Union Special 39500 Maximum Performance 9M Series Manual

Maximum

Performance

9M

Series

-High

speed

overedge

machines

CATALOG

NO.

IO3XQA

First

Edition

SERIES

9M

Adjusting

instructions

and

illustrated

parts

list

U,

U

Finest

Quality

Zua

Equipment

From the library of: Superior Sewing Machine & Supply LLC

CATALOG

NO.

103

XQA

ADJUSTING

INSTRUCTIONS

AND

ILLUSTRATED

PARTS

LIST

FOR

MAXIMUM

PERFORMANCE

-

9M

SERIES

STYLES

39500

XQA

39500

XRN

39500

CXQJ

39500

XQB

39500

XSD

39500

CXRN

39500

XQJ

39500

XTA

39500

CXSD

39500

XRB

39500

CXQA

39500

XSQB

39500

XRC

39500

CXQB

39500

CXSQB

First

Edition

Copyright

1983

By

Union

Special

Corporation

Rights

Reserved

in

All

Countries

Printed

in

U.S.A.

January

1983

2

From the library of: Superior Sewing Machine & Supply LLC

FORE

WARD

This

technical

manual

has

been

prepared

to

guide

you

in

the

maintenance

of

your

new

UNION

SPECIAL

machine.

Careful

attention

to

the

instructions

for

oper

ating

and

adjusting

these

machines

will

enable

you

to

maintain

the

superior

per

forinance

and

reliability

designed

and

built

into

every

UNION

SPECIAL

machine.

The

Adjusting

Instruction

portion

of

this

manual

explains

in

detail

the

proper

setting

for

each

of

the

components

related

to

forming

the

stitch

and

com

pleting

the

functions

of

the

machine.

Figures

are

used

to

illustrate

the

adjust

ments

using

reference

letters

to

point

out

specific

items

discussed.

Adjustments

are

presented

in

sequence

so

that

a

logical

progression

is

accom

plished.

Some

adjustments

performed

out

of

sequence

may

have

an

adverse

effect

on

the

function

of

other

related

parts.

Implementation

of

preventative

maintenance

procedures

can

bring

about

signi

ficant

improvements

in

operator

productivity

by

avoiding

costly

equipment

break

downs.

Whenever

it

becomes

necessary

to

make

repairs

or

replace

parts

on

your

machine,

be

sure

to

insist

on

genuine

UNION

SPECIAL

Repair

Parts.

These

parts

are

designed

specifically

for

your

machine

and

manufactured

with

utmost

precision

to

assure

long

lasting

service.

To

simplify

indentification

of

epair

parts,

the

mechanisms

are

illustrated

by

exploded

views.

These

illustrations

will

usually

be

shown

in

conjuction

with

a

KEY

VIEW

which

presents

the

mechanisms

of

the

machine

assembled.

The

specific

parts

illustrated

on

this

page

will

appear

shaded

in

the

KEY

VIEW.

3

From the library of: Superior Sewing Machine & Supply LLC

IDENTIFICATION

OF

MACHINES

Each

UNION

SPECIAL

machine

carries

a

style

number,

which

on

this

class

machine

is

stamped

in

the

style

plate

located

on

the

right

rear

of

the

machine.

Serial

number

is

stamped

in

the

extension

of

bed

casting

at

the

right

rear

base

of

machine.

STYLES

OF

MACHINES

Super

high

speed,

maximum

performance,

one

or

two

curved

blade

needles,

two

or

three

thread

machines.

Trimming

mechanism

with

spring

pressed

lower

knife,

cam

adjusted

feeds,

needle

bearings

for

feed

drive

eccentrics,

needle

cooler,

improved

internal

lubricating

system

with

self-contained

oil

filter

and

oil

cooler.

Maximum

recommended

speed

9000

R.P.M.,

depending

on

operation.

39500

XQA

Light

to

medium

duty,

differential

feed,

single

needle,

two

looper,

three

thread

machine

for

seaming

light

and

medium

weight

flat,

warp

and

ribbed

knit

fabrics

of

cotton,

silk

or

similar

weight

synthetics.

Sewing

com

bination

designed

especially

for

use

on

women’s

and

children’

slips,

pajamas,

nightgowns,

or

similar

articles

where

long

straight

hanging

seams

are

a

primary

requisite.

Type

154

GAS

needle;

seam

specification

504-SSa-l;

standard

seam

widths

3/32

and

1/8

inch

(2.4

and

3.2mm);

stitch

range

8-30

per

inch.

39500

XQB

Same

as

Style

39500

XQA

except

-

sewing

combination

designed

for

general

purpose

seaming

of

“T”

shirts,

polo

shirts,

panties,

infant

and

children’s

knit

wear

and

similar

garments.

39500

XQJ

Light

to

medium

duty,

plain

feed,

single

needle,

one

looper,

one

spreader,

two

thread

machine

for

serging

light,

medium

and

heavy

weight

trousers

and

similar

garments.

Type

154

GAS

needle;

seam

specification

503-EFd—l;

standard

seam

width

3/16

inch

(4.8mm);

stitch

range

5

1/2-8

per

inch.

39500

XRB

Light

to

medium

duty,

differential

feed,

two

needle,

one

looper,

one

spreader,

three

thread

machine

for

closing

toe

sections

of

women’s

seam

less

nylon

hosiery.

Type

154

GFS

needle;

seam

specification

521-SSa-1;

standard

seam

widths

approximately

1/8

and

5/32

inch

(3.2

and

4.0mm)

from

left

needle;

stitch

range

20-100

per

inch.

39500

XRC-045

Light

to

medium

duty,

differential

feed,

two

needle,

one

looper,

one

spreader,

three

thread

machine

for

closing

toe

sections

of

men’s

hosiery

and

socks.

Type

154

GFS

needle;

seam

specification

521-SSa-l;

standard

seam

width

approximately

3/16

inch

(4.8mm)

from

left

needle;

stitch

range

20-100

per

inch.

39500

XRC-060

Same

as

Style

39500

XRC-045

except

-

Type

154

GDS

needle;

standard

seam

width

approximately

7/32

inch

(5.6mm)

from

left

needle.

39500

XRN

Light

to

medium

duty,

differential

feed,

single

needle,

one

(upper)

looper,

one

(lower)

spreader,

two

thread

machine

for

blind

stitch

welting

or

hemming

on

light

weight

knit

fabrics.

Fitted

with

a

compact

hemming

guide

assembly.

Type

154

GAS

needle;

seam

specification

503-EFc-1;

stitch

range

8-30

per

inch.

39500

XSD

Same

as

Style

39500

XRN

except

-

one

(lower)

looper

and

one

(upper)

spreader.

4

From the library of: Superior Sewing Machine & Supply LLC

MACHINE

STYLES

(Continued)

39500

XTA

39500

CXQA

39500

CXQB

39500

CXQJ

39500

CXRN

39500

CXSD

39500

XSQB

39500

CXSQB

Light

duty,

differential

feed,

single

needle,

two

looper,

three

thread

machine

for

toe

closing

on

women’s

seamless

hosiery.

Type

154

GAS

needle;

seam

specification

505-tEe-i;

standard

seam

width

1/16

to

3/32

inch

(1.6

to

2.4mm)

depending

on

material;

stitch

range

15-100

per

inch.

Same

as

Style

39500

XQA

except

-

fitted

with

Power

“AIR-KLIPP”®

chain

cutter.

Same

as

Style

39500

XQB

except

-

fitted

with

Power

“AIR-KLIPP”

chain

cutter.

Same

as

Style

39500

XQJ

except

-

fitted

with

Power

“AIR-KLIPP”

chain

cutter.

Same

as

Style

39500

XRN

except

-

fitted

with

Power

“AIR—KLIPP”

chain

cutter.

Same

as

Style

39500

XSD

except

-

fitted

with

Power

“AIR-KLIPP”

chain

cutter.

Same

as

Style

39500

XQB

except

-

designed

to

use

SHORT,

STIFF

NEEDLE

(Type

162

SAS)

which

reduces

needle

cutting.

Same

as

Style

39500

CXQB

except

-

designed

to

use

SHORT,

STIFF

NEEDLE

(Type

162

SAS)

which

reduces

needle

cutting.

SPEED

RECOMMENDATION

39500

9M

machines

have

been

tested

in

their

complete

stitch

range

at

their

maximum

rated

speeds.

Varied

sewing

applications

may

necessitate

operating

at

a

lower

speed.

When

operating

from

50-100%

machine

running

cycle

and

longer

than

recommended

stitch

length,

it

may

be

necessary

to

reduce

machine’s

speed

by

10-15%.

The

9M

is

a

precision

manufactured

and

tested

sewing

machine,

and

are

run-in

at

the

factory

to

achieve

maximum

speed.

