Page 1

precision electronic solutions

CODE SCANNER

FAVOR DE LEER INSTRUCTCTIVO ANTES DE USAR EL ARTICULO

Car Computer

Code Reader

Domestic Ford, Lincoln,

Mercury with EEC-IV or

MCU Engine Computer

Control Systems

Lector de Códigos

de Computadoras

de Automóvil

Ford, Lincoln, Mercury

nacionales de EE.UU. con

Systemas MCU y EEC-IV (para EUA)

Instrucciónes

en español - página 67

CP9015

Lecteur de code

d'ordinateur

automobile

Ford, Lincoln, Mercury

domestiques Étas-Unis

avec Systèmes MCU ou EEC-IV

Instructions en

français - page 133

AUDI O

ON

OFF

T

O

S

E

U

T

T

P

F

U

L

E

T

S

STO

T

M

Domestic Ford,

Lincoln & Mercury

¨

TEST

HOLD

Tensi

ón: 16V

Hecho en: China

Para Nombre, Domicilio y Telefono

del Importador: Ver Empaque

1

CP9015

Page 2

2

Page 3

CP9015

™

Congratulations on purchasing your

Actron Code Scanner for accessing

engine trouble-codes required for

repairing vehicles equipped with

computers. Y our Actron Code Scanner is

made by Actron, the largest and most

trusted name in automotive diagnostic

equipment for the home mechanic. Y ou

can have confidence this product

maintains the highest quality in

manufacturing, and will provide you

years of reliable service.

This instruction manual is divided into

several key sections. Y ou will find

detailed steps on using the Code

Scanner and important information about

trouble code meanings, how a computer

controls engine operation, and more!

Identifying the problem is the first step in

solving that problem. Y our Actron Code

Scanner can help you determine by

accessing the engine computer trouble

codes. Armed with that knowledge, you

can either refer to an appropriate service

manual or discuss your problem with a

knowledgeable service technician. In

either event you can save yourself a lot

of valuable time and money in auto

repair. And feel confident that your

vehicle’s problem has been fixed!

Actron offers a compete

line of high quality

automotive diagnostic and

repair equipment.

See your local Actron

dealer for other

Actron products.

CONTENTS

1 About Codes: Where do they

come from and what are they for? .. 3

2 Code Scanner Basics: When do

you use it and what does it do?....... 5

3 Connector Location: Connector

type identifies the computer system

in your vehicle: EEC-IV or MCU. .....7

4 Using the Code Scanner – EEC-IV

system: Complete description for

reading and using service codes ....8

5 Code Meanings – EEC-IV system:

Service Code Definitions for Ford

EEC-IV engines ............................20

6 Other Features – EEC-IV system:

Additional Code Scanner Diagnostic

Tests.............................................. 31

7 Using the Code Scanner – MCU

system: Includes engine off and

engine running tests...................... 37

8 Code Meanings – MCU system:

Service Code Definitions for Ford

MCU engines ................................ 47

9 Computer Basics: What does the

engine computer do?

Learn more about how your engine

computer operates and controls

vehicle functions............................ 49

10

Reference Glossary: Includes

component descriptions and term

definitions commonly used in

reference to engine computer

systems......................................... 55

Instrucciónes en español67

Instructions en français131

3

Page 4

General Safety Guidelines to follow

when working on vehicles

• Always wear approved eye protection.

• Always operate the vehicle in a well ventilated area.

Do not inhale exhaust gases – they are very poisonous!

• Always keep yourself, tools and test equipment away from all

moving or hot engine parts.

• Always make sure the vehicle is in park (Automatic transmission) or neutral (manual transmission) and that the parking

brake is firmly set. Block the drive wheels.

• Never leave vehicle unattended while running tests.

• Never lay tools on vehicle battery . You may short the terminals

together causing harm to yourself, the tools or the battery.

• Never smoke or have open flames near vehicle.

Vapors from gasoline and charging battery are highly flammable and explosive.

• Always keep a fire extinguisher suitable for gasoline/electrical/

chemical fires handy .

• Always turn ignition key OFF when connecting or disconnecting electrical components, unless otherwise instructed.

• Always follow vehicle manufacturer’s warnings, cautions and

service procedures.

CAUTION:

Some vehicles are equipped with safety air bags.

You must follow vehicle service manual cautions when working

around the air bag components or wiring. If the cautions are not

followed, the air bag may open up unexpectedly , resulting in

personal injury . Note that the air bag can still open up several

minutes after the ignition key is off (or even if the vehicle battery

is disconnected) because of a special energy reserve module.

4

Page 5

About Codes

Where do they come from and what are they for?

Engine computers can find

problems.

The computer system in today’s vehicles

does more than control engine operation

– it can help you find problems, too!

Special testing abilities are permanently

programmed into the computer by factory

engineers. These tests check the

components connected to the computer

which are used for (typically): fuel

delivery, idle speed control, spark timing

and emission systems. Mechanics have

used these tests for years. Now you can

do the same thing by using the Actron

Code Scanner tool!

Engine computers perform special

tests.

The engine computer runs the special

tests. The type of testing varies with

manufacturer, engine, model year etc.

There is no “universal” test that is the

same for all vehicles. The tests examine

INPUTS (electrical signals going IN to

the computer) and OUTPUTS (electrical

signals coming OUT of the computer.)

Input signals which have “wrong” values

or output circuits which don’t behave

correctly are noted by the test program

and the results are stored in the

computer’s memory. These tests are

important. The computer can not control

the engine properly if it has bad inputs or

outputs!

Code numbers give test results.

The test results are stored by using code

numbers, usually called “trouble codes”

or “service codes.” For example, a code

63 might mean “throttle position sensor

signal voltage is too low.” Code meanings

are listed in Sections 5 and 8. Specific

code definitions vary with manufacturer,

engine and model year, so you may want

to refer to a vehicle service manual for

additional information. These manuals

are available from the manufacturer,

other publishers or your local public

library. (See manual listing on page 4.)

Read Codes with the Code

Scanner.

Y ou obtain trouble codes from the

engine computer memory by using the

Actron Code Scanner tool. Refer to

section 4 or 7 for details. After you get

the trouble codes, you can either:

• Have your vehicle professionally

serviced. Trouble codes indicate

problems found by the computer.

or,

• Repair the vehicle yourself using

trouble codes to help pinpoint the

problem.

Trouble Codes and Diagnostics

help you fix the problem.

To find the problem cause yourself, you

need perform special test procedures

called “diagnostics”. These procedures

are in the vehicle service manual. There

are many possible causes for any

problem. For example, suppose you

turned on a wall switch in your home

and the ceiling light did not turn on. Is it

a bad bulb or light socket? Is the bulb

installed correctly? Are there problems

with the wiring or wall switch? Maybe

there is no power coming into the

house! As you can see, there are many

possible causes. The diagnostics written

for servicing a particular trouble code

take into account all the possibilities. If

you follow these procedures, you should

be able to find the problem causing the

code and fix it if you want to “do-ityourself.”

Actron makes it easy to fix

computer-controlled vehicles

Using the Actron Code Scanner to

obtain trouble codes is fast and easy.

5

Page 6

Trouble codes give you valuable

knowledge – whether you go for

professional vehicle servicing or “do-ityourself. ” Now that you know what

trouble codes are and where they come

from, you are well on your way to fixing

today’s computer controlled vehicles!

Vehicle Service Information

The following is a list of publishers who have manuals containing trouble code repair

procedures and related information. Some manuals may be available at auto parts

stores or your local public library. For others, you need to write for availability and

prices, specifying the make, style and model year of your vehicle.

Vehicle Service Manuals:

Chilton Book Co.

Chilton Way

Radnor, PA 19089

Haynes Publications

861 Lawrence Drive

Newbury Park, CA 91320

Cordura Publications

Mitchell Manuals, Inc.

P . O. Box 26260

San Diego, CA 92126

“Electronic Engine Controls”

“Fuel Injection and Feedback Carbure-

tors”

“Fuel Injection and Electronic Engine

Controls”

“Emissions Control Manual”

...or similar titles

Vehicle Service Manuals from Ford

Motor Company: (Ford, Lincoln,

Mercury)

Ford Publication Department

Helm Incorporated

P . O. Box 07150

Detroit, MI 48207

1985 & Newer: “Emission Diagnosis

Engine/Electronics”

1981-1984: “Engine/Emissions

Diagnosis”

6

Page 7

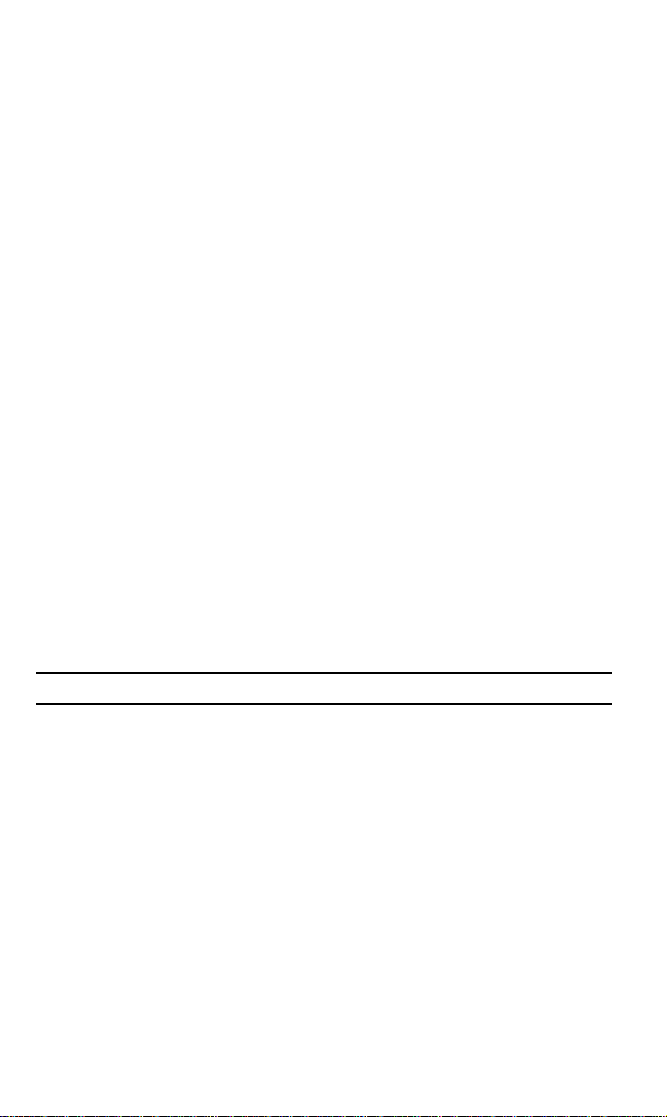

Scanner Basics

When Do You Use it and What Does it Do?

