®

Home Appliances

IMPORTANT:

Gas Large Capacity Thin Twin

Washer•Dryer – 120 Volt

Installation Instructions

Gas Large Capacity Thin Twin

Read and save

these instructions.

IMPORTANT:

Installer: Leave Installation Instructions

with the homeowner.

Homeowner: Keep Installation Instructions

for future reference.

Save Installation Instructions for local

electrical inspector’s use.

www.whirlpool.com

Part No. 3395326 Rev. F

Panel A

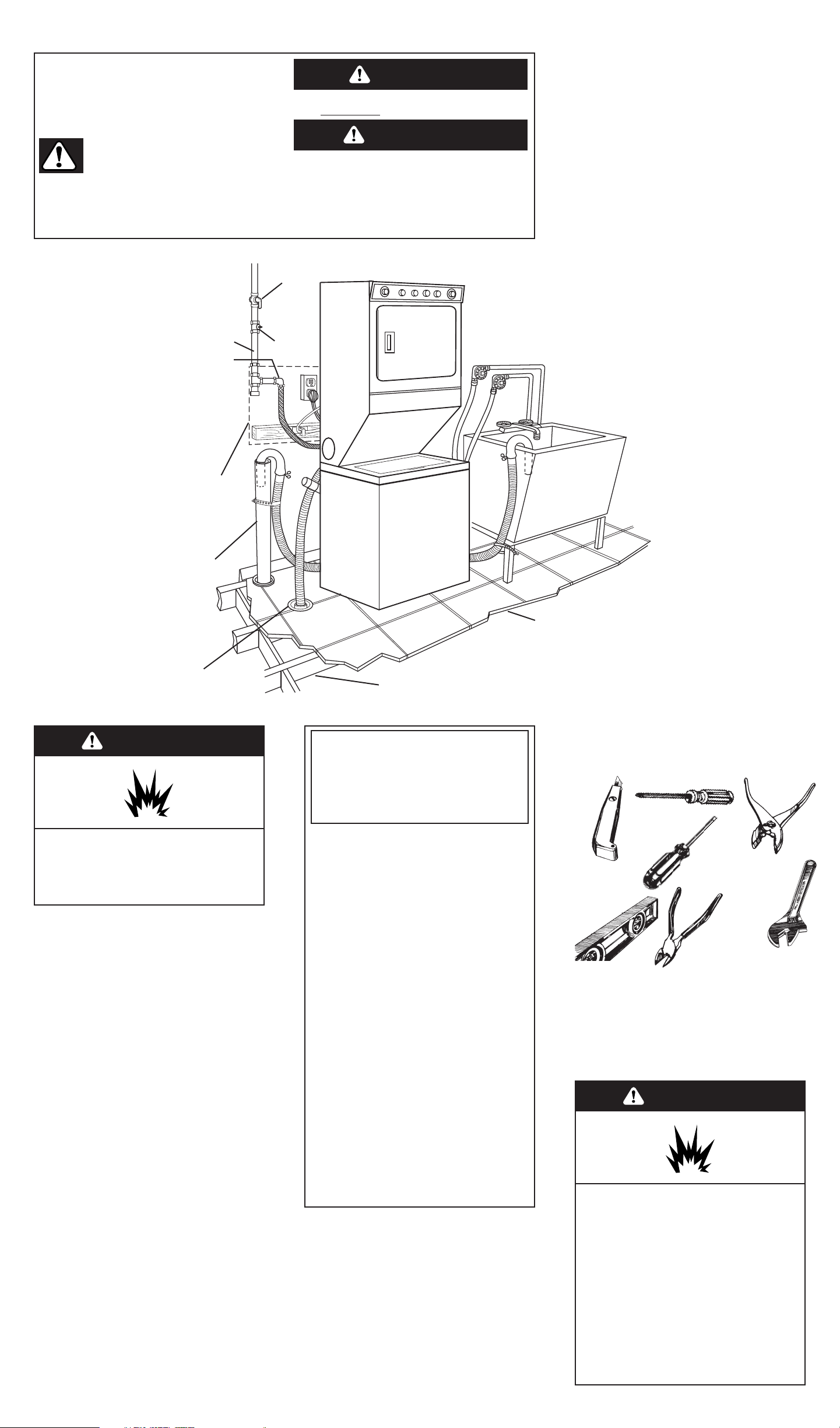

Tools and materials

needed for installation:

Phillips screwdriver

diagonal

cutters

utility

knife

adjustable

wrench (two

may be

required)

flat-blade

screwdriver

level

pliers

A 1" x 4" x 24" board and fasteners are also

required (but are not included with this product).

