Page 1

MP2600iec

Hardware Manual

™

Page 2

Page 3

Table of Contents

1 Introduction

1.1 MP2600iec Features - - - - - - - - - - - - - - - - - - - - - - - - 3

1.2 MP2600iec Appearance- - - - - - - - - - - - - - - - - - - - - - 4

1.3 Model Number Reference - - - - - - - - - - - - - - - - - - - - 5

2 Specifications

2.1 General Specifications- - - - - - - - - - - - - - - - - - - - - - - 7

2.2 MP2600iec Hardware Specifications - - - - - - - - - - - - - 8

3 Mechanical Installation

3.1 Mounting Information- - - - - - - - - - - - - - - - - - - - - - - - 9

3.2 Installation Standards - - - - - - - - - - - - - - - - - - - - - - 10

3.3 Dimensions- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 11

Table of Contents

4 Inputs/Outputs

4.1 CN13 Connection Diagram - - - - - - - - - - - - - - - - - - 13

4.2 CN13 Connection Description - - - - - - - - - - - - - - - - 14

4.3 External Encoder Interface - - - - - - - - - - - - - - - - - - 15

4.4 Controller Digital I/O - - - - - - - - - - - - - - - - - - - - - - - 16

4.5 Sigma-5 I/O - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 18

4.6 Analog I/O - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 19

5 DIP Switches

5.1 Switch Settings - - - - - - - - - - - - - - - - - - - - - - - - - - - 21

6 LED Outputs - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 23

7 Battery

7.1 Battery Installation- - - - - - - - - - - - - - - - - - - - - - - - - 25

1

Page 4

Table of Contents

8 Ethernet

8.1 Connectivity Information- - - - - - - - - - - - - - - - - - - - - 27

8.2 Ethernet Connector Details- - - - - - - - - - - - - - - - - - - 27

8.3 Ethernet Cable - - - - - - - - - - - - - - - - - - - - - - - - - - - 28

8.4 Ethernet Connection Examples- - - - - - - - - - - - - - - - 28

9 Cable Diagrams

9.1 CBK-U-MP2B-xx (Terminal Block-Controller) - - - - - - 31

9.2 CFC-U-MP2B-xx (Flying Lead-Controller) - - - - - - - - 32

9.3 SBK-U-VBA-xx (Terminal Block-Servo Amp) - - - - - - 33

9.4 JZSP-CSI02-x-E (Flying Lead-Servo Amp) - - - - - - - 34

10 Firmware Upgrade Procedure- - - - - - - - - - - - - - - - - 35

11 EMC Installation Conditions - - - - - - - - - - - - - - - - - - 37

2

Page 5

1 Introduction

1.1 MP2600iec Features

MP2600iec is a single-axis machine controller option card that is

attached to a Sigma-5 servo amplifier. The servo amplifier and

controller are factory assembled, providing a compact, all-in-one

servo/controller package with the following features:

PLCopen for Motion Control, including indexing, camming, gearing, and

servo parameter maintenance capability.

Sigma-5 self-tuning, anti-vibration, and other high performance,

easy-to-implement servo control features

Ethernet (100Mbps) Auto crossover switching

• EtherNet/IP

• Modbus TCP

• Allows high-speed communications with MotionWorks IEC

• Enables communication with the application program by using a

touch panel

• Enables communication with the application program from another

controller

1.1

MP2600iec Features

Combined Amplifier/Controller I/O features

• 15 digital inputs

• 11 digital outputs

• 1 analog input

• 1 analog output

• 1 external encoder (quadrature, pulse + direction, up/down)

• 1 external encoder latch

3

Page 6

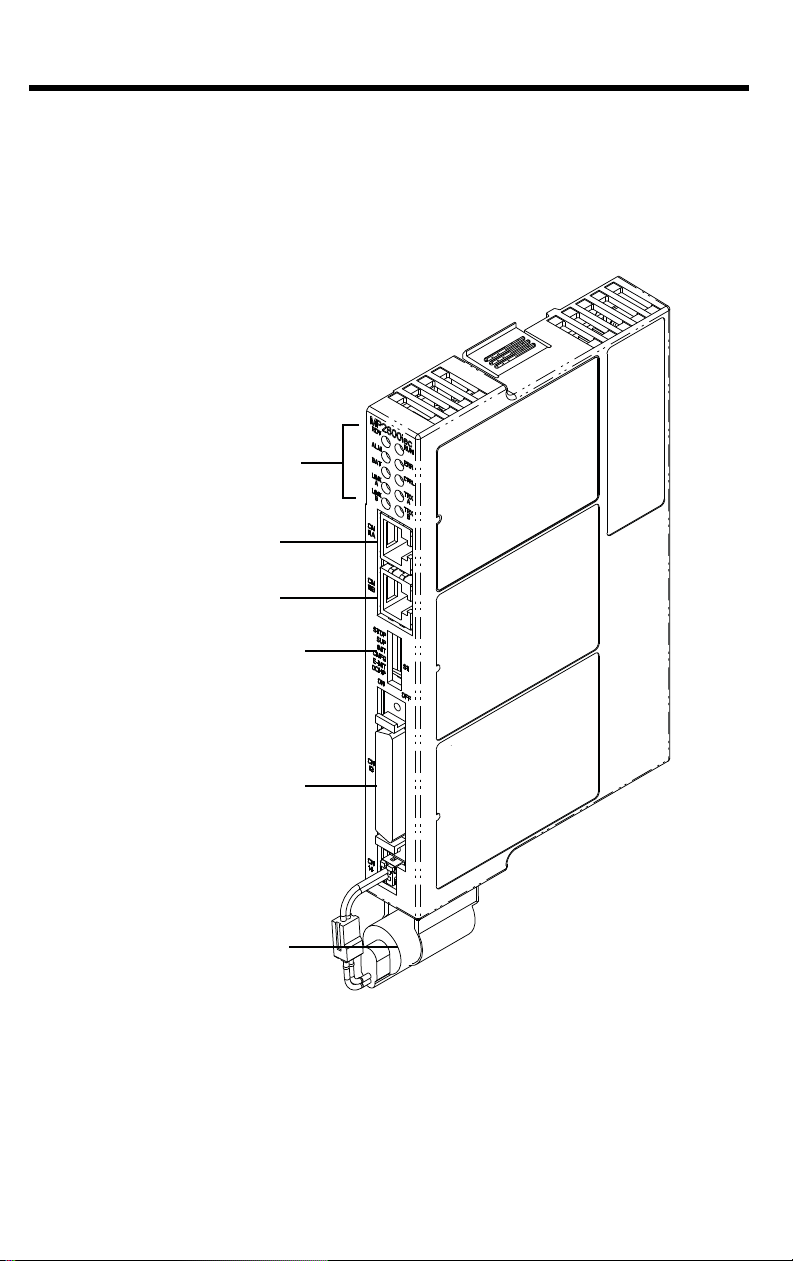

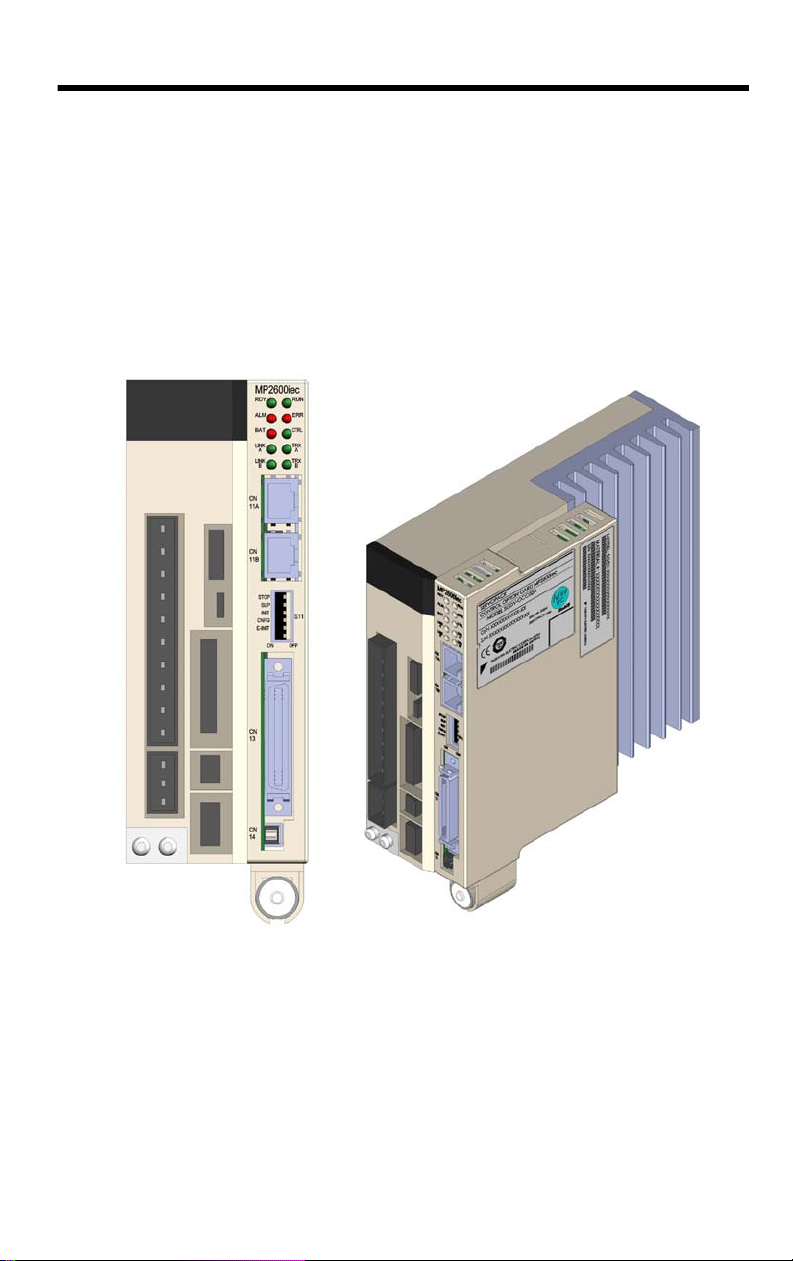

1.2

MP2600iec Appearance

1.2 MP2600iec Appearance

The following figure shows the external appearance of the MP2600iec

controller (Note: The servo amplifier is not shown).

