Xylem CWM29-V3, CWM41-H3, CWM21-V3, CWM40-V3, CWM41-HT3 Installation, Operating & Safety Instructions

...

© Cleghorn Waring 2017

WATER STORAGE HEATERS

(CALORIFIERS)

INSTALLATION

,

OPERATING

AND SAFETY

To obtain the best performance from your C-Warm water storage heater

please read these instructions carefully.

Failure to observe the recommended

procedures may resul t in damage to equipme nt or in pe rsonal injury, and may

invalidate the supplier’s warranty.

INSTRUCTIONS

3 bar rated

Issue

B

for BOATS

Z/PWL6

DOC597/17

2

CONTENTS Page no.

Introducing your C-Warm water storage heater ............................ 3

Safety ...................................................................................................... 4

Adapting the engine cooling circuit ................................................. 5

Before you start: p re-installation checks ........................................... 6

Location ................................................................................................. 6

How to fit an auxiliary header tank if necessary ............................. 7

Fixing the heater in place ................................................................... 8

Connecting the pipework ................................................................... 10

Fitting the temperature/pressure relief valve ................................... 11

Fitting an electric immersion heater .................................................. 12

Regulating the temperature of engine-heated stored water ...... 14

Hot water expansion ............................................................................ 15

Regulating the cold water inlet pressure .......................................... 15

Using the heater ................................................................................... 16

Maintenance ........................................................................................ 16

Winter precautions ............................................................................... 16

Problem solving ..................................................................................... 17

Table of connections and fitting sizes ............................................... 18

Warranty ................................................................................................ 21

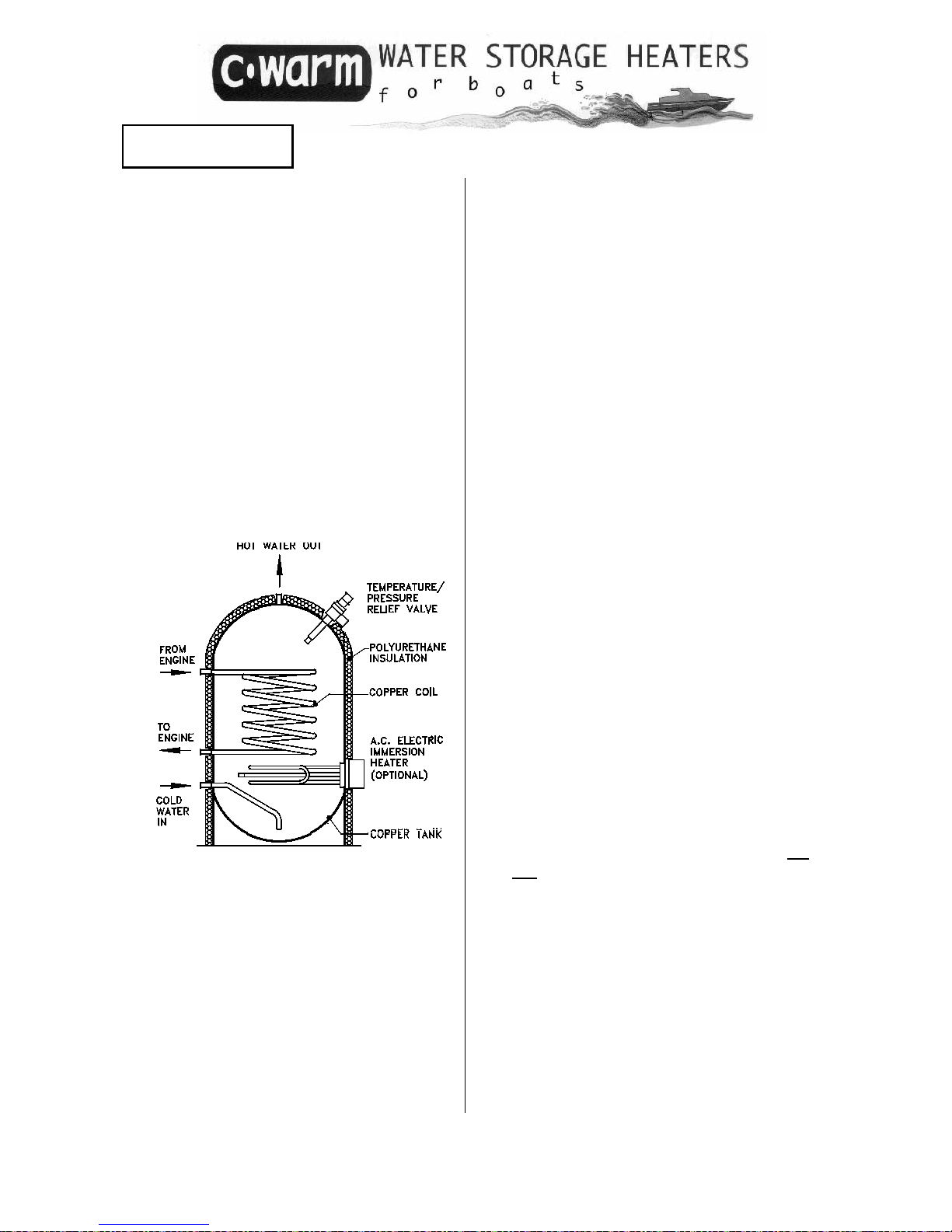

Calorifiers and Water Storage Heaters – what’s the difference?

None. ‘Calorifier’ is a word borrowed from industrial process heating, meaning a water vessel containing

a heat exchanger (such as a coiled pipe) through which steam or hot water passes, giving up its heat to

the water contained in the vessel.

3

A C-Warm water storage heater offers a

simple and convenient means of

enjoying the benefits of stored hot water

on board your vessel, at no extra cost in

fuel.

