Westinghouse WVG655SCLP, WVG655SCNG, WVG613WCLP, WVG665SCLP, WVG615SCLP User Manual

...

USER MANUAL

GAS BUILT-IN OVENS

WVG613SC/WC, WVG615SC WVG655SC, WVG665SC/WC

CONGRATULATIONS

Dear customer,

Congratulations and thank you for choosing our oven. We are sure you will find it a pleasure to use. Before you use the oven, we recommend that you read through the relevant sections of this manual, which provides a description of your appliance and its functions.

To avoid the risks that are always present when you use an appliance, it is important that the appliance is installed correctly and that you read the safety instructions carefully to avoid misuse and hazards.

We recommend that you keep this instruction booklet for future reference and pass it on to any future owners.

After unpacking the appliance, please check it is not damaged. If in doubt, do not use the appliance but contact your local customer care centre.

This appliance complies with requirements of Australian Standards AS/NZS 60335.2.6 and AS4551.

Conditions of use

This appliance is intended to be used in household and similar applications such as:

•Staff kitchen areas in shops, offices and working henvironments

•Farm houses

•By clients in hotels, motels and other residential type environments

•Bed and breakfast type environments

•Catering and similar non-retail applications

Please ensure you read the instruction manual fully before you call for service, or a full service fee could be applicable.

Record model and serial number here:

Model number:........................................................................................

Serial number:.........................................................................................

PNC:.............................................................................................................

IMPORTANT INFORMATION THAT MAY IMPACT YOUR MANUFACTURER’S WARRANTY

Adherence to the directions for use in this manual is extremely important for health and safety. Failure to strictly adhere to the requirements in this manual may result in personal injury, property damage

and affect your ability to make a claim under the Westinghouse manufacturer’s warranty provided with your product. Products must be used, installed and operated in accordance with this manual.

You may not be able to claim on the Westinghouse manufacturer’s warranty in the event that your product fault is due to failure to adhere this manual.

CONTENTS |

|

Important safety instructions........................................................ |

3 |

Installing your appliance.................................................................. |

5 |

Gas installation information.......................................................... |

10 |

Product description.......................................................................... |

12 |

Before using your appliance for the first time .................. |

13 |

Installing oven accessories............................................................ |

14 |

Using your oven................................................................................ |

16 |

Cooking guide ................................................................................... |

22 |

Grilling guide ..................................................................................... |

23 |

Dealing with cooking problems................................................. |

24 |

Getting to know your oven.......................................................... |

25 |

Cleaning your appliance .............................................................. |

26 |

Cleaning the oven door................................................................. |

28 |

Troubleshooting................................................................................ |

32 |

Warranty............................................................................................... |

35 |

Please read the user manual carefully and store in a handy place for later reference.

The symbols you will see in this booklet have these meanings:

WARNING

WARNING

This symbol indicates information concerning your personal safety.

CAUTION

CAUTION

This symbol indicates information on how to avoid damaging the appliance.

IMPORTANT

IMPORTANT

This symbol indicates tips and information about use of the appliance.

ENVIRONMENT

This symbol indicates tips and information about economical and ecological use of the appliance.

2 CONTENTS

IMPORTANT SAFETY INSTRUCTIONS

Please read the user manual carefully and store in a handy place for later reference.

IMPORTANT

IMPORTANT

Important – check for any damages or marks

If you find the oven is damaged or marked, you must report it within 7 days if you wish to claim for damage/ marks under the manufacturer’s warranty. This does not affect your statutory rights.

ENVIRONMENT

Information on disposal for users

•Most of the packing materials are recyclable. Please dispose of those materials through your local recycling depot or by placing them in appropriate collection containers.

•If you wish to discard this product, please contact your local authorities and ask for the correct method of disposal.

WARNING

WARNING

These warnings have been provided in the interest of safety. You MUST read them carefully before installing or using the appliance.

•An authorised person must install this appliance

and carry out servicing. (Certificate of Compliance to be retained)

•Before using the appliance, ensure that all packing materials are removed from the appliance.

