bad sensor signal, the

wire between the sensor signal pin and the

computer may be open.

–

Testing is complete.

Problem exists (Bad sensor or wiring)

– TEST light position does not change during test.

–

Go to step 9 and continue testing to find cause.

Do all steps to avoid replacing a good sensor!

YST

CE BOOSTER

G GAP

U.S.A.

M

9) Ignition key OFF.

HVAC

CRUISE

EGR

VAC

REG

EGR

VAC

REG

BRAKE BOOSTER

FUEL

PRESS

REG.

TO TRANS

MODE

FRONT

OF CAR

12RA C8

10) Check MAP sensor vacuum hose for...

• Correct hook-up.

• Pinches, kinks or collapsed sides.

• Splits, cuts, breaks or clogs

Repair as necessary, then retest. If no

trouble found, go to next step.

2-31

Page 40

Section 2

HIGH

LOW

POWER OFF

RANGE

VOLTS

OHMS

FREQUENCY

FUNCTION

TEST

Testing Sensor s

11) Check MAP sensor power circuit.

Keep sensor connected to vehicle wiring.

• YELLOW test lead to sensor POWER circuit.

Use backprobe adapter.

• BLACK test lead to good vehicle GROUND.

• RANGE on HIGH.

• FUNCTION on VOLTS.

• Ignition key ON.

Good power circuit:

light ON.

Go to next step.

Bad power circuit:

(or next to top) position.

Repair open or short in power circuit wiring, then

retest.

12) Check MAP sensor ground circuit.

• Same set-up as previous step, but move

YELLOW test lead to sensor GROUND circuit.

(Use backprobe adapter.)

Good ground circuit:

Go to next step.

Bad ground circuit:

Repair open in ground circuit wiring, then retest.

Top (or next to top) TEST

TEST light OFF or not in top

TEST light OFF.

Any TEST light ON.

2-32

13) Check for connector problems.

• Ignition key OFF.

• Disconnect wiring harness from MAP sensor.

(Some vehicles use a metal snap ring to secure

wiring harness to sensor. Remove this snap ring

before disconnecting wiring harness.)

• Check terminals for damage, corrosion, bad

wire crimps or improper seating in connector.

Repair as necessary, then retest. If no trouble

found, go to next step.

Page 41

Manifold Absolute Pressur e MAP/B ARO

14) Check MAP signal wire for short to ground.

•Verify ignition key OFF and MAP sensor wiring

harness disconnected.

• RANGE on LOW.

• FUNCTION on OHMS.

• YELLOW test lead to MAP signal pin on

vehicle harness connector.

• BLACK test lead to good vehicle GROUND.

Good circuit (no short):

TEST light ON in any

position.

Go to next step.

Bad circuit (shorted):

TEST light OFF.

Repair short in signal circuit wiring, then retest.

15) Testing is complete.

Verify ignition key OFF. Set RANGE switch to

POWER OFF and remove all test leads.

If steps 10 through 14 are all good (but step 8

showed a problem) then the sensor is bad and

needs to be replaced.

RANGE

FUNCTION

HIGH

LOW

POWER OFF

VOLTS

OHMS

FREQUENCY

2-33

Page 42

Section 2

Mass Air Flow (MAF) Sensors

Testing Sensor s

FLOW

Typical

- F +

MAF

Sensor

What is It?

How it is

Location

When to Test

2-34

used?

This sensor is an electronic module which sends a

signal to the computer indicating the amount of air

entering the engine. Depending upon sensor type,

the signal may be a dc voltage or a frequency. The

signal level increases (higher voltage or frequency)

as the air flow increases.

Within the sensor is a heated wire located in the

path of incoming air. The module determines air

flow by measuring the temperature drop of the

heated wire as air passes around it.

The computer needs to know incoming air flow to

properly adjust air/fuel mixture and ignition timing

for varying engine load and operating conditions.

The sensor is mounted in the engine incoming air

ducts—typically just behind the air cleaner assembly or near the throttle body.

• Related trouble codes sent by computer.

• Driveability problems such as hard starting,

rough idle, stalling, hesitation, stumble, surging,

knocking (pinging), poor fuel economy, black

exhaust smoke, backfiring, catalytic converter

overheating or no torque converter lock-up.

Page 43

Mass Air Flow MAF

Vehicle Harness Connectors for MAF Sensor

(Mating side of connector shown.)

