Page 1

SERVICE MANUAL

ZOLL MEDICAL CORPORATION

9650-0450-01 Rev P

Page 2

© Zoll Medical Corporation, 2004. All rights reserved.

Warranty (U.S. Only)

(a) ZOLL Medical Corporation warrants to the original equipment purchaser that beginning on the date of installation, or thirty (30) days after the date of shipment from

ZOLL Medical Corporation's facility, whichever first occurs, the equipment (other than accessories and electrodes) will be free from defects in material and workmanship

under normal use and service for the period of one (1) year. Durin g such peri od ZOLL Medical Corpor ation will, at no charge to the customer, either repair or replace (at

ZOLL Medical Corporation's sole option) any part of the equipment found by ZOLL Medical Corporation to be defective in material or workmanship. If ZOLL Medical

Corporation's inspection detects no defects in material or workmanship, ZOL L Medical Corporation's regular service char ges shall apply. (b) ZOLL Medical Corporation

shall not be responsible for any equipment defect, the failure of the equipment to perform any function, or any other nonconformance of the equipment, caused by or

attributable to: (i) any modification of the equipment by the customer, unless such modification is made with the prior written approval of ZOLL Medical Corporatio n; (ii)

the use of the equipment with any associated or complementary equipment, (iii) installation or wiring of the equipment other than in accordance with ZOLL Medical

Corporation's instructions. (c) This warranty does not cover items subject to normal wear and burnout during use, including but not limited to lamps, fuses, batteries, patient

cables and accessories. (d) The foregoing warranty constitutes the exclusive remedy of the customer and the exclusive liability of ZOLL Medical Corporation for any

breach of any warranty related to the equipment supplied hereunder. (e) Limitation of Liability: ZOLL shall not in any event be liable to Purchaser, nor shall Purchaser

recover, for special, incidental or consequential damages resulting from any breach of warranty, failure of essential purpose, or under any other legal theory including but

not limited to lost profits, lost savings, downtime, goodwill, damage to or replacement of equipment and property, even if ZOLL has been advised of the possibility of such

damages.

THE WARRANTY SET FORTH HEREIN IS EXCLUSIVE AND ZOLL MEDICAL CORPORATION EXPRESSLY DISCLAIMS ALL OTHER WARRANTIES

WHETHER WRITTEN, ORAL, IMPLIED, OR STATUTORY, INCLUDING BUT NOT LIMITED TO ANY WARRANTIES OF MERCHANTABILITY OR FITNESS

FOR A P ARTICULAR PURPOSE.

For additional information, please call ZOLL Medical Corporation at 1-800-348-9011 (in Massachusetts 1-978-421-9655). International customers should call the nearest

authorized ZOLL Medical Corporation service center.

Software License

Read this License agreement carefully before operating any of the M Series products.

Software incorporated into the system is protected by copyright laws and international copyright treaties as well as other intellectual property laws and treaties. This

software is licensed, not sold. By taking delivery of and using this system, the Purchaser signifies agreement to and acceptance of the following terms and conditions:

Grant of License: In consideration of payment of the software license fee which is part of the price paid for this product ZOLL Medical Corporation grants the Purchaser

a non-exclusive license, without right to sublicense, to use the system software in object-code form only.

Ownership of Software/Firmware: Title to, ownership of and all rights and interests in the system software and all copies thereof remain at all times vested in the

manufacturer, and Licensors to ZOLL Medical Corporation and they do not pass to Purchaser.

Assignment: Purchaser agrees not to assign, sub-license or otherwise transfer or share its rights under the license without the express written permission of ZOLL Medical

Corporation.

Use Restrictions: As the Purchaser, you may physically transfer the products from one location to another provided that the software/firmware is not copied. You may not

disclose, publish, translate, release or distribute copies of the software/firmware to others. You may not modify , adapt, translate, reverse engineer, decompile, crosscompile,

disassemble or create derivative works based on the software/firmware.

No Implied License

Possession or purchase of this device does not convey any express or implied license to use the device with replacement parts which would, alone, or in combination with

this device, fall within the scope of one or more of the patents relating to this device.

Page 3

TABLE OF CONTENTS

PREFACE ....................................................................................................................................................................................... V

Overview ..............................................................................................................................................................................................v

Safety Considerations ...........................................................................................................................................................................v

Additional Reference Material ........................................................................................................................................................... vi

Conventions ....................................................................................................................................................................................... vii

Service Policy Warranty .................................................................................................................................................................... vii

Technical Service .............................................................................................................................................................................. vii

Technical Service for International Customers ................................................................................................................................ viii

CHAPTER 1 MAINTENANCE TESTS .............................................................................................................................................1

Overview ..............................................................................................................................................................................................1

Before You Begin the Maintenance Tests ............................................................................................................................................2

Equipment You Need to Perform the Maintenance Tests ....................................................................................................................2

Equipment You Need for the M Series Options Maintenance Tests ....................................................................................................3

CHAPTER 2TROUBLESHOOTING ................................................................................................................................................37

Overview ............................................................................................................................................................................................37

Troubleshooting ..................................................................................................................................................................................38

Zoll M Series Error Messages ............................................................................................................................................................42

CHAPTER 3DISASSEMBLY PROCEDURES ..................................................................................................................................59

Overview ............................................................................................................................................................................................59

Required Equipment ...........................................................................................................................................................................60

Parts That May Need Replacing After Disassembly ..........................................................................................................................60

Safety Precautions ..............................................................................................................................................................................61

Overview of Modules .........................................................................................................................................................................62

1. Removing the ZIF Keeper ............................................................................................................................................65

2. Removing the Front Panel ............................................................................................................................................66

2A.Removing the Display .................................................................................................................................................67

2B.Removing the Control Board ......................................................................................................................................68

3. Removing the Upper Housing Assembly .....................................................................................................................70

i

Page 4

M Series Service Manual

4. Removing the System Board Assembly .......................................................................................................................71

5. Removing the Battery Interconnect Board Assembly ..................................................................................................73

6. Removing the High Voltage/Charger Assembly .........................................................................................................74

7. Removing the High Voltage Module Assembly ..........................................................................................................76

8. Removing the High Voltage Capacitor Assembly .......................................................................................................77

9. Removing the System Interconnect Board ...................................................................................................................78

10.Removing the Printer/Recorder Motor ........................................................................................................................79

11.Removing the Lower Housing Assembly ....................................................................................................................80

12.Removing the Print Head Assembly ............................................................................................................................81

13.Removing the PCMCIA Card Slot Assembly .............................................................................................................82

14.Removing the Paddle Release Latch ...........................................................................................................................83

CHAPTER 4 REPLACEMENT PARTS ...........................................................................................................................................85

Overview ............................................................................................................................................................................................85

Replacement Parts ..............................................................................................................................................................................86

Field Replacement Parts .....................................................................................................................................................................90

CHAPTER 5FUNCTIONAL DESCRIPTION ...................................................................................................................................93

Overview ............................................................................................................................................................................................93

Main System Board ............................................................................................................................................................................94

Main System Board Functions ...........................................................................................................................................................96

Power Supply ................................................................................... ...................................................................................................98

ECG Front End ...................................................................................................................................................................................99

Multifunction Electrode (MFE)/PADS (System Board and High Voltage Module) .........................................................................99

CPU and EPU .....................................................................................................................................................................................99

High Voltage Module .......................................................................................................................................................................100

Defibrillator Charging and Discharging ...........................................................................................................................................101

High Voltage Capacitor Monitor ......................................................................................................................................................102

Pacer/Defibrillator Control Signals ..................................................................................................................................................103

Internal Discharge Resistor Module .................................................................................................................................................105

AC/DC Charger Module ...................................................................................................................................................................105

System Interconnect Module ............................................................................................................................................................105

Stripchart Recorder ...........................................................................................................................................................................106

PCMCIA Slots ..................................................................................................................................................................................106

Front Panel and Controls PWBA ......................................................................................................................................................106

M Series Options ............................................................... ...............................................................................................................106

ii

Page 5

M Series Service Manual

Isolated Power Supply Module .........................................................................................................................................................107

12 Lead Option .................................................................................................................................................................................107

Pulse Oximetry (SpO2) .......................................................... ..........................................................................................................108

End Tidal Carbon Dioxide (EtCO2) .................................................................................................................................................108

Biphasic Waveform ......................................... .................................................................................................................................109

INDEX ..........................................................................................................................................................................................113

APPENDIX ...................................................................................................................................................................................117

Overview ..........................................................................................................................................................................................117

Interconnect Diagram for the M Series Monophasic Unit ...............................................................................................................118

Interconnect Diagram for the M Series Biphasic Unit .....................................................................................................................119

Interconnect Diagram for the M Series CCT Biphasic Unit ............................................................................................................120

iii

Page 6

M Series Service Manual

iv

Page 7

M Series Service Manual

Overview

ZOLL Medical Corporation’s M Series Service Manual is intended for the service technician whose responsibility is

to identify malfunctions and/or make repairs at the subassembly level. The Zoll M Series Service Manual has five

main sections and one appendix.

Preface—Contains safety warnings and an overview of the manual’s contents. Be sure to review this section

thoroughly before attempting to use or service the M Series unit.

Chapter 1—Maintenance T ests explains how to check the defibrillator’s performance using a series of recommended

checkout procedures to be conducted every six months.

Chapter 2—Troubleshooting provides a listing of the procedures and error messages to help the service technician

detect faults and repair them.

Chapter 3—Disassembly Procedures describes step-by-step procedures for removing subassemblies from the

M Series unit.

Chapter 4—Replacement Parts List displays a complete list of ZOLL part numbers for field replaceable parts

available for the M Series unit, allowing the service person to identify and order replacement parts from ZOLL.

Chapter 5—Functional Description provides technical descriptions for the M Series major subassembly modules.

Appendix A—M Series Operator’s Manual.

Preface

Safety Considerations

The following section describes general warnings and safety considerations for operators and patients. Service

technicians should review the safety considerations prior to servicing any equipment and read the manual carefully

before attempting to disassemble the unit. Only qualified personnel should service the M Series unit.

Federal (U.S.A.) law restricts this unit for use by or on the order of a physician.

Safety and effectiveness data submitted by ZOLL Medical Corporation to the Food and Drug Administration (FDA)

under section 510(K) of the Medical Device Act to obtain approval to market is based upon the use of ZOLL

accessories such as disposable electrodes, patient cables and batteries. The use of external pacing/defibrillation

v

Page 8

M Series Service Manual

electrodes and adapter units from sources other than ZOLL is not recommended. ZOLL makes no representations or

warranties regarding the performance or effectiveness of its products when used in conjunction with pacing/

defibrillation electrodes and adapter units from other sources. If unit failure is attributable to pacing/defibrillation

electrodes or adapter units not manufactured by ZOLL, this may void ZOLL's warranty.

Only qualified personnel should disassemble the M Series unit.

WARNING! This unit can generate up to 4500 volts with sufficient current to cause lethal shocks.

All persons near the equipment must be warned to “STAND CLEAR” prior to discharging the defibrillator.

Do not discharge the unit’s internal energy more than three times in one minute or damage to the unit may result.

Do not discharge a battery pack except in a Base PowerCharger

Do not use the M Series in the presence of flammable agents (such as gasoline), oxygen-rich atmospheres, or

flammable anesthetics. Using the unit near the site of a gasoline spill may cause an explosion.

Do not use the unit near or within puddles of water.

NOTE The M Series is protected against interference from radio frequency emissions typical of two-way radios and cellular

phones (digital and analog) used in emergency service/public safety activities. Users of the M Series should assess the

unit’s performance in their typical environment of use for the possibility of radio frequency interference from

high-power sources. Radio Frequency Interference (RFI) may be observed as shifts in monitor baseline, trace

compression, or transient spikes on the display.

4x4

or compatible ZOLL Battery Charging/Testing unit.

Additional Reference Material

In addition to this guide, there are several other components to the Zoll M Series documentation. They include:

• Operator’s Guide - A comprehensive reference work that describes all the user tasks needed to operate the M Series.

• Configuration Guide - Describes the M Series features and functions whose operation can be customized by

authorized users.

vi

Page 9

M Series Service Manual

Conventions

WARNING! Warning statements describe conditions or actions that can result in personal injury or death.

CAUTION Caution statements describe conditions or actions that can result in damage to the unit.

NOTE Notes contain additional information on using the defibrillator.

Service Policy Warranty

In North America: Consult your purchasing agreement for terms and conditions associated with your warranty. Outside

of North America, consult ZOLL authorized representative.

In order to maintain this warranty , the instructions and procedures contained in this manual must be strictly followed.

For additional information, please call the ZOLL Technical Service Department 1-800-348-9011 in North America.

Technical Service

If the ZOLL M Series unit requires service, contact the ZOLL Technical Service Department:

Telephone: 1-978-421-9655; 1-800-348-9011

Fax 1-978-421-0010

Have the following information available for the Technical Service representative:

• Unit serial number.

• Description of the problem.

• Department where equipment is used.

• Sample chart recorder strips documenting the problem, if applicable.

• Purchase Order to allow tracking of loan equipment.

• Purchase Order for a unit with an expired warranty.

vii

Page 10

M Series Service Manual

If the unit needs to be sent to ZOLL Medical Corporation, obtain a service order request number from the Technical

Service representative. Return the unit in its original container to:

Technical Service for International Customers

International customers should return the unit in its original container to the nearest authorized ZOLL Medical

Corporation Service Center. To locate an authorized service center, contact the International Sales Department at

ZOLL Medical at the above address.

Units are available on loan while your unit is being repaired.

ZOLL Medical Corporation

269 Mill Road

Chelmsford, Massachusetts 01824-4105

Attn: Technical Service Department

Telephone: 1-800-348-9011; 1-978-421-9655 FAX: 978-421-0010

viii

Page 11

M Series Service Manual

Overview

The M Series has two checkout procedures: the operator’s shift checklist and the extensive six-month maintenance

tests checkout procedures.

Because the M Series units must be maintained ready for immediate use, it is important for users to conduct the

Operator’s Shift Checklist procedure at the beginning of every shift. This procedure can be completed in a few minutes

and requires no additional test equipment. (See the ZOLL M Series Operator’s Guide for the Operator’s Shift

Checklist.)