•Always be careful when you move the appliance because it is heavy. Always wear safety gloves.

•Do not pull the appliance by the door handle.

•This appliance must be earthed.

•In order to avoid any potential hazard, the enclosed installation instructions must be followed.

•Ensure that all specified vents, openings and air spaces are not blocked.

•Do not modify this appliance.

•This appliance must not be used as a space heater.

•Where the appliance is built into a cabinet, the cabinet material must be capable of withstanding 70°C. If adjacent to vinyl wrapped surfaces, use installation kit from vinyl wrap supplier.

•Ensure the appliance is switched off before cleaning or replacing parts. This can be done by switching off the appliance via the powerpoint or isolating switch (if available), or the switchboard.

•Do not use steam cleaners, as this may cause moisture build up.

•Switch the appliance off before removing the oven light glass for globe replacement.

•Always keep the appliance clean. Ensure fats and oils do not accumulate around elements, burners or fans.

•Care must be taken when wiping exposed stainless steel edges.…they can be sharp!

•Do not spray flammable materials in or under the appliance, e.g. aerosols.

•Do not store flammable materials in or under the appliance e.g. Aerosols

•Do not leave the grill on unattended.

•Always turn the grill off immediately after use as fat left behind may catch fire.

•Do not cover the grill insert with foil, as fat left there may catch fire.

•Always keep the oven dish, grill dish and bake trays clean as any fat residue may catch fire.

•To avoid an accident, ensure that the oven shelves and fittings are always inserted into the appliance in accordance with the instructions.

•The door glass on this appliance is made from a tough, durable material that withstands heating and cooling without breaking. As a precaution however, do not put cold water on hot glass.

•Door glass that is damaged should be immediately replaced.

•This appliance is not intended for use by persons (including children) with reduced physical, sensory or mental capabilities, or lack of experience and knowledge, unless they have been given supervision or instruction concerning use of the appliance by a persvvon responsible for their safety.

•Children should be supervised to ensure that they do not play with the appliance.

•Accessible parts will become hot when in use. To avoid burns and scalds children should be kept away.

•During use, this appliance becomes hot. Care should be taken to avoid touching hot surfaces, e.g. oven door, heating elements or internal surfaces of

the oven.

•Always use gloves when handling hot items inside the oven.

•To maintain safe operation, it is recommended that the product be inspected every 5 years by an authorised service person.

•New appliances can have an odour during the first operation. It is recommended to ‘run in’ the oven before you cook. Run the oven(s) at 180°C for 30 minutes and ensure the room is well ventilated.

•This appliance must not be installed behind a decorative door.

•The cooking process has to be supervised. A short term cooking process has to be supervised continuously.

SAFETY 3

IMPORTANT SAFETY INSTRUCTIONS

CAUTION

CAUTION

Read the following carefully to avoid damage to the appliance.

•The grill door must be left fully open whilst grilling in a separate grill wall oven and a separate grill underbench oven.

•The grill tray must be fully inserted whilst grilling.

•Do not place thick portions of food under the grill. Foods may curl, catch and ignite.

•Do not use the door as a shelf.

•Do not push down on the open oven door.

•Do not use harsh abrasive cleaners or metal scrapers to clean the oven door glass since they can scratch the surface which may result in shattering of

the glass.

•Do not use harsh abrasive cleaners, powder cleaners, steel wool or wax polishes on enamel.

•Do not use sharp metal implements or utensils on any surface, as these may leave permanent scratches or marks.

•Do not use stainless steel cleaners, abrasive cleaners or harsh solvents to clean your stainless steel appliance.

•Do not line the bottom of the oven or grill with foil or cookware, it will damage the enamel.

•Do not use the base of the oven for cooking – it will damage the enamel.

•Do not put water directly into the hot appliance.

•Always clean the appliance immediately after any food spills.

NOTE: You must read these warnings carefully before installing or using the appliance. If you need assistance, contact your Customer Care Centre. The manufacturer will not accept liability, should these instructions or any other safety instructions incorporated in this book

be ignored.

