Van Air Systems AHP High Pressure Alloy Filter Series IOM User Manual

FEBRUARY 2012

P/N 32-0313

REV A

INSTALLATION, OPERATION & MAINTENANCE INSTRUCTIONS

AHP SERIES

COMPRESSED AIR FILTERS

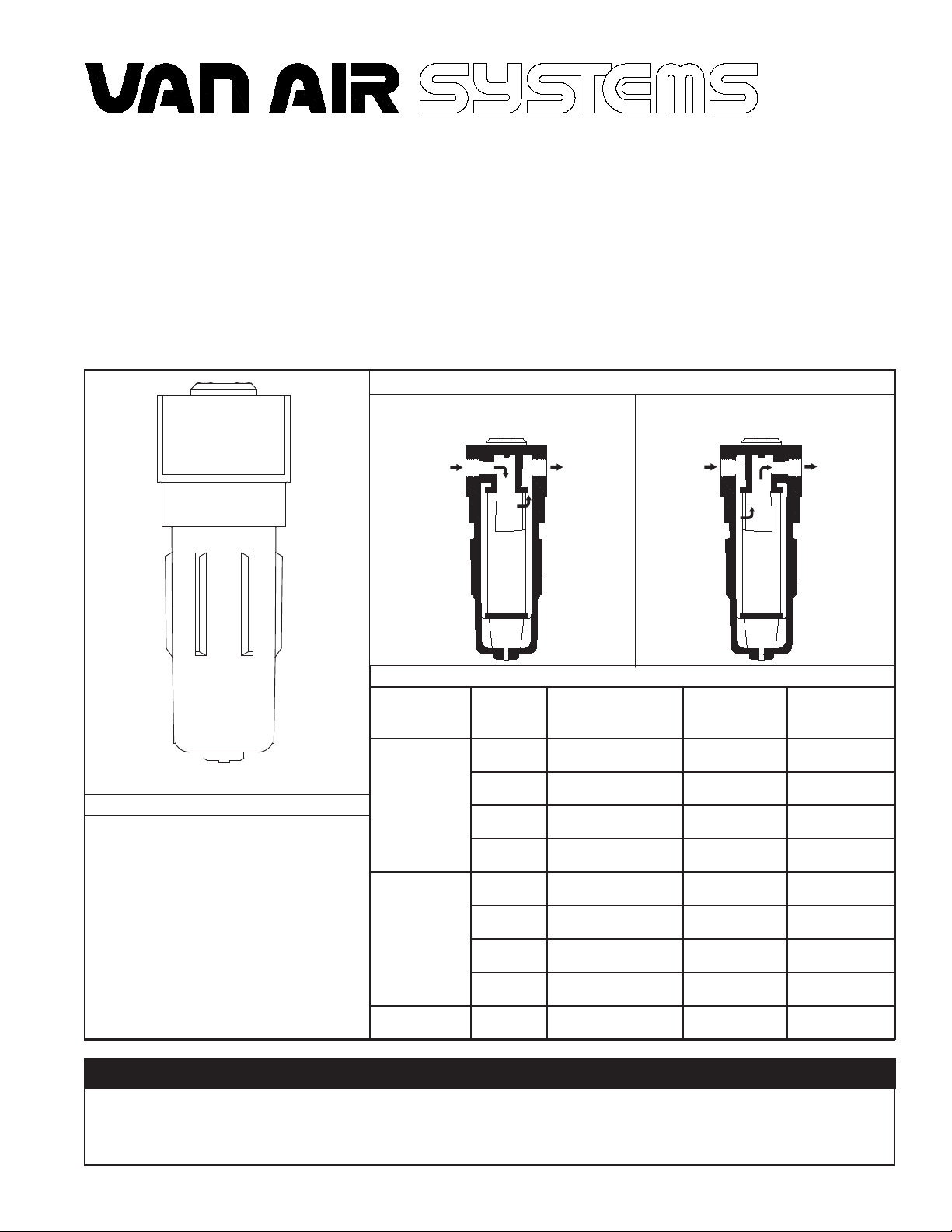

PRODUCT PURPOSE & FUNCTION:

Van Air's AHP series lters are designed to remove contaminants from compressed air systems. Available in 1/4" to 2" con-

nection sizes and ow capacities from 94 to 1882 scfm (at MWP @ 725 psig) in 8 housings and 9 ltration grades, the AHP series can

remove oil aerosols, oil vapors, water and particulates. Housings are made of cast aluminum and coated with black high temperature

paint for corrosion resistance. All units include push-on elements with durable polyester drain layer (except RD grade).

