INSTRUCTION MANUAL

IM223R04

Hydrovar Pump Control

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

INDEX

1 Important Safety Instructions ........................................................................................................................................ 4

2 System Design................................................................................................................................................................... 5

2.1 Pressure tank ................................................................................................................................................................ 6

3 Product Overview ............................................................................................................................................................7

3.1 Hardware congurations .............................................................................................................................................7

3.2 Operation modes ......................................................................................................................................................... 7

3.2.1 Actuator (for single pump operation only!) .................................................................................................... 7

3.2.2 Controller ............................................................................................................................................................ 7

3.2.3 Cascade Relay .................................................................................................................................................... 7

3.2.4 Cascade Serial/Synchron .................................................................................................................................. 8

4 Model Number ................................................................................................................................................................ 10

5 Technical Data .................................................................................................................................................................12

5.1 General technical data ..............................................................................................................................................13

5.2 EMC requirements (Electromagnetic compatibility) .............................................................................................14

6 Dimensions and Weights .............................................................................................................................................. 15

7 Additional Components ................................................................................................................................................ 17

7.1 Cable glands provided .............................................................................................................................................17

7.2 Assembly Instructions – All models..........................................................................................................................18

8 Electrical Installation and Wiring ................................................................................................................................ 19

8.1 Equipment protection ............................................................................................................................................... 19

8.2 EMC- electromagnetic compatibility ....................................................................................................................... 21

8.3 Recommended Wire Types .......................................................................................................................................22

8.4 Wiring and connections ............................................................................................................................................ 22

8.4.1 Input voltage terminals ....................................................................................................................................23

8.4.2 Motor connection .............................................................................................................................................24

8.4.3 Power unit..........................................................................................................................................................24

8.4.3.1 Solo run (Hand Mode) ........................................................................................................................ 25

8.4.3.2 Addressing ...........................................................................................................................................27

8.4.4 Control unit ....................................................................................................................................................... 28

2

INDEX

9 Programming ...................................................................................................................................................................35

9.1 Display – Control panel of the Master / Single Inverter ........................................................................................35

9.2 Function of the push buttons ...................................................................................................................................35

9.3 Basic Drive Display ....................................................................................................................................................36

9.4 Software parameters .................................................................................................................................................36

00 MAIN MENU .......................................................................................................................................................... 37

20 SUBMENU STATUS ...............................................................................................................................................40

40 SUBMENU DIAGNOSTICS ..................................................................................................................................43

60 SUBMENU SETTINGS...........................................................................................................................................44

0100 SUBMENU BASIC SETTINGS .......................................................................................................................... 44

0200 SUBMENU CONF INVERTER ..........................................................................................................................47

0300 SUBMENU REGULATION ................................................................................................................................52

0400 SUBMENU SENSOR ......................................................................................................................................... 54

0500 SUBMENU SEQUENCE CNTR ........................................................................................................................ 56

0600 SUBMENU ERRORS .........................................................................................................................................60

0700 SUBMENU OUTPUTS ......................................................................................................................................61

0800 SUBMENU REQUIRED VALUES ...................................................................................................................... 62

0900 SUBMENU OFFSET .......................................................................................................................................... 64

1000 SUBMENU TEST RUN ......................................................................................................................................66

1100 SUBMENU SETUP ............................................................................................................................................67

1200 SUBMENU RS485-INTERFACE ....................................................................................................................... 67

10 Failure Messages ..........................................................................................................................................................69

10.1 Basic Inverter ..........................................................................................................................................................69

10.2 Master / Single Inverter ........................................................................................................................................70

10.3 Internal errors.........................................................................................................................................................73

11 Maintenance .................................................................................................................................................................75

12 Programming Flow Chart ........................................................................................................................................... 76

Limited Warranty ...............................................................................................................................................................80

3

DANGER

Hazardous

voltage

DANGER

Hazardous

Pressure

CAUTION

! SAFETY INSTRUCTIONS

WARNING

CAUTION

CAUTION

Section 1

Important: Read all safety information prior to installation of the Controller.

NOTE

This is a SAFETY ALERT SYMBOL. When you see this symbol on the controller, pump or in this

manual, look for one of the following signal words and be alert to the potential for personal

injury or property damage. Obey all messages that follow this symbol to avoid injury or death.

Indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury.

Indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury.

Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury.

Used without a safety alert symbol indicates a potentially hazardous situation which, if

not avoided, could result in property damage.

NOTE Indicates special instructions which are very important and must be followed.

NOTE

All operating instructions must be read, understood, and followed by the operating personnel. Xylem

Inc. accepts no liability for damages or operating disorders which are the result of non-compliance with

the operating instructions.

1. This manual is intended to assist in the installation, operation and repair of the system and must be kept with

the system.

2. Installation and maintenance MUST be performed by properly trained and qualied personnel.

3. Review all instructions and warnings prior to performing any work on the system.

4. Any safety decals MUST be left on the controller and/or pump system.

5. The system MUST be disconnected from the main power supply before removing the cover or

attempting any operation or maintenance on the electrical or mechanical part of the system.

Failure to disconnect electrical power before attempting any operation or maintenance can result

in electrical shock, burns, or death.

6. When in operation, the motor and pump could start unexpectedly and cause serious injury.

Section 1A

Review Hydrovar components and ensure that all parts are included. Inspect all components supplied for

shipping damage.

Included Hydrovar components:

1. Hydrovar motor mount variable 4. 4 Attachment brackets, (bottom hook,

speed drive extender, and screws)

2. Pressure transducer with cable 5. Precision screwdriver.

3. Conduit plate caps and reducers 6. Instruction and Operation Manual

4

Hazardous

Pressure

CAUTION

SYSTEM DESIGN

Section 2

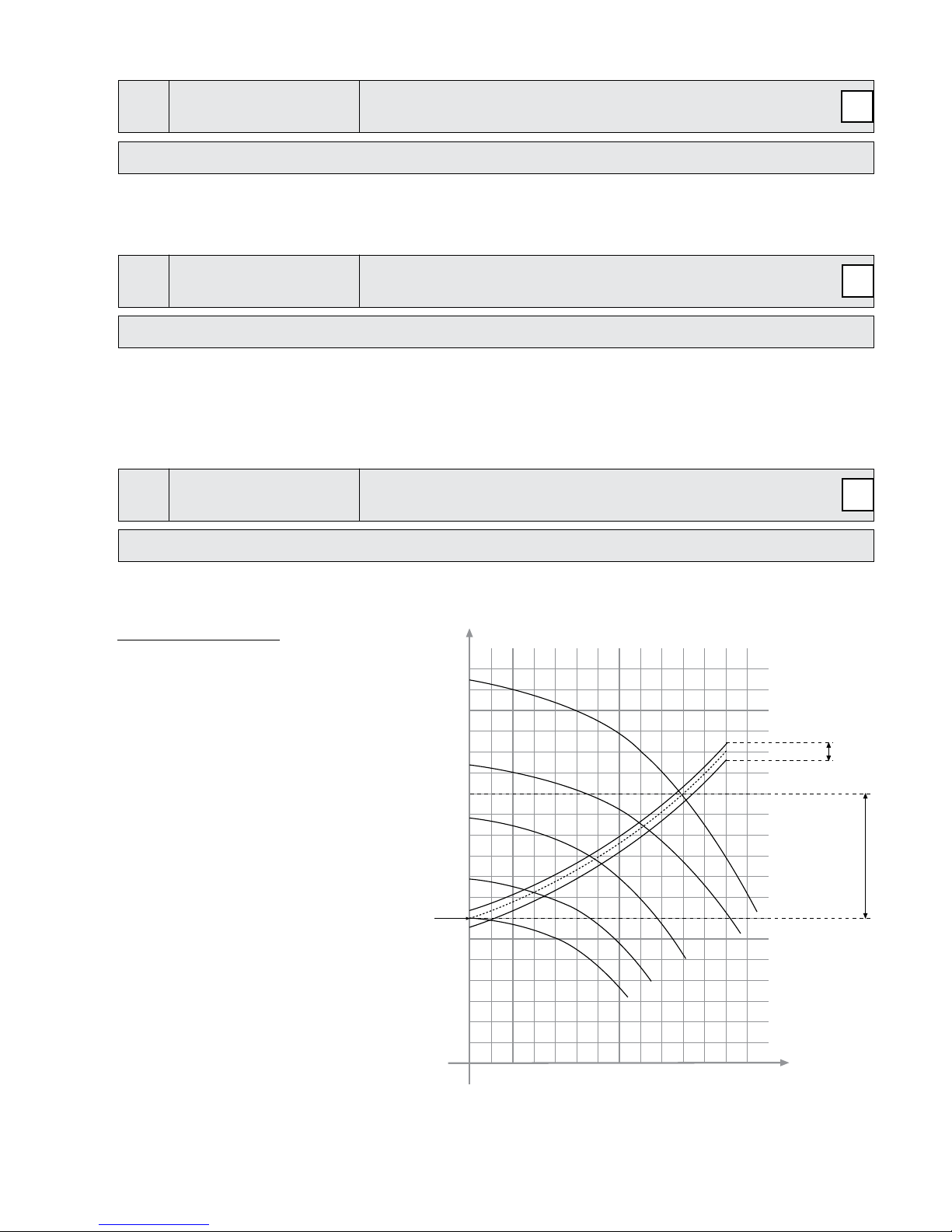

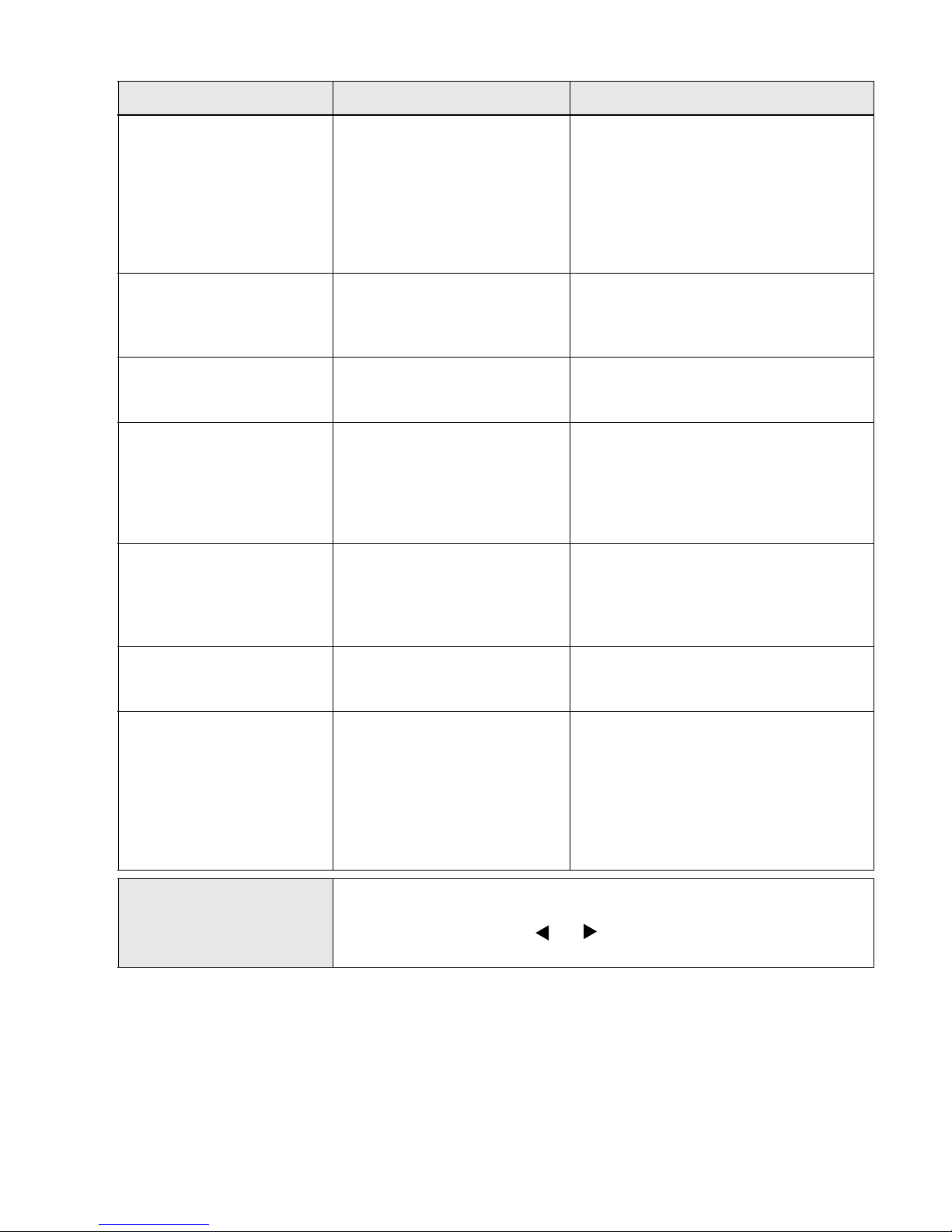

The following diagrams show typical single and multi-pump systems using the HYDROVAR Variable Speed Drive.

Connect directly to water supply. Use of a low suction pressure switch is recommended.

NOTE

Systems MUST be designed by qualied technicians only and meet all applicable state and local code requirements.

Single Pump Layout Multi-Pump Layout

2

2

9

7

4

67 7

8

1

445

3

8

9

7

6

4

1

4 45

8

1

4 45

8

1

4 45

(1) pump with HYDROVAR (4) gate valve (7) pressure gauge

(2) diaphragm tank (5) check valve or ball valve (8) pressure transducer

(3) fusible disconnect (6) low suction pressure switch (9) pressure relief valve

General

NOTE

All plumbing work must be performed by a qualied technician. Always follow all local, state and provincial

codes.

A proper installation requires a pressure relief valve, a ¼" female N.P.T. threaded tting for the pressure sensor,

and properly sized pipe. Piping should be no smaller than the pump discharge and/or suction connections.

Piping should be kept as short as possible. Avoid the use of unnecessary ttings to minimize friction losses.

Some pump and motor combinations supplied with this system can create dangerous pressure.

Select pipe and ttings according to your pipe suppliers’ recommendation. Consult local codes for

piping requirements in your area.

All joints must be airtight. Use Teon tape or another type of pipe sealant to seal threaded connections. Use

caution when using thread sealant as any excess that gets inside the pipe may plug the pressure sensor.

Galvanized ttings or pipe should never be connected directly to the stainless steel discharge head or casing as

galvanic corrosion may occur. Barb type connectors should always be double clamped.

5

Hazardous

Pressure

CAUTION

SYSTEM DESIGN

Pressure Tank, Pressure Relief Valve and Discharge Piping

Use only “pre-charged” tanks on this system. Do not use galvanized tanks. Select an area that is always above

34º F (1.1º C) in which to install the tank, pressure sensor and pressure relief valve. If this is an area where a water

leak or pressure relief valve blow-off may damage property, connect a drain line to the pressure relief valve. Run

the drain line from the pressure relief valve to a suitable drain or to an area where water will not damage

property.