LED (10 points)

Ethernet Port A

Ethernet Port B

DIP Switch (6 points)

CN13 Port

Analog I/O, Digital I/O

External Encoder (incremental)

3.6V Lithium Battery

(preserves retained variables,

absolute encoder offset,

and real-time clock data)

4

Page 7

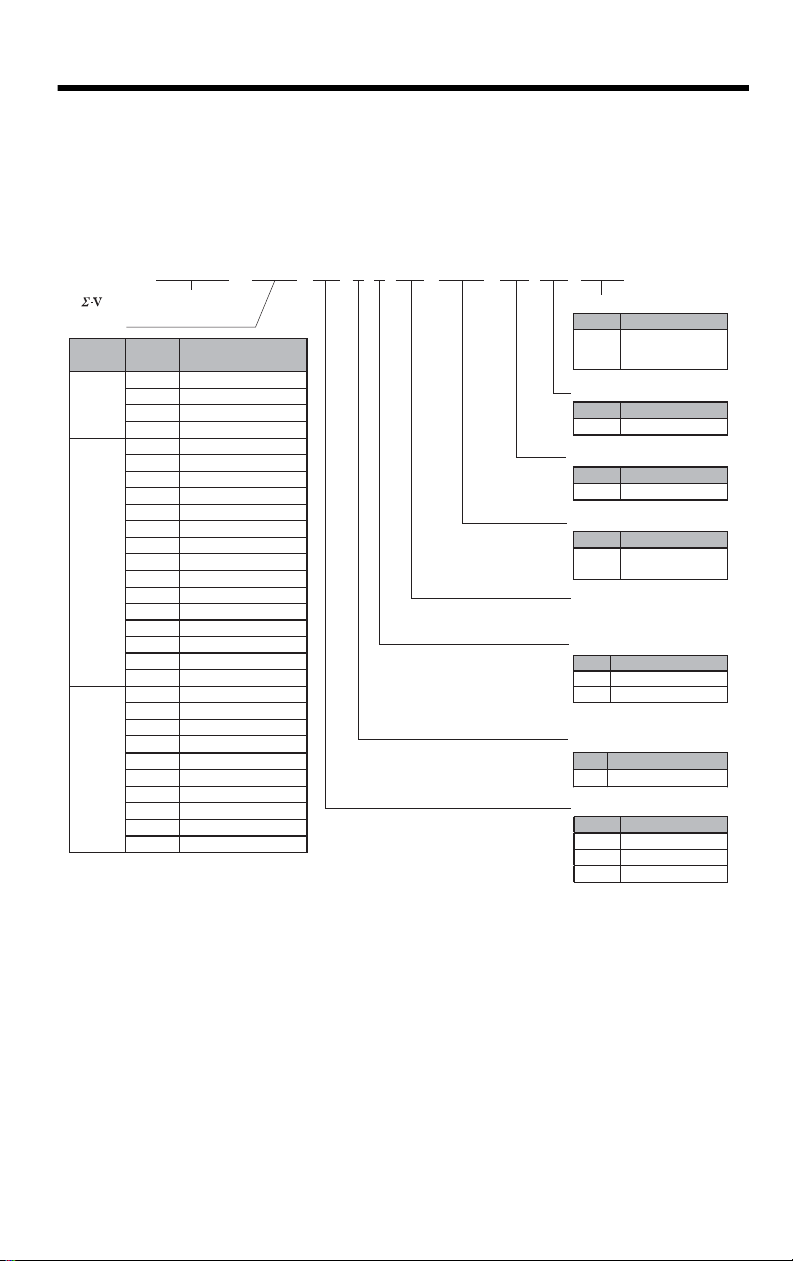

1.3 Model Number Reference

1.3.1 Model Number Designation

1.3

Model Number Reference

1.3.1 Model Number Designation

SGDV

Series SGDV SERVOPACK

Current

Volt age

100V

200V

400V

* These amplifiers can be powered with single or three-phase.

♣ SGDV-120A¡¡A008000¡¡¡, a special version of the 1.5kW

amplifier can be used for single-phase operation.

Applicable Servomotor

Code

R70 0.05

R90 0.1

2R1 0.2

2R8 0.4

R70* 0.05

R90* 0.1

1R6* 0.2

2R8* 0.4

3R8 0.5

5R5* 0.75

7R6 1.0

120

♣1.5

180 2.0

200 3.0

330 5.0

470 6.0

550 7.5

590 11

780 15

1R9 0.5

3R5 1.0

5R4 1.5

8R4 2.0

120 3.0

170 5.0

210 6.0

260 7.5

280 11

370 15

R70 A E 1 A 000 00 0 300

Max. Capacity kW

Option Module

Code Specifications

MP2600iec 1.5 Axis

300

Machine Controller

Module

Options (parameter)

Code Specifications

0 standard

Options (software)

Code Specifications

00 standard

Options (hardware)

Code Specifications

000 Base-mounted

(standard)

Design Revision Order

A, B…

Motor Type

Code Specifications

1 Rotary Servomotors

5** Linear Servomotors

** Under Development

Interface Options

Code Specifications

E

Communication Reference

Voltage

Code Specifications

F 100 VAC

A 200 VAC

D 400 VAC

5

Page 8

1.3

Model Number Reference

1.3.2 Accessory Model Numbers

1.3.2 Accessory Model Numbers

System Components

Type Model Part Number Note

Battery JZSP-BA01 Replacement

Battery Holder Kit SGDV-OZC02A Replacement (does not include battery)

CN13 (MP2600iec)

Terminal Block

Conversion Kit

CN13 (MP2600iec)

(Flying Leads)

CN1 (Servo Amp)

Accessories/Cables

Terminal Block

Conversion Kit

CN1 (Servo Amp) Cable

(Flying Leads)

CBK-U-MP2Bxx

CFC-U-MP2Bxx

SBK-U-MP2Bxx

JZSP-CSI02-x-E

xx denotes cable length (m)

A5 = 0.5

01 = 1

03 = 3

x denotes cable length (m)

