Page 1

Manual - Technical Documentation

ATEX

Watson-Marlow MasoSine - Pumps

EC 25 / EC 40 / EC 60

Revision 4.4 / November 2010 1

Page 2

Content

Technical datasheet ........................................................................................................................................4

1 GENERAL ............................................................................................................ 5

2 PURPOSE ............................................................................................................ 5

3 FUNCTIONING PRINCIPLE................................................................................. 5

4 SAFETY INSTRUCTIONS.................................................................................... 5

4.1 Basic safety instructions......................................................................................................................5

4.2 Safety symbols ...................................................................................................................................5

4.3 Obligation of the operator....................................................................................................................5

4.4 Organizational measures ....................................................................................................................5

4.5 Obligation of the personnel .................................................................................................................6

4.6 Training of the personnel ....................................................................................................................6

4.7 Informal safety measures....................................................................................................................6

4.8 Dangers when handling the machine..................................................................................................6

4.9 Safety measures in normal operation .................................................................................................6

4.10 Protective devices ...............................................................................................................................6

4.11 Dangers due to hazardous pumped material......................................................................................6

4.12 Dangers due to electrical energy ........................................................................................................6

4.13 Dangers due to hydraulic energy ........................................................................................................6

4.14 Special danger points..........................................................................................................................6

4.15 Constructional changes to the machine..............................................................................................7

4.16 Noise of the machine ..........................................................................................................................7

4.17 Maintenance and repair, troubleshooting............................................................................................7

4.18 Maintenance of the bearings...............................................................................................................7

4.19 Cleaning the machine .........................................................................................................................7

4.20 Faults...................................................................................................................................................7

4.21 Use as intended ..................................................................................................................................7

5 SAFETY INSTRUCTIONS (ATEX)....................................................................... 7

5.1 Safety signs.........................................................................................................................................7

5.2 Pump classification .............................................................................................................................7

5.3 Zone classification...............................................................................................................................8

5.4 Classification of the ex-atmospheres ..................................................................................................8

5.5 Ignition protection ................................................................................................................................8

5.6 Temperature classes...........................................................................................................................8

5.7 Limit values for the pump ....................................................................................................................8

5.8 Grounding the pump ...........................................................................................................................8

5.9 Material properties ..............................................................................................................................8

5.10 Pressure Conditions............................................................................................................................8

5.11 Maintenance / Repair ..........................................................................................................................9

5.12 Cleaning ..............................................................................................................................................9

5.13 Medium to be pumped ........................................................................................................................9

5.14 Coupling ..............................................................................................................................................9

5.15 Drive ....................................................................................................................................................9

6 WARRANTY AND LIABILITY.............................................................................. 9

7 TRANSPORT INSTRUCTIONS ........................................................................... 9

8 INSTALLATION ................................................................................................. 10

9 CONNECTION TO THE PIPING ........................................................................ 10

10 POSSIBLE CONNECTION POSITIONS ......................................................... 10

Revision 4.4 / November 2010 2

Page 3

11 CHANGING THE CONNECTION POSITION.................................................. 11

12 CHANGING THE DIRECTION OF ROTATION............................................... 11

13 IMPORTANT: OBSERVE BEFORE START-UP!............................................ 11

14 CLEANING ...................................................................................................... 12

14.1 Cleaning in own circuit with water, alkali, acid ..................................................................................12

14.2 Cleaning in the CIP circuit.................................................................................................................12

14.3 Manual cleaning ................................................................................................................................12

14.4 Sterilization........................................................................................................................................12

15 OIL CHANGE .................................................................................................. 13

15.1 Filling volumes ..................................................................................................................................13

16 DISPOSAL ...................................................................................................... 13

17 SPARE PARTS ............................................................................................... 13

18 TAKING OUT OF SERVICE............................................................................ 13

18.1 Provisional taking out of service .......................................................................................................13

18.2 Final putting out of service ................................................................................................................13

19 TROUBLESHOOTING .................................................................................... 14

20 ADJUSTING DIMENSION............................................................................... 15

21 TIGHTENING TORQUES ................................................................................ 16

22 DISMANTLING ............................................................................................... 17

23 DISMANTLING „LIP SEAL SYSTEM“ ........................................................... 19

24 DISMANTLING „MECHANICAL SEAL SYSTEM“ ......................................... 20

25 ASSEMBLY..................................................................................................... 21

25.1 Assembly „Rotor-Assembly“..............................................................................................................21

26 PUMP SIZES ................................................................................................... 22

26.1 Cross section drawing EC 25 with Lip Seal System.........................................................................22

26.2 Cross section drawing EC 25 Mechanical Seal System ...................................................................22

26.3 Cross section drawing EC 40 with Lip Seal System.........................................................................23

26.4 Cross section drawing EC 40 with Mechanical Seal System............................................................23

26.5 Cross section drawing EC 60 with Lip Seal System.........................................................................24

26.6 Cross section drawing EC 60 with Mechanical Seal System............................................................24

26.7 Parts list for an EC 25 / EC 40 / EC 60 Pump...................................................................................25

26.8 Parts list for the Lip Seal System EC 25 / EC 40 / EC 60.................................................................25

26.9 Parts list for the Mechanical Seal System EC 25 / EC 40 / EC 60 ...................................................25

27 CODE-STRUCTURE FOR SPARE PART ORDERS ...................................... 26

28 DIMENSIONAL DRAWINGS........................................................................... 27

28.1 Dimension table for pump with German Milk Fittings .......................................................................27

28.2 Dimension table for pump with TRI-CLAMP (TC).............................................................................28

28.3 Dimension table for pump with RJT ..................................................................................................28

28.4 Dimension table for pump with SMS (Swedish norm) ......................................................................28

28.5 Dimension table for pump with SMS (French norm).........................................................................28

Revision 4.4 / November 2010 3

Page 4

Technical datasheet

Please remove all technical information from the technical Data Sheet.

For spare parts ordering refer to software component list.

If you have problems to identify parts, please refer the drawing and parts list. In case of any questions

please contact the Technical Support

Revision 4.4 / November 2010 4

Page 5

1 General

The operating instructions apply for the Watson-Marlow MasoSine:

EC 25 / EC 40 / EC 60

The operating instructions must be read before installing the pumps. Please observe the safety instructions and the safety

regulations.

2 Purpose

The purpose of your pump is defined exactly in the delivery note. The warranty becomes null and void following any changes to

the purpose, including changes to components and materials.

Always consult the manufacturer before any changes are to be made to the pump, its components or application.

3 Functioning principle

The functioning principle of the Watson-Marlow MasoSine Pump is ingeniously simple. The pump consists of modular

components to allow for easy assembly, disassembly and in-line maintenance, preventing the need to return the pump for

factory repair. The MASO-Sine pump’s exclusive sinusoidal rotor creates four symmetrical pumping chambers that draw product

through the pump. As product is drawn through in a continuous flow, it encounters the scrapergate and is discharged by product

flowing behind it creating a continuos pulse-free laminar flow. The MASO-Sine pump’s large pumping chambers maintain

constant volumetric displacement throughout the entire pumping cycle that eliminates product compression and minimizes

damage to large particles.

