WINDSHIELD / WINDOWGLASS – POWER WINDOW CONTROL SYSTEM

BODYWINDSHIELD / WINDOWGLASS

POWER WINDOW CONTROL SYSTEM

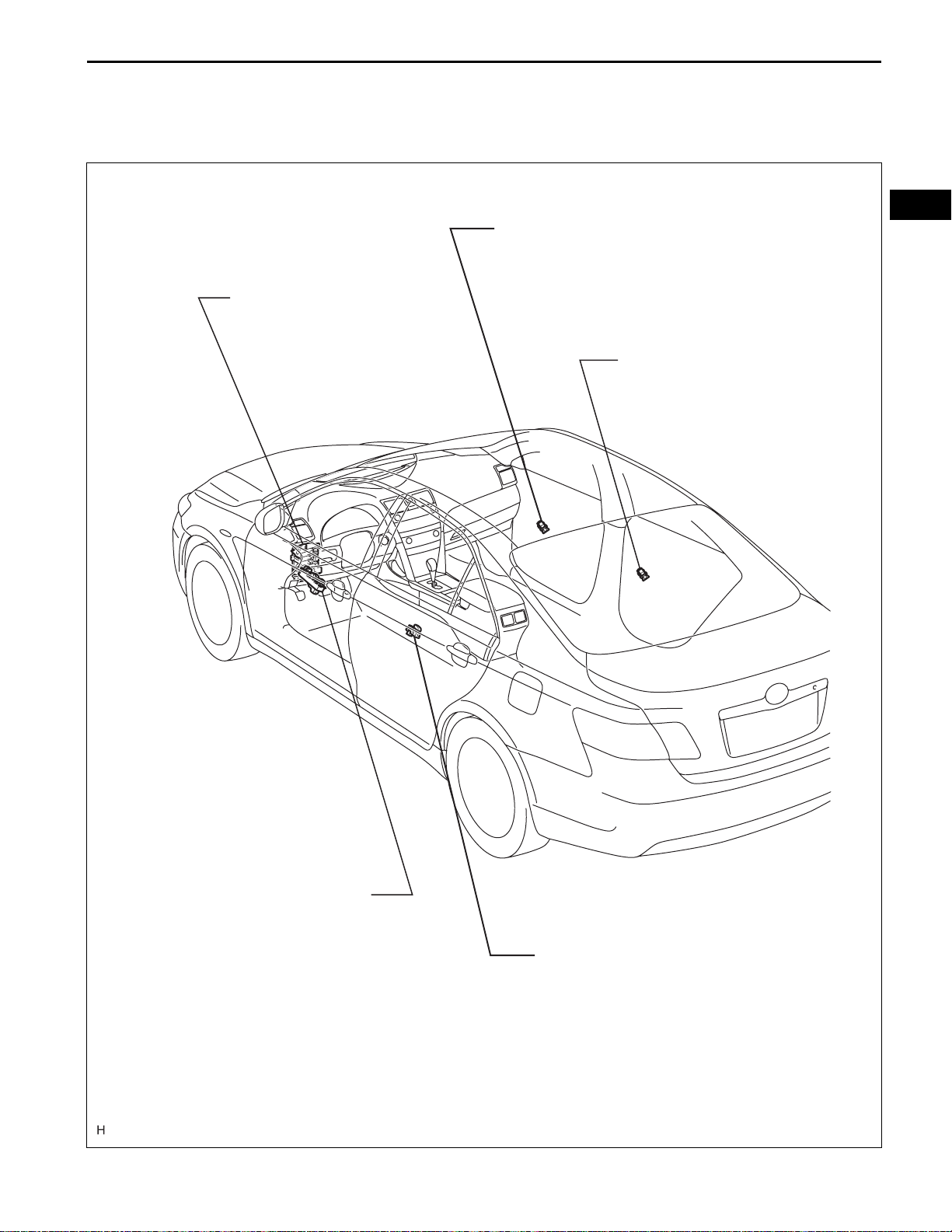

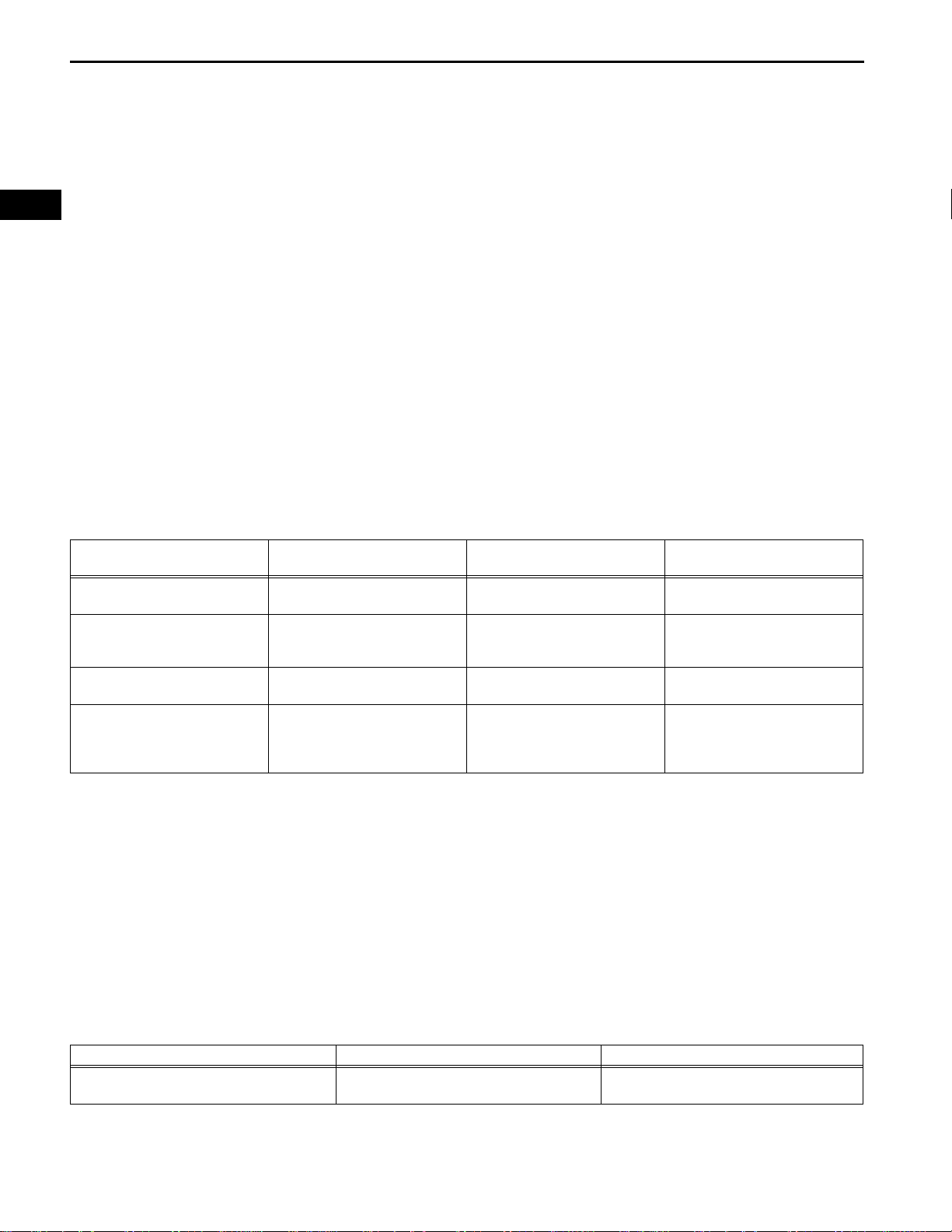

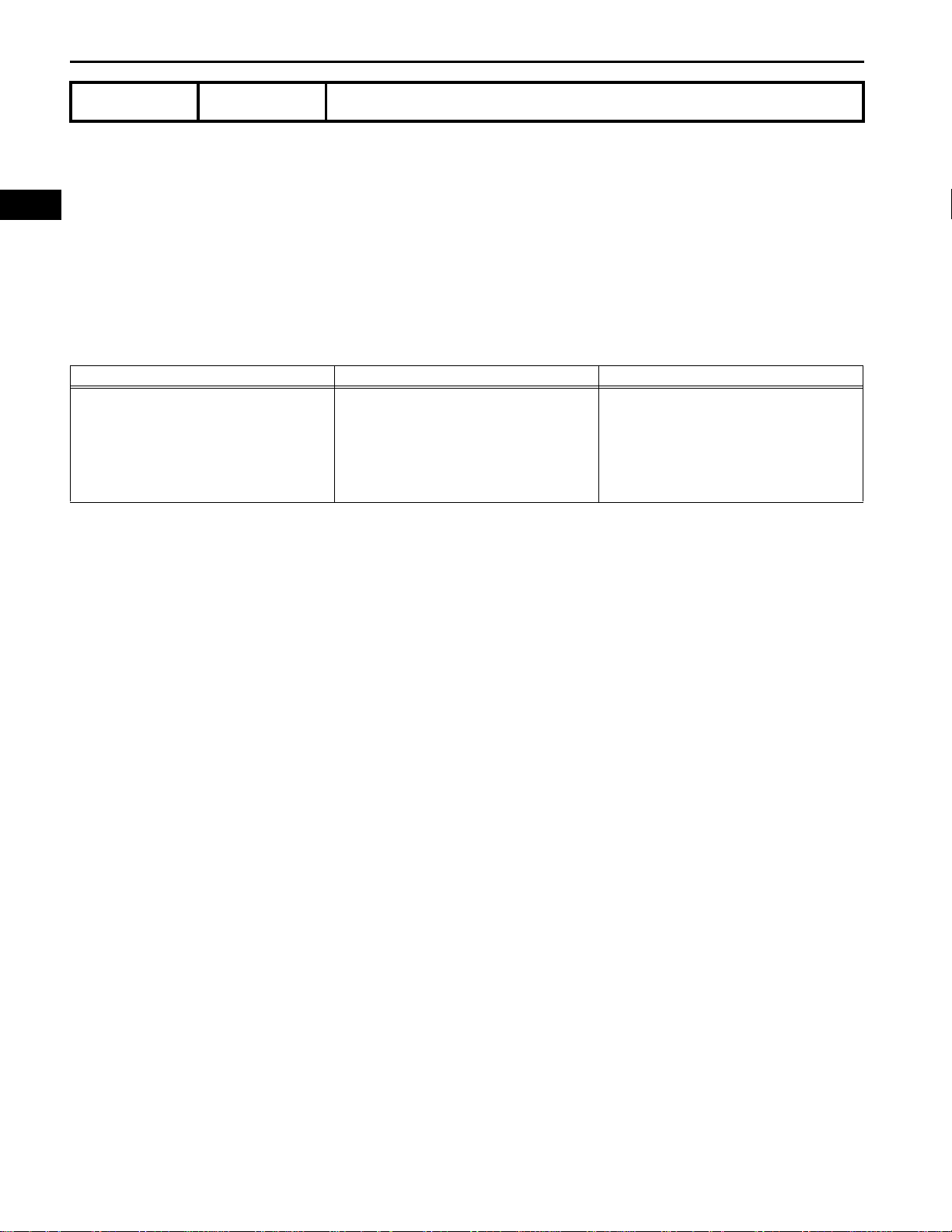

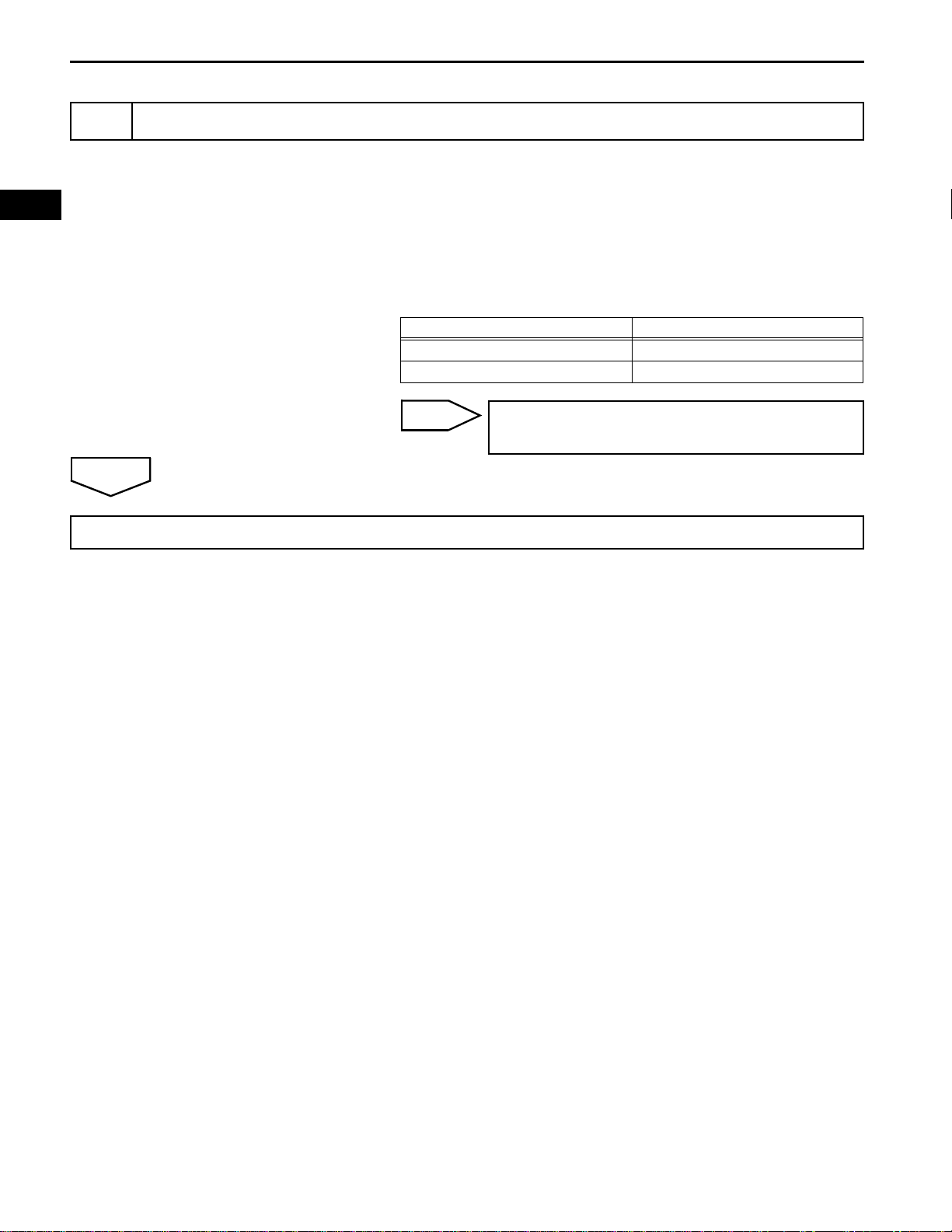

PARTS LOCATION

WS–1

MAIN BODY ECU

(INSTRUMENT PANEL J/B)

- POWER FUSE

- RR DOOR LH FUSE

- RR DOOR RH FUSE

POWER WINDOW REGULATOR

SWITCH ASSEMBLY (FRONT RH)

POWER WINDOW REGULATOR

SWITCH ASSEMBLY (REAR RH)

WS

POWER WINDOW REGULATOR

MASTER SWITCH ASSEMBLY

POWER WINDOW REGULATOR

SWITCH ASSEMBLY (REAR LH)