Installation is straightf orward. Provided a

few simple rules are obeyed, your

heater will give you lengthy service with

virtually no maintenance.

INDIRECT COOLED ENGINE

DIRECT COOLED ENGINE

INTRODUCING YOUR C-WARM WATER STORAGE HEATER (CALORIFIER)

C-Warm storage heaters are designed

for use with INDIRECT MARINE ENGINE

COOLING SYSTEMS using a closed loop

of hot water circulating through the

engine heat exchanger. Twin coil

models may also be used with a second

engine or with gas or diesel burners. A

mains

voltage a.c. immersion heater

can be fitted.

If an auxiliary burner is used follow the

fitting and operating instructions

supplied with it.

With water entering the coil at 82°C, a

C-Warm heater is designed to provide a

full charge of hot water at 60°C w

ithin

15 to 25 minutes. The larger heaters

have more coil turns, so heating time is

virtually independent of the volume of

water contained in the storage heater.

With DIRECT COOLED ENGINES, the

temperature of the water leaving the

engine is more variable

. For effective

use of a storage heater, the

temperature of the water entering the

coil should be at least 50°C.

Before you adapt a new engine’s

cooling circuit to take a water storage

heater, check with your engine supplier

to ensure that you do not inv

alidate the

engine’s warranty.

4

Your C-Warm water storage heater is

part of an unvented (‘closed’)

pressurised water system. Most domestic

systems in the UK are vented to

atmosphere (‘open’). In continental

Europe and elsewhere unvented

domestic systems are the normal type.

With proper protection against

overheating, unvented systems present

no hazard to the user. Safety

precautions are required by law for

unvented systems installed in houses in

the UK. The requirements are set out in

Building Regulations and local Bye-laws.

Although no such regulations exist (at

the time of printing) for unvented

systems in boats, these instructions

describe and recommend precautions

that comply with UK law for domestic

systems.

C-Warm heaters are designed for use

with clean, fresh, drinkable water. Salty

or heavily chlorinated water is more

corrosive than pure water, and the

working life of the heater and its fittings

may be shortened.

Copper is moderately resistant to

corrosion in hot sea water, so the heater

itself can be used with sea water,

though its working life may be

shortened. Because the temp/pressure

relief valve may corrode, C-Warm is not

recommended for sea water use with an

electric immersion heater.

CAN I USE A C-WARM STORAGE HEAT E R TO HEAT SEA WATE R ?

SAFETY

WATER QUALITY

● Fit a C-Warm double-protected electric immersion heater. See page 12

● The temperature/pressure relief valve supplied with your C-Warm water

storage heater MUST be fitted in the heater.

- in the event of overheating due to thermostat failure in an electric

immersion heater, the relief valve will open before the water can boil,

eliminating the risk of a sudden release of large amounts of scalding

water and steam.

- the relief valve protects the storage heater itself from excessive pressure

and possible damage caused by hot water expansion or by failure of

the pressure switch on the pump.

Some additional precautions are noted in the text. These precautions are

marked as shown:

ESSENTIAL PRECAUTIONS

5

The schematic diagram shows the installation principle. Contact your engine

supplier for advice about the recommended connection points on your engine.

INDIRECT CO OLED ENGINE

For maximum flow through the coil, the

inlet connection should be close to the

engine (A) and the discharge

connection should be close to the

circulation pump (D). Somewhat less

flow through the coil can be attained, if

required, by taking off hot water from a

point (B) downstream of (A) and

returning it to point (C) upstream of (D),

so that the pressure difference between

the coil take-off and return is a little less.

DIRECT COOLED ENGINE

Some direct-cooled engines provide for

a relatively high engine block

temperature. The recommended

connection points for the C-Warm

heating coil will vary according to the

engine design. Check your engine

manual and if necessary contact your

engine supplier for advice

ADAPTING THE ENGINE COOLING CIRCUIT

6

I. Check that you have received

the correct C-Warm heater and

accessories. Check immersion

heater power and voltage.

Report any damage or

discrepancies to your supplier

without delay.

II. Check the dimensions of the

heater and recheck the

dimensions of the space for its

installation in your boat.

III. Read through these instructions

carefully, noting additional items

required for installation.

Your C-Warm water storage heater may be located in any convenient and

accessible position subject to the following considerations:

I. With pumped cooling water

circulation, the storage heater

can be located above or below

engine level. For best circulation,

natural convection should assist

the pumped flow.

II. There must be no air locks in the

cooling water circuit. Either

locate the water storage heater

with its upper coil connection

below the engine’s water filling

point, or fit an auxiliary

header/filler tank above the

highest point in the cooling water

circuit. See page 7.

III. The longer the pipe run

between water storage heater

and engine, the more work the

engine’s cooling water

circulation pump has to do.

Minimise the reduction in water

flow rate by locating the

storage heater near the engine.

IV. Vertical C-Warm storage heaters

MUST be mounted vertically,

horizontal heaters MUST be

mounted horizontally.

BEFORE YOU START

LOCATION

7

For installations where the upper coil connection is above the level of the engine’s

water filling point.

How to fit an auxiliary header tank if necessary

1. Blank the existing header tank by

using a flat cap that does not

obstruct the overflow pipe.

2.

Fit a new expansion tank nearby, at

a height just above the top of the CWarm water storage heater coil.

Connect it to the overflow outlet on

the original header tank, using a

suitable pressure hose (see diagram

)

The expansion tank for a car radiator

is suitable for engine cooling systems

up to about 200 litres in total volume.

3.

Fit an air bleed close to the top coil

connection of the water storage

heater. On filling the system with

water, ensure that all the air in the

cooling circuit escapes via this bleed

or from the engine.

4.

On starting the engine check for loss

of liquid and for air locks in the

extended cooling circuit.