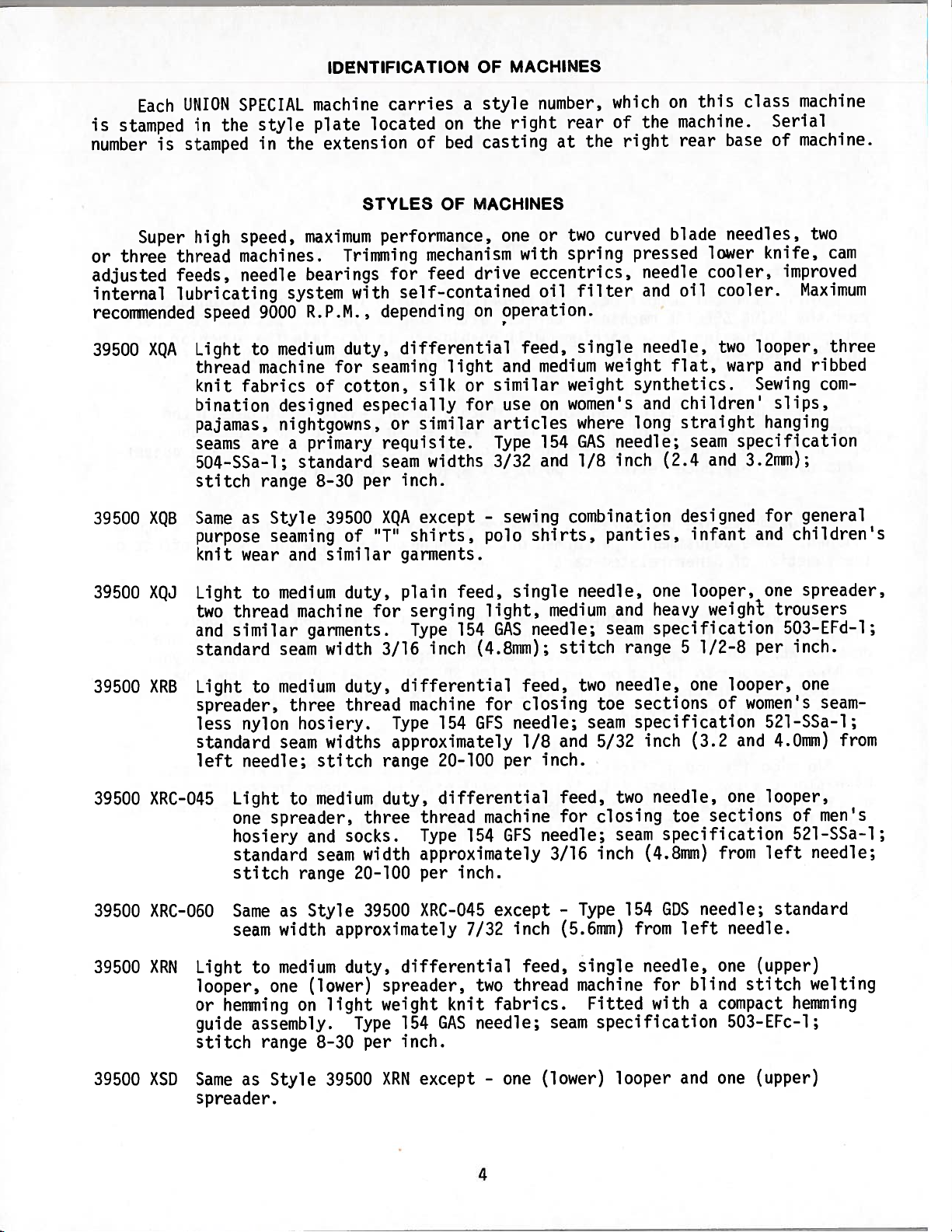

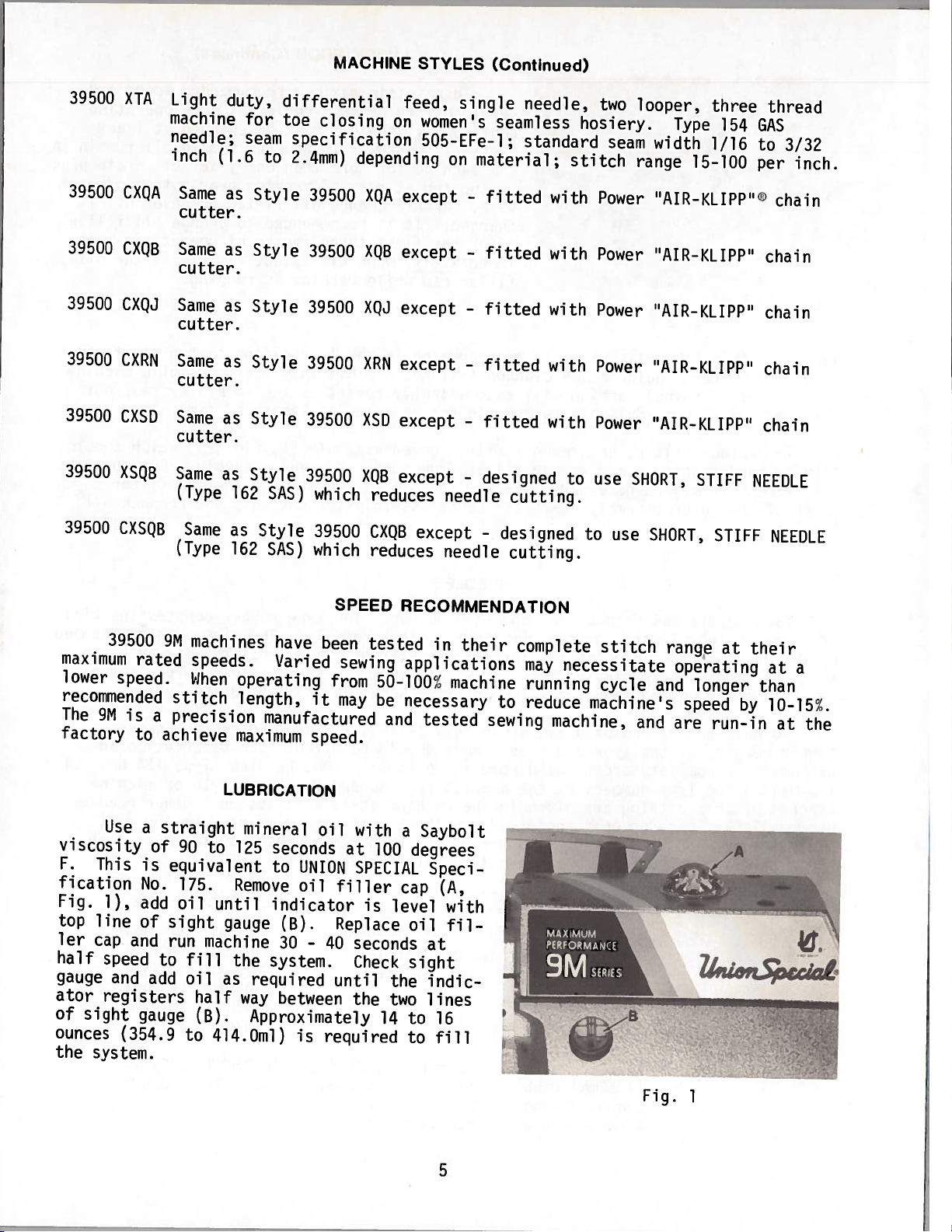

LUBRICATION

Use

a

straight

mineral

oil

with

a

Saybolt

viscosity

of

90

to

125

seconds

at

100

degrees

F.

This

is

equivalent

to

UNION

SPECIAL

Speci

fication

No.

175.

Remove

oil

filler

cap

(A,

Fig.

1),

add

oil

until

indicator

is

level

with

top

line

of

sight

gauge

(B).

Replace

oil

fil

ler

cap

and

run

machine

30

-

40

seconds

at

half

speed

to

fill

the

system.

Check

sight

gauge

and

add

oil

as

required

until

the

indic

ator

registers

half

way

between

the

two

lines

of

sight

gauge

(B).

Approximately

14

to

16

ounces

(354.9

to

414.Oml)

is

required

to

fill

the

system.

Z1aL

Fig.

1

5

From the library of: Superior Sewing Machine & Supply LLC

LUBRICATION

(Continued)

To

maintain

maximum

reconnended

speed

and

servicability

of

this

equipment

when

operating

continously,

the

oil

must

be

changed

at

least

every

six

months.

In

no

case

should

oil

remain

in

the

machine

for

more

than

one

year.

Oil

drain

plug

is

located

at

rear

of

machine

near

bottom

edge

of

base.

ALWAYS

change

oil

filter

whenever

oil

is

changed.

It

is

recommended

to

change

oil

filter

after

the

first

three

months

of

operation

-

or

immediately,

when

oil

is

not

visible

in

the

oil

filler

cap

while

machine

is

running.

NOTE:

An

oil

by-pass

valve

is

incorporated

in

the

lubricating

system

so

if

oil

filter

should

become

clogged

(oil

not

visible

in

filler

cap

while

machine

is

running)

machine

will

automatically

revert

to

the

splash

system,

but

it

is

not

advisable

to

operate

for

an

extended

length

of

time.

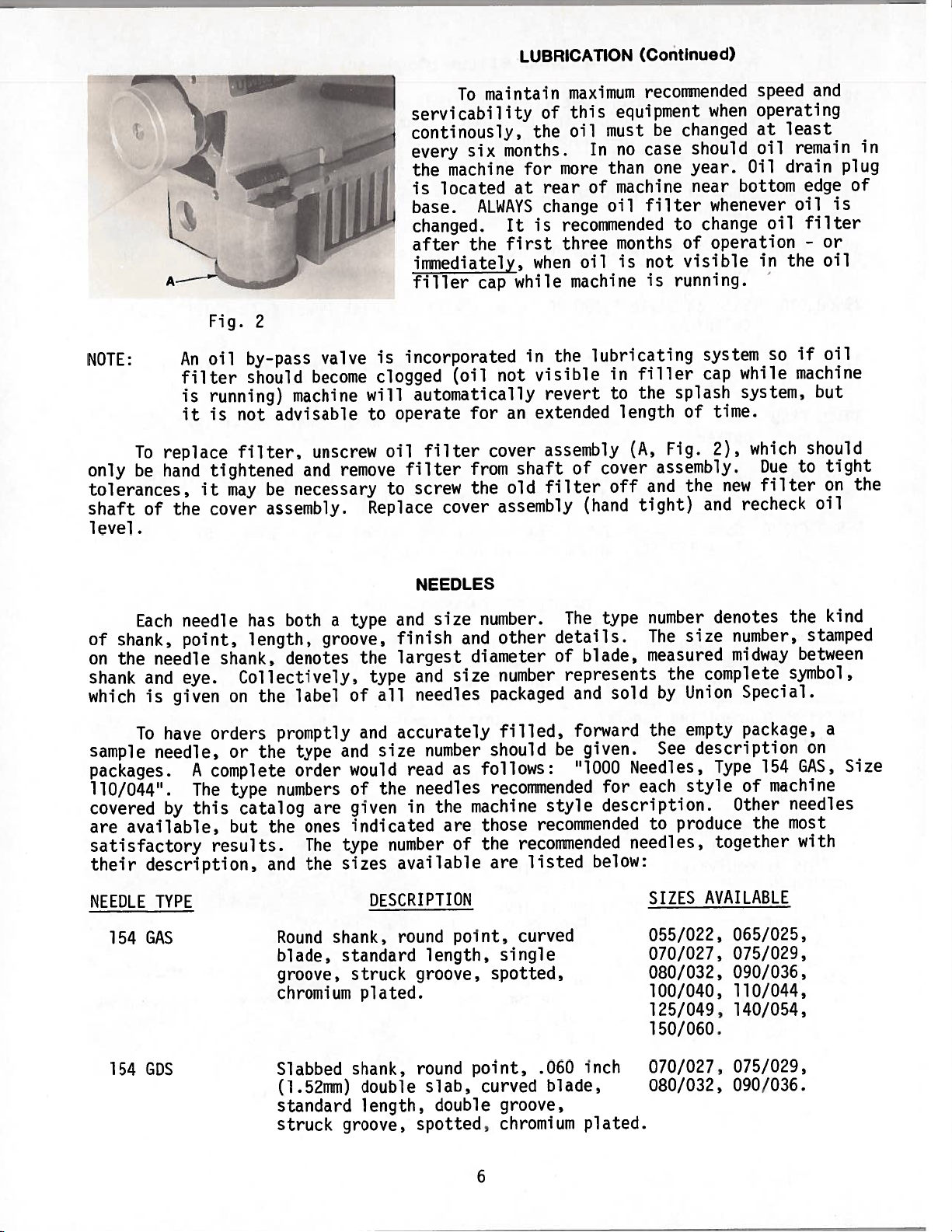

To

replace

filter,

unscrew

oil

filter

cover

assembly

(A,

Fig.

