Yamaha DGX-620, YPG-625 Service manual

/

SERVICE MANUAL

DGX-620

YPG-625

CONTENTS

SPECIFICATIONS .................................................................... 3

PANEL LAYOUT........................................................................ 4

CIRCUIT BOARD LAYOUT & WIRING ..................................... 6

BLOCK DIAGRAM .................................................................... 8

DISASSEMBLY PROCEDURE ................................................. 9

LSI PIN DESCRIPTION .......................................................... 20

IC BLOCK DIAGRAM.............................................................. 23

CIRCUIT BOARDS ................................................................. 24

TEST PROGRAM ................................................................... 33

INITIALIZATION ...................................................................... 37

USER DATA BACKUP ............................................................. 38

MIDI IMPLEMENTATION CHART ........................................... 42

MIDI DATA FORMAT ............................................................... 43

PA RTS LIST

OVERALL CIRCUIT DIAGRAM

PK 001760

HAMAMATSU, JAPAN

Copyright (c) Yamaha Corporation. All rights reserved. PDF ’06.03

DGX-620/YPG-625

p

p

IMPORTANT NOTICE

This manual has been provided for the use of authorized Yamaha Retailers and their service personnel. It has been assumed that

basic service procedures inherent to the industry, and more specifically Yamaha Products, are already known and understood by the

users, and have therefore not been restated.

WARNING:

IMPORTANT:

The data provided is believed to be accurate and applicable to the unit(s) indicated on the cover. The research engineering, and

service departments of Yamaha are continually striving to improve Yamaha products. Modifications are, therefore, inevitable

and changes in specification are subject to change without notice or obligation to retrofit. Should any discrepancy appear to

exist, please contact the distributor's Service Division.

WARNING:

IMPORTANT:

Failure to follow appropriate service and safety procedures when servicing this product may result in personal injury, destruction of expensive components and failure of the product to perform as specified. For

these reasons, we advise all Yamaha product owners that all service required should be performed by an

authorized Yamaha Retailer or the appointed service representative.

This presentation or sale of this manual to any individual or firm does not constitute authorization certification, recognition of any applicable technical capabilities, or establish a principal-agent relationship of

any form.

Static discharges can destroy expensive components. Discharge any static electricity your body may have

accumulated by grounding yourself to the ground bus in the unit (heavy gauge black wires connect to

this bus.)

Turn the unit OFF during disassembly and parts replacement. Recheck all work before you apply power to

the unit.

WARNING: CHEMICAL CONTENT NOTICE!

The solder used in the production of this product contains LEAD. In addition, other electrical/electronic and/or plastic (Where

applicable) components may also contain traces of chemicals found by the California Health and Welfare Agency (and possibly

other entities) to cause cancer and/or birth defects or other reproductive harm.

DO NOT PLACE SOLDER, ELECTRICAL/ELECTRONIC OR PLASTIC COMPONENTS IN YOUR MOUTH FOR ANY REASON

WHAT SO EVER!

Avoid prolonged, unprotected contact between solder and your skin! When soldering, do not inhale solder fumes or expose eyes to

solder/flux vapor!

If you come in contact with solder or components located inside the enclosure of this product, wash your hands before handling food.

WARNING

Components having special characteristics are marked and must be replaced with parts having specification equal to those

originally installed.

SAVING DATA

Saving and backing up your data

The panel settings and some other types of data are not retained in memory when you turn off the power to the

instrument. Save data you want to keep to the Registration Memory.

Saved data may be lost due to malfunction or incorrect operation.

Be sure to

erform it

Save important data to a USB storage device/or other external device such as a computer.

Backing up the USB storage device/external media

To protect against data loss through media damage, we recommend that you save your important data onto two

USB storage devices/external media.

Be sure to

erform it

2

■ SPECIFICATIONS

Keyboards

• 88 Graded Hammer Standard keys (A-1–C7), with Touch

Response.

Display

• 320 x 240 dots LCD display (backlit)

Setup

• STANDBY/ON

• MASTER VOLUME: MIN–MAX

• LCD CONTRAST

Panel Controls

• SONG, VOICE, STYLE, EASY SONG ARRANGER,

P.A.T. ON/OFF, LESSON L, LESSON R, LESSON START,

METRONOME ON/OFF, PORTABLE GRAND, DEMO,

FUNCTION, MUSIC DATABASE, HARMONY ON/OFF,

DUAL ON/OFF, SPLIT ON/OFF, TEMPO/TAP, [0]–[9], [+],

[-], CATEGORY, Dial, REPEAT & LEARN (ACMP ON/OFF),

A-B REPEAT (INTRO/ENDING/rit.), PAUSE (SYNC START),

START/STOP, REW (MAIN/AUTO FILL), FF (SYNC STOP),

REGIST MEMORY ([MEMORY/BANK], [1], [2]),

SONG MEMORY (REC, [1]–[5], [A]), File Control [MENU],

File Control [EXECUTE], [EXIT], [LYRICS], [SCORE],

[CHORD FINGERING]

Realtime Control

• Pitch Bend Wheel

Voice

• 127 panel voices + 12 drum/SFX kits + 361 XGlite voices

• Polyphony: 32

• DUAL

• SPLIT

Style

• 150 Preset Styles + 1 User Style File

• Style Control: ACMP ON/OFF, SYNC STOP, SYNC START,

START/STOP, INTRO/ENDING/rit.,

MAIN/AUTO FILL

• Fingering: Multi Finger, Full Keyboard

• Style Volume

Music Database

• 267

Education Feature

• Dictionary

• Lesson 1–3, Repeat & Learn

Registration Memory

•8 banks x 2 types

Function

• VOLUME: Style Volume, Song Volume

• OVERALL: Tuning, Transpose, Split Point, Touch Sensitiv-

ity, Pitch Bend Range, Chord Fingering

• MAIN VOICE: Volume, Octave, Pan, Reverb Level,

Chorus Level

• DUAL VOICE: Volume, Octave, Pan, Reverb Level,

Chorus Level

• SPLIT VOICE: Volume, Octave, Pan, Reverb Level,

Chorus Level

• EFFECT: Reverb Type, Chorus Type, Master EQ Type,

Sustain

• HARMONY: Harmony Type, Harmony Volume

• Performance assistant technology:

Performance assistant technology Type

• PC: PC Mode

• MIDI: Local On/Off, External Clock, Initial Send,

Keyboard Out, Style Out, Song Out

• METRONOME: Time Signature Numerator, Time Signature

Denominator, Metronome Volume

• SCORE: Quantize

• LESSON: Lesson Track (R), Lesson Track (L), Grade

• UTILITY: Demo Cancel, Language

DGX-620/YPG-625

Effects

• Reverb: 9 types

• Chorus: 4 types

• Harmony: 26 types

Song

• 30 Preset Songs + 5 User Songs + Accessory CD-ROM Songs (70)

• Song Clear, Track Clear

• Song Volume

• Song Control: REPEAT & LEARN, A-B REPEAT, PAUSE,

Performance assistant technology

• Chord, Chord/Free, Melody, Chord/Melody

Recording

• Song

User Song: 5 Songs

Recording Tracks: 1, 2, 3, 4, 5, STYLE

MIDI

• Local On/Off • Initial Send • External Clock

• Keyboard Out • Style Out • Song Out

Auxiliary jacks

• PHONES/OUTPUT, DC IN 12V, USB TO HOST,

USB TO DEVICE, SUSTAIN

Ampli er

• 6W + 6W

Speakers

• 12cm x 2 + 3cm x 2

Power Consumption

• 22W

Power Supply

• Adaptor: Yamaha PA-5D AC power adaptor

Dimensions (W x D x H)

••1,398 x 457 x 153 mm (55-1/16" x 18" x 6")

with keyboard stand:

1,405 x 485 x 773 mm (55-1/3" x 19-1/8" x 30-3/8")

Weight

••18.0kg (39 lbs. 11 oz.)

with keyboard stand:

25.5kg (56 lbs. 3 oz.)

Supplied Accessories

•

Music Rest • Accessory CD-ROM

•

Keyboard Stand • Owner’s Manual • Footswitch FC5

•

AC Power adaptor (May not be included depending on your particular area.)

