V-ZUG GAS731GKBZ Installation Guide

J004133-R12

Installation instructions

12/06/2018

For flush installation of a frameless hob

with cement set and sealing strips

J004133-R12

Validity

These installation instructions apply to the following models:

005, 008, 009, 027, 028, 031, 032, 039–041, 226, 307, 527, 533, 878, 973–979, 84A, 87A–91A, 94A–97A, 31001–31200

Accessories

Designation |

Article no. |

|

|

Instant adhesive for installation of the steel angle (50 ml) |

B11657 |

|

|

Straight mixing nozzle, 10x |

B11656 |

|

|

TREMCLEAN isopropyl alcohol (1000 ml) |

1056609 |

|

|

Black silicone FA880 (310 ml) |

B11555 |

|

|

Anthracite silicone FA880 (310 ml) |

B11556 |

|

|

White silicone FA880 (310 ml) |

1031313 |

|

|

Stone grey silicone FA880 (310 ml) |

1031314 |

Marble smoothing agent AA320 (1000 ml) |

B11557 |

Fugenboy set (silicone finishing tool set) |

B75158 |

|

|

In case of doubt as to the suitability of cement set materials, especially when using them for the first time, we recommend that you carry out adhesion trials on test pieces or at non-visible locations.

Sealing strip set included with the hob

Art. no. |

Characteristics |

Thickness × width |

Length per roll |

|

|

|

|

H63283 |

Sealing strip, open-cell (soft) |

5 mm × 8 mm |

2.75 m |

|

|

|

|

|

Spacer set (H60330) |

0.5/1.0/2.0 × 7 mm |

– |

|

|

|

|

1

J004133-R12

Installation instructions

12/06/2018

For flush installation of a frameless hob

with cement set and sealing strips

J004133-R12

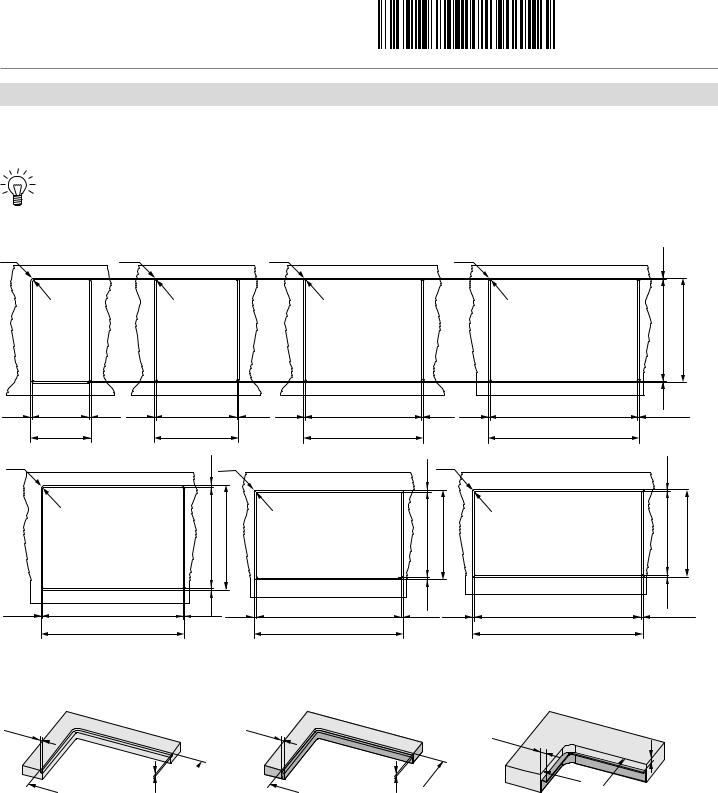

Cut-out with integral mounting surfaces or with mounting angles

Cut-out dimensions

It is recommended to use a work surface (cover) with a material thickness of at least 20 mm. Ream out the cut-out as accurate and

rectangular as possible and ensure compliance with the stated measurement tolerances.

Access must be guaranteed to the hob from below over the entire cut-out area. For servicing, the entire hob base can be taken out from below. It must be possible for touch protection covers to be unscrewed and removed from underneath.