When to Use the Code Scanner

Use the Code Scanner:

• When you experience a driveability

problem with your vehicle.

• When the “Check Engine” light comes

on (if used on vehicle).

• For a routine system check – even on

vehicles with a “Check Engine” light.

3

AUDIO

ON

OFF

CP9015 – Ford, Lincoln & Mercury

T

S

E

T

F

L

E

S

ST0

Domestic 1981& Newer

2

O

U

T

P

U

T

®

TM

HOLD

1

What the Code Scanner Does

The Code Scanner makes the vehicle

computer run special tests to check out

various parts of the system. The Code

Scanner plugs into vehicle wiring which

connects directly into two engine

computer circuits. One circuit is called

Self-T est Input (STI). The Code Scanner

uses this wire to tell the computer to run

the tests. The other circuit is called SelfT est Output (STO).

The computer sends test results back to

the Code Scanner by using a pulse type

signal on this wire.

TEST

M

T

HOLD

AUDIO

ON

OFF

9015 - Ford, Lincoln & Mercury

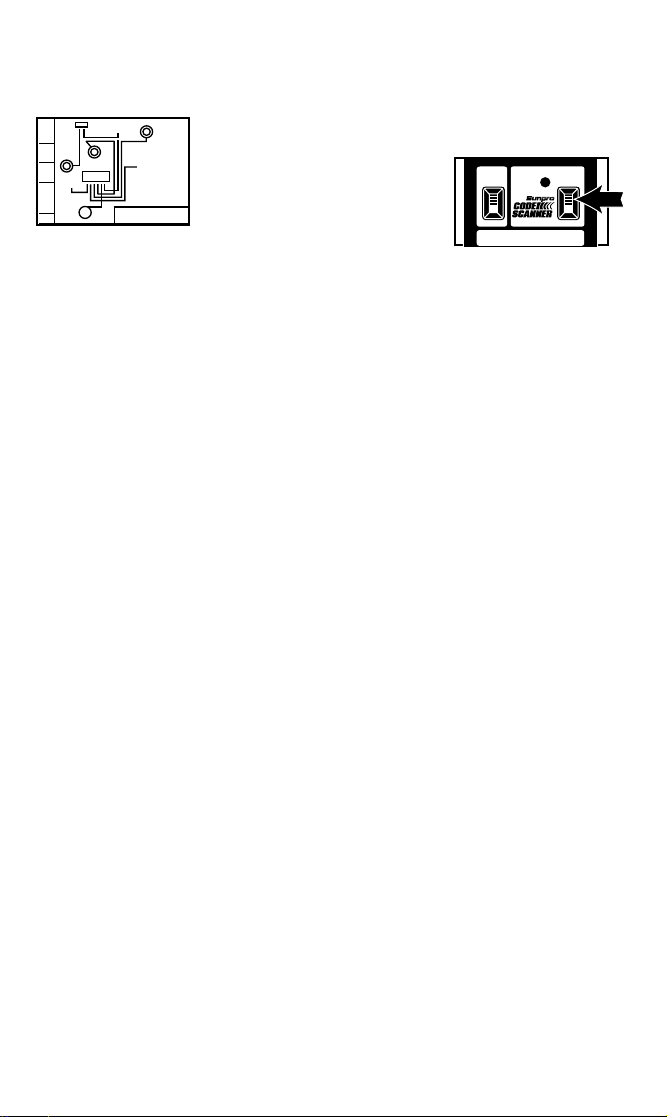

Code Scanner Controls

1 HOLD/TEST switch

This switch connects to the computer’s

Self-Test Input (STI) circuit.

•

HOLD – The STI wire is unconnected.

(Normal position – no testing.)

• TEST – The STI wire is connected to

vehicle ground. (Computer starts

testing procedure.)

2 SELF-TEST OUTPUT light

This light is connected to the STO circuit

coming from the computer.

• Light OFF – The STO signal is “high”

(about 5 volts present).

• Light ON – The STO signal is “low”

(near zero volts).

A pulse type signal on the STO wire will

cause this light to blink. This is how the

computer sends test results to the Code

Scanner. See Section 4 or 7 for details.

Note: With the Code Scanner connected and ignition key OFF, the light

may be ON or OFF – depends upon

vehicle. This does not affect testing

performance.

3 AUDIO switch

•

Switch ON – A tone sounds whenever

the Self-Test Output light is lit.

• Switch OFF – Tone is always OFF.

This feature is useful when the STO light

can not be easily seen, such as when

performing the “wiggle” test described in

Section 6.

Note: With the Code Scanner connected, Audio switch ON and ignition key

OFF, the tone may be ON or OFF (no

matter what the light does) – depends

upon vehicle. This does not affect testing

performance.

7

Page 8

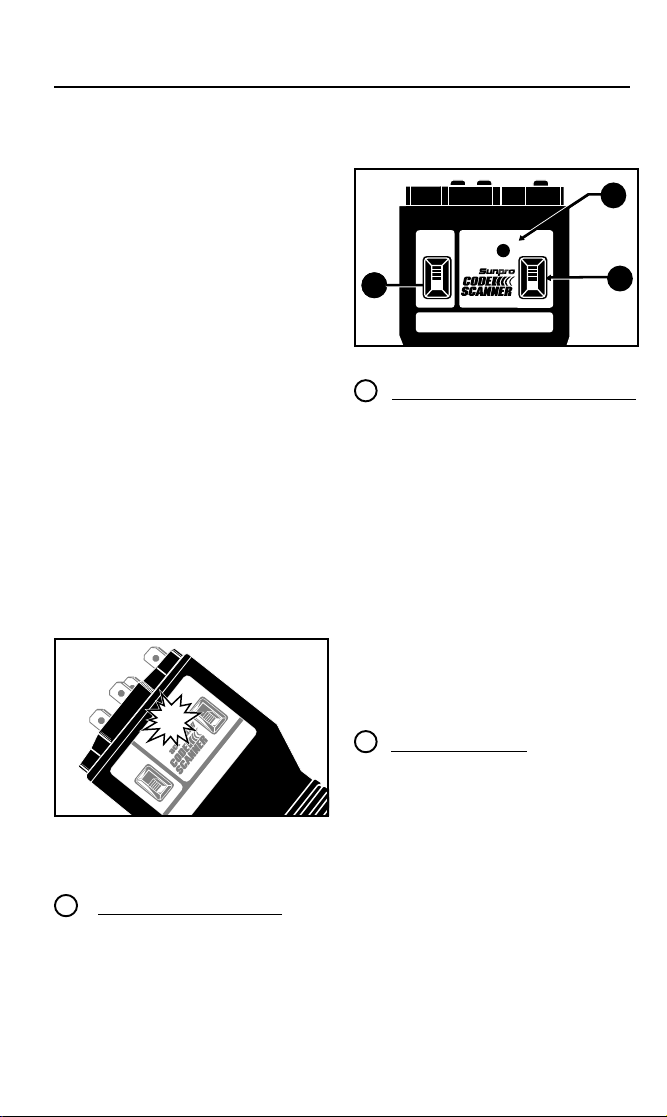

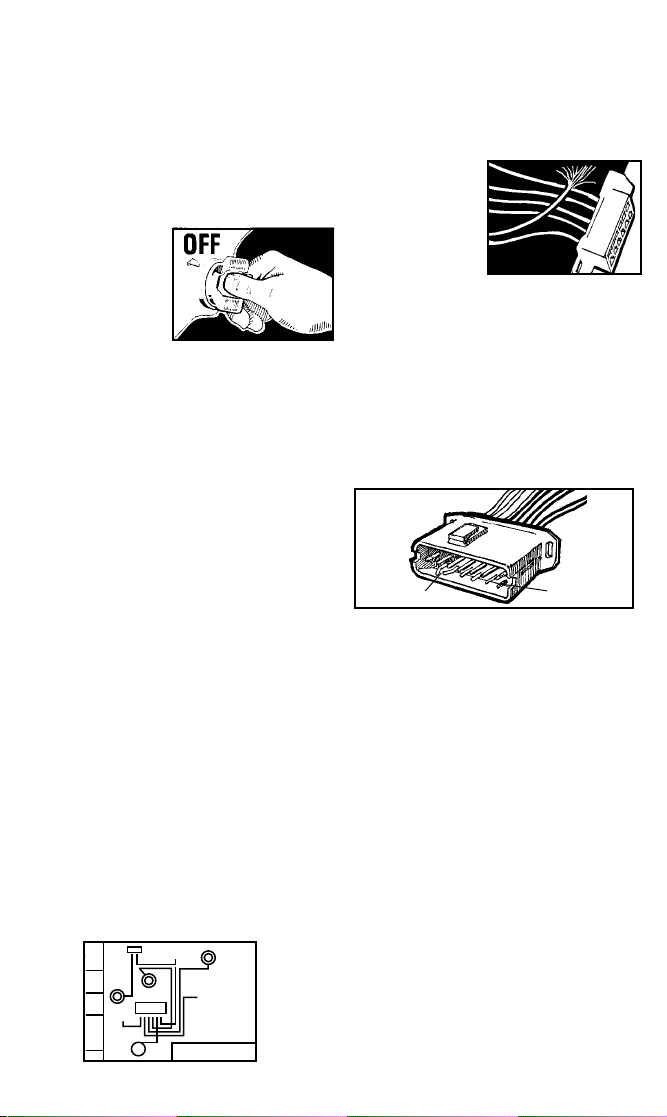

Code Scanner Power

A 9 volt transistor radio battery (NEDA

1604) is required to power the Code

Scanner. Either a regular or alkaline

battery may be used. The Code

Scanner has an automatic battery shutoff when not in use. There is no “power

off” switch because the unit uses no

power when the light is off and the tone

is quiet. The battery must be installed

before use.

Installing the Battery

Do the following:

1) Remove two screws from the bottom

side of the Code Scanner.

2) Separate the two halves of the Code

Scanner.

