WIKA S-11 Operating Manual

|

Operating instructions |

|

|

Betriebsanleitung |

|

|

Mode d'emploi |

|

|

Manual de instrucciones |

|

|

|

|

Pressure transmitter, model S-10 |

|

EN |

|

|

|

Druckmessumformer, Typ S-10 |

|

DE |

|

|

|

Transmetteur de pression, type S-10 |

|

FR |

|

|

|

Transmisor de presión, modelo S-10 |

|

ES |

Pressure transmitter, model S-10

EN |

Operating instructions model S-10 |

Page |

3 |

- 26 |

|

|

|

|

|

DE |

Betriebsanleitung Typ S-10 |

Seite |

27 |

- 50 |

|

|

|

|

|

FR |

Mode d‘emploi type S-10 |

Page |

51 |

- 74 |

|

|

|

|

|

ES |

Manual de instrucciones modelo S-10 |

Página |

75 |

- 99 |

© 2002 WIKA Alexander Wiegand SE & Co. KG All rights reserved. / Alle Rechte vorbehalten.

WIKA® is a registered trademark in various countries. WIKA® ist eine geschützte Marke in verschiedenen Ländern.

Prior to starting any work, read the operating instructions!

Keep for later use!

Vor Beginn aller Arbeiten Betriebsanleitung lesen!

Zum späteren Gebrauch aufbewahren!

Lire le mode d‘emploi avant de commencer toute opération !

A conserver pour une utilisation ultérieure !

¡Leer el manual de instrucciones antes de comenzar cualquier trabajo! ¡Guardar el manual para una eventual consulta!

2 |

WIKA operating instructions pressure transmitter, model S-10 |

1604457.16 09/2017 EN/DE/FR/ES

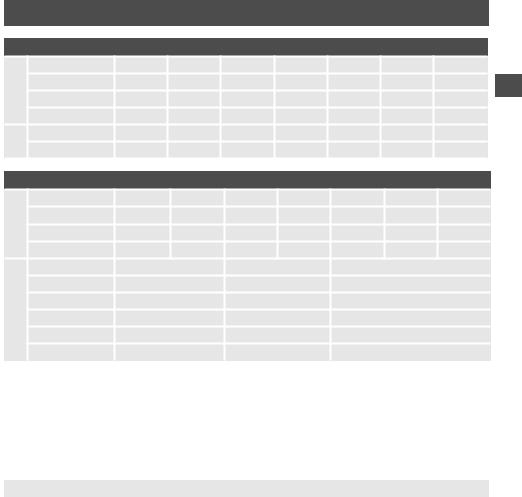

Contents

Contents

|

|

|

|

EN |

|

|

|

|

|

||

1. |

General information |

4 |

|

||

|

|||||

|

|

|

|

|

|

2. |

Design and function |

5 |

|

|

|

|

|

|

|

|

|

3. |

Safety |

6 |

|

|

|

|

|

|

|

|

|

4. |

Transport, packaging and storage |

8 |

|

|

|

|

|

|

|

|

|

5. |

Commissioning, operation |

9 |

|

|

|

|

|

|

|

|

|

6. |

Adjustment of zero point and span |

12 |

|

|

|

|

|

|

|

|

|

7. |

Faults |

13 |

|

|

|

|

|

|

|

|

|

8. |

Maintenance and cleaning |

15 |

|

|

|

|

|

|

|

|

|

9. |

Dismounting, return and disposal |

16 |

|

|

|

|

|

|

|

|

|

10. |

Specifications |

18 |

|

|

|

|

|

|

|

|

Declarations of conformity can be found online at www.wika.com

1604457.16 09/2017 EN/DE/FR/ES

WIKA operating instructions pressure transmitter, model S-10 |

3 |

|

|

1. General information |

|||

|

|

|

|

||

|

|

1. General information |

|||

|

■■ The instrument described in the operating instructions has been designed and manufactured using state-of-the- |

||||

EN |

|||||

|

art technology. All components are subject to stringent quality and environmental criteria during production. Our |

||||

|

|

management systems are certified to ISO 9001 and ISO 14001. |

|||

|

■■ These operating instructions contain important information on handling the instrument. Working safely requires that |

||||

|

|

all safety instructions and work instructions are observed. |

|||

|

■■ Observe the relevant local accident prevention regulations and general safety regulations for the instrument's range |

||||

|

|

of use. |

|

|

|

|

■■ The operating instructions are part of the product and must be kept in the immediate vicinity of the instrument and |

||||

|

|

readily accessible to skilled personnel at any time. Pass the operating instructions onto the next operator or owner of |

|||

|

|

the instrument. |

|

|

|

|

■■ Skilled personnel must have carefully read and understood the operating instructions prior to beginning any work. |

||||

|

■■ The general terms and conditions contained in the sales documentation shall apply. |

||||

|

■■ Subject to technical modifications. |

||||

|

■■ Further information: |

|

|

||

|

|

- Internet address: |

www.wika.de / www.wika.com |

||

|

|

- Relevant data sheet: |

PE 81.01 |

||

|

|

- Application consultant: |

Tel.:+49 9372 132-8976 |

||

Fax:+49 9372 132-8008976 support-tronic@wika.de

1604457.16 09/2017 EN/DE/FR/ES

4 |

WIKA operating instructions pressure transmitter, model S-10 |

2. Design and function

2. Design and function

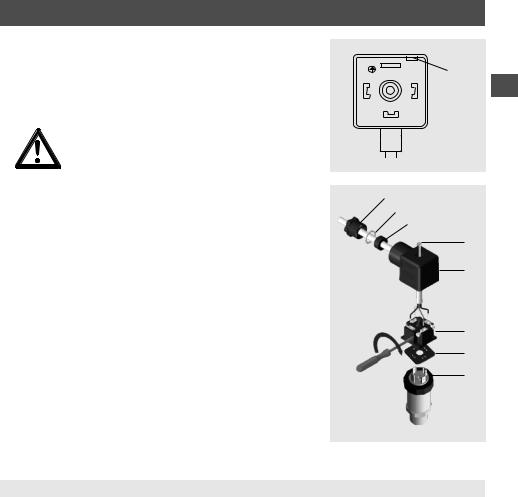

2.1 Overview

Electrical connection (depending on version) |

EN |

Case; product label |

|

Process connection, spanner flats |

|

Process connection, thread |

|

2.2 Scope of delivery

■■ Pressure transmitter ■■ Operating instructions

Cross-check scope of delivery with delivery note.

