Expression

LIGHTING – LIGHTING SYSTEM

LIGHTING SYSTEM

PRECAUTION

1. PRECAUTION FOR USING BATTERY DURING

INSPECTION

(a) While using the battery during inspection, do not

bring the positive and negative tester probes too

close to each other as a short circuit may occur.

2. PRECAUTION FOR HEADLIGHT BULB

REPLACEMENT

(a) If even a thin film of oil is left on the surface of the

halogen light, the bulb may be damaged because

the light will burn at a higher temperature.

(b) Handle any halogen light with great care. Dropping,

hitting or damaging the bulb, in any way, may result

in exploding and shattering because the internal

pressure is high.

(c) Always prepare a new bulb for immediate

replacement. While replacing the bulb, the lens may

attract dust and moisture if removed from the

vehicle for too long.

(d) Always use a bulb of the same wattage for

replacement.

(e) Firmly reinstall the socket after bulb replacement.

The lens may become cloudy or the light cavity may

fill with water through the gaps around the socket.

3. EXPRESSIONS OF IGNITION SWITCH

(a) The type of ignition switch used on this model differs

according to the specifications of the vehicle.

The expressions listed in the table below are used

in this section.

Switch Type Ignition Switch (position) Engine Switch (condition)

Ignition switch off LOCK Off

Ignition switch on (IG) ON On (IG)

Ignition switch on (ACC) ACC On (ACC)

