Van Air Systems SG-23 User Manual

INSTALLATION INSTRUCTIONS

DISPOSABLE CARTRIDGE SG-23

FOR IN-LINE DESICCANT DRYER MODEL ID15/SW

AND MINI DRYER MODEL MD4/SW

VAN AIR PART NUMBER: 26-0888

August 2008

432-00160-B

WHEN TO REPLACE CARTRIDGE:

Crystals in cartr idge as seen through sight window of

housing will change from blue to pink when silica gel in cartridge

is saturated with moisture. Install fresh cartridge when cr ystals

turn to pink.

WARNING

BEFORE INSTALLING NEW CARTRIDGE, READ THE

FOLLOWING INSTRUCTIONS CAREFULLY.

REPLACING OLD CARTRIDGE:

Close inlet and outlet shutoff valves (and open bypass if

1.

provided); or lock out all compressed air supply to dryer

housing.

Slowly open ball valve on bottom of housing and allow unit to

2.

depressurize completely.

WARNING

DO NOT REMOVE BOWL FROM DRYER HEAD UNTIL

VESSEL IS COMPLETELY DEPRESSURIZED.

3.

Grasp bottom portion of housing (Bowl) with one hand and

turn clamp knob with the other to loosen. Slide clamp down

and off vessel.

4.

Remove used cartridge from head and discard the cartridge.

5.

Remove new cartridge from packaging.

6.

Push new cartridge onto boss of dryer head.

7.

Reinstall bowl and clamp. Make sure that the bowl is tight

against the head and the o-ring is correctly seated in the

groove.

8.

Close the ball valve and slowly pressurize the vessel. If any

leaks occur, depressurize vessel completely and correct the

problem before repressurizing.