B137050E01

WS

WS–2

WINDSHIELD / WINDOWGLASS – POWER WINDOW CONTROL SYSTEM

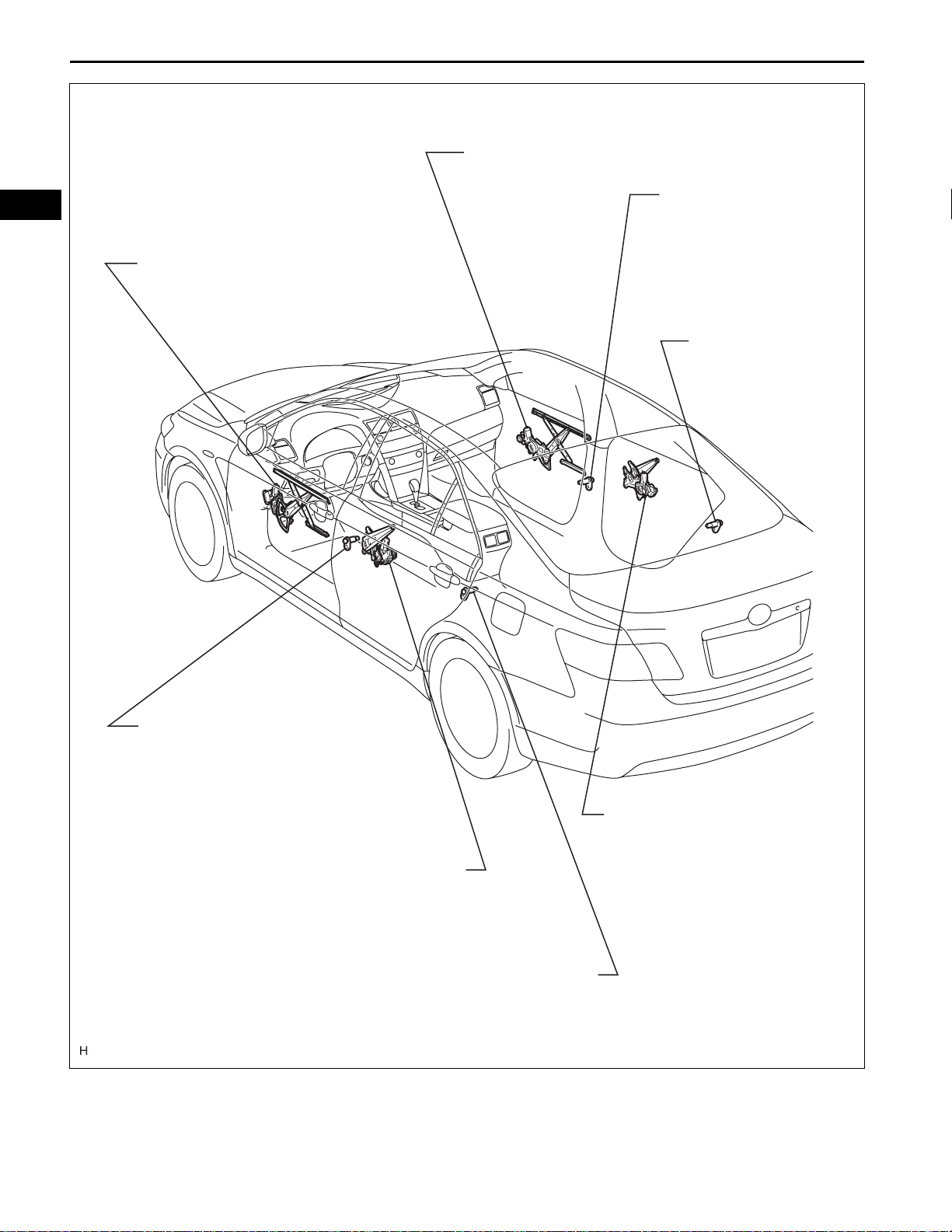

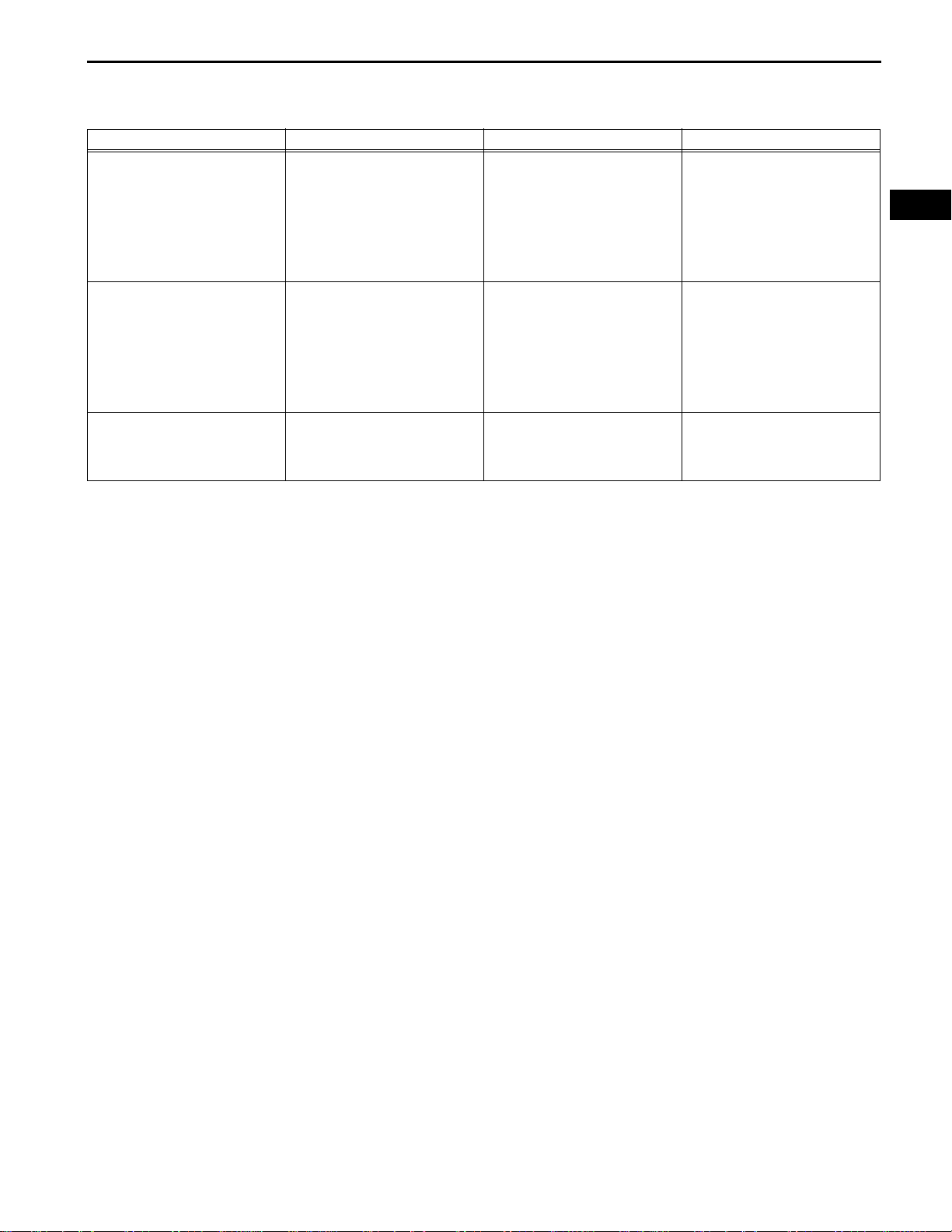

POWER WINDOW REGULATOR MOTOR

(FRONT RH)

DOOR COURTESY

SWITCH (FRONT RH)

POWER WINDOW REGULATOR

MOTOR

(FRONT LH)

DOOR COURTESY

SWITCH (REAR RH)

DOOR COURTESY

SWITCH (FRONT LH)

POWER WINDOW REGULATOR

MOTOR

(REAR LH)

POWER WINDOW REGULATOR

MOTOR

(REAR RH)

DOOR COURTESY

SWITCH (REAR LH)

B137082E01

WINDSHIELD / WINDOWGLASS – POWER WINDOW CONTROL SYSTEM

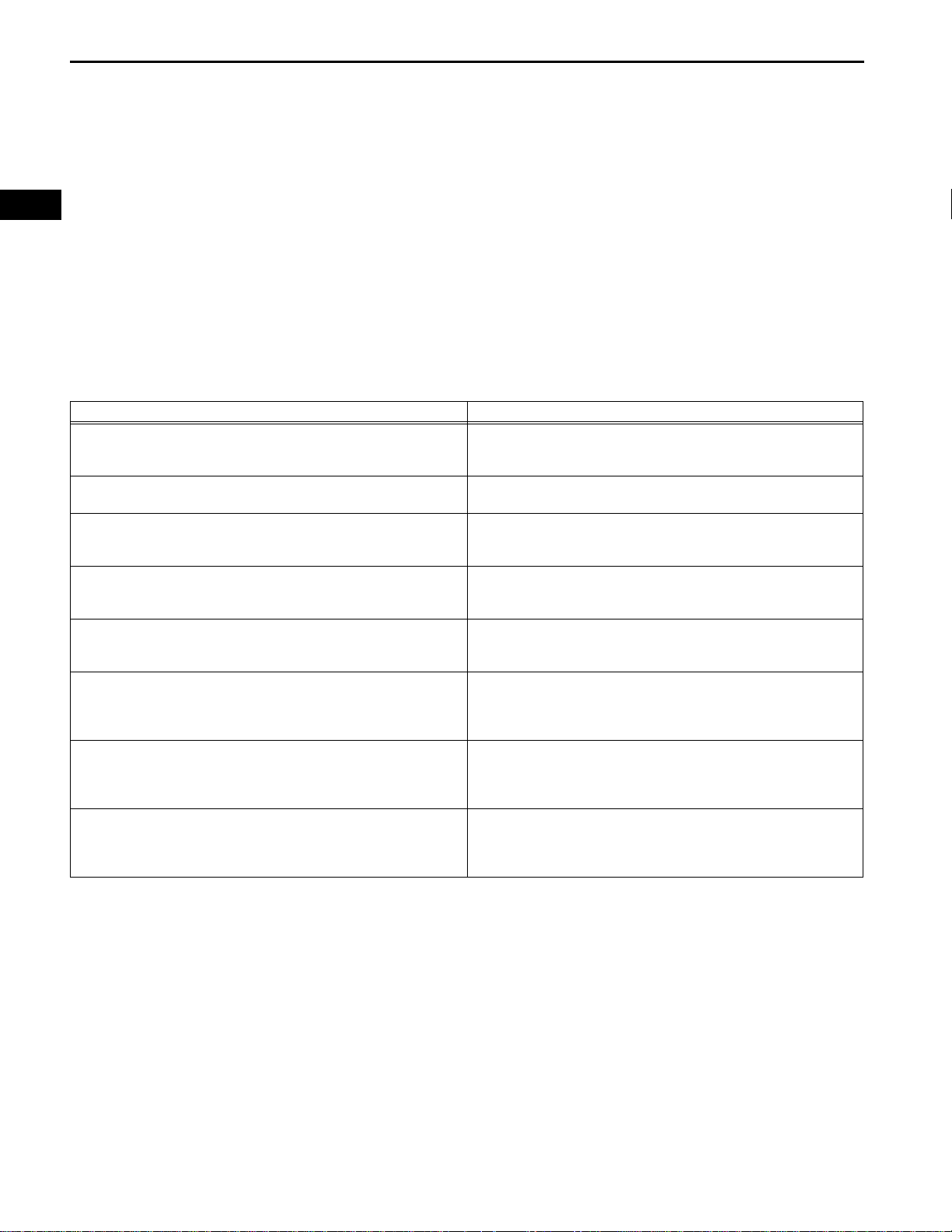

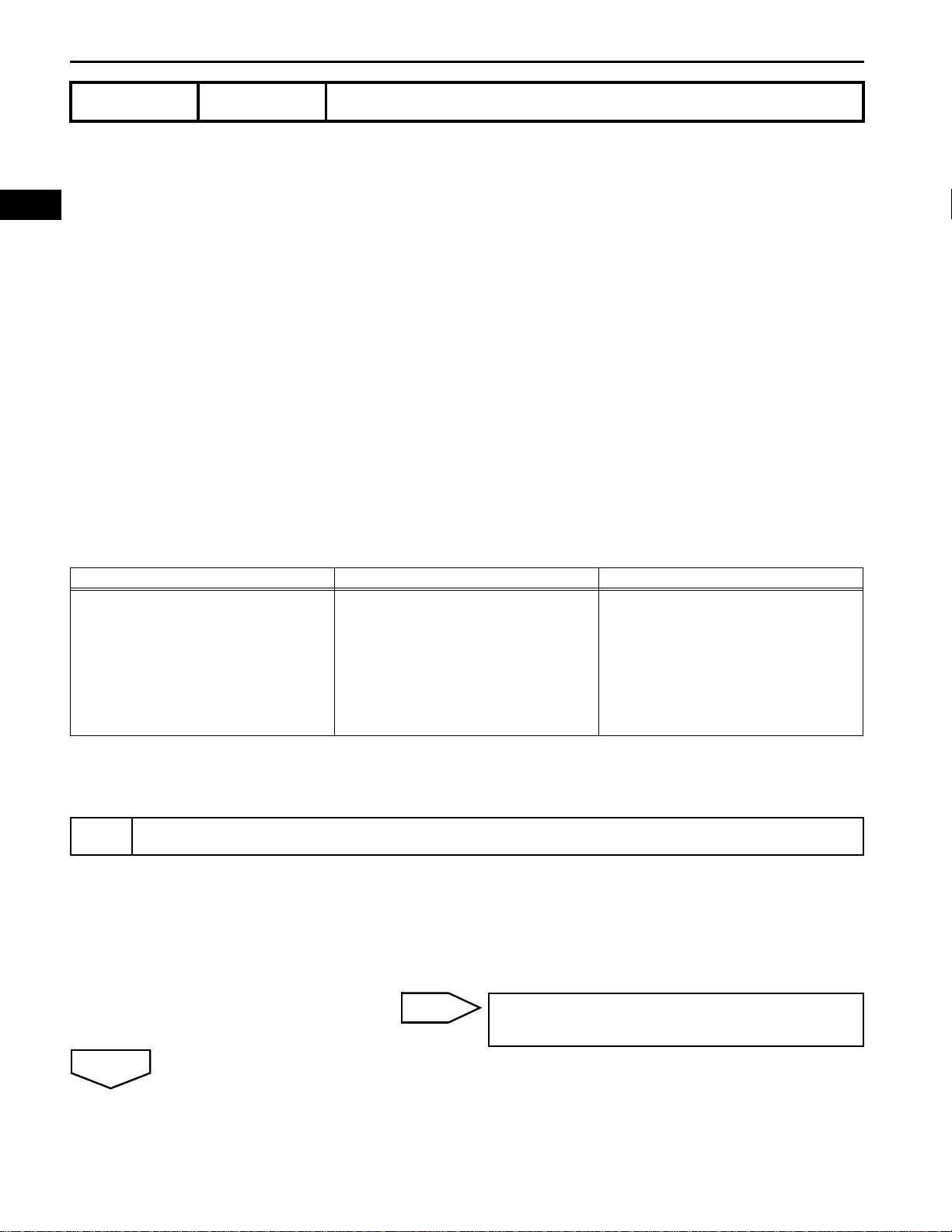

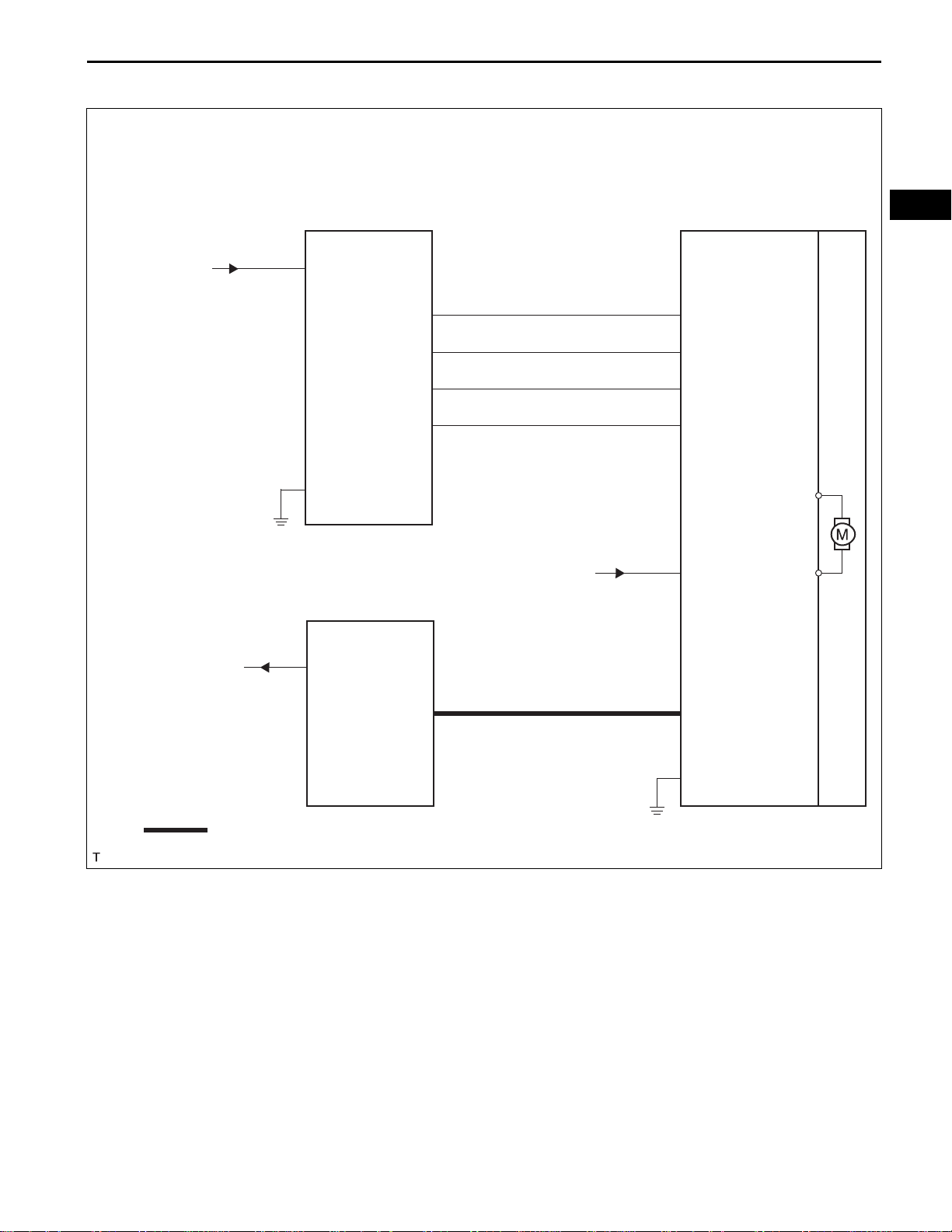

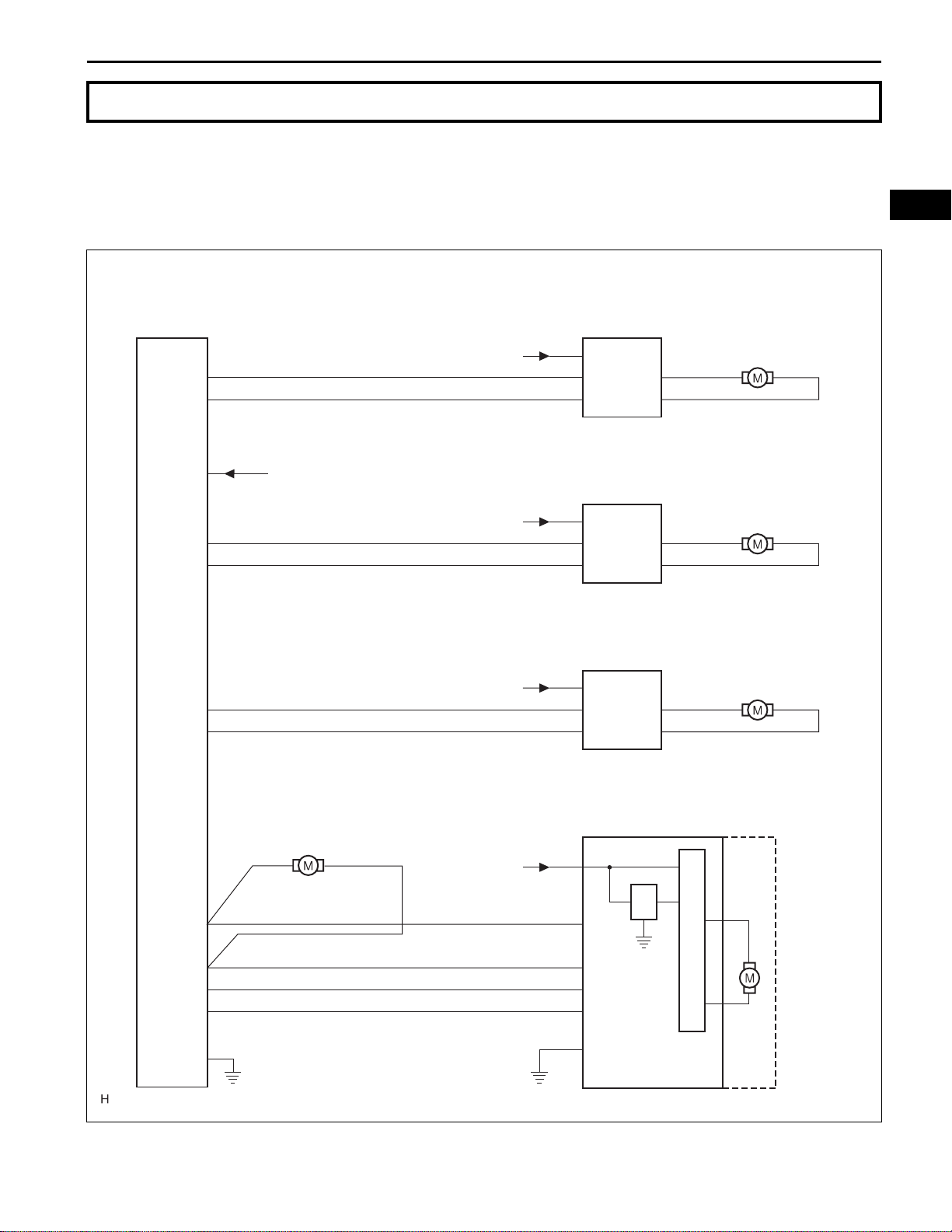

SYSTEM DIAGRAM

WS–3

Power Window Regulator

Master Switch Assembly

PU

PD

B

RRU

RRD

RLU

RLD

from POWER fuse

from RR DOOR RH fuse

from RR DOOR LH fuse

Power Window Regulator

Switch Assembly (Front RH)

from POWER fuse B

Power Window Regulator

Switch Assembly (Rear RH)

Power Window Regulator

Switch Assembly (Rear LH)

SU

SD

B

SU

SD

B

SU

SD

Power Window

Regulator Motor

WS

U

D

Power Window

Regulator Motor

U

D

Power Window

Regulator Motor

U

D

DN

UP

AUTO

E

LED

Main Body ECU

: LIN Communication Line

Power Window Regulator

Motor (Front LH)

from PWR fuse

(*1)

(*2)

(*1)

(*2)

(*2)

(*2)

*1: without Jam Protection

*2: with Jam Protection

(*2)

Power Window Regulator

Motor (Front LH)

B

(*2)

DWN1

UP1

AUTO

LED

LINLIN

E

(*2)

B137051E01

WS

WS–4

WINDSHIELD / WINDOWGLASS – POWER WINDOW CONTROL SYSTEM

SYSTEM DESCRIPTION

1. POWER WINDOW CONTROL SYSTEM

DESCRIPTION

(a) The power window control system controls the

power window operation using the power window

regulator motors. The main controls of this system

are the power window regulator master switch,

which is mounted on the driver side door, and the

power window regulator switches, which are

mounted on the passenger side door and rear

doors. Operating a window switch results in

electrical power being transmitted to the

corresponding power window regulator motor.

