Whirlpool WTW8440YW, WTW8400YW, WTW8240YW, WTW8200YW, MVWB980BG Installation Instructions

...

WASHER |

INSTRUCTIONS |

INSTALLATION |

D’INSTALLATION |

INSTRUCTIONS |

DE LA LAVEUSE |

Table of Contents

WASHER SAFETY.............................................................. |

2 |

. |

|

INSTALLATION REQUIREMENTS.................................... |

3 |

Tools and Parts.................................................................... |

3 |

Location Requirements....................................................... |

4 |

Drain System........................................................................ |

5 |

Electrical Requirements...................................................... |

5 |

INSTALLATION INSTRUCTIONS...................................... |

6 |

Remove Shipping Base and Packing Ring........................ |

6 |

Connect Drain Hose............................................................ |

6 |

Connect Inlet Hoses............................................................ |

7 |

Level Washer........................................................................ |

9 |

COMPLETE INSTALLATION CHECKLIST...................... |

10 |

Table des matières

SÉCURITÉ DE LA LAVEUSE............................................ |

11 |

. |

|

EXIGENCES D’INSTALLATION........................................ |

12 |

Outillage et pièces.............................................................. |

12 |

Exigences d’emplacement................................................. |

13 |

Système de vidange .......................................................... |

14 |

Spécifications électriques.................................................. |

15 |

INSTRUCTIONS D’INSTALLATION.................................. |

15 |

Retrait de la base d’expédition |

|

et de l’emballage en anneau.............................................. |

16 |

Raccordement du tuyau de vidange................................. |

16 |

Raccordement des tuyaux d’alimentation........................ |

17 |

Mise à niveau de la laveuse............................................... |

18 |

LISTE DE VÉRIFICATION |

|

POUR INSTALLATION TERMINÉE.................................. |

20 |

INSTALLATION NOTES |

NOTES CONCERNANT L’INSTALLATION |

Date of purchase:_________________________________ |

Date d’achat :_____________________________________ |

Date of installation:_ _______________________________ |

Date d’installation :_ ________________________________ |

Installer:_________________________________________ |

Installateur :_______________________________________ |

Model number:____________________________________ |

Numéro du modèle :_________________________________ |

Serial number:____________________________________ |

Numéro de série :___________________________________ |

Para una versión de estas instrucciones en español, visite www.whirlpool.com

W10410358C W10410359C-SP

WASHER SAFETY

2

INSTALLATION REQUIREMENTS

TOOLS AND PARTS

Gather the required tools and parts before starting installation.

Tools needed:

|

|

|

Pliers that open to 19/16" |

|

Flashlight (optional) |

(39.5 mm) |

|

|

4" min (102 mm)

Adjustable or open-end |

Wood block |

|||||

wrench 9/16" (14 mm) |

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Tape measure or ruler |

Level |

Parts supplied (located in the washer basket):

Drain hose form |

Cable Tie |

Parts needed (Not supplied with washer):

To order, please refer to the phone number or website on the back page of your “Use and Care Guide.”

■■ |

8212656RP |

10 ft. (3.0 m) Inlet hose, Black EPDM (2 pack) |

■■ |

8212641RP |

5 ft. (1.5 m) Inlet hose, Black EPDM (2 pack) |

■■ |

8212646RP |

4 ft. (1.2 m) Inlet hose, Black EPDM (2 pack) |

■■ |

8212545RP |

5 ft. (1.5 m) Inlet hose, Red and Blue EPDM |

|

|

(2 pack) |

■■ |

8212487RP |

5 ft. (1.5 m) Nylon braided inlet hose (2 pack) |

■■ |

8212638RP |

6 ft. (1.8 m) Nylon braided inlet hose, space |

|

|

saving 90° elbow, hypro-blue steel couplings |

|

|

(2 pack) |

■■ |

8212637RP |

6 ft. (1.8 m) Inlet hose, Black EPDM, space |

|

|

saving 90° elbow, hypro-blue steel couplings |

|

|

(2 pack) |

Alternate parts (Not supplied with washer):

Your installation may require additional parts. To order, please refer to the phone number or website on the back page of your “Use and Care Guide.”