Optional Accessories

• Headphones: HPE-150

REW, FF, START/STOP

3

DGX-620/YPG-625

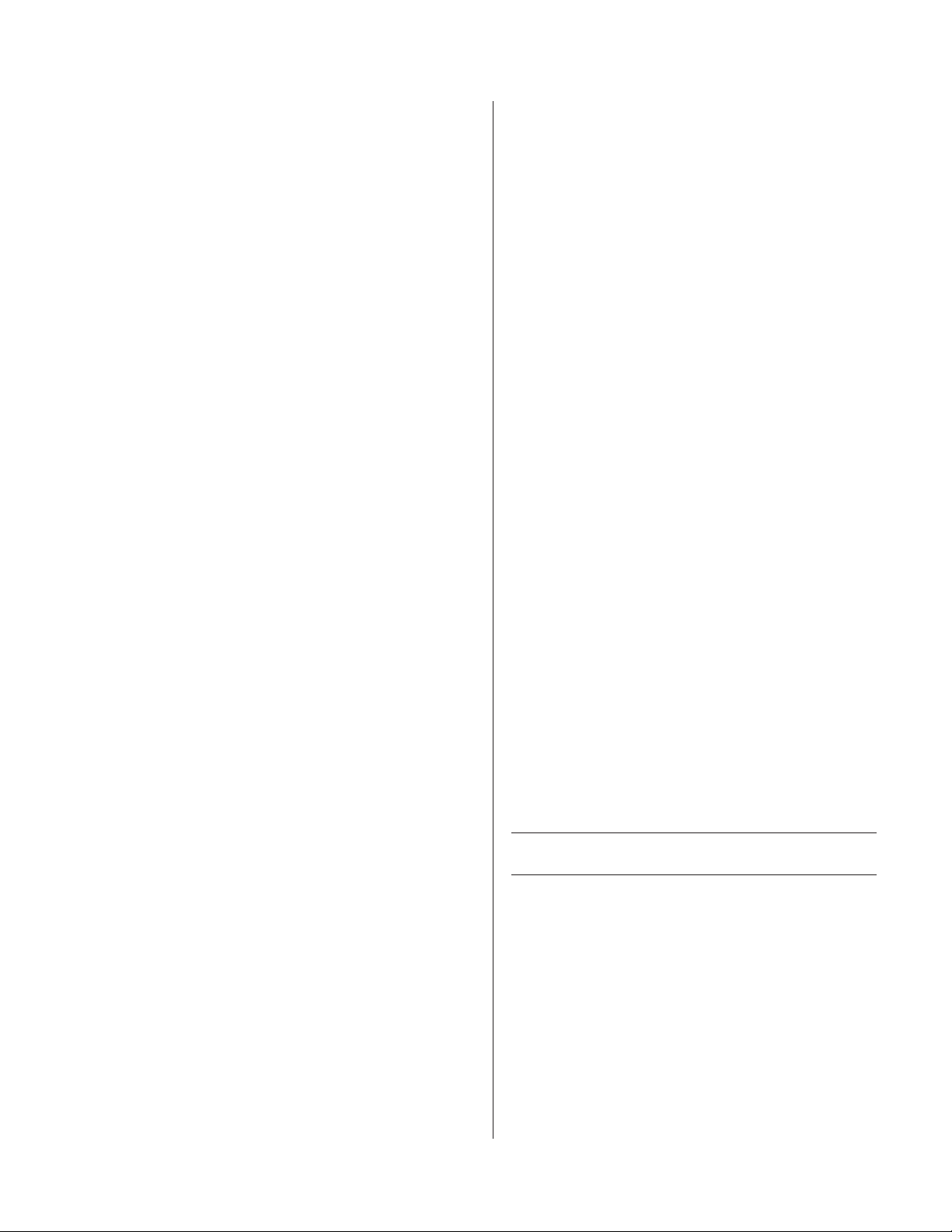

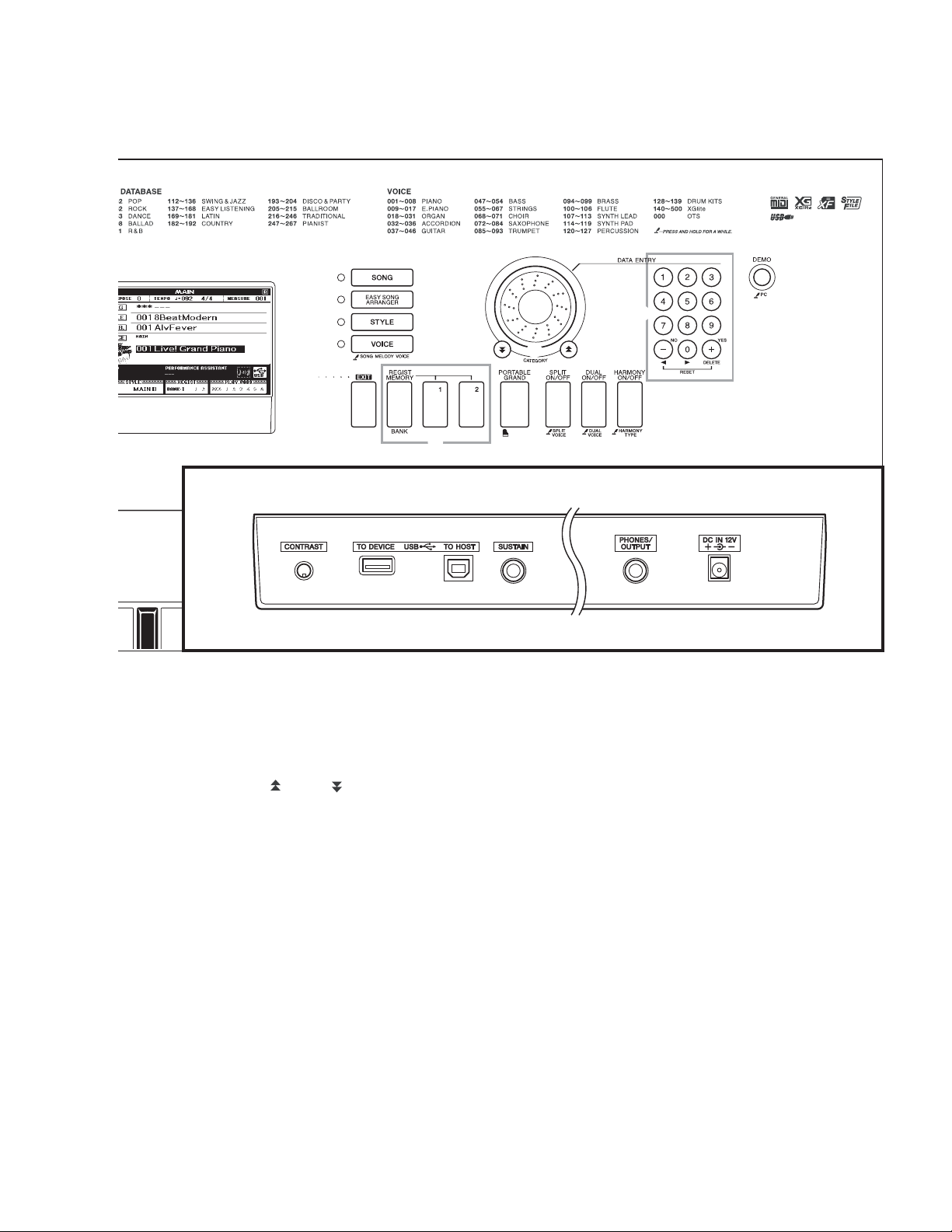

■ PANEL LAYOUT

• Front Panel

#4

q

w

e

r t y

!1 !2

u i o

!4 !5

!0

!3

!6 !7 !8 !9

• Front Panel

[STANDBY/ON] switch

q

[MASTER VOLUME control

w

e FILE CONTROL [MENU], [EXECUTE] button

[LYRICS] button

r

[SCORE] button

t

y [CHORD FINGERING] button

u [P.A.T. ON/OFF] button

i [MUSIC DATABASE] button

o

[FUNCTION] button

!0

LESSON [L],[R], [START] buttons

[METRONOME ON/OFF] button

!1

[TEMPO/TAP] button

!2

SONG MEMORY [REC], [1]-[5], [A] buttons

!3

[REPEAT & LEARN]/ [ACMP ON/OFF] button

!4

!5 [A-B REPEAT]/[INTRO/ENDING/rit.] button

[REW]/[MAIN/AUTO FULL] button

!6

!7 [FF]/[SYNC STOP] button

[PAUSE]/[SYNC START] button

!8

[START/STOP] button

!9

[SONG] button

@0

@1 [EASY SONG] ARRANGER] button

@2 [STYLE] button

@3 [VOICE] button

4

DGX-620/YPG-625

Rear Panel

@0

@1

@2

@3

@8

@9

#5 #6 #7 #8 #9

@4

@5

#0 #1 #2 #3

@6

@7

@4 Dial

@5 CATEGORY[ ] and [ ] buttons

@6 Number buttons [0]–[9],[+] and [-] buttons

[DEMO] button

@7

[EXIT] button

@8

REGIST MEMORY [MEMORY/BANK], [1], [2] buttons

@9

[PORTABLE GRAND] button

#0

[SPLIT ON/OFF] button

#1

[DUAL ON/OFF] button

#2

[HARMONY ON/OFF] button

#3

[PITCH BEND] wheel

#4

• Rear Panel

CONTRAST knob

#5

USB TO DEVICE, TO HOST terminals

#6

SUSTAIN jack

#7

PHONES/OUTPUT jack

#8

DC IN 12V jack

#9

5

DGX-620/YPG-625

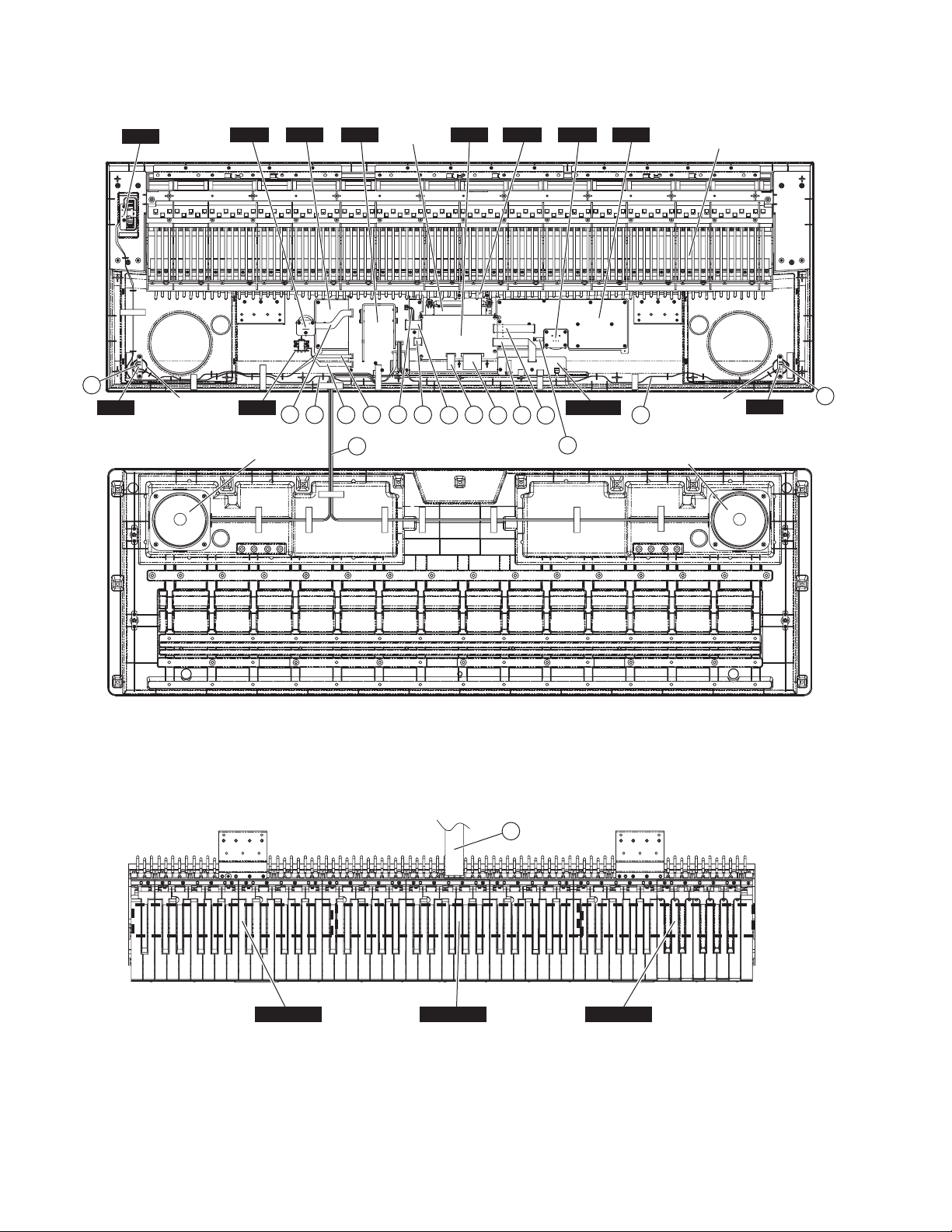

■ CIRCUIT BOARDS LAYOUT & WIRING

• Upper case

PB

MVR

PNL

AM

LCD unit

DM ENC PNR

MKO

Keyboard assembly

< Bottom view >

15

TW (L)

Speaker

(Tweeter (L))

PSW

• Lower case

• Keyboard assembly

< Top view >

13

10

Speaker

(Woofer (L))

15

7

9

12

3

8

1

6

2

5

5

4

DJACK

14

11

(Tweeter (R))

Speaker

(Woofer (R))

Speaker

TW (R)

GHL88L GHL88M GHL88H

6

No.