Cut-outs up to the end of 2012 and for Quicklight hobs

RA |

|

RA |

|

|

|

|

RA |

|

|

|

|

RA |

|

0 -1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

8.5 |

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

R |

|

R |

|

|

|

|

R |

|

|

|

|

R |

|

|

|

|

|

I |

|

I |

|

|

|

|

I |

|

|

|

|

I |

|

|

|

|

|

INSTALLATION |

|

INSTALLATION |

|

|

INSTALLATION |

|

|

|

|

INSTALLATION DIMENSION 70 |

466 |

483 ±1 |

T |

|||

|

DIMENSION |

|

DIMENSION 40 |

|

|

DIMENSION 60 |

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

30 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0 1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

- |

|

|

|

0 |

|

0 |

|

|

|

|

0 |

|

|

|

|

0 |

|

8.5 |

|

0 |

|

8.5 -1 |

261 |

8.5 -1 |

373 |

|

|

8.5 -1 |

536 |

|

|

|

8 .5 -1 |

680 |

8.5-1 |

||||

|

|

|

|

|

|

|

|||||||||||

|

278 ±1 |

|

390 ±1 |

|

|

|

553 ±1 |

|

|

|

|

697 ±1 |

|

|

|

|

|

|

B |

|

B |

|

|

|

|

B |

|

|

|

|

B |

|

|

|

|

RA |

|

|

0 |

8.5 -1 |

RA |

|

|

0 |

8.5 -1 |

RA |

|

0 |

8.5 -1 |

|

|

||

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

R |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

I |

|

|

|

|

|

R |

|

|

|

|

|

R |

|

|

|

|

|

|

|

|

|

|

|

I |

|

|

|

|

|

I |

|

|

|

|

|

INSTALLATION DIMENSION 80 |

466 |

483 ±1 |

|

INSTALLATION DIMENSION 80 |

|

403 |

420 ±1 |

T |

INSTALLATION DIMENSION 90 |

|

369 |

386 ±1 |

T |

|||

|

T |

|

PANORAMA |

|

PANORAMA |

|

|||||||||||

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|||||||||

0 |

|

|

0 |

8.5 -1 |

|

0 |

|

733 |

0 |

8.5 -1 |

|

0 |

|

0 |

8.5 -1 |

|

0 |

8.5 -1 |

|

726 |

8.5-1 |

|

8.5 -1 |

869 |

8.5-1 |

||||||||||

|

|

743 ±1 |

|

|

|

|

|

750 ±1 |

|

|

|

|

886 ±1 |

|

|

|

|

|

|

B |

|

|

|

|

|

B |

|

|

|

|

B |

|

|

|

|

Creating the hob mounting

The mounting surface can either be reamed out (Fig. 1), or created by installing wood/stone supports (Fig. 2) or steel angles (Fig. 3).

8.5 |

0 |

|

FIG. 1 |

-1 |

|

|

|

|

|

|

|

|

|

B |

H |

|

|

|

Reamed out stone panel

T

8.5 |

0 |

|

FIG. 2 |

|

-1 |

|

|

|

|

|

|

|

|

|

|

|

B |

H |

T |

|

|

|

Execution with wood/stone supports, bonded or screw mounted

8.5 |

|

|

FIG. 3 |

0 |

|

|

|

|

-1 |

|

H |

|

|

|

|

|

|

B |

T |

|

|

|

Execution with steel angle, bonded or screw mounted

Installation dimension |

H |

Ra |

Ri |

Art. no. angle set |

|

|

|

|

|

30 |

8.5 0/+1 |

14 |

0–5 |

H62570 |

|

|

|

|

|

40 |

8.5 0/+1 |

14 |

0–5 |

H62571 |

|

|

|

|

|

60 |

8.5 0/+1 |

14 |

0–5 |

H62084 |

|

|

|

|

|

70 |

8.5 0/+1 |

14 |

0–5 |

H62567 |

|

|

|

|

|

80 |

8.5 0/+1 |

14 |

0–5 |

H62085 |

|

|

|

|

|

90 |

8.5 0/+1 |

14 |

0–5 |

H62981 |

80 Panorama |

8.5 0/+1 |

5 |

0–5 |

H62679 |

90 Panorama |

8.5 0/+1 |

5 |

0–5 |

H62568 |

|

|

|

|

|

2

Loading...

Loading...