Carrier 50QQ User Manual

50QQ

#

HEATING A COOLING

Single-Package Heat Pumps

Installation, Start-Up and Service Instructions

CONTENTS

Page

SAFETY CONSIDERATION

INSTALLATION..................................................................1-7

Step 1—Check Equipment and Jobsite............................. 1

• UNPACK UNIT

• INSPECT EQUIPMENT

• COMPLETE SYSTEM REQUIREMENTS

Step 2—Mount Unit.............................................................. 2

• ON THE GROUND

• ON THE ROOF

Step 3—Make Ductwork Connections

• CONNECT RETURN AND SUPPLY AIR

DUCTWORK

Step 4—Provide for Cooling Cycle

Condensate Disposal

• CONNECT DRAIN LINE

Step 5—Make Electrical Connections

• INSTALL A BRANCH CIRCUIT DISCONNECT PER

NEC

• ROUTE LINE POWER LEADS INTO UNIT

• CONNECT GROUND LEAD TO GROUND LUG

• SET INDOOR FAN MOTOR SPEED

• ROUTE CONTROL POWER WIRES

• ACCESSORY DUCT FLANGE KIT INSTALLATION

• ELECTRIC HEATER INSTALLATION

START-UP

SERVICE...........................................................................8-15

............................................................................

SAFETY CONSIDERATIONS

Installing and servicing air conditioning equipment can be

hazardous due to system pressure and electrical compo

nents. Only treuned and qualified service personnel should

install or service air conditioning equipment.

Untrained personnel can perform basic maintenance func

tions such as cleaning coils and filters and replacing filters.

All other operations should be performed by trained service

personnel. When working on air conditioning equipment,

observe precautions in the literature and on tags and labels

attached to unit.

Follow all safety codes. Wear safety glasses and work

gloves. Use quenching cloth for brazing operations. Have

fire extinguisher available.

.................................................

...............................

......................................................

...............................