Location Part No. Connector Assembly Destination Remarks

q

w

e

r

t

y

u

i

o

!0

!1

!2

!3

!4

!5

-- -- Flexible flat cable

240 WG317700

230 DM-CN601 *1 *4 PNL-CN01 *1 *4 12P

250 DM-CN602 *1 *4 PNR-CN02 *1 *4 15P

2 DM-CN701 *1 *4

260 DM-CN901 *1 *4 AM-CN104 *1 *4 19P

WG317600

WG317800

WG318100

WG317900

WH501 (WG45930) AM-CN101 *1 *5 PSW-CN501 *2 *5 4P

290 WB092100 AM-CN102 *1 *5 LCD *3 *6 2P

WH401 (WG46060) AM-CN103 *1 *5 PB-CN401 *2 *5 3P

WH201 (WG46040)

WH202 (WG46050)

Flexible flat cable

Flexible flat cable

Flexible flat cable

Flexible flat cable

Flexible flat cable

PSW

BL

PB

TWL

TWR

30 (WG45880) SP2 AM-CN203 *1 *9

WH601 (WG46070) MVR

WH901 (WB09270)

ENC PNR-CN03 *1 *5 ENC-CN901 *2 *5 3P

DM-CN201 *1 *4 LCD *3 *4 14P

DM-CN301 *1 *4 DJACK-CN301 *1 *4 14P

GHL88M-CN02

*1 *4 27P

AM-CN201 *2 *5 TW(L) *3 *6 2P

AM-CN202 *2 *5 TW(R) *3 *6 2P

Speaker Lch

Speaker Rch

*9

*3

*10

*3

AM-CN204 *1 *5 MVR-CN601 *2 *5 5P

-- -- -- Speaker *11 -- TW *3 *10 2P

* The parts with "( )" in "Part No." are not available as spare parts.

* 1 : Installation

* 2 : Dip soldering

* 3 : Manual soldering

* 4 : The conductor of a cable and the point of contact of a connector are untited.

* 5 : Edge mark is adjusted to Pin 1 (왕) side.

* 6 : Edge mark is connected to + side.

* 7 : Edge mark is connected to + terminal.

* 8 : White wire is adjusted to Pin 1 (왕) side.

* 9 : White wire is connected to + terminal.

* 10 : Red wire is connected to + terminal.

* 11 : Connected

Caution: Be sure to attach the removed filament tape just as it was before removal.

DGX-620/YPG-625

4P

X0159A00

7

8

USB

DATA ENTRY

ENC

ROTARY

ENCODER

CN901(3P)

CN03(3P)

SW

MATRIX

LED

PNR

PNL

SW

MATRIX

LED

EC901

IN[0-6]

PA[4-7]

IN[0-6]

PA[0-3]

CN02(15P)

CN01(12P)

DJACK

DM

+5D

IC102 (5P)

RESET

5

3.6V

16.9344

MHz

X101

PB0-7

TA601-604

CN602(15P)

LED

DRIVER

CR701

5MHz

CPU

IC701 (44P)

uPD789022GB

CN601(12P)

Keyboard(GHL)

88KEY

with touch response

GHL88L

SUSTAIN

JK301

4

12,13

PA0-7

+5D

R704

18,3814,15

16

27

22

TO DEVICE

JK303

6MHz

X301

+3.3D

20

PD3

*A

ICN

*A:24,47,66,90,120

*B:15,46,89,119

PD1,2

YMW767-V

RXD1

TXD1 SD0

38

CONTROLLER

+3.3D

56,58

+2.5D

*B

CPU

IC101

(128P)

37 40

CN701(27P)

B[1-15]

N[11-16]

N[21-26]

GHL88M

TO HOST

JK302

CN301(14P)

CN301(14P)

ISP1161A

USB

IC301

(64P)

MA/MD

SDI

+5D

+3.3D

37

38

41

BCLK, WCLK

SYSCLK, BCLK, WCLK

CN2(27P)

CONTRAST

VR301

+29V

DC/DC

CONVERTER

IC202

(8P)

MA0-23

MD0-15

128M

ROM

PROG

/WAVE

IC802(48P)

+21~27V

7,12,22,25

32,40,48,55

+3.3D

37

FLASH

ROM

IC803(48P)

GHL88H

+3.3D

8M

IC501(10P)

PCM1742K

2

IC401(16P)

BACK LIGHT

LCD

DISPLAY

320 X 240

STN

CN201(14P)

LCDC

IC201

(64P)

S1D13700F00A

+3.3D

1,6

16M

25

DRAM

IC804(50P)

ADC

8bit

14

DAC

24bit

XD0-3

YD,LP

XCSL,WF

CS0:128M ROM

CS1:LCDC

CS3:8M FLASH

CS5:USBC

+3.3D

2

PITCH BEND

+5A

7

826

IC402(8P)

LPF

+3.3D

+2.5D

+5A

8

17L

R

IC902 (3P)

+3.3V

REG.

+2.5V

REG.

IC901 (3P)

+5D

+5A

MVR

+5D

CN901(19P)

CN104(19P)

VR601

MASTER

VOLUME

PB

PITCH BEND

VR401

AM

CN204(5P)

CN601(5P)

CN401(3P)

CN103(3P)

L

POWER AMP

61R

TWEETER

3cm

IC201(14P)

6W X 2

LA4625

R

WOOFER

12cm

4

CN102(2P)

3

3

Vcc

CN202(2P)

TW

IC102(3P)

+5V

REG.

IC101(3P)

+5V

REG.

14

11

8

(R)

PSW

STANDBY/ON

SW501

CN501(4P)

CN101(4P)

1

2

1

2

D101

FZ001

CN203(4P)

CN201

(2P)

TW

JK101

JK201

(L)

