ABB ACS850 Catalog Page

ABB industrial drives

ACS850, drive modules, 1.5 to 600 Hp (1.1 to 500 kW)

ABB industrial drive modules are

designed for fast, cost effective

installation and integration into

cabinets. The IP20/UL Type Open

compliant modules (G frame IP00),

the smallest only 3.7 in wide, allow

side-by-side installation.

The compact size leads to cabinets

with shorter run lengths, ultimately

providing smaller and less expensive

control rooms.

Customizable to meet all needs

The modularity and wide range of

options, including different fieldbus

adapters and speed feedback

devices, increases the potential for

customization. Embedded ModBus as

standard and one of the most extensive

standard I/O offering on the market

make these new drive modules ideal

for complex applications. In addition,

the drive´s flexible construction allows

you to select only the features that are

needed.

All application parameters can be

easily selected via the control panel.

In addition, intuitive PC tools are

available to carry out function block

programming, allowing the user

to customize a drive for a specific

application without the need for

additional hardware.

Maximized process uptime

Many features have been implemented

to enhance the reliability and durability

of the drives:

− Maintenance assistant: to take care

of the preventive maintenance of the

drive and its components

− Diagnostic assistant: to help locate

the cause of any disturbance to the

drive and suggest possible remedies

− Coated boards within the drive: for

increased protection

A removable memory unit provides easy

maintenance by storing the complete

firmware and all user settings and motor

data. Thus, if the drive is replaced, it

can be recommissioned quickly and

easily without needing to install software

or download data.

Fast and easy commissioning

ABB industrial drive modules feature

several macros which have pre-set,

application-specifi c parameter settings,

enabling fast and easy commissioning.

Complementing the pre-set macros,

the drive has an intelligent and intuitive

start-up assistant with help function to

make parameter-by-parameter setting

easy. In addition, there are several

advanced functions such as short and

long parameter menus, I/O mapping and

changed parameters list, making the

drive easy to use. All these functions are

accessed via the user-friendly control

panel.

Safety as standard

Additional safety is provided by an

integrated Safe Torque-Off (STO)

feature, which removes the torque from

the motor shaft. This safety feature

conforms with the requirements of

SIL 3/IEC 61508, Cat 4/EN 954-1,

EN ISO 13849-1:PL e. Solutions for

other safety functions such as Safe

Brake Control (SBC) and Safe Limited

Speed (SLS) are also available.

Precise and reliable control

The performance and functionality

of ABB industrial drive modules is

For master-follower configurations,

drive-to-drive communication is

provided as standard.

based on the ultimate in motor control

technology, Direct Torque Control (DTC).

DTC has new enhanced features such as:

Save money and the environment

The modules feature an energy optimizer

which maximizes the total effi ciency

− Low motor noise mode

− Enhanced motor identification at

standstill

− Higher output frequency

− Support for both asynchronous

and permanent magnet motors as

of the drive and the motor. The energy

saving calculator records the amount of

energy consumed and saved in kWh.

The drive cooling fans are also monitored

and controlled for even greater energy

savings.

