WIKA GA11 Operating Instructions Manual

Operating instructions

Betriebsanleitung

Mode d‘emploi

Manual de instrucciones

EN

DE

FR

ES

Analysegerät zur Ermittlung der Gasqualität

von Isoliergasen, Typ GA11

SF₆ gas or g³ gas

Analytic instrument for determining the quality

of insulated gases, model GA11

Instrument d‘analyse pour déterminer la

qualité du gaz isolants , Type GA11

Analizador para determinar la calidad del gas

aislante, modello GA11

2

14065341.02 11/2016 EN/DE/FR/ES

WIKA operating instructions analytic instrument, model GA11

EN

DE

FR

ES

© 09/2016 WIKA Alexander Wiegand SE & Co. KG

All rights reserved. / Alle Rechte vorbehalten.

WIKA

®

is a registered trademark in various countries.

WIKA

®

ist eine geschützte Marke in verschiedenen Ländern.

Prior to starting any work, read the operating instructions!

Keep for later use!

Vor Beginn aller Arbeiten Betriebsanleitung lesen!

Zum späteren Gebrauch aufbewahren!

Lire le mode d'emploi avant de commencer toute opération !

A conserver pour une utilisation ultérieure !

¡Leer el manual de instrucciones antes de comenzar cualquier trabajo!

¡Guardar el manual para una eventual consulta!

Betriebsanleitung Typ GA11 Seite

39 - 74

Operating instructions model GA11 Page

3 - 38

Mode d‘emploi type GA11 Page

75 - 110

Manual de instrucciones modello GA11 Página

111 - 147

3

WIKA operating instructions analytic instrument, model GA11

EN

14065341.02 11/2016 EN/DE/FR/ES

Contents

1. General information...............................................5

2. Design and function ..............................................6

2.1 Overview.......................................................6

2.2 Description .....................................................7

2.3 Scope of delivery ................................................8

3. Safety ..........................................................8

3.1 Intended use....................................................9

3.2 Personnel qualication...........................................10

3.3 Personal protective equipment ....................................10

3.4 Handling of insulating gases and gas mixtures .......................11

3.5 Valid standards and guidelines ....................................12

3.6 Dealing with pressure-retaining components.........................13

3.7 Residual risks..................................................13

3.8 Labelling, safety marks ..........................................13

4. Transport, packaging and storage .................................14

5. Commissioning, operation ........................................15

5.1 Battery / mains operated .........................................15

5.2 Connecting the gas compartment..................................15

5.3 Switching on and o.............................................16

5.4 Performing measurements .......................................17

5.5 Cancelling an ongoing measurement...............................19

5.6 Emptying depot and depressurised gas compartment .................20

5.7 Saving the measuring result ......................................21

5.8 Managing the saved measuring results .............................21

Contents

4

WIKA operating instructions analytic instrument, model GA11

EN

14065341.02 11/2016 EN/DE/FR/ES

Contents

6. Settings........................................................23

6.1 Calling the settings mode ........................................23

6.2 Settings.......................................................23

6.3 System .......................................................24

6.4 Importing/exporting the list of measurement names via USB interface ....24

6.5 Limit values for gases ...........................................25

6.6 Firmware upgrade ..............................................26

7. Software Q-Analyser Measurement Viewer ..........................27

8. Maintenance and cleaning ........................................28

8.1 Maintenance...................................................28

8.2 Cleaning ......................................................28

8.3 Recalibration ..................................................28

9. Replacing sensors...............................................29

10. Faults..........................................................31

11. Dismounting, return and disposal..................................33

12. Specications ..................................................34

13. Accessories ....................................................37

Declarations of conformity can be found online at www.wika.com

5

WIKA operating instructions analytic instrument, model GA11

EN

14065341.02 11/2016 EN/DE/FR/ES

1. General information

1. General information

■

The analytic instrument described in the operating instructions has been designed

and manufactured using state-of-the-art technology.

All components are subject to stringent quality and environmental criteria during

production. Our management systems are certied to ISO 9001 and ISO 14001.

■

These operating instructions contain important information on handling the instrument. Working safely requires that all safety instructions and work instructions are

observed.

■

Observe the relevant local accident prevention regulations and general safety regulations for the instrument’s range of use.

■

The operating instructions are part of the product and must be kept in the immediate

vicinity of the instrument and readily accessible to skilled personnel at any time.

■

Skilled personnel must have carefully read and understood the operating instructions

prior to beginning any work.

■

The manufacturer's liability is void in the case of any damage caused by using the

product contrary to its intended use, non-compliance with these operating instructions, assignment of insuciently qualied skilled personnel or unauthorised modications to the instrument.

■

The general terms and conditions contained in the sales documentation shall apply.

■

Subject to technical modications.

■

Factory calibrations/DKD/DAkkS calibrations are carried out in accordance with

international standards.

■

Further information:

- Internet address: www.wika.com/sf6

- Relevant data sheet: SP 62.11

- Application consultant:

Tel.: +49 9372 132-8971

sf6-sales@wika.com

6

WIKA operating instructions analytic instrument, model GA11

EN

14065341.02 11/2016 EN/DE/FR/ES

2. Design and function

2. Design and function

2.1 Overview

Power supply unit

Adapter

Storage for hoses

Storage for power cord

User interface

ON/OFF key

Touchscreen

Network connection (LAN)

Inlet, return pumps

Outlet, gas cylinder

Power and charging

indicators

Outlet for gas recovery bag

USB interface

Power connection

7

WIKA operating instructions analytic instrument, model GA11

EN

14065341.02 11/2016 EN/DE/FR/ES

2. Design and function

2.2 Description

Data processing and data storage

The analytic instrument model GA11 is a multi-sensor system for examining the quality

of SF₆ gas and g³ gas, e.g. in switchgear. The basic instrument consists of a built-in

computer with touchscreen for processing and storage of up to 500 data records. The

data records can be exported via the integrated USB interface.

The accompanying software “Q-Analyser Measurement Viewer” enables you to display

the data on a PC or print the measurement reports (only for SF₆-Q-Analyser).

Extendable sensor system (only for SF₆-Q-Analyser)

The sensor system of GA11 is module-based and can be extended to up to 7 sensors.

In addition, there is the possibility of storing measuring gas internally as well as pumping

it back into the original gas compartment without losses after the measurement.

Automatic adjustment of the gas quality

After the measurement, the results will be compared with customer-specically adjustable limit values according to e.g. CIGRE B3.02.01 or IEC 60480 standards. The operator

thus obtains a reliable statement on whether the insulating gas is suitable for the given

application or not, or whether it is necessary to perform a gas processing or a gas

exchange.

There are no

standards

to compare with for g³ gas.

The operator can enter his own limit

values for quality.

Battery life

If the lithium-ion accumulator is fully charged, the analytic instrument can perform at least

5 measurements with the “back pumping” function. The number of the battery-powered

pump-back cycles is largely dependent on the tank pressure of the gas to be measured.

The GA11 sends a warning message on the display when battery is low.

If the instrument is not connected to the mains in time, it will shut down automatically in

order to prevent damages and data loss. In the mains operation, the battery is charged

and the instrument can be switched on again at the same time and operate without

restrictions.

Power and charging indicators

The front control panel has two LEDs which indicate the charging status (red) or mains

operation (green).

If an error occurs during the charge cycle, the charging indicator ashes (red).

8

WIKA operating instructions analytic instrument, model GA11

EN

14065341.02 11/2016 EN/DE/FR/ES

2. Design and function / 3. Safety

2.3 Scope of delivery

■

Analytic instrument model GA11 in a sturdy transport case

■

Power supply unit with power cord

■

Calibration certicate

■

Touchpen

■

USB stick

■

Operating instructions

■

See delivery note for optionally ordered sensor system and accessories.

Cross-check scope of delivery with delivery note.

3. Safety

Explanation of symbols

WARNING!

... indicates a potentially dangerous situation that can result in serious injury

or death, if not avoided.

CAUTION!

... indicates a potentially dangerous situation that can result in light injuries

or damage to equipment or the environment, if not avoided.

Information

... points out useful tips, recommendations and information for ecient and

trouble-free operation.

9

WIKA operating instructions analytic instrument, model GA11

EN

14065341.02 11/2016 EN/DE/FR/ES

3. Safety

3.1 Intended use

The analytic instrument model GA11 is available in two dierent versions:

SF

6

-Q-Analyser and g³-Q-Analyser. The GA11 is used for determining the gas quality of

the following insulating gases and gas mixtures.

Permissible insulating gases and gas mixtures for SF₆-Q-Analyser

■

SF₆ gas

■

SF₆/N₂

■

SF₆/CF₄

■

CO₂

Permissible insulating gases and gas mixtures for g³-Q-Analyser

■

g³ gas

■

CO₂

■

Novec 4710

Application areas

The instrument is especially designed for applications that full the following conditions:

■

The use is only allowed in buildings or dry surroundings.

■

Use only for commercial purposes and in industrial environment.

■

The height of the operation site should not exceed 2,000 m.

■

Ambience with max. pollution degree of 3.

■

Voltage supply of overvoltage category II.