4 Safety instructions

4.1 Basic safety instructions

Failure to follow these safety instructions may result in damage to property, personal injury or death.

A basic requirement for safe handling and troublefree operation of this machine is knowledge of the basic safety instructions and

practice of the safety regulations.

These operating instructions contain the most important instructions to operate the machine safely.

These operating instructions, especially the safety instructions, must be observed by all persons who work on the machine.

Moreover the rules and regulations for accident prevention applicable at the place of use must be complied with.

The following safety instructions must be observed absolutely.

They are an essential and indispensable part of the user documentation. Non-compliance can result in loss of warranty claims.

It is recommended in the interest of all involved to enter all installation measures, maintenance, fault and repair cases, training

courses, instructions and special occurrences in a logbook assigned to the machine.

4.2 Safety symbols

Safety instructions that must be followed. Failure to comply with these instructions may result in damage

to property, personal injury or death.

Safety instruction for electrical voltage. Failure to comply with these instructions may result in damage to

property, personal injury or death.

CCAAUUTTIIOONN

Safety instruction to prevent damage to the pump or system.

4.3 Obligation of the operator

Only persons who are familiar with the basic regulations concerning working safety and accident prevention, have read and

understand this manual, and are instructed in handling the MASO-Sine pump are to be allowed to on or with the machine.

The safety-conscious working of the personnel should be checked at regular intervals.

4.4 Organizational measures

Any required personal protective equipment shall be provided by the operator.

All existing safety devices shall be checked regularly.

Revision 4.4 / November 2010 5

Page 6

4.5 Obligation of the personnel

All persons who are authorized to work with or on the machine obligate themselves to observe the basic regulations concerning

working safety and accident prevention before starting work. All persons to read and understand the safety chapter and warning

notes in the operating instructions and to confirm by their signature that they have understood these. If there are any questions

regarding this manual or the proper use and maintaining of the MASO-Sine pump, contact the factory before use..

4.6 Training of the personnel

Only trained and instructed personnel may work with or on the machine. The responsibilities of the personnel shall be defined

clearly for assembly, disassembly, start-up, operation, maintenance and repair.

Personnel under training may work on the machine only under supervision of an experienced person.

4.7 Informal safety measures

The operating instructions must be kept on file and be made readily available to all persons who work with or on the MASO-Sine

pump. The generally valid as well as the local regulations for accident prevention and environmental protection shall be provided

and observed in addition to the operating instructions. All safety and danger warnings on the machine shall be kept in legible

condition. Contact the factory if additional manuals are required.

4.8 Dangers when handling the machine

The Watson-Marlow MasoSine Pump is built according to the state of the art and the recognized safety engineering rules at

the time of manufacture. Danger to life and limb of the user or other persons or impairments to the machine or to other assets

can arise if safety instructions are not followed.

The machine must be used only:

• for the intended use delivery note

• in perfect safety engineering condition.

Faults which can impair safety must be rectified immediately.

4.9 Safety measures in normal operation

Operate the machine only if all safety devices are fully functioning. Before switching the machine on make sure that the starting

machine can endanger no one. At least once per shift inspect the machine for “externally detectable damage” and for

functioning of the safety devices.

4.10 Protective devices

All protective devices must be attached correctly and functioning before every start-up.

Protective devices may be removed only

- After standstill and simultaneous protection against restarting the machine. Always follow proper LOCKOUT – TAGOUT

procedures.

- The pump is not under pressure.

- All components are allowed to reach a comfortable temperature.

4.11 Dangers due to hazardous pumped material

In the case of hazardous pumped material as defined by MSDS, the corresponding regulations must be followed.

4.12 Dangers due to electrical energy

Follow proper LOCKOUT – TAGOUT procedures before handling electrical components.

Have work on the electrical supply performed only by a qualified electrician.

Check the electrical equipment of the machine regularly. Rectify loose connections and scorched cables

immediately.

Keep the control cabinet closed always. Access is allowed only to authorized personnel

Only qualified personnel should handle electrical components.

4.13 Dangers due to hydraulic energy

Only personnel with special knowledge and experience in hydraulics may work on hydraulic devices.

Relieve the pressure in system sections and pressure lines to be opened before starting repair work. Replace hydraulic hose

lines at appropriate intervals, even if no safety-relevant defects are detectable.

4.14 Special danger points

This pump and equipment utilize rotating components that may pose

potential injury. The user must protect the pump so that there is no

exposure to rotating components. In the case of work on the stationary

rotor, the drive must be secured against unintentional switching on.

Follow proper LOCKOUT – TAGOUT procedures. Increased danger

exists with dismantled pipes and opened pump.

Revision 4.4 / November 2010 6

Page 7

4.15 Constructional changes to the machine

Make no changes, attachments or conversions to the machine without prior written approval of the manufacturer. All conversion

measures require the written approval of the Watson-Marlow MasoSine Company. Damaged or improperly functioning parts

should be immediately replaced. Use only original MASO-Sine parts. Use of parts not supplied by MASO-Sine or other

aftermarket parts will void all warranties. Aftermarket parts are not authorized by Watson-Marlow MasoSine and void all

certifications such as 3-A, USDA and FDA.

4.16 Noise of the machine

The continuous sound level proceeding from the pump is less than 70 dB(A). A higher sound pressure level that causes noise

deafness can arise depending upon the local conditions. In this case protect the operating personnel with corresponding

protective equipment / protective measures.

4.17 Maintenance and repair, troubleshooting

Perform specified adjustment, maintenance and inspection work in a timely manor to prevent possible damage. Inform operating

personnel before starting the maintenance and repair work. Protect all plant parts and operating media connected before and

after the machine such as compressed air and hydraulics and similar against unintentional start-up. Follow proper LOCKOUT –

TAGOUT procedures before performing any maintenance. In all maintenance, inspection and repair work switch

the machine free of voltage and secure the main switch against unexpected starting. Fasten and secure larger

assemblies on replacement carefully to lifting gear. Be sure all fasteners are tightened to proper specifications. Use

only original spare parts.

After ending the maintenance work check the safety devices for function.

4.18 Maintenance of the bearings

• For pumps in series, EC 25 and EC 40 both bearings must be replaced by new ones after running for 10,000 hours!

