2GR-FE EMISSION CONTROL – EMISSION CONTROL SYSTEM

ENGINE2GR-FE EMISSION CONTROL

EMISSION CONTROL SYSTEM

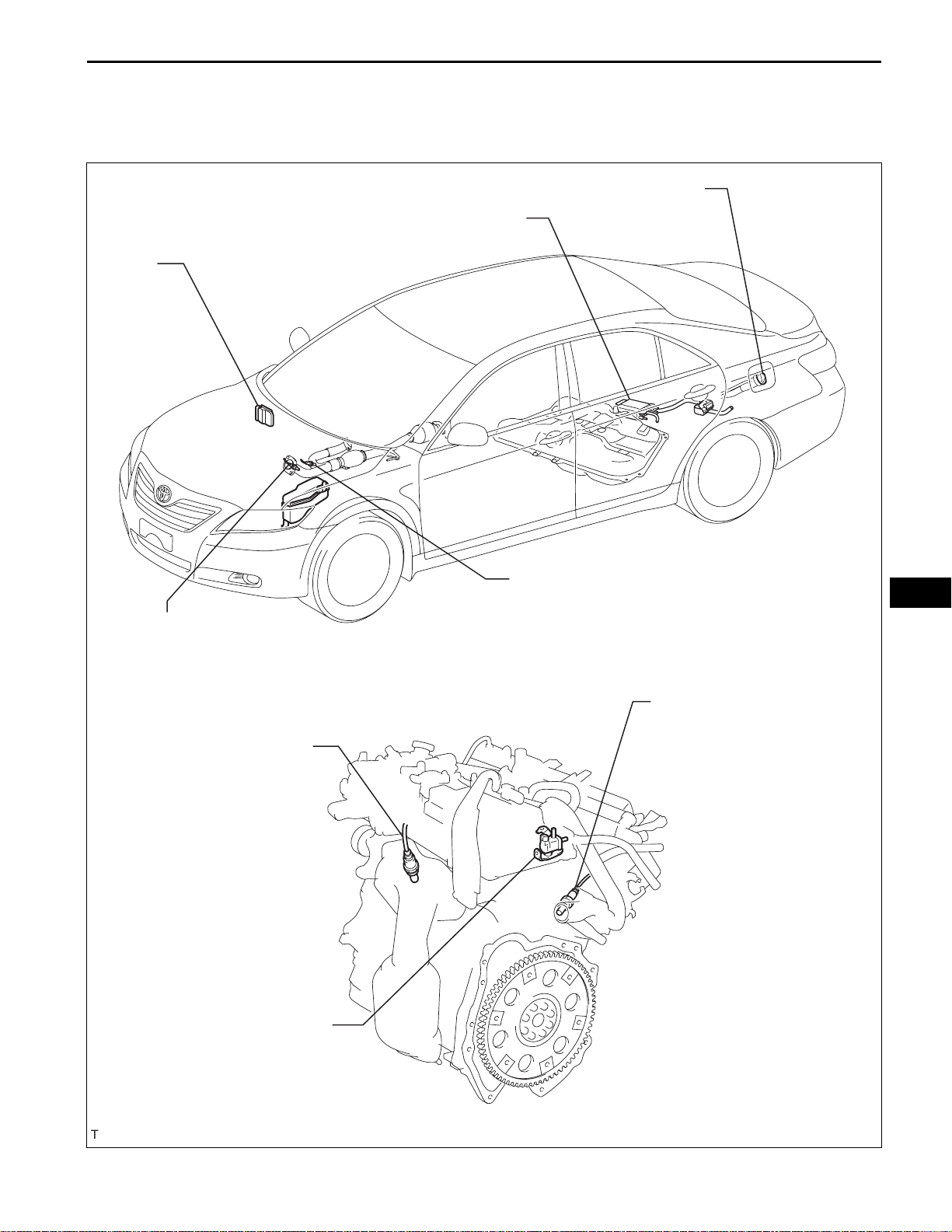

PARTS LOCATION

CANISTER

ECM

EC–1

FUEL TANK CAP

HEATED OXYGEN SENSOR

(BANK 2 SENSOR 2)

AIR FUEL RATIO SENSOR

(BANK 2 SENSOR 1)

VACUUM SWITCHING VALVE

HEATED OXYGEN SENSOR

(BANK 1 SENSOR 2)

AIR FUEL RATIO SENSOR

(BANK 1 SENSOR 1)

