Page 1

FULL ONE (1) YEAR WARRANTY

Actron Manufacturing Company, 15825 Industrial Parkway, Cleveland, Ohio 44135, warrants to the user that

this unit will be free from defects in materials and workmanship for a period of one (1) year from the date of

original purchase.

Any unit that fails within this period will be repaired or replaced at Actrons option and without charge when

returned to the Factory. Actron requests that a copy of the original, dated sales receipt be returned with the unit

to determine if the warranty period is still in effect.

This warranty does not apply to damages caused by accident, alterations, or improper or unreasonable use.

Expendable items, such as batteries, fuses, lamp bulbs, flash tubes are also excluded from this warranty.

ACTRON MANUFACTURING COMPANY DISCLAIMS ANY LIABILITY FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES FOR BREACH OF ANY WRITTEN WARRANTY ON THE UNIT. Some states do not allow the

disclaimer of liability for incidental or consequential damages, so the above disclaimer may or may not apply to

you. This warranty gives specific legal rights, and you may also have rights which vary from state to state.

GARANTIA COMPLETA POR UN (1) AÑO

Actron Manufacturing Company, 15825 Industrial Parkway, Cleveland, Ohio 44135, garantiza al usuario que

esta unidad estará libre de defectos de materiales y mano de obra por un período de un (1) año a partir de la

fecha original de compra.

Toda unidad que falle dentro de este período será reparada o reemplazada a la opción de Actron y sin cargo

cuando sea devuelta a la fábrica. Actron requiere que se devuelva una copia del recibo original fechado de

compra con la unidad, para determinar si el período de garantía está todavía en efecto.

Esta garantía no se aplica a daños causados por accidentes, modificaciones, o uso inadecuado o irrazonable.

Los artículos descartables tales como pilas, fusibles, bulbos de lámparas, tubos flash se excluyen también

de esta garantía.

ACTRON MANUFACTURING COMPANY NIEGA CUALQUIER RESPONSABILIDAD POR PERJUICIOS

INCIDENTALES O CONSECUENTES POR VIOLACION DE CUALQUIER GARANTIA ESCRITA PARA LA

UNIDAD. Algunos estados no permiten la negación de responsabilidad por perjuicios incidentales o consecuentes,

de manera que la negativa anterior puede o no aplicarse a usted. Esta garantía otorga derechos legales

específicos, y usted puede tener también derechos que pueden variar de estado a estado.

NO VALIDA ÉN MEXICO

UN (1) AN DE GARANTIE COMPLÈTE

Actron Manufacturing Company, 15825 Industrial Parkway, Cleveland, Ohio 44135, garantit à l'utilisateur que

cet appareil sera exempt de tout défaut lié aux matériaux ou à la main d'uvre pendant une période de un (1)

an à compter de la date d'achat d'origine.

Toute unité qui tomberait en panne durant cette période sera réparée ou remplacée, au choix d'Actron, et sans

frais si elle a été retournée à l'usine. Actron demande qu'une copie de la facture d'achat d'origine datée soit

retournée avec l'appareil pour contrôler que la période de garantie est toujours effective.

Cette garantie ne s'applique pas aux dommages causés par accident, modifications ou utilisation inadéquate

ou hors du raisonnable. Les éléments consommables, tels que piles, fusibles, ampoules ou tubes fluorescents

sont également exclus de cette garantie.

ACTRON MANUFACTURING COMPANY REJETTE TOUTE RESPONSABILITÉ POUR DOMMAGES

ACCESSOIRES OU INDIRECTS POUR MANQUEMENT À N'IMPORTE QUELLE GARANTIE ÉCRITE SUR

CETTE UNITÉ. Certains états ne permettent pas le déni de responsabilité pour dommages accessoires ou

indirects, cette clause peut donc n'être pas applicable dans votre cas. Cette garantie vous octroie des droits

légaux spécifiques, et vous pouvez aussi avoir des droits supplémentaires qui varient d'un état à l'autre.

ACTRON MANUFACTURING CO.

15825 Industrial Parkway

Cleveland, Ohio 44135

1-800-228-7667

8

2004 Actron Manufacturing Co.

©

All Rights Reserved

0002-002-2376

INSTALLATION INSTRUCTIONS

GENERAL MOUNTING INSTRUCTIONS

INSTRUCCIONES GENERALES DE MONTAJE TENSIÓN 12 V

INSTRUCTIONS GÉNÉRALES DE MONTAGE

The manufacturer produces a full line of gauges

with many different styles.