2),

which

should

only

be

hand

tightened

and

remove

filter

from

shaft

of

cover

assembly.

Due

to

tight

tolerances,

it

may

be

necessary

to

screw

the

old

filter

off

and

the

new

filter

on

the

shaft

of

the

cover

assembly.

Replace

cover

assembly

(hand

tight)

and

recheck

oil

level.

NEEDLES

Each

needle

has

both

a

type

and

size

number.

The

type

number

denotes

the

kind

of

shank,

point,

length,

groove,

finish

and

other

details.

The

size

number,

stamped

on

the

needle

shank,

denotes

the

largest

diameter

of

blade,

measured

midway

between

shank

and

eye.

Collectively,

type

and

size

number

represents

the

complete

symbol,

which

is

given

on

the

label

of

all

needles

packaged

and

sold

by

Union

Special.

To

have

orders

promptly

and

accurately

filled,

forward

the

empty

package,

a

sample

needle,

or

the

type

and

size

number

should

be

given.

See

description

on

packages.

A

complete

order

would

read

as

follows:

“1000

Needles,

Type

154

GAS,

Size

110/044”.

The

type

numbers

of

the

needles

recommended

for

each

style

of

machine

covered

by

this

catalog

are

given

in

the

machine

style

description.

Other

needles

are

available,

but

the

ones

indicated

are

those

recommended

to

produce

the

most

satisfactory

results.

The

type

number

of

the

recommended

needles,

together

with

their

description,

and

the

sizes

available

are

listed

below:

NEEDLE

TYPE

DESCRIPTION

SIZES

AVAILABLE

154

GAS

Round

shank,

round

point,

curved

055/022,

065/025,

blade,

standard

length,

single

070/027,

075/029,

groove,

struck

groove,

spotted,

080/032,

090/036,

chromium

plated.

100/040,

110/044,

125/049,

140/054,

150/060.

154

GDS

Slabbed

shank,

round

point,

.060

inch

070/027,

075/029,

(1.52mm)

double

slab,

curved

blade,

080/032,

090/036.

standard

length,

double

groove,

struck

groove,

spotted,

chromium

plated.

Fig.

2

6

From the library of: Superior Sewing Machine & Supply LLC

NEEDLES

(Continued)

NEEDLE

TYPE

DESCRIPTION

SIZES

AVAILABLE

Slabbed

shank,

round

point,

.046

inch

(1.17mm)

double

slab,

curved

blade,

standard

length,

single

groove,

struck

groove,

ball

point,

spotted,

chromium

plated.,

162

SAS

Round

shank,

round

point,

curved

065/025,

blade,

single

groove,

struck

075/029,

groove,

spotted,

chromium

plated.

090/036,

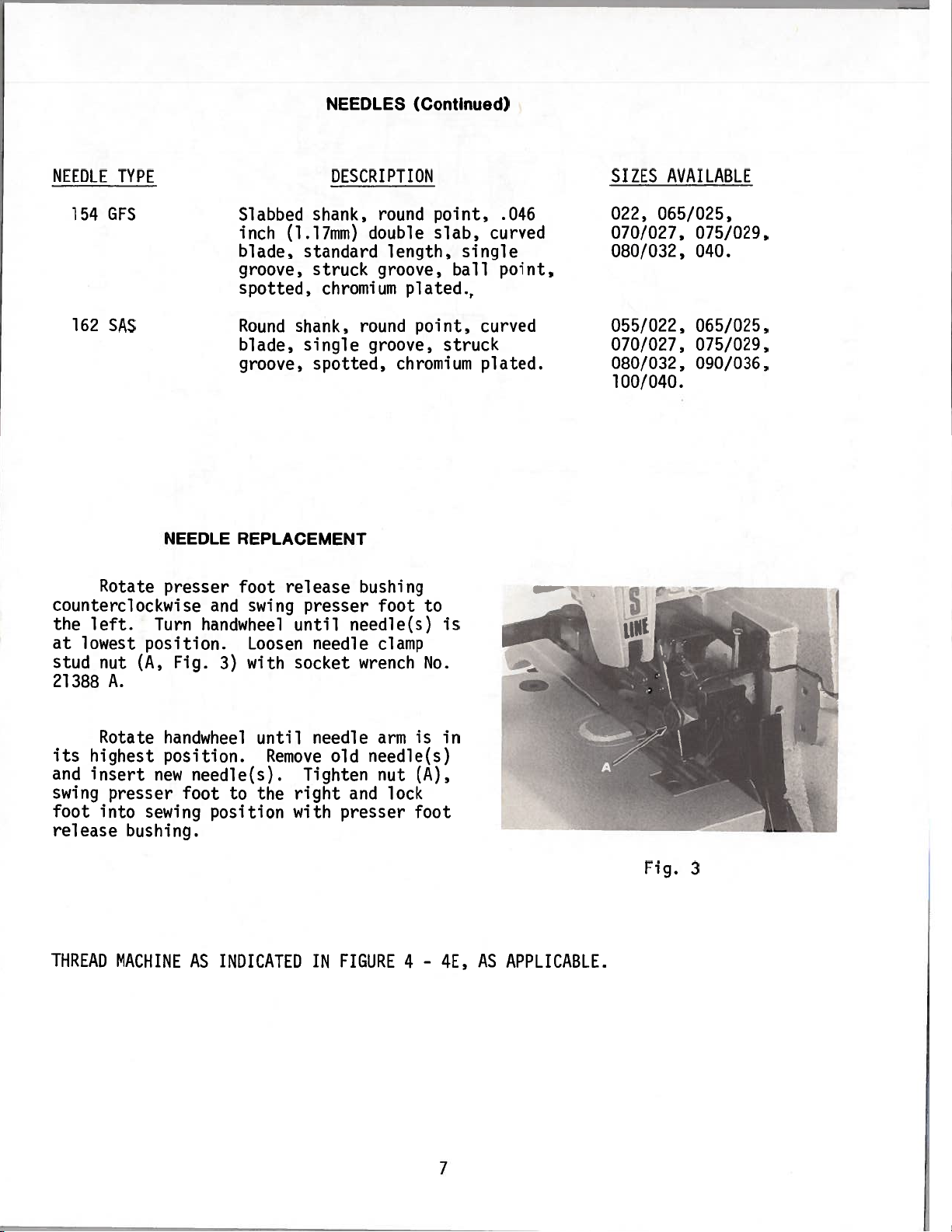

NEEDLE

REPLACEMENT

Rotate

presser

foot

release

bushing

counterclockwise

and

swing

presser

foot

to

the

left.

Turn

handwheel

until

needle(s)

is

at

lowest

position.

Loosen

needle

clamp

stud

nut

(A,

Fig.

3)

with

socket

wrench

No.

21388

A.

Rotate

handwheel

until

needle

arm

is

in

its

highest

position.

Remove

old

needle(s)

and

insert

new

needle(s).

Tighten

nut

(A),

swing

presser

foot

to

the

right

and

lock

foot

into

sewing

position

with

presser

foot

release

bushing.

154

GFS

022,

065/025,

070/027,

075/029,

080/032,

040.

055/022,

070/027,

080/032,

100/040.

Fig.

3

THREAD

MACHINE

AS

INDICATED

IN

FIGURE

4

-

4E,

AS

APPLICABLE.

7

From the library of: Superior Sewing Machine & Supply LLC

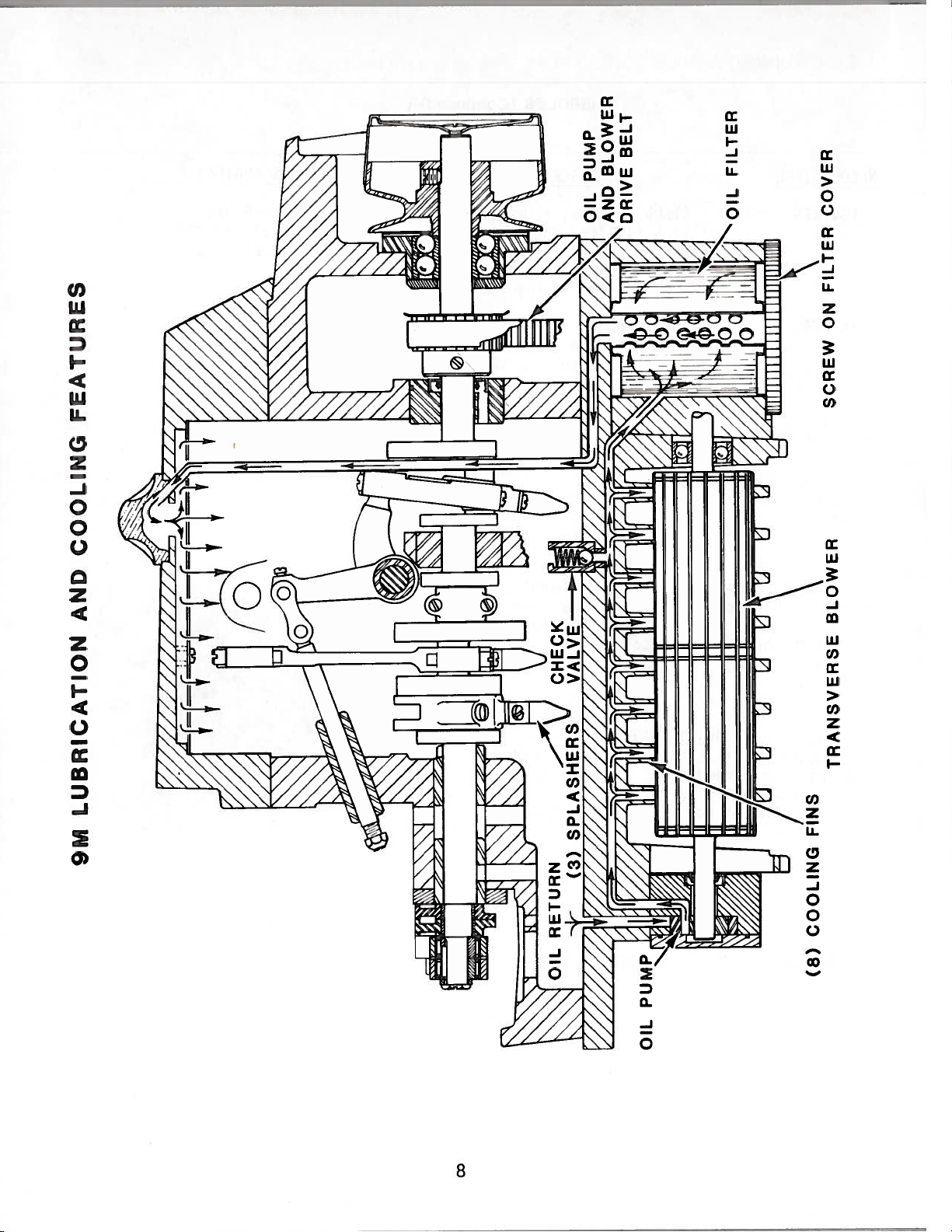

9M

LUBRICATION

AND

COOLING

FEATURES

(8)