EC

A135647E03

EC–2

to Charcoal Canister

2GR-FE EMISSION CONTROL – EMISSION CONTROL SYSTEM

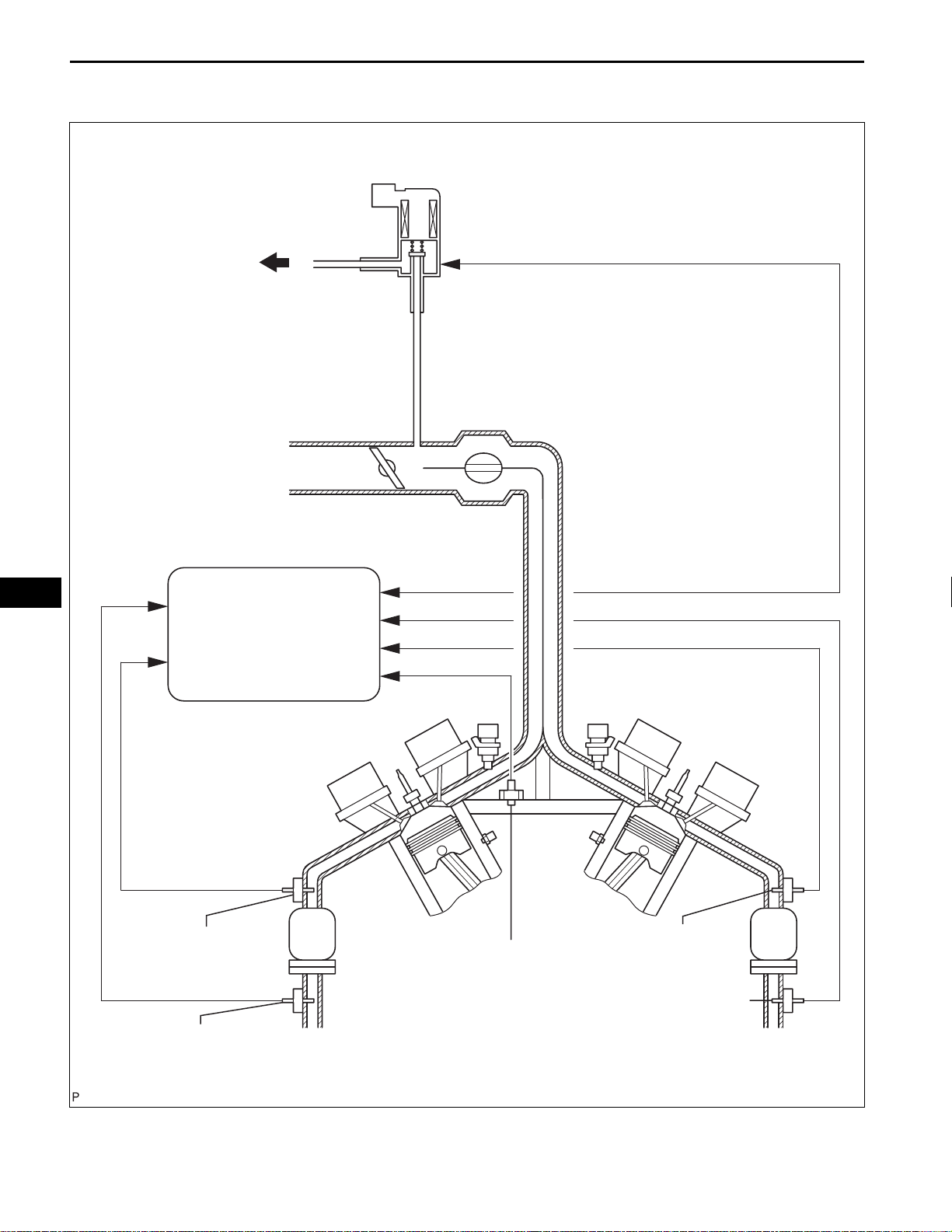

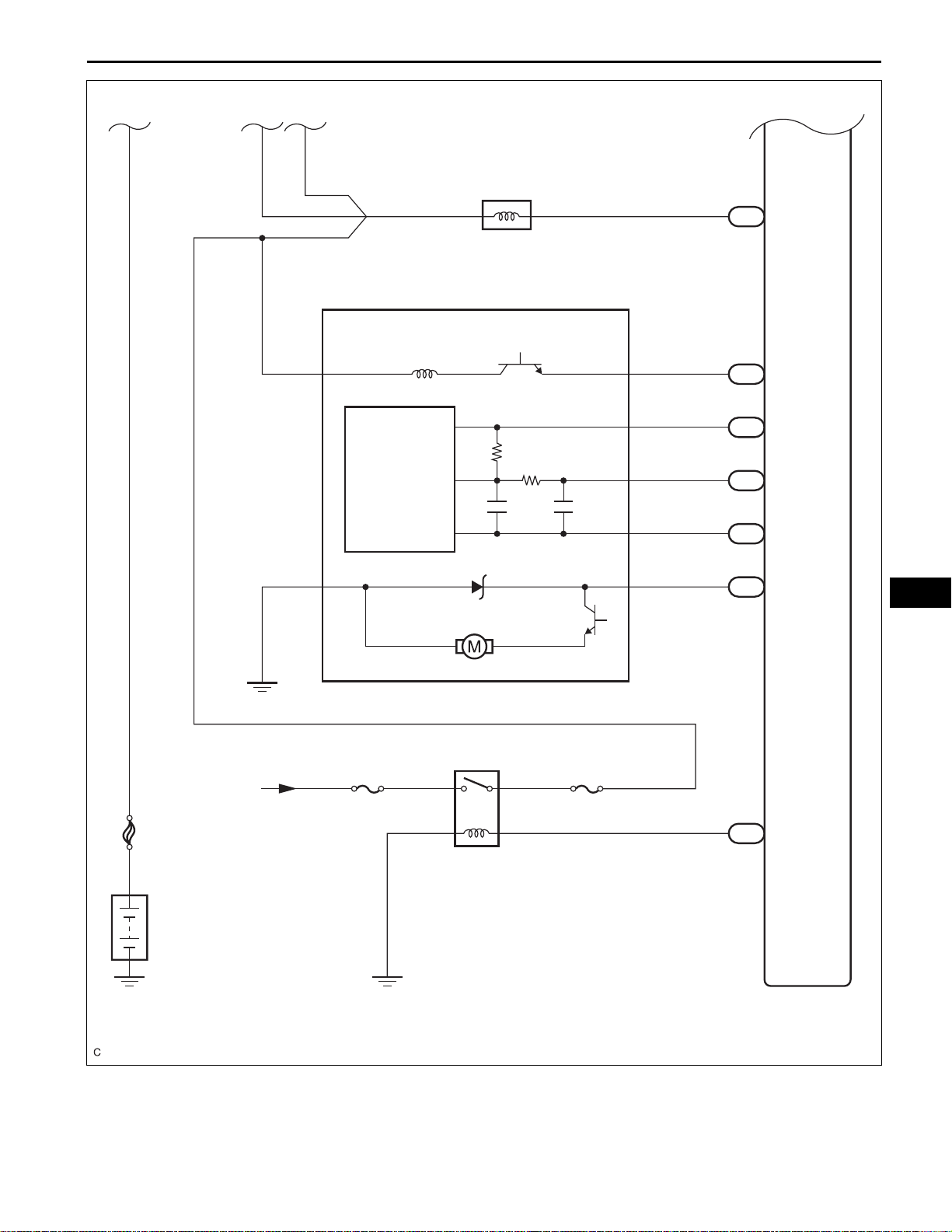

SYSTEM DIAGRAM

VSV for EVAP

EC

ECM

Air Fuel Ratio Sensor

(Bank 1)