■

Ambient temperature between 0 ... 40 °C.

■

Max. inlet pressure: 35 bar (SF₆-Q-Analyser)

■

Max. outlet pressure: 10 bar (SF₆-Q-Analyser)

■

Max. inlet pressure: 12 bar (g³-Q-Analyser)

■

Max. outlet pressure: 10 bar (g³-Q-Analyser)

The instrument has been designed and built solely for the intended use described here,

and may only be used accordingly.

Only use the instrument with original accessories from WIKA.

Refrain from unauthorised modications to the instrument.

Any use beyond or dierent to the intended use is considered as improper use.

The technical specications contained in these operating instructions must be

observed. Improper handling or operation of the instrument outside of its technical

specications requires the instrument to be taken out of service immediately and

inspected by an authorised WIKA service engineer.

10

WIKA operating instructions analytic instrument, model GA11

EN

14065341.02 11/2016 EN/DE/FR/ES

3. Safety

Handle electronic precision measuring instruments with the required care (protect from

humidity, impacts, strong magnetic elds, static electricity and extreme temperatures,

do not insert any objects into the instrument or its openings). Plugs and sockets must be

protected from contamination.

The manufacturer shall not be liable for claims of any type based on operation contrary

to the intended use.

3.2 Personnel qualication

WARNING!

Risk of injury should qualication be insucient!

Improper handling can result in considerable injury and damage to equipment.

■

The activities described in these operating instructions may only be

carried out by skilled personnel who have the qualications described

below.

■

Keep unqualied personnel away from hazardous areas.

Trained personnel

The plant operator must ensure that the handling of SF

6

gas and g³ gas is only carried

out by a qualied company or by qualied persons which have been specially trained in

accordance with IEC 61634, section 4.3.1 or IEC 60480, section 10.3.1.

Special operating conditions require further appropriate knowledge, e.g. of aggressive

media.

3.3 Personal protective equipment

The personal protective equipment is designed to protect the skilled personnel from

hazards that could impair their safety or health during work. When carrying out the

various tasks on and with the instrument, the skilled personnel must wear personal

protective equipment.

Follow the instructions displayed in the work area regarding personal protective

equipment!

11

WIKA operating instructions analytic instrument, model GA11

EN

14065341.02 11/2016 EN/DE/FR/ES

3. Safety

The requisite personal protective equipment must be provided by the operating company.

Wear safety goggles!

Safety goggles to EN 166, class 2.

They protect the eyes from ying parts during coupling or releasing of

the quick connections under pressure.

Wear protective gloves!

Protect hands from friction, abrasion, cuts or deep injuries and also from

contact with hot surfaces.

3.4 Handling of insulating gases and gas mixtures

SF

6

gas is a greenhouse gas which is listed in the Kyoto Protocol. SF6 gas must not be

released into the atmosphere, but must be collected in suitable containers.

Properties of insulating gases

■

Colourless and odourless

■

Chemically neutral

■

Inert

■

Not ammable

■

Heavier than air

■

No toxicity

■

No damage to the ozone layer

Detailed information is given in IEC 60376 and IEC 61634.

Danger of suocation caused by insulating gases and gas mixtures

High concentrations of gases and gas mixtures may lead to suocation, especially at

ground level or in lower-lying areas.

12

WIKA operating instructions analytic instrument, model GA11

EN

14065341.02 11/2016 EN/DE/FR/ES

3. Safety

Danger caused by decomposition products

Insulating gas in electrical systems may contain decomposition products generated by

electric arcs:

■

Gaseous sulphur uoride

■

Sulphur hexauoride

■

Solid and atomized metal uorides, metal suldes, metal oxides

■

Hydrogen uoride

■

Sulphur dioxide

Decomposition products can be harmful to health.

■

They can cause poisoning by inhalation, ingestion or contact with the skin.

■

They may be irritating to the eyes, the respiratory system or the skin and burn them.

■

Inhalation of large quantities may damage the lungs.

Observe the following safety instructions in order to avoid danger from insulating gas:

■

Wear personal protective equipment.

■

Read the material safety data sheet of the gas supplier.

■

With large leaks, evacuate the area quickly.

■

Ensure good ventilation.

■

Ensure the leak tightness of the equipment with a leak detector (e.g. model GIR-10).

3.5 Valid standards and guidelines

Installation, assembly, commissioning:

■

BGI 753 (SF₆ plants and equipment in Germany)

■

IEC 61634 (Handling of SF₆ gas)

■

IEC 60376 (New SF₆ gas, technical grade SF₆ gas)

■

IEC 60480 (Used SF₆ gas)

■

CIGRE report 276, 2005 (Practial SF₆ gas handling instructions)

Leaks during operation:

■

IEC 60376 (New SF₆ gas, technical grade SF₆ gas)

■

IEC 60480 (Used SF₆ gas)

■

CIGRE 2002 (“SF₆ gas in the electrical industry”)

Repair work and maintenance:

■

IEC 61634 (Use and handling of SF₆ gas in high-voltage switchgear and controlgear)

■

CIGRE 1991 (Handling of SF₆ gas)

■

CIGRE report 276, 2005 (Practical SF₆ gas handling instructions)

■

CIGRE report 163, 2000 (Guide for SF₆ gas mixtures)

Insulating gas is a colourless and odourless, chemically neutral, inert and

non-inammable gas which is heavier than air, not toxic and not harmful to

the ozone layer. Detailed information is given in IEC 60376 and IEC 61634.

13

WIKA operating instructions analytic instrument, model GA11

EN

14065341.02 11/2016 EN/DE/FR/ES

3. Safety

3.6 Dealing with pressure-retaining components

Pneumatic energy can lead to serious injury.

With damaged individual components, highly pressurised air can escape and cause eye

injuries, for example.

Pressure-retaining components (e.g. adapters, hoses and external containers) may

explode due to overpressure.

Observe the following safety instructions in order to avoid danger from pneumatic

energy:

■

Depressurise the instrument before starting any work on it. Be careful of the accumulator, and ensure it is fully discharged.

■

Do not alter the pressure settings above the maximum permissible levels.

■

Make sure that all pressure-retaining components are designed for the quoted

nominal pressures (→ see chapter 12 “Specications”).

3.7 Residual risks

Despite compliance with all relevant safety regulations for the design and construction

of our instruments as well as intended use of them by the operator, residual risks may

occur during operation.

Residual risks are described in detail in the individual chapters. It is vital that you comply

with all safety instructions.

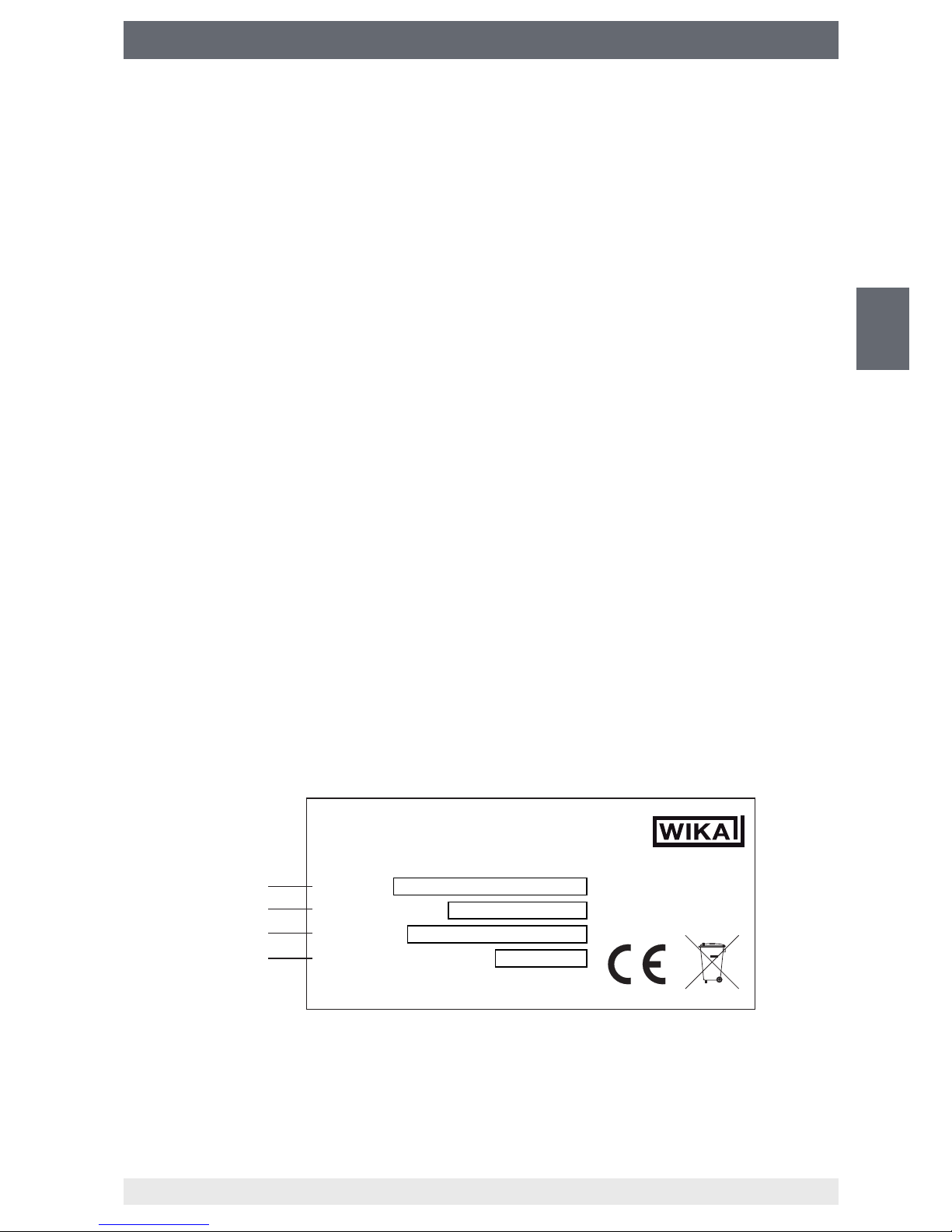

3.8 Labelling, safety marks

Product label (example)

The product label is located at the rear of the display frame.