A = 1 B = 2 C = 3

Ethernet Cable N/A

Communication

MotionWorks IEC

Express

MotionWorks IEC Pro PDE-U-IEPx

Software

OPC Server PDE-U-OPCPx

PDE-U-IESx

Use commonly available shielded Ethernet

cable

denotes MotionWorks IEC Version

C = 1 2 = 2

x denotes number of software licenses

A = 1 B = 5 C = 10

x denotes number of software licenses

A = 1 B = 5 C = 10 D = 20

6

Page 9

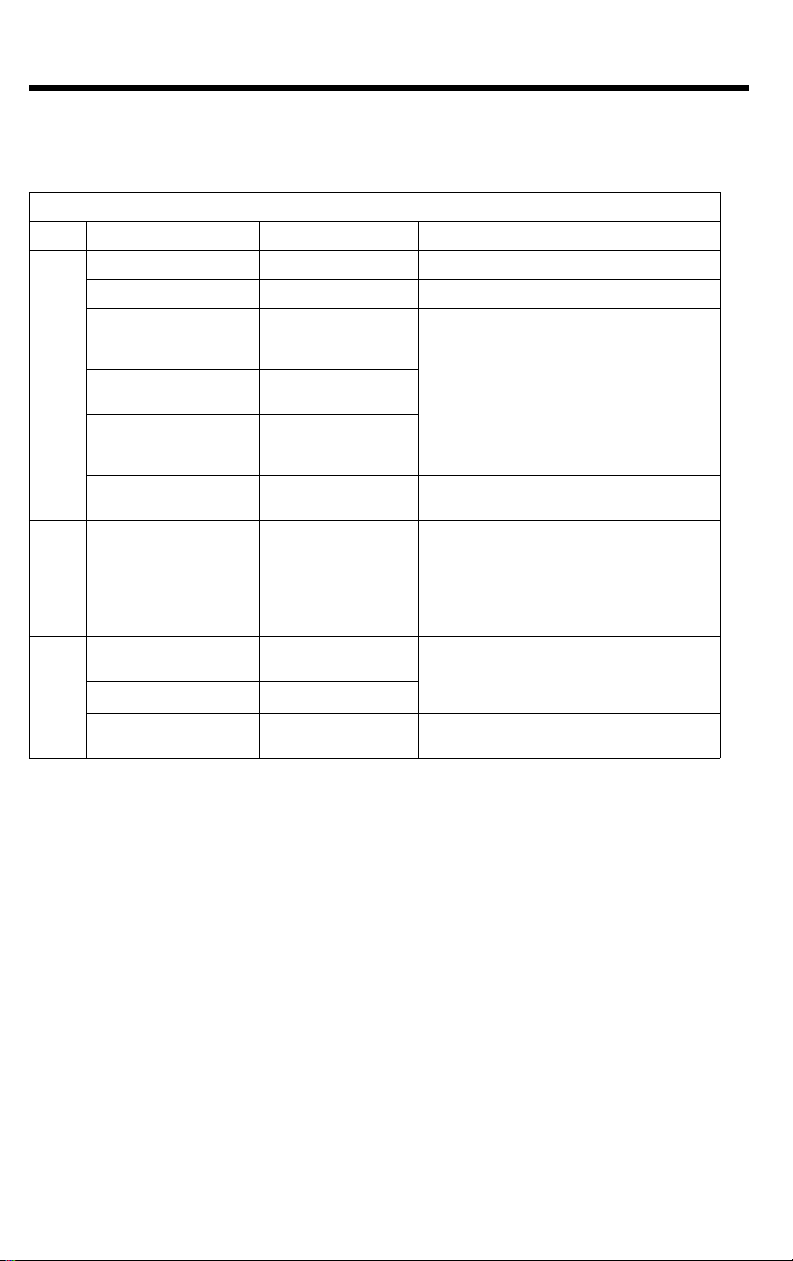

2 Specifications

2.1 General Specifications

Item Specifications

Environmental

Conditions

Mechanical

Operating

Conditions

Ambient Operating

Temperature

Ambient Storage

Temperature

Ambient Operating

Humidity

Ambient Storage

Humidity

Protection Class/

Pollution Degree

Operating Altitude 1,000 m above sea level or lower

Vibration

Resistance

Shock Resistance

Others

0 to 55°C

-20°C to +85°C

90% RH or less (with no condensation)

90% RH or less (with no condensation)

Protection class: IP10, Pollution degree: 2

An environment that satisfies the following conditions.

• Free of corrosive or explosive gases

• Free of exposure to water, oil or chemicals

• Free of dust, salts or iron dust

2

4.9 m/s

2

19.6 m/s

Free of static electricity, strong electromagnetic fields,

magnetic fields or exposure to radioactivity

2.1 General Specifications

7

Page 10

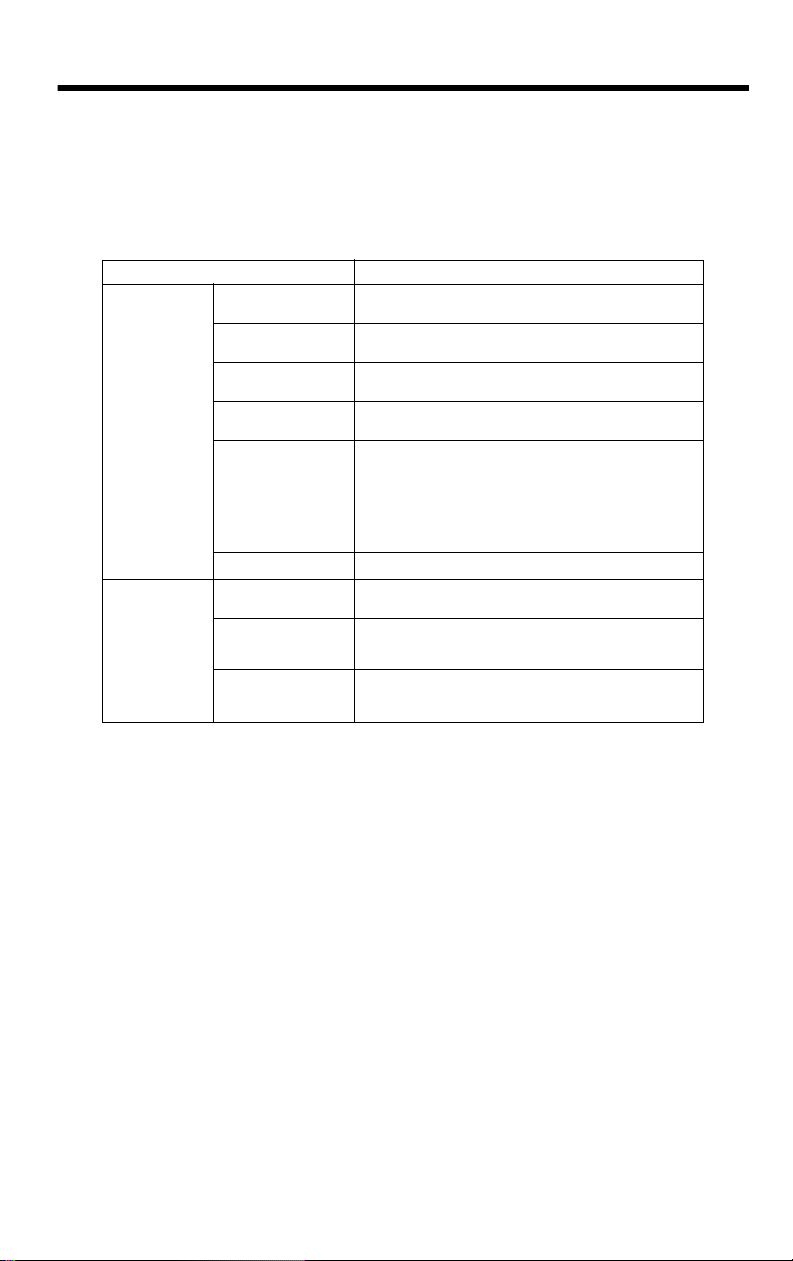

2.2

MP2600iec Hardware Specifications

2.2 MP2600iec Hardware Specifications

Item Specification

CPU 200 MHz, 32 bit, ARM 9

SDRAM 32 MB

Memory

Operator interface

Controller

Side

(CN13)

User

I/O

ServoSide

(CN1)

Network capability

Programming standards IEC61131-3/PLCopen

Diagnostic and configuration interface Web interface

Motion control performance

Servo-Side Safety Functions

SRAM 512 kB with battery backup

Flash 4 MB flash. Code and parameter storage.

LED

User Configuration

Network 2x 100baseTX Ethernet

Digital input 8 programmable inputs

Digital output 8 programmable outputs

Analog input 1 ch., +/- 10V, 16 bit

Analog output 1 ch., +/- 10V, 16 bit

Pulse Counter

Sequence

Input

Sequence

Output

Allocated*

Fixed Servo Alarm (ALM)

Allocated*

Input

Output

10 LEDs (red and green - operating mode,

communication and error status)

6x DIP switch (operating mode and communication

configuration)

RS-422-compatible pulse counter input (quadrature,

pulse and direction, and up/down co unter modes) wi th

5, 12, or 24V position latch input

Number of Inputs: 7

Functions: The signal allocation and positive/negative

logic can be modified. Forward run prohibited (P-OT),

reverse run prohibited (N-OT), forward torque limit (/PCL), reverse torque limit (/N-CL), general-purpose

input signal (/SI0 to /SI6)

Number of Outputs: 3

Functions: The signal allocation and positive/negative

logic can be modified. Positioning completion (/COIN),

speed coincidence detection(/V-CMP), servomotor

rotation detection (/TGON), servo ready (/S-RDY),

torque limit detection (/CLT), speed limit detection

(VLT), bra ke (/BK ), warn in g (/WARN), near (/NEAR)

OPC (Client and Server required)

EtherNet/IP

Modbus/TCP

1 controlled axis and one external position input at a

trajectory update rate of 1 kHz

/HWBB1, /HWBB2: Baseblock signal for power

module

EDM1: Status monitor (fixed output) of built-in safety

circuit

* Allocated I/O can also be used as programmable I/O if the output functions are disabled.

8

Page 11

3 Mechanical Installation

3.1 Mounting Information

The MP2600iec controller is pre-assemble d to th e Sigm a -5 serv o

amplifier by the factory.

3.1 Mounting Information

9

Page 12

3.2 Installation Standards

3.2 Installation Standards

The servo amplifier must be installed in a fully enclosed metal control panel. Observe the standards

for mounting servo amplifiers in control panels, including those for the mounting servo amplifiers side

by side in one control panel as shown in the following illustration.

• Servo Amplifier Mounting Orientation

Mount the servo amplifier vertically to the wall, with the fr

display)

facing out.

• Cooling

Refer to the following diagram and leave sufficient space for cooling by fans and natural convection.