A qualified biomedical technician must perform a more thorough maintenance test checkout every six months to

ensure that the functions of the M Series unit work properly. This chapter describes the step by step procedures for

performing the six month maintenance test checkout. Use the checklist at the back of this document (ZOLL M Series

Maintenance Tests Checklist) to record your results of the maintenanc e tests.

Chapter 1

Maintenance Tests

This chapter describes the following maintenance tests:

• 1. Physical Inspection of the Unit

• 2. Front Panel Button Test

• 3. 3, 5, and 12 Leads Test

• 4. Power Supply Test

• 5. Leakage Current Test

• 6. Paddles Test

• 7. Heart Rate Display Test

• 8. Calibrating Pulses on Strip Chart Test

• 9. Notch Filter Test

• 10. Heart Rate Alarm Test

1

Page 12

M Series Service Manual

• 11. Defibrillator Self Test

• 12. Synchronized Cardioversion Test

• 13. Shock Test

• 14. Summary Report Test

• 15. Advisory Message Test

• 16. Pacer Test

•17. SpO

•18. EtCO

Before You Begin the Maintenance Tests

• Assemble the tools or specialized testing equipment listed in the “Equipment You Need to Perform the Maintenance

• Keep an extra fully charged ZOLL M Series battery available.

• Schedule an hour to conduct the entire maintenance test.

• Photocopy the checklist at the back of this document and use the copy to record your results. As you conduct each

Monitor Test

2

Monitor Test

2

Tests” section shown below.

step of a procedure, mark the Pass/Fail/NA check boxes on your checklist and then save it for your maintenance file.

• Perform the tests in the order presented.

• Perform all the steps of each test procedure.

• Complete all the steps of the procedure before evaluating the test results.

Equipment You Need to Perform the Maintenance Tests

For testing purposes, you can substitute an equivalent device.

• Zoll Medical Electrode Adapter from Dynatech Nevada Inc. (DNI part number 3010-0378).

• Dynatech Impulse 4000 Defibrillator Analyzer with 1.06 software or higher.

•Bio-Tek

•Bio-Tek

• Novametrix Medical Systems, Inc. Capnostat Simulator TB1265/7100 or equivalent. (For EtCO

®

601 Pro Series International Safety Analyzer.

®

Index 2PFE SpO2 Simulator or equivalent. (For SpO2 units only.)

2

2

units only.)

Page 13

M Series Service Manual

• ECG Simulator; 12 Lead Simulator for 12 Lead test (e.g., Symbio CS1201).

• Stop watch.

• Standard series II PC flash memory cards.

• PCMCIA card reader and PC.

• Zoll Data Control (ZDC) for Windows

• Phillips #1 screwdriver.

• Phillips #2 screwdriver.

• Flatblade screwdriver.

• Needle nose pliers without teeth.

• Orange (wooden) sticks.

Equipment You Need for the M Series Options Maintenance

®

software from Pinpoint T echnologies, Version 1.5 or higher (no equivalent)

or Zoll Data Control (ZDC) for DOS software, Version 5.5 or higher (no equivalent).

Tests

•SpO2 cable and sensor (if option is installed).

•EtCO

• Paddles.

•Printer Paper.

• Battery.

• AC line cord.

• 3 lead, 5 lead and 12 lead ECG cables. (12 lead cable needed if 12 lead option is installed.)

cable and sensor (if option is installed).

2

3

Page 14

M Series Service Manual

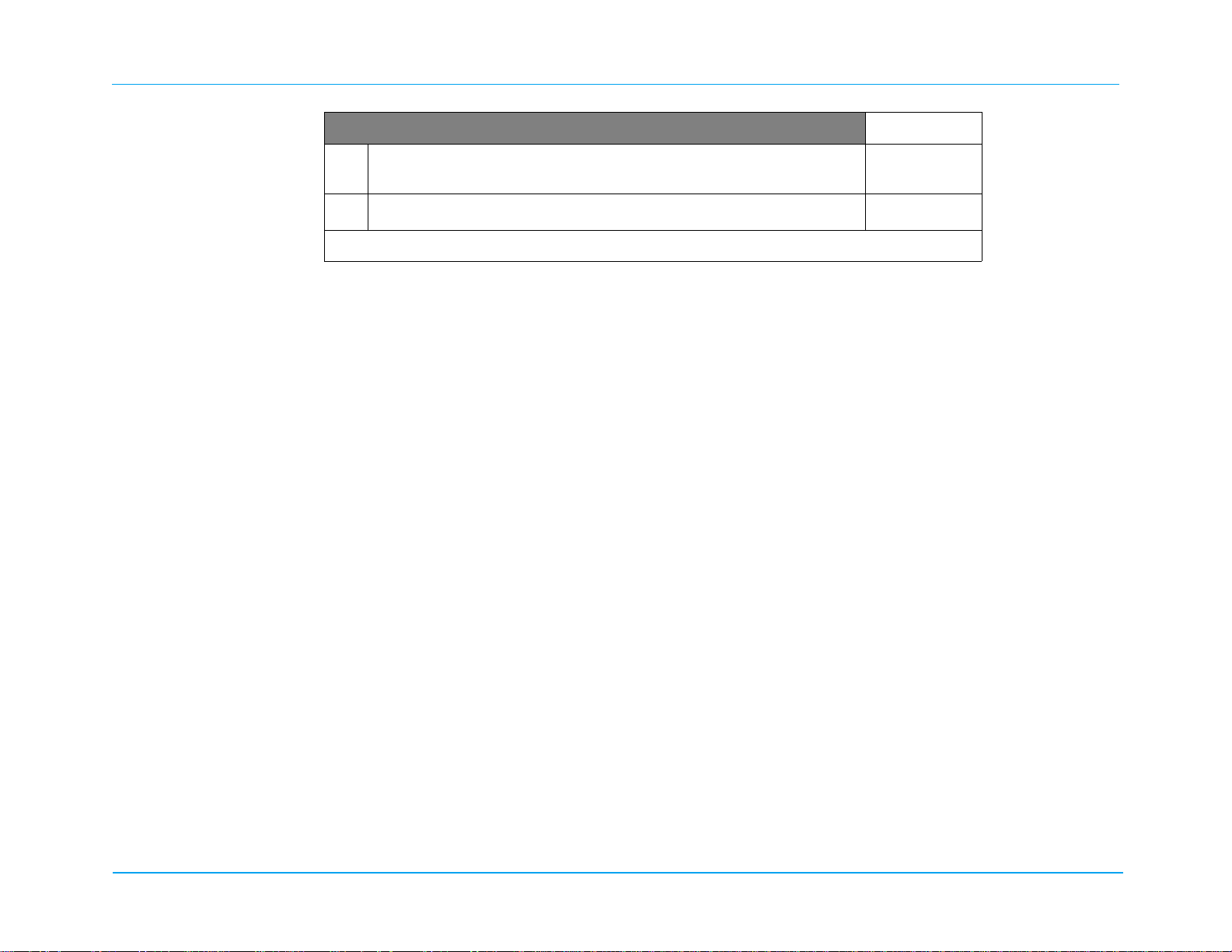

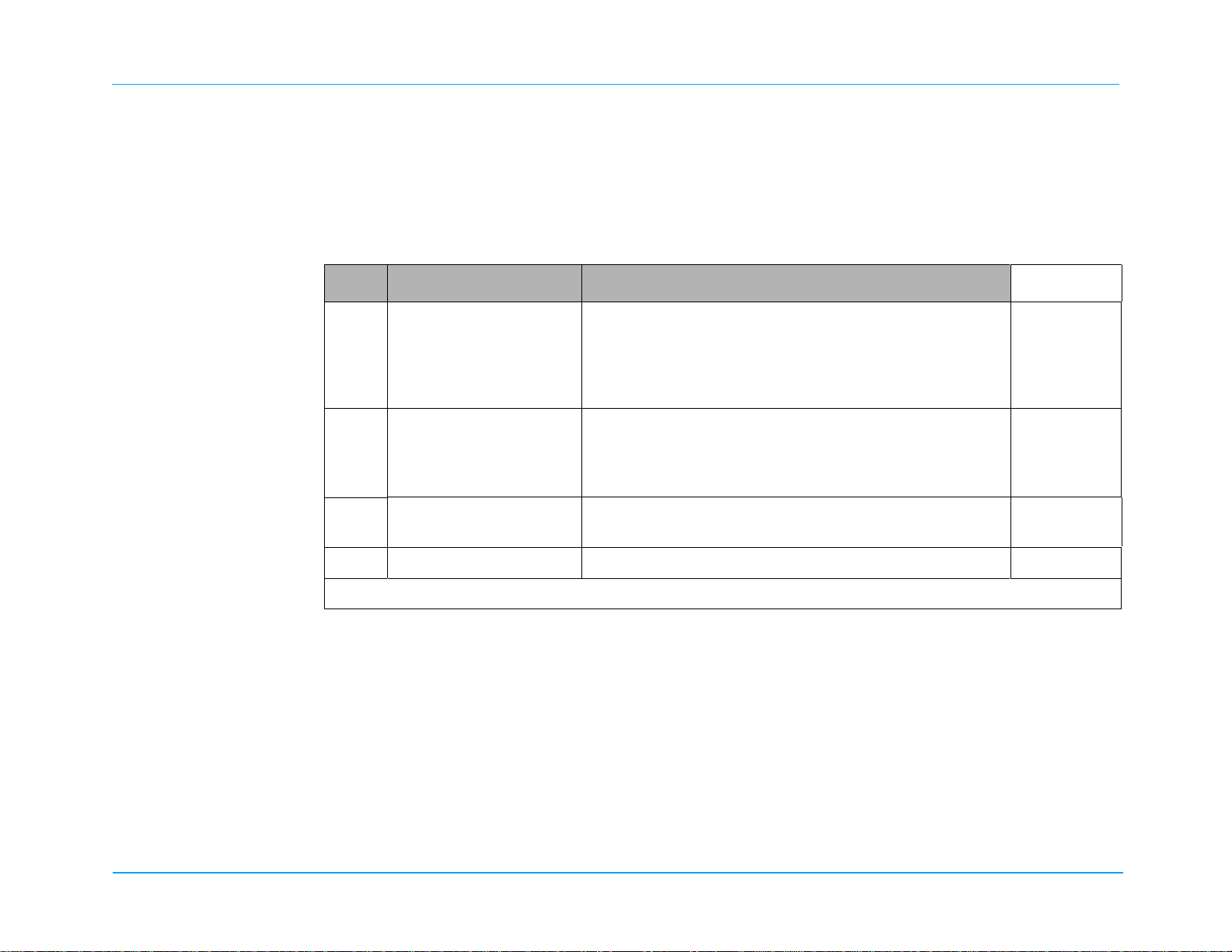

1.0 Physical Inspection of the Unit

Tools Needed None.

Test Setup None.

Observe this... Pass/Fail

1.1 Housing

Is the unit clean and undamaged?

1.2 Does the unit show signs of excessive wear?

1.3 Does the handle work properly?

1.4 Does the recorder drawer open and close properly?

1.5 Are input connectors clean and undamaged?

1.6 Are there any cracks in the housing?

1.7 Do the front panel or selector switches have any damage or cracks?

1.8 Are there any loose housing parts?

1.9 Do the paddle latches work properly?

1.10 Paddles

Do the adult and pedi plates have major scratches or show signs of damage?

1.11 Do the adult shoes slide on and off easily to expose the covered pedi plates?

oo

oo

oo

oo

oo

oo

oo

oo

oo

oo

oo

1.12 Are the paddles clean (e.g., free of gel) and undamaged? (if applicable)

1.13 Cables

Are all cables free of cracks, cuts, exposed or broken wires?

1.14 Are all bend/strain reliefs undamaged and free of excessive cable wear?

4

oo

oo

oo

Page 15

M Series Service Manual

Observe this... Pass/Fail

1.15 Battery

Is the ZOLL battery fully charged?

1.16 Is the battery seated in the battery well correctly?

Record your results on the Maintenance Test Checklist.

oo

oo

5

Page 16

M Series Service Manual

2.0 Front Panel Button Test

Tools Needed None.

Test Setup Do the following:

• Install strip chart paper into the recorder tray.

• Install the battery in the unit or connect the A/C power cord to the unit and then plug the cord into an electrical outlet.

• Connect the universal cable and ECG cable (3 lead, 5 lead, or 12 lead) to the ZOLL simulator, or Dynatech Impulse

4000 Analyzer (or equivalent).

Do this... Observe this... Pass/Fail/NA

2.1 Turn the selector switch to

MONITOR.

(For AED units, turn the

selector switch to ON and

select Manual mode.)

2.2 Press the LEAD button;

three times for the 3 lead

cable and seven times for

the 5 lead cable.

2.3 Connect the 12 lead cable to

unit and simulator. Press the

LEAD button and select the

lead for each of the 12 lead

settings.

2.4 Set the simulator to NSR of

120 BPM. T o check the size

of the ECG waveform,

press the SIZE button.

Listen for 4 beep tones. PADS and MONITOR display on the

monitor.

NOTE: PADS is a factory default setting.

Each time you press the LEAD button, a different lead number

appears under the LEAD heading on the display.

PADS, I, II, III will display a 3 lead ECG cable if connected or no

ECG cable is connected.

PADS, I, II, III, AVR, AVL, AVF, V1 will display a 5 lead ECG

cable.

A 12 Lead cable will display PADS, I, II, III, AVR, AVL, AVF,

VI, V2, V3, V4, V4, V5, V6.

As you press the SIZE button five times (0.5, 1.0, 1.5, 2.0, 3.0),

note that the size of the ECG waveform appropriately changes on

the display.

oo

oo

ooo

ooo

6

Page 17

M Series Service Manual

Do this... Observe this... Pass/Fail/NA

2.5 Press the ALARM

SUSPEND button.

2.6 Press the RECORDER

button (if equipped).

2.7 Open the paper tray.

Press RECORDER button.

2.8 Close the paper tray.

Press RECORDER button.