Pressure Tank, System Pressure

Sizing – A diaphragm tank (not included) is used to cushion the pressure system during start-up and shut-down.

It should be sized to at least 20% of the total capacity of your pump. Example: If your pump is sized for 100 GPM

then size your tank for at least 20 gal. total volume, not draw down. Pre-charge your bladder tank to 15-20 PSI

below your system pressure. The controller is pre-set for 50 PSI at the factory. Therefore a 35-40 PSI pre-charge in

your tank would be required. Use the higher tank pre-charge setting if the system drifts over 5 PSI at a constant

ow rate. NOTE: Pre-charge your tank before lling with water!

CAUTION

Maximum working pressure of HydroPro diaphragm tank is 125 psi.

Installing the Pressure Sensor

The pressure sensor requires a ¼" FNPT tting for installation. Install the pressure sensor with the electrical

connector pointing up to avoid clogging the pressure port with debris. Install the pressure sensor in a straight

run of pipe away from elbows or turbulence. For optimum pressure control install the pressure sensor in the

same straight run of pipe as the pressure tank. Ensure the pressure sensor is within 10 feet of the pressure tank.

Installing the pressure sensor far away from the pressure tank may result in pressure oscillations. Do not install

the pressure sensor in a location where freezing can occur. A frozen pipe can cause damage to the pressure

sensor.

The pressure sensor cable is 30' as standard. The cable can be shortened for a cleaner installation. Longer cable

lengths are available, consult factory. Maximum recommended pressure sensor cable length is 300 feet. Avoid

leaving a coil of pressure sensor cable as this can induce unwanted transient voltages and noise into the system.

Do not run the pressure sensor cable alongside the input or output wiring. Maintain a distance of at least 8”

between the pressure sensor cable and input or output wiring.

WARNING

Discharge pressure within the piping system prior to removing pressure transducer or disconnecting any part

of the piping system. Open a valve until pressure on an external gauge reads 0 psi.

6

PRODUCT OVERVIEW

Section 3

3.1 Hardware Congurations

The HYDROVAR variable speed drive consists of two separate components: the power unit and the control card.

In its basic conguration (consisting of only the power unit) the HYDROVAR can be used as a Basic Inverter. In

that conguration the HYDROVAR can be used as a sequence pump in a multi pump system, or as a simple soft

starter for single pump applications.

By extending this Basic controller with the additional control card, the HYDROVAR is able to work in different

modes and can be used for multipump applications.

Three types of drives are available. They are each capable of different levels of control. They are:

Master controller:

• Full variable speed controller of itself in a single pump conguration, with more features than the Single

controller

• Full variable speed control of the attached motor and up to 7 additional Master or Basic controllers.

• Full variable speed control of the attached motor and on/off, xed speed control of up to 5 additional pumps.

(This requires an additional relay card.)

Basic controller:

• Single pump soft start control

• Full variable speed control when connected to a Master controller

Single controller:

• Full variable speed control of a single pump with fewer features than the Master controller

3.2 Modes of Operation

3.2.1 Actuator (for single pump operation only!)

In this mode the HYDROVAR operates as an actuator with external speed signal or switching between 2

programmed frequencies by using the corresponding digital input. For this application the HYDROVAR

operates like a standard frequency converter when an external controller is used.

NOTE

This mode can only be programmed with a Master or Single controller, and is for single pump systems

only.

3.2.2 Controller

This mode should be selected if only one HYDROVAR pump is in operation and there is no connection to

any other HYDROVAR via RS485 interface.

→ Typical single pump operation

3.2.3 Cascade Relay

One pump is tted with a HYDROVAR Master controller and up to 5 xed speed pumps can be switched ON

and OFF on demand. For this purpose an additional Relay Card with 5 relays is used in the Master controller.

Separate motor starters are needed for each motor relay, because the relays in the HYDROVAR are control

contacts only.

Lead/Lag switching of the xed speed pumps to provide even wear and achieve even operating hours can

be programmed in this mode.

This conguration is a cost effective alternative compared with other solutions using VFD’s on each pump,

but additional equipment is required, and you only have xed speed control of the pumps.

7

PRODUCT OVERVIEW

Application Example

Booster sets up to 6 pumps where only one pump is speed controlled by the HYDROVAR and the others are

xed speed (1 HYDROVAR Master Inverter+5 xed speed). This should be the standard conguration when

the additional Relay Card is used.

3.2.4 Cascade Serial and Cascade Synchron

In these modes each of the pumps is equipped with a HYDROVAR unit. All units are connected and

communicate via the RS485 interface.

At least one Master controller is used. The other pumps can be controlled by Basic or Master drives. The

Master controller continually reads the status and failures of the Basic controllers. All failures are indicated on

the master unit, including the date and time.

The Master controller has complete control of all pumps in the system, including automatic alternation of the

lead and lag pumps, which provides even wear and achieves even operating hours for each pump.

If the control card of a Master controller fails, each of the Basic controllers can be manually started by an

external switch (manual operation) for “emergency operation” of the system.

Application Example

Each pump, (up to 8 pumps), is equipped with a HYDROVAR unit. At least one Master controller will be

connected to up to seven Basic controllers. All units are connected via the serial interface (RS485).

The combination of the different HYDROVAR units that are used in a multi-pump-system depends on the

system requirements (i.e. in a 6 pump system 2 or more Master controllers can be used to increase reliability,

and up to 4 Basic controllers

without control card.

Minimum requirement: 1

Master controller and the other

pumps equipped with Basic

controllers.

8

PRODUCT OVERVIEW

To increase the reliability of a system, (in the event of a Master controller failure) a second Master controller

can be used.

Full-featured possibility: Each pump is equipped with a Master controller.

In this mode it is possible to run all pumps in cascade serial mode and synchronous mode as well.

This conguration allows each pump to become the lead pump. This also ensures a proper operation if one

Master controller fails. In this case another HYDROVAR takes control. This ensures that the operating hours of

each pump will be the same to ensure even wear of the pumps.

9

MODEL NUMBER CODE

Section 4

Hydrovar Variable Speed Drive Type and Catalog Number

Hydrovar Example Product Code

HV M 3 4 20 0

Filter (optional): Standard = 0, (no lter)

Residential = B

HP Rating: 02 = 2 03 = 3 05 = 5

07 = 7.5 10 = 10 15 = 15

Volts: 2 = 230V 4 = 460V

Phase: 1 = Single Phase 3 = 3 Phase

Type: M - Master

S - Single

B - Basic

Series: HV

The following applies to this example:

HV - Hydrovar Variable Speed Drive

M - Master Drive, (full control and communications)

3 - 3 Phase input power

4 - 460 Volt input power

20 - 20 Horsepower rated

Blank: Standard Commercial Filter, (not residential)

10

MODEL NUMBER CODE

Section 4 (continued)

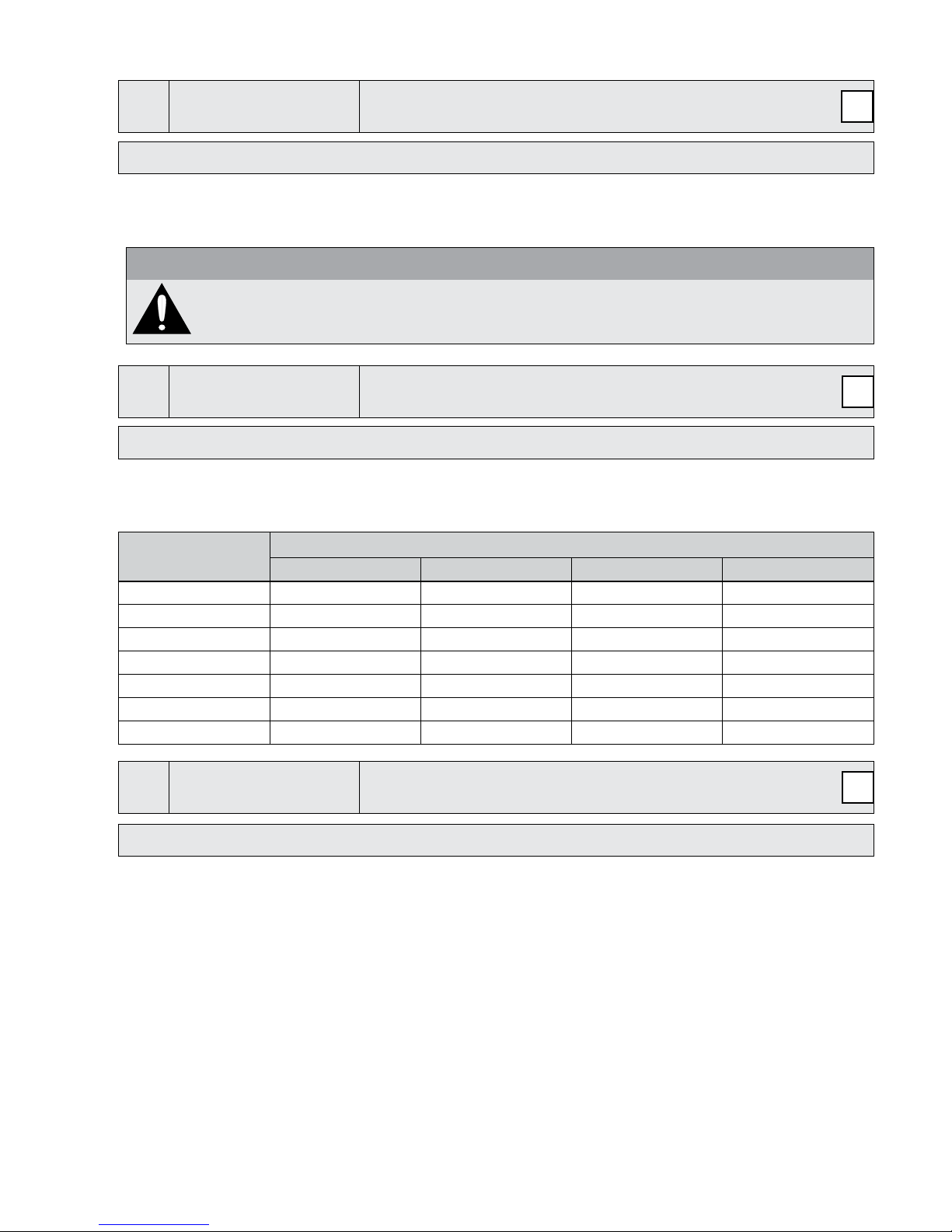

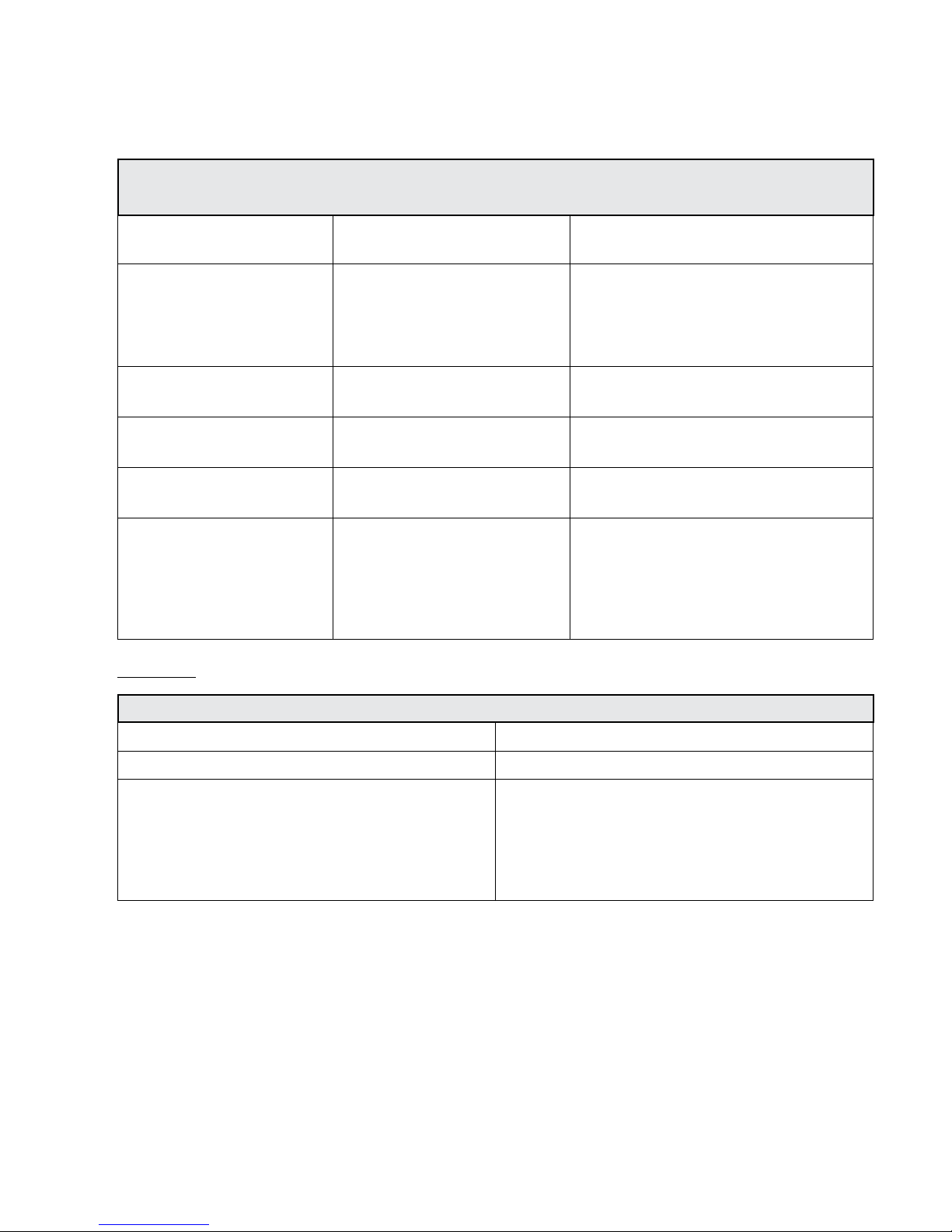

Hydrovar Product Numbering Chart

Voltage Phase Normal Duty HP Drive Type Model Number

MASTER HVM1202

230 V 1

460 V 3

2

3

3

5

7.5

10

15

BASIC HVB1202

SINGLE HVS1202

MASTER HVM1203

BASIC HVB1203

SINGLE HVS1203

MASTER HVM3403

BASIC HVB3403

SINGLE HVS3403

MASTER HVM3405

BASIC HVB3405

SINGLE HVS3405

MASTER HVM3407

BASIC HVB3407

SINGLE HVS3407

MASTER HVM3410

BASIC HVB3410

SINGLE HVS3410

MASTER HVM3415

BASIC HVB3415

SINGLE HVS3415

11

TECHNICAL DATA

Section 5

Hydrovar Power Supply

Rated Output Voltage Limits 48-62 HZ

Cat #* HP V Amps Amps AWG

HVM1202 2

HVM1203 3 20 25 10

HVM3403 3

HVM3405 5 11.4 15 14

HVM3407 7.5 15.1 20 12

HVM3410 10 19.6 20 10

HVM3415 15 27.8 30 8

* Listed catalog numbers are for master drives. Details also apply to corresponding basic and single units.

