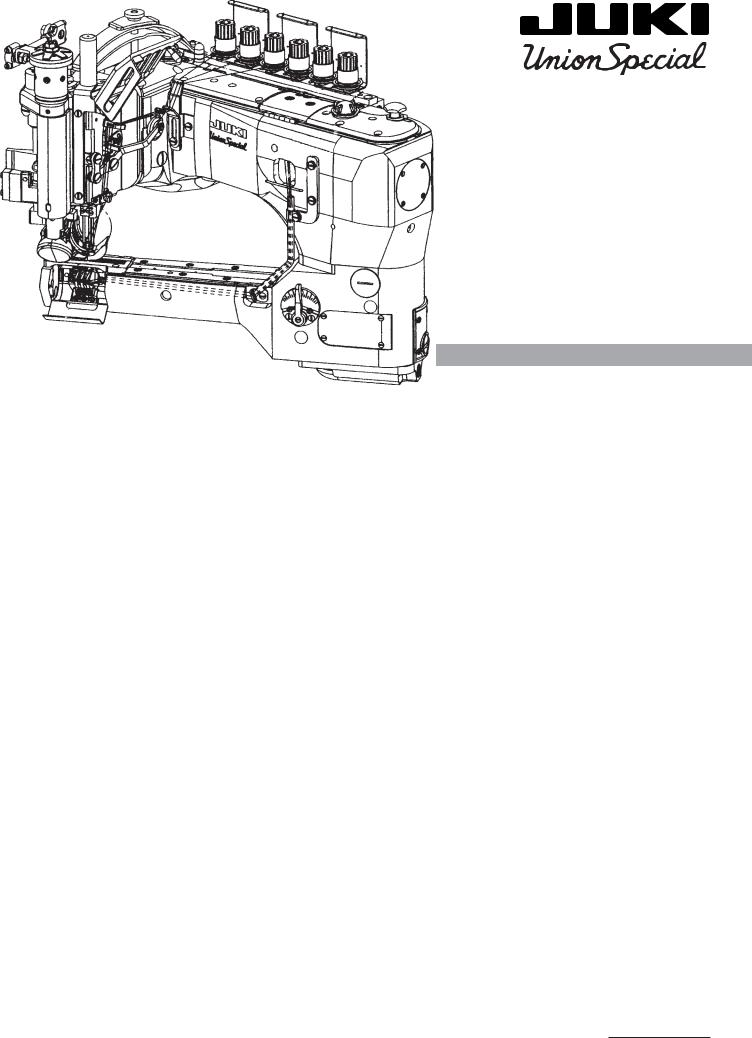

Union Special 35800 Parts List

®

Feed-off-the arm, 3-Needle, Double Chainstitch Machine

35800 Series

ENGINEER’S MANUAL

40052737

No.E376-00

Introduction

This Engineer’s Manual is written for the technical personnel who are responsible for the service and maintenance of the machine.

The maintenance services to be done on this sewing machine should be based on this manual.

This manual gives the "Standard Adjustment" on the former section under which the most basic adjustment value is described and on the latter section the "Results of Improper Adjustment" under which stitching errors and troubles arising from mechanical failures and "How To Adjust" are described.

CONTENTS

1. |

Specifications ........................................................................................................ |

1 |

||

|

(1) |

Roller mechanism/clutch type ............................................................................................... |

1 |

|

|

(2) |

Roller mechanism/belt type ................................................................................................... |

2 |

|

2. |

Model list ................................................................................................................ |

3 |

||

|

(1) |

Model list using the roller mechanism of the clutch type ................................................... |

3 |

|

|

(2) |

Model list using the roller mechanism of the belt type ....................................................... |

3 |

|

3. |

Description of US model code .................................................................... |

5 |

||

4. |

Description of model code .......................................................................... |