1

2

4

5

8

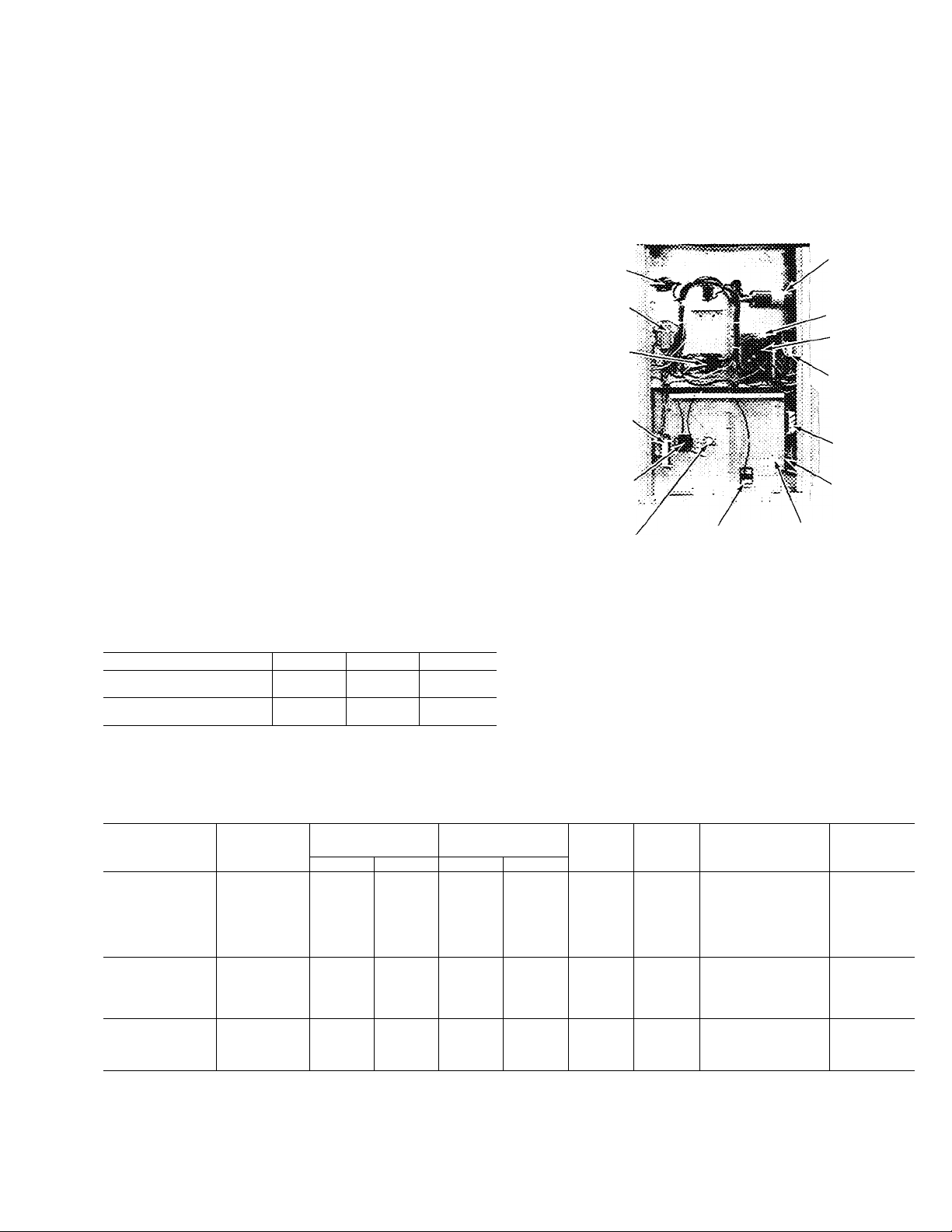

1-5/8” DIAM KNOCKOUT ELECTRIC HEAT

> OUTDOOR AIRFLOW

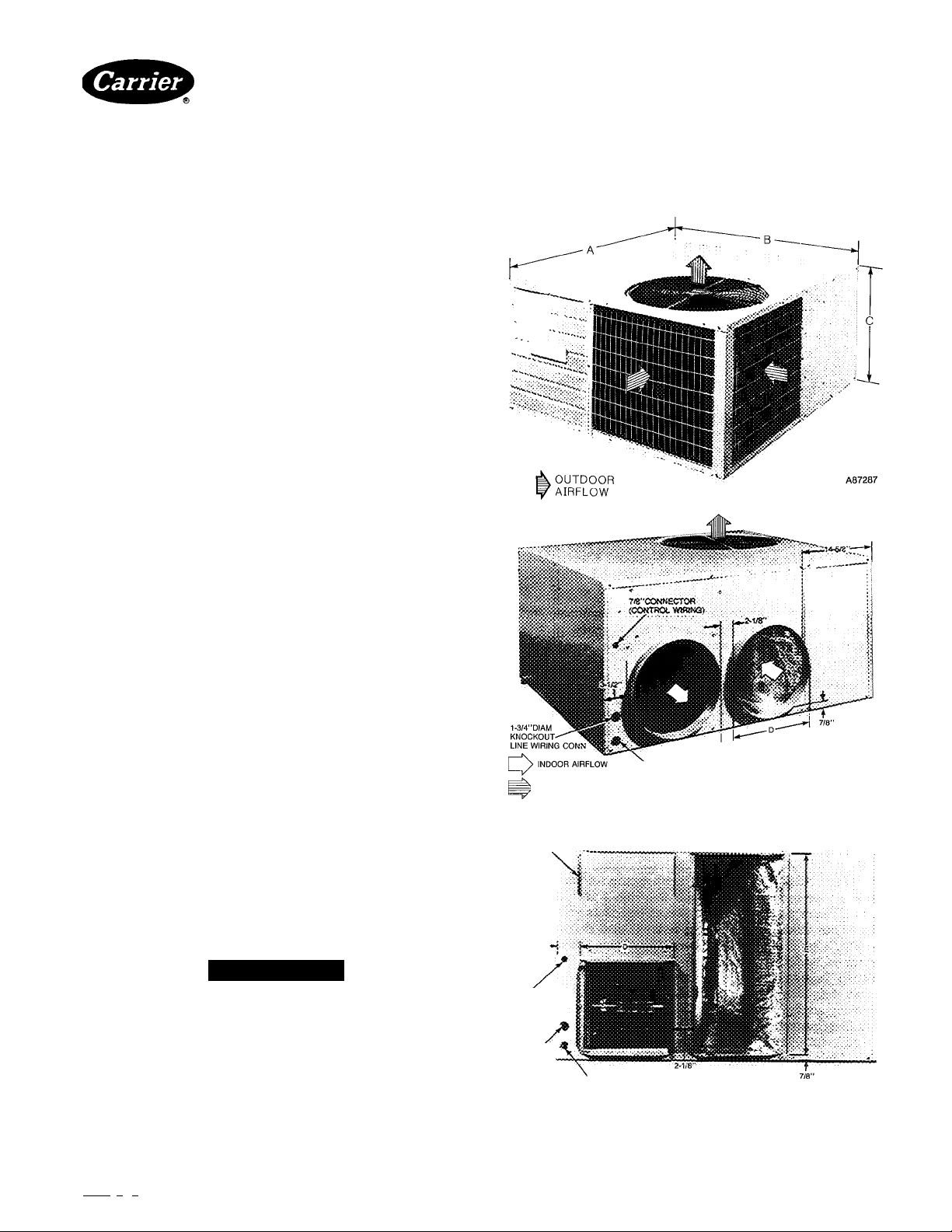

RIGHT-SIDE VIEW - MODEL 018 048(TYPICAL)