1 Ph, 220-240V -10%,

+15%

3 Ph, 380-460V

+-15%

Rated Current

Input

14 20 14

7.6 10 14

Hydrovar Output to the Motor

Rated Output Voltage Limits 48-62 HZ Rated Current Output Motor Connection Wires

Cat #* HP V Amps AWG

HVM1202 2

HVM1203 3 10 14

HVM3403 3

HVM3405 5 9 14

HVM3407 7.5 13.5 14

HVM3410 10 17 12

HVM3415 15 23 10

3 Ph, 240V

3 Ph, 480V

Recommended

Line Protection

7 14

5.7 14

Maximum

Wire Size

12

06

TECHNICAL DATA

5.1 General Technical Data

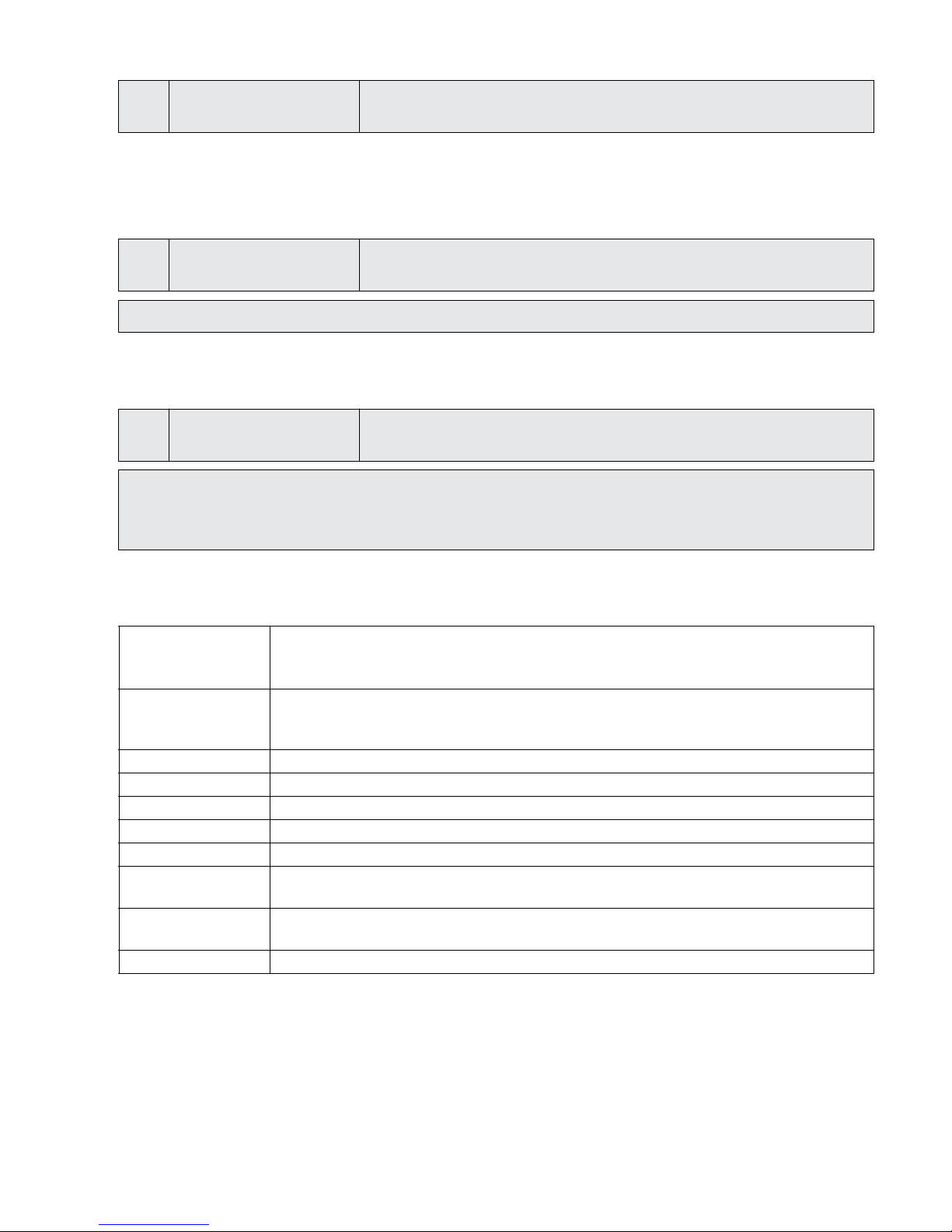

Ambient temperature: 0° C ... +40° C, 32º F... +104º F

At higher temperatures reduce the output current as shown below or

upsize to the next largest HYDROVAR.

110

100

90

80

70

60

50

40

30

Maximum Output Current (%)

20

10

0

0102030405

Maximum Ambient Temperature (ºC)

0

The enclosure rating of the HYDROVAR is IP55 however, please note

the following:

• Protect the HYDROVAR from direct sunlight!

• Protect the HYDROVAR from direct rainfall

• Outdoor installation without protection from sun will void warranty!

Storage temperature: -25° C ... +55° C, -10º F ... +130º F

Humidity: RH maximum 50% at 104º F, unlimited

RH maximum 90% at 70º F, maximum 30 days per year

75% average per year (class F)

Condensation is not allowed and will void warranty!

During long periods of inactivity or shutdown, the HYDROVAR should

remain connected to the power supply but turned off to prevent

inadvertant pump run. This will maintain power to the internal heater and

reduce internal condensation.

Air pollution: The air may contain dry dust as found in workshops where there is

excessive dust due to machines. Excessive amounts of dust, acids,

corrosive gases, salts etc. are not permitted

Altitude: Maximum 1000 m, 3280 feet above sea level.

At sites over 1000 m above sea level, the maximum output power should

be de-rated by 1% for every additional 100 m. For installations higher

than 2000 m above sea level, please contact your local distributor.

Class of protection: IP 55, NEMA 4 (Indoor use only)

Certications: CE, UL, C-Tick, cUL

13

TECHNICAL DATA

5.2 EMC Requirements (Electromagnetic Compatibility)

The EMC requirements depend on the intended use.

Class B environment (EN 61800-3: Class C2)

Environment that includes domestic premises, it also includes establishments directly connected without intermediate transformers to a low-voltage power supply network which supplies buildings used for domestic

purposes. Examples of class B environments include houses, apartments, commercial premises or ofces in a

residential building.

CAUTION: The relevant EMC regulations for which the HYDROVAR was tested in class B environments is based

on the restricted use of the product and the following limitations:1) the drive voltage is less than 1000 V; 2) it

is neither a plug in device nor a movable device and, 3) when used in the class B environment, it is intended to

be installed and utilized by technicians with the necessary training and skills required for installing and/or using

power drive systems, including specic training with respect to EMC requirements.

Class A environment (EN 61800-3: Class C3)

Environment that includes all establishments other than those directly connected to a low voltage power supply

network which supplies buildings used for domestic purposes e.g. Industrial areas, technical areas of any building fed from a dedicated transformer are typical examples of class A environment locations.

The HYDROVAR complies with the general EMC regulations and is tested according to the following

standards: EN 61800-3/2004

EN 55011 (2002) Disturbance voltages / Disturbance eld strength

First environment Second Environment

– class B / class C2 – class A / class C3

Disturbance voltages OK OK

Disturbance eld strength * OK

* Warning - In a domestic environment, this product may cause radio interference, in which case supplementary mitigation measures

may be required.

EN 61000-4-2 (2001) Electrostatic discharge

EN 61000-4-3 (2002) Electromagnetic eld immunity test

EN 61000-4-4 (2001) Burst immunity test

EN 61000-4-5 (2001) Surge immunity test

EN 61000-4-6 (1996) Immunity of conducted RF-Disturbance

14

DIMENSIONS AND WEIGHTS

Section 6

HVM1202, HVM1203, HVM3403, 3405

8.9

8.2

7.9

3.353.35

6.7

7.9

7.4

All dimensions in inches! Drawings are not to scale!

Dimensions are nominal

Basic Master / Single

Weight [lbs]

Type

2, 3 HP

1 Ph

3, 5 HP

3 Ph

8.8 9.7

a … minimum center-distance between HYDROVARs 12"

b … header space for maintenance 12"

15

DIMENSIONS AND WEIGHTS

HVM3407, HVM3410, HVM3415

10.9

10.2

9.9

3.35

6.7

3.35

10.2

9.4

All dimensions in inches! Drawings are not to scale!

Dimensions are nominal

Weight [lbs]

Type

Basic Master / Single

7.5, 10, 15 HP

3 Ph

16.9 17.8

a … minimum centre-distance between HYDROVARs 17"

b … minimum header space for maintenance 12"

16

ADDITIONAL COMPONENTS

Section 7

7.1 Cable Glands Provided

Included

components

Gland sizer

Cable

size

AWG

2.015- 2.022 2 (3) 2 2 3 1 1 4 1

4.022- 4.040 2 (3) 2 2 3 1 1 4 1

4.055- 4.110 2 (3) 2 2 3 1 1 4 1

( ) maximum available cable entries

12 16 20 25 12 16

#8-#1 4,5-10 7-1 3 9-17

Cable gland

and lock nut

M M M M M M

Conduit

plugs

Thermistor

Mounting

clamps

Centring - bit

7.2 Assembly Instructions – All models

To remove the HYDROVAR cover, loosen the 4 fastening screws.

• Verify that there is no liquid on the unit before you open the cover.

• The HYDROVAR is installed on the motor fan cover using the mounting brackets, the four screws and the relevant washers.

• Center the HYDROVAR and tighten the four screws holding the brackets.

• Tighten each screw until the two bottom teeth in the brackets start to grip the fan cover.

• After the electrical components are connected, the top cover of the HYDROVAR can be mounted and tightened by the four fastening screws.

• Ensure the integrity of the ground wire connection. Failure to properly ground the controller or motor will create an electrical shock hazard.

• Ensure HYDROVAR cover gasket is in place before tightening the cover screws.

• Ensure cable glands are properly installed and close conduit openings that are not being used with conduit

plugs.

17

ADDITIONAL COMPONENTS

7.2 Assembly Instructions – All models (continued)

18

ELECTRICAL INSTALLATION AND WIRING

Section 8

NOTE

All installations and maintenance must be performed by properly trained and qualied

personnel. Use personal protection equipment.

NOTE

In case of a failure, the electrical power must be disconnected or switched off. Wait at least 5

minutes for capacitor discharge before servicing the HYDROVAR. Shock, burns or death are

possible hazards if the capacitor discharges during maintenance, repair, or assembly.

8.1 Equipment Protection

Follow state, and local codes for proper equipment protection.

Applicable: • proper grounding

• AC and DC Ground Fault Circuit Interrupter (GFCI)

Proper grounding:

• Please note that leakage to ground can occur due to the capacitors in the input lter.

• A suitable protection unit has to be selected (according local regulations).

Ground Fault Circuit Interrupter (GFCI):

• When using a GFCI, make sure that it also releases in the event of a short circuit inside the DC-part of the HYDROVAR to ground!

• single phase HYDROVAR => use pulse sensitive GFCI's

• three phase HYDROVAR => use AC/DC sensitive GFCI's

• The GFCI should be installed according to local regulations!

Fuses:

• Use Very fast acting Class T fuses

• Bussman T-tron type JJN and JJS fuses are acceptable (or equal)

Internal equipment protection:

• The Hydrovar has internal protections against the following malfunctions: short circuit; under and over-voltage,

overload and the overheating of the electronic components.

External protective devices:

• Additional protective functions like motor overheat and low water protection are controlled by separate equipment.

19

ELECTRICAL INSTALLATION AND WIRING

Fused Disconnect Box:

DISCONNECT

SINGLE

PHASE

CUSTOMER SUPPLIED

VOLTAGE

THREE

PHASE

CUSTOMER SUPPLIED

VOLTAGE

Disconnect

Part Number

L1

L2

L1

L2

L3

Input

Voltage

1

2

3

4

5

6

GND

DISCONNECT

1

2

3

4

5

6

GND

Disconnect

HP / AMP

Rating

HFD512C1 230/1/60 OT25F3 2 HP / 25A

HFD512E1 230/1/60 OT40F3 3 HP / 40A

HFD534A1 460/3/60 OT16F3 3 HP / 16A

HFD534B1 460/3/60 OT16F3 3 HP / 16A

HFD534C1 460/3/60 OT25F3 3 HP / 25A

HFD534C2 460/3/60 OT25F3 3 HP / 25A

HFD534E2 460/3/60 OT40F3 3 HP / 40A

12 AWG

12 AWG

12 AWG

12 AWG

12 AWG

Wire

Range

#18-

8AWG

#18-

8AWG

#18-

8AWG

#18-

8AWG

#18-

8AWG

#18-

8AWG

#18-

8AWG

FUSE BLOCK

FUSE BLOCK

Tightening

Torque

Supplier

7 IN/LB Bussman 20 KTK-R-20 600V

7 IN/LB Bussman 30 KTK-R-30 600V

7 IN/LB Bussman 10 KTK-R-10 600V

7 IN/LB Bussman 15 KTK-R-15 600V

7 IN/LB Bussman 20 KTK-R-20 600V

7 IN/LB Bussman 20 KTK-R-20 600V

7 IN/LB Bussman 30 KTK-R-30 600V

CUSTOMER SUPPLIED

HYDROVAR

U1

U2

V1

V2

W1

W2

16 AWG

GND

PE

CUSTOMER SUPPLIED

HYDROVAR

U1

U2

V1

V2

W1

W2

16 AWG

GND

PE

Fuse

AMP

Rating

GND

GND

Part

Number

MTR

MTR

Voltage

Rating

NOTE: Recommended protection (not included with drive only). This fused disconnect is available as part of the PHV series packaged

Hydrovar, see price book.

MOTOR

MOTOR

20

ELECTRICAL INSTALLATION AND WIRING

8.2 EMC – Electromagnetic Compatibility

To ensure electromagnetic compatibility the following points must be observed for cable installation:

Control Cables

General Recommendations

Use shielded cables, temperature rated at 60º C (140º F) or above:

• Control cables must be multi-core cables with a braided copper wire screen.

Double Shielded Single Shielded

Example: JAMAK by Draka NK Cables Example: NOMAK by Draka NK Cables

• The screen must be twisted together into a bundle not longer than ve times its width and connected to

terminal X1-1 (for digital and analog I/O cables) or to either X1-28 or X1-32 (for RS485 cables).

Route control cables to minimize radiation to the cable:

• Route as far away as possible from the input power and motor cables (at least 20 cm (8 in)).

• Where control cables must cross power cables make sure they are at an angle as near 90º as possible.