6 |

||

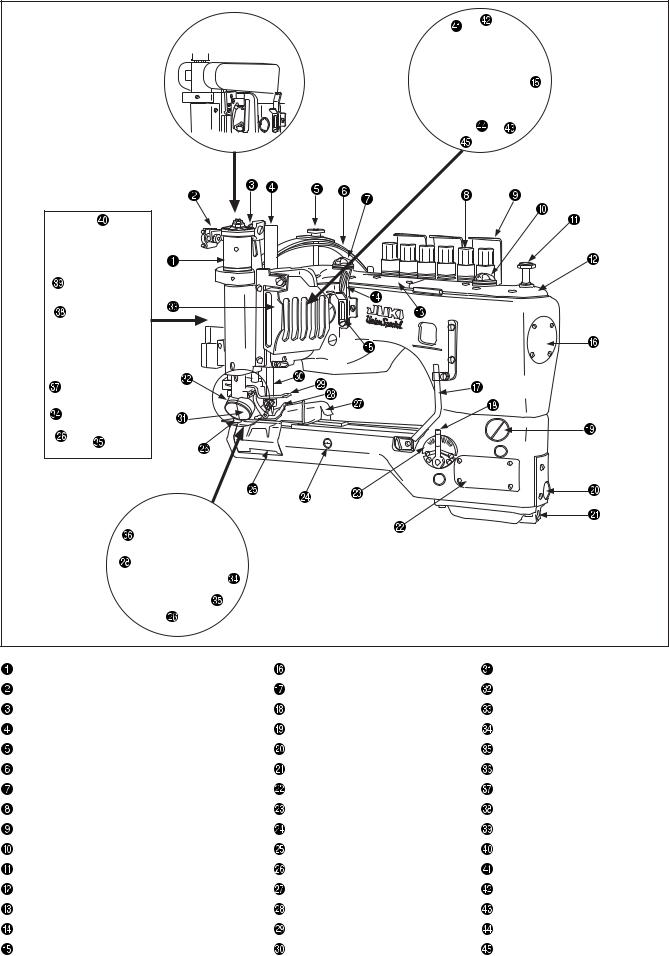

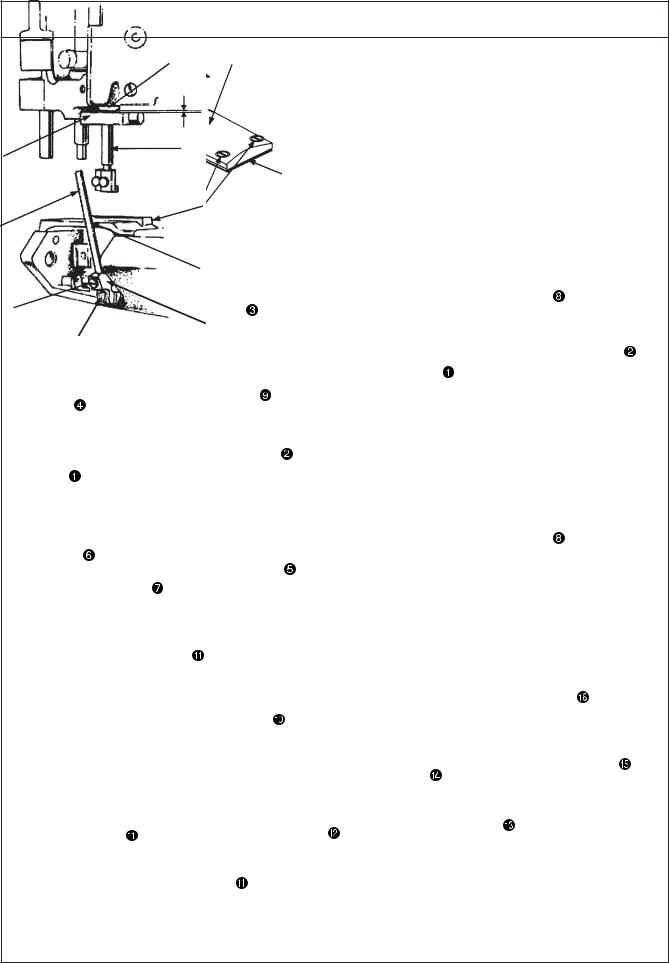

5. Names of machine head .............................................................................. |

7 |

|||

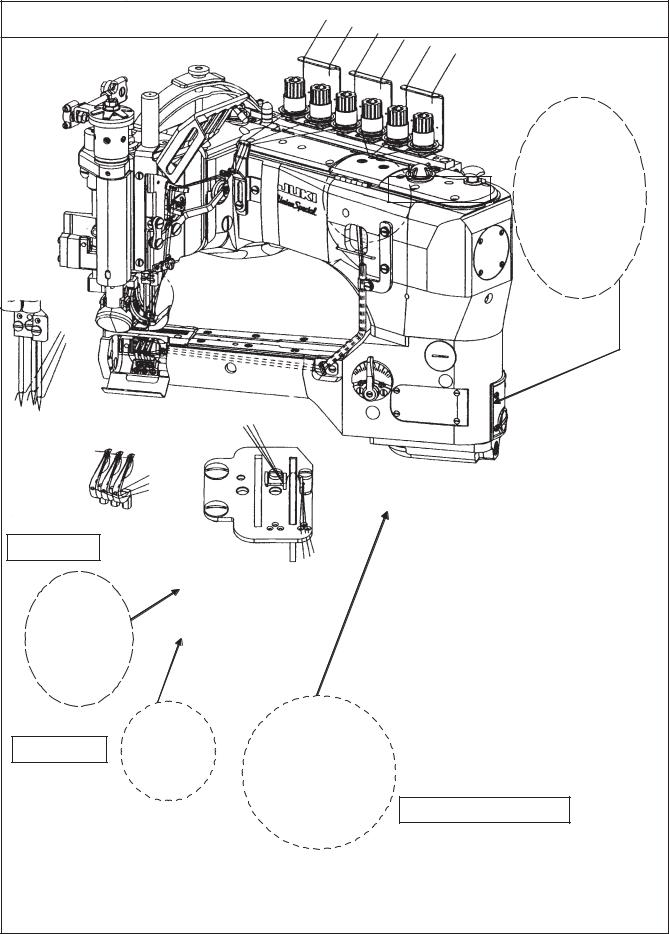

6. How to pass the threads.............................................................................. |

8 |

|||

|

(1) |

Differential feed....................................................................................................................... |

8 |

|

|

(2) |

1 piece feed ............................................................................................................................. |