GM

POWER

MAF SIGNAL

GROUND

1988 and Older

RANGE on LOW

FUNCTION on FREQUENCY

POWER

GROUND

MAF SIGNAL

1989 and Newer

RANGE on HIGH

FUNCTION on FREQUENCY

Ford

NOTE:

MAF RETURN is

not connected to

vehicle GROUND.

MAF SIGNAL

MAF RETURN

GROUND

POWER

MAT SIGNAL

MAT RTN

POWER

GROUND

MAF SIGNAL

1988 2.8L only

RANGE on LOW

FUNCTION on FREQUENCY

GROUND

MAF RETURN

MAF SIGNAL

BURN-OFF SIGNAL

POWER

All 5-Pin except 1988 2.8L

RANGE on HIGH

FUNCTION on VOLTS

RANGE on HIGH

FUNCTION on VOLTS

Refer to vehicle service manual for connectors not shown.

2-35

Page 44

Section 2

Testing Sensor s

Vehicle Harness Connectors for MAF Sensor

(Mating side of connector shown.)

Nissan

MAF

Signal

1985-86 Maxima

1985-86 300ZX

1985-86 300ZX Turbo

Power Ground

1987-88 Maxima

1987-88 200SX SE

1987-89 300ZX

MAF

Signal

PowerGround

Pulsar NX SE

All except 1987-88 1987-88 Pulsar NX SE only

MAF

Signal

MAF

Return

Power Ground

PowerGround

MAF

Signal

PowerGround

MAF

Signal

1987 Pulsar NX

1987 Sentra (E16i)

1988 Pulsar NX XE

1988 Sentra

MAF

Signal

1989-90 Sentra

1990 Pulsar NX

MAF

Signal

PowerGround

GroundPower

MAF

Return

MAF

Signal

PowerGround

PowerGround

MAF

Signal

2-36

1989 and Up Maxima

1990 and Up 300ZX

All Nissan:

RANGE on HIGH

FUNCTION on VOLTS

MAF

Power Ground

Return*

*

May not be used

MAF

Signal

= May not be used

Refer to vehicle service manual for connectors not shown.

Page 45

Mass Air Flow MAF

Mass Air Flow (MAF) Sensor Test Procedure

Testing is done on-vehicle.

Warning: This test involves running the engine. Observe all safety

precautions (see page ii). Work in well-ventilated area.

1) Verify ignition key is OFF.

2) Check Tester battery

Refer to page 1-4. Set RANGE switch to POWER

OFF when done.

3) Connect test leads - refer to hook-up diagram.

Keep sensor connected to vehicle wiring.

• YELLOW to sensor SIGNAL circuit. Use

backprobe adapter.

• BLACK to good vehicle GROUND.

4) Verify test clips make good contact.

Make sure unused clips are not touching anything.

5) Set switches - refer to hook-up diagram.

6) Turn ignition key ON but DO NOT START

ENGINE.

7) Note TEST light position on tester.

• Typically, the TEST light will be off, at the

bottom of the column or blinking.

• Ignore any PULSE light action.

• If the sensor is good, the light will move upwards

during engine run.

8) Start engine and let idle - Watch TEST light for

results.

Good Sensor:

– TEST light moves upward after engine starts.

TEST light moves up even further if engine RPM

is momentarily increased. (Move throttle to

check.) Range of TEST light movement

varies with sensor type and engine speed.

2-37

Page 46

Section 2

Testing Sensor s

– Note: If test results are O.K. but a computer

trouble code indicates a bad sensor signal, the

wire between the sensor signal pin and the

computer may be open.

–

Testing is complete.

Problem exists (Bad sensor or wiring):

– TEST light position does not change during test.

–

Go to step 9 and continue testing to find cause.

Do all steps to avoid replacing a good sensor!

– Note: Sensor is defective if TEST light jumps

erratically when sensor GENTLY tapped with

lightweight tool.

9) Ignition key OFF.

10) Check for air intake problems.

• Air leaks - around MAF sensor, ductwork or

throttle body.

• Obstructions in air duct.

• Clogged air filter.

Repair as necessary, then retest. If no trouble

found, go to next step.

2-38

RANGE

FUNCTION

TEST

HIGH

LOW

POWER OFF

VOLTS

OHMS

FREQUENCY

11) Check MAF sensor power circuit.

