Van Air Systems Zero Loss Pneumatic PDV User Manual

INSTALLATION INSTRUCTIONS

FOR PDV-500 Series

32-0277-A 2/09

The PDV-500 is designed for trouble-free and maintenancefree draining of unwanted accumulations of condensation

and other foreign matter from any collection point in a compressed air system without the need for electricity.

INSTALLATION

CAUTION: COMPRESSED AIR CAN BE DANGEROUS.

Before attempting to install the drain, be certain that the pressure vessel on which the drain will be installed is completely

depressurized.

The drain should not be installed in areas that are exposed to

freezing temperatures (heater option is available). Be certain

the air system pressure does not exceed the 250 PSI working

pressure of the drain and the pressure to the control system

does not exceed 120 psi. The inlet temperature should not

exceed 180 degrees F.

Connecting the drain to the air system should be done by using

one of the recommended installation diagrams shown herein.

The installation of a strainer is not required or recommended.

Install the drain as close to the source to be drained as possible.

Since the PDV-500

drain must be installed below the vessel to be drained when

using the top inlet. If flexible tubing is used on the discharge,

be certain it is properly fastened to prevent it from whipping

when the drain discharges the condensation.

The PDV-500 will accept condensation from either the top or

the bottom of the reservoir. We recommend the use of the

top entry port. If the bottom inlet is used, then a vent line

be used. The vent line should be installed down stream from

the vessel that is being drained. This will insure that the air

in the reservoir will properly exit as the condensation fills the

tank and replaces the air. Remove plastic plug and Install the

vent line in the 1/8" port located on the end plate in the upper

right corner (same endplate the control air/filter connects to).

The other end of the vent line should be run back to the air

system to a point just down stream from the source that is

being drained to a point of equal or lesser pressure. Use nongalling pipe sealant on all joints. The use of shut-off valves,

unions and bypass valves is recommended. A backup wrench

should be used on the discharge ball valve to prevent it from

turning and causing the linkage to bind.

uses gravity to fill the reservoir, the entire

must

The power to operate the PDV-500 comes from compressed air.

ONLY CLEAN DRY AIR SHOULD BE USED. The supply pressure

should be between 80 and 120 psig. The PDV-500 is supplied

with an inlet filter, which should be installed in the PDV-500 head

(See Dwg 2 on back). The use of unfiltered air can cause the drain

to fail.

Once the drain is installed, close the By-Pass drain valve and open

the Shut-Off valve. The pressure vessel can now be repressurized.

CHECKING THE DRAIN'S OPERATION

After installation is complete and the drain is on line, a check should

be made that the condensation is properly entering the reservoir.

This can easily be done by looking through the translucent reservoir.

If condensation is not entering the reservoir, check for the following:

1. Make sure the auxiliary shut-off valve is open.

2. Do not use the bottom inlet on the PDV-500 without

installing a vent line.

3. If a vent line is installed, make sure it is down stream

from the vessel that is being drained.

4. Be certain that the PDV-500 reservoir is not higher than

the vessel that is being drained. This is very important

when using the top inlet on the PDV-500 reservoir.

5. Check to make sure the vessel being drained has

condensation in it.

If the top inlet is being used and no condensation is entering the

PDV-500 reservoir, and all the above items have been checked,

we recommend that the bottom inlet be used with a vent line out

of the top.

If condensate fills the reservoir and the drain does not operate,

check to see if control line air is supplied to control line port. If the

drain is supplied with an optional test button, the supply of control

line air can be checked by pushing the test button. If the unit does

not operate, then no air is being supplied or the inlet filter is plugged.