9 |

|

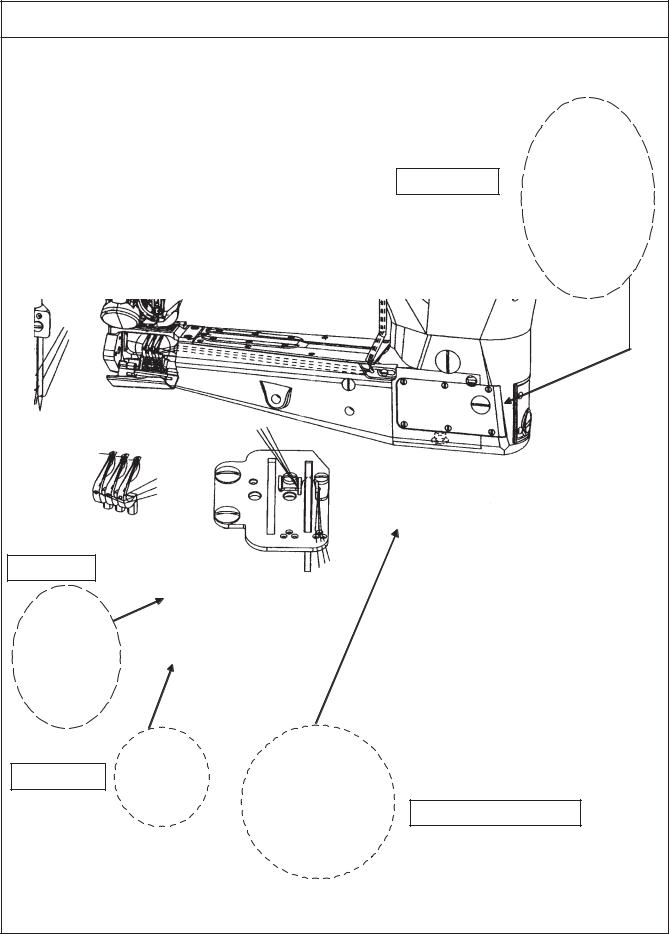

7. Standard adjustment ............................................................................................ |

10 |

|||

|

(1) |

How to remove the gauge components and upper feed roller ......................................... |

10 |

|

|

|

(differential feed mechanism and 1 piece feed mechanism) |

|

|

|

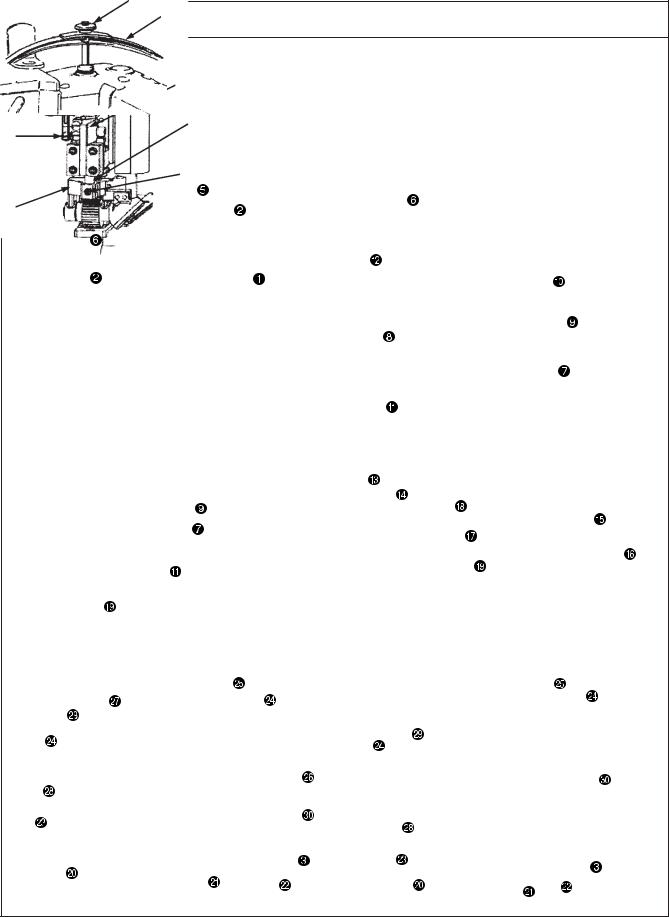

(2) |

Timing between the looper and needle bar ........................................................................ |

12 |

|

|

(3) |

Adjustment of the needle entry positions in the right-left and front-rear directions ..... |

14 |

|

|

(4) |

Looper adjustment ............................................................................................................... |

16 |

|

|

|

1) |

Looper return ..................................................................................................................................... |

16 |

|

|

2) |

Adjustment of the clearance between the looper and needle ............................................................ |

16 |

|

(5) |

Adjustment of the needle bar height .................................................................................. |

18 |

|

|

(6) |

Adjustment of the looper motion paths .............................................................................. |

20 |

|

|

(7) |

Adjustment of rear needle guide ......................................................................................... |

22 |

|

|

|

1) |

Longitudinal adjustment of the rear needle guide .............................................................................. |

22 |

|

|

2) |

Height adjustment of rear needle guide ............................................................................................. |

22 |

|

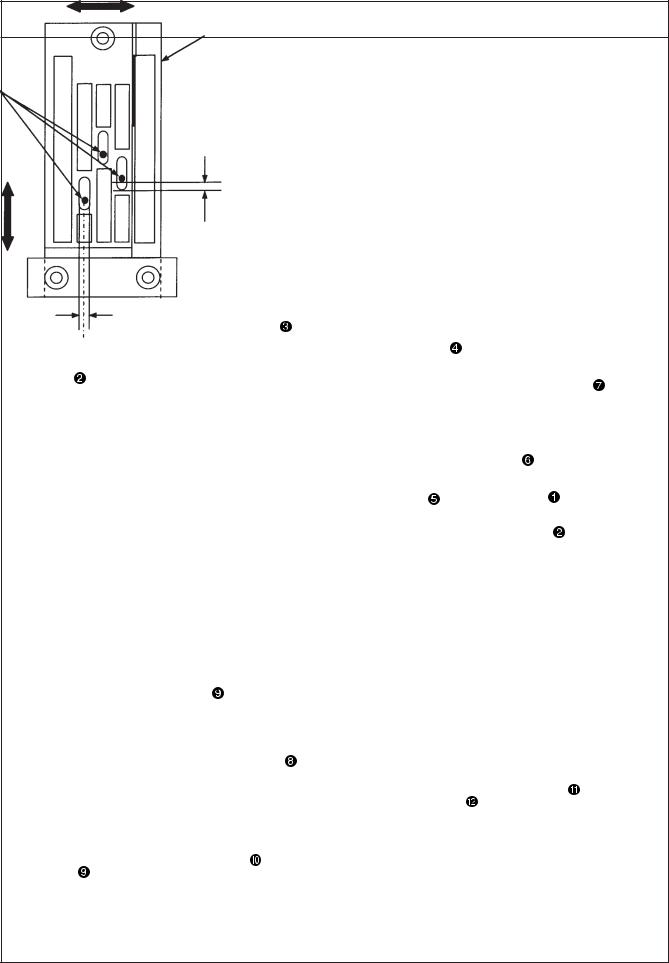

(8) |

Adjustment of feed dog height and longitudinal movement |

|

|

|

|

(differential feed dog mechanism) ...................................................................................... |

