ABB ACS850 Catalog

Low voltage AC drives

ABB machinery drives

ACS850

0.5 to 700 hp / 0.37 to 560 kW

Catalog

Selecting and ordering your drive

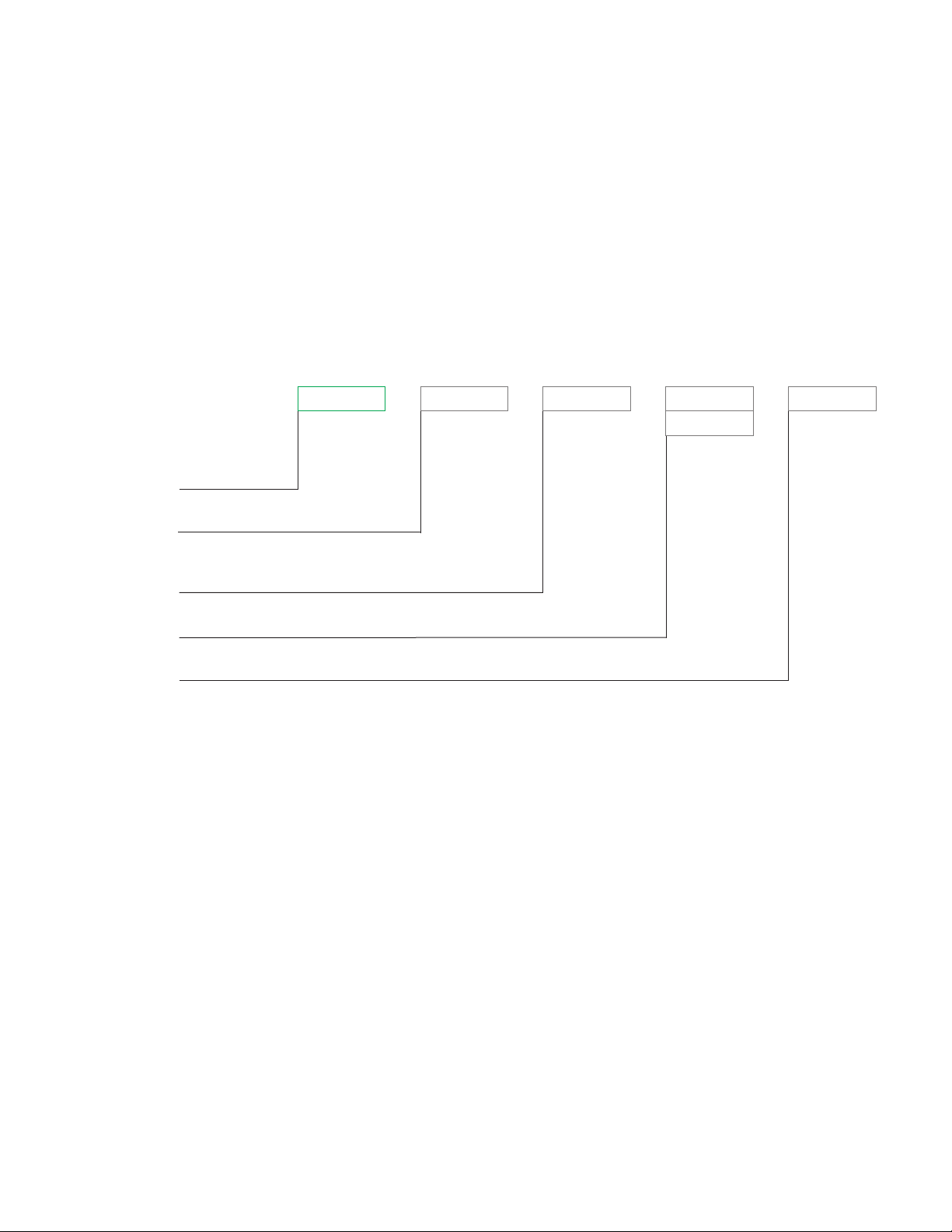

Type designation is a unique reference number that clearly

identifies the drive by construction, power and voltage

rating and selected options. Using the type designation

you can specify your drives from the wide range of options

available. Options are added to the type designation using the

corresponding “plus” (+) code.

Type designation:

Product series

Types and

construction

Ratings

Voltages

ACS850 - 04 - XXXX - 2 + XXXX

Build up your own ordering code using the type designation

key below or contact your local ABB drives sales office and let

them know what you want. Use page 3 as a reference section

for more information.