• Stay at least 20 cm (8 in) from the sides of the drive.

Use care in mixing signal types on the same cable:

• Do not mix analog and digital input signals on the same cable.

• Run relay-controlled signals as twisted pairs (especially if voltage > 48 V). Relay-controlled signals using

less than 48 V can be run in the same cables as digital input signals.

NOTE! Never mix 24 VDC and AC power signals in the same cable.

Motor Wires

To ensure the EMC compatibility and minimize noise level and leakage currents, use the shortest possible motor wires. Use shielded wires only if the total length exceeds 6 feet.)

Line Reactors

Line reactors are available as an option and should be mounted between the HYDROVAR and the main fuse.

The Line reactor should be as close to the HYDROVAR as possible, (max. 12").

Advantages:

• more efcient

• reduction of harmonic currents

For the following applications additional line reactors are strongly recommended:

• high short circuit currents

• compensation-plants without a coil

• asynchronous motors which are responsible for a voltage drop >20% of the line voltage

EMC Summary

• Install proper grounds according to local codes and regulations

• Do not install the power wires in parallel to control wires

• Use screened control cables

• Connect both ends of the motor wire screen to ground

• Connect only one end of the control wire screen to ground

• Motor wires should be as short as possible

21

ELECTRICAL INSTALLATION AND WIRING

8.3 Recommended Wire Types

For maximum 40º C ambient temperature, recommend use of 75º C wire of the following types:

RHW, THHW, THW, THWN, XHHW, USE, ZW.

8.4 Wiring and Connections

Remove the screws holding the top cover of the HYDROVAR.

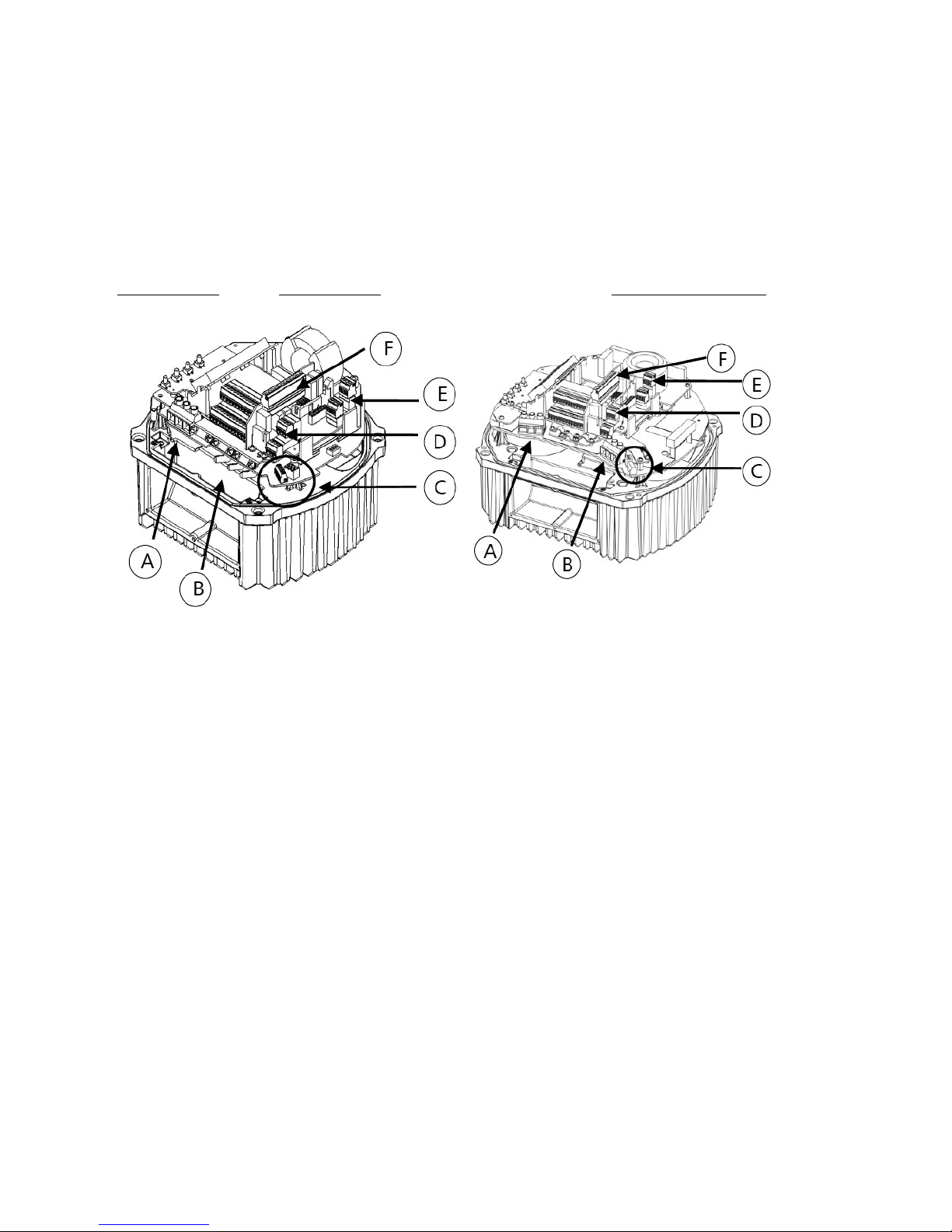

Lift off the top cover. The following parts can be seen on a HYDROVAR Master / Single Drive:

1 Ph / 2, 3 HP 3 Ph / 3, 5 HP 3 Ph / 7.5, 10, 15 HP

(A) Power supply (B) Motor connections (C) Terminal block:

- START/STOP

(D) RS-485 Interface (E) Status-Relays - SOLORUN (hand mode)

- User interface - RS-485 Interface

- Internal interface (F) Optional Relay Card

22

ELECTRICAL INSTALLATION AND WIRING

8.4.1 Input Voltage Terminals

The power supply is connected to the power section:

Terminal L + N (230 VAC, single-phase)

Terminal L1+ L2 + L3 (460 VAC, three-phase)

2, 3 HP / 1Ø 3, 5 HP / 3Ø

7.5, 10, 15 HP / 3Ø

23

ELECTRICAL INSTALLATION AND WIRING

8.4.2 Motor Connection

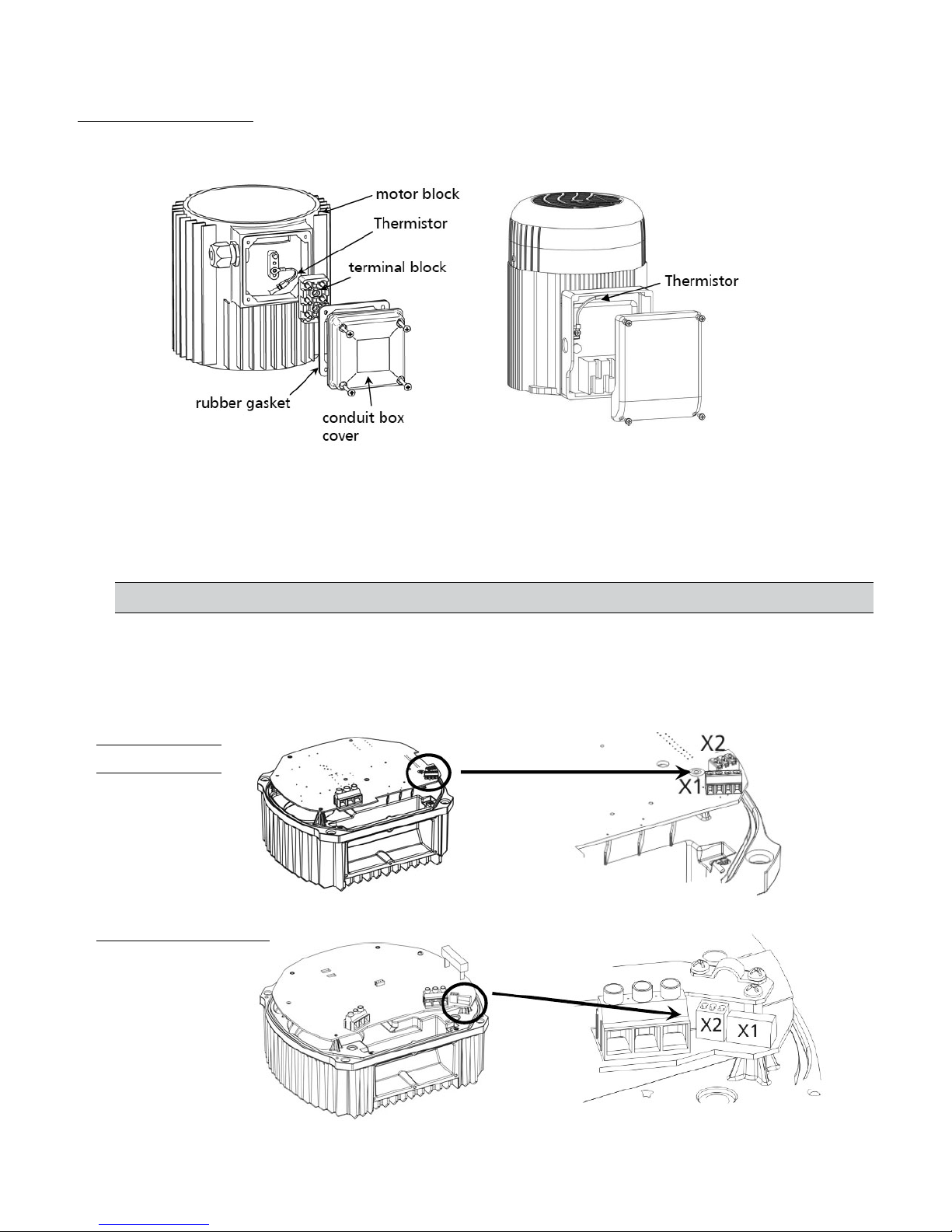

Attaching the Thermistor

Method A : Method B :

1. Remove conduit box cover

2. Attach the thermistor (Method A or B)

3. Replace the terminal block, if necessary

4. Wire the motor according to the motor manufacturer's instructions.

NOTE! The thermistor must be attached to the motor. This is required to measure the motor temperature!

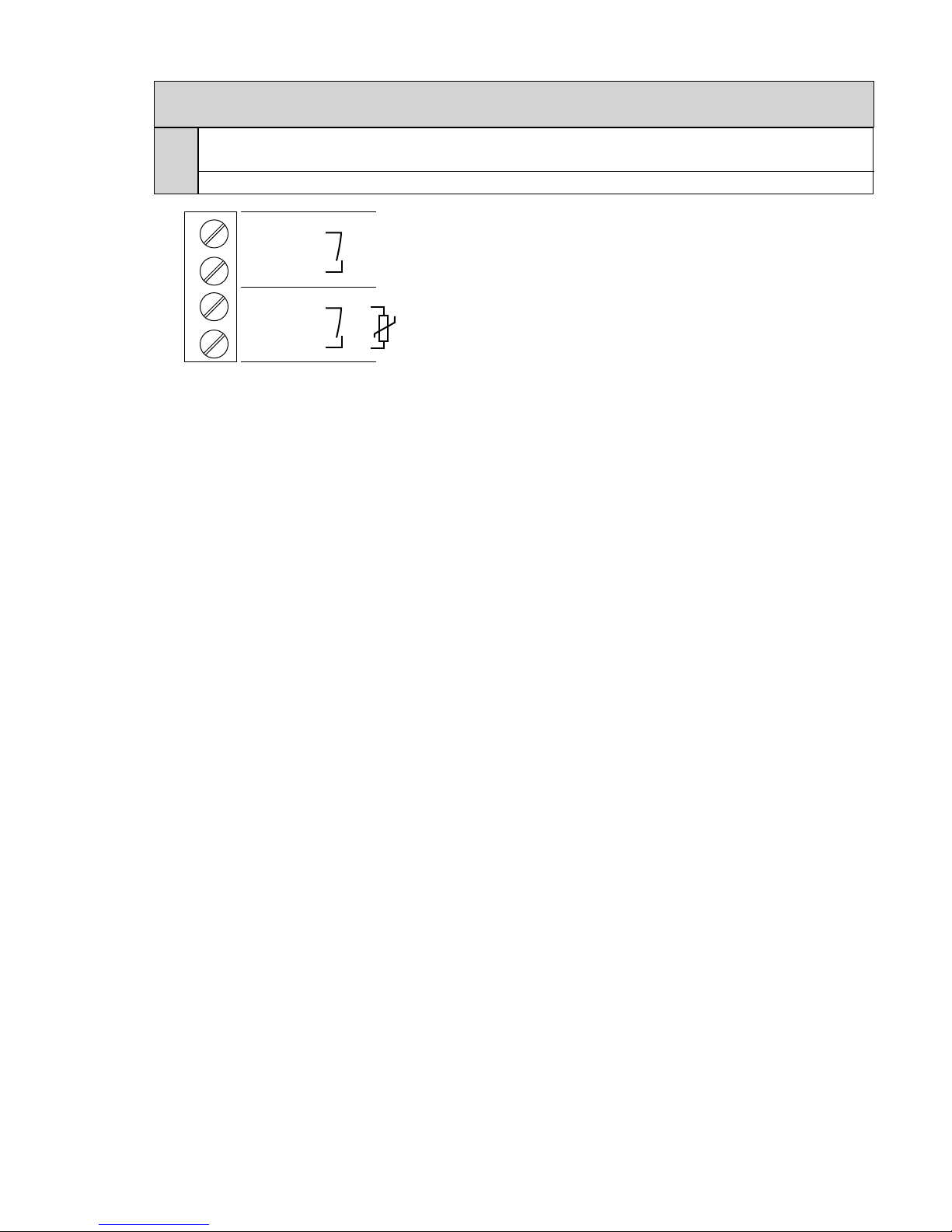

8.4.3 Power Unit

The basic drive has two control terminal blocks.

HVB 1202, 1203

HVB 3403, 3405

HVB 3407, 3410, 3415

24

ELECTRICAL INSTALLATION AND WIRING

X1 Control terminals – power unit

PTC Terminals have Jumper between them.

Remove jumper and attach Thermistor leads

SL SOLO RUN (Hand Mode)

SL

SOLO RUN (Hand Mode)

SL

PTC

START/STOP via Thermistor

PTC

X1

To protect the motor against thermal overload, a thermistor should be connected to the drive at the terminals labeled PTC. This input can also be attached to an external ON / OFF switch when using the HYDROVAR as a Basic

drive. Either the thermistor or on/off switch must be closed between X1/PTC or the drive will stop running! A low

water switch or other protective device can also be connected to these terminals!

If these terminals are not used, they must be jumpered, otherwise the HYDROVAR will not start.

8.4.3.1 Solo Run (Hand Mode)

Terminals X1/SL are used to enable a Basic drive (when used in a multi-pump application) when the communication from the Master drive fails, or if the Master drive itself fails, or to use the Basic drive as a soft-starter.