Product designation (model)

Power supply

Serial no.

Date of manufacture

WIKA

Alexander Wiegand SE & Co. KG, 63911 Klingenberg, Germany

Product:

Power Supply:

Serial No:

Manufacturing Year:

Made in Germany

14

WIKA operating instructions analytic instrument, model GA11

EN

14065341.02 11/2016 EN/DE/FR/ES

4. Transport, packaging and storage

4. Transport, packaging and storage

4.1 Transport

Check the analytic instrument for any damage that may have been caused by transport.

Obvious damage must be reported immediately.

4.2 Packaging

Do not remove packaging until just before mounting.

Keep the packaging as it will provide optimum protection during transport (e.g. calibration,

sending for repair).

4.3 Storage

Permissible conditions at the place of storage:

Storage temperature: 0 ... 40 °C

Avoid exposure to the following factors:

■

Direct sunlight or proximity to hot objects

■

Mechanical vibration, mechanical shock (putting it down hard)

■

Soot, vapour, dust and corrosive gases

■

Hazardous environments, ammable atmospheres

■

Storage outdoors or in humid environment

■

Unauthorized access

15

WIKA operating instructions analytic instrument, model GA11

EN

14065341.02 11/2016 EN/DE/FR/ES

5. Commissioning, operation

5. Commissioning, operation

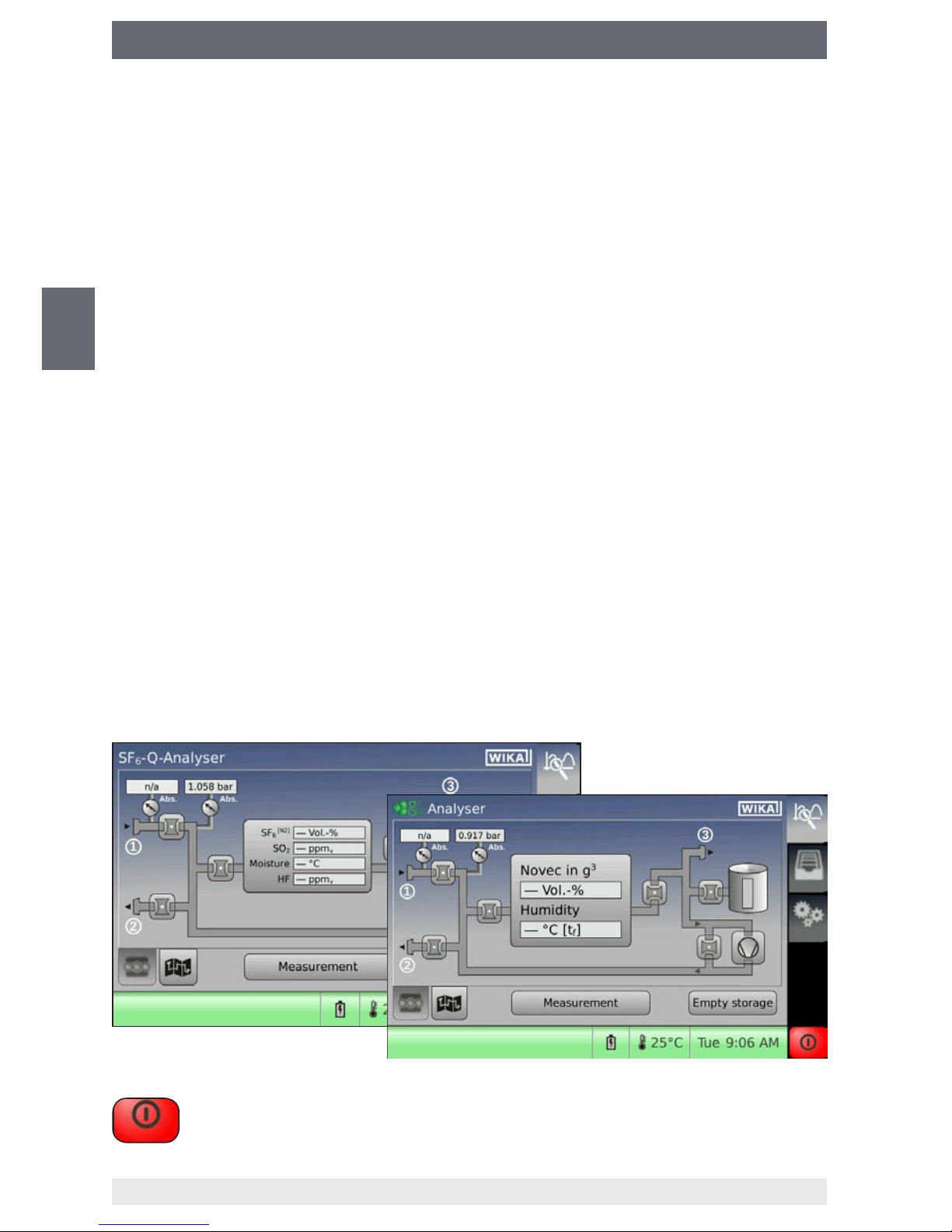

Depending on the version of the analytic instrument, the user interface may dier from

those illustrated in these operating instructions. However, the procedure is always the

same.

5.1 Battery / mains operated

The analytic instrument can be operated in battery mode and in the mains supply.

If the lithium-ion accumulator is fully charged, the analytic instrument can perform at least

5 measurements with the “back pumping” function. The number of the battery-powered

pump-back cycles is largely dependent on the tank pressure of the gas to be measured.

The GA11 sends a warning message on the display when battery is low.

If the instrument is not connected to the mains in time, it will shut down automatically in

order to prevent damages and data loss. In the mains operation, the battery is charged

and the instrument can be switched on again at the same time and operate without

restrictions.

Establishing connection to mains supply

1. Connect power supply unit to the power cord.

2.

Connect power supply unit to mains connection on the operating panel.

3.

Connect the power cord to the socket.

⇒

Connection to mains supply is established.

5.2 Connecting the gas compartment

CAUTION!

Escaping SF₆ gas results in environmental hazards!

If there are leakages at the connecting elements, the environmentally

hazardous SF₆ gas may be released to the atmosphere.

▶

Make sure that there is no leakage at any connections (e.g. by using gas

detector GIR-10).

To perform a measurement, the pressure of the gas compartment to be measured has

to be at least 1.3 bar abs. If the inlet pressure is below 1.3 bar abs., it is possible to use

an inlet pressure control unit (e.g. model GA05) to raise the pressure.

5.2.1 Pumping back in the measured gas compartment

▶

Connect “Inlet, return pumps ” to the gas compartment.

⇒

The gas compartment is connected.

During back pumping, the gas is pumped back into the gas compartment via the “Inlet,

return pumps ”.

16

WIKA operating instructions analytic instrument, model GA11

EN

14065341.02 11/2016 EN/DE/FR/ES

5. Commissioning, operation

5.2.2 Back pumping in external gas compartment (pressurised)

Requirement:

The lling pressure of the external gas compartment is between 1.3 ... 10 bar abs.

(SF₆-Q-Analyser)

The lling pressure of the external gas compartment is between 1.3 ... 12 bar abs.

(g³-Q-Analyser)

1.

Connect “Inlet, return pumps ” to the gas compartment to be measured.

2.

Connect “Outlet for gas cylinder ” to the external gas compartment.

⇒

The gas compartment is connected.

5.2.3 Back pumping in external gas compartment (depressurised)

1.

Connect “Inlet, return pumps ” to the gas compartment to be measured.

2.

Connect “Outlet for gas recovery bag ” to the external gas compartment.

⇒

The gas compartment is connected.

5.3 Switching on and o

Switching on

▶

Press On/Off switch.

⇒

A self-test is performed.

⇒

The residual gas is filtered.

⇒

The instrument is ready for operation.

⇒

Start screen with sensor values is displayed (the actual display may vary from the

example).

Switching o

▶

Press the following button.