3) Insert battery:

4) Reassemble Code Scanner case

and replace screws.

Checking the Battery

Do the following:

1) Put the Hold/Test switch in TEST

position.

T

O

S

E

AUDIO

ON

OFF

CP9015 – Ford, Lincoln & Mercury

Domestic 1981& Newer

U

T

T

P

F

U

L

E

T

S

TEST

ST0

®

TM

HOLD

2) Put the Audio switch in ON position.

3) Use a coin to touch the two side-byside terminals on the bottom row (the

one with three terminals) of the Code

Scanner connector.

4) Both the STO light and the tone

should turn ON. Replace battery

when the light or tone gets weak.

8

Page 9

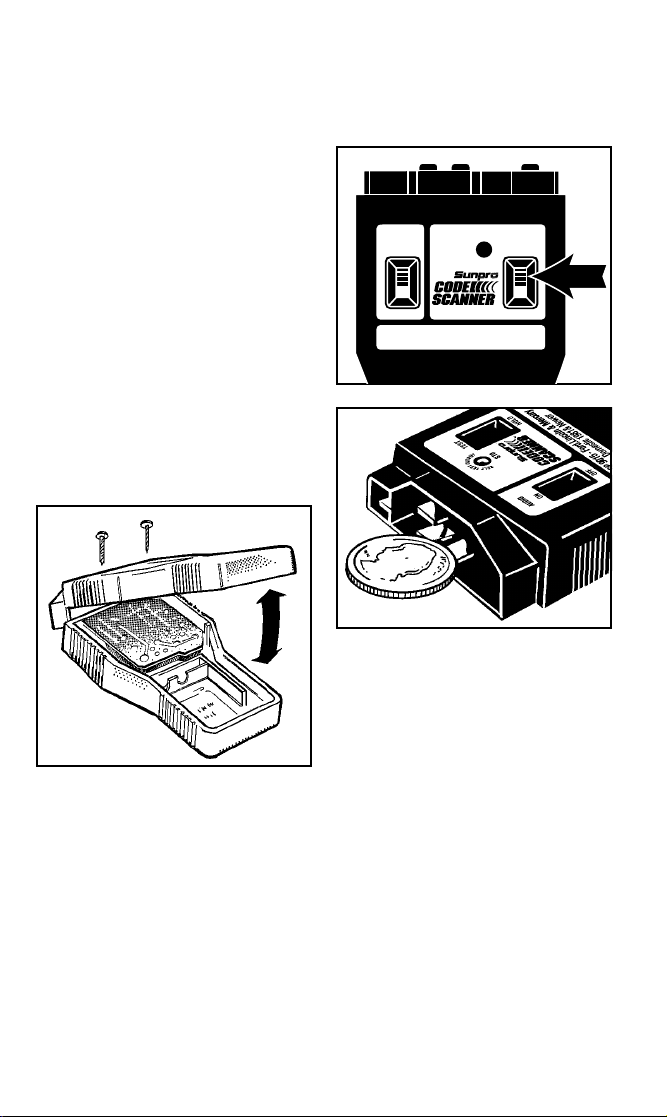

Connector Location

Where the Self-Test connector can be found.

Connector Types

The Code Scanner plugs into the

vehicle “Self-T est” connector which is

located in the engine compartment.

• The EEC-IV computer system (most

1984 & up vehicles) uses TWO test

connectors.

– A large six sided connector.

– A small single wire “pigtail”

connector.

Both of these connectors must be

plugged into the Code Scanner

before use.

• The MCU system (most 1981 – 1983

vehicles) uses ONE test connector.

– A large six sided connector,

identical to the one used with EEC-IV

systems. This connector must be

plugged into the Code Scanner

before use. The MCU system does

NOT use the small “pigtail” connector.

TEST

U

T

P

O

U

T

T

S

E

T

F

L

E

S

M

T

HOLD

AUDIO

ON

81 & Newer

, Lincoln & Mercury

Connector locations

Y ou can tell which computer system is in

your vehicle by noting which connector

type is installed!

The connectors are located in one of six

general areas.

• Near the fire wall (right or left side of

vehicle)

• Near the wheel well (right or left side

of vehicle)

• Near the front corner of the engine

compartment (right or left side of

vehicle)

The connectors are easy to miss – take

your time looking! They are usually gray ,

or other dark color, and located close to

a wiring harness. They may be capped

with a plastic cover or shroud labeled

“EEC TEST” or similar wording.

Other Test Connectors

Vehicles made after 1988 may have

additional computer controlled systems

installed, such as Anti-Lock Brakes

(ABS), active suspension and the like.

These systems use a test connector

identical to EEC-IV six sided one. These

systems do NOT use the extra “pigtail”

connector! The Code Scanner is

compatible with most of these systems –

refer to vehicle service manual for

system description and test methods.

9

Page 10

EEC-IV System

Using the Code Scanner (EEC-IV Systems).

Complete Description for Reading and Using Service Codes.

Do This First

This section shows you how to use the

Code Scanner for:

• Running tests of the engine computer

system. (Engine off, ignition timing

and engine running tests.)

• Reading service codes to pinpoint

problem causes.

Before using this section:

– Read Sections 1 and 2 to learn

about service codes and the Code

Scanner tool.

– Read Section 3 to find the location

of the Self-Test connector in your

vehicle. The connector type will tell

you whether you have an EEC-IV

system or an MCU system.

– Read this section (4) if you have an

EEC-IV system. Use Section 7 if you

have an MCU system.

Self-Test Summary

The Self-Test procedure (also called

“Quick Test”) involves engine off and

engine running tests. The entire

procedure is summarized in the chart.

Each part is fully explained on the

following pages.

IMPORTANT: All parts must be

performed as shown for accurate

testresults!

Part 1: Test Preparation.

• Safety First! Follow all safety rules.

• Perform Visual Inspection. This often

reveals the problem.

• Prepare Vehicle. Engine must be

thoroughly warmed-up.

Part 2: To Key On Engine Off (KOEO)

Self-Test.

• Get service codes to help pinpoint

problems.

Part 3: Check Engine Timing.

• Verify correct “base” timing (no

computer

control) before doing next part.

Part 4: Do Key On Engine Running

(KOER) Self-Test.

• Get more service codes to pinpoint

problems found during engine

operating conditions.

Part 5: Evaluate/Erase “Continuous

Memory” Codes

• Helps locate intermittent problems.

• Removes service codes stored in

computer memory.

10

Page 11

Self-Test Part 1: Test Preparation

1) Safety First!

• Set the parking brake.

• Put shift lever in PARK (automatic

transmission) or NEUTRAL (manual

transmission).

• Block the drive wheels.

• Make sure

ignition key

is in OFF

position.

2) Perform

Visual Inspection.

Doing a thorough visual and “handson” underhood inspection before

starting any diagnostic procedure is

essential!! Y ou can find the cause of

many drivability problems by just

looking, thereby saving yourself a lot

of time.

• Has the vehicle been serviced

recently?

Sometimes things get reconnected

in the wrong place, or not at all.

• Don’t take shortcuts. Inspect hoses

and wiring which may be difficult to

see because of location beneath air

cleaner housings, alternators and

similar components.

• Inspect the air cleaner and ductwork

for defects.

• Check sensors and actuators for

damage.

• Inspect all vacuum hoses for:

– Correct routing. Refer to vehicle

service manual, or Vehicle Emission

Control Information (VECI) decal

located in the engine compartment.

– Pinches and kinks.

– Splits, cuts or breaks.

HVAC/

ER

P

A.

CRUISE

EGR

VAC

REG

EGR

VAC

REG

FUEL

PRESS

REG

. ..

BRAKE BOOSTER

TO TRANS

MODE

FRONT

OF CAR

9RAC2LAB

• Inspect wiring for:

– Contact with sharp edges. (This

happens often.)

– Contact with

hot surfaces,

such as

exhaust

manifolds.

– Pinched,

burned or

chafed

insulation.

– Proper routing and connections.

• Check Electrical Connectors for:

– Corrosion on pins.

– Bent or damaged pins.

– Contacts not properly seated in

housing.

– Bad wire crimps to terminals.

Bent Pins Corrosion

Problems with connectors are common

in the engine control system. Inspect

carefully. Note that some connectors use

a special grease on the contacts to

prevent corrosion. Do not wipe off!

Obtain extra grease, if needed, from

your vehicle dealer. It is a special type

for this purpose.

3) Prepare Vehicle.

• Turn off all electrical equipment and

accessories in vehicle.

• Keep all vehicle doors closed during

testing.

• Make sure radiator coolant and

transmission fluid are at proper

levels.

• Start the engine and let it idle until

the upper radiator hose is hot and

pressurized and RPM has settled to

warm engine idle speed.

Check for leaks around hose

connections.

11

Page 12

• Turn ignition key to OFF position.

WARNING: Always operate vehicle

in a well ventilated area.

Do NOT inhale exhaust gases – they

are very poisonous!

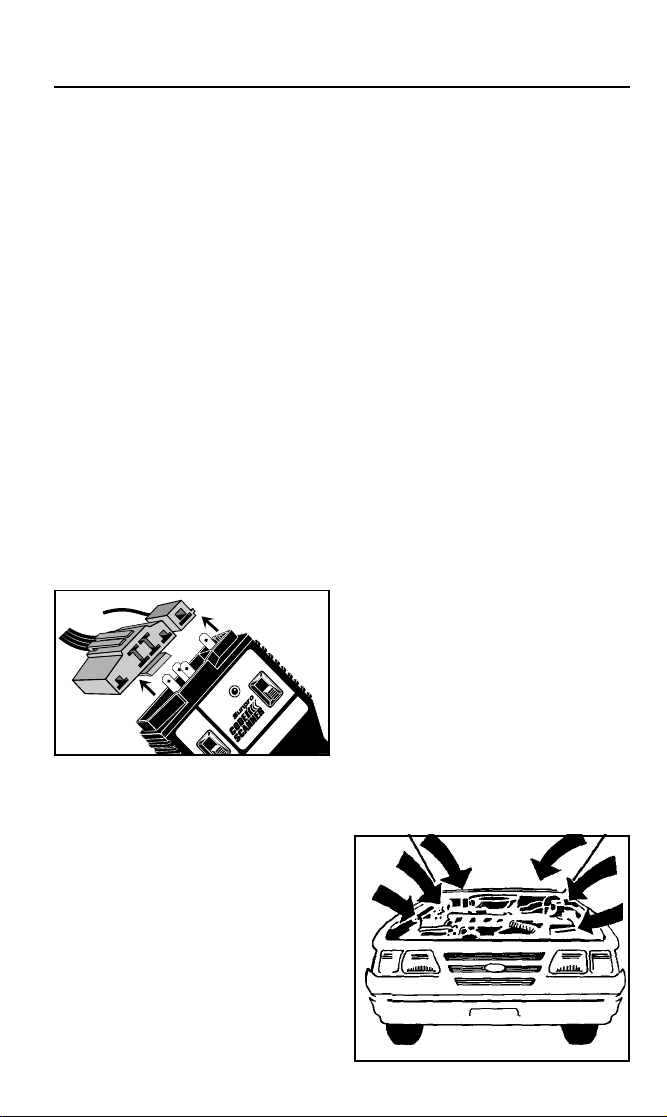

4) Check Code Scanner Battery.