Heated Oxygen Sensor

(Bank 1)

Engine Coolant

Temperature Sensor

Air Fuel Ratio Sensor

(Bank 2)

Heated Oxygen Sensor

(Bank 2)

A113656E02

EVAP System Circuit :

2GR-FE EMISSION CONTROL – EMISSION CONTROL SYSTEM

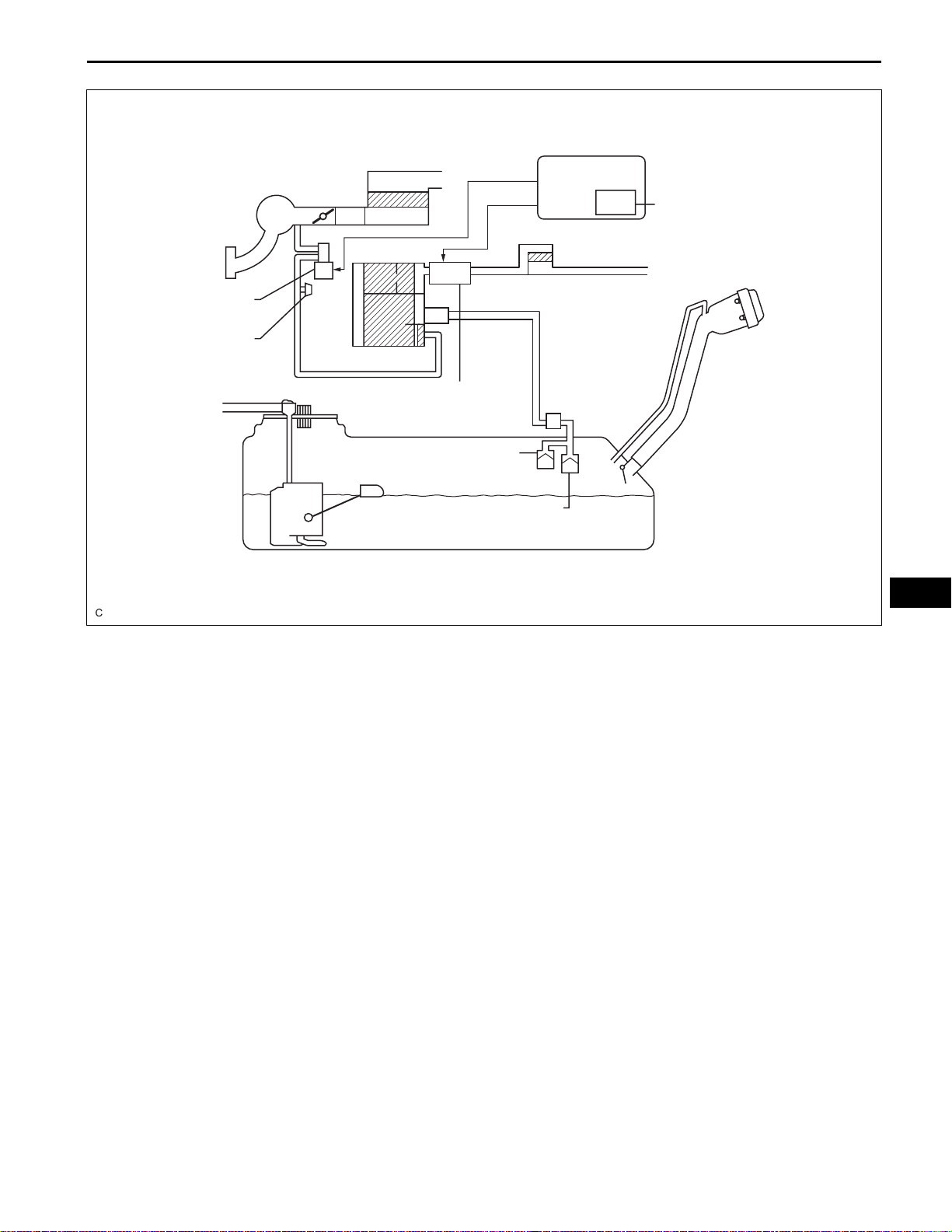

Air Cleaner

ECM

EC–3

Intake Manifold

EVAP VSV

Service Port

Canister

Pump Module

Roll-over Valve

Cut-off Valve

Fuel Tank

Air Filter

Soak Timer

Fuel Cap

A128936E03

EC

EC–4

2GR-FE EMISSION CONTROL – EMISSION CONTROL SYSTEM

EC

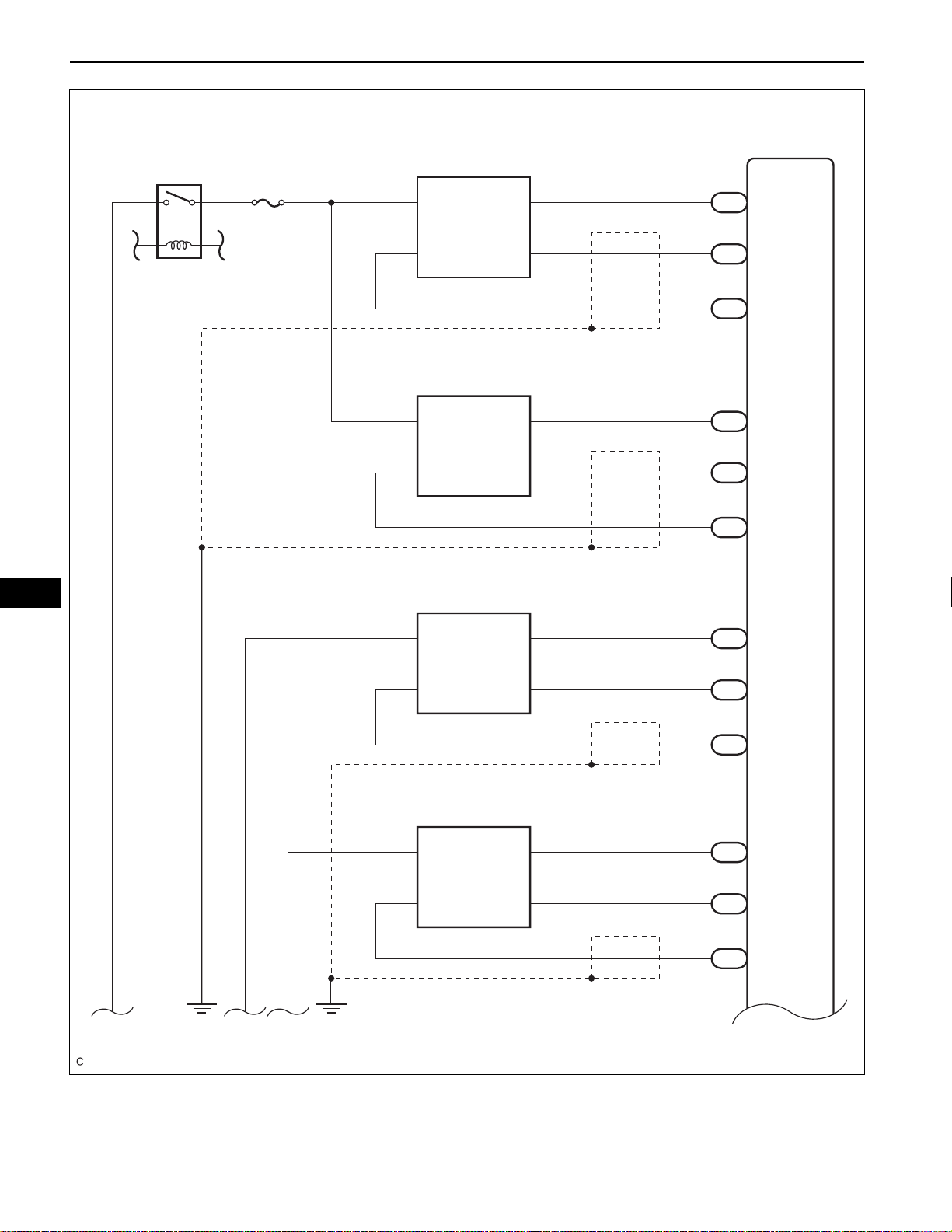

A/F

A/F

C15

Air Fuel Ratio Sensor (Bank 1 Sensor 1)

+B

2

A1A-

4

C35

Air Fuel Ratio Sensor (Bank 2 Sensor 1)

+B

2

A2A-

4

C52

Heated Oxgen Sensor (Bank 1 Sensor 2)

+B

2

OX1B

3

HA1A

A1A+

HA2A

A2A+

E2

HT1B

1

3

1

3

4

1

(*1)

(*1)

(*1)

86

C55

93

C55

116

C55

109

C55

120

C55

119

C55

65

C55

48

C55

88

C55

ECM

HA1A

A1A+

A1A-

HA2A

A2A+

A2A-

EX1B