▶

17

WIKA operating instructions analytic instrument, model GA11

EN

14065341.02 11/2016 EN/DE/FR/ES

5. Commissioning, operation

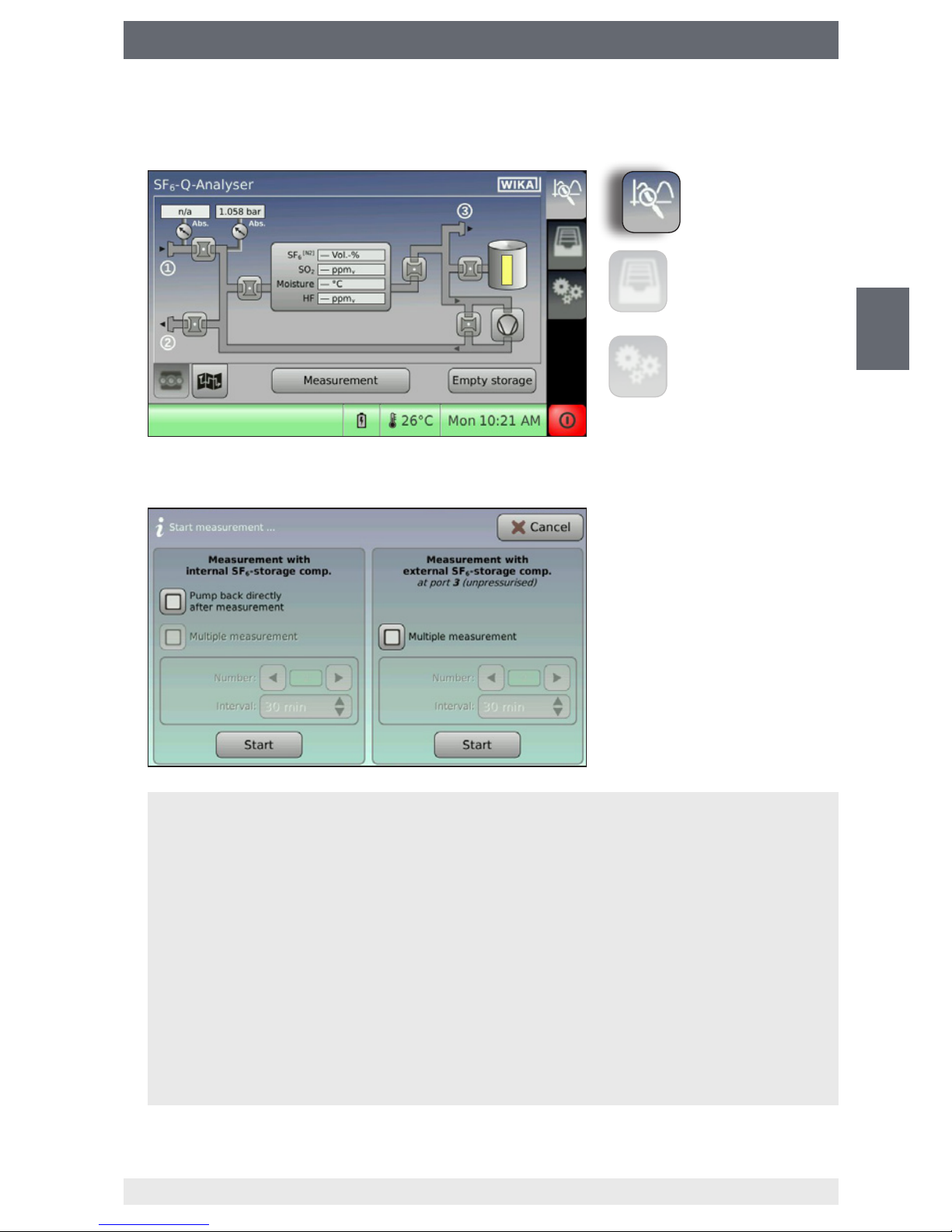

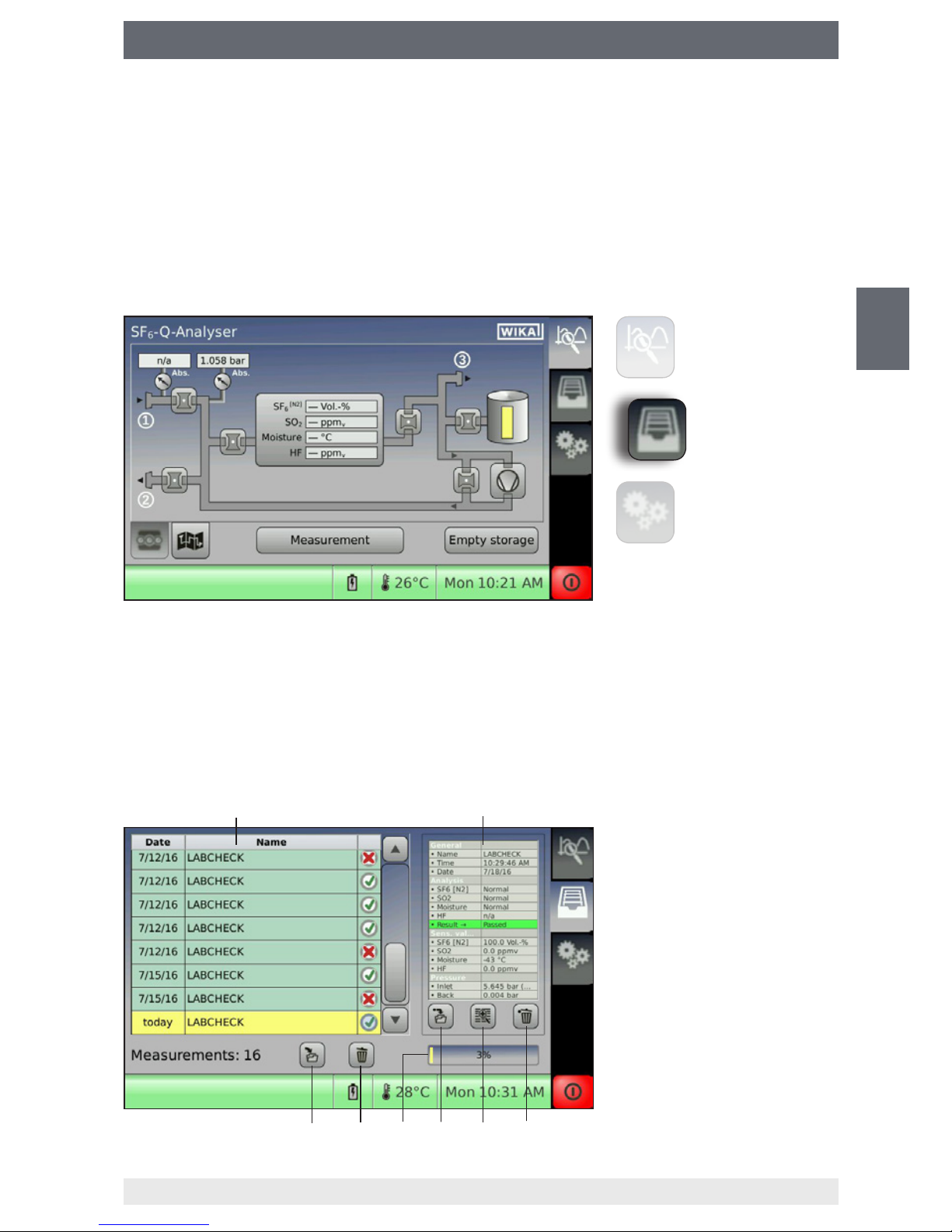

5.4 Performing measurements

1. Press “Measurement”.

2. Congure the measuring methods and press “Start” to conrm.

⇒

The measurement begins.

Measurement with internal depot

The measuring gas will be stored temporarily in the internal depot and later be pumped back

into the gas compartment to be measured or a pressurised external gas compartment.

Measurement with external container (depressurised)

The measuring gas will be directly pumped into a depressurised external gas compartment

(e.g. gas recovery bag, model GA45).

Back pumping after the measurement

Once the measurement is nished, a selection window will open, which enables the selection of the storage location.

Multiple measurement

The multiple measurement makes it possible to perform the gas quality check at specic

intervals automatically.