OPTIONS

zz

z High Level Alarm.

zz

zz

z Heater.

zz

WARRANTY

The inlet port that is not used must be plugged by using a

standard 3/4" npt plug. When using the top inlet, any reduction

in the 3/4"pipe size is not recommended and the PDV-500

reservoir cannot be higher than the bottom of the vessel that

is being drained. It is best to run the drain in a downward pitch

from the bottom of the vessel being drained to the PDV-500

inlet

Van Air Systems, Inc. 2950 Mechanic St. Lake City, PA 16423

Phone: (814) 774-2631 Toll Free: (800) 840-9906

The PDV-500 is warranted to be free from defects in workmanship and materials for a period of one year from the date of

shipment. The liability of the manufacturer is limited to repair or

replacement of the drain at its option. In no event shall the

manufacturer be liable for special or consequential damages or

for delay in performances of this warranty.

CAUTION: Any attempt to repair the drain without authorization will

void any warranty.

INSTALLATION DIAGRAMS ON REVERSE SIDE

IN GENERAL

32-0277-A 2/09

In order for the condensate to properly enter the PDV-500 reservoir, the

condensate line to the PDV-500 must always be installed below the bottom of

the vessel to be drained. It is equally important to provide a means for the air

that is contained in the reservoir to escape (vent) as the condensate enters

the reservoir. If the air can not escape, the condensate will not enter the

reservoir. Below are suggestions on how to best install the PDV-500 on

typical types of vessels that have to drained of condensate. However, it is

possible to install the PDV-500 without a balance line (Dwg. not shown),

providing the condensate enters the

top inlet and the flow rates are less than

9 GPH (750 cfm for an aftercooler or 1500 cfm drier) for a 1/2" drain line and

19 GPH (1500 cfm for an aftercooler or 3000 cfm drier) for a 3/4" line. The

use of unions and shut-off valves are recommended for both the condensate

line and the balance line.