1604457.16 09/2017 EN/DE/FR/ES

WIKA operating instructions pressure transmitter, model S-10 |

5 |

3. Safety

3.Safety

3.1Explanation of symbols

EN |

WARNING! |

|

... indicates a potentially dangerous situation that can result in serious injury or death, if not avoided. |

CAUTION!

... indicates a potentially dangerous situation that can result in light injuries or damage to equipment or the environment, if not avoided.

Information

...points out useful tips, recommendations and information for efficient and trouble-free operation.

3.2 Intended use

The pressure transmitter is used for measuring pressure. The measured pressure is output as an electrical signal.

Only use the pressure transmitter in applications that lie within its technical performance limits (e.g. max. ambient temperature, material compatibility, ...). The pressure transmitter is suitable for applications with pollution degree 3 and an ambient temperature of -20 ... +80 °C.

→ For performance limits, see chapter 9 “Specifications”.

The instrument has been designed and built solely for the intended use described here, and may only be used accordingly.

The manufacturer shall not be liable for claims of any type based on operation contrary to the intended use.

1604457.16 09/2017 EN/DE/FR/ES

6 |

WIKA operating instructions pressure transmitter, model S-10 |

3.Safety

3.3Personnel qualification

Skilled personnel

Skilled personnel, authorised by the operator, are understood to be personnel who, based on their technical training, EN knowledge of measurement and control technology and on their experience and knowledge of country-specific

regulations, current standards and directives, are capable of carrying out the work described and independently recognising potential hazards.

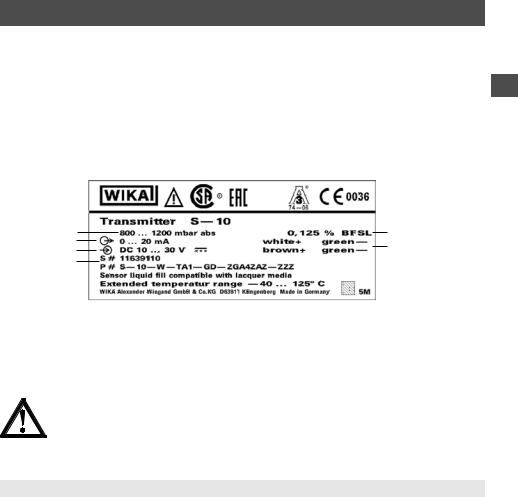

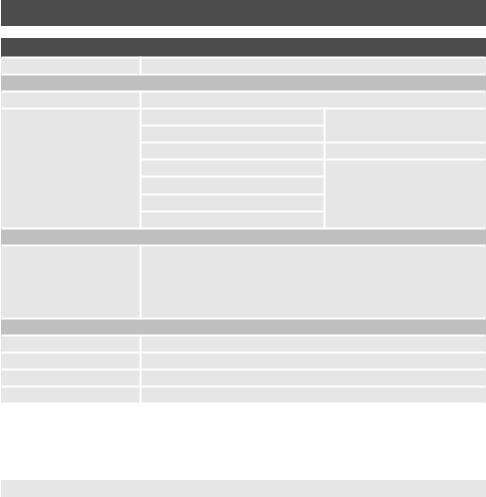

3.4 Labelling, safety marks

Product label

|

|

|

|

|

|

|

|

1604457.16 09/2017 EN/DE/FR/ES

S# Serial no., P# Model code Power supply

Output signal Measuring range

Symbols

Accuracy

Pin assignment

Before mounting and commissioning the instrument, ensure you read the operating instructions!

WIKA operating instructions pressure transmitter, model S-10 |

7 |

|

|

4. Transport, packaging and storage |

|

|

|

|

|

|

|

4. Transport, packaging and storage |

|

|

4.1 Transport |

||

EN |

Check the pressure transmitter for any damage that may have been caused during transportation. |

||

Obvious damage must be reported immediately. |

|||

|

4.2 Packaging and storage |

||

|

Do not remove packaging until just before mounting. |

||

|

Keep the packaging as it will provide optimum protection during transport (e.g. change in installation site, sending for |

||

|

repair). |

||

|

Permissible conditions at the place of storage: |

||

|

■■ Storage temperature:-40 ...+100 °C |

||

|

■■ Humidity:45 ...75 % relative humidity (no condensation) |

||

1604457.16 09/2017 EN/DE/FR/ES

8 |

WIKA operating instructions pressure transmitter, model S-10 |

1604457.16 09/2017 EN/DE/FR/ES

5. Commissioning, operation

5. Commissioning, operation

5.1 Mounting the instrument |

|

Prior to commissioning, the pressure transmitter must be subjected to a visual inspection. |

EN |

■■ Leaking fluid is indicative of damage. |

|

■■ Only use the pressure transmitter if it is in perfect condition with respect to safety. |

|

Requirements for mounting point |

|

The mounting point must meet the following conditions: |

|

■■ Ambience corresponds to a max. pollution degree of 3. |

|

■■ Humidity ≤ 80 % r.h.(non-condensing). |

|

■■ Protected from weather influences. |

|

■■ Sealing faces are clean and undamaged. |

|

■■ Sufficient space for a safe electrical installation. |

|

■■ For information on tapped holes and welding sockets, seeTechnical information IN 00.14 at www.wika.com. |

|

■■ Permissible ambient and medium temperatures remain within the performance limits. Consider possible restrictions |

|

on the ambient temperature range caused by mating connector used. |

|

→ For performance limits, see chapter 9 “Specifications” |

|

Sealing variants

Parallel threads

Seal the sealing face with a flat gasket, lens-type sealing ring or WIKA profile sealing.

per EN 837 |

per DIN 3852-E |

Tapered threads

Wrap threads with sealing material (e.g. PTFE tape).