(b) The power window control system has the following

functions:

Function Outline

Function that causes window to go up while power window switch is

Manual up-and-down function

Driver's door auto up-and-down function *

Jam protection function

Remote control function

Key-off operation function

Key-linked up-and-down function

Diagnosis

Fail-safe

being pulled halfway up and to go down while pushed halfway down.

Window stops as soon as the switch is released.

Function that enables windows of driver's doors to be fully opened or

closed by one press of power window switch.

Function that automatically stops power window and moves it

downward if a foreign object gets jammed in door window during autoup operation.

Function that allows power window master switch to control MANUAL

up-and-down operations of front passenger door window and rear

door windows.

Function that makes it possible to operate power window for approx.

45 seconds after ignition switch is turned on (ACC) or off, if either front

door is not opened.

Function that causes window to go up while driver's door key is turned

to lock side for more than 1.5 seconds and to go down while turned to

unlock side for more than 1.5 seconds. Window stops as soon as the

key is returned to original position.

Function that allows the power window switch to make a diagnosis for

failed section when power window switch detects a malfunction in

power window system. Power window switch light comes on or blinks

to inform driver.

A fail-safe function to disable a part of power window functions if pulse

sensor in power window motor has a malfunction:

Driver's door auto up-and-down function and remote control function

are disabled.

*: with Jam Protection

1

NEXT

2

NEXT

3

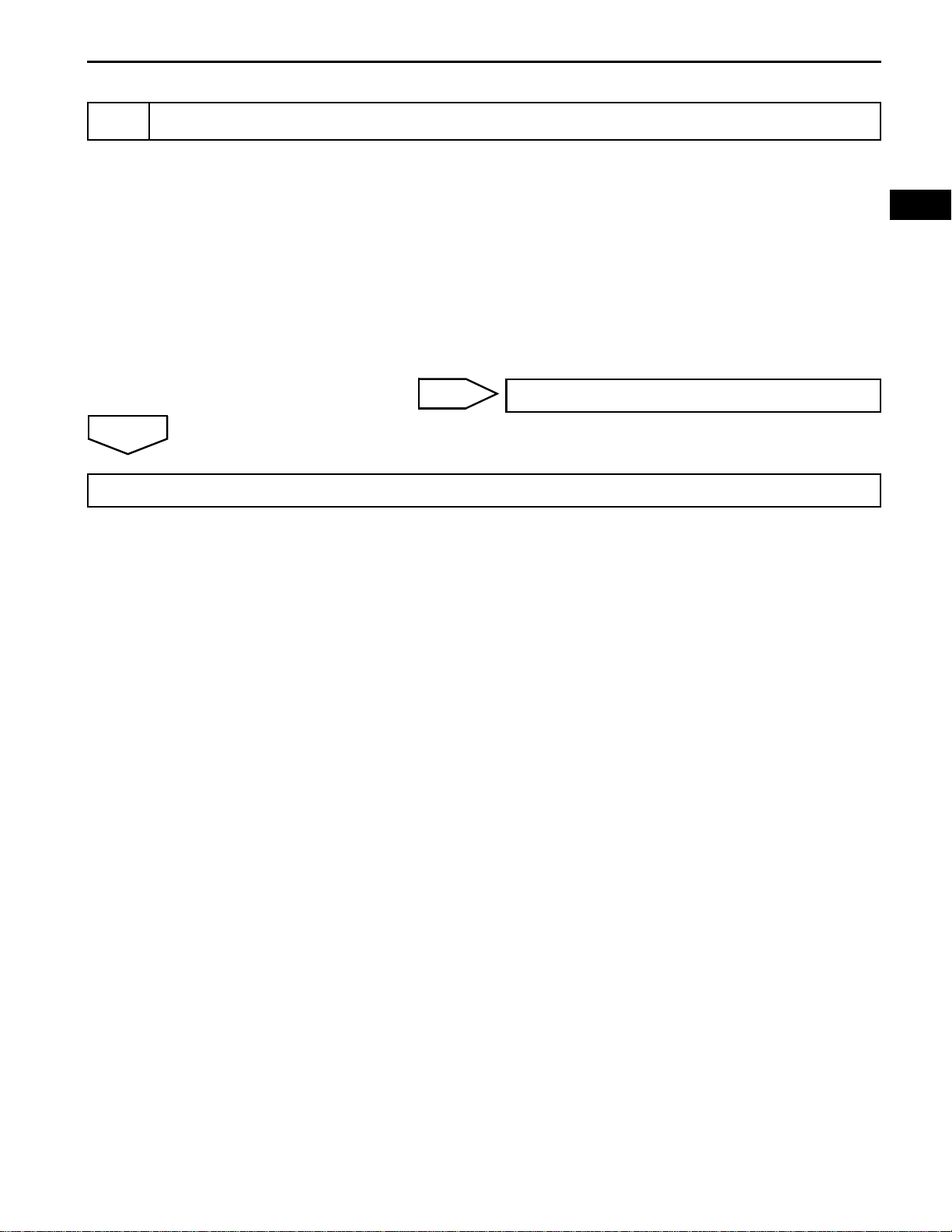

WINDSHIELD / WINDOWGLASS – POWER WINDOW CONTROL SYSTEM

HOW TO PROCEED WITH

TROUBLESHOOTING

HINT:

• Use the following procedure to troubleshoot the power

window control system.

• The intelligent tester should be used in steps 3 and 5.

VEHICLE BROUGHT TO WORKSHOP

CUSTOMER PROBLEM ANALYSIS CHECK AND SYMPTOM CHECK

CHECK COMMUNICATION FUNCTION OF LIN COMMUNICATION SYSTEM

WS–5

WS

A

4

NEXT

5

(a) Use the intelligent tester , inspect the LIN communication

function to ensure there are no malfunctions in the

communication system.

Result

Result Proceed to

No DTCs output A

DTCs output B

B

PROBLEM SYMPTOMS TABLE

HINT:

See page WS-9.

OVERALL ANALYSIS AND TROUBLESHOOTING

GO TO DIAGNOSIS TROUBLE CODE CHART

NEXT

(a) Data list/Active test

HINT:

See page WS-17.

(b) Circuit inspection

(c) Terminal of ECU

HINT:

See page WS-9.

WS

WS–6

6

NEXT

7

NEXT

END

Standard

WINDSHIELD / WINDOWGLASS – POWER WINDOW CONTROL SYSTEM

ADJUST, REPAIR OR REPLACE

RESET POWER WINDOW MOTOR

B140183

HINT:

See page WS-8.

OPERATION CHECK

1. CHECK WINDOW LOCK SWITCH

(a) Check that the front passenger side power window

and rear power windows operation are disabled

when the window lock switch of the power window

master switch is pressed.

Standard:

Front passenger side power window and rear

power windows operation are disabled.

(b) Check that the front passenger side power window

and rear power windows can be operated when the

window lock switch is pressed again.

Standard:

Front passenger side power window and rear

power windows can be operated.

2. CHECK MANUAL UP/DOWN FUNCTION

(a) Check that the driver side power window operates

as follows:

Condition Master Switch Switch Operation Power Window

Ignition switch on (IG) Driver side

Standard

Condition Switch Switch Operation Power Window

• Ignition switch on (IG)

• Window lock switch OFF

Passenger side

Rear LH

Rear RH

Pulled halfway up UP (Closed)

Pushed halfway down DOWN (Open)

(b) Check that the power windows except the driver

side power window operate as follows:

Pulled up UP (Closed)

Pushed down DOWN (Open)

Pulled up UP (Closed)

Pushed down DOWN (Open)

Pulled up UP (Closed)

Pushed down DOWN (Open)

WINDSHIELD / WINDOWGLASS – POWER WINDOW CONTROL SYSTEM

Standard

Condition Master Switch Switch Operation Power Window

Ignition switch on (IG) Driver side

Standard

Condition Master Switch Switch Operation Power Window

• Ignition switch on (IG)

• Window lock switch OFF

Passenger side

Rear LH

Rear RH

WS–7

3. CHECK AUTO UP/DOWN FUNCTION

(a) Check that the driver side power window operates

as follows:

Pulled up fully UP (Closed)

Pushed down fully DOWN (Open)

4. CHECK REMOTE MANUAL UP/DOWN FUNCTION

(a) Check that the power windows except the driver

side power window operate as follows:

Pulled up UP (Closed)

Pushed down DOWN (Open)

Pulled up UP (Closed)

Pushed down DOWN (Open)

Pulled up UP (Closed)

Pushed down DOWN (Open)

WS

Check Jig

B051853E05

5. CHECK JAM PROTECTION FUNCTION

NOTICE:

• The jam protection function can activate when

either the AUTO UP function or MANUAL UP

function is used.

• Limbs, fingers or other body parts should not be

used to test the jam protection function. Do not

allow any body parts to get caught by the moving

window or regulator.

HINT:

The jam protection function can activate when either the

AUTO UP function or MANUAL UP function are used

with the ignition switch ON. The jam protection function

can also activate as long as the driver's door remains

closed, within 45 seconds after the ignition switch is

turned off.

(a) Check the reversing distance.

(1) Fully open the door glass.

(2) Place a check jig measuring 4 to 10 mm (0.16 to

0.40 in.) thick near the window fully closed

position.

(3) When the door glass is closed using AUTO or

MANUAL operation, check that the door glass

goes down after contacting the check jig. The

glass should go 200 to 240 mm (7.90 to 9.44 in.)

away from the position where it contacted the

check jig.

(4) While the door glass is going down, verify that

the window switch can not be used to make the

glass go up.

(b) Check the reversing distance.

(1) Fully open the door glass.

WS

WS–8

WINDSHIELD / WINDOWGLASS – POWER WINDOW CONTROL SYSTEM

(2) Place a check jig measuring 200 to 250 mm

(7.90 to 9.84 in.) thick near the window fully

closed position.

(3) When the door glass is closed using AUTO or

MANUAL operation, check that the door glass

goes down after contacting the check jig. The

door glass should go 80 to 100 mm away from

the position where it contacted the check jig.

(4) While the door glass is going down, verify that

the window switch can not be used to make the

glass go up.

WINDSHIELD / WINDOWGLASS – POWER WINDOW CONTROL SYSTEM

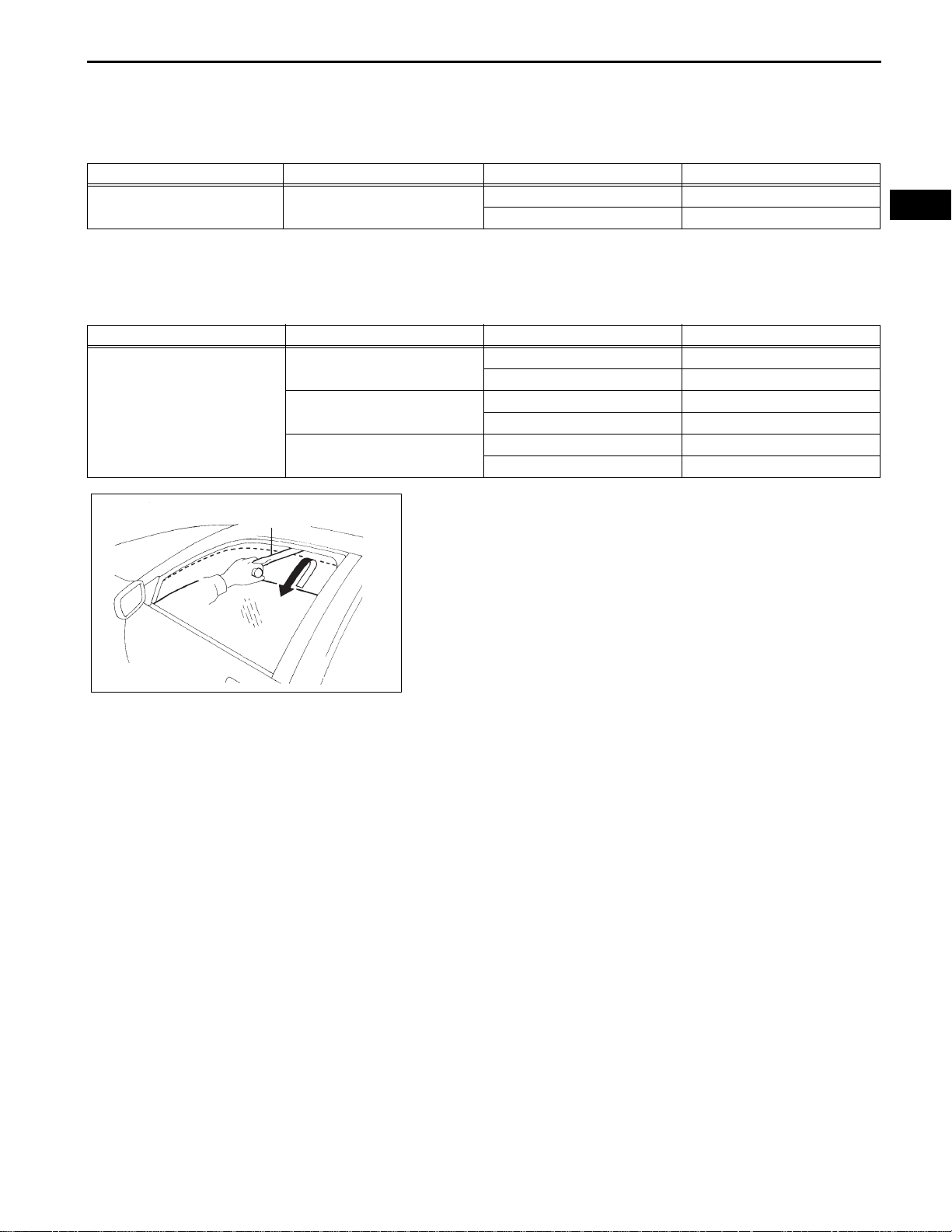

INITIALIZATION

1. INITIALIZE POWER WINDOW REGULATOR MOTOR

FRONT LH (WITH JAM PROTECTION)

NOTICE:

• If the power window motor or power window

regulator assembly is replaced, initialization is

required (initialization is not necessary when the

negative battery terminal is disconnected and

reconnected).

• No other electrical systems should be operated

during initialization. Initialization will be

interrupted if a voltage drop occurs in the power

being supplied to the power window motor.

• Replacing the door glass or door glass run may

cause a difference to exist between the current

door glass position and the position memorized

in the ECU. In this case, the jam protection

function may work improperly. Return the system

to the pre-initialized condition and reinitialize the

system.

HINT:

• The AUTO UP function will not work unless

initialization is completed.

• The indicator on the power window master switch will

blink when the ignition switch is ON, until initialization

has been completed. The indicator will remain on

after initialization is successfully completed.

(a) Connect the negative battery terminal.

(b) Turn the ignition switch on (IG). The ind icator on the

power window master switch will blink.

(c) Fully close the door glass by operating the power

window master switch. After the door glass stops,

hold the power window master switch in the AUTO

UP position for 1 second or more.

(d) Check that the indicator on the power window

master switch remains on.

HINT:

If the indicator does not remain on, this means that

initialization has not been completed successfully . In

this case, lower the door glass at least 50 mm (1.96

in.) and hold the power window master switch in the

AUTO UP position for 1 second after the window

closes fully.

2. TO RETURN THE SYSTEM TO THE PRE-INITIALIZES

CONDITION

Disconnect the power window regulator motor connector

during power window operation. This will return the

motor to the pre-initialized condition.