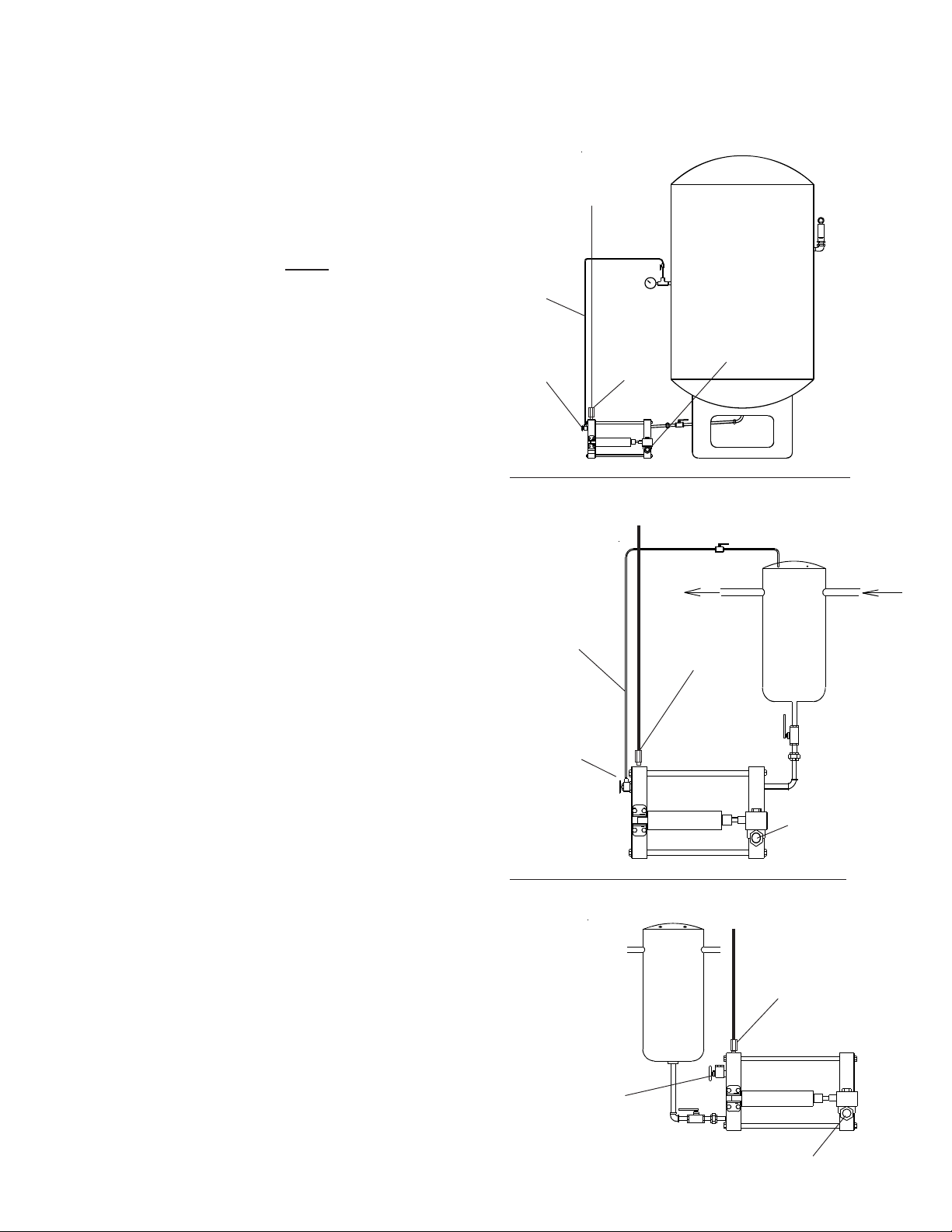

RECEIVER TANK

The preferred installation for a PDV-500 on a receiver t ank is having the

condensate enter the top inlet port and having the balance line go back to the

tank at a position that is above the level of the condensate (Dwg. 1).

FILTER and AFTERCOOLER MOISTURE SEPARA TOR

If a cyclone separator or filter has pipe plugs located in the top of the head,

the plug closest to the discharge pipe should be removed and the balance

line should be installed (Dwg. 2). If there is no provision on the cyclone

separator or filter for a balance line, install it in the discharge side of the pipe

line and as close to the cyclone separator as possible.

Dwg. 1

Clean Dry Control

Air, 80 to 120psi

Vent Line

Needle Valve

1/8 npt

(Not Supplied)

Dwg. 2

Control Line

Inlet Filter

Clean Dry Control

Air, 80 to 120psi

Discharge Port

1/2" npt

REFRIGERATED DR YER

If a balance line is required, it must be connected to the port located on top of

the separator that is closest to the discharge side (Dwg. 2), or between the

separator and the air-to-air heat exchanger. If a port is not available as

described above, then venting to atmosphere is recommended. When venting

to atmosphere, the condensate should enter through the bottom entry port on

the drain. The bleed or needle valve is installed on the 1/8" NPT vent port and

allows the air in the PDV-500 reservoir to escape to the atmosphere (Dwg 3).

The bleed valve (not included) should be adjusted so that only 3 to 5 bubbles

per second are visible. We do not recommend installing a vent line down

stream from the dryer. The vent line can be a conduit for transferring moisture

from the drain to the previously dried air. This can result in unwanted moisture

being sent down stream.

INTERCOOLERS

Install the condensate drain line into the upper port only . This will prevent the

possibility of condensate being drawn back into the intercooler on some

systems. It is important that the vent line be installed on the same stage that

is being drained or to atmosphere.

BALANCE LINE

As mentioned above, both the use and the placement of a balance line is very

important. Most drain failures are the result of an improper balance line

installation. The balance line should be 1/4" tubing or larger , and installed on

top of a pipe or vessel, not the bottom. A needle valve is recommended for

controlling the air flow. Avoid having any loops or low areas in the balance

line that might allow moisture to collect in the line and prevent the passage of

air from the drains reservoir.

Vent Line

Needle Valve

1/8 npt

(Not Supplied)

Dwg. 3

Venting to

Atmosphere With

Needle Valve

(Not Supplied)

Control Line

Inlet Filter

Discharge

Port 1/2" npt

Clean Dry Control

Air, 80 to 120psi

Control Line

Inlet Filter

Discharge Port

1/2" npt

Loading...

Loading...