Page 1

Spartan-6 FPGA

PCB Design and

Pin Planning Guide

UG393 (v1.1) April 29, 2010

Page 2

Xilinx is disclosing this user guide, manual, release note, and/or specification (the "Documentation") to you solely for use in the development

of designs to operate with Xilinx hardware devices. You may not reproduce, distribute, republish, download, display, post, or transmit the

Documentation in any form or by any means including, but not limited to, electronic, mechanical, photocopying, recording, or otherwise,

without the prior written consent of Xilinx. Xilinx expressly disclaims any liability arising out of your use of the Documentation. Xilinx reserves

the right, at its sole discretion, to change the Documentation without notice at any time. Xilinx assumes no obligation to correct any errors

contained in the Documentation, or to advise you of any corrections or updates. Xilinx expressly disclaims any liability in connection with

technical support or assistance that may be provided to you in connection with the Information.

THE DOCUMENTATION IS DISCLOSED TO YOU “AS-IS” WITH NO WARRANTY OF ANY KIND. XILINX MAKES NO OTHER

WARRANTIES, WHETHER EXPRESS, IMPLIED, OR STATUTORY, REGARDING THE DOCUMENTATION, INCLUDING ANY

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE, OR NONINFRINGEMENT OF THIRD-PARTY

RIGHTS. IN NO EVENT WILL XILINX BE LIABLE FOR ANY CONSEQUENTIAL, INDIRECT, EXEMPLARY, SPECIAL, OR INCIDENTAL

DAMAGES, INCLUDING ANY LOSS OF DATA OR LOST PROFITS, ARISING FROM YOUR USE OF THE DOCUMENTATION.

© 2009–2010 Xilinx, Inc. XILINX, the Xilinx logo, Virtex, Spartan, ISE, and other designated brands included herein are trademarks of Xilinx

in the United States and other countries. All other trademarks are the property of their respective owners.

Revision History

The following table shows the revision history for this document.

Date Version Revision

09/21/09 1.0 Initial Xilinx release.

04/29/10 1.1 Changed guide title and added Chapter 6 and Appendix A. Replaced

Ta bl e 2 -1 .

Spartan-6 FPGA PCB Design and Pin Planning www.xilinx.com UG393 (v1.1) April 29, 2010

Page 3

Table of Contents

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Preface: About This Guide

Guide Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Additional Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Additional Support Resources. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Chapter 1: PCB Technology Basics

PCB Structures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Traces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Planes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Vias . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Pads and Antipads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Lands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Transmission Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Return Currents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Chapter 2: Power Distribution System

PCB Decoupling Capacitors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Recommended Capacitors per Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Required PCB Capacitor Quantities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Capacitor Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

PCB Bulk Capacitors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

PCB High-Frequency Capacitors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Capacitor Consolidation Rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

PCB Capacitor Placement and Mounting Techniques . . . . . . . . . . . . . . . . . . . . . . . . . . 17

PCB Bulk Capacitors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

0805 Ceramic Capacitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

0402 Ceramic Capacitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Basic PDS Principles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Noise Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Role of Inductance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Capacitor Parasitic Inductance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

PCB Current Path Inductance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Capacitor Mounting Inductance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Plane Inductance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

FPGA Mounting Inductance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

PCB Stackup and Layer Order . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Capacitor Effective Frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Capacitor Anti-Resonance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Capacitor Placement Background . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

V

Stabilization Capacitors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

REF

Power Supply Consolidation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Unconnected V

Pins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

CCO

Spartan-6 FPGA PCB Design and Pin Planning www.xilinx.com 3

UG393 (v1.1) April 29, 2010

Page 4

Simulation Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

PDS Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Noise Magnitude Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Noise Spectrum Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Optimum Decoupling Network Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Possibility 1: Excessive Noise from Other Devices on the PCB . . . . . . . . . . . . . . . . . . 37

Possibility 2: Parasitic Inductance of Planes, Vias, or Connecting Traces . . . . . . . . . . 37

Possibility 3: I/O Signals in PCB are Stronger Than Necessary . . . . . . . . . . . . . . . . . . 38

Possibility 4: I/O Signal Return Current Traveling in Sub-Optimal Paths . . . . . . . . . 38

Chapter 3: SelectIO Signaling

Interface Types. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Single-Ended versus Differential Interfaces. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

SDR versus DDR Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Single-Ended Signaling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Modes and Attributes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Input Thresholds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Chapter 4: PCB Materials and Traces

How Fast is Fast? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Dielectric Losses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Relative Permittivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Loss Tangent . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Skin Effect and Resistive Losses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Choosing the Substrate Material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Traces. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Trace Geometry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Trace Characteristic Impedance Design for High-Speed Transceivers . . . . . . . . . . . . 43

Trace Routing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Plane Splits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Return Currents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Simulating Lossy Transmission Lines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Skew Between Conductors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Chapter 5: Design of Transitions for High-Speed Signals

Excess Capacitance and Inductance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Time Domain Reflectometry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

BGA Package . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

SMT Pads. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Differential Vias . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

P/N Crossover Vias. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

SMA Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Backplane Connectors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Microstrip/Stripline Bends . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

4 www.xilinx.com Spartan-6 FPGA PCB Design and Pin Planning

UG393 (v1.1) April 29, 2010

Page 5

Chapter 6: I/O Pin and Clock Planning

Configuration Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Configuration Pin Planning Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Multi-function Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Configuration Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Memory Controller Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

MCB Pin Planning Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

MCB Clocking Considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

PCI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

GTP Transceivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

GTP Transceiver Pin Planning Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

GTP Transceiver Clocking Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

PCI Express . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Other GTP Transceiver Based Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Global and I/O Clocking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

GCLK Pin Assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

BUFIO2 I/O Clock Buffer Usage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Overview of BUFIO2 Resource Usage per Interface Type . . . . . . . . . . . . . . . . . . . . . . . 66

Bidirectional I/O. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Serializing Interfaces. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Pin Planning Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Single-Ended SerDes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Differential SerDes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Power Management—Using Suspend/Awake. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

I/O Standards and I/O Banking Rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Simultaneous Switching Output (SSO) Management . . . . . . . . . . . . . . . . . . . . . . . . 67

Running Design Rule Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Density Migration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Appendix A: Recommended PCB Design Rules

Recommended PCB Design Rules for QFP Packages . . . . . . . . . . . . . . . . . . . . . . . . . 69

Recommended PCB Design Rules for BGA and CSP Packages . . . . . . . . . . . . . . . 70

Spartan-6 FPGA PCB Design and Pin Planning www.xilinx.com 5

UG393 (v1.1) April 29, 2010

Page 6

6 www.xilinx.com Spartan-6 FPGA PCB Design and Pin Planning

UG393 (v1.1) April 29, 2010

Page 7

About This Guide

This guide provides information on PCB design for Spartan®-6 devices, with a focus on

strategies for making design decisions at the PCB and interface level.

Guide Contents

This guide contains the following chapters:

• Chapter 1, PCB Technology Basics, discusses the basics of current PCB technology

focusing on physical structures and common assumptions.

• Chapter 2, Power Distribution System, covers the power distribution system for

Spartan-6 FPGAs, including all details of decoupling capacitor selection, use of

voltage regulators and PCB geometries, simulation and measurement.

• Chapter 3, SelectIO Signaling, contains information on the choice of SelectIO™

standards, I/O topographies, and termination strategies as well as information on

simulation and measurement techniques.

• Chapter 4, PCB Materials and Traces, provides some guidelines on managing signal

attenuation to obtain optimal performance for high-frequency applications.

• Chapter 5, Design of Transitions for High-Speed Signals, addresses the interface at

either end of a transmission line. The provided analyses and examples can greatly

accelerate the specific design.

Preface

Additional Documentation

The following documents are also available for downloaded at

http://www.xilinx.com/support/documentation/spartan-6.htm

• Spartan-6 Family Overview

This overview outlines the features and product selection of the Spartan-6 family.

• Spartan-6 FPGA Data Sheet: DC and Switching Characteristics

This data sheet contains the DC and switching characteristic specifications for the

Spartan-6 family.

• Spartan-6 FPGA Packaging and Pinout Specifications

This specification includes the tables for device/package combinations and maximum

I/Os, pin definitions, pinout tables, pinout diagrams, mechanical drawings, and

thermal specifications.

• Spartan-6 FPGA Configuration User Guide

Spartan-6 FPGA PCB Design and Pin Planning www.xilinx.com 7

UG393 (v1.1) April 29, 2010

.

Page 8

Preface: About This Guide

• Spartan-6 FPGA SelectIO Resources User Guide

•Spartan-6 FPGA Clocking Resources User Guide

• Spartan-6 FPGA Configurable Logic Block User Guide

• Spartan-6 FPGA Block RAM Resources User Guide

• Spartan-6 FPGA DSP48A1 Slice User Guide

• Spartan-6 FPGA Memory Controller User Guide

This all-encompassing configuration guide includes chapters on configuration

interfaces (serial and parallel), multi-bitstream management, bitstream encryption,

boundary-scan and JTAG configuration, and reconfiguration techniques.

This guide describes the SelectIO™ resources available in all Spartan-6 devices.

This guide describes the clocking resources available in all Spartan-6 devices,

including the DCMs and PLLs.

This guide describes the capabilities of the configurable logic blocks (CLBs) available

in all Spartan-6 devices.

This guide describes the Spartan-6 device block RAM capabilities.

This guide describes the architecture of the DSP48A1 slice in Spartan-6 FPGAs and

provides configuration examples.

This guide describes the Spartan-6 FPGA memory controller block, a dedicated

embedded multi-port memory controller that greatly simplifies interfacing Spartan-6

FPGAs to the most popular memory standards.

• Spartan-6 FPGA GTP Transceiver User Guide

This guide describes the GTP transceivers available in the Spartan-6 LXT FPGAs.

Additional Support Resources

To search the Answer Database of silicon, software, and IP questions and answers, or to

create a technical support WebCase, see the Xilinx website at:

http://www.xilinx.com/support/mysupport.htm

.

8 www.xilinx.com Spartan-6 FPGA PCB Design and Pin Planning

UG393 (v1.1) April 29, 2010

Page 9

PCB Technology Basics

Printed circuit boards (PCBs) are electrical systems, with electrical properties as

complicated as the discrete components and devices mounted to them. The PCB designer

has complete control over many aspects of the PCB; however, current technology places

constraints and limits on the geometries and resulting electrical properties. The following

information is provided as a guide to the freedoms, limitations, and techniques for PCB

designs using FPGAs.