COOLING

FINS

OIL

PUMP

AND

BLOWER

DRIVE

BELT

OIL

FILTER

TRANSVERSE

B

SCREW

ON

FILTER

COVER

From the library of: Superior Sewing Machine & Supply LLC

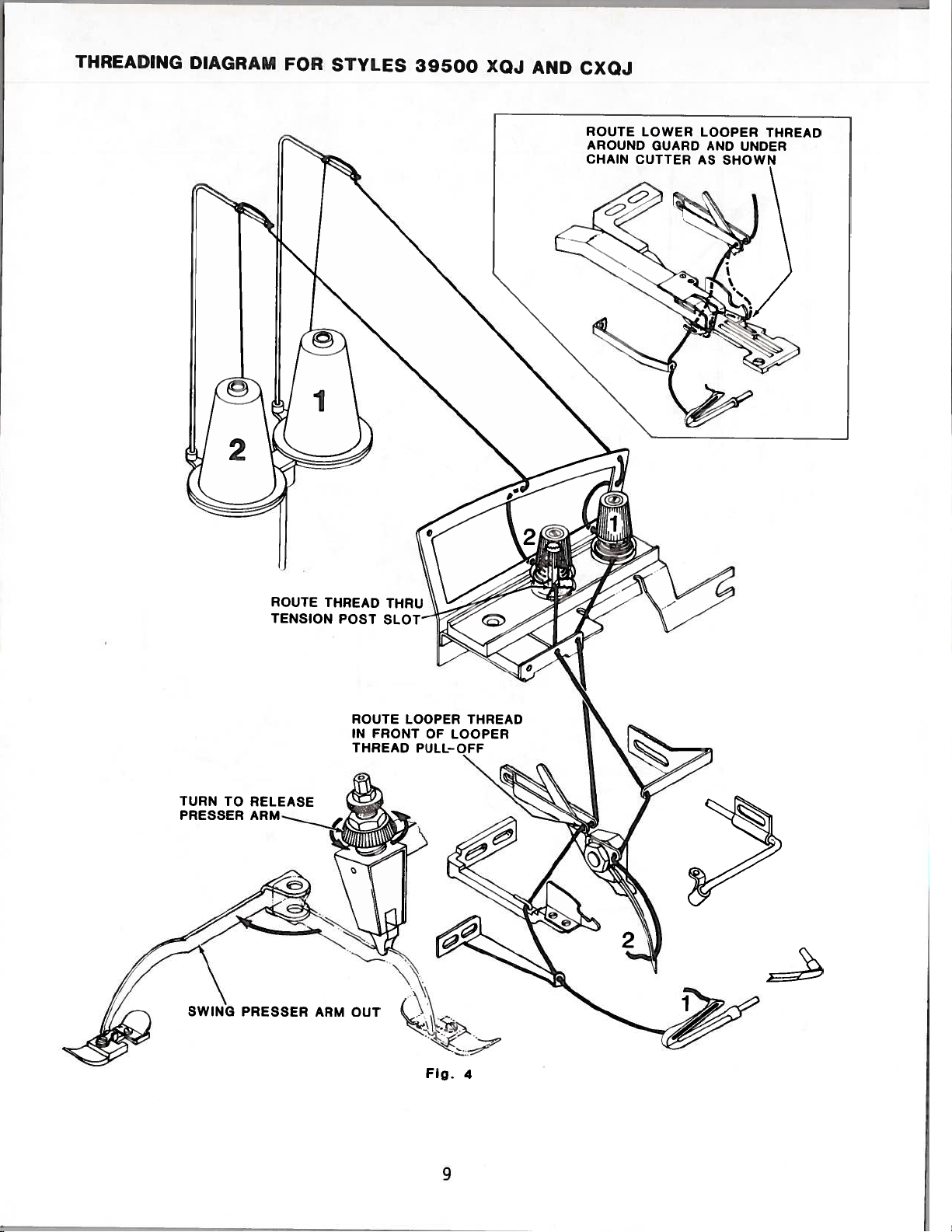

-.

THREADING

DIAGRAM

FOR

STYLES

39500

XOJ

AND

CXOJ

ROUTE

THREAD

TENSION

POST

ROUTE

LOOPER

THREAD

IN

FRONT

OF

LOOPER

THREAD

PULL-OFF

ROUTE

LOWER

LOOPER

THREAD

AROUND

GUARD

AND

UNDER

CHAIN

CUTTER

AS

SHOWN

TURN

TO

RELEASE

PRESSER

SWING

PRESSER

ARM

OUT

Fig.

4

9

From the library of: Superior Sewing Machine & Supply LLC

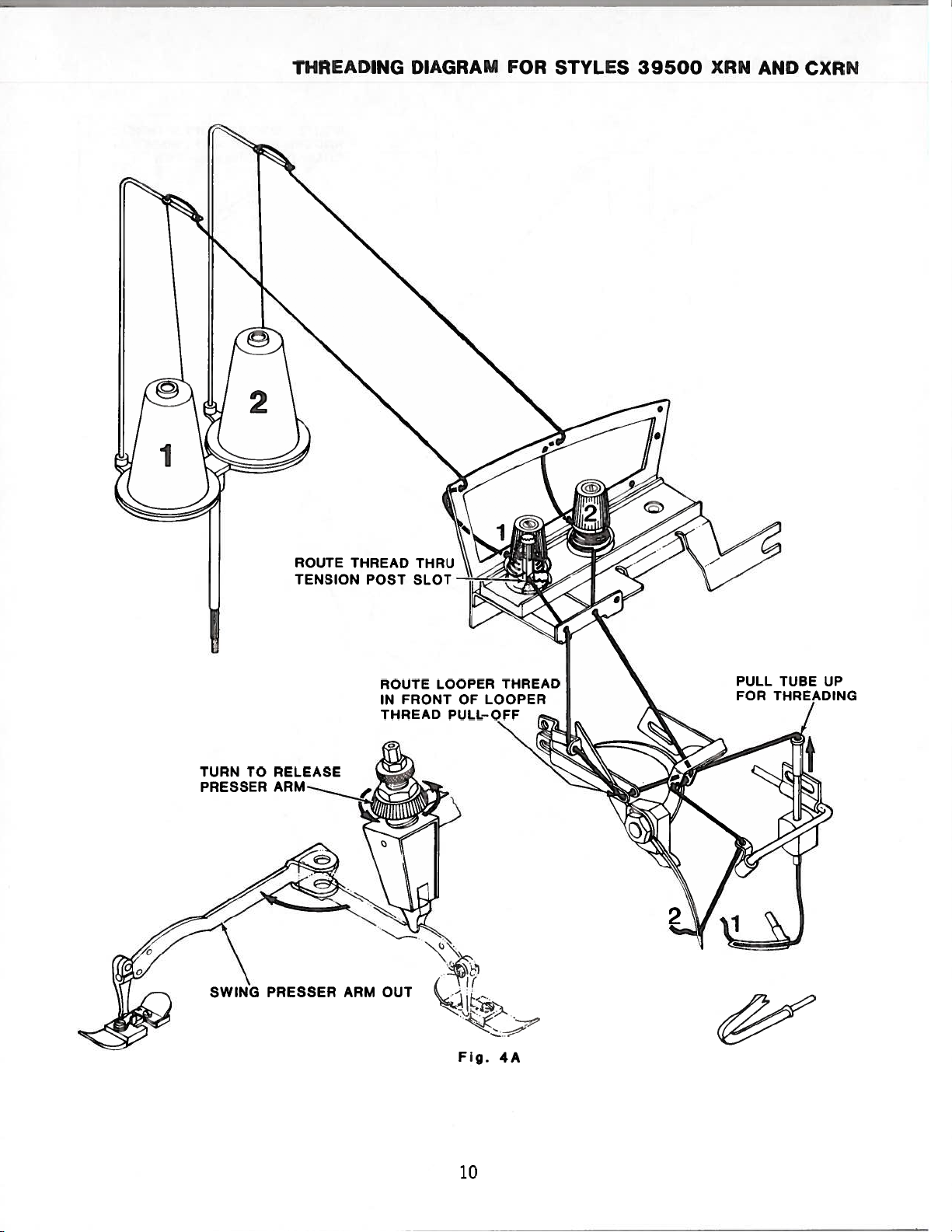

THREADING

DIAGRAM

FOR

STYLES

39500

XRN

AND

CXRN

ROUTE

THREAD

TENSION

POST

SLOT

ROUTE

LOOPER

THREAD

IN

FRONT

OF

LOOPER

THREAD

PULL-OFF

PULL

TUBE

UP

TURN TO

RELEASE

PRESSER

PRESSER

ARM

OUT

Fig.