6

4

8

FIXING THE WAT E R STO RAGE HEATER IN PL ACE

When full of water the heater has a substantial mass. It must be secured firmly in

place to prevent damage to the heater and pipework or to the supporting

structure, from the effects of rough weather or other shocks of marine use.

1. Support the WEIGHT on a strong bas e

2 Support the MASS against horizontal forces

The exact method you use to hold the heater in place will depend on the

construction of the vessel and on the available space.

Some suggested installation methods are indicated below.

VERTICAL MODELS

1 litre of water

weighs 1 kg

Locate the heater on a firm level base strong enough to

support at least twice the weight of the (full) heater

Either

: construct suitable supports to hold the heater in

place

or: use one or more restraining straps as shown be

low

BRACKET KIT

CWAB-V series

contains:

1 bracket assembly

or…

STRAP KIT

CWA-STRKIT

contains:

2 webbing straps

4 stainless steel brackets

Instructions for use

Use…

BRACKET

ASSEMBLY

BRACKETS

WEBBING STRAPS

WITH BUCKLES

9

BRACKET KIT

CWAB-H series

contains:

2 bracket assemblies

STRAP KIT

CWA-STRKIT

contains:

2 webbing straps

4 stainless steel brackets

Instructions for use

or…

Use…

Either a C-Warm Strap Kit or a C-Warm Bracket Kit (H-series) can be used to secure

the heater in place. Leave space under the heater for pipe connections on some

models. See dimensions page 23.

HORIZONTAL MODELS

CONNECTING THE PIPEWORK

C-Warm heaters may be connected

into the engine cooling and pressurised

water systems with any suitable pipe

material. Most commonly used are:

Hep2O push-fit piping system

Hep2 O CONNECTION KITS are available

for all C-Warm heaters. See C-Warm

Selection guide for details. The kit

contains Hep2 O fittings for the

pressurised water connections and brass

hose connections to the heating coil.

Copper pipe

Connecting the coil into the engine

cooling circuit

Use ½” or ¾” bore rubber (car or lorry)

heater hose, obtainable from vehicle

accessory suppliers. This will minimise

the engine vibration reaching the

heater.

Connect the coil into the engine cooling

circuit and/or auxiliary heater. Fasten

the hose securely to the connectors

using stainless steel hose clips. Do not

allow loops of hose to form air locks.

If copper pipework is preferred for the

pressurised water connections, suitable

adapters and compression fittings

should be used. These may be

obtained from a plumber’s merchant or

from most ‘Do-it-Yourself’ stores. See

pages 18 - 20 for connection sizes.

The pipework connections to the heater

must not be stressed. Make sure that

the copper pipework is fully supported

Flexible hose

If flexible hose is preferred for the

pressurised hot and cold water

connections, suitable connectors will be

required. Use opaque hose (to

discourage algal growth) and stainless

steel hose clips. See pages 18 - 20 for

connection sizes.

Do not over-tighten

the coil connections.

Over-tightening may

distort the copper

wall of the storage

heater, causing

immediate or

eventual leakage.

Max. torque should

not exceed 70Nm

(50lb.ft)

l The heating coil may safely remain

incorporated into the engine

cooling circuit whether the heater

itself is full of water, partly full or

empty.

l The coils in a twin-coil C-Warm

heater are completely independent

in operation. The water storage

heater will work satisfactorily with

either coil alone or with both coils

together in use.

10

Connecting the cold water inlet and

the hot water outlet into your

pressurised water system

C-Warm heaters with ½” BSP

connections require 15mm bore

pipework; models with ¾” BSP

connections require 22mm pipework.

See page 18 - 20 for connection sizes.

C-Warm CONNECTION KITS contain

connectors suitable for Hep2 o (ACORN)

push-fit pipework.

•

The cold water inlet line should be

fitted with a drain cock, close to the

heater, to allow drainage if

maintenance becomes necessary,

and to avoid the risk of freezing in the

winter.

Fitting the temperature-and-pressure

relief valve

See pages 18 to 20 for the correct

location of the relief valve on your

heater.

Ensure that the coloured knob on the

valve is in an accessible position. The

discharge port of the valve must point

downwards, with a suitable hose to

allow hot water or steam to escape

safely to the bilge or another suitable

area.

The relief valve supplied with the heater

is non-adjustable and is pre-set to lift at

3bar (44psi) or at 90°C.

WARNING

The temperature-and-pressure-

relief valve is essential for the safe

operation of your C-Warm heater.

Failure to fit the relief valve, or any

alteration to or interference with its

function, or fitting of any valve

other than that supplied with the

heater, carries a risk of serious

personal injury or death in the

event of overheating. It will also

invalidate the supplier’s warranty.

Marine pressurised water pumps

normally have pressure switches set to

cut out below 2.5bar (36psi). Check

that your pressure switch cuts out at or

below this pressure. Use of a pressure

switch cutting out at or close to 3bar

(44psi) could lead to continuous

discharge of water through the relief

valve.

11

FITTING AN ELECTRIC IMMERSION HEATER

Before fitting the immersion heater,

check that your a.c. supply voltage

corresponds to that indicated on the

immersion heater. Remove the dummy

boss from the calorifier.

AVOID LEAKS - make sure all surfaces

are clean! Clean the seating surface on

the calorifier boss, and the screw

threads on the boss and the immersion

heater. Lightly coat the ‘O’ ring and

threads on the calorifier and immersion

heater with silicone grease.

Screw in the heater. Remove the heater

cover, bend the cable to one side, fit a

2¼” box spanner over the hexagonal

base of the heater, and tighten

carefully.

To make the electrical connections,

follow the wiring instructions on page 13.

The use of a standard domestic

immersion heater with a single

thermostat is not recommended.