• For pumps in series EC 60, please refer to the enclosed table:

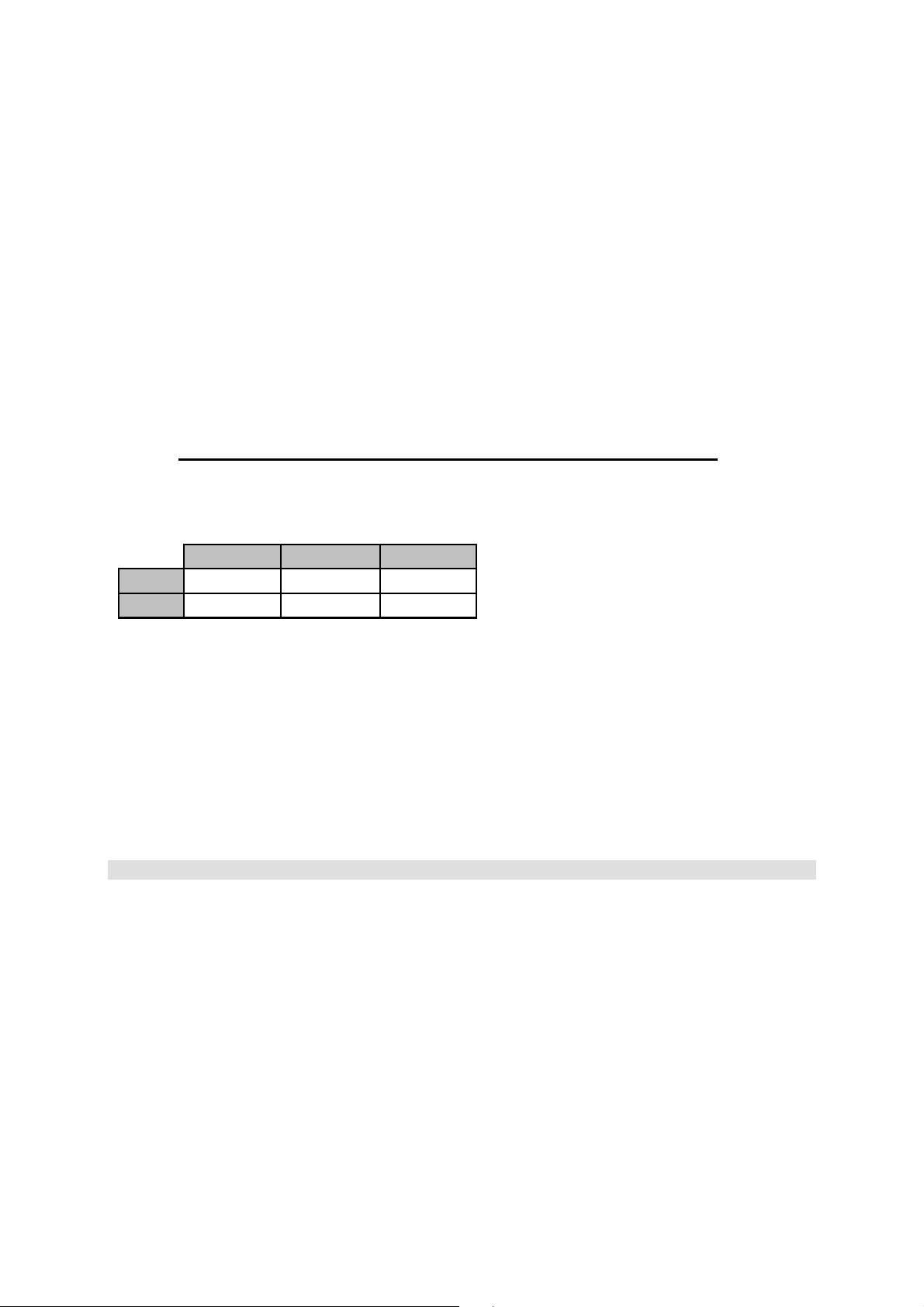

200 rpm 400 rpm 600 rpm

3 bar

6 bar

4.19 Cleaning the machine

Handle substances and materials used correctly, especially

- when working on lubricating systems

- when cleaning with solvents.

10000 hours

9199 hours 6133 hours

4.20 Faults

In the case of operating faults switch off the machine and secure it against unauthorized or inadvertent starting up again.

4.21 Use as intended

The accurate intention is listed in the order confirmation. Another use or use going beyond this is not as intended.

If you want to change the product, the pressure, the speed or the temperature, you must firstly consult us or one of our

representatives.

5 Safety instructions (ATEX)

Watson-Marlow MasoSine - Pump used in production machinery with explosive mixtures will be equipped accordingly in the

factory.

5.1 Safety signs

Grounding symbol

5.2 Pump classification

The pumps are only designed for jobs lasting several days and are therefore assigned to the Device Group II – Application field

“dust – or gas – explosive areas”!

Revision 4.4 / November 2010 7

Page 8

5.3 Zone classification

The Watson-Marlow MasoSine - Pumps can be used in explosive areas of the zone 1 / 21.

This corresponds to the category 2 G / D.

It is expressly forbidden to use the pump(s) in the zone 0!

5.4 Classification of the ex-atmospheres

A distinction is made between dust and gas explosive atmospheres. In the model code, the atmosphere is abbreviated with G

(Gas) and D (Dust). Watson-Marlow MasoSine - Pumps are only designed for the explosive atmospheres G (Gas) and D

(Dust)!

5.5 Ignition protection

Our pumps are subject to ignition protection "c" constructive safety according to the standard for "non-electric appliances for use