WOOFER

DC IN 12V

PHONES/

OUTPUT

TWEETER

3cm

L

12cm

4

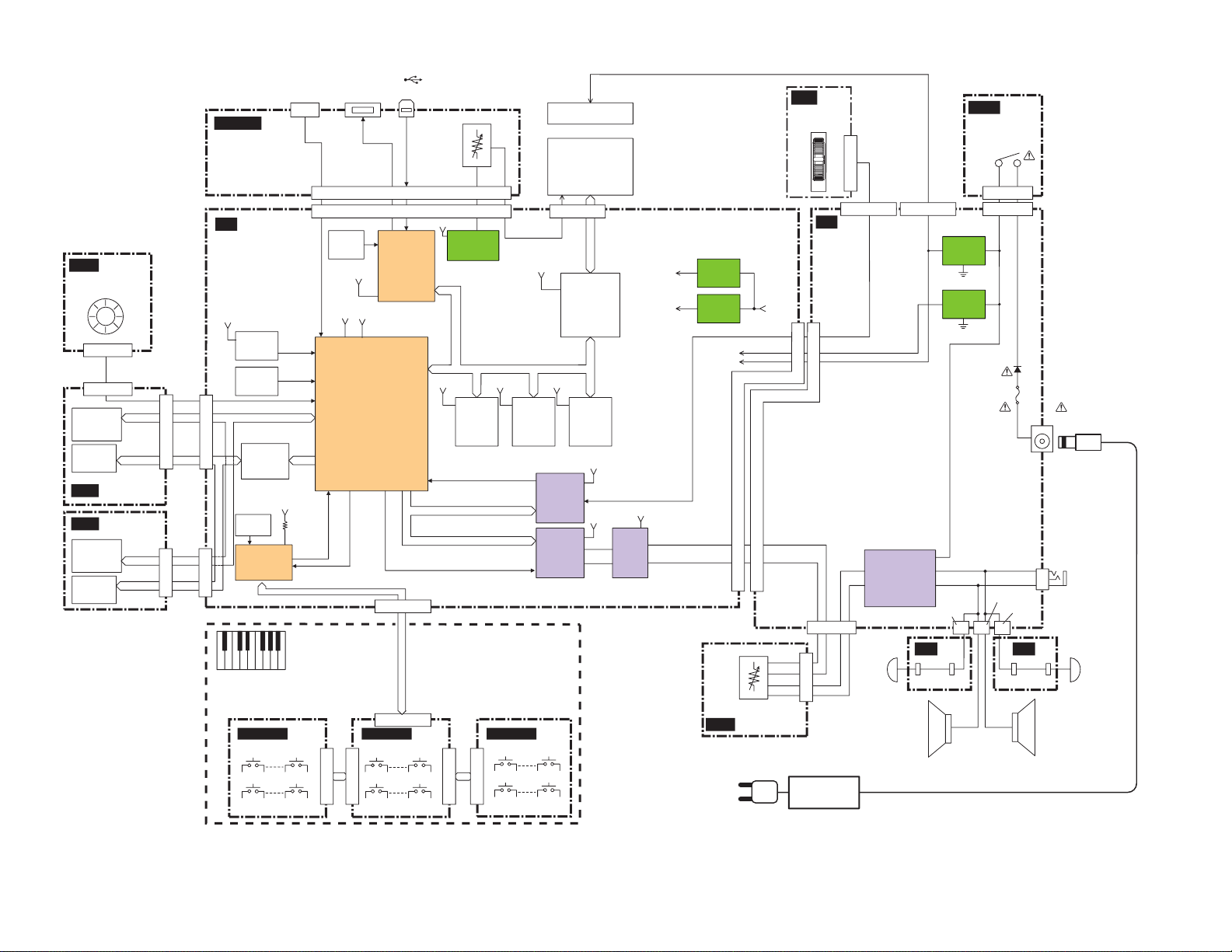

DGX-620/YPG-625

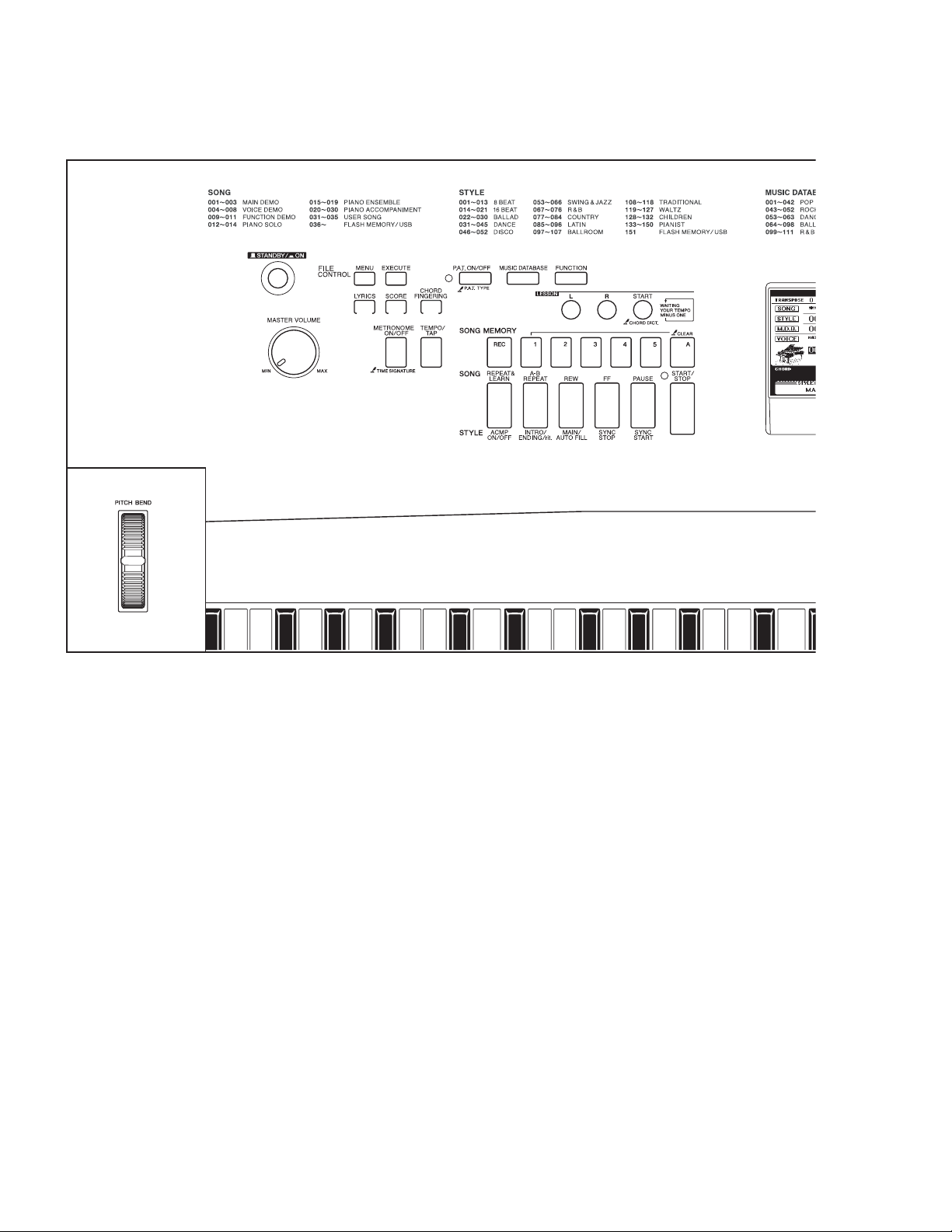

BLOCK DIAGRAM

■

(A-1~C2)

CN1(17P)

CN1(17P)

(C#2~C5)

CN3(17P)

CN1(17P)

(C#5~C7)

PA-5D

(AC Adaptor)

28CA1-2001000277

■ DISASSEMBLY PROCEDURE

Caution: 1) Flat cable’s contacts are visible from the back.

Pay attention not to insert and install the cable to the connector inversely. (Fig.1)

2) Be sure to attach the removed filament tape just as it was before removal.

Front Side (Printed Side) Back side

(Fig.1)

<Bottom View>

DGX-620/YPG-625

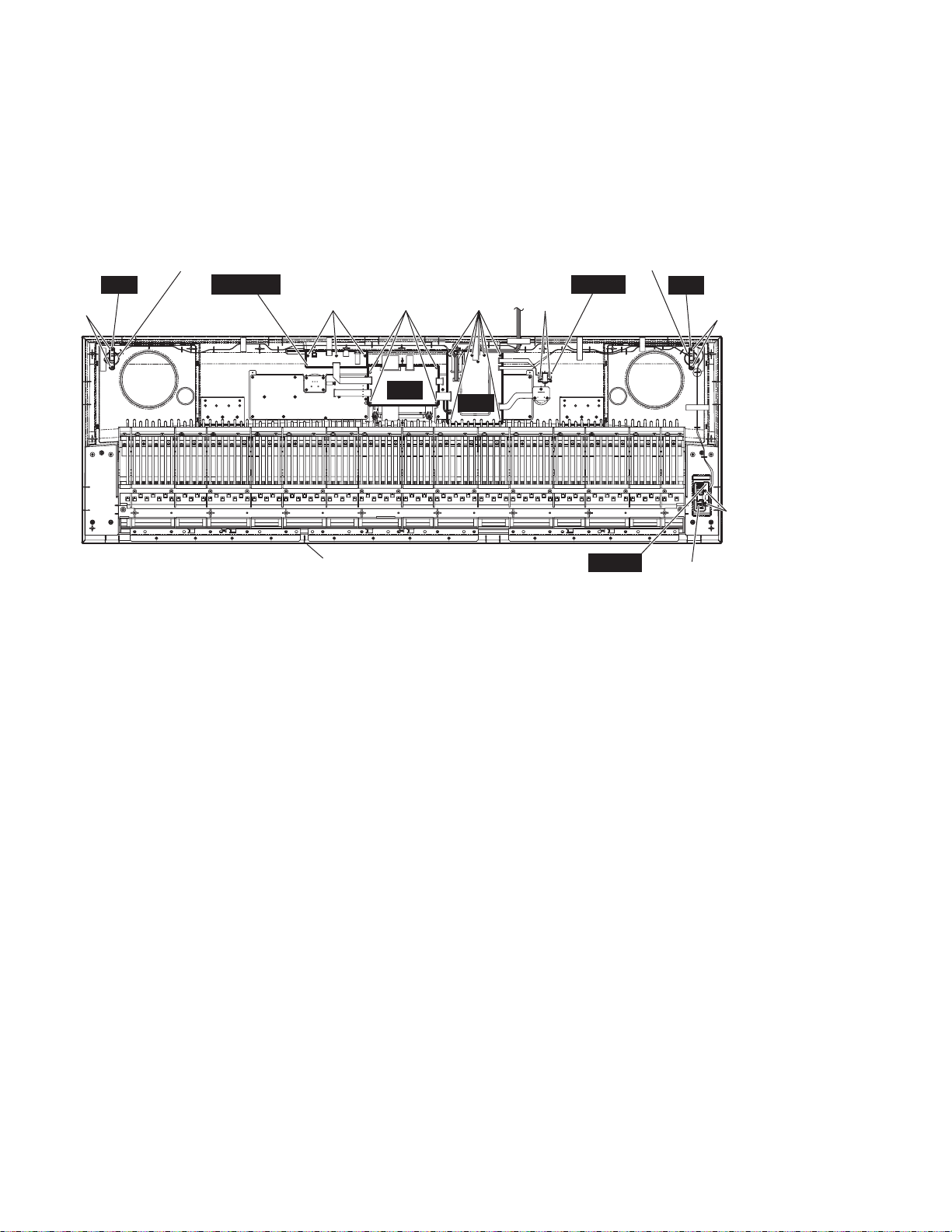

1. Lower Case Assembly (Time required: About 9 minutes)

1-1 Remove the twenty (20) screws marked [510A].

The bottom boards L and R can then be removed.

(Fig.2)

1-2 Remove the thirty six (36) screws marked [500] and

the forty six (46) screws marked [510B].