2.9 Press RECORDER button. Strip chart paper stops flowing out of paper tray.

2.10 Press the VOLUME

softkey.

To increase the volume of

the beep, press the Inc.

softkey.

Bell changes from disabled to enabled. If the alarm sounds, press

the ALARM SUSPEND button to turn it off. The alarm will only

be suspended for 90 seconds at this point. Press and hold the

ALARM SUSPEND button for 3 seconds to disable alarms.

The strip chart paper moves out of the unit from the paper tray.

Check that the correct time, date, ECG lead annotation and

waveform are recorded on the paper. (Set Time and Date, if

necessary.)

CHECK RECORDER message appears on the monitor.

Strip chart paper flows out of paper tray. Verify that the CHECK

RECORDER message no longer displays.

The volume bar graph displays.

Audible beep when the QRS wave displays. The bar graph

increases on the display indicating an increase in volume. This

action does not increase the volume which is normal.

Note: The QRS tone is on or off. There is no gradual change in

volume. If equipped, voice prompts are gradual. Note: The voice

volume has 5 settings. Setting 3 is in the mid-range.

ooo

ooo

ooo

ooo

ooo

oo

2.11 To decrease the volume of

the beep, press the Dec.

softkey.

2.12 Press the CONTRAST

button.

The bar graph decreases on the display indicating a decrease in

volume. The volume shuts off at the last bar; otherwise, the

volume is the same as originally set.

Contrast menu displays.

7

oo

oo

Page 18

M Series Service Manual

Do this... Observe this... Pass/Fail/NA

2.13 (For LCD monitors only.)

Press the CONTRAST

button.

To increase the contrast of

the display, press the Inc.

softkey.

2.14 To decrease the contrast of

the display, press the Dec.

softkey.

2.15 Press the SUMMARY

button (if available).

2.16 Press the CODEMARKER

button (if available).

2.17 Connect A/C current and

install the battery. Turn the

unit off.

Background light and characters display.

The contrast increases on the monitor display (LCD).

The brightness increases on the monitor display (EL).

The bar graph increases on the display indicating an increase in

contrast.

NOTE Electro luminescence (EL) displays have only two settings

independent of the bar graph without any gradual changes.

If EL brightness is already set to its highest level,

brightness will not change.

The bar graph decreases on the display indicating a decrease in

contrast (LCD) and brightness (EL). The display contrast and

brightness changes.

Summary menu displays on the monitor showing the summary

report options.

Code marker menu displays.

CHARGER ON indicator lights.

The amber or green lights illuminate.

Note: If both lights flash ON/OFF, the unit is defective or no

battery is installed.

For LCD

monitors

ooo

ooo

oo

ooo

ooo

ooo

2.18 If applicable, connect D/C

current and install the

battery. Turn the unit off.

2.19 Remove the battery. Note that both charge lights (green and amber) flash alternately.

2.20 Replace the battery and the

turn unit on.

CHARGER ON indicator lights.

The amber or green lights illuminate.

The yellow light indicates the battery is being charged. The green

light indicates the battery is fully charged to present capacity.

NOTE If both lights flash ON/OFF, the unit is defective or no

battery is installed.

Note that the yellow charge light illuminates.

8

ooo

oo

oo

Page 19

M Series Service Manual

Do this... Observe this... Pass/Fail/NA

2.21 Press the ANALYZE

button (if available).

2.22 Move the selector switch to

DEFIB. Select 2J. Press the

CHARGE button.

2.23 Press and hold the

ENERGY SELECT down

arrow.

2.24 Press and release the

ENERGY SELECT up

arrow 19 times.

2.25 Press the CHARGE button. Note the disp lay shows the unit charged up to 360J (200J -

2.26 Press the SHOCK button. The unit discharges and the SHOCK button is no longer lit. A 15

Record your results on the Maintenance Test Checklist.

SELECT DEFIB MODE message appears on the monitor. (For

manual devices.)

The display shows that the unit is charging. The SHOCK button

lights when the unit is charged. Ready tone for DEFIB sounds.

Unit discharges internally and selected energy decrements to 1J.

The following energy amounts display incrementally 2, 3, 4, 5, 6,

7, 8, 9, 10, 15, 20, 30, 50, 75, 100, 150, 200, 300, 360J (for DSW).

Biphasic: 1-10, 15, 20, 30, 50, 75, 100, 120, 150, 200J.

Biphasic) and the SHOCK button lights.

second strip chart automatically prints, displaying the number of

joules delivered (if equipped with recorder).

ooo

ooo

ooo

ooo

ooo

ooo

9

Page 20

M Series Service Manual

3.0 3, 5, and 12 Leads Test

Tools Needed 3 lead, 5 lead, and 12 lead cables.

Test each cable separately.

Test Setup Note: The M Series unit must be configured to display ECG LEAD OFF message.

Connect the lead wires appropriate to each test to the Dynatech Impulse 4000 or equivalent (Symbio CS1201).

Do this... Observe this... Pass/Fail/NA

3.1 Turn the selector switch to

MONITOR. Select leads.

3.2 Disconnect one lead from

the simulator .

3.3 Reconnect the lead. Repeat

step 3.2 with the remaining

leads.

3.4 Repeat 3.2 and 3.3 for 5

lead and 12 lead cables.

Record your results on the Maintenance Tests Checklist.

NO ECG LEADS OFF message displayed.

The ECG LEAD OFF message displays within 3 seconds (if

configured).

Wait for ECG LEAD OFF message to clear from the display (if

configured).

NOTE: If heart rate alarm sounds, press and hold the ALARM

SUSPEND button for 4 seconds to disable the alarms.

NOTE: When testing the 12 lead cable, the ECG LEAD OFF

message displays when you pull off a limb lead. When you pull

off a V lead, the ECG VX LEAD OFF message displays where

“X” is the number between 1 and 6.

ooo

ooo

ooo

ooo

10

Page 21

M Series Service Manual

4.0 Power Supply Test (Optional)

Tools Needed 2 red miniature alligator to miniature alligator leads.

1 black miniature alligator to miniature alligator test lead.

DC power supply (15 Amp minimum).

0.1

Ω 1% resistor (¼W or greater).

1000

Ω 1% ¼W resistor.

Fluke 75 multimeter or equivalent.

Test Setup Make sure the unit and power supply are turned off.

Connect one end of the black lead to the “-” terminal in the battery well.

Connect the other end of the black lead to the “-” terminal of the power supply.

Connect the red lead to “+” terminal socket of the battery well. Use the middle pin with the plastic guard around it.

Connect the other end of the red lead to the “+” terminal of the power supply.

Set the power supply voltage to 7V.

CAUTION Be sure to connect the power supply properly to the M Series battery well terminals or damage to the unit may result.

Do NOT raise the power supply voltage above 12V.

Red

+

Battery Well

+

_

15 Amp

Supply

_

Black

11

Page 22

M Series Service Manual

Do this... Observe this... Pass/Fail

4.1 Turn the selector switch to

MONITOR.

(For AED units, turn the

selector switch to ON and

select Manual mode.)

4.2 Turn the unit off.

4.3 Adjust the power supply

voltage to 10.3V and turn

the selector switch to

MONITOR (for AED

units, turn the selector

switch to ON).

4.4 Low Battery Test

Set voltage to 9.8V.

4.5 Set voltage to 9.3V. LOW BATTERY message displays within 30 seconds.

4.6 Shut Down Voltage Test

Set voltage to 8.5V.

Record your results on the Maintenance Tests Checklist.

The unit should not turn on.

The unit should turn on.

No LOW BATTERY message displays.

Unit should shut off within 30 seconds.

oo

oo

oo

oo

oo

oo

12

Page 23

M Series Service Manual

Test Setup Remove red lead from power supply and connect to 0.1Ω resistor.

Connect other end of resistor to “+” terminal of power supply using a second red lead.

Connect multimeter across the resistor.

Set voltage scale (if DVM is not autoranging) to 220 mV.

Red

+

Battery Well

_

Black

Do this... Observe this... Pass/Fail/NA

_

+

+

_

DMM

15 Amp

Supply

4.7 System Current Test

Set power supply to 10.3V.

4.8 Turn the selector switch to

MONITOR.

(For AED units, turn the

selector switch to ON and

select Manual mode.)

4.9 Turn unit off.

Record your results on the Maintenance Tests Checklist.

Voltage across resistor should be 80 mV or less (<800 mA of ON

current). NOTE: Without optional parameters.

a) With green screen or LCD and no options <80mV

b) With yellow screen and no options <81mV

c) With yellow screen and SpO

d) With yellow screen and voice recording <91mV

e) With yellow screen, voice recording and SpO

f) All devices with EtCO

13

<121mV

2

<104mV

2

<114mV

2

ooo

ooo

ooo

ooo

ooo

ooo

ooo

oo

Page 24

M Series Service Manual

Test Setup for Off Current

Test

Remove 0.1Ω resistor and replace with 1KΩ.

Connect DMM across resistor.

Set voltage scale to DCV.

Measure voltage across resistor.

Do this... Observe this... Pass/Fail

4.10 Off Current Test

Measure across resistor

with unit turned off.

Record your results on the Maintenance Tests Checklist.

Voltage should be less than 450 mV (<450

µA of current).

oo

14

Page 25

M Series Service Manual

5.0 Leakage Current Test

Tools Needed See the manufacturer’s instructions or supplied specifications for the leakage tester you use.

Setup See the manufacturer’s instructions or supplied specifications for the leakage tester you use. Repeat leakage test with

accessories: MFC, external paddles, internal paddles, and anterior/posterior paddles.

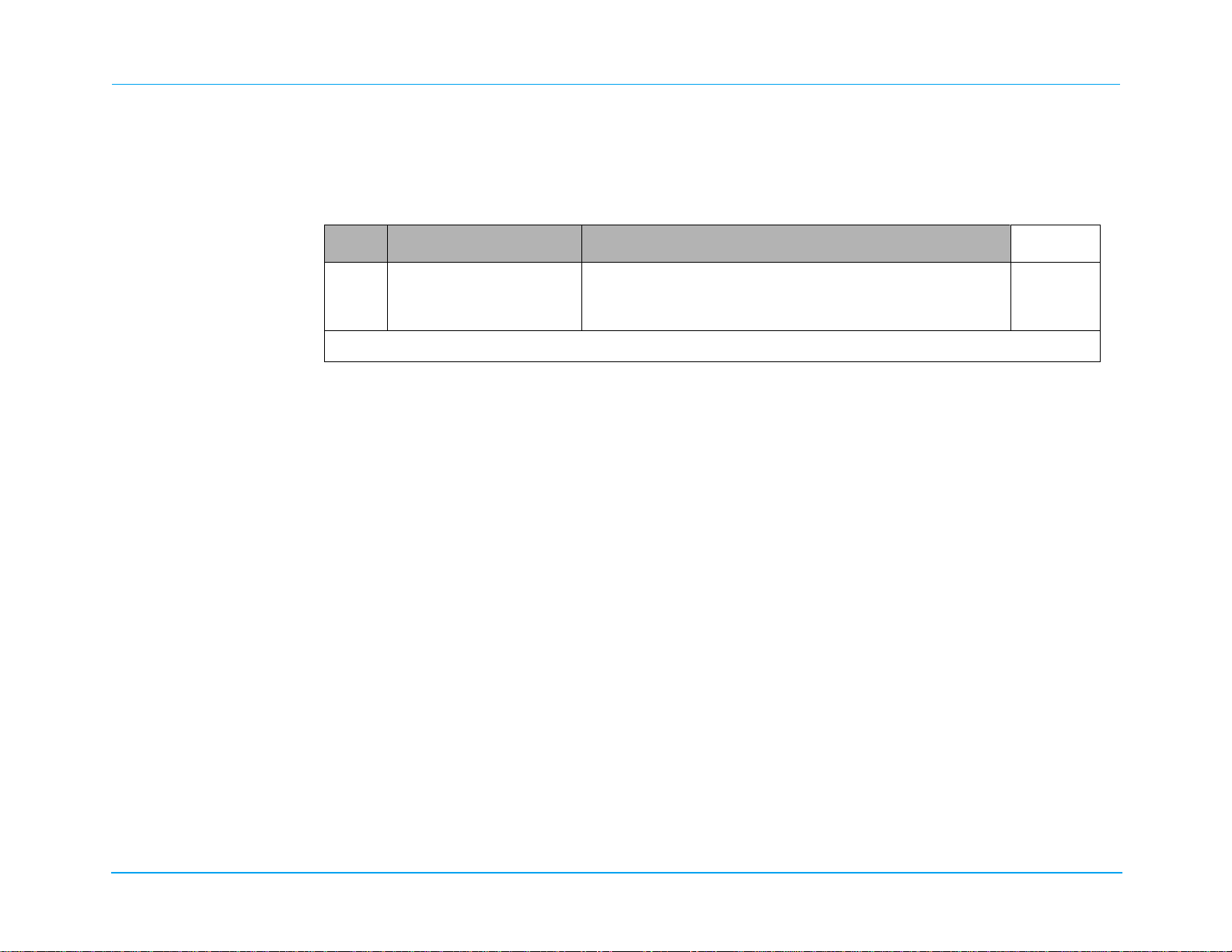

Maximum Leakage Acceptance Limits

Normal Condition Single Fault Condition*

ECG 10µΑ 50µΑ

MFC 100µΑ 100µΑ

Earth 500µΑ 1000µΑ

*Single fault considered AC mains on applied part.

15

Page 26

M Series Service Manual

6.0 Paddles Test

Tools Needed None.

Test Setup If applicable, connect the universal cable to the paddles. Place paddles in paddle wells.

Do this... Observe this... Pass/Fail/NA

6.1

6.2 Press and release the

6.3 Press and release the

6.4 Select 30J using the paddle

6.5

6.6

6.7

Turn the selector switch to

DEFIB. Press and hold the

ENERGY DOWN button on

the sternum paddle.

ENERGY UP button on

the sternum paddle for each

setting.

RECORDER button on the

sternum paddle.

ENERGY button. Press the

CHARGE button on the

Apex paddle.

Press and release the APEX

SHOCK button.

Press and release the

STERNUM SHOCK

button.

