White-rodgers 36E36 User Manual

INstAllAtIoN INstRuctIoNs hoNeyWell vR8205 ANd WhIte-RodGeRs 36e23, 36f23, 36e36, & 36e37 GAs vAlve used oN GAs/electRIc Rooftops WIth dIRect spARK IGNItIoN

thIs KIt NumbeR RxGJ-ep94d Is foR

coNveRtING fRom NAtuRAl GAs to pRopANe GAs

! Recognize this symbol as an indication of Important Safety Information!

pARts lIst

|

descRIptIoN |

pARt NumbeR |

QuANtIty |

|

|

|

|

Conversion Kit Index |

|

92-21519-47 (or -48) |

1 |

Installation Instructions |

|

92-22999-NEW-108 |

1 |

Conversion Label |

|

92-18153-06 |

1 |

Conversion Kit #396221-2 (Honeywell) |

60-22513-03 |

1 |

|

Conversion Kit #92-0659 (White-Rodgers) |

60-21193-01 |

1 |

|

Orifice - Burner (#54) |

|

62-21551-54 |

6 |

Orifice - Burner (#55) |

|

62-21551-55 |

6 |

Orifice - Burner (3/64) |

|

62-21551-13 |

6 |

! WARNING

this conversion kit is to be installed by a qualified service professional in accordance with the manufacturer’s instructions and all codes and requirements of the authority having jurisdiction. failure to follow instructions can result in fire or explosion causing property damage, severe personal injury or death. the qualified service personnel performing this work assumes responsibility for this conversion.

ImpoRtANt: dAmAGe to the pRoduct ResultING fRom fAIluRe to folloW INstRuctIoNs oR use of uNAuthoRIzed pARts mAy be excluded fRom the mANufActuReR’s pRoduct WARRANty coveRAGe.

ThereImpoRtANtare 3 sizesNoteof mainfoRburnerAltItudorificessinAbovethis kit. 2,000Thesefeet:orifice sizes will cover all models installed at 0 - 2000 feet (0 - 610 meters) in the USA and Canada and all derated high altitude models installed in Canada at 2000 - 4500 feet (610 - 1373 meters). Refer to Chart in the Conversion Kit Index (92- 21519-47) included with thisIII kit to select the correct orifice size for the nameplate heating input, elevation, and country (USA or Canada) of the furnace to be converted. Orifices for elevations over 2000 feet (610 meters) in the USA must be obtained through the Parts Department if they are not included with this kit..

All gas piping must comply with the latest NFPA 54 INNationalusA: Fuel Gas Code and all state and local codes. All electrical wiring must comply with the latest NFPA 70, National Electrical Code and all state and local codes.

All gas piping must comply with the latest CAN 1IN-B149cANAdA:-1 & 2 installation codes for gas burning appliances and all provincial and local codes. All electrical wiring must comply with the Canadian Electrical Code, Part 1 - CSA Standard C22.1 and all provincial and local codes.

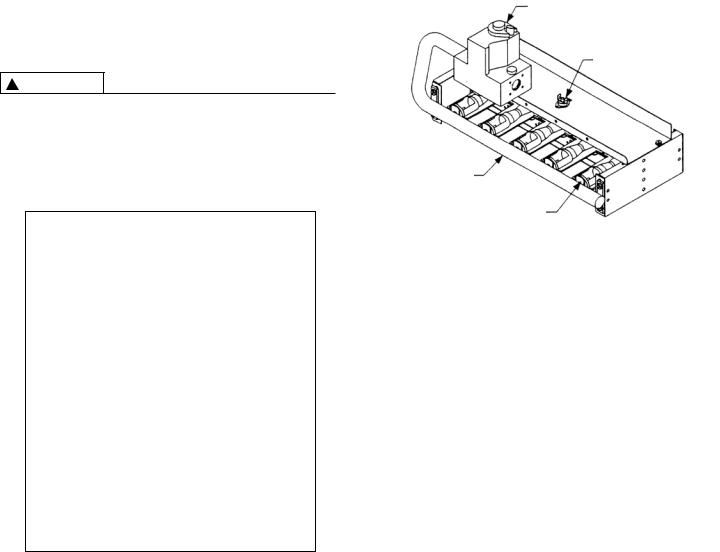

KIt INstAllAtIoN (see IllustRAtIoN, pAGe 2)

! WARNING

tuRN off electRIcAl poWeR ANd tuRN off mAIN GAs supply befoRe beGINNING modIfIcAtIoN. fAIluRe to do so cAN cAuse electRIcAl shocK, explosIoN oR fIRe ResultING IN pRopeRty dAm-

AGe, peRsoNAl INJuRy oR deAth.