This chapter contains the following sections:

• PCB Structures

• Transmission Lines

• Return Currents

PCB Structures

Chapter 1

Tr ac e s

Planes

PCB technology has not changed significantly in the last few decades. An insulator

substrate material (usually FR4, an epoxy/glass composite) with copper plating on both

sides has portions of copper etched away to form conductive paths. Layers of plated and

etched substrates are glued together in a stack with additional insulator substrates

between the etched substrates. Holes are drilled through the stack. Conductive plating is

applied to these holes, selectively forming conductive connections between the etched

copper of different layers.

While there are advancements in PCB technology, such as material properties, the number

of stacked layers used, geometries, and drilling techniques (allowing holes that penetrate

only a portion of the stackup), the basic structures of PCBs have not changed. The

structures formed through the PCB technology are abstracted to a set of physical/electrical

structures: traces, planes (or planelets), vias, and pads.

A trace is a physical strip of metal (usually copper) making an electrical connection

between two or more points on an X-Y coordinate of a PCB. The trace carries signals

between these points.

A plane is an uninterrupted area of metal covering the entire PCB layer. A planelet, a

variation of a plane, is an uninterrupted area of metal covering only a portion of a PCB

layer. Typically, a number of planelets exist in one PCB layer. Planes and planelets

distribute power to a number of points on a PCB. They are very important in the

Spartan-6 FPGA PCB Design and Pin Planning www.xilinx.com 9

UG393 (v1.1) April 29, 2010

Page 10

Chapter 1: PCB Technology Basics

transmission of signals along traces because they are the return current transmission

medium.

Vias

A via is a piece of metal making an electrical connection between two or more points in the

Z space of a PCB. Vias carry signals or power between layers of a PCB. In current platedthrough-hole (PTH) technology, a via is formed by plating the inner surface of a hole

drilled through the PCB. In current microvia technology (also known as High Density

Interconnect or HDI), a via is formed with a laser by ablating the substrate material and

deforming the conductive plating. These microvias cannot penetrate more than one or two

layers, however, they can be stacked or stair-stepped to form vias traversing the full board

thickness.

Pads and Antipads

Because PTH vias are conductive over the whole length of the via, a method is needed to

selectively make electrical connections to traces, planes, and planelets of the various layers

of a PCB. This is the function of pads and antipads.

Pads are small areas of copper in prescribed shapes. Antipads are small areas in prescribed

shapes where copper is removed. Pads are used both with vias and as exposed outer-layer

copper for mounting of surface-mount components. Antipads are used mainly with vias.

For traces, pads are used to make the electrical connection between the via and the trace or

plane shape on a given layer. For a via to make a solid connection to a trace on a PCB layer,

a pad must be present for mechanical stability. The size of the pad must meet drill

tolerance/registration restrictions.

Antipads are used in planes. Because plane and planelet copper is otherwise

uninterrupted, any via traveling through the copper makes an electrical connection to it.

Where vias are not intended to make an electrical connection to the planes or planelets

passed through, an antipad removes copper in the area of the layer where the via

penetrates.

Lands

For the purposes of soldering surface mount components, pads on outer layers are

typically referred to as lands or solder lands. Making electrical connections to these lands

usually requires vias. Due to manufacturing constraints of PTH technology, it is rarely

possible to place a via inside the area of the land. Instead, this technology uses a short

section of trace connecting to a surface pad. The minimum length of the connecting trace is

determined by minimum dimension specifications from the PCB manufacturer. Microvia

technology is not constrained, and vias can be placed directly in the area of a solder land.

Dimensions

The major factors defining the dimensions of the PCB are PCB manufacturing limits, FPGA

package geometries, and system compliance. Other factors such as Design For

Manufacturing (DFM) and reliability impose further limits, but because these are

application specific, they are not documented in this user guide.

The dimensions of the FPGA package, in combination with PCB manufacturing limits,

define most of the geometric aspects of the PCB structures described in this section (PCB

Structures), both directly and indirectly. This significantly constrains the PCB designer. The

10 www.xilinx.com Spartan-6 FPGA PCB Design and Pin Planning

UG393 (v1.1) April 29, 2010

Page 11

Transmission Lines

package pin or ball pitch (1.0 mm for FG packages) defines the land pad layout. The

minimum surface feature sizes of current PCB technology define the via arrangement in

the area under the device. Minimum via diameters and keep-out areas around those vias are

defined by the PCB manufacturer. These diameters limit the amount of space available

in-between vias for routing of signals in and out of the via array underneath the device.

These diameters define the maximum trace width in these breakout traces. PCB

manufacturing limits constrain the minimum trace width and minimum spacing.

The total number of PCB layers necessary to accommodate an FPGA is defined by the

number of signal layers and the number of plane layers.

• The number of signal layers is defined by the number of I/O signal traces routed in

and out of an FPGA package (usually following the total User I/O count of the

package for array packages).

• The number of plane layers is defined by the number of power and ground plane

layers necessary to bring power to the FPGA and to provide references and isolation

for signal layers.

PCBs for larger FPGAs can range from 4 to 22 layers.

System compliance often defines the total thickness of the board. Along with the number

of board layers, this defines the maximum layer thickness, and therefore, the spacing in the

Z direction of signal and plane layers to other signal and plane layers. Z-direction spacing

of signal trace layers to other signal trace layers affects crosstalk. Z-direction spacing of

signal trace layers to reference plane layers affects signal trace impedance. Z-direction

spacing of plane layers to other plane layers affects power system parasitic inductance.

Z-direction spacing of signal trace layers to reference plane layers (defined by total board

thickness and number of board layers) is a defining factor in trace impedance.Trace width

(defined by FPGA package ball pitch and PCB via manufacturing constraints) is another

factor in trace impedance. A designer often has little control over trace impedance in area

of the via array beneath the FPGA. When traces escape the via array, their width can

change to the width of the target impedance (usually 50Ω single-ended).

Decoupling capacitor placement and discrete termination resistor placement are other

areas of trade-off optimization. DFM constraints often define a keep-out area around the

perimeter of the FPGA (device footprint) where no discrete components can be placed. The

purpose of the keep-out area is to allow room for assembly and rework where necessary.

For this reason, the area just outside the keep-out area is one where components compete

for placement. It is up to the PCB designer to determine the high priority components.

Decoupling capacitor placement constraints are described in Chapter 2, Power

Distribution System. Termination resistor placement constraints must be determined

through signal integrity simulation, using IBIS or SPICE.

Transmission Lines

The combination of a signal trace and a reference plane forms a transmission line. All I/O

signals in a PCB system travel through transmission lines.

For single-ended I/O interfaces, both the signal trace and the reference plane are necessary

to transmit a signal from one place to another on the PCB. For differential I/O interfaces,

the transmission line is formed by the combination of two traces and a reference plane.

While the presence of a reference plane is not strictly necessary in the case of differential

signals, it is necessary for practical implementation of differential traces in PCBs.

Good signal integrity in a PCB system is dependent on having transmission lines with

controlled impedance. Impedance is determined by the geometry of the traces and the

Spartan-6 FPGA PCB Design and Pin Planning www.xilinx.com 11

UG393 (v1.1) April 29, 2010

Page 12

Chapter 1: PCB Technology Basics

dielectric constant of the material in the space around the signal trace and between the

signal trace and the reference plane.

The dielectric constant of the material in the vicinity of the trace and reference plane is a

property of the PCB laminate materials, and in the case of surface traces, a property of the

air or fluid surrounding the board. PCB laminate is typically a variant of FR4, though it can

also be an exotic material.

While the dielectric constant of the laminate varies from board to board, it is fairly constant

within one board. Therefore, the relative impedance of transmission lines in a PCB is

defined most strongly by the trace geometries and tolerances. Impedance variance can

occur based on the presence or absence of glass in a local portion of the laminate weave,

but this rarely poses issues except in high-speed (>6 Gb/s) interfaces.

Return Currents

An often neglected aspect of transmission lines and their signal integrity is return current.

It is incorrect to assume that a signal trace by itself forms a transmission line. Currents

flowing in a signal trace have an equal and opposite complimentary current flowing in the

reference plane beneath them. The relationship of the trace voltage and trace current to

reference plane voltage and reference plane current defines the characteristic impedance of

the transmission line formed by the trace and reference plane. While interruption of

reference plane continuity beneath a trace is not as dramatic in effect as severing the signal

trace, the performance of the transmission line and any devices sharing the reference plane

is affected.

It is important to pay attention to reference plane continuity and return current paths.

Interruptions of reference plane continuity, such as holes, slots, or isolation splits, cause

significant impedance discontinuities in the signal traces. They can also be a significant

source of crosstalk and contributor to Power Distribution System (PDS) noise. The

importance of return current paths cannot be underestimated.

12 www.xilinx.com Spartan-6 FPGA PCB Design and Pin Planning

UG393 (v1.1) April 29, 2010

Page 13

Power Distribution System

This chapter documents the power distribution system (PDS) for Spartan®-6 FPGAs,

including decoupling capacitor selection, placement, and PCB geometries. A simple

decoupling method is provided for each device in the Spartan-6 family. Basic PDS design

principles are covered, as well as simulation and analysis methods. This chapter contains

the following sections:

• PCB Decoupling Capacitors

• Basic PDS Principles

• Simulation Methods

• PDS Measurements

• Troubleshooting

PCB Decoupling Capacitors

Chapter 2

Recommended Capacitors per Device

A simple PCB-decoupling network for each Spartan-6 device is listed in Tab le 2 -1 .