The lower case assembly can then be removed. (Fig.3)

[500]

<Bottom View>

[510A] [510A]

Bottom Board (L) Bottom Board (R)

(Fig.2)

[510]: Bind Head Tapping Screw-B 4.0X16 MFZN2W3 (WF154100)

[500] [500] [500]

[500]

(Fig.3)

[500]: Bind Head Tapping Screw-B 4.0X12 MFZN2W3 (WE981200)

[510]: Bind Head Tapping Screw-B 4.0X16 MFZN2W3 (WF154100)

[500] [500]

[500][500]

[510B][510B]

[500]

9

DGX-620/YPG-625

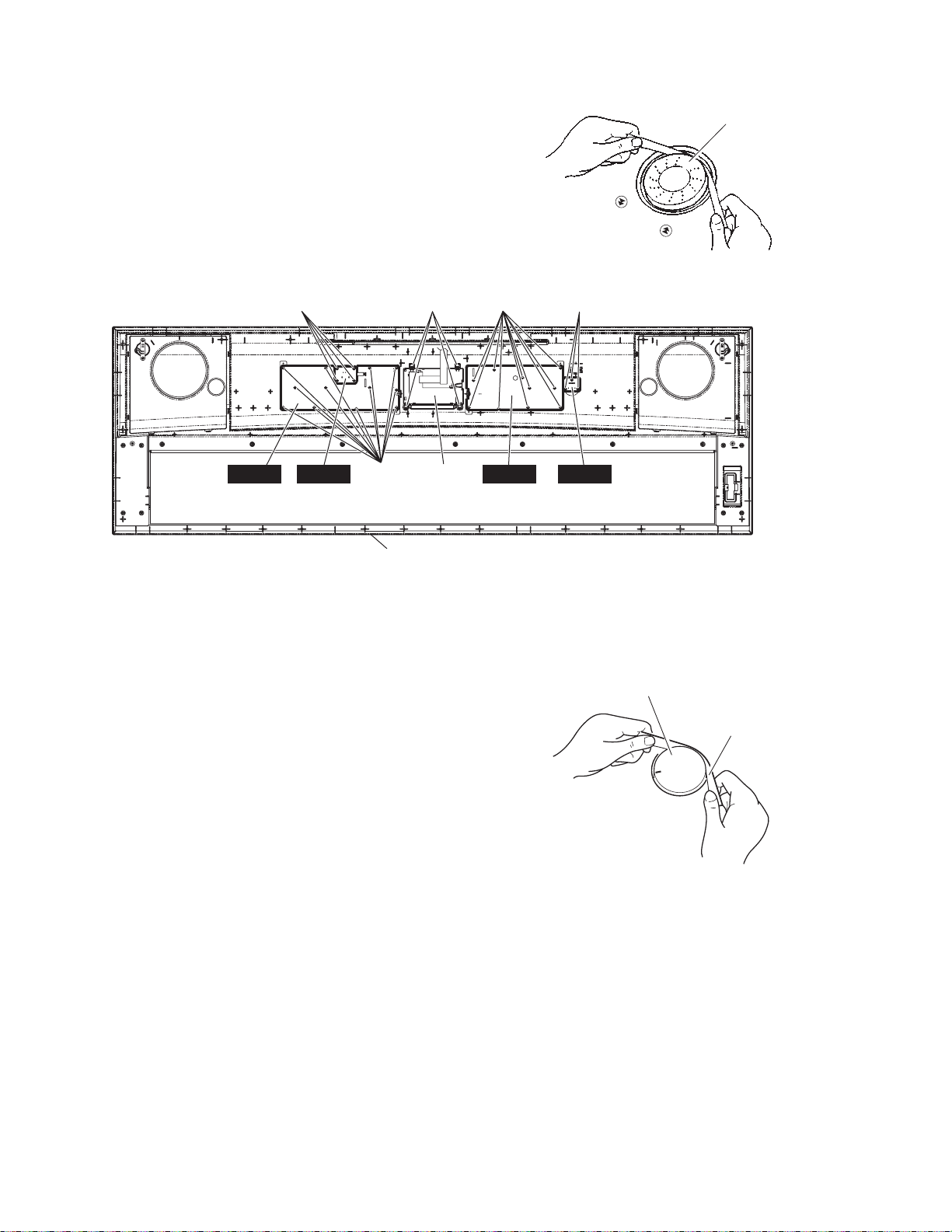

2. DM Circuit Board (Time required: About 10 minutes)

2-1 Remove the lower case assembly. (See procedure 1.)

2-2 Remove the four (4) screws marked [480A].

The DM circuit board can then be removed. (Fig.4)

Speaker

(Tweeter(R))

[480B]

TW

(R)

DJACK

[480G]

[480A] [480D] [480E]

DM

Upper Case

[480]: Bind Head Tapping Screw-B 3.0X8 MFZN2W3 (WE774300)

3. TW Circuit Board, Speaker (Tweeter) (Time required: About 9 minutes)

3-1 Remove the lower case assembly. (See procedure 1.)

3-2 Remove the two (2) screws marked [480B]. The TW

circuit board and speaker (tweeter) can then be removed.

(Fig.4)

* The left and right speakers (tweeters) can be removed in

the same way.

4. PB Circuit Board, Wheel Assembly (Time required: About 9 minutes)

4-1 Remove the lower case assembly. (See procedure 1.)

4-2 Remove the two (2) screws marked [480C]. The PB

circuit board and the wheel assembly can then be

removed. (Fig.4)

* Make sure to mount the wheel assembly on the volume

shaft of the PB circuit board by firmly inserting it into the

shaft.

Speaker

(Tweeter(L))

PSW

TW

(L)

[480B]

AM

[480C]

PB

(Fig.4)

5. AM Circuit Board (Time required: About 10 minutes)

5-1 Remove the lower case assembly. (See procedure 1.)

5-2 Remove the seven (7) screws marked [480D]. The AM

circuit board can then be removed. (Fig.4)

6. PSW Circuit Board (Time required: About 9 minutes)

6-1 Remove the lower case assembly. (See procedure 1.)

6-2 Remove the two (2) screws marked [480E].

The PSW circuit board can then be removed. (Fig.4)

7. DJACK Circuit Board (Time required: About 10 minutes)

7-1 Remove the lower case assembly. (See procedure 1.)

7-2 Remove the three (3) screws marked [480G].

The DJACK circuit board can then be removed. (Fig.4)

Wheel Assembly

10

DGX-620/YPG-625

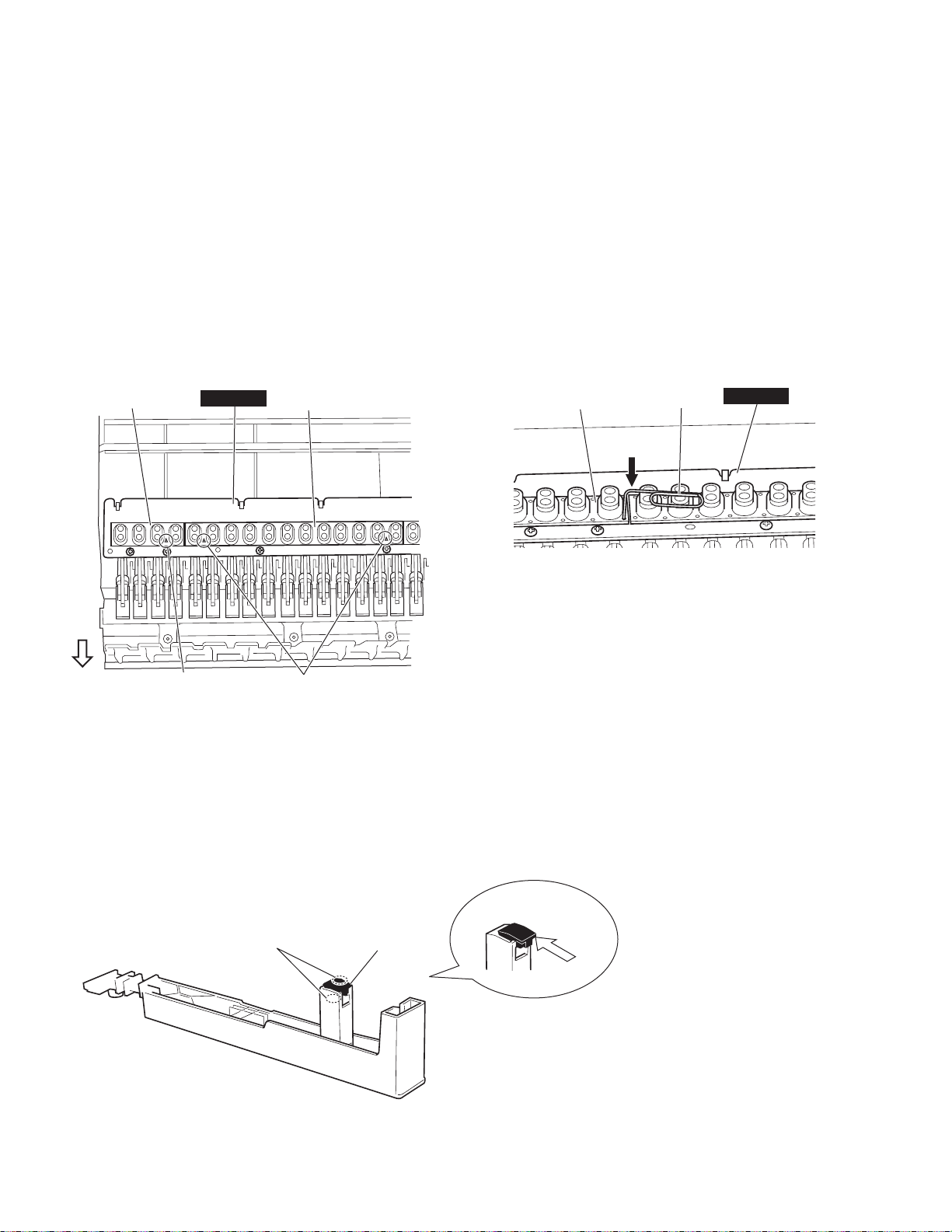

8. ENC Circuit Board (Time required: About 10 minutes)

8-1 Remove the lower case assembly. (See procedure 1.)

8-2 Remove the encoder knob from the control panel. (Fig.5)

8-3 Remove the four (4) screws marked [480H]. The ENC

circuit board can then be removed. (Fig.6)

[480H]

PNR ENC MVR

[480I]

Upper Case

[480J] [480F]

LCD Unit

Encoder knob

(Fig.5)

[480K]

PNL

(Fig.6)

[480]: Bind Head Tapping Screw-B 3.0X8 MFZN2W3 (WE774300)

9. PNR Circuit Board (Time required: About 11 minutes)

9-1 Remove the lower case assembly. (See procedure 1.)

9-2 Remove the twelve (12) screws marked [480I]. The PNR

circuit board can then be removed. (Fig.6)

10. MVR Circuit Board (Time required: About 10 minutes)

10-1 Remove the lower case assembly. (See procedure 1.)

10-2 Remove the volume knob from the control panel. (Fig.7)

10-3 Remove the three (3) screws marked [480K]. The MVR

circuit board can then be removed. (Fig.6)

11. PNL Circuit Board (Time required: About 12 minutes)

11-1 Remove the lower case assembly. (See procedure 1.)

11-2 Remove the AM circuit board. (See procedure 5.)

11-3 Remove the ten (10) screws marked [480F]. The PNL

circuit board can then be removed. (Fig.6)

Volume Knob

Cloth

(Fig.7)

11

DGX-620/YPG-625

12. LCD Unit (Time required: About 11 minutes)

12-1 Remove the lower case assembly. (See procedure 1.)

