PRODUCTS

Coin-Operated

Stacked Dryers

Electric

/IMPORTANT:

IRead and save

1the-B instructions.

Important:

*Read these instructions before you start

to install the dryers.

*Save Installation Instructions for local

electrical inspectors use.

l

Keep Installation Instructions for future

reference.

windows and windows and

raised handles raised handles

not available not available

on all models.

VI3

Part No. 3390148 Rev.ip

Before vou start

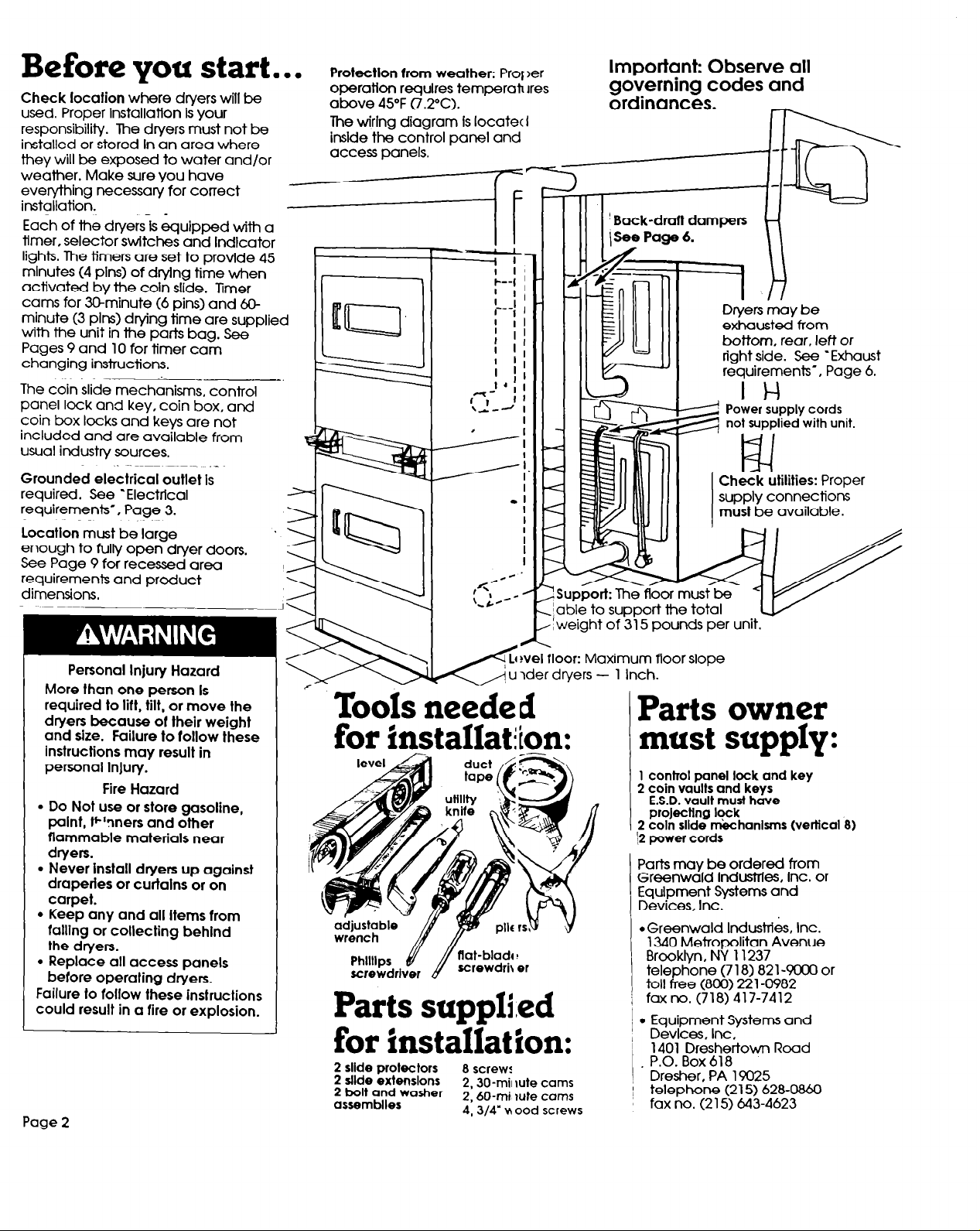

Check location where dryers will be

used. Proper installation ls your

responsibility. The dryers must not be

installed or stored In an area where

they will be exposed to water and/or

weather. Make sure you have

everything necessary for correct

installation.