• If the circuit is open between the two X1/SL terminals, the HYDROVAR works in standard operation as

controlled by a Master drive.

• When contact between the two X1/SL terminals is closed, (contact between X1/PTC terminals must also

be closed), the HYDROVAR starts up to the pre-selected Max Frequency, (set via xed speed, (parameter

0245) using ramps 1 and 2 or the fast ramps FminA and FminD).

A manual override switch can be placed between the 2 X1/SL terminals. When the circuit is open, the drive

will work with the Master. When it is closed, the drive will operate manually.

25

ELECTRICAL INSTALLATION AND WIRING

Connection Example

External switch to enable the

SOLO RUN (Hand Mode)

Example:

Low water or other

X1

emergency off switch

Thermistor

(mounted in the motor terminal box)

Recommended connections of external protective devices:

Basic drive Thermistor X1/PTC

Emergency switch X1/PTC As described above

Low water switch X1/PTC

Master drive Thermistor X1/PTC As described above

External release X3/7-8

Low water switch X3/11-12

SL

SL

PTC

PTC

Auto

SW 1

Manual

On the control card

When the HYDROVAR is used as a Basic drive in a multi-pump system, the X2 terminals on the power unit are

used for the serial RS-485 connection to the other HYDROVAR units in the system. (Note: Internal interface is

not available on Single Inverters!)

X2 RS485-Interface – Power Unit

X2/ SIO - Internal SIO-interface: SIO-

SIO+ Internal SIO-interface: SIO+

GND GND, electronic ground

S

……. Terminals not available for HYDROVAR Single drives

The internal RS-485 Interface on the power unit is used for the communication between up to 8 HYDROVARs

in a multi-pump system (minimum 1 Master drive). Use the same terminals to continue on to the next

HYDROVAR if required. Terminals X4/4-6 can also be used for RS-485 communication on all Master drives.

X2

GND

SIO + RS485 – internal interface

Internal interface

for multi-pump-systems

}

S

SIO -

26

ELECTRICAL INSTALLATION AND WIRING

Terminating Control Wires:

- Use recommended cable type (see section 8.2)

- Strip the end of the wire aproximately 1/4"

- Push down the orange wedges using a small screwdriver

- Insert the stripped wire

- Remove the screwdriver to complete the connection

- To remove, push down the orange wedges and pull out the wire!

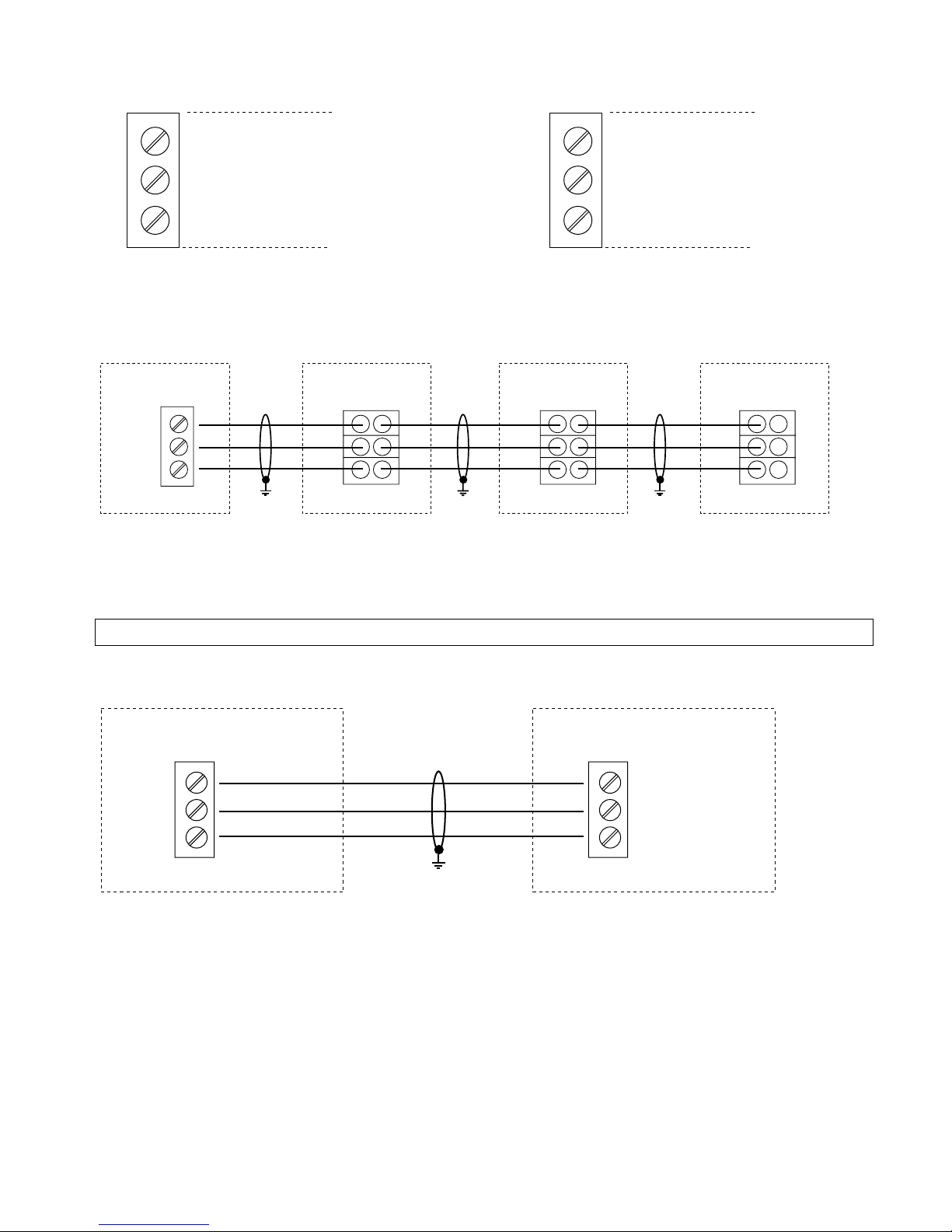

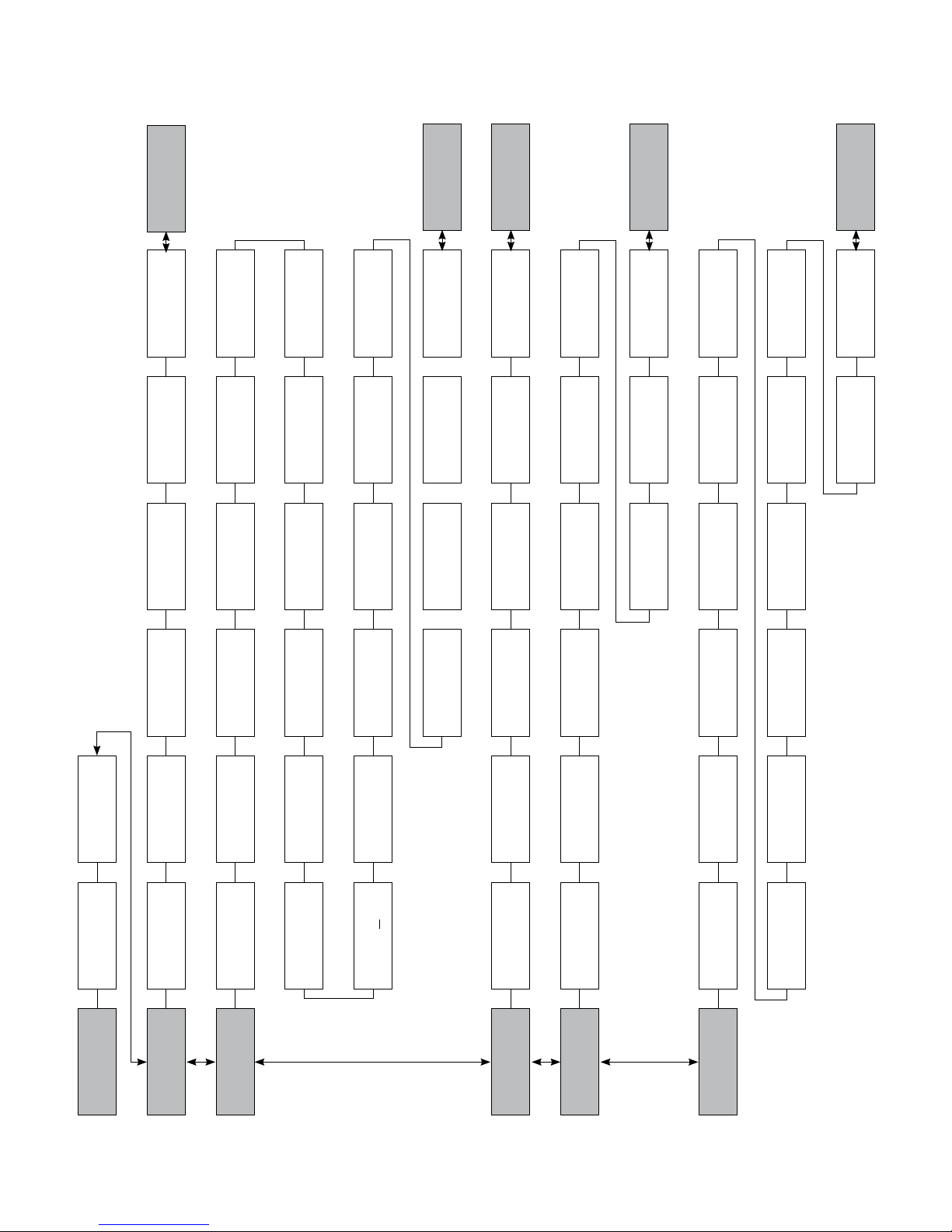

Connection Example Using One Master and Three Basic Drives:

HYDROVAR Master Inverter

Control Card

HYDROVAR Basic Inverter

Power Unit

HYDROVAR Basic Inverter

Power Unit

HYDROVAR Basic Inverter

Power Unit

GND

SIO +

SIO -

6

5

4

X4

GND

SIO +

SIO -

X2 X2 X2

GND

SIO +

SIO -

GND

SIO +

SIO -

8.4.3.2 Addressing

When using the cascade serial/synchron mode in a multi-pump-application (where more than drive is used),

each drive must be addressed correctly.

Master drive – The address of the Master drive is set using the Hydrovar software. Dip switches are used to

program the Basic drives to a specic address. On all Master drives the dip switches must be set to address 1

(default setting, see below).

Basic Drive – When using a Basic drive in a Multi-pump-system the dip switches must be set to the appropriate address for each drive in the system. The addresses for the Basic drives start after the last address of the

nal Master drive in the system. The S1 switchbank is located on the lower board behind the control panel.

(See pictures below for locations.)

Example:

Multi-pump-system with 3 Master and 4 Basic drives

• Set address 1-3 for the Master Inverters via appropriate software parameters (See submenu CONF

INVERTER [0100] or submenu RS485-INTERFACE [1200])

• Address 4-7 for the Basic Inverters via dip-switches

The pre-selected address also denes the initial pump sequence.

HVB 1202 / 1203, HVB 3403 / 3405 HVB 3407 / 3410 / 3415

Basic Inverter Basic Inverter

27

ELECTRICAL INSTALLATION AND WIRING

Switch 1 Switch 2 Switch 3 Address

OFF OFF OFF

OFF OFF ON Address 2

OFF ON OFF Address 3

OFF ON ON Address 4

ON OFF OFF Address 5

ON OFF ON Address 6

ON ON OFF Address 7

ON ON ON

Setting the correct address on Basic drives:

• The HYDROVAR must be disconnected from power supply for at least 5 minutes before removing the top

cover!

• Use the dip-switch on the power unit. (See picture above!)

• Set the desired address for each HYDROVAR

E.g. Address 4 -> switch 1 is set to OFF

switch 2 and 3 are set to ON

• Mount the cover on the HYDROVAR and tighten the four fastening screws

• Reconnect HYDROVAR to power supply

Address 1 (default setting)

(Required setting for the use with control card)

ON

1 2 3 4

Address 8

Switch 4 not used!

8.4.4 Control Terminals

All control wires connected to the control-unit must be screened (See section 8.2 for recommended wire types).

External voltage free contacts must be suitable for switching <10 VDC.

NOTE

If unscreened control wires are used, signal interference may occur and could interfere with

the function of the HYDROVAR.

Do not connect the control card ground to other voltage potentials. All electronic ground terminals and GND of

the RS 485-interface are connected internally.

28

ELECTRICAL INSTALLATION AND WIRING

X3 Digital and Analogue I/O

X3/ 1 GND, electronic ground

2 Actual value current input sensor 1 0-20mA / 4-20mA [Ri=50Ω]

3 Power supply for external sensors 24VDC, ** max. 100mA

4 Actual value current input sensor 2 0-20mA / 4-20mA [Ri=50Ω]

5 Actual value voltage input sensor 2 *DI 2 0-10 VDC

6 Actual value voltage input sensor 1 *DI 1 0-10 VDC

7 External ON/OFF (E-Stop) *** Switch or jumper

8 GND, electronic ground

9 Congurable digital input 1 Switch between DI 1

10 GND, electronic ground and DI 2

11 Low water *** Switch or jumper

12 GND, electronic ground

13 Voltage signal input (required value 1) (Offset) 0-10VDC

14 GND, electronic ground

15 Voltage signal input (required value 2) *Dig 3

(Offset)

16 GND, electronic ground

17 GND, electronic ground

18 Current signal input (required value 1) (Offset) 0-20mA / 4-20mA

[Ri=50Ω]

19 +10V internal ref. for analogue output 10,00VDC, max. 3mA

20 Analogue output 1 0-10VDC, max. 2mA

21 Analogue output 2 4-20mA

22 GND, electronic ground

23 Current signal input (required value 2) (Offset) 0-20mA / 4-20mA [Ri=50Ω]

24 +24V power supply for control inputs 24VDC, ** max. 100mA

0-10VDC

* Terminals 5 and 6 can be used as actual value voltage input and also as digital input. Also the

voltage signal input on terminal X3/15 can be used as digital input.

** X3/3 and X3/24 → maximum 100mA

*** Must be connected through a switch or a jumper

(Offset) These terminals can be used as required value or offset signal input. Conguration: see

submenu REQUIRED VALUES [0800] and submenu OFFSET [0900].

29

ELECTRICAL INSTALLATION AND WIRING

Additional power supply ** max. 100 mA

Current signal input (required val. 2) 0-20mA / 4-20mA [Ri=50Ω]

To determine the required value or the offset

Analogue output 2 4-20mA

Analogue output 1 0-10 VDC

Current signal input (required val. 1) 0-20mA / 4-20mA [Ri=50Ω]

To determine the required value or the offset

Voltage signal input (required value 2) 0-10 VDC *DIG 4

To determine the required value or the offset

Voltage signal input (required value 1) 0-10 VDC

To determine the required value or the offset

24 +24V

23

22

21

20

19 +10V

18

17

16

15

14

13

X3X3

Low water

incoming pressure switch or water level switch required (or jumper)

Congurable digital input 1 DIG 1

for switching between 2 required values or sensors

External ON/OFF (E-Stop) (Connect through switch or jumper)

Actual-value-voltage input sensor 1 0-10 VDC *DIG 2

Actual-value-voltage input sensor 2 0-10 VDC *DIG 3

Actual-value-current input sensor 2 0-20mA / 4-20mA [Ri=50Ω]

Sensor supply voltage ** maximum 100 mA

Actual value current input sensor 1 0-20mA / 4-20mA [Ri=50Ω]

Ground

12

11

10

9

8

7

6

5

4

3 +24V

2

1

* Terminals X3/5 and 6 can be used as actual value voltage input and also as digital input. Also the

voltage signal input on terminal X3/15 can be used as digital input.