Engine start START Start

LI–1

LI

LI–2

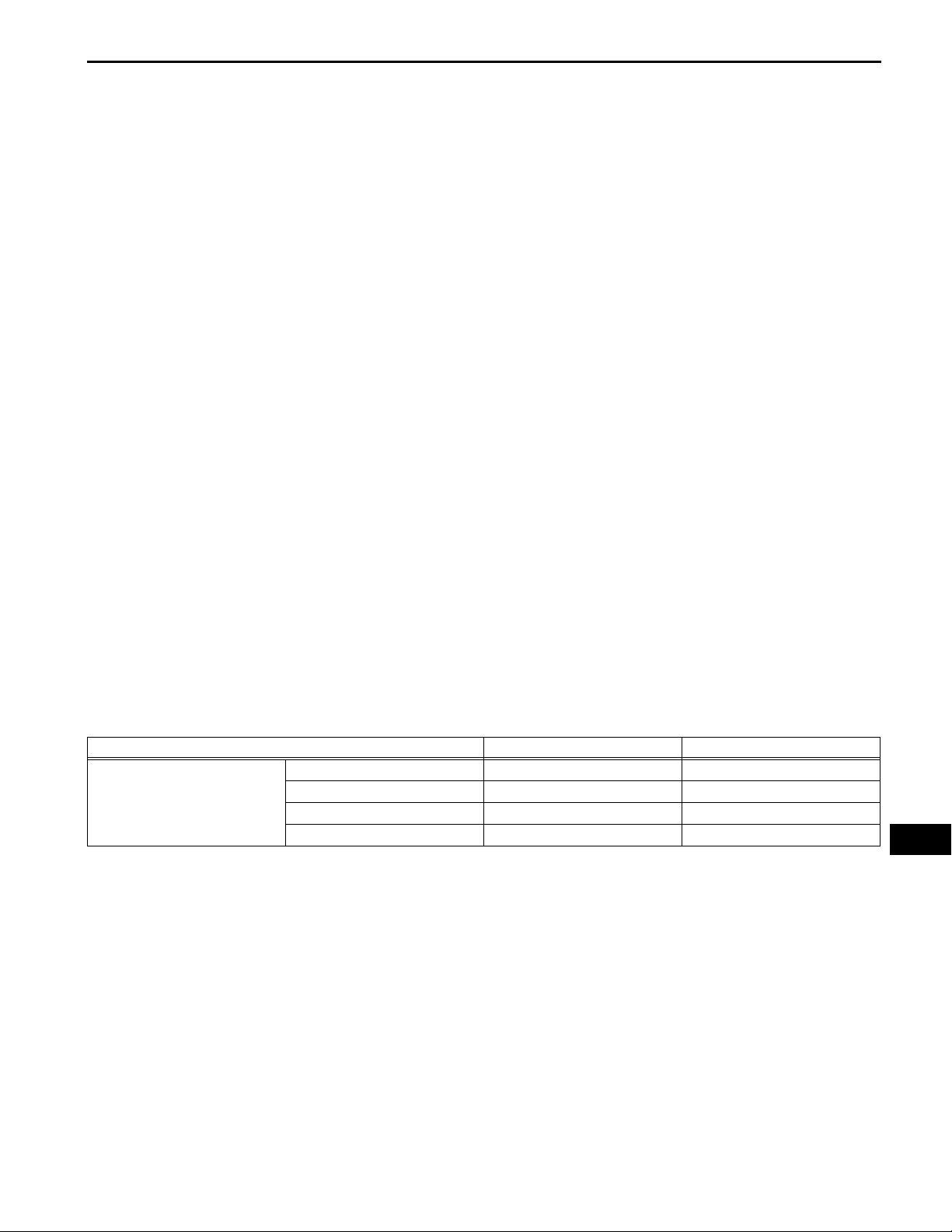

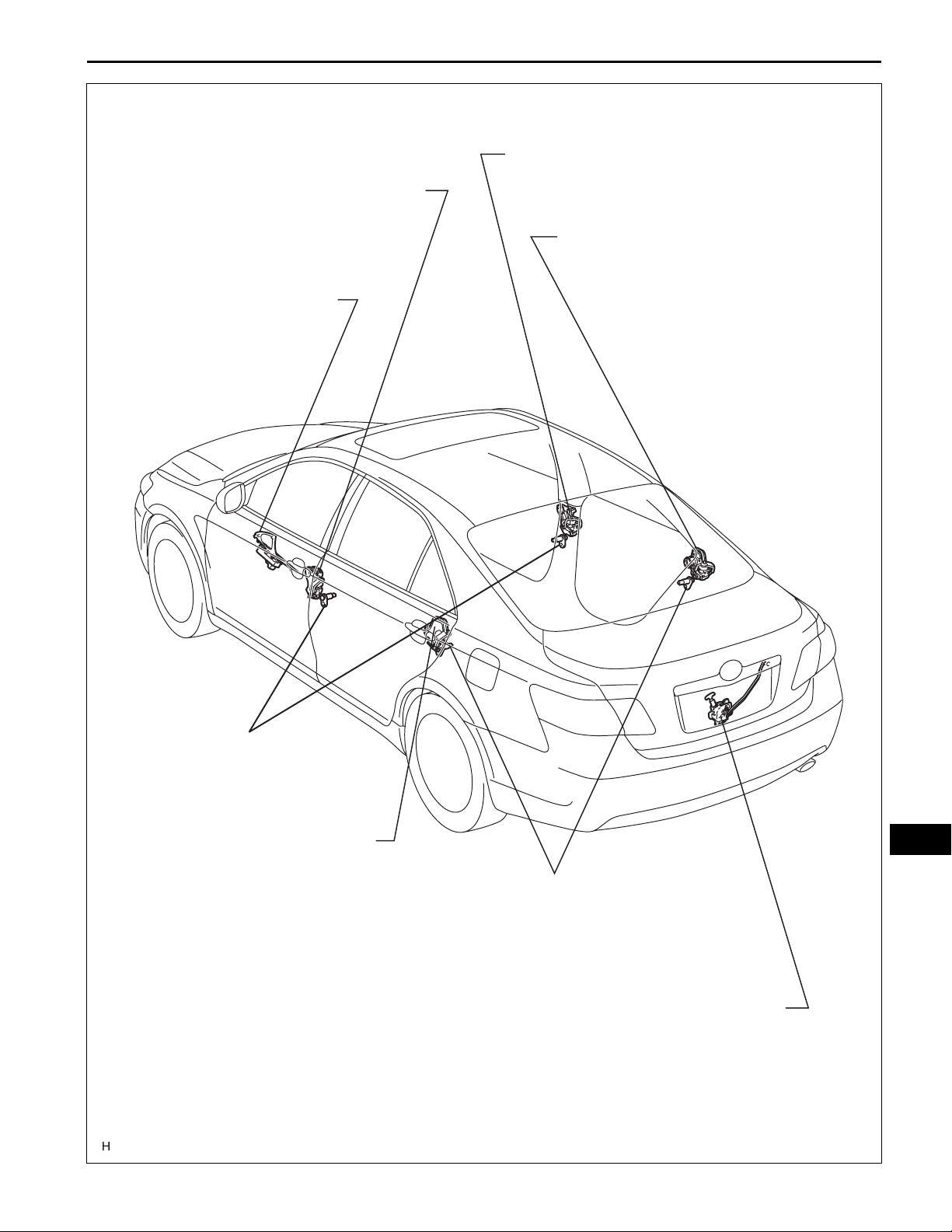

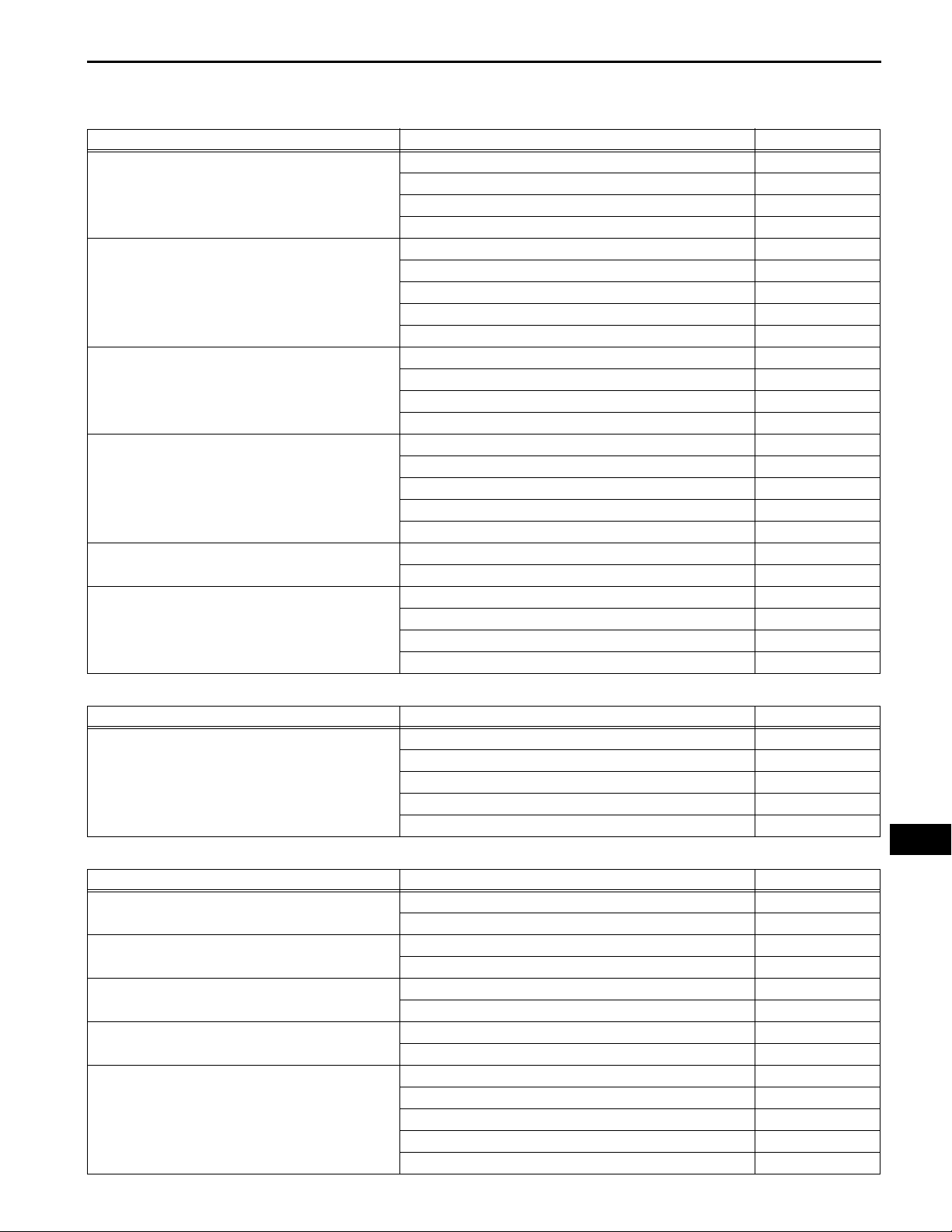

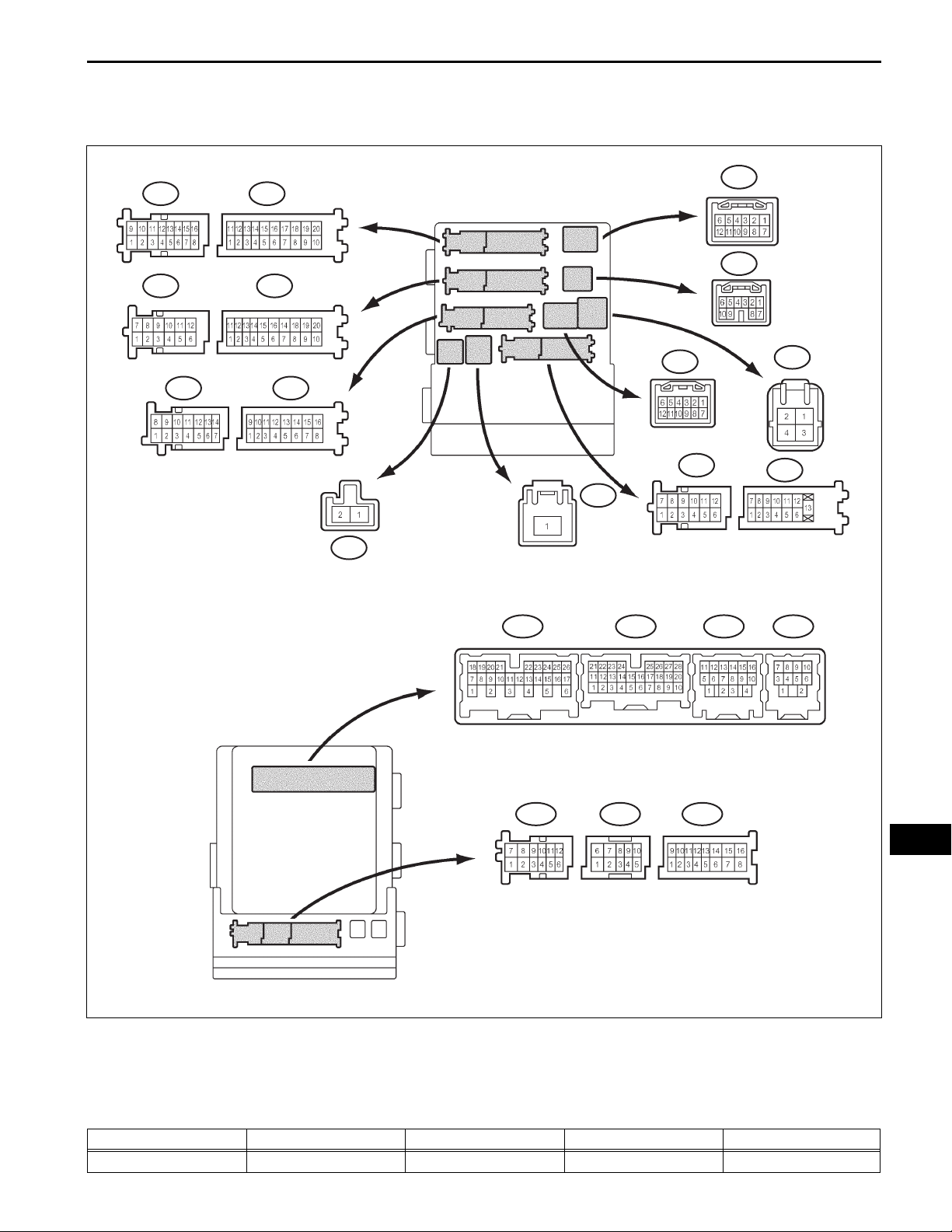

PARTS LOCATION

LIGHTING – LIGHTING SYSTEM

HEADLIGHT ASSEMBLY

- LOW BEAM HEADLIGHT

- HIGH BEAM HEADLIGHT

- FRONT SIDE MARKER LIGHT

- TURN SIGNAL AND PARKING LIGHT

GENERATOR

ENGINE ROOM J/B ASSEMBLY

- POWER DISTRIBUTOR

- H-LP (LL) FUSE

- H-LR (RL) FUSE

- H-LP (LH) FUSE

- H-LP (RH) FUSE

ECM

ENGINE ROOM R/B

- DOME FUSE

- HAZ FUSE

LI

FOG LIGHT ASSEMBLY

PARK / NEUTRAL POSITION SWITCH

(FOR U250E A/T)