in explosion-risk areas" EN 13463-5

5.6 Temperature classes

For product temperature up to max. 95°C: EX II 2 G c T4

EX II 2 D c T=120°C

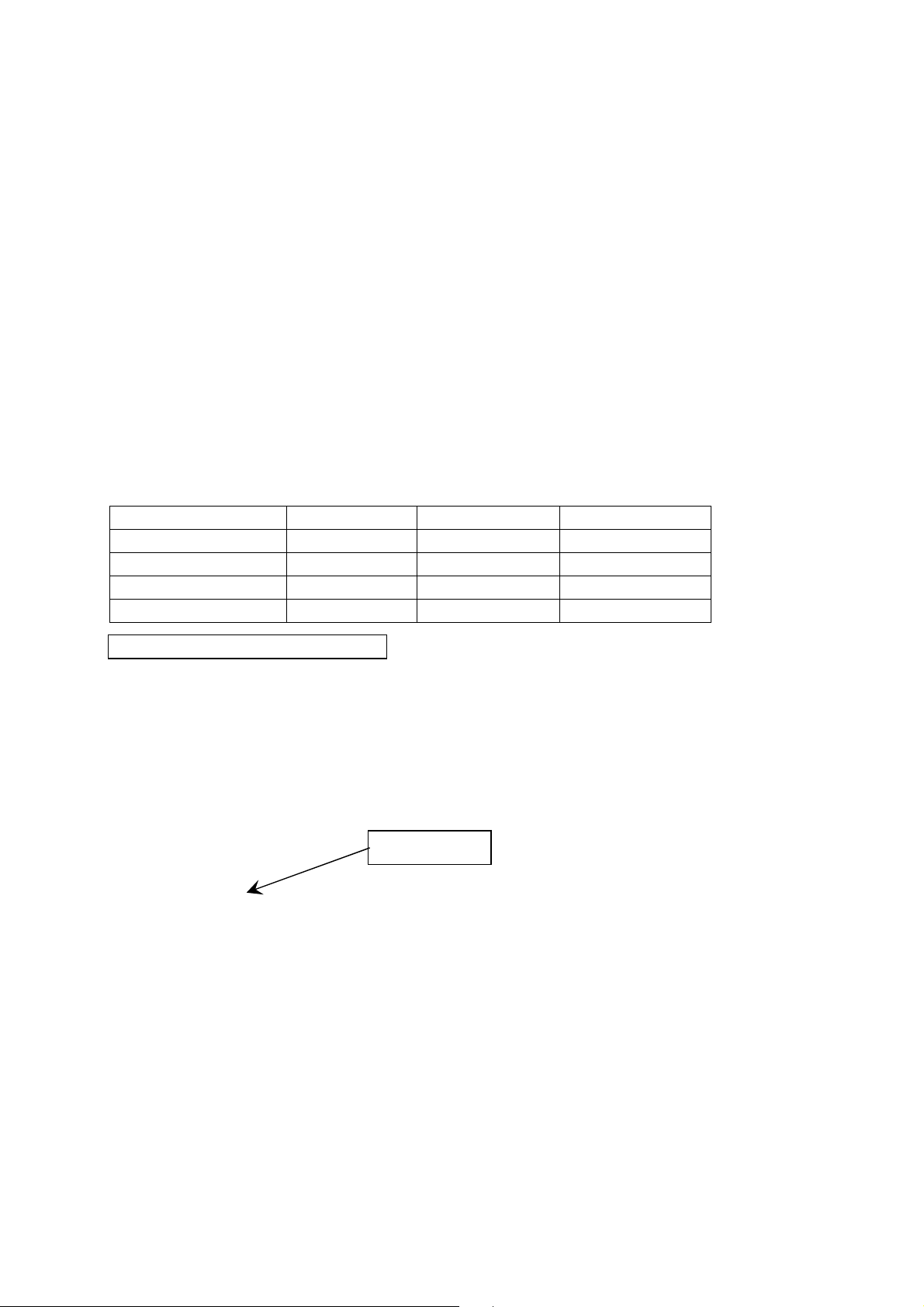

5.7 Limit values for the pump

The limit values for the pump (max. speed, max. pressure, max. temperature) are stated in the data sheet (see page 4). These

limit values must never be exceeded under any circumstances! This applies in particular when using a frequency converter.

If the pumps are supplied without a drive, the following values apply!

EC25 EC40 EC60

max. Pressure * 6 bar 6 bar 6 bar

max. Speed * 600 rpm 600 rpm 600 rpm

max. Temperature *

95°C* 95°C* 95°C*

Ambient temperature -12°C bis +40°C -12°C bis +40°C -12°C bis +40°C

* depending on the rating of the pump (pls. see order confirmation)

5.8 Grounding the pump

All supplied pumps are equipped with a grounding option.

In particular in ex-areas, the pump must be grounded by fixing a grounding cable to the corresponding position (see diagram).

In addition to the grounding of the pump, the motor also needs to be grounded! If the drive is not grounded, the pump aggregate

may not be operated.

Grounding

5.9 Material properties

Plastic parts that are fitted inside the pump react more to temperature changes that stainless steel parts. For this reason, the

specified maximum medium temperature (Tm=95°C), for which the pump is designed, may not be exceeded. If the specified

temperature is exceeded, this may cause a linear expansion and may block single components; this in turn could cause the

pump to fail or could result in damage to parts of the pump. Also, excessive temperatures can accelerate the wear of dynamic

parts and therefore reduce the lifespan of the plastic parts.

Corrosion may occur to the Power Frame of the pump if the paintwork is damaged. Corrosion represents a hazard for the use of

pumps in explosive areas (for measures, see Troubleshooting Chap. 21).

5.10 Pressure Conditions

To avoid any over-pressure in the pump as a result of a closed pressure line, a pressure controller must be installed.

Revision 4.4 / November 2010 8

Page 9

5.11 Maintenance / Repair

• The Filling of the pump is only permitted outside the explosion aria. Tools that are used should in compliance with

ATEX.

• The pump aggregate always needs to be kept clean of dust with a damp cloth to prevent the dust from smouldering.

• The rinsing channels in the power frame must always be checked for blockages and if necessary cleaned.

5.12 Cleaning

Caution! No solvent cleaning agents may be used to clean the pump as this could create an uncontrollable explosive

atmosphere.

5.13 Medium to be pumped

Chemicals that are combustible below the temperature 120 degrees Celsius (T4/T=120°C) and Carbon disulphide must not be

pumped.

5.14 Coupling

If the pump is used in an explosion-risk area, the pump must only be coupled to the drive by means of an elastic, positive

coupling with ATEX certification, at least corresponding to the supplied pump. Chains, toothed belts, v-belts or similar equipment

which may transmit radial forces on the bearings should not be used.

5.15 Drive

Any preceding reduction gears and/or control units must have the corresponding ATEX certification, at least corresponding to

the supplied pump. Combustion engines must never be used!

For operation with a frequency converter, this must either be installed outside the ex-zone, or have the same ATEX certification

corresponding to the delivered pump. In any case the converter must have the properties required for operation in ex-zones, for

example, temperature monitoring, speed limitation, etc.

6 Warranty and liability

Basically our “General sales and delivery conditions” apply.

These are available to the operator at the latest since conclusion of the contract.

Warranty and liability claims for personal and material damage are excluded if they are attributable to one or several of the

following causes:

- Use of the machine not as intended

- Incorrect installation, operation and maintenance of the machine

- Operating the machine with defective safety devices or not correctly attached or not functioning safety and protective

- Non-compliance with the instructions in the operating instructions regarding

transport,

storage,

installation,

start-up,

operation, maintenance and setting of the machine.

- Unauthorized constructional changes to the machine

- Insufficient monitoring of machine parts subject to wear

- Incorrectly performed repairs

- Cases of catastrophe due to effect of foreign bodies and acts of God.

Watson-Marlow MasoSine grants no warranty on this documentation as well as no implicit warranties on commercially

customary quality and suitability for a certain application.

Watson-Marlow MasoSine undertakes no liability for errors contained in it or consequential damage occurring by chance

arising due to the design, performance and the use of this documentation.

This publication contains own information protected by copyright. All rights are reserved.

This publication may be neither photocopied, nor duplicated nor translated without previous agreement of Watson-Marlow

MasoSine. Rights reserved to make changes in these operating instructions.

devices

7 Transport instructions

The choice of the means of transport is according to the size of the pump and of the drive. The pump must be suspended

correctly for transport. The crane/forklift truck and the ropes/belts must be sufficiently dimensioned. If the pump is transported

with a lift truck or a forklift truck, it must be noted that the console centre point is not automatically the centre of gravity.

Wrong! Rright!