** X3/3 and X3/24 → Σ maximum 100mA

30

ELECTRICAL INSTALLATION AND WIRING

Connection Examples:

• Sensor–Actual-value-signal Input

Connecting a 3-wire transducer

(e.g. standard pressure transducer)

3

2

X3

Possible Connections: Standard Pressure

Transducer:

Actual-value-signal input 0/4-20mA X3/4 … Sensor 2

+24VDC sensor supply X3/3 brown

Actual-value-signal input 0/4-20mA X3/2 … Sensor 1 white

Ground X3/1 screen / shield

• Switching between two individual sensors

External switching between two sensors by closing digital input 1 (X3/9-10). How to program see SUBMENU

SENSORS [0400].

1

4-20mA

Connecting an active actual-value-signal

3

X3

2

1

4-20mA

~

X3

24

23

22

21

20

19

18

17

16

15

14

X3

12

11

10

9

8

7

6

5

4

3

2

Digital Input 1

Sensor 2

4-20mA

Sensor 1

4-20mA

31

ELECTRICAL INSTALLATION AND WIRING

• Switching between two different required values

External switching between two connected required value signals (e.g.: between voltage and current signal

input) by closing digital input 1 (X3/9-10).

In ACTUATOR mode the drive can switch between two different frequencies from the digital inputs. The

input signals (current or voltage) will be proportional to the frequency.

(For programming see SUBMENU REQUIRED VALUES [0800].)

22

21

20

19

18

17

16

15

14

X3

• Actual value – Frequency Indicator

e.g. to display the actual motor frequency

How to program see SUBMENU OUTPUTS [0700].

X3

10

9

8

7

2

Digital Input 1 (to switch between

required value 1 and

required value 2)

Required Value 1

0/4 - 20mA

0 - 10V

- external current signal

Required Value 2

- external voltage signal

Possible connections:

20 or 21

Analogue output 1 (0-10V): X3/20

Analogue output 2 (4-20mA): X3/21

X3

X4 RS485-Interface

X4/ 1 User SIO-Interface: SIO-

2 User SIO-Interface: SIO+

3 GND, electronic ground

4 Internal SIO-Interface: SIO-

5 Internal SIO-Interface: SIO+

6 GND, electronic ground

32

}

}

User interface

for external communication

Internal interface between Hydrovars

for multi-pump systems

ELECTRICAL INSTALLATION AND WIRING

RS-485 – Internal interface RS-485 - User interface

X4

6 GND

5 SIO +

4 SIO -

X4

3 GND

2 SIO +

1 SIO -

The internal RS-485 Interface is used for communicating between up to 8 HYDROVARs in a multi-pump

application. This connection uses terminals X4/4-6 on the control card, or terminals X2/1-3 on the power unit.

(Example: using one master and three basic drives.)

HYDROVAR Master Inverter

Control Card

GND

SIO +

SIO -

6

5

4

X4

HYDROVAR Basic Inverter

Power Unit

GND

SIO +

SIO -

X2 X2 X2

HYDROVAR Basic Inverter

Power Unit

GND

SIO +

SIO -

HYDROVAR Basic Inverter

Power Unit

GND

SIO +

SIO -

Using the RS-485 – User interface on the control card, one or more HYDROVAR can communicate by standard Modbus-protocol with an external control device (e.g. PLC). This interface can be used for controlling the

HYDROVAR with external devices. Also available on HYDROVAR Single drives.

Do not use the internal interface for communicating with Modbus!

HYDROVAR User Interface

GND

SIO +

SIO -

3

2

1

X4

PLC

GND

SIO +

SIO -

33

ELECTRICAL INSTALLATION AND WIRING

X5 Status-Relays

X5/ 1 CC

2 Status Relay 1 NC

3 NO

4 CC

5 Status Relay 2 NC

6 NO

Status Relay 1 Status Relay 2

[Max. 250VAC] [250mA]

[Max. 220VDC] [250mA]

[Max. 30VDC] [2A]

X5X5

3 NO

2 NC

1 CC

Status Relay 1 is programmed for "Pump Run" when closed between terminals 1 and 3.

Status Relay 2 is programmed for "Fault" when closed between 4 and 5.

Factory setting: The output relays are used to signal pump-running or fault-signal.

See connection example below (To program see parameters

CONF REL 1 [0715] and CONF REL 2 [0720]).

Connection examples:

Pump Run Signal Fault Signal

Ext. 250VAC / 220VDC Ext. 250VAC / 220VDC

6 NO

5 NC

4 CC

Notice:

Do not transmit any voltage or

electronic noise on these contacts.

X5

3

2

1

X5/ 1 and 3 closed: X5/ 4 and 5 closed:

- motor run indication - signals a fault/error

34

X5

6

5

4

PROGRAMMING

Section 9

NOTE

Read and follow the operating instructions carefully before programming to avoid incorrect

settings which will cause drive errors! All programming must be completed by qualied

technicians!

9.1 Display – Control Panel of the Master / Single Drive

9.2 Function of the Push Buttons

▲ Start the HYDROVAR

▼ Stop the HYDROVAR

and Reset: pressing both buttons simultaneously for 5 seconds

▲ Increase a value / selection in the submenu

▼ Decrease a value / selection in the submenu

▲ + short ▼ Scroll slower

▼ + short ▲ Scroll faster

Tap: enter submenu / Next parameter in the menu

Tap: leave submenu / Previous parameter in the menu

Press and hold: Select a specic action

Press and hold: Back to the main menu

35

PROGRAMMING

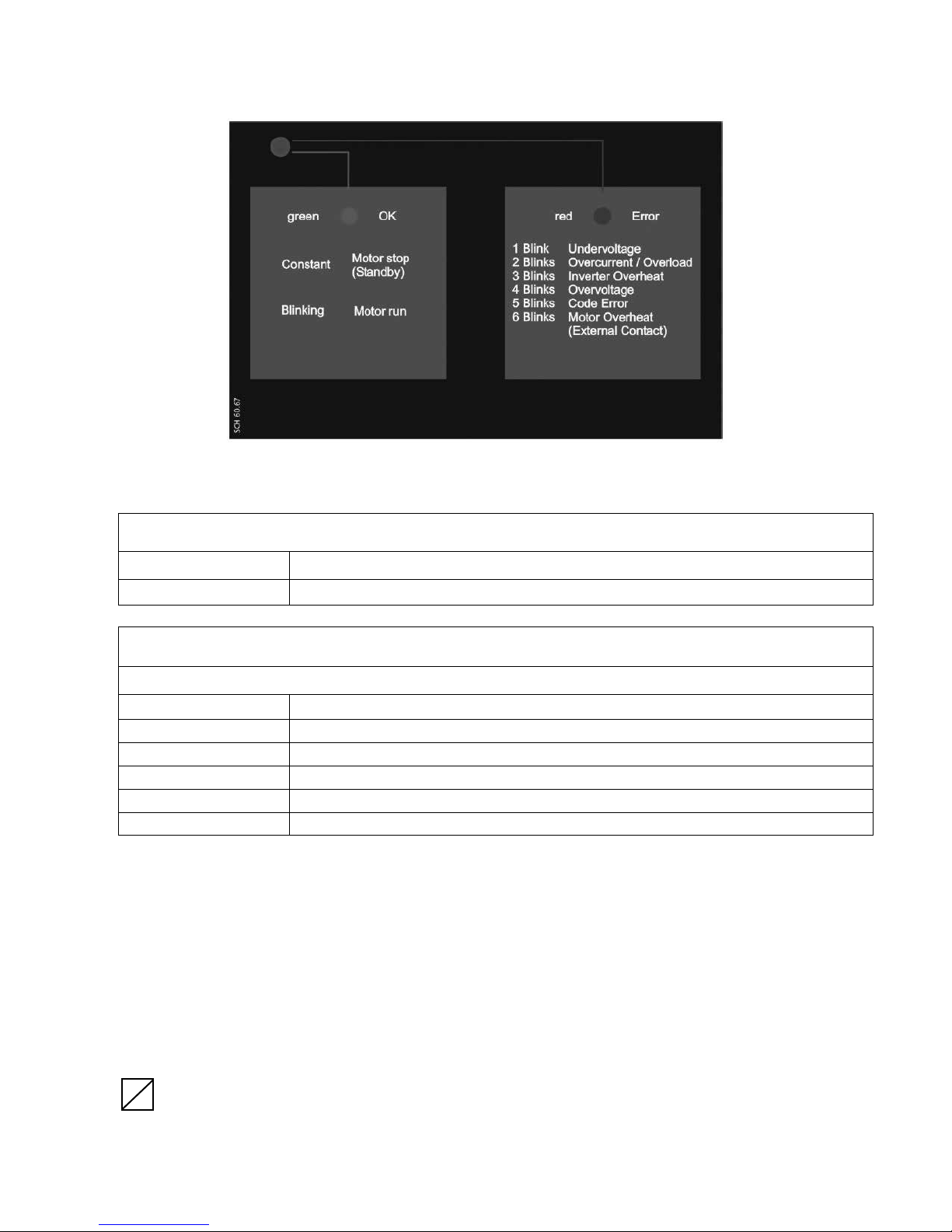

9.3 Basic Drive Display

Status LED - green

Constant Motor stopped (Standby)

Blinking Motor run

Error LED - red

The type of error is indicated by the number of blinks of the red ERROR LED.

1 blink Undervoltage

2 blinks Overcurrent / Overload

3 blinks Drive thermal overload

4 blinks Overvoltage

5 blinks Code Error

6 blinks Motor thermal overload (external contact is open)

For detailed information see chapter 11 Failure messages.

9.4 Software parameters

In the following chapters all parameters of the main menu and submenus are listed. The upper window

shows the factory setting and the line below the possible range of settings. The general parameter descrip-

tion is written for the HYDROVAR Master Inverter (Full featured HYDROVAR including the high level control card

which also supports the optional modules like the optional Relay Card and all specic software features).

When using a HYDROVAR Single drive there are fewer software features available than with the HYDROVAR

Master drive. All parameters which are not active for the HYDROVAR Single drive are marked with the following

symbol:

S

… Parameter not available for HYDROVAR Single drive

36

PROGRAMMING

Parameters which are available on all HYDROVAR drives are marked with the following symbol:

G

… “global” parameter (available on all HYDROVAR drives)

NOTICE! All changes are saved automatically and will not be lost with the removal of power supply!

00 00 MAIN MENU

The 1st windows, REQUIRED VALUE [02] and EFFECTIVE REQUIRED VALUE [03], depend on parameter

MODE [0105]. The differences within the windows in the various modes are shown below:

a) Active MODE [0105] = Controller (Default setting)

XYLEM XX.X Hz

STOP X.XX PSI

This window shows the current run status of the drive.

ON Running Stop the HYDROVAR by pressing ▼

STOP Manually stopped Start the HYDROVAR by pressing ▲

OFF E-Stop (X3/7-8) is open To start the HYDROVAR close E-Stop or bridge terminal X3/7-8

b) For Active MODE [0105] = Cascade Relay, Cascade Serial, or Cascade Synchron

* ADR X PX XX.X Hz

STOP X.XX PSI

This window shows the drive status.

* Indicates which HYDROVAR controls the system. The parameters are described further below:

ADR X Pump address, (1, 2, 3.....8)

Cascade relay mode: Indicates the number of pumps that are running

Cascade serial/synchron mode: Indicates where the drive is in the existing sequence.

(ex. P3 …. Master + 2 xed speed pumps are running)

P X

1st window display in Controller mode

Display for cascade serial and cascade relay modes

S

37

PROGRAMMING

ON Running Stop the HYDROVAR by pressing ▼

STOP Manually stopped Start the HYDROVAR by pressing ▲

OFF E-Stop (X3/7-8) is open

X3/7-8

Parameters 02 and 03 for Modes: Controller, Cascade Relay, Cascade Serial, Cascade Synchron

02 02 REQUIRED VAL

D1 X.XX PSI

The current REQUIRED VALUE and its source (D1 in this example) are displayed.

The available sources are listed below:

D1 internal - required value 1 (set by parameter 0820)

D2 internal - required value 2 (set by parameter 0825)

U1 required value 1 - voltage signal input (Connected to X3/13)

U2 required value 2 - voltage signal input (Connected to X3/15)

I1 required value 1 – current signal input (Connected to X3/18)

I2 required value 2 – current signal input (Connected to X3/23)

03 03 EFF REQ VAL

D1 X.XX PSI

Shows the calculated required value based on ACTUAL VALUE INCREASE (0505), ACTUAL VALUE DECREASE (0510) and LIFT AMOUNT (0330). If the required value is inuenced by an offset signal (SUBMENU

OFFSET [0900]) the current active required value is also shown in this window.

To start the HYDROVAR close E-Stop circuit or bridge terminal

Set the desired required value with ▲ or ▼

Effective required value

G

Example: Multi-pump-application with two pumps

REQUIRED VALUE [02]: 75.00 PSI

ACT. VALUE INCREASE [0505]: 10.00 PSI

ACT. VALUE DECREASE [0510]: 5.00 PSI

-> REQ VAL EFF [03]: 80.00 PSI

The second pump will increase system pressure to 80.00 PSI.

c) Parameters 02 and 03 for Active MODE [0105] = Actuator

Frequency XX.X Hz

STOP X.XX PSI

If parameter MODE [0105] is set to Actuator, the parameter REQUIRED VALUE [02] will change to ACTUAL.

FREQ. and is equivalent to parameter [0830]. This allows the HYDROVAR to run to up to two pre-selected

frequencies to manually control the drive.

02 02 ACTUAT. FRQ.

D1 XX.X Hz

Use this parameter to program the drive to up to 2 set frequencies. Requires programming parameter

0805, 0810, and 0815. To manually set the frequency use parameters ACTUATOR FREQUENCY 1 (0830)

and ACTUATOR FREQUENCY 2 (0835).

Display in Mode actuator

Set the desired frequency with either ▲ or ▼

38

PROGRAMMING

Parameter [03] is not used in Mode: Actuator

04 04 START VALUE

OFF

Possible settings: 0 – 99 % – OFF

This parameter denes the restart value after the pump has stopped in % of the required value.