Decoupling methods other than those presented in Ta bl e 2- 1 can be used, but the

decoupling network should be designed to meet or exceed the performance of the simple

decoupling networks presented here. The impedance of the alternate network must be less

than or equal to that of the recommended network across frequencies from 100 KHz to

500 MHz.

Because device capacitance requirements vary with CLB and I/O utilization, PCB

decoupling guidelines are provided on a per-device basis. V

are listed as the quantity per device, while V

I/O bank. Device performance at full utilization is equivalent across all devices when

using these recommended networks.

and V

capacitors are listed as the quantity per

CCO

CCINT

CCAUX

capacitors

Spartan-6 FPGA PCB Design and Pin Planning www.xilinx.com 13

UG393 (v1.1) April 29, 2010

Page 14

Chapter 2: Power Distribution System

Required PCB Capacitor Quantities

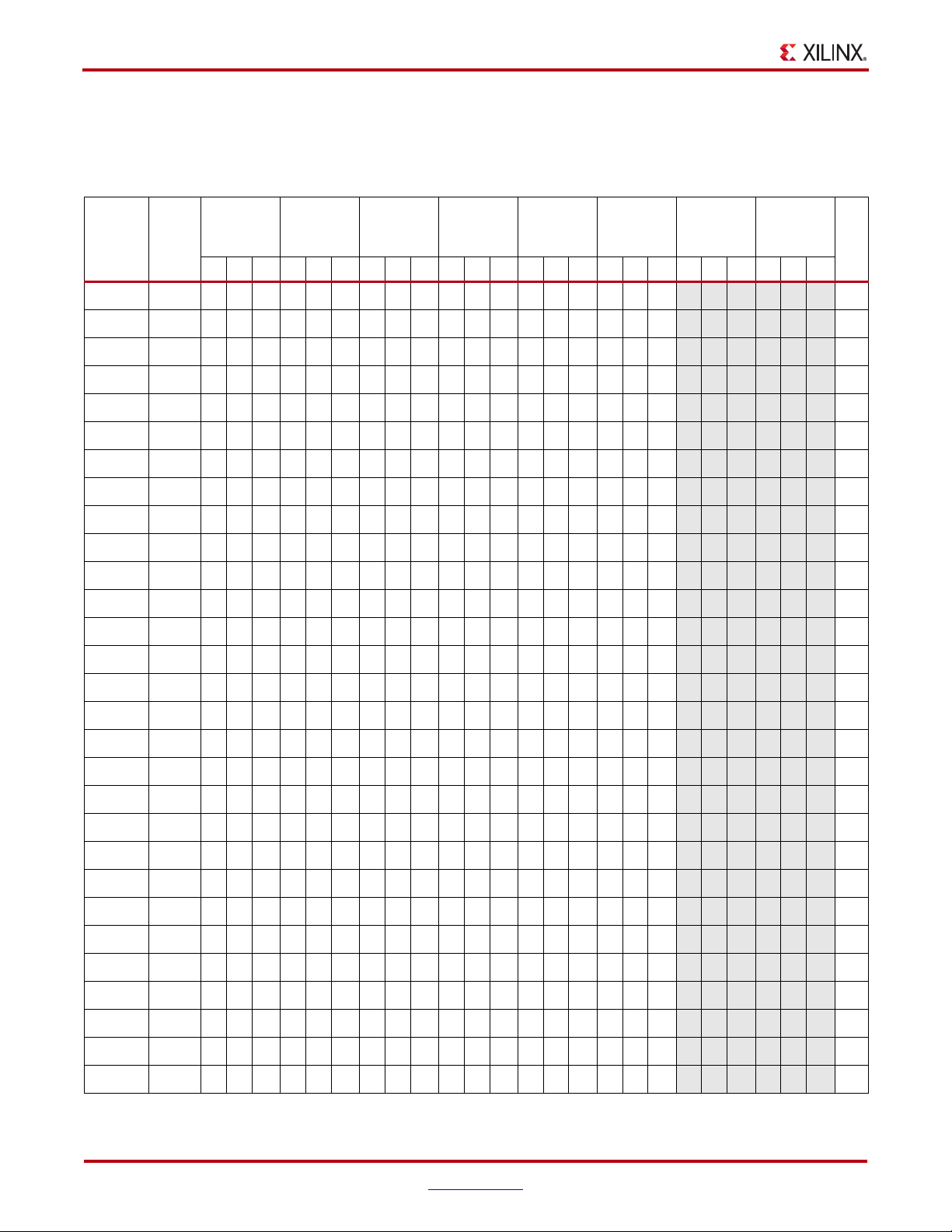

Tab le 2 -1 lists the PCB decoupling capacitor guidelines per VCC supply rail.

CCO

(1)

V

CCO

Bank 2

in µF

V

CCO

Bank 3

in µF

V

CCO

Bank 4

in µF

V

CCO

Bank 5

in µF

Tot al

Table 2-1: Required PCB Capacitor Quantities per Device

V

Bank 1

in µF

Package

Device

(XC6S)

V

V

CCINT

in µF

100 4.7 0.47 100 4.7 0.47 100 4.7 0.47 100 4.7 0.47 100 4.7 0.47 100 4.7 0.47 100 4.7 0.47 100 4.7 0.47

V

CCAUX

in µF

CCO

Bank 0

in µF

TQG144LX4 051073012012012012 28

TQG144LX9 112073012012012012 26

CPG196LX4 051113112112112112 27

CPG196LX9 112113112112112112 25

CPG196LX16 124 11 3112 112 11211 2 28

CSG225LX4 051124123123123123 37

CSG225LX9 012124123123123123 34

CSG225LX16 124 12 4123 12 3123 123 38

CSG324LX9 112135123124123124 39

CSG324LX16 124 13 6124 12 4134 124 46

CSG324LX25 137 13 6124 12 4134 124 50

CSG324 LX25T 1 3 7 1 2 5 1 1 1 1 2 4 1 3 4 1 2 4 44

(2)

CSG324LX45 2612136 12 3124 13 4124 58

CSG324 LX45T 2 6 12 1 2 5 1 1 1 1 2 4 1 3 4 1 2 4 53

FT(G)256LX9 112125123124123124 38

FT(G)256LX16 12412 5 123 12 4123 12 4 41

FT(G)256LX25 13712 5 123 12 4123 12 4 45

CSG484LX45 2612148 12 3148 12 4147

71

CSG484 LX45T 2 6 12 1 4 7 1 2 3 1 4 7 1 2 4 1 4 7 69

CSG484LX75 31020148124148124148 86

CSG484 LX75T 3 10 20 1 4 7 1 2 3 1 4 7 1 2 4 1 4 7

82

CSG484 LX100 4 13 27 1 4 9 1 2 4 1 4 8 1 3 5 1 4 8 100

CSG484 LX100T 4 13 27 1 4 7 1 2 3 1 4 7 1 2 4 1 4 7 93

CSG484 LX150 7 20 40 1 4 9 1 2 4 1 4 8 1 3 5 1 4 8 123

CSG484 LX150T 7 20 40 1 4 7 1 2 3 1 4 7 1 2 4 1 4 7 11 6

FG(G)484LX25 13 7137 124 13413 613 4 55

FG(G)484 LX25T 1 3 7 1 3 6 1 2 3 1 3 4 1 3 6 1 3 4

53

FG(G)484LX45 261214812 3 136 14 7146 72

FG(G)484 LX45T 2 6 12 1 4 7 1 2 3 1 3 6 1 3 6 1 3 6 68

14 www.xilinx.com Spartan-6 FPGA PCB Design and Pin Planning

UG393 (v1.1) April 29, 2010

Page 15

PCB Decoupling Capacitors

CCO

(1)

(Continued)

V

CCO

Bank 2

in µF

V

CCO

Bank 3

in µF

V

CCO

Bank 4

in µF

V

CCO

Bank 5

in µF

Tot al

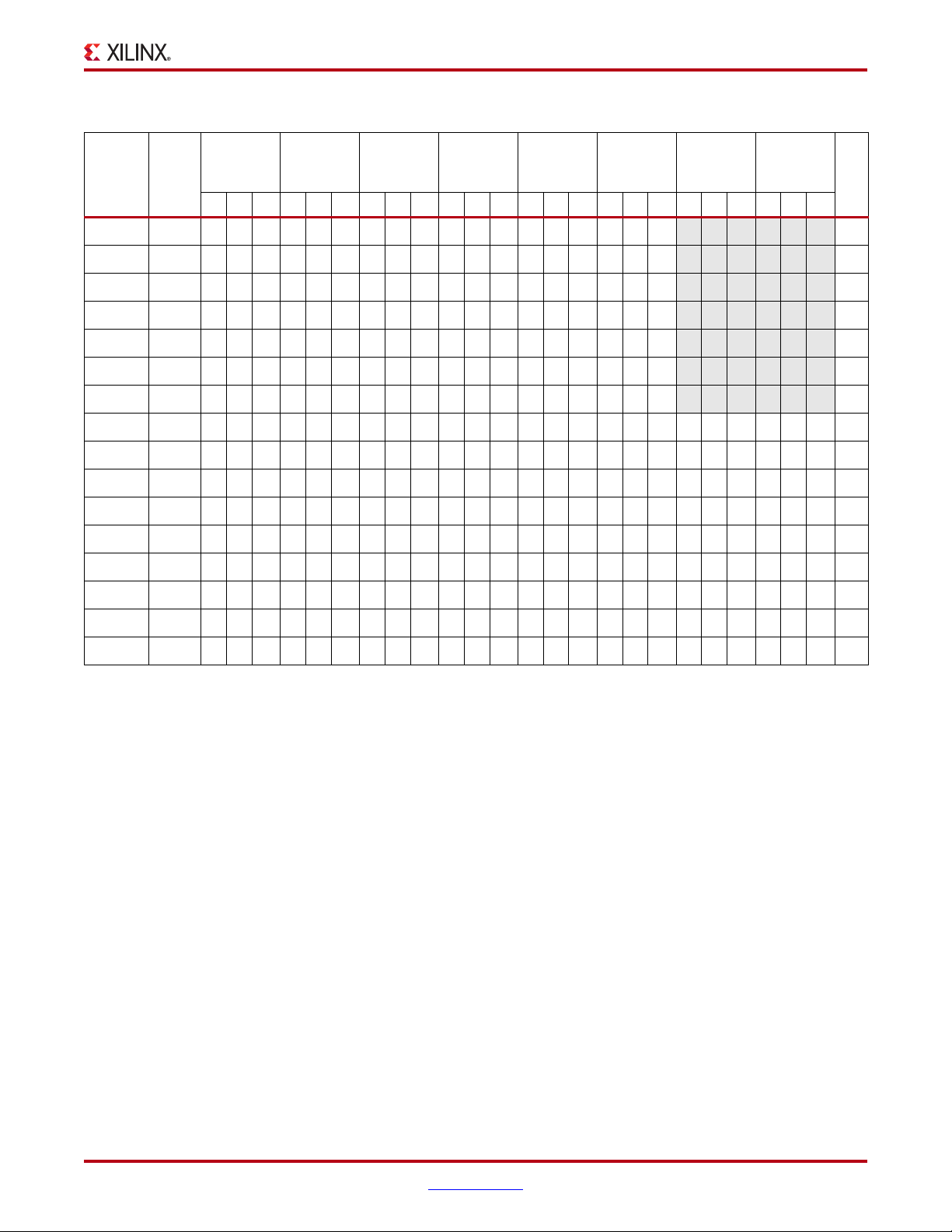

Table 2-1: Required PCB Capacitor Quantities per Device

V

Bank 1

in µF

Package

Device

(XC6S)

V

V

CCINT

in µF

100 4.7 0.47 100 4.7 0.47 100 4.7 0.47 100 4.7 0.47 100 4.7 0.47 100 4.7 0.47 100 4.7 0.47 100 4.7 0.47