• Mounting Servo Amplifiers Side by Side in a Control Panel

Fan Fan

ont panel (the side with the panel operator

40 mm or more

40 mm or more

30 mm or more

Width varies with

servo amplifier model

Leave sufficient space on each side and at the top and the bottom of each servo amplifier. The

width on each side varies in accordance with the models of the servo amplifiers used.

Servo Amplifier Model SGDV-

R70F, R90F, 2R1F, R70A, R90A, 1R6A, 2R8A 1 mm or more

2R8F, 3R8A, 5R5A, 7R6A 1 mm or more 10 mm or more

120A, 180A, 200A, 330A, 470A, 550A, 590A, 780A,

1R9D, 3R5D, 5R4D, 8R4D, 120D, 170D, 210D, 260D,

280D, 370D

Side

Left Right

10 mm or more

Top and bottom

40 mm or more

Also install cooling fans above the servo amplifiers to disperse local pockets of warmer air around

the servo amplifiers.

• Inside the Control Panel

The conditions inside the control panel should be the same as the environmental conditions of

the servo amplifier. Refer to the environmental conditions in 2.1 General Specifications

.

• During Operation

Do not touch the connectors or IO cables during operation if the panel door is open.

.

10

Page 13

3.3 Dimensions

20

160

(22)

97

(20)

Dimensions in mm.

20

3.3.1 MP2600iec Controller

3.3 Dimensions

3.3.1 MP2600iec Controller

11

Page 14

3.3 Dimensions

3.3.1 MP2600iec Controller

This page left intentionally blank

12

Page 15

4 Inputs/Outputs

4.1 CN13 Connection Diagram

CN13

+15

V

Analog

Output

Analog

Input

Z-phase

Latch Input

Digital

Input

+

+15

V

+

Encoder

Interface

+5V

Digital

Output

Polyswitch Device:

A self-resetting

fuse if excessive

current is drawn

from the output

-15V

-15V

FG Connector Shell)

AO

1

AO_GND

26

AI

2

AI_GND

27

PA+

4

PA-

5

PB+

29

PB-

30

GND

6

GND

31

PILC(24V)

10

PILC(12V)

34

PILC(5V)

9

PIL

35

DICOM

13

DICOM

38

DI_00

14

DI_01

39

DI_02

15

DI_03

40

DI_04

16

DI_05

41

DI_06

17

DI_07

42

DO_00+

21

DO_00-

11

DO_01+

46

DO_01-

36

DO_02+

22

DO_02-

12

DO_03+

47

DO_03-

37

DO_04+

23

DO_04-

18

DO_05+

48

DO_05-

43

DO_06+

24

DO_06-

19

* DO_07+

49

* DO_07-

44

7 + Battery

32 - Battery

Connect a positive voltage to pin 10, 34, or 9 based on signal level

NOTE: For a more detailed circuit drawing, see section 4.4.2.

* DO_07 can also be used as a high speed output when

configured via parameter 1050

4.1 CN13 Connection Diagram

External Device

L

+10V

-10

FG

External Device

V

-10 +10V

FG

Pulse

Generator

FG

Latch Input

Signal

External Input

+24VDC

L

0V

+24VDC

L

0V

+24VDC

L

0V

+24VDC

L

0V

+24VDC

L

0V

+24VDC

L

0V

+24VDC

L

0V

+24VDC

L

0V

L

Load

External Fuse

(installed by

customer)

13

Page 16

4.2

Numerical

Alphabetical

CN 13 Pin Code Description

1 AO Analog Output

2 AI Analog Input

3 n/c no connection

4 PA+ Encoder A phase +

5 PA- Encoder A phase 6 GND Encoder ground

7 BAT + SRAM Positive Battery input

8 n/c no connection

9PILC

PC+ /

External Encoder Latch

+5V

10 PILC

PC+ /

External Encoder Latch

+24V

11 DO_00- Digital Output 0 12 DO_02- Digital Output 2 13 DICOM Digital Input Common

14 DI_00 Digital Input 0

15 DI_02 Digital Input 2

16 DI_04 Digital Input 4

17 DI_06 Digital Input 6

18 DO_04- Digital Output 4 19 DO_06- Digital Output 6 20 n/c no connection

21 DO_00+ Digital Output 0 +

22 DO_02+ Digital Output 2 +

23 DO_04+ Digital Output 4 +

24 DO_06+ Digital Output 6 +

25 n/c no connection

26 AO_GND Analog Output Ground

27 AI_GND Analog Input Ground

28 n/c no connection

29 PB+ Encoder B phase +

30 PB- Encoder B phase 31 GND Encoder ground

32 BAT - SRAM Negative Battery input

33 n/c no connection

34 PILC

PC+ /

External Encoder Latch

+12V

35 PIL PC- / External Encoder Latch

36 DO_01- Digital Output 1 37 DO_03- Digital Output 3 38 DICOM Digital Input Common

39 DI_01 Digital Input 1

40 DI_03 Digital Input 3

41 DI_05 Digital Input 5

42 DI_07 Digital Input 7

43 DO_05- Digital Output 5 44 DO_07- Digital Output 7 45 n/c no connection

46 DO_01+ Digital Output 1 +

47 DO_03+ Digital Output 3 +

48 DO_05+ Digital Output 5 +

49 DO_07+ Digital Output 7 +

50 n/c no connection

Description Code CN 13 Pin

Analog Input AI 2

Analog Input Ground AI_GND 27

Analog Output AO 1

Analog Output Ground AO_GND 26

Digital Input 0 DI_00 14

Digital Input 1 DI_01 39

Digital Input 2 DI_02 15

Digital Input 3 DI_03 40

Digital Input 4 DI_04 16

Digital Input 5 DI_05 41

Digital Input 6 DI_06 17

Digital Input 7 DI_07 42

Digital Input Common DICOM 13

Digital Input Common DICOM 38

Digital Output 0 - DO_00- 11

Digital Output 0 + DO_00+ 21

Digital Output 1 - DO_01- 36

Digital Output 1 + DO_01+ 46

Digital Output 2 - DO_02- 12

Digital Output 2 + DO_02+ 22

Digital Output 3 - DO_03- 37

Digital Output 3 + DO_03+ 47

Digital Output 4 - DO_04- 18

Digital Output 4 + DO_04+ 23

Digital Output 5 - DO_05- 43

Digital Output 5 + DO_05+ 48

Digital Output 6 - DO_06- 19

Digital Output 6 + DO_06+ 24

Digital Output 7 - DO_07- 44

Digital Output 7 + DO_07+ 49

Encoder A phase - PA- 5

Encoder A phase + PA+ 4

Encoder B phase - PB- 30

Encoder B phase + PB+ 29

Encoder ground GND 6

Encoder ground GND 31

no connection n/c 3

no connection n/c 8

no connection n/c 20

no connection n/c 25

no connection n/c 28

no connection n/c 33

no connection n/c 45

no connection n/c 50

PC- / External Encoder Latch PIL 35

PC+ / External Encoder Latch+12V

PILC 34

PC+ /

External Encoder Latch

+24V

PILC 10

PC+ /

External Encoder Latch

+5V

PILC 9

SRAM Negative Battery input BAT - 32

SRAM Positive Battery input BAT + 7

Note: DO_07 can also be used as a high speed output when configured via parameter 1050. See the PLCopen Plus

Axis Parameters for more details.

CN13 Connection Description

4.2 CN13 Connection Description

14

Page 17

4.3 External Encoder Interface

4.3 External Encoder Interface

Item Specification

Number of

channels

Input circuit

Counter modes

PIL Latch input

DI_01 Latch Input

Two RS-422 compatible inputs are provided for encoder phases A and

B. One position latch input which supports a 5V, 12V , or 24V digit al input

signal is provided.

One channel (Phase A, Phase B, Index pulse)

Phase A & B: 5V differential input (RS-422 compatible), non-insulated.

Maximum frequency 4MHz.

Index pulse: 5V/12V/24V photo coupler input. Maximum frequency

500kHz (pre-quadrature. This signal is used for external encoder latch.

Quadrature, pulse and direction, up/down

Hardware latency: 5s or less, sinking input

Hardware latency: 600s or less, sinking input

R

CN13 Connector

R

R

R

R

R

4

PA+

5

PA-

29

PB+

30

PB-

6

GND

31

GND

35

PIL

9

PILC(5V)

34

PILC(12V)

10

PILC(24V)

+5V

Phase A

Phase B

Pulse generator

+5V

0V

+5V

0V

Encoder Input Circuit (PILC refers to positive input side of sensor)

15

Page 18

4.4 Controller Digital I/O

4.4.1 Inputs

4.4 Controller Digital I/O

4.4.1 Inputs

• 8 general purpose

• Optically isolated

• 24 V @ 5 mA

• Entire bank is configurable as either current sinking or sourcing via

connection of common

16

Digital Input Circuit

To configure all controller inputs as sinking, wire +24VDC to pins 13

and 38. To configure all controller inputs as sourcing, wire 0VDC to

pins 13 and 38. Refer to diagram in Section 5.1.