• Refer to Section 2.

5) Plug the Code Scanner into the

Vehicle Self-Test Connectors.

• Refer to Section 3, “Connector

Location”.

• Connect the Code Scanner to

BOTH test connectors: the small,

single wire connector and the larger

6-sided one.

Note: One Code Scanner pin plugs

into an unused position on large test

connector. This is normal. Also, large

test connector may have other

contacts not used by Code Scanner.

• The Code Scanner

will not harm

vehicle engine computer.

TEST

U

T

P

O

U

T

T

S

E

T

F

L

E

S

M

T

HOLD

AUDIO

ON

1981 & Newer

ord, Lincoln & Mercury

6) Have a Pencil

and Paper

Ready.

• This is for

writing down

all the codes.

7) Go to SELF-TEST PART 2: Key On

Engine Off (KOEO) Self-Test.

• Do Self-Test Part 2 even if engine

will not start, stalls or runs rough.

The service codes you get may

pinpoint the problem. If not, refer to

vehicle service manual for

troubleshooting charts related to

the vehicle symptom.

the

12

Page 13

Self-Test Part 2:

Domestic 1981& Newer

Key On Engine Off (KOEO) Self-Test.

IMPORTANT: You must complete all steps in Self-Test Part 1 before

proceeding to Part 2.

Verify good battery in Code Scanner

(Section 2).

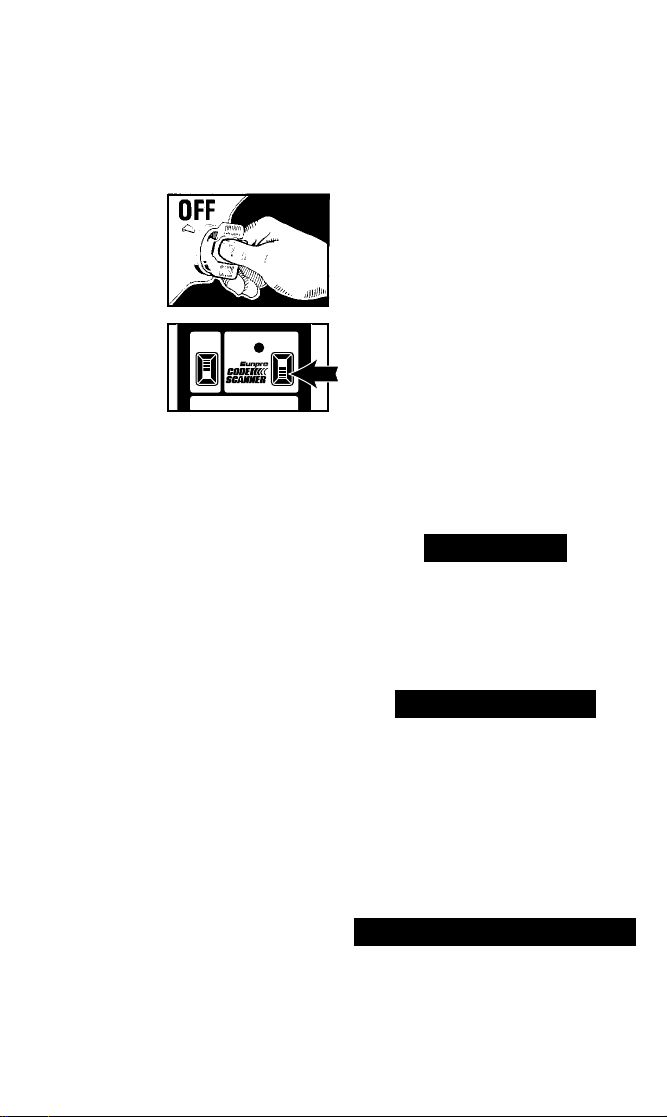

1) Verify

Ignition

Key is in

OFF

Position.

T

O

S

E

2) Put Code

Scanner

HOLD/TEST

Switch in

AUDIO

CP9015 – Ford, Lincoln & Mercury

U

T

T

P

F

U

L

E

T

S

ON

OFF

TEST

ST0

®

TM

HOLD

HOLD

Position.

• Do the following also:

– For 4.9L only, depress clutch until

Step 5 (codes sent).

– For 7.3L diesel only , completely

depress throttle until Step 5 (codes

sent).

– For 2.3L turbo with octane switch,

put switch in premium position.

3) Turn Ignition Key to ON Position

but DO NOT START THE ENGINE.

4) Put Code Scanner HOLD/TEST

Switch in TEST Position.

• This starts the KOEO Self-Test.

• Testing takes anywhere from 10

seconds to one minute before codes

are sent.

• Y ou may hear clicking sounds in the

engine compartment as relays are

being tested.

WARNING: Stay away from

the radiator cooling fan! It

may turn on momentarily

during the test procedure. (On

certain vehicles with

electrically operated fans.)

5) Get Codes from the Flashing STO

Light.

NOTE: If the light does not flash, go

back and repeat SELF-TEST P A R T 2

starting with Step 1. If the light still

does not flash, you have a problem

which must be repaired before

proceeding. Refer to the vehicle

service manual “No Codes” troubleshooting chart.

• Pay no attention to the brief, rapid

blinks which occur before the regular

codes are sent.

• Count flashes to get service codes.

Code 12 looks like:

PAUSE

❊

FLASH (pause) FLASH FLASH

(FLASH = 1, FLASH FLASH = 2.

Put 1 and 2 together = code 12.)

Code 23 looks like:

❊❊

FLASH FLASH (pause)

FLASH FLASH FLASH

NOTE: Certain 1991 and newer vehicles

use 3 digit codes (refer to vehicle service

manual to determine whether your

system uses 2 or 3 digit codes).

These codes are sent as follows:

Code 123 looks like:

PAUSE

❊

FLASH (pause) FLASH FLASH (pause)

• Two groups of codes are sent at this

❊❊

FLASH FLASH FLASH

time. Each group is separated by a

PAUSE

❊❊

❊❊❊

PAUSE

❊❊❊

13

Page 14

single flash (called a “separator

code”)

• The first code group has KOEO

(Key On Engine Off) codes – for

problems which are present now.

Some service manuals call these

“hard” or “on demand” codes.

– The KOEO group will always

contain at least one code. This will

be a “system pass” code (11 or 111)

if no problems were seen.

– The KOEO code group is sent

twice (so you can double check your

code list).

• The second code group has

Continuous Memory codes – for

problems which occurred in the past

and have been “memorized” by the

computer. These problems

(sometimes called “intermittences”)

may or may not be present now.

– The Continuous Memory group

will always contain at least one

code. This will be a “system pass”

code (11 or 111) if no problems

were seen.

– The Continuous Memory code

group is sent twice (so you can

double check your code list).

• Code sequence example with

KOEO codes = 21 and 32,

Continuous Memory code =14:

PAUSE

❊❊

FLASH FLASH (pause) FLASH

(longer pause).

❊❊❊

FLASH FLASH FLASH (pause)

FLASH FLASH

(longer pause).

❊❊

FLASH FLASH (pause) FLASH

(longer pause).

❊❊❊

FLASH FLASH FLASH (pause)

FLASH FLASH

(very long pause)

SEPARA T OR CODE

❊

FLASH (“separator code”)

PAUSE

PAUSE

PAUSE

❊

❊❊

❊

❊❊

14

(very long pause)

PAUSE

❊

FLASH FLASH FLASH FLASH

❊

FLASH FLASH FLASH FLASH

❊❊❊❊

FLASH (pause)

(longer pause).

PAUSE

❊❊❊❊

FLASH (pause)

Page 15

• Write down codes in the order they are sent.

6) Turn Ignition Key to OFF Position.

At this point you can either:

• Have your vehicle professionally serviced. Codes indicate problems found by the

computer.

or,

• Repair the vehicle yourself using service codes to help pinpoint the problem.

Refer to Test Results Chart.

Key On Engine Off (KOEO) Test Results

KOEO SEPARATOR MEMORY

CODES CODES CODES ACTION TO T AKE:

11 1 11 System pass. No problem found by computer during

(or 111) (or 111) KOEO Self-Test. No codes stored in computer

Any 1 11 KOEO codes indicate system problems are present

Code(s) (or 111) now. Write down all codes. Make repairs based on

Any 1 Any KOEO and Continuous Memory codes indicate

Code(s) Code(s) system problems. Write down ALL codes. DO NOT

11 1 Any Code(s) Continuous Memory codes indicate system faults.

(or 111) not in Write down ALL codes but DO NOT repair these

CONTINUOUS MEMORY 15 1989 & older

CODE EXCEPTIONS 56, 66 1988-1989 5.0L SFI Mustang only

(REPAIR NOW) 45, 46, 48, 215, 216, 217, 232 and 238 vehicles with

DIS (Distributorless Ignition System) only.

CONTINUOUS

memory. Go to SELF-TEST PART 3: Check Engine

Note:

Timing.

rough, refer to vehicle service manual for

troubleshooting charts related to the symptom.

KOEO codes starting with the first code received.

Refer to vehicle service manual for code troubleshooting charts and repair procedures. Repeat

KOEO Self-T est after every repair. (Sometimes a

repair procedure will eliminate more than one code.)