DUCT FLANGE

FOR 14”X28”

CONNECTION

A88061

A WARNING

Before performing service or maintenance operations on

7/8”

CONNECTOR^

system, turn off main power switches to unit. Turn off

accessory heater power switch if applicable. Electric

shock can cause personal injury.

INSTALLATION

Step 1—Check Equipment and Jobsite

1-3/8”DIAM

KNOCKOUT

LINE WIRING

CONN

RIGHT - SIDE VIEW • MODEL 060

1-5/8”DIAM KNOCKOUT

ELECTRIC HEAT

UNPACK UNIT—Move unit to final location. Lift off car

ton tEiking special care not to damage unit.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obiigations.

Bookl 1 I 4 PC 101 Catalog No 565-097 Printed in USA Form 50QQ-8Si 11/87 Pg 1 Replaces: 50QQ-7Si

Tab i5a 15a

Fig. 1 —Dimensions and Connections

Table 1—Physical Data and bimensions

MODEL 50QQ

REFRIGERANT (R-22)

Operating Charge (lb)

Refrigerant Control

SHIPPING WEIGHT (lb) 323 1 329 1 346 1 357 | 402 | 445 | 484

DIMENSIONS (in.)

DUCT CONNECTIONS (in.)

FILTER SIZE (in.)t

Disposable

Permanent

*Dimension C includes %-in built-in base support channels

tOptional square duct flanges are available as an accessory for 14-in x 14-in duct.

ijiRecommended field-supplied filters are one-in. thick.

A

B

C*

D

E

018 024

7 lbs 4 oz

20x25 20x25 (2)15x20

15x20 15x20 20x20

6 lbs 8 oz 8 lbs 0 oz

22'k 1 2472 1 29% 32%

030

Side-By-Side

Round!

036

7 lbs 4 oz

Piston

48

14

15x20

20x20 (2) 20 X 20

20x25

8 lbs 2 oz

INSPECT EQUIPMENT—File claim with shipping com

pany if shipment is damaged or incomplete.

COMPLETE SYSTEM REQUIREMENTS before

installing.

Consult local building codes and National Electrical Code

(NEC) ANSI/NFPA 70-1987 for special installation

requirements.

Provide sufficient space for coil airflow clearance, wiring,

and servicing unit. See Fig. 1 and 2. Locate unit where sup

ply and return air ducts can be conveniently brought out to

unit duct connections.

Unit may be placed with duct side as close to building as

top removal, duct connections and power connections per

mit. Position unit so water or ice from roof does not drop

directly on top of unit or in front of coil. Make provisions for

condensate drainage and defrost water disposal. Maintain a

4-ft clearance above unit for vertical air discharge.

Roof installation method for 50QQ depends on building con

struction and special requirements of local building codes.

Ensure that roof can support unit weight. Protect unit from

prevailing winds to ensure adequate defrost.