PARK / NEUTRAL POSITION SWITCH

(FOR U660E A/T)

BACK-UP LIGHT SWITCH

(FOR M/T)

E121472E01

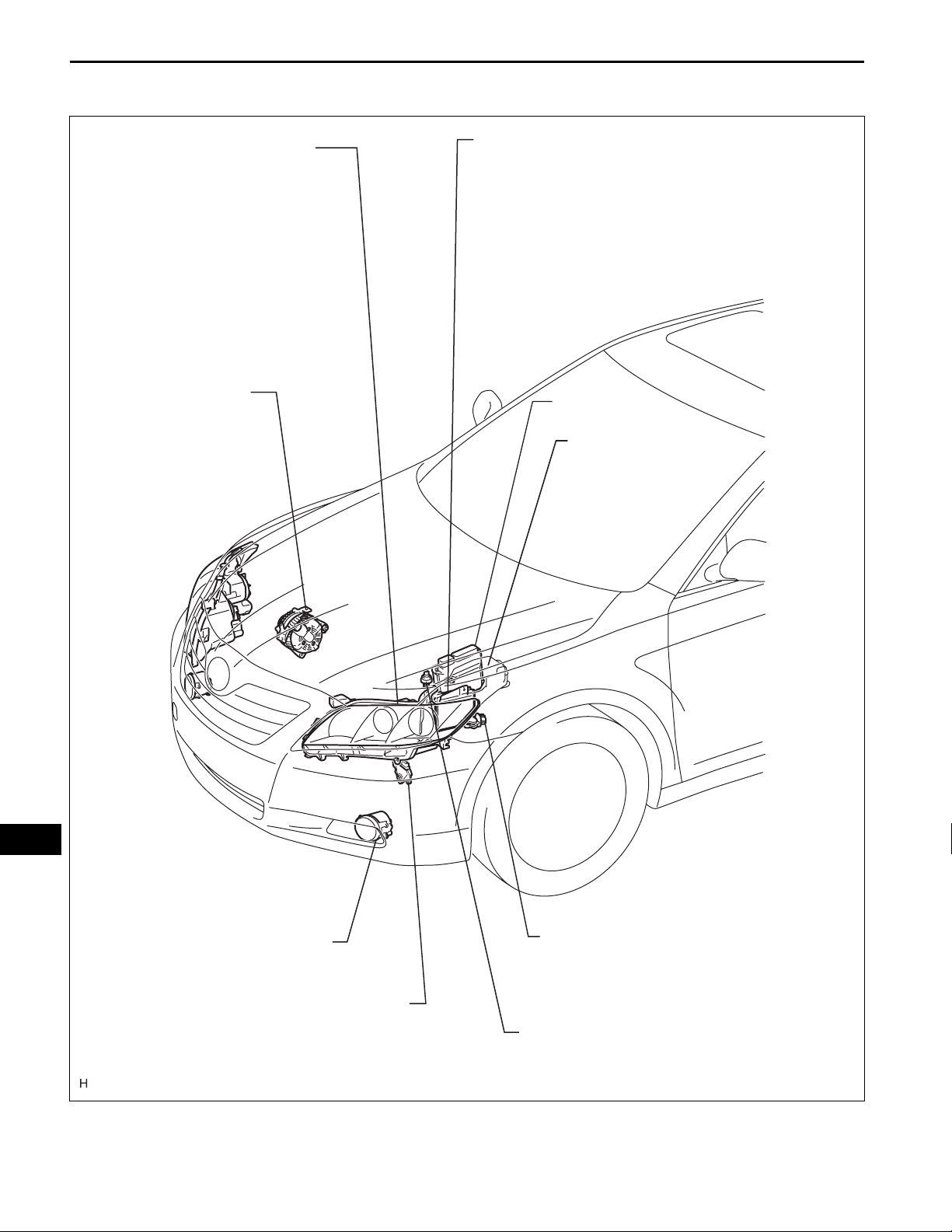

LIGHTING – LIGHTING SYSTEM

LI–3

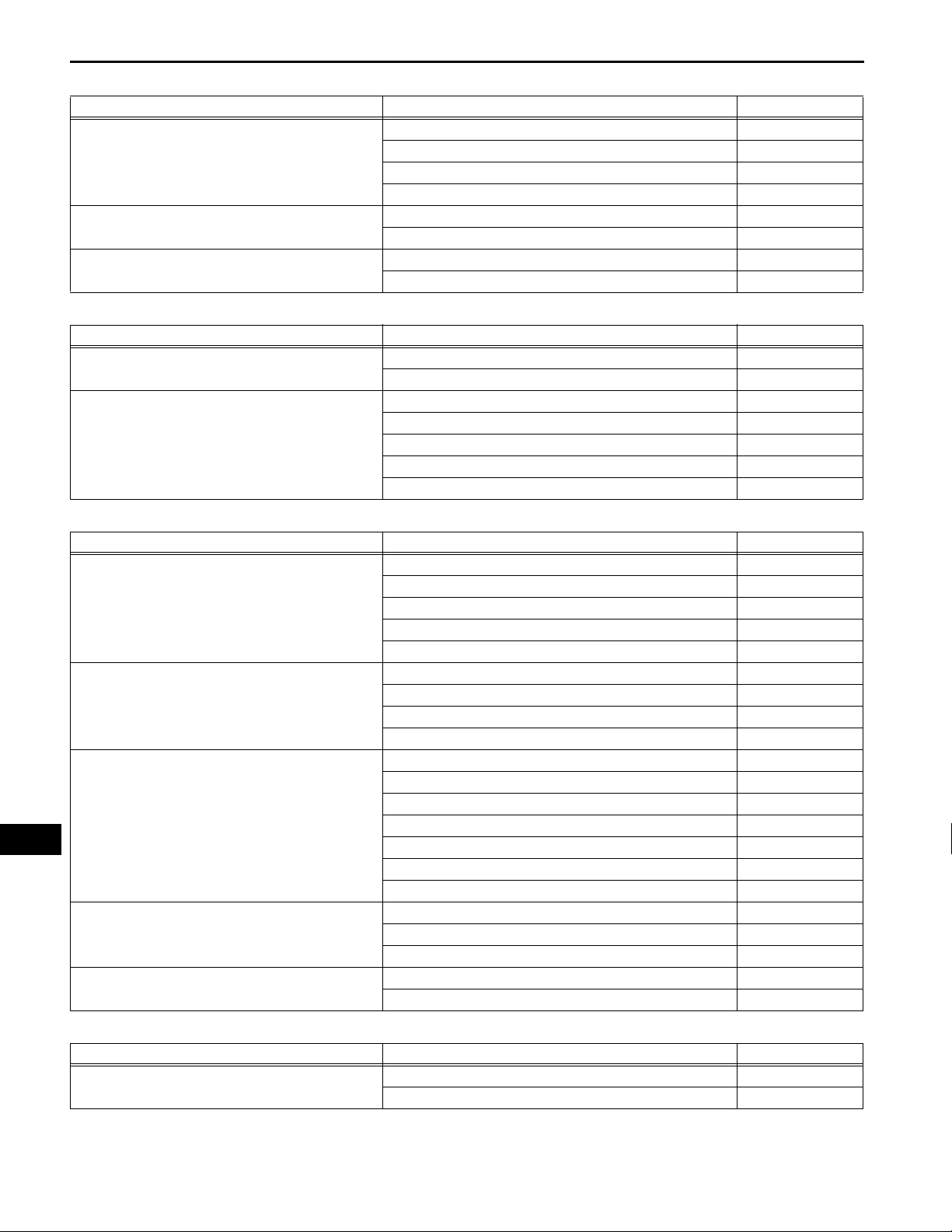

WITHOUT SLIDING ROOF:

PERSONAL LIGHT ASSEMBLY

(OVERHEAD J/B)

- FRONT PERSONAL LIGHTS

- INTERIOR LIGHT

PERSONAL LIGHT ASSEMBLY (OVERHEAD J/B)

- FRONT PERSONAL LIGHTS

REAR ROOM LIGHT ASSEMBLY

- INTERIOR LIGHT

VANITY LIGHT

REAR ROOM LIGHT ASSEMBLY

- REAR PERSONAL LIGHTS

REAR COMBINATION LIGHT ASSEMBLY

- TAIL/STOP AND SIDE MARKER LIGHT

VANITY LIGHT

- TURN SIGNAL LIGHT

REAR LIGHT ASSEMBLY

- BACK-UP LIGHT

- TAILLIGHT

HIGH MOUNTED STOP LIGHT

LI

DOOR COURTESY LIGHT

LUGGAGE ROOM LIGHT

LICENSE PLATE LIGHT

E121473E01

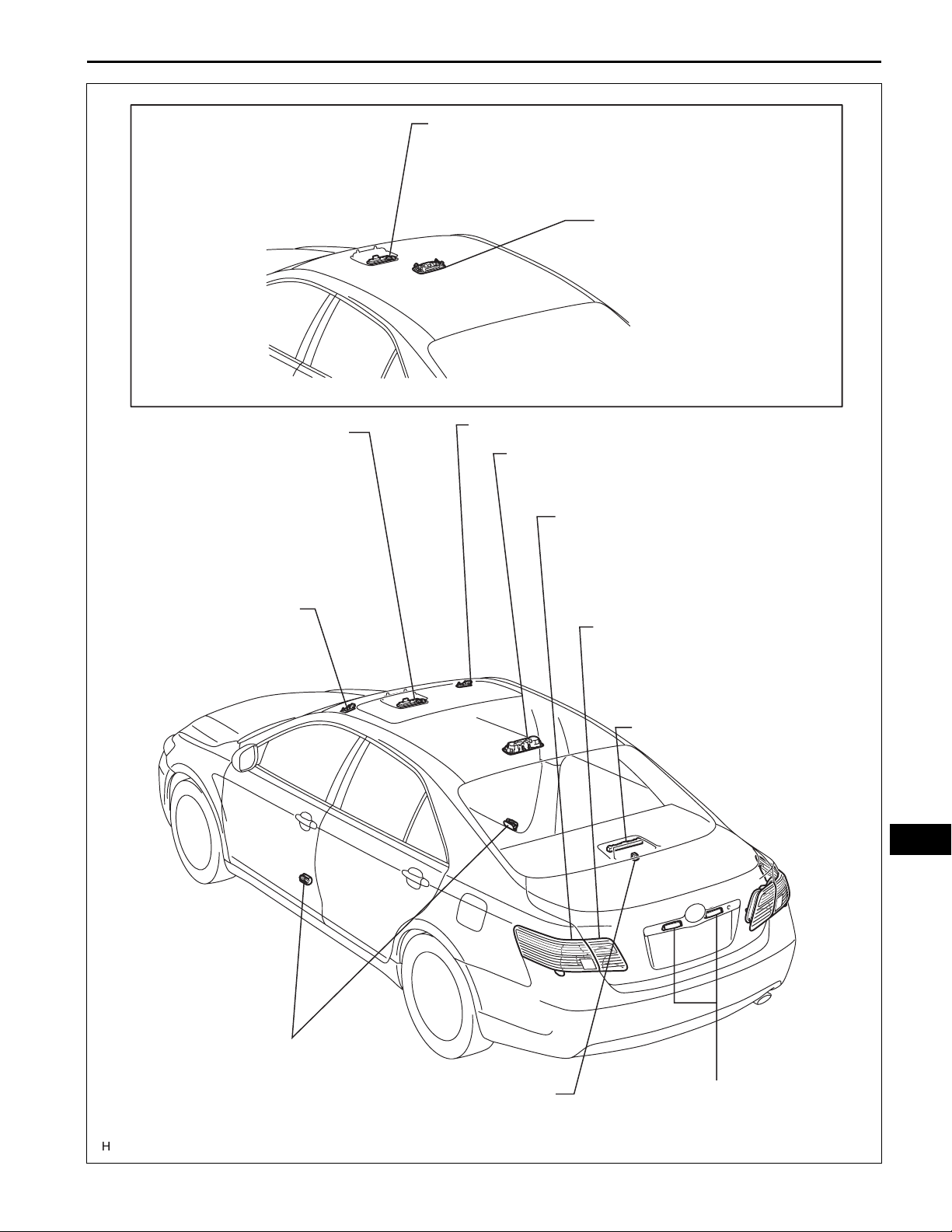

LI–4

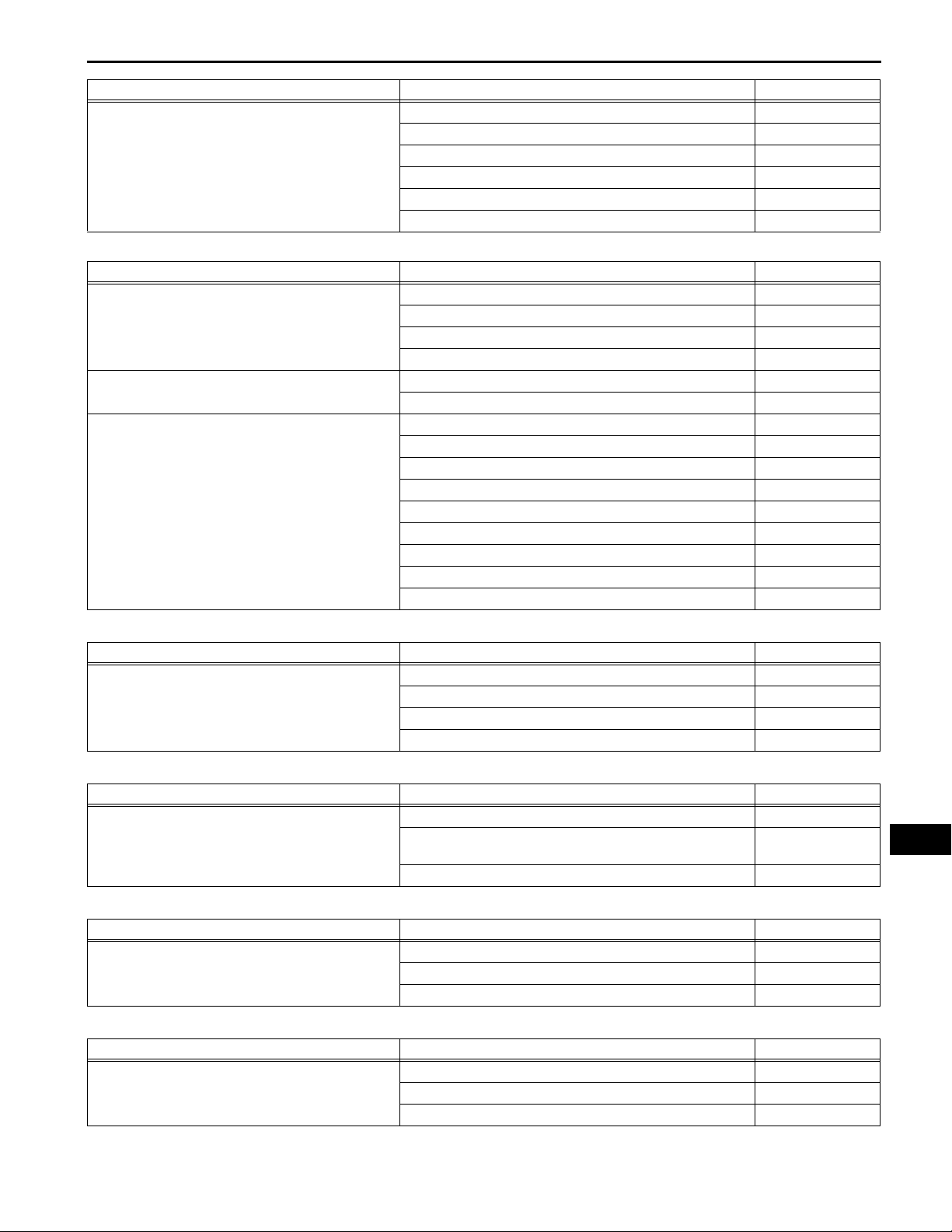

LIGHTING – LIGHTING SYSTEM

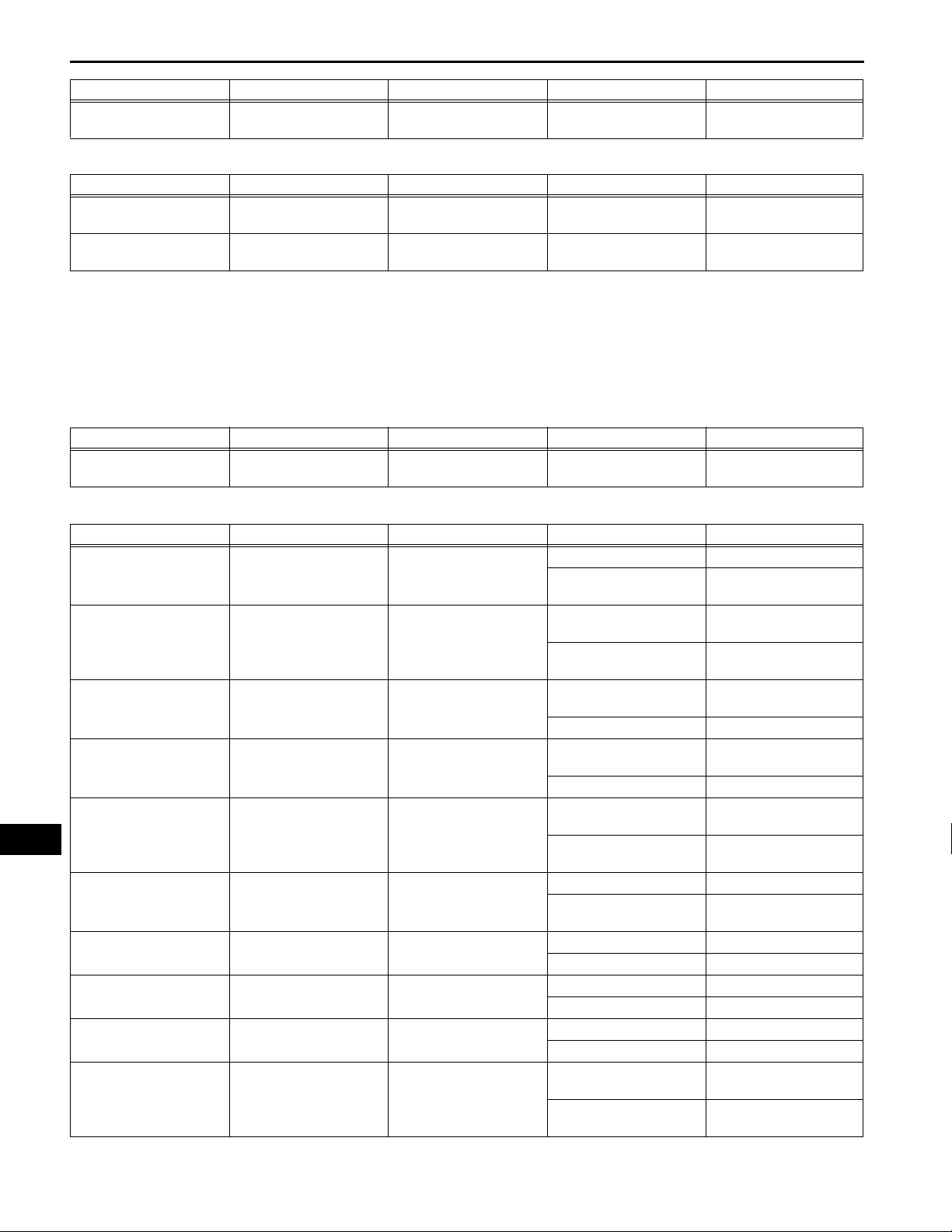

INSTRUMENT PANEL J/B

- MAIN BODY ECU

- IG1 RELAY

- ACC RELAY

- TAIL RELAY

- FOG RELAY

- TAIL FUSE

- AM1 FUSE

- STOP FUSE

- FR FOG FUSE

- GAUGE NO.1 FUSE

HEADLIGHT DIMMER SWITCH

- LIGHT CONTROL SWITCH

- DIMMER SWITCH

- TURN SIGNAL SWITCH

- FOG LIGHT SWITCH

TRANSPONDER KEY AMPRIFIER

IGNITION KEY CYLINDER LIGHT

-

AUTOMATIC LIGHT CONTROL SENSOR

(COMBINATION SWITCH)

