Van Air Systems AC 50 User Manual

INSTALLATION, OPERATION & MAINTENANCE INSTRUCTIONS

AIR-COOLED AFTERCOOLER

FOR COMPRESSED AIR SYSTEMS

MODELS AC-50 thru AC-130

(ALL VOLTAGES)

JULY 2005

REV. A

P/N 32-0225

WARNING

BEFORE STARTING INSTALLATION OR MAINTENANCE PROCEDURES, TURN OFF ELECTRICAL POWER AND COMPLETELY

DEPRESSURIZE THE UNIT. FAILURE TO HEED THIS WARNING MAY RESULT IN SERIOUS PERSONAL INJURY AND/OR DAMAGE TO

THE UNIT.

NEVER REMOVE, REPAIR, OR REPLACE ANY ITEM ON THIS UNIT WHILE IT IS UNDER PRESSURE.

WHEN INSTALLING THIS UNIT, ALWAYS COMPLY WITH THE NATIONAL ELECTRICAL CODE AND ALL OTHER APPLICABLE FEDERAL,

STATE AND LOCAL CODES.

NEVER OPERATE THIS AFTERCOOLER IF THERE IS A LEAK IN THE CORE. IMMEDIATELY TAKE THE UNIT OUT OF SERVICE AND FIX

OR REPLACE THE CORE.

NEVER OPERATE THE AFTERCOOLER ABOVE THE MAXIMUM RATED OPERATING CONDITIONS, AS OUTLINED IN SECTION 3.1.

NEVER REMOVE THE FAN GUARD WHILE THE AFTERCOOLER IS OPERATING. CONTACT WITH THE ROTATING FAN BLADE(S) MAY

RESULT IN SERIOUS PERSONAL INJURY.

DURING NORMAL OPERATION, THE INLET PIPING MAY REACH TEMPERATURES OF 150oF TO 400oF. CONTACT WITH THE PIPING MAY

RESULT IN SERIOUS PERSONAL INJURY.

HANDLING INSTRUCTIONS SECTION 1

1.1 HANDLING THE AFTERCOOLER

CAUTION

NEVER LIFT THE AFTERCOOLER BY THE CORE OR INLET

AND OUTLET.

WHEN MOVING OR LIFTING THE UNIT, PROTECT THE

CORE FROM ACCIDENTAL DAMAGE.

1.2 EQUIPMENT CHECK

Inspect the aftercooler for any damage that may have occured

during shipment. Inspect all items shipped with the unit.

IF THE UNIT HAS BEEN DAMAGED DURING SHIPMENT:

(1) Notify carrier immediately

Take extreme care when unpacking, moving or installing. The core is

exposed. Damage to the core or fins may render the unit inoperable.