HT1B

OX1B

C51

Heated Oxgen Sensor (Bank 2 Sensor 2)

2

3

+B

OX2B

E2

HT2B

*1 : Shielded

4

1

(*1)

64

C55

47

C55

87

C55

EX2B

HT2B

OX2B

A135721E02

2GR-FE EMISSION CONTROL – EMISSION CONTROL SYSTEM

C6

VSV (Purge)

21

N17

Canister Pump Module

Vent Valve

VLVB

9

Canister

Pressure

Sensor

MGND

Leak Detection Pump

VGND

1

VCC

4

VOUT

3

SGND

2

MTRB

86

108

C55

34

A55

75

C55

77

C55

76

C55

42

A55

PRG

MPMP

VCPP

PPMP

EPPM

VPMP

EC–5

EC

From Battery

FL MAIN

Battery

EFI MAIN

EFI

EFI No. 3

44

A55

MREL

A135722E01

EC

EC–6

2GR-FE EMISSION CONTROL – EMISSION CONTROL SYSTEM

ON-VEHICLE INSPECTION

1. INSPECT FUEL CUT-OFF RPM

(a) Increase the engine speed to at least 3,500 rpm.

(b) Use a sound scope to check for injector operating

sounds.

(c) Check that when the throttle lever is released,

injector operating sounds stop momentarily (at

2,500 rpm) and then resume (at 1,400 rpm).