V

CCAUX

in µF

CCO

Bank 0

in µF

FG(G)484LX75 31020149135136147146 89

FG(G)484 LX75T 3 10 20 1 4 7 1 2 3 1 3 6 1 3 6 1 3 6 81

FG(G)484 LX100 4 13 27 1 4 8 1 3 5 1 3 6 1 4 6 1 4 6 98

FG(G)484 LX100T 4 13 27 1 4 7 1 2 3 1 3 6 1 3 6 1 3 6 92

FG(G)484 LX150 7 20 40 1 4 8 1 3 5 1 3 6 1 4 6 1 4 6 121

FG(G)484 LX150T 7 20 40 1 4 7 1 2 3 1 3 6 1 3 6 1 3 6 115

FG(G)676LX45 261215913 5 136 14 6148 78

FG(G)676 LX75 3 10 20 2 6 12 1 4 6 1 4 6 1 4 7 1 4 7 1 2 4 1 2 4 113

FG(G)676 LX75T 3 10 20 1 5 10 1 3 6 1 2 4 1 3 6 1 3 5 1 2 4 1 2 4 99

FG(G)676 LX100 4 13 27 2 6 12 1 4 6 1 4 6 1 4 7 1 4 7 1 2 4 1 2 4 124

FG(G)676 LX100T 4 13 27 1 5 10 1 3 5 1 2 4 1 3 5 1 3 5 1 2 3 1 2 4 107

FG(G)676 LX150 7 20 40 2 6 12 1 4 6 1 4 6 1 4 7 1 4 7 1 2 4 1 2 4 147

(2)

FG(G)676 LX150T 7 20 40 1 5 10 1 3 5 1 2 4 1 3 5 1 3 5 1 2 3 1 2 4 130

FG(G)900 LX100T 4 13 27 2 6 13 1 4 6 1 4 7 1 4 7 1 5 8 1 2 4 1 2 4 128

FG(G)900 LX150 7 20 40 2 7 15 1 5 9 1 4 7 1 5 9 1 5 8 1 2 4 1 2 4 161

FG(G)900 LX150T 7 20 40 2 7 14 1 5 8 1 4 7 1 5 8 1 5 8 1 2 4 1 2 4 158

Notes:

1. PCB Capacitor specifications are listed in Tab le 2- 2.

2. Total includes all capacitors for all supplies, accounting for the number of I/O banks in the device.

Spartan-6 FPGA PCB Design and Pin Planning www.xilinx.com 15

UG393 (v1.1) April 29, 2010

Page 16

Chapter 2: Power Distribution System

Capacitor Specifications

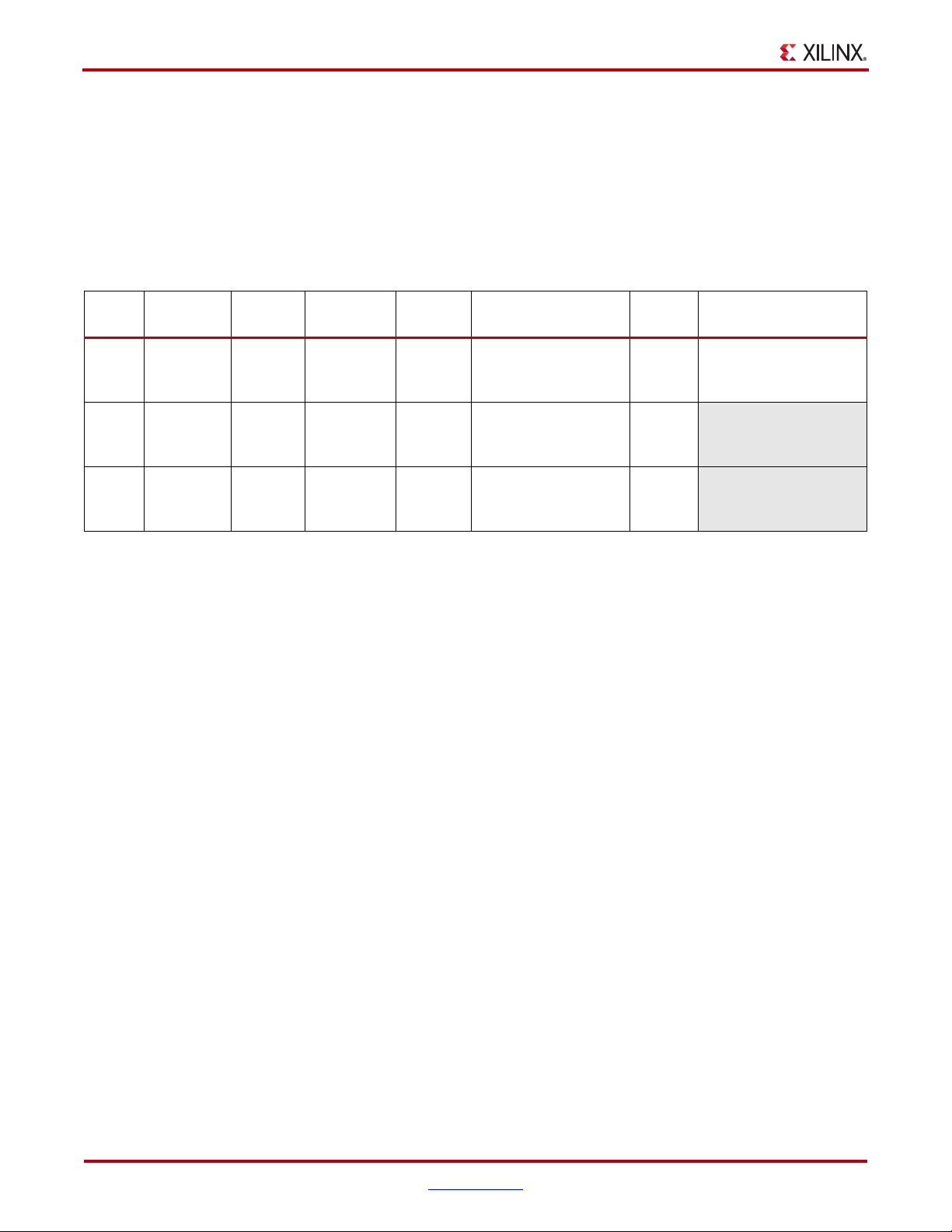

The electrical characteristics of the capacitors in Tab le 2 -1 are described in this section.

Characteristics of the PCB bulk and high-frequency capacitors are specified in Ta bl e 2 -2 ,

followed by guidelines on acceptable substitutions. The equivalent series resistance (ESR)

ranges specified for these capacitors can be over-ridden. However, this requires analysis of

the resulting power distribution system impedance to ensure that no resonant impedance

spikes result.

Table 2-2: PCB Capacitor Specifications

Ideal

Val ue

100 µF C > 100 µF 1210

4.7 µF C > 4.7 µF 0805

0.47 µF C > 0.47 µF

PCB Capacitor Substitution Rules:

1. Values can be larger than specified.

2. Body size can be smaller than specified.

3. ESR must be within the specified range.

4. Voltage rating can be higher than specified.

Val ue

Range

(1)

Body

(2)

Size

0204 or

0402

Typ e

2-Terminal

Ceramic

X7R or X5R

2-Terminal

Ceramic

X7R or X5R

2-Terminal

Ceramic

X7R or X5R

PCB Bulk Capacitors

The purpose of the bulk capacitors is to cover the low-frequency range between where the

voltage regulator stops working (~100 KHz) and where the high-frequency capacitors start

working (~2 MHz). As specified in Ta bl e 2 -1 , all FPGA supplies require bulk capacitors.

The bulk capacitors in Tab le 2 -1 and Ta bl e 2- 2 are not necessarily in addition to the voltage

regulator output capacitors required by the regulator manufacturer, provided there is no

inductor, ferrite bead, choke, or other filter between the FPGA and the bulk capacitors.

However, if the FPGA bulk and regulator output requirements are merged, the total

capacitance of this network must not be less than the total bulk specified in Ta bl e 2- 1 and

Tab le 2 -2, and must comply with the regulator manufacturer’s output capacitor

requirements.

ESL

Maximum

5nH 10mΩ <ESR<60mΩ 6.3V GRM32ER60J107ME20L

2nH 10mΩ <ESR<60mΩ 6.3V

1.5 nH 10 mΩ <ESR<60mΩ 6.3V

ESR Range

(3)

Volt ag e

Rating

(4)

Suggested

Part Number

The bulk PCB capacitors specified in Ta ble 2 -1 are ceramic capacitors from Murata, a

capacitor manufacturer. This capacitor was selected for its value, size, and low-cost. It is

also RoHS compliant. If another manufacturer’s capacitors or another type of capacitor

(e.g., tantalum or high-performance electrolytic) meet the specifications listed in Tab le 2 -2 ,

substitution is acceptable.

PCB High-Frequency Capacitors

There are two high-frequency capacitor values in Tab le 2 -2 : the 4.7 µF capacitor in an 0805

package and the 0.47 µF capacitor in an 0402 or 0204 package. Substitutions can be made

for some characteristics, but not others; see the notes attached to Tab le 2 -2 for details.

16 www.xilinx.com Spartan-6 FPGA PCB Design and Pin Planning

UG393 (v1.1) April 29, 2010

Page 17

Capacitor Consolidation Rules

Sometimes a number of I/O banks are powered from the same voltage (e.g., 1.8V) and the

recommended guidelines call for multiple bulk capacitors. This is also the case for V

and V

fewer (larger value) bulk capacitors provided the electrical characteristics of the

consolidated capacitors (ESR and ESL) are equal to the electrical characteristics of the

parallel combination of the recommended capacitors.

in the larger devices. These many smaller capacitors can be consolidated into

CCAUX

PCB Decoupling Capacitors

CCINT

For most consolidations of V

CCO

, V

CCINT

, and V

CCAUX

capacitors, large bulk capacitors

(ceramic, tantalum, or high-performance electrolytic) with sufficiently low ESL and ESR

are readily available. High-frequency capacitors cannot be consolidated as the usefulness

of high-frequency capacitors depends on the number of PCB vias accessed.

Example

This example is of an FPGA with a single interface spanning three I/O banks, all powered

from the same voltage. The required PCB capacitor table (Tabl e 2- 1) calls for one 100 µF

capacitor per bank. These three capacitors can be consolidated into one capacitor since

three 100 µF capacitors can be covered by one 330 µF capacitor. The following is then true:

• The ESL of the combination must be one-third of the specified capacitor. Three

capacitors at 5 nH are equivalent to one capacitor at 1.7 nH. This implies that a 330 µF

capacitor is acceptable provided its ESL is less than 1.7 nH.

• The ESR of the combination must be one-third of the specified capacitor. Three

capacitors each in the range of 10 mΩ to 60 mΩ are equivalent to one capacitor in the

range of 3.3 mΩ to 20 mΩ. A 330 µF capacitor is acceptable provided its ESL is in this

range.