Each of the dryers-b equipped with a

timer, selector switches and lndlcator

lights. The timers are set to provlde 45

minutes (4 pins) of drying time when

activatti by the coin slide. Timer

cams for 3&minute (6 pins) and 60minute (3 pins) drying time are supplied

with the unit in the parts bag. See

Pages 9 and 10 for timer cam

changing instructions.

The coin slide mechanisms, control

panel lock and key, coin box, and

coin box locks and keys are not

included and are available from

usual industry sources.

a - --~ -

.a

Protection from weather: Pro1 )er

operation requlres temperah 1res

above 45°F (7.2%).

The wiring diagram Is locate< I

inslde the control panel and

acces panels.

q

.

-’

Important: Observe all

governing codes and

ordinances.

’ Back-draft dampers

Dryers may be

exhausted from

bottom, rear, left or

right side. See ‘Exhaust

reauirements’, Page 6.

h-4 -

9

Power

4 not supplied with unit.

supply cords

Grounded electrical outlet Is

required. See ‘Electrical

requirements’, Page 3.

Location must be large

enough to fully open dryer doors.

See Page 9 for recessed area

requirements and prduct

dimensions.

Personal Injury Hazard

More fhan one person Is

required to lift. tilt, or move the

dryers because of their weight

and size. Failure to follow these

instructions may result in

personal injury.

Fire Hazard

l

Do Not use or store gasoline,

paint, tb’nners and other

flammable materials near

dryers.

l

Never install dryers up against

draperies or curtains or on

carpet.

l

Keep any and all Items from

falling or collecting behlnd

the dryers.

l

Replace all access panels

before operating dryers.

Failure to follow these instructions

could result in a fire or explosion.

Page 2

>

\

.:

<

II

\

‘I

-‘\

.’

d:r dryers - 1 Inch.

7

.!a& to support the total

/Iweight of 315 pounds per unit.

.

! LI !vel floor: Maximum floor slope

Tools needed

for installatiton:

Phlltlps

xrewdrlver

v

flat-blade!

screwdrh er

Parts suppEed

for installat ion:

2 slide protectors

2 slide extensions

2 bolt and washer

assemblies

8 screw:

2,30-mil lute cams

2,60-mi lute corns

4, ?+I” good screws

II

Ill I

Check utilities: Proper

supply connections

must be available.

Parts owner

must supply:

1 control panel lock and key

2

coin vaults and keys

E.S.D.

vault mud hove

projecting lock

2 coin slide m‘echanlsms (vertical 8)

j2

power cords

Parts may be ordered from

Greenwald Industries. Inc. or

Equlpment Systems and

Devices, Inc.

l

Greenwald Industti& Inc.

1340 Metropolitan Avenue

Brooklyn, NY 11237

telephone (7 18) 821 -WOO or

toll free (800) 221-0982

fax no. (718) 417-7412

1

l

Equipment Systems and

I

Devices, Inc.

/

1401 Dreshertown Road

. P.O. Box 618

( Dresher PA 19025

I telephone (215) 628-0860

fax no. (215) 643-4623

Electrical

requirements.

OBSERVE AU GOVEdNlNG COdES

AND ORDINANCES.

Electrical Shock Hazard

.

Electrical ground Is required on this

appliance.

.

If cold water pipe Is interrupted by

plastic, non-metallic gaskets, or

other insulating materials, Do Not

use for grounding.

.

Do Not ground to a gas pipe.

.

