Van Air Systems AC 10-1 User Manual

INSTALLATION, OPERATION & MAINTENANCE INSTRUCTIONS

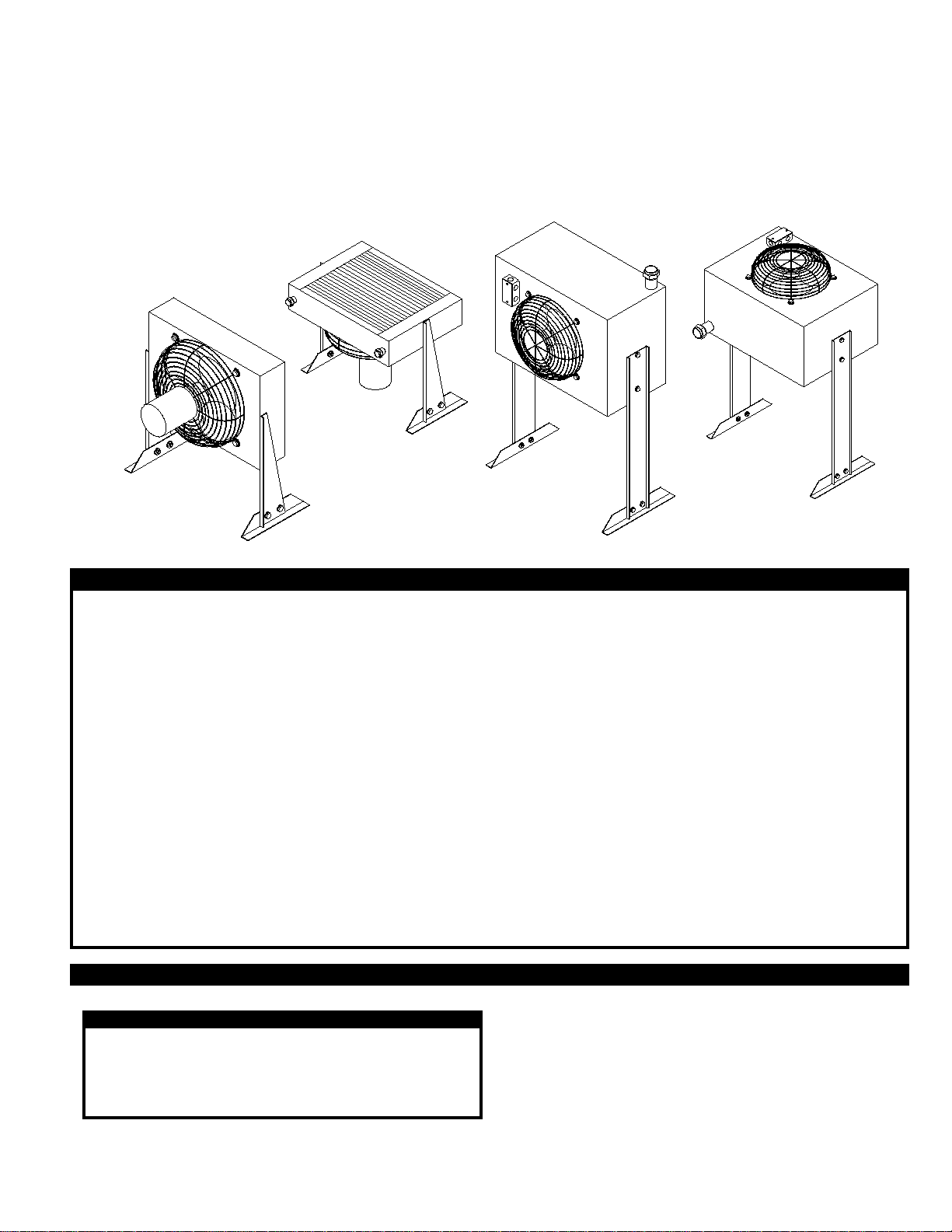

AIR-COOLED AFTERCOOLER

FOR COMPRESSED AIR SYSTEMS

MODELS AC-10-1 thru AC-40-1

AUGUST 1995

P/N 32-0224

WARNING

BEFORE STARTING INSTALLATION OR MAINTENANCE PROCEDURES, TURN OFF ELECTRICAL POWER AND

COMPLETELY DEPRESSURIZE THE UNIT. FAILURE TO HEED THIS WARNING MAY RESULT IN SERIOUS PERSONAL

INJURY AND/OR DAMAGE TO THE UNIT.

NEVER REMOVE, REPAIR, OR REPLACE ANY ITEM ON THIS UNIT WHILE IT IS UNDER PRESSURE.