A Cleghorn Waring double-protected immersion heater, fitted with a hightemperature cut-out in addition to the control thermostat, is strongly

recommended. Should the control thermostat fail, the high-temperature cutout will isolate the immersion heater when the water temperature reaches 90°C.

Thermostat Settings

The control thermostat on the immersion

heater is pre-set to cut out when the

water temperature reaches 60°C. This is

ample for domestic use. In an attempt

to reduce the likelihood of scalding, we

recommend that the control thermostat

is set no higher than 65ºC

The high temperature cut-out thermostat

is adjustable up to a maximum of 85°C.

It is pre-set to 85°C.

Check the thermostat settings before

using your immersion heater for the first

time. Isolate the immersion heater from

its power supply before removing the

cover. If necessary adjust the control

thermostat setting by turning the dial

with a screwdriver blade until the arrow

points to the desired temperature.

DO NOT set the high temperature cutout to operate below the cut-out

temperature of the control thermostat.

CONTROL THERMOSTAT DIAL

40ºC = 104ºF

50ºC = 122ºF

60ºC = 140ºF

70ºC = 158ºF

80ºC = 176ºF

Screwdriver Slot

In the event of a high temperature cutout the system should be thoroughly

checked before the manual re-set

button is pushed. It is advisable to

replace the control thermostat before

the immersion heater is used again.

Contact your supplier for a replacement

thermostat.

12

13

Wiring Instructions

1. It is essential that the correct

size of fuse or circuit breaker be

fitted.

2. Check that the mains supply

voltage corresponds with the

voltage indicated on the

heater.

3. Isolate the electrical supply to

the cable.

4. Make the supply cable

connections as follows.

Standard colours in the UK are:

Brown = Live

Blue = Neutral

Green/Yellow = Earth

THE IMMERSION HEATER

MUST BE EARTHED

Before you switch on the immersion

heater, check that the water storage

heater is full of water, and that the

temperature-and-pressure relief valve

has been properly fitted.

IF YOU ARE IN ANY DOUBT ABOUT FITTING

THE IMMERSION HEATER, OBTAIN THE

SERVICES OF A QUALIFIED ELECTRICIAN.

Wiring diagram for a Cleghorn Waring

double-protected Immersion Heater

Model Number CW279

2kW

Voltage = 220-240 v a.c.

Recommended fuse: 10 amp

Model Number CW278

1.25kW

Voltage = 220-240 v a.c.

Recommended fuse: 5 amp

Model Number CW240

0.75kW

Voltage = 220-240 v a.c.

Recommended fuse: 3 amp

Model Number CW239

1kW

Voltage = 110-115 v a.c.

Recommended fuse: 10 amp

IF AN ELECTRIC IMMERSION HEATER IS NOT FITTED

boss

washer

plug

1. Before you install and fill the

heater…unscrew the plug

from the immersion heater

boss

2.

Check that the faces of the

plug, the boss and the

sealing washer are clean

and undamaged. Apply a

small quantity of silicone

grease to each face

3. Screw the boss

firmly into

position.

Do not over

tighten. (Max

torque =70Nm)

High tempera tu r e

Cut

-out set to 85ºC

14

C-Warm storage heaters are highly efficient, and the stored water can reach

almost the same temperature as the water in the engine cooling circuit. (90°-95°C).

Domestic hot water is not normally hotter than 60°C.

C-Warm’s efficient insulation will keep your stored water hot for many hours after

the engine has stopped

Legionella bacteria occur naturally in many water systems. People exposed to them can develop

Legionnaire’s disease.

Water temperature Risk

Above 60ºC Can scald, but Legionella bacteria cannot survive

20º to 45ºC Legionella multiply

Below 20ºC Legionella will not multiply but remain a potential threat

Store hot water at 60º or above. Use a blender valve in the hot water supply line to add cold water

in controlled amounts.

REGULATING THE TEMPERATURE OF THE ENGINE HEATED WATER

You can limit the temperature of the hot

water supply by:

l

fitting a C-Warm adjustable thermostat,

model CW276A. This also avoids the

possibility of tripping the high

temperature cut-out in a C-Warm

double-protected electric immersion

heater if the stored water temperature

reaches 90°C. Do not use on direct

cooled engines

l

fitting a blender valve in the hot water

discharge line, to add a controllable

proportion of cold water. This method

has the potential advantage o f

extending the capacity of the C-Warm

heater (X litres of water at 85°C plus Y

litres of cold water = X + Y litres of water

at 55°C)

MAKING SURE YOUR WATER STAYS HOT

l Long pipe runs can delay the arrival of hot water at the hot taps, wasting water.

Heat loss can be minimised by insulating the hot water pipes.

l

Occasionally a thermo-syphon will start of its own accord in the engine cooling

circuit, silently extracting heat from your stored water and warming the

(stationary) engine! This is an unlikely event, but if it does happen, contact your

C-Warm supplier for advice.