Press and hold both paddles

SHOCK buttons.

The energy selection decreases to 1J.

The energy selection increases incrementally to 360J (2, 3, 4, 5, 6,

7, 8, 9, 10, 15, 20, 30, 50, 75, 100, 150, 200, 300, 360J).

Biphasic: 1-10, 15, 20, 30, 50, 75, 100, 120, 150, 200J.

The recorder turns on. Press and release again to turn off.

The unit charges to 30J, then the red LED charge indicator

illuminates and the charge tone sounds. (Note that the front panel

shock button does not illuminate).

No discharge.

No discharge.

The unit discharges. The TEST OK message displays and the red

LED turns off. The recorder runs.

oo

oo

ooo

oo

oo

oo

oo

Record your results on the Maintenance Tests Checklist.

16

Page 27

M Series Service Manual

7.0 Heart Rate Display Test

Tools Needed Calibrated ECG simulator with 60Hz sine wave output capability.

Mini-phone plug for measuring output signal from 1 Volt ECG OUT jack (optional).

ECG Cable (3 or 5 leads).

Test Setup Turn the selector switch to MONITOR. Press LEAD button until “I” displays.

Connect the ECG leads to the DYNATECH Impulse 4000 or equivalen t .

Connect the ECG cable to the unit.

Do this... Observe this... Pass/Fail/NA

7.1 Set the ECG Simulator to

120BPM.

Record your results on the Maintenance Tests Checklist.

The Heart Rate displays as 120 +/- 2 bpm

ooo

17

Page 28

M Series Service Manual

8.0 Calibrating Pulses on Strip Chart Test

Tools Needed None.

Test Setup None.

Do this... Observe this... Pass/Fail/NA

8.1

8.2 Press and hold SIZE button

Record your results on the Maintenance Tests Checklist.

Press the RECORDER

button.

to activate the calibration

signal.

The strip chart displays a signal of 300 ppm with an amplitude of

10 mm +/- 1 mm. The signal also appears on the video display.

ooo

18

Page 29

M Series Service Manual

9.0 Notch Filter Test

Tools Needed Dynatech Impulse 4000 (or equivalent).

Test Setup Connect the ECG cable to the DYNATECH Impulse 4000 or equivalent.

Connect the ECG cable to the unit

Do this... Observe this... Pass/Fail/NA

9.1

9.2

9.3 Press RECORDER button. Verify that the waveform amplitude on the strip chart is less than

9.4 Turn the ECG simulator off.

Record your results on the Maintenance Tests Checklist.

Turn the selector switch to

MONITOR mode.

(For AED units, turn the

selector switch to ON and

select Manual mode.)

Select lead I, size 3x.

Select 60Hz (or 50 Hz for a

50Hz unit) on the Dynatech

Impulse 4000.

.

1.5 mm.

ooo

19

Page 30

M Series Service Manual

10.0 Heart Rate Alarm Test

Tools Needed Dynatech Impulse 4000.

Do this... Observe this... Pass Fail/NA

10.1

10.2 Press ALARMS.

10.3 Press SELECT PARAM softkey

10.4 Press INC> for state.

10.5 Press DEC>for state.

10.6

10.7

10.8

Turn the selector switch to

MONITOR mode.

(For AED units, turn the selector

switch to ON and select Manual

mode.)

Connect the ECG leads to the

Dynatech Impulse 4000. Set the

simulator to 120 BPM and the

defibrillator to lead II.

until ECG HR displays.

Press INC> until ENABLE displays. ENABLE displays.

Set LOW limit to 30, HIGH limit to

150 then, press the RETURN

softkey.

Press ALARM SUSPEND button. No alarm sounds.

Lead II message displays.

NSR ECG at 120 BPM +/- 2 displayed.

The alarm menu displays.

Cursor scrolls through parameters.

Cursor scrolls through ENABLE, AUTO and

DISABLE.

Cursor scrolls through ENABLE, DISABLE, AND

AUTO.

MONITOR displays.

ooo

ooo

ooo

ooo

ooo

ooo

ooo

ooo

10.9 Remove a lead wire from the

Dynatech Impulse 4000.

The bell symbol flashes and the heart symbol stops

flashing. The ECG LEAD OFF alarm tone sounds.

Recorder prints a stripchart showing a low heart rate, if

enabled.

20

ooo

Page 31

M Series Service Manual

Do this... Observe this... Pass Fail/NA

10.10 Reattach ECG Lead wire to

Dynatech Impulse 4000 and hold the

ALARM SUSPEND button on unit

for 4 seconds.

10.11 Press the ALARM SUSPEND

button.

10.12 Set simulator to 160 BPM or higher.

10.13 Press the ALARM SUSPEND

button in the unit.

10.14 Press and hold ALARM SUSPEND

for 4 seconds to disable alarms.

Record your results on the Maintenance Tests Checklist.

The bell symbol has an “X through it.

The heart symbol flashes with each QRS wave.

Alarm is enabled. Bell symbol (without “X”) displays.

Heart Rate Value is highlighted, alarm tone sounds, the

bell and the heart symbol both flash.

Alarm is suspended for 90 seconds. The bell symbol has

an “X” through it. The heart symbol flashes with each

QRS wave.

ooo

ooo

ooo

ooo

ooo

21

Page 32

M Series Service Manual

11.0 Defibrillator Self Test

SHOCK HAZARD!

TAKE THE NECESSRY PRECAUTIONS TO GUARD AGAINST SHOCK OR INJURY BEFORE YOU

START CONDUCTING THE DEFIRBILLATOR TESTS.

Keep hands and all other objects clear of the multi-function cable connections and defibrillator analyzer when

discharging the defibrillator.

Before you discharge the defibrillator, warn everyone near the equipment to STAND CLEAR.

CAUTION Do NOT internally discharge the unit more than 3 times in 1 minute. Note that multiple rapidly repeating internal

discharges at more than 30 Joules may damage the unit.

Tools Needed MFC Test Port Connector 1004-0053-99 with universal cable.

MFC Test Adaptor Connector (Dynatech Nevada Part Number 3010-0378 or equivalent).

Dynatech Impulse 4000 or equivalent defibrillator analyzer.

ECG Cable.

Stop watch.

Test Setup Ensure the unit is turned off and the ECG cable is connected to the unit and analyzer. The universal cable should not

be connected to any equipment at the beginning of this test.

Do this... Observe this... Pass/Fail

11.1 Turn the selector switch to

DEFIB mode.

(For AED units, turn the

selector switch to ON and

select Manual mode.)

Set leads to PADS.

CHECK PADS/POOR PAD CONTACT message displays.

22

oo

Page 33

M Series Service Manual

Do this... Observe this... Pass/Fail

11.2 Connect the universal cable to

the MFC test port.

11.3

11.4

11.5

11.6

11.7

Record your results on the Maintenance Tests Checklist.

Select energy level of 100J and

press the CHARGE button.

Press the SHOCK button. Unit does not discharge. DEFIB PAD SHORT message displays.

Set energy level to 30J. Unit internal ly disch arges.

Press the CHARGE button. Unit charges to 30J and displays DEFIB 30J READY. The charge

Press and hold SHOCK button. Unit discharges. TEST OK message and number of joules

DEFIB PAD SHORT message displays.

The charge time is >2 second and <10 seconds and SELECT 30J

FOR TEST is displayed.

ready tone sounds.

delivered message displays. For example, using the message at

the top of the printed strip chart would read as follows:

For monophasic unit:

30 JOULES TEST OK. 37-47A JOULES DEL=30 IMPED=0.

For Biphasic Unit:

30 JOULES TEST OK. TEST_CUR=10-14A DEFIB_IMPED=0.

NOTE The impedance value may range from 0 to 5Ω.

oo

oo

oo

oo

oo

oo

23

Page 34

M Series Service Manual

12.0 Synchronized Cardioversion Test

Tools Needed Dynatech Impulse 4000 or equivalent defibrillator analyzer.

Test Setup Connect the universal cable via the adapter (D.N.I #3010-0378) to the defibrillator analyzer.

Select cardioversion on analyzer. Input 1mV ECG signal at 60 -120 BPM.

Do this... Observe this... Pass/Fail

12.1

12.2

12.3

12.4

Record your results on the Maintenance Tests Checklist.

Press LEAD button to select

PADS and Size X1.

Press the SYNC softkey on the

defibrillator. Enter

synchronized cardioversion

timing test mode on the

defibrillator analyzer.

Select 360J (200J for Biphasic

unit).

Press the CHARGE button.

When the SHOCK button

lights, press and hold the

SHOCK button.

Sync appears on display.

Sync markers display on the monitor. The sync marker appears as

a down arrow over the ECG R-wave peaks on strip chart and

display.

Observe that the R-wave to shock delay (sync delay) is less than

60 milliseconds on the analyzer display.

Defibrillator discharges.

oo

oo

24

Page 35

M Series Service Manual

13.0 Shock Test

Tools Needed Dynatech Impulse 4000 or equivalent defibrillator analyzer.

Test Setup Stop watch.

Connect the universal cable via the adapter (D.N.I #3010-0378) to the defibrillator analyzer.

Ensure that a fully charged battery is installed in the unit.

NOTE: If your M Series AED does not have manual override capability, do not perform this test.

Do this... Observe this... Pass/Fail/NA

13.1 Turn the selector switch to DEFIB

mode.

(For AED units, turn the selector

switch to ON and select Manual

mode.)

13.2 Press the ENERGY SELECT down

arrow until 1J displays.

13.3 Press the CHARGE button.Wait for

the SHOCK button to illuminate.

13.4 Press the SHOCK button.

13.5 Repeat for all settings 1-300J

(DSW); 1-150J (Biphasic)

13.6 Press the ENERGY SELECT up

arrow until 360J (200J for Biphasic)

displays.

DEFIB 1J SEL displays.

DEFIB 1J RDY displays.

Unit discharges 0J-2J into the simulator. (Note: The

displayed rhythm may change shape for 30 seconds

before it returns to an original rhythm. This is caused by

the operation of the adaptive bandwidth defibrillator

recovery circuit.)

Energy delivered is within + /- 15% or 2J of setting

which ever is greater.

DEFIB 360J SEL displays

or

DEFIB 200J SEL displays (for Biphasic unit).

ooo

ooo

ooo

ooo

ooo

ooo

25

Page 36

M Series Service Manual

Do this... Observe this... Pass/Fail/NA

13.7

13.8

13.9

13.10

Record your results on the Maintenance Tests Checklist.

Press the CHARGE button and start

timing with a stopwatch. Stop timing

when the SHOCK button

illuminates.

Press the SHOCK button.

Record the value of the discharge

energy that is displayed on the

analyzer.

(Biphasic unit only) Note the Patient

Current and Defib Impedance on the

strip chart.

(AED unit only) Disconnect the

cable from the analyzer.

Observe and record the value of the charge time on the

stop watch.

Charge time (DSW) 4.0-8.0 sec.

Charge time (Biphasic) 3.0-6.0 sec.

360J discharge energy (DSW) 306-414J.

200J discharge energy (Biphasic)170-230J.

Patient Current 22-24A.

Defib Impedance 46-54 Ohms.

CHECK PADS audio prompt.

ooo

ooo

ooo

ooo

26

Page 37

M Series Service Manual

14.0 Summary Report Test (if applicable)

Tools Needed None.

Test Setup Connect the universal cable to the defibrillator analyzer. If you are using paddles, place the paddles on the analyzer’s

discharge plates.

Do this... Observe this... Pass/Fail

14.1 Press and hold the

SUMMARY softkey for 4

to 8 seconds to erase any

previously stored data.

14.2 Set selector switch to

DEFIB. Select 300J (200J

for Biphasic) using the

ENERGY SELECT

button, and press the

CHARGE button. When

charged, press the SHOCK

button to discharge into the

defibrillator analyzer.

14.3 Wait 18 seconds, then press

the Code Marker softkey.

Press the CPR softkey.

14.4 Turn the unit off. Wait 10

seconds and then turn the

unit on. Press the

SUMMARY softkey, then

press the PRINT CHART

softkey.

ERASING REPORT displays.

The unit successfully discharges and prints a strip chart.

The Code Markers display.

Summary report prints. The report displays the correct date, time,

the shock delivered and Code Marker event.

oo

oo

oo

oo

Record your results on the Maintenance Tests Checklist.

27

Page 38

M Series Service Manual

15.0 Advisory Message Test (for AED and Manual/Advisory Units)

Tools Needed None.

Test Setup Connect the universal cable via the adapter (D.N.I #3010-0378), then attach to the defibrillator analyzer.

Do this... Observe this... Pass/Fail

15.1

15.2

15.3

15.4

Record your results on the Maintenance Tests Checklist.

Connect universal cable to

the simulator.

Turn the selector switch to

DEFIB mode.

(For AED units, turn the

selector switch to ON.)

Select VF (ventricular

fibrillation) on the

simulator, then press the

ANALYZE button.

Press the SHOCK button. Unit discharges.

Select the NSR (normal

sinus rhythm) on the

simulator, then press the

ANALYZE button.

ANALYZING ECG message displays.

STAND CLEAR message displays.*

SHOCK ADVISED message displays.*

PRESS SHOCK message displays*+

*AED’s audio prompts are standard. Advisory audio prompts are

user configurable on later manufactured units.

+If configured for auto charge.

ANALYZING ECG message.

STAND CLEAR message.*

NO SHOCK ADVISED message.*

*AED’s audio prompts are standard.

oo

oo

oo

28

Page 39

M Series Service Manual

16.0 Pacer Test

Tools Needed Dynatech Impulse 4000 Analyzer (software 1.06 or higher) with optional external plug in pacing module (TQA-17) or

equivalent.

Note: The following tests are to be performed only on M Series units equipped with the optional pacing function.