Measurement

Data management

Settings

18

WIKA operating instructions analytic instrument, model GA11

EN

14065341.02 11/2016 EN/DE/FR/ES

5. Commissioning, operation

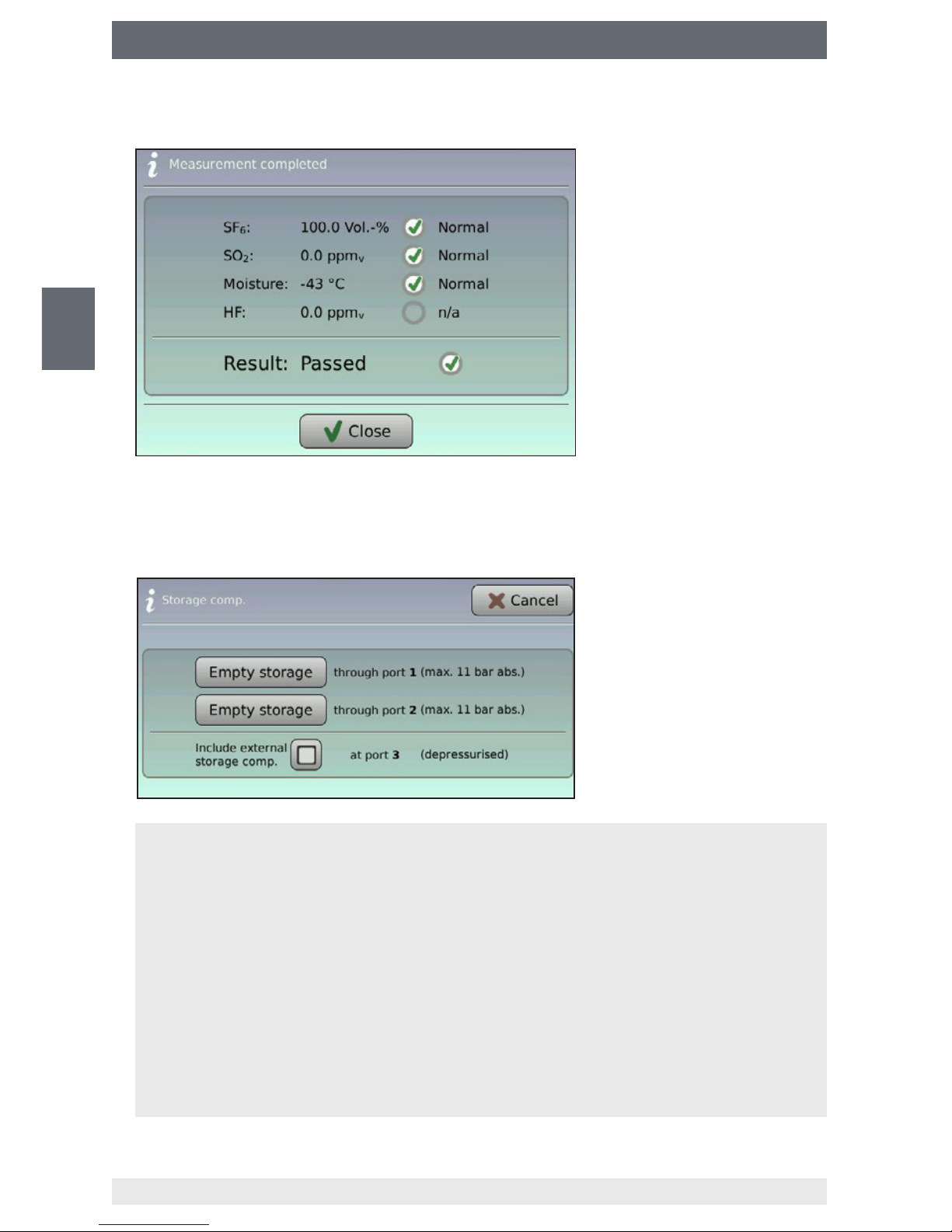

3. Save or skip the measuring result.

4. Select the gas compartment for back pumping the measuring gas (only available

when the “back pumping” function is selected).

⇒

Measuring gas is pumped back.

⇒

Measurement is finished.

Connection

The measuring gas is directly pumped back into the measured gas compartment.

Connection

The measuring gas is pumped into a pressurised external gas compartment (e.g. gas cylinder).

The maximal pumping capacity of the analytic instrument is:

■

10 bar abs. (SF₆-Q-Analyser)

■

12 bar abs. (g³-Q-Analyser)

External container

With the function activated, the measuring gas is emptied from an external container at

connection as well.

19

WIKA operating instructions analytic instrument, model GA11

EN

14065341.02 11/2016 EN/DE/FR/ES

5. Commissioning, operation

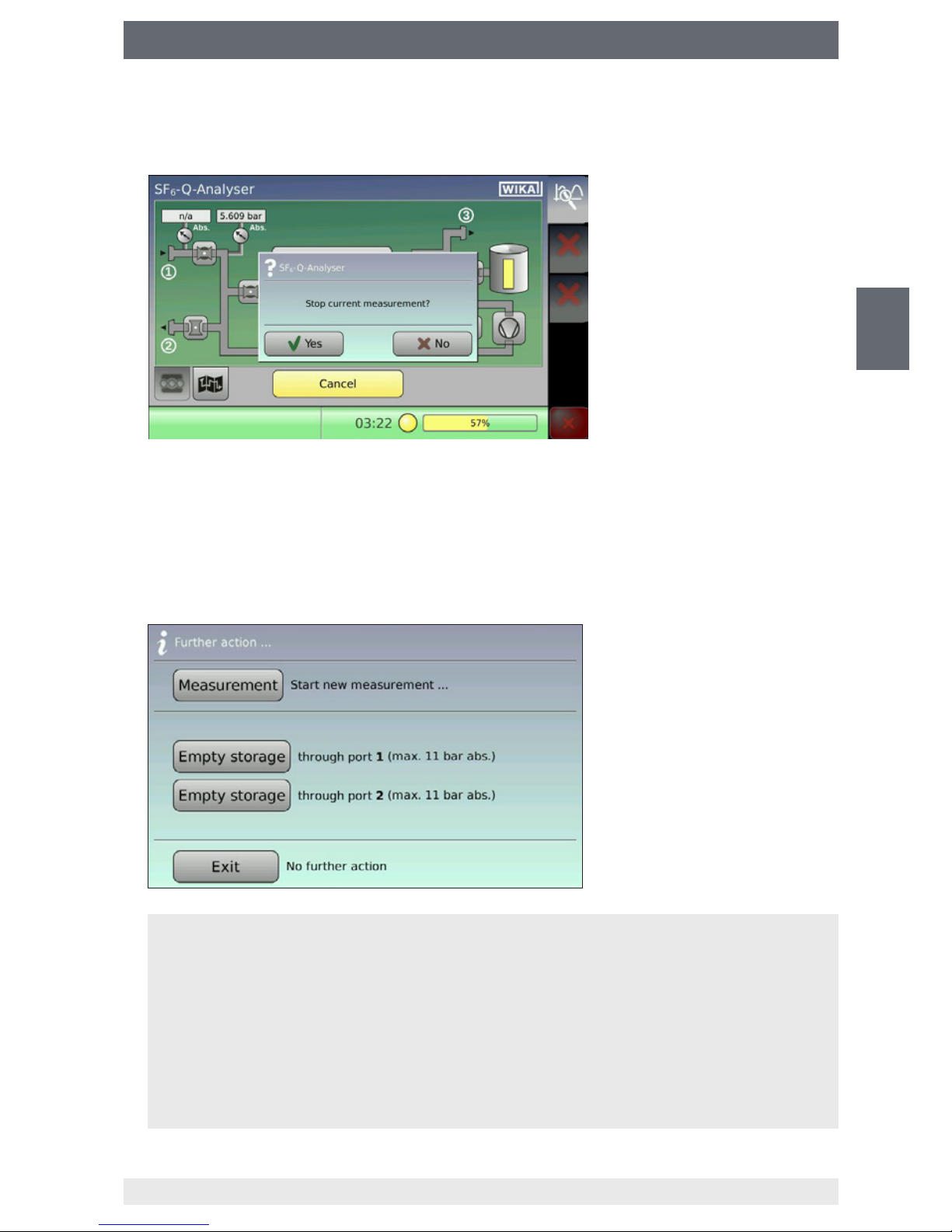

5.5 Cancelling an ongoing measurement

1. Press “Cancel” and conrm by pressing “Yes”.

2. Select the gas compartment for back pumping the measuring gas (only available

when the “back pumping” function is selected).

⇒

Measuring gas is pumped back.

⇒

Measurement is finished.

Connection

The measuring gas is directly pumped back into the measured gas compartment.

Connection

The measuring gas is pumped into a pressurised external gas compartment (e.g. gas cylinder).