• Three 100 µF capacitors with 3 nH ESL and 20 mΩ ESR are replaced by one 330 µF

capacitor with a 0.5 nH ESL and a 15 mΩ ESR.

PCB Capacitor Placement and Mounting Techniques

Placement and mounting restrictions presented in this section are unique to each capacitor

type listed in the Capacitor Specifications section.

PCB Bulk Capacitors

Bulk capacitors can be large and difficult to place very close to the FPGA. Fortunately, this

is not a problem because the low-frequency energy covered by bulk capacitors is not as

sensitive to capacitor location. Bulk capacitors can be placed almost anywhere on the PCB,

but the best placement is as close as possible to the FPGA. Capacitor mounting should

follow normal PCB layout practices, tending toward short and wide shapes connecting to

power planes with multiple vias.

Spartan-6 FPGA PCB Design and Pin Planning www.xilinx.com 17

UG393 (v1.1) April 29, 2010

Page 18

Chapter 2: Power Distribution System

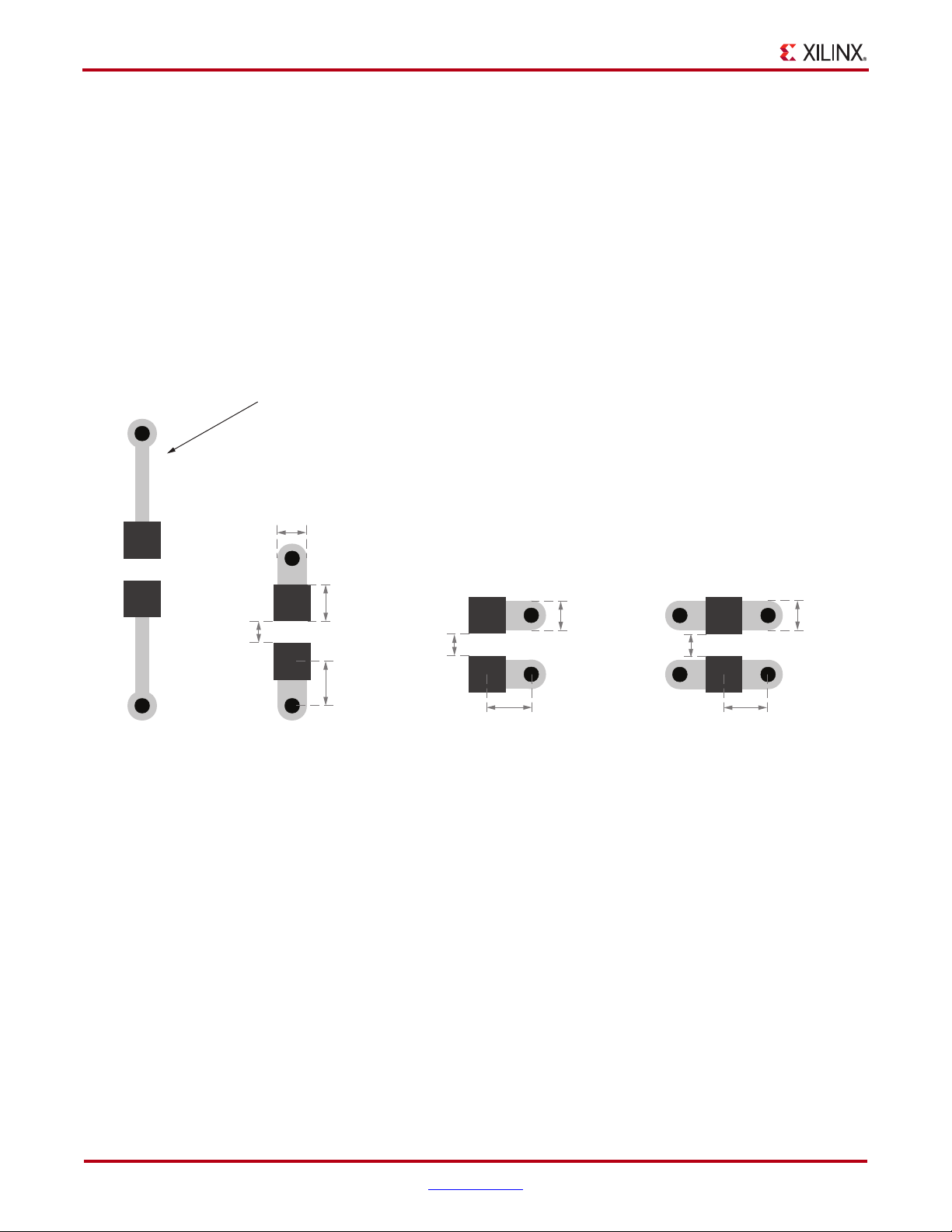

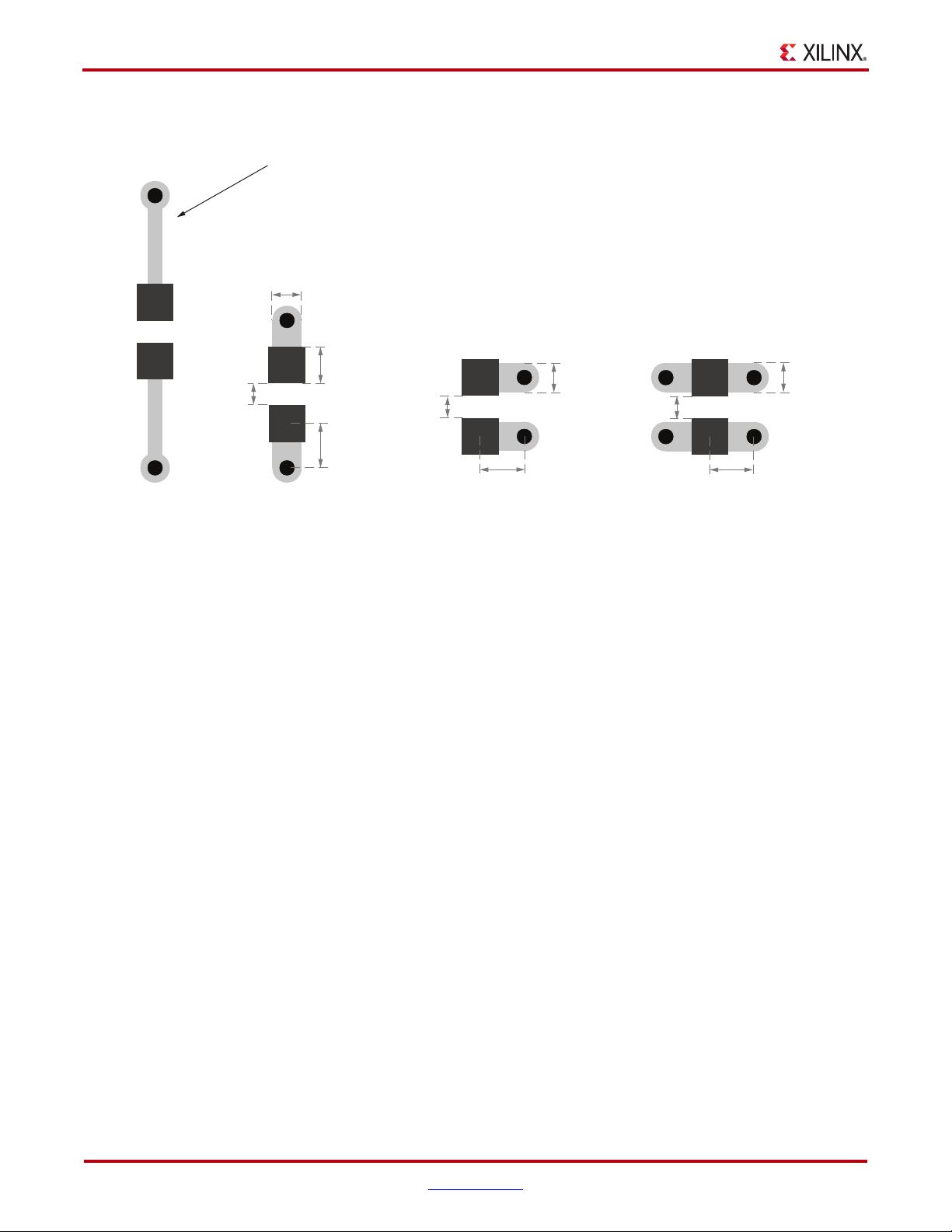

0805 Land Pattern

End Vias

Long Traces

(A)

UG393_c2_01_091809

(B)

0805 Land Pattern

End Vias

Not Recommended.

Connecting Trace is Too Long

1.27 mm

(50 mils)

0.61mm

(24 mils)

1.07 mm

(42 mils)

0.61mm

(24 mils)

(C)

0805 Land Pattern

Side Vias

1.12 mm

(44 mils)

0.61 mm

(24 mils)

0.61mm

(24 mils)

(D)

0805 Land Pattern

Double Side Vias

0.61mm

(24 mils)

0.61 mm

(24 mils)

1.12 mm

(44 mils)

0805 Ceramic Capacitor

The 4.7 µF 0805 capacitor covers the middle frequency range. Placement has some impact

on its performance. The capacitor should be placed as close as possible to the FPGA. Any

placement within two inches of the device’s outer edge is acceptable.

The capacitor mounting (solder lands, traces, and vias) should be optimized for low

inductance. Vias should be butted directly against the pads. Vias can be located at the ends

of the pads (see Figure 2-1B), but are more optimally located at the sides of the pads (see

Figure 2-1C). Via placement at the sides of the pads decreases the mounting’s overall

parasitic inductance by increasing the mutual inductive coupling of one via to the other.

Dual vias can be placed on both sides of the pads (see Figure 2-1D) for even lower parasitic

inductance, but with diminishing returns.

X-Ref Target - Figure 2-1

18 www.xilinx.com Spartan-6 FPGA PCB Design and Pin Planning

Figure 2-1: Example 0805 Capacitor Land and Mounting Geometries

UG393 (v1.1) April 29, 2010

Page 19

PCB Decoupling Capacitors

0402 Ceramic Capacitor

The 0.47 µF 0402 capacitor covers the high-middle frequency range. Placement and

mounting are critical for these capacitors.

The capacitor should be mounted as close to the FPGA as possible (achieves the least

parasitic inductance possible).

For PCBs with a total thickness of < 1.575 mm (62 mils), the best placement location is on

the PCB backside, within the device footprint (in the empty cross with an absence of vias).

V

and GND vias corresponding to the supply of interest should be identified in the via

CC

array. Where space is available, 0402 mounting pads should be added and connected to

these vias.