_

+

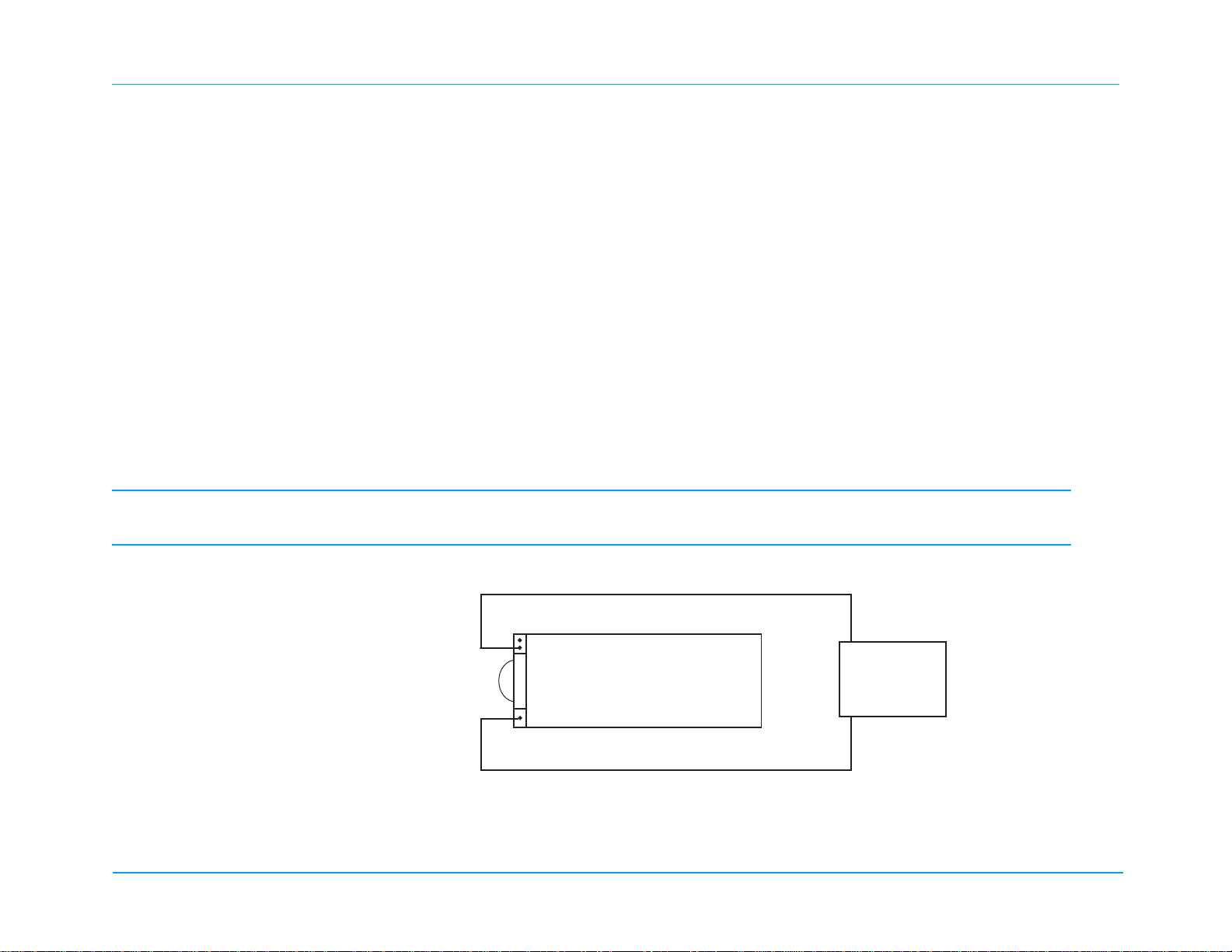

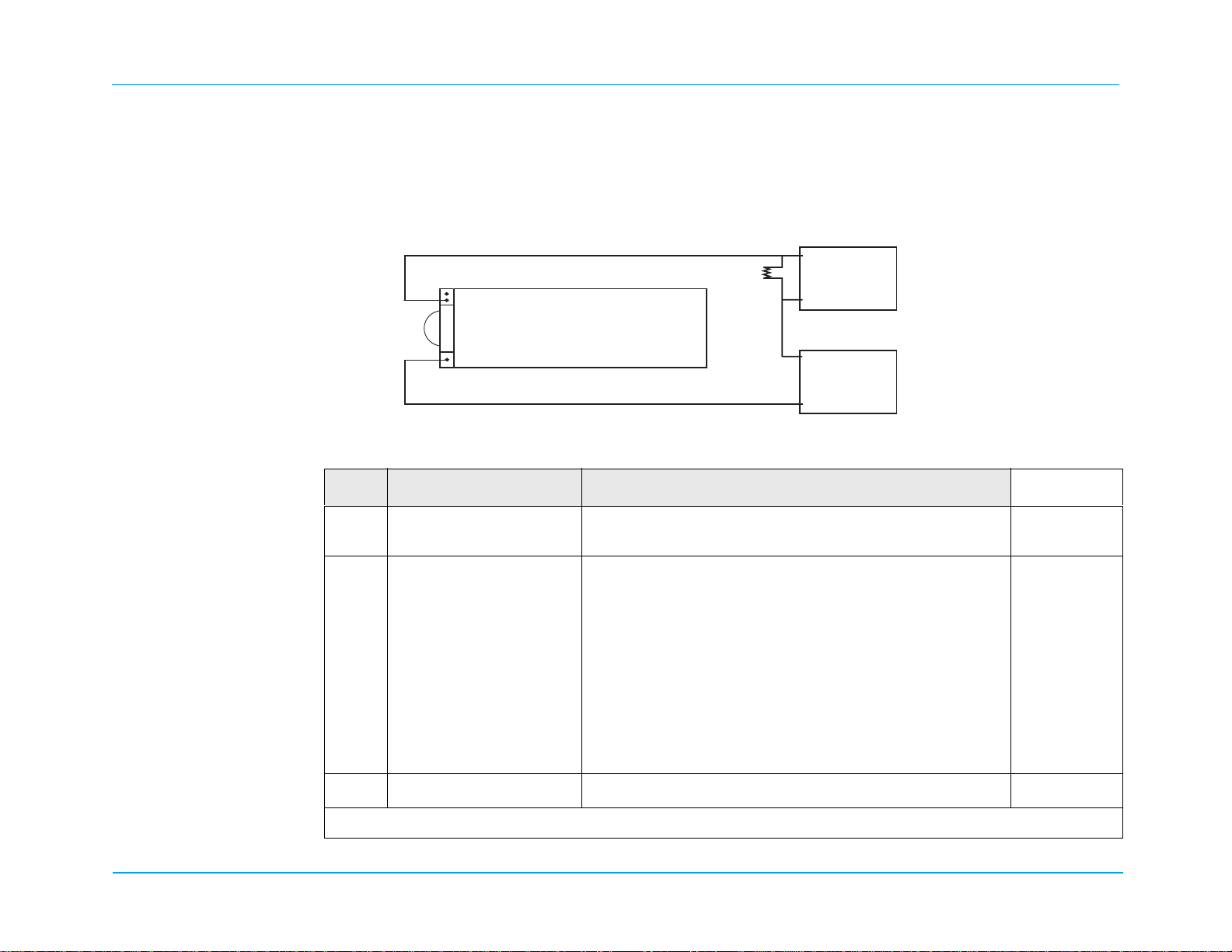

The pacer output can be measured using an oscilloscope set to DC coupling connected across a load resistor. (See

diagram in column for universal cable connector polarity.) The load resistor is a 100 ohm, 5 watt or greater. The pacer

output is a positive going pulse, 40 +/- 2 ms duration with an amplitude of 0.1 volt per milliamp of selected output

(e.g., 40 milliamps of selected output has an amplitude of 4 +/- 0.5 volts the specified tolerance displayed on the

oscilloscope).

If an external non-invasive pacer analyzer is being used, then follow the manufacturer’s guidelines for measuring the

frequency (ppm), output (mA) and the pulse width measured in milliseconds. Note that the analyzer pace load resistor

must be less than 250 ohms.

Test Setup Connect the universal cable from the M Series to the External Pacer Load (TQA-17) of the Impulse 4000.

Turn the Main Selector knob of the M Series to the Pacer mode.

Do this... Observe this... Pass/Fail

16.1

16.2

Set the PACER OUTPUT to

14 mA and disconnect MFC

connector from the Dynatech

Impulse 4000.

Reconnect the

to the

Dynatech Impulse 4000.

Press Clear Pace Alarm

softkey.

universal cable

CHECK PADS AND POOR PAD CONTACT message displays.

The pace alarm is active.

CHECK PADS AND POOR PAD CONTACT message

disappears. The pace alarm is cleared.

oo

oo

16.3

16.4

Set rate to 180 ppm; output to

0mA.

Increase the output to 20mA. Output on the Dynatech Impulse 4000 is 20mA +/- 5mA. Pulse

No output appears on the Dynatech Impulse 4000.

width is 40mS +/-2mS.

29

oo

oo

Page 40

M Series Service Manual

Do this... Observe this... Pass/Fail

16.5

16.6

16.7

16.8

16.9

16.10

16.11

16.12

16.13

16.14

Increase the output to 40mA. Output on the Dynatech Impulse 4000 is 40m A +/- 5 mA. Pulse

width is 40mS +/-2mS.

Increase the output to 60mA. Output on the Dynatech Impulse 4000 is 60mA or +/- 5mA. Pulse

width is 40mS +/-2mS.

Increase the output to 80mA Output on the Dynatech Impulse 4000 is 80mA or +/- 5mA. Pulse

width is 40mS +/-2mS.

Increase the output to 100mA. Output on the Dynatech Impulse 4000 is 100mA or +/- 5mA.

Pulse width is 40mS +/-2mS.

Increase the output to 120mA. Output on the Dynatech Impulse 4000 is 120mA or +/- 6mA.

Pulse width is 40mS +/-2mS.

Increase the output to 140mA. Output on the Dynatech Impulse 4000 is 140mA or +/- 7mA.

Pulse width is 40mS +/-2mS.

Decrease the output to 60mA.

Decrease the rate to 30 ppm.

Increase the rate to 40ppm. Pacer rate on Dynatech is 39-41 ppm.

Increase the rate to 60ppm. Pacer rate on is Dynatech is 59-61 ppm.

Increase the rate to 80ppm. Pacer rate on Dynatech is 78-82 ppm.

Pacer rate on Dynatech is 29-31 ppm.

oo

oo

oo

oo

oo

oo

oo

oo

oo

oo

16.15

16.16

16.17

16.18

Increase the rate to 100ppm. Pacer rate on Dynatech is 98-102 ppm.

Increase the rate to 120ppm. Pacer rate on Dynatech is 118-122 ppm.

Increase the rate to 180ppm. Pacer rate on Dynatech is 177-183 ppm.

Decrease the rate to 50 ppm. Pacer rate on Dynatech is 49-51 ppm.

30

oo

oo

oo

oo

Page 41

M Series Service Manual

Do this... Observe this... Pass/Fail

16.19

16.20

16.21

16.22

Record your results on the Maintenance Tests Checklist.

Connect the ECG cable to the

M Series and Dynatech

Impulse 4000. Select the ECG

at 60 BPM on the Dynatech

Impulse 4000.

Press the Async Pace softkey. ECG at 60 BPM seen on the display with the pace stimulus

Turn off Dynatech. Set Pacer

Rate to 100ppm. Press the

RECORDER ON button.

Press and hold 4:1 button. Observe the pace stimulus markers every 60 mm+/- 1.5 mm.

ECG at 60 BPM is seen on the display and no stimulus markers.

markers displayed. Async pace message displays.

Observe the pace stimulus markers every 15mm +/-1mm.

oo

oo

oo

oo

31

Page 42

M Series Service Manual

17.0 SpO2 Monitor Test for SpO2 Option

Tools Needed Masimo

Masimo

Bio-Tek Index 2PFE SpO

Test Setup Connect the universal cable to the MFC test plug.

®

Reusable Sensor.

®

Patient Cable.

Simulator (or equivalent).

2

DO NOT connect the ECG cable to the simulator.

Install the Masimo

Connect the Masimo

®

Patient Cable and attach the Masimo® sensor to the patient cable.

®

sensor to the finger simulation post.

Place a fully charged battery into the battery well or connect to AC power (DC power, if equipped).

Ensure that the SpO

Do this... Observe this... Pass/Fail

17.1 Turn the selector switch to

MONITOR.

(For AED units, turn the

selector switch to ON and

select Manual mode.)

17.2 Wait ten seconds.

Turn on the SpO

Press the SIM softkey on the

Index SpO

the MAN softkey.

Simulator is off.

2

simulator.

2

Simulator. Press

2

The SpO

monitor.

The SpO

saturation percentage appears as a dashed line on the

2

PULSE SEARCH message displays.

2

oo

oo

17.3 Press the 02+ or 02- softkey of

the simulator until the SpO

output is at 98%.

2

The M Series

monitor. Note that you may need to wait up to 2 minutes for the

information to appear on the ZOLL display.

32

SpO

reading of 98 +/- 1% appears on the M Series

2

oo

Page 43

M Series Service Manual

Do this... Observe this... Pass/Fail

17.4

17.5

17.6

17.7 Press Wave 2 softkey.

17.8 Press RECORDER. The plethysmographic waveform prints on the strip chart paper.

17.9

Using the Index

Simulator, press the BPM+ or

BPM- softkey until the heart

rate is 230 BPM.

Using the Index

Simulator, press the BPM-

softkey until the heart rate is

50 BPM

Using the Index

Simulator, press the 02+

softkey until the SpO

is at 72%.

Select the SpO

Using the Index

Simulator, press the BPM-

softkey until the heart rate is at

230 BPM.

SpO

2

SpO

2

SpO

2

output

2

waveform.

2

SpO

2

The SpO2 rate 230 BPM displays on the simulator screen.

Note that you may need to wait up to 2 minutes for the

information to appear on the ZOLL display.

SpO

The

The heart

The SpO2 saturation of 96-100% displays on the unit.

The heart rate of 46-54 BPM displays on the M Series monitor.

The

The heart rate of 46-54 BPM displays on the M Series monitor.

Plethysmographic waveform appears on the ZOLL display.

The

The heart rate in the heart position of 226-234 BPM displays on

the monitor.

saturation of 96-100% appears on the M Series display.

2

rate of 226-234 BPM displays on the M Series monitor.