FLOW DIRECTION THROUGH ELEMENT

(COALESCING)

IN/OUT

(PARTICULATE)

OUT/IN

OPERATING CONDITIONS

MAXIMUM WORKING PRESSURE

All Models

OPERATING TEMPERATURE

Minimum

Maximum

MAXIMUM RECOMMENDED INLET TEMPERATURE

AA, A, RAA, RA, RB, and RC Series

B Series

C Series

RD Series

725 PSIG

35°F

248°F

225°F

175°F

125°F

80°F

INLET

APPLICATION ELEMENT

OIL

REMOVAL

(LIQUIDS)

PARTICULATE

REMOVAL

(SOLIDS)

OIL VAPOR

REMOVAL

GRADE

AA

A

B

C

RAA

RA

RB

RC

RD

OUTLET

INLET

FILTRATION GRADES

PURPOSE NOMINAL

Extra Coarse

Coalescing

Coarse

Coalescing

General Purpose

Coalescing

High Efciency

Coalescing

Extra Coarse

Particulate

Coarse

Particulate

General Purpose

Particulate

High Efciency

Particulate

Vapor Absorbing

OUTLET

PARTICLE

REMOVAL

25.00 μ IN/OUT

5.00 μ IN/OUT

1.00 μ IN/OUT

0.01 μ IN/OUT

25.00 μ OUT/IN

5.00 μ OUT/IN

1.00 μ OUT/IN

0.01 μ OUT/IN

0.01 μ OUT/IN

ELEMENT FLOW

DIRECTION

WARNINGS

DO NOT REPLACE ANY ITEM ON FILTER WHILE IT IS PRESSURIZED.

•

DO NOT OPERATE A LEAKING FILTER. TAKE FILTER OUT OF SERVICE IMMEDIATELY.

•

DO NOT OPERATE ABOVE MAXIMUM WORKING PRESSURE (MWP) AT MAXIMUM OPERATING TEMPERATURE (°F).

