Whirlpool 3395339 User Manual

stud

lnst

‘ted

b

‘IUC

I

c

Drye

tiol

%s

Part No. 3395339

Before you start...

Check location where dryers will be

used. Proper installation is your

responsibility The dryer must not be

installed or stored in an area where it

will be exposed to water and/or

weather. Make sure you have

everything necessary for correct

installation.

Each of the dryers is equipped with a

timer, selector switches and indicator

lights. The timers are set to provide 45

minutes (4 pins) of drying time when

activated by the coin slide. Timer

cams for 30-minute (6 pins) and 60minute (3 pins) drying timers are

supplied with the unit in the parts

bag. See Pages 7 and 8 for timer

cam changing instructions.

The coin-slide mechanisms, control

panel lock and key, coin box and

coin box locks and keys are not

included and are available from

usual industry sources,

Fire Hazard

For your safety, the information in

this manual must be followed to

minimize the risk of fire or explosion

or to prevent property damage,

personal injury or loss of life.

- Do Not store or use gasoline or

other flammable vapors and

liquids in the vicinity of this or any

other appliance.

- WHAT TO DO IF YOU SMELL GAS:

l

Do Not try to light any

appliance.

l

Do Not touch any electrical

switch; Do Not use any phone

in your building.

l

Clear the room, building or area

of all occupants.

l

Immediately call your gas

supplier from a neighbor’s

phone. Follow the gas supplier’s

instructions.

- If you cannot reach your gas

supplier, call the fire department.

- Never install dryer up against

draperies or curtains or on carpet.

- Keep any and all items from falling

or collecting behind the dryer.

Installation and service must be

performed by a qualified installer,

service agency or the gas supplier.

Post this warning in a prominent

location.

It is recommended that the operator

post, in a prominent location,

instructions for the customer’s use in

the event that the customer smells

gas. This information should be

obtained from your local gas supplier.