Gas supply requirements

OBSERVE ALL GOVERNING CODES

AND ORDINANCES

Before you start...

Location: Should be large enough to fully

open dryer door to 90°. (See Panel G for

“Recessed and closet installation

instructions” and “Product dimensions.”)

WARNING

Explosion Hazard

Keep flammable materials and vapors,

such as gasoline, away from dryer.

Failure to do so can result in death,

explosion, or fire.

Grounded electrical

outlet is required. See

“Electrical

requirements.”

Check location where washer/dryer will

be installed. Proper installation is your

responsibility. The washer/dryer must not

be installed or stored in an area where it

will be exposed to water and/or

weather. Make sure you have

everything necessary for correct

installation.

Water heater: Set to deliver 140°F water to the

washer.

Laundry tub drain system: Needs a 20-gallon

laundry tub. Top of tub must be at least

34 inches high and no higher than 72 inches

from floor.

If a longer drain hose is needed, drain hose

(Part No. 388423) and hose extension kit (Part

No. 285442) are available from Whirlpoolauthorized parts distributors.

Dryer may be exhausted from the rear or

left or right side. Exhausting through the

side requires Part No. 3391335. (See

“Exhaust requirements,” Panels B

and C.)

Four-inch metal exhaust

vent is required.

SEE RECESSED AREA

INSTRUCTIONS ON PANEL G.

Important: Observe all governing

codes and ordinances.

gas supply line

coupling

38" min. to 41"

max.

from floor

Support: Floor must be sturdy enough

to support washer/dryer weight, with

water and clothes, of 500 pounds.

Level floor:

1-inch maximum slope

under entire washer/dryer.

gas shutoff

valve

Hot and cold

water faucets:

Must be within

4 feet of the

back of the

washer/dryer

and provide

water pressure

of 5 -100 PSI.

1/8-inch

NPT

plugged

tapping

rigid

gas

supply

line

Standpipe drain system: Needs

a two-inch diameter standpipe

with minimum carry-away

capacity of 17 gallons per

minute. Top of standpipe must

be at least 34 inches high and

no higher than

72 inches from floor.

Floor drain system requires a

siphon break, Part No. 285320,

available from a Whirlpoolauthorized parts distributor.

This appliance must be attached to

a wall. The cable bracket must be

secured to a wall stud within a

27-inch-wide area that is 28 inches

minimum to 41 inches maximum

from floor. (See Panel F.)

1/8-inch NPT plugged

tapping is required.

(See Panel B, Step L.)

Do Not store or operate washer/dryer below

32°F (some water may remain in washer).

Proper operation of dryer cycles requires

temperatures above 45°F. See Use & Care

Guide for “Winterizing” information.

Check code requirements: Some codes

limit or do not permit installation of clothes

dryers in garages, closets, mobile homes

and sleeping quarters. (Contact your local

building inspector.)

Check utilities: Proper gas, water and

electric supply connections must be

available.

WARNING: For your safety the

information in this manual

must be followed to minimize

the risk of fire or explosion or

to prevent property damage,

personal injury or death.

— Do not store or use gasoline

or other flammable vapors and

liquids in the vicinity of this or

any other appliance.

— WHAT TO DO IF YOU SMELL

GAS

• Do not try to light any

appliance.

• Do not touch any electrical

switch; do not use any

phone in your building.

• Clear the room, building or

area of all occupants.

• Immediately call your gas

supplier from a neighbor’s

phone. Follow the gas

supplier’s instructions.