For PCBs with a total thickness > 1.575 mm (62 mils), the best placement location could be

on the PCB top surface. The depth of the V

factor: if the V

surface is optimal; if the V

plane is in the PCB stackup’s top half, capacitor placement on the top PCB

CC

plane is in the PCB stackup’s bottom half, capacitor

CC

placement on the bottom PCB surface is optimal.

Any 0402 capacitors placed outside the device footprint (whether on the top or bottom

surface) should be within 0.5 inch of the device’s outer edge.

The capacitor mounting (solder lands, traces, and vias) must be optimized for low

inductance. Vias should be butted against the pads with no trace length in-between. These

vias should be at the sides of the pads if at all possible (see Figure 2-2C). Via placement at

the sides of the pads decreases the mounting’s parasitic inductance by increasing the

mutual inductive coupling of one via to the other. Dual vias can be placed on both sides of

the pads (see Figure 2-2D) for even lower parasitic inductance, but with diminishing

returns.

plane of interest in the PCB stackup is the key

CC

Many manufacturing rules prevent mounting any device within 0.1 inch of the FPGA on

the PCB top surface. Manufacturing rules can also prevent capacitor placement on the PCB

backside within the device footprint, whether because backside mounting is prohibited or

geometries necessary to fit mounting pads in the tight spaces between vias are too small

for reliable soldering. These rules decrease the available options for capacitor placement

but do not preclude meeting the Xilinx placement recommendations. Discuss any specific

concerns with a PCB fabrication, assembly, and/or quality department.

Spartan-6 FPGA PCB Design and Pin Planning www.xilinx.com 19

UG393 (v1.1) April 29, 2010

Page 20

Chapter 2: Power Distribution System

0402 Land Pattern

End Vias

Long Traces

(A) (C)(B) (D)

UG393_c2_02_091809

0402 Land Pattern

End Vias

0.381 mm

(15 mils)

0.635 mm

(25 mils)

1.07 mm

(42 mils)

0.61mm

(24 mils)

0402 Land Pattern

Double Side Vias

0.762 mm

(30 mils)

0.381 mm

(15 mils)

0.61mm

(24 mils)

0402 Land Pattern

Side Vias

0.762 mm

(30 mils)

0.381 mm

(15 mils)

0.61mm

(24 mils)

Not Recommended.

Connecting Trace is Too Long

X-Ref Target - Figure 2-2

Basic PDS Principles

Figure 2-2: Example 0402 Capacitor Land and Mounting Geometries

Noise Limits

The purpose of the PDS and the properties of its components are discussed in this section.

The important aspects of capacitor placement, capacitor mounting, PCB geometry, and

PCB stackup recommendations are also described.

In the same way that devices in a system have a requirement for the amount of current

consumed by the power system, there is also a requirement for the cleanliness of the

power. This cleanliness requirement specifies a maximum amount of noise present on the

power supply, often referred to as ripple voltage (V

all Spartan-6 FPGAs, require that V

V

value. This means that the peak-to-peak V

CC

nominal V

power supplies: V

. In this document the term VCC is used generically for the following FPGA

CC

CCINT

, V

CCO

supplies not fluctuate more than ±5% of the nominal

CC

RIPPLE

, V

CCAUX

, and V

REF

exactly the nominal value provided in the data sheet. If not, then V

). Most digital devices, including

RIPPLE

must be no more than 10% of the

. This assumes that nominal VCC is

must be adjusted

RIPPLE

to a value correspondingly less than 10%.

The power consumed by a digital device varies over time and this variance occurs on all

frequency scales, creating a need for a wide-band PDS to maintain voltage stability.

• Low-frequency variance of power consumption is usually the result of devices or

large portions of devices being enabled or disabled. This variance occurs in time

frames from milliseconds to days.

• High-frequency variance of power consumption is the result of individual switching

events inside a device. This occurs on the scale of the clock frequency and the first few

harmonics of the clock frequency up to about 1 GHz.

20 www.xilinx.com Spartan-6 FPGA PCB Design and Pin Planning

UG393 (v1.1) April 29, 2010

Page 21

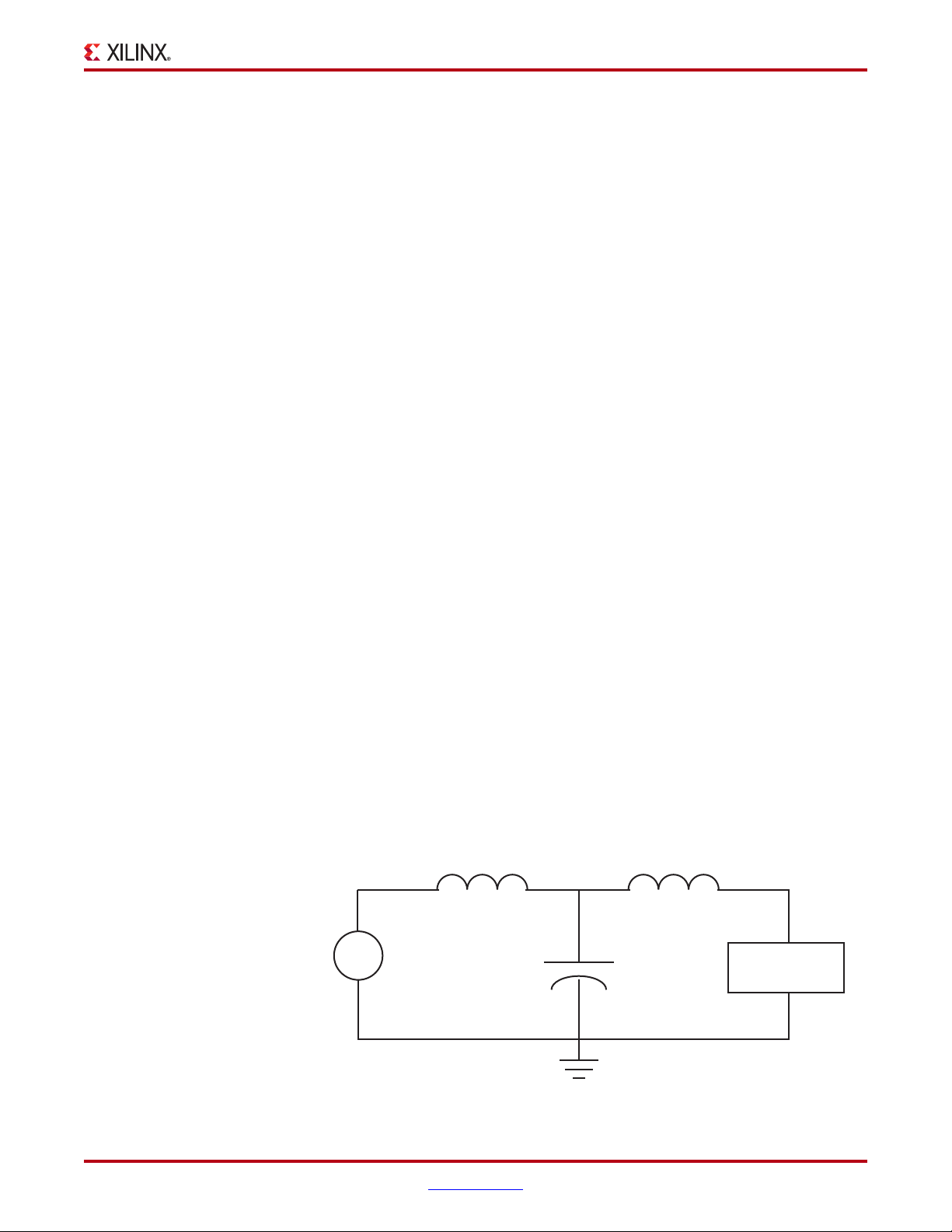

Basic PDS Principles

+

FPGA

L

REGULATOR

L

DECOUPLING

C

DECOUPLING

Voltage

Regulator

V

UG393_c2_03_091809

Because the voltage level of VCC for a device is fixed, changing power demands are

manifested as changing current demand. The PDS must accommodate these variances of

current draw with as little change as possible in the power-supply voltage.

When the current draw in a device changes, the PDS cannot respond to that change

instantaneously. As a consequence, the voltage at the device changes for a brief period

before the PDS responds. Two main causes for this PDS lag correspond to the two major

PDS components: the voltage regulator and decoupling capacitors.

The first major component of the PDS is the voltage regulator. The voltage regulator

observes its output voltage and adjusts the amount of current it is supplying to keep the

output voltage constant. Most common voltage regulators make this adjustment in

milliseconds to microseconds. Voltage regulators effectively maintain the output voltage

for events at all frequencies from DC to a few hundred kHz, depending on the regulator

(some are effective at regulating in the low MHz). For transient events that occur at

frequencies above this range, there is a time lag before the voltage regulator responds to

the new current demand level.

For example, if the device’s current demand increases in a few hundred picoseconds, the

voltage at the device sags by some amount until the voltage regulator can adjust to the

new, higher level of required current. This lag can last from microseconds to milliseconds.

A second component is needed to substitute for the regulator during this time, preventing

the voltage from sagging.

This second major PDS component is the decoupling capacitor (also known as a bypass

capacitor). The decoupling capacitor works as the device’s local energy storage. The

capacitor cannot provide DC power because it stores only a small amount of energy

(voltage regulator provides DC power). This local energy storage should respond very

quickly to changing current demands. The capacitors effectively maintain power-supply

voltage at frequencies from hundreds of kHz to hundreds of MHz (in the milliseconds to

nanoseconds range). Decoupling capacitors are not useful for events occurring above or

below this range.

For example, if current demand in the device increases in a few picoseconds, the voltage at

the device sags by some amount until the capacitors can supply extra charge to the device.

If current demand in the device maintains this new level for many milliseconds, the

voltage-regulator circuit, operating in parallel with the decoupling capacitors, replaces the

capacitors by changing its output to supply this new level of current.

Figure 2-3 shows the major PDS components: the voltage regulator, the decoupling

capacitors, and the active device being powered (FPGA).