5

Options

2 ABB machinery drives ACS850 | Catalog

Contents

ABB machinery drives, ACS850

ABB machinery drives 4

Main features 5

Technical data 7

Ratings, types and dimensions 8

Standard control program 10

Standard software features 11

Standard I/O 12

Options 13

Control and communication modules 13

Control panel 14

EMC filters 15

Mains circuit 16

PC tools 20

Remote monitoring and diagnostic tools 21

Catalog | ABB machinery drives ACS850 3

ABB machinery drives

ACS850 - 04 - XXXX - 2 + XXXX

5

ABB machinery drives are designed to meet the production

and performance needs of machine builders, system

integrators, panel builders and end users in a broad range

of applications. ACS850 drives are ideal for applications like

cranes, extruders, winches, conveyors, winders, pumps, fans

and mixers in industries such as material handling, plastic and

rubber, food and beverage, textile and metals.

The drives can be configured to meet the precise needs of

these industries, as order-based configuration is an integral

part of the offering. Covering a wide power and voltage

range with standard and optional features, the drives are

readily programmable, making their adaptation to different

applications easy.

Wide range of options

ACS850 drives offer a wide range of built-in options such

as different I/O and communications. A wide selection of

external accessories is also available. The flexibility and

programmability of the drives make them suitable for many

applications in different areas of industry.

Robust design

The current ratings of ABB machinery drives are designed for

applications that have a high overload requirement. At the

heart of the drive is the motor control platform, direct torque

control (DTC) that provides accurate motor torque and speed

control even without feedback. The drive is designed for a

long working life and as such, parts like fans and capacitors

are selected to maximize their lifetime. This, together with

the extensive protection features and design details such

as coated boards, results in excellent reliability for the

demanding industrial market.

Optimized cabinet assembly

ACS850 drives are designed to be built into a customer’s

own cabinet, using minimal cabinet space while ensuring that

cabinet assembly is as easy as possible. The drives can be

mounted side-by-side and cabinet assembly documentation

is included. The documentation gives examples of different

cabinet configurations, examples of drawings and hints on the

selection of auxiliary equipment.

4 ABB machinery drives ACS850 | Catalog

Main features

Feature Advantage Benefi t

Modular and compact design

Compact size Smallest frame size is only 4 in (93 mm) wide.

More drives can be placed in the same cabinet.

Side-by-side mounting Minimized cabinet wall space.

No need to remember air gaps between drives.

Modular design Many standard features and a wide range of options

allow different system configurations.

Optimal location of power

terminals

Integrated brake chopper Brake chopper as standard up to 30 hp (frames A to D)

User interface and programming

Intuitive human-machine

interface

Drive programming and

configuration

Memory unit for easy drive

management

Designed for reliability

Robust main circuit design Enhanced reliability.

Extensive protection Advanced thermal protection of the drive semiconductors

Maintenance assistant Indicates preventive maintenance needs of drive, motor

Diagnostic assistant Drive helps in locating failures or reasons for performance

Optimized use

Energy saving calculator Monitors used and saved energy, displayed in kWh,

Load analyzer Shows the load profile of the drive. Easy process analysis.

Energy optimizer Maximizes efficiency by optimizing the motor flux. Improves motors performance therefore makes process

Top-down power flow in frames A to D and G1 to G2

enables the most optimal cabinet layout in many cases.

and a built-in option for other frame sizes.

Large alphanumeric display showing different assistants

and macros.

Extremely easy to use and commission the drive.

DriveStudio PC-tool offers easy access to drive

parameter setting and start-up features.

Can replace relays and small PLCs with function block

programming.

Complete drive configuration and settings are stored in a

separate memory unit.

Power or control unit can be replaced without parameter

setting.

Coated boards and long life time components.

Cooling supervision (depending on frame size).

and motor.

Several adjustable protections for the drive and adjoining

equipment ensure a reliable operation.

or machine.

User-set alarms and triggering limits.

Monitors running hours, cooling fan running hours,

number of relay switchings etc.

changes and suggests remedies.

currency ($ or Euros) or volume of CO

emission.

2

Optimum installation layout and efficient cabinet space

usage.

Space and cost savings.

Space and cost savings.

Fits many application needs.

Offers flexibility in system design.

Easy connection of power cables.

Optimum installation layout and efficient cabinet space

usage.

Optimized EMC design.

Compact and cost-effective design.

Faster and more accurate drive configuration.

Optimal drive settings as assistants offer interactive help.

Lower investment cost.

Higher flexibility in system design.

Drive functionality can be easily configured, modified or

updated with the memory unit.

Offers quick and easy after-sales service.

Less process interruptions.

Lower maintenance costs.

Higher process uptime.

Early warning of any production interruptions.

Helps with maintenance schedules and cost control of

maintenance.

Fewer unexpected process interruptions.

Reduced process downtime.

Faster recovery to drives optimum performance.

Easy to check the return on investment.

more efficient.

Energy savings are realized and money saved.

Catalog | ABB machinery drives ACS850 5

Main features

Feature Advantage Benefi t

Control and performance

Compatible with AC induction

and permanent magnet

motors

Standard drive-to-drive link,

configurable as Modbus link

Different communication

options

Integrated safe torque-off

function (up to SIL 3)

Extensive configurable

standard I/Os.