Do not proceed to SELF-TEST PART 3 until a

KOEO pass code (11 or 111) is received.

repair Continuous Memory codes at this time! (But

keep them written down for later use in Self-Test

Step 5.) First make repairs based on KOEO codes

starting with the first code received. Refer to vehicle

service manual for code troubleshooting charts and

repair procedures. Repeat KOEO Self-T est after

every repair. (Sometimes a repair procedure will

eliminate more than one code.)

SELF-TEST PART 3 until a KOEO pass code (11 or

111) is received.

Exceptions List codes at this time! Keep them written down for later

use in Self-T est Step 5. Continue the Self-Test

procedure: go to SELF-TEST P ART 3.

EXCEPTIONS: Some Continuous Memory codes

must be repaired before going to Part 3. These are

listed below. Refer to vehicle service manual for

code troubleshooting charts and repair procedures.

Repeat KOEO Self-T est after every repair . Do not

proceed to SELF-TEST PART 3 until all code

exceptions are eliminated.

If engine will not start, stalls or runs

Do not proceed to

15

Page 16

Self-Test Part 3: Check Engine Timing.

OFF

AUDIO

ON

CP9015 – Ford, Lincoln & Mercury

Domestic 1981& Newer

TM

®

TEST

ST0

HOLD

S

E

L

F

T

E

S

T

O

U

T

P

U

T

HVAC/

ER

P

A.

CRUISE

EGR

VAC

REG

BRAKE BOOSTER

FUEL

TO TRANS

PRESS

MODE

REG

. ..

EGR

VAC

REG

FRONT

OF CAR

9RAC2LAB

(NOTE: 7.3L

Diesel This

Part does

not apply. Go

to Part 4.)

This portion of

the Self-Test procedure is where you

check both the “base” engine timing (no

computer adjustment ) and the ability of

the computer to control spark advance.

The correct value for base engine timing

is printed on the Vehicle Emission

Control Information (VECI) decal, located

in the engine compartment. (Base timing

is 10° BTDC if not specified on the VECI

decal.) A timing light is required for this

test. Connect it to vehicle according to

manufacturers directions. (For 2.3L dual

plug engines, use exhaust side plug.

Refer to ignition system section in vehicle

service manual for specific instructions.)

For 1991 & Older Vehicles:

(See page 15 for 1992 & newer

vehicles.)

1) Turn Ignition Key OFF.

• Wait 10 seconds before proceeding.

2) Put Code Scanner HOLD/TEST

Switch in HOLD Position.

WARNING: The next step involves

starting the engine. Observe safety

precautions.

• Always operate vehicle in a well

ventilated area. Do NOT inhale

exhaust gases – they are very

poisonous!

• Set the parking brake.

• Put shift lever in PARK (automatic

transmission) or NEUTRAL (manual

transmission).

• Block the drive wheels.

• Stay away from moving engine parts.

3) Start the Engine.

• If engine will not start, stalls or runs

rough, refer to vehicle service

manual for troubleshooting charts

related to the symptom.

4) Put Code

Scanner

HOLD/TEST

Switch in

TEST

Position.

• The computer is now performing an

Engine Running Self-Test, but do not

be concerned with the test or the

resulting codes at this time. It takes

several seconds before codes are

sent.

5) Wait For End of All Service Code

Signals.

• STO light on Code Scanner stops

blinking.

6) Check Ignition Timing.

• After the last code is sent, the

timing will remain fixed for 2

minutes (unless Self-Test is

deactivated by moving T est/Hold

switch to HOLD position).

• Ignition timing (only during this 2

minute period) should be 20

degrees more than the base timing

value (give or take 3 degrees).

EXAMPLE: If base timing is

specified at 10°, the measured

value in this step should be

10°+20°=30°±3°. That is, the timing

should be in the range of 27° to 33°

BTDC.

• If measured timing does not meet

this specification, refer to vehicle

service manual for procedures to

check base timing and computer

timing advance circuits.

• If measured timing is OK, proceed

to SELF-TEST P AR T 4: Key On

Engine Running (KOER) Self-Test.

7) Turn Ignition Key to OFF Position.

16

Page 17

For 1992 & Newer Vehicles:

(See page 14 for 1991 & older vehicles.)

1) Turn Ignition Key OFF.

• Wait 10 seconds before proceeding.

2) Turn off Electrical Loads.

• This includes radio, headlights,

blower fans, air conditioner, and the

like.

4) Start the

Engine.

• Only use the

ignition key to

start engine –

do not use a

remote starter.

• If engine will not start, stalls or runs

rough, refer to vehicle service

manual for troubleshooting charts

related to the symptom.

3) Disconnect the In-Line SPOUT or

SAW Connector. (Depends upon

ignition system: SPOUT= Spark

Output; SAW = Spark Advance

Word.)

• This disconnects the computer

advance timing signal from the

ignition system.

• The ignition system will now operate

at “base engine” timing.

• The connector is located close to the

ignition module.

• There are 3 different styles

illustrated, depending upon your

vehicle type.

WARNING: The next step involves

starting the engine. Observe safety

precautions.

• Always operate vehicle in a well

ventilated area. Do NOT inhale

exhaust gases – they are very

poisonous!

• Set the parking brake.

• Put shift lever in PARK (automatic

transmission) or NEUTRAL (manual

transmission).

• Block the drive wheels.

• Stay away from moving engine

parts.

5) Check Engine Timing.

• Base timing should be the same as

the VECI decal specification, give or

take 2°. Example: Specified timing is

10° BTDC. Measured timing should

be in the range of 8° to 12°BTDC.

— Distributor System: If base timing

not correct, adjust or repair as

necessary before proceeding.

Refer to ignition system section in

vehicle service manual for

instructions.

— Distributorless System: Base

timing is NOT adjustable. If timing

not correct, refer to ignition system

section in vehicle service manual for

possible causes. Repair as

necessary before proceeding.

6) Reconnect the In-Line SPOUT or

SAW Connector.

7) Check for Timing Advance (or RPM

Increase).

• Timing change (or RPM increase)

should occur as soon as connector

is reconnected.

• If O.K. proceed to SELF-TEST

PART 4.

• If not O.K. proceed to SELF-TEST

PAR T 4, but repair Engine Run

codes 213 or 218 immediately, if

received.

8) Turn Ignition Key to OFF Position.

17

Page 18

Self-Test Part 4: Key On Engine Running (KOER) Self-Test.

IMPORTANT: You must complete all steps in Self-Test Parts 1,2 and 3 before

proceeding to Part 4.

Verify good battery in Code Scanner (Section 2).

1) Verify Ignition Key is in OFF

Position.

2) Put Code Scanner HOLD/TEST

Switch in HOLD Position.

WARNING: The next step involves

starting the engine. Observe safety

precautions.

• Always operate vehicle in a well

ventilated area. Do NOT inhale

exhaust gases – they are very

poisonous!

• Set the parking brake.

• Put shift lever in PARK (automatic

transmission) or NEUTRAL (manual

transmission).

• Block the drive wheels.

• Stay away from moving engine

parts.

3) Start the Engine.

• If engine will not start, stalls or runs

rough, refer to vehicle service

manual for troubleshooting charts

related to the symptom.

4) Run the Engine to Warm the EGO

Sensor.

• The EGO (Exhaust Gas Oxygen)

sensor must be warmed-up to

operate for this test.

• Run engine at 2000 RPM for at

least 2 minutes.

7) Get Engine Identification (ID) Code

from the Flashing STO Light.

NOTE: If the light does not flash, go

back and repeat SELF-TEST P A R T 4

starting with Step 5. If the light still

does not flash, you have a problem

which must be repaired before

proceeding. Refer to the vehicle

service manual “No Codes” troubleshooting chart.

• An engine ID code is sent after a

few seconds to signal the beginning

of KOER Self-T est.

• Count flashes on the STO light.

– 4 cylinder: 2 Flashes.

– 6 cylinder: 3 Flashes.

– 8 cylinder: 4 Flashes.

– 7.3L Diesel: 5 Flashes.

IMPORTANT:

required at this time.

• Vehicles with PSPS (Power Steering

Pressure Switch): Turn steering

wheel one half turn and release

within 1 or 2 seconds AFTER

seeing engine ID code. (The

computer checks for switch action.)

• Vehicles with BOO (Brake On/Off

switch) when used by computer:

Press and release the brake pedal

AFTER seeing engine ID code. (The

computer checks for switch action.)

• Vehicles with OCS (Overdrive

Cancel Switch): Toggle the switch

on and off AFTER seeing engine ID

code. (The computer checks for

switch action.)

Some actions may be

5) Turn Engine OFF – Wait 10

Seconds – Restart Engine.

6) Put Code Scanner HOLD/TEST

Switch in TEST Position.

• This starts the KOER (Key On

Engine Running) Self-Test.

8) Perform WOT Action After

“Dynamic Response” Signal.

• The Dynamic Response signal is a

single flash on the STO light

occurring 6 to 20 seconds after the

engine ID code is sent.

DYNAMIC RESPONSE

❊

18

Page 19

• Perform a brief Wide-Open-Throttle

(WOT) action right after the Dynamic

Response

signal.

(Completely

press and

release

throttle.)

• Some

vehicles do

not use this signal – no throttle

action is necessary.

9) Get Codes from the Flashing STO

Light.

• The KOER (Key On Engine

Running) codes are sent 4 to 15

seconds after the Dynamic

Response signal. There are no other

code groups or separator signals

sent.

• Pay no attention to the brief, rapid

blinks which occur before the regular

codes are sent.

• Count flashes to get service codes.

This is done the same way as in

Self-Test Part 2.

Code 12 looks like:

PAUSE

❊

FLASH (pause) FLASH FLASH

(FLASH = 1, FLASH FLASH = 2.

Put 1 and 2 together = code 12.)

Code 23 looks like:

❊❊

FLASH FLASH (pause)

FLASH FLASH FLASH

NOTE: Certain 1991 and newer vehicles

use 3 digit codes (refer to vehicle service

manual to determine whether your

system uses 2 or 3 digit codes).

These codes are sent as follows:

Code 123 looks like:

PAUSE

❊

FLASH (pause) FLASH FLASH (pause)

• The KOER (Key On Engine

❊❊

FLASH FLASH FLASH

PAUSE

❊❊

❊❊❊

PAUSE

❊❊❊

Running) codes are sent as a

group.

— The KOER group will always

contain at least one code. This will

be a “system pass” code (11 or 111)

if no problems are seen.

— The KOER code group is sent

twice (so you can double check your

code list).