24 |

|

|

|

1) |

Height of main feed dog ..................................................................................................................... |

24 |

|

|

2) |

Height of differential feed dog ............................................................................................................ |

24 |

|

|

3) |

Adjustment of longitudinal movement of main feed dog .................................................................... |

24 |

|

|

4) |

Adjsutment of vertical height of main feed dog and differential feed dog .......................................... |

24 |

|

|

5) |

Gradient of main feed dog and differential feed dog ......................................................................... |

24 |

|

(9) |

Adjustment of feed dog height and longitudinal movement |

|

|

|

|

(1 piece feed dog mechanism) ............................................................................................ |

26 |

|

|

|

1) |

Height of main feed dog ..................................................................................................................... |

26 |

|

|

2) |

Adjustment of longitudinal movement of main feed dog .................................................................... |

26 |

|

(10) Adjustment of feed mechanisms ........................................................................................ |

28 |

||

|

|

1) |

Adjustment of stitch length ................................................................................................................. |

28 |

|

|

2) |

Adjustment of differential feed amount .............................................................................................. |

28 |

|

(11) Presser adjustment .............................................................................................................. |

30 |

||

|

|

1) |

Adjustment of amount of rise of presser ............................................................................................ |

30 |

|

|

2) |

Adjustment of presser bar pressure ................................................................................................... |

30 |

(12) Adjustment of upper feed roller .......................................................................................... |

32 |

(13) Replacement of upper feed roller ........................................................................................ |

34 |

(14) Adjustment of drawing amount of upper feed roller ......................................................... |

36 |

|

(15) Adjustment of needle thread path ....................................................................................... |

38 |

|

1) Height of needle thread adjusting path .............................................................................................. |

38 |

|

2) Height of rocking take-up path ........................................................................................................... |

38 |

|

3) Height of needle thread guide adjuster .............................................................................................. |

38 |

|

(16) Adjustment of bobbin thread cam ...................................................................................... |

40 |

|

(17) Adjustment of tension disk rise .......................................................................................... |

42 |

|

(18) Adjustment of air nozzle (air blow) ..................................................................................... |

44 |

|

(19) Adjustment of folder ............................................................................................................ |

46 |

8. |

Lubrication ........................................................................................................... |

48 |

9. |

Folder types ......................................................................................................... |

49 |

10. Maintenance ........................................................................................................ |

50 |

|

|

(1) Spare parts ............................................................................................................................. |