If you have: |

You will need: |

Laundry tub or |

Sump pump system (if not already |

standpipe taller |

available) |

than 96" (2.4 m) |

|

1" (25 mm) |

2" (50 mm) diameter to 1" (25 mm) |

diameter standpipe |

diameter Standpipe Adapter Kit, |

|

Part Number 3363920 and |

|

Connector Kit, Part Number 285835 |

Overhead sewer |

Standard 20 gal. (76 L) 39" (990 mm) |

|

tall drain tub or utility sink, sump |

|

pump, and connectors (available |

|

from local plumbing suppliers) |

Floor drain |

Siphon Break Kit, |

|

Part Number 285834 |

|

Extension Drain Hose, |

|

Part Number 285863 |

|

Connector Kit, Part Number 285835 |

Drain hose too short |

Extension Drain Hose, |

|

Part Number 285863 |

|

Connector Kit, Part Number 285835 |

Lint clogged drain |

Drain protector, Part Number 376031 |

Water inlet hoses (2) |

Flat inlet hose washers (4) |

3

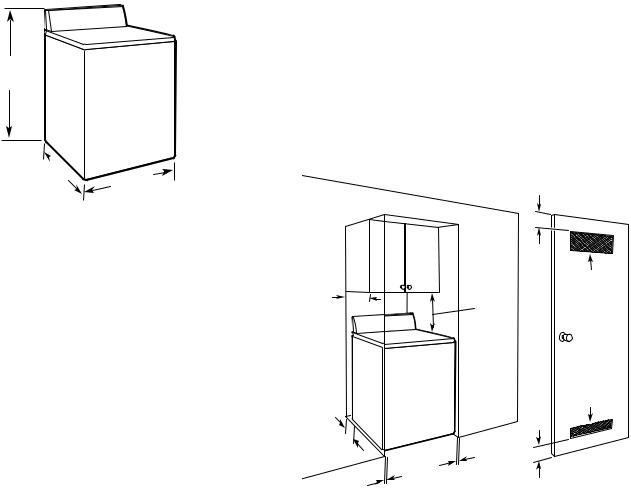

LOCATION REQUIREMENTS

Select proper location for your washer to improve performance and minimize noise and possible “washer walk.” Install your washer in a basement, laundry room, closet, or recessed area.

45.5" (1156 mm)

27.5"

(698 mm) 27.5"

(698 mm)

You will need:

■■ A water heater set to deliver 120°F (49°C) water to the washer.

■■ A grounded electrical outlet located within 4 ft. (1.2 m) of where the power cord is attached to the back of the washer. See “Electrical Requirements.”

■■ Hot and cold water faucets located within 3 ft. (900 mm) of the hot and cold water fill valves, and water pressure of 20–100 psi (138–690 kPa) for best performance.

■■ Level floor with maximum slope of 1" (25 mm) under entire washer. Installing the washer on carpet is not recommended.

■■ A sturdy floor to support the washer weight (washer, water, and load) of 315 lbs (143 kg).

IMPORTANT: Do not operate, install, or store washer where it will be exposed to water, weather, or at temperatures below 32° F (0° C). Some water can remain in washer and can cause damage in low temperatures. See your “Use and Care Guide” for information on winterizing.

Proper installation is your responsibility.

Spacing for recessed area or closet installation

All dimensions show recommended spacing allowed, with tested spacing of 0" (0 mm) clearance on sides.

■■ Additional spacing should be considered for ease of installation and servicing.

■■ Additional clearances might be required for wall, door, and floor moldings.

■■ Additional spacing should be considered on all sides of the washer to reduce noise transfer.

■■ For closet installation, with a door, minimum ventilation openings in the top and bottom of the door are required. Louvered doors with equivalent ventilation openings are acceptable.

■■ Companion appliance spacing should also be considered.