• Code sequence example with

KOER codes = 21 and 32:

PAUSE

❊❊

FLASH FLASH (pause) FLASH

(longer pause).

❊❊❊

FLASH FLASH FLASH (pause)

FLASH FLASH

(longer pause).

❊❊

FLASH FLASH (pause) FLASH

(longer pause).

❊❊❊

FLASH FLASH FLASH (pause)

• Write down codes in the order they

are sent.

• Code definitions are listed in

Section 5, “Code Meanings (EEC-IV

system).”

10)

Turn Ignition Key to OFF Position.

Refer to KOER Test Results chart

following.

19

FLASH FLASH

PAUSE

PAUSE

PAUSE

❊

❊❊

❊

❊❊

Page 20

Key On Engine Running (KOER) Test Results

ENGINE RESPONSE RUNNING

ID CODE CODE CODE ACTION TO TAKE:

2,3,4 or 5 1 11 No problems found by computer during KOER Self-

2,3,4 or 5 1 Any Engine Running codes indicate system problems

(or 998) performed. The computer has spotted system

DYNAMIC ENGINE

•If Continuous Memory codes were obtained in

•If Continuous Memory codes were NOT obtained

•If Continuous Memory codes were NOT obtained in

Codes are present now. Write down all codes. Make repairs

98 Not sent Any Codes The Key On Engine Running Self-Test CANNOT be

(or 111) Test, however…

Self-Test Part 2, go to SELF-TEST PART 5:

Evaluate “Continuous Memory” codes.

in Self-Test Part 2, BUT other vehicle symptoms are

still present, refer to Diagnosis by Symptom

Troubleshooting Charts in vehicle service manual.

(The faults are probably not related to the computer

system.)

Self-Test Part 2 and NO other vehicle symptoms are

present, the Self-Test Diagnostic Procedure is

complete.

based on Engine Running codes starting with the

first code received. (

213 or 218 first, if received.) Refer to vehicle service

manual for code troubleshooting charts and repair

procedures. Repeat KOER Self-T est after every

repair. (Sometimes a repair procedure will eliminate

more than one code.)

problems which must be repaired before running

this test. Go to Part 2: Key On Engine Off (KOEO)

Self-Test and follow all steps.

Exception:

Take care of code

20

Page 21

Self-Test Part 5: Evaluate/Erase Continuous

Memory Codes.

Do this Part if “Continuous Memory”

codes (other than an 11 or 111 pass

code) were received during SELF-TEST

PAR T 2: Key On Engine Off (KOEO)

and, all other Parts of the Self-T est

procedure have been completed.

• Continuous Memory codes come

from faults which occurred in the past.

The problem may still be present, or it

may have gone away. Regardless, the

codes will remain in stored in

computer memory (for retrieval during

Self-Test Part 2) until:

• The codes are erased using the

procedure detailed later in this part.

or,

• Power is removed from the computer

for more than a few minutes. (NOTE:

The KAPWR circuit supplies vehicle

battery power to the computer

memory when the ignition key is off.)

or,

• The problem goes away and does not

reappear. After at least 40 engine

warm-up cycles (depends upon

vehicle) the code will automatically be

erased from computer memory if the

problem stays away during that time.

4) If any codes remain, refer to vehicle

service manual for Continuous

Memory code troubleshooting charts

and repair procedures.

5) Erase Continuous Memory codes

after all repairs have been made.

Erasing Continuous Memory

Codes

1) Verify Ignition Key is in OFF

Position.

2) Put Code Scanner HOLD/TEST

Switch in HOLD Position.

3) Turn Ignition Key to ON Position

but DO NOT START THE ENGINE.

4) Put Code Scanner HOLD/TEST

Switch in TEST Position.

• This starts the normal KOEO Self-

Test.

WARNING: Stay away from the

radiator cooling fan! It may turn on

momentarily. (On certain vehicles

with electrically operated fans.)

5) Wait for the STO Light to Start

Blinking (Codes are Being Sent).

What to Do:

1) Look at the list of Continuous

Memory codes obtained during SelfTest Part 2: Key On Engine Off

(KOEO).

2) Previous repairs may have eliminated

the causes of some (or all) of these

codes!

3) Disregard codes which are related to

repairs already made. For example, if

repairs were made to the Engine

Coolant Temperature (ECT) sensor

circuit as the result of a KOEO code,

then a Continuous Memory code 21

(ECT signal voltage too high) would

be disregarded.

6) Put Code Scanner HOLD/TEST

Switch in HOLD Position.

• The switch must be moved during

the time the STO light is blinking

(the time period when codes are

being sent).

7) The “Continuous Memory” Codes

are Now Erased.

8) Turn Ignition Key to OFF Position.

9) Disconnect Code Scanner.

21

Page 22

CODE MEANINGS

Code Definitions for FORD Engines with EEC-IV Computer System (Electronic

Engine Control system,

version IV)

Code definitions

are listed in this

section

• If more than one

definition is listed,

consult your vehicle

service manual to get

the specific meaning

for your vehicle.

• Code meanings can

vary with vehicle,

model year, engine

type, options and type

of test being performed.

• Many of the codes

listed may not apply to

your vehicle.

• Follow vehicle service

manual procedures to

find the cause of the

code. Always start with

the first code

displayed.

Remember:

1) Visual inspections are

important!

2) Problems with wiring

and connectors are

common, especially for

intermittent faults.

3) Mechanical problems

(vacuum leaks, binding

or sticking linkages,

etc.) can make a good

sensor look bad to the

computer.

4) Incorrect information

from a sensor may

cause the computer to

control the engine in

the wrong way. Faulty

engine operation might

even make the

computer show a

different good sensor

as being bad!

Three Digit Codes:

Certain 1991 and newer

vehicles use 3 digit codes

to report the results of the

system Self-Test

procedure. Refer to your

vehicle service manual to

determine if your system

uses 2 or 3 digit codes.

The listing of 3 digit code

meanings begins on

page 24.

11

System pass.

12

System cannot raise engine

speed above normal idle.

13

RPM out of specification

during normal idle

operation.

or,

D.C. motor does not follow

dashpot.

14

The Electronic Control

Assembly (ECA) has

detected an intermittent loss

of Profile Ignition Pick-up

(PIP) signal during recent

operation.

15

Failure in Electronic Control

Assembly (ECA) –

problems with Keep Alive

Memory.

16

RPM too low during Engine

Run Self-Test (lean fuel

test).

or,

Idle Speed Control (ISC)

RPM out of Self-Test

specification.

or,

Electronic Distributorless

Ignition System (EDIS)

fault – Ignition Diagnostic

Monitor (IDM) signal not

received.

or,

Exhaust Gas Oxygen

(EGO) sensor – signal

voltage indicates “rich”

during Engine Run SelfTest (lean air/fuel

conditions).

17

Exhaust Gas Oxygen

(EGO) sensor - signal

voltage indicates “rich”

during Engine Run SelfTest (lean air/fuel

conditions).

or,

RPM too low during Engine

Run Self-Test (rich fuel

test).

or,

Idle Speed Control (ISC)

RPM below Self-Test

specification.

18

Loss of TACH signal to

Electronic Control

Assembly (ECA).

or,

Distributorless Ignition

System (DIS) fault –

primary circuit failure in coil

1,2,3 or 4.

or,

Electronic Distributorless

Ignition System (EDIS) fault

– failure in Spark Angle

Word (SAW) circuit.

19

Failure in Electronic Control

Assembly (ECA) –

problems with internal

voltage regulator.

or,

RPM too low for EGR

check during Engine Run

Self-Test.

or,

Cylinder Identification (CID)

sensor input failure.

22

Page 23

21

Engine Coolant

Temperature (ECT) sensor

signal voltage: out of range

(Key On Engine Off SelfTest), not at normal

operating temperature

(Engine Run Self-Test) or

loss of signal (during

normal engine operation).

or,

Electronic Distributorless

Ignition System (EDIS) fault

– problems with Crankshaft

Position Sensor (CPS)

circuit.

22

Manifold Absolute Pressure

(MAP) sensor or Barometric

Pressure (BP) sensor –

signal voltage out of

specification (engine off) or

not at normal vacuum levels

(engine running).

23

Throttle Position (TP)

sensor – signal voltage out

of Self-Test specification.

24

Air Charge Temperature

(ACT) sensor or Vane Air

Temperature (VAT) sensor –

signal voltage is out of

specification (engine off) or

not at normal levels (engine

running).

or,

Electronic Distributorless

Ignition System (EDIS) fault –

failure in coil 1 primary

circuit.

25

Knock Sensor (KS) signal

not detected during Engine

Run Self-Test (Dynamic

Response test).

26

Vane Air Flow (VAF) sensor

or Mass Air Flow (MAF)

sensor – signal voltage out

of Self-Test specifications.

or,

Transmission Oil

Temperature (TOT) sensor

– signal voltage is out of

Self-Test specification.

27

Vehicle Speed Sensor

(VSS) – signal voltage is

too low.

or,

Electronic Distributorless

Ignition System (EDIS) fault

– failure in coil 2 primary

circuit.

28

Vane Air Temperature

(VAT) sensor – signal

voltage out of Self-Test

specification.

or,

Electronic Distributorless

Ignition System (EDIS) fault

– failure in coil 3 primary

circuit.

or,

Distributorless Ignition

System (DIS) fault – Loss of

right side TACH signal.

29

Vehicle Speed Sensor (VSS)

– signal voltage is too low.

31

EGR Valve Position (EVP)

sensor or Pressure

Feedback EGR (PFE)

sensor – signal voltage is

below minimum

specification.

or,

EGR Vacuum Regulator

(EVR) solenoid circuit

problems.

or,

EGR valve is not in its

normal closed position.

32

EGR Valve Position (EVP)

sensor or Pressure

Feedback EGR (PFE)

sensor – signal voltage is

below closed limit or has

gone beyond set limits.

or,

Problems with EGR valve

controlling.

33

EGR Valve Position (EVP)

sensor or Pressure

Feedback EGR (PFE)

sensor indicates EGR valve

is not opening.

or,

EGR Valve Position (EVP)

sensor or Pressure

Feedback EGR (PFE)

sensor indicates EGR valve

not seated (closed) properly.