WS–9

WS

WS

WS–10

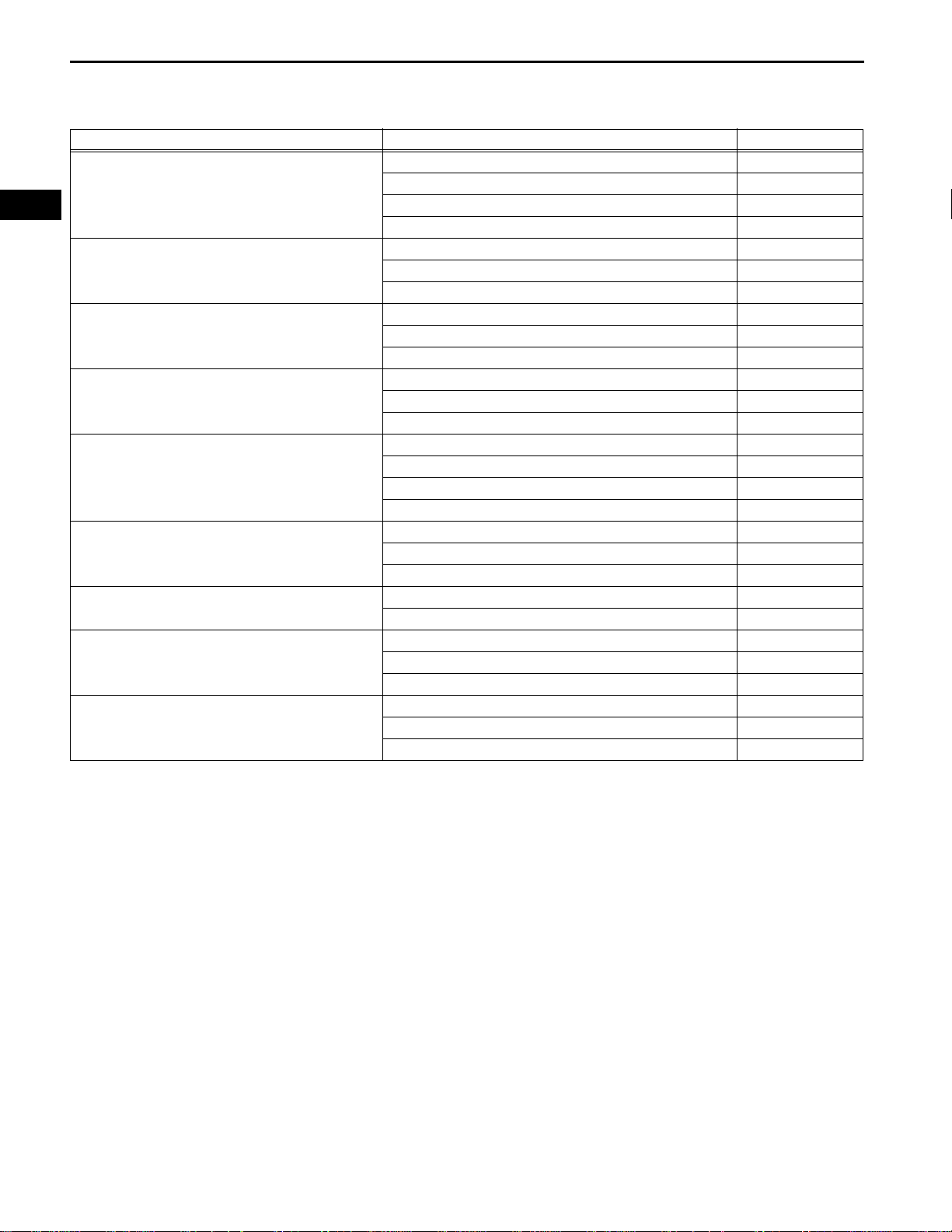

WINDSHIELD / WINDOWGLASS – POWER WINDOW CONTROL SYSTEM

POWER WINDOW CONTROL SYSTEM

Symptom Suspected area See page

Power window does not operate with power window

regulator master switch

Front passenger side power window does not operate

with power window regulator switch

Rear LH side power window does not operate with

power window regulator switch

Rear RH side power window does not operate with

power window regulator switch

AUTO UP/DOWN function does not operate on driver

side (Only jam protection assistant)

Remote UP/DOWN function does not operate

Power window can be operated after ignition switch is

turned off even if operated conditions are not met

AUTO UP operation does not fully close power window

(Jam protection function is activated)

AUTO DOWN function does not operate on driver side

(only DOWN AUTO)

PROBLEM SYMPTOMS TABLE

1. PWR, POWER, RR DOOR LH/RH fuses -

2. Power window master switch circuit (power source) WS-26

3. Power window regulator motor circuit WS-33

4. Power window regulator master switch -

1. Power window master switch circuit (power source) -

2. Power window regulator motor circuit (front passenger side) WS-36

3. Power window regulator switch (front LH side) WS-30

1. Power window regulator switch circuit (power source) -

2. Power window regulator motor circuit (rear LH side) WS-38

3. Power window regulator switch (rear LH side) WS-31

1. Power window regulator switch circuit (power source) -

2. Power window regulator motor circuit (rear RH side) WS-40

3. Power window regulator switch (rear RH side) WS-32

1. Diagnosis check WS-14

2. Power window regulator motor reset WS-8

3. Power window regulator master switch -

4. Wire harness -

1. DATA LIST/ACTIVE TEST WS-17

2. Power window regulator master switch -

3. Wire harness -

1. Front door courtesy switch LI-109

2. Wire harness (LIN communication line) -

1. Power window regulator motor reset WS-8

2. Check & clean glass run -

3. Power window regulator master switch -

1. Power window regulator master switch -

2. Power window regulator motor circuit (driver side) WS-33

3. Wire harness -

WINDSHIELD / WINDOWGLASS – POWER WINDOW CONTROL SYSTEM

WS–11

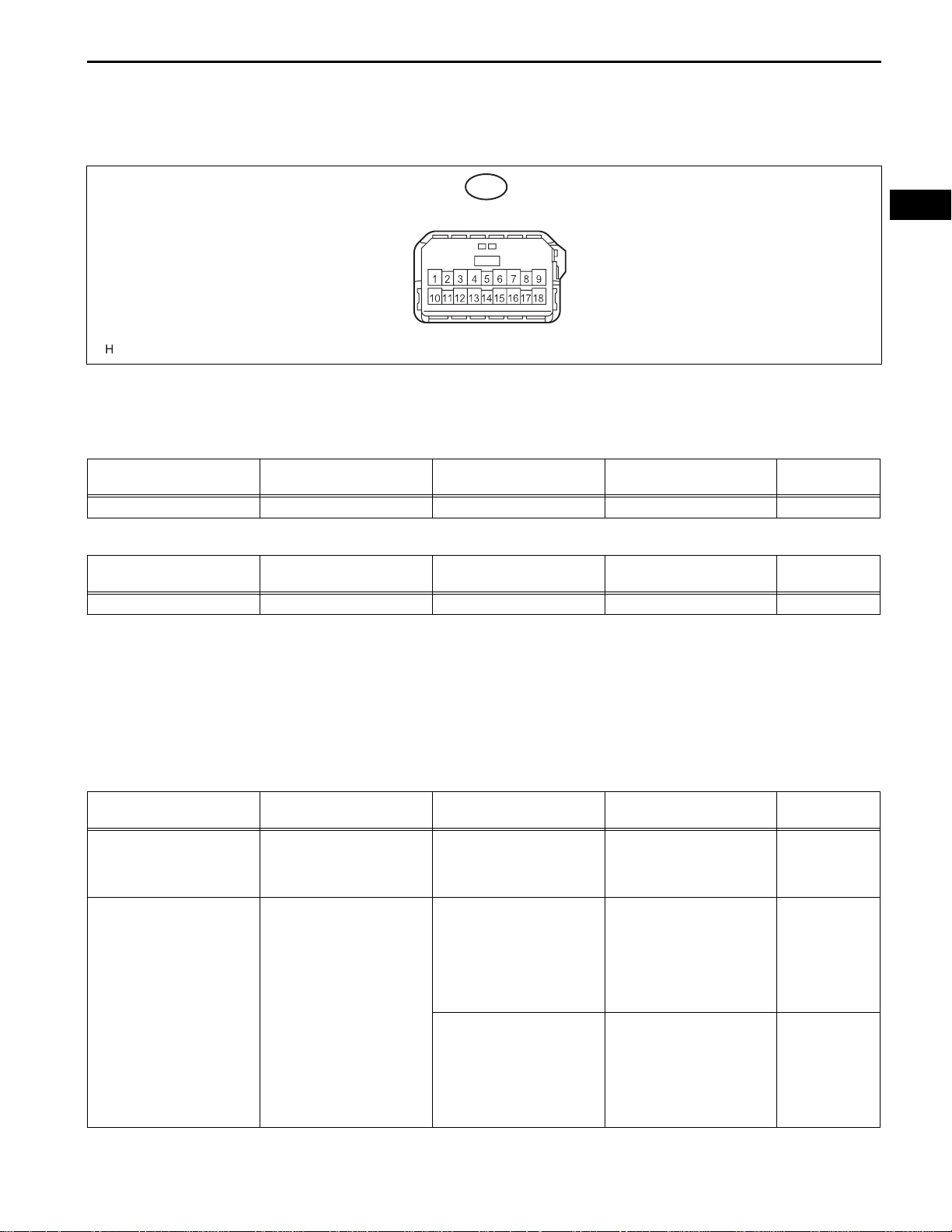

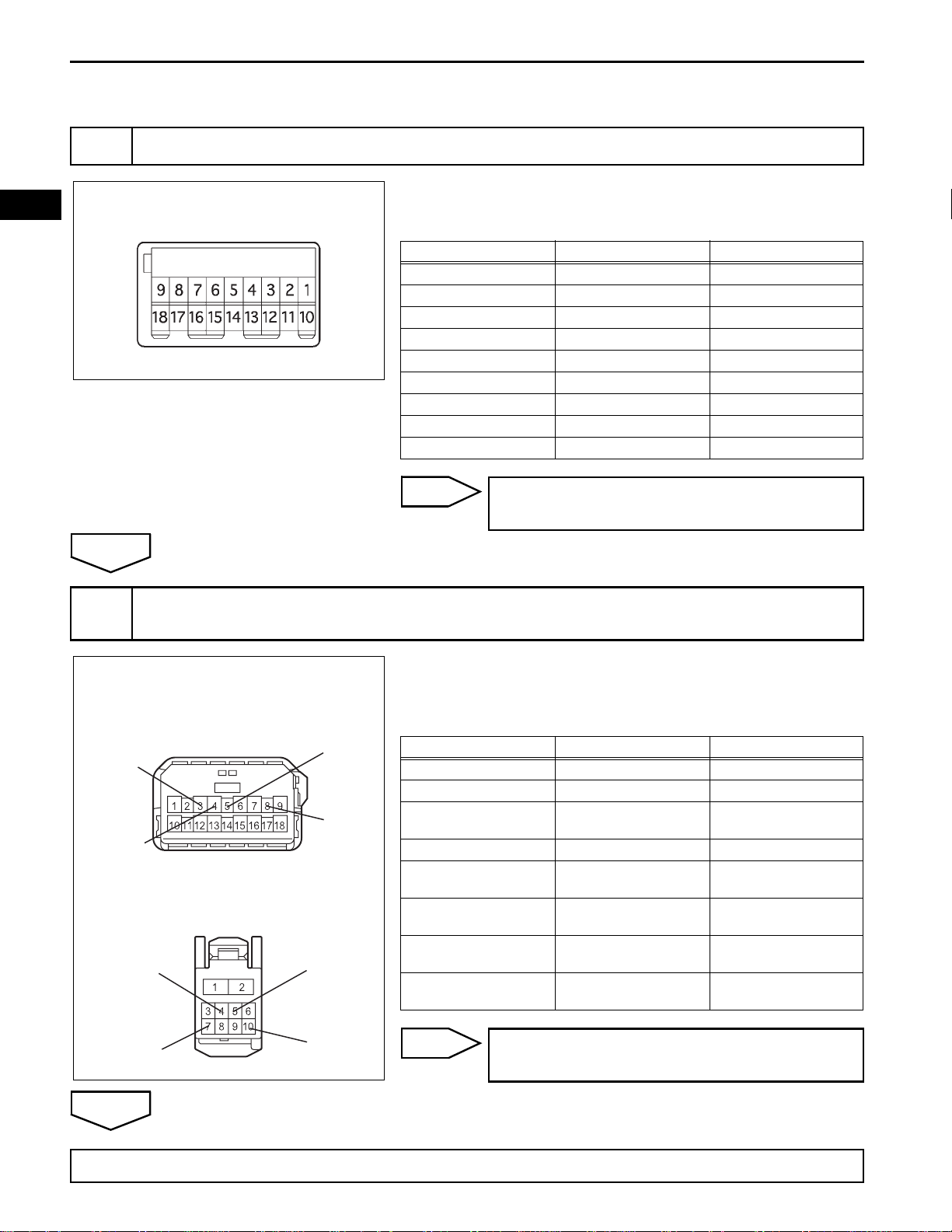

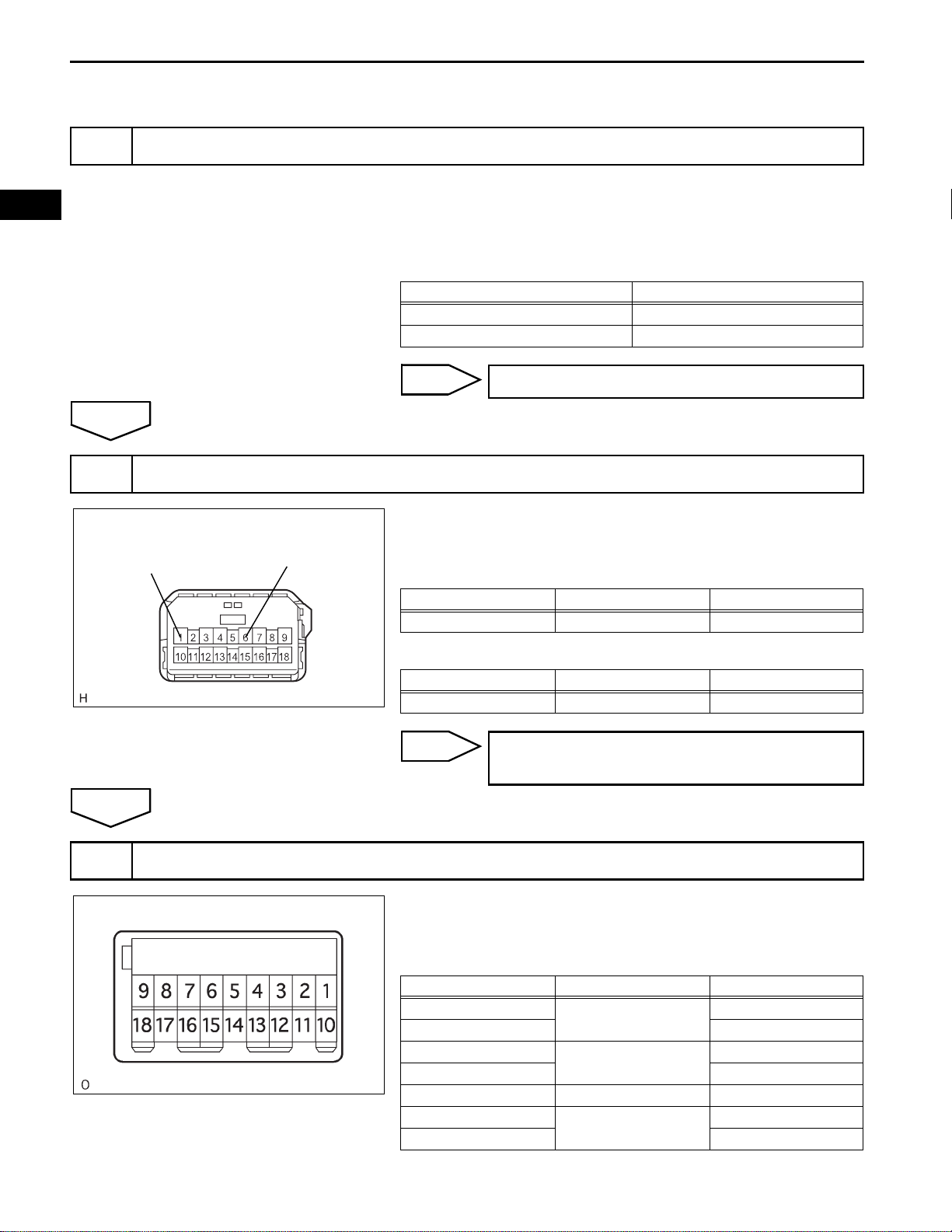

TERMINALS OF ECU

1. POWER WINDOW REGULATOR MASTER SWITCH

ASSEMBLY

M1

B137056E01

(a) Disconnect the M1 switch connector.

(b) Measure the voltage and resistance of each

terminal according to the value(s) in the table below.

Standard resistance

Symbols (Terminal No.) Wiring Color Terminal Description Condition

E (M1-1) - Body ground W-B - Body ground Ground Always Below 1 Ω

Specified

Condition

WS

Standard voltage

Symbols (Terminal No.) Wiring Color Terminal Description Condition

B (M1-6) - E (M1-1) GR - W-B Power supply Ignition switch on (IG) 10 to 14 V

Specified

Condition

If the result is not as specified, there may be a

malfunction in the wire harness.

(c) Reconnect the M1 switch connector and reset the

power window motor.

(d) Measure the voltage according to the value(s) in the

table below.

Standard voltage:

with Jam protection

Symbols (Terminal No.) Wiring Color Terminal Description Condition

Ignition switch on (IG),

UP (M1-8) - E (M1-1) G - W-B

AUTO (M1-4) - E (M1-1) B - W-B

Power window motor UP

output

Power window motor

AUTO UP output

Power window motor

AUTO DOWN output

driver side power window

switch OFF → UP (Manual

operation)

Ignition switch on (IG),

driver side power window

fully open → driver side

power window switch UP

(AUTO UP position) →

driver side power window

fully closed

Ignition switch on (IG),

driver side power window

fully closed → driver side

power window switch

DOWN (AUTO UP position)

→ driver side power

window fully open

Specified

Condition

10 to 14 V → 0

V

10 to 14 V → 0

V → 10 to 14 V

10 to 14 V → 0

V → 10 to 14 V

WS–12

WINDSHIELD / WINDOWGLASS – POWER WINDOW CONTROL SYSTEM

WS

Symbols (Terminal No.) Wiring Color Terminal Description Condition

Ignition switch on (IG),

DN (M1-5) - E (M1-1) R - W-B

PU (M1-16) - E (M1-1) W - W-B

PD (M1-15) - E (M1-1) R - W-B

RLU (M1-12) - E (M1-1) L - W-B

RLD (M1-13) - E (M1-1) B - W-B

RRU (M1-10) - E (M1-1) Y - W-B

RRD (M1-18) - E (M1-1) LG - W-B

Power window motor

DOWN output

Power window motor UP

output

Power window motor

DOWN output

Power window motor UP

output

Power window motor

DOWN output

Power window motor UP

output

Power window motor

DOWN output

driver side power window

switch OFF → DOWN

(Manual operation)

Ignition switch on (IG),

front passenger side

power window switch OFF

→ UP (Manual operation)

Ignition switch on (IG),

front passenger side

power window switch OFF

→ DOWN (Manual

operation)

Ignition switch on (IG), rear

LH side power window

switch OFF → UP (Manual

operation)

Ignition switch on (IG), rear

LH side power window

switch OFF → UP (Manual

operation)

Ignition switch on (IG), rear

RH side power window

switch OFF → UP (Manual

operation)

Ignition switch on (IG), rear

RH side power window

switch OFF → UP (Manual

operation)

Specified

Condition

10 to 14 V → 0

V

0 V → 10 to 14

V

0 V → 10 to 14

V

0 V → 10 to 14

V

0 V → 10 to 14

V

0 V → 10 to 14

V

0 V → 10 to 14

V

without Jam protection

Symbols (Terminal No.) Wiring Color Terminal Description Condition

Ignition switch on (IG),

UP (M1-3) - E (M1-1) G - W-B

DN (M1-4) - E (M1-1) G - W-B

PU (M1-16) - E (M1-1) W - W-B

PD (M1-15) - E (M1-1) R - W-B

RLU (M1-12) - E (M1-1) L - W-B

Power window motor UP

output

Power window motor

DOWN output

Power window motor

AUTO DOWN output

Power window motor UP

output

Power window motor

DOWN output

Power window motor UP

output

driver side power window

switch OFF → UP (Manual

operation)

Ignition switch on (IG),

driver side power window

switch OFF → DOWN

(Manual operation)

Ignition switch on (IG),

driver side power window

fully closed → driver side

power window switch

DOWN (AUTO operation)

→ driver side power

window fully open

Ignition switch on (IG),

front passenger side

power window switch OFF

→ UP (Manual operation)

Ignition switch on (IG),

front passenger side

power window switch OFF

→ DOWN (Manual

operation)

Ignition switch on (IG), rear

LH side power window

switch OFF → UP (Manual

operation)

Specified

Condition

0 V → 10 to 14

V

0 V → 10 to 14

V

10 to 14 V → 0

V → 10 to 14 V

0 V → 10 to 14

V

0 V → 10 to 14

V

0 V → 10 to 14

V

WINDSHIELD / WINDOWGLASS – POWER WINDOW CONTROL SYSTEM

WS–13

Symbols (Terminal No.) Wiring Color Terminal Description Condition

Ignition switch on (IG), rear

RLD (M1-13) - E (M1-1) B - W-B

RRU (M1-10) - E (M1-1) Y - W-B

RRD (M1-18) - E (M1-1) LG - W-B

Power window motor

DOWN output

Power window motor UP

output

Power window motor

DOWN output

LH side power window

switch OFF → DOWN

(Manual operation)

Ignition switch on (IG), rear

RH side power window

switch OFF → UP (Manual

operation)

Ignition switch on (IG), rear

RH side power window

switch OFF → DOWN

(Manual operation)

If the result is not as specified, there may be a

malfunction in the wire harness.