1-1/2" Gauges

2 Gauges

2-5/8" Gauges

(See page 2 for hole sizes.)

MICROPROCESSOR-CONTROLLED ENGINES

Many newer vehicles employ microprocessors

that control most of the engine and electrical functions. Microprocessors are very sensitive electrical components. Before installing any aftermarket equipment consult the vehicles manufacturer

or shop manual to make certain that no damage

will result.

Some of these newer vehicles use electric cooling fans or microprocessor engine controls that

depend on readings from the original equipment

INSTALLATION & SAFETY PRECAUTIONS

1. Read the entire instructions for your gauge

before proceeding.

2. Be sure the gauge is suitable for your vehicle:

Does the gauges range cover the vehicles

operating range?

Will the tubing of the mechanical gauges

reach from the engine connection point to the

gauge (temperature gauges cannot be lengthened)?

Is the vehicles electrical system 12 volt and

negatively grounded?

GAUGE MOUNTING

All gauges can be mounted into a surface of

your choice or into a panel. Single, dual & triple

gauge mounting panels are produced for all size

gauges. Some panels are in black or chrome

finishes. A fully chromed mounting cup is available for the 2-5/8" gauges.

1. Choose a location to mount the gauge where

it will be viewable from a normal driving position (fuel pressure gauges should never be

mounted within the interior of the vehicle).

2. If you are using a mounting panel, mount it at

the chosen location with the screws provided.

If you are creating a hole, use the following sizes:

Gauge Style Hole Size

1-1/2" 1-5/8" (41 mm)

2" 2-1/16" (53 mm)

2-5/8" 2-5/8" (67 mm)

PARA NOMBRE, DOMICILIO Y TELEFONO DE IMPORTADOR: VER EMPAQUE.

Gauges allow you to monitor the condition of

your vehicle and tell how well it is performing. If

there are any problems, you can detect them

immediately before they become severe. Warning lights only tell you when the problem already

requires immediate attention. You will find that

the addition of these gauges will add to your

peace of mind and driving comfort.

sending units for correct operation. If your vehicle

is one of these you CANNOT replace the

sender(s) with any other. You can add an additional oil pressure sender with a Tee Adapter Kit,

but the only possible way to install a non OEM

water temperature sender is to install the new

sender in a different location, retaining the OEM

unit in its original location. Check with the vehicles

manufacturer or dealer to see if this is possible.

3. It is recommended that the battery ground

cable be disconnected before any electrical

work is performed, especially when installing

Ammeters or Voltmeters.

4. Route all wiring and gauge tubing away from

linkages, high heat or moving parts.

5. Never smoke while working on your vehicle

and always keep a fire extinguisher nearby.

It should be rated for gas/chemical/electrical

fires.

6. Never lay tools on top of the battery or wear

jewelry during .electrical work to avoid severe

electrical shorts.

