White Rodgers CZ-4K, CMM-3U, CAZ-2, CZ-4, CMM-3UK Design Guide

ZONING DESIGN

ZONING SYSTEM DESIGN

Zoning any forced air system is easy once you know a few of the basic rules. The main consideration is to maintain a constant amount of air flow (CFM) through the HVAC Unit. This needs to occur when only one zone is open and if the zones are of varying size when the smallest zone is open. The other consideration is not to oversize a duct system too much in order to maintain adequate velocity and airflow when all zones are open and may be calling for conditioning on those design temperature days.

The design of the duct system for today’s zoning is an important factor to a comfortable and efficient zoning system. The number of zones, along with their size, often determine the best type of design.

There are scenarios for zoning. The first, which is typically on new installations where the duct work can be designed for zoning would be to oversize the ducts for each zone in order to get more air to the zone when it may be the only one calling. The scenario for all others would be to use a by-pass damper to relieve the excess air pressure in the duct system when a minority number of zones are calling.

The reason for each zone duct being the same size is that any zone could be the only zone calling and therefore that zone must handle the CFM of the HVAC Unit. When the duct is sized for 2/3 of the total

CFM the smaller size does restrict the airflow and forces the air at a higher pressure and velocity, however it does not increase the air typically over that static pressure rating of the blower motor, usually 0.5”W.C. This also keeps the air velocity from being noticeably noisy.

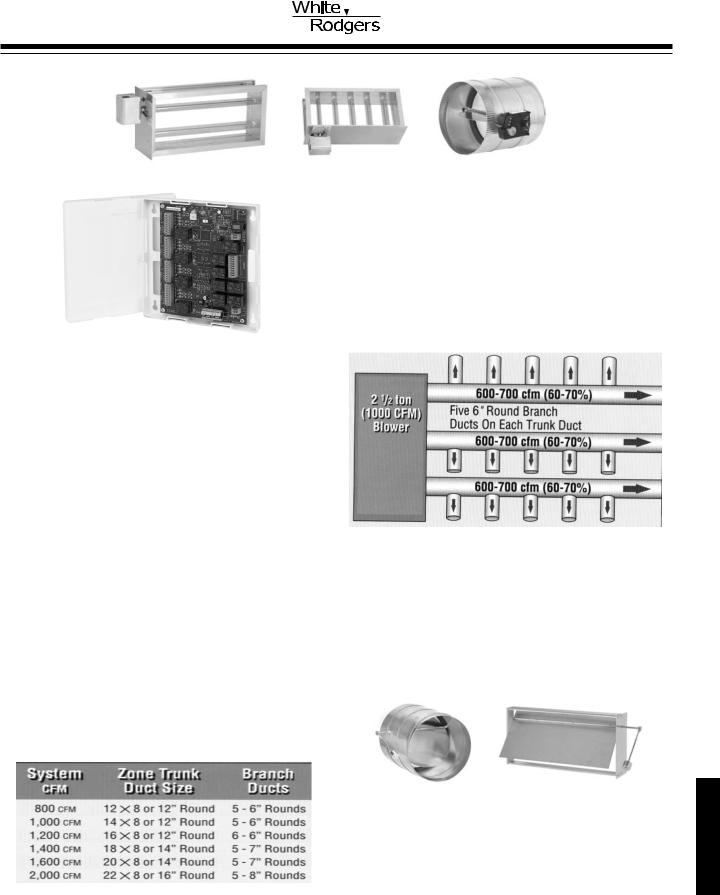

Below is a quick guide to determine the minimum equivalent size of a zone duct for each size HVAC Unit.

In retrofit and systems with 4 zones or more, over sizing the ducts is not practical. In these instances a by-pass damper is used to relieve the excess air back into the return air duct or dump the air into a central area of the building, such as a hallway, where often there is a common return. In this instance try to locate the by-pass air as far away from the return air intake as possible.