4A

10

From the library of: Superior Sewing Machine & Supply LLC

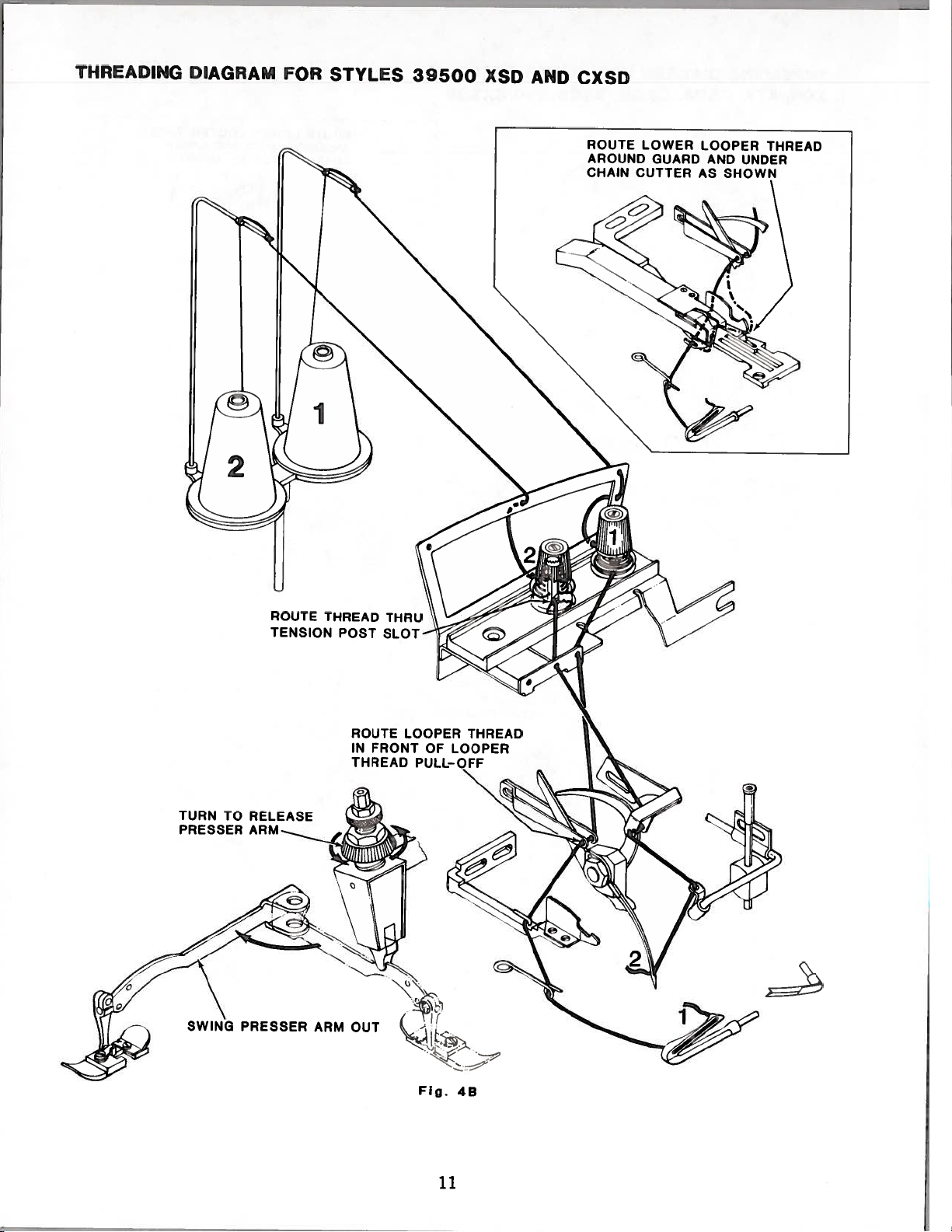

THREADING

DIAGRAM

FOR

STYLES

39500

XSD

AND

CXSD

ROUTE

THREAD

TENSION

POST

SLOT

ROUTE

LOOPER

THREAD

IN

FRONT

OF

LOOPER

THREAD

PULL-OFF

ROUTE

LOWER

LOOPER

THREAD

AROUND

GUARD

AND

UNDER

CHAIN

CUTTER

AS

SHOWN

TURN

TO

RELEASE

PRESSER

PRESSER

ARM

OUT

Fig.

48

11

From the library of: Superior Sewing Machine & Supply LLC

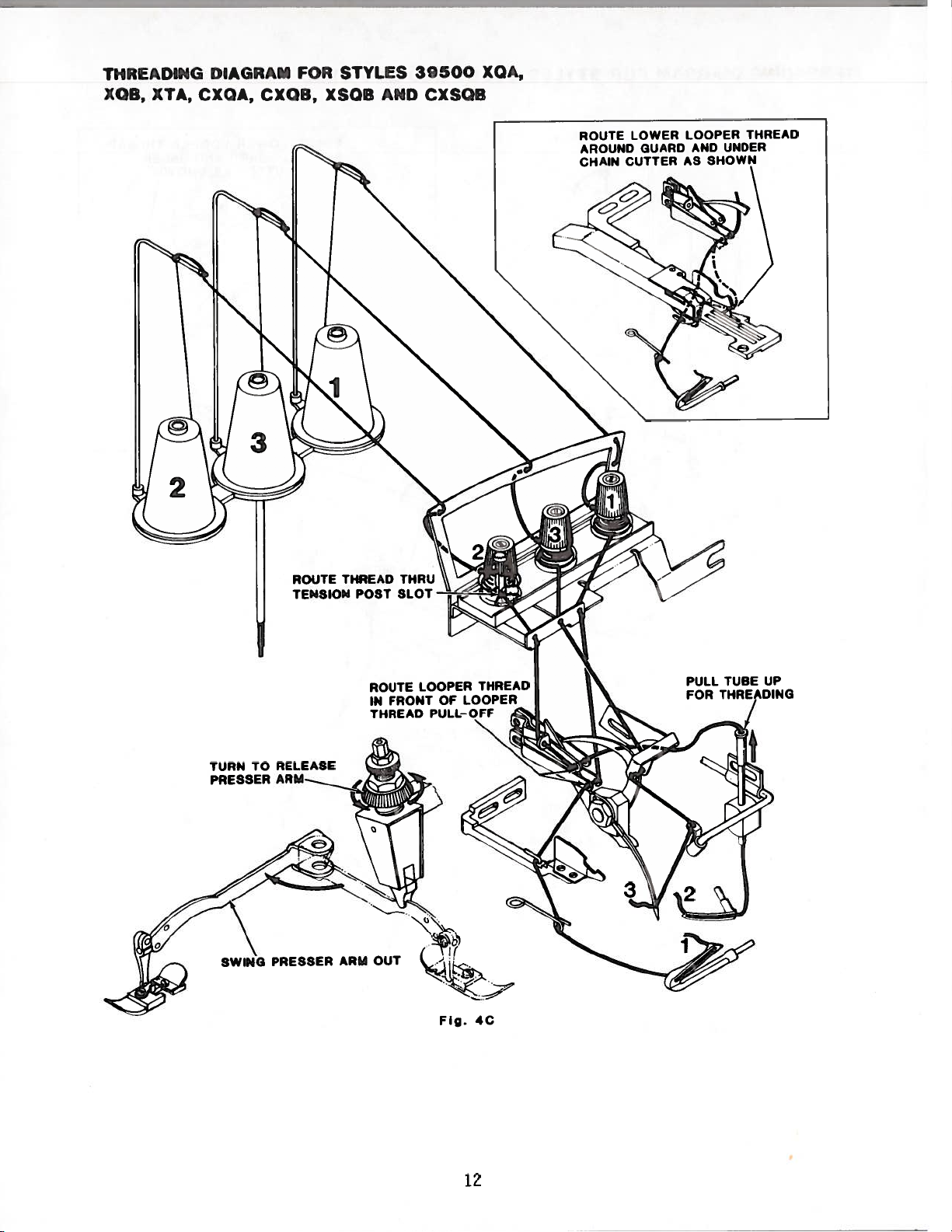

I

THREADING

DIAGRAM

FOR

STYLES

39500

XQA,

XQB,

XTA,

CXQA,

CXQB,

XSQB

AND

CXSOB

ROUTE

THREAD

TENSION

POST

SLOT

ROUTE

LOOPER

THREAD

IN

FRONT

OF

LOOPER

THREAD

PULL-OFF

TURN

TO

RELEASE

PRESSER

AR

PULL

TUBE

UP

FOR

THREADING

Fig.