4 SAFETY

INSTALLING YOUR APPLIANCE

WARNING

WARNING

To avoid any potential hazard, you must follow our instructions when you install your appliance. Failure to install the appliance correctly could invalidate any warranty or liability claims and lead to prosecution.

•This appliance must be installed by an authorised person according to all codes and regulations as stated in the local municipal building code and other relevant statutory regulations.

•Refer to data plate for rating information. The data plate is positioned behind the bottom of the oven door.

WARNING

WARNING

This appliance must be properly earthed.

•This range must be connected with cable of 90°C rating minimum.

•This product has passed the insulation resistance test after manufacture. If the resistance reading is low at installation, it is probably caused by moisture from the atmosphere being absorbed by the elements after the range has been produced. (Pass at 0.01MΩ AS/NZS 3000 Wiring Rules Clause 8.3.6.2).

•Do not lift the appliance by the door handles.

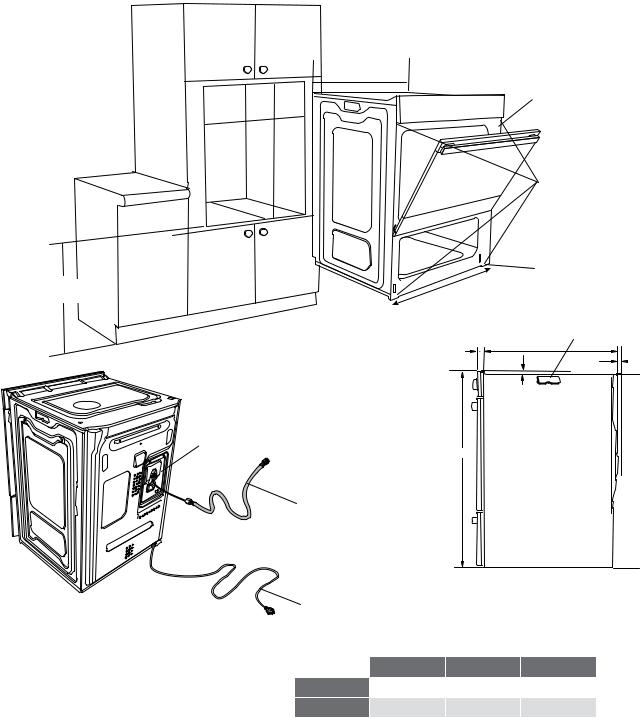

•Prepare the cupboard opening to match your appliance measurements. (See diagrams)

•Slide appliance into the cupboard, ensuring that the supply cable (where fitted) does not kink.

•To prevent tipping, use the screws supplied to secure your oven into the cupboard. Use just 2 screws for underbench and separate grill underbench ovens, and 4 screws for separate grill wall ovens. Remove the bottom door in separate grill wall ovens to provide access to the bottom 2 screwing points.

•For appliances fitted with a flexible supply cord, if the cord is damaged, it must be replaced by the manufacturer or its service agent or similarly

qualified person in order to avoid a hazard. The plug must be accessible after installation.

•Where the appliance is built into a cabinet, the cabinet material must be capable of withstanding 70°C. Installation into low temperature tolerant cabinetry (e.g. vinyl coated) may result in deterioration of the low temperature coating by discolouring or bubbling.

•If the appliance is installed adjacent to vinyl-wrapped surfaces, use an installation kit available from the vinyl-wrap supplier.

•Electrolux Home Products cannot accept responsibility for damage caused by installation into low temperature tolerant cabinets.

•After installation, test and ensure that the appliance operates correctly before handing it over to the customer.

•If a powerpoint is fitted it must be accessible with the appliance installed, as the plug must be accessible after installation.

•This appliance must be mounted on a flat surface for the full width and depth of the product.

•To avoid overheating, the appliance must not be installed in a recess or cupboard behind a decorative door.