GLOVE BOX LIGHT

LI

PARKING BRAKE SWITCH

HAZARD WARNING SWITCH

TURN SIGNAL FLASHER ASSEMBLY

DLC3

STOP LIGHT SWITCH

E121474E01

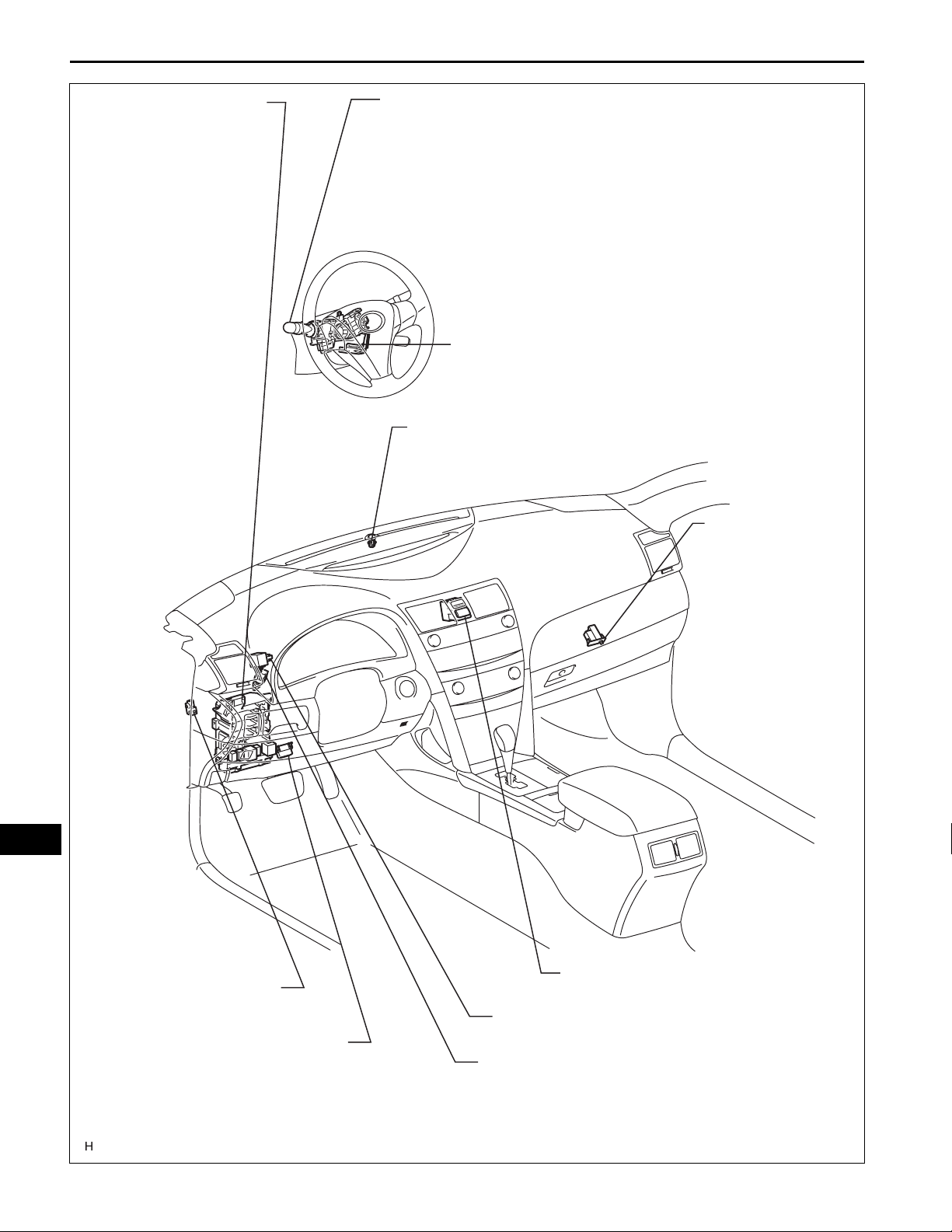

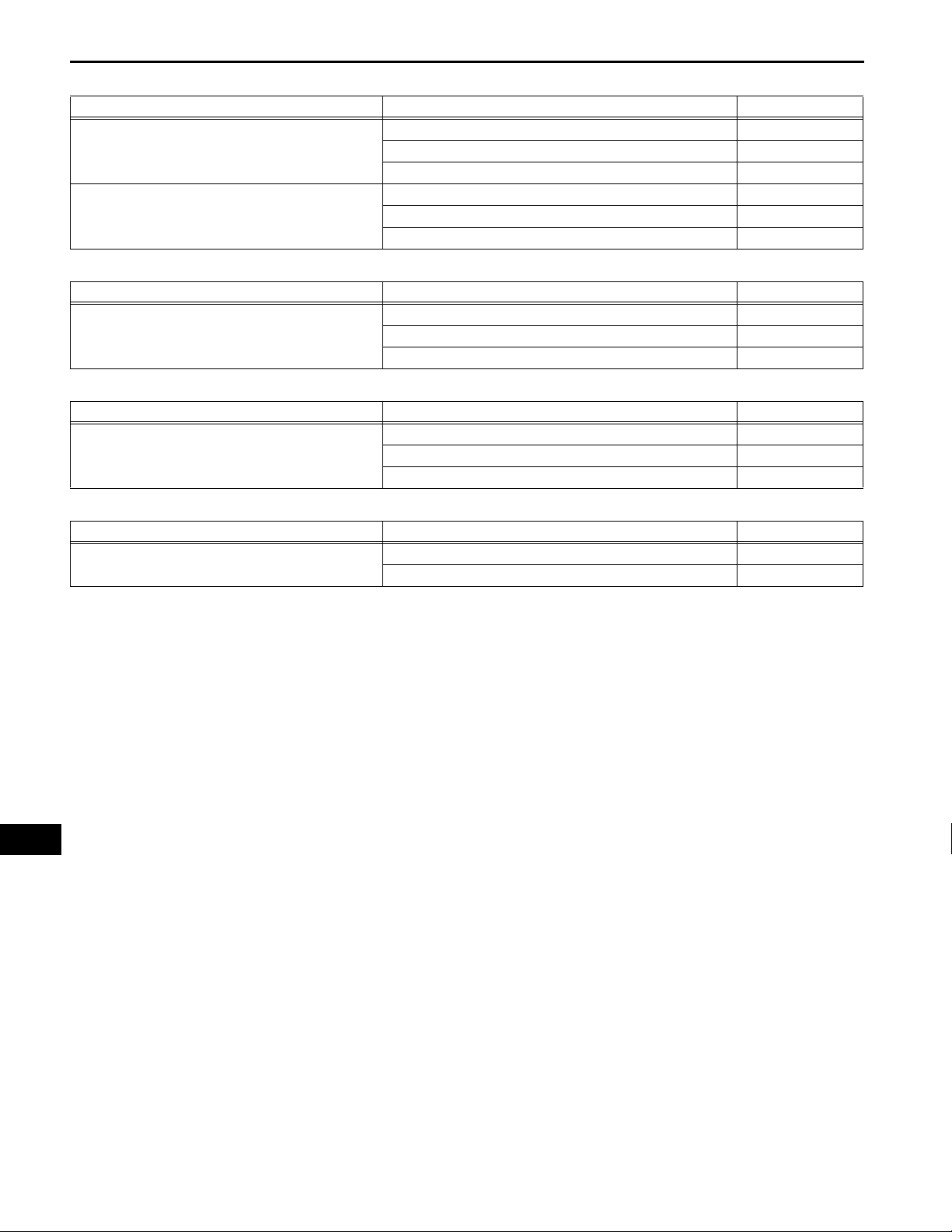

LIGHTING – LIGHTING SYSTEM

DOOR LOCK ASSEMBLY (FRONT RH)

LI–5

DOOR LOCK ASSEMBLY (FRONT LH)

- DOOR UNLOCK DETECTION SWITCH

MASTER SWITCH ASSEMBLY

- DOOR UNLOCK DETECTION SWITCH

DOOR LOCK ASSEMBLY (REAR RH)

- DOOR UNLOCK DETECTION SWITCH

FRONT DOOR COURTESY SWITCH

DOOR LOCK ASSEMBLY (REAR LH)