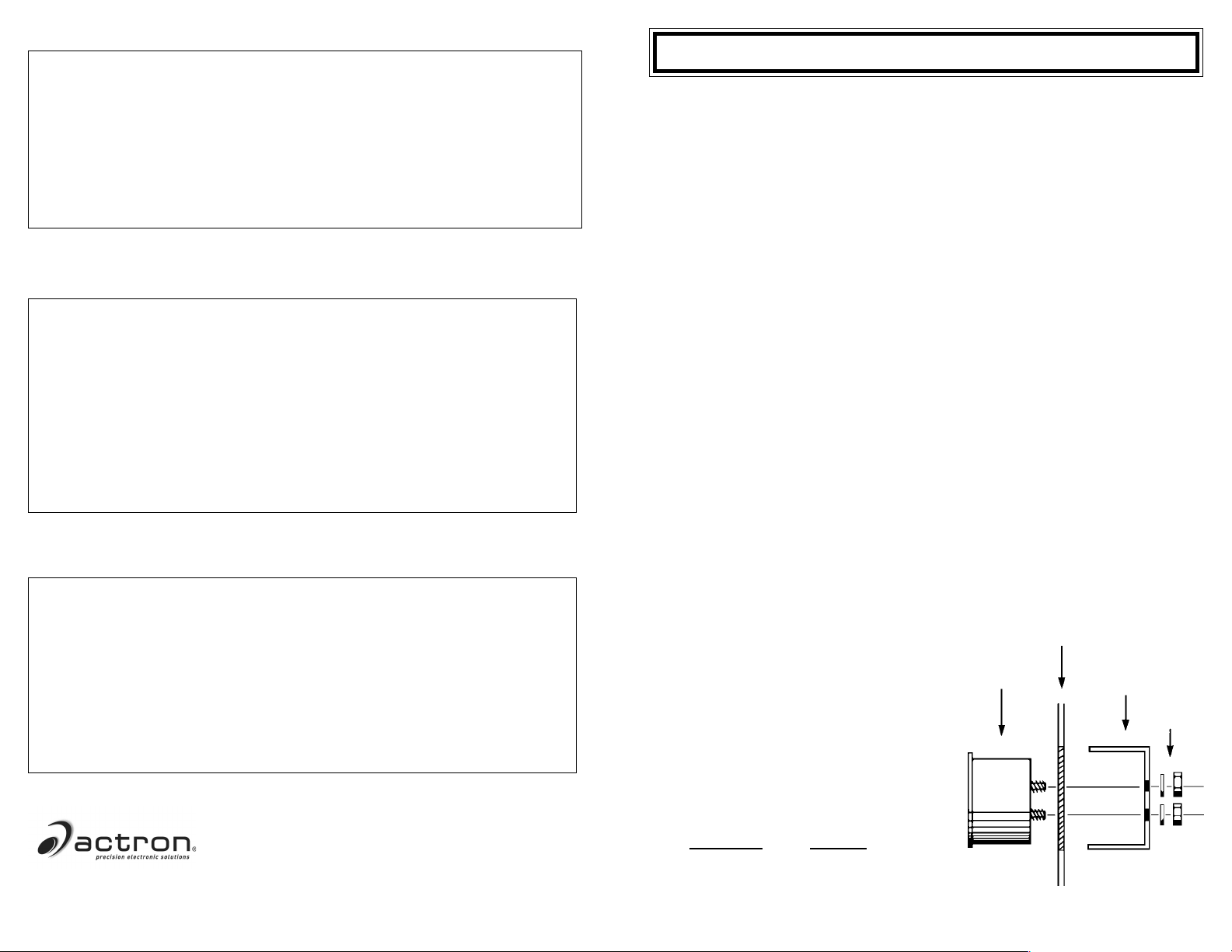

DASHBOARD

Diagram 1

Top View

1

GAUGE

BRACKET

NUTS &

WASHERS

Page 2

3. Dimmer Control.

For dash lighting dimmers that control the

positive side (Diagram 2A) of the lighting circuit:

Diagram 2A

For Positive Dimmer Controls

DASH LIGHTING

DIMMER

CONTROL

+12 VOLTS

RED

- For Two-wire Bulb Holder -

Connect the red wire into the circuit between

the dimmer control and the dash lights. Connect

the black wire to a good electrical ground.

- For One-wire Bulb Holder -

Connect the one wire into the circuit between

the dimmer control and the dash lights. Obtain a

length of 18-gauge insulated copper wire and

connect one end of the wire to a good electrical

ground source and the other end to one of the

mounting bracket posts.

For dash lighting dimmers that control the

grounded side (Diagram 2B) of the lighting circuit:

Diagram 2B

For Ground Dimmer Controls

DASH LIGHTING

GROUND

GAUGE

BLACK/

GROUND

GROUND

4. Refer to specific instructions for the gauge

you are installing. They explain other connections that should be made before mounting is completed.

5. Insert the gauge into the mounting panel or

hole.

6. Insert the bulb holder into the bulb socket on

the back of the gauge.