PRINTED IN THE U.S.A. PAGE 1

(2) DO NOT operate the unit before consulting factory

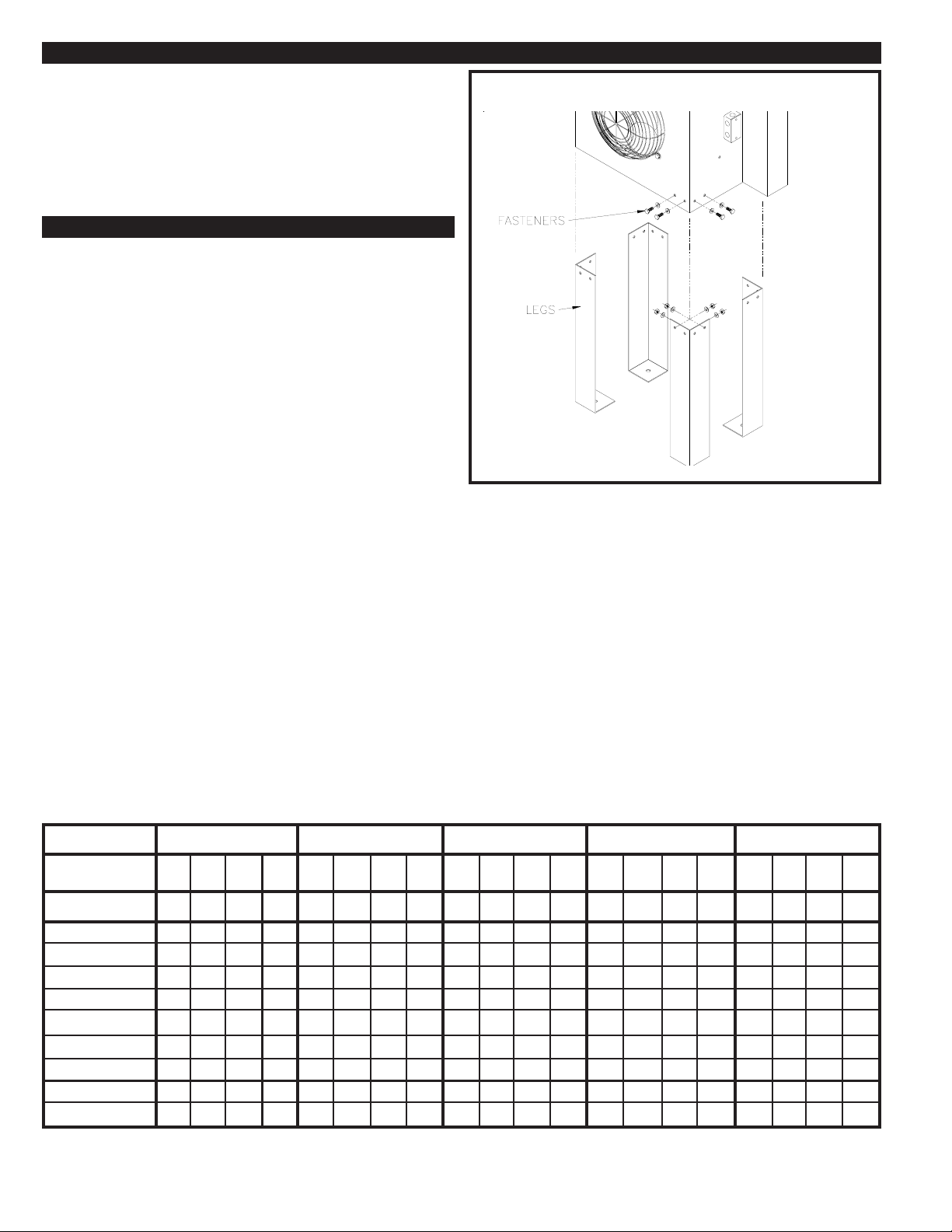

ASSEMBLY, LEG INSTALLATION SECTION 2

2.1 INSTALLING THE LEGS

This unit was shipped without the legs installed. The legs should be

installed before placing the aftercooler in the piping system. Carefully lift

and support the unit several feet from the floor.

Position the legs against the unit and fasten them in place using the

fasteners provided. Make sure the fasteners are tightened in place.

SPECIFICATIONS AND DIMENSIONS SECTION 3

3.1 SPECIFICATIONS

WEIGHT

AC-50 ...................... 110 LBS AC-100 .................. 140 LBS

AC-60 ...................... 110 LBS AC-110 .................. 145 LBS

AC-70 ...................... 120 LBS AC-120 .................. 200 LBS

AC-80 ...................... 120 LBS AC-130 .................. 300 LBS

AC-90 ...................... 140 LBS

DIMENSIONS .............. See Section 3.2

INLET/OUTLET CONNECTIONS

AC-50 .............. 1" NPT (F) AC-100 ........ 1-1/2" NPT (F)

AC-60 .............. 1" NPT (F) AC-110 ........ 1-1/2" NPT (F)

AC-70 .............. 1-1/2" NPT (F) AC-120 ........ 2" NPT (F)

AC-80 .............. 1-1/2" NPT (F) AC-130 ........ 2" NPT (F)

AC-90 .............. 1-1/2" NPT (F)

MAXIMUM WORKING PRESSURE

ALL MODELS .................. 250 PSIG

MAXIMUM WORKING TEMPERATURE

ALL MODELS .................. 350OF

MATERIALS OF CONSTRUCTION

CABINET ......................... Galvanized steel

FAN GUARD ................... Steel with baked enamel finish

FAN ................................. Heavy gauge aluminum with steel hub

CORE .............................. Aluminum fins on copper tubes

MOTOR ........................... Open vented

MOTOR SPECIFICATIONS AND DATA

See Wiring Diagram, Figure 5 on page 6.

FIGURE 1 LEG INSTALLATION DETAIL

FAN DATA (AMBIENT AIR FLOW)

AC-50 THRU AC-80 ........ 1375 SCFM

AC-90 THRU AC-100 ...... 2450 SCFM

AC-110 ............................ 2350 SCFM

AC-120 ............................ 4600 SCFM

AC-130 ............................ 4700 SCFM

ELECTRICAL REQUIREMENTS

AC-50-1 thru AC-130-1 .......... 115-1-60 w/ ODP motor

AC-50-2 thru AC-130-2 .......... 115-1-60 w/ TEFC motor

AC-50-3 thru AC-130-3 .......... 230-1-60 w/ TEFC motor

AC-50-4 thru AC-130-4 .......... 230-3-60 w/ TEFC motor

AC-50-5 thru AC-130-5 .......... 460-3-60 w/ TEFC motor

MAXIMUM CAPACITY (SCFM)

Rated capacities are based on the following conditions: Inlet and approach temperature at inlet pressures 80 to 125 PSIG.