- DOOR UNLOCK DETECTION SWITCH

REAR DOOR COURTESY SWITCH

LUGGAGE COMPARTMENT DOOR LOCK ASSEMBLY

-

BACK DOOR COURTESY SWITCH

LI

E121475E01

LI–6

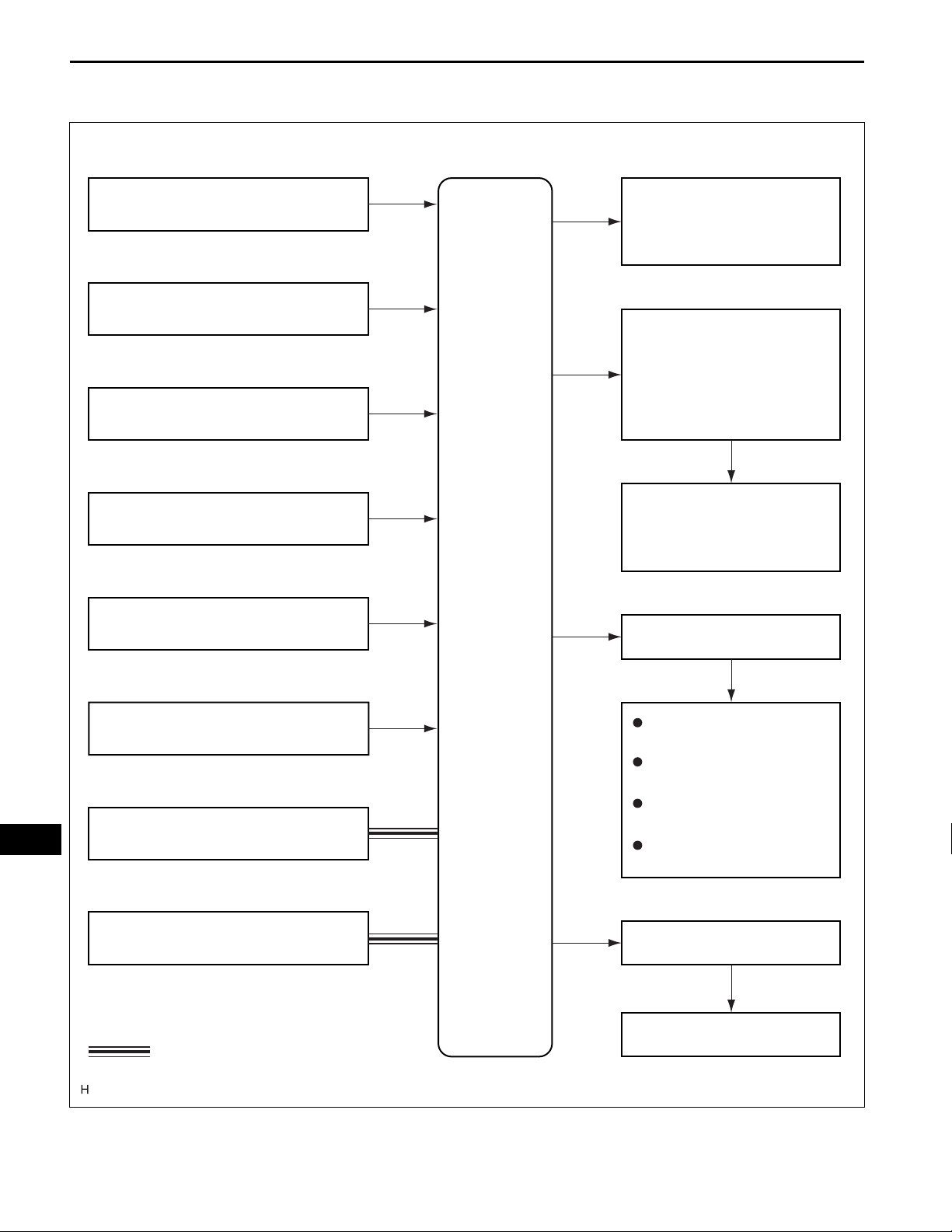

LIGHTING – LIGHTING SYSTEM

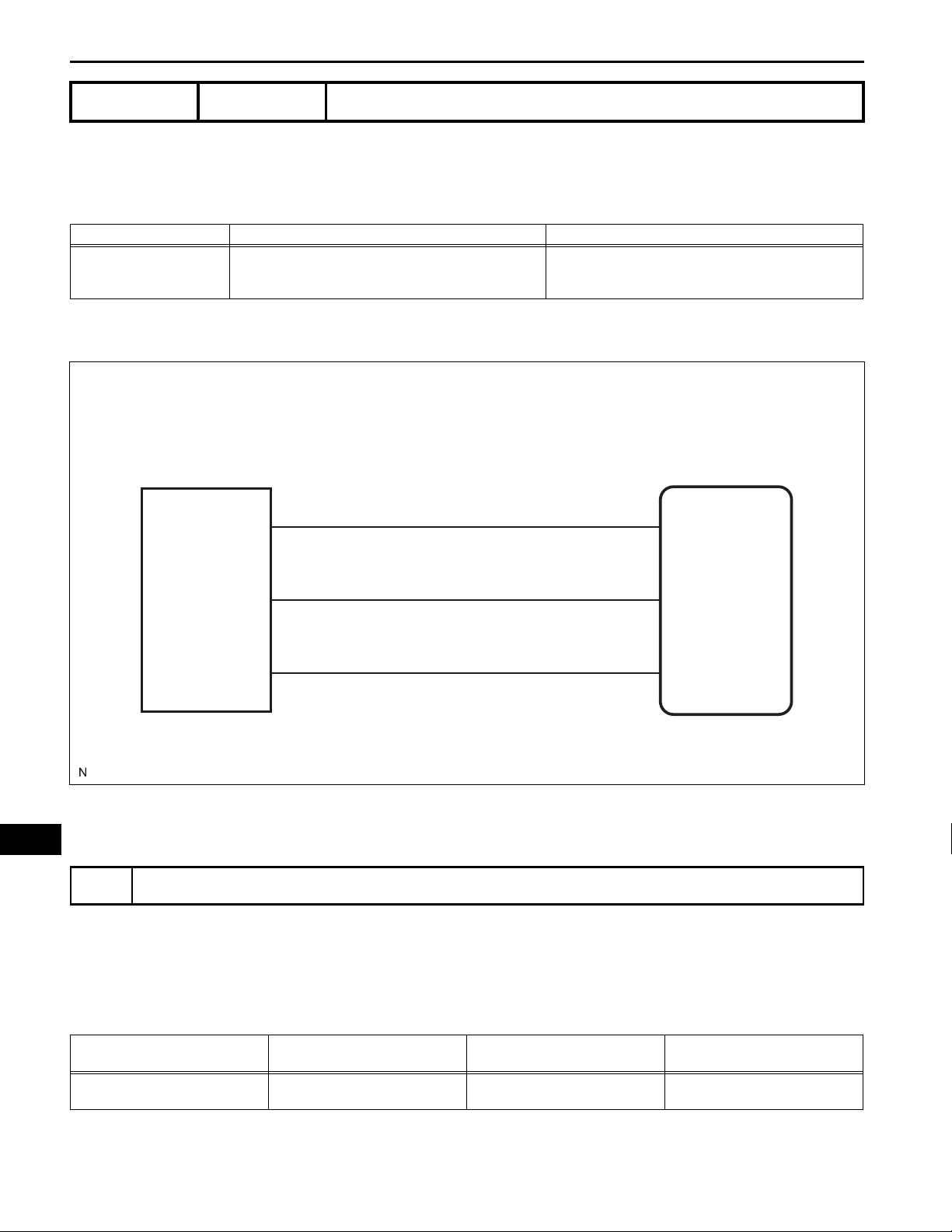

SYSTEM DIAGRAM

Headlight Dimmer Switch Assembly

Automatic Light Control Sensor

Door Courtesy Switches

Door Unlock Detection Switches

Parking Brake Switch

Ignition Key Cylinder Light

Interior Light

Power Distributor

- HEAD Relay

- DRL Relay

Low Beam Headlights

High Beam Headlights

Main Body

ECU

TAIL Relay

LI

Ignition Switch or Engine Switch

ECM

DLC3

: CAN

Taillights

Parking Lights

License Plate Lights

Side Marker Lights

FOG Relay

Front Fog Lights

E121511E01

LIGHTING – LIGHTING SYSTEM

SYSTEM DESCRIPTION

1. MANUAL LIGHT CONTROL SYSTEM

This system functions if the lights such as the headlights

and taillights come on by manual operation of the light

control switch.

(a) The main body ECU controls this system based on

the signals listed below.

Input Output Lights that illuminate

• Taillights

Light control switch TAIL signal Taillight relay drive signal

Light control switch HEAD signal Headlight relay drive signal Low beam headlights

2. AUTOMATIC LIGHT CONTROL SYSTEM

When the light control switch is in the AUTO position, the

automatic light control sensor detects ambient light,

converts it into an electrical signal, and outputs it to the

main body ECU. The main body ECU automatically turns

the headlights and taillights on or off according to the

signal.

(a) The main body ECU controls this system based on

the signals listed below.

• License plate lights

• Side marker lights

• Parking lights

LI–7

Input Output Lights that illuminate

• Light control switch AUTO signal

• Automatic light control sensor signal

Input Output Lights that operate

• Door courtesy switch signal

• Ignition switch or engine switch signal

• Headlight relay drive signal

• Taillight relay drive signal

3. LIGHT AUTO TURN OFF SYSTEM

When the headlights and taillights are on through the

operation of the automatic light control system or through

the light control switch, if the ignition switch is turned off

and all doors are closed, this system continues to

illuminate the headlights and taillights for approximately

30 seconds, and then turns off the headlights and

taillights.

However, if the ignition switch is turned off and all doors

are locked, this system turns off the headlights and

taillights immediately.

(a) The main body ECU controls this system based on

the signals listed below.

• Headlight relay OFF demand

• Taillight relay OFF demand

• DRL relay OFF demand

• FOG light relay OFF demand

• Low beam headlights

• Taillights

• License plate lights

• Side marker lights

• Parking lights

LI

• Low beam headlights

• Taillights, license plate lights, parking

lights, and side marker lights

• High beam headlights

• Front fog lights

LI–8

Items Conditions

Ignition switch or engine switch On (IG)

Engine Running

Light control switch position

Parking brake switch Released (OFF)

Operation Condition

Fade in

Fade out immediately

Illuminate for approximately 15 seconds,

and then fade out

Fade out (Battery saving)

LIGHTING – LIGHTING SYSTEM

OFF, TAIL or AUTO position (if headlight-on control is not being performed by the automatic light

control)

When any of the following conditions is met, the interior light and ignition key cylinder light fade in.

• Any door is opened.

• Any door is unlocked when the ignition switch is off and all doors are closed.

• Ignition switch is turned from on (ACC) to off when all doors are closed.

When either of the following conditions is met, the interior light and ignition key cylinder light fade

out immediately.

• Ignition switch is turned from off to on (ACC or IG) when all doors are closed.

• All doors are locked when the ignition switch is off.

All doors are closed when the ignition switch is off.

When the following conditions are met, the interior light and ignition key cylinder light fade out.

• A key is not in the actuation area (with smart key system).

• A key is not inserted in the ignition key cylinder (without smart key system).

• There are no changes in the condition of the doors for 20 minutes.

4. DAYTIME RUNNING LIGHT SYSTEM

The daytime running light system is designed to

automatically illuminate the headlights (dimmed HI

beams), during the daytime to make the car more visible

to other vehicle.

(a) The main body ECU controls this system.

The daytime running light system starts operating

when all of the following conditions are met:

5. ILLUMINATED ENTRY SYSTEM

When a door is unlocked through a key or transmitter

operation, or if a door is opened, the illuminated entry

system turns on the interior light and the ignition key

cylinder light.