Optional I/O extensions Plug-in analog and digital I/O extensions. Extends drives’ scope, performance and applications

Direct torque control Accurate, dynamic and static speed and torque control.

High overload and high starting

torque

Made by ABB

Global market leader in AC drives

with long experience

World wide service and support

network

Same drive can be used to control different motor types. Savings in investment costs.

Savings in spares stockholding.

No additional hardware needed for master-follower

communication or Modbus.

Galvanic isolation.

Flexibility with master communication - drive supports

PROFIBUS, CANopen

Modbus TCP and Ethernet / IP

Safe torque-off (STO) is used to prevent unexpected

start-up.

High SIL class means high reliability of the

safety function.

Can also be used to implement Emergency Stop without

contactors.

Optimized accessibility. Lower cost.

Excellent process control even without pulse encoder.

Power interruption ride-through using kinetic energy of

load.

Fast reaction to load or voltage variations.

No shock torques.

No torque ripple - minimized risk for torsional vibration.

Less noise during motor operation.

Output frequency up to 500 Hz.

Enhanced motor identification at stand still.

Smooth start without over-dimensioning the drive. Longer motor and gear lifetime thereby reduced

Well proven, safe and reliable solutions.

Application know-how.

Professional support available around the world. High quality service and support wherever you need it.

®

, DeviceNetTM, Modbus, EtherCAT,

TM

communication.

Lower investment cost.

More reliable, disturbance-free isolation.

Drive can be applied to many existing processes.

Enhances safety of the machines.

Cost-effective and certified solution for safe machine

maintenance.

Fulfils new safety directives IEB 61508, IEC 62061 and

EN ISO 13489-1.

Fewer parts and installation work needed for cabinet

assembly.

opportunities.

Improves product quality, productivity and reliability.

Lower investment cost.

No unnecessary trips or process interruptions.

Less maintenance.

Suitable for use where audible noise is an issue.

Applicable in high speed applications.

Better process control due to more accurate

identification.

Can do motor identification without decoupling the load.

maintenance costs.

Highly reliable drives.

6 ABB machinery drives ACS850 | Catalog

Technical data

ACS850 - 04 - XXXX - 2 + XXXX

5

Mains connection

Supply voltage

Frequency

DC connection

DC voltage level

Charging circuit

Motor connection

Motor types

Output frequency

Motor control

Torque control:

Open loop

Closed loop

Open loop

Closed loop

Speed control:

Open loop

Closed loop

Open loop

Closed loop

Braking power connection

Brake chopper

Brake resistor

3-phase 380 to 500 V AC +10 /-15%

3-phase 200 to 240 V AC ± 10%

50 to 60 Hz ± 5%

485 to 675 V DC ± 10% (-5 types)

270 to 324 V DC ± 10% (-2 types)

Internal in frames A to D

External in frames E0 to G2

AC induction motors and permanent magnet

motors

0 to 500 Hz

Direct torque control (DTC) or scalar control

Torque step rise time:

<5 ms with nominal torque

<5 ms with nominal torque

Non-linearity:

± 4% with nominal torque

± 3% with nominal torque

Static accuracy:

10% of motor slip

0.01% of nominal speed

Dynamic accuracy:

0.3 to 0.4% sec. with 100% torque step

0.1 to 0.2% sec. with 100% torque step

Standard in frames A to D, built-in option in the

other frame sizes

External resistor connected to drive

Operating conditions

Degree of protection

Ambient temperature

Installation altitude

Relative humidity

Climatic/

environmental

conditions

Vibration

EMC (According to

EN 61800-3)

Functional safety

Compliance

IP20 according to EN 60529 (G frame IP00);

Open type according to UL 508

14 to 131 °F / (-10 to +55 °C), derating above

104 °F (40 °C)

No frost allowed

0 to 13000 ft (0 to 4000 m) (IT network:

6560 ft (2000 m)), derating above 3280 ft

(1000 m): 1% / 328 ft (100 m)

Max. 95%, no condensation allowed

Class 3K3, 3C2 according to EN 60721-3-3.

Oil mist, formation of ice, moisture condensation,

water drops, water spray, water splashes and

water jets are not permissible (EN 60204, Part 1)

Class 3M4 according to EN 60721-3-3

Categories C2 and C3 with optional filter

(according to EN 61800-3)

Safe torque-off (STO according EN 61800-5-2)