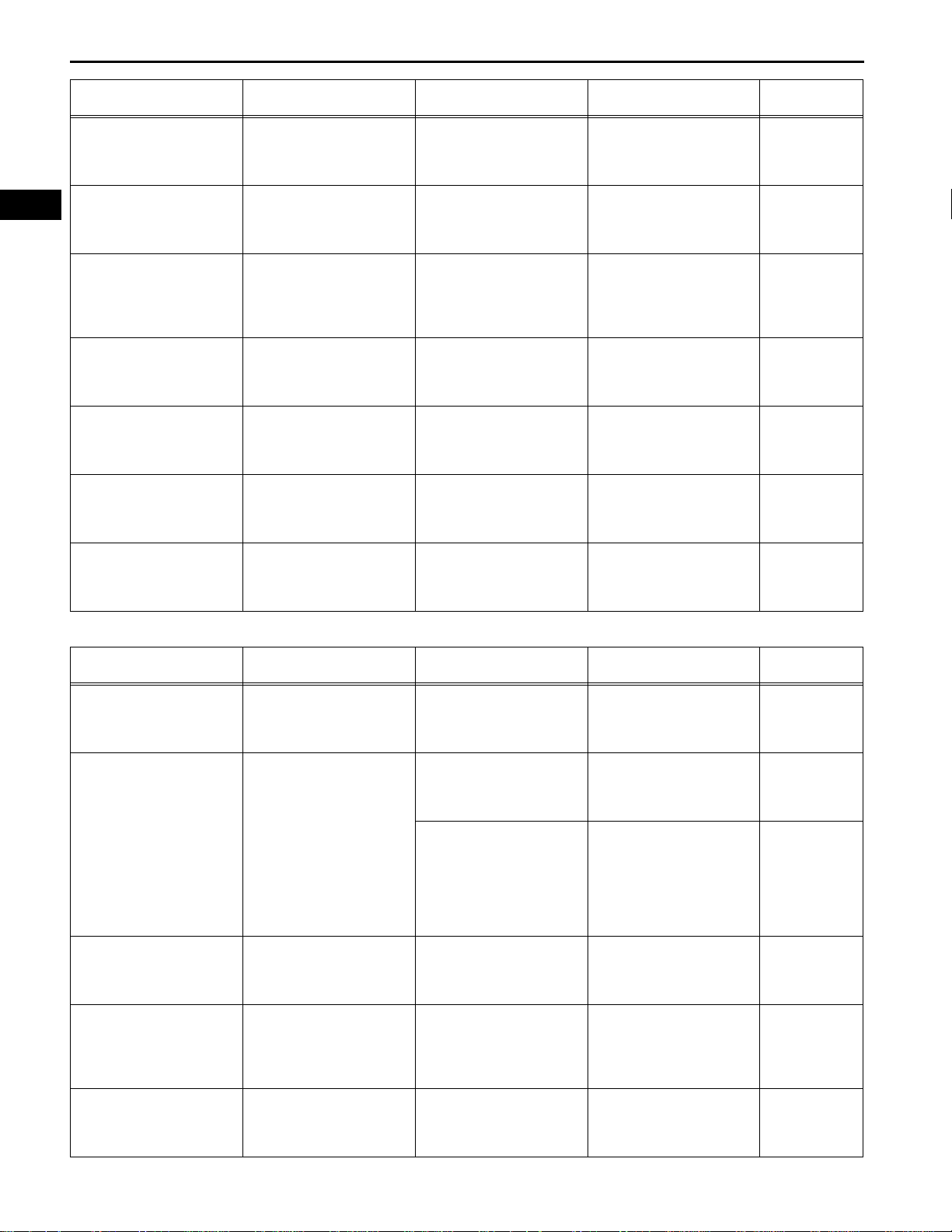

2. CHECK POWER WINDOW REGULATOR SWITCH

ASSEMBLY (FRONT RH)

H6

Specified

Condition

0 V → 10 to 14

V

0 V → 10 to 14

V

0 V → 10 to 14

V

WS

B137057E01

(a) Disconnect the H6 switch connector.

(b) Measure the voltage according to the value(s) in the

table below.

Standard voltage

Symbols (Terminal No.) Wiring Color Terminal Description Condition

B (H6-3) - Body ground GR - Body ground Power supply Ignition switch on (IG) 10 to 14 V

Specified

Condition

If the result is not as specified, there may be a

malfunction in the wire harness.

(c) Reconnect the H6 switch connector and reset the

power window motor.

(d) Measure the voltage according to the value(s) in the

table below.

Standard voltage

Symbols (Terminal No.) Wiring Color Terminal Description Condition

Ignition switch on (IG),

U (H6-4) - Body ground G - Body ground

D (H6-1) - Body ground Y - Body ground

Power window motor UP

output

Power window motor

DOWN output

front passenger side

power window switch OFF

→ UP (Manual operation)

Ignition switch on (IG),

front passenger side

power window switch OFF

→ DOWN (Manual

operation)

Specified

Condition

0 V → 10 to 14

V

0 V → 10 to 14

V

If the result is not as specified, the power window

regulator switch assembly may have a malfunction.

WS

WS–14

WINDSHIELD / WINDOWGLASS – POWER WINDOW CONTROL SYSTEM

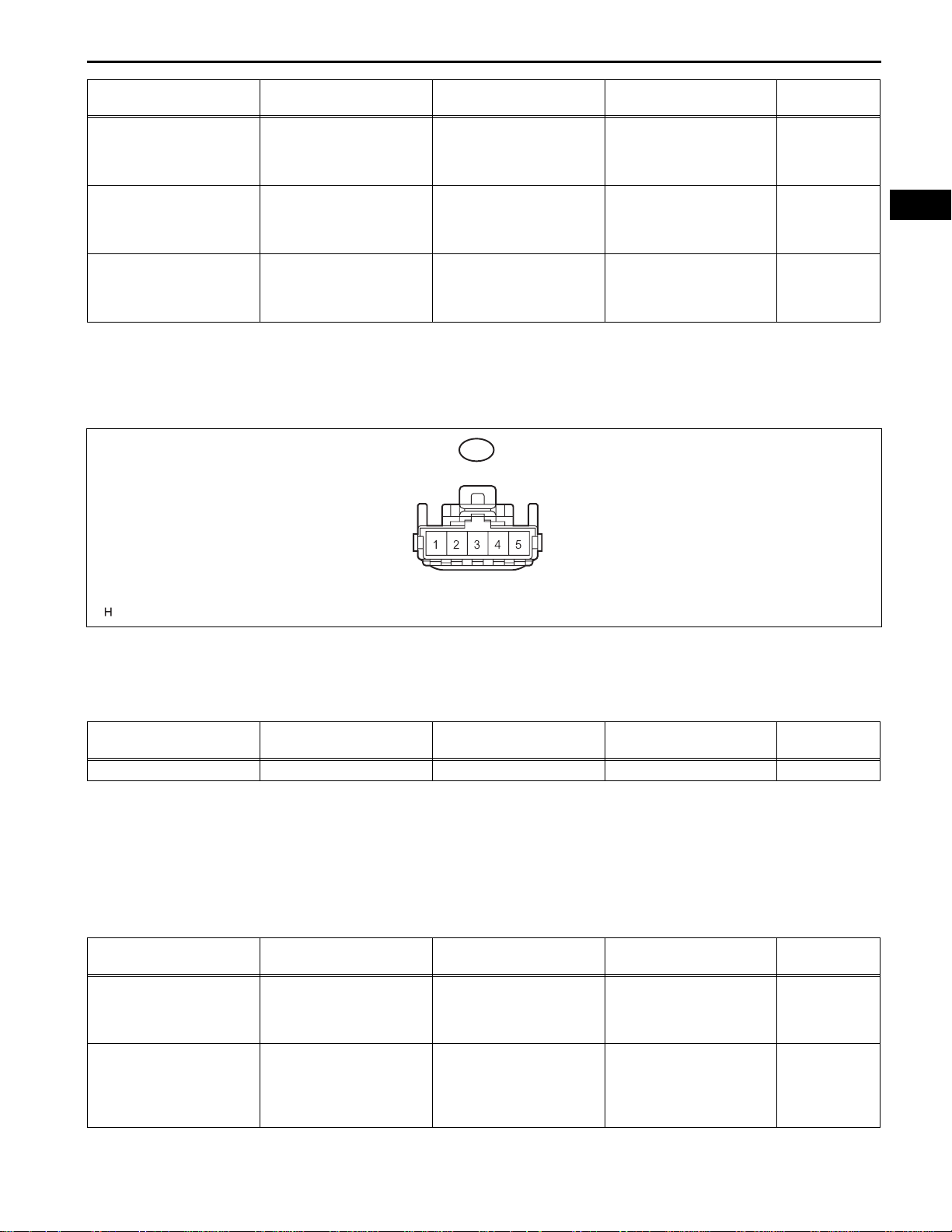

3. CHECK POWER WINDOW REGULATOR SWITCH

ASSEMBLY (REAR LH)

K1

B137057E02

(a) Disconnect the K1 switch connector.

(b) Measure the voltage according to the va lue(s) in the

table below.

Standard voltage

Symbols (Terminal No.) Wiring Color Terminal Description Condition

B (K1-3) - Body ground V - Body ground Power supply Ignition switch on (IG) 10 to 14 V

Specified

Condition

If the result is not as specified, there may be a

malfunction in the wire harness.

(c) Reconnect the K1 switch connector and reset the

power window motor.

(d) Measure the voltage according to the va lue(s) in the

table below.

Standard voltage

Symbols (Terminal No.) Wiring Color Terminal Description Condition

Ignition switch on (IG),

U (K1-4) - Body ground G - Body ground

D (K1-1) - Body ground R - Body ground

Power window motor UP

output

Power window motor

DOWN output

front passenger side

power window switch OFF

→ UP (Manual operation)

Ignition switch on (IG),

front passenger side

power window switch OFF

→ DOWN (Manual

operation)

If the result is not as specified, the power window

regulator switch assembly may have a malfunction.

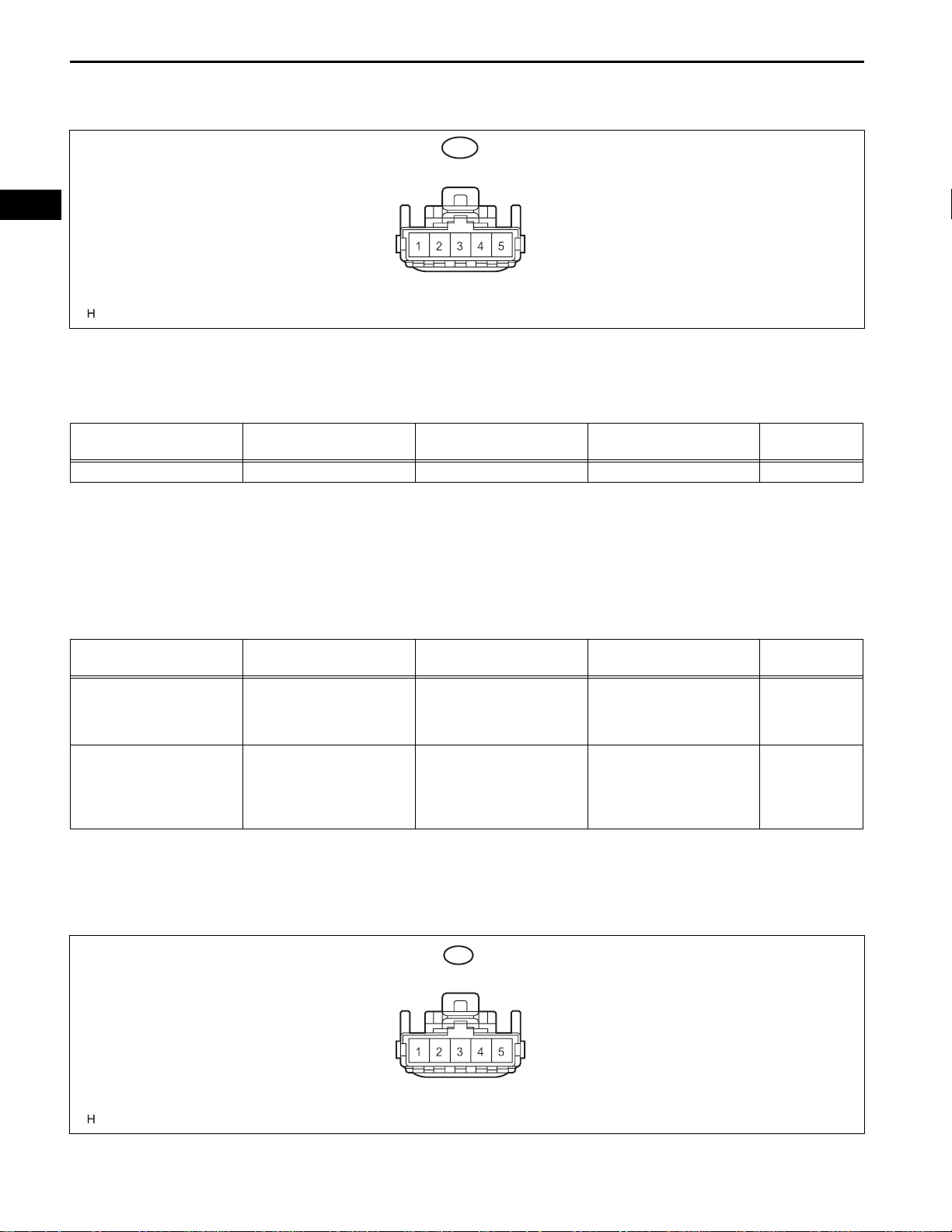

4. CHECK POWER WINDOW REGULATOR SWITCH

ASSEMBLY (REAR RH)

Specified

Condition

0 V → 10 to 14

V

0 V → 10 to 14

V

J1

(a) Disconnect the J1 switch connector.

B137057E03

WINDSHIELD / WINDOWGLASS – POWER WINDOW CONTROL SYSTEM

WS–15

(b) Measure the voltage according to the value(s) in the

table below.

Standard voltage

Symbols (Terminal No.) Wiring Color Terminal Description Condition

B (J1-3) - Body ground G - Body ground Power supply Ignition switch on (IG) 10 to 14 V

Specified

Condition

If the result is not as specified, there may be a

malfunction in the wire harness.

(c) Reconnect the J1 switch connector and reset the

power window motor.

(d) Measure the voltage according to the value(s) in the

table below.

Standard voltage

WS

Symbols (Terminal No.) Wiring Color Terminal Description Condition

Ignition switch on (IG),

U (J1-4) - Body ground V - Body ground

D (J1-1) - Body ground R - Body ground

Power window motor UP

output

Power window motor

DOWN output

front passenger side

power window switch OFF

→ UP (Manual operation)

Ignition switch on (IG),

front passenger side

power window switch OFF

→ DOWN (Manual

operation)

If the result is not as specified, the power window

regulator switch assembly may have a malfunction.

Specified

Condition

0 V → 10 to 14

V

0 V → 10 to 14

V

WS

WS–16

WINDSHIELD / WINDOWGLASS – POWER WINDOW CONTROL SYSTEM

DIAGNOSIS SYSTEM

1. DESCRIPTION

(a) The power window control system data can be read

from the Data Link Connector 3 (DLC3) of the

vehicle. When the system seems to be

malfunctioning, use the intelligent tester to check for

malfunctions and perform repairs.

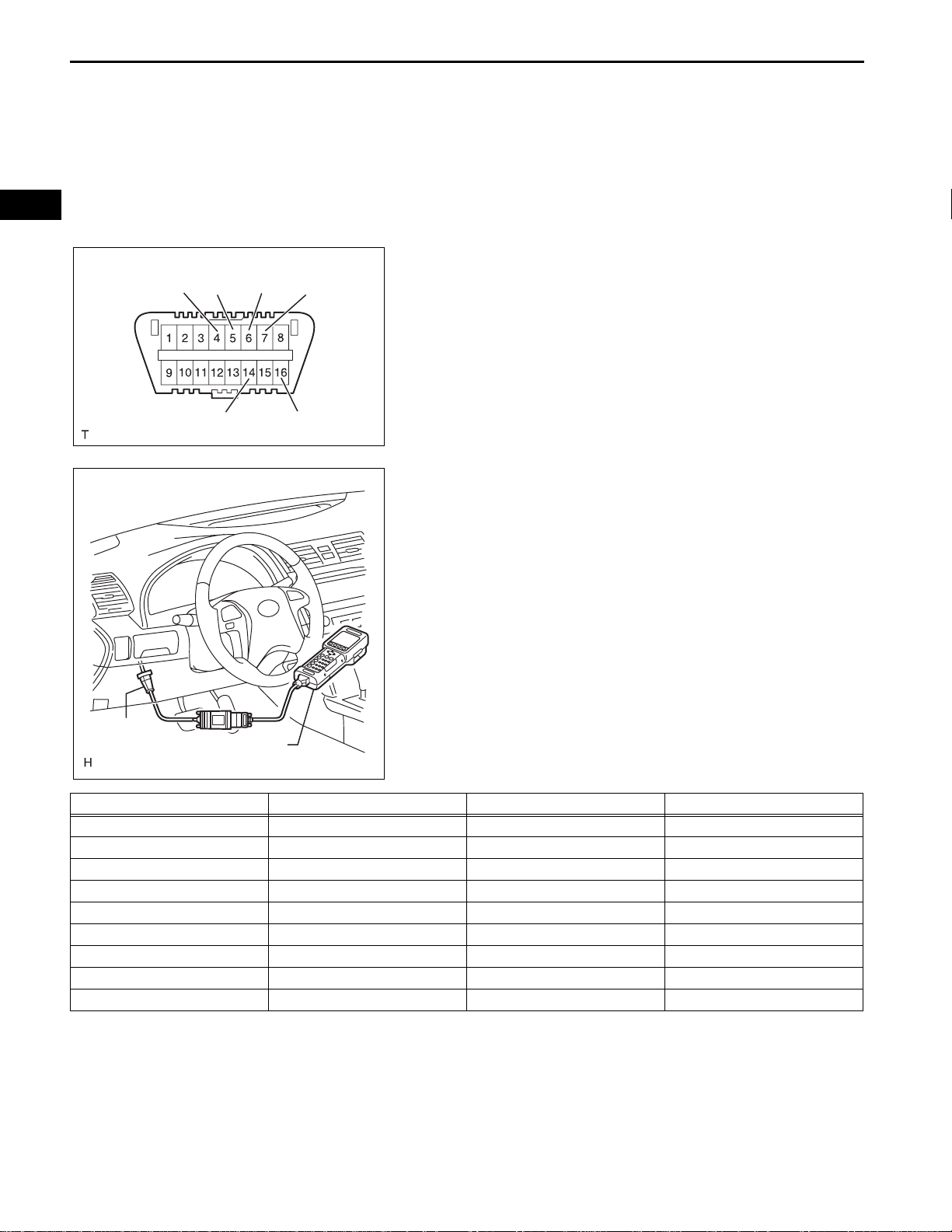

2. CHECK DLC3

CG

SG

CANH

SIL

CANL

BAT

H100769E16

(a) The ECU uses ISO 15765-4 communication. The

terminal arrangement of the DLC3 complies with

SAE J1962 and matches the ISO 15765-4 format.