12-2 Remove the DM circuit board. (See procedure 2.)

12-2 Remove the four (4) screws marked [480J].

The LCD unit can then be removed. (Fig.6)

[40]

Speaker

(Woofer(L))

Lower Case

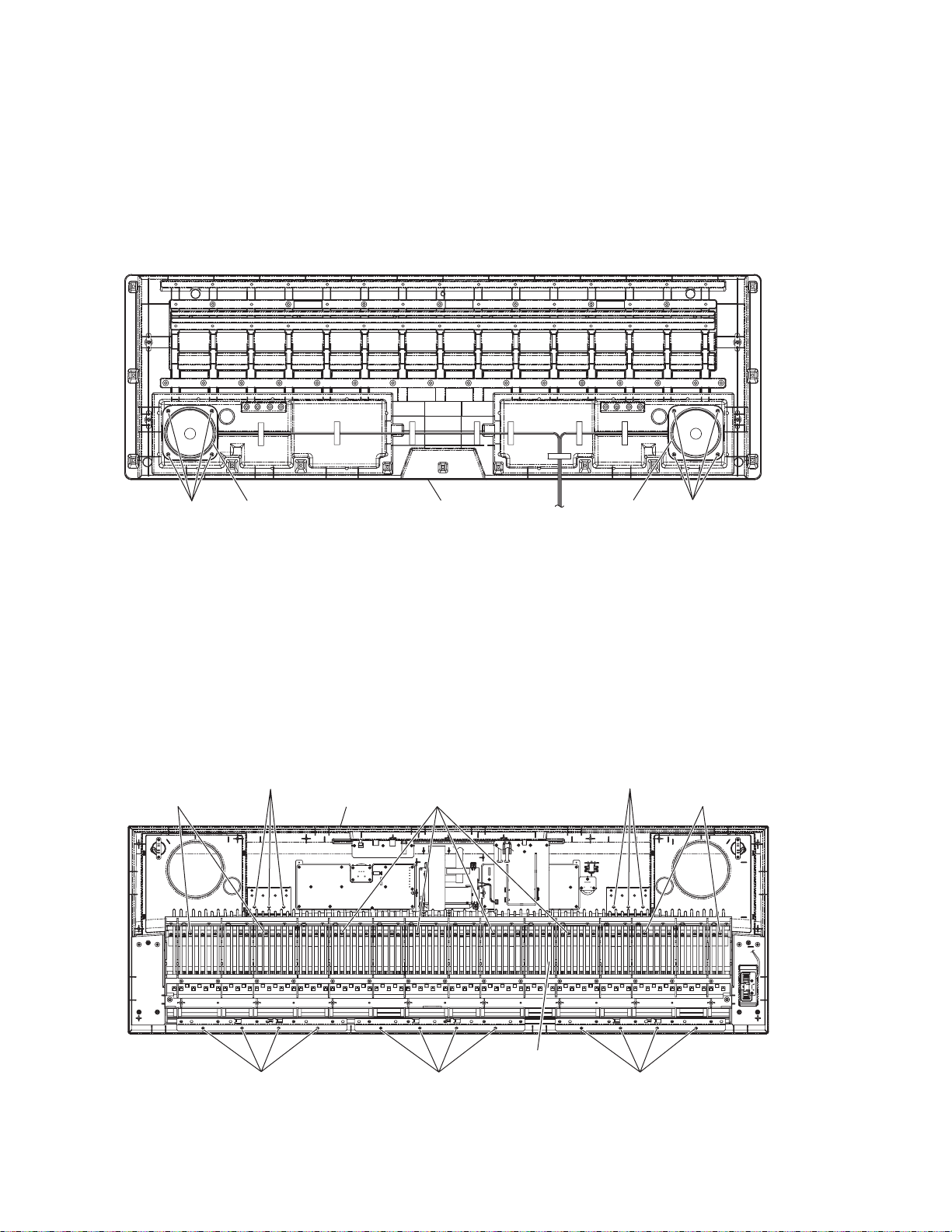

13. Speaker (Woofer) (Time required: About 10 minutes)

13-1 Remove the lower case assembly. (See procedure 1.)

13-2 Remove the four (4) screws marked [40]. The speaker

(woofer) can then be removed. (Fig.8)

* The left and right speakers (woofers) can be removed

in the same way.

Speaker

(Woofer(R))

[40]

(Fig.8)

[40]: Bind Head Tapping Screw-B 4.0X12 MFZN2W3 (WE981200)

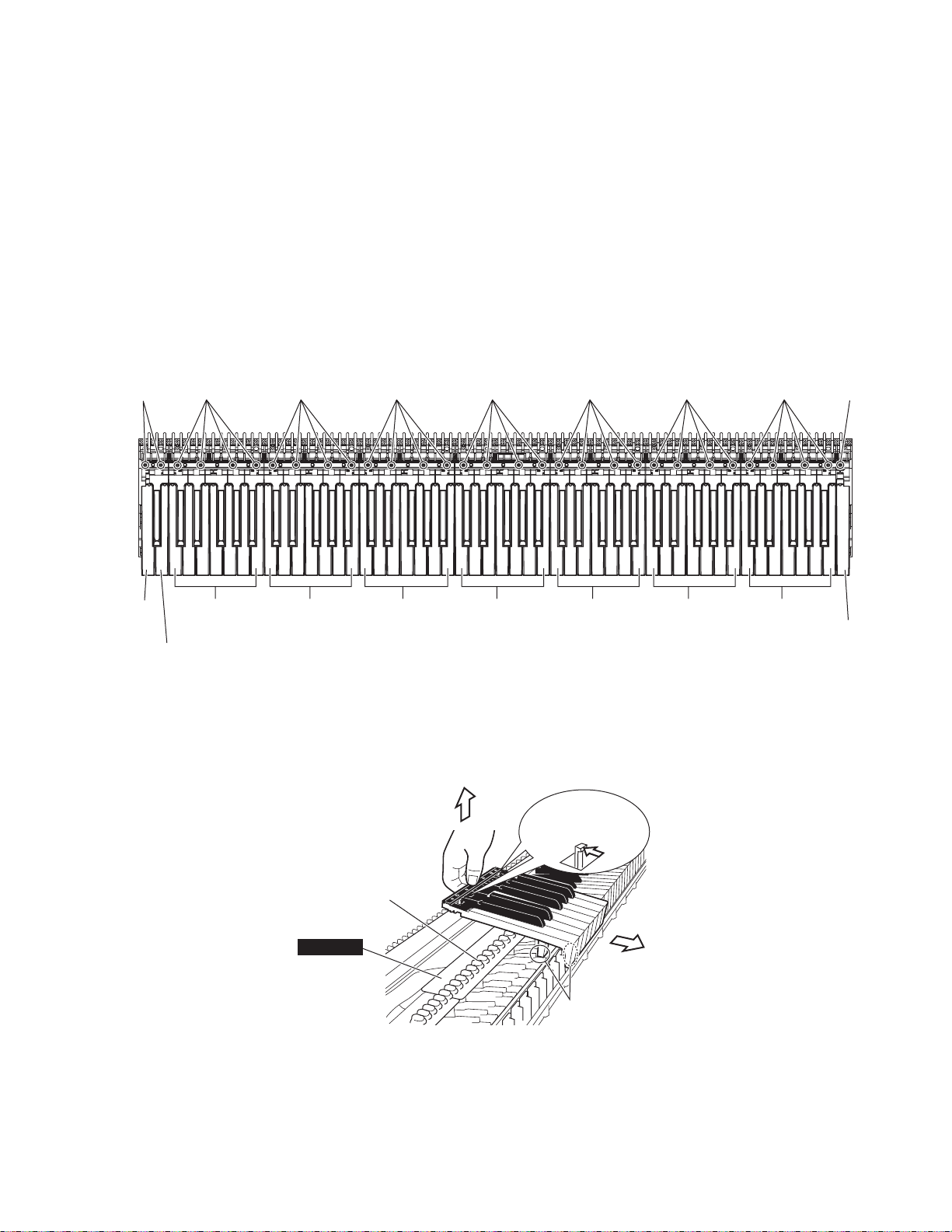

14. Keyboard Assembly

(Time required: About 13 minutes)

14-1 Remove the lower case assembly. (See procedure 1.)

14-2 Remove the six (6) screws marked [480L], the twelve (12)

screws marked [480M] and the eight (8) screws marked

[560].

[480L]

Upper Case

[560][560]

The keyboard assembly can then be removed from the

upper case assembly. (Fig.9)

[480L]

[560]

12

Keyboard Assembly

[480M] [480M] [480M]

(Fig.9)

[480]: Bind Head Tapping Screw-B 3.0X8 MFZN2W3 (WE774300)

[560]: Bind Head Tapping Screw-B 3.0X20 MFZN2W3 (WF489300)