NPT, R and PT

WIKA operating instructions pressure transmitter, model S-10 |

9 |

|

|

5. Commissioning, operation |

|

Mounting the instrument |

|

|

|

The max. torque depends on the mounting point (e.g. material and shape). If you have any questions, |

EN |

|

please contact our application consultant. |

|

→ For contact details, see chapter 1 “General information”or the back page of the operating instructions. |

|

1. Seal the sealing face (→ see “Sealing variants”).

2. At the mounting point, screw the pressure transmitter in hand-tight. 3. Tighten with a torque spanner using the spanner flats.

5.2 Connecting the instrument to the electric system

Requirements for voltage supply

→ For power supply, see product label

The power supply for the pressure transmitter must be made via an energy-limited electrical circuit in accordance with section 9.4 of UL/EN/IEC 61010-1, or an LPS per UL/EN/IEC 60950-1 / CSA C22.2 no.60950-1, or class 2 in accordance with UL1310/UL1585 (NEC or CEC).The voltage supply must be suitable for operation above 2,000 m should the pressure transmitter be used at this altitude.

Requirements for electrical connection

■■ Cable diameter matches the cable bushing of the mating connector. ■■ Cable gland and seals of the mating connector are correctly seated. ■■ With cable outlets, no humidity can ingress at the cable end.

Requirement for shielding and grounding

The pressure transmitter must be shielded and grounded in accordance with the grounding concept of the plant.

Connecting the instrument

1.Assemble the mating connector or cable outlet.

→For pin assignments, see product label

2. Establish the plug connection.

1604457.16 09/2017 EN/DE/FR/ES

10 |

WIKA operating instructions pressure transmitter, model S-10 |

1604457.16 09/2017 EN/DE/FR/ES

5.Commissioning, operation

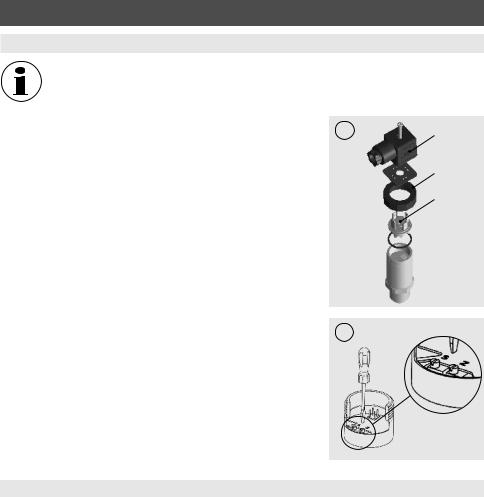

5.3Fitting a DIN 175301-803 angular connector

1.Loosen the screw (1).

2.Loosen the cable gland (2).

3.Pull the angular connector (5) + (6) away from the instrument.

4.CAUTION! Improper mounting

The seal of the angle housing will be damaged.

Do not try to push the terminal block (6) out using the screw hole (1) or the cable gland (2).

Via the mounting hole (D), lever the terminal block (6) out of the angle housing (5).

5.Slide the cable through the cable gland (2), the ring (3), the sealing (4) and the angle housing (5).

6.Connect the cable ends to the terminal blocks (6) in accordance with the connection diagram.

7.Press the angle housing (5) onto the terminal block (6).

8.Make sure that the seals are not damaged and that the cable gland and seals are correctly seated in order to ensure ingress protection.

9.Tighten the cable gland (2) around the cable.

10.Place the flat gasket (7) over the instrument's connection pins.

11.Push the angular connector (5) + (6) onto the instrument.

12.Tighten the screw (1).

(D)

EN

(2)

(3)

(4)

(1)

(5)

(6)

(7)

(8)

WIKA operating instructions pressure transmitter, model S-10 |

11 |

6.Adjustment of zero point and span

6.Adjustment of zero point and span

|

Only adjust the span-setting potentiometer if calibration equipment is available which has at least three |

|

EN |

||

times the accuracy of the pressure transmitter. |

7.1 Preparation (figure A)

To gain access to the potentiometers, open the instrument as follows: ■■ Disconnect the electrical connection from the instrument.

■■ Remove the clamping nut .

■■ Carefully pull the instrument connector from the instrument.

■■ Connect the instrument connector to the power supply and a display unit (e.g. ammeter, voltmeter) according to the connection diagram.

7.2Adjustment of zero point (figure B)

■■ Go to the start of the measuring range.

■■ Using potentiometer "Z", adjust the minimum output signal (e.g.4 mA)

7.3Setting the span (figure B)

■■ Go to the end of the measuring range.

■■ Using potentiometer "S", adjust the maximum output signal (e.g.20 mA)

■■ Check the zero point and if there is any deviation, re-adjust it.

■■ Repeat the procedure until the zero point and the span are set correctly.

A

B

1604457.16 09/2017 EN/DE/FR/ES

12 |

WIKA operating instructions pressure transmitter, model S-10 |

1604457.16 09/2017 EN/DE/FR/ES

7. Faults

7. Faults

CAUTION! |

EN |

Physical injuries and damage to property and the environment |

|

If faults cannot be eliminated by means of the listed measures, the pressure transmitter must be taken |

|

out of operation immediately. |

|

Ensure that pressure or signal is no longer present and protect against accidental commissioning. |

|

Contact the manufacturer. |

|

If a return is needed, please follow the instructions given in chapter 8.2 “Return”. |

|

WARNING!

Physical injuries and damage to property and the environment caused by hazardous media

Upon contact with hazardous media (e.g.oxygen, acetylene, flammable or toxic substances), harmful media (e.g. corrosive, toxic, carcinogenic, radioactive), and also with refrigeration plants and compressors, there is a danger of physical injuries and damage to property and the environment.