It is recommended that this product is not installed in an unvented living space, particularly if that space

incorporates sleeping quarters.

CAUTION

CAUTION

To avoid any potential hazard, you must follow our instructions below when you install your appliance. Failure to install the appliance correctly could invalidate any warranty or liability claims and lead to prosecution.

This appliance is only suitable for connection to fixed consumer piping where the maximum over-pressure is limited to 14kPa or less. Refer clause 5.2.1 and 5.2.2

of AS5601.1.

Cabinet construction for your appliance

For the best integration within a kitchen, install this appliance in a standard 600mm wide cupboard that gives a flush fit with the surrounding cupboard fronts (Figure A).

A recess of 20mm is ideal. It can also be installed using a proud fit with the surrounding cupboard (Figure B).

NOTE: Your appliance must be mounted on a flat surface for the full width and depth of the product.

infill panel |

|

20mm |

16mm cleat |

cupboard door

600mm

600mm

cupboard door

cupboard door

Figure A - flush fit (top view)

565mm

cupboard front

Figure B - proud fit (top view)

INSTALLATION 5

INSTALLING YOUR APPLIANCE (CONTINUED)

Levelling oven

Place a level in the oven as below making sure the level sits on the front and rear forms.

Underbench ovens

Your underbench oven looks best when the control panel is directly under the benchtop. An upper infill panel

may have to be added if the cooktop placed above the benchtop is too deep.

Refer to cooktop installation instructions for required clearance between cooktop and oven.

upper infill (if required)

|

|

|

|

|

|

|

|

carry handle |

|

|

|

|

|

*20 |

|

553 |

8 min. |

|

|

|

|

|

|

|

||

|

|

A |

|

|

|

|

|

clearance |

|

|

|

|

|

|

|

|

|

|

|

B |

561 |

|

|

15 |

|

|

|

|

|

|

|

|

|

|

|

|

|

C |

|

|

|

|

|

|

|

|

|

|

|

595 |

|

|

|

|

|

|

|

|

mounting |

|

|

|

|

|

|

|

|

holes |

|

|

|

|

|

use black |

|

|

|

|

|

|

|

D |

installation |

|

596 |

|

|

|

|

|

screws supplied |

|

|

|

|

|||

|

|

|

|

|

|

|

||

|

|

1.7m flexible gas hose |

|

|

|

|

|

|

|

E |

(supplied unfitted) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1.5m electrical |

GAS TYPE |

|

A |

B |

|

C |

|

|

FLUSH FIT |

600 |

600 |

|

581min |

||

|

|

service cord |

|

|||||

|

|

|

PROUD FIT |

565 |

590 |

|

560min |

|

D Gas connection |

- 150mm from right hand side |

|

|

|

|

|

|

|

|

- 220mm from bottom |

|

|

|

|

|

|

|

E Electrical service cord |

- 50mm from right hand side |

|

|

|

|

|

|

|

- at bottom

6 INSTALLATION

Separate grill underbench ovens

NOTE TO INSTALLER: For separate grill underbench installations where a cooktop is installed directly above the appliance, a minimum clearance distance of 10mm must be allowed for between the bottom of the cooktop and the top of the separate grill underbench oven.

|

|

|

|

D |

|

|

|

|

|

|

|

|

1.7m flexible gas hose |

|

|

|

|

|

|

(supplied unfitted) |

|

|

|

|

E |

|

|

|

|

|

|

|

|

1.5m electrical |

|

|

A |

561 |

|

|

service cord |

|

|

|

|

|

||

|

|

|

|

D Gas connection |

- 150mm from right hand side |

|

|

|

B |

|

|

- 220mm from bottom |

|

|

|

|

|

|

|

|

|

|

|

|

E Electrical service cord |

|

|

|

|

C |

|

|

- 50mm from right hand side |

|

|

|

|

|

|

||

|

|

|

|

|

- at bottom |

|

|

|

|

|

mounting |

|

|

|

|

|

|

holes |

|

|

|

|

|

|

|

|

carry handle |

|

|

|

|

*20 |

553 |

8 min. |

|

|

|

|

|

||

|

|

|

|

|

|

clearance |

|

|

|

|

|

15 |

|

|

|

use black installation |

596 |

|

|

|

|

|

screws supplied |

|

|

|

|

|

|

|

|

725 |

|

|

GAS TYPE |

A |

B |

C |

|

|

|

FLUSH FIT |

600 |

731 |

581min |

|

|

|

PROUD FIT |

565 |

723 |

560min |

|

|

|

INSTALLATION 7

INSTALLING YOUR APPLIANCE (CONTINUED)