Revision 4.4 / November 2010 9

Page 10

8 Installation

CCAAUUTTIIOONN CCAAUUTTIIOONN

CCAAUUTTIIOONN

CCAAUUTTIIOONN

CCAAUUTTIIOONN CCAAUUTTIIOONN

DO NOT LET RUN THE P

UMP

CAUTION!

Cavitation destroys the pump!

The motor shaft and pump shaft connection

must be protected against contact!

Place the pump on a level ground.

Do not start without the protection against contact!!

The foundation should be dimensioned sufficiently for the weight of the pump.

There should be sufficient space for maintenance work around the pump.

It must be guaranteed that the motor receives an adequate air supply.

If the pump is used in explosion endangered rooms, an Ex protected motor must be

used.

The total unit must be protected against static charge.

Align the shaft of the pump with the shaft of the drive.

WITHOUT COUPLING GUARD!

9 Connection to the piping

Before connection clean the piping and remove foreign bodies.

(e.g. there can still be residues in the pipes due to welding work).

Fit elastic intermediate members (compensators) between pump and fixed piping on the suction

and pressure side. This should prevent vibrations of the pump being transmitted to the piping

system.

Forces and torques acting from the piping on the pump connections (e.g. due to distortion,

expansion due to temperatures etc.) must be avoided.

The pressure line should point upwards, so that later residual liquid can always flow back into the

pump. Thus total dry running is avoided. Further it facilitates the later suction process.

The operator has to ensure that an inadmissible pressure rise (above the pressure agreed in the

order and listed in the technical data) is not possible.

The SINUS pumps normally run with such a low resonant frequency that no corresponding

damage is caused. However, particularly when running with converters, certain frequencies can

cause interfering vibrations which must be avoided. It is important during initial commissioning to

ascertain whether such vibrations exist and to define them accordingly, so that the frequency

converter can then be programmed to avoid these frequencies. Similarly, interference from

cavitation or rigid lines must be ruled out.

The operator has to ensure that the pump can work free of cavitation!

10 Possible connection positions

Counterclockwise rotation of the rotor and motor Clockwise rotation of the rotor and motor

Revision 4.4 / November 2010 10

Unless otherwise ordered, the pump is delivered in 10-2 position.

Page 11

Changing the direction of rotation for a EC 25, EC 40 and

EC 60.

11 Changing the connection position

The standard nozzle configuration is set at the 10-2 position from the

Pos. 10

Pos. 9

Pos. 30

in the vertical position and reinstall on the pump housing. Tighten the screws Pos.9 according the specified torque. Mind that the shim

kit, Pos. 24 is on the housing.

Torque for Pos. 9: EC 25 25 Nm EC 40 50 Nm EC 60 90 Nm

Observe that the pump is filled with product before starting to facilitate suction and to avoid dry run. (see chapter 12)!

When the connection position is changed, the motor must be protected

against unintentional switching on!!

12 Changing the direction of rotation

factory. To change the nozzle position, all internal parts must first be

removed as in illustration 001. Remove the screw, Pos. 30, as well

as the screws Pos.9 (2 pcs.). The housing and shaft can now be

removed from the baseplate. Note: once removed from the base, the

housing will be free and should be secured to prevent possible

damage or personal injury. CAUTION: EC 40 AND EC 60

HOUSINGS WILL BE HEAVY. Rotate the pump housing into the

desired position and replace the screws to reinstall the baseplate.

The bearing assembly musty now be rotated so that the vent and oil

sight glass are in the proper position. Remove the screws, Pos.10 (4

pcs.) and remove the shaft and bearing housing assembly from the

pump housing. Rotate the bearing housing assembly until the vent is

Due to construction, the pump is able to turn clockwise as well as

counter clockwise. For doing this any conversion or modification is not

necessary.

All you have to do is changing the direction of the gear motor.

13 Important: Observe before start-up!

If you have performed cleaning or repair work or make the first start-up, check before start-up that all screws are correctly and

completely tightened.

Observe the corresponding regulations in the case of hazardous pumped material (according to ArbStoffV).

The pump can possibly be contaminated by transport, therefore remove the pump cover and clean if necessary before start-up.

Before you start up the pump, convince yourself once again that the scraper and the guide cartridge are in the correct position in

relation to the pressure side (see change of direction of rotation).

CCAAUUTTIIOONN

The operator must ensure that the pump is installed in an appropriate position with all necessary

safety precautions (sensors, switches, pressure gauges, etc.)!

Liquid level

Revision 4.4 / November 2010 11

The pump must always be filled with the

corresponding medium before commissioning

and during operation, with the liquid level

above the rotor (see diagram).

Never let the pump run dry!!!

Page 12

CCAAUUTTIIOONN

CCAAUUTTIIOONN CCAAUUTTIIOONN

The motor must be connected by an expert according to DIN EN 60204.

Make sure before start-up that all valves on the pressure and suction side are open. The pump

may not pump against a closed valve without overpressure valve.

If the pump leaks, end operation as quickly as possible to replace the damaged sealing elements.

The operator must ensure that the pump can work free of cavitation.

Cavitation destroys the pump.

14 Cleaning

All Watson-Marlow MasoSine Pumps are fully capable of CIP cleaning. Please observe our CIP cleaning regulations.

14.1 Cleaning in own circuit with water, alkali, acid

1. Set control gear to maximum speed (at least 400 rpm).

2. Choke after the pump so that a counterpressure of 3 to 4 bar (44 to 58 psi) arises.

3. Should the required cleaning effect not be achieved after this process,

it is necessary to dismantle the pump.

This is done in a few minutes as described in detail in the operating instructions.

Manual cleaning of the pump can be performed after complete dismantling of the pump.

Pay attention to parts sensitive to breakage!!

14.2 Cleaning in the CIP circuit

1. Purging surge

back to the CIP plant

Choke Valve

Open / Close Valve

X + 3 bar

X - bar

from CIP plant

Open the choke valve and let the Watson-Marlow MasoSine Pumpe run

with maximum speed to perform the first rough cleaning.

2. Purging

Set the choke valve so that the pressure side of the pump is at least

3.0 bar higher than the suction side.

Open the open/close valve to guarantee cleaning of the series connected

devices.

14.3 Manual cleaning

Manual cleaning of the pump can be performed after complete dismantling of the pump.

Pay attention to parts sensitive to breakage!!

If the pump is stopped during the process and opened for the purpose of cleaning or checking,

the responsible fitter or electrician must be notified to undertake suitable measures so that the pump

cannot be put into operation (remove fuses, notify electrician).

The pump may also never be put into operation if the housing cover is removed. Should the pump

not yet be connected to the piping system, then reliable care must be taken that the drive machine

cannot be switched on.

Observe the accident prevention regulations!!

14.4 Sterilization

Sterilization of the pump with standard equipment is possible up to 110°C only in standstill!

In the case of special equipment of the pump or higher temperatures, please always firstly consult the manufacturer!