•

PAGE 1

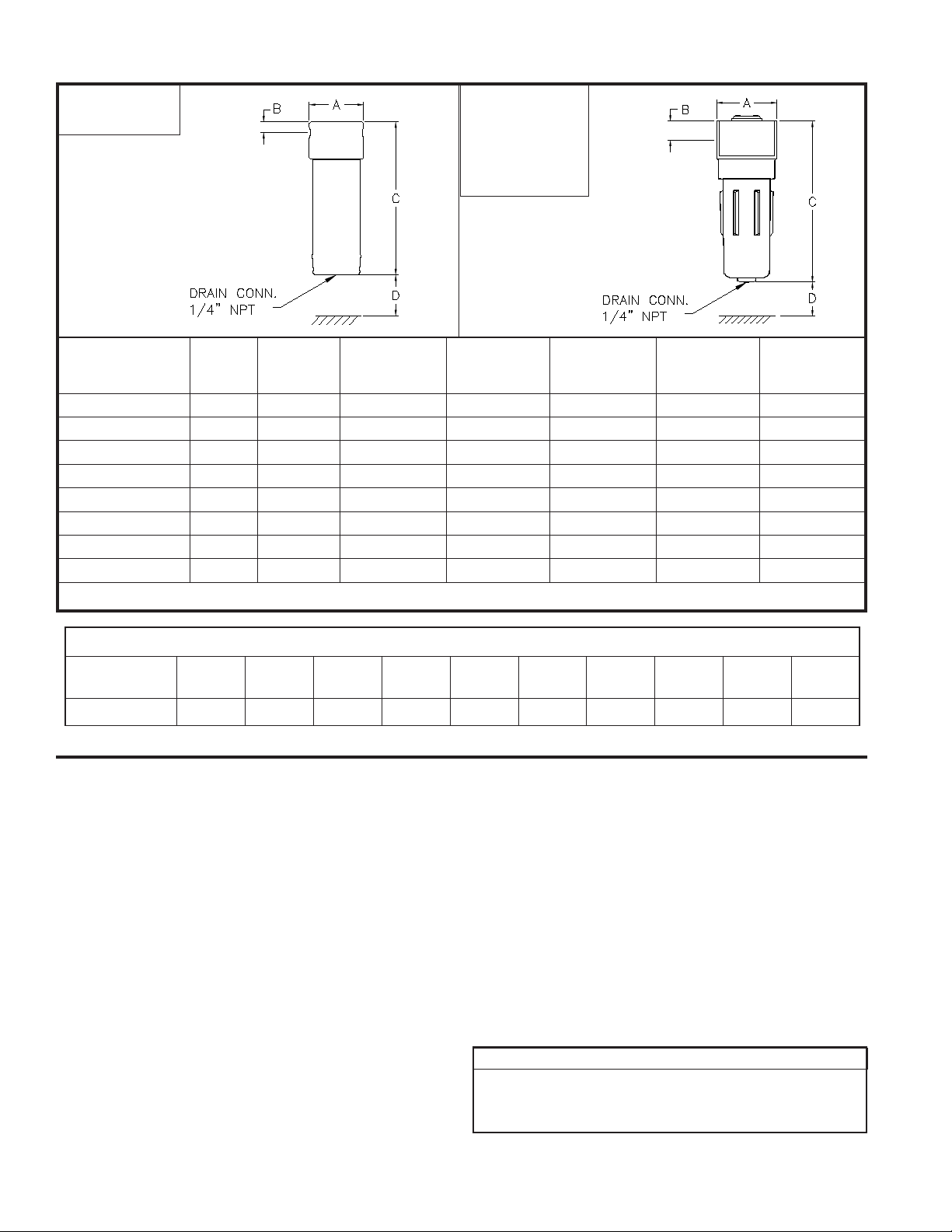

DIMENSIONS FOR:

AHP-25

AHP-40

FILTER HOUSING DIMENSIONS & WEIGHTS

DIMENSIONS FOR:

AHP-65

AHP-80

AHP-125

AHP-255

AHP-285

AHP-470

FILTER MODEL

FLOW**

(SCFM)

IN/OUT

CONN.

(NPT)

A B C D

HOUSING

WEIGHT

AHP-25-7.25-(*) 94 1/4" 2-1/2" 1/2" 6" 2" 0.5

AHP-40-7.25-(*) 147 3/8" 2-1/2" 1/2" 7-1/2" 2" 0.6

AHP-65-7.25-(*) 265 1/2" 4-1/2" 1-1/2" 12" 6" 5.7

AHP-80-7.25-(*) 324 3/4" 4-1/2" 1-1/2" 12" 6" 5.7

AHP-125-7.25-(*) 492 1" 4-1/2" 1-1/2" 15-1/2" 6" 7.3

AHP-255-7.25-(*) 1015 1-1/2" 5-3/4" 2" 21" 7" 16.5

AHP-285-7.25-(*) 1132 2" 5-3/4" 2" 21" 7" 16.5

AHP-470-7.25-(*) 1882 2" 5-3/4" 2" 25" 7" 22

*Insert appropriate ltration grade here; for example AHP-25-7.25-B. **Flow is based on SCFM @ 725 PSIG @ 100°F.

FLOW CORRECTION FACTORS FOR OTHER PRESSURES

OPERATING

PRESSURE

Correction Factor 0.25 0.51 0.57 0.66 0.77 0.82 0.87 0.92 0.98 1.00

100

PSIG

250

PSIG

300

PSIG

400

PSIG

500

PSIG

550

PSIG

600

PSIG

650

PSIG

700

PSIG

INSTALLATION

1. Before installing lter, check operating temperature and

pressure conditions to verify that they are within the specied

ranges. (See Operating Conditions on page 1). Also verify

that system ow rate corresponds to the rated capacity of

the lter. Operating at ows above rated capacity will result

in increased pressure drop.

2. Locate Filter at the point of lowest operating temperature to

ensure that water and oil vapor do not condense downstream

of the lter. Filter should be installed close to the point of

use to minimize the risk of pipe scale, dirt, etc. recontaminating the compressed air. This is particularly important when

installing a new lter on an existing system that has not had

proper ltration.

3. Protect lter from reverse ow conditions. Do not install lter

downstream of quick opening valves.

4. Install lter vertically. Provide required minimum clearance

below lter to allow for replacement of element.

(See Element Removal Clearance on page 2).

5. Remove lter head from the bowl by turning bowl counterclockwise. Pull element from lter head. Set bowl and

element aside for use later.

PAGE 2

6. Install inlet and outlet shutoff valves to facilitate replacement of element. Bypass piping is recommended. (See Fig-

ure 1A). MAKE SURE VALVES ARE CLOSED BEFORE

PROCEEDING.

7. Depressurize piping and connect lter head into piping. Avoid

reducers or bushings to match inlet size. The resulting restriction will increase pressure drop. Make sure head is installed

with ow arrows pointing in proper direction. Use pipe thread

compound as required.

If multiple lters are being installed in series, use pipe nipples

to connect lters, do not attempt to bolt lters together.

8. Install element by pushing into lter head.

IMPORTANT

INSTALL FILTER HEAD WITH ARROWS POINTING

IN THE PROPER DIRECTION TO ENSURE PROPER

OPERATION. (SEE FIGURE 1A).

(LBS)

725

PSIG

Loading...

Loading...