IEC 61508: SIL 3

IEC 61511: SIL3

IEC 62061: SILCL 3

EN ISO 13849-1: PL e

Certified by TÜV

Frames A to D: CE, GOST R, UL, cUL, CSA,

C-Tick

Frames E0 to G: CE, GOST R; pending: UL,

cUL, CSA, C-Tick

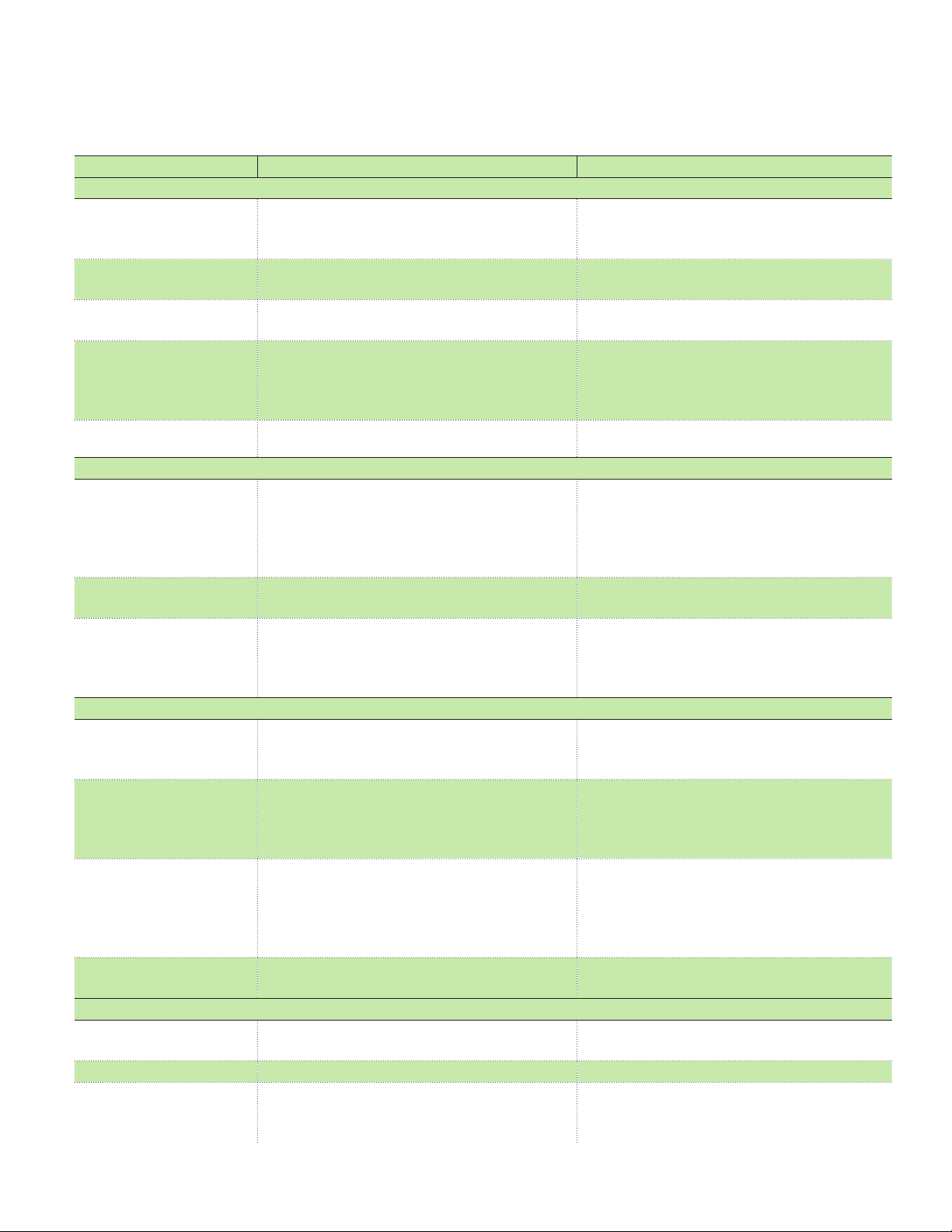

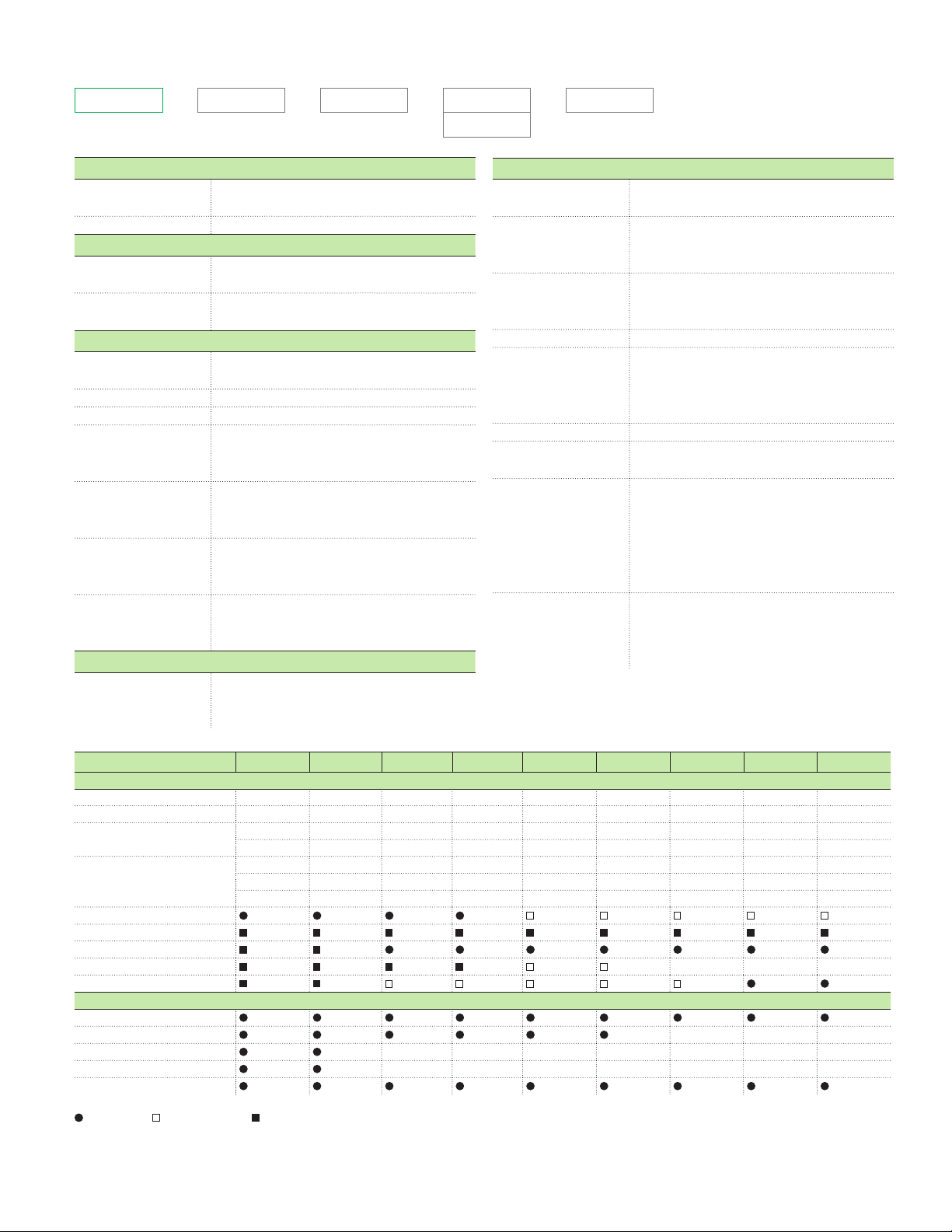

Feature / frame size A B C D E0 E G G1* G2 *

Current and power

Nominal current 3 to 8 A 10.5 to 18 A 25 to 50 A 61 to 94 A 103 to 144 A 166 to 290 A 430 to 720 A 387 to 680 A 710 to 875 A

Maximum current 4.4 to 10.5 A 13.5 to 21 A 33 to 66 A 78 to 124 A 138 to 170 A 202 to 348 A 588 to 1017 A 470 to 710 A 850 to 1100 A

Typical motor power in hp (230 V)

(480 V)

Typical motor power in kW (230 V) 0.37 to 1.5 kW 2.2 to 4 kW 5.5 to 11 kW 15 to 22 kW

(400 V) 1.1 to 3 kW 4 to 7.5 kW 11 to 22 kW 30 to 45 kW 55 to 75 kW 90 to 160 kW 200 to 400 kW 200 to 355 kW 400 to 500 kW

(500 V) 1.5 to 4 kW 5.5 to 11 kW 15 to 30 kW 37 to 55 kW 55 to 90 kW 110 to 200 kW 250 to 500 kW 250 to 400 kW 500 to 560 kW

Brake chopper

Brake resistor

Input choke

EMC filter / C2 –––

EMC filter / C3

Mounting and cooling

Air cooling

Side-by-side mounting –––

DIN rail mounting

Removable power connectors

Removable control connectors

= standard = option, built-in = option, external – = not available * available during 2011

0.5 to 2 hp 3 to 5 hp 7.5 to 15 hp 20 to 30 hp

1.5 to 5 hp 5 to 10 hp 15 to 30 hp 40 to 60 hp 75 to 100 hp 125 to 200 hp 350 to 600 hp 300 to 550 hp 600 to 700 hp