WHEN INSTALLING THIS UNIT, ALWAYS COMPLY WITH THE NATIONAL ELECTRICAL CODE AND ALL OTHER

APPLICABLE FEDERAL, STATE AND LOCAL CODES.

NEVER OPERATE THIS AFTERCOOLER IF THERE IS A LEAK IN THE CORE. IMMEDIATELY TAKE THE UNIT OUT OF

SERVICE AND FIX OR REPLACE THE CORE.

NEVER OPERATE THE AFTERCOOLER ABOVE THE MAXIMUM RATED OPERATING CONDITIONS, AS OUTLINED IN

SECTION 3.1.

NEVER REMOVE THE FAN GUARD WHILE THE AFTERCOOLER IS OPERATING. CONTACT WITH THE ROTATING FAN

BLADE(S) MAY RESULT IN SERIOUS PERSONAL INJURY.

DURING NORMAL OPERATION, THE INLET PIPING MAY REACH TEMPERATURES OF 150oF TO 400oF. CONTACT WITH

THE PIPING MAY RESULT IN SERIOUS PERSONAL INJURY.

HANDLING INSTRUCTIONS SECTION 1

1.1 HANDLING THE AFTERCOOLER

CAUTION

NEVER LIFT THE AFTERCOOLER BY THE CORE OR

INLET AND OUTLET..

1.2 EQUIPMENT CHECK

Inspect the aftercooler for any damage that may have

occured during shipment. Inspect all items shipped with

the unit.

WHEN MOVING OR LIFTING THE UNIT, PROTECT

THE CORE FROM ACCIDENTAL DAMAGE.

Take extreme care when unpacking, moving or installing. The

core is exposed. Damage to the core or fins may render the

unit inoperable.

PRINTED IN THE U.S.A. © 1995 VAN AIR SYSTEMS INC. 2950 MECHANIC STREET, LAKE CITY, PA 16423 PAGE 1

IF THE UNIT HAS BEEN DAMAGED DURING SHIPMENT:

(1) Notify carrier immediately

(2) DO NOT operate the unit before consulting factory

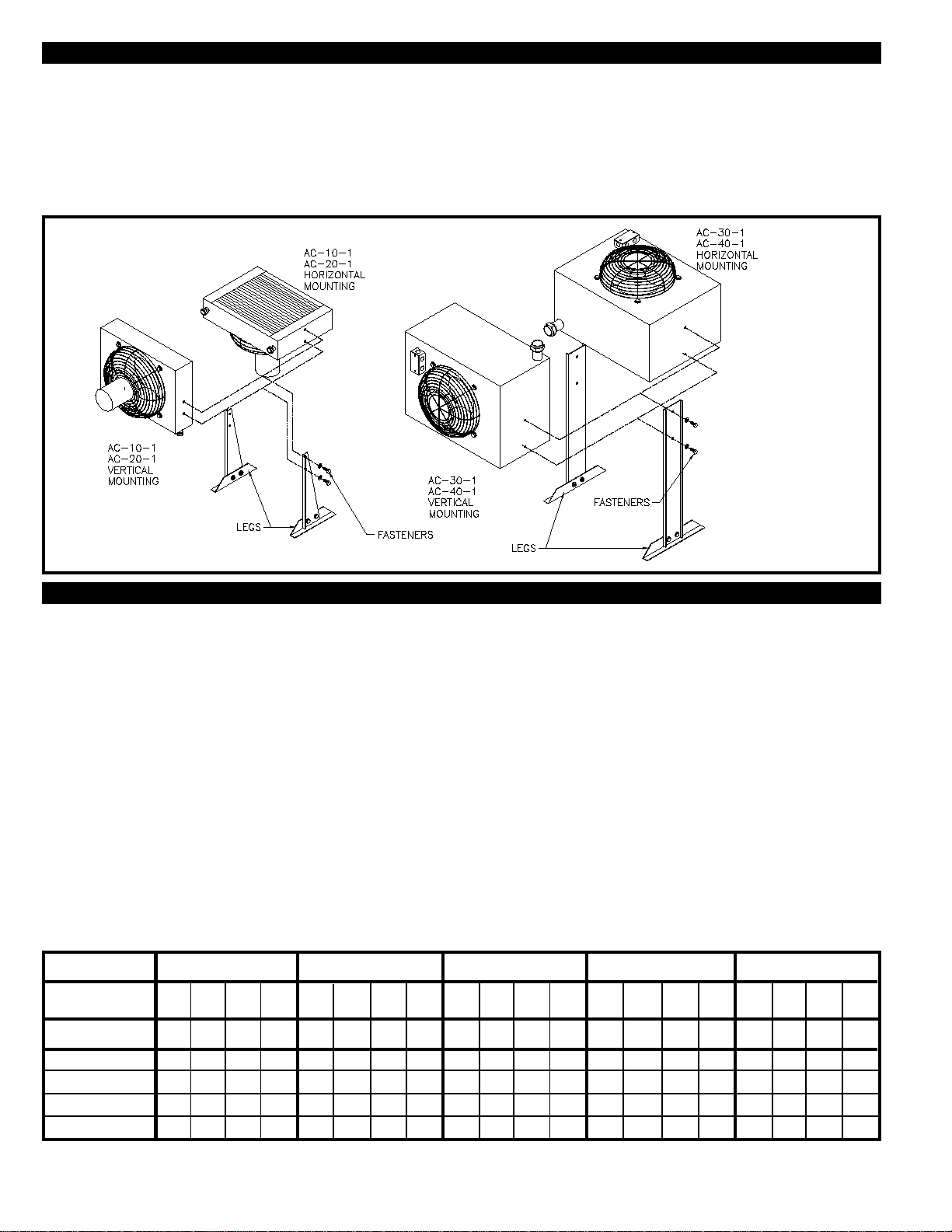

ASSEMBLY, LEG INSTALLATION SECTION 2

2.1 INSTALLING THE LEGS

This unit was shipped without the legs installed. The legs

should be installed before placing the aftercooler in the

piping system.

The legs can be mounted two ways:

1. Core mounted horizontally

2. Core mounted vertically

FIGURE 1 LEG INSTALLATION DETAIL

Determine the desired position for your installation. Place the

aftercooler in that position (horizontal or vertical). Carefully lift

and support the unit approximately 1 to 2 feet from the floor.

Position the legs against the unit and fasten them in place

using the fasteners provided. Make sure the fasteners are

tightened in place.

SPECIFICATIONS AND DIMENSIONS SECTION 3

3.1 SPECIFICATIONS

WEIGHT

AC-10-1............... 25 LBS AC-20-1..............27 LBS

AC-30-1............... 61 LBS AC-40-1..............67 LBS

DIMENSIONS .............. See Section 3.2

INLET/OUTLET CONNECTIONS

AC-10-1........1/2" NPT (F) AC-20-1 ...... 1/2" NPT (F)

AC-30-1........1" NPT (F) AC-40-1 ..... 1-1/2" NPT (F)

MAXIMUM WORKING PRESSURE

ALL MODELS ............ 250 PSIG

MAXIMUM WORKING TEMPERATURE

ALL MODELS ............ 3 50OF

MAXIMUM CAPACITY (SCFM)

Rated capacities are based on the following conditions: Inlet and approach temperature at inlet pressures 80 to 125 PSIG.

Approach Temperature: The number of degrees above the temperature of the cooling medium (in this case ambient air) to

which the aftercooler reduces the compressed air. A higher approach does not mean better performance.

INLET TEMP.

APPROACH

TEMP. OF

MODEL

AC-10-1

AC-20-1

AC-30-1

AC-40-1

150OF 200OF 350OF250OF 300OF

10

5

17

29

43

95

35*

43*

72

125*

15

35*

43*

72*

125*

20

35*

43*

72*

125*

11

17

28

66

5

10

15

20

22

35

35*

36

43*

43*

50

70

72*

111

125*

125*

ELECTRICAL REQUIREMENTS

ALL MODELS ............ 115V-1PH-60Hz, w/ ODP motor

MATERIALS OF CONSTRUCTION

CABINET.................... Steel with baked enamel finish

FAN GUARD .............. Steel, zinc chromate plated

FAN ............................ Heavy gauge aluminum with steel hub

CORE ......................... Aluminum fins on copper tubes

MOTOR...................... Open vented

MOTOR SPECIFICATIONS AND DATA

See Wiring Diagram, Figure 5 on page 6.

FAN DATA (AMBIENT AIR FLOW)

AC-10-1 & AC-20-1.... 615 SCFM

AC-30-1 & AC-40-1.... 945 SCFM

5

10

15

20

5

10

15

20

5

10

8

16

20

35

6

12

19

26

5

10

12

27

35

43*

10

20

31

42*

8

16

22

35

50

70

18

32

45

57

15

28

52

88

100

125*

44

74

100

125

38

64

15

15

26

39

86

20

21

35

50

108

MAXIMUM PRESSURE DROP LESS THAN 3 PSI.

* Maximum ratings restricted by pressure drop: actual thermal capacities are higher.