SpO2 saturation of 70-74% displays on the unit.

SpO

saturation rate of 70-74% displays on the unit.

2

oo

oo

oo

oo

oo

oo

oo

oo

17.10

17.11

Record your results on the Maintenance Tests Checklist.

Select Wave 2

Remove the Masimo

cable.

SpO

.

2

®

patient

Verify that the waveform is displayed at the correct rate.

Print the waveform.

33

oo

Page 44

M Series Service Manual

18.0 EtCO2 Monitor Test (for EtCO2 Option)

Tools Needed Novametrix Capnostat Simulator Tb 1265/7100.

Test Setup Install the battery.

On the Novatrix Simulator, set the following:

Set inspired CO

Set% CO

2

Set Sensor Location to ZERO CELL.

Set Source Current to NORMAL.

Set CO

mode to CONTINUOUS.

2

Set Temperature to NORMAL.

to OFF.

2

to 0.

Do this... Observe this... Pass/Fail

18.1

18.2 Attach the EtCO

18.3 On the Novametrix

Turn the selector switch to

MONITOR mode.

(For AED units, turn the

selector switch to ON and

select Manual mode.)

simulator

2

to the M Series input

connections.

Simulator, set SENSOR

LOCATION to REF

CELL.

CO2 SENSOR WARMUP message displays.

Note: You may need to wait up to 5 minutes for the warm-up

message to disappear.

If the message REPLACE CO

Novametrix Simulator Cable.

Note that the message ZEROING CO

an additional 20 seconds. Automatic zeroing will occur if the unit

had not been zeroed at the time of its last use.

The EtCO

Note that you may need to wait up to 10 seconds for the unit to

stabilize.

34

reading of 36-40 mmHg displays on the monitor.

2

SENSOR displays, reinsert the

2

SENSOR may display for

2

oo

oo

Page 45

M Series Service Manual

Do this... Observe this... Pass/Fail

18.4 On the Novametrix

Simulator, set SENSOR

LOCATION to AA CELL.

Set% CO

Set CO

to 10.

2

mode to

2

The EtCO

reading of 74-84 mmHg appears on the M Series

2

display. Note that you may need to wait up to 10 seconds for the

unit to stabilize.

RESPIRATION.

18.5 On the Novametrix

Simulator, set% CO

to 5.

2

The EtCO

monitor.

reading of 34-42 mmHg displays on the M Series

2

Note that you may need to wait up to 10 seconds for the unit to

stabilize. The Respiration Rate (RR) of 22-24 displays on the M

Series monitor. Press WAVE 2 softkey. The EtCO

displays. Press RECORDER button. The EtCO

Note that the CO

millimeters per second scale.

Record your results on the Maintenance Tests Checklist.

waveform

2

waveform prints.

2

waveform is displayed and printed at 12.5

2

oo

oo

35

Page 46

M Series Service Manual

36

Page 47

M Series Service Manual

Overview

This chapter describes the most common technical problems that biomedical technicians experience when checking

the M Series during routine maintenance or when there is a malfunction of the unit. It also contains a list of error

messages that users may see if the unit is not operating properly.

This chapter contains the following:

• Troubleshooting tables for ECG Leads Off Messages and Monitor Displays

• Zoll M Series Error Messages

Chapter 2

Troubleshooting

If the problems you encounter are not listed below, call ZOLL Medical Corporation’s Technical Service Department

for further assistance. (See page iii for contact information.)

37

Page 48

M Series Service Manual

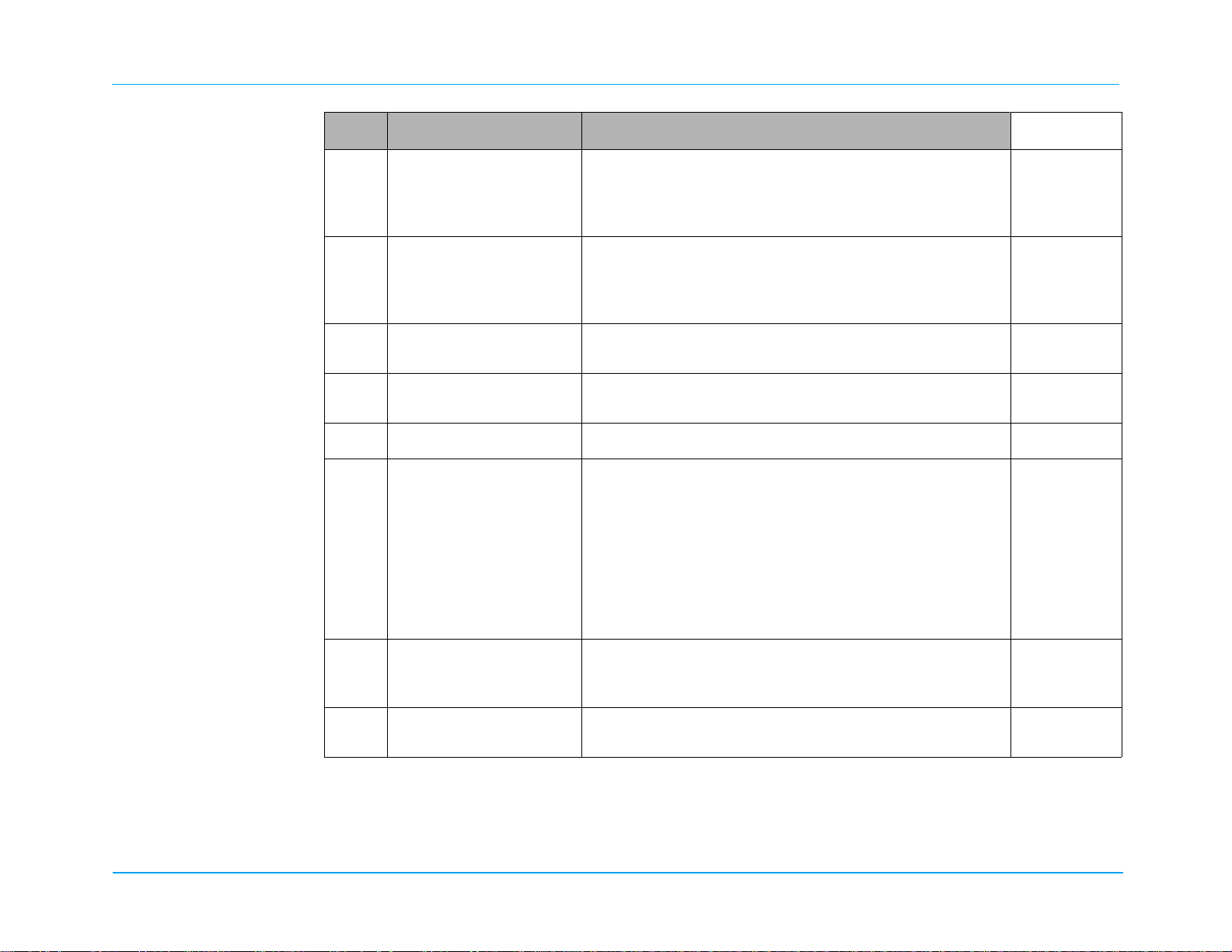

Troubleshooting

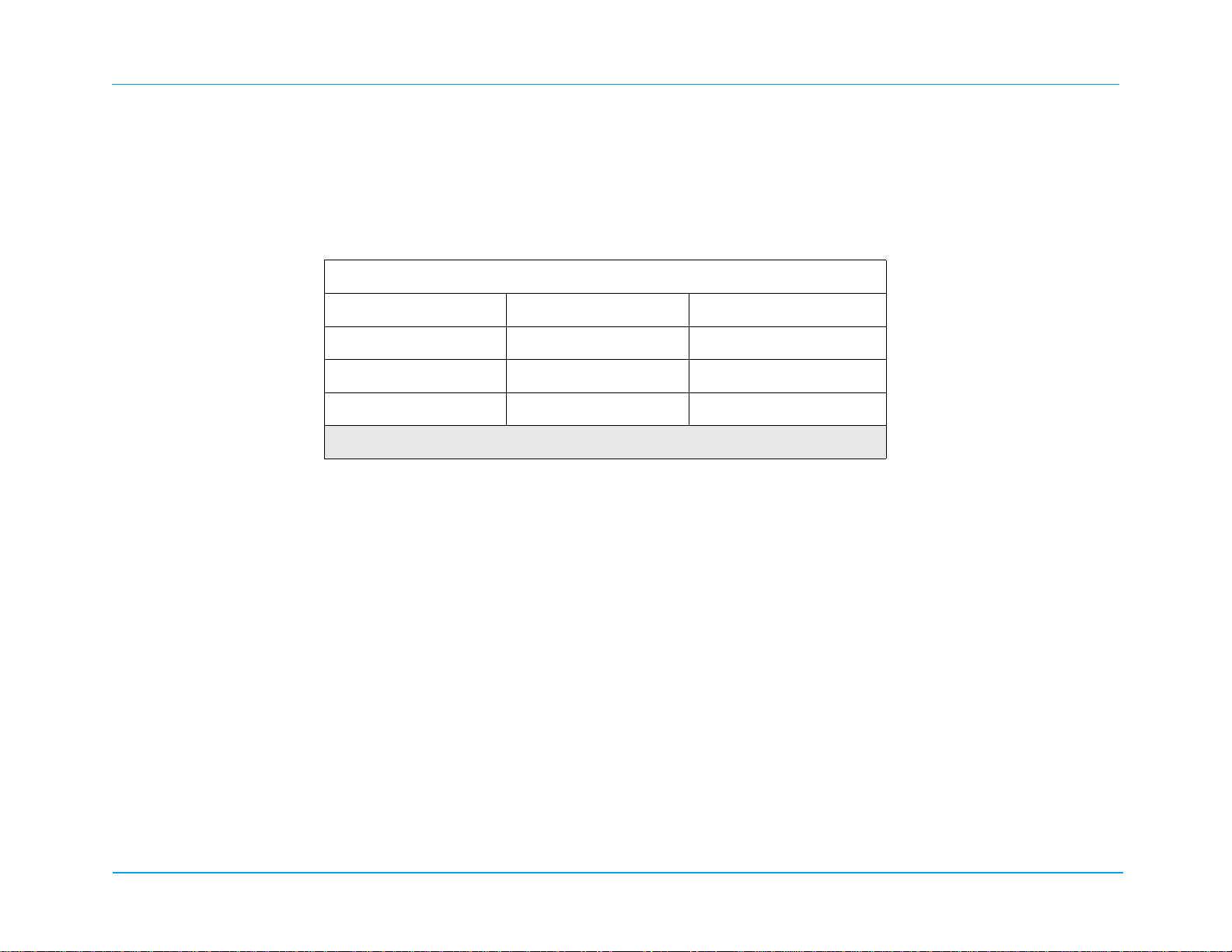

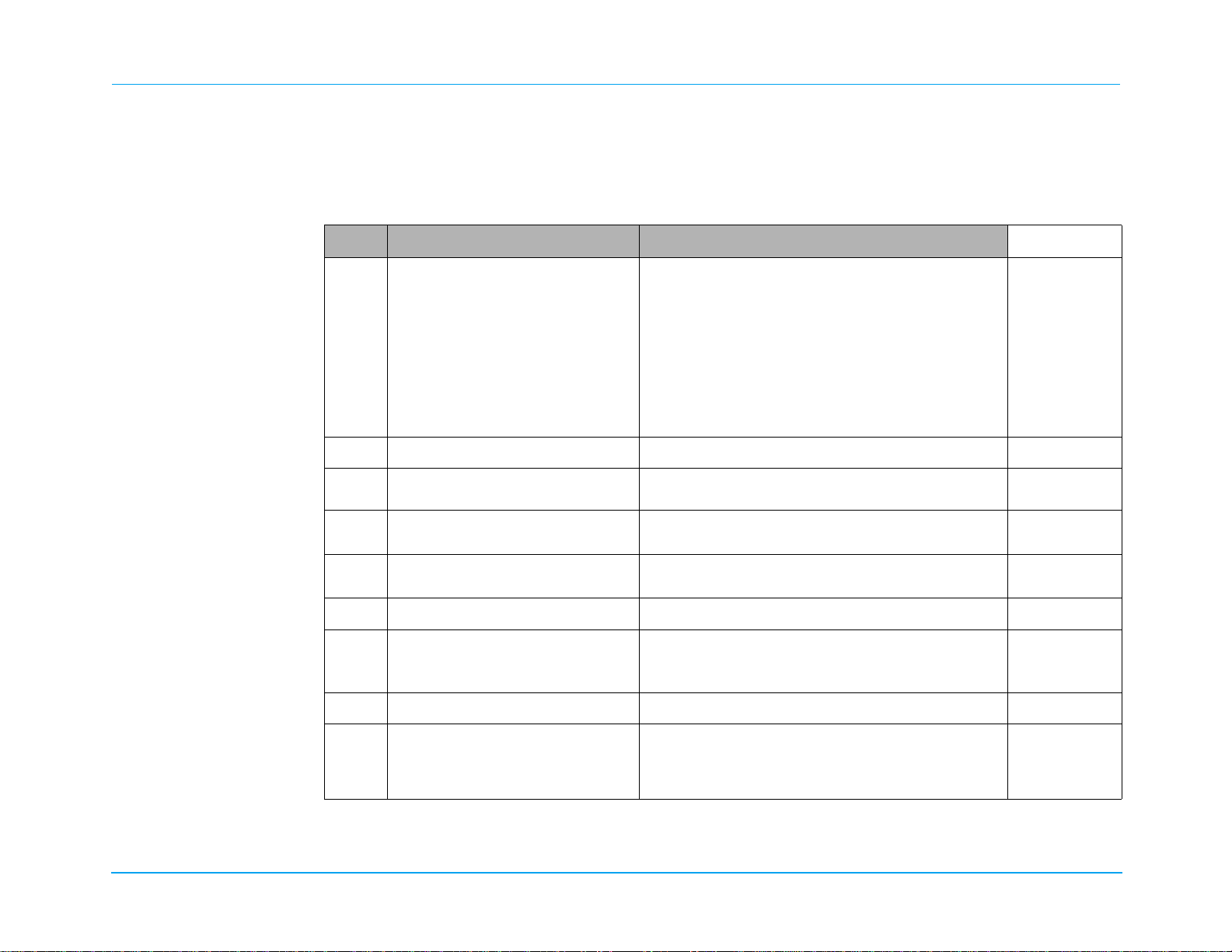

The following tables show the most common troubleshooting issues and their solutions.