Revision 4.4 / November 2010 12

Page 13

Watson

-

Marlow MasoSine

15 Oil change

For pumps in the series EC 25 / EC 40 / EC 60 check every day and in particular every time before starting up, that there

is enough oil in the component bearing block. The oil sight glass in the support must be filled to the middle. Please use the

following oil grade for your specific application! If the pump is to be used in an area that is combustible where ATEX applies, the

oil viewing glass is replaced by a screwed plug.

Standard first filling of Watson-Marlow MasoSine Pumps

• For –10°C to 60°C / 14° F to 140° F

Klüberoil 4 UH 1-220 N (lube oil for the food and pharmaceutical industry)

Oil grades for ex-zones

• Only the following oil type may be used in pumps operated in explosive areas:

Klüberoil 4 UH 1-220 N (lubrication oil for the food and pharmaceuticals industries)

15.1 Filling volumes

EC 25 approx. 0,10 litre / US qt EC 40 approx. 0,15 litre / US qt EC 60 approx. 0,50 litre / US qt

16 Disposal

Send the old oil or old grease for treatment.

17 Spare parts

Basically repairs should be performed only by factory personnel or by customer service agencies authorized by the factory. If

you make repairs yourself, observe the relevant safety regulations and contact the factory customer service before starting the

work, especially if warranty obligations which can be lost by not approved repairs still exist.

Only Watson-Marlow MasoSine spare parts may be used.

You should record changes in the fixtures and fittings, for example another sealing

system or a material change, in writing.

Please provide all data when ordering:

- Pump number - Description

- Type - Material

- Item No. - Quantity

Ask for our express delivery!

Postfach 100

Steinbeisstraße. 3

D-74358 Ilsfeld (Germany)

Telefone : +49 (0)7062 9560-0

Telefax : +49 (0)7062 64593

EMail : Info@masosine.com

Internet : http://www.masosine.com

18 Taking out of service

18.1 Provisional taking out of service

Short term:

Remove product residues (cleaning) Switch off main switch Clean pump surface

Longer term:

Remove product residues carefully (cleaning ) Switch off main switch Clean pump surface Disconnect connections

Store the scraper in water.

18.2 Final putting out of service

Separate power and purging liquid supply. Send oils and greases for treatment.

If you send us the remaining parts freight paid, we will dispose of the parts.

Revision 4.4 / November 2010 13

Page 14

19 Troubleshooting

Error Cause Remedy

Pump does not draw in

Pump does not deliver

Pump is noisy

Pump leaking at leakage

hole

Pump is noisy

Pump leaking at the front

housing

Pump has blocked

Strong wear after short

operating time

Rotor has wear on one

side

Pump not clean after CIP

cleaning

Rotor has seized on

stator

Direction of rotation not correct Check direction of rotation

No wetting liquid in the pump Fill pump with liquid

Screw fastening not tight Check screw fastening

Suction pipe too long Adapt suction pipe

Pipe cross-section too narrow Adapt suction pipe

Seals leaking Check all seals for damage

Wear in the pump Change wearing parts

Motor speed not correct Measure, regulate speed

Direction of rotation not correct Check direction of rotation

Suction pipe is leaking Check pipe system

Motor speed not correct Check speed based on output

diagrams

Wearing parts worn Replace wearing parts

Inserted closed gate valve Check pipe system

Noises come from the drive / pump Consult

Watson-Marlow MasoSine

Suction pipe too small (cavitation) Shorten suction pipe or increase

diameter, reduce speed

Knocking noises from the pump head Scrapergate wear

Noises from bearing housing Fill oil, change tapered roller

bearings

Coupling not aligned Align coupling with hairline

Seal system leaking Change Mechanical or Lip seal

system

O-ring seal leaking Replace O-ring

Lip seals on the bearing block

leaking, oil escapes

O-rings in the Liner not or wrongly

installed

Foreign body in the pump Remove foreign body, examine

Power supply interrupted Check electrical installations

Defect on the drive (Separate the coupling and turn

Solids in the pumped material

Pumped material is abrasive

Rotor not tightened correctly on

installation

Adjusting dimensions changed after

working on the bearing housing

Cleaning regulation not complied with Choke on the pressure side

Rotor not correctly tightened Tighten closing nut firmly on block

Temperature too high

(thermal expansion)

Dismantle bearing block,

replace radial shaft sealing rings

Install housing O-ring correctly or

replace

pump for damage

(fuses, drive)

the pump by hand)

Frequent change of the wearing

parts, change material pairing

Choose larger pump,

reduce speed

Tighten closing nut firmly on block

Check and correct the adjusting

dimensions (see page 12)

Check differential pressure 3-4 bar

Choose Liner with larger

tolerances

Revision 4.4 / November 2010 14

Page 15

20 Adjusting dimension

For the pumps of the series EC 25 / EC 40 / EC 60

Laminum-Ring

Pump type Adjusting dimension X

EC 25

EC 40

53.00 mm ±0.05

2.087” ±.002

74.90 mm ±0.05

2.949” ±.002

EC 60

Remeasure the adjusting dimension X.

If this dimension is not correct, install a new Laminum ring and measure the

adjusting dimension once again. Then peel off the layer(s) by the difference

so that the necessary adjusting dimension is achieved.

One layer is 0.05 mm or .002” thick.

120.75 mm ±0.05

4.754” ±.002

Revision 4.4 / November 2010 15

Page 16

21 Tightening torques

WATSON-MARLOW MASOSINE PUMP EC 25

Flange - Bearing Housing M6 DIN 7984

Flange - Pump Housing M8 DIN 931

Adapter Plate - Pump Housing M8 DIN 933

Shaft Nut - Pump Shaft

RIGHT-HAND THREAD

SW30

Cap Nut / Wing Nut - Pump Housing SW 22

Oil Plug - Bearing Housing R ¼“ DIN 910

WATSON-MARLOW MASOSINE PUMP EC 40

Flange - Bearing Housing M8 DIN 7984

Flange - Pump Housing M10 DIN 933

10 N•m

7 lb•ft

25 N•m

18 lb•ft

25 N•m

18 lb•ft

80 N•m

59 lb•ft

45 Nm / 19 N•m

33 / 14 lb•ft

10 N•m

7 lb•ft

25 N•m

18 lb•ft

50 N•m

37 lb•ft

Adapter Plate - Pump Housing M8 DIN 933

Shaft Nut - Pump Shaft

RIGHT-HAND THREAD

SW 38

Cap Nut / Wing Nut - Pump Housing SW 22

Oil plug - Bearing Housing R ¼“ DIN 910

WATSON-MARLOW MASOSINE PUMP EC 60

Flange - Bearing Housing M12 DIN 7984

Flange - Pump Housing M12 DIN 933

Adapter plate - Pump Housing M8 DIN 933

Shaft Nut - Pump Shaft

RIGHT-HAND THREAD

SW 50

25 N•m

18 lb•ft

108 N•m

80 lb•ft

45 Nm / 19 N•m

33 / 14 lb•ft

10 N•m

7 lb•ft

90 N•m

66 lb•ft

90 N•m

66 lb•ft

25 N•m

18 lb•ft

135 N•m

100 lb•ft

Cap Nut / Wing Nut - Pump Housing SW 22

33 / 25 lb•ft

10 N•m

45 Nm / 34 N•m

Oil Plug - Bearing Housing R ¼“ DIN 910

Revision 4.4 / November 2010 16

7 lb•ft

Page 17

22 Dismantling

Remove the Front Cover to the front

Before the work starts, the shaft has to be fixed

against movement

Remove Cap Nuts / Wing Nuts (RIGHT-HAND thread)