–––––––

–––––––

–

–––––

––––

Catalog | ABB machinery drives ACS850 7

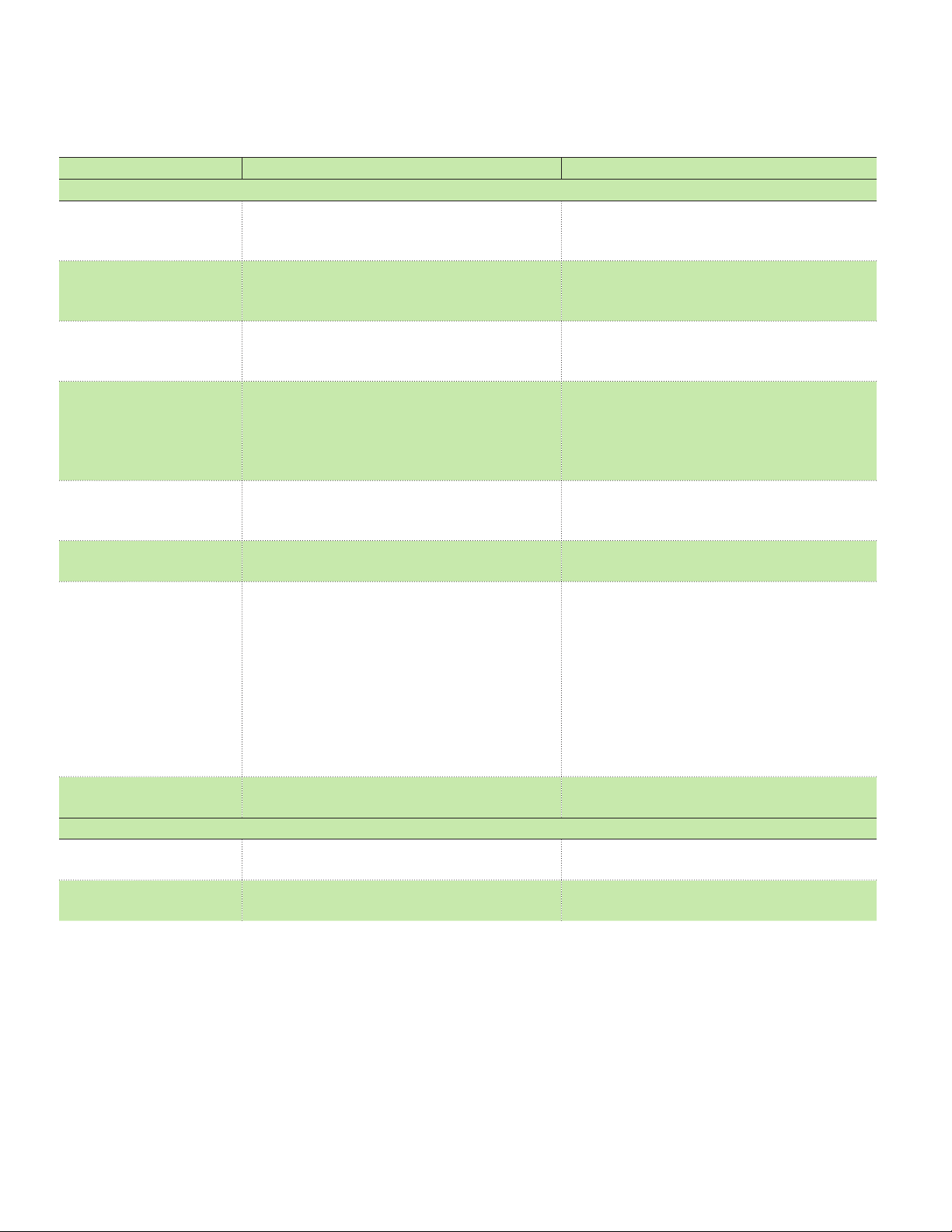

Ratings, types and dimensions

ACS850 - 04 - XXXX - 2 + XXXX

5

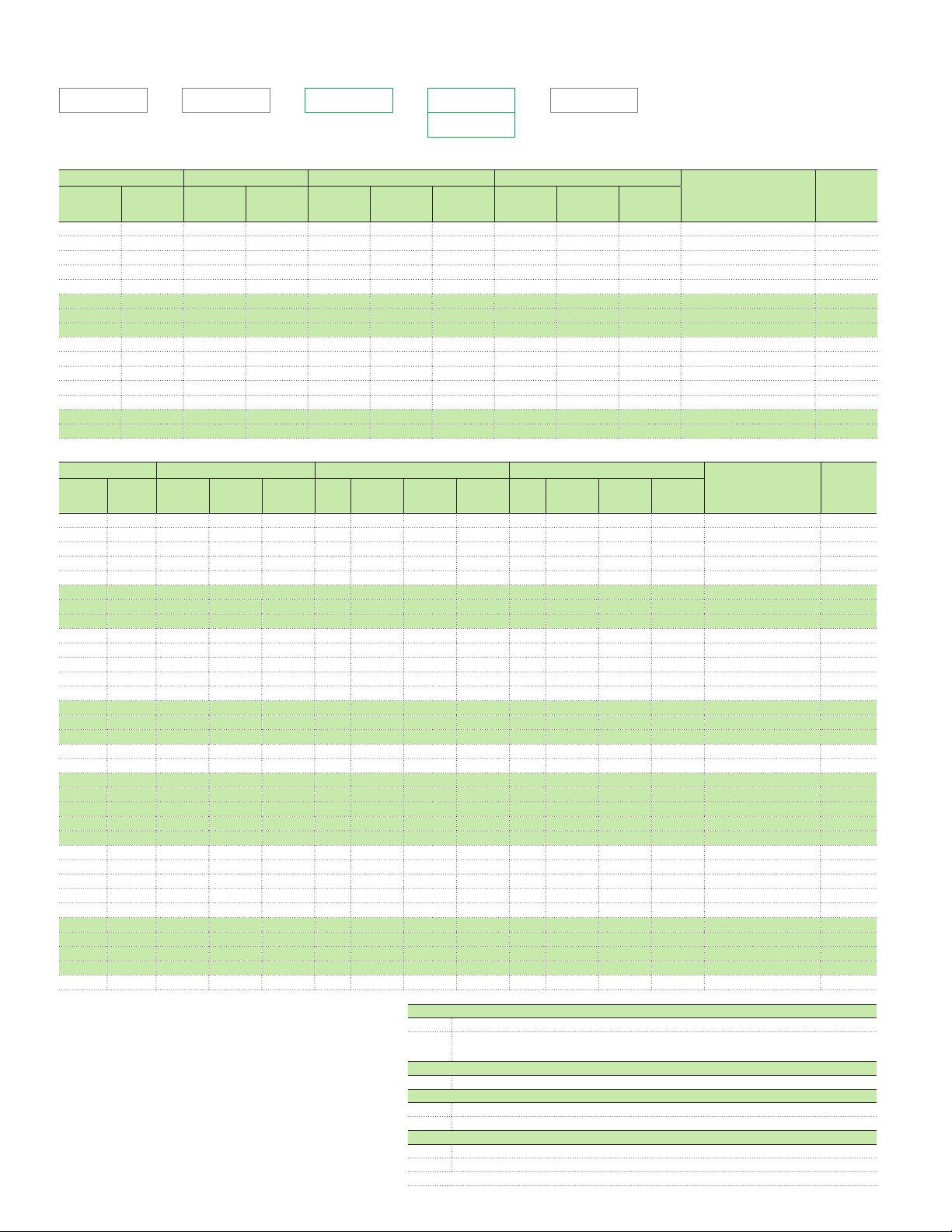

Ratings 200 to 240 V

Nominal ratings No-overload use Light-duty use Heavy-duty use Type designation Frame

I

(A) I

2N

(A) PN (hp)

Max

U

N = 230 V

PN (kW)

U

N = 230 V

I

(A) P

Ld

Ld

U

N = 230 V

(hp)

P

Ld

U

N = 230 V

(kW)

I

(A) P

Hd

Hd

U

N = 230 V

(hp)

P

Hd

U

N = 230 V

(kW)

3 4.4 0.5 0.37 2.8 0.5 0.37 2.5 0.5 0.37 ACS850-04-03A0-2 A

3.6 5.3 0.75 0.55 3.4 0.75 0.55 3 0.5 0.37 ACS850-04-03A6-2 A

4.8 7 1 0.75 4.5 1 0.75 4 0.75 0.55 ACS850-04-04A8-2 A