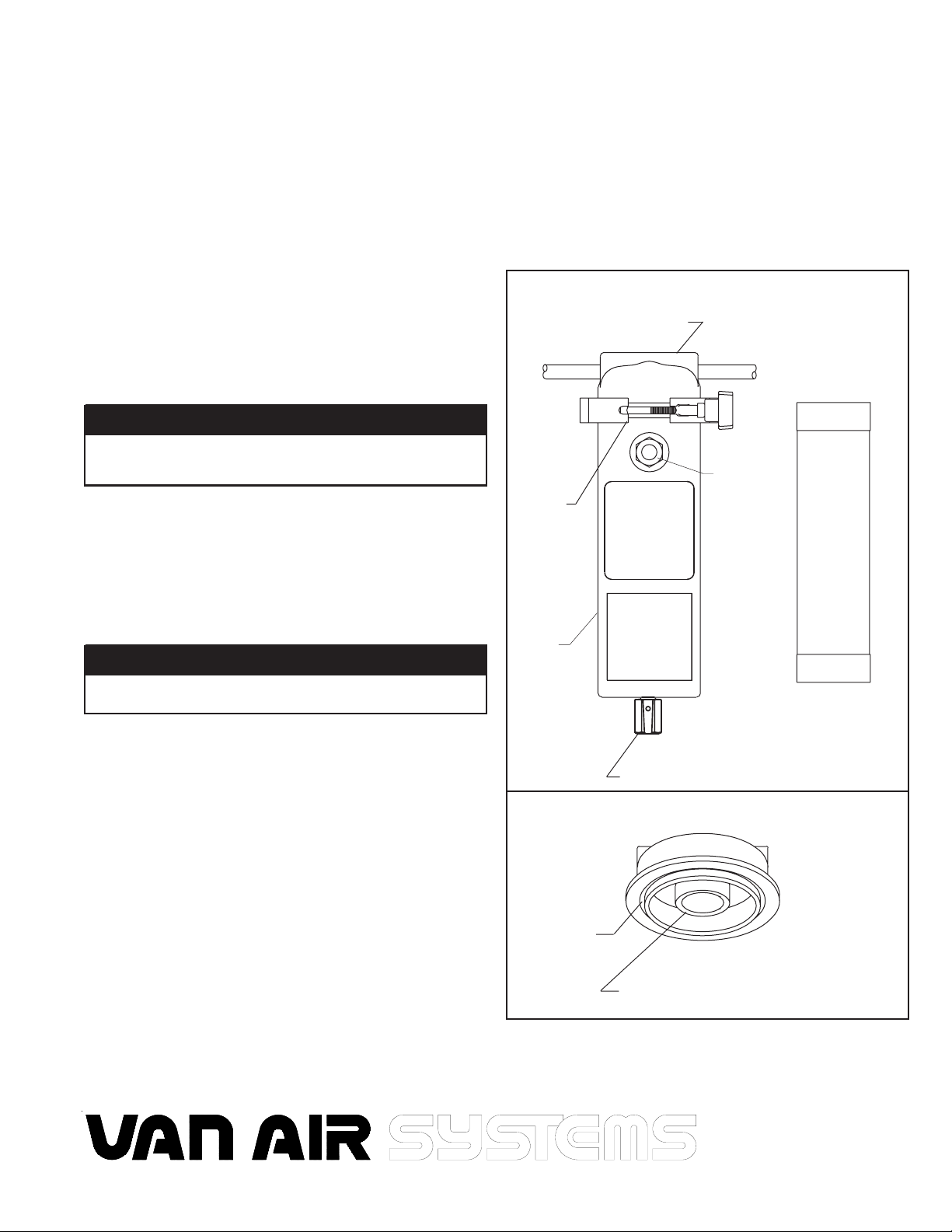

DRYER WITH CARTRIDGE

HEAD

INLET

1/2" NPT

CLAMP

BOWL

VIEW FROM BOTTOM OF DRYER HEAD

O-RING

GROOVE

A

1/4" BALL VALVE

B

OUTLET

1/2" NPT

SIGHT

WINDOW

SG-23 SILICA GEL

CARTRIDGE

BOSS (INSTALL CARTRIDGE

HERE)

2950 Mechanic Street

Lake City, PA 16423-2095

Phone: 814-774-2631

Fax: 814-774-3482

www.vanairsystems.com

2950 Mechanic Street, Lake City, PA

consulted for specific requirements.

16423-2095

Phone: 814/774-2631

Or 800/840-9906

Order Fax: 814/774-3482

Corporate Fax: 814/774-0778

E-mail: vanair@vanairsystems.com

www.vanairsystems.com

U.S. Department of Labor Occupational

Safety and Health Administration (non-

mandatory form)

May be used to comply with OSHA’s

Hazard Communication Standard, 29

CFR 1910.1200. Standard must be

Material Safety Data Sheet

Section 1 – Chemical Product Information Date Prepared: May 1, 2000

Product: Silica Gel (Indicator & Non-Indicator)

Indicator (Sorbead Blue); Non-Indicator (Sorbead R, H, WS & 22)

O

11

Part No.: 33-0105, 33-0243 thru 33-0247, 33-0248, 33-0249, 33-0315, 33-0316,

E

33-0317 & 38-0106

Section 2 – Hazardous Ingredients/Identity Information

Hazardous Components Other Limits

(Specific Chemical Identity/Common Name(s)) OSHA PEL ACGIH TLV Recommended % Optional

Silica, Amorphous, SiO

(CAS No. 7631-86-9) 6 Mg/mm

Alumina, AL

2O3

2

3

(No Hazard) 96.5

(CAS No. 1327-36-2) (No Hazard) 3.0

Cobalt Chloride, CoCL

(Indicator Only)

2

(CAS No. 7646-79-9) Harmful 0.5

The synthetic aluminosilicate in this product is amorphous and does not contain any crystalline forms. It

should not be confused with crystalline silica or any other naturally occurring forms that normally contain

crystalline silica.

Section 3 – Physical Chemical Characteristics

Boiling Point: Not applicable.

Specific Gravity (Water=1): Not applicable.

Vapor Pressure (mm Hg): Not applicable.

Melting Point: >1,000

o

C

Vapor Density (Air=1): Not applicable.

Solubility in Water: Insoluble.

Evaporation Rate (Butyl Acetate=1): Not applicable.

Appearance and Odor: Indicator = blue (dry) or pink (wet) odorless beads – 3.5 mm diameter.

Non-Indicator = brown or white odorless beads – 3.5 mm diameter.

Section 4 – Fire and Explosion Hazard Information

Flammable Properties

Flash Point: Not applicable.

Method Used: Not applicable.

Flammability Limits

LEL: Not applicable.

UEL: Not applicable.

Fire Fighting Instructions: Non-flammable.

Extinguishing Media: As necessary for surrounding fire.

Unusual Fire and Explosion Hazards: When handling near flammable gases or vapor take precautionary

measures against static discharges.

Loading...

Loading...