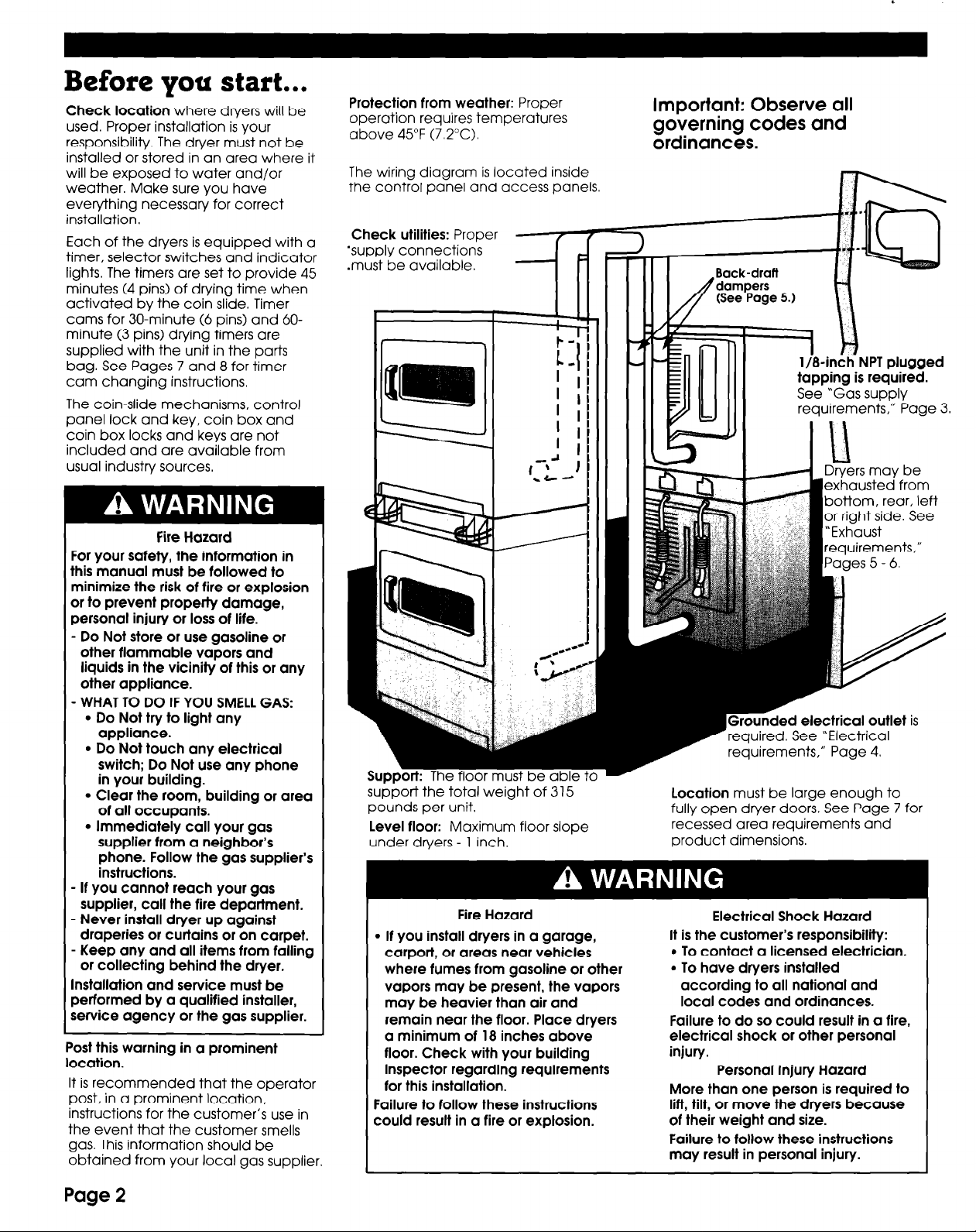

Protection from weather: Proper

operation requires temperatures

above 45°F (7.2”C).

The wiring diagram is located inside

the control panel and access panels.

Support: The floor must be able to

support the total weight of 3 15

pounds per unit.

Level floor: Maximum floor slope

under dryers - 1 inch.

Fire Hazard

l

If you install dryers in a garage,

carport, or areas near vehicles

where fumes from gasoline or other

vapors may be present, the vapors

may be heavier than air and

remain near the floor. Place dryers

a minimum of 18 inches above

floor. Check with your building

inspector regarding requirements

for this installation.

Failure to follow these instructions

could result in a fire or explosion.

Important: Observe all

governing codes and

ordinances.

l/S-inch-NPT plugged

tapping is required.

See “Gas supply

requirements,” Page 3.

Dryers may be

-4

ded electrical outlet is

-required. See “Electrical

requirements,” Page 4.

Location must be large enough to

fully open dryer doors. See Page 7 for

recessed area requirements and

product dimensions.

Electrical Shock Hazard

It is the customer’s responsibility:

l

To contact a licensed electrician.

. To have dryers installed

according to all national and

local codes and ordinances.

Failure to do so could result in a fire,

electrical shock or other personal

injury.

Personal Injury Hazard

More than one person is required to

lift, tilt, or move the dryers because

of their weight and size.

Failure to follow these instructions

may result in personal injury.

exhausted from

bottom, rear, left

or right side. See

“Exhaust

requirements,”

Pages 5 - 6.

Page 2

Tools needed for

installation:

adjustable wrench

utility knife

Phillips screwdriver

flat-blade screwdriver

level

pliers

duct tape

Parts supplied for

hstallation:

2 slide protectors 8 screws

2 slide extensions 2,30-minute cams

2 bolt and washer 2,60-minute cams

assemblies 4,3/4” wood screws

Parts owner must

supply:

1 control panel lock and key

2 coin vaults and keys (E.S.D. vault must

have projecting lock.)

2 coin-slide mechanisms (vertical 8)

Parts may be ordered from

Greenwald Industries, Inc. or

Equipment Systems and Devices, Inc.

l

Greenwald Industries, Inc.

1340 Metropolitan Avenue

Brooklyn, NY 11237

telephone (7 18) 82 l-9000 or

toll free (800) 22 l-0982

fax no. (718) 417-7412

l

Equipment Systems and

Devices, Inc.

270 New Jersey Dr.

Fort Washington, PA 19034

telephone (2 15) 628-0860 or

toll free (800) 523-1510

fax no. (2 15) 643-4623

Gas supply

reauirements

a

Fire Hazard

l

These dryers must be connected

to a regulated gas supply.

Failure to do so could result in highpressure gas release, resulting in a

fire or explosion.

l

Have L.P. gas checked by a

qualified person before installing

the dryer. The L.P. gas supply must

not exceed a pressure of 13”

water column.

l

New flexible tubing should be

used. Reusing old, flexible tubing

might result in possible leaks or

fire hazard.

Failure to follow these instructions

could result in fire or explosion.

OBSERVE ALL GOVERNING CODES

AND ORDINANCES.