The maximal pumping capacity of the analytic instrument is:

■

10 bar abs. (SF₆-Q-Analyser)

■

12 bar abs. (g³-Q-Analyser)

20

WIKA operating instructions analytic instrument, model GA11

EN

14065341.02 11/2016 EN/DE/FR/ES

5. Commissioning, operation

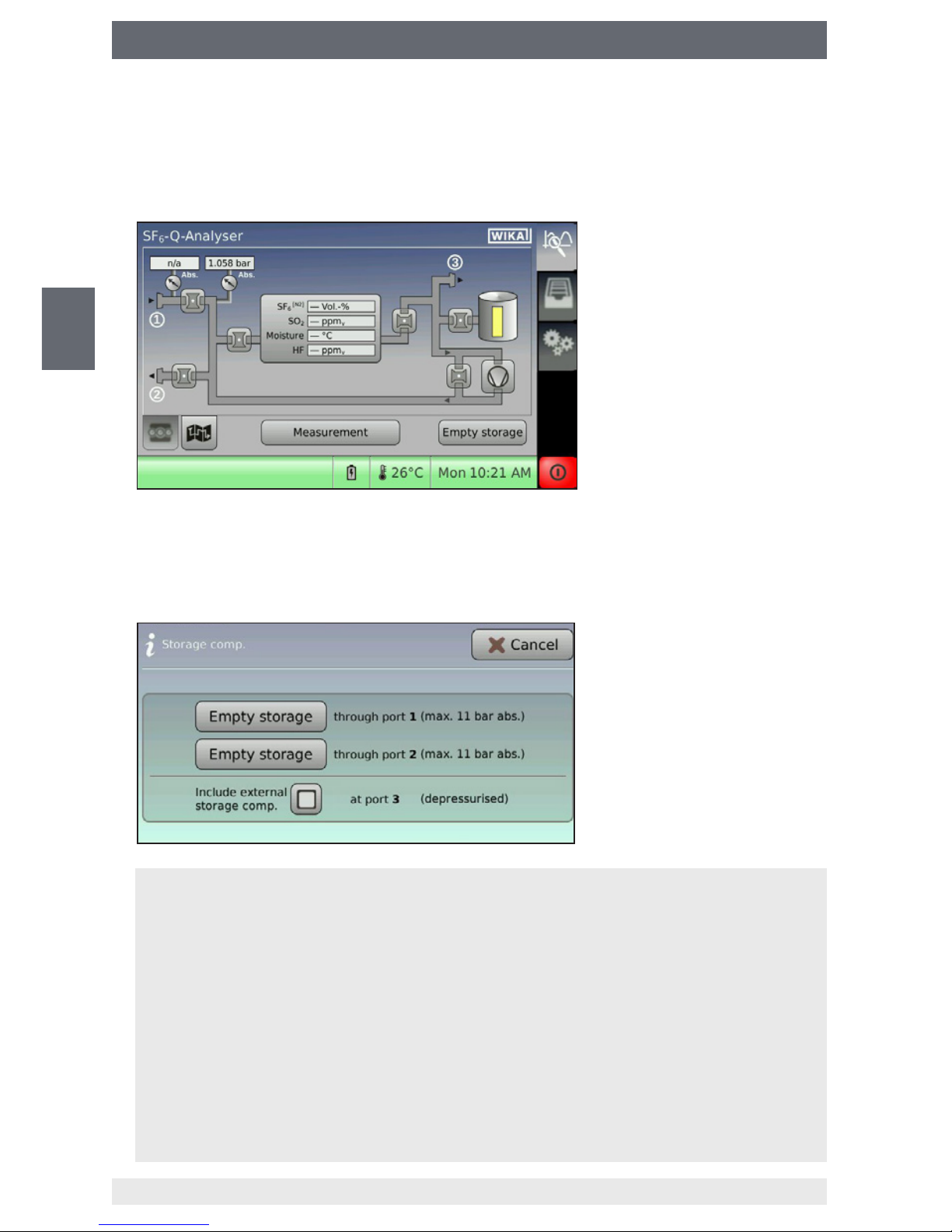

5.6 Emptying depot and depressurised gas compartment

The depot can be emptied only when there is measuring gas inside. If the depot is

already empty, the procedure is cancelled with an error message.

1. Press “Empty depot”.

2. Select the gas compartment for back pumping the measuring gas (only available

when the “back pumping” function is selected).

⇒

Measuring gas is pumped back.

⇒

Measurement is finished.

Connection

The measuring gas is directly pumped back into the measured gas compartment.

Connection

The measuring gas is pumped into a pressurised external gas compartment (e.g. gas cylinder).

The maximal pumping capacity of the analytic instrument is:

■

10 bar abs. (SF₆-Q-Analyser)

■

12 bar abs. (g³-Q-Analyser)

External container

With the function activated, the measuring gas is emptied from an external container at

connection as well.

21

WIKA operating instructions analytic instrument, model GA11

EN

14065341.02 11/2016 EN/DE/FR/ES

5. Commissioning, operation

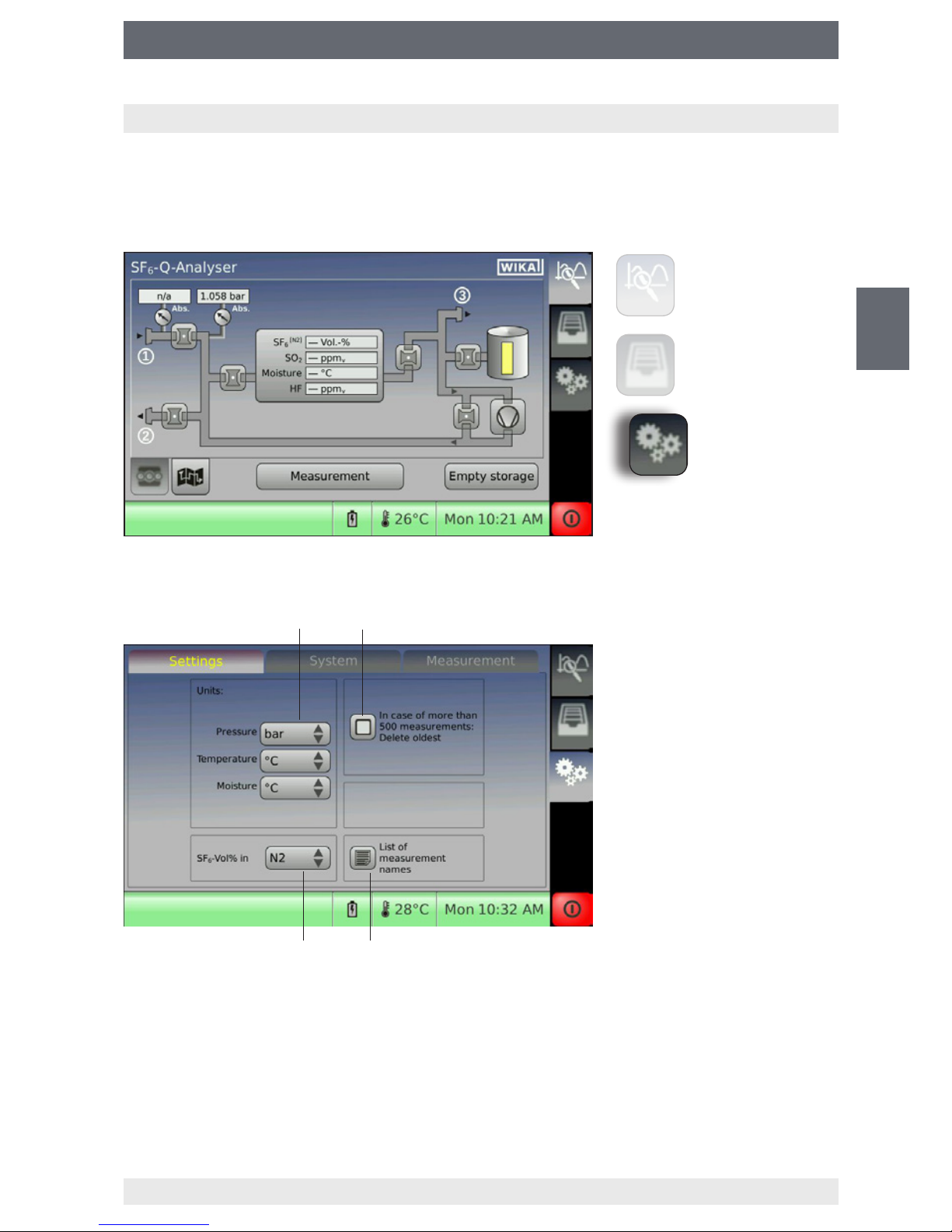

Data record list

Detail window of the selected

data record

Deletes the selected data

record

Opens the data record details

in a magnied window

Saves the selected data

record on the USB data carrier

Memory utilization in %

Delete all data records

Save all data records to the

USB data carrier

5.7 Saving the measuring result

The easiest way is to use the name allocation in advance on a PC. You can create a

name list (separated by commas) and load it into the analytic instrument via the USB

interface (see chapter 6.4 “Importing/exporting the list of measurement names via USB

interface”).

5.8 Managing the saved measuring results

The main menu “Data management” must be enabled in order to access the data

management of the analytic instrument.

5.8.1 Internal memory

The internal memory can save up to 500 data records.

Depending on system setting, when the memory limit is reached, the instrument will

either send an error message or automatically overwrite the oldest data records without

warning (see chapter 6.4 “Importing/exporting the list of measurement names via USB

interface”). The data records deposited in the internal memory can be transmitted to a

USB data carrier.

Measurement

Data management

Settings

22

WIKA operating instructions analytic instrument, model GA11

EN

14065341.02 11/2016 EN/DE/FR/ES

5. Commissioning, operation

Transmitting data records to the USB data carrier

1. Connect USB data carrier to the USB interface.

2.

■

Copying all data records to the USB data carrier

Press button [8].

■

Copying individual data records to the USB data carrier

Choose a data record via the touchscreen (the data record will be marked in

yellow) and press button [5].