Remove the Liner, front

Compare the tool kit illustration

Revision 4.4 / November 2010 17

Page 18

Loosen and remove the Shaft Nut

Remove the Rotor-Assembly, consisting of Rotor,

Scraper and Guide Rail

Revision 4.4 / November 2010 18

Page 19

23 Dismantling „Lip Seal System“

The Liner, back consists of the Lip Seal System

The nose of the tool has to be hooked in the

groove of the Liner

Remove the Shaft Sleeve

Take off the Lip Seals and Lip Seal Support

Rings for exchanging

Remove the Liner, back with the aid of tool kit

Revision 4.4 / November 2010 19

Page 20

Face, static

24 Dismantling „Mechanical Seal System“

The Liner, back consists of the Mechanical Seal

System

The nose of the tool has to be hooked in the

groove of the Liner

Remove the Dynamic Ring Holder together with

Face, dynamic

Remove the Liner, back with aid of tool kit

Revision 4.4 / November 2010 20

Remove carefully the Face, static

Page 21

25 Assembly

The assembly has to be done in the same instruction order as the disassembly.

25.1 Assembly „Rotor-Assembly“

During mounting of the

Rotor-Assembly the noses of

the Guide rail mustn’t be

laid on the surface of the

Rotor. To achieve this you

have to fit Scraper and

Guide rail in a position that

the noses of the Guide rail

are touching the gable end

of the Rotor.

After that you have to put the

assembly unit non-violently

into the Liner.

Revision 4.4 / November 2010 21

Page 22

26 Pump sizes

26.1 Cross section drawing EC 25 with Lip Seal System

26.2 Cross section drawing EC 25 Mechanical Seal System

Revision 4.4 / November 2010 22

Page 23

26.3 Cross section drawing EC 40 with Lip Seal System

26.4 Cross section drawing EC 40 with Mechanical Seal System

Revision 4.4 / November 2010 23

Page 24

26.5 Cross section drawing EC 60 with Lip Seal System

26.6 Cross section drawing EC 60 with Mechanical Seal System

Revision 4.4 / November 2010 24

Page 25

26.7 Parts list for an EC 25 / EC 40 / EC 60 Pump

No. Qty. Item Description No. Qty. Item Description

1 3 XX-1610-ZZ Cap Nut EC 25 14 1 XX-1400-ZZ Bearing Housing

1 XX-1600-ZZ Wing Nut EC 25 15 1 XX-3101-ZZ Lip Seal, Outboard

1 6 XX-1610-ZZ Cap Nut EC 40 16 1 XX-3702-ZZ Shaft Key

1 XX-1600-ZZ Wing Nut EC 40 17 1 XX-1000-ZZ Shaft

1 10 XX-1610-ZZ Cap Nut EC 60 18 1 XX-2800-ZZ Bearing Lock Nut

1 XX-1600-ZZ Wing Nut EC 60 19 1 XX-3703-ZZ Tabwasher

2 3 XX-1800-ZZ Front Cover Stud EC 25 20 1 XX-3704-ZZ Drain Plug

2 6 XX-1800-ZZ Front Cover Stud 40 21 2 XX-2600-ZZ Tapered Roller Bearing

2 10 XX-1800-ZZ Front Cover Stud EC 60 22 1 XX-8000-ZZ Mounting Plate

3 2 XX-3000-ZZ O-Ring, Rotor 24 1 XX-1401-ZZ Shims

4 1 XX-0300-ZZ Pump Housing 25 4 XX-3705-ZZ Safety Pin

5 1 XX-0100-ZZ Rotor 28 1 XX-1200-ZZ Liner, back

7 1 XX-3001-ZZ O-Ring, Bearing Housing 29 2 XX-3002-ZZ O-Ring, Liner

8 1 XX-1300-ZZ Flange 30 1 XX-3707-ZZ Bearing Housing Cap Screw

9 8 XX-3200-ZZ Housing Mounting Bolt 32 1 XX-1250-ZZ Liner, front

10 4 XX-3201-ZZ Cap Screw, Bearing Housing 33 1 XX-0200-ZZ Front Cover

11 1 XX-3700-ZZ Snap Ring EC 25 / EC 40 34 1 XX-0800-ZZ Shaft Nut

11 1 XX-3700-ZZ Snap Ring EC 40 35 1 XX-0400-ZZ Scrapergate

12 1 XX-3103-ZZ Lip Seal, inboard 36 1 XX-0700-ZZ Guide Rail

13 1 XX-3701-ZZ Vent Valve

47 1 25-3800-ZZ Oil Sight Glass

26.8 Parts list for the Lip Seal System EC 25 / EC 40 / EC 60

6 2 XX-3102-ZZ Lip Seal EC 25 27 1 XX-3708-ZZ Lip Seal Support Ring EC 25

6 3 XX-3102-ZZ Lip Seal EC 40 / EC 60 27 2 XX-3708-ZZ Lip Seal Support Ring EC 40

23 1 XX-3103-ZZ Lip Seal EC 25

26 1 XX-3706-ZZ Spacer Ring EC 25

27 2 XX-3708-ZZ Lip Seal Support Ring EC 60

31 1 XX-0610-ZZ Shaft Sleeve, Lip Seal

26.9 Parts list for the Mechanical Seal System EC 25 / EC 40 / EC 60

No. Qty. Item Description No. Qty. Item Description

31 1 XX-3611-ZZ Dynamic Ring Holder 42 4 XX-3606-ZZ Set Screw EC 40 / EC 60

37 1 XX-3601-ZZ Face dyn. 43 1 XX-3607-ZZ Static Ring Holder

38 1 XX-3602-ZZ Face stat. 44 1 XX-3608-ZZ Snap Ring

39 1 XX-3603-ZZ O-Ring, Face static 45 1 XX-3609-ZZ Spring Retainer Ring

40 1 XX-3604-ZZ O-Ring, Static Ring Holder 46 6 XX-3610-ZZ Spring EC 25

41 1 XX-3605-ZZ Spring Spacer 46 8 XX-3610-ZZ Spring EC 40 / EC 60

42 3 XX-3606-ZZ Set Screw EC 25

Please ensure you quote the Type when ordering spare parts!