(a) The main body ECU controls this system. The

operation and condition of the illuminated entry

system are described below.

LI

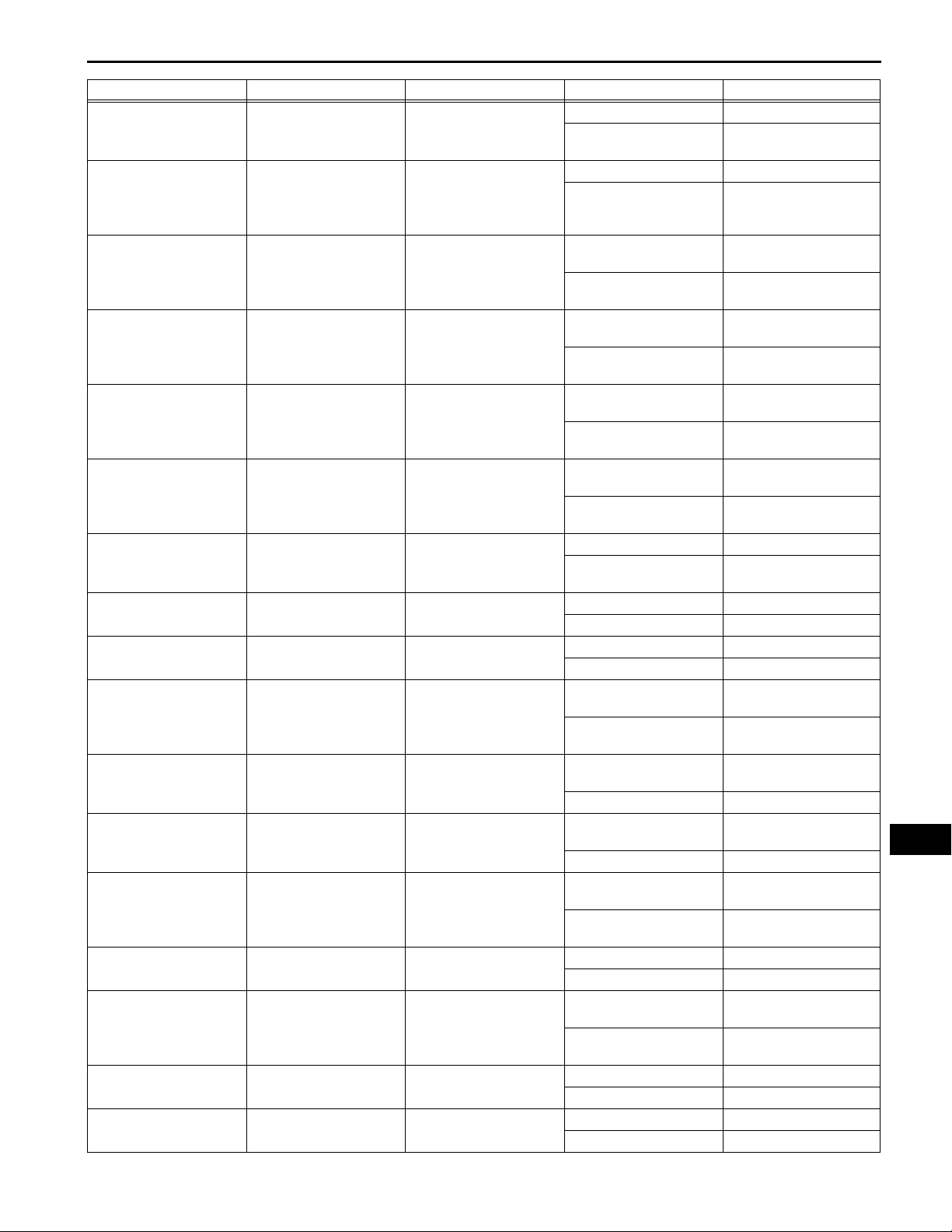

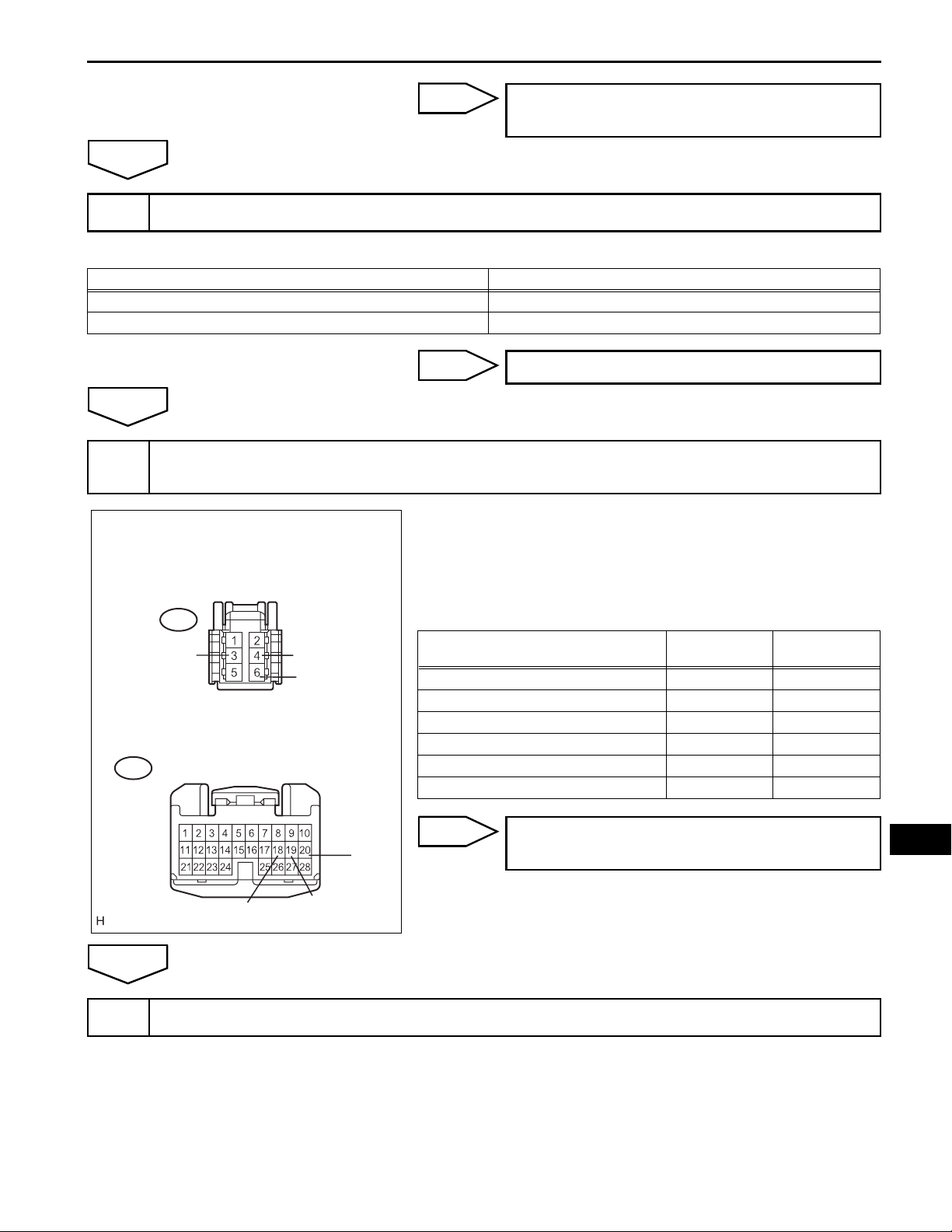

Power Distributor (Engine Room J/B)

LIGHTING – LIGHTING SYSTEM

6. POWER DISTRIBUTOR

(a) The power distributor (engine room J/B assembly) is

installed in the engine room R/B.

(b) The HEAD relay and DRL relay are installed in the

power distributor (engine room J/B assembly).

(c) When a short circuit occurs between the power

distributor (engine room J/B assembly) and high

beam headlight bulbs, a fail-safe function operates.

(d) When the fail-safe function operates, the power

distributor stops the operation of the DRL relay.

E121471E02

LI–9

LI

LI–10

1

NEXT

2

NEXT

3

LIGHTING – LIGHTING SYSTEM