1. Remove furnace/controls compartment access panel.

2. Disconnect gas line at union ahead of combination gas valve.

3. If the unit being converted is a Nox model, follow steps “A” through “d” below and then continue with step #4. If the unit being converted is not a Nox model, skip to step #4 now.

A. this furnace is not designed to operateThe NOxoninsertsl.p. aregasrequiredwith thetoNoxmeetinsertsNOx emissionin place.levels when operating on natural gas only. Carefully remove these inserts before firing this furnace on L.P. gas.

B. To remove inserts, remove the four screws securing the burner try assembly to the heat exchanger mounting panel. Remove the burner tray.

92-22999-108-00

|

C. The NOx inserts are the cylindrical screens inserted |

|

into the entrance of the heat exchangers. Remove the |

|

NOx inserts from the heat exchangers and discard. |

|

D. Replace the burner tray assembly. |

4. |

Remove screws that attach gas manifold to burner tray |

|

and remove gas manifold. |

5. |

Each one of the burner orifices must be removed from the |

|

gas manifold and replaced with an orifice from the enve- |

|

lope marked with the proper orifice size to convert unit to |

|

operate on Propane Gas. Refer to Chart III in the |

|

Conversion Kit Index (92-21519-47 or -48) included with |

|

this kit) and verify the correct burner orifice size required. |

|

Open the burner orifice envelope marked with the orifice |

|

drill size required. Note: see altitude note above. |

6. |

Replace regulator spring in the gas valve with the L.P. |

|

regulator spring included in the envelope kit for the gas |

|

valve being converted. Refer to the instructions included |

|

in the envelope. |

7. |

Reattach gas manifold to burner tray. |

8. |

Reconnect gas line at union. |

Note: A pipe compound resistant to the action of liquefied |

|

petroleum gases must be used at all threaded pipe connec- |

|

tions. |

|

9. |

Reconnect all wiring previously disconnected. Refer to |

|

wiring diagram on the back side of the unit control box |

|

cover. |

10. |

Turn on gas and electrical supply. |

11. |

Check unit thoroughly for gas leaks with soap and water. |

! WARNING

do Not use AN opeN flAme to checK foR leAKs. use of AN opeN flAme cAN cAuse AN explosIoN oR fIRe ResultING IN pRopeRty dAmAGe, seveRe

peRsoNAl INJuRy oR deAth.

12. Follow lighting instructions to put furnace into operation.

After the gas valve has been converted for use with l.p. gas, adjust the gas manifold pressure to 10( w.c.,

CAPSCREW

PRESSURE REGULATOR

ADJUSTING SCREW

SPRING (TAPERED

END DOWN)

PRESSURE

REGULATOR

HOUSING

with the furnace in operation and with the proper gas supply pressure. the gas supply line pressure must be between 11( ANd 14( w.c. at the inlet to the gas

control valve.

13. Operate thermostat to check unit operation for ignition and extinction characteristics.

completING coNveRsIoN

1. Using an indelible pen, record the burner orifice size on label 92-18153-06.

2. Select the appropriate conversion label (included with kit) that corresponds to the orifice size actually used in this conversion.

3. Place completed conversion label adjacent to the rating plate.

AtteNtIoN: do Not Remove oR defAce oRIGINAl

RAtING plAte.

4. Place label “ATTENTION: THIS VALVE HAS BEEN CONVERTED FOR USE WITH LP GAS” onto the gas valve.

5. Install the burner compartment access door.

6. Run furnace through a complete cycle to assure proper operation.

GAS VALVE

FLAME ROLL-OUT SWITCH

GAS MANIFOLD

BURNER ORIFICE

OR

FLAME ROLL-OUT

SWITCH

GAS VALVE

GAS MANIFOLD

BURNER ORIFICE

IllustRAtIoN foR coNveRtING hoNeyWell vR8205 GAs vAlve fRom NAtuRAl GAs to l.p. GAs

2

GAs coNtRol & buRNeR oRIfIce locAtIoNs foR vARIous Rooftop models

Loading...

Loading...