(See technical data sheet)

Revision 4.4 / November 2010 25

Page 26

27 Code-Structure for spare part orders

Structure of the article number:

xx-yyyy-zz

Type of pump Part number Code of material

. Type of pump

1

code pump size

E25 EC 25

E60 EC 60

E40 EC 40

2. Part numbers: Please see attached technical data sheet.

3. Code of material

a. Elastomer

b. Plastics

c. Carbide / Carbon

Code Material Code Material

80 NBR / BUNA 82 EPDM

84 VITON 88 PTFE

86 Silicone

Code Material

49 MASOTRONIC-2070-WR

50 MASOTRONIC-2800-PO or MASOTRONIC-2810-PO

53 MASOTRONIC-2050-UH

62 MASOTRONIC-2080-PK

Code Material Code Material

40 ceramic 41 silicon carbide

66 carbon

Revision 4.4 / November 2010 26

Page 27

28 Dimensional drawings

28.1 Dimension table for pump with German Milk Fittings

EC 25

mm 235 290 35 339 185 155 15 52 88 32,2 NW 65

EC 40

mm 296 382 35 431 200 170 20 50 130 30.2 NW 100

EC 60

mm 463 602 54 654 315 285 20 82 150 56,2 NW 150

EC 25

mm 118,5 160 278 125 140 23 28 17 60,2 Ø 9 NW 65

EC 40

mm 173 220 393 255 270 25,5 38 22 97,4 Ø 9 NW 100

EC 60

mm 234 315 549 315 330 25,5 50 28,5 146,8 Ø 9 NW 150

IN 9.25 11.42 1.38 13.35 7.28 6.11 0.59 2.05 3.46 1.27 NW 65

IN 11.65 15.04 1.38 16.97 7.87 6.69 0.79 1.97 5.12 1.19 NW 100

IN 18.23 23.71 2.13 25.75 12.41 11.22 0.79 3.22 5.91 2.21 NW 150

IN 4.67 6.3 10.94 4.92 5.51 0.91 1.1 0.67 2.37 0.36 NW 65

IN 6.81 8.66 15.47 10.04 10.63 1 1.5 0.87 3.83 0.36 NW 100

IN 9.21 12.4 21.61 12.41 12.99 1 1.97 1.12 5.78 0.36 NW 150

A B C D E F G H I K Fittings

L M P R S T U V W X Fittings

Revision 4.4 / November 2010 27

Page 28

28.2 Dimension table for pump with TRI-CLAMP (TC)

EC 25

mm 235 290 35 339 185 155 15 52 88 32,2 TC 2,5"

EC 40

mm 296 382 35 431 200 170 20 50 130 30,2 TC 4"

EC 60

mm 463 602 54 654 315 285 20 82 150 56,2 TC 6"

EC 25

mm 118,5 133 251 125 140 23 28 17 60,2 Ø 9 TC 2,5"

EC 40

mm 173 179 352 255 270 25,5 38 22 97,4 Ø 9 TC 4"

EC 60

mm 234 295 530 315 330 25,5 50 28,5 146,8 Ø 9 TC 6"

IN 9.25 11.42 1.38 13.35 7.28 6.11 0.59 2.05 3.46 1.27 TC 2,5"

IN 11.65 15.04 1.38 16.97 7.87 6.69 0.79 1.97 5.12 1.19 TC 4"

IN 18.23 23.71 2.13 25.75 12.41 11.22 0.79 3.22 5.91 2.21 TC 6"

IN 4.67 5.22 9.88 4.92 5.51 0.91 1.1 0.67 2.37 0.36 TC 2,5"

IN 6.81 7.04 13.86 10.04 10.63 1 1.5 0.87 3.83 0.36 TC 4"

IN 9.21 11.61 20.86 12.41 12.99 1 1.97 1.12 5.78 0.36 TC 6"

A B C D E F G H I K Fittings

L M P R S T U V W X Fittings

28.3 Dimension table for pump with RJT

EC 25

mm 235 290 35 339 185 155 15 52 88 32,2 RJT 2,5"

EC 40

mm 296 382 35 431 200 170 20 50 130 30,2 RJT 4"

EC 25

mm 118,5 146 264 125 140 23 28 17 60,2 Ø 9 RJT 2,5"

EC 40

mm 173 192 365 255 270 25,5 38 22 97,4 Ø 9 RJT 4"

IN 9.25 11.42 1.38 13.35 7.28 6.11 0.59 2.05 3.46 1.27 RJT 2,5"

IN 11.65 15.04 1.38 16.97 7.87 6.69 0.79 1.97 5.12 1.19 RJT 4"

IN 4.67 5.75 10.39 4.92 5.51 0.91 1.1 0.67 2.37 0.36 RJT 2,5"

IN 6.81 7.56 14.37 10.04 10.63 1 1.5 0.87 3.83 0.36 RJT 4"

A B C D E F G H I K Fittings

L M P R S T U V W X Fittings

28.4 Dimension table for pump with SMS (Swedish norm)

EC 25

mm 235 290 35 339 185 155 15 52 88 32,2 SMS 2,5"

EC 40

mm 296 382 35 431 200 170 20 50 130 30,2 SMS 4"

EC 25

mm 118,5 144 262 125 140 23 28 17 60,2 Ø 9 SMS 2,5"

EC 40

mm 173 201 374 255 270 25,5 38 22 97,4 Ø 9 SMS 4"

IN 9.25 11.42 1.38 13.35 7.28 6.11 0.59 2.05 3.46 1.27 SMS 2,5"

IN 11.65 15.04 1.38 16.97 7.87 6.69 0.79 1.97 5.12 1.19 SMS 4"

IN 4.67 5.67 10.31 4.92 5.51 0.91 1.1 0.67 2.37 0.36 SMS 2,5"

IN 6.81 7.91 14.72 10.04 10.63 1 1.5 0.87 3.83 0.36 SMS 4"

A B C D E F G H I K Fittings

L M P R S T U V W Z Fittings

28.5 Dimension table for pump with SMS (French norm)

EC 25

mm 235 290 35 339 185 155 15 52 88 32,2 SMS 2,5"

EC 40

mm 296 382 35 431 200 170 20 50 130 30,2 SMS 4"

EC 25

mm 118,5 144 262 125 140 23 28 17 60,2 Ø 9 SMS 2,5"

EC 40

mm 173 196 369 255 270 25,5 38 22 97,4 Ø 9 SMS 4"

IN 9.25 11.42 1.38 13.35 7.28 6.11 0.59 2.05 3.46 1.27 SMS 2,5"

IN 11.65 15.04 1.38 16.97 7.87 6.69 0.79 1.97 5.12 1.19 SMS 4"

IN 4.67 5.67 10.31 4.92 5.51 0.91 1.1 0.67 2.37 0.36 SMS 2,5"

IN 6.81 7.72 14.52 10.04 10.63 1 1.5 0.87 3.83 0.36 SMS 4"

A B C D E F G H I K Fittings

L M P R S T U V W X Fittings

Revision 4.4 / November 2010 28

Loading...

Loading...