In new installations where ducts are being added it is recommended to size each zone duct the same and to size the duct for approximately 2/3 of the total HVAC System CFM. This is practical on systems with 2 or 3 zones and when all zones are approximately equal in size. This is NOT practical in an installation where 80% of conditioned area is one zone and 20% is the other zone.

The key to a good zoning system is to deliver the conditioned air to the calling zone as fast and quietly as possible in order to satisfy the demand. Whatever air cannot be directed into the zone must then by by-passed. This develops the formula for calculating the size of the by-pass damper.

Total CFM - Smallest Zone CFM = By-Pass CFM

Once the amount of by-pass air is known it is just common sense to size a duct adequately to handle the amount of air. White-Rodgers has both round and rectangular/square by-pass damper sizes.

TECHNICAL HELP

Systems over 5 Tons typically are commercial and would use a bypass damper to relieve the excess air pressure when the majority of zones shut down.

www.white-rodgers.com |

237 |

TECHNICAL HELP

ZONING DESIGN

DUMP ZONE

|

|

1CLOSED |

|

|

ZONE |

|

|

|

|

|

|

|

|

|

DUMPER |

DAMPER |

|||

|

||||

|

|

ZONE 3 |

CLOSED |

|

|

|

2OPEN

2OPEN

ZONE

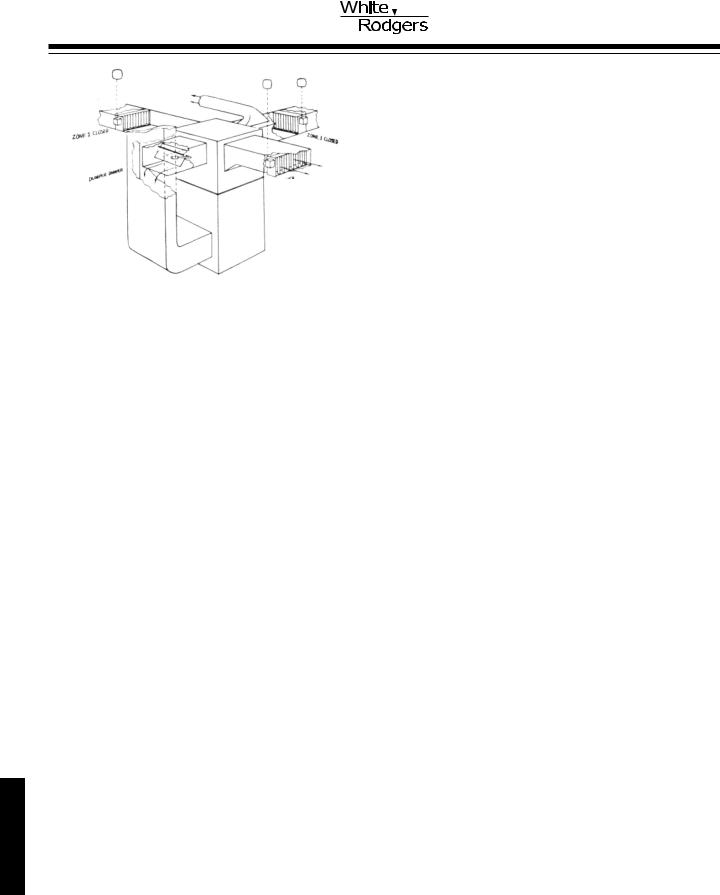

The diagram above shows a typical three zone damper system with a barometric by-pass, Model CSPRD, between the supply air and return air duct. A round take-off is also shown as an uncontrolled dump zone delivering air continuously to a non-critical temperature area, such as a basement or hallway as another method of relieving excess air. Either a by-pass or a dump zone is used but rarely ever is there a need for both.