TOO HOT? TOO COLD? A HEALTH NOTE

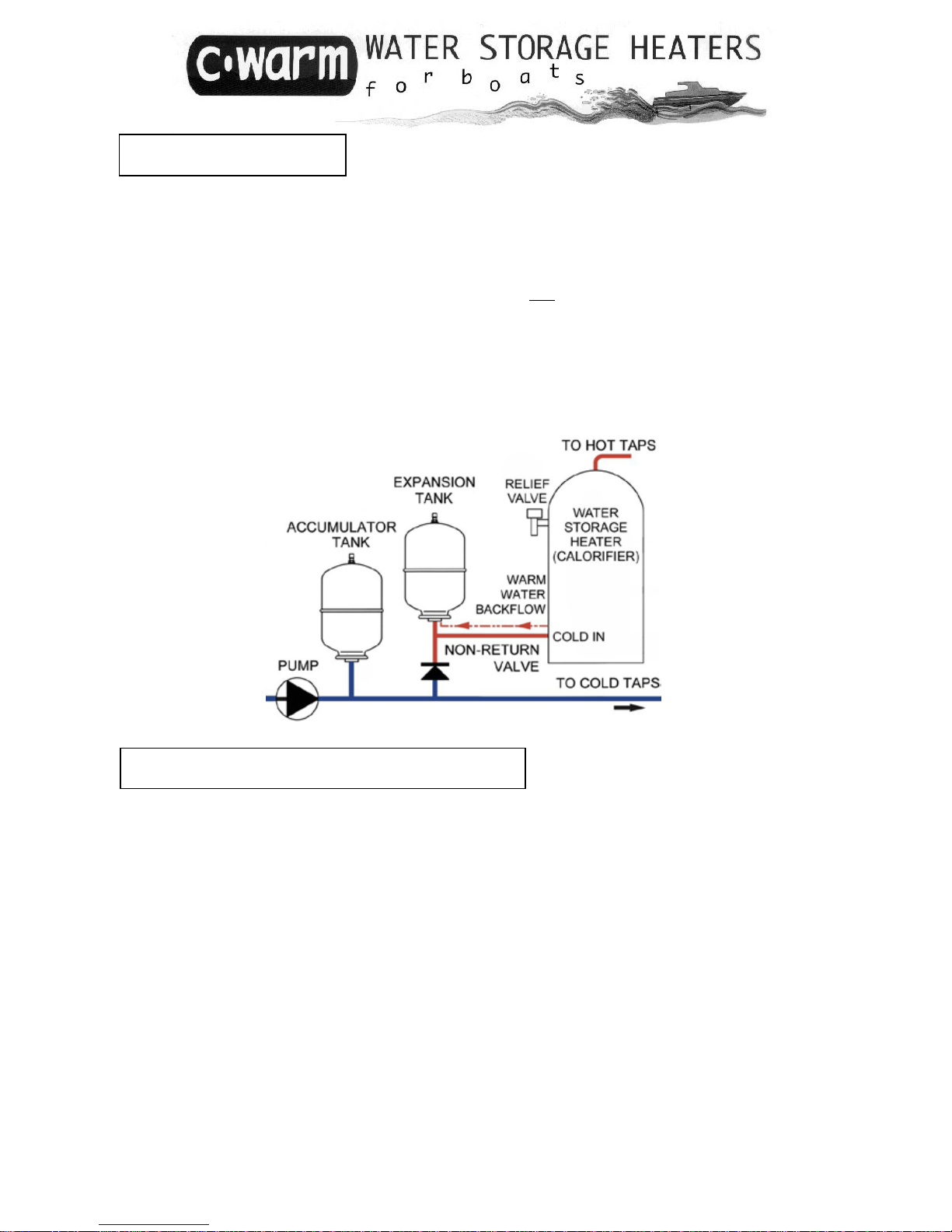

HOT WATER EXPANSION

The water in your C-Warm storage heater expands as it heats up. Provided your pressurised

system incorporates an accumulator tank, this expansion will be absorbed as it takes place.

In the process, a small amount of hot water may flow back into the cold water line. If hot

water backflow cannot be tolerated, fit a non-return valve and a separate expansion tank

in the cold water supply line to the heater.

Set the gas pressure in the expansion tank to the cut-out pressure of the pump.

If your system has no accumulator or e xpansion tank, thermal expansion will cause the

temperature-and-pressure relief valve to discharge a little hot water every time the stored

water is heated. The valve includes a hose connector to allow this water to be drained into

the bilge. Eventually, a deposit of scale may build up in the relief valve, preventing it from

closing fully. An expansion tank is recommended for this reason.

REGULATING THE COLD WATER INLET PRESSURE

Where the cut-out pressure of the pressure system pump exceeds or is close to the pressure

of the temperature-and-pressure relief valve (TPRV), a PRESSURE REDUCING VALVE is

required in the cold water inlet to the water storage heater

Expansion tank

When a Pressure-Reducing Valve is fitted, it is necessary to fit an expansion tank (Why? See

above). The gas pressure in the expansion tank should be the same as the setting of the

Pressure-Reducing Valve. This should be done before the system is pressurised by the

pump.

Selecting a Pressure-Reducing Valve and an Expansion Tank

Please contact Cleghorn Waring to establish the correct size of expansion tank and the

correct pressure setting for the Pressure-Reducing Valve. You will need to know the

capacity of your water storage heater and the pressure rating of the TPRV.

Using a Pressure-Reducing Valve in conjunction with a Blender Valve

If a blender valve is to be fitted, its cold water inlet should be connected into the pipework

between the Pressure-Reducing Valve and the cold inlet fitting on your hot water storage

tank

15

16

1 Check that the pipework is complete

and fully connected.

2 If necessary, refill the engine coo l ing

system with the recommen ded

coolant.

3 To fill your pressurised water system,

including your C-Warm heater, w ith

water proceed as follows:

● check that the pipe work is

complete and fully connected

● open all the hot and cold outlets

● fill the cold water supply tan k

● open the isolating valv e fro m t he

water supply tank to the

pressurised system

● start the pump, which should prime

itself in a few seconds. The system

will begin to fill with water. As the

system fills up, the t aps will start to

discharge air and water. Close

each tap slowly, until only one hot

tap remains open. When this ta p

stops discharging air, the C-Warm

heater is full. Close the t ap. T h e

pump will stop within a short time.

● check all the fittings and

connections thoroughly for leaks

● test the temperature-and-pressure

relief valve by rotating th e coloured

knob one full turn anticlockwise;

water should flow freely from the

valve discharge

● refill your water storage tank

● check all the connections once more

when the water is heated for th e fi rst

time.

4. Your pressurised system and C-Warm

heater are now ready fo r use.