First, attempt to solve the problem with “Recommended User Action.” If these steps do not solve the problem, follow

the steps listed in the “Recommended Technical Action” column.

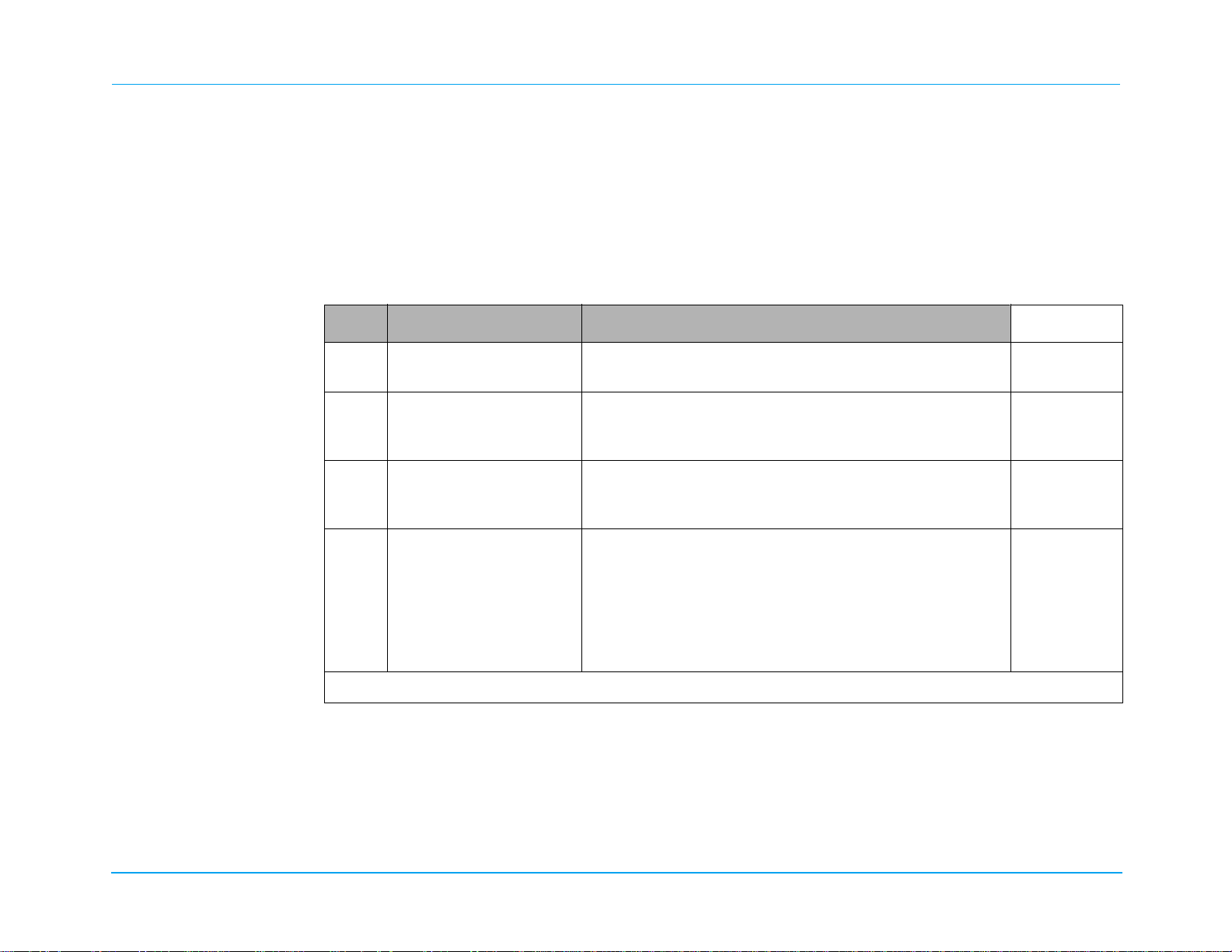

Reported Problem Recommended User Action Recommended Technical Action

ECG LEAD OFF message

displays.

(3, 5, 12 lead cable)

• Check preparation of ECG electrode site by

cleaning the site, lightly abrading the patient’s skin

and/or clipping the patient’s hair at the electrode

site.

• If electrode gels are dry, replace electrodes with

new ones from a freshly opened package.

• Verify that all leads are attached.

• Set monitor to another lead.

• Verify that the electrodes have not exceeded their

expiration date.

• T ry to reproduce the problem using

a simulator.

• Inspect the ECG cables looking for

corrosion or broken connector pins.

• Check the cable for intermittent

connections by flexing the cable at

the yoke and snap connectors.

• Check the cable connection to the

defibrillator.

• Inspect the ECG input connector

and its pins. Replace it, if

necessary.

• Inspect the ECG cable connection

to the system board.

• Inspect the system board ECG

shielding.

• Remove and replace the system

board.

38

Page 49

M Series Service Manual

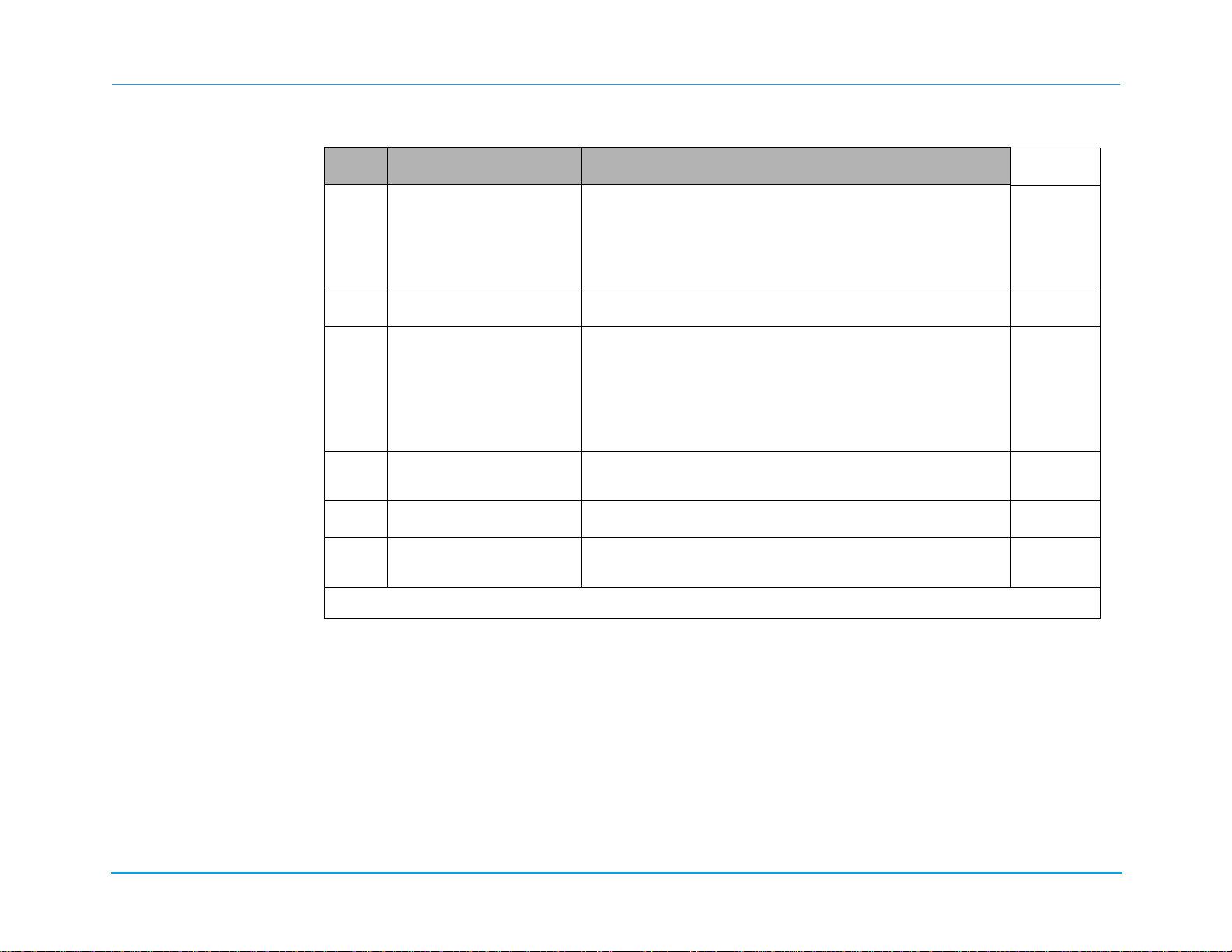

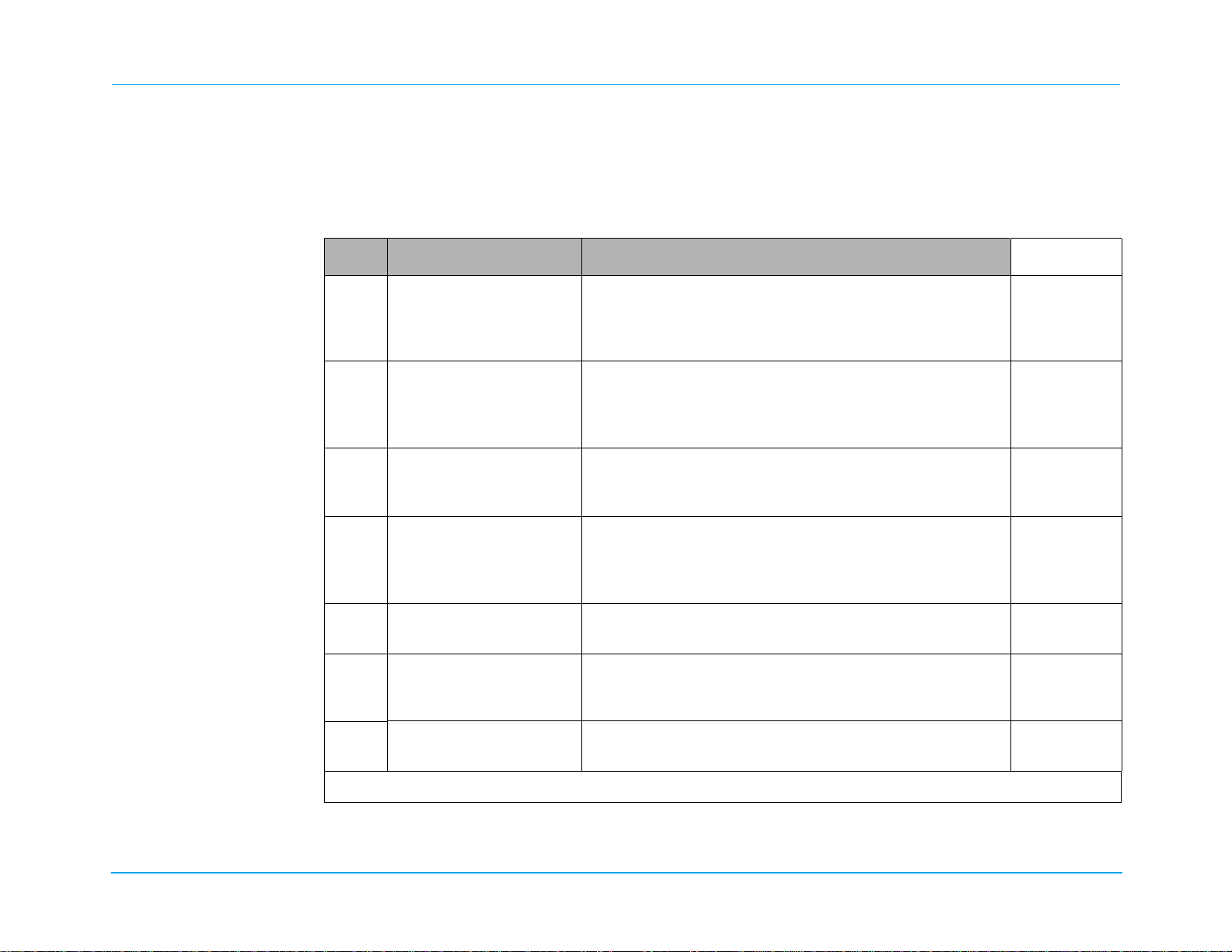

Reported Problem Recommended User Action Recommended Technical Action

V LEADS OFF message

displays.

CHECK P ADS/POOR PAD

CONTACT message

displays.

• If the user is not using V leads, attach V lead

connector terminator plug to the cable’s V lead

connector.

• If a V1 lead wire metal snap comes in contact with

the patient’s skin, then the system will show all V

leads as OFF.

• Remove V1 leads and others away from the

patient. Turn off the unit and wait ten seconds

before turning it back on.

• Remove and reinsert PADS connector into the

universal cable.

• Check for damaged defibrillator pads, wires and or

connector.

• Check for dried out or expired defibrillator pads.

• Clip (not shave) the patient’s hair and wipe pad

contact area dry.

• Connec t the cable to the test plug. The DEFIB PAD

SHORT message displays to indicate that the cable

is functioning properly.

• If the DEFIB PAD SHORT message displays, then

check the connections of the pads to the patient and

to the defibrillator cable.

• If the DEFIB PAD SHORT message does not

display, remove the defibrillator from service.

• Connect universal cable to the

shorting plug. The DEFIB PAD

SHORT message should display,

when you SELECT PADS. If the

message does not display , then:

• Try another universal cable.

• Chec k the cable from the universal

cable connector to the High

Voltage Module.

• Chec k the cable from the High

Voltage Module to the system

board.

• Remove and replace the High

Voltage Module.

• Remove and replace the system

board.

• Call ZOLL Technical Support for

assistance.