A

n

with American National Standard,

National Fuel Gas Code ANSI 2223. llatest edition”, and all local codes

and ordinances.

B

been certified bv the American Gas

Association for use at altitudes up to

10,000 feet above sea level at the

B.T.U. rating indicated on the

model/serial plate. Burner input

adjustments are not required when

the dryer is operated up to this

elevation.

When installed above 10,000 feet, a

four percent (4%) reduction of the

burner B.T.U. rating shown on the

model/serial plate is required for

each 1,000 foot increase in elevation.

For assistance when converting to

other gas types and/or installing

above 10,000 feet elevation, contact

your local service company.

C

equipped with the correct burner for

the particular type of gas used.

Burner information will be found on

the rating plate in door well of the

appliance. If this information does not

agree with the type of gas available,

see your dealer.

D

use with NATURAL GAS. They are

certified by the American Gas

Association for manufactured, mixed

and L.P. (propane and butane) gases

with appropriate conversion. No

attempt shall be made to convert the

appliance from the gas specified on

the rating plate for use with a

different gas without consulting the

serving gas supplier. Conversion must

be done by a qualified service

technician. Gas conversion kit part

numbers are listed on the gas valve

burner base.

of l/2-inch IPS pipe to the dryer’s

location. If the total length of the

supply line is more than 20 feet, larger

pipe will be needed. For L.P. gas

usage, 3/8-inch, approved copper

tubing may be used. Pipe-joint

compounds suitable for use with L.P.

gas should be used.