E.g. REQUIRED VALUE [02]: 50.0 PSI

START VALUE [04]: 80 % --> 40.0 PSI

If the pump system has reached the required pressure of 50.0 PSI and meets demand the HYDROVAR

shuts off the pump. When demand increases, and the pressure drops the pump starts. If a START VALUE

[04] of 80% has been selected the pump won’t start until the pressure drops below 40 PSI, (80% of 50 PSI).

The following parameters in the main-menu are valid for all selected modes:

05 05 LANGUAGE

ENGLISH

Possible settings: To select the desired language press ▲ or ▼

The information on the display and all parameters are available in various languages. Scroll up and down

through the available options.

The following two parameters set the current date and time. This is useful for tracking timing of failure messages.

Regulation Restart Value

Language selection

G

06 06 DATE

DD.MM.YYYY

Set the date by pressing

to set current DAY / MONTH / and YEAR.

07 07 TIME

HH:MM

Set the time by pressing for approx. 3 sec.

to set current HOUR and MINUTE.

Current date

for approx. 3 sec.

Current time

S

S

39

PROGRAMMING

08 08 AUTO - START

ON

Possible settings: ON – OFF

Select ON with ▲ or OFF with the ▼ button.

If AUTO-START = ON the HYDROVAR starts automatically after reconnecting power following interruption.

If AUTO-START = OFF the HYDROVAR will not start automatically after reconnecting power following

interruption.

After reconnection of the power supply the following message is shown: AUTO START = OFF

XYLEM XX.X Hz

STOP X.XX PSI

09 09 OPERAT. TIME

0000 h.

Total operating hours. To reset to 0 see parameter CLR OPERAT. [1135].

Auto Start

Press ▲ to restart the HYDROVAR.

Operating hours

G

20 20 SUBMENU STATUS Status of all units within a pump group

Use this submenu to check the status (including failures and motor hours) of all connected units.

21 21 STATUS UNITs

00000000

This parameter gives a quick overview about the run status of the connected drives.

• In Cascade serial/synchron mode the status of all (max. 8) connected units is shown

(1=running / 0=stopped)

• In Cascade relay mode the status of the 5 Relay- switching contacts is shown.

E.g. Mode – Cascade serial/synchron

21 STATUS UNITs

11001000

E.g. Mode – Cascade relay

21 STATUS UNITs

10100 - - -

Status of all units

Unit 1, 2 and 5 are running

Relay Contact 1 and 3 are closed

G

S

G

G

40

PROGRAMMING

22 22 SELECT DEVICE

* 1 *

Possible settings: 1-8

Check the current status, the motor hours and the most recent failures of any given drive. The drive selection is determined by the current selected mode [105]. Select desired unit by pressing ▲ or ▼.

CASCADE SERIAL/SYNCHRON:

The selection species the address of the HYDROVAR units

E.g. Device 1 -> Master Inverter with pre-selected address 1

Device 2 -> Basic Inverter with pre-selected address 2

Device 3 -> Basic Inverter with pre-selected address 3

To set the address on a Basic Inverter, see chapter addressing.

To set the address on a Master Inverter, see parameter [106] or submenu [1200] RS485-Interface.

Mode CASCADE RELAY:

Device Enabled By

1 Master Inverter

2 xed speed pump Relay 1 X10: 1

3 xed speed pump Relay 2 X10: 2

4 xed speed pump Relay 3 X10: 3

5 xed speed pump Relay 4 X10: 4

6 xed speed pump Relay 5 X10: 5

7 not used

8 not used

Select device

S

23 23 STATUS DEVICE

Stopped

Possible messages: Running, Stopped, Disabled, OFF, Preparing (Mode Casc. Serial/Synchr)

relay on, relay off (Mode: Cascade Relay)

Solorun, Faulted (all Modes)

Shows the status of the device

Mode CASCADE RELAY:

relay_on -> Relay contact is closed -> xed-speed-pump is running

relay_off -> Relay contact is opened -> xed-speed-pump is stopped

Mode CASCADE SERIAL/SYNCHRON:

running -> Pump is running

stopped -> Pump is stopped

disabled -> Pump is disabled by an external input.

(Stopped with buttons or disabled with parameter ENABLE DEVICE [24]) or by external

on/off contact open

preparing -> A new unit is connected to the multi-pump system and Data is being transferred

solo run -> Solorun (Hand Mode) is activated (XSL closed)

faulted -> A failure has occurred on the current unit

Status of the selected device

G

S

41

PROGRAMMING

24 24 ENABLE DEVICE

Enable

Possible settings: Enable - Disable

Allows the drive to be be enabled or disabled by an external switch between X3 7 and 8. (Either in cascade

relay / serial / synchron or controller mode).

25 25 MOTOR HOURS

XXXXX h

Total number of hours the motor has run. To reset see parameter CLR MOTORH. [1130].

Error memory

All errors, including those occuring on Basic Inverters are saved on the Master Inverter in this menu. The

errors saved in this menu include the failure message text of the drive where the failure happened, and the

date and time when the failure occurred. (For more information about errors, see chapter 10 failure messages.)

26 26 1st ERROR

ERROR XX

Enable – Disable of the selected device

Runtime of the selected drive

Most recent error on the selected drive

G

S

G

G

Message: ERROR XX, FAILURE TEXT, DATE, TIME

Press ▲ or ▼ to scroll up or down!

27 27 2nd ERROR

ERROR XX

Message: ERROR XX, FAILURE TEXT, DATE, TIME

Press ▲ or ▼ to scroll up or down!

28 28 3rd ERROR

ERROR XX

Message: ERROR XX, FAILURE TEXT, DATE, TIME

Press ▲ or ▼ to scroll up or down!

29 29 4th ERROR

ERROR XX

Message: ERROR XX, FAILURE TEXT, DATE, TIME

Press ▲ or ▼ to scroll up or down!

2nd most recent error on the selected drive

3rd most recent error on the selected drive

4th most recent error on the selected drive

G

G

G

30 30 5th ERROR

ERROR XX

Message: ERROR XX, FAILURE TEXT, DATE, TIME

Press ▲ or ▼ to scroll up or down!

42

5th most recent error on the selected drive

G

PROGRAMMING

40 40 SUBMENU

DIAGNOSTICS

41 41 PROD. DATE

XX.XX.XXXX

In the following parameters the current temperature, voltage and frequency of the chosen HYDROVAR can

be monitored during operation of the unit. These parameters are read only!

42 42 SEL. INVERTER

* 1 *

Possible settings: 1-8

43 43 TEMP. INVERTER

XX % XX°C

The current value determines the temperature inside the selected HYDROVAR and is shown in °C and also

in percent of the maximum allowed temperature.

44 44 CURR. INVERTER

XXX %

This value determines the output current of the HYDROVAR in percent to the maximum rated current

output.

production date of the HYDROVAR (Master/Single only)

Select the desired unit

Temperature of the selected unit

Current of the selected unit

G

G

G

45 45 VOLT. INVERTER

XXX V

This value displays the input voltage supplied to the HYDROVAR.

46 46 OUTPUT FREQ.

XX.X Hz

This value displays the output frequency generated by the HYDROVAR.

47 47 VER. INVERTER

01

This parameter displays the software version of the BASIC drive (located on the main board).

Possible indications:

00 All power sizes (2-15 HP) prior production 05/2008

01 Sizes HV 2 - 5 HP - related to control board software V01.3

02 Sizes HV7.5 - 15 - related to control board software V01.3

Input Voltage of the selected unit

Output frequency of the selected unit

Software version of the selected drive

G

G

G

43

PROGRAMMING

60 60 SUBMENU SETTINGS

NOTE

Carefully read these instructions before changing the remaining parameters. Improper

settings can cause the drive to malfunction.

These parameters can be changed during operation. Therefore they should be changed only by trained

and qualied technicians. It is recommended to stop the HYDROVAR by pressing ▼ in the main menu

before changing parameters in submenues.

61 61 PASSWORD

0000

NOTICE! If the submenu is opened with the correct password it will remain open for a period of 10 minutes without entering the password again to access the secondary menu.

61 PASSWORD

0066

62 62 JOG 0.0Hz

X.XX PSI

• By pressing ▲ or ▼ in this menu, the drive switches from control via external input (transducer) to manual

frequency control.

• Use the ▲ and ▼ buttons to change output frequency and pump speed to achieve the desired pressure

and ow.

• If this value becomes 0.00 Hz the HYDROVAR stops.

• Exit this menu by pressing or , and the HYDROVAR returns to the previously selected mode.

0100 SUBMENU BASIC

0100

SETTINGS

enter password (0066 = Default) by pressing ▲ or ▼

Conrm by pressing and the rst window of the sub menu is shown

Both current output frequency and actual value are shown.

0105 MODE

0105

Controller

Possible settings: Controller, Cascade Relay, Cascade Serial, Cascade Synchron, Actuator

44

Select the operating mode

PROGRAMMING

Controller (Default Setting):

Select this mode when only one HYDROVAR Master/Single Drive is used and there is no connection to any

other HYDROVAR via RS-485 interface.

Cascade Serial:

Selected if multiple HYDROVAR controlled pumps operate together via the RS-485 interface.

The standard application for this mode is a multi-pump system with up to 8 pumps, each controlled by a

HYDROVAR Master Drive or a combination of Master and Basic Drives. Advantages: reliability, lead/lag for

balanced usage and wear and tear, automatic alternation in the event of a drive failure (duty standby).

Cascade Synchron:

The Synchronous Controller mode is similar to cascade serial mode. The difference is that all pumps in the

multi pump system run at the same frequency.

Advantages: In the synchronous mode the pumps can operate in a better efciency range and the system

Actuator: (For single pump operation only!)

Actuator mode is used if a xed speed setting is required or an external speed signal is connected to control the speed of the drive.

In this mode, the HYDROVAR does not control the set value but runs the connected motor at a frequency

proportional to the input signal from the analogue input, or is programmed on the HYDROVAR. The following input signals can be used:

S

S

may provide additional energy savings compared to standard Cascade Serial mode.

X3/13: Voltage signal input (Required value 1) 0-10V 0 - MAX.FREQ.[0245]

X3/15: Voltage signal input (Required value 2) 0-10V 0 - MAX.FREQ.[0245]

X3/18: Current signal input (Required value 1) 4-20mA 0 - MAX.FREQ.[0245]

0-20mA 0 - MAX.FREQ.[0245]

X3/23: Current signal input (Required value 2) 4-20mA 0 - MAX.FREQ.[0245]

0-20mA 0 - MAX. FREQ. [0245]

• Manual switching between the analogue inputs can be controlled by the corresponding digital inputs.

• The frequency varies along the programmed Ramps 1 (accelerating) and 2 (decelerating). The functions

thermal protection and external ON/OFF remain active.

• The functions “External ON/OFF”, “Motor Overheat”, “Lack of water” and all other internal protections still

work.

45

PROGRAMMING

In actuator mode the drive can work with pre-selected frequencies for manual control of the HYDROVAR.

Two different frequencies can be set in the submenu REQUIRED VALUES [0800]. Switch between these

frequencies using parameter SW REQ. VAL [0815].