X-Ref Target - Figure 2-3

Spartan-6 FPGA PCB Design and Pin Planning www.xilinx.com 21

UG393 (v1.1) April 29, 2010

Figure 2-3: Simplified PDS Circuit

Page 22

Chapter 2: Power Distribution System

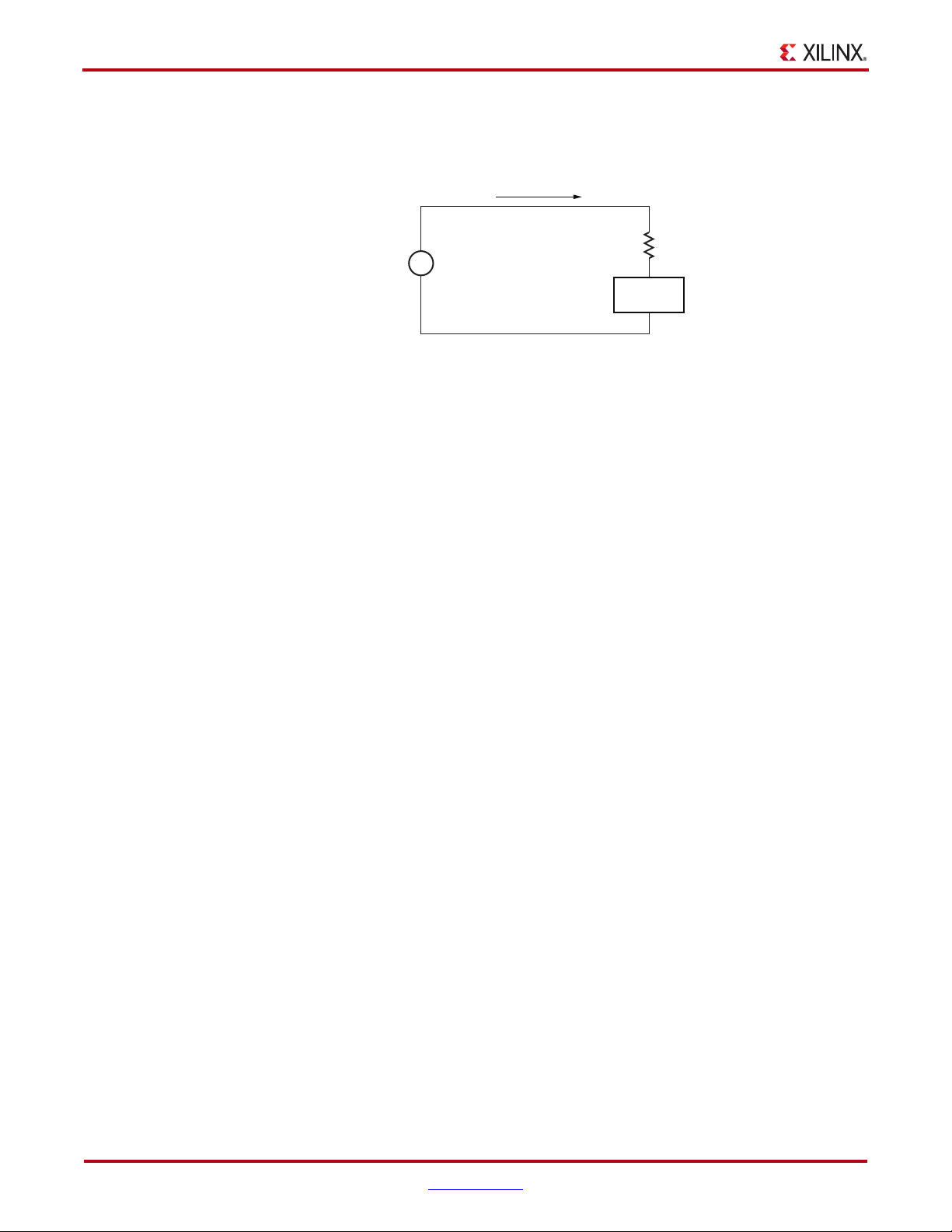

l

TRANSIENT

FPGA

ug393_c2_04_091809

Z

P

(f)

V

RIPPLE

+

−

+

V

Figure 2-4 shows a simplified PDS circuit with all reactive components represented by a

frequency-dependent resistor.

X-Ref Target - Figure 2-4

Role of Inductance

Inductance is the property of the capacitors and the PCB current paths that slows down

changes in current flow. Inductance is the reason why capacitors cannot respond

instantaneously to transient currents or to changes that occur at frequencies higher than

their effective range.

Figure 2-4: Further Simplified PDS Circuit

Inductance can be thought of as the momentum of charge. Charge moving through a

conductor represents some amount of current. If the level of current changes, the charge

moves at a different rate. Because momentum (stored magnetic-field energy) is associated

with this charge, some amount of time and energy is required to slow down or speed up

the charge flow. The greater the inductance, the greater the resistance to change, and the

longer the time required for the current level to change. A voltage develops across the

inductance as this change occurs.

The PDS, made up of a regulator and multiple stages of decoupling capacitors,

accommodates the device current demand and responds to current transients as quickly as

possible. When these current demands are not met, the voltage across the device's power

supply changes. This is observed as noise. Inductance in the current path of the capacitors

should be minimized, because it retards the ability of decoupling capacitors to quickly

respond to changing current demands.

Inductances occur between the FPGA device and capacitors and between the capacitors

and the voltage regulator (see Figure 2-3). These inductances occur as parasitics in the

capacitors and in all PCB current paths. It is important that each of these parasitics be

minimized.

Capacitor Parasitic Inductance

The capacitance value is often considered the bypass capacitors’s most important

characteristic. In power system applications, the parasitic inductance (ESL) has the same or

greater importance. Capacitor package dimensions (body size) determine the amount of

parasitic inductance. Physically small capacitors usually have lower parasitic inductance

than physically large capacitors.

22 www.xilinx.com Spartan-6 FPGA PCB Design and Pin Planning

UG393 (v1.1) April 29, 2010

Page 23

Basic PDS Principles

Requirements for choosing decoupling capacitors:

• For a specific capacitance value, choose the smallest package available.

- or -

• For a specific package size (essentially a fixed inductance value), choose the highest

capacitance value available in that package.

Surface-mount chip capacitors are the smallest capacitors available and are a good choice

for discrete decoupling capacitors:

• For values from 100 µF to very small values such as 0.01 µF, X7R or X5R type

capacitors are usually used. These capacitors have a low parasitic inductance and a

low ESR, with an acceptable temperature characteristic.

• For larger values, such as 100 µF to 1000 µF, tantalum capacitors are used. These

capacitors have a low parasitic inductance and a medium ESR, giving them a low Q

factor and consequently a very wide range of effective frequencies.

If tantalum capacitors are not available or cannot be used, low-ESR, low-inductance

electrolytic capacitors can be used, provided they have comparable ESR and ESL values.

Other new technologies with similar characteristics are also available (Os-Con, POSCAP,

and Polymer-Electrolytic SMT).

A real capacitor of any type then not only has capacitance characteristics but also

inductance and resistance characteristics. Figure 2-5 shows the parasitic model of a real

capacitor. A real capacitor should be treated as an RLC circuit (a circuit consisting of a

resistor (R), an inductor (L), and a capacitor (C), connected in series).

X-Ref Target - Figure 2-5

ESR

ESL

C

ug393_c2_05_091809

Figure 2-5: Parasitics of a Real, Non-Ideal Capacitor

Figure 2-6 shows a real capacitor’s impedance characteristic. Overlaid on this plot are

dashed-line curves corresponding to the capacitor’s capacitance and parasitic inductance

(ESL). These two curves combine to form the RLC circuit’s total impedance characteristic,

softened or sharpened by the capacitor’s ESR.

Spartan-6 FPGA PCB Design and Pin Planning www.xilinx.com 23

UG393 (v1.1) April 29, 2010

Page 24

Chapter 2: Power Distribution System

Frequency

Impedance

Capacitive

Contribution (C)

Inductive

Contribution (ESL)

To tal Impedance Characteristic

ug393_c2_06_091809

X-Ref Target - Figure 2-6

Figure 2-6: Contribution of Parasitics to Total Impedance Characteristics

As capacitive value is increased, the capacitive curve moves down and left. As parasitic

inductance is decreased, the inductive curve moves down and right. Because parasitic

inductance for capacitors in a specific package is fixed, the inductance curve for capacitors

in a specific package remains fixed.

As different capacitor values are selected in the same package, the capacitive curve moves

up and down against the fixed inductance curve, as shown in Figure 2-8.

The low-frequency capacitor impedance can be reduced by increasing the value of the

capacitor; the high-frequency impedance can be reduced by decreasing the inductance of

the capacitor. While it might be possible to specify a higher capacitance value in the fixed

package, it is not possible to lower the inductance of the capacitor (in the fixed package)

without putting more capacitors in parallel. Using multiple capacitors in parallel divides

the parasitic inductance, and at the same time, multiplies the capacitance value. This

lowers both the high and low frequency impedance at the same time.

PCB Current Path Inductance

The parasitic inductance of current paths in the PCB have three distinct sources:

•Capacitor mounting

• PCB power and ground planes

•FPGA mounting

Capacitor Mounting Inductance

Capacitor mounting refers to the capacitor's solder lands on the PCB, the trace (if any)

between the land and via, and the via.

The vias, traces, and capacitor mounting pads of a 2-terminal capacitor contribute

inductance between 300 pH to 4 nH depending on the specific geometry.

Because the current path’s inductance is proportional to the loop area the current traverses,

it is important to minimize this loop size. The loop consists of the path through one power

plane, up through one via, through the connecting trace to the land, through the capacitor,

through the other land and connecting trace, down through the other via, and into the

other plane, as shown in Figure 2-7.

24 www.xilinx.com Spartan-6 FPGA PCB Design and Pin Planning

UG393 (v1.1) April 29, 2010

Page 25

X-Ref Target - Figure 2-7

Solderable End Terminal

0402 Capacitor Body

Surface Trace

Capacitor Solder Land

Via

PCB

GND

V

CC

Power and

Ground Planes

Mounted Capacitor Current Loop

UG393_c2_07_091809

Basic PDS Principles

Figure 2-7: Example Cutaway View of PCB with Capacitor Mounting

A connecting trace length has a large impact on the mounting’s parasitic inductance and if

used, should be as short and wide as possible. When possible, a connecting trace should

not be used (Figure 2-1A) and the via should butt up against the land (Figure 2-1B).

Placing vias to the side of the capacitor lands (Figure 2-1C) or doubling the number of vias

(Figure 2-1D), further reduces the mounting’s parasitic inductance.

Some PCB manufacturing processes allow via-in-pad geometries, an option for reducing

parasitic inductance. Using multiple vias per land is important with ultra-low inductance

capacitors, such as reverse aspect ratio capacitors that place wide terminals on the sides of

the capacitor body instead of the ends.

PCB layout engineers often try to squeeze more parts into a small area by sharing vias

among multiple capacitors. This technique should not be used under any circumstances. PDS

improvement is very small when a second capacitor is connected to an existing capacitor’s

vias. For a larger improvement, reduce the total number of capacitors and maintain a oneto-one ratio of lands to vias.

The capacitor mounting (lands, traces, and vias) typically contributes about the same

amount or more inductance than the capacitor's own parasitic self-inductance.

Plane Inductance

Some inductance is associated with the PCB power and ground planes. The geometry of

these planes determines their inductance.