Should a failure occur, aggressive media with extremely high temperature and under high pressure or vacuum may be present at the instrument.

For these media, in addition to all standard regulations, the appropriate existing codes or regulations must also be followed.

Wear the requisite protective equipment (see chapter 3.4 “Personal protective equipment”).

For contact details, see chapter 1 “General information”or the back page of the operating instructions.

In the event of any faults, first check whether the pressure transmitter is mounted correctly, mechanically and electrically. If complaint is unjustified, the handling costs will be charged.

WIKA operating instructions pressure transmitter, model S-10 |

13 |

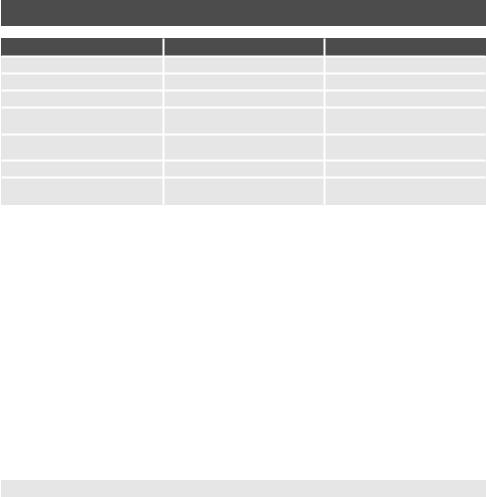

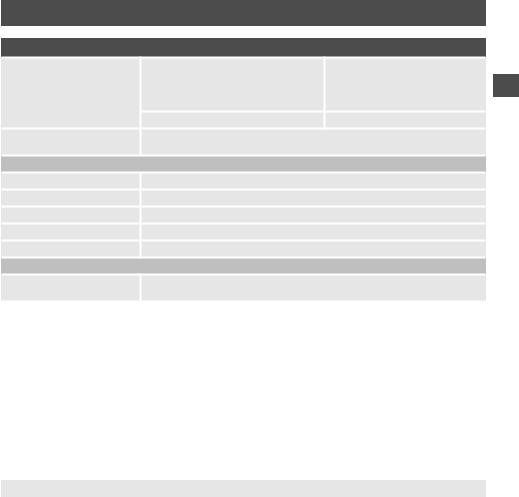

7. Faults

|

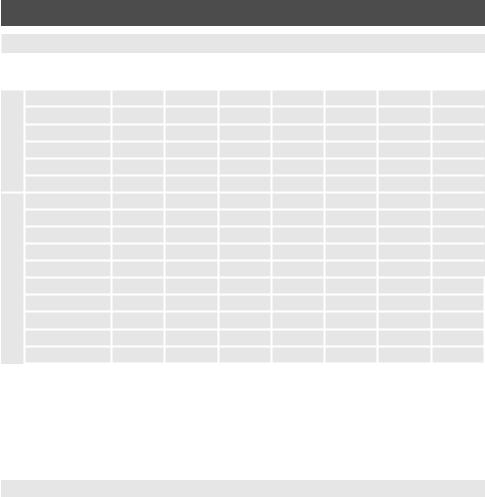

Faults |

Causes |

Measures |

|

No output signal |

Cable break |

Check the continuity |

EN |

Deviating zero point signal |

Overload safety exceeded |

Observe the permissible overload safety |

|

Deviating zero point signal |

Too high/low working temperature |

Observe the permissible temperatures |

|

Constant output signal upon change in |

Mechanical overload caused by overpres- |

Replace instrument; if it fails repeatedly, |

|

pressure |

sure |

contact the manufacturer |

|

Signal span varies |

EMC interference sources in the environ- |

Shield instrument; cable shield; remove |

|

|

ment; for example, frequency converter |

source of interference |

|

Signal span varies/inaccurate |

Too high/low working temperature |

Observe the permissible temperatures |

|

Signal span drops/too small |

Mechanical overload caused by overpres- |

Replace instrument; if it fails repeatedly, |

|

|

sure |

contact the manufacturer |

If complaint is unjustified, we will charge you the complaint processing fees.

1604457.16 09/2017 EN/DE/FR/ES

14 |

WIKA operating instructions pressure transmitter, model S-10 |

8. Maintenance and cleaning

8. Maintenance and cleaning

8.1 |

Maintenance |

|

This pressure transmitter is maintenance-free. |

EN |

|

Repairs must only be carried out by the manufacturer. |

||

8.2 |

Cleaning |

|

CAUTION!

Unsuitable cleaning agents

Cleaning with unsuitable cleaning agents may damage the instrument and the product label.Do not use any aggressive cleaning agents.

Do not use any hard or pointed objects.Do not use any abrasive cloths or sponges.

Suitable cleaning agents

■■ Water

■■ Conventional dishwashing detergent

Cleaning the instrument

1.Depressurise and de-energise the pressure transmitter.

2.Wipe the instrument surface using a soft, damp cloth.

1604457.16 09/2017 EN/DE/FR/ES

WIKA operating instructions pressure transmitter, model S-10 |

15 |

9. Dismounting, return and disposal

9.Dismounting, return and disposal

9.1Dismounting

EN |

WARNING! |

|

Physical injuries and damage to property and the environment caused by hazardous media |

|

Upon contact with hazardous media (e.g.oxygen, acetylene, flammable or toxic substances), harmful |

|

media (e.g. corrosive, toxic, carcinogenic, radioactive), and also with refrigeration plants and compres- |

|

sors, there is a danger of physical injuries and damage to property and the environment. |

|

Should a failure occur, aggressive media with extremely high temperature and under high pressure |

|

or vacuum may be present at the instrument. |

|

Wear the requisite protective equipment. |

Dismounting the instrument

1. Depressurise and de-energise the pressure transmitter.

2. Disconnect the electrical connection.

3. Unscrew the pressure transmitter with a spanner using the spanner flats.

9.2 Return

Strictly observe the following when shipping the instrument:

All instruments delivered to WIKA must be free from any kind of hazardous substances (acids, bases, solutions, etc.) and must therefore be cleaned before being returned.