4C

12

From the library of: Superior Sewing Machine & Supply LLC

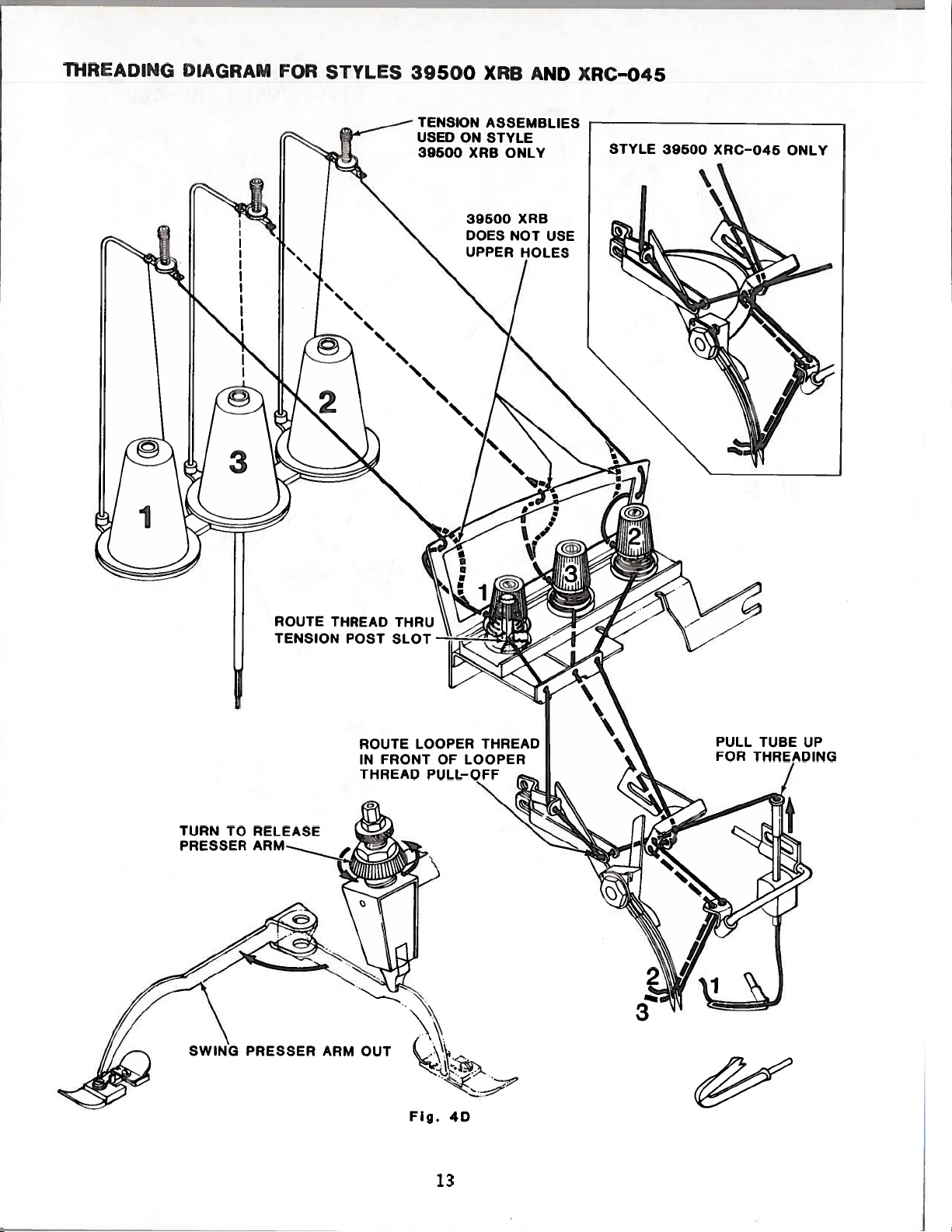

ThREADING

DIAGRAM

FOR

STYLES

39500

XRB

AND

XRC-045

TENSION

ASSEMBLIES

USED

ON

STYLE

39500

XRB

ONLY

39500

XRB

DOES

NOT

USE

UPPER

HOLES

ROUTE

LOOPER

THREAD

IN

FRONT

OF

LOOPER

THREAD

PULL-OFF

STYLE

39500

XRC-045

ONLY

TURN

TO

RELEASE

PRESSER

PRESSER

ARM

OUT

Fig.

40

ROUTE

THREAD

THRU

TENSION

POST

SLOT

UP

13

From the library of: Superior Sewing Machine & Supply LLC

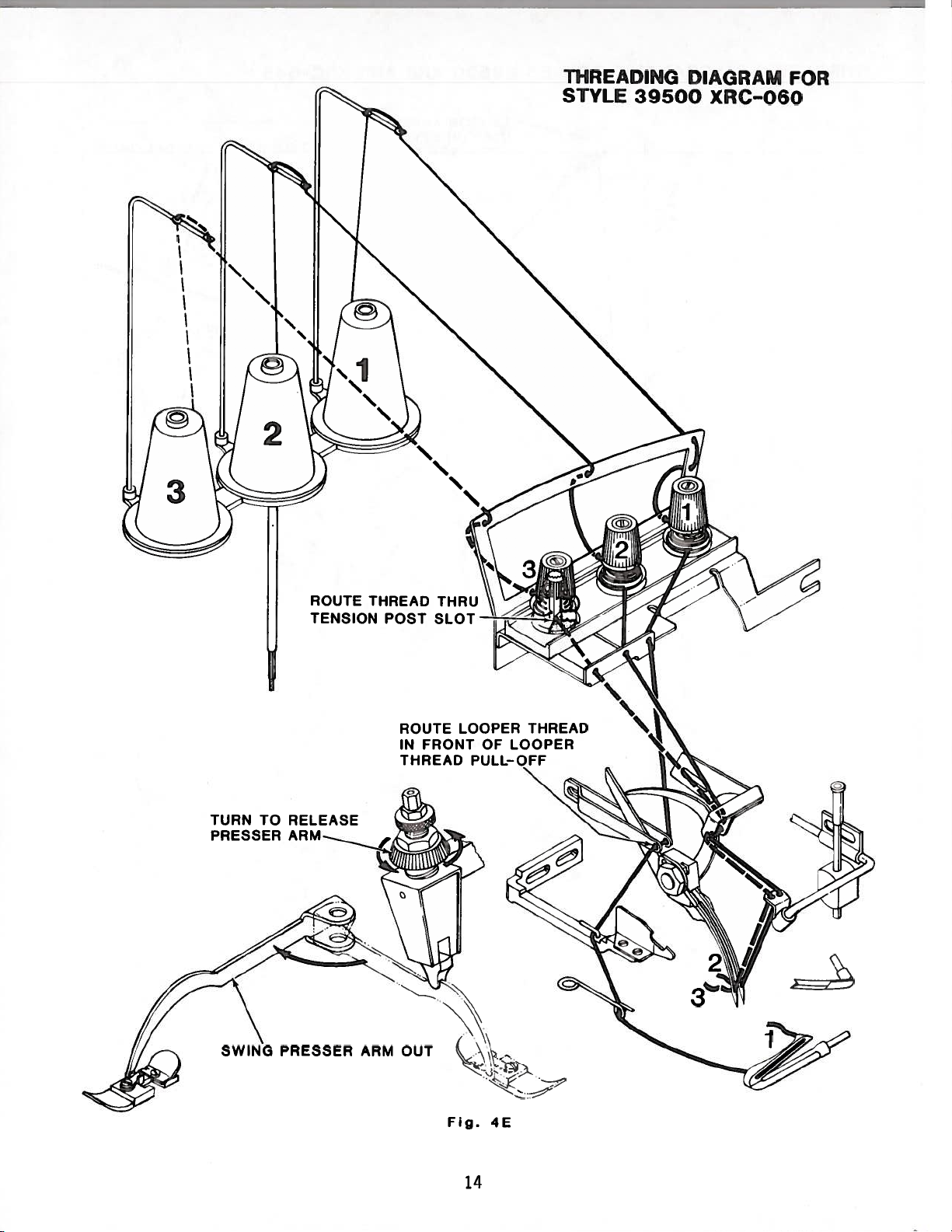

ROUTE

THREAD

TENSION

POST

SLOT

THREADING

DIAGRAM

FOR

STYLE

39500

XRC-060

TURN

TO

RELEASE

PRESSER

ARM

ROUTE

LOOPER

THREAD

IN

FRONT

OF

LOOPER

THREAD

PULL-OFF

SWING

PRESSER

ARM

OUT

Fig.

4E

14

From the library of: Superior Sewing Machine & Supply LLC

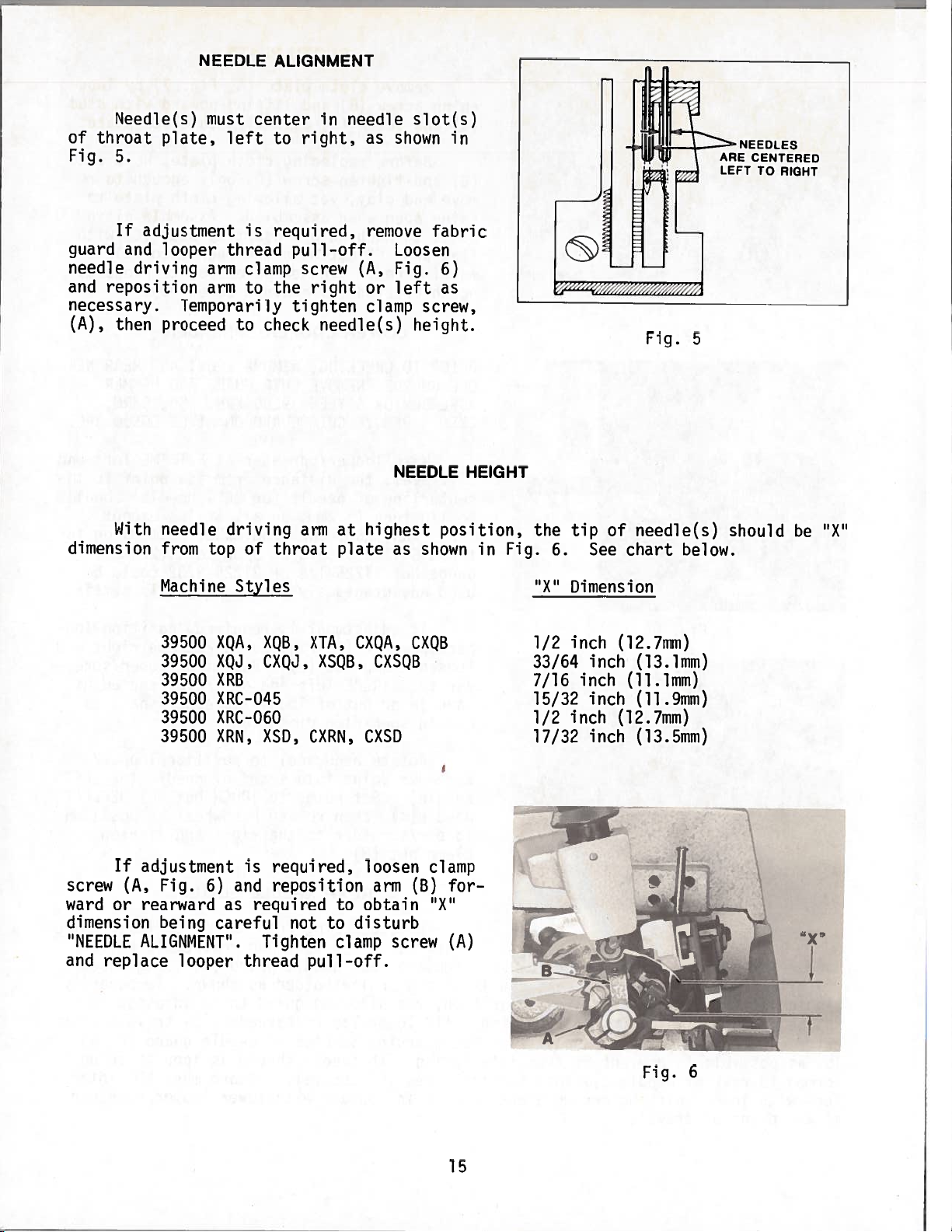

NEEDLE

ALIGNMENT

Needle(s)

must

center

in

needle

slot(s)

of

throat

plate,

left

to

right,

as

shown

in

Fig.

5.

If

adjustment

is

required,

remove

fabric

guard

and

looper

thread

pull-off.

Loosen

needle

driving

arm

clamp

screw

(A,

Fig.

6)

and

reposition

arm

to

the

right

or

left

as

necessary.