Standard

Item Specified Condition

Fuel cut off rpm 2,500 rpm

Fuel return rpm 1,400 rpm

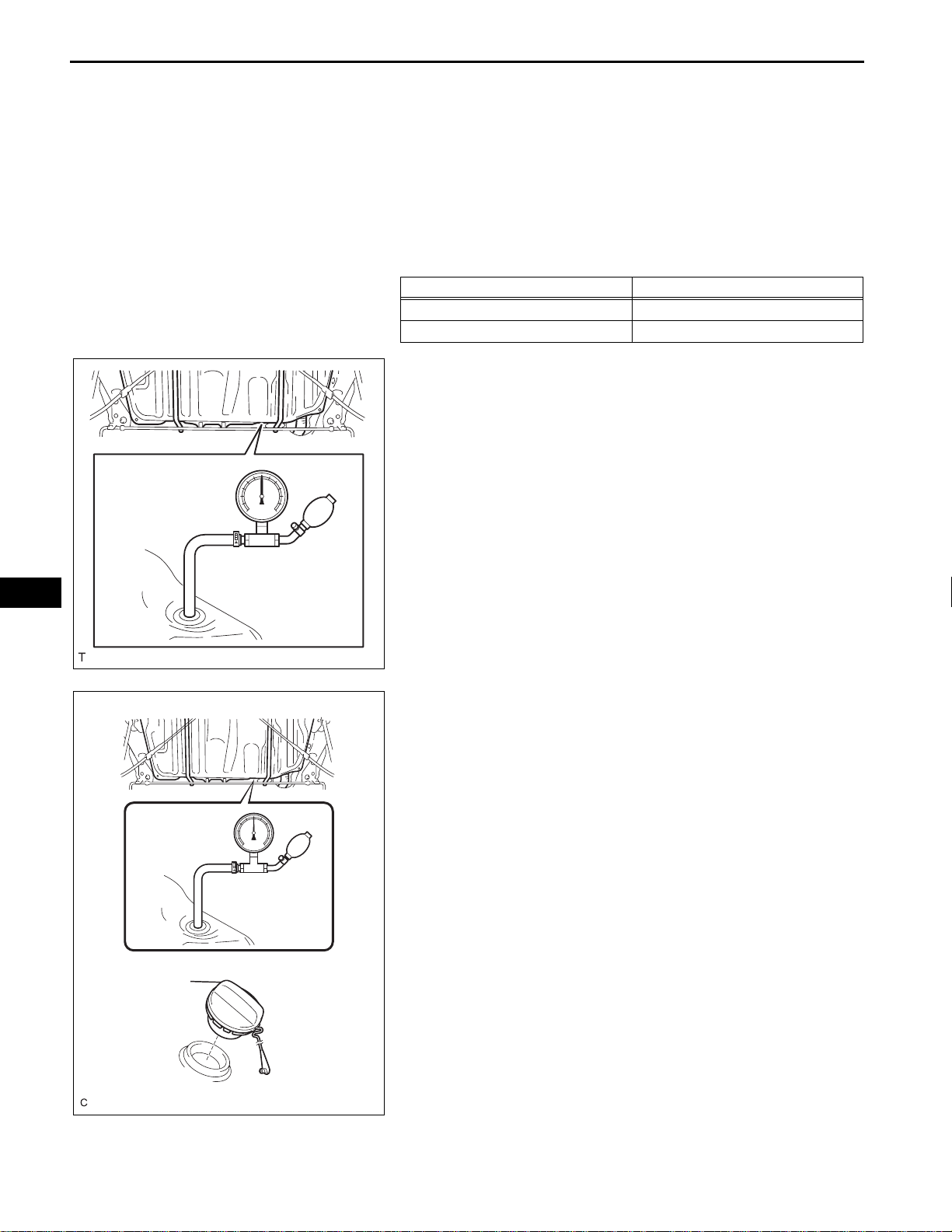

2. CHECK AIR TIGHTNESS IN FUEL TANK AND FILLER

PIPE

(a) Disconnect the vent line hose from the fuel tank.

(b) Connect the pressure gauge to the fuel tank.

(c) Apply pressure to the fuel tank to create an internal

pressure of 4 kPa (41 gf/cm

(d) Check that the internal pressure of the fuel tank is

maintained for 1 minute.

(e) Check the connected portions of each hose and

pipe.

(f) Check the installed parts on the fuel tank.

If any malfunctions, damage or other problems are

found, replace the fuel tank and filler pipe.

(g) Reconnect the vent line hose to the fuel tank.

2

, 0.58 psi).

Fuel Tank Cap

A128092

A126204E01

3. INSPECT FUEL CUT OFF VALVE AND FUEL CHECK

VALVE

(a) Disconnect the vent line hose from the fuel tank.

(b) Connect the pressure gauge to the fuel tank.

(c) Fill the fuel tank with fuel.

(d) Apply pressure of 4 kPa (41 gf/cm

2

, 0.58 psi) to the

vent port of the fuel tank.

HINT:

Check the amount of fuel in the fuel tank. When the

fuel tank is full, the float valve of the fill check valve

is closed and no air can pass through.

(e) Remove the fuel tank cap, and check that the

pressure drops.

If the pressure does not drop, replace the fuel tank

assembly.

(f) Reconnect the vent line hose to the fuel tank.