WARNING!

Physical injuries and damage to property and the environment through residual media

Residual media in the dismounted instrument can result in a risk to persons, the environment and equipment.

With hazardous substances, include the material safety data sheet for the corresponding medium.

Clean the instrument, see chapter 7.2 “Cleaning”.

1604457.16 09/2017 EN/DE/FR/ES

16 |

WIKA operating instructions pressure transmitter, model S-10 |

9. Dismounting, return and disposal

When returning the instrument, use the original packaging or a suitable transport packaging.

Information on returns can be found under the heading “Service”on our local website. |

|

|

EN |

||

|

||

9.3 Disposal |

|

|

Incorrect disposal can put the environment at risk. |

|

|

Dispose of instrument components and packaging materials in an environmentally compatible way and in accordance |

|

|

with the country-specific waste disposal regulations. |

|

1604457.16 09/2017 EN/DE/FR/ES

WIKA operating instructions pressure transmitter, model S-10 |

17 |

10.Specifications

10. Specifications

EN |

|

Measuring ranges and overload safety (gauge pressure) |

|

|

|

|

|

|

|

|

|||||||

|

bar |

Measuring range |

0 |

0.01 |

0 |

0.16 |

0 |

0.25 |

0 |

0.4 |

0 |

0.6 |

0 |

1 |

0 |

1.6 |

|

|

|

||||||||||||||||

|

|

|

Overload safety |

1 |

|

1.5 |

|

2 |

|

2 |

|

4 |

|

5 |

|

10 |

|

|

|

|

Measuring range |

0 ... |

2.5 |

0 ... |

4 |

0 ... |

6 |

0 ... |

10 |

0 ... |

16 |

0 ... |

25 |

0 ... |

40 |

|

|

|

Overload safety |

10 |

|

17 |

|

35 |

|

35 |

|

80 |

|

50 |

|

80 |

|

|

|

|

Measuring range |

0 ... |

60 |

0 ... |

100 |

0 ... |

160 |

0 ... |

250 |

0 ... |

400 |

0 ... |

600 |

0 ... |

1,000 |

|

|

|

Overload safety |

120 |

|

200 |

|

320 |

|

500 |

|

800 |

|

1,200 |

1,500 |

||

|

|

psi |

Measuring range |

0 ... |

5 |

0 ... |

10 |

0 ... |

15 |

0 ... |

20 |

0 ... |

25 |

0 ... |

30 |

0 ... |

50 |

|

|

|

Overload safety |

29 |

|

29 |

|

72.5 |

145 |

|

145 |

|

145 |

|

240 |

|

|

|

|

|

Measuring range |

0 ... |

60 |

0 ... |

100 |

0 ... |

150 |

0 ... |

160 |

0 ... |

170 |

0 ... |

200 |

0 ... |

250 |

|

|

|

Overload safety |

240 |

|

500 |

|

500 |

|

1,160 |

1,160 |

1,160 |

1,160 |

||||

|

|

|

Measuring range |

0 ... |

300 |

0 ... |

400 |

0 ... |

500 |

0 ... |

600 |

0 ... |

750 |

0 ... |

800 |

0 ... |

1,000 |

|

|

|

Overload safety |

1,160 |

1,160 |

1,160 |

1,160 |

1,740 |

1,740 |

1,740 |

|||||||

|

|

|

Measuring range |

0 ... |

1,500 |

0 ... |

1,600 |

0 ... |

2,000 |

0 ... |

3,000 |

0 ... |

4,000 |

0 ... |

5,000 |

0 ... |

6,000 |

|

|

|

Overload safety |

2,900 |

4,600 |

4,600 |

7,200 |

7,200 |

7,200 |

11,600 |

|||||||

|

|

|

Measuring range |

0 ... |

7,500 |

0 ... |

8,000 |

0 ... |

10,000 |

0 ... |

15,000 |

|

|

|

|

|

|

|

|

|

Overload safety |

17,400 |

17,400 |

17,400 |

21,700 |

|

|

|

|

|

|

||||

1604457.16 09/2017 EN/DE/FR/ES

18 |

WIKA operating instructions pressure transmitter, model S-10 |

10.Specifications

Measuring ranges and overload safety (absolute pressure)

bar |

Measuring range |

0 ... |

0.25 |

0 ... |

0.4 |

0 ... |

0.6 |

0 ... |

1 |

0 ... |

1.6 |

0 ... 2.5 |

0 ... 4 |

|

Overload safety |

2 |

|

2 |

|

4 |

|

5 |

|

10 |

|

10 |

17 |

|

Measuring range |

0 ... |

6 |

0 ... |

10 |

0 ... |

16 |

0 ... |

25 |

0.8 |

...1.2 |

|

|

|

Overload safety |

35 |

|

35 |

|

80 |

|

80 |

|

5 |

|

|

|

psi |

Measuring range |

0 ... |

15 |

0 ... |

25 |

0 ... |

50 |

0 ... |

100 |

0 ... |

250 |

|

|

|

Overload safety |

72.5 |

145 |

|

240 |

|

500 |

|

1,160 |

|

|

||

EN

Measuring ranges and overload safety (vacuum and +/- measuring range)