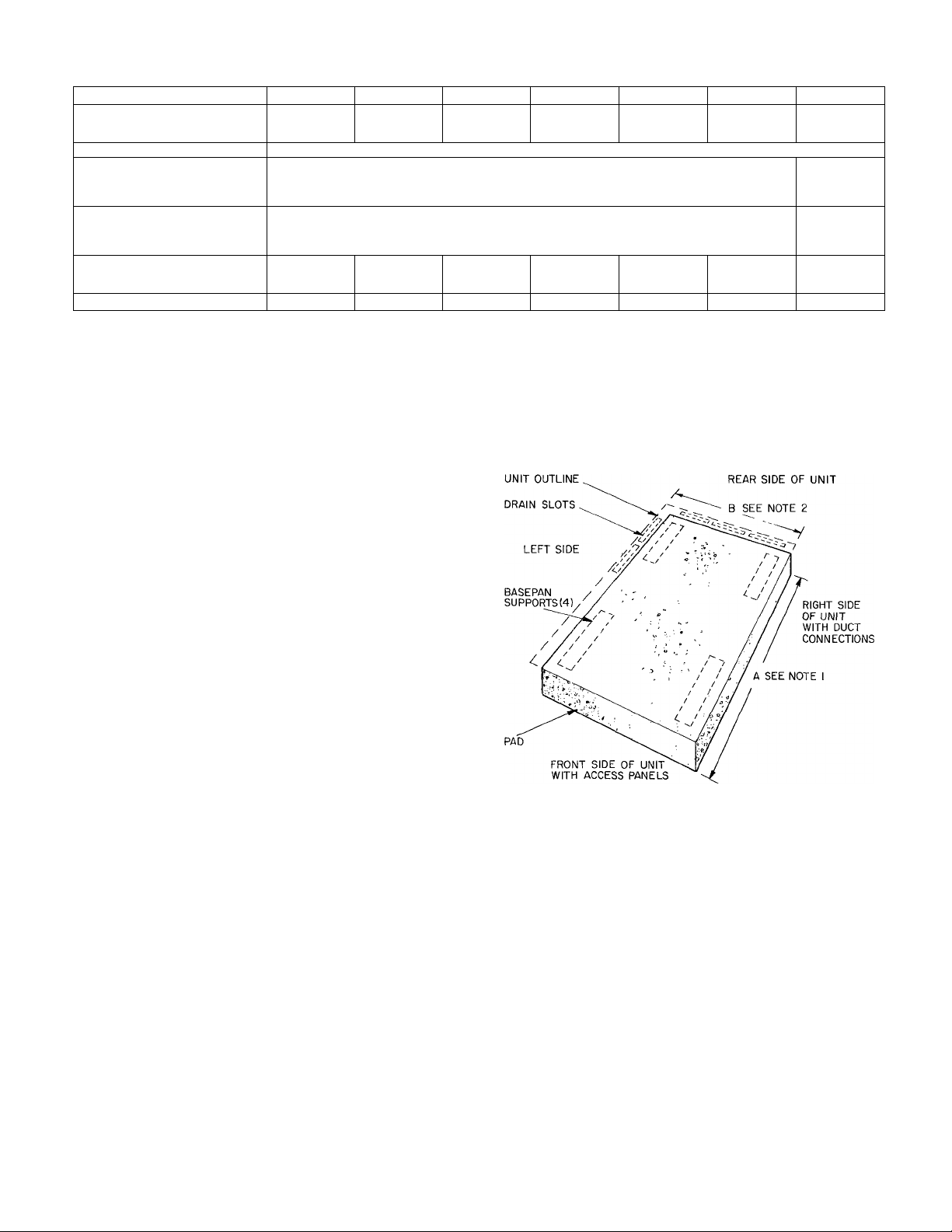

Step 2—Mount Unit

NOTES:

1

In areas of snowfall or subfreezing temperatures when elevated

frame Is used Dimension A is 48-in., Dimension B is 42-in. In areas

where elevated frame is not used Dimension A is 45-in , Dimension

B is 39-in

Allow a 3-ft service clearance at front and rear sides of unit

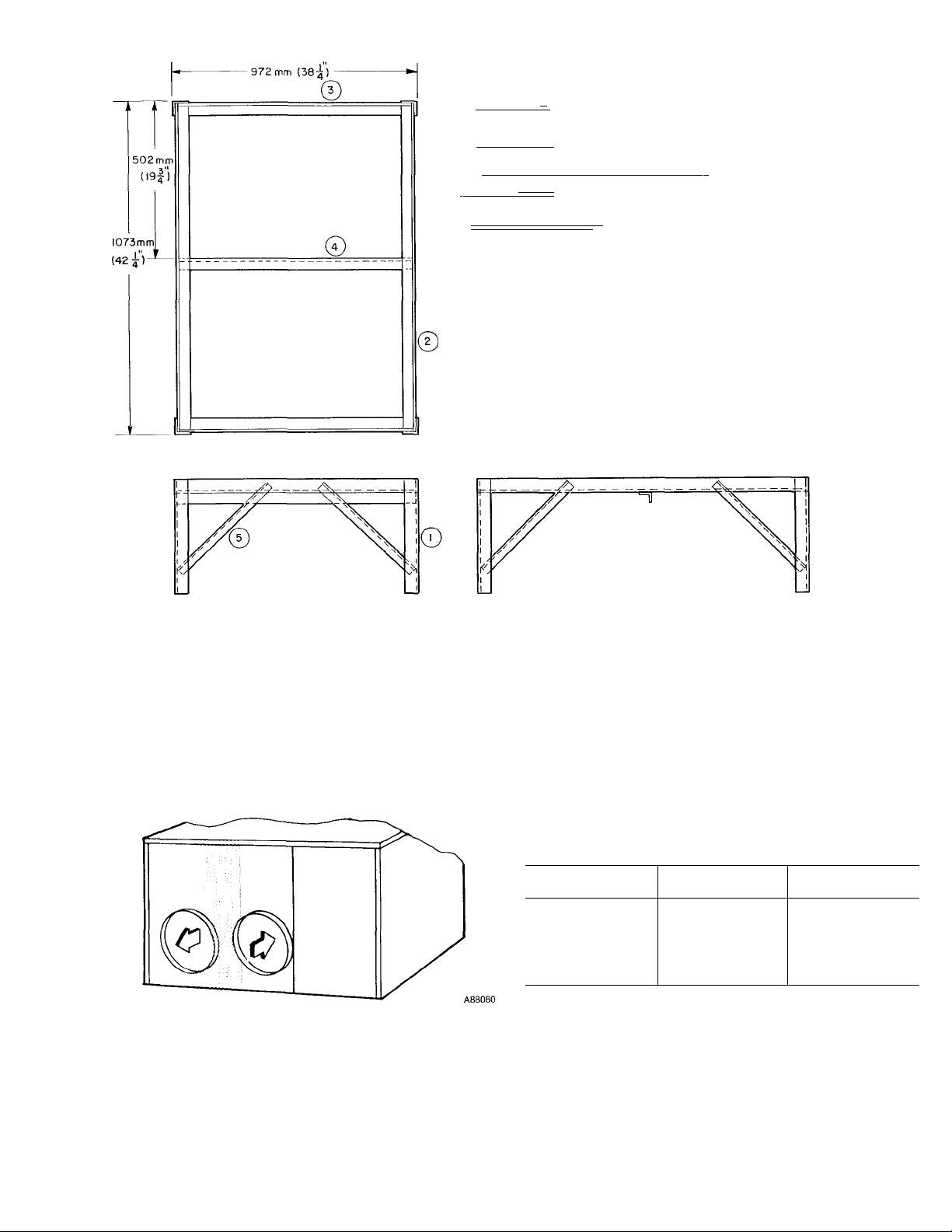

ON THE GROUND—Mount heat pump on an elevated

frame positioned on a level pad. See Fig. 2 for pad dimen

Fig. 2—Pad Dimensions

sions. Ensure pad does not obstruct coil slots in unit basepan. (Slots drain water during heating and defrost cycles.

See Fig. 2 for drain slot locations.) Construct pad to provide

clearance under basepan coil slots for drainage and ice

buildup. In areas where prolonged subfreezing temperatures

or snowfall occur, increase clearance to 12 to 18-in. by con

structing an angle-iron frame to support unit 12 to 18-in. off

base. Design cross angle of frame so as not to obstruct basepan coil slots. See Fig. 3 for recommended frame construc

tion. Alternate construction should follow dimensions.

Extend a 24-in. gravel apron around pad for condensate and

defrost water drainage field.

ON THE ROOF—Mount unit on a level platform or frame.

Elevate unit for proper clearance as described under ground

insteJlation above. Design roof and plan water runoff so as

to prevent unit and its duct flashing from sitting in water,

in accordance with eJl applicable codes.

Step 3—Make Ductwork Connections

CONNECT RETURN AND SUPPLY AIR DUCT

WORK—Connect ductwork to unit supply and return air

duct connections. Refer to Fig. 1 and Table 1 for unit supply

and return air connection sizes and locations.

Flanges are provided on Models 018-048 for round duct con

nections, on Model 060 for rectanguleu- duct connections.

Accessory duct flange kit is available for squeire or rectan

gular connections on 018-048 units. Refer to accessory

Installation Instructions on page 5 for connections to

ductwork.

Fig. 4 shows a typical duct system with 50QQ installed. Do

not operate unit longer than 5 minutes without ductwork or

damage to blower motor may result.