50 |

11. Part numbers and names of the modification parts for the |

|

|

|

35800 Class – B8/B9 soft chain stitches (balloon stitches) ............................ |

52 |

12. Troubles and corrective measures ........................................................... |

53 |

|

1. Specifications

(1) Roller mechanism/clutch type

No. |

Model |

|

|

|

|

Specifications |

|

|

|||

|

Item |

35800DLU9 |

|

35800DNU8/9 |

35800DZ32/36 |

35800DRU8/9 |

35800PZ32/36 |

35800DWW8/9 |

|||

|

|

|

|

|

|

|

|

|

|||

1 |

Stitch type |

|

|

3-needle, 6-thread, double chainstitch machine (401 LSc-3) |

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

2 |

Application |

|

|

|

Denim, working clothes, felt, etc. |

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

3 |

Max. sewing speed |

|

|

|

|

4500 rpm |

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

4 |

Sewing speed |

|

|

|

|

3500 rpm |

|

|

|||

|

|

|

|

|

|

|

|

|

|

||

5 |

Needle gauge |

|

|

|

8 gauge: 3.2 mm, total width: 6.4 mm |

|

|||||

|

|

|

9 gauge: 3.6 mm, total width: 7.2 mm |

|

|||||||

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|||

6 |

Stitch length |

|

|

2.1 to 3.6 mm (standard: 3.2 mm) at 1-inch intervals |

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

7 |

Needle (standard size) |

|

|

|

UY130GS (standard) (Caution 1) |

|

|

||||

|

|

|

|

|

|

|

|

|

|||

125 (#21) |

|

|

|

|

140 (#24) |

|

|

|

|||

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

8 |

Needle bar stroke |

|

|

|

|

33mm |

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

9 |

Number of threads |

|

|

|

|

6 pcs. |

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

10 |

External dimensions |

|

|

|

H : 420 x W : 285 x D : 345 mm |

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

11 |

Machine head weight |

|

|

|

|

23.5 kg |

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

12 |

Lifting amount of presser |

|

|

|

|

9mm |

|

|

|

10mm |

|

|

|

|

|

|

|

|

|

|

|

|

|

13 |

Feed roller width |

|

|

|

|

11.9mm |

|

|

|

14.9mm |

|

|

|

|

|

|

|

|

|

|

|

||

14 |

Feed roller shape |

Standard |

|

Inverted |

Standard |

|

Inverted |

Standard |

|||

(narrow type) |

|

(narrow type) |

(narrow type) |

|

(narrow type) |

(wide type) |

|||||

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|||

|

|

|

Main feed: Slide type stitch pitch adjusting system |

|

|||||||

15 |

Feed adjustment |

|

|

Differential feed |

|

|

|

Differential feed |

|||

lever adjusting system |

1 piece feed |

lever adjusting |

|||||||||

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

system |

|

|

|

|

|

|

|

|

|

|

|

||

16 |

Lubrication |

|

|

|

Automatic rotary pump lubrication system |

|

|||||

|

|

|

|

|

|

|

|

|

|

||

17 |

Lubricating oil |

|

|

|

Union Special Spec 175 (ISO grade 22) or |

|

|||||

|

|

|

|

JUKI OIL SUP2000-1L |

|

|

|||||

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

18 |

Oil tank capacity |

|

|

|

Front tank capacity: 70 to 80 ml |

|

|

||||

|

|

|

Rear tank capacity: 60 to 70 ml |

|

|

||||||

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

19 |

Installation |

|

|

|

|

Pedestal type |

|

|

|||

|

|

|

|

Table and auxiliary drive type |

|

|

|||||

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

20 |

Working temperature/ |

Temperature: 5 - 35°C, humidity: 35 - 85% (No dew condensation permissible) |

|||||||||

humidity ranges |

|||||||||||

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|||

21 |

Supply voltage/frequency |

|

|

|

|

Rated voltage ±10%, 50/60Hz |

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

(Caution 1) Please be aware that many customers use the needle of UY128GLS with the needle size of 125 (No. 21) in Japan and check the needle number at shipment.

– 1 –

(2) Roller mechanism/belt type

No. |

Model |

|

|

Specifications |

|

|

|||

|

Item |

35800BLW9 |

35800BQW8/9 |

35800BWDN8/9 |

35800BWDR8/9 |

35800BRWH9 |

35800BWW8/9 |

||

|

|

|

|

|

|

|

|

||

1 |

Stitch type |

|

3-needle, 6-thread, double chainstitch machine (401 LSc-3) |

|

|||||

|

|

|

|

|

|

|

|

|

|

2 |

Application |

|

Denim, working clothes, felt, etc. |

|

|

||||

|

|

|

|

|

|

|

|

|

|

3 |

Max. sewing speed |

|

|

4500rpm |

|

|

|||

|

|

|

|

|

|

|

|

|

|

4 |

Sewing speed |

|

|

3500rpm |

|

|

|||

|

|

|

|

|

|

|

|

||

5 |

Needle gauge |

|

8 gauge: 3.2 mm, total width: 6.4 mm |

|

|||||

|

9 gauge: 3.6 mm, total width: 7.2 mm |

|

|||||||

|

|

|

|

||||||

|

|

|

|

|

|

|

|

||

6 |

Stitch length |

|

2.1 to 3.6 mm (standard: 3.2 mm) at 1-inch intervals |

|

|||||

|

|

|

|

|

|

|

|

|

|

7 |

Needle (standard size) |

|

UY130GS (standard) (Caution 1) |

|

|

||||

|

|

|

|

|

|

|

|||

125 (#21) |

140 (#24) |

|

|

|

|||||

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

8 |

Needle bar stroke |

|

|

33mm |

|

|

|||

|

|

|

|

|

|

|

|

|

|

9 |

Number of threads |

|

|

6 pcs. |

|

|

|||

|

|

|

|

|

|

|

|

|

|

10 |

External dimensions |

|

H : 420 x W : 285 x D : 345 mm |

|

|

||||

|

|

|

|

|

|

|

|

|

|

11 |

Machine head weight |

|

|

23.5kg |

|

|

|||

|

|

|

|

|

|

|

|

|

|

12 |

Feed roller width |

|

|

14.9mm |

|

|

|||

|

|

|

|

|

|

|

|

|

|

13 |

Feed roller shape |

|

|

Standard |

|

Rubber |

Standard |

||

|

|

(wide type) |

|

(wide type) |

(wide type) |

||||

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

14 |

Lifting amount of presser |

|

|

9mm |

|

10mm |

|||

|

|

|

|

|

|

|

|

||

|

|

Main feed: Slide type stitch pitch adjusting system |

|

||||||

15 |

Feed adjustment |

Differential feed |

|

Differential feed |

|

|

|

||

lever adjusting |

1 piece feed |

lever adjusting |

|

|

1 piece feed |

|

|||

|

|

|

|

||||||

|

|

system |

|

system |

|

|

|

||

|

|

|

|

|

|

|

|

||

16 |

Lubrication |

|

Automatic rotary pump lubrication system |

|

|||||

|

|

|

|

|

|

|

|

||

17 |

Lubricating oil |

|

Union Special Spec 175 (ISO grade 22) or |

|

|||||

|

|

JUKI OIL SUP2000-1L |

|

|

|||||

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

18 |

Oil tank capacity |

|

Front tank capacity: 70 to 80 ml |

|

|

||||

|

Rear tank capacity: 60 to 70 ml |

|

|

||||||

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

19 |

Installation |

|

|

Pedestal type |

|

|

|||

|

|

Table and auxiliary drive type |

|

|

|||||

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

20 |

Working temperature/ |

Temperature: 5 - 35°C, humidity: 35 - 85% (No dew condensation permissible) |

|||||||

humidity ranges |

|||||||||

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

||||

21 |

Supply voltage/frequency |

|

Rated voltage ±10%, 50/60Hz |

|

|

||||

|

|

|

|

|

|

|

|

|

|

(Caution 1) Please be aware that many customers use the needle of UY128GLS with the needle size of 125 (No. 21) in Japan and check the needle number at shipment.