34

EGR Valve Position (EVP)

sensor or Pressure

Feedback EGR (PFE)

sensor: signal voltage out of

Self-Test specification limits,

or,

signal voltage above closed

limit during normal engine run

operation,

or,

signal indicates insufficient

EGR flow.

35

EGR Valve Position (EVP)

sensor or Pressure

Feedback EGR (PFE)

sensor: signal voltage above

Self-Test specification limits,

or,

23

signal voltage too high

during normal engine run

operation.

or,

RPM too low to perform

EGR test (Engine Run SelfTest).

38

Idle Tracking Switch (ITS)

circuit open.

39

Transaxle problem: lock-up

failed in torque convertor,

or,

convertor bypass clutch not

applying properly.

41

Exhaust Gas Oxygen

(EGO) sensor: voltage

signal always “lean” (low

value) – does not switch.

42

Exhaust Gas Oxygen (EGO)

sensor: voltage signal

always “rich” (high value) –

does not switch.

43

Exhaust Gas Oxygen

(EGO) sensor: voltage

signal “lean” (low value)

during wide-open -throttle

driving condition,

or,

sensor has cooled down

and may not have

responded properly during

Engine Run Self-Test.

44

Problems in Thermactor Air

Control system.

45

Thermactor air flow is

always upstream during

Engine Run Self-Test.

or,

Distributorless Ignition

System (DIS) or Electronic

Distributorless Ignition

System (EDIS) problems –

primary circuit failure in coil

1, 2, 3 or 4.

46

Thermactor Air System

unable to bypass air (vent

to atmosphere).

or,

Distributorless Ignition

System (DIS) or Electronic

Distributorless Ignition

System (EDIS) problems –

primary circuit failure in coil

2.

47

Exhaust Gas Oxygen

(EGO) sensor signal

voltage indicates “rich”

during “lean” air/fuel

conditions.

or,

Page 24

Vane AIr Flow (VAF)

sensor – voltage signal is

too low.

or,

Transaxle problem – 4x4L

switch is closed.

48

Vane Air Flow (VAF)

sensor – voltage signal too

high.

or,

Distributorless Ignition

System (DIS) problems:

Coil 3 circuit failure,

or,

Loss of left side

TACH signal.

or,

Exhaust Gas Oxygen

(EGO) sensor – signal

voltage indicates opposite

from fuel.

49

Electronic Distributorless

Ignition System (EDIS) –

Spark Advance Word

(SAW) signal error.

or,

Spark Output (SPOUT)

signal changed ignition

timing to 10° BTDC (Before

Top Dead Center).

or,

Transaxle problem: 1-2

shift error.

51

Engine Coolant

Temperature (ECT) sensor

– signal voltage is too high.

52

Power Steering Pressure

Switch (PSPS) – circuit is

open or no changes

detected.

53

Throttle Position (TP)

sensor – signal voltage is

too high (as if indicating

wide-open-throttle

condition).

54

Air Charge Temperature

(ACT) sensor or Vane Air

Temperature (VAT) sensor

– signal voltage is too high.

55

Open connection in

Keypower circuit or

electrical charging voltage

too low.

56

Mass Air Flow (MAF)

sensor or Vane Air Flow

(VAF) sensor – voltage

signal too high.

or,

Electronic 4-Speed

Overdrive Automatic

Transaxle (E4OD):

Transmission Oil

Temperature (TOT) sensor

– signal voltage is too high.

57

Neutral Pressure Switch

(NPS) – open circuit failure,

or,

Circuit failed in Neutral

position.

or,

Octane adjust service pin

installed.

58

Vane Air Temperature (VAT)

sensor – signal voltage too

high (open connection in

circuit).

or,

Crank fuel delay service pin in

use – circuit connected to

ground.

or,

Idle Tracking Switch (ITS)

circuit failure – incorrect switch

signal indications during SelfTest.

59

Transaxle problem – failure

in 4/3 pressure switch

circuit (open connection).

or,

Low speed fuel pump circuit

failure.

or,

Idle speed adjust service

pin in use – circuit

connected to ground.

61

Engine Coolant

Temperature (ECT) sensor

– signal voltage is too low.

or,

Indicates that the Idle

Tracking Switch is open (in

contact with the throttle

lever) with the Idle Speed

Control Motor fully

retracted.

62

Transaxle problem – 4/3 or

3/2 pressure switch circuit

failed closed,

or,

convertor clutch failure.

63

Throttle Position (TP)

sensor – signal voltage is

too low.

64

Air Charge Temperature

(ACT) sensor or Vane Air

Temperature (VAT) sensor

– signal voltage is too low.

65

Electrical charging system

problem occurred – voltage

too high (over 17.5 volts).

24

or,

Engine control system

never went into closed loop

fuel operation.

or,

Transaxle problem –

Overdrive Cancel Switch

(OCS) was not cycled

during Engine Run SelfTest.

66

Mass Air Flow (MAF)

sensor or Vane Air Flow

(VAF) sensor – voltage

signal too low.

or,

Transmission Oil

Temperature (TOT) sensor

– signal voltage is too low.

67

Improper signals are being

received from either the

Neutral Drive Switch (NDS),

Neutral Gear Switch (NGS),

Neutral Pressure Switch

(NPS), Clutch Switch (CS),

Manual Lever Position

(MLP) sensor or Air

Conditioner Clutch (ACC).

or,

Air Conditioner (A/C) on

during Self-Test.

68

Vane Air Temperature

(VAT) sensor – signal

voltage is too low.

or,

Transmission Temperature

Switch (TTS) – open circuit

failure.

or,

Idle Tracking Switch (ITS)

circuit failure – incorrect

switch signal indications

during Self-Test.

69

Transaxle problem – Open

circuit failures with 3/2

pressure switch or 3/4

pressure switch,

or,

3-4 switch error.

70

Problem with Electronic

Control Assembly (ECA) –

failure in Data

Communications Link

(DCL).

71

Problem with Electronic

Control Assembly (ECA) –

software reset detected.

or,

Problem with Message

Center Control Assembly

(MCCA) – failure in Data

Communications Link

(DCL).

Page 25

72

Insufficient manifold

vacuum change detected

during Dynamic Response

portion of Engine Run SelfTest.

or,

Problem with Message

Center Control Assembly

(MCCA) – failure in Data

Communications Link

(DCL).

or,

Power interrupt detected.

73

Insufficient throttle position

change detected during

Dynamic Response portion

of Engine Run Self-Test.

74

Brake ON/OFF (BOO)

switch action not detected

during Dynamic Response

portion

of Engine Run Self-Test.

75

Brake ON/OFF (BOO)

switch always closed

circuit.

76

Insufficient Vane Air Flow

(VAF) sensor change

detected during Dynamic

Response portion of Engine

Run Self-Test.

77

Operator error during

Dynamic Response portion

of Engine Run Self-Test.

78

Power interrupt detected.

or,

Flexible fuel sensor circuit

failure.

79

Air Conditioner (A/C) on

during Self-Test.

81

Thermactor Air Diverter

(TAD or AM-2) solenoid:

circuit failure.

or,

Electro-Drive Fan: circuit

failure.

or,

Intake Air Control (IAC)

valve: circuit failure.

or,

Boost solenoid – circuit

failure.

82

Thermactor Air Bypass

(TAB or AM-1) solenoid:

circuit failure.

or,

Electro-Drive Fan: circuit

failure.

or,

Supercharger Bypass

Solenoid (SBS): circuit

failure.

83

High Speed Electro-Drive

Fan (HEDF) – circuit failure.

or,

EGR Control (EGR-C)

solenoid–open circuit failure.

or,

Low speed fuel pump relay –

open circuit failure.

84

EGR Vacuum (EGR-V)

solenoid – circuit failure.

or,

EGR Vacuum Regulator

(EVR) solenoid–circuit failure.

or,

EGR Shut-Off (EGR S/O)

solenoid – circuit failure.

85

Cannister Purge (CANP)

solenoid – circuit failure.

or,

Transaxle problem – 3/4 shift

solenoid circuit failure.

or,

Electronic Control Assembly

(ECA) status – adaptive

“lean” limit reached in fuel

control program.

86

Transaxle problem – 3/4 shift

solenoid circuit failure.

or,

Electronic Control Assembly

(ECA) status – adaptive

“rich” limit reached in fuel

control program.

or,

Wide-open-throttle Air

conditioner Clutch (WAC)

solenoid – circuit failure.

87

Fuel Pump (FP) relay –

circuit failure.

88

Electro-Drive Fan (EDF)

relay – circuit failure.

or,

Converter Clutch Override

(CCO) solenoid – circuit

failure.

or,

Distributorless Ignition

System (DIS) problems –

loss of dual plug control.

or,

Throttle Kicker (TK) solenoid

– circuit failure.

89

Lock-Up Solenoid (LUS) –

circuit failure.

or,

Converter Clutch Override

(CCO) solenoid – circuit

failure.

or,

Exhaust Heat Control

(EHC) solenoid – circuit

failure.

91

Exhaust Gas Oxygen (EGO)

sensor – signal voltage

always indicates “lean”

either during Engine Run

Self-Test (“rich” air/fuel

conditions) or normal

engine operating

conditions.

or,

Transaxle problem – Shift

Solenoid 1 (SS1) circuit

failure.

92

Right side Exhaust Gas

Oxygen (EGO) sensor –

signal voltage always

indicates “rich” during

Engine Run Self-Test

(“lean” air/fuel conditions).

or,

Transaxle problem – Shift

Solenoid 2 (SS2) circuit

failure.

93

Throttle Position (TP)

sensor – signal voltage too

low during Self-Test (at

maximum extension of idle

speed control motor).

or,

Right side Exhaust Gas

Oxygen (EGO) sensor –

cool down occurred.

or,

Transaxle problem – Coast

Clutch Solenoid (CCS)

circuit failure.

94

Thermactor Air System –

problem on the right bank

(passenger side).

or,

Transaxle problem – Shift

Solenoid 1 (SS1) circuit

failure.

95

Thermactor Air System

problem – right (passenger)

side air flow always

upstream.

or,

Fuel Pump Monitor (FPM)

signal – indicates circuit

problem.

96

Thermactor Air System

problem – right (passenger)

side air flow will not bypass.

or,

Fuel Pump (FP) circuit

failure.

or,

High speed fuel pump relay

circuit failure.

25

Page 26

97

Right side Exhaust Gas

Oxygen (EGO) sensor –

signal voltage indicates

“rich” during “lean” air/fuel

conditions.

or,

Overdrive Cancel Indicator

Light (OCIL) – circuit

failure.