3. Select le format and conrm with “OK”.

Saving as measurement (*.mea)

The data record is saved in the analytic instrument's own format (*.mea)

Exporting in “CSV” format (*.csv)

The data record is saved in *.csv format. This format is supported by spreadsheet

programs (e.g. Microsoft Excel

®

).

4. Remove the USB data carrier once the saving process is nished (when the

hourglass symbol is extinguished).

In order to avoid data loss, only remove the USB data carrier when

the saving process is completed (when the hourglass symbol is

extinguished).

23

WIKA operating instructions analytic instrument, model GA11

EN

14065341.02 11/2016 EN/DE/FR/ES

6. Settings

6. Settings

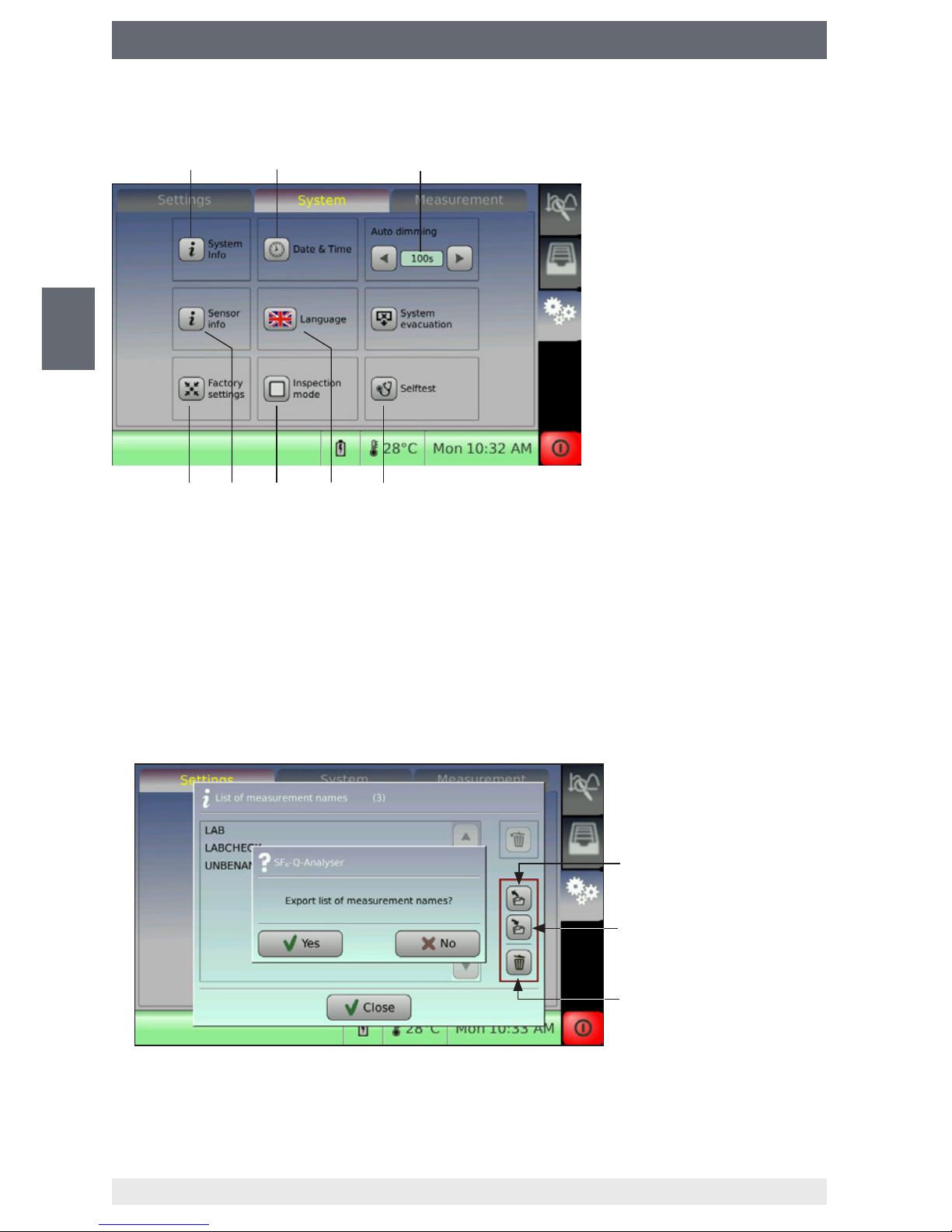

6.1 Calling the settings mode

The main menu “Settings” must be enabled before settings to the analytic instrument

can be made.

6.2 Settings

Setting the units

Activated: The oldest data records will be deleted when the limit of 500 data records is reached.

Deactivated: There will be an error message “Memory is full” when the limit of 500 data records is reached.

Importing/exporting the list of measurement names via USB interface

Calibration gas of SF6 percentage sensor

Measurement

Data management

Settings

24

WIKA operating instructions analytic instrument, model GA11

EN

14065341.02 11/2016 EN/DE/FR/ES

6. Settings

6.3 System

6.4 Importing/exporting the list of measurement names via USB interface

1. Create a list with any word processing program.

Separate measurement names with commas from each other:

Name1, Name2, Name3, ...

2. Save the list to the USB data carrier (le format is *.csv).

3. The list can be imported by clicking the icon on the analytic instrument. The imported

list will overwrite the existing list in the internal memory of the analytic instrument.

Import the list from the USB

data carrier

Export the list to the USB

data carrier

Delete the list

Information on the system

Setting date and time

After expiration of this time, the

display lighting will be dimmed

for energy saving.

Performing self-test

Changing language

The inspection mode is reserved

for WIKA service.

Information on the sensor

system

Reset to factory settings

25

WIKA operating instructions analytic instrument, model GA11

EN

14065341.02 11/2016 EN/DE/FR/ES

6. Settings

6.5 Limit values for gases

SF₆-Q-Analyser

The factory settings are the limits for the reusable SF

6

gas according to the Cigré

Recycling Guide or IEC 60480. The limits of the installed sensors can be adjusted

according to customer guidelines.

■

Lower limit of SF6: 97.0 Vol.-%

■

Upper limit of SO2: 12 ppm

v

■

Upper limit of humidity: -36.0 °C dew point

■

Flow duration: 450 seconds, ow duration = measurement duration

g³-Q-Analyser

The factory settings are preset to 0 %. There are no standards to compare with for g³

gas. The operator can enter his own limit values for quality.

Default:

■

Lower limit of g³: 3% default

■

Upper limit of humidity: -36.0 °C dew point

■

Flow duration: 450 seconds, ow duration = measurement duration

26

WIKA operating instructions analytic instrument, model GA11

EN

14065341.02 11/2016 EN/DE/FR/ES

6. Settings

6.6 Firmware upgrade

You can update the analytic instrument by upgrading the rmware.

The latest rmware can be downloaded from www.wika.de.

CAUTION!

Incomplete rmware upgrade may cause damage to the instrument!

If the power supply is terminated during the rmware installation, the instrument may be damaged.

■

Do not disconnect the analytic instrument from the mains or shut it down

during installation.

■

Ensure continuous voltage supply.

Performing upgrade

1. Download rmware from www.wika.de.

Unzip the le (*.zip) in the dened directory “UPGRADE” on the USB data carrier

(drive letter:\UPGRADE).

2. Connect USB data carrier to the switched o analytic instrument.

3. Connect the analytic instrument to the mains (no battery operation).

4. Switch on analytic instrument.

5. Wait until the installation is nished. Do not disconnect the analytic instrument from

the mains during installation.

The following screen will appear during installation.

6. Calibrate the touchscreens. Conrm the positions of 5 cross hairs with the touchpen.

7. Disconnect the USB data carrier from the analytic instrument after the “Update

completed” message shows up.