39

Page 50

M Series Service Manual

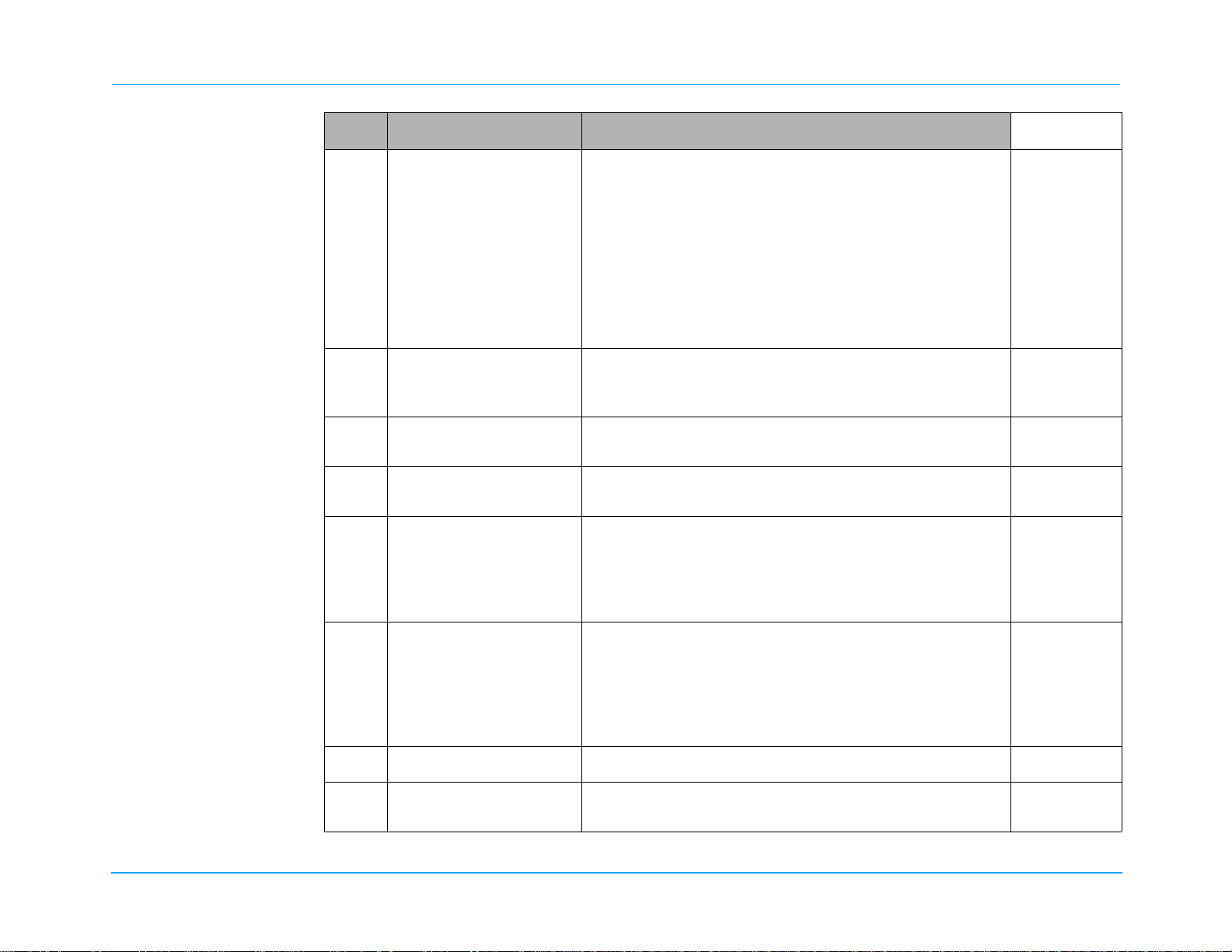

Reported Problem Recommended User Action Recommended Technical Action

Flash or arcing under

defibrillator pad.

Displayed HR not accurate.

No artifact present.

• Avoiding using alcohol and betadine in and around

the treatment area because these skin preparations

may lead to increased conductivity and/or bonding

between the electrode’s adhesive and skin.

• Check for ge l droop. If the gel has leaked out of the

gel treatment area, replace the electrode.

• Ensure pads are coupling to the patient’s skin and

connected to the universal cable.

• Check for dried out gel on the defibrillator pad.

• Clip patient’s excessive hair. Do not shave hair.

• Check expiration date. Replace pad if date has

expired.

• Do not conduct chest compression through the

pads because the pads could be damaged leading to

the possibility of arcing and skin burns.

• Apply the back electrode first. If the front electrode

is already in place when the patient is being

maneuvered for placement on the back, the front

may become partially lifted, possibly causing

arching and skin burns.

Verify heart rate flashes with each QRS on display.

• Change lead selection.

• Change ECG size.

• Reposition ECG electrodes.

• Ensure that wet gel pads are stored

flat.

40

Page 51

M Series Service Manual

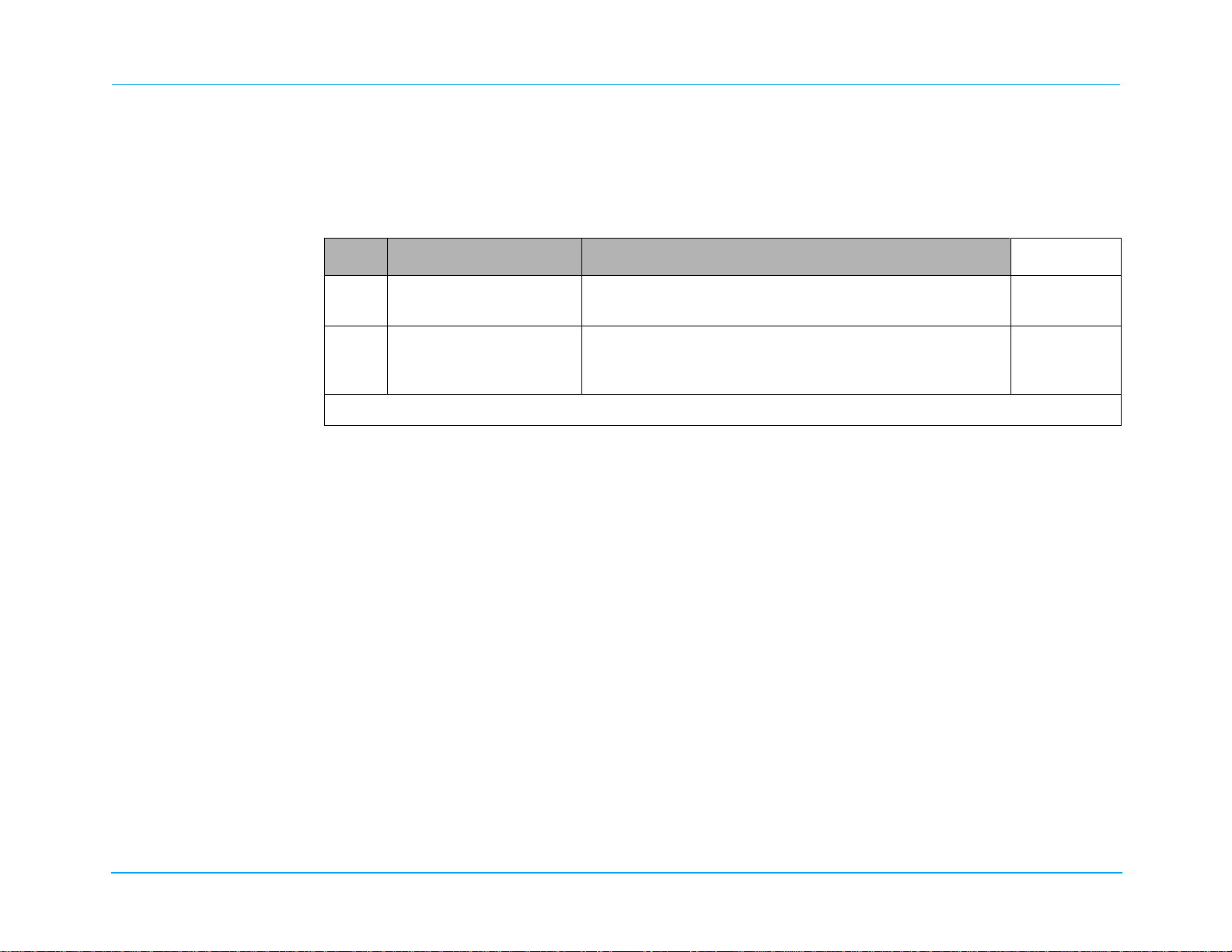

Reported Problem Recommended User Action Recommended Technical Action

Displayed HR not accurate;

artifact present.

• Reduce or eliminate ECG artifact due to

electrode or patient cable movement. Route

cables so that they don’t pull on electrodes or

swing excessively .

• Ensure patient is motionless.

• Check for possible excessive radio frequency

interference.

• Verify a good connection of electrodes to the

patient.

• Prepare the patient’s skin prior to the electrode

attachment.

• Move patient cables away from other electrical

equipment, especially any RFI source.

• Ensure ECG cable fits snugly in unit.

• Change ECG cable.

• Replace/reposition ECG electrodes.

Wandering baseline. See “Displayed HR not accurate.” above. Note that

in 90% of electrode issues, size and lead changes

don’t help.

Electronic interference. Check for possible excessive radio frequency

interference.

Move patient cables away from other electrical

equipment.

• Chec k for contamination on snaps.

Ensure springs are intact.

• Check for intermittent ECG patient

cable or connector wiring.

• Replace ECG input connector.

• Replace ECG connector to the

system board cable.

• Replace system board.

Same as above example.

• Turn off sources of excessive RFI.

• Move M Series unit away from

RFI source.

41

Page 52

M Series Service Manual

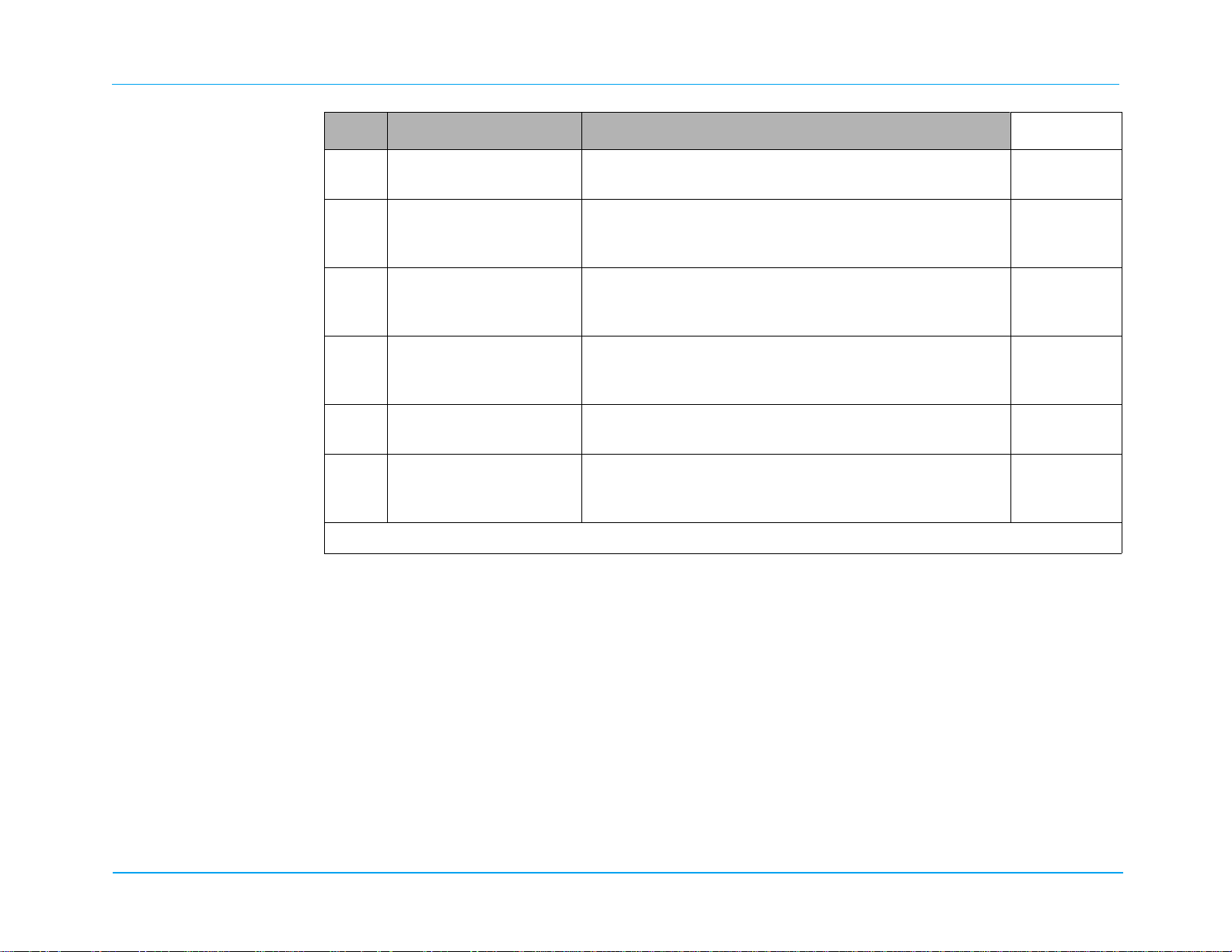

Zoll M Series Error Messages

The following is a list of Zoll M Series error messages that may appear on your display. The “User Advisory” column

informs you about an action in progress or provides feedback on a user correctable situation that typically does not

require further technical support. The “T echnical Action” column describes what you as a technician can do to correct

the situation. Note that these messages will sometimes overlap part of the waveform display.

First, attempt to clear the message by turning the Selector Switch to OFF for ten seconds, then back to the desired

operating mode. If the fault persists, call ZOLL Technical Service.

Error Message Explanation

200J MAX BIPHASIC User attempted to set defibrillation energy >200J on

Biphasic Unit. No higher energy is available.

50J MAX Energy < 50J for internal paddles. No higher energy

is available.

ADJUST ECG Unit is in sync mode and heart rate is < 20 BPM.

Or, QRS size set too small for proper

synchronization.