Separate grill wall oven

561

|

|

|

use black installation |

|

|

|

screws supplied |

|

A |

|

|

|

B |

|

|

|

|

|

mounting |

|

|

|

holes |

|

C |

|

|

|

|

|

use black installation |

|

|

|

screws with plastic |

Recommended |

596 |

|

spacers provided |

|

|

||

650mm min. |

|

|

|

|

|

|

|

|

|

|

carry handle |

|

*20 |

553 |

8 min. |

|

|

||

|

|

|

clearance |

|

|

15 |

|

|

D |

|

|

|

888 |

|

|

1.7m flexible gas hose (supplied unfitted)

E

E

D Gas connection

-150mm from right hand side

-220mm from bottom

E Electrical service cord

-50mm from right hand side

-at bottom

1.5m electrical service cord

GAS TYPE |

A |

B |

C |

FLUSH FIT |

600 |

893 |

581min |

PROUD FIT |

565 |

885 |

560min |

8 INSTALLATION

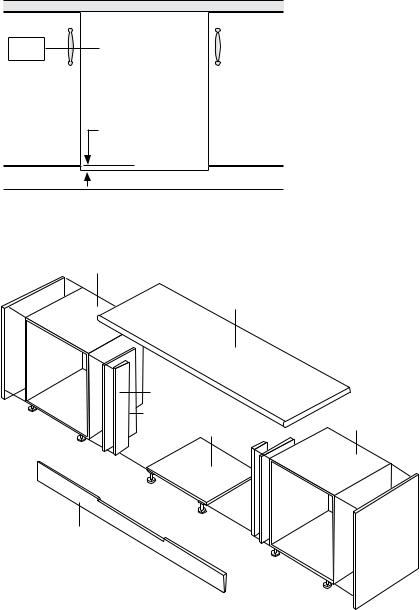

Recommended cabinet design

NOTE: Powerpoint connection must be accessible with the appliance installed.

Front View

Area for mounting of powerpoint.

Supporting shelf 8mm below door line to give perfect alignment of cooker & cupboard (kick panel notched to suit).

720mm Module(s)

Bench Top

Cleat (2)

Infill Panel (2)

Cooker Platform |

720mm Module(s) |

|

Kick Panel

INSTALLATION 9

GAS INSTALLATION INFORMATION

Gas Connection

Before commencing installation, check to ensure the type of gas to which the appliance is intended to be connected matches the gas type given on the appliance data plate.

Check the data plate (located behind the oven door) to determine gas type. A gas type label is located on the back panel near the gas inlet.

A 1700mm long flexible hose is supplied in the pack for installation purposes.

Internal flange

Important: flat fibre washer must be installed

Connecting flexible hose

•Place a spanner on the flats provided on the gas inlet to brace the inlet against the action of wrenching when connecting the hose to the appliance gas inlet. Failure to do so may damage the appliance.

•An approved thread sealing tape or compound is required for the connection between the hose and the appliance gas inlet.

•Ensure there is no kink in the gas hose when the appliance is in the installed position.

Appliances for operation on N.G. & S.N.G.

For N.G. and S.N.G appliances the supplied N.G. regulator must be fitted. For L.P.G appliances (Propane or Universal LP) the test point fitting supplied must be fitted.

NOTE: The inlet of the regulator or test point fitting should be fitted to the consumer piping first. The arrow on the regulator or test point fitting indicates the direction of gas flow. Then connect the hose to the outlet of the regulator or test point fitting using the swivel connection on the hose and fibre washer supplied.