Do Not modify the power supply

cord plugs. iflplugs will not fit the

outlets, have proper outlets installed

by a qualified electrician.

.

Use new 30-ampere power supply

cord kits. Do Not reuse old power

supply cords. Possible electrical

shock or fire could occur if old

power supply cords are used.

.

Do Not have a fuse in the neutral or

grounding circuit. A fuse in the

neutral or grounding circuit could

result in an electrical shock.

.

Do Not use an extension cord with

this appliance.

.

Check with a qualified electrician if

you are in doubt as to whether the

appliance is properly grounded.

.

1 Do Not plug the power supply cords

(pigtails) into a live wail receptacle

before connecting the pigtails to the

dryer terminal blocks. Read ‘Direct

wiring connectton’. Pages 4 and 5

for detailed instructions.

F

:aiiure to follow these instructions

c

:ouid result in serious injury or death.

codes permit and a Separate ’

I ”

rounding wire Is used, it is recom-

9’

m

lended that a eiectriclan determine

th

tat the grounding path Is adequate.

*. It

Is-tie personal responsibility and

ot

3llgatlon of the customer to

cc

Intact-a qualified electrlclan to

a:

;ylr& that the electrlcai Installation

is

adequate and In conforjmance

w

WI Natlonal ElectrIcal Code ANSI/

NI

FPA 70-jlatest edltlon. and all local

cc

2des and ordinances. Allow sldck Iti

ttl

le line between the wall and the

Dpllance so that It can be moved if

aI

SE

rrvlclng is ever necessary.

ihis appliance must be connectec

to copper wlre only,

A 3/4’. U.L.-llsted strain relief must

be provided at each end of the

power supply cables (at the

appliance and at the Junctionbox).

1. A three-wire. slngie 1 Y-C+% 120/

240voit, &Hz, AC-on1 y, electrical

supply (or three-wire, ’ 20/208-volt if

spedfled on namepla tee> is

required on a separat 3.30-ampere

circuit, fused on both : Ides of the

line. (llme-deiay fuse <f clrcult

breaker ls recommenc ed.) The

wlrlng diagram is loca’ed l&de the

control panel and act ess panels.

J-wire. 30-amp

recepL ~cie (IO-30R)

Figure 1

Typical Xl-ampere rece >tacle for use

where local codes pem It use of

flexible power supply cc rds (pIgtolls).

2. Local codes may pc ~rrnlt the USB of

U-L-Wed, 120/24&volt mlnlmum. 3G

ampere dryer power SI apply cord kits

(plgtails). The cords coltaln three.

No.-10 copper wires ar Id match

three-wire receptacles of NEMA

Type 1 G3OR, shown In I :gure 1.

Connectors on the dry x end must

be ring terminals or spc Ide terminals

with upturned ends. U L.-listed.

3/4’ strain reliefs must t 8 provlded at

the polnt the power su >ply cords

enter the appliance.

3. This appliance can t 8 connected

dlrecity to the fuse disconnect or

circuit breaker box thrcugh flexible

i armored or nonmetallic: sheathed,

lOgauge minimum, cc pper cable.

A 3/4’, U.L.-listed strain I elief must be

provlded at each end Df the power

1 supply cables (at the a Dpliance and

at the junction box).

4. For four-wire installat on, the

appliance wiring must x revised.

The appliance cabinet must not be

grounded to the neutrc II terminal.

must be connectec 1 to me

grounding wire (green: of the power

supply cords.

i When four-wlre receptc icles of NEMA

i Type 14-30R are used, (see Figure 2)

1 matching 120/240-volt nlnlmum, 3&

ampere, U.L.-listd dryc r power

supply cord kits (pigtall: #> must be

‘used. The cords contalr1 four, No.-10

copper conductors wit I ring terml-

nals or spade terminals wlth

upturned ends on drye end

tetmlnating In a NEW “.ype 14-30P

plug on supply end. The I fourth

(groundlng) conductor must be

: identified by a green OI green/

j yellow cover and the n, ?&al

CC onductor by a white cover. Cords

Sk

muld be Type SRD or SRDT, with

/4’. U.L.-llsted strain reliefs and be at

3,

le at 4 feet long. The four-wire power

sl apply cords and strain reliefs are not

rovlded with the dryers.