DLC3

Intelligent Tester

C131977E01

Symbols (Terminal No.) Terminal Description Condition Specified Condition

SIL (7) - SG (5) Bus "+" line During transmission Pulse generation

CG (4) - Body ground Chassis ground Always Below 1 Ω

SG (5) - Body ground Signal ground Always Below 1 Ω

BAT (16) - Body ground Battery positive Always 10 to 14 V

CANH (6) - CANL (14) CAN bus line Ignition switch OFF* 54 to 69 Ω

CANH (6) - CG (4) HIGH-level CAN bus line Ignition switch OFF* 200 Ω or more

CANL (14) - CG (4) LOW-level CAN bus line Ignition switch OFF* 200 Ω or more

CANH (6) - BAT (16) HIGH-level CAN bus line Ignition switch OFF* 6 kΩ or more

CANL (14) - BAT (16) LOW-level CAN bus line Ignition switch OFF* 6 kΩ or more

NOTICE:

*: Before measuring the resistance, leave the

vehicle as is for at least 1 minute and do not

operate the ignition switch, any other switches

or the door.

WINDSHIELD / WINDOWGLASS – POWER WINDOW CONTROL SYSTEM

If the result is not as specified, the DLC3 may have

a malfunction. Repair or replace the harness and

connector.

HINT:

Connect the cable of the intelligent tester to the

DLC3, turn the ignition switch on (IG) and attempt to

use the tester. If the display indicates that a

communication error has occurred, there is a

problem either with the vehicle or with the tester.

• If communication is normal when the tester is

connected to another vehicle, inspect the DLC3

of the original vehicle.

• If communication is still not possible when the

tester is connected to another vehicle, the

problem may be in the tester itself. Consult the

Service Department listed in the tester's

instruction manual.

3. CHECK DIAGNOSIS (WITH JAM PROTECTION)

HINT:

If there is a malfunction in the pulse sensor, manually

operating the power window switch will cause the power

window switch light to blink.

(a) Turn the ignition switch on (IG).

(b) Manually operate the power window master switch

or power window switch on each door.

(c) Check the blinking pattern of the AUTO light as

B140750

shown in the illustration.

WS–17

WS

Brinking Pattern of Light:

(A): LIN communication fail

ON

OFF

1.5

(Light)

2.0

(sec.)

- Initial fail (Window position)

Normal(B):

- Palse sensor fail

0.5

1.0

(sec.)

(1) If pattern (A) is displayed, check the wire

harness or power window ECU.

(2) If pattern (B) is displayed, check the power

window regulator motor or power window ECU.

(3) If the normal pattern is displayed, replace the

power window regulator master switch.

B145472E01

WS–18

WINDSHIELD / WINDOWGLASS – POWER WINDOW CONTROL SYSTEM

DTC CHECK / CLEAR

1. CHECK DTC

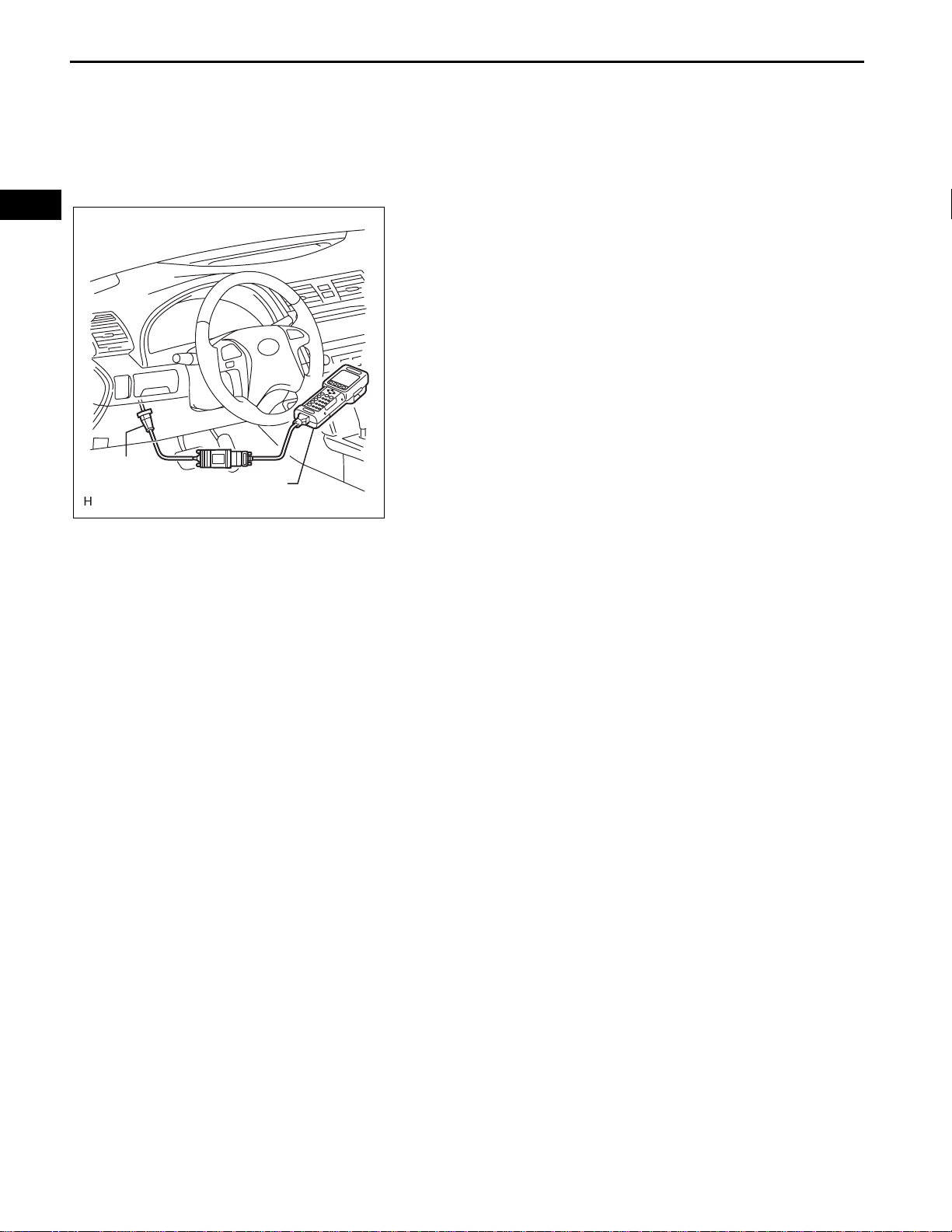

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch on (IG).

(c) Check the DTC(s).

WS

2. CLEAR DTC

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch on (IG) .

(c) Clear the DTCs.

(d) Check that "DTCs are cleared" is displayed.

NOTICE:

If any DTCs are output, troubleshoot those

DTCs again.

DLC3

Intelligent Tester

C131977E01

WINDSHIELD / WINDOWGLASS – POWER WINDOW CONTROL SYSTEM

FAIL-SAFE CHART

1. POWER WINDOW OPERATION IN FAIL-SAFE MODE

HINT:

If the pulse sensor built into the power window regulator

motor (on the driver side) malfunctions, the power

window control system enters fail-safe mode.

Fail mode Fail Detection Condition

Pulse direction error

Pulse stop error

Power window control system

Power window operation Ignition switch on (IG)

Manual UP Operation prohibited Operation prohibited Operation prohibited

Manual DOWN

AUTO UP

(hold switch at AUTO UP

position)

AUTO UP Operation prohibited Operation prohibited Operation prohibited

AUTO DOWN Operation prohibited Operation prohibited Operation prohibited

Operative

(Jam protection not operative)

Operative

(in MANUAL mode)

(Jam protection not operative)

With the door glass going up or down, the pulse that indicates door

glass operation in the opposite direction is detected for 400 msec.

With the door glass going up or down, no pulse is detected for 350 to

450 msec.

(a) The power window control system prohibits the

following power window operation when the pulse

sensor for the jam protection function has problems

and the window position or the learned value is

abnormal.

Key-off

(Within approx. 45 seconds

after ignition switch turned off)

Operation prohibited Operation prohibited

Operation prohibited Operation prohibited

Key-off

(After approx. 45 seconds

elapsed after ignition switch

turned off)

WS–19

WS

HINT:

When the pulse sensor is normal, the AUTO UP /

DOWN function can be resumed by deactivating

fail-safe mode. To deactivate fail-safe mode, pull up

the driver door power window switch to the AUTO

UP position and hold it for at least 1 second to fully

close the window from the fully open position.

(b) If the LIN communication system malfunctions

(communication blackout), the power window

control system prohibits the following operations.

LIN communication system

Power window operation Ignition switch on (IG)

MANUAL UP Operative (Jam protection operative)

MANUAL DOWN Operative (Jam protection not operative)

AUTO UP (hold switch at AUTO UP position) Operative (Jam protection operative)

AUTO UP Operative (Jam protection operative)

AUTO DOWN Operative (Jam protection not operative)

WS

WS–20

WINDSHIELD / WINDOWGLASS – POWER WINDOW CONTROL SYSTEM

DATA LIST / ACTIVE TEST

1. USING INTELLIGENT TESTER

2. DATA LIST

Body:

Item

Communication Master SW

Ignition Switch Ignition switch signal/ON or OFF

D Door Courtesy SW

P Door Courtesy SW

Measurement Item/Display

(Range)

Master switch communication

signal OK/STOP

Driver side door courtesy switch

signal/ON or OFF

Front passenger side door

courtesy switch signal/ON or OFF

(a) Connect the intelligent tester to the DLC3.

(b) Monitor the ECU data by following the prompts on

the tester screen.

HINT:

The intelligent tester has a "Snapshot" function

which records the monitored data. Refer to the

intelligent tester operator's manual for further

details.

HINT:

Using the DATA LIST displayed on the intelligent tester,

the value of the switches, sensors, actuators, etc. can be

read without part removal. Reading the DATA LIST as

the first step in troubleshooting is one way to shorten the

labor time.

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch on (IG).

(c) Read the DAT A LIST according to the display on the

tester.

Normal Condition

OK: Communication is normal

STOP: Communication is stop

ON: Power source mode is (IG)

OFF: Power source mode is off or

on (ACC)

ON: Driver side door is open

OFF: Driver side door is closed

ON: Front passenger side door is

open

OFF: Front passenger side door

is closed

Diagnostic Note

-

-

-

-

Body:

Item Test Detail Diagnostic Note

IG OFF P/W Control Permission Output

3. ACTIVE TEST

HINT:

Performing the ACTIVE TEST using the intelligent tester

allows you to operate the relay, VSV, actuator, etc.

without parts removal. Performing the ACTIVE TEST as

the first step in troubleshooting is one way to shorten the

labor time. It is possible to display the DATA LIST during

the ACTIVE TEST.

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch on (IG).

(c) Perform the ACTIVE TEST according to the display

on the tester.

Operates power window ON/OFF (After

ignition OFF)

-

WINDSHIELD / WINDOWGLASS – POWER WINDOW CONTROL SYSTEM

POWER WINDOW CONTROL SYSTEM

DTC No. Detection Item Trouble Area See page

B2311 Driver Door Motor Malfunction

B2312

B2313

Driver Side Door Master Switch

Malfunction

Glass Position Initialization

Incomplete

WS–21

DIAGNOSTIC TROUBLE CODE CHART

1. Battery disconnection when the

ignition switch is on (IG)

2. Power window regulator motor

(on driver side)

3. Incorrect installation of power

window components

4. Overheated power window

regulator motor (on driver side)

1. Power window regulator motor

(on driver side)

2. Power window regulator

master switch

3. Wire harness

4. Power window regulator

master switch is held same

position for more than 20 seconds

1. Power window regulator motor

(on driver side)

2. Power window regulator motor

(on driver side) not initialized

WS-19

WS-21

WS-24

WS

WS

WS–22

WINDSHIELD / WINDOWGLASS – POWER WINDOW CONTROL SYSTEM

DTC B2311 Driver Door Motor Malfunction

DESCRIPTION

The portion of the power window control system that is located in the driver door consists of a power

window master switch, regulator, and a motor with an integrated ECU. The driver door power window

regulator motor is controlled by the ECU when the power window master switch is operated (models with

jam protection).

DTC B2311 is set when the ECU for the driver door power window regulator motor assembly

malfunctions.

NOTICE:

The power window control system uses a serial communication protocol (LIN) to communicate

with the main body ECU. Inspect the communication function by following HOW TO PROCEED

WITH TROUBLESHOOTING. Troubleshoot the power window control system after confirming that

the communication system is functioning properly.

HINT:

• Initialization is required only when the power window regulator motor is replaced. However, replacing

the motor may cause the motor gear to be engaged in a different position. This can cause a difference

to exist between the current door glass position and the position memorized in the ECU. In this case,

the jam protection function may work improperly. Return the system to the pre-initialized condition and

reinitialize the system.

• To return the system to the pre-initialized condition:

Disconnect the power window regulator motor connector during power window operation. This will

return the motor to the pre-initialized condition.

DTC No. DTC Detection Condition Trouble Area

B2311

When either condition below is met:

• The power window regulator motor (on

driver side) malfunctions

• When the ECU in the power widow

regulator motor (on driver side)

determines that the fully closed window

position has deviated approximately 20

mm (0.79 in.) or more from the normal

position

• Battery disconnection when the ignition

switch is on (IG)

• Power window regulator motor (on driver

side)

• Incorrect installation of power window

components

• Overheated power window regulator

motor (on driver side)

INSPECTION PROCEDURE

INITIALIZE POWER WINDOW CONTROL SYSTEM

1

OK

(a) Initialize the power window regulator motor assembly (on

the driver side) (see page WS-8).

(b) Check that the power window operates normally by

opening and closing the window.

OK:

Driver side power window operates normally.

NG

REPLACE POWER WINDOW REGULATOR

MOTOR ASSEMBLY (for Driver Side)

WINDSHIELD / WINDOWGLASS – POWER WINDOW CONTROL SYSTEM

CHECK WHETHER PARTS HAVE BEEN INSTALLED CORRECTLY

2

(a) Check that the power window components (on the driver

side) are installed correctly.

OK:

Power window components (on driver side) are

installed correctly.

HINT:

When the power window components are installed

correctly, the problem has been caused by battery

disconnection while the ignition switch is on (IG),

improper installation of the power window components or

the motor being overheated.

WS–23

WS

OK

END

NG

INSTALL PARTS CORRECTLY

WS

WS–24

WINDSHIELD / WINDOWGLASS – POWER WINDOW CONTROL SYSTEM

DTC B2312 Driver Side Door Master Switch Malfunction

DESCRIPTION

The portion of the power window control system that is located in the driver door consists of a power

window master switch, regulator, and a motor with an integrated ECU. The driver door power window

regulator motor is controlled by the ECU when the power window master switch is operated (models with

jam protection).

When the ECU determines that the power window master switch is stuck, DTC B2312 is set.

NOTICE:

The power window control system uses a serial communication protocol (LIN) to communicate

with the main body ECU. Inspect the communication function by following HOW TO PROCEED

WITH TROUBLESHOOTING. Troubleshoot the power window control system after confirming that

the communication system is functioning properly.

DTC No. DTC Detection Condition Trouble Area

• Power window regulator motor (on driver

side)

• Power window regulator master switch

• Wire harness

• Power window regulator master switch is

held in same position for more than 20

seconds

B2312

The power window regulator master switch is

stuck

WINDSHIELD / WINDOWGLASS – POWER WINDOW CONTROL SYSTEM

WIRING DIAGRAM

WS–25

with Jam Protection:

from POWER fuse

M1

Power Window

Master Switch

6

B

1

E

Main Body ECU

UP

LED

AUTO

DN

8

3

4

5

from PWR fuse

I5

Power Window Regulator

Motor Assembly (Front LH)

10

UP1

5

LED

4

AUTO

7

DWN1

2

B

WS

to PWR Relay

: LIN Communication Line

18

PWS

LIN2

10

9

LIN

1

E

B140744E01

WS

WS–26

WINDSHIELD / WINDOWGLASS – POWER WINDOW CONTROL SYSTEM

INSPECTION PROCEDURE

INSPECT POWER WINDOW REGULATOR MASTER SWITCH ASSEMBLY

1

B108710

(a) Measure the resistance according to the value(s) in the

table below.

Standard resistance

Tester Connection Condition Specified Condition

8 (UP) - 1 (E) - 4 (AUTO) Auto UP Below 1 Ω

5 (DN) - 6 (B) Auto UP Below 1 Ω

8 (UP) - 1 (E) Manual UP Below 1 Ω

5 (DN) - 6 (B) Manual UP Below 1 Ω

8 (UP) - 5 (DN) - 6 (B) OFF Below 1 Ω

5 (DN) - 1 (E) Manual DOWN Below 1 Ω

8 (UP) - 6 (B) Manual DOWN Below 1 Ω

4 (AUTO) - 5 (DN) - 1 (E) Auto DOWN Below 1 Ω

8 (UP) - 6 (B) Auto DOWN Below 1 Ω

OK

CHECK WIRE HARNESS (WINDOW REGULATOR MASTER SWITCH - WINDOW

2

REGULATOR MOTOR)

M1

Power Window Regulator Master

Switch Assembly:

LED

AUTO

I5

Power Window Regulator Motor

(Front LH):

AUTO

DN

UP

LED

NG

REPLACE POWER WINDOW REGULATOR

MASTER SWITCH

(a) Disconnect the M1 and I5 connectors.

(b) Measure the resistance according to the value(s) in the

table below.