bar |

Measuring range |

-0.6 |

...0 |

-0.4 |

... 0 |

-0.25 ... 0 |

-0.16 ...0 |

-0.1 |

...0 |

-1 ... |

0 |

-1 ...+0.6 |

|

Overload safety |

4 |

|

2 |

|

2 |

1.5 |

1 |

|

5 |

|

10 |

|

Measuring range |

-1 ... |

+1.5 |

-1 ... |

+3 |

-1 ...+5 |

-1 ...+9 |

-1 ... |

+15 |

-1 ... |

+24 |

|

|

Overload safety |

10 |

|

17 |

|

35 |

35 |

80 |

|

50 |

|

|

psi |

Measuring range |

-15 inHg ... |

0 |

|

-30 inHg ... |

0 |

-30 inHg ... |

+15 |

|

|

||

|

Overload safety |

72.5 |

|

|

|

72.5 |

|

145 |

|

|

|

|

|

Measuring range |

-30 inHg ... |

+30 |

|

-30 inHg ... |

+60 |

-30 inHg ... |

+100 |

|

|

||

|

Overload safety |

240 |

|

|

|

240 |

|

500 |

|

|

|

|

|

Measuring range |

-30 inHg ... |

+160 |

|

-30 inHg ... |

+200 |

-30 inHg ... |

+300 |

|

|

||

|

Overload safety |

1,160 |

|

|

1,160 |

|

1,160 |

|

|

|

||

1604457.16 09/2017 EN/DE/FR/ES

WIKA operating instructions pressure transmitter, model S-10 |

19 |

10.Specifications

Specifications

|

Vacuum tightness |

Yes |

|

EN |

Output signal |

|

|

|

Output signal |

see product label |

|

|

Load |

4 ... 20 mA (2-wire) |

≤ (power supply - 10V) / 0.02 A |

|

|

20 ... 4 mA (2-wire) |

|

|

|

0 ... 20 mA (3-wire) |

≤ (power supply - 3V) / 0.02 A |

|

|

DC 0 ...10V (3-wire) |

> max.output signal / 1 mA |

|

|

DC 0 ... 5 V (3-wire) |

|

|

|

DC 1 ...5V (3-wire) |

|

|

|

DC 0.5 ... 4.5 V ratiometric (3-wire) |

|

|

Voltage supply |

|

|

|

Power supply |

see product label |

|

|

|

The power supply for the pressure transmitter must be made via an energy-limited electri- |

|

|

|

cal circuit in accordance with section 9.3 of UL/EN/IEC 61010-1, or an LPS per UL/EN/IEC |

|

|

|

60950-1, or class 2 in accordance with UL1310/UL1585 (NEC or CEC).The voltage supply |

|

|

|

must be suitable for operation above 2,000 m should the pressure transmitter be used at this |

|

|

|

altitude. |

|

|

Accuracy specifications |

|

|

|

Non-linearity (per IEC 61298-2) |

≤ ±0.2 % of span BFSL |

|

|

Non-repeatability |

≤ ±0.1 % of span |

|

|

Accuracy at reference conditions |

see product label |

|

|

Adjustability of zero point and span |

±5 % |

|

1604457.16 09/2017 EN/DE/FR/ES

20 |

WIKA operating instructions pressure transmitter, model S-10 |

10.Specifications

Specifications

Temperature error at 0 ... 80 °C |

Mean temperature coefficient of zero point |

Measuring ranges ≤ 0.25 bar: |

|

|

≤ 0.4 % of span/10 K |

|

|

Measuring ranges > 0.25 bar |

|

|

≤ 0.2 % of span/10 K |

|

Mean temperature coefficient of span: |

≤ 0.2 % of span/10 K |

Long-term stability at reference |

≤ ±0.2 % of span/year |

|

conditions |

|

|

Reference conditions |

|

|

Ambient temperature |

15 ...25 °C |

|

Atmospheric pressure |

860 ...1,060 mbar |

|

Humidity |

45 ...75 % r.h. |

|

Power supply |

DC 24 V |

|

Mounting position |

Calibrated in vertical mounting position with process connection facing downwards. |

|

EN

Time response

Settling time |

≤ 1 ms |

|

≤ 2 ms for output signal DC 0.5…4.5V ratiometric and measuring ranges < 400 mbar, 10 psi |

1604457.16 09/2017 EN/DE/FR/ES

WIKA operating instructions pressure transmitter, model S-10 |

21 |

10.Specifications

Specifications

|

|

Operating conditions |

|

|

EN |

|

Ingress protection |

The stated ingress protection only applies when plugged in using mating connectors that have |

|

|

|

the appropriate ingress protection. |

|

|

|

|

|

Angular connector DIN 175301-803 A |

IP65 |

|

|

|

Angular connector DIN 175301-803 with ½ NPT |

IP65 |

|

|

|

Circular connector M12 x 1 (4-pin) |

IP67 |

|

|

|

Bayonet connector (6-pin) |

IP67 |

|

|

|

½ NPT conduit male, with cable outlet |

IP67 |

|

|

|

Cable outlet (standard) |

IP67 |

|

|

|

Cable outlet (not adjustable) |

IP68 |

|

|

|

Cable outlet (adjustable) |

IP68 |

|

|

Shock resistance |

1,000 g (IEC 60068-2-27, mechanical) |

|

|

|

Vibration resistance |

20 g (per IEC 60068-2-6) |

|

|

|

Permissible temperature ranges |

Medium:-30 ...+100 °C (option:-40 ...+125 °C) |

|

|

|

|

Ambient: -20 ... +80 °C |

|

|

|

|

Storage:-40 ...+100 °C |

|

|

|

Pollution degree |

max. 3 |

|

|

|

Humidity |

≤ 80 % r.h.(non-condensing) |

|

1604457.16 09/2017 EN/DE/FR/ES

22 |

WIKA operating instructions pressure transmitter, model S-10 |

10.Specifications

1604457.16 09/2017 EN/DE/FR/ES

Specifications

Electrical connection

Short-circuit resistance |

S+ vs.U- |

|

EN |

|

|

||

Reverse polarity protection |

U+ vs.U- |

|

|

|

|

||

Insulation voltage |

DC 500 V |

|

|

Materials |

|

|

|

Wetted parts |

Stainless steel |

|

|

Non-wetted parts |

Case |

Stainless steel |

|

|

Internal pressure transmission medium |

Synthetic oil |

|

|

|

Instruments with a measuring range of > |

|

|

|

25 bar relative do not contain any pressure |

|

|

|

transmission medium (dry measuring cell). |

|

|

Clamping nut |

PA |

|

|

Angular connector |

PA |

|

|

O-rings at the clamping nut |

NBR |

|

|

Flat gasket |

VMQ |

|

CE conformity |

|

|

|

Pressure equipment directive

RoHS directive

EMC directive, EN 61326 emission (group 1, class B) and interference immunity (industrial application)

The existence of strong electromagnetic fields in a frequency range of < 2.7 GHz can result in increased measuring errors up to 1 %.Do not install the instruments in the vicinity of strong electromagnetic sources of interference (e.g. transmitting devices, radio equipment), or use sheath current filters where applicable.