Keep sensor connected to vehicle wiring.

• YELLOW test lead to sensor POWER circuit.

Use backprobe adapter.

• BLACK test lead to good vehicle GROUND.

• RANGE on HIGH.

• FUNCTION on VOLTS.

• Ignition key ON.

Good power circuit:

Top (or next to top) TEST

light ON.

Go to next step.

Bad power circuit:

TEST light OFF or not in top

(or next to top) position.

Repair open or short in power circuit wiring, then

retest.

Page 47

RANGE

FUNCTION

HIGH

LOW

POWER OFF

VOLTS

OHMS

FREQUENCY

Mass Air Flow MAF

12) Check MAF sensor ground circuit.

• Same set-up as previous step, but move YELLOW

test lead to sensor GROUND circuit.

MAF RETURN pin. Use backprobe adapter.

Good ground circuit:

TEST light OFF.

Go to next step.

Bad ground circuit:

Any TEST light ON.

Repair open in ground circuit wiring, then retest.

13) Check for connector problems.

• Ignition key OFF.

• Disconnect wiring harness from MAF sensor. (Some

vehicles use a metal snap ring to secure wiring

harness to sensor. Remove this snap ring before

disconnecting wiring harness.)

• Check terminals for damage, corrosion, bad wire

crimps or improper seating in connector.

Repair as necessary, then retest. If no trouble found, go

to next step.

14) Check MAF signal wire for short to ground.

• Verify ignition key OFF and MAF sensor wiring

harness disconnected.

• RANGE on LOW.

• FUNCTION on OHMS.

• YELLOW test lead to MAF signal pin on vehicle

harness connector.

• BLACK test lead to good vehicle GROUND.

Good circuit (no short):

TEST light ON in any position.

Go to next step.

Bad circuit (shorted):

TEST light OFF.

Repair short in signal circuit wiring, then retest.

Do not probe

15) Testing is complete.

Verify ignition key OFF. Set RANGE switch to POWER

OFF and remove all test leads.

If steps 10 through 14 are all good (but step 8

showed a problem) then the sensor is bad and

needs to be replaced.

2-39

Page 48

Section 2

Testing Sensor s

Typical VAF Sensor

What

is It?

How it is

used?

Location

AIR FLOW

Referred to as Vane Air Flow

(VAF) sensor or Air Flow Meter

Vane Air Flow Sensors

This sensor sends a dc voltage signal to the computer

indicating the amount of air entering the engine. The

voltage signal increases as the air flow increases. The

sensor assembly has a pivoting door (“vane”) which is

opened by incoming air. The vane is connected to a

potentiometer (a variable resistor - like a dashboard

dimmer control) which generates the voltage signal. Some

sensor assemblies also contain an air temperature sensor

or a vane position switch (or both).

The computer needs to know incoming air flow to properly

adjust air/fuel mixture and ignition timing for varying

engine load and operating conditions.

The sensor is mounted in the engine incoming air duct between the air cleaner and the throttle body.

2-40

When to

Test

What to

Inspect

• Related trouble codes sent by computer.

• Driveability problems such as hard starting, rough idle,

stalling, hesitation, stumble, surging, knocking (pinging), poor fuel economy, black exhaust smoke, backfiring, catalytic converter overheating or no torque

converter lock-up.

Sensor operation (see tests on pages 2-43 through 2-44).

Poor connections at sensor or computer. Faulty sensor

wiring (open or short circuits). Airflow obstructions in

ductwork or clogged air filter. Binding pivot on vane

“door”. Air leaks around sensor or throttle body.

Page 49

V ane Air Flow V AF

Sensor Connectors

Toyota

1234567

Red Yellow

Black

Black

#1

#2

Black

Black

YellowRed

YellowRed

Yellow

*Toyota uses

two sensor

types. Try

hook-up #1

first. If good

A *

test results are

not obtained,

retest using

hook-up #2

before judging

sensor.

A *

Nissan

A *

#1

A *

#2

Red

1234567

Black Yellow

12345671234567

Yellow

*Nissan uses two sensor types. Try hook-up

#1 first. If good test results are not obtained,

retest using hook-up #2 before judging sensor.

Yellow

= NOT

USED

Black

Black

Red

B

C

A

B

B

Black

Yellow

Ford

A

Black Black

Red

Refer to vehicle service manual

for connectors not shown.