Approach Temperature: The number of degrees above the temperature of the cooling medium (in this case ambient air) to

which the aftercooler reduces the compressed air. A higher approach does not mean better performance.

INLET TEMP.

APPROACH

TEMP.

O

F

150OF 200OF 350OF250OF 300OF

10

5

15

20

5

10

15

20

5

10

15

20

5

10

15

20

5

10

MODEL

AC-50

AC-60

AC-70

AC-80

AC-90

AC-100

AC-110

AC-120

AC-130

MAXIMUM PRESSURE DROP LESS THAN 3 PSI.

25

34

42

50

60

81

92

160

184

42

58

73

87

102

138

160

275

318

58

79

99

119

140

190

220

380

440

73

99

125

150

177

235

270

425*

480*

18

25

32

40

48

61

73

120

145

31

43

55

69

81

105

125

207

250

43

59

77

94

112

142

172

285

345

53

74

95

117

140

177

215

355

430

15

21

27

34

43

51

63

100

125

25

36

47

59

73

87

110

175

217

35

50

65

80

100

120

150

240

300

44

62

81

100

124

150

187

300

375

13

18

24

30

38

43

55

84

110

22

31

41

52

64

75

95

145

190

30

42

57

71

87

102

130

204

257

37

52

71

89

110

127

160

250

320

11

16

22

28

34

40

50

78

100

19

27

37

47

59

69

86

135

175

* Maximum ratings restricted by pressure drop: actual thermal capacities are higher.

15

26

38

52

65

81

94

120

185

240

20

32

47

65

82

100

116

148

231

300

PAGE 2 PRINTED IN THE U.S.A.