6 8.8 1.5 1.1 5.5 1 1.1 5 1 0.75 ACS850-04-06A0-2 A

8 10.5 2 1.5 7.6 2 1.5 6 1.5 1.1 ACS850-04-08A0-2 A

10.5 13.5 3 2.2 9.7 3 2.2 9 2 1.5 ACS850-04-010A-2 B

14 16.5 3 3 13 3 3 11 3 2.2 ACS850-04-014A-2 B

18 21 5 4 16.8 5 4 14 3 3 ACS850-04-018A-2 B

25 33 7.5 5.5 23 7.5 5.5 19 5 4 ACS850-04-025A-2 C

30 36 10 7.5 28 10 7.5 24 7.5 5.5 ACS850-04-030A-2 C

35 44 10 7.5 32 10 7.5 29 10 7.5 ACS850-04-035A-2 C

44 53 15 11 41 15 11 35 10 7.5 ACS850-04-044A-2 C

50 66 15 11 46 15 11 44 15 11 ACS850-04-050A-2 C

61 78 20 15 57 20 15 52 15 11 ACS850-04-061A-2 D

78 100 25 18.5 74 25 18.5 66 20 15 ACS850-04-078A-2 D

Ratings 400 to 500 V

Nominal ratings No-overload use Light-duty use Heavy-duty use Type designation Frame