5. Your engine cooling circuit will heat the

stored fresh water in your C-Warm

heater automatically, whenever you run

the engine. The engine cannot

overheat C-Warm: once t he st ored

water has reached its maximum

temperature, no added heat is

absorbed from the engine coo ling

circuit.

6. C-Warm’s efficient instal lation will keep

the stored water hot for many h o urs after

you have stopped the engin e

7. If the stored water is too hot, check the

C-Warm Instructions to find out how to

limit its temperature

8. An electric immersion h e a t er will swit ch

itself on and off automatically, just as in

a domestic water tank. Reset t he m ain

thermostat in the immers ion h eater if

necessary (factory setting is 60ºC). Do

not adjust the high temperatu re cut-out

thermostat (factory setting is 85ºC).

9. Use your hot and cold water outlets just

as you would at home.

10. Apart from checking the operation of

the temperature-and-pressure relief

valve once a week (see instructions)

your C-Warm storage heater needs no

regular maintenance. Don’t forget to

drain it when you store the boat for the

winter!

USING THE HEATER

17

PROBLEM

POSSIBLE CAUSE

ACTION

Water not hot enough

Coil inlet temperature too low

Air lock(s) in engine cooling

circuit

Top of storage heater above

engine cooling header tank

Thermostat in engine cooling

circuit not adjusted correctly

Thermo-syphon in coil circuit

when engine is not running

Check coil inlet water

temperature and correct if

necessary

Check for air locks

Raise header tank

Check setting on thermostat

Contact your supplier for advice

Water too hot

Engine cooling circuit water too

hot

Immersion heater control

thermostat set too high

Immersion heater control

thermostat has failed

Fit thermostat CW276A or

blender valve CW268 OR

CW272B

Adjust immersion heater control

thermostat

Check control thermostat.

Do not reset high temperature

cut-out until the cause of the

overheating has been

established

Water discharges continuously

through temperature/pressure

relief valve

Pump pressure switch cut-out

setting is higher than relief valve

setting.

Pressure switch has failed

Stored water too hot

Immersion heater control

thermostat set too high or has

failed.

Temperature/pressure relief

valve has failed

Check cut-out setting. Adjust or

replace switch, or fit pressurereducing valve

Replace pressure switch

Fit thermostat CW276A

Adjust or replace control and

high temp. thermostats

Replace temperature/pressure

relief valve

Hot water flows back into cold

water line

Thermal expansion

Fit non-return valve and

expansion tank, as outlined in

these instructions

Immersion heater does not

operate

Electric supply failure

Control thermostat temperature

set too low.

High temperature cut-out has

operated

Restore electric supply.

Check control thermostat and

correct if necessary.

Check control thermostat and

replace if necessary.

Inspect system before using

heater again.