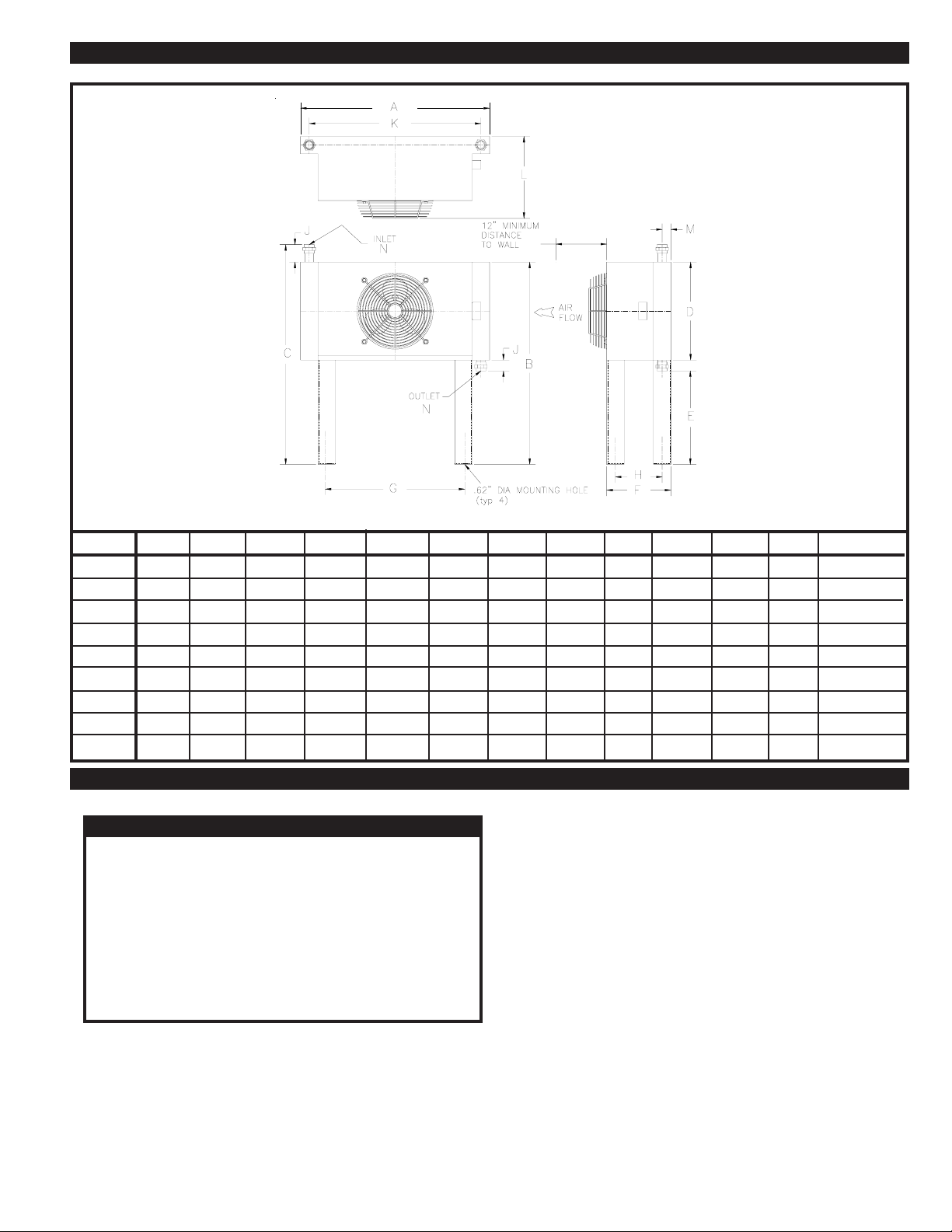

SPECIFICATIONS AND DIMENSIONS SECTION 3

3.2 DIMENSIONS AND COMPONENT LOCATIONS

MODEL

AC-50

AC-60

AC-70

AC-80

AC-90

AC-100

AC-110

AC-120

AC-130

A

30.50"

30.50"

30.50"

30.50"

43.50"

43.50"

43.50"

47.63"

51.68"

B

46.50"

46.50"

46.50"

46.50"

46.50"

46.50"

46.50"

49.50"

55.50"

C

50.50"

50.50"

50.50"

50.50"

50.50"

50.50"

50.50"

53.50"

59.50"

D

22.50"

22.50"

22.50"

22.50"

22.50"

22.50"

22.50"

25.50"

31.50"

E

22.00"

22.00"

21.50"

21.50"

21.50"

21.50"

22.00"

22.00"

22.00"

F

14.75"

14.75"

14.75"

14.75"

14.75"

14.75"

14.75"

14.75"

14.75"

G

19.09"

19.09"

19.09"

19.09"

32.09"

32.09"

32.09"

32.09"

36.09"

H

10.75"

10.75"

10.75"

10.75"

10.75"

10.75"

10.75"

10.75"

10.75"

J

4.00"

4.00"

4.00"

4.00"

4.00"

4.00"

4.00"

4.00"

4.00"

K

28.12"

28.12"

28.12"

28.12"

41.12"

41.12"

41.12"

40.80"

44.80"

L

18.29"

18.29"

18.29"

18.29"

18.29"

18.29"

18.29"

18.23"

18.50"

M

2.17"

2.17"

2.17"

2.17"

2.17"

2.17"

2.79"

2.85"

2.83"

N IN/OUT

1" NPT

1" NPT

1-1/2" NPT

1-1/2" NPT

1-1/2" NPT

1-1/2" NPT

1-1/2" NPT

2" NPT

2" NPT

INSTALLATION SECTION 4

4.1 LOCATION

CAUTION

DO NOT LOCATE THIS AFTERCOOLER WHERE PERSONNEL

MAY CONTACT THE INLET PIPING UNLESS THE UNIT IS

PROTECTED BY WARNING SIGNS AND/OR A BARRIER.

DURING NORMAL OPERATION, THE INLET PIPING MAY

BECOME EXTREMELY HOT (150OF TO 400OF). CONTACT

MAY RESULT IN SERIOUS PERSONAL INJURY.

DO NOT INSTALL THIS UNIT IN AN ENVIRONMENT OF

CORROSIVE GASES OR CHEMICALS. MAKE SURE THAT

THE MATERIALS USED IN THIS UNIT (listed on the previous

page) ARE COMPATIBLE WITH THE ATMOSPHERIC

CONDITIONS.

The aftercooler should be located far enough away from the compressor so that there are no vibrations transmitted from the compressor. A

FLEXIBLE HOSE MUST BE INSTALLED IN THE PIPING TO

VALIDATE THE WARRANTY AND TO PREVENT DAMAGE TO THE

AFTERCOOLER FROM VIBRATION IN THE PIPING! REFERENCE

Section 4.3 for instructions.

level to allow proper drainage of fluids from the outlet manifold.

The aftercooler must be installed at least 1 foot from walls or obstructions. It is important for the unit to have an adequate air supply for

cooling at all times. If more than one unit is to be installed in the same

area, allow at least 1 foot between them.

Aftercoolers equipped with an ODP motor must be installed indoors.

All others can be installed indoors or outdoors. If the unit is to be

installed outdoors or in an area where ambient temperatures can fall

below 35oF, precautions must be made to prevent freeze-up and

damage to the unit. The drain lines and separator must be heat traced

and/or insulated and the unit should be protected from the wind.

REFERENCE Section 4.5 for details.

4.2 MOUNTING THE UNIT

After selecting the proper location as outlined above, the aftercooler

should be mounted to the installation surface. Mounting holes are

provided on the leg support braces. Reference Section 3.2 for

mounting hole locations and dimensions. Use hardware (not supplied)

sized for the mounting holes.

The location should be level and capable of supporting the aftercooler

and all components and piping to be installed. The aftercooler must be

PRINTED IN THE U.S.A. PAGE 3

Loading...

Loading...