• If you cannot reach your

gas supplier, call the fire

department.

— Installation and service must

be performed by a qualified

installer, service agency or

the gas supplier.

WARNING

Explosion Hazard

Use a new AGA or CSA approved gas

supply line.

Install a shut-off valve.

Securely tighten all gas connections.

If connected to LP, have a qualified

person make sure gas pressure does

not exceed 13" water column.

Examples of a qualified person include

licensed heating personnel, authorized

gas company personnel, and

authorized service personnel.

Failure to do so can result in death,

explosion, or fire.

Your safety and the safety of others are

very important.

We have provided many important safety messages

in this manual and on your appliance. Always read

and obey all safety messages.

This is the safety alert symbol.

This symbol alerts you to potential

hazards that can kill or hurt you and

others.

All safety messages will follow the safety alert

symbol and either the word “DANGER” or

“WARNING”. These words mean:

All safety messages will tell you what the potential

hazard is, tell you how to reduce the chance of

injury, and tell you what can happen if the

instructions are not followed.

You can be killed or seriously injured if you

don’t immediately

follow instructions.

You can be killed or seriously injured if you don’t

follow instructions.

WARNING

D ANGER

Important: Observe all governing codes

and ordinances.

Exhaust your dryer to the outside.

Moisture and lint indoors may cause:

• Lint to gather around the dryer where

it can be fuel for a fire.

• Moisture damage to woodwork,

furniture, paint, wallpaper, carpet,

etc.

• Housecleaning problems and health

problems.

If the washer/dryer is installed in a

confined area such as a bedroom,

bathroom or closet, it must be

exhausted to the outside and provision

must be made for enough air for

ventilation. Check governing codes and

ordinances. Also refer to the “Recessed

and closet installation instructions” on

Panel G.

Dura Safe

TM

vent products are

recommended and are available from

your dealer. See Panel G.

Four-inch diameter vent is required.

Use a heavy metal vent. Do not use plastic or

metal foil vent.

• Do Not use non-metal flexible vent, or

exhaust hoods with magnetic latches.

• Do Not exhaust dryer into a chimney,

furnace, cold air vent, attic or crawl space,

or any other vent used for venting.

• Do Not install flexible vent in enclosed walls,

ceilings or floors.

Rigid metal vent is recommended to prevent

crushing and kinking.

Flexible metal vent must be fully extended

and supported when the dryer is in its final

position.

Remove excess flexible vent to avoid

sagging and kinking that may result in

reduced air flow.

An exhaust hood should cap the exhaust

vent to prevent rodents and insects from

entering the home.

Exhaust outlet hood must be at least 12

inches from the ground or any object that

maybe in the path of the exhaust (such as

flowers, rocks or bushes, etc.).

If using an existing exhaust system, clean lint

from entire length of system and make sure

exhaust hood is not plugged with lint.

Panel B

G.If the washer/dryer is installed in a

confined area such as a bedroom,

bathroom or closet, it must be

exhausted to the outside and provision

made for enough combustion air and

ventilation air. (Check governing codes

and ordinances. Also refer to the

section in this instruction covering

Recessed and closet installations.)

gas

supply

line

H.This washer/dryer is equipped

with its own permanent, flexible gas

connector, design-certified by CSA

International, for connecting the

appliance to the gas supply line.

I.If rigid pipe is

used as a gas

supply line, a

combination of

pipe fittings must

be used to

obtain an in-line

connection to

the washer/dryer.

J.Make sure the back and sides of

the cabinet are free of obstructions to

permit adequate clearance of air

openings for combustion air. (See

“Recessed and closet installation

instructions” for minimum spacing

requirements, Panel G.)

household rigid

gas supply pipe

K.For ease of installation, operating

and servicing (if ever needed),

adequate space should be provided

around the washer/dryer.

L.An 1/8-inch NPT plugged tapping,

accessible for test gauge connection,

must be installed immediately upstream

of the gas supply connector to the

dryer.