Check that high temperature

cut-out setting is above control

thermostat setting: reset at 90ºC

PROBLEM SOLVING

18

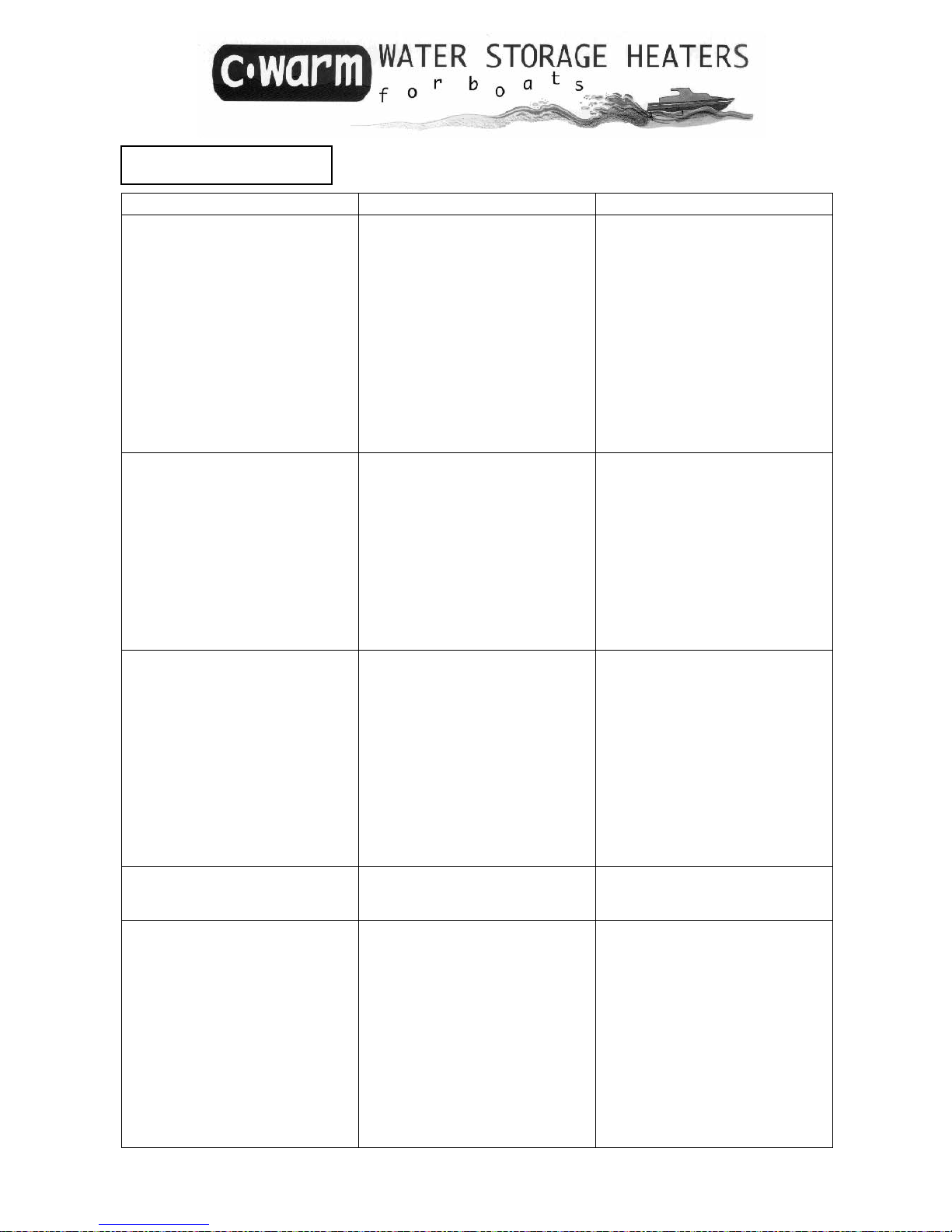

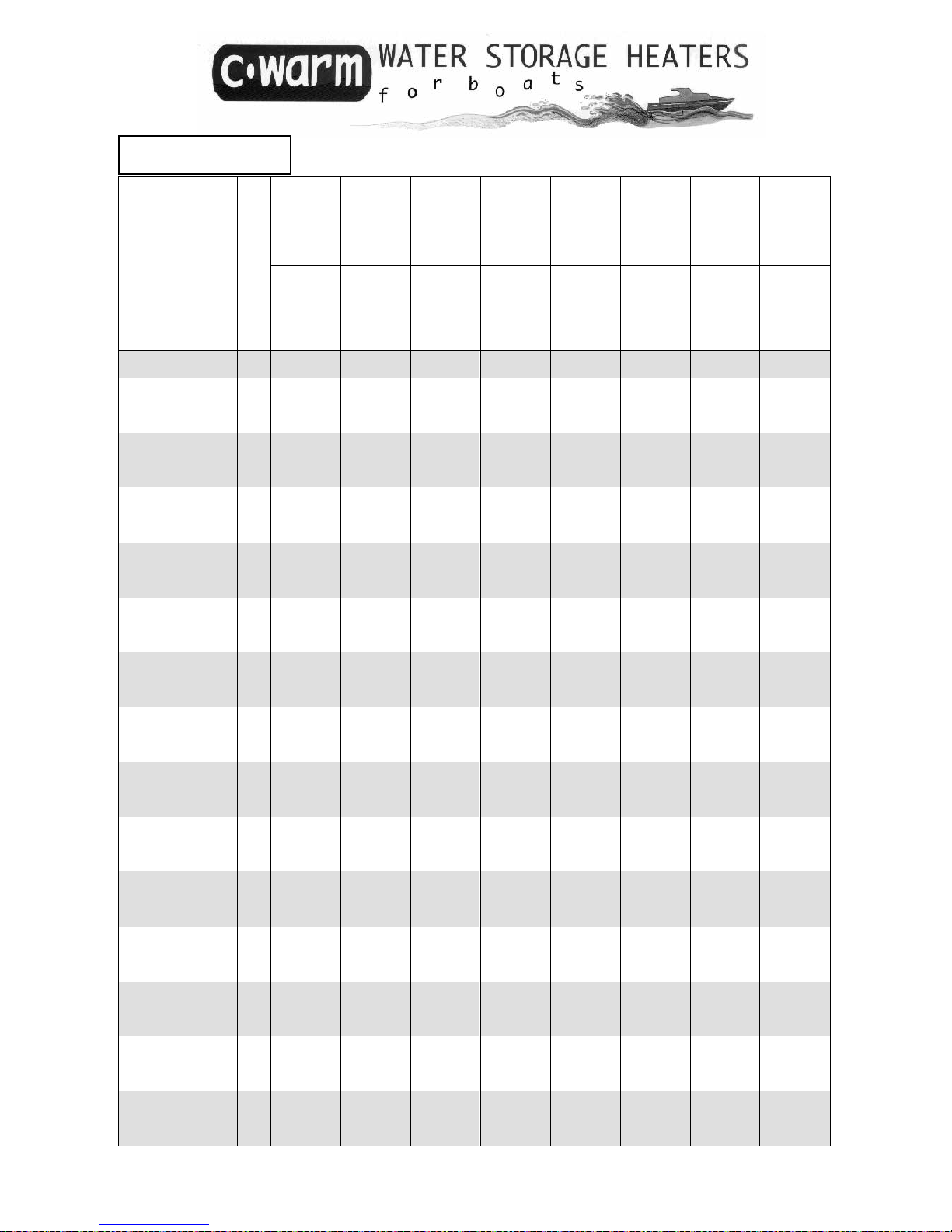

C-Warm

Model

No

H= horizontal

V= vertical

T= twin coil

Capacity litres

A B C

D1

D2

E1

E2

F

Hot

water

outlet

cold

water

inlet

relief

valve

coil

inlet

coil

outlet

2nd coil

inlet

2nd coil

outlet

Imm.

heater

BSP

(gas)

thread

BSP

(gas)

thread

BSP

(gas)

thread

BSP

(gas)

thread

BSP

(gas)

thread

BSP

(gas)

thread

BSP

(gas)

thread

BSP

(gas)

thread

ext.

ext.

int.

ext.

ext.

ext.

ext.

int.

CWM18-H3 18 ½” ½” ½” ¾” ¾” - - 2¼”

CWM21-V3 20 ½” int. ½” int. ½” ¾” ¾” - - 2¼”

CWM29-V3 29 ½” ½” ½” ¾” ¾” - - 2¼”

CWM29-VT3 29 ½”

½” ½” ¾” ¾” ¾” ¾”

2¼”

CWM32-H3 32 ½” ½” ½” ¾” ¾” - - 2¼”

CWM40-V3 40 ½” int. ½” int. ½” ¾” ¾” - - 2¼”

CWM41-H3 40 ½”int. ½”int. ½” ¾” ¾” - - 2¼”

CWM41-HT3 40 ½”int. ½”int.