Yellow

Hook up as follows: Red lead to sensor power pin.

Yellow lead to sensor signal pin.

Black lead to sensor ground pin.

Yellow

Yellow

Black

B

2-41

Page 50

Section 2

Testing Sensor s

TEST PREPARATION:

All Air Flow Meter Sensor Tests

IMPORTANT:

• Test all hook-ups shown for the sensor.

• The letter next to the hook-up refers to the test procedure for that hook-up.

• Each hook-up should test O.K.

an asterisk (*) only

sary because some sensors look alike, but have different internal connections.

Sensor may be tested on or off vehicle.

Warning: Observe all safety precautions (see page ii) if testing sensor on

vehicle.

one of the two hook-ups has to test O.K. This is neces-

1) Verify ignition key is OFF.

2) Check Tester battery

Refer to page 1-4. Set RANGE switch to POWER OFF when

done.

3) Disconnect wiring harness from sensor - Inspect for

damage.

Some vehicles use a metal snap ring to secure wiring harness

to sensor. Remove this snap ring before disconnecting wiring

harness.

4) Disconnect ductwork from sensor air intake.

This is so you can operate the sensor element for testing.

Refer to vehicle service manual for disassembly procedure.

5) Off-Car testing only: Remove sensor.

Exception: If two hook-ups are marked with

2-42

6) Test Preparation is complete. Do tests referenced in

hook-up diagrams.

• Test A - Air Flow Meter Sensor (page 2-43)

• Test B - Air Temperature Sensor (page 2-44)

• Test C - Air Flow Meter Position Switch (page 2-45)

Page 51

Mass Air Flow MAF

TEST A - Air Flow Meter Sensor

Warning: Observe all safety precautions (see page ii) if testing sensor on

vehicle.

1) Do all Test Preparation steps.

Refer to page 2-42.

2) Connect test leads.

• Connect TEST leads according to diagram A in the

component drawing.

• Important: If two hook-ups are marked with an asterisk

RANGE

FUNCTION

HIGH

LOW

POWER OFF

VOLTS

OHMS

FREQUENCY

(*) only

necessary because some sensors look alike, but have

different internal connections.

3) Verify test clips make good contact and do not touch

each other.

Make sure unused clips are not touching anything.

4) Set RANGE switch to HIGH.

5) Set FUNCTION switch to VOLTS.

6) Operate sensor - Watch TEST light for results.

Slowly move the sensor element (pivoting “door” or sliding

cone) back and forth from fully closed to fully open

position. Use a pencil, or similar object, to push on the

“door”. This will not harm the sensor.

Good Sensor

sensor is operated. (The TEST light may go off if it moves

to the bottom of the column - this is O.K.) Range of TEST

light movement varies with sensor type.

Bad Sensor

test OR light movement is erratic, showing a sudden jump

or dip during smooth sensor operation.

one of the two hook-ups has to test O.K. This is

- TEST light smoothly moves up or down as

- TEST light position does not change during

7) Test A is complete.

Set RANGE switch to POWER OFF and remove all test

leads. Reconnect sensor to vehicle if all testing is done.

2-43

Page 52

Section 2

Testing Sensor s

TEST B - Air Temperature Sensor

Warning: Observe all safety precautions (see page ii) if testing sensor on

vehicle.

1) Do all Test Preparation steps.

Refer to page 2-42.

2) Connect test leads.

Connect TEST leads according to diagram B in the component

drawing.

RANGE

FUNCTION

HIGH

LOW

POWER OFF

VOLTS

OHMS

FREQUENCY

3) Verify test clips make good contact and do not touch each other.

Make sure unused clips are not touching anything.

4) Set RANGE switch to HIGH.

5) Set FUNCTION switch to OHMS.

6) Note TEST light position on tester.

If the sensor is good, the light will move downwards as the sensor

heats up.

7) Heat temperature sensor thoroughly.

• The air temperature sensor is located either...

– In a small tube extending into the air intake passage in front of

the closed vane “door” OR

– In its own housing threaded into the side of the air flow meter

assembly.

• Heat sensor using a hair dryer or similar device. DO NOT use a

match or open flame.

8) Observe TEST light position for test results.

Good Sensor

(TEST light may go off if sensor is very hot - this is OK.) The TEST

light will move upwards as the sensor cools off. Range of TEST

light movement varies with sensor type and temperature change.