DGX-620/YPG-625

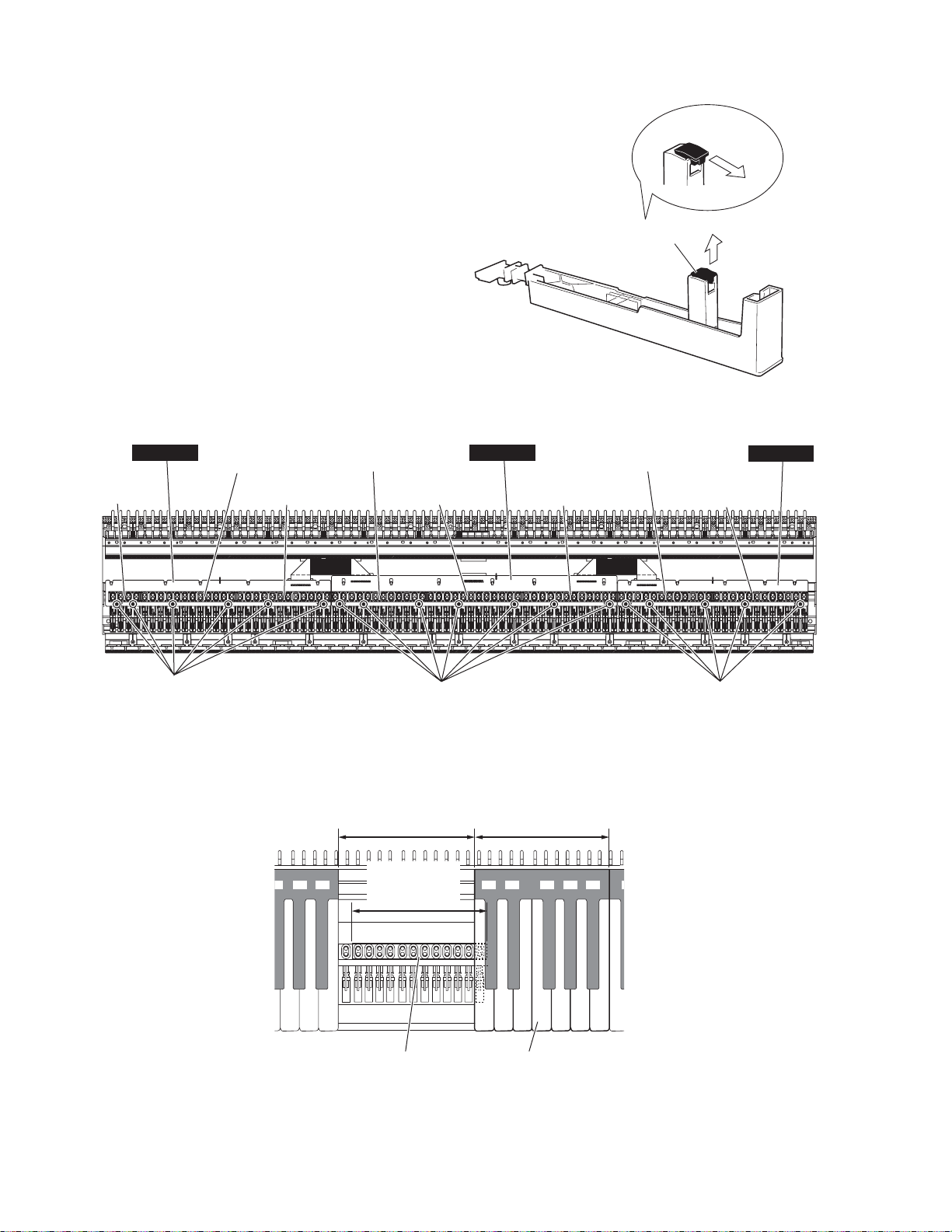

15. Disassembling the Keyboard Assembly

15-1 White key assembly and black key assembly

Remove the four (4) screws marked [270A] fixing the

black and white key assembly for one octave (C-B).

To remove the back of the black and white key assembly

of each octave, while pushing the end lug of white keys

rearward and lifting the back of keys, slide the black and

white key assembly towards you. (Fig.10, Fig.11)

<Top view>

[270B]

[270A] [270A] [270A] [270A] [270A] [270A] [270A] [270C]

15-2 When removing white keys numbered as A-1 and B-1

key and black key, remove two (2) screws marked

[270B] and then lift the back of the keys and slide the

black and white keys towards you. (Fig.10)

15-3 When removing the C7 key, remove a screw marked

[270C] and then lift the back of C7 key and slide it

towards you. (Fig.10)

Note: When removing white key assembly and black key

assembly, be careful not to allow grease to attach to the

circuit board and rubber contacts, etc. (Fig.11)

A-1 Key

One octave

B-1 Key

(C0-B0)

One octave

(C1-B1)

One octave

(C2-B2)

One octave

(C3-B3)

One octave

(C4-B4)

(Fig.10)

[270]: Bind Head Tapping Screw-P 3.0X16 MFZN2W3 (WE973000)

End lug of white key

Rubber contact

GHL88M

Grease

(Fig.11)

One octave

(C5-B5)

One octave

(C6-B6)

C7 Key

13

DGX-620/YPG-625

15-4 Actuate Rubber

Remove the actuate rubber. (Fig.12)

15-5 Rubber Contact

Remove the black and white key assembly for two octaves

related to the subject rubber contact. The rubber contact

can then be removed. (Fig.13, Fig.14)

* Note that the rubber contact has a specific installation

direction.

* One rubber contact fits for C#-C (for C-B keys).

<Top View>

Remove in this way.

Actuate rubber

(Fig.12)

Rubber contact

[260A]

Rubber contact

Rubber contact

[260]: Bind Head Tapping Screw-P 2.6X8 MFZN2W3 (WF267300)

Rubber contact Rubber contact

Rubber contact

[260B] [260C]

GHL88MGHL88L

Rubber contact Rubber contact

(Fig.13)

One octave

(C-B)

One octave

(C#-C)

One octave

(C-B)

GHL88H

14

Rubber contact Key

To remove the rubber contact for one octave, keys for 2 octaves need to be removed.

(Fig.14)