½” ¾” ¾” ¾” ¾”

2¼”

CWM45-H3 45 ½” ½” ½” ¾” ¾” - - 2¼”

CWM50-V3 50 ½” ½” ½” ¾” ¾” - - 2¼”

CWM50-VT3 50 ½” ½” ½” ¾” ¾” ¾” ¾” 2¼”

CWM50-H3 50 ½”

½” ½” ¾” ¾”

- - 2¼”

CWM50-HT3 50 ½” ½” ½” ¾” ¾” ¾” ¾” 2¼”

CWM53-H3 53 ½” ½” ½” ¾” ¾” - - 2¼”

CWM53-HT3 53 ½” ½” ½” ¾” ¾” ¾” ¾” 2¼”

CWM53-V3 53 ½”

½” ½” ¾” ¾”

- - 2¼”

CWM53-VT3 53 ½” ½” ½” ¾” ¾” ¾” ¾” 2¼”

CWM64-H3 67 ¾”int. ¾”int.

½” ¾” ¾” - - 2¼”

CWM64-HT3 67 ¾”int. ¾”int.

½” ¾” ¾” ¾” ¾” 2¼”

CWM67-V3 67 ¾” ¾”

½” ¾” ¾”

- - 2¼”

CWM67-VT3 67 ¾” ¾”

½” ¾” ¾” ¾” ¾” 2¼”

CWM73-H3 73 ¾”int. ¾”int.

½” ¾” ¾” - - 2¼”

CWM73-HT3 73 ¾”int. ¾”int.

½” ¾” ¾” ¾” ¾” 2¼”

CWM78-V3 78 ¾” ¾”

½” ¾” ¾”

- - 2¼”

CWM78VT3 78 ¾” ¾”

½” ¾” ¾” ¾” ¾” 2¼”

CWM93-V3 93 ¾” ¾”

½” ¾” ¾” - - 2¼”

CWM93-VT3 93 ¾” ¾”

½” ¾” ¾” ¾” ¾” 2¼”

CWM141-V3 141 ¾” ¾”

½” ¾” ¾”

- - 2¼”

CWM141-VT3 141 ¾” ¾”

½” ¾” ¾” ¾” ¾” 2¼”

CONNECTIONS

19

See Table, page 18 NOT TO SCALE

HORIZONTAL MODELS

20

See Table, page 18 NOT TO SCALE

VERTICAL MODELS

WARRANTY

We warrant that all new equipment sold by us is free from defects in material or workmanship. Our liability under this warranty is limited

to making good any part or parts which shall be within one year from the date when the equipment was delivered new to the customer be

returned to us and which we are satisfied on our examination to have been defective in material or workmanship. Included in this

warranty are the costs of labour incurred by us in making good such part or parts.

This warranty is given on condition that:

i we are notified in writing within fourteen days after such defects appear and the equipment or defective parts are returned to as

soon as reasonably practical or where this is not practical made available for inspection by us

ii t he equi pm ent has in our judgement been correct l y install ed and norm ally used in accordance with the instructi ons provided f or its

installation operation and maintenance

iii unless performance figures and performance tolerances have been stipulated by the purchaser and agreed by us at the time of

ordering the equipment we shall be under no liability in the absence of any defect in material or workmanship for failure to obtain

any particular performance

iv if the equipment has in our judgement been altered taken apart repaired tampered with neglected damaged or used in any way

so as adversely to affect its performance or condition we shall not be liable for any fault arising from its use

v we shall not be liable for faults arising from the use of any spare or replacement parts not authorised or recommended by us

vi any equipment or defective part replaced by us shall become our property

vii the decisi on whether to repair or replace a defective part under warranty claim shall be at our discretion

viii excluded from this warranty are any parts which need replacement due to normal wear and tear

ix carriage to our works of any equipment or parts returned to us under a warranty claim shall be the responsibility of and at the

expense of the claimant

x we accept no responsibility for loss or damage howsoever occasioned to customers’ goods whilst such goods are in transit to or

from ourselves or in the possession of or in transit to or from our agents

xi we give no warranty in respect of equipment supplied by us except the foregoing warranty and without prejudice t o the generality

of the foregoing we shall be under no liability whether in contract or otherwise in respect of any defects in the goods or from any

injury loss or damage resulting from such defects or from any work done in connection therewith and we shall not in any

circumstances be liable for any consequential loss or damage suffered including any loss of use loss of contract or loss of profits.

Our liability shall in no case exceed the value of goods in relation to which the claim is made

xii the purchaser acknowledges that the equipment is sold to him in consideration of payment of the price and of the undertaking of

the part of the purchaser to

a) obs erve all prudent trade practices in relation to installation and user so that the equipment is not used when it is in an

unsafe condition for whatsoever reason

b) ens ure i n so far as the equipment is incorporated i nto ot her equi pment that such other equipment is in good working

order and that such incorporation is in accordance with what the manufacturer would require

c) ensure that his staff and all users of the equipment are adequately informed of their duties in relation to use of the

equipment

d) obs erve t he Heal th and Safety at Work legislation as amended from time to time in relation to the equipment supplied so

that we shall not be liable in any respect as a result of the purchaser’s failure to observe the conditions a) to d) set out

above.

The foregoing warranty is given without prejudice to purchasers’ statutory rights.

MANUFACTURED IN THE UK FOR:

Xylem Water Solutions UK Ltd

Bingley Road

Hoddesdon

Hertfordshire

EN11 0BU

UK

Telephone: +44 (0)1462 480380

Fax: +44 (0)1462 482422

www.jabscoshop.com

e-mail: mail@jabsco.co.uk

Loading...

Loading...