(A) I

I

2N

3 4.4 1.5 1.1 1.5 2.8 1 1.1 1.1 2.5 1 0.75 1.1 ACS850-04-03A0-5 A

3.6 5.3 2 1.5 1.5 3.4 2 1.5 1.5 3 1.5 1.1 1.5 ACS850-04-03A6-5 A

4.8 7 3 2.2 2.2 4.5 2 1.5 2.2 4 2 1.5 2.2 ACS850-04-04A8-5 A

6 8.8 3 2.2 3 5.5 3 2.2 3 5 3 2.2 2.2 ACS850-04-06A0-5 A

8 10.5 5 3 4 7.6 5 3 4 6 3 2.2 3 ACS850-04-08A0-5 A

10.5 13.5 5 4 5.5 9.7 5 4 5.5 9 5 4 4 ACS850-04-010A-5 B

14 16.5 7.5 5.5 7.5 13 7.5 5.5 7.5 11 7.5 5.5 5.5 ACS850-04-014A-5 B

18 21 10 7.5 11 16.8 10 7.5 7.5 14 10 7.5 7.5 ACS850-04-018A-5 B

25 33 15 11 15 23 15 11 11 19 10 7.5 11 ACS850-04-025A-5 C

30 36 20 15 18.5 28 20 15 15 24 15 11 15 ACS850-04-030A-5 C

35 44 25 18.5 22 32 20 15 18.5 29 20 15 18.5 ACS850-04-035A-5 C

44 53 30 22 30 41 30 22 22 35 25 18.5 22 ACS850-04-044A-5 C

50 66 30 22 30 46 30 22 30 44 30 22 30 ACS850-04-050A-5 C

61 78 40 30 37 57 40 30 37 52 40 22 30 ACS850-04-061A-5 D

78 100 60 37 45 74 50 37 45 66 50 37 45 ACS850-04-078A-5 D

94 124 60 45 55 90 60 45 55 75 50 37 45 ACS850-04-094A-5 D

103 138 75 55 55 100 75 55 55 83 60 45 55 ACS850-04-103A-5 E0

144 170 100 75 90 141 100 75 90 100 75 55 55 ACS850-04-144A-5 E0

166 202 125 90 110 155 125 75 90 115 75 55 75 ACS850-04-166A-5 E

202 282 150 110 132 184 150 90 110 141 100 75 90 ACS850-04-202A-5 E

225 326 150 110 132 220 150 110 132 163 125 90 110 ACS850-04-225A-5 E

260 326 200 132 160 254 200 132 160 215 150 110 132 ACS850-04-260A-5 E

290 348 200 160 200 286 200 160 200 232 150 132 160 ACS850-04-290A-5 E

430 588 350 200 250 425 350 200 250 340 250 160 200 ACS850-04-430A-5 G

521 588 450 250 355 516 450 250 355 370 300 200 250 ACS850-04-521A-5 G

602 840 500 315 400 590 500 315 400 477 400 250 315 ACS850-04-602A-5 G

693 1017 550 355 450 679 550 355 450 590

720 1017 600 400 500 704 600 400 500 635

387 470 300 200 250 377 300 200 250 300 200 160 200 ACS850-04-387A-5 G1*

460 533 350 250 315 450 350 250 315 355 250 200 250 ACS850-04-460A-5 G1*

558 640 450 315 355 550 450 315 355 414 350 200 250 ACS850-04-558A-5 G1*

680 710 500 355 400 664 500 355 400 477 400 250 315 ACS850-04-680A-5 G1*

710 850 600 400 500 700 600 400 500 566 450 315 400 ACS850-04-710A-5 G2*

(A) PN (hp)

Max

U

N = 480 V

PN (kW)

U

N = 400 V

PN (kW)

U

N = 500 V

I

(A) PLd (hp)

Ld

U

N = 480 V

PLd (kW)

U

N = 400 V

PLd (kW)

U

N = 500 V

I

(A)

Hd

(hp)

Hd

N = 480 V

PHd (kW)

U

P

U

1)

500 315 400 ACS850-04-693A-5 G

2)

500 355 450 ACS850-04-720A-5 G

N = 400 V

PHd (kW)

U

N = 500 V

size

size

Notes

1)

For ambient temperature of less than 95 °F (35 °C) ,

maximum overload is 150% of I

104 °F (40 °C), maximum overload is 145% of I

2)

For ambient temperature of less than 86 °F (30 °C),

maximum overload is 150% of I

104 °F (40 °C)0, maximum overload is 140% of I

. For ambient temperature of

Hd

. For ambient temperature of

Hd

.

Hd

.

Hd

* Available during 2011.

8 ABB machinery drives ACS850 | Catalog

Nominal ratings

I

Rated current available continuously without overloading at 104 °F (40 °C).

2N

I

Maximum output current. Available for 10 s at start, otherwise as long as allowed by

max

drive temperature. Note: max. motor shaft power is 150% P

Typical ratings: No-overload use

Typical motor power in no-overload use.

P

N

Light-duty use

Continuous current allowing 110% ILd for 1 min / 5 min at 104 °F (40 °C).

I

Ld

Typical motor power in light-duty use.

P

Ld

Heavy-duty use

Continuous current allowing 150% IHd for 1 min / 5 min at 104 °F (40 °C).

I

Hd

P

Typical motor power in heavy-duty use.

Hd

The current ratings are the same regardless of the supply voltage within one voltage range.

.

Hd

The ratings apply at 104 °F (40 °C) ambient temperature.

Loading...

Loading...