– 2 –

2. Model list

The standard model is the feed-off-the-arm 3-needle, double chainstitch machine for double lap seam

(1) Model list using the roller mechanism of the clutch type

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Needle |

Number of |

Needle gauge |

Number of |

Differential |

Lifting |

Upper puller |

Roller width |

Roller |

Optional roller |

Presser |

Unevenness |

Feed shape |

Standard |

Sewing |

Max. |

No. |

Model |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Application |

|

|

|

|

Number of needles |

threads |

8ga-3.2mm |

stitches (mm) |

amount |

|

shape |

|

width |

type folder |

speed |

sewing |

|||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3 pieces as |

6 pieces as |

8 stitches as |

motion |

of |

drive |

|

|

|

of throat |

(side view) |

|

speed |

|||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(front view) |

|

(rpm) |

||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

standard |

standard |

9ga-3.6mm |

standard |

|

presser |

|

|

|

|

plate |

|

|

(rpm) |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

1 |

35800DNU8 |

|

|

|

|

|

|

|

|

|

|

Double lap seam, hip overlapped seam |

|

|

|

|

130GS |

|

3.2+3.2 |

2.1 to 3.6mm |

|

|

|

|

Standard |

Inverted type |

|

|

|

|

|

|

|||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

6.4mm |

|

|

|

|

type narrow |

narrow roller |

|

|

|

23420 |

3500 |

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(Denim fabric of 10 to 14 oz.) |

|

|

|

|

|

Yes |

|

|

|

|

|

|

4500 |

||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(140) |

4-6 |

|

(at 1-inch intervals) |

9mm |

Clutch type |

11.9mm |

(35875AW) |

|

|

|

AY18-1/8 |

||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3.6+3.6 |

roller |

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||

2 |

35800DNU9 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Rubber type narrow |

Narrow |

2.4mm |

|

|

|

||||||||||

|

|

|

|

|

|

|

For medium-weight to heavy-weight materials |

|

|

|

|

2-3 |

|

7 to 12 stitches |

|

|

|

|

(35875AV) |

|

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

7.2mm |

|

|

|

|

|

roller (35826EF) |

|

|

|

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3 |

35800DZ32 |

|

|

|

|

|

|

|

|

|

|

Double lap seam, hip overlapped seam |

|

|

|

|

130GS |

|

3.2+3.2 |

2.1 to 3.6mm |

|

|

|

|

Inverted |

Standard type |

|

|

|

23420 |

|

|

|||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(Denim fabric of 10 to 14 oz.) |

|

|

|

|

4-6 |

6.4mm |

Yes |

9mm |

Clutch type |

11.9mm |

type narrow |

narrow roller |

|

|

|

3500 |

4500 |

||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(140) |

|

(at 1-inch intervals) |

(35875AV) |

|

|

|

AY18-1/8 |

|||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||

4 |

35800DZ36 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2-3 |

|

3.6+3.6 |

7 to 12 stitches |

|

|

|

|

roller |

Rubber type narrow |

Narrow |

2.4mm |

|

|

|

|

|

|

|

|

|

|

|

For medium-weight to heavy-weight materials |

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

7.2mm |

|

|

|

|

(35875AW) |

roller (35826EF) |

|

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5 |

35800DRU8 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Double lap seam |

|

|

|

|

130GS |

|

3.2+3.2 |

2.1 to 3.6mm |

|

|

|

|

Standard |

Inverted type |

|

|

|

|

|

|

|||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

6.4mm |

|

|

|

|

narrow roller |

|

|

|

23420 |

|

|

|||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Denim (denim fabric of 10 to 14 oz.) |

|

|

|

|

(140) |

4-6 |

(at 1-inch intervals) |

No |

9mm |

Clutch type |

|

type narrow |

|

|

|

3500 |

4500 |

||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

11.9mm |

(35875AW) |

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3.6+3.6 |

roller |

|

|

0.8 mm of |

AY18-1/8 |

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||

6 |

35800DRU9 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2-3 |

|

7 to 12 stitches |

|

|

|

|

Rubber type narrow |

Narrow |

2.4mm |

|

|

||||

|

|

|

|

|

|

|

For medium-weight to heavy-weight materials |

|

|

|

|

7.2mm |

|

|

|

|

(35875AV) |

roller (35826EF) |

unevenness |

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

7 |

35800PZ32 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Double lap seam |

|

|

|

|

130GS |

|

3.2+3.2 |

2.1 to 3.6mm |

|

|

|

|

Inverted |

Standard type |

|

|

|

23420 |

|

|

|||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Denim (denim fabric of 10 to 14 oz.) |