Bad Sensor

- TEST light moved downwards below original position.

- TEST light position did not change during test.

2-44

9) Test B is complete.

Set RANGE switch to POWER OFF and remove all test leads.

Reconnect sensor to vehicle if all testing is done.

Page 53

Mass Air Flow MAF

Test C - Air Flow Meter Position Switch

Warning: Observe all safety precautions (see page ii) if testing sensor on

vehicle.

1) Do all Test Preparation steps.

Refer to page 2-42.

2) Connect test leads.

Connect TEST leads according to diagram C in the component drawing.

3) Verify test clips make good contact and do not touch

HIGH

LOW

POWER OFF

RANGE

VOLTS

OHMS

FREQUENCY

FUNCTION

TEST TEST

each other.

Make sure unused clips are not touching anything.

4) Set RANGE switch to HIGH.

5) Set FUNCTION switch to OHMS.

6) Operate sensor - Watch TEST light for results.

Slowly move the sensor element (pivoting “door” or sliding

cone) back and forth from fully closed to fully open position.

Use a pencil, or similar object, to push on the “door”. This will

not harm the sensor.

Good Switch

- TEST light switches between being

ON at top of column and OFF

Bad Switch

- TEST light always ON at top of

column or always OFF.

7) Test C is complete.

Set RANGE switch to POWER OFF and remove all

test leads. Reconnect sensor to vehicle if all testing

is done.

2-45

Page 54

Section 2

Testing Sensor s

Magnet

To

Computer

Reluctance Sensor Operation

Wire Coil

Tooth

NS

Air Gap

Reluctor Ring

Rotation

Positive

SENSOR

Zero

VOLTAGE

Negative

ROTATION

Typical Sensor Signal Voltage

Crankshaft/Camshaft Position sensors

What is It

and

How is It

Used?

— The computer needs to know rotational speed (or

position) of the engine crankshaft/camshaft for controlling

ignition and fuel injector systems. If the computer is

handling a Distributorless (or Direct) ignition system or

controlling the operation of individual fuel injectors, it also

needs to know when cylinder #1 is active. The sensors have

various names such as:

Flywheel, Distributor Pick-Up, Camshaft Position, Cylinder,

TDC and RPM.

— Similar sensors are used in anti-lock brake and electronically shifted transmission systems. These sensors have

names such as:

Driveshaft.

— The sensors come many styles using different connectors.

Sometimes an assembly contains more than one sensor.

Other versions combine two functions into a single sensor

(usually camshaft position and cylinder #1 identification).

— The most common sensor types are

tance

and

Optical

types which are in limited use.

Wheel Speed, Vehicle Speed and

Hall Effect.

Crankshaft Position, Crank Angle,

Magnetic Reluc-

These are described below along with

2-46

• Magnetic

Reluctance

The basic reluctance sensor consists of a permanent

magnet with a coil of wire wrapped around it. Nearby the

sensor is a toothed ring made of iron or steel (sometimes

called a “reluctor”). The ring is attached to a rotating

component such as the crankshaft or camshaft. Whenever

a tooth from the ring passes by the sensor, it attracts the

magnetic field lines surrounding the magnet. As the field

lines move, they pass through the wire coil and generate a

small voltage pulse (magnetic induction principle). Thus a

voltage pulse is generated every time a tooth passes by

the sensor coil.

Page 55

Crankshaft/Camshaft Position

SHUTTER

HALL

POWER

GROUND

SIGNAL

Typical Hall Effect Sensor Typical Sensor Signal Voltage

SWITCH

MAGNET

HIGH

SIGNAL

VOLTAGE

LOW

ROTATION

The computer determines rotational speed (or position) by

measuring how fast (or when) pulses appear. Note: The

voltage pulses get larger when the teeth pass by more

quickly. Values can range from a fraction of a volt (crank

RPM) to over a hundred volts (high RPM).

• Hall Effect The basic Hall effect sensor consists of a permanent

magnet and a small module containing a transistorized Hall

effect switch. (Power and ground connections are required

for operation.) A small air gap separates the sensor and the

magnet. The magnetic field causes the Hall switch to turn

on and send out a low voltage signal. If a metal strip (iron or

steel) is placed in the gap, it blocks the magnetic field from

reaching the Hall device. This causes the Hall switch to turn

off and send a high voltage signal out on the signal wire.