Ensure the regulator or test point fitting is in a position that is accessible with the appliance installed and which will allow the appliance to be withdrawn without disconnecting the hose.

Check all joints and ensure that connections are sound.

N.G. Regulator

Pressure point test

Pressure point test

Gas flow

to appliance

10 INSTALLATION

Operating Pressures

Supply and operating pressures for various gases and corresponding injector sizes for each burner.

|

SUPPLY |

NOMINAL |

OVEN |

GAS TYPE |

PRESSURE |

TEST POINT |

INJECTOR |

(KPA) |

PRESSURE |

|

|

|

|

||

|

|

(KPA) |

|

NG & SNG 1.13 - 5.00 |

1.00 |

1.50 |

|

UNIVERSAL |

2.75 |

2.75 |

0.82 |

LP |

|

|

|

|

|

|

|

Testing the operation of the appliance

This product has an Electronic Burner Control with a flame safeguard system, which includes a safety

shutdown function that operates when the presence of a flame is not detected within a prescribed period.

It may be necessary to interrupt the operation of the control system in order to facilitate purging of air from the appliance.

During the purging procedure the product should be closely monitored to ensure that the ignition spark can be observed through the round hole in the left hand side of the cover on the bottom of the oven, and that the solenoid valve can be heard to open and close.

1.After connecting the gas and leak testing the gas connection, plug in the service cord and turn on the power.

2.Set the time of day clock (if fitted).

3.Purging procedure:

a.Turn on the oven.

b.The unit will commence sparking and the solenoid valve will open for a short period. If a flame is not established, the controller will shut the solenoid valve and stop sparking, then pause for a moment before repeating this cycle. At this point if there is still no flame, the control system will go into safety shutdown.

c.If the control system does go into safety shutdown, turn off all the controls and switch off the power supply for a few seconds.

d.Then turn the power back on and repeat steps 2. to 3.c. until the gas ignites.

NOTE: If the power supply is not switched off, then a delay of 90 seconds will be required after each safety shutdown before a new ignition cycle can be attempted. For more details about how the Electronic Burner Control works refer to ‘Electronic Burner Control’.

4.Check the manometer zero point is correct.

5.Connect the manometer to the cooker pressure test point. This is located on the regulator or LPG inlet fitting.

6.Check the operating pressure (refer table above). For LPG Cookers: Adjust the regulator if necessary (this may be remote from the cooker).

For NG Cookers: The outlet pressure should not vary from the nominal outlet pressure of 1.00kPa by more than ±0.20kPa.

If the regulator apppears to not be performing satisfactorily, then check the following points:

a.If the outlet pressure is consistently too low then the inlet pressure may be too low and adjustment of an upstream regulator may be needed, or an upstream regulator or valve with insufficient flow capacity may be present in the gas supply line. If this is suspected then it may be necessary to repeat the checks whilst measuring both the inlet and outlet pressure to determine

if the inlet pressure is in the range 1.13 – 5kPa.

b.Check that the regulator has been fitted to the gas supply line in the correct orientation, the arrow on the base of the body indicates the direction of gas flow.

Once these checks have been completed, if the regulator still fails to perform in a satisfactory manner it should be replaced.

7.Observe the flame appearance on the burner. If it is much larger or much smaller than expected, the injector size may require checking. Where a flame is

unsatisfactory refer to the servicing instructions and correct the fault if possible.

8.Check the operation of the timer, light and fan.

If the appliance cannot be adjusted to perform correctly, inform the customer of the problem and affix an appropriate warning notice to the appliance. If the

fault appears to be dangerous, the appliance should be disconnected. However, if only a minor fault exists,

the customer may wish to use the appliance while awaiting service.

The customer should be advised that, in the event of a fault, they should contact the manufacturer’s local service organisation or the retailer from whom the appliance was purchased.

INSTALLATION 11

Loading...

Loading...