Temporarily

tighten

clamp

screw,

(A),

then

proceed

to

check

needle(s)

height.

NEEDLE HEIGHT

With

needle

driving

arm

at

highest

position,

the

tip

of

needle(s)

should

be

“X”

dimension

from

top

of

throat

plate

as

shown

in

Fig.

6.

See

chart

below.

Machine

Styles

“X”

Dimension

XQA,

XQB,

XTA,

CXQA,

CXQB

XQJ,

CXQJ,

XSQB,

CXSQB

X

RB

XRC-045

XRC-060

XRN,

XSD,

CXRN,

CXSD

If

adjustment

is

required,

loosen

clamp

screw

(A,

Fig.

6)

and

reposition

arm

(B)

for—

ward

or

rearward

as

required

to

obtain

“X”

dimension

being

careful

not

to

disturb

“NEEDLE

ALIGNMENT”.

Tighten

clamp

screw

(A)

and

replace

looper

thread

pull-off.

1/2

inch

(12.7mm)

33/64

inch

(13.1mm)

7/16

inch

(11.1mm)

15/32

inch

(11

.9mm)

1/2

inch

(12.7mm)

17/32

inch

(13.5mm)

NEEDLES

ARE

CENTERED

LEFT

TO

RIGHT

Fig.

5

39500

39500

39500

39500

39500

39500

——1

.4

Fig.

6

15

From the library of: Superior Sewing Machine & Supply LLC

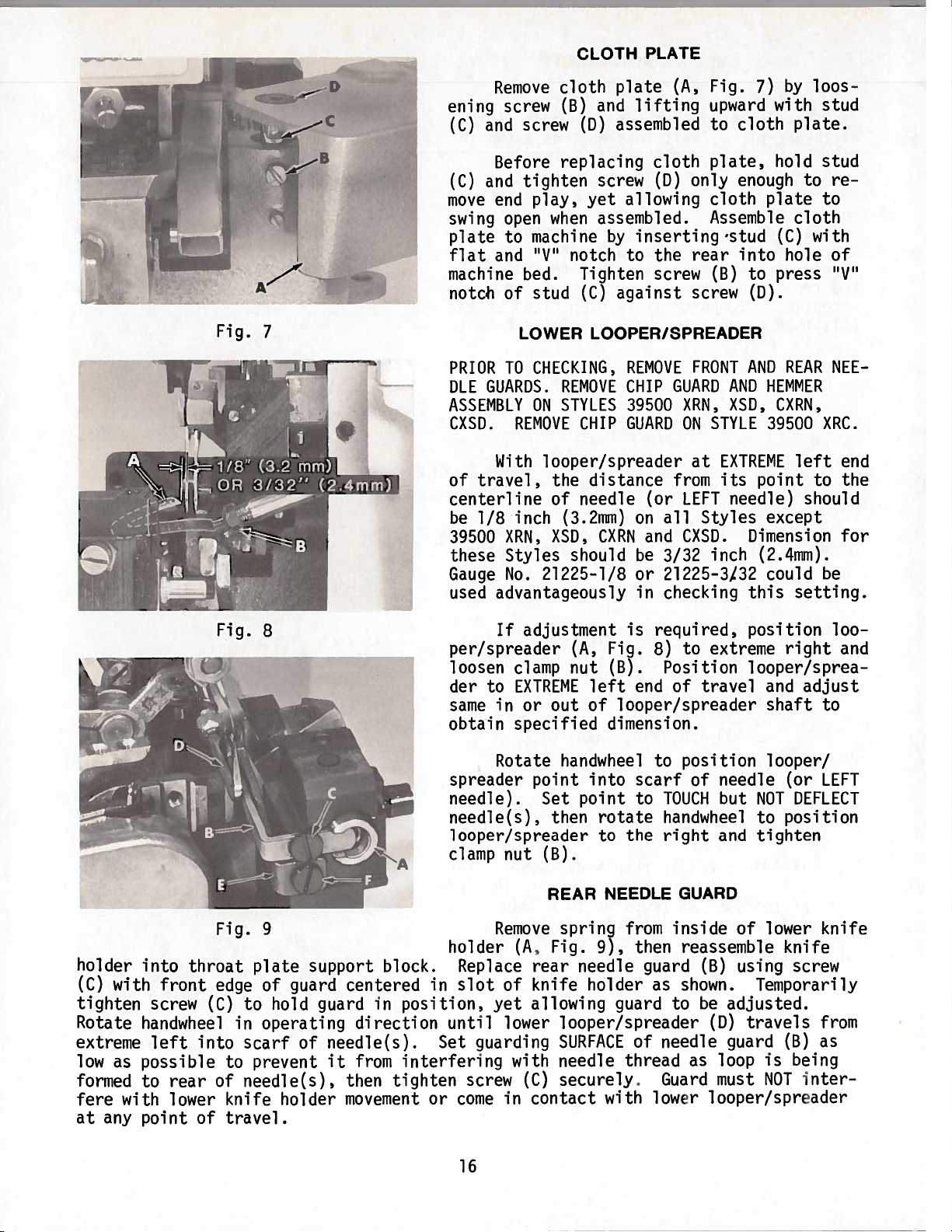

CLOTH

PLATE

Remove

cloth

plate

(A,

Fig.

7)

by

loos

ening

screw

(B)

and

lifting

upward

with

stud

(C)

and

screw

CD)

assembled

to

cloth

plate.

Before

replacing

cloth

plate,

hold

stud

(C)

and

tighten

screw

(D)

only

enough

to

re

move

end

play,

yet

allowing

cloth

plate

to

swing

open

when

assembled.

Assemble

cloth

plate

to

machine

by

inserting

‘stud

(C)

with

flat

and

“V’

notch

to

the

rear

into

hole

of

machine

bed.

Tighten

screw

(B)

to

press

“V’

notch

of stud

(C)

against

screw

(D).

LOWER

LOOPER/SPREADER

PRIOR

TO

CHECKING,

REMOVE

FRONT

AND

REAR

NEE

DLE

GUARDS.

REMOVE

CHIP

GUARD

AND

HEMMER

ASSEMBLY

ON

STYLES

39500

XRN,

XSD,

CXRN,

CXSD.

REMOVE

CHIP

GUARD

ON

STYLE

39500

XRC.

With

looper/spreader

at

EXTREME

left

end

of

travel,

the

distance

from

its

point

to

the

centerline

of

needle

(or

LEFT

needle)

should

be

1/8

inch

(3.2mm)

on

all

Styles

except

39500

XRN,

XSD,

CXRN

and

CXSD.

Dimension

for

these

Styles

should

be

3/32

inch

(2.4mm).

Gauge

No.

21225-1/8

or

21225—3/32

could

be

used

advantageously

in

checking

this

setting.

If

adjustment

is

required,

position

loo

per/spreader

(A,

Fig.

8)

to

extreme

right

and

loosen

clamp

nut

(B).

Position

looper/sprea

der to

EXTREME

left

end

of

travel

and

adjust

same

in

or

out of

looper/spreader

shaft

to

obtain

specified

dimension.

Rotate

handwheel

to

position

looper/

spreader

point

into

scarf

of

needle

(or

LEFT

needle).

Set

point

to

TOUCH

but

NOT

DEFLECT

needle(s),

then

rotate

handwheel

to

position

looper/spreader

to

the

right

and

tighten

clamp

nut

(B).

REAR

NEEDLE

GUARD

Fig.

9

Remove

spring

from

inside

of

lower

knife

holder

(A,

Fig.

9),

then

reassemble

knife

holder

into

throat

plate

support

block.

Replace

rear

needle

guard

(B)

using

screw

(C)

with

front

edge

of

guard

centered

in

slot

of

knife

holder

as

shown.

Temporarily

tighten

screw

(C)

to

hold

guard

in

position,

yet

allowing

guard

to

be

adjusted.

Rotate

handwheel

in

operating

direction

until

lower

looper/spreader

(D)

travels

from

extreme

left

into

scarf

of

needle(s).

Set

guarding

SURFACE

of needle

guard

(B)

as

low

as

possible

to

prevent

it

from

interfering

with

needle

thread

as

loop

is

being

formed

to

rear

of

needle(s),

then

tighten

screw

(C)

securely.

Guard

must

NOT

inter

fere

with

lower

knife

holder

movement

or

come

in

contact

with

lower

looper/spreader

at

any

point

of

travel.

C

B

Fig.

7

Fig.

8

16

From the library of: Superior Sewing Machine & Supply LLC

FRONT

NEEDLE

GUARD

Replace

front

needle

guard

(E,

Fig.

9)

using

screw

(F).

Temporarily

tighten

screw

(F)

to

hold

guard

in

position,

yet

allowing

guard

to

be

adjusted.

Rotate

hand-

wheel

in

operating

direction

until

needle(s)

is

at

lowest

position.

Set guarding

SURFACE

of

needle

guard

CE)

to

needle(s)

with

minimum

clearance

-

approximately

.004

inch

(.10mm)

and

tighten

screw

(F)

securely.

Check

to

ensure

needle(s)

is

NOT

being

pinched

between

front

and

rear

needle

guards.