27

WIKA operating instructions analytic instrument, model GA11

EN

14065341.02 11/2016 EN/DE/FR/ES

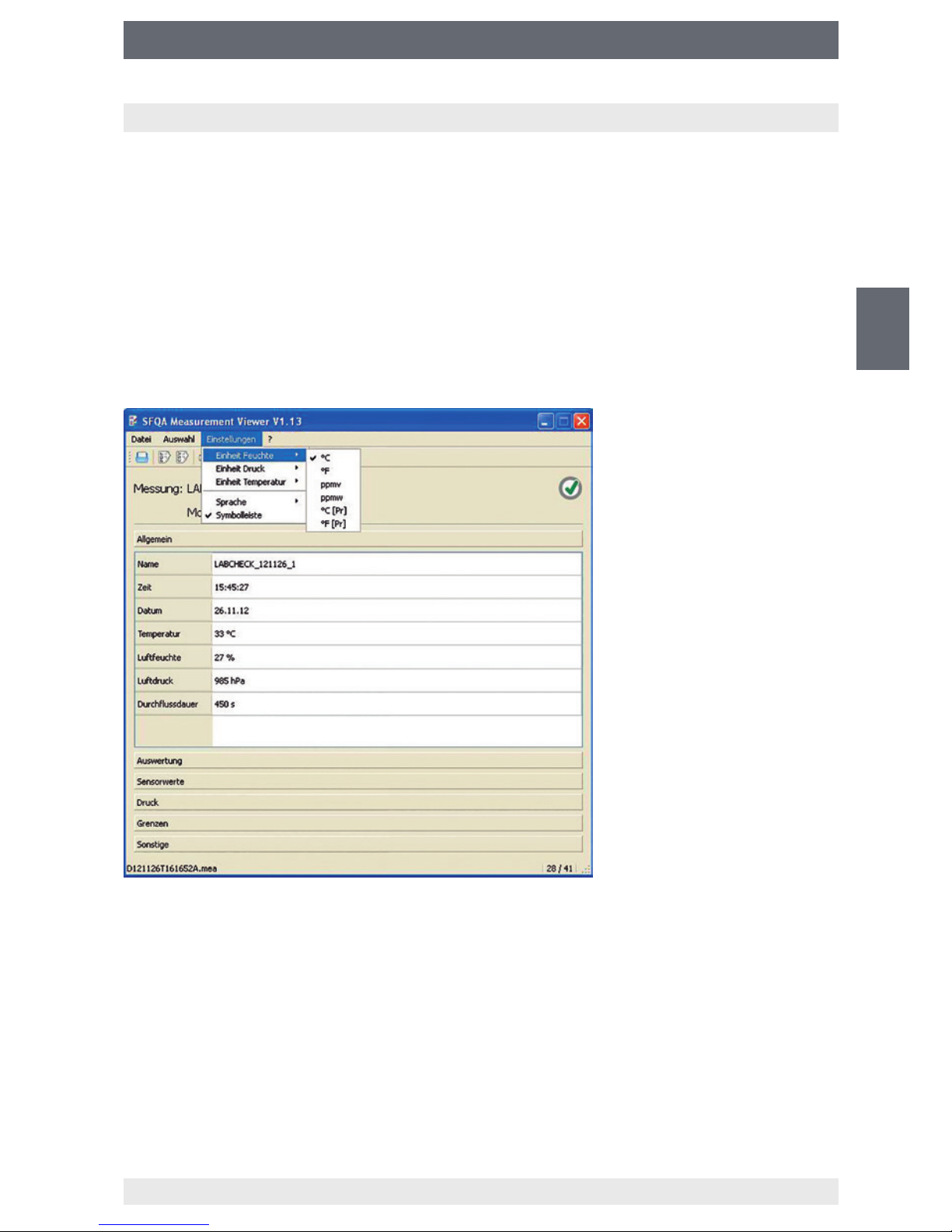

7. Software Q-Analyser Measurement Viewer

7. Software Q-Analyser Measurement Viewer

Functional description

The enclosed USB stick and the CD-ROM contain the software (only for SF₆-Q-Analyser).

System requirements:

■

Operating system: Microsoft® Windows® or Linux

This easy-to-use tool makes it possible to view the measurement les (*.mea) of the

analytic instrument, to print them out or to export them as PDF or CSV les.

The measuring results can be subsequently displayed in other units.

For the sake of clarity, the individual les are arranged in categories.

Click on the corresponding category (e.g. sensor values) to show the les.

Printing and exporting the measured data

You can generate a print report or PDF report to ensure reliable documentation and

ling of the measured data Click the respective entry or the button in the menu “File”.

It is possible to generate a CSV le from the measured data for further data evaluation,

which can be opened by spreadsheet programs.

28

WIKA operating instructions analytic instrument, model GA11

EN

14065341.02 11/2016 EN/DE/FR/ES

8. Maintenance and cleaning

8. Maintenance and cleaning

8.1 Maintenance

Repairs and maintenances must only be carried out by the manufacturer or manufacturer-approved service partners.

8.2 Cleaning

CAUTION!

■

Clean the instrument with a moist cloth.

■

Electrical connections must not come into contact with moisture.

■

Wash or clean the dismounted instrument before returning it, in order to

protect persons and the environment from exposure to residual media.

■

Residual media in the dismounted instrument can result in a risk to

persons, the environment and equipment.

Take sucient precautionary measures.

For information on returning the instrument see chapter 11.2 “Return”.

8.3 Recalibration

We recommend that the analytic instrument is regularly recalibrated by the manufacturer. In addition, every factory calibration includes a free-of-charge check of all system

parameters with respect to their compliance with the specication. The basic settings

will be corrected if necessary.

SF₆-Q-Analyser: 2 years

g³-Q-Analyser: 1 year

The time until the next recalibration for each individual sensor can be queried under

“Sensor info”.

Settings > System > Sensor info

29

WIKA operating instructions analytic instrument, model GA11

EN

14065341.02 11/2016 EN/DE/FR/ES

9. Replacing sensors

9. Replacing sensors

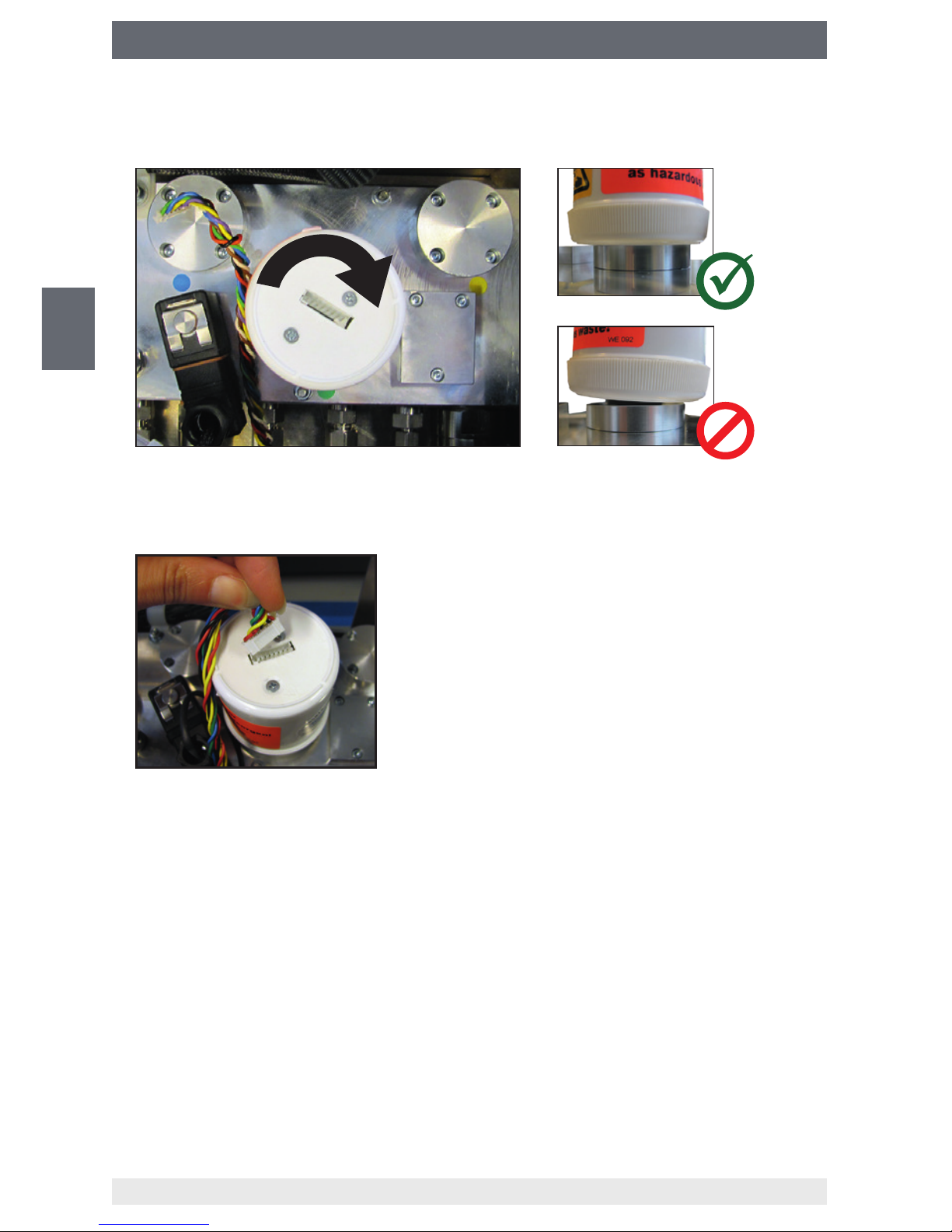

1. Switch o the analytic instrument and remove the front panel.

Remove the 4 screws of the front panel (see arrows) and fold back the front panel.

2. Pull the plug o the sensor (in this example: SO

2

sensor)

3. Screw out the sensor counterclockwise.

30

WIKA operating instructions analytic instrument, model GA11

EN

14065341.02 11/2016 EN/DE/FR/ES

9. Replacing sensors

4. Screw in the new sensor in clockwise direction.

Screw in the sensor in a straight manner because it can easily tilt.

5. Connect the plug to the sensor.

The plug can only be inserted in one direction. The groove prevents the plug from

being inserted in a wrong way.

6. Reassemble the front panel and switch on the instrument (see step 1).

⇒

The sensor is recognised automatically.

7. Flood the analytic instrument with pure gas.

Perform 3 measurements with pure gas.

Loading...

Loading...