|

|

|

|

(140) |

4-6 |

6.4mm |

No |

9mm |

Clutch type |

11.9mm |

type narrow |

narrow roller |

|

|

|

3500 |

4500 |

|||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(at 1-inch intervals) |

(35875AV) |

|

|

|

AY18-1/8 |

||||||||||||||||||||||||||||||||||||||||||||||||||

8 |

35800PZ36 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2-3 |

|

3.6+3.6 |

7 to 12 stitches |

|

|

|

|

roller |

Rubber type narrow |

Narrow |

2.4mm |

0.8 mm of |

|

|

|

|

|

|

|

|

|

|

For medium-weight to heavy-weight materials |

|

|

|

|

|

|

7.2mm |

|

|

|

|

(35875AW) |

roller (35826EF) |

|

|

unevenness |

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

9 |

35800DWW8 |

|

|

|

Double lap seam/high throw feed eccentric mechanism |

|

|

|

|

130GS |

|

3.2+3.2 |

2.1 to 3.6mm |

|

|

|

|

Standard |

Inverted type wide |

|

|

|

23420 |

3500 |

4500 |

||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

Denim (denim fabric of 15 to 14 oz.), felt, etc. |

|

|

|

|

(140) |

4-6 |

6.4mm |

(at 1-inch intervals) |

Yes |

10mm |

Clutch type |

|

type wide |

roller (35826CB) |

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3.6+3.6 |

14.9mm |

roller |

Rubber type wide |

|

|

0.8 mm of |

AY18-1/8 |

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||

10 |

35800DWW9 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2-3 |

|

7 to 12 stitches |

|

|

|

|

roller (35826DZ) |

Wide |

2.4mm |

|

|

||||

|

|

|

|

|

|

For heavy-weight to extra-heavy-weight materials |

|

|

|

|

7.2mm |

|

|

|

|

(35826X) |

unevenness |

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||

(2) Model list using the roller mechanism of the belt type

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Needle |

Number of |

Needle gauge |

Number of |

|

Lifting |

|

Roller width |

Roller |

Optional roller |

Presser |

Unevenness |

Feed shape |

Standard |

Sewing |

Max. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Number of needles |

threads |

stitches (mm) |

Differential |

amount |

Upper puller |

|

shape |

|

type folder |

sewing |

|||||

No. |

Model |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Application |

3 pieces as |

6 pieces as |

8ga-3.2mm |

8 stitches as |

motion |

of |

drive |

|

|

|

width |

of throat |

(side view) |

|

speed |

speed |

||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

standard |

standard |

9ga-3.6mm |

standard |

|

presser |

|

|

|

|

(front view) |

plate |

|

|

(rpm) |

(rpm) |

1 |

35800BLW9 |

|

|

|

|

|

Double lap seam, denim (denim fabric of 6 to 9 oz.), |

130GS |

4-6 |

3.6+3.6 |

2.1 to 3.6mm |

Yes |

9mm |

Belt type |

14.9mm |

Standard |

Inverted type wide |

|

|

|

23420 |

3500 |

4500 |

|||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

working clothes, working pants, etc |

(125) |

(at 1-inch intervals) |

type narrow |

Rubber type wide |

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

roller (35826CB) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2-3 |

|

7.2mm |

7 to 12 stitches |

|

|

|

|

roller |

roller (35826DZ) |

Wide |

1.0mm |

|

AY18-1/8 |

|

|

|

|

|

|

|

|

|

|

|

|

For light-weight to medium-weight materials |

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(35826X) |

|

|

|

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2 |

35800BQW8 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Double lap seam, |

130GS |

|

3.2+3.2 |

2.1 to 3.6mm |

|

|

|

|

Standard |

Inverted type wide |

|

|

|

|

|

|

|||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

6.4mm |

|

|

|

|

type narrow |

roller (35826CB) |

|

|

|

23420 |

|

|

||||||||||||||||||||||||||||||||||||||||

|

|

denim (denim fabric of 6 to 9 oz.), jacket, working clothes, etc. |

(125) |

4-6 |

(at 1-inch intervals) |

No |

9mm |

Belt type |

14.9mm |

|

|

|

3500 |

4500 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3 |

35800BQW9 |

3.6+3.6 |

roller |

Rubber type wide |

|

1.0mm |

|

AY18-1/8 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2-3 |

|

7 to 12 stitches |

|

|

|

|

roller (35826DZ) |

Wide |

|

|

|

||||||

|

|

|

|

|

|

|

|

For light-weight to medium-weight materials |

|

|

|

|

|

(35826X) |

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

7.2mm |

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4 |

35800BWDN8 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Double lap seam, |

130GS |

|

3.2+3.2 |

2.1 to 3.6mm |

|

|

|

|

Standard |

Inverted type wide |

|

|

|

|

|

|

|||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

6.4mm |

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

denim (denim fabric of 10 to 14 oz.) |

(140) |

4-6 |

(at 1-inch intervals) |

Yes |

9mm |

Belt type |

14.9mm |

type narrow |

roller (35826CB) |

|

|

|

23420 |

3500 |

4500 |

|||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Rubber type wide |

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||

5 |

35800BWDN9 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2-3 |

|

3.6+3.6 |

7 to 12 stitches |

|

|

|

|

roller |

roller (35826DZ) |

Wide |

2.4mm |

|

AY18-1/8 |

|

|

|

|

|

|

|

|

|

For medium-weight to heavy-weight materials |

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

7.2mm |

|

|

|

|

(35826X) |

|

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

6 |

35800BWDR8 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Double lap seam, |

130GS |

|

3.2+3.2 |

2.1 to 3.6mm |

|

|

|

|

Inverted |

Inverted type wide |

|

|

|

|

|

|

|||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4-6 |

6.4mm |

No |

9mm |

Belth type |

|

type narrow |

roller (35826CB) |

|

|

|

23420 |

|

|

||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

denim (denim fabric of 10 to 14 oz.) |

(140) |

(at 1-inch intervals) |

14.9mm |

|

|

|

3500 |

4500 |

||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Rubber type wide |

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3.6+3.6 |

roller |

|

|

0.8 mm of |

||||||||||||||||||||||||||||||||||||||||||||||||||||||

7 |

35800BWDR9 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2-3 |

|

7 to 12 stitches |

|

|

|

|

roller (35826DZ) |

Wide |

2.4mm |

AY18-1/8 |

|

|

|||

|

|

|

|

|

|

|

For medium-weight to heavy-weight materials |

|

|

|

|

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

7.2mm |

|

|

|

|

|

(35875AW) |

|

|

|

unevenness |

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Double lap seam, |

130GS |

|

|

2.1 to 3.6mm |

|

|

|

|

Standard |

Standard type |

|

|

|

|

|

|

|||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3.6+3.6 |

|

|

|

|

type wide |

wide roller |

|

|

|

23420 |

|

|

||||||||||||||||||||||||||||||||||||||

8 |

35800BRWH9 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(denim fabric of 10 to 14 oz.) |