Standard resistance

Tester Connection Condition Specified Condition

M1-8 (UP) - I5-10 (UP1) Always Below 1 Ω

M1-3 (LED) - I5-5 (LED) Always Below 1 Ω

M1-4 (AUTO) - I5-4

(AUTO)

M1-5 (DN) - I5-7 (DWN1) Always Below 1 Ω

M1-8 (UP) - Body

ground

M1-3 (LED) - Body

ground

M1-4 (AUTO) - Body

ground

M1-5 (DN) - Body

ground

Always Below 1 Ω

Always 10 kΩ or higher

Always 10 kΩ or higher

Always 10 kΩ or higher

Always 10 kΩ or higher

DWN1

UP1

B137046E02

NG

REPAIR OR REPLACE HARNESS OR

CONNECTOR

OK

REPLACE DRIVER SIDE POWER WINDOW REGULATOR MOTOR ASSEMBLY

WINDSHIELD / WINDOWGLASS – POWER WINDOW CONTROL SYSTEM

WS–27

DTC B2313 Glass Position Initialization Incomplete

DESCRIPTION

The portion of the power window control system that is located in the driver door consists of a power

window master switch, regulator, and a motor with an integrated ECU. The driver door power window

regulator motor is controlled by the ECU when the power window master switch is operated (models with

jam protection).

When the ECU determines that the driver's door power window regulator motor assembly has not been

initialized, DTC B2313 is set.

NOTICE:

The power window control system uses a serial communication protocol (LIN) to communicate

with the main body ECU. Inspect the communication function by following HOW TO PROCEED

WITH TROUBLESHOOTING. Troubleshoot the power window control system after confirming that

the communication system is functioning properly.

HINT:

• Replacing the door glass or door glass run may cause a difference to exist between the current door

glass position and the position memorized in the ECU. In this case, the jam protection function may

work improperly. Return the system to the pre-initialized condition and reinitialize the system.

• To return the system to the pre-initialized condition:

Disconnect the power window regulator motor connector during power window operation. This will

return the motor to the pre-initialized condition.

DTC No. DTC Detection Condition Trouble Area

• Power window regulator motor (on driver

side)

• Power window regulator motor (on driver

side) not initialized

B2313

• The power window regulator motor (on

driver side) is not initialized

• The power window regulator motor (on

driver side) malfunctions

WS

INSPECTION PROCEDURE

NOTICE:

When using the intelligent tester to troubleshoot the LIN communication line: Connect the

intelligent tester to the vehicle, and turn the courtesy light switch on and off at 1.5 second

intervals until communication between the tester and vehicle begins.

CHECK DTC OUTPUT

1

(a) Turn the ignition switch off.

(b) Wait for at least 10 seconds, and then turn the ignition

switch on (IG).

(c) Check whether the DTC output recurs.

Result

Display (DTC Output) Proceed to

B2313 A

No output B

B

A

END

WS

WS–28

2

WINDSHIELD / WINDOWGLASS – POWER WINDOW CONTROL SYSTEM

SYSTEM INITIALIZE (POWER WINDOW CONTROL SYSTEM)

(a) Turn the ignition switch on (IG) and initialize the power

window regulator motor (on the driver side) (see page

WS-8).

(b) Turn the ignition switch off.

(c) Wait for at least 10 seconds, and then turn the ignition

switch on (IG).

(d) Check whether the DTC output recurs.

Display (DTC Output) Proceed to

No output A

B2313 B

END

B

A

REPLACE POWER WINDOW REGULATOR

MOTOR ASSEMBLY FRONT LH

WINDSHIELD / WINDOWGLASS – POWER WINDOW CONTROL SYSTEM

Power Window Master Switch Circuit

DESCRIPTION

This circuit transmits signal from the power window regulator master switch assembly to the power

window regulator switch.

WIRING DIAGRAM

WS–29

WS

M1

Power Window Regulator

Master Switch

16

PU

15

PD

6

B

12

RLU

13

RLD

10

RRU

18

RRD

from POWER fuse

from RR DOOR LH fuse

from RR DOOR RH fuse

from POWER fuse

H6

Power Window Regulator

Switch (Front RH)

3

B

5

SU

2

SD

K1

Power Window Regulator

Switch (Rea LH)

3

B

5

SU

2

SD

J1

Power Window Regulator

Switch (Rear RH)

3

B

5

SU

2

SD

4

U

1

D

4

U

1

D

4

U

1

D

H4

Power Window Regulator

Motor (Front RH)

K3

Power Window Regulator

Motor (Rear LH)

J3

Power Window Regulator

Motor (Rear RH)

DN

UP

AUTO

LED

I4

Power Window Regulator

Motor (Front LH)

12

*1

5 (4)

8 (3)

4

3

*1: without Jam Protection

1

E

*2: with Jam Protection

from PWR fuse

*1

*2

*2

*2

*2

( ): without Jam Protection

I5

Power Window Regulator

Motor (Front LH)

2

*2

B

7

DWN1

10

UP1

4

AUTO

5

LED

1

E

*2

B140723E01

WS

WS–30

WINDSHIELD / WINDOWGLASS – POWER WINDOW CONTROL SYSTEM

INSPECTION PROCEDURE

CHECK DTC OUTPUT

1

(a) Turn the ignition switch off.

(b) Wait for at least 10 seconds, and then turn the ignition

switch on (IG).

(c) Check whether the DTC output recurs.

Result

Display (DTC output) Proceed to

No output A

Output DTCs B

B

GO TO DTC CHART

A

INSPECT POWER WINDOW REGULATOR MASTER SWITCH ASSEMBLY

2

(a) Disconnect the M1 connector.

(b) Measure the voltage and resistance according to the

M1

E

B

value(s) in the table below.

Standard voltage

Tester Connection Condition Specified Condition

6 (B) - Body ground Ignition switch on (IG) 10 to 14 V

Standard resistance

B137060E01

Tester Connection Condition Specified Condition

1 (E) - Body ground Always Below 1 Ω

NG

REPAIR OR REPLACE HARNESS OR

CONNECTOR

OK

INSPECT POWER WINDOW REGULATOR MASTER SWITCH ASSEMBLY

3

(a) Measure the resistance according to the value(s) in the

table below.

Standard resistance:

(with Jam Protection)

Tester Connection Condition Specified Condition

B050518E04

8 (UP) - 1 (E) - 4 (AUTO)

5 (DN) - 6 (B) Below 1 Ω

8 (UP) - 1 (E)

5 (DN) - 6 (B) Below 1 Ω

8 (UP) - 5 (DN) - 6 (B) OFF Below 1 Ω

5 (DN) - 1 (E)

8 (UP) - 6 (B) Below 1 Ω

Auto UP

Manual UP

Manual DOWN

Below 1 Ω

Below 1 Ω

Below 1 Ω

WINDSHIELD / WINDOWGLASS – POWER WINDOW CONTROL SYSTEM

Tester Connection Condition Specified Condition

4 (AUTO) - 5 (DN) - 1 (E)

8 (UP) - 6 (B) Below 1 Ω

1 (E) - 10 (RRU)

1 (E) - 12 (RLU)

1 (E) - 13 (RLD)

1 (E) - 15 (PD)

1 (E) - 16 (PU)

1 (E) - 18 (RRD)

Auto DOWN

Lock/Unlock switch

(without Jam Protection)

Tester Connection Condition Specified Condition

1 (E) - 3 (UP)

1 (E) - 4 (DN) Below 1 Ω

1 (E) - 10 (RRU)

1 (E) - 12 (RLU)

1 (E) - 13 (RLD)

1 (E) - 15 (PD)

1 (E) - 16 (PU)

1 (E) - 18 (RRD)

OFF

Lock/Unlock switch

WS–31

Below 1 Ω

UNLOCK (Below 1 Ω)

→LOCK (10 kΩ or

higher)

Below 1 Ω

UNLOCK (Below 1 Ω)

→LOCK (10 kΩ or

higher)

WS

OK

CHECK WIRE HARNESS (POWER WINDOW MASTER SWITCH - FRONT LH, REAR LH/RH

4

SWITCH)

M1

Power Window Regulator Master

Switch Assembly:

RLU PD

RRU

RLD

H6 (K1, J1)

Power Window Switch

(Front RH, Rear LH/RH):

RRD

PU

B137067E01

NG

REPLACE POWER WINDOW REGULATOR

MASTER SWITCH ASSEMBLY

(a) Disconnect the M1 and H6 (K1, J1) connectors.

(b) Measure the resistance according to the value(s) in the

table below.

Standard resistance:

Front RH side

Tester Connection Condition Specified Condition

M1-16 (PU) - H6-5 (SU) Always Below 1 Ω

M1-15 (PD) - H6-2 (SD) Always Below 1 Ω

M1-16 (PU) - Body

ground

M1-15 (PD) - Body

ground

Always 10 kΩ or higher

Always 10 kΩ or higher

Rear LH side

Tester Connection Condition Specified Condition

M1-12 (RLU) - K1-5 (SU) Always Below 1 Ω

M1-13 (RLD) - K1-2 (SD) Always Below 1 Ω

M1-12 (RLU) - Body

ground

M1-13 (RLD) - Body

ground

Always 10 kΩ or higher

Always 10 kΩ or higher

Rear RH side

WS

WS–32

WINDSHIELD / WINDOWGLASS – POWER WINDOW CONTROL SYSTEM

Tester Connection Condition Specified Condition

M1-10 (RRU) - J1-5 (SU) Always Below 1 Ω

M1-18 (RRD) - J1-2 (SD) Always Below 1 Ω

M1-10 (RRU) - Body

ground

M1-18 (RRD) - Body

ground

Always 10 kΩ or higher

Always 10 kΩ or higher

NG

REPAIR OR REPLACE HARNESS OR

CONNECTOR

OK

PROCEED TO NEXT CIRCUIT INSPECTION SHOWN IN PROBLEM SYMPTOMS TABLE

WINDSHIELD / WINDOWGLASS – POWER WINDOW CONTROL SYSTEM

Front Passenger Side Power Window Switch Power Source Circuit

DESCRIPTION

This circuit supplies power to operate the power window regulator switch assembly (Front RH).

WS–33

WIRING DIAGRAM

C

from POWER fuse

H6

Power Window Regulator Switch

Assembly (Front RH)

3

B

B137059E01

WS

INSPECTION PROCEDURE

CHECK WIRE HARNESS (POWER WINDOW REGULATOR SWITCH - BATTERY AND

1

BODY GROUND)

(a) Disconnect the H6 connector.

(b) Measure the voltage according to the value(s) in the

H6

B

B137048E01

OK

PROCEED TO NEXT CIRCUIT INSPECTION SHOWN IN PROBLEM SYMPTOMS TABLE

table below.

Standard voltage

Tester Connection Condition Specified Condition

3 (B) - Body ground Ignition switch on (IG) 10 to 14 V

NG

REPAIR OR REPLACE HARNESS OR

CONNECTOR

WS–34

WINDSHIELD / WINDOWGLASS – POWER WINDOW CONTROL SYSTEM

Rear Power Window Switch LH Circuit

DESCRIPTION

This circuit supplies power to operate the power window regulator switch assembly (Rear LH).

WS

WIRING DIAGRAM

C

from RR DOOR LH fuse

K1

Power Window Regulator Switch

Assembly (Rear LH)

3

B

B137059E02

INSPECTION PROCEDURE

CHECK WIRE HARNESS (POWER WINDOW REGULATOR SWITCH - BATTERY AND

1

BODY GROUND)

(a) Disconnect the K1 connector.

(b) Measure the voltage according to the value(s) in the

K1

B

B137048E02

OK

PROCEED TO NEXT CIRCUIT INSPECTION SHOWN IN PROBLEM SYMPTOMS TABLE

table below.

Standard voltage

Tester Connection Condition Specified Condition

3 (B) - Body ground Ignition switch on (IG) 10 to 14 V

NG

REPAIR OR REPLACE HARNESS OR

CONNECTOR

WINDSHIELD / WINDOWGLASS – POWER WINDOW CONTROL SYSTEM

Rear Power Window Switch RH Circuit

DESCRIPTION

This circuit supplies power to operate the power window regulator switch (Rear RH).

WS–35

WIRING DIAGRAM

C

from RR DOOR RH fuse

J1

Power Window Regulator Switch

Assembly (Rear RH)

3

B

B137059E03

WS

INSPECTION PROCEDURE

CHECK WIRE HARNESS (POWER WINDOW REGULATOR SWITCH - BATTERY AND

1

BODY GROUND)

(a) Disconnect the J1 connector.

(b) Measure the voltage according to the value(s) in the

J1

B

B137048E03

OK

PROCEED TO NEXT CIRCUIT INSPECTION SHOWN IN PROBLEM SYMPTOMS TABLE

table below.

Standard voltage

Tester Connection Condition Specified Condition

3 (B) - Body ground Ignition switch on (IG) 10 to 14 V

NG

REPAIR OR REPLACE HARNESS OR

CONNECTOR

WS

WS–36

WINDSHIELD / WINDOWGLASS – POWER WINDOW CONTROL SYSTEM

Driver Side Power Window Motor Circuit

DESCRIPTION

This circuit transmits signals from the power window regulator master switch assembly to the power

window regulator motor (Front LH).

WIRING DIAGRAM

with Jam Protection:

M1

Power Window Regulator Master

I5

Power Window Regulator Motor (Front LH)

Switch Assembly

from PWR fuse

C

without Jam Protection:

I4

Power Window Regulator Motor (Front LH)

2

B

UP1

DWN1

AUTO

E

10

7

4

1

8

UP

5

DN

4

AUTO

B137064E01

M1

Power Window Regulator Master

Switch Assembly

2

1

C

3

UP

4

DN

B137065E04

WINDSHIELD / WINDOWGLASS – POWER WINDOW CONTROL SYSTEM

INSPECTION PROCEDURE

INSPECT POWER WINDOW REGULATOR MOTOR

1

Motor Gear

Counterclockwise

Clockwise

Counterclockwise

Motor Gear

Clockwise

B127535E01

B137055E01

without Jam protection:

(a) Remove the power window motor.

(1) Apply battery voltage to the motor connector

according to the table below.

NOTICE:

Do not apply battery voltage to any terminals

except terminals 1 and 2.

Standard

Measurement Condition Specified Condition

Battery positive (+) → Terminal 2

Battery negative (-) → Terminal 1

Battery positive (+) → Terminal 1

Battery negative (-) → Terminal 2

Motor gear rotates clockwise

Motor gear rotates counterclockwise

(b) with Jam protection:

Remove the power window motor.

(1) Apply battery voltage to the motor connector

according to the table below.

NOTICE:

Do not apply battery voltage to any terminals

except terminals 1, 2, 4, 7 and 10.

Standard

Switch Condition Measurement Condition Specified Condition

Battery positive (+) →

Motor gear rotates

clockwise

Motor gear rotates

counterclockwise

Motor gear rotates

clockwise

Motor gear rotates

counterclockwise

Manual Operation

Auto Operation

Terminal 2 (PWR)

Battery negative (-) →

Terminal 1 (E), 7 (DN)

Battery positive (+) →

Terminal 2 (PWR)

Battery negative (-) →

Terminal 1 (E), 10 (UP)

Battery positive (+) →

Terminal 2 (PWR)

Battery negative (-) →

Terminal 1 (E), 4

(AUTO), 7 (DN)

Battery positive (+) →

Terminal 2 (PWR)

Battery negative (-) →

Terminal 1 (E), 4

(AUTO), 10 (UP)

WS–37

WS

OK

NG

REPLACE POWER WINDOW REGULATOR

MOTOR

WS

WS–38

2

CHECK WIRE HARNESS (WINDOW REGULATOR MOTOR - WINDOW REGULATOR

WINDSHIELD / WINDOWGLASS – POWER WINDOW CONTROL SYSTEM

MASTER SWITCH)

M1

Power Window Regulator Master

Switch Assembly:

UP DN

I4

Power Window Regulator Motor

(Front LH):

(a) without Jam protection:

Disconnect the M1 and I4 connectors.

(1) Measure the resistance according to the value(s) in

the table below.

Standard resistance

Tester Connection Condition Specified Condition

M1-3 (UP) - I4-2 Always Below 1 Ω

M1-4 (DN) - I4-1 Always Below 1 Ω

M1-3 (UP) - Body

ground

M1-4 (DN) - Body

ground

Always 10 kΩ or higher

Always 10 kΩ or higher

M1

Power Window Regulator Master

Switch Assembly:

DN

I5

Power Window Regulator Motor

(Front LH):

B137061E01

UP

B137046E01

(b) with Jam protection:

Disconnect the M1 and I5 connectors.

(1) Measure the resistance according to the value(s) in

the table below.

Standard resistance

Tester Connection Condition Specified Condition

M1-8 (UP) - I5-10 Always Below 1 Ω

M1-5 (DN) - I5-7 Always Below 1 Ω

M1-8 (UP) - Body

ground

M1-5 (DN) - Body

ground

NG

REPAIR OR REPLACE HARNESS OR

Always 10 kΩ or higher

Always 10 kΩ or higher

CONNECTOR

OK

PROCEED TO NEXT CIRCUIT INSPECTION SHOWN IN PROBLEM SYMPTOMS TABLE

WINDSHIELD / WINDOWGLASS – POWER WINDOW CONTROL SYSTEM

WS–39

Front Passenger Side Power Window Motor Circuit

DESCRIPTION

This circuit transmits signals from the power window regulator switch assembly (Front RH) to the power

window regulator motor (Front RH).

WIRING DIAGRAM

H6

Power Window Regulator Switch

Assembly (Front RH)

H4

Power Window Regulator Motor (Front RH)

WS

2

1

C

INSPECTION PROCEDURE

INSPECT POWER WINDOW REGULATOR MOTOR

1

Motor Gear

Clockwise

Couterclockwise

B127536E02

4

U

1

D

B137065E01

(a) Remove the power window motor.

(b) Apply battery voltage to the motor connector according

to the table below.

NOTICE:

Do not apply battery voltage to any terminals except

terminals 1 and 2.

Standard

Measurement Condition Specified Condition

Battery positive (+) → Terminal 1

Battery negative (-) → Terminal 2

Battery positive (+) → Terminal 2

Battery negative (-) → Terminal 1

Motor gear rotates clockwise

Motor gear rotates counterclockwise

OK

NG

REPLACE POWER WINDOW REGULATOR

MOTOR

WS

WS–40

2

CHECK WIRE HARNESS (WINDOW REGULATOR MOTOR - POWER WINDOW

WINDSHIELD / WINDOWGLASS – POWER WINDOW CONTROL SYSTEM

REGULATOR SWITCH)

H6

Power Window Regulator

Switch Assembly (Front RH):

DU

H4

Power Window Regulator

Motor (Front RH):

(a) Disconnect the H6 and H4 connectors.

(b) Measure the resistance according to the value(s) in the

table below.

Standard resistance

Tester Connection Condition Specified Condition

H6-4 (U) - H4-2 Always Below 1 Ω

H6-1 (D) - H4-1 Always Below 1 Ω

H6-4 (U) - Body ground Always 10 kΩ or higher

H6-1 (D) - Body ground Always 10 kΩ or higher

NG

REPAIR OR REPLACE HARNESS OR

CONNECTOR

B137066E01

OK

PROCEED TO NEXT CIRCUIT INSPECTION SHOWN IN PROBLEM SYMPTOMS TABLE

WINDSHIELD / WINDOWGLASS – POWER WINDOW CONTROL SYSTEM

WS–41

Rear Power Window Motor LH Circuit

DESCRIPTION

This circuit transmits signals from the power window regulator switch assembly (Rear LH) to the power

window regulator motor (Rear LH).