This installation must conform

n

The desian of this drver has

n

Check that dryers are

n

These dryers are shipped for

E

n

Provide a rigid gas supply line

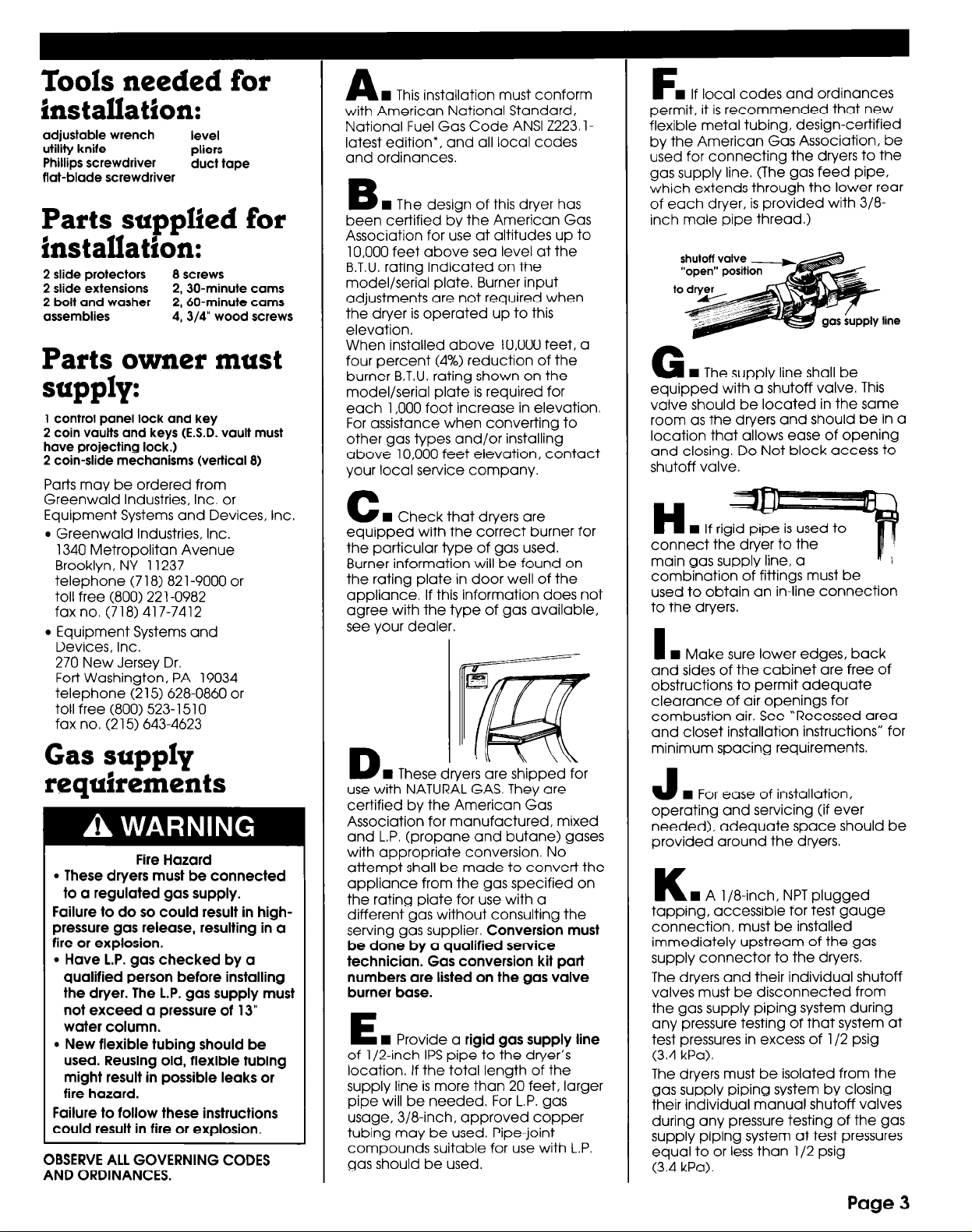

H If local codes and ordinances

F

permit, it is recommended that new

flexible metal tubing, design-certified

by the American Gas Association, be

used for connecting the dryers to the

gas supply line. (The gas feed pipe,

which extends through the lower rear

of each dryer, is provided with 3/8inch male pipe thread.)

n

G

equipped with a shutoff valve. This

valve should be located in the same

room as the dryers and should be in a

location that allows ease of opening

and closing. Do Not block access to

shutoff valve.

main gas supply line, a

combination of fittings must be

used to obtain an in-line connection

to the dryers.

I

and sides of the cabinet are free of

obstructions to permit adequate

clearance of air openings for

combustion air. See “Recessed area

and closet installation instructions” for

minimum spacing requirements.

J

operating and servicing (if ever

needed), adequate space should be

provided around the dryers.

K

tapping, accessible for test gauge

connection, must be installed

immediately upstream of the gas

supply connector to the dryers.

The dryers and their individual shutoff

valves must be disconnected from

the gas supply piping system during

any pressure testing of that system at

test pressures in excess of l/2 psig

(3.4 kPa).

The dryers must be isolated from the

gas supply piping system by closing

their individual manual shutoff valves

during any pressure testing of the gas

supply piping system at test pressures

equal to or less than l/2 psig

(3.4 kPa).