042

20x25

048

9 lbs 0 oz

20x25

20x20

(2) 15x 20 (2) 20 X 20

060

9 lbs 0 oz

Side-By-Side

Rectangular

13"/,eXl3’7,e

13"Ae X 277a

25x25

20x25

A88063

I =\ = = = ^ 305 mm (12") TO 610 mm (24") (4) REQ

I

^ ----- —---------------------------------------------------------------------'(411") (2) REQ

' I ---------------1 I 959mm (37|")(2)REQ

^ I

----------------------

gj I I - |-^ 406 mm (16") (8) REQ

material:

ANGLE IR0N-3L8mm(l^) TO 38mm (1^) COMM'L STD

WELD FRAME TOGETHER

PAINT WITH ZINC-RICH PAINT (RUSTPROOF)

-| 959mm(375 )(l) REQ.

r 38 mm (1-5) 3"

#

Fig. 3—Heat Pump Mounting Frame

When designing and installing ductwork, consider the

following:

1. When connecting ductwork to 042, 048 and 060 units,

do not drill deeper than one inch in shaded area shown

below. Coil may be damaged.

2.

Install field-supplied filters in return air ductwork. Rec

ommended sizes for filters are shown in Table 1.

3.

Avoid abrupt duct size increases and reductions.

Abrupt change in duct size adversely affects air

performance.

4.

Use flexible connectors between ductwork and unit to

prevent transmission of vibration. When electric heater

is installed, use fireproof canvas (or similar heat resis

tant material) connector between ductwork and unit

discharge connection. If flexible duct is used, insert a

sheet metal sleeve inside duct. Heat resistant duct con

nector (or sheet meted sleeve) must extend 24-in. from

electric heat element.

5. Size ductwork for cooling air quantity (cfm). The mini

mum air quantity for proper electric heater operation is

listed below. Heater limit switches may trip at air

quantities below those recommended.

MODEL

50QQ

018

024

030

036

042

048

060

INDOOR FAN

SPEED SETTING

Low 1400

MIN CFM

675

875

875

1400

1700

1800

6. Insulate and weatherproof all external ductwork. Insu

late and cover with a vapor barrier all ductwork pass

ing through unconditioned spaces. Follow latest

SMACNA (Sheet Metal and Air Conditioning Contrac

tors National Association) minimum installation stand

ards for residential heating and air conditioning

systems.

7. Secure all ducts to building structure. Weatherproof

duct openings in wall or roof according to good con

struction practices.

PARAT NO.

99TZ900521

99T2900571

50LQ90002106

50LQ90001106

38RQ900012

50LQ90000106 Outdoor Thermostat (Six 50LQ900001)

50LQ900031

32LT900301

32LT900611

50YM900051

88EM0050MA01

88EM0075MA01

88EM0100MA01

88EM0150MA01

88EM0200MA01

88EM0250MA01

88EM0100EA01

88EM0150EA01

88EM0200EA01

88EM0250EA01

88EM0100FA01

88EM0150FA01

88EM0200FA01

88EM0250FA01

HC95DE023

HC95DD058

HC95DE088

HC95DE208

HN61HB510

HN61KB021

HN61KB075

♦Available through Service Parts

NOTE: Electric heaters are rated at 240 and 480 volts

Thermostat 1 -stage cooling, automatic changeover

Subbase 2-stage heating, Carrier, Honeywell

Thermostat 2-stage cooling, manual changeover

Subbase 2-stage heating, Carrier, Honeywell

Solid-State Time Guard® Control (Six 50LQ900021)

Service Sentry (Six 50LQ900011)