WIRING DIAGRAM

K1

Power Window Regulator Switch

Assembly (Rear LH)

K3

Power Window Regulator Motor (Rear LH)

WS

1

2

C

INSPECTION PROCEDURE

INSPECT POWER WINDOW REGULATOR MOTOR

1

Motor Gear

Clockwise

Couterclockwise

B127536E02

4

U

1

D

B137065E02

(a) Remove the power window motor.

(b) Apply battery voltage to the motor connector according

to the table below.

NOTICE:

Do not apply battery voltage to any terminals except

terminals 1 and 2.

Standard

Measurement Condition Specified Condition

Battery positive (+) → Terminal 1

Battery negative (-) → Terminal 2

Battery positive (+) → Terminal 2

Battery negative (-) → Terminal 1

Motor gear rotates clockwise

Motor gear rotates counterclockwise

OK

NG

REPLACE POWER WINDOW REGULATOR

MOTOR

WS

WS–42

2

CHECK WIRE HARNESS (WINDOW REGULATOR MOTOR - WINDOW REGULATOR

WINDSHIELD / WINDOWGLASS – POWER WINDOW CONTROL SYSTEM

SWITCH)

K1

Power Window Regulator

Switch Assembly (Rear LH):

DU

K3

Power Window Regulator

Motor (Rear LH):

(a) Disconnect the K1 and K3 connectors.

(b) Measure the resistance according to the value(s) in the

table below.

Standard resistance

Tester Connection Condition Specified Condition

K1-4 (U) - K3-1 Always Below 1 Ω

K1-1 (D) - K3-2 Always Below 1 Ω

K1-4 (U) - Body ground Always 10 kΩ or higher

K1-1 (D) - Body ground Always 10 kΩ or higher

NG

REPAIR OR REPLACE HARNESS OR

CONNECTOR

B137066E02

OK

PROCEED TO NEXT CIRCUIT INSPECTION SHOWN IN PROBLEM SYMPTOMS TABLE

WINDSHIELD / WINDOWGLASS – POWER WINDOW CONTROL SYSTEM

WS–43

Rear Power Window Motor RH Circuit

DESCRIPTION

This circuit transmits signals from the power window regulator switch assembly (Rear RH) to the power

window regulator motor (Rear RH).

WIRING DIAGRAM

J1

Power Window Regulator Switch

Assembly (Rear RH)

J3

Power Window Regulator Motor (Rear RH)

WS

1

2

C

INSPECTION PROCEDURE

INSPECT POWER WINDOW REGULATOR MOTOR

1

Motor Gear

Counterclockwise

Clockwise

B127535E01

4

U

1

D

B137065E05

(a) Remove the power window motor.

(b) Apply battery voltage to the motor connector according

to the table below.

NOTICE:

Do not apply battery voltage to any terminals except

terminals 1 and 2.

Standard

Measurement Condition Specified Condition

Battery positive (+) → Terminal 2

Battery negative (-) → Terminal 1

Battery positive (+) → Terminal 1

Battery negative (-) → Terminal 2

Motor gear rotates clockwise

Motor gear rotates counterclockwise

OK

NG

REPLACE POWER WINDOW REGULATOR

MOTOR

WS

WS–44

2

CHECK WIRE HARNESS (WINDOW REGULATOR MOTOR - WINDOW REGULATOR

WINDSHIELD / WINDOWGLASS – POWER WINDOW CONTROL SYSTEM

SWITCH)

J1

Power Window Regulator

Switch Assembly (Rear RH):

DU

J3

Power Window Regulator

Motor (Rear RH):

(a) Disconnect the J1 and J3 connectors.

(b) Measure the resistance according to the value(s) in the

table below.

Standard resistance

Tester Connection Condition Specified Condition

J1-4 (U) - J3-1 Always Below 1 Ω

J1-1 (D) - J3-2 Always Below 1 Ω

J1-4 (U) - Body ground Always 10 kΩ or higher

J1-1 (D) - Body ground Always 10 kΩ or higher

NG

REPAIR OR REPLACE HARNESS OR

CONNECTOR

B137066E03

OK

PROCEED TO NEXT CIRCUIT INSPECTION SHOWN IN PROBLEM SYMPTOMS TABLE

WS–42

WINDSHIELD / WINDOWGLASS – POWER WINDOW MASTER SWITCH

POWER WINDOW MASTER

SWITCH

INSPECTION

WS

B050518E04

1. INSPECT POWER WINDOW MASTER SWITCH (w/

Jam Protection Function)

(a) Measure the resistance when the switch is operated

according to the value(s) in the table below.

Standard resistance

Tester Connection Switch Condition Specified Condition

8 (UP) - 1 (E) - 4 (AUTO)

5 (DN) - 6 (B) Below 1 Ω

8 (UP) - 1 (E)

5 (DN) - 6 (B) Below 1 Ω

8 (UP) - 5 (DN) - 6 (B) OFF Below 1 Ω

5 (DN) - 1 (E)

8 (UP) - 6 (B) Below 1 Ω

4 (AUTO) - 5 (DN) - 1 (E)

8 (UP) - 6 (B) Below 1 Ω

1 (E) - 10 (RRU)

1 (E) - 12 (RLU)

1 (E) - 13 (RLD)

1 (E) - 15 (PD)

1 (E) - 16 (PU)

1 (E) - 18 (RRD)

Auto UP

Manual UP

Manual DOWN

Auto DOWN

Lock/Unlock switch

Below 1 Ω

Below 1 Ω

Below 1 Ω

Below 1 Ω

UNLOCK (Below 1 Ω) →

LOCK (10 kΩ or higher)

B050518E04

2. INSPECT POWER WINDOW MASTER SWITCH (w/o

Jam Protection Function)

(a) Measure the resistance when the switch is operated

according to the value(s) in the table below.

Standard resistance

Tester Connection Switch Condition Specified Condition

1 (E) - 3 (DU)

1 (E) - 4 (DD) Below 1 Ω

1 (E) - 10 (RRU)

1 (E) - 12 (RLU)

1 (E) - 13 (RLD)

1 (E) - 15 (PD)

1 (E) - 16 (PU)

1 (E) - 18 (RRD)

OFF

Lock/Unlock switch

Below 1 Ω

UNLOCK (Below 1 Ω) →

LOCK (10 kΩ or higher)

WINDSHIELD / WINDOWGLASS – FRONT PASSENGER SIDE POWER WINDOW SWITCH

FRONT P ASSENGER SIDE POWER

WINDOW SWITCH

INSPECTION

WS–43

B102538E01

1. INSPECT POWER WINDOW SWITCH

(a) Remove the power window switch.

(b) Measure the resistance when the switch is operated

according to the value(s) in the table below.

Standard resistance

Tester Connection Switch Condition Specified Condition

1 (D) - 2 (SD)

3 (B) - 4 (U) Below 1 Ω

1 (D) - 2 (SD)

4 (U) - 5 (SU) Below 1 Ω

4 (U) - 5 (SU)

1 (D) - 3 (B) Below 1 Ω

UP

OFF

DOWN

Below 1 Ω

Below 1 Ω

Below 1 Ω

WS

WS

WS–44

WINDSHIELD / WINDOWGLASS – REAR POWER WINDOW SWITCH

REAR POWER WINDOW SWITCH

INSPECTION

1. INSPECT POWER WINDOW SWITCH (for Rear RH)

(a) Remove the power window switch.

(b) Measure the resistance when the switch is operated

according to the value(s) in the table below.

Standard resistance

B102538E01

B102538E01

Tester Connection Switch Condition Specified Condition

1 (D) - 2 (SD)

3 (B) - 4 (U) Below 1 Ω

1 (D) - 2 (SD)

4 (U) - 5 (SU) Below 1 Ω

4 (U) - 5 (SU)

1 (D) - 3 (B) Below 1 Ω

UP

OFF

DOWN

2. REMOVE POWER WINDOW SWITCH (for Rear LH)

(a) Remove the power window switch.

(b) Measure the resistance when the switch is operated

according to the value(s) in the table below.

Standard resistance

Tester Connection Switch Condition Specified Condition

1 (D) - 2 (SD)

3 (B) - 4 (U) Below 1 Ω

1 (D) - 2 (SD)

4 (U) - 5 (SU) Below 1 Ω

4 (U) - 5 (SU)

1 (D) - 3 (B) Below 1 Ω

UP

OFF

DOWN

Below 1 Ω

Below 1 Ω

Below 1 Ω

Below 1 Ω

Below 1 Ω

Below 1 Ω

WINDSHIELD / WINDOWGLASS – POWER WINDOW REGULATOR MOTOR

BODYWINDSHIELD / WINDOWGLASS

POWER WINDOW REGULATOR MOTOR

COMPONENTS

WS–45

for Front Door:

FRONT DOOR GLASS SUB-ASSEMBLY

FRONT DOOR INNER GLASS WEATHERSTRIP

FRONT DOOR SERVICE

HOLE COVER

WS

FRONT DOOR LOWER FRAME BRACKET GARNISH

BUTYL TAPE

FRONT DOOR WINDOW

REGULATOR SUB-ASSEMBLY

FRONT DOOR INSIDE

HANDLE BEZEL PLUG

ASSIST GRIP COVER

COURTESY LIGHT ASSEMBLY

N*m (kgf*cm, ft.*lbf)

Non-reusable part

Apply MP grease

5.5 (56, 49 in.*lbf)

: Specified torque

8.0 (82, 71 in.*lbf)

5.4 (55, 48 in.*lbf)

FRONT NO. 1

SPEAKER ASSEMBLY

FRONT POWER WINDOW REGULATOR

MOTOR ASSEMBLY

FRONT DOOR TRIM BOARD SUB-ASSEMBLY

B142333E01

WS–46

for Rear Door:

WINDSHIELD / WINDOWGLASS – POWER WINDOW REGULATOR MOTOR

NO. 1 DOOR SCUFF PLATE CLAMP

WS

REAR DOOR INNER GLASS WEATHERSTRIP

REAR DOOR QUARTER

WINDOW GLASS

REAR DOOR GLASS SUB-ASSEMBLY

REAR DOOR LOWER WINDOW

FRAME SUB-ASSEMBLY

REAR DOOR GLASS RUN

REAR DOOR INSIDE

HANDLE BEZEL PLUG

DOOR ASSIST

GRIP COVER

N*m (kgf*cm, ft.*lbf)

Non-reusable part

: Specified torque

BUTYL TAPE

REAR DOOR SERVICE HOLE COVER

REAR DOOR TRIM BOARD SUB-ASSEMBLY

5.4 (55, 48 in.*lbf)

8.0 (82, 71 in.*lbf)

REAR DOOR WINDOW

REGULATOR SUB-ASSEMBLY

REAR POWER WINDOW REGULATOR

MOTOR ASSEMBLY

Apply MP grease

B142334E01

WINDSHIELD / WINDOWGLASS – POWER WINDOW REGULATOR MOTOR

REMOVAL

1. REMOVE FRONT DOOR LOWER FRAME BRACKET

GARNISH (See page ED-14)

2. REMOVE FRONT DOOR INSIDE HANDLE BEZEL

PLUG (See page ED-14)

3. REMOVE ASSIST GRIP COVER (See page ED-15)

4. REMOVE COURTESY LIGHT ASSEMBLY (See page

ED-15)

5. REMOVE FRONT DOOR TRIM BOARD SUBASSEMBLY (See page ED-15)

6. REMOVE FRONT DOOR INNER GLASS

WEATHERSTRIP (See page ED-16)

7. REMOVE FRONT NO. 1 SPEAKER ASSEMBLY (See

page AV-155)

8. REMOVE FRONT DOOR SERVICE HOLE COVER

(See page ED-17)

WS–47

WS

9. REMOVE FRONT DOOR GLASS SUB-ASSEMBLY

(See page ED-17)

10. REMOVE FRONT DOOR WINDOW REGULATOR

SUB-ASSEMBLY (See page ED-18)

11. REMOVE FRONT POWER WINDOW REGULATOR

MOTOR ASSEMBLY (See page ED-18)

12. REMOVE REAR DOOR INSIDE HANDLE BEZEL

PLUG (See page ED-38)

13. REMOVE DOOR ASSIST GRIP COVER (See page ED-

38)

14. REMOVE REAR DOOR TRIM BOARD SUBASSEMBLY (See page ED-39)

15. REMOVE REAR DOOR INNER GLASS

WEATHERSTRIP (See page ED-40)

16. REMOVE REAR DOOR SERVICE HOLE COVER (See

page ED-41)

17. REMOVE REAR DOOR GLASS RUN (See page ED-

42)

18. REMOVE REAR DOOR LOWER WINDOW FRAME

SUB-ASSEMBLY (See page ED-42)

19. REMOVE REAR DOOR QUARTER WINDOW GLASS

(See page ED-43)

20. REMOVE REAR DOOR GLASS SUB-ASSEMBL Y (See

page ED-43)

21. REMOVE REAR DOOR WINDOW REGULATOR SUBASSEMBLY (See page ED-43)

22. REMOVE REAR POWER WINDOW REGULATOR

MOTOR ASSEMBLY (See page ED-43)

WS

WS–48

Motor Gear

WINDSHIELD / WINDOWGLASS – POWER WINDOW REGULATOR MOTOR

INSPECTION

Motor Gear

Clockwise

Couterclockwise

B127536E02

Counterclockwise

Clockwise

B127535E01

1. INSPECT POWER WINDOW REGULATOR MOTOR

(FRONT RH)

(a) Apply battery voltage to the motor connector

according to the table below.

NOTICE:

Do not apply battery voltage to any terminals

except terminals 1 and 2.

Standard

Measurement Condition Specified Condition

Battery positive (+) → Terminal 1

Battery negative (-) → Terminal 2

Battery positive (+) → Terminal 2

Battery negative (-) → Terminal 1

Motor gear rotates counterclockwise

2. INSPECT POWER WINDOW REGULATOR MOTOR

(FRONT LH)

(a) without Jam protection:

Apply battery voltage to the motor connector

according to the table below.

NOTICE:

Do not apply battery voltage to any terminals

except terminals 1 and 2.

Standard

Measurement Condition Specified Condition

Battery positive (+) → Terminal 2

Battery negative (-) → Terminal 1

Battery positive (+) → Terminal 1

Battery negative (-) → Terminal 2

Motor gear rotates counterclockwise

Motor gear rotates clockwise

Motor gear rotates clockwise

Counterclockwise

Motor Gear

Clockwise

B137055E01

(b) with Jam protection:

Apply battery voltage to the motor connector

according to the table below.

NOTICE:

Do not apply battery voltage to any terminals

except terminals 1, 2, 4, 7 and 10.

Standard

Switch Condition Measurement Condition Specified Condition

Manual Operation

Auto Operation

Battery positive (+) →

Terminal 2 (PWR)

Battery negative (-) →

Terminal 1 (E), 7 (DN)

Battery positive (+) →

Terminal 2 (PWR)

Battery negative (-) →

Terminal 1 (E), 10 (UP)

Battery positive (+) →

Terminal 2 (PWR)

Battery negative (-) →

Terminal 1 (E), 4

(AUTO), 7 (DN)

Battery positive (+) →

Terminal 2 (PWR)

Battery negative (-) →

Terminal 1 (E), 4 (AUTO)

10 (UP)

Motor gear rotates

clockwise

Motor gear rotates

counterclockwise

Motor gear rotates

clockwise

Motor gear rotates

counterclockwise

Clockwise

Couterclockwise

Motor Gear

WINDSHIELD / WINDOWGLASS – POWER WINDOW REGULATOR MOTOR

3. INSPECT POWER WINDOW REGULATOR MOTOR

Motor Gear

(REAR RH)

(a) Apply battery voltage to the motor connector

according to the table below.

NOTICE:

Do not apply battery voltage to any terminals

except terminals 1 and 2.

Standard

B127536E02

Measurement Condition Specified Condition

Battery positive (+) → Terminal 2

Battery negative (-) → Terminal 1

Battery positive (+) → Terminal 1

Battery negative (-) → Terminal 2

Motor gear rotates clockwise

Motor gear rotates counterclockwise

4. INSPECT POWER WINDOW REGULATOR MOTOR

(REAR LH)

(a) Apply battery voltage to the motor connector

according to the table below.

NOTICE:

Counterclockwise

Do not apply battery voltage to any terminals

except terminals 1 and 2.

Standard

Clockwise

B127535E01

Measurement Condition Specified Condition

Battery positive (+) → Terminal 1

Battery negative (-) → Terminal 2

Battery positive (+) → Terminal 2

Battery negative (-) → Terminal

Motor gear rotates clockwise

Motor gear rotates counterclockwise

WS–49

WS

WS

WS–50

WINDSHIELD / WINDOWGLASS – POWER WINDOW REGULATOR MOTOR

INSTALLATION

1. INSTALL REAR POWER WINDOW REGULATOR

MOTOR ASSEMBLY (See page ED-51)

2. INSTALL REAR DOOR WINDOW REGULATOR SUBASSEMBLY (See page ED-51)

3. INST ALL REAR DOOR GLASS RUN (See page ED-52)

4. INST ALL REAR DOOR GLASS SUB-ASSEMBLY (See

page ED-52)

5. INSTALL REAR DOOR QUARTER WINDOW GLASS

(See page ED-52)

6. INSTALL REAR DOOR LOWER WINDOW FRAME

SUB-ASSEMBLY (See page ED-52)

7. INSTALL REAR DOOR SERVICE HOLE COVER (See

page ED-53)

8. INSTALL REAR DOOR INNER GLASS

WEATHERSTRIP (See page ED-54)

9. INSTALL REAR DOOR TRIM BOARD SUBASSEMBLY (See page ED-55)

10. INSTALL DOOR ASSIST GRIP COVER (See page ED-

56)

11. INSTALL REAR DOOR INSIDE HANDLE BEZEL

PLUG (See page ED-56)

12. INITIALIZATION POWER WINDOW CONTROL

SYSTEM

(See page WS-8)

13. INSTALL FRONT POWER WINDOW REGULATOR

MOTOR ASSEMBLY (See page ED-31)

14. INSTALL FRONT DOOR WINDOW REGULATO R SUBASSEMBLY (See page ED-31)

15. INSTALL FRONT DOOR GLASS SUB-ASSEMBLY

(See page ED-31)

16. INST ALL FRONT DOOR SERVICE HOLE COVER (See

page ED-32)

17. INSTALL FRONT NO. 1 SPEAKER ASSEMBLY (See

page AV-157)

18. INSTALL FRONT DOOR INNER GLASS

WEATHERSTRIP (See page ED-32)

19. INSTALL FRONT DOOR TRIM BOARD SUBASSEMBLY (See page ED-33)

20. INSTALL COURTESY LIGHT ASSEMBLY (See page

ED-34)

21. INSTALL ASSIST GRIP COVER (See page ED-34)

22. INSTALL FRONT DOOR INSIDE HANDLE BEZEL

PLUG (See page ED-34)