UPPER

LOOPER/SPREADER

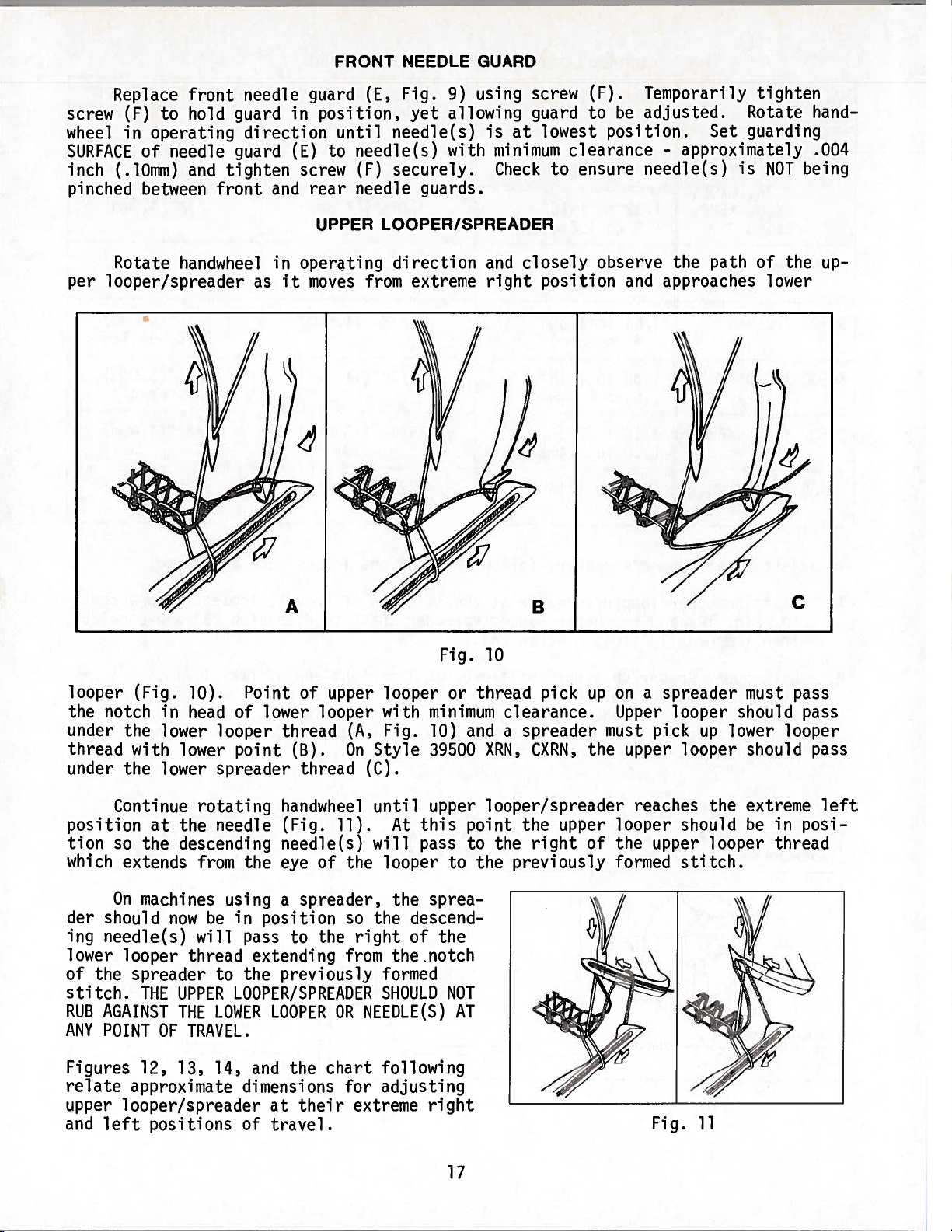

Rotate

handwheel

in

operating

direction

and

closely

observe

the

path

of the

up

per

looper/spreader

as

it

moves

from

extreme

right

position

and

approaches

lower

looper

(Fig.

10).

Point

of

upper

looper

or

thread

pick

up

on

a

spreader

must

pass

the

notch

in

head

of

lower

looper

with

minimum

clearance.

Upper

looper

should

pass

under

the

lower

looper

thread

(A,

Fig.

10)

and

a

spreader

must

pick

up

lower

looper

thread

with

lower

point

(B).

On

Style

39500

XRN,

CXRN,

the

upper

looper

should

pass

under

the

lower

spreader

thread

(C).

handwheel

until

upper

looper/spreader

reaches

the

extreme

left

(Fig.

11).

At

this

point

the

upper

looper

should

be

in

posi

needle(s)

will

pass

to

the

right

of

the

upper

looper

thread

eye

of the

looper

to

the

previously

formed

stitch.

On

machines

using

a

spreader,

the

sprea

der

should

now

be

in

position

so

the

descend

ing

needle(s)

will

pass

to

the

right

of

the

lower

looper

thread

extending

from

the.notch

of

the

spreader

to

the

previously

formed

stitch.

THE

UPPER

LOOPER/SPREADER

SHOULD

NOT

RUB

AGAINST

THE

LOWER

LOOPER

OR

NEEDLE(S)

AT

ANY

POINT

OF

TRAVEL.

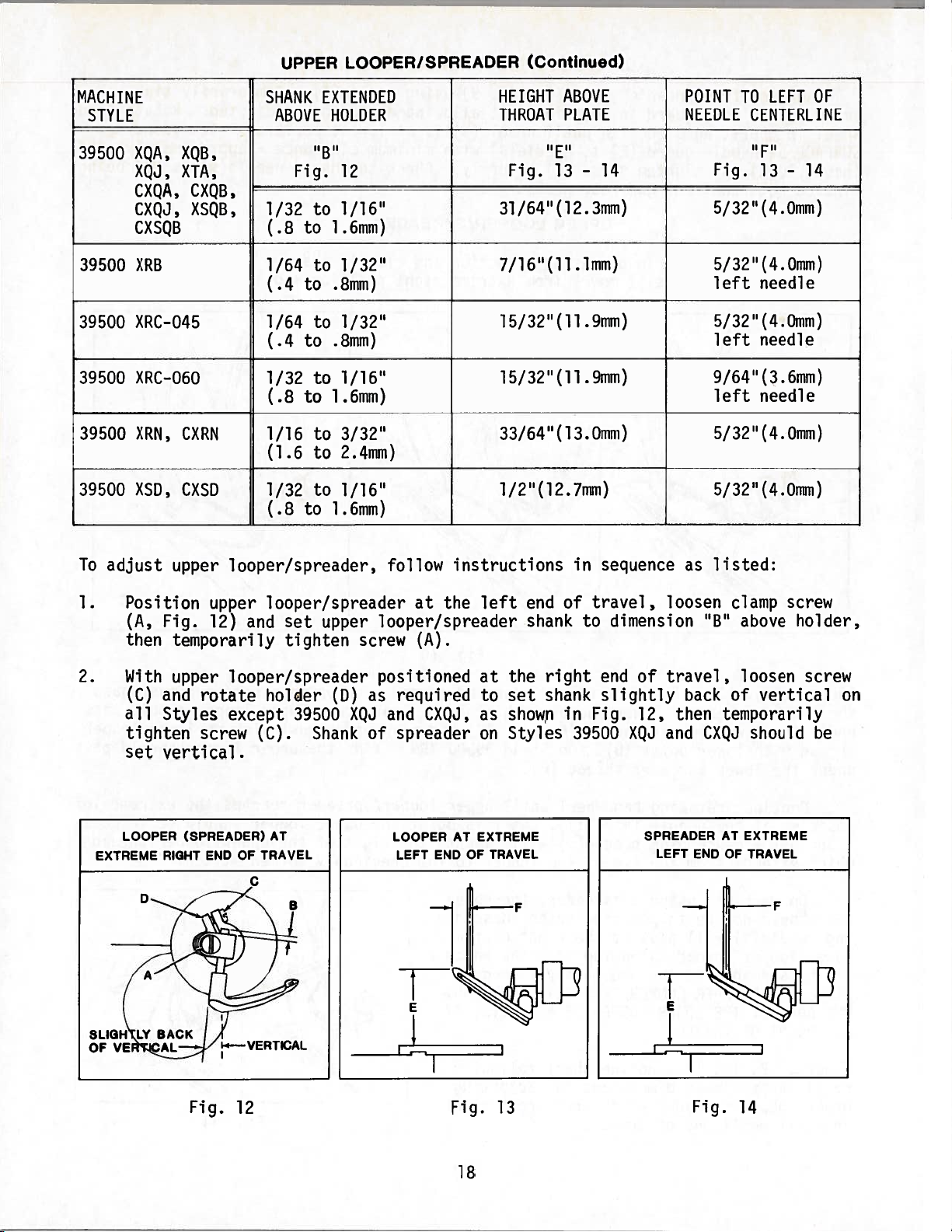

Figures

12,

13,

14,

and

the

chart

following

relate

approximate

dimensions

for

adjusting

upper

looper/spreader

at

their

extreme

right

and

left

positions

of

travel.

B

C

Fig.

10

Continue

rotating

position

at

the

needle

tion

so

the

descending

which

extends

from

the

Fig.

11

17

From the library of: Superior Sewing Machine & Supply LLC

UPPER

LOOPER/SPREADER

(Continued)

MACHINE

SHANK

EXTENDED

HEIGHT

ABOVE

POINT

TO

LEFT

OF

STYLE

ABOVE

HOLDER

THROAT

PLATE

NEEDLE

CENTERLINE

39500

XQA,

XQB,

“B

t

’

“E”

“F”

XQJ,

XTA,

Fig.

12

Fig.

13

-

14

Fig.

13

-

14

CXQA,

CXQB,

CXQJ,

XSQB,

1/32

to

1/16”

31/64(12.3mm)

5/32(4.0mm)

CXSQB

(.8

to

1.6mm)

39500

XRB

1/64

to

1/32”

7/16(11.1mm)

5/32(4.0mm)

(.4

to

.8mm)

left

needle

39500

XRC—O45

1/64

to

1/32”

15/32(11.9mm)

5/32(4.0mm)

(.4

to

.8mm)

left

needle

39500

XRC-06O

1/32

to

1/16”

15/32(11.9mm)

9/64(3.6mm)

(.8

to

1.6mm)

left

needle

39500

XRN,

CXRN

1/16

to

3/32”

33/64(13.0mm)

5/32(4.0mm)

(1.6

to

2.4mm)

39500

XSD,

CXSD

1/32

to

1/16”

l/2”(12.7mm)

5/32(4.0mm)

(.8

to

1.6mm)

To

adjust

upper

looper/spreader,

follow

instructions

in

sequence

as

listed:

1.

Position

upper

looper/spreader

at

the

left

end

of

travel,

loosen

clamp

screw

(A,

Fig.

12)

and

set

upper

looper/spreader

shank

to

dimension

“B”

above

holder,

then

temporarily

tighten

screw

(A).

2.

With

upper

looper/spreader

positioned

(C)

and

rotate

holder

(D)

as

required

all

Styles

except

39500

XQJ

and

CXQJ,

(C).

Shank

of

spreader

tighten

screw

set

vertical.

at

the

right

end

of

travel,

loosen

screw

to

set

shank

slightly

back

of

vertical

on

as

shown

in

Fig.

12,

then

temporarily

on

Styles

39500

XQJ

and

CXQJ

should

be

LOOPER

AT

EXTREME

LEFT

END

OF

TRAVEL

LOOPER

(SPREADER)

AT

EXTREME

RIGHT

END

OF

TRAVEL

C

Fig.

12

Fig.

13

Fig.

14

18

From the library of: Superior Sewing Machine & Supply LLC

Loading...

Loading...