Air

2GR-FE EMISSION CONTROL – EMISSION CONTROL SYSTEM

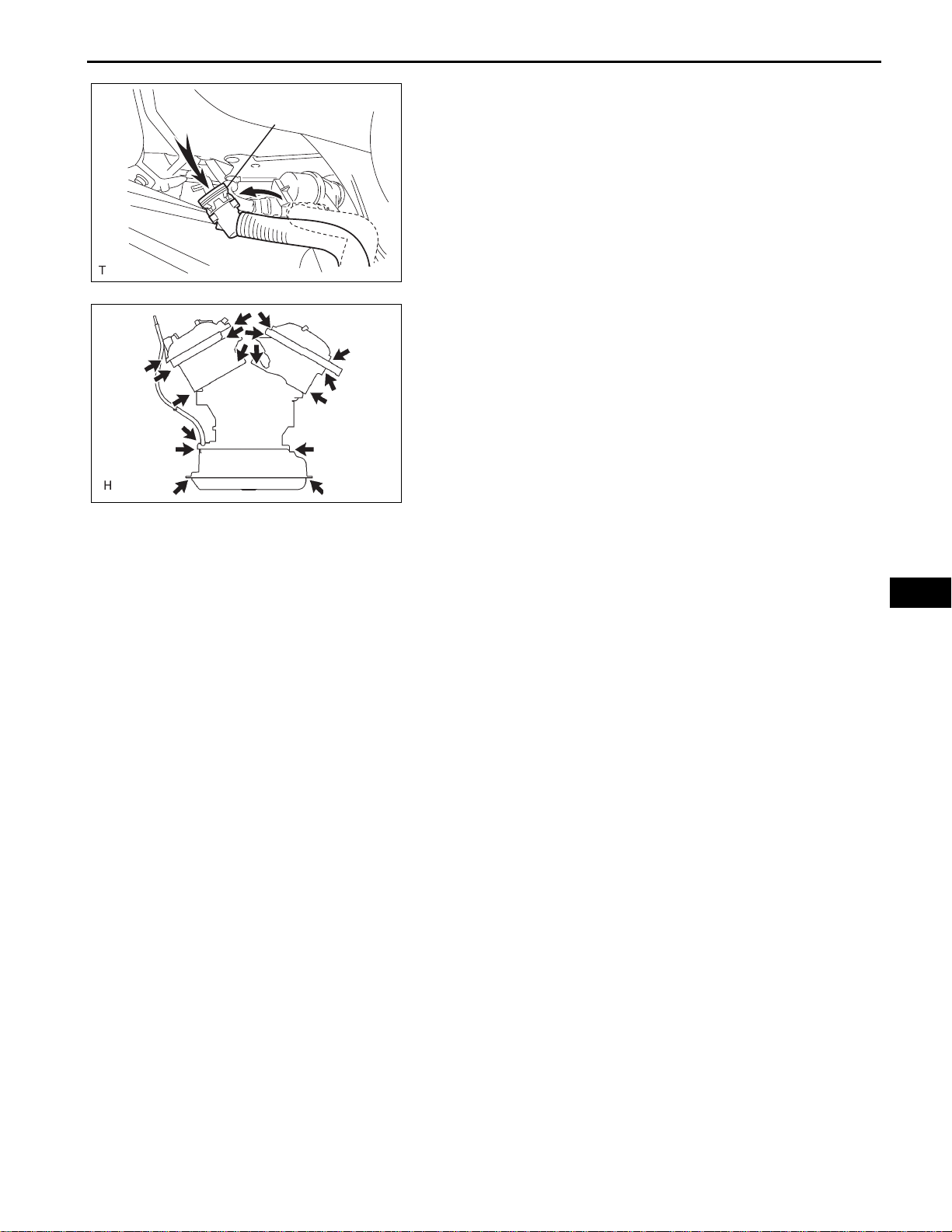

4. CHECK AIR INLET LINE

Air Inlet Hose

(a) Disconnect the air inlet line hose from the charcoal

canister.

(b) Check that air can flow freely into the air inlet line.

If air cannot flow freely into the air inlet line, repair or

replace it.

(c) Reconnect the air inlet line hose to the charcoal

canister.

A128093E02

5. VISUALLY INSPECT HOSES, CONNECTIONS AND

GASKETS

(a) Check for cracks, leaks or damage.

HINT:

Removal or problems with the engine oil dipstick, oil

filler cap, PCV hose and other components may

cause the engine to run improperly. Disconnection,

looseness or cracks in the parts of the air induction

system between the throttle body and cylinder head

A094394

will allow air suction and cause the engine to run

improperly.

If necessary, replace any damaged parts.

EC–7

EC

EC–8

ENGINE2GR-FE EMISSION CONTROL

CANISTER

COMPONENTS

2GR-FE EMISSION CONTROL – CANISTER

EC

CHARCOAL CANISTER ASSEMBLY

39 (398, 29)

N*m (kgf*cm, ft.*lbf)

: Specified torque

A135648E04

Pinch A

2GR-FE EMISSION CONTROL – CANISTER

REMOVAL

1. REMOVE FUEL TANK ASSEMBLY

HINT:

(See page FU-36)

2. REMOVE CHARCOAL CANISTER ASSEMBLY

(a) Disconnect the fuel tank vent hose from the

charcoal canister.

A

(1) Push the connector deep inside.

(2) Pinch portion A.

(3) Pull out the connector.

EC–9

Pinch A

Pinch

Pinch

Push

Push

A

A132954E01

(b) Disconnect the charcoal canister filter sub-assembly

from the charcoal canister.

(1) Push the connector deep inside.

A

(2) Pinch portion A.

(3) Pull out the connector.

(c) Disconnect the vapor pressure sensor connector.

A

(d) Disconnect the wire harness clamp.

(e) Disconnect the purge line hose from the charcoal

canister.

A128095E01

EC

(f) Remove the 2 bolts, clip and charcoal canister.

A128096

A128097

INSPECTION

1. INSPECT CHARCOAL CANISTER ASSEMBLY

(a) Visually check the charcoal canister for cracks or

damage.

If cracks or damage are found, replace the charcoal

canister assembly.

EC–10

Purge Port

Air

2GR-FE EMISSION CONTROL – CANISTER

(b) Check charcoal canister operation.

(1) With the purge port closed, blow 1.67 kPa (17.0

2

gf/cm

, 0.24 psi) of air into the vent port, and

check that air flows from the air inlet port.

If the result is not as specified, replace the

charcoal canister assembly.