PAGE 2 © 1995 VAN AIR SYSTEMS INC. 2950 MECHANIC STREET, LAKE CITY, PA 16423 PRINTED IN THE U.S.A.

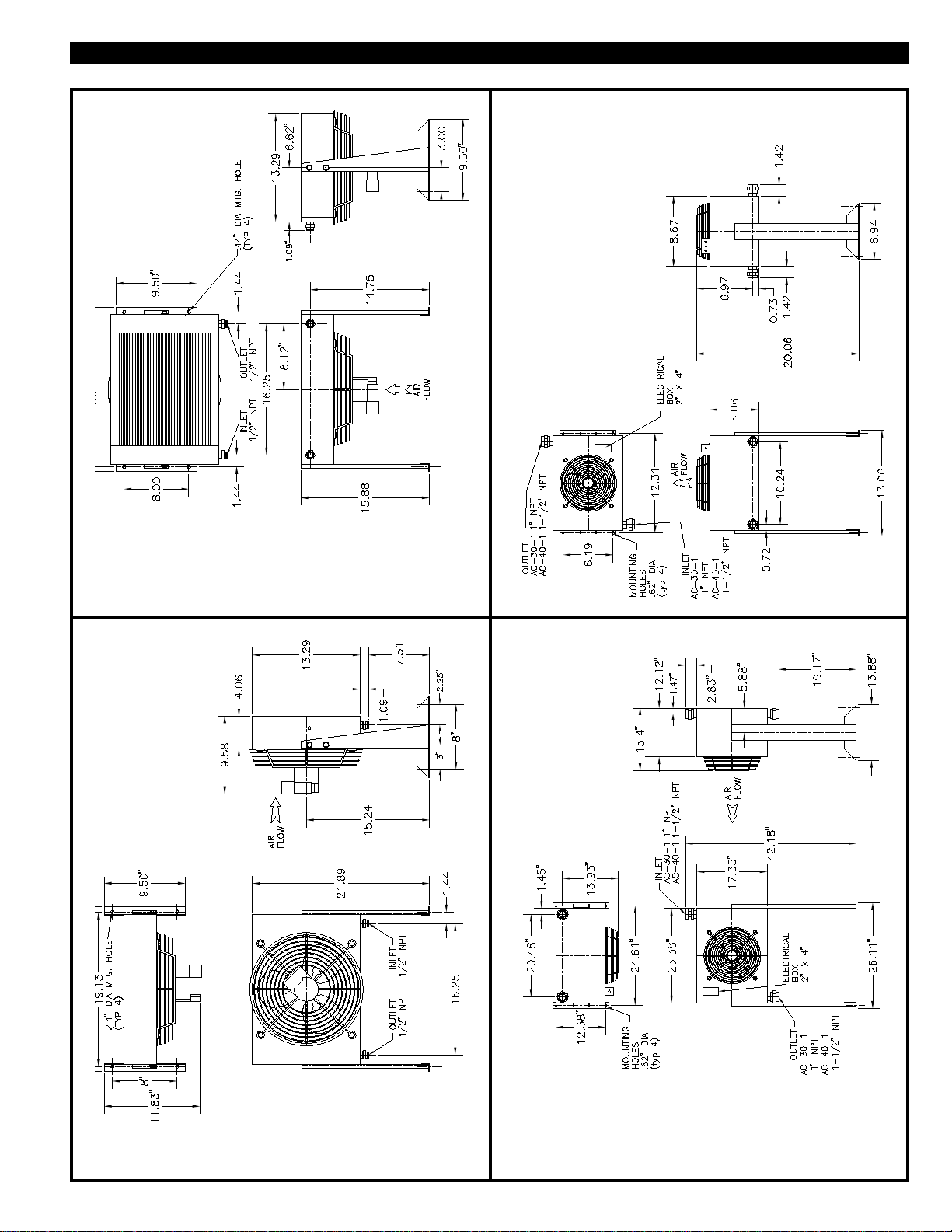

SPECIFICATIONS AND DIMENSIONS SECTION 3

3.2 DIMENSIONS AND COMPONENT LOCATIONS

AC-10-1& AC-20-1

CORE MOUNTED

HORIZONTALLY

AC-30-1& AC-40-1

CORE MOUNTED

HORIZONTALLY

AC-30-1& AC-40-1

CORE MOUNTED

VERTICALLY

AC-10-1& AC-20-1

CORE MOUNTED

VERTICALLY

PRINTED IN THE U.S.A. © 1995 VAN AIR SYSTEMS INC. 2950 MECHANIC STREET, LAKE CITY, PA 16423 PAGE 3

Loading...

Loading...