The supply line shall be

n

Make sure lower edges, back

n

For ease of installation,

n

A l/8-inch, NPT plugged

Page 3

Electrical

Kz+;rdmended grounding

P

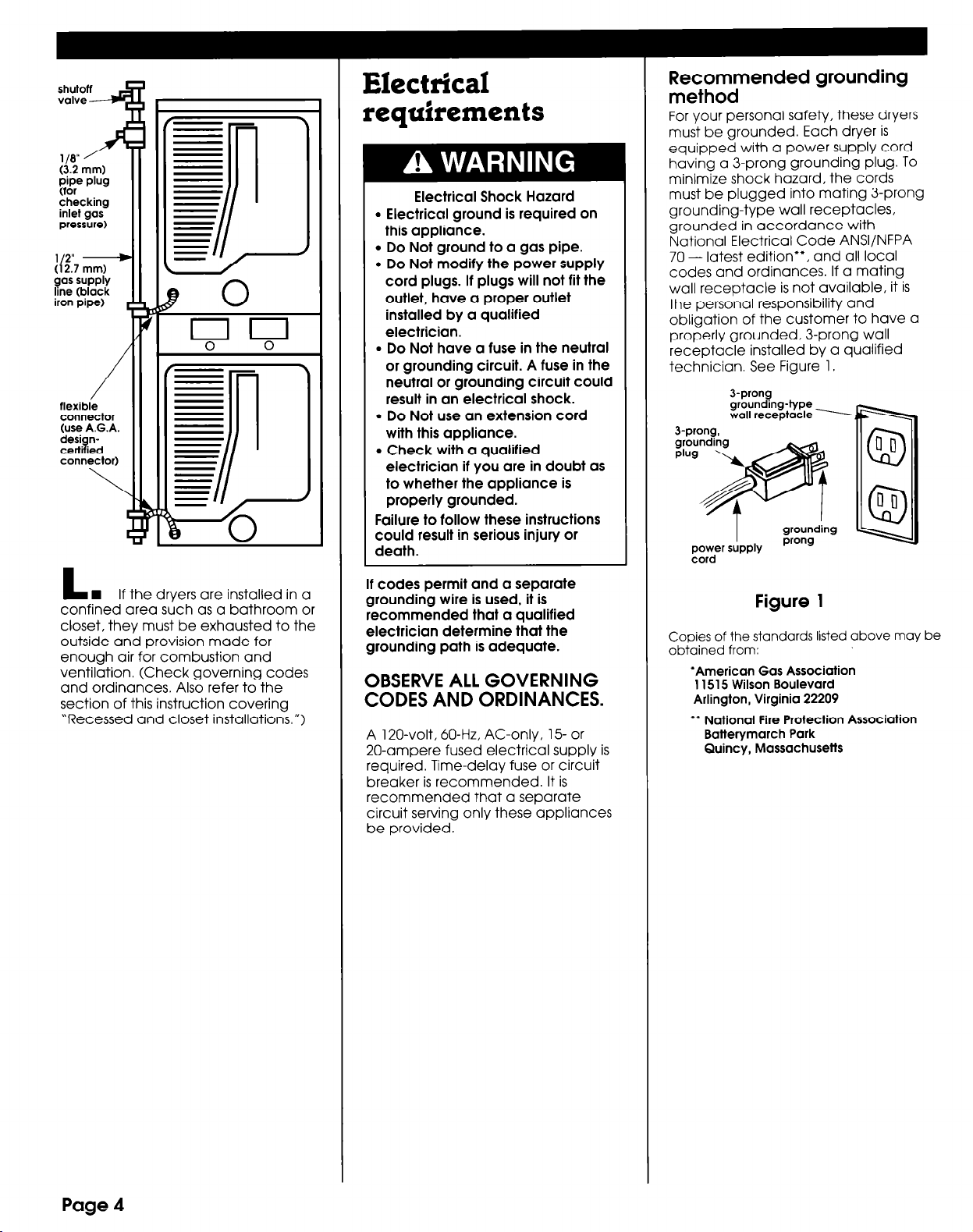

l/0”

(?.2 mm)

pltre Plug

checking

inlet gas

pressure)

l/2” -

(12.7 mm)

gas SUPPLY

line (black

iron pipe) t

/

flexible

connector

(use A.G.A.

desi n-

3

certi ied

connector)

\

W If the dryers are installed in a

L

confined area such as a bathroom or

closet, they must be exhausted to the

outside and provision made for

enough air for combustion and

ventilation. (Check governing codes

and ordinances. Also refer to the

section of this instruction covering

“Recessed and closet installations.“)

requirements

Electrical Shock Hazard

l

Electrical ground is required on

this appliance.

l

Do Not ground to a gas pipe.

l

Do Not modify the power supply

cord plugs. If plugs will not fit the

outlet, have a proper outlet

installed by a qualified

electrician.

l

Do Not have a fuse in the neutral

or grounding circuit. A fuse in the

neutral or grounding circuit could

result in an electrical shock.

l

Do Not use an extension cord

with this appliance.

l

Check with a qualified

electrician if you are in doubt as

to whether the appliance is

properly grounded.

Failure to follow these instructions

could result in serious injury or

death.

If codes permit and a separate

grounding wire is used, it is

recommended that a qualified

electrician determine that the

grounding path is adequate.

OBSERVE ALL GOVERNING

CODES AND ORDINANCES.

A 120-volt, 60-Hz, AC-only, 1.5 or

20-ampere fused electrical supply is

required. Time-delay fuse or circuit

breaker is recommended. It is

recommended that a separate

circuit serving only these appliances

be provided.

For your personal safety, these dryers

must be grounded. Each dryer is

equipped with a power supply cord

having a 3-prong grounding plug. To

minimize shock hazard, the cords

must be plugged into mating 3-prong

grounding-type wall receptacles,

grounded in accordance with

National Electrical Code ANWNFPA

70 - latest edition”‘, and all local

codes and ordinances. If a mating

wall receptacle is not available, it is

the personal responsibility and

obligation of the customer to have a

properly grounded, 3-prong wall

receptacle installed by a qualified

technician. See Figure 1.

00

8

00

8

I

cord

Figure 1

Copies of the standards listed above may be

obtained from:

*American Gas Association

11515 Wilson Boulevard

Arlington, Virginia 22209

** National Fire Protection Association

Batterymarch Park

Quincy, Massachusetts

Page 4

Loading...

Loading...