Current spreads out as it flows from one point to another (due to a property similar to skin

effect) in the power and ground planes. Inductance in planes can be described as spreading

inductance and is specified in units of henries per square. The square is dimensionless; the

shape of a section of a plane, not the size, determines the amount of inductance.

Spartan-6 FPGA PCB Design and Pin Planning www.xilinx.com 25

UG393 (v1.1) April 29, 2010

Page 26

Chapter 2: Power Distribution System

Spreading inductance acts like any other inductance and resists changes to the amount of

current in a power plane (the conductor). The inductance retards the capacitor’s ability to

respond to a device’s transient currents and should be reduced as much as possible.

Because the designer’s control over the X-Y shape of the plane can be limited, the only

controllable factor is the spreading inductance value. This is determined by the thickness

of the dielectric separating a power plane from its associated ground plane.

For high-frequency power distribution systems, power and ground planes work in pairs,

with their inductances coexisting dependently with each other. The spacing between the

power and ground planes determines the pair’s spreading inductance. The closer the

spacing (the thinner the dielectric), the lower the spreading inductance. Approximate

values of spreading inductance for different thicknesses of FR4 dielectric are shown in

Tab le 2 -3.

Table 2-3: Capacitance and Spreading Inductance Values for Different Thicknesses

of FR4 Power-Ground Plane Sandwiches

Dielectric Thickness Inductance Capacitance

(micron) (mil) (pH/square) (pF/in

102 4 130 225 35

51 2 65 450 70

2

) (pF/cm2)

25 1 32 900 140

Decreased spreading inductance corresponds to closer spacing of V

When possible, place the V

stackup. Facing V

use of V

– GND sandwiches was not necessary in the past for previous technologies

CC

and GND planes are sometimes referred to as sandwiches. While the

CC

planes directly adjacent to the GND planes in the PCB

CC

and GND planes.

CC

(lead frames, wire bond packages), the speeds involved and the sheer amount of power

required for fast, dense devices often demand it.

Besides offering a low-inductance current path, power-ground sandwiches also offer some

high-frequency decoupling capacitance. As the plane area increases and as the separation

between power and ground planes decreases, the value of this capacitance increases.

Capacitance per square inch is shown in Ta bl e 2-3 .

FPGA Mounting Inductance

The PCB solder lands and vias that connect the FPGA power pins (VCC and GND)

contribute an amount of parasitic inductance to the overall power circuit. For existing PCB

technology, the solder land geometry and the dogbone geometry are mostly fixed, and

parasitic inductance of these geometries does not vary. Via parasitic inductance is a

function of the via length and the proximity of the opposing current paths to one another.

The relevant via length is the portion of the via that carries transient current between the

FPGA solder land and the associated V

power plane and the PCB backside) does not affect the parasitic inductance of the via (the

shorter the via between the solder lands and the power plane, the smaller the parasitic

inductance). Parasitic via inductance in the FPGA mounting is reduced by keeping the

relevant V

and GND planes as close to the FPGA as possible (close to the top of the PCB

CC

stackup).

or GND plane. Any remaining via (between the

CC

Device pinout arrangement determines the proximity of opposing current paths to one

another. Inductance is associated with any two opposing currents (for example, current

flowing in a V

26 www.xilinx.com Spartan-6 FPGA PCB Design and Pin Planning

and GND via pair). A high degree of mutual inductive coupling between

CC

UG393 (v1.1) April 29, 2010

Page 27

Basic PDS Principles

the two opposing paths reduces the loop’s total inductance. Therefore, when given a

choice, V

The via field under an FPGA has many V

and GND vias should be as close together as possible.

CC

and GND vias, and the total inductance is a

CC

function of the proximity of one via to another:

•For core V

supplies (V

CC

CCINT

and V

), opposing current is between the VCC

CCAUX

and GND pins.

•For I/O V

current path, whether carried by a V

supplies (V

CC

), opposing current is between any I/O and its return

CCO

or GND pin.

CCO

To reduce parasitic inductance:

•V

and GND are placed in a checkerboard arrangement in the center area of the

CCINT

BGA packages.

•V

and GND pins are distributed among the I/O pins.

CCO

In BGA packages, FPGA pinout arrangement determines the PCB via arrangement. The

PCB designer cannot control the proximity of opposing current paths but has control over

the trade-offs between the capacitor’s mounting inductance and FPGA’s mounting

inductance:

• Both mounting inductances are reduced by placing power planes close to the PCB

stackup’s top half and placing the capacitors on the top surface (reducing the

capacitor’s via length).

• If power planes are placed in the PCB stackup’s bottom half, the capacitors must be

mounted on the PCB backside. In this case, FPGA mounting vias are already long, and

making the capacitor vias long (by coming down from the top surface) is a bad

practice. A better practice is to take advantage of the short distance between the

underside of the PCB and the power plane of interest, mounting capacitors on the

underside.

PCB Stackup and Layer Order

VCC and ground plane placement in the PCB stackup (the layer order) has a significant

impact on the parasitic inductances of power current paths. Layer order must be

considered early in the design process:

• High-priority supplies should be placed closer to the FPGA (in the PCB stackup’s top

half)

• Low-priority supplies should be placed farther from the FPGA (in the PCB stackup’s

bottom half)

Power supplies with high transient current should have the associated V

the top surface (FPGA side) of the PCB stackup. This decreases the vertical distance (V

and GND via length) that currents travel before reaching the associated V

planes. To reduce spreading inductance, every V

plane should have an adjacent GND

CC

plane in the PCB stackup. The skin effect causes high-frequency currents to couple tightly,

and the GND plane adjacent to a specific V

current complementary to that in the V

plane tends to carry the majority of the

CC

plane. Thus, adjacent VCC and GND planes are

CC

treated as a pair.

Not all V

and GND plane pairs reside in the PCB stackup’s top half because

CC

manufacturing constraints typically require a symmetrical PCB stackup around the center

(with respect to dielectric thicknesses and etched copper areas). The PCB designer chooses

the priority of the V

and GND plane pairs: high priority pairs carry high transient

CC

planes close to

CC

and GND

CC

CC

Spartan-6 FPGA PCB Design and Pin Planning www.xilinx.com 27

UG393 (v1.1) April 29, 2010

Page 28

Chapter 2: Power Distribution System

F

1

2π LC

-------------------=

currents and are placed high in the stackup, while low priority pairs carry lower transient

currents (or can tolerate more noise) and are placed in the lower part of the stackup.

Capacitor Effective Frequency

Every capacitor has a narrow frequency band where it is most effective as a decoupling

capacitor. This band is centered at the capacitor’s self-resonant frequency F

effective frequency bands of some capacitors are wider than others. A capacitor’s ESR

determines the capacitor’s quality (Q) factor, and the Q factor can determine the width of

the effective frequency band:

• Tantalum capacitors generally have a very wide effective band.

• Ceramic chip capacitors with a lower ESR, generally have a very narrow effective

frequency band.

An ideal capacitor only has a capacitive characteristic, whereas real non-ideal capacitors

also have a parasitic inductance (ESL) and a parasitic resistance (ESR). These parasitics

work in series to form an RLC circuit (Figure 2-5). The RLC circuit’s resonant frequency is

the capacitor’s self-resonant frequency.

To determine the RLC circuit’s resonant frequency, use Equation 2-1:

. The

RSELF

Equation 2-1

Another method of determining the self-resonant frequency is to find the minimum point

in the impedance curve of the equivalent RLC circuit. The impedance curve can be

computed or generated in SPICE using a frequency sweep. See the Simulation Methods

section for other ways to compute an impedance curve.

It is important to distinguish between the capacitor's self-resonant frequency and the

mounted capacitor’s effective resonant frequency when the capacitor is part of the system,

F

. This corresponds to the resonant frequency of the capacitor with its parasitic

RIS

inductance, plus the inductance of the vias, planes, and connecting traces between the

capacitor and the FPGA.

The capacitor’s self-resonant frequency, F

higher than its effective mounted resonant frequency in the system, F

, (capacitor data sheet value) is much

RSELF

RIS

. Because the

mounted capacitor's performance is most important, the mounted resonant frequency is

used when evaluating a capacitor as part of the greater PDS.

Mounted parasitic inductance is a combination of the capacitor's own parasitic inductance

and the inductance of: PCB lands, connecting traces, vias, and power planes. Vias traverse

a full PCB stackup to the device when capacitors are mounted on the PCB backside. For a

board with a finished thickness of 1.524 mm (60 mils), these vias contribute approximately

300 pH to 1,500 pH, (the capacitor’s mounting parasitic inductance, L

MOUNT

) depending

on the spacing between vias. Wider-spaced vias and vias in thicker boards have higher

inductance.

To determine the capacitor’s total parasitic inductance in the system, L

parasitic inductance, L

, is added to the mounting’s parasitic inductance, L

SELF

L

IS

= L

SELF

+ L

MOUNT

, the capacitor's

IS

MOUNT

Equation 2-2

:

For example, using X7R Ceramic Chip capacitor in 0402 body size:

C=0.01μF (selected by user)

L

= 0.9 nH (capacitor data sheet parameter)

SELF

28 www.xilinx.com Spartan-6 FPGA PCB Design and Pin Planning

UG393 (v1.1) April 29, 2010

Page 29

Basic PDS Principles

F

RIS

1

2π L

IS

C

-------------------------=

F

RIS

1

2π 1.7

9–

×10 H()0.016–×10 F()⋅

------------------------------------------------------------------------------------

38

6

×10 Hz==

F

L

To determine the effective in-system parasitic inductance (L

= 53 MHz (capacitor data sheet parameter)

RSELF

MOUNT

= 0.8 nH (based on PCB mounting geometry)

L

IS=LSELF+LMOUNT

L

= 1.7 nH Equation 2-3

IS

), add the via parasitics:

IS

=0.9nH+0.8nH

The values from the example are used to determine the mounted capacitor resonant

frequency (F

). Using Equation 2-1:

RIS

Equation 2-4

Equation 2-5

F

RSELF

is 53 MHz, but F

is lower at 38 MHz. The addition of mounting inductances

RIS

shifts the effective-frequency band down.

A decoupling capacitor is most effective at the narrow-frequency band around its resonant

frequency, and thus, the resonant frequency must be reviewed when choosing a capacitor

collection to build up a decoupling network. This being said, capacitors can be effective at

frequencies considerably higher and lower than their resonant frequency. Recall that

capacitors of differing values in the same package share the same inductance curve. As

shown in Figure 2-8, for any given frequency along the inductive portion of the curve, the

capacitors are equally effective.

X-Ref Target - Figure 2-8

Inductance (Z)

Figure 2-8: Effective Frequency Example

0805

4.7 μF

0805

0.47 μF

Frequency

Z Value at F2 is Equal

Inductive

Portion