(140) |

4-6 |

(at 1-inch intervals) |

No |

9mm |

Belt type |

14.9mm |

(35826X) |

|

|

|

3500 |

4500 |

||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

7.2mm |

roller |

Wide |

2.4mm |

|

AY18-1/8 |

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2-3 |

|

7 to 12 stitches |

|

|

|

|

Rubber type wide |

|

|

|

|||||

|

|

|

|

|

|

|

|

|

For medium-weight to heavy-weight materials |

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(35826X) |

roller (35826CB) |

|

|

|

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

9 |

35800BWW8 |

|

|

|

Double lap seam/high throw feed eccentric mechanism |

130GS |

|

3.2+3.2 |

|

|

|

|

|

Standard |

Inverted type wide |

|

|

|

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

6.4mm |

2.1 to 3.6mm |

|

|

|

|

|

|

|

234-20 |

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

Denim (denim fabric of 15 to 14 oz.), felt, etc. |

(140) |

4-6 |

|

(at 1-inch intervals) |

No |

10mm |

Belt type |

14.9mm |

type narrow |

roller (35826CB) |

|

|

|

3500 |

4500 |

|||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

3.6+3.6 |

roller |

Rubber type wide |

|

|

0.8 mm of |

AY18-1/8 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

10 |

35800BWW9 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2-3 |

|

7 to 12 stitches |

|

|

|

|

Wide |

2.4mm |

|

|

|||||

|

|

|

|

|

|

For heavy-weight to extra-heavy-weight materials |

|

7.2mm |

|

|

|

|

(35826X) |

roller (35826DZ) |

unevenness |

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

* In regard to the JUKI part numbers, refer to [10. Maintenance-(1) Spare parts.]

– 3 –

MEMO

– 4 –

3. Description of US model code

Model name: Feed-off-the-arm, 3-Needle, Double Chainstitch Machine

1 |

2 |

3 |

4 |

5 |

6 |

|

7 |

8 |

9 |

10 |

11 |

|

||

3 |

5 |

8 |

0 |

0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Code |

Puller drive |

|

|

B |

Belt type |

|

|

D |

Clutch type (mechanical type) |

|

|

P |

Same as "D", only for PZ |

|

|

Code |

Classification of needle gauge |

|

|

8 |

3.2mm |

|

|

9 |

3.6mm |

|

|

32 |

3.2mm |

|

|

36 |

3.6mm |

|

|

|

|

|

|

Code |

Application and outline |

||

|

|

|

|

|

Differential feed mechanism/Double lap seam/For lightand medium- |

||

LW |

weight materials (denim fabric of 6 to 9 oz.)/1 mm of throat plate un- |

||

evenness/Standard type wide roller equipped/Denim, jacket, working |

|||

|

|||

|

clothes, etc. |

||

|

|

|

|

QW |

Same as above, but 1 piece feed mechanism |

||

|

|

|

|

|

Differential feed mechanism/Double lap seam/For mediumand heavy- |

||

WDN |

weight materials (denim fabric of 10 – 14 oz.)/2.4 mm of throat plate |

||

unevenness/Standard type wide roller equipped/Denim, jacket, work- |

|||

|

|||

|

ing clothes, etc. |

||

|

|

|

|

WDR |

Same as above, but 1 piece feed mechanism |

||

|

|

|

|

RWH |

Same as WDN, but rubber type wide roller equipped |

||

|

|

|

|

|

Differential feed mechanism/Double lap seam/For mediumand heavy- |

||

NU |

weight materials (denim fabric of 10 – 14 oz.)/2.4 mm of throat plate |

||

unevenness/Standard type narrow roller equipped/Denim, jacket, work- |

|||

|

|||

|

ing clothes, etc. |

||

|

|

|

|

RU |

Same as above, but 1 piece feed mechanism |

||

|

|

|

|

|

Differential feed mechanism/Double lap seam/For heavy-weight ma- |

||

WW |

terials (denim fabric of 15 – 16 oz.)/2.4 mm of throat plate uneven- |

||

|

ness/Standard type wide roller equipped/Denim, felt, etc. |

||

|

|

|

|

Z |

Same as DNU and DRU, but inverted type narrow roller equipped |

||

|

|

|

|

– 5 –

4. Description of model code

Machine name: Feed-off-the-arm, 3-needle, double chainstitch machine

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

11 |

12 |

13 |

14 |

15 |

|

|

|

|

|

|

||

3 5 |

8 |

0 |

0 |

|

|

|

|

|

– |

A |

A |

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

6 to 10 |

|

|

|

|

|

|

|

|

|

|

|

Name |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

Sewing material |

|

Stitch |

Needle |

|

Differential motion |

Puller drive |

Roller width |

Roller shape |

|

Unevenness |

||||||||

|

|

|

|

|

count |

gauge |

|

|

Yes |

No |

of throat plate |

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

BLW |

9 |

|

|

For lightand medium- |

|

3 |

3.6mm |

|

|

● |

|

|

|

|

|

|

|

|

|

|||

|

|

|

weight materials (6 to 9 oz.), |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

BQW |

8 |

|

|

3 |

3.2mm |

|

|

|

● |

Belt type |

14.9mm |

|

|

1.0mm |

||||||||

|

|

denim, working clothes, |

|

|

|

|

|

|

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

BQW |

9 |

|

|

|

3 |

3.6mm |

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

pants, etc. |

|

|

|

|

|

● |

|

|

|

|

|

|

|

|

|||||

BWDN 8 |

|

|

|

|

|

|

|

3 |

3.2mm |

|

|

● |

|

|

|

|

|

|

Steel gear |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

BWDN 9 |

|

|

|

|

|

|

|

3 |

3.6mm |

|

|

● |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

BWDR 8 |

|

|

|

|

|

|

|

3 |

3.2mm |

|

|

|

● |

Belt type |

14.9mm |

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

BWDR 9 |

|

|

|

|

|

|

|

3 |

3.6mm |

|

|

|

● |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

BRWH 9 |

|

|

|

|

|

|

|

3 |

3.6mm |

|

|

|

● |

|

|

|

|

|

Rubber roller |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

DNU |

8 |

|

|

For mediumand heavy- |

|

3 |

3.2mm |

|

|

● |

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

DNU |

9 |

|

|

|

3 |

3.6mm |

|

|

● |

|

|

|

|

|

|

|

|

|

||||

|