P

4-wire. JO-amp

receptacle

(14-JOB)

Figure 2

LIternate electrical

:onnection

Eiectrlcal Shock Hazard

l

Electrical ground Is required on

.this appilance.

l

This appliance must be

connected to a grounded

metal. permanent wiring system;

or an equlpment-grounding

conductor must be run with

the circuit conductors and

connected to the equipmentgrounding terminal or lead on

the appliance.

l

Disconnect power supply cord

from the electric supply before

making these changes. Failure

to do so may result in personal

injury.

Failure to do so may result in

electrical shock or personal injury.

his appliance ls manufactured with

ie neutral terminal connected to

Cle cabinet.

‘0 connect a separate

younding wire-

Jse grounding wire and clamp

lssembiy (Part No. 685463) or No.-10

Jauge mlnimum, copper grounding

rrire. Connect grounding wire to a

grounded cold water pipe’ with the

clamp and then to the external

grounding connector on the dryers.

Do Not ground to a gas supply pipe

or hot water pipe. Do Not connect

me power supply cords to electric

power supply until the dryers are

permanently grounded.

Do

Not ground to &gas supply pipe

or hot water pipe, Do Not connect

the power supply cords to electric

power supply until the dryers are

permanently grounded.

Page 3

Figure 3

*Grounded cold water pipe must

have metal continuity to electrical

ground and not be interrupted by

plastic, rubber or other electrical

lnsulatin connectors such as

hoses, 8 i ngs. washer or gaskets

(includi

Any elec cat Insulating connector

should be Jumped as shown in

Figure 3 with a length of No.-4 wire

securely clamped to bare metal at

bath ends.

7%

water

meter or pump).

Direct wiring connection_

1. Strip the outer covering back 3

Inches from the end exposing the

three wires.

2. Strip the Insulation back 1 inch

from the end of each wire. Form

the bare wires into a V-shaped

hook.

I Direct wiring connection

Figure 4

3.

Loosen, do not remove, the

center, silver-colored xrew of the

terminal block.

4. Slide the end of the neutral

(white or center) wire under the

screw head with the open side of

the screw hook on the right.

Squeeze the wire together to form

a loop.

A.

If local codes permlt c01 lnection of

cabinet-grounding concjuctors to

the neutral wires of the F Bower supply

1 cords:

1 exte ,nal grounding

,,

Figure 5

\ 1. Disconnect the power supply.

2. Remove the terminal I >lock covers

by removing the screw s ?own in

Figure 5.

Rear panel

3/4’. VI.-llsted

strain relief (outside di yer)

Figure 6

3. Attach a 3/4’, U.L.-listed straln relief

to each dryer through tt e power

supply cord holes. (See -igure 6.)

Tighten each strain relief firmly to

cabinet. Place a power supply cord

or direct wire through ec ch strain

rellef.

gw;(;)eundlw

(green wlth

yellow stripes)

to fused

disconnect box

or approved

wiring device tor

power supply cord

power supply cord

with strain relief

(30 amperes)

copper -

center,

silver-

colored

termlnal

block

screw

Grounded Neutral

Figure 7

4. Connect the neutral wire of each

power supply cord to the center,

silvercolored termlnal of the terminal

block;. Connect the other wires to

the outer termlnals. (See Flgure 7.)

Tighten screws.

5. Replace the termlnal block covers

by first installlng the tab of each

cover Into tie slot of the dryer rear

panel. (See Figure 5.) Secure the

covers with the mounting screws.

6. Tighten the strain relief clamps on

the power supply cords. (See

Figure 6.)

5. lighten the screw firmly.

6. Connect the remalnlng 2 wires

to the outer screws the same way.

7. Tighten strain relief screws firmly.

Page 4

Loading...

Loading...