Supplemental Heat Relay—Used with 25 kW heater and 2 outdoor thermostats

Reversible Filter Drier and AccuRater Assembly

Motormaster® Head Pressure Control

Motormaster Head Pressure Control

Duct Flange Kit

Electric Heater—5 kW, 240-1

Electric Heater—7.5 kW, 240-1

Electric Heater—10 kW, 240-1

Electric Heater—15 kW, 240-1

Electric Heater—20 kW, 240-1

Electric Heater—25 kW, 240-1

Electric Heater—10 kW, 240-3

Electric Heater—15 kW, 240-3

Electric Heater—20 kW, 240-3

Electric Heater—25 kW, 240-3

Electric Heater—10 kW, 480-3

Electric Heater—15 kW, 480-3

Electric Heater—20 kW, 480-3

Electric Heater—25 kW, 480-3

Start Capacitor^

Start Capacitor^

Start Capacitor^

Start Capacitor^

Start Relays

Start Relays

Start Relays

Table 2—Accessories

DESCRIPTION

MODEL

50QQ

All

All

All

All

060

All

All

All 208/230-v

All 460-v

018-048

All

All

All

030-060

036-060

060

030-060

030-060

042-060

060

036-060

036-060

036-060

060

018

024, 030

036-048

060

018

024-048

060

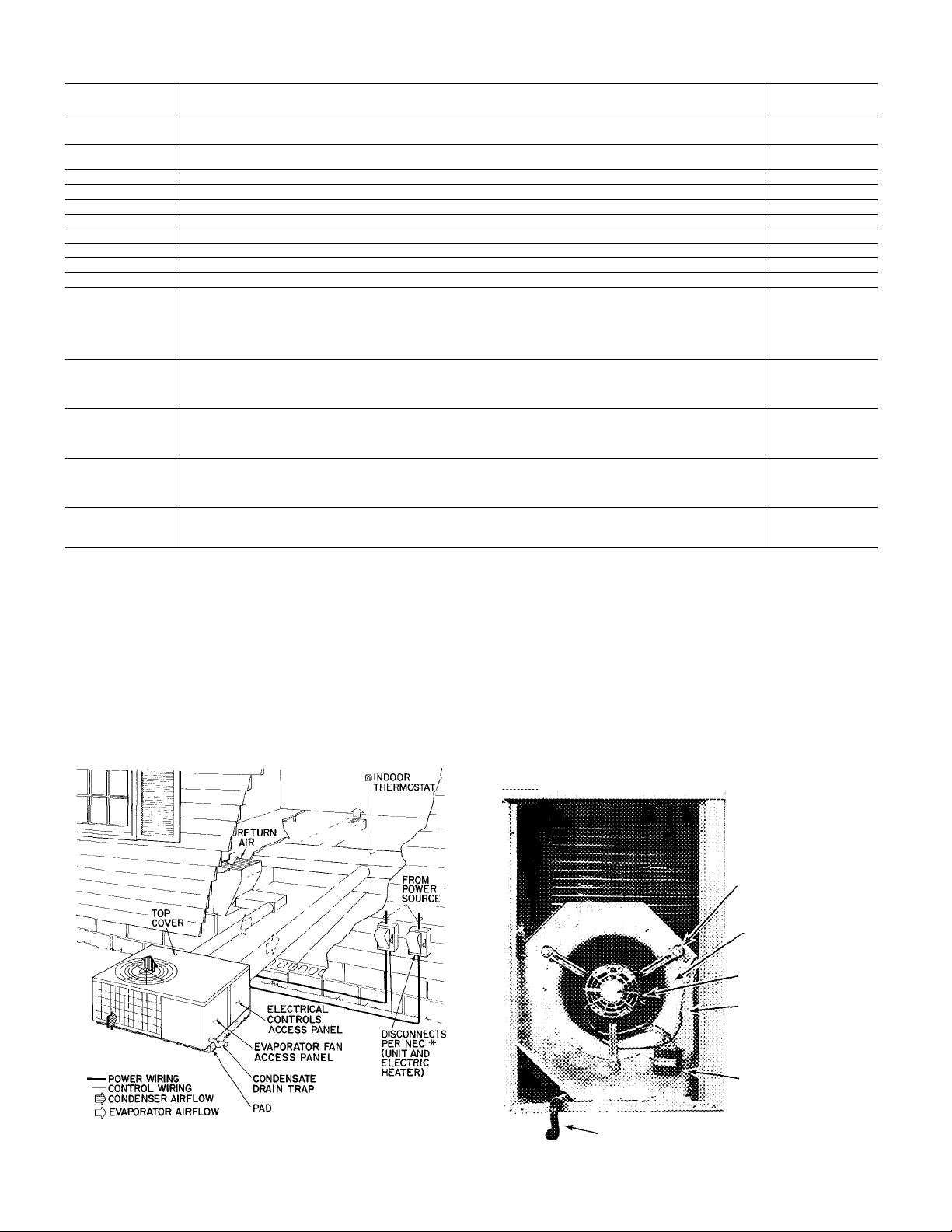

Step 4—Provide for Cooling Cycle condensate Disposal-

Condensate may be drained directly onto gravel apron or

connected by drain line(s) to a dry well. Follow local codes.

CONNECT DRAIN LINE to rubber condensate drain fit

ting on side of unit (see Fig. 5). Use clamp provided. Install

factory-supplied condensate trap (taped to indoor fan com

partment for shipment) at end of dredn line. If a drain line is

not used, connect condensate trap to unit drain fitting as

shown in Fig. 4.

FAN MOTOR

MOUNTING BOLTS

ORIFICE RING

FAN MOTOR

BLOWER

HOUSING

CAPACITOR

♦Separate disconnect per NEC required for electric heater

Fig. 4—Typical Installation

CONDENSATE TRAP

Fig. 5—Condensate Drain and Trap Details

m

step 5—Make Electrical Connections—Install field wiring

in compliance with loced and national fire, safety and electri

cal codes. Be sure voltage to unit is within ± 10% of volt

age indicated on nameplate. Contact local power company

for correction of improper line voltage.