3"* (76 mm)

14" max. |

* |

48 in.2 * |

(356 mm) |

|

(310 cm2) |

17"* (432 mm)

24 in.2 * 5" (155 cm2)

(126 mm)

|

1" |

|

1" |

(25 mm) |

3"* |

|

||

(25 mm) |

|

(76 mm) |

|

|

* Required spacing

4

DRAIN SYSTEM |

ELECTRICAL REQUIREMENTS |

Drain system can be installed using a floor drain, wall standpipe, floor standpipe, or laundry tub. Select method you need.

Floor standpipe drain system

41/2"

(114 mm)

39" |

(990 mm) |

Minimum diameter for a standpipe drain: 2" (51 mm). Minimum carry-away capacity: 17 gal. (64 L) per minute. Top of standpipe must be at least 39" (990 mm) high; install no higher than 96" (2.4 m) from bottom of washer. If you must install higher than 96" (2.4 m), you

will need a sump pump system.

Wall standpipe drain system

41/2"

(114 mm)

See requirements for floor standpipe drain system.

Floor drain system

Floor drain system requires a Siphon Break Kit (Part Number 285834), 2 Connector Kits (Part Number 285835), and an Extension Drain Hose (Part Number 285863) that may be purchased separately. To order, please see toll-free phone numbers in your “Use and Care Guide.” Minimum siphon break: 28" (710 mm) from bottom of washer. (Additional hoses may

be needed.)

Laundry tub drain system

41/2" (114 mm)

39"0 (762990 mm)

■■ A 120 volt, 60 Hz., AC only, 15or 20-amp, fused electrical supply is required. A time-delay fuse or circuit breaker on

a separate circuit serving only this washer is recommended.

■■ This washer is equipped with a power supply cord having a 3-prong grounding plug.

■■ To minimize possible shock hazard, the cord must be plugged into a mating, 3-prong, grounding-type outlet, grounded in accordance with local codes and ordinances. If a mating outlet is not available, it is the personal responsibility and obligation of the customer to have the properly grounded outlet installed by a qualified electrician.

■■ If codes permit and a separate ground wire is used, it is recommended that a qualified electrician determine that the ground path is adequate.

■■ Do not ground to a gas pipe.

■■ Check with a qualified electrician if you are not sure the washer is properly grounded.

■■ Do not have a fuse in the neutral or ground circuit.

Minimum capacity: 20 gal. (76 L). Top of laundry tub must be at least 39" (990 mm) above floor; install no higher than 96" (2.4 m) from bottom of washer.

IMPORTANT: To avoid siphoning, no more than 4 1⁄2" (114 mm) of drain hose should be inside standpipe or below the top of wash tub. Secure drain hose with cable tie.

5

REMOVE SHIPPING BASE AND PACKING RING

1. Remove shipping base and packing ring

INSTALLATION INSTRUCTIONS

Before you start: remove shipping materials.

It is necessary to remove all shipping materials for proper operation and to avoid excessive noise from washer.

NOTE: To avoid floor damage during installation, set the washer onto cardboard before moving across the floor.

IMPORTANT:

■■ Be sure the foam shipping base has been removed from the bottom of the washer as directed in the “Remove Shipping Base and Packing Ring” section.

■■ If foam shipping base has not been removed, be sure lid is secured with tape before laying washer on its back.

■■ Removing the foam shipping base is necessary for proper operation.

Place cardboard supports from shipping carton on floor behind washer for support. Secure the lid with tape. Using two or more people, tip the washer onto its back and place on cardboard supports. Remove foam shipping base. Then, set washer back upright, and remove the tape from the lid so that you can open the lid and remove the foam packing ring from the washer tub.

NOTE: Keep foam packing ring in case you need to move the washer in the future.

CONNECT DRAIN HOSE

IMPORTANT: Proper connection of the drain hose helps to avoid water leakage and damage to your floors. The drain hose is connected to your washer and is stored inside the washer cabinet.

1. Remove drain hose from washer cabinet

Gently pull hose out of back of washer cabinet from top until end emerges.

IMPORTANT: Do not force excess drain hose back into rear of washer.

6

Loading...

Loading...