The dryer and its individual shutoff valve

must be disconnected from the gas

supply piping system during any

pressure testing of that system at test

pressures in excess of 1/2 psig (3.45 kPa).

The dryer must be isolated from the gas

supply piping system by closing its

individual manual shutoff valve during

any pressure testing of the gas supply

piping system at test pressures equal to

or less than 1/2 psig (3.45 kPa).

Electrical requirements

A three-wire, single-phase, 120-volt,

60-Hz, AC-only, 15- or 20-ampere, fused,

electrical supply is required. A timedelay fuse or circuit breaker is

recommended. If your home has a

circuit wired and fused for 20 amperes,

this is preferred. If you are installing a

new circuit, one wired and fused for

20 amperes is recommended. It is also

recommended that a separate circuit

serving only this appliance be provided.

Recommended ground method

For your personal safety, this appliance

must be grounded. This washer/dryer is

equipped with a power supply cord

having a 3-prong ground plug. To

minimize possible shock hazard, the

cord must be plugged into a mating,

3-prong, ground-type outlet, grounded

in accordance with the National

Electrical Code, ANSI/NFPA

70 — latest edition,** and all local codes

and ordinances. (See Figure 1.) If a

mating outlet is not available, it is the

personal responsibility and obligation of

the customer to have a properly

grounded, 3-prong outlet installed by a

qualified electrician.

3-prong

ground

plug

power

supply

cord

Figure 1

ground

prong

3-prong

ground-type

outlet

Exhaust requirements

A.This installation must conform with

American National Standard, National

Fuel Gas Code ANSI Z223.1 — latest

edition,* and all local codes and

ordinances.

B.The design of this dryer has been

certified by CSA International for use at

altitudes up to 10,000 feet above sea

level at the B.T.U. rating indicated on

the model/serial plate. Burner input

adjustments are not required when the

dryer is operated up to this elevation.

When installed above 10,000 feet, a four

C.Check that this

dryer is equipped with

the correct burner for

the particular type of

gas in the home.

Burner information will

be found on the rating plate in the door

well of the appliance. If this information

does not agree with the type of gas

available, see your dealer.

D.This dryer is equipped for use with

NATURAL GAS. It is certified by CSA

International for manufactured, mixed

and L.P. (propane or butane) gases with

appropriate conversion. No attempt

shall be made to convert the appliance

from the gas specified on the

model/serial rating plate for use with a

different gas without consulting the

service gas supplier or a Whirlpooldesignated service company.

Conversion must be done by a qualified

service technician. Gas conversion kit

part numbers are listed on the burner

bracket behind the access panel.

(See Panel E.)

E.Provide a rigid gas supply line to

the dryer location. When rigid pipe is

used, it should be 1/2-inch IPS. Pipe-joint

compounds resistant to the action of

L.P. gas must be used.

to

dryer

shutoff valve

“open” position

F. The supply line shall be equipped

with a shutoff valve. This valve should be

located in the same room as the

washer/dryer and should be in a

location that allows ease of opening

and closing. Do Not block access to the

shutoff valve.

Important: Observe all governing codes

and ordinances.

If codes permit and a separate ground

wire is used, it is recommended that a

qualified electrician determine that the

ground path is adequate.

WARNING

Electrical Shock Hazard

Plug into a grounded 3-prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can

result in death, fire, or electrical shock.

Fire Hazard

Use a heavy metal vent.

Do not use a plastic vent.

Do not use a metal foil vent.

Failure to follow these instructions

can result in death or fire.

percent (4%) reduction of the burner

B.T.U. rating shown on the model/serial

plate is required for each 1,000 foot

increase in elevation. For assistance

when converting to other gas types

and/or installing above 10,000 feet

elevation, contact your local service

company.

WARNING

Copies of the standards listed may be obtained from:

*CSA International

8501 East Pleasant Valley Road

Cleveland, Ohio 44131-5575

**National Fire Protection Association

Batterymarch Park

Quincy, Massachusetts 02269

Use pipe-joint

compound.

Adapter

supplied

Do Not use

pipe-joint

compound.

flexible gas

connector

Loading...

Loading...