DGX-620/YPG-625

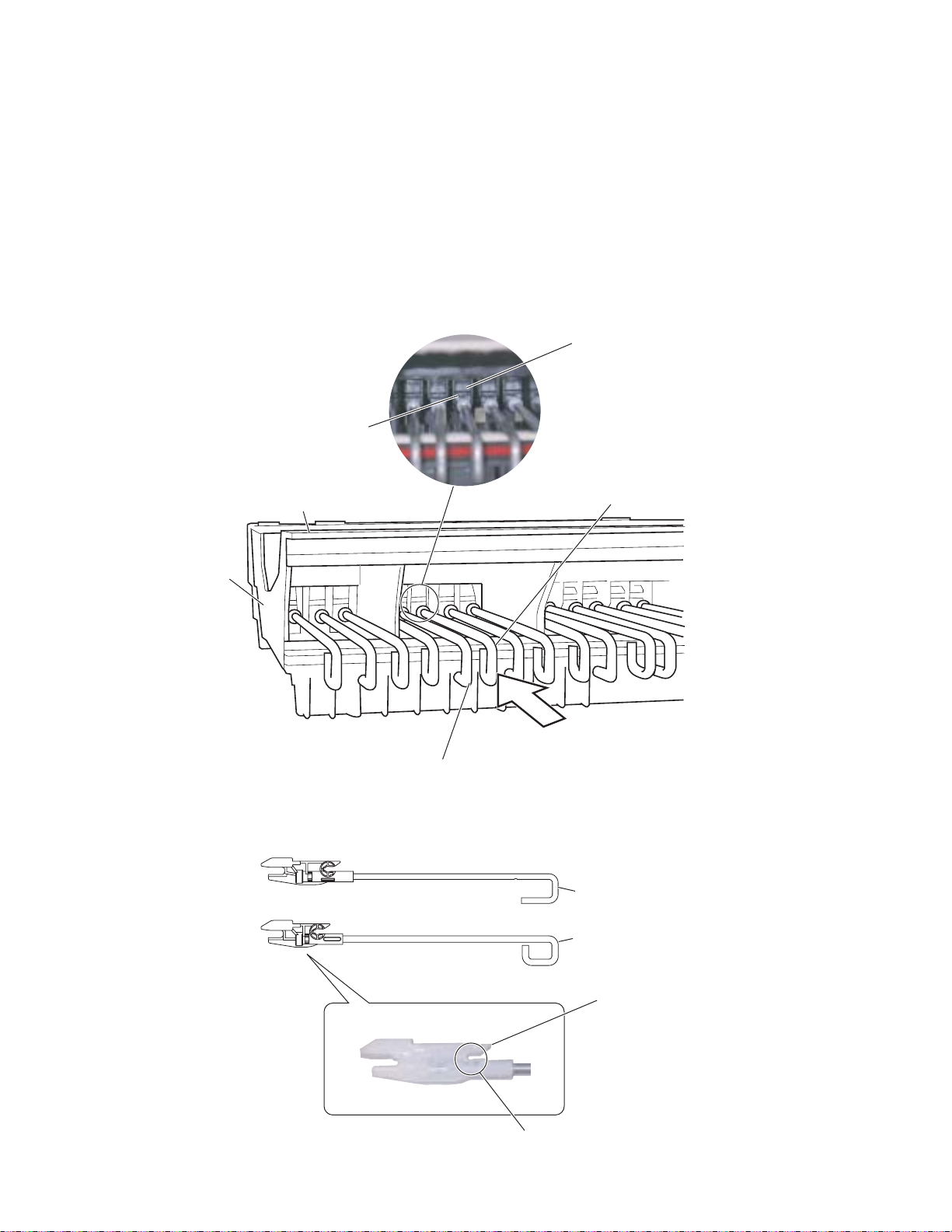

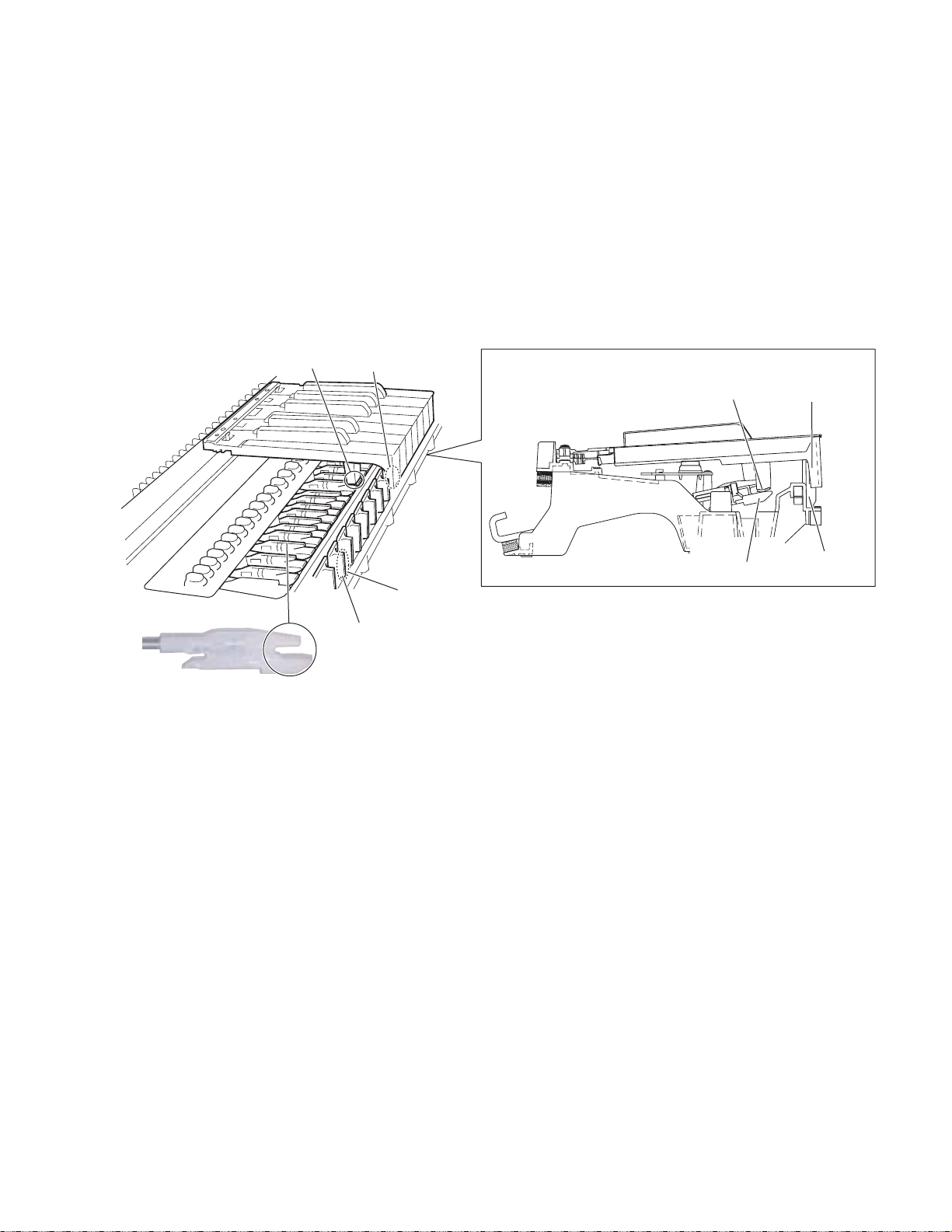

15-6 GHL88L Circuit Board

Remove the black and white key assembly (A1-B2).

(See procedure 15-1.)

Remove the six (6) screws marked [260A]. The GHL88L

circuit board can then be removed. (Fig.13)

15-7 GHL88M Circuit Board

Remove the black and white key assembly (C1-B5).

(See procedure 15-1.)

Remove the seven (7) screws marked [260B]. The

GHL88M circuit board can then be removed. (Fig.13)

Detach the filament tape and disconnect the FFC cable.

(Fig.15)

<Top view> <Side view>

Keyboard assembly

FFC cable

Filament tape

FFC cable

Filament tape

Frame

GHL88M

CN2 (27P)

(Fig.15)

Through hole

GHL88M

CN2

(27P)

15

DGX-620/YPG-625

15-8 GHL88H Circuit Board

Remove the black and white key assembly (C5-C7).

(See procedure 15-1.)

Remove the five (5) screws marked [260C]. The GHL88H

circuit board can then be removed. (Fig.13)

<Rear view>

Hammer axis

Bottom side

15-9 Hammer (White Key), (Black Key)

Remove the black and white key assembly for the

related keys.

With the key frame placed upside down, push the

hammer forward from the rear, then a click sound is

heard and the hammer bearing section can be removed

from the hammer axis of the key frame.

Take out the hammer sideways. (Fig.16, Fig.17)

* When removing the hammer, take care not to cause

damage to the hammer bearing and its claw.

Bearing claw

Hammer, white key

Frame

Push

Hammer, black key

(Fig.16)

Hammer, B1 (black key)

Hammer, W1 (white key)

Bearing claw

16

Bearing section

(Fig.17)

DGX-620/YPG-625

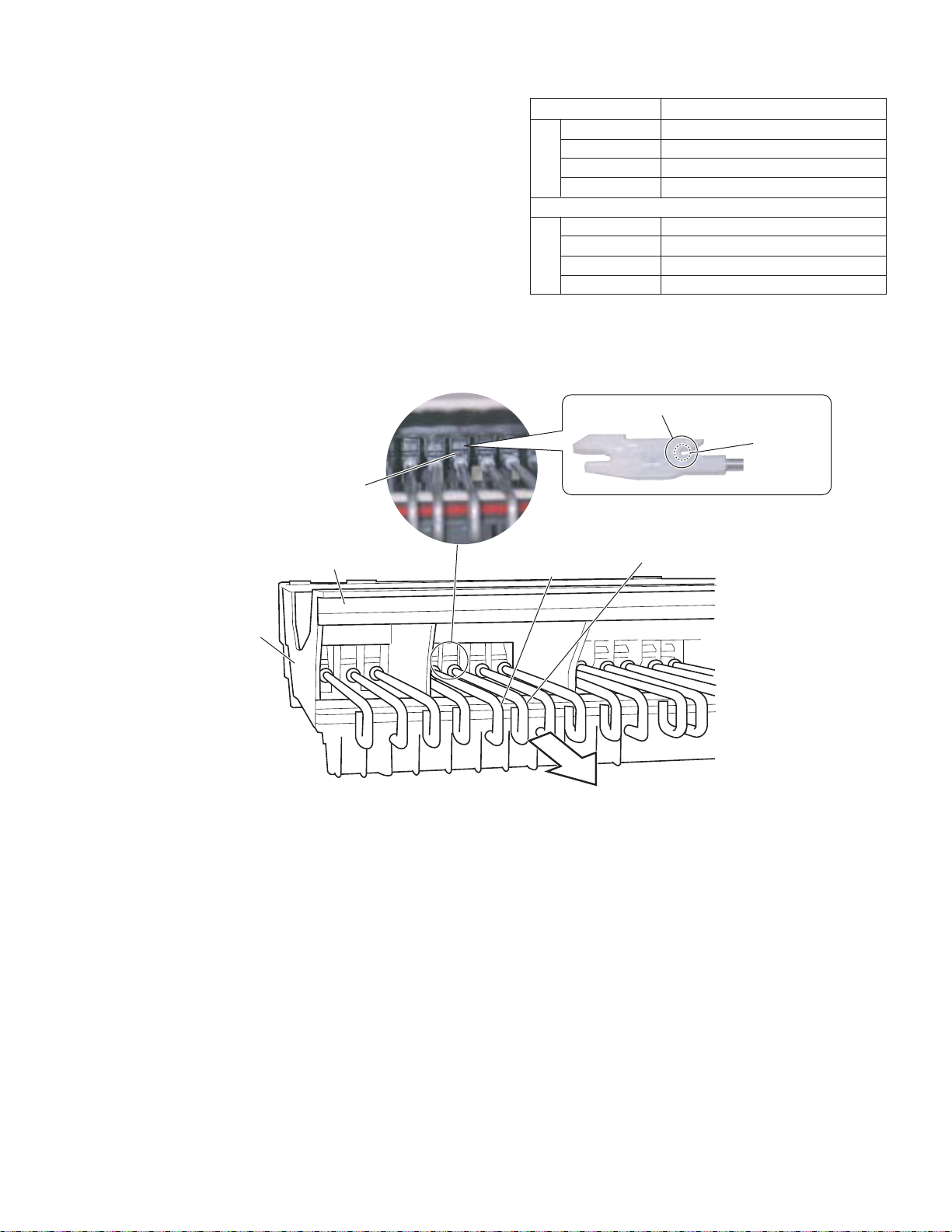

16. Assembling the Keyboard Assembly

16-1 Hammer (White Key), (Black Key)

After applying grease to the bearing section of the

hammer, bring the hammer (white key)(black key)

sideways from the rear, fit its bearing section to the

hammer axis of the key frame and pull it forward until a

click sound is heard. (Fig.18)

* There are 8 hammer types differing in weight. Be sure to

check the type of the hammer for correct installation.

(Table 1)

<Rear view>

Hammer axis

Bottom side

Part Name Range for Applicable Tone Keys

Hammer, W1

Hammer, W2

Hammer, W3

White KeyBlack Key

Hammer, W4

Hammer, B1

Hammer, B2

Hammer, B3

Hammer, B4 D#5 - A#6

Bearing section

Hammer, black key

A-1 - F1

G1 - E3

F3 - D5

E5 - C7

A#-1 - F#1

G#1 - D#3

F#3 - C#5

(Table 1)

Apply grease

Hammer, white key

Frame

Pull forward

(Fig.18)

17

DGX-620/YPG-625

16-2 GHL88L Circuit Board

Tighten the six (6) screws marked [260A] to fix the

GHL88L circuit boards. (Fig.13)

16-3 GHL88M Circuit Board

Connect the FFC cable to CN2 of the GHL88M circuit

board, attach the filament tape. (Fig.15)

Pass the end of the cable into the through hole in the

frame and pull it out from its outlet. (Fig.15)

Tighten the seven (7) screws marked [260B] to fix the

GHL88M circuit board. (Fig.13))

Rubber contact

GHL88L

Rubber contact

16-4 GHL88H Circuit Board

Tighten the five (5) screws marked [260C] to fix the

GHL88H circuit board. (Fig.13)

16-5 Rubber Contact

Note that the rubber contact has s specific installation

direction. Be careful not to install it in the wrong

direction.

* A triangle mark (

∆

) on the rubber contact must face

the front. (Fig.19)

To prevent looseness of the rubber contact, fit it

securely in place using a clip or similar object.

(Fig.20)

Rubber contact Clip

GHL88L

Front

Triangle mark Triangle mark

(Fig.19)

16-6 Actuate Rubber

After applying grease to top and bottom faces of the

actuate rubber, fit it to the white key (black key). (Fig.21)

Apply grease

(Fig.20)

Fit in this way.

Actuate rubber

18

(Fig.21)

DGX-620/YPG-625

16-7 White key assembly and black key assembly

After applying grease to the key guide, install the white

key assembly/black key assembly.

At this time, check to make sure that the key guide of the

key frame and inside slit at the front of white key as well

as the contact arm of the hammer and actuate rubber of

the white key assembly/black key assembly are installed

properly. (Fig.22)

Use the four (4) screws marked [270A] to fix 1 octave

white key assembly/black key assembly. (Fig.10)

Actuate rubber

Slit

16-8 Use the two (2) screws marked [270B] to fix the A-1 to

B-1 keys. (Fig.10)

16-9 Use a screw marked [270C] to fix the C7 key. (Fig.10)

<Side view>

Actuate rubber

Slit

Hammer

Contact arm

Key guide

Apply grease

(Fig.22)

Contact arm

Key guide

19

Loading...

Loading...