EC

Purge Port

Port B

Port A

Vent Port

Air Inlet Port

Air Inlet Port

Vent Port

Purge Port

Air Inlet Port

A128098E01

Air

A128099E02

(2) With the vent port closed, blow 1.10 kPa (11.2

2

gf/cm

, 0.16 psi) of air to the air inlet port, and

check that air flows from the purge port.

If the result is not as specified, replace the

charcoal canister assembly.

(c) Check for air leakage.

(1) Remove the air hose between ports A and B.

(2) Connect the SST (pressure gauge) to the vent

port of the charcoal canister.

SST 09992-00242

(3) While holding port B, with the purge port and

the air inlet port closed and port A open, apply

19.6 kPa (0.2 kgf/cm

2

, 2.81 psi) of pressurized

air into the vent port, then confirm that pressure

is retained for 1 minute.

If the result is not as specified, replace the

charcoal canister assembly.

Vent Port

SST

Air

Pressure Gauge

A128100E02

(d) Check the leak detection pump.

(1) Remove the detection pump from the charcoal

canister.

C

(2) Check that air flows from port A to B and then

C.

If the result is not as specified, replace the

charcoal canister assembly.

A

B

A128108E01

2GR-FE EMISSION CONTROL – CANISTER

EC–11

76

Valve

Closed

(3) Connect the positive (+) lead to terminal 7 and

the negative (-) lead to terminal 6.

(4) Check that the valve is closed.

If the result is not as specified, replace the

charcoal canister assembly.

(5) Install the detection pump.

A128109E01

INSTALLATION

1. INSTALL CHARCOAL CANISTER ASSEMBLY

(a) Install the 2 bolts, clip and charcoal canister.

Torque: 39 N*m (398 kgf*cm, 29 ft.*lbf)

(b) Connect the purge line hose to the charcoal

canister.

(c) Connect the wire harness clamp.

(d) Connect the vapor pressure sensor connector.

(e) Connect the charcoal canister filter sub-assembly to

the charcoal canister.

(f) Connect the fuel tank vent hose to the charcoal

canister.

A128096

2. INSTALL FUEL TANK ASSEMBLY

HINT:

(See page FU-41)

EC

EC–12

ENGINE2GR-FE EMISSION CONTROL

2GR-FE EMISSION CONTROL – VACUUM SWITCHING VALVE (for EVAP)

VACUUM SWITCHING VALVE (for EVAP)

COMPONENTS

V-BANK COVER SUB-ASSEMBLY

VACUUM HOSE

5.0 (51, 44 in.*lbf)

EC

VACUUM HOSE

NO. 1 VACUUM SWITCHING VALVE

N*m (kgf*cm, ft.*lbf)

: Specified torque

A135653E03

2GR-FE EMISSION CONTROL – VACUUM SWITCHING VALVE (for EVAP)

REMOVAL

1. REMOVE V-BANK COVER SUB-ASSEMBLY (See

page EM-23)

2. REMOVE NO. 1 VACUUM SWITCHING VALVE

(a) Disconnect the 2 vacuum hoses and No. 1 vacuum

switching valve connector.

A132952E01

(b) Remove the bolt and No. 1 vacuum switching valve.

EC–13

A132953

INSPECTION

EC

1. INSPECT EVAP VSV

(a) Check the VSV for an open circuit.

(1) Measure the resistance.

2

1

Standard resistance

Tester Connection Specified Condition

1 - 2 23 to 26Ω at 20°C (68°F)

1 - Body ground

2 - Body ground

10 kΩ or higher

If the resistance is not as specified, replace the

VSV assembly.

2

1

A128939E02

EC–14

2GR-FE EMISSION CONTROL – VACUUM SWITCHING VALVE (for EVAP)

(b) Check VSV operation.

(1) Check that air does not flow from the port as

shown in the illustration.

EC

F

E

Air

A128937E01

(2) Apply battery positive voltage across the

terminals.

(3) Check that air flows from the ports.

If the result is not as specified, replace the VSV

F

E

Air

A128938E01

assembly.

INSTALLATION

1. INSTALL NO. 1 VACUUM SWITCHING VALVE

(a) Install the No. 1 vacuum switching valve with the

bolt.

Torque: 5.0 N*m (51 kgf*cm, 44 in.*lbf)

A132953

A132952E01

(b) Disconnect the 2 vacuum hoses and No. 1 vacuum

switching valve connector.

2. INSTALL V-BANK COVER SUB-ASSEMBLY (See

page EM-52)

2GR-FE EMISSION CONTROL – VENTILATION VALVE

ENGINE2GR-FE EMISSION CONTROL

VENTILATION VALVE

COMPONENTS

EC–15

V-BANK COVER SUB-ASSEMBLY

VENTILATION VALVE

27(275, 20)

VENTILATION HOSE

EC

: Specified torque

Precoated partN*m (kgf*cm, ft.*lbf)

A135651E03

EC–16

2GR-FE EMISSION CONTROL – VENTILATION VALVE

REMOVAL

1. REMOVE V-BANK COVER SUB-ASSEMBLY (See

page EM-23)

2. DISCONNECT VENTILATION HOSE

(a) Disconnect the ventilation hose from the ventilation

valve.

A135715E01

3. REMOVE VENTILATION VALVE

(a) Remove the ventilation valve.

EC

Air

Clean Hose

Cylinder Head Side

Clean Hose

Intake Manifold Side

Air

A138519E01

A113429E01

A105281E01

INSPECTION

1. INSPECT VENTILATION VALVE

(a) Install a clean hose to the ventilation valve.

(b) Check the ventilation valve operation.

(1) Blow air into the cylinder head side, and check

that air passes through easily.

NOTICE:

Do not suck air through the valve.

Petroleum substances inside the valve are

hazardous to your health.