Page 19

4.4.2 Outputs

0V

Relay

5 to 24 VDC

SERVOPACK

• 8 general purpose

• Optically isolated

• 24 V @ 50 mA

• Current source or sink (connection to both emitter and collector are

provided)

• High speed digital output feature can set DO_07 within 13s of passing a

specified encoder position. See Axis Parameters in the PLCopen Plus

Function Block Manual to configure

Digital Output Circuit

Connection Examples of Output Circuits

• Relay Circuit Example

4.4 Controller Digital I/O

4.4.2 Outputs

.

• Line Receiver Circuit Example

SERVOPACK

5 to 12 VDC

17

Page 20

4.5 Sigma-5 I/O

4.4.2 Outputs

4.5 Sigma-5 I/O

The Sigma-5 includes seven digital inputs and three digital outputs

that can be monitored and controlled by the MP2600iec.

Control power supply

for sequence signal

Forward run prohibited

(Prohibited when OFF)

Reverse run prohibited

(Prohibited when OFF)

Command option

module input 3

Command option

module input 4

Command option

module input 5

Command option

module input 6

General-purpose input 0

*

3

*

4

*

4

*

4

*

4

Backup battery

(2.8 to 4.5 V)

*

2

Photocoupler output

Max. operating voltage: 30 VDC

Sigma-5 SGDV Servo Amp

CN1

3.3kΩ

6

+24V

/SI1

7

/SI2

8

/SI3

9

/SI4

10

/SI5

11

12

/SI6

/SI0

13

BAT+

14

BAT-

15

*

1

Max. operating current: 50 mA DC

ALM+

3

Servo alarm output

(OFF for an alarm)

ALM-

4

SO1+ / BK+

1

2

23

24

25

26

17

18

19

20

21

22

16

SO1- / BK-

/SO2+

/SO2-

/SO3+

/SO3-

/PAO

/PBO

PAO

PBO

PCO

/PCO

SG

Brake output

(Brake released when ON)

General-purpose outputs

Encoder output

pulses phase A

Encoder output

pulses phase B

Encoder output

pulses phase C

Signal ground

Applicable line

receiver

SN75ALS175

manufactured by

Texas Instruments

or an MC3486

equivalent

18

Page 21

4.6 Analog I/O

4.6.1 Analog Input

Item Specification

Analog input range -10V ~ +10V

Number of input channels 1

Electrical isolation None

Absolute maximum input ± 15V

Input Impedance 20k

Resolution 16 bit

Accuracy

Input filter

Conversion time 50s

25°C ±0.1% (± 10mV)

0 ~ 55°C ±0.3% (± 30mV)

Time constant =130s (63.2% rise time)

Delay time

1ms maximum (for full-range -10V to

+10V slew)

CN13 Connector

4.6 Analog I/O

4.6.1 Analog Input

To A/D

Conversion

20K

10K

10K

GND

Analog Input Circuit

2

27

AI

AI_GND

19

Page 22

4.6 Analog I/O

CN13 Connector

1

26

AO

AO_GND

+

-

+15

V

-15V

4.6.2 Analog Output

4.6.2 Analog Output

Item Specification

Analog output range -10V ~ +10V

Number of output channels 1

Electrical isolation None

Maximum load current ± 5mA

Resolution 16 bit

Accuracy

Output delay time less than 1ms

25°C ±0.45% (± 45mV)

0 ~ 55°C ±0.60% (± 60mV)

20

Analog Output Circuit

Page 23

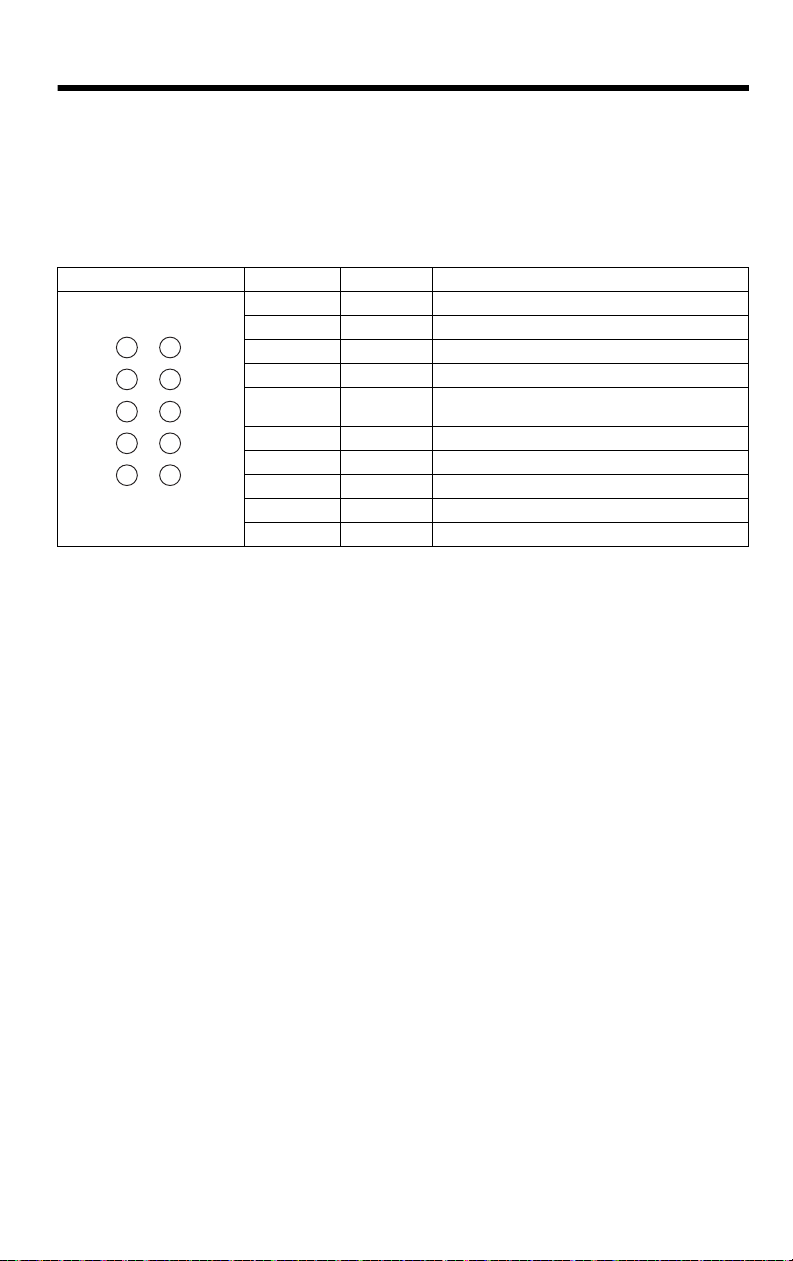

5 DIP Switches

5.1 Switch Settings

STOP

SUP

INT

CNFG

EINIT

DHCP

S11

NO

5.1 Switch Settings

Switch Name Setting Operating Mode

User program execution

ON

STOP

1

SUP

2

3

INIT

CNFG

4

E-INIT

5

DHCP

6

inhibited

OFF Normal operation

Firmware programming

ON

mode

OFF Normal operation

SRAM/clock initialization

ON

and configuration bypass

mode

OFF Normal operation

ON Normal operation

Do not set (reserved for

OFF

future use)

Force Ethernet address

setting for Port A to

ON

192.168.1.1 and Port B

to 192.168.2.1

OFF Normal Operation

DHCP-configured IP

ON

settings

Manually-configured IP

OFF

settings

Setting for

Normal

Operation

OFF

OFF

OFF

ON

OFF

OFF

Details

Inhibits user program execution

Enables controller firmware programming.

(See Section 11)

Set to ON to bypass the stored configuration

(e.g. in case of a configuration problem that

prevents controller startup) or t o initialize the

SRAM contents and clock settings after

backup power has been lost (See Section

7.1).

Always set to ON

Enables use of the default Ethernet

addresses

Enables use of DHCP for IP setti n g

configuration

21

Page 24

5.1 Switch Settings

22

This page left intentionally blank

Page 25

6 LED Outputs

A

The following table shows the indicators that show the operating

status of the controller and error information.

Indicator Color Status

RDY

RUN

RDY

LM

BAT

LINK

A

LINK

B

RUN

ERR

CTRL

TRX

A

TRX

B

ALM

ERR

CTRL

BAT

TRX A

LINK A

TRX B

LINK B

Green

Green

Red

Red

Green

Red

Green

Green

Green

Green

6 LED Outputs

Lit during normal operation.

Lit during execution of user program.

Lit when alarm occurs.

Lit when malfunction occurs.

Lit when option card is communicating to the

servo amplifier.

Lit during battery alarm.

Lit during Ethernet CN11A activity.

Lit during Ethernet CN11A link up.

Lit during Ethernet CN11B activity.

Lit during Ethernet CN11B link up.

23

Page 26

6 LED Outputs

This page left intentionally blank

24

Page 27

7 Battery

Option Case

(snaps off unit)

Screw

Battery

Metal plate for

connection

Battery Holder

1

2

3

+

-

7.1 Battery Installation

A 3.6V lithium battery must be used to retain SRAM data in the

controller when the power is off. SRAM will last for one hour without

the battery connected. The battery power can be applied through the

battery connector (CN14), or through the I/O connector (CN13 pins

7[+] & 32[-]). The battery is necessary for preserving retained

variables, absolute encoder offset, and real-time clock data.