For further specifications seeWIKA data sheet PE 81.01 and the order documentation.

WIKA operating instructions pressure transmitter, model S-10 |

23 |

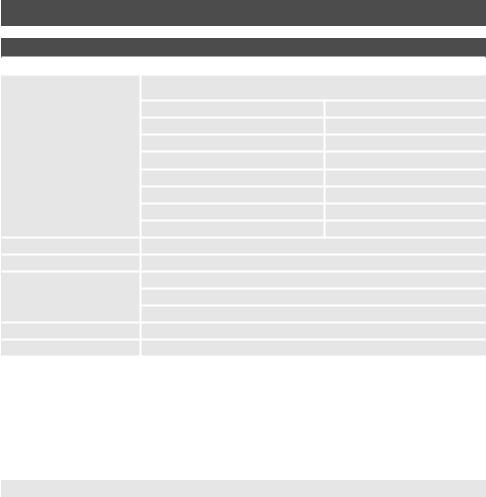

10.Specifications

Dimensions in mm

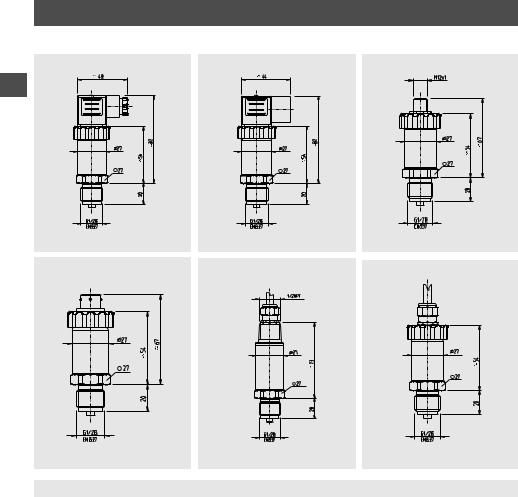

Angular connector DIN 175301-803 A |

Angular connector DIN 175301-803 with |

EN |

½ NPT |

|

Weight: approx. 200 g |

Weight: approx. 200 g |

Bayonet connector (6-pin) |

½ NPT conduit male, with cable outlet |

Circular connector M12 x 1 (4-pin)

Weight: approx. 200 g

Cable outlet, standard

Weight: approx. 200 g |

Weight: approx. 200 g |

Weight: approx. 200 g |

1604457.16 09/2017 EN/DE/FR/ES

24 |

WIKA operating instructions pressure transmitter, model S-10 |

10.Specifications

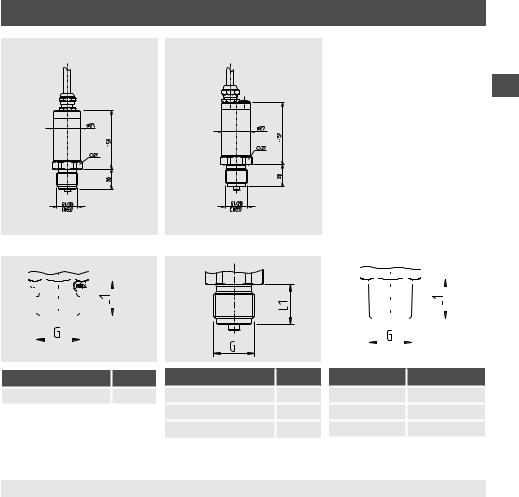

Cable outlet, not adjustable |

Cable outlet, adjustable |

EN

Weight: approx. 200 g |

|

|

|

|

|

|

Weight: approx. 200 g |

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1604457.16 09/2017 EN/DE/FR/ES

G |

L1 |

G ¼ A DIN 3852-E |

14 |

G |

L1 |

G ¼ B EN 837 |

13 |

G ½ B EN 837 |

20 |

M20 x 1.5 |

20 |

G |

L1 |

¼ NPT |

13 |

½ NPT |

19 |

R ¼ |

13 |

WIKA operating instructions pressure transmitter, model S-10 |

25 |

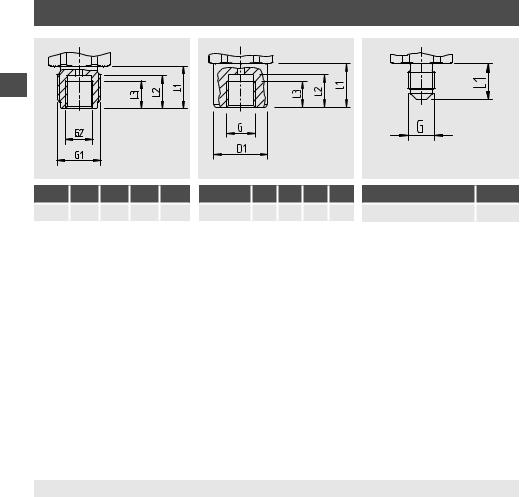

10.Specifications |

|

|

|

|

|

|

|

|

|||

EN |

|

|

|

|

|

|

|

|

|

|

|

G1 |

G2 |

L1 |

L2 |

L3 |

G |

D1 |

L1 |

L2 |

L3 |

G |

L1 |

G ½ B |

G ¼ |

20 |

15.5 |

13 |

G ¼ female |

25 |

20 |

15 |

12 |

7/16-20 UNF with 74° taper |

15 |

For special models S-10000 or special version S-10, other technical specifications apply.Please note the specifications stated on the order confirmation and the delivery note.