(2) Blow air into the intake manifold side, and

check that air passes through with difficulty.

If the result is not as specified, replace the

ventilation valve.

(c) Remove the clean hose from the ventilation valve.

Adhesive

2GR-FE EMISSION CONTROL – VENTILATION VALVE

INSTALLATION

1. INSTALL VENTILATION VALVE

(a) Install the ventilation valve.

(1) Apply adhesive to 2 or 3 threads.

Adhesive:

Part No. 08833-00070, THREE BOND 1324

or equivalent.

A105280E01

(2) Install the ventilation valve.

Torque: 27 N*m (275 kgf*cm, 20 ft.*lbf)

A138519E01

EC–17

A135715E01

2. CONNECT VENTILATION HOSE

(a) Connect the ventilation hose to the ventilation valve.

3. INSTALL V-BANK COVER SUB-ASSEMBLY (See

page EM-52)

EC

EC–18

ENGINE2GR-FE EMISSION CONTROL

2GR-FE EMISSION CONTROL – AIR FUEL RATIO SENSOR

AIR FUEL RATIO SENSOR

COMPONENTS

AIR FUEL RATIO SENSOR

44 (449, 33)

EC

AIR FUEL RATIO SENSOR

N*m (kgf*cm, ft.*lbf)

: Specified torque

44 (449, 33)

A135655E03

2GR-FE EMISSION CONTROL – AIR FUEL RATIO SENSOR

EC–19

Bank 1:

Bank 2:

+B

HT

SST

A128101E02

REMOVAL

1. REMOVE AIR FUEL RATIO SENSOR

(a) Disconnect the 2 air fuel ratio sensor connectors.

(b) Using SST, remove the 2 air fuel ratio sensors from

the front pipe assembly.

SST 09224-00010

INSPECTION

1. INSPECT AIR FUEL RATIO SENSOR

(a) Measure the resistance between terminals 1 (HT)

and 2 (+B).

Standard resistance

EC

Bank 1:

Bank 2:

AF-

Fulcrum Length

AF+

A075325E04

SST

Fulcrum Length

SST

Condition Specified Condition

20 °C (68°F) 1.8 to 3.4 Ω

If the result is not as specified, replace the sensor.

INSTALLATION

1. INSTALL AIR FUEL RATIO SENSOR

(a) Using SST, install the 2 air fuel ratio sensors to the

front pipe assembly.

SST 09224-00010

Torque: 44 N*m (449 kgf*cm, 32 ft.*lbf)

(b) Connect the 2 air fuel ratio sensor connectors.

A128102E03

EC–20

ENGINE2GR-FE EMISSION CONTROL

2GR-FE EMISSION CONTROL – HEATED OXYGEN SENSOR

HEATED OXYGEN SENSOR

COMPONENTS

EC

FRONT EXHAUST PIPE ASSEMBLY

HEATED OXYGEN SENSOR

(BANK 1 SENSOR 2)

62 (632, 46)

GASKET

62 (632, 46)

44 (449, 32)

44 (449, 32)

HEATED OXYGEN SENSOR

(BANK 2 SENSOR 2)

GASKET

56 (571, 41)

GASKET

56 (571, 41)

33 (337, 24)

REAR EXHAUST PIPE NO. 1

SUPPORT BRACKET

FRONT EXHAUST PIPE NO. 1

SUPPORT BRACKET

33 (337, 24)

ENGINE UNDER

COVER RH

N*m (kgf*cm, ft.*lbf)

FRONT EXHAUST PIPE SUPPORT BRACKET

: Specified torque

ENGINE UNDER COVER LH

Non-reusable part

A135657E03

2GR-FE EMISSION CONTROL – HEATED OXYGEN SENSOR

REMOVAL

1. REMOVE ENGINE UNDER COVER LH

2. REMOVE ENGINE UNDER COVER RH

3. REMOVE FRONT EXHAUST PIPE ASSEMBLY (See

page EX-2)

4. REMOVE HEATED OXYGEN SENSOR (for Bank 1)

SST

A135716E01

(a) Using SST, remove the oxygen sensor.

SST 09224-00010

5. REMOVE HEATED OXYGEN SENSOR (for Bank 2)

(a) Using SST, remove the oxygen sensor.

SST 09224-00010

EC–21

+B

E1

SST

EC

A135724E01

INSPECTION

HT

2

1

4

3

OX

A091027E03

1. INSPECT HEATED OXYGEN SENSOR

(a) Measure the resistance between terminals 1 (HT)

and 2 (+B).

Standard resistance

Condition Specified Condition

20°C (68°F) 11 to 16 Ω

If the result is not as specified, replace the sensor.

INSTALLATION

1. INSTALL HEATED OXYGEN SENSOR (for Bank 2)

(a) Using SST, install the heated oxygen sensor.

SST 09224-00010

Torque: 44 N*m (449 kgf*cm, 32 ft.*lbf)

SST

A135725E01

EC–22

2GR-FE EMISSION CONTROL – HEATED OXYGEN SENSOR

2. INSTALL HEATED OXYGEN SENSOR (for Bank 1)

SST

A135717E01

(a) Using SST, install the heated oxygen sensor.

SST 09224-00010

3. INSTALL FRONT EXHAUST PIPE ASSEMBLY (See

page EX-4)

4. INSTALL ENGINE UNDER COVER LH

5. INSTALL ENGINE UNDER COVER RH

EC

2GR-FE EMISSION CONTROL – FUEL TANK CAP

FUEL TANK CAP

INSPECTION

1. REMOVE FUEL TANK CAP ASSEMBLY

(a) Visually check if the cap and gasket are deformed

or damaged.

If necessary, replace the cap.

A126203

EC–23

EC

Loading...

Loading...