7.1 Battery Installation

To initialize the non-vo latile memory and clock settings after a battery

is attached for the first time (or any time backup power has been lost),

use the following procedure.

1. Power off the MP2600iec.

2. Set the “INIT” switch (S11) to ON.

3. Power on the MP2600iec and wait for the “RDY” LED to illuminate.

4. Power off the MP2600iec.

5. Set the “INIT” switch (S11) to OFF.

25

Page 28

7.1 Battery Installation

Battery Holder Installation Instructions:

1. Remove the plastic case from the

controller by pressing the tabs at the

top and bottom.

2. Insert the tab of the metal plate

into the last vent slot on the bottom

front of the case as shown.

3. Line up the hole in battery holder

with the hole in the metal plate and

secure the battery holder with the

screw provided.

4. Attach the extension cable to the

battery and place the battery into the

battery holder with the cable facing

forward.

5. Attach the plastic case to the

controller.

26

6. Plug the battery extension cable

into the battery connector (CN14).

Page 29

8 Ethernet

Ethernet

8.1 Connectivity Information

The MP2600iec supports 100MB speeds exclusively. Two separate

networks are possible using both CN11A and CN11B. A default

gateway can be specified only for the network attached to CN11A.

8.2 Ethernet Connector Details

Ethernet Connector Specification and Pin Array

The following table provides the Ethernet connector specifications.

8.1 Connectivity Information

Connector

Name

Ethernet

Number

of Pins

8 RJ-45 CAT5 Socket RJ-45 CAT5 Plug Pulse Engineering

Module Side Cable Side Manufacturer

Connector Model

The following table provides Ethernet connector pin array / indicator

light details.

Pin Number Signal Nam e Description

1TXD+

2TXD3RXD+

4–

5–

6RXD7–

8–

Transmitted data + side

Transmitted data – side

Received data + side

–

–

Received data – side

–

–

27

Page 30

8.3 Ethernet Cable

8.3 Ethernet Cable

For the Ethernet cable, use a twisted pair cable with RJ-45

connector. Yaskawa strongly recommends the use of shielded

ethernet cables. Ethernet ports are capable of auto-crossover, so

crossover cables are not necessary.

8.4 Ethernet Connection Examples

Connection Example 1 (When using a repeater HUB)

Sigma-5 with

MP2600iec

Station*

Station*

28

100Base-TX

Up to 100m

100Base-TX

Ethernet Switch

Up to 100m

Specification

Cable Length between Node-HUB 100 m or less

Cable Length between HUBs 100 m or less

Number of HUBs between Nodes Unlimited

Item

Up to 100m

Up to 100m

Up to 100m

Station*Station*

Up to 100m

100Base-TX

Ethernet Switch

* Note: The MP2600iec can only be plugged into

a 100Base-TX Ethernet port.

When Connecting to a

Ethernet Switch

Page 31

8.4 Ethernet Connection Examples

Model Manufacturer

E04SR301334

Seiwa Electric Mfg. Co., Ltd

Connection Example 2

Sigma-5 with MP2600iec

100 Base-TX (up to 100m)

Note: The MP2600iec can only be plugged

into a 100Base-TX Ethernet port.

Caution

High frequency wave noise from other devices in the installat ion environment

may cause errors in communications. When designing a system, use protective

measures to avoid the influence of high frequency wave noise as follows:

1. Wiring

Wire Ethernet cables so that they are well-separated from other cable

systems such as the main circuit or power lines.

2. Communication system (Ethernet)

• Communicate data to a remote device.

• Yaskawa strongly recommends shielded Ethernet cables.

3. Attach a ferrite core.

This will help reduce the occurrence of electrical interference.

Recommended ferrite core:

29

Page 32

8.4 Ethernet Connection Examples

100Base-TX

Ethernet Switch

MotionWorks IEC

Sigma-5 with MP2600iec

Core

Core

100Base-TX

Servomotor

Station*

* Note: The MP2600iec can only be plugged

into a 100Base-TX Ethernet port

Connection Example 3

30

Page 33

9 Cable Diagrams

CBK-U-MP2B-XX Function Chart for MP2600iec

I = Input, O = Output, P = Power

Pin

No.

Signal

Name

I/O Function

Pin

No.

Signal

Name

I/O Function

1 AO O Analog output 26 AO_GND O Analog output ground

2 AI I Analog input 27 AI_GND I Analog input ground

3 - - - 28 reserved -

4 PA+ I Phase A pulse (+) 29 PB+ I Phase B pulse (+)

5 PA- I Phase A pulse (-) 30 PB- I Phase B pulse (-)

6 GND P Encoder input ground 31 GND P Encoder input ground

7 BAT+ P Controller SRAM Battery (+) 32 BAT- P Controller SRAM Battery (-)

8 - - - 33 - - -

9PILC5V I

Phase-C latch pulse (-) for

5VDC input

34 PILC12V I

Phase-C latch pulse (-) for 12VDC

input

10 PILC24V I

Phase-C latch pulse (-) for

24VDC input

35 PIL I Phase-C latch pulse (+)

11 DO_00- O Digital output 0 (-) 36 DO_01- O Digital output 1 (-)

12 DO_02- O Digital output 2 (-) 37 DO_03- O Digital output 3 (-)

13 DICOM I Digital input common 38 DICOM I Digital input common

14 DI_00 I Digital input 0 39 DI_01 I

Digital input 1

(shared with pulse latch input)

15 DI_02 I Digital input 2 40 DI_03 I Digital input 3

16 DI_04 I Digital input 4 41 DI_05 I Digital input 5

17 DI_06 I Digital input 6 42 DI_07 I Digital input 7

18 DO_04- O Digital output 4 (-) 43 DO_05- O Digital output 5 (-)

19 DO_06- O Digital output 6 (-) 44 DO_07- O Digital output 7 (-)

20 - - - 45 - - -

21 DO_00+ O Digital output 0 (+) 46 DO_01+ O Digital output 1 (+)

22 DO_02+ O Digital output 2 (+) 47 DO_03+ O Digital output 3 (+)

23 DO_04+ O Digital output 4 (+) 48 DO_05+ O Digital output 5 (+)

24 DO_06+ O Digital output 6 (+) 49 DO_07+ O

Digital output 7 (+) (shared with

position agreement 'COIN' signal)

25 - - - 50 - - -

9.1 CBK-U-MP2B-xx

Terminal Block - Controller

9.1 CBK-U-MP2B-xx

31

Page 34

9.2 CFC-U-MP2B-xx

Model X =Cable Length

CFC-U-MP2B-A5 500 mm

CFC-U-MP2B-01 1000 mm

CFC-U-MP2B-03 3000 mm

Dimensions in mm

Pin

No.

Color

(Solid/Band)

Signal

Name

I/O Function

Pin

No.

Color

(Solid/Band)

Signal

Name

I/O Function

1 BLK/RED AO O Analog output 26 RED/BLK AO_GND O

Analog output

ground

2 BLK/WHT AI I Analog input 27 WHT/BLK AI_GND I Analog input ground

3 RED/GRN - - - 28 GRN/RED - - -

4 BLK/BLU PA+ I Phase A pulse (+) 29 BLK/BRN PB+ I Phase B pulse (+)

5 BLU/BLK PA- I Phase A pulse (-) 30 BRN/BLK PB- I Phase B pulse (-)

6RED/BLUGND P

Encoder input

ground

31 BLU/RED GND P

Encoder input

ground

7 RED/WHT BAT+ P

Controller SRAM

Battery (+)

32 W HT/RED BAT- P

Controller SRAM

Battery (-)

8 BLK/GRN - - - 33 GRN/BLK - - -

9 BLK/YEL PILC5V I

Phase-C latch pulse

(-) for 5VDC input

34 ORG/BLK PILC12V I

Phase-C latch pulse

(-) for 12VDC input

10 BLK/ORG PILC24V I

Phase-C latch pulse

(-) for 24VDC input

35 YEL/BLK PIL I

Phase-C latch pulse

(+)

11 RED/YEL DO_00- O Digital output 0 (-) 36 W HT/ORG DO_01- O Digital output 1 (-)

12 RED/BRN D O_02- O Digital output 2 (-) 37 BLU/YEL DO_03- O Digital output 3 (-)

13 RED/ORG DICOM I Digital input common 38 ORG/RED DICOM I

Digital input

common

14 GRN/WHT DI_00 I Digital input 0 39 WHT /GRN DI_01 I

Digital input 1

(shared with pulse

latch input)