MINIMUM POSITION DAMPER

Another form of by-pass is using minimum position dampers, such as the CZD and CRDS dampers. Setting the larger zone dampers to a minimum position can also be a method of relieving excess air pressure. This should be used when only small amounts of air need to be by-passed as the minimum position air in some cases can cause a zone to overshoot its comfort zone. Caution must be exercised when using minimum position dampers for by-pass.

ZONING HEAT PUMPS

Heat Pumps are a very popular form of heating and cooling in the milder climates of the country. These efficient units use the compressor for both heating and cooling and have a reversing valve that reverse the flow of refrigerant in order to switch between heating and cooling modes.

Heat pumps, while very efficient, are also most efficient in milder climates where often there is more of a cooling demand than a heating demand, such as the southern United States. A heat pump is also rated based upon its cooling capacity and not the heating capacity and rely typically on electric resistance heating to supplement the heat pump in colder weather, often less than 35°F to 40°F. When this back-up form of heat is used to supplement the heat pump compressor, the cost to heat the home rises dramatically. It is this reason that zoning should be installed with every heat pump.

Heat pumps with their limited capacity for heating cannot afford to be run on the colder climates heating the entire home or building. However if the heat pump is zoned, most likely less than the total building requires heat at any one time. The zone calling typically requires less than the total BTU capacity of the heat pump, more evenly matching the heat pumps capacity to the load of the calling zone. By doing so this lessens the need for the supplemental heat to come on, therefore providing substantial energy savings.

For example, a typical home may have a 3 Ton (36,000 BTU) heat pump. The total heating load for the home at heating design temperature maybe 60,000 BTUs or even more. Obviously with only 36,000 BTUs the heat pump can never keep up at design temperatures. However during milder temperature days, those above 45°F, the heat pump will often be more than adequate.

Heat pumps most efficient outdoor temperature, typically 45°F to 50°F and the amount of BTUs produced by the heat pump decreases as the temperature moves further below this temperature. This is when the supplemental electric resistance heat is often needed. As the heat pump compressor heats the air, the electric resistance heaters, located downstream of the heat pump coil, can come on to supplement the heat pump air. However if the system is zoned and heating is required for typically only one room or zone, the capacity of the heat maybe equal to or greater than the heating load of that zone and even as the output of the heat pump diminishes as the outdoor temperature falls, the capacity of the heat pump, (BTU output) is adequate for the zone(s) calling therefore not requiring the use of the supplemental heating.

The combined use of zoning and heat pumps allows more equally matched capacity to match the load of those zones calling allowing the most efficient form of heating to be used. Even during the colder times when the supplemental electric heat is needed, it is important to remember that a smaller amount of heating is always required for one room or zone vs. the whole house. Zoning allows the heating to be directed only to those areas needing it.

Fossil Fuel Furnaces and Add-On Heat Pumps

When a heat pump is added on to a fossil fuel (gas or oil) furnace, the sequence of operation is somewhat different than using electric resistance heating as supplemental heating. The heat pump coil is often on the supply side of the furnace and both the heat pump and furnace cannot be run together as the high temperature from the furnace will cause the heat pump compressor safeties to engage.

All heat pump manufacturers use a fossil fuel kit in order to make the most effective use of the heat pump and furnace. Simply this fossil fuel kit uses an outdoor thermostat to switch between the heat pump and furnace based upon the outdoor temperature or balance point. The balance point is calculated to determine the most effective temperature to operate the heat pump vs. the furnace. See the heat pump manufacturer’s information to calculate the balance point.

When using a White-Rodgers System with an add-on heat pump it is recommended to use the manufacturer’s fossil fuel kit in order maintain the manufacturer’s warranty. The zone control panel equipment terminal block will be wired to the thermostat connections on the fossil fuel kit.

When using any heat pump it is important to remember that with a limited amount of heating capacity, ZONING is imperative in order to make maximum use of the heat pump and where the individual zone load is more closely matched to the capacity of the heat pump.

238 |

www.white-rodgers.com |

Loading...

Loading...