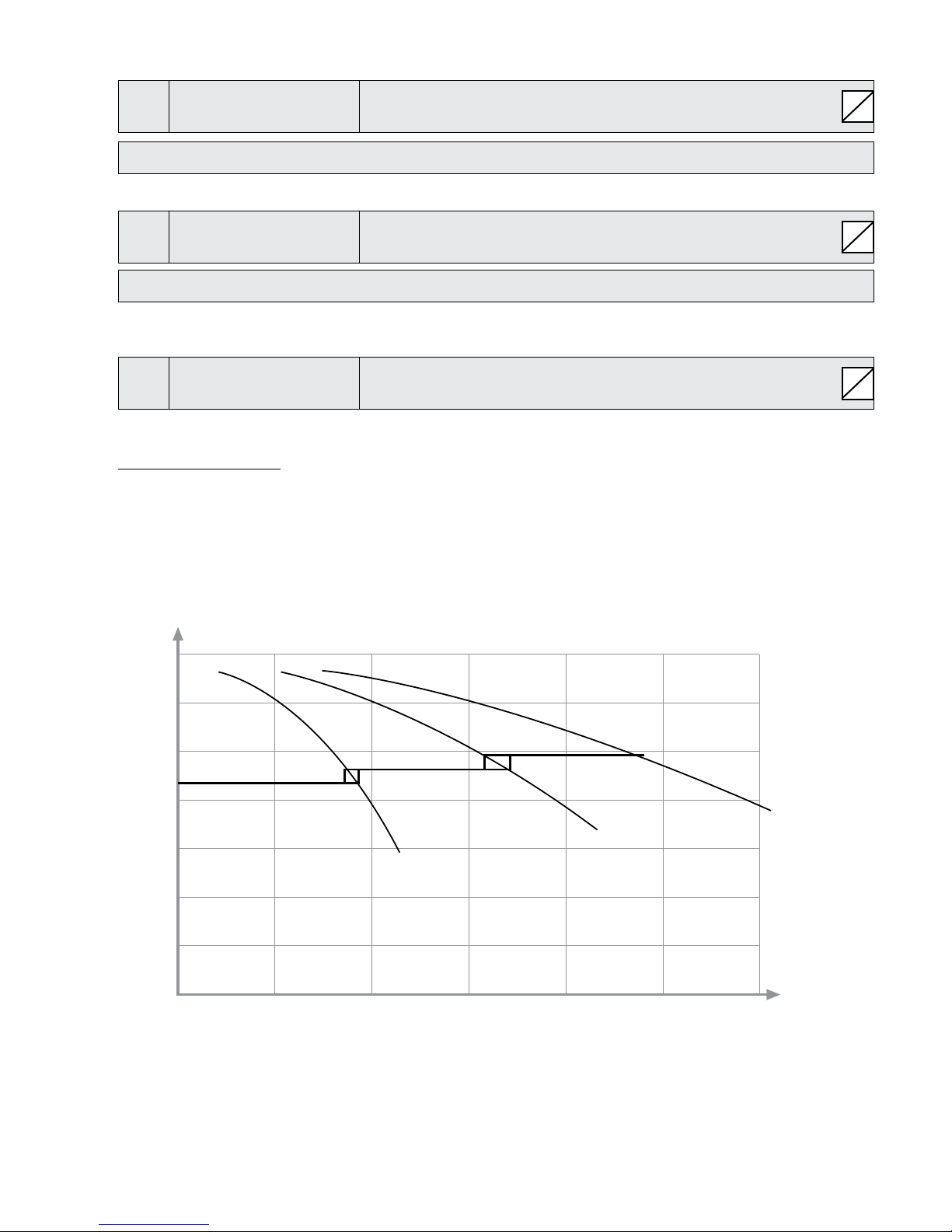

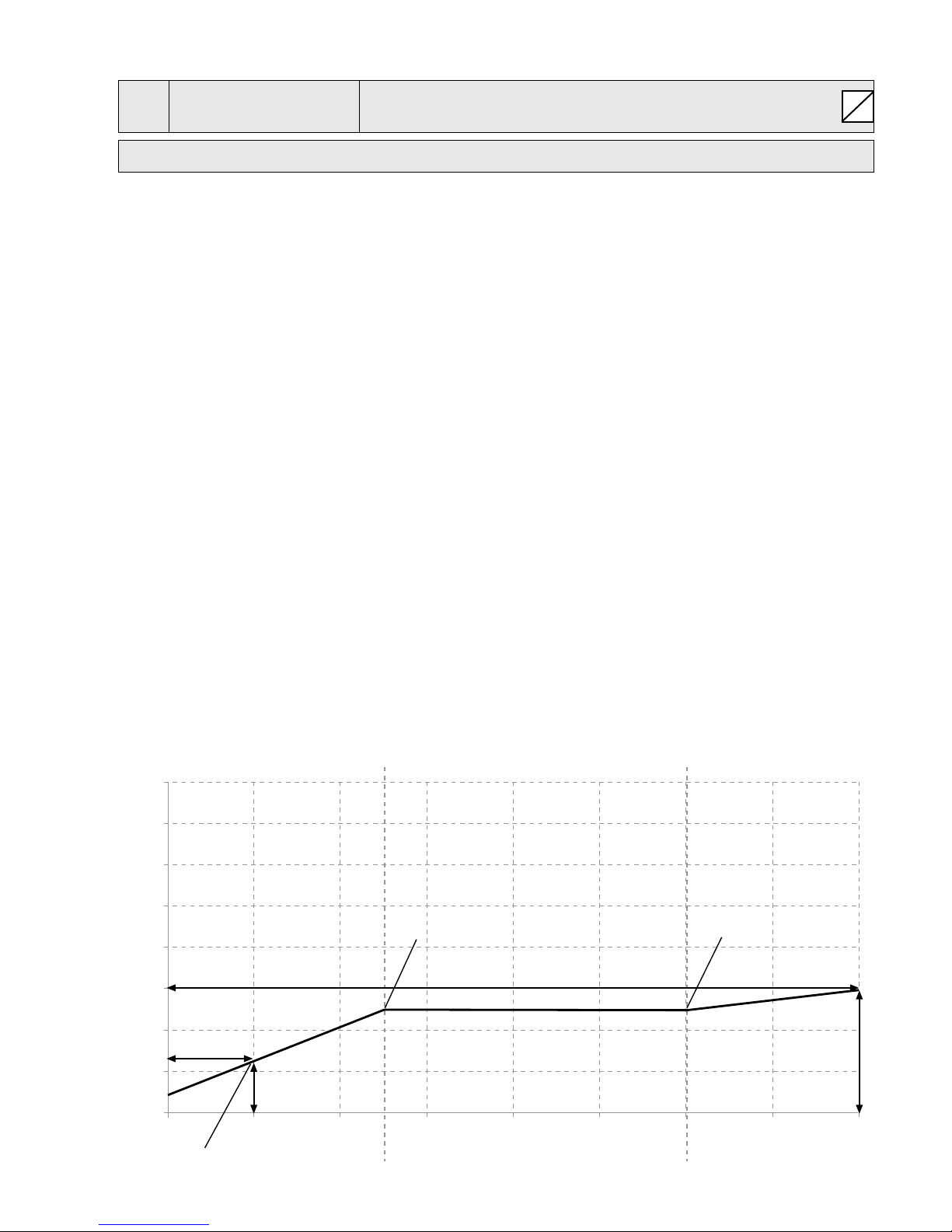

f[Hz] 1/3 2/3 3/3

OF ON

fmax

[0255] f ->min

[0255] f ->0

range of control

fmin

0Vdc

0mA

4mA

0106 PUMP ADDR.

0106

* 1 *

= signal range *

f min

f max

+ zeropoint

Select desired address for the Master Inverter

10Vdc

20mA

20mA

S

Possible settings: 1-8

Set desired address on each Master Inverter and press button for approximately 3 seconds and the

following messages will appear:

Addressing

Addressing * 1 * - 1 -

1220 PUMP ADDR.

->

1220 PUMP ADDR.

or

Address Set Address failed - retry

When using Master and Basic drives together in a multi-pump system the Basic Inverters have separate addresses. For detailed Information see chapter 8.4.3.2 Addressing.

0110 SET PASSW.

0110

0066

Set Password by pressing ▲ or ▼

Possible settings: 0000 - 9999

Caution: Resetting the password is not recommended! However, the pre-set password (0066) can be

changed. After the password has been changed, the new password should be recorded where multiple

people have access to it.

0115 LOCK FUNCT.

0115

OFF

Possible settings: ON - OFF

46

Change with ▲ or ▼

PROGRAMMING

OFF: All parameters in the MAIN menu (only) can be changed without entering the password.

ON: If the LOCK FUNCTION is activated, no changes can be made in any parameter without rst entering

the password. The HYDROVAR can be started and stopped with the up/down arrows. To change the set

value, the LOCK FUNCTION must be set to OFF.

0120 DISP. CONTR.

0120

75 %

Possible settings: 10 – 100%

Can be adjusted between 10 - 100%, to improve the display.

0125 DISP. BRIGHT

0125

100 %

Possible settings: 10 – 100%

The backlight intensity of the display can be adjusted.

0200 SUBMENU CONF

0200

INVERTER

Display Contrast

Display Brightness

0202 SOFTWARE

0202

HV V01.3

0202 SW RD V01.0 Software version of the Remote display (RD) (not available) and

0202

HV V01.3 the control board (HV)

0203 SET VER.INV

0203

sel:01 act:01

Possible settings: 00 - 02

Activates skip frequency parameter and current limit functions. These functions are not commonly used,

and may have undesirable effects. They should only be used to solve application problems in the eld.

Press and hold the right arrow for 5 seconds to activate the function, and "Done" is displayed.The following

parameters [0285], [0286], [0290] and [0291] are added to the parameter list.)

Setting 00: all units with production date prior 05/2008

Setting 01: Basic 2 - 5 HP (on control board software V01.3)

Setting 02: Basic 7.5 - 15 HP (on control board software V01.3)

0205 MAX. UNITS

0205

06

Software version of the control board

Activate additional settings. Contact factory to use.

Maximum number of units

G

G

S

Possible settings: 1 - 8

Select: The maximum number of units that can be set up as a multi-pump system.

0210 INVERTER

0210

ALL

Possible settings: ALL, 1-8

G

Selection of the HYDROVAR address for parameterizing

S

47

PROGRAMMING

If several HYDROVAR Master Inverters and even Basic Inverters are connected via the RS-485 interface, the

parameters in SUMBENU [200] can be entered on one unit and will be carried over to the other units in the

group. If programming only one unit press the button for 3 seconds and then choose the unit (1-8) for

which the parameters are being entered.

Select “ALL” to program all the units simultaneously.

Caution, if you select "ALL" the new settings will be copied to all units!

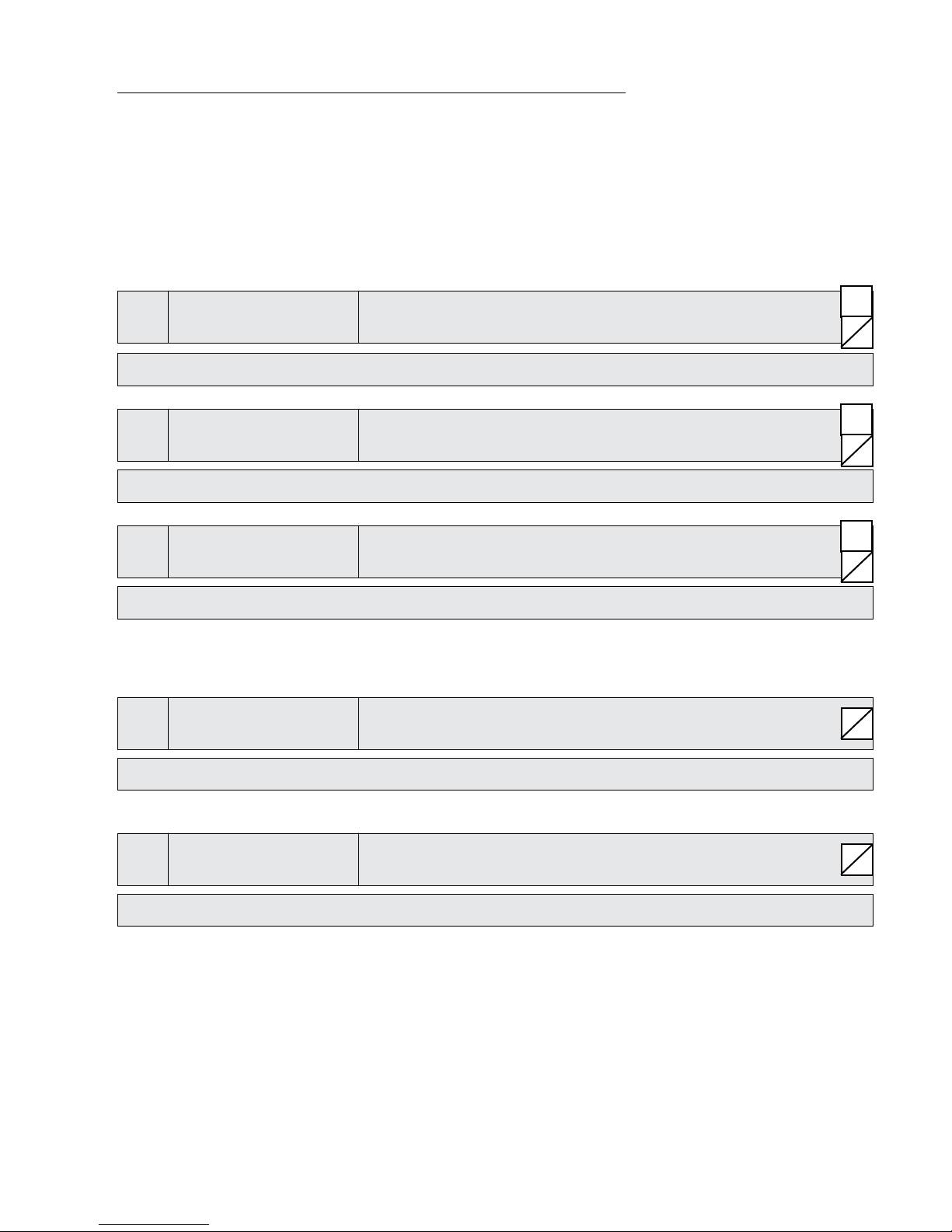

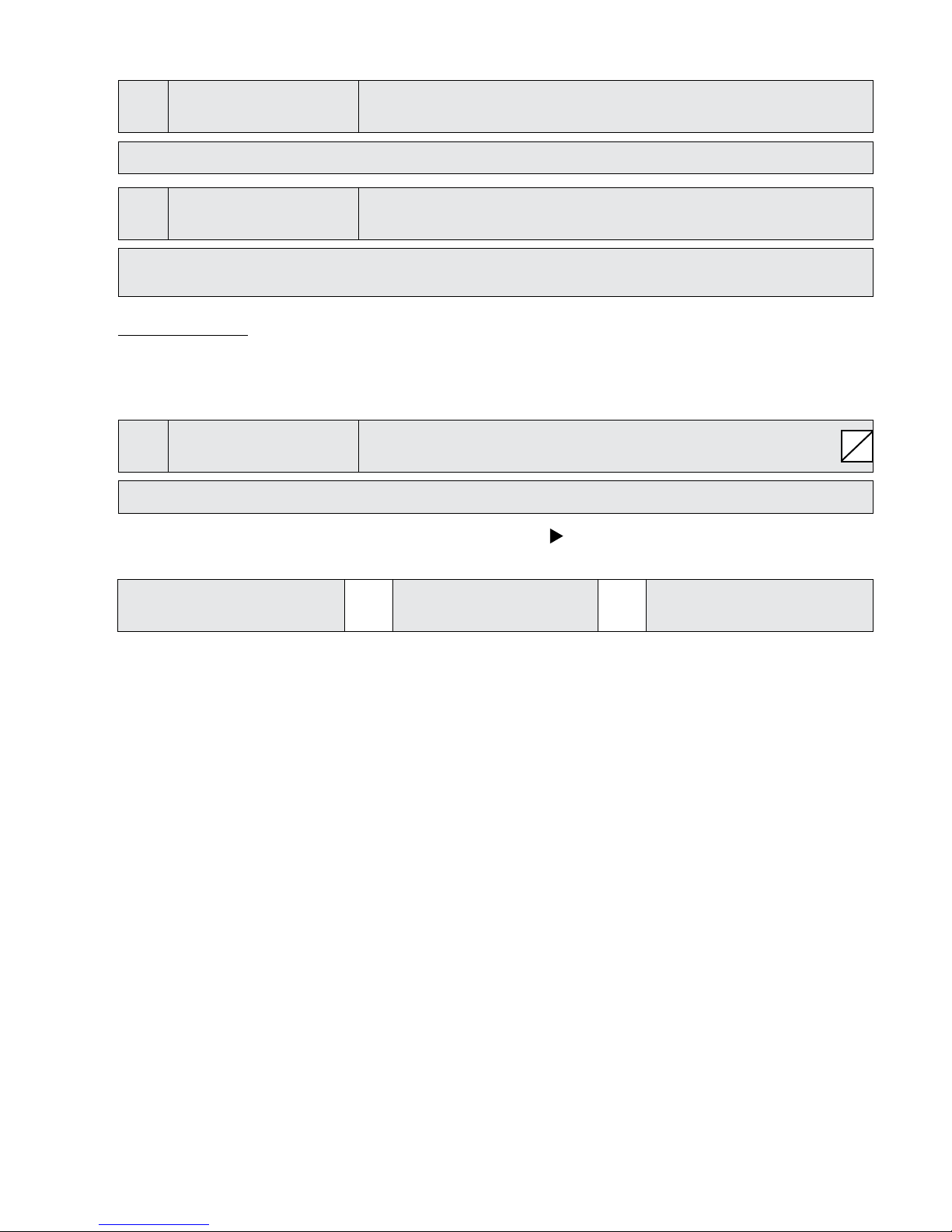

Ramp settings:

• The ramps inuence the rate of change in speed.

• The fast ramps 1 and 2 control the rate of acceleration and deceleration of the drive when the system

pressure is outside the hysteresis window, set at Parameter (0310). Default = 4 seconds. The ramps

should be lengthened, (increased) up to 15 seconds for higher horsepower drives to avoid overload er-

ror.

• The slow ramps 3 and 4 determine the acceleration/deceleration rates of the drive when the pressure is

within the hysteresis window. (Default = 70 sec.)

• The Ramps FminA and FminD are used for start-up and shut off. These parameters allow faster accel-

eration and deceleration and should be used for applications where pumps shouldn’t operate below a

determined frequency for a certain time. (to prevent damages or decrease wear) To adjust the Ramps,

press ▲ or ▼.

set rated REQUIRED VALUE [02]

R3

R4 R4 R4

R3

RA

RA: Ramp F

RD: Ramp F

R3

R1