15 GRN/BLU DI_02 I Digital input 2 40 BLU/GRN DI_03 I Digital input 3

16 GRN/YEL DI_04 I Digital input 4 41 YEL/GRN DI_05 I Digital input 5

17 GRN/BRN DI_06 I Digital input 6 42 BRN/GRN DI_07 I Digital input 7

18 GRN/ORG DO_04- O Digital output 4 (-) 43 BLU/BRN DO_05- O Digital output 5 (-)

19 WHT/BLU D O_06- O Digital output 6 (-) 44 BLU/ORG DO_07- O Digital output 7 (-)

20 WHT/YEL - - - 45 YEL/WHT - - -

21 YEL/RED DO_00+ O Digital output 0 (+) 46 ORG/WHT DO_01+ O Digital output 1 (+)

22 BRN/RED DO_02+ O Digital output 2 (+) 47 YEL/BLU DO_03+ O Digital output 3 (+)

23 ORG/GRN DO _04+ O Digital output 4 (+) 48 BRN/BLU DO_05+ O Digital output 5 (+)

24 BLU/WHT DO_06+ O Digital output 6 (+) 49 ORG/BLU DO_07+ O

Digital output 7 (+)

(shared with position

agreement 'COIN'

signal)

25 W HT/BRN - - - 50 BRN/WHT - - -

9.2 CFC-U-MP2B-xx

Flying Lead - Controller

32

Page 35

9.3 SBK-U-VBA-xx

Signal Function

1

/BK+ (/SO1+) Brake interlock output (+) (General purpose output 1 (+))

2

/BK- (/SO1-) Brake interlock output (-) (General purpose output 1 (-))

3 ALM+ Servo alarm output (+)

4 ALM- Servo alarm output (-)

56+24VIN

Control power supply for sequence signal input

7

P-OT (/SI1) Forward run prohibited input (General purpose input 1)

8

N-OT (/SI2) Reverse run prohibited input (General purpose input 2)

9

/DEC (/SI3) Zero-point return deceleration switch input (General purpose input 3)

10

/EXT1 (/SI4) External latch signal 1 input (General purpose input 4)

11

/EXT2 (/SI5) External latch signal 2 input (General purpose input 5)

12

/EXT3 (/SI6) External latch signal 3 input (General purpose input 6)

13 /SI0 General purpose input 0

14 BAT (+) Battery (+) input

15 BAT (-) Battery (-) input

16 SG Signal ground

17 PAO Phase-A pulse output (+)

18 /PAO Phase-A pulse output (-)

19 PBO Phase-B pulse output (+)

20 /PBO Phase-B pulse output (-)

21 PCO Phase-C pulse output (+)

22 /PCO Phase-C pulse output (-)

23 /SO2+ General purpose output 2 (+)

24 /SO2- General purpose output 2 (-)

25 /SO3+ General purpose output 3 (+)

26 /SO3- General purpose output 3 (-)

SGDV Mechatrolink-II type / SGDV Option type

Pin No.

Terminal Block - Servo Amplifier.

SBK-U-VBA-xx Function Chart for SGDV Servo Amplifier

9.3 SBK-U-VBA-xx

Note: General purpose input and output signals are shown with their default signals assigned - signal

assignment may have been changed by parameter

33

Page 36

9.4 JZSP-CSI02-x-E

/BK

+

/BK

−

ALM

+

ALM

−

–

+

24VIN

P-OT

N-OT

/DEC

/EXT1

/EXT2

/EXT3

/SI0

BAT

+

BAT

−

SG

PAO

/PAO

PBO

/PBO

PCO

/PCO

/SO2

+

/SO2

−

/SO3

+

/SO3

−

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

Blue

Blue

Pink

Pink

Green

Green

Orange

Orange

Gray

Gray

Blue

Blue

Pink

Pink

Green

Green

Orange

Orange

Gray

Gray

Blue

Blue

Pink

Pink

Green

Green

Red

Black

Red

Black

Red

Black

Red

Black

Red

Black

Red

Black

Red

Black

Red

Black

Red

Black

Red

Black

Red

Black

Red

Black

Red

Black

1

1

1

1

1

1

1

1

1

1

2

2

2

2

2

2

2

2

2

2

3

3

3

3

3

3

Pin No.

Wire

Color

Signal

Marking

Color

SERVOPACK End

Dots

Lead

Marker

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

Represents

twisted-pair

wires.

Host

Controller End

Model Cable Length

JZSP-CSI02-1-E 1000 mm

JZSP-CSI02-2-E 2000 mm

JZSP-CSI02-3-E 3000 mm

SERVOPACK End

Connector

10126-6000

EL (by Sumitomo 3M Ltd.

)

Shell

10326-52A0-008

Cable (Ivory

)

SSRFPVV-SB AWG#

28

× 13P

UL

20276

VW-1SC

L

37

.

2

14 100

+

10

-

0

3

Dia. Wire Markers

(

6

.

3

Dia.

)

Dimensions in mm

9.4 JZSP-CSI02-x-E

Flying Lead - Servo Amplifier

34

Page 37

10 Firmware Upgrade

10 Firmware Upgrade

It is possible to upgrade the Controller firmware in the field.

For detailed instructions, please refer to Product Note PN.MCD.08.083:

Upgrading the MP2

be downloaded from our website, www.yaskawa.com.

iec Controller Firmware. This document may

35

Page 38

10 Firmware Upgrade

This page left intentionally blank

36

Page 39

11 EMC Installation Conditions

1 1 EMC Installation Conditions

This section describes the recommended installation conditions that

satisfy EMC guidelines for each model of the SGDV SERVOP ACK. The

conditions required for the standard type (base-mounted) of the

SERVOPA CK are de scr ibe d . Refer to this section for other

SERVOPACK models such as the rack-mounted types as well.

This section describes the EMC installation conditions satisfied in test

conditions prepared by Yaskawa. The actual EMC level may differ

depending on the actual system’s configuration, wiring, and other

conditions. However, because this product is built-in, check that the

following conditions are still met after being installed in the user’s

product.

The applicable standards are EN55011/A2 group 1 class A, EN61800-3,

and EN61000-6-2.

Ethernet Communication Cables: Use a category 5 or higher cable with

double, aluminum tape and braided shielding according to the standard

EN50288-2-2.

37

Page 40

11 EMC Installation Conditions

Single-phase 100 V

SGDV-FE1A ( = R70, R90, 2R1, 2R8) + SGDV-OCC02A

Shield box

Brake Power

Supply

One turn

SERVOPACK

Power supply:

Single-phase 100 VAC

General I/O

PC

Controller

Noise

Clamp

Surge

absorber

One turn

Clamp

One turn

filter

Two t urn

Core Core

Core

CN13

Core

CN11 A/B

Two t urn Two t urn

General

5

PE

1

6

L1, L2

L1C, L2C

MP2600iec

MP2600iec

CN1

Core Core

I/O

1

Safety unit

U, V, W

CN2

CN8

Clamp

Core

One turn

Core

2

ClampClamp

Brake

Clamp

3

Servomotor

Encoder

4

PE

38

Symbol Cable Name Specification

I/O signal cable Shield cable

Safety signal cable Shield cable

Motor main circuit cable Shield cable

Encoder cable Shield cable

Main circuit cable Shield cable

Ethernet communication cable Shield cable

Page 41

11 EMC Installation Conditions

U, V, W

L1, L2, L3

L1C, L2C

CN2

CN1

PE

PE

2

1

3

4

5

CN8

Power supply:

Three-phase 200 VAC

Shield box

SERVOPACK

Encoder

Servomotor

Brake

Clamp

ClampClamp

Clamp

Noise

filter

Brake Power

Supply

Surge

absorber

Two turn Two turn

Core

CoreCore

Core

Core Core

Clamp

General

I/O

Safety unit

One turn

One turn

PC

Controller

6

CN11 A/B

MP2600iec

Core

One turn

General I/O

1

CN13

MP2600iec

Core

Clamp

One turn

Three-phase 200 V

SGDV-AE1A ( = R70, R90, 1R6, 2R8, 3R8, 5R5, 7R6) +

SGDV-OCC02A

Symbol Cable Name Specification

I/O signal cable Shield cable

Safety signal cable Shield cable

Motor main circuit cable Shield cable

Encoder cable Shield cable

39

Main circuit cable Shield cable

Ethernet communication cable Shield cable

Page 42

11 EMC Installation Conditions

U, V, W

L1, L2, L3

L1C, L2C

CN2

CN1

PE

PE

2

1

3

4

5

CN8

Power supply:

Three-phase 200 VAC

Clamp

Noise

filter

Surge

absorber

Brake Power

Supply

SERVOPACK

Shield box

One turn

Two turn

CoreCore

Clamp

Clamp

Clamp

Two turn

Safety unit

General

I/O

Core Core

Clamp

Encoder

Servomotor

Brake

PC

Controller

6

CN11 A/B

MP2600iec

Core

One turn

General I/O

1

CN13

MP2600iec

Core

Clamp

One turn

Three-phase 200 V

SGDV-AE1A ( = 120) + SGDV-OCC02A

40

Symbol Cable Name Specification

I/O signal cable Shield cable

Safety signal cable Shield cable

Motor main circuit cable Shield cable

Encoder cable Shield cable

Main circuit cable Shield cable

Ethernet communication cable Shield cable

Page 43

11 EMC Installation Conditions

Three-phase 200 V

SGDV-AE1A ( = 180, 200, 330) + SGDV-OCC02A

Brake Power

Supply

SERVOPACK

Power supply:

Three-phase 200 VAC

General I/O

PC

Controller

5

PE

1

6

Clamp

Surge

absorber

One turn

Clamp

One turn

Noise

filter

Core

Core

Two turn

CN13

MP2600iec

CN11 A/B

MP2600iec

General

I/O

L1, L2, L3

L1C, L2C

CN1

Core Core

1

U, V, W

CN2

CN8

Clamp

2

Safety unit

Shield box

One turn

Core

Two turn

Clamp

Clamp

Clamp

3

4

Brake

Servomotor

Encoder

PE

Symbol Cable Name Specification

I/O signal cable Shield cable

Safety signal cable Shield cable

Motor main circuit cable Shield cable

Encoder cable Shield cable

Main circuit cable Shield cable

Ethernet communication cable Shield cable

41

Page 44

11 EMC Installation Conditions

Three-phase 200 V

SGDV-AE1A ( = 470, 550, 590, 780) + SGDV-OCC02A

Brake Power

SERVOPACK

Power supply:

Three-phase 200 VAC

5

PE

Clamp

Surge

absorber

One turn

Noise

filter

Regenerative

resistor unit

L1, L2, L3

L1C, L2C

6

B1, B2

Supply

U, V, W

CN2

Shield box

Clamp Clamp

Clamp

7

Cooling fan

Brake

Clamp

3

Servomotor

Encoder

4

General I/O

PC

Controller

1

8

One turn

Clamp

Core

Core

CN13

MP2600iec

CN11 A/B

MP2600iec

CN1

Clamp Clamp

General

I/O

1

Safety unit

CN8

2

Symbol Cable Name Specification

I/O signal cable Shield cable

Safety signal cable Shield cable

Motor main circuit cable Shield cable

Encoder cable Shield cable

Main circuit cable Shield cable

Regenerative resistor unit cable Non-shield cable

Cooling fan cable Shield cable

Ethernet communication cable Shield cable

PE

42

Page 45

11 EMC Installation Conditions

Three-phase 400 V

SGDV-DE1A ( = 1R9, 3R5, 5R4, 8R4, 120, 170)

+ SGDV-OCC02A

Shield box

Power supply:

Single-phase

200 VAC

Power supply:

Three-phase

400 VAC

PE

General I/O

PC

Controller

5

Clamp

6

Clamp

absorber

1

7

Surge

Surge

absorber

One turn

Noise

filter*

One turn

Clamp

2

Noise

filter*

Control

power

supply

24 VDC*

3

Core

Core

1

One turn

General I/O

Brake Power

SERVOPACK

24 V, 0 V

Core

L1, L2, L3

Core

CN13

MP2600iec

CN11 A/B

MP2600iec

CN1

Core Core

Clamp Clamp

1

Supply

U, V, W

CN2

CN8

Safety unit

3

Clamp

Core

One turn

4

Core

Clamp

Two t urnTwo turn

2

Clamp

One turn

Core

Brake

Servomotor

Encoder

PE

Symbol Cable Name Specification

I/O signal cable Shield cable

Safety signal cable Shield cable

Motor main circuit cable Shield cable

Encoder cable Shield cable

Control power cable Shield cable

Main circuit cable Shield cable

Ethernet communication cable Shield cable

* 1. Products that have received CE marking are recommended for the 24 VDC power supply.

* 2. Install the following noise filter on the power line between the single-phase 200 V power

supply and the 24 VDC power supply.

Model number: FN2070-6/07 (SCHAFFNER).

* 3. For more information on this filter , refer to Sigma-5 Product Catalog

(YEA-KAEPS80000042).

43

Page 46

11 EMC Installation Conditions

U, V, W

L1, L2, L3

24 V, 0 V

CN2

CN1

PE

PE

1

2

3

6

5

CN8

B1, B2

7

4

Power supply:

Single-phase

200 VAC

Power supply:

Three-phase

400 VAC

Clamp

Surge

absorber

Surge

absorber

Clamp

Noise

filter*

2

Noise

filter*

3

Brake Power

Supply

Shield box

Control

power

supply

24 VDC*

1

SERVOPACK

Encoder

Servomotor

Brake

Clamp

Clamp

Clamp

General I/O Safety unit

Clamp Clamp

Regenerative

resistor unit

PC

Controller

8

CN11 A/B

MP2600iec

Core

One turn

General I/O

1

CN13

MP2600iec

Core

Clamp

One turn

Three-phase 400 V

SGDV-DE1A ( = 210, 260, 280, 370) + SGDV-OCC02A

44

Symbol Cable Name Specification

I/O signal cable Shield cable

Safety signal cable Shield cable

Motor main circuit cable Shield cable

Encoder cable Shield cable

Control power cable Shield cable

Main circuit cable Shield cable

Regenerative resistor unit cable Non-shield cable

Ethernet communication cable Shield cable

* 1. Products that have received CE marking are recommended for the 24 VDC power supply.

* 2. Install the following noise filter on the power line between the single-phase 200 V power

supply and the 24 VDC power supply.

Model number: FN2070-6/07 (SCHAFFNER).

* 3. For more information on this filter, refer to Sigma-5 Product Catalog

(YEA-KAEPS80000042).

Page 47

11 EMC Installation Conditions

Host controller side

Ground plate

Cable

Cable

clamp

Shield (cable sheath stripped)

Fix and ground the cable shield

using a piece of conductive metal.

Remove paint on mounting surface.

Attachment Methods of Ferrite Cores

One turn Two turn

Cable

Ferrite core

Cable

Ferrite core

Recommended Ferrite Core

Cable Name Ferrite Core Model Manufacturer

Motor main circuit cable ESD-SR-250 NEC TOKIN Corp.

Recommended Noise Filter and Surge Absorber

For more information on recommended noise filters and surge absorbers, refer

to Sigma-5 Product Catalog. (YEA-KAEPS800000 42)

Fixing the Cable

Fix and ground the cable shield using a piece of conductive metal.

Example of Cable Clamp

Shield Box

A shield box, which is a closed metallic enclosure, is effective as reinforced

shielding against electromagnetic interference (EMI) from SERVOPACKs. The

structure of the box should allow the main body, door, and cooling unit to be

attached to the ground. The box opening should be as small as possible.

Note: Do not connect the digital operator and the analog monitor cable to the

SERVOPACK during operations. Connect them only when the machinery is

stopped during maintenance.

45

Page 48

11 EMC Installation Conditions

46

Page 49

Page 50

IRUMA BUSINESS CENTER (SOLUTION CENTER)

480, Kamifujisawa, Iruma, Saitama, 358-8555, Japan

Phone: 81-4-2962-5696 Fax: 81-4-2962-6138

YASKAWA ELECTRIC CORPORATION

New Pier Takeshiba South Tower, 1-16-1, Kaigan, Minatoku, Tokyo, 105-6891, Japan

Phone: 81-3-5402-4511 Fax: 81-3-5402-4580

http://www.yaskawa.co.jp

YASKAWA AMERICA, INC.

2121 Norman Drive South, Waukegan, IL 60085, U.S.A.

Phone: (800) YASKAWA (800-927-5292) or 1-847-887-7000 Fax: 1-847-887-7370

http://www.yaskawa.com

YASKAWA ELÉTRICO DO BRASIL COMÉRCIO LTDA.

Avenda Fagundes Filho, 620 Bairro Saude, São Paulo, SP04304-000, Brasil

Phone: 55-11-3585-1100

http://www.yaskawa.com.br

YASKAWA ELECTRIC EUROPE GmbH

Hauptstraβe 185, 65760 Eschborn, Germany

Phone: 49-6196-569-300 Fax: 49-6196-569-398

YASKAWA ELECTRIC UK LTD.

1 Hunt Hill Orchardton Woods, Cumbernauld, G68 9LF, United Kingdom

Phone: 44-1236-735000

YASKAWA ELECTRIC KOREA CORPORATION

7F, Doore Bldg. 24, Yeoido-dong, Youngdungpo-Ku, Seoul, 150-877, Korea

Phone: 82-2-784-7844

YASKAWA ELECTRIC (SINGAPORE) PTE. LTD.

151 Lorong Chuan, #04-01, New Tech Park, 556741, Singapore

Phone: 65-6282-3003

YASKAWA ELECTRIC (SHANGHAI) CO., LTD.

No. 18 Xizang Zhong Road, Room 1702-1707, Harbour Ring Plaza, Shanghai, 200001, China

Phone: 86-21-5385-2200

YASKAWA ELECTRIC (SHANGHAI) CO., LTD. BEIJING OFFICE

Room 1011A, Tower W3 Oriental Plaza, No. 1 East Chang An Ave.,

Dong Cheng District, Beijing, 100738, China

Phone: 86-10-8518-4086

YASKAWA ELECTRIC TAIWAN CORPORATION

9F, 16, Nanking E. Rd., Sec. 3, Taipei, Taiwan

Phone: 886-2-2502-5003

Fax: 55-11-5581-8795

Fax: 44-1236-458182

Fax: 82-2-784-8495

Fax: 65-6289-3003

Fax: 86-21-5385-3299

Fax: 86-10-8518-4082

Fax: 886-2-2505-1280

™

MANUAL NO. YEA-SIA-IEC-6D

Published in U.S.A November, 2012

Loading...

Loading...