98

A system problem is present

causing the Electronic

Control Assembly (ECA) to

operate in Failure

Management and Effects

Mode (FMEM).

or,

Right side Exhaust Gas

Oxygen (EGO) sensor –

signal voltage indicates

“lean” during “rich” air/fuel

conditions.

or,

Electronic Pressure Control

(EPC) solenoid – circuit

failure.

99

The Electronic Control

Assembly (ECA) has not

learned to control engine

idle speed (ignore code 12

or 13).

or,

Electronic Pressure Control

(EPC) solenoid – circuit

failure.

Three Digit Codes

Certain 1991 and newer

vehicles use 3 digit codes

to report the results of

the system Self-Test

procedure. Refer to your

vehicle service manual to

determine if your system

uses 2 or 3 digit codes.

• Code meanings can

vary with vehicle, model

year, engine type,

options and type of test

being performed.

• Many of the codes

listed may not apply to

your vehicle.

• Follow vehicle service

manual procedures to

find the cause of the

code. Always start with

the first code displayed.

Remember:

1) Visual inspections are

important!

2) Problems with wiring

and connectors are

common, especially for

intermittent faults.

3) Mechanical problems

(vacuum leaks, binding

or sticking linkages,

etc.) can make a good

sensor look bad to the

computer.

4) Incorrect information

from a sensor may

cause the computer to

control the engine in

the wrong way. Faulty

engine operation might

even make the

computer show a

different good sensor

as being bad!

111

System pass.

112

Air Charge Temperature

(ACT) sensor – signal

voltage is too low.

113

Air Charge Temperature

(ACT) sensor – signal

voltage is too high.

114

Air Charge Temperature

(ACT) sensor – signal

voltage is higher or lower

than expected.

116

Engine Coolant

Temperature (ECT) sensor

– signal voltage is higher or

lower than expected.

117

Engine Coolant

Temperature (ECT) sensor

– signal voltage is too low.

118

Engine Coolant

Temperature (ECT) sensor

– signal voltage is too high.

121

Throttle Position (TP)

sensor– signal voltage is

higher or lower than

expected.

or,

Throttle Position (TP)

sensor– signal voltage

inconsistent with engine

intake air flow.

122

Throttle Position (TP)

sensor – signal voltage is

too low.

123

Throttle Position (TP)

sensor – signal voltage is

too high.

124

Throttle Position (TP)

sensor – signal voltage is

higher than expected.

125

Throttle Position (TP)

sensor – signal voltage is

lower than expected.

126

Manifold Absolute Pressure

(MAP) or Barometric

Pressure (BP) – signal

values higher or lower than

expected.

128

Manifold Absolute Pressure

(MAP) sensor – vacuum

hose disconnected or

damaged.

129

Manifold Absolute Pressure

(MAP) sensor or Mass Air

Flow (MAF) sensor –

insufficient signal value

change during Dynamic

Response test (Engine Run

Self-Test).

26

Page 27

136

Heated Exhaust Gas

Oxygen (HEGO) sensor –

voltage signal not switching

during Engine Run SelfTest. Indicates “lean” (Bank

#2).

137

Heated Exhaust Gas

Oxygen (HEGO) sensor –

voltage signal not switching

during Engine Run SelfTest. Indicates “rich” (Bank

#2).

138

Cold Start Injector (CSI) –

insufficient flow during

Engine Run Self-Test.

139

Exhaust Gas Oxygen

(EGO) sensor – no

switching detected (Bank

#2).

141

Fuel system indicates

“lean” with high flow

demand.

144

Exhaust Gas Oxygen

(EGO) sensor – no

switching detected (Bank

#1).

157

Mass Air Flow (MAF)

sensor – signal voltage is

too low

158

Mass Air Flow (MAF)

sensor – signal voltage is

too high

159

Mass Air Flow (MAF)

sensor – signal voltage is

higher or lower than

expected.

165

“Downstream” Heated

Exhaust Gas Oxygen

(HEGO) sensor – voltage

signal indicates “lean”

(Bank #1).

166

“Downstream” Heated

Exhaust Gas Oxygen

(HEGO) sensor – voltage

signal indicates “rich”

(Bank #1).

167

Throttle Position (TP)

sensor – insufficient signal

voltage change during

Dynamic Response test

(Engine Run Self-Test).

168

“Downstream” Heated

Exhaust Gas Oxygen

(HEGO) sensor – signal

voltage too high.

169

“Downstream” Heated

Exhaust Gas Oxygen

(HEGO) sensor – signal

voltage too low.

171

Heated Exhaust Gas

Oxygen (HEGO) sensor –

voltage signal not switching

(Bank #1).

172

Heated Exhaust Gas

Oxygen (HEGO) sensor –

voltage signal indicates

“lean” (Bank #1).

173

Heated Exhaust Gas

Oxygen (HEGO) sensor –

voltage signal indicates

“rich” (Bank #1).

175

Heated Exhaust Gas

Oxygen (HEGO) sensor –

voltage signal not switching

(Bank #2).

176

Heated Exhaust Gas

Oxygen (HEGO) sensor –

voltage signal indicates

“lean” (Bank #2).

177

Heated Exhaust Gas

Oxygen (HEGO) sensor –

voltage signal indicates

“rich” (Bank #2).

179

Heated Exhaust Gas

Oxygen (HEGO) sensor –

voltage signal not

switching: indicates “rich”

during part throttle engine

operation (Bank #1).

181

Heated Exhaust Gas

Oxygen (HEGO) sensor –

voltage signal not

switching: indicates “lean”

during part throttle engine

operation (Bank #1).

182

Electronic Control

Assembly (ECA) status –

adaptive “rich” limit reached

in fuel control program

(engine idle, Bank #1).

183

Electronic Control

Assembly (ECA) status –

adaptive “lean” limit

reached in fuel control

program (engine idle, Bank

#1).

184

Mass Air Flow (MAF)

sensor – signal voltage is

higher than expected.

27

185

Mass Air Flow (MAF)

sensor – signal voltage is

lower than expected.

186

Injector pulsewidth higher

than expected or Mass Air

Flow (MAF) sensor signal

voltage is lower than

expected.

187

Injector pulsewidth lower

than expected or Mass Air

Flow (MAF) sensor signal

voltage is higher than

expected.

188

Heated Exhaust Gas

Oxygen (HEGO) sensor –

voltage signal not

switching: indicates “rich”

during part throttle engine

operation (Bank #2).

189

Heated Exhaust Gas

Oxygen (HEGO) sensor –

voltage signal not

switching: indicates “lean”

during part throttle engine

operation (Bank #2).

191

Electronic Control

Assembly (ECA) status –

adaptive “rich” limit reached

in fuel control program

(engine idle, Bank #2).

192

Electronic Control

Assembly (ECA) status –

adaptive “lean” limit

reached in fuel control

program (engine idle, Bank

#2).

193

Flexible Fuel Sensor –

circuit failure.

211

Profile Ignition Pick-Up

(PIP) sensor – circuit

failure.

212

Loss of Ignition Diagnostic

Monitor (IDM) signal –

short

to ground in Spark Output

(SPOUT) circuit.

213

Spark Output (SPOUT)

circuit – open connection

failure.

214

Cylinder Identification (CID)

sensor – circuit failure.

215

Ignition system (distributorless) problem – Coil #1

primary side circuit failure.

Page 28

216

Ignition system (distributorless) problem – Coil #2

primary side circuit failure.

217

Ignition system (distributorless) problem – Coil #3

primary side circuit failure.

218

Ignition system (distributorless) problem – Loss of left

side Ignition Diagnostic

Monitor (IDM) signal.

219

Ignition system problem –

Spark Output (SPOUT)

signal open circuit (no

spark advance timing).

221

Distributorless Ignition

System (DIS) problem –

Spark timing error.

222

Distributorless Ignition

System (DIS) problem –

Loss of right side Ignition

Diagnostic Monitor (IDM)

signal.

223

Distributorless Ignition

System (DIS) problem –

Loss of Dual Plug Inhibit

(DPI) control.

224

Distributorless Ignition

System (DIS) problem –

Primary circuit failure in

Coil #1, 2, 3 or 4.

225

Knock Sensor (KS) signal

not detected during

Dynamic Response Test

(Engine Run Self-Test).

226

Electronic Distributorless

Ignition System (EDIS)

problem – Ignition

Diagnostic Monitor (IDM)

signal not received.

227

Electronic Distributorless

Ignition System (EDIS)

problem – Crankshaft

Position Sensor (CPS)

error.

232

Electronic Distributorless

Ignition System (EDIS)

problem – Coil #1, 2, 3 or 4

circuit failure.

233

Electronic Distributorless

Ignition System (EDIS)

problem – Spark Advance

Word (SAW) signal error.

238

Ignition system

(distributorless) problem –

Coil #4 primary side circuit

failure.

239

Electronic Distributorless

Ignition System (EDIS)

problem – Crankshaft

Position Sensor (CPS)

signal received with engine

off.

241

Ignition Diagnostic Monitor

(IDM) signal problem –

pulsewidth error between

Electronic Distributorless

Ignition System (EDIS) and

Electronic Control

Assembly (ECA).

242

Distributorless Ignition

System (DIS) problem –

operating in failure mode.

243

Electronic Distributorless

Ignition System (EDIS)

problem – Secondary

circuit failure in Coil #1, 2, 3

or 4.

244

Cylinder Identification (CID)

circuit failure during

Cylinder Balance Test.

311

Thermactor Air System

problem – no operation

during Engine Run SelfTest (Bank #1).

312

Thermactor Air System

problem – air flow

misdirected during Engine

Run Self-Test.

313

Thermactor Air System

problem – air flow not

bypassed (vented to

atmosphere) during Engine

Run Self-Test.

314

Thermactor Air System

inoperative during Engine

Run Self-Test (Bank #2

with dual oxygen sensors).

315

Thermactor Air System

problem – inadequate air

flow during cold start.

316

Thermactor Air System

problem – inadequate air

flow during hot engine low

RPM.

28

317

Thermactor Air System

problem – air flow not

bypassed (vented to

atmosphere) during Engine

Run Self-Test.

318

Engine Air Management

(EAM) System problem –

monitor circuit signal

voltage is high when

commanded off.