For further specifications seeWIKA data sheet PE 81.01 and the order documentation.

1604457.16 09/2017 EN/DE/FR/ES

26 |

WIKA operating instructions pressure transmitter, model S-10 |

Inhalt

Inhalt

|

|

|

|

|

|

1. |

Allgemeines |

28 |

|

|

|

|

|

|

|

DE |

|

2. |

Aufbau und Funktion |

29 |

|

||

|

|||||

|

|

|

|

|

|

3. |

Sicherheit |

30 |

|

|

|

|

|

|

|

|

|

4. |

Transport, Verpackung und Lagerung |

32 |

|

|

|

|

|

|

|

|

|

5. |

Inbetriebnahme, Betrieb |

33 |

|

|

|

|

|

|

|

|

|

6. |

Einstellung Nullpunkt und Spanne |

36 |

|

|

|

|

|

|

|

|

|

7. |

Störungen |

37 |

|

|

|

|

|

|

|

|

|

8. |

Wartung und Reinigung |

39 |

|

|

|

|

|

|

|

|

|

9. |

Demontage, Rücksendung und Entsorgung |

40 |

|

|

|

|

|

|

|

|

|

10. |

Technische Daten |

42 |

|

|

|

|

|

|

|

|

Konformitätserklärungen finden Sie online unter www.wika.de

1604457.16 09/2017 EN/DE/FR/ES

WIKA Betriebsanleitung Druckmessumformer, Typ S-10

27

1. Allgemeines

1. Allgemeines

■■ Das in der Betriebsanleitung beschriebene Gerät wird nach dem aktuellen Stand der Technik konstruiert und

|

gefertigt.Alle Komponenten unterliegen während der Fertigung strengen Qualitätsund Umweltkriterien.Unsere |

||

|

Managementsysteme sind nach ISO 9001 und ISO 14001 zertifiziert. |

||

DE |

|||

■■ Diese Betriebsanleitung gibt wichtige Hinweise zum Umgang mit dem Gerät.Voraussetzung für sicheres Arbeiten ist |

|||

|

|||

|

die Einhaltung aller angegebenen Sicherheitshinweise und Handlungsanweisungen. |

||

|

■■ Die für den Einsatzbereich des Gerätes geltenden örtlichen Unfallverhütungsvorschriften und allgemeinen Sicher- |

||

|

heitsbestimmungen einhalten. |

||

|

■■ Die Betriebsanleitung ist Produktbestandteil und muss in unmittelbarer Nähe des Gerätes für das Fachpersonal |

||

|

jederzeit zugänglich aufbewahrt werden. Betriebsanleitung an nachfolgende Benutzer oder Besitzer des Gerätes |

||

|

weitergeben. |

|

|

|

■■ Das Fachpersonal muss die Betriebsanleitung vor Beginn aller Arbeiten sorgfältig durchgelesen und verstanden |

||

|

haben. |

|

|

|

■■ Es gelten die allgemeinen Geschäftsbedingungen in den Verkaufsunterlagen. |

||

|

■■ Technische Änderungen vorbehalten. |

||

|

■■ Weitere Informationen: |

|

|

|

- Internet-Adresse: |

www.wika.de / www.wika.com |

|

|

- Zugehöriges Datenblatt: |

PE 81.01 |

|

|

- Anwendungsberater: |

Tel.:+49 9372 132-8976 |

|

Fax:+49 9372 132-8008976 support-tronic@wika.de

28 |

WIKA Betriebsanleitung Druckmessumformer, Typ S-10 |

1604457.16 09/2017 EN/DE/FR/ES

2. Aufbau und Funktion

2. Aufbau und Funktion

2.1 Überblick

Elektrischer Anschluss (je nach Ausführung)

Gehäuse; Typenschild DE Prozessanschluss, Schlüsselfläche

Prozessanschluss, Gewinde

2.2 Lieferumfang

■■ Druckmessumformer ■■ Betriebsanleitung

Lieferumfang mit dem Lieferschein abgleichen.

1604457.16 09/2017 EN/DE/FR/ES

WIKA Betriebsanleitung Druckmessumformer, Typ S-10

29

3. Sicherheit

3.Sicherheit

3.1Symbolerklärung

WARNUNG!

DE ... weist auf eine möglicherweise gefährliche Situation hin, die zum Tod oder zu schweren Verletzungen führen kann, wenn sie nicht gemieden wird.

VORSICHT!

... weist auf eine möglicherweise gefährliche Situation hin, die zu geringfügigen oder leichten

Verletzungen bzw.Sachund Umweltschäden führen kann, wenn sie nicht gemieden wird.

Information

...hebt nützlicheTipps und Empfehlungen sowie Informationen für einen effizienten und störungsfreien

Betrieb hervor.

3.2 Bestimmungsgemäße Verwendung

Der Druckmessumformer dient der Messung von Druck. Der gemessene Druck wird als elektrisches Signal ausgegeben.

Den Druckmessumformer nur in Anwendungen verwenden, die innerhalb seiner technischen Leistungsgrenzen liegen

(z.B.max.Umgebungstemperatur, Materialverträglichkeit, ...).Der Druckmessumformer eignet sich für Anwendungen mitVerschmutzungsgrad 3 und einer Umgebungstemperatur von -20 ...+80 °C.

→ Leistungsgrenzen siehe Kapitel 9 „Technische Daten“.

Das Gerät ist ausschließlich für den hier beschriebenen bestimmungsgemäßen Verwendungszweck konzipiert und konstruiert und darf nur dementsprechend verwendet werden.

Ansprüche jeglicher Art aufgrund von nicht bestimmungsgemäßer Verwendung sind ausgeschlossen.

30 |

WIKA Betriebsanleitung Druckmessumformer, Typ S-10 |

1604457.16 09/2017 EN/DE/FR/ES

Loading...

Loading...