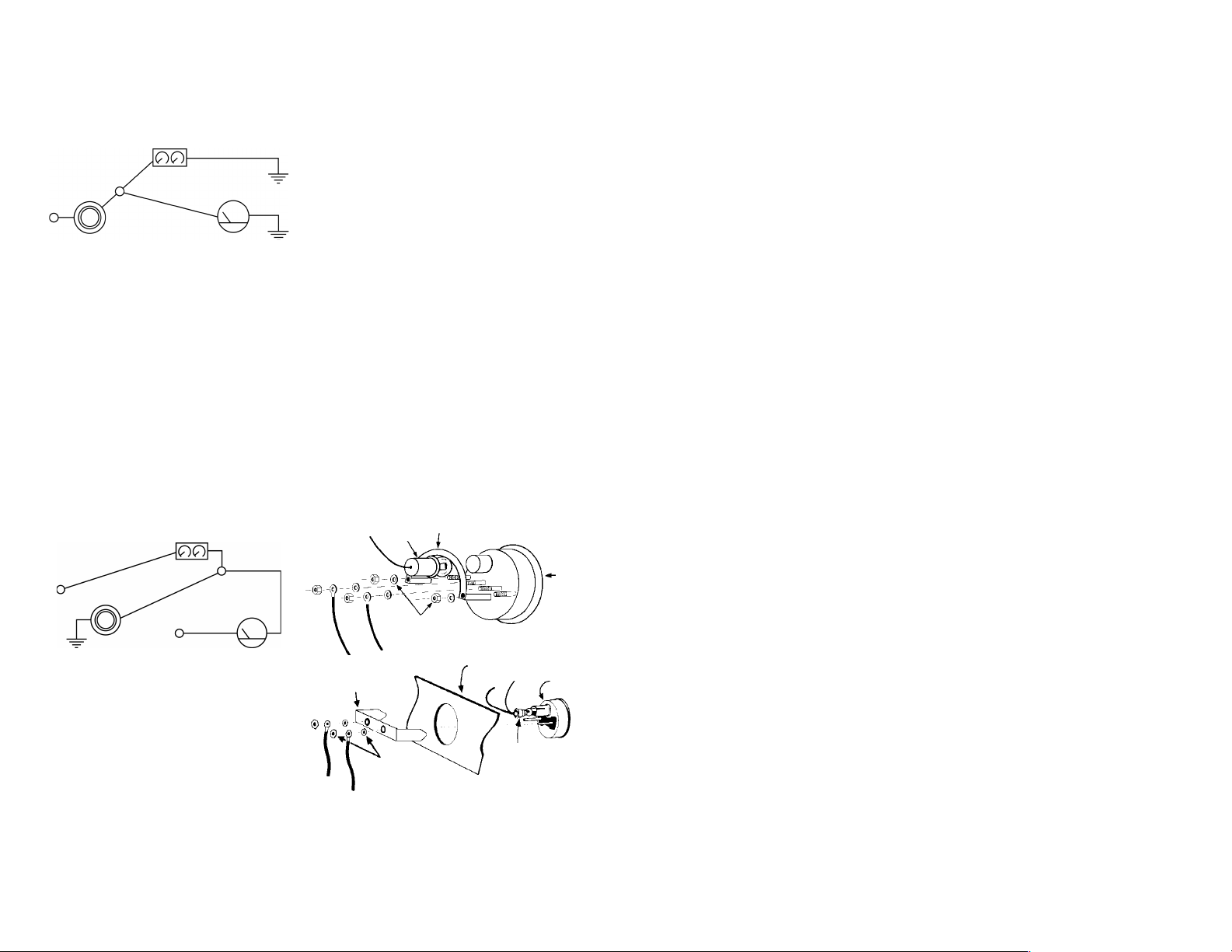

7. Install the appropriate mounting bracket (Diagram 1: insulated or non-insulated) over the

mounting posts (Diagram 3), slide on washer,

plus a lock washer if supplied, and tighten

the nut with only light pressure. If the gauge

is an electrical model, be sure you use a

bracket that has grommets to insulate the

posts from the mounting bracket. This does

not apply to gauges using separate bracket

mounting posts from the posts used for wire

connections.

8. Position the gauge for best visibility and appearance, then tighten the bracket nuts with

moderate pressure. Do not over- tighten these

nuts when using an insulated bracket. Excess pressure can distort the grommets causing them to crack and short the wiring, even

months after installation.

9. Refer to the specific instructions for the gauge

you are now installing to complete any other

connections.

Diagram 3

Electrical Gauges Shown

U-BRACKET

LIGHT

+12 VOLTS

GROUND

DIMMER

CONTROL

+12 VOLTS

BLACK/GROUND

RED

GAUGE

- For Two-wire Bulb Holder -

Connect the black wire into the circuit between

the dimmer control and the dash lights. Connect

the red wire to the fuse box so that the wire only

receives +12-volt power when the dash lights are

turned on.