standard

− Improved torque and speed

performance, especially at low speed

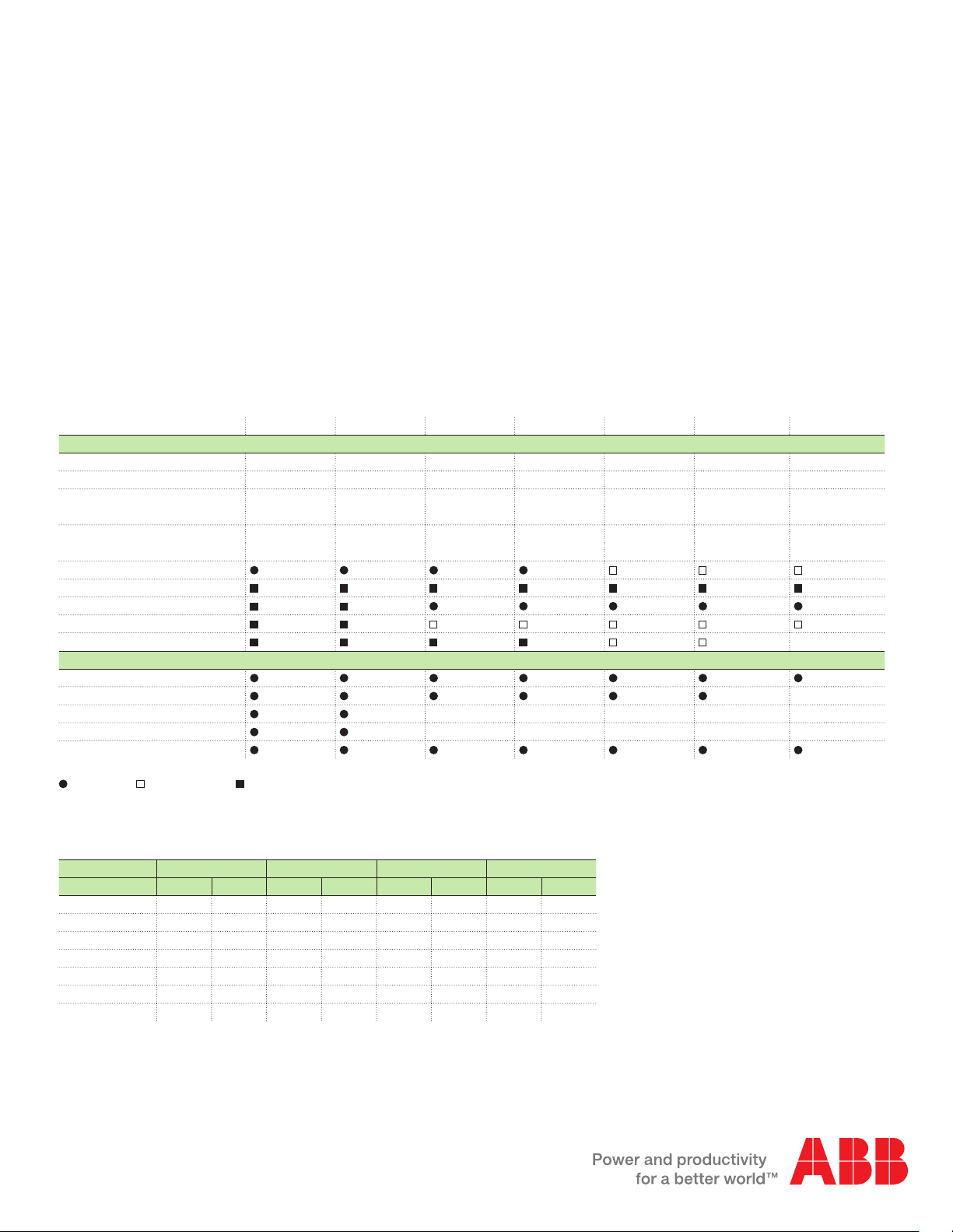

Feature / frame size A B C D E0 E G

Current and power

Nominal current

Maximum current

Typical motor power (400 V)

Typical motor power (500 V)

Braking chopper

Braking resistor

Input choke

EMC filter / C3 *

EMC filter / C2

Mounting and cooling

Air cooling

Side-by-side mounting

DIN-rail mounting

Removable power connectors

Removable control connectors

3 to 8 A 10.5 to 18 A 25 to 50 A 61 to 94 A 103 to 144 A 166 to 210 A 430 to 720 A

4.4 to 10.5 A 13.5 to 21 A 33 to 66 A 78 to 124 A 131 to 170 A 202 to 348 A 588 to 1017 A

1.5 to 5 hp 5 to 10 hp 15 to 30 hp 40 to 60 hp 75 to 100 hp 125 to 200 hp 250 to 500 hp

(1.1 to 3 kW) (4 to 7.5 kW) (9 to 22 kW) (30 to 45 kW) (55 to 75 kW) (90 to 160 kW) (200 to 400 kW)

1.5 to 5 hp 5 to 10 hp 15 to 30 hp 40 to 60 hp 75 to 100 hp 125 to 200 hp 350 to 600 hp

(1.5 to 4 kW) (5.5 to 11 kW) (15 to 30 kW) (37 to 55 kW) (55 to 90 kW) (110 to 200 kW) (220 to 500 kW)

These features will allow users to lower

their power consumption, helping them

reduce CO

emissions.

2

–––– –

–––– –

Services and support

The modules are complemented by

extensive documentation and support

material for cabinet installation.

Advanced PC tools are also available

for dimensioning, programming,

commissioning and maintaining of the

drives.

The ABB industrial drive modules are

supported by the company’s extensive

global service infrastructure covering

more than 60 countries along with a

strong partner network.

ACS850-PHPB01U-EN / 3AUA0000067052 REV B EN 9.9.2009

–

–

= standard = option, built-in = option, external – = not available

* External EMC fi lters are plug-in type fi lters that fi t to the drive within its installation footprint.

Dimensions

Frame size Height 1) Depth

in mm in mm in mm lb kg

A

B

C

D

E0

E

G

Notes

All dimensions and weights are without options.

1)

Height is the maximum measure without clamping plates.

2)

An additional 50 mm should be reserved for feedback cabling if FEN-01, 11 or 21 options is used.

14.3 364 7.8 197 3.7 93 7 3

15.0 380 10.8 274 4.0 101 11 5

22.3 567 10.9 276 6.5 166 35 16

22.3 567 10.9 276 8.7 221 51 23

23.7 602 13.9 354 10.9 276 77 35

27.6 700 17.4 443 12.3 312 147 67

61.6 1564 22.4 568 22.1 562 451 205

2)

Width Weight

For more information please contact:

www.abb.us/drives

© Copyright 2009 ABB. All rights reserved.

Specifications subject to change without notice.

Loading...

Loading...