Operation of unit on improper line voltage constitutes

abuse and may cause unit damage that could affect war

ranty.

See Table 3 for recommended fuse sizes.

INSTALL A BRANCH CIRCUIT DISCONNECT PER

NEC of adequate size to handle unit starting current. Pro

vide a separate disconnect for unit and for each accessory

electric heater circuit as required. (See electric heater Instal

lation, Start-Up and Service Instructions.) Locate disconnect(s) within sight from and readily accessible from the

unit, per Section 440-14 of National Electriced Code (NEC).

ROUTE LINE POWER LEADS INTO UNIT-Extend

leads from disconnect per NEC through hole provided

(Fig. 1) into line wiring splice box. Use copper wire only.

CONNECT GROUND LEAD TO GROUND LUG in splice

box for safety. Connect power wiring. See Fig. 7. Connect

line power leads to yellow and black pigtails on single-phase

units.

SET INDOOR FAN MOTOR SPEED-Refer to page 3 for

minimum edlowable eiir quantity for safe electric heater

operation. Indoor fan motor is factory wired for low-speed

operation on all models. Fan motor is equipped with spadetype speed selector terminals marked 1, 2 and 3 on 3-speed

motors (042 and 048), and 1 and 2 on 2-speed motors (018,

024, 030, 036 and 060).

For electric heater operation, set motor at: LOW—sizes 018

through 042, and 060; MED—size 048.

MOTOR TERMINAL

FAN SPEED

(3-speed, 042, 048)

FAN SPEED

(2-Speed, 018-036, 060)

1

High

High

2

Medium

Low

3

Low

—

For air delivery performeuice, refer to Table 4.

ROUTE CONTROL POWER WIRES (24v) through 78-in.

connector provided in unit. Fig. 1. Extend leads to unit con

trol wiring terminal boeu-d in unit control box. Fig. 6. Con

nect leads to terminal board as shown in Fig. 8.

The unit transformer supplies 24-v power for complete sys

tem including accessory electric heater. A resettable circuit

breaker is provided in the 24-v circuit.

RUN

HEATER

CAPACITOR

CONTROL

VOLTAGE

CIRCUIT

BREAKER

CONTROL

BOARD

SUPPLE

MENTAL

HEAT

RELAY

SERVICE

SENTRY

UNIT

GROUNDING

LUG

START

THERMISTOR

TRANSFORMER

CONTACTOR

HEATER

CONTROL RELAY

TIME GUARD

LIM^i7cONTROL S^PLT^AGE GROUNDING

HEATER

connection

Fig. 6—Control Section

ACCESSORY DUCT FLANGE KIT INSTALLATION018-048

1. Refer to Fig. 8 for duct adapter dimensions and hole

locations.

2. Mark hole locations.

MODEL

5000

018

024

030

036

042

048

060

030

036

042

048

060

036

042

048

060

FLA —Full Load Amps

HACR—Heating, Air Conditioning, Refrigeration

IFM —indoor Fan Motor

LRA —Locked Rotor Amps

MCA —Minimum Circuit Amps

OFM —Outdoor Fan Motor

RLA —Rated Load Amps

V-PH

208/230-1 253 187 82 0

208/230-3 253 187 79 5

460-3

Max Min LRA

506 414 398

Table 3—Unit Electrical Data (60 Hz)

OPER

VOLTAGE*

COMPRESSOR

r RLA

50 0

53.0

65.0

106.0

1100

178.0

53 0

67 5

90.0

124.0

33.8

45 0

62.0

9.3 3.5 1 4

11 6 35

13.9

17.2

20 7 35

22.4 4.6 2.2

30.2 6.7

81

108

12.0

146 4.6

20.5 6.7

5.0

63 20

7.0 20

10.3

*Permissibie limits of the voltage range at which units will operate

satisfactorily.

tMaximum dual element fuse

NOTE: Use copper wire only.

IFM

FLA

35 1.4

35 22

35

35

46

1 7

3.4

OFM

FLA

1.4

22

2.8

1 4

2.2

2.2

22

2.8

07

1.3

1.3

1.3

MAX FUSEt

OR HACR CKT

BKR AMPS

25

30

35

40

50

50

60

20

25

30

35

45

15

15

15

25

MCA

165

19.4

22.2

27 2

31.6

34.8

47.3

15.0

19 2

21.8

25 0

35.1

8.7

11 2

12.1

17.6

Loading...

Loading...