- For One-wire Bulb Holder -

Connect the wire to the fuse box so it receives

only +12-volt power when the dash lights are on.

Obtain a length of 18-gauge insulated copper wire

and connect one end to the gauge mounting

bracket or panel. Connect the other end of the

wire into the circuit between the dimmer control

and the dash lights. Insulate the gauge and

bracket from grounded surfaces.

GAUGE

NUTS &

WASHERS

INSULATED

U-BRACKET

NUTS &

WASHERS

2

DASHBOARD

GAUGE

LIGHT

7

Page 3

Si vous avez à percer un trou, voici les

dimensions:

STYLE TAILLE DE

D'APPAREIL TROU

38,0 mm (1-1/2") 41,3 mm (1-5/8")

50,1 mm (2") 52,4 mm (2-1/16")

66,7 mm (2-5/8") 66,7 mm (2-5/8")

3. Commande de gradateur.

Pour la commande d'intensité d'éclairage du

tableau de bord, qui contrôle le côté positif

(Schéma 2A) du circuit d'éclairage.

ÉCLAIRAGE DES INSTRUMENTS

MASSE

NOIR/MASSE

MASSE

+12 V

COMMANDE DE GRADATEUR

ROUGE

INDICATEUR

Schéma 2A

Pour Les Cdes D'intensité D'éclairage Sur Positif

- Support D'ampoule À 2 Fils -

Connectez le fil rouge dans le circuit entre le

contrôle d'intensité et les ampoules d'éclairage.

Connectez le fil noir sur une bonne masse

électrique.

- Support D'ampoule À 1fil -

Connectez le fil unique dans le circuit entre le

contrôle d'intensité et les ampoules d'éclairage.

Trouvez une longueur de fil cuivre isolé de calibre 18, connectez-en une extrémité sur une bonne

masse électrique et l'autre sur l'un des montants

du support de montage.

ÉCLAIRAGE DES INSTRUMENTS

NOIR/MASSE

+12

COMMANDE DE

V

GRADATEUR

MASSE

+12 V

ROUGE

INDICATEUR

Schéma 2B

Pour Les Cdes D'intensité D'éclairage Sur Masse

Pour la commande d'intensité d'éclairage

du tableau de bord, qui contrôle le côté

masse (Schéma 2B) du circuit d'éclairage:

- Support D'ampoule À 2 Fils -

Connectez le fil noir dans le circuit entre le

contrôle d'intensité et les ampoules d'éclairage.

Connectez le fil rouge sur une sortie de boîte à

fusibles où il ne recevra du +12 V que lorsque le

tableau de bord est éclairé.

- Support D'ampoule À 1fil -

Connectez le fil unique sur une sortie de boîte à

fusibles où il ne recevra du +12 V que lorsque le

tableau de bord est éclairé. Trouvez une longueur

de fil cuivre isolé de calibre 18, connectez-en une

extrémité sur l'un des montants du support de

montage. Connectez son autre extrémité dans le

circuit entre le contrôle d'intensité et les ampoules

d'éclairage. Isolez l'appareil de mesure et son

support de toutes surfaces à la masse.

4. Reportez-vous aux instructions spécifiques

pour l'appareil que vous installez. Elles

expliquent lesautresliaisons que vous devez

réaliser avant de finir le montage.

5. Insérez l'appareil dans le tableau de

montage ou le trou.

6. Insérez la douille d'ampoule dans le fourreau

d'éclairage à l'arrière de l'appareil.

7. Installez le support de montage approprié

(Schéma 1 : isolé ou non isolé) par dessus

les montants Schéma 3), glissez à chaque

une rondelle, plus une rondelle frein s'il y en

a de fournies, et serrez sans forcer la fixation

avec un écrou. Si l'appareil de mesure est du

type électrique, assurez-vous que vous

utilisez un support qui possède des rondelles

isolantes pour séparer les montants du support de montage. Cetteprécaution ne

s'applique pas aux appareils qui utilisent des

montants séparés pour fixation sur le support

de ceux utilisés pour raccorder les fils

électriques.

8. Positionnez l'appareil pour la meilleure

visibilité et apparence, puis serrez les écrous

de montants avec une pression raisonnable.

Ne serrez pas trop quand le support est isolé.

Un serrage excessif peut déformé les

rondelles isolantes, ce qui peut provoquer leur

cassure et un court-circuit, même des mois

Schéma 3

après l'installation.

Les Appareils Montrés Sont Électriques

9. Reportez-vous aux instructions spécifiques

pour l'appareil que vous installez maintenant

ÉCLAIRAGE

pour terminer ses éventuelles autres

SUPPORT EN U

connexions.

APPAREIL

ÉCROUS ET

RONDELLES

TABLEAU DE

BORD

SUPPORT

EN U ISOLÉ

ÉCROUS ET

RONDELLES

APPAREIL

ÉCLAIRAGE

6

INSTRUCCIONES DE INSTALACION

DE LOS INDICADORES

INSTRUCCIONES GENERALES DE MONTAJE

El fabricante produce una línea completa de

indicadores con muchos estilos diferentes.

38 mm Indicadores

50 mm Indicadores

67 mm Indicadores

(Vea la página 4 para los tamaños de

los orificios)

Los indicadores le permiten monitorear el estado

MOTORES CONTROLADOS POR MICROPROCESADORES

Muchos de los vehículos más nuevos emplean

microprocesadores que controlan la mayoría de

las funciones del motor y eléctricas. Los

microprocesadores son componentes eléctricos

muy sensibles. Antes de instalar cualquier equipo

de otra fabricación consulte con el fabricante del

vehículo o manual del taller para asegurarse que

no resultará pipo averías.

Algunos de esos vehículos más nuevos usan

ventiladores enfriadores eléctricos o controles por

microprocesador del motor que dependen de

lecturas de las unidades emisoras del equipo

INSTALACION Y PRECAUCIONES DE SEGURIDAD

1. Antes de proceder lea todas las instrucciones

para su indicador.

2. Asegúrese que el indicador es adecuado

para su vehículo.

¿Cubre el alcance del indicador el alcance

operativo del vehículo?

¿Alcanzarán las tuberías de los indicadores

mecánicos desde el punto de conexión del

motor al indicador (¿no pueden extenderse

los indicadores de temperatura?)

¿Es el sistema eléctrico del vehículo de tensión

12 V y está conectado negativamente a

tierra?

Todos los indicadores pueden montarse en una

superficie de su selección o dentro de un panel.

Nosotros produce paneles de montaje de indicador

simples, dobles y triples para indicadores de todos

los tamaños. Algunos paneles tienen acabados

en negro o cromo. Para los indicadores de 66,7

mm está disponible una copa de montaje

completamente cromada

1. Localice una ubicación de montaje del

indicador donde será visible desde una

posición normal de manejo (los indicadores

de presión de combustible no deben montarse

nunca dentro del interior del vehículo).

2. Si usted está usando un panel de montaje,

móntelo en la ubicación seleccionada con los

tornillos provistos.

MONTAJE DEL INDICADOR

de su vehículo e informarle acerca de cuán bien

se desempeña. Si hubiera problemas, usted

puede detectarlos inmediatamente antes de que

se conviertan pipo graves. Las luces de

advertencia le informan cuando el problema

requiere atención inmediata solamente. Usted

notará que la adición de esos indicadores le

proporcionará más tranquilidad y comodidad de

manejo.

original para una operación correcta. Si su

vehículo es uno de ellos usted NO PUEDE

reemplazar el emisor(es) por ningún otro. Usted

puede agregar un emisor adicional de presión

de aceite con un Juego de Adaptador pipo T

pero la única manera posible de instalar un emisor

de temperatura de agua no OEM

(MANUFACPURA DE EQUIPO) es instalar el

nuevo emisor pipo una ubicación diferente,

reteniendo la unidad OEM pipo su ubicación original. Para verificar si esto es posible consulte

con el fabricante o distribuidor del vehículo.

3. ¿Se recomienda que se desconecte el cable

de conexión a tierra antes de efectuar

cualquier trabajo eléctrico, especialmente al

instalar amperímetros o voltímetros?

4. Encamine todo el cableado y las tuberías de

los indicadores alejado de los acoples y del

calor intenso o piezas móviles.

5. Nunca fume mientras trabaja en su vehículo

y mantenga siempre un extintor de incendios

cerca. Debe tener una clasificación nominal

para incendios ocasionados por gas/materias

químicas/eléctricos.

6. Nunca coloque herramientas sobre la batería

ni use joyas durante el trabajo eléctrico para

evitar cortocircuitos eléctricos peligrosos.

Diagrama 1

INDICADOR

TABLERO

SOPORTE

3

TUERCAS Y

ARANDELAS

Page 4

Si usted está perforando un orificio hágalo así:

ESTILO DEL TAMAÑODEL

INDICADOR ORIFICIO

38 mm 41 mm

50,1 mm 53 mm

66,7 mm 67 mm

3. Control del atenuador.

Para atenuadores de iluminación del tablero

que controlan el lado positivo (Diagrama 2A)

del circuito de iluminación:

Diagrama 2A

Para Controles Positivos Del Atenuador

ILUMINACION DEL TABLERO

CONEXION A

TENSIÓN +12

CONTROL DEL

ROJO

INDICADOR

CONEXION

CONEXION

- Para Sujetador De Bulbo De Dos Cables -

Conecte el cable rojo dentro del circuito entre el

control del atenuador y las luces del tablero.

Conecte el cable negro a una conexión a tierra

en buen estado.

- Para Sujetador De Bulbo De Un Solo Cable -

Conecte a un cable dentro del circuito entre el

control del atenuador y las luces del tablero.

Obtenga un tramo de cable aislado de cobre de

calibre 18 y conecte un extremo del cable a una

fuente de conexión eléctrica a tierra en buen

estado y el otro extremo a uno de los postes de

soporte de montaje.

Para los atenuadores de iluminación de

tablero que controlan el lado conectado a

tierra (Diagrama 2B) del circuito de

iluminación.

Diagrama 2B

Para Los Controles De Atenuador Conectados a

TENSIÓN

+12 V

CONTROL DEL

ATENUADOR

CONEXION A TIERRA INDICADOR

- Para Sujetador De Bulbo De Dos Cables -

Conecte el cable negro dentro del circuito entre

el control del atenuador y las luces del tablero.

Conecte el cable rojo a la caja de fusibles de

manera que el cable reciba potencia de tensión

+12 V solamente cuando se enciendan las luces

del tablero.

- Para Sujetador De Bulbo De Un Cable -

Conecte el cable a la caja de fusibles de manera

que reciba potencia de tensión +12 V solamente

ILUMINACION DEL TABLERO

TENSIÓN

+12 V

ROJO

CONEXION

NEGRAATIERRA

cuando se encienden las luces del tablero.

Obtenga un tramo de cable aislado de cobre de

calibre 18 y conecte un extremo del cable al

soporte de montaje del indicador o al panel.

Conecte el otro extremo del cable dentro del

circuito entre el control del atenuador y las luces

del tablero. Aísle el indicador y el soporte

de las superficies conectadas a tierra.

4. Refiérase a las instrucciones específicas

para el indicador que está instalando. Ellas

explican otras conexiones que deben

efectuarse antes de completar el montaje.

5. Inserte el indicador dentro del panel u orificio

de montaje.

6. Inserte el sujetador del bulbo dentro del

receptáculo del bulbo en el reverso del

indicador.

7. Instale el soporte adecuado de montaje

(Diagrama 1: aislado o no aislado) sobre los

postes de montaje (Diagrama 3), deslice la

arandela, además de una arandela de

seguridad si ha sido provista, y ajuste la

tuerca con una presión leve solamente. Si el

indicador es un modelo eléctrico, asegúrese

de usar un soporte que tenga arandelaspara

aislar los postes del soporte de montaje. Si

esto no se aplica a los indicadores queusan

postes separados de soporte de mon-taje

de los postes usados para las conexiones

del cable.

8. Coloque en posición el indicador para obtener

la mejor visibilidad y apariencia, a

continuación ajuste las tuercas del soporte

con una presión moderada. No ajuste en

exceso esas tuercas al usar un soporte

aislado. Una presión excesiva puede

distorsionar las arandelas causando que se

agrieten y causar cortocircuitos en el cable,

aun después de varios meses de la

instalación.

9. Para completar otras conexiones, refiérase

a las instrucciones específicas para el

indicador que está instalando ahora.

Diagrama 3

Indicadores Eléctricos Ilustrados

SOPORTE EN U

LUZ

INDICADOR

TUERCAS Y

ARANDELAS

SOPORTE EN U

AISLADO

4

TUERCAS Y

ARANDELAS

TABLERO

INDICADOR

LUZ

INSTRUCTIONS D'INSTALLATION

INSTRUCTIONS GÉNÉRALES DE MONTAGE

Le constructeur produit une gamme complète

d'appareils de mesure avec différents styles:

38,0 mm (1-1/2") Appareils

50,1 mm (2") Appareils

66,7 mm (2-5/8") Appareils

(Voir en page 6 les tailles de trous)

Les appareils de mesure vous permettent de

contrôler l'état de votre véhicule et de savoir dans

MOTEURS PILOTÉS PAR MICROPROCESSEUR

De nombreux véhicules récents utilisent des

microprocesseurs pour commander la plupart des

fonctions de moteur et électriques. Ces

microprocesseurs sont des composants

électriques très fragiles. Avant d'installer n'importe

quel équipement du marché des accessoires,

consultez le fabricant du véhicule ou le manuel

de réparations pour vous assurer qu'aucun

dommage n'en résultera. Certains de ces

derniers véhicules utilisent des ventilateurs de

refroidissement électriques ou des commandes

moteur à microprocesseur qui dépendent pour

INSTALLATION ET PRÉCAUTIONS DE SÉCURITÉ

1. Lisez toutes les instructions relatives à votre

appareil de mesure avant de commencer.

2. Assurez-vous que l'appareil convient bien à

votre véhicule:

Sa plage couvre-t-elle la plage de service du

véhicule?

Est-ce que la gaine de l'appareil est assez

longue pour aller du point de capture au

moteur jusqu'à l'emplacement de l'affichage

(les liaisons de thermomètres ne peuvent pas

être rallongés)?

Le système électrique du véhicule est-il bien

en 12 V avec négatif à la masse?

3. Il est recommandé que le câble de masse de

la batterie soit débranché avant d'exécuter

MONTAGE DE L'APPAREIL

Tous les appareils de mesure peuvent se monter

sur la surface de votre choix ou sur tableau. Des

panneaux pour un seul, deux ou trois appareils

sont disponibles pour toutes leurs tailles. Certains

panneaux ont une finition noire ou chromée. Une

bague extérieure de montage entièrement

chromée est disponible pour les appareils en 66,7

mm.

1. Choisissez un emplacement pour monter

l'appareil d'où il sera visible en position de

conduite normale (les indicateur de pression

de carburant ne doivent jamais être montés

dans l'habitacle du véhicule).

2. Si vous utilisez un tableau de montage, fixez-

le dans la zone choisie avec les vis fournies.

quelle mesure il fonctionne bien. S'il y avait des

problèmes quelconques, vous pouvez les détecter

tout de suite avant qu'ils ne s'aggravent. Des

voyants de signalisation ne vous préviennent que

quand les problèmes nécessitent une attention

immédiate. Vous constaterez que l'ajout des ces

appareils agira sur votre tranquillité d'esprit et

votre confort de conduite.

leur bon fonctionnement des lectures des unités

d'équipements d'origine. Si votre véhicule est l'un

de ceux-là, VOUS NE POUVEZ PAS remplacer

un appareil émetteur par un autre. Vous pouvez

installer un capteur-émetteur de pression d'huile

supplémentaire avec un kit adaptateur en té, mais

la seule façon d'installer un capteur-émetteur de

température d'eau qui ne soit pas du matériel

d'origine et de le placer à autre endroit, en laissant

celui d'origine à sa place. Vérifiez auprès du

constructeur du véhicule ou de son

concessionnaire pour savoir ce qui est possible.

n'importe quelle intervention. électrique, tout

spécialement à l'installation d'ampèremètres

ou voltmètres.

4. Faites passez le câblage et la tuyauterie

d'appareil de mesure à l'écart des tringleries,

hautes températures et pièces mobiles.

5. Ne fumez jamais quand vous travaillez sur le

véhicule, et ayez toujours un extincteur à

portée de main. Il doit être classé pour les

incendies d'origine gazeuse/chimique/

électrique.

6. Ne laissez jamais d'outil sur le dessus de la

batterie et ne portez pas de bijoux durant votre

intervention électrique, pour éviter de graves

court-circuits.

Schéma 1

Vue De Dessus

INDICATEUR

TABLEAU DE BORD

SUPPORT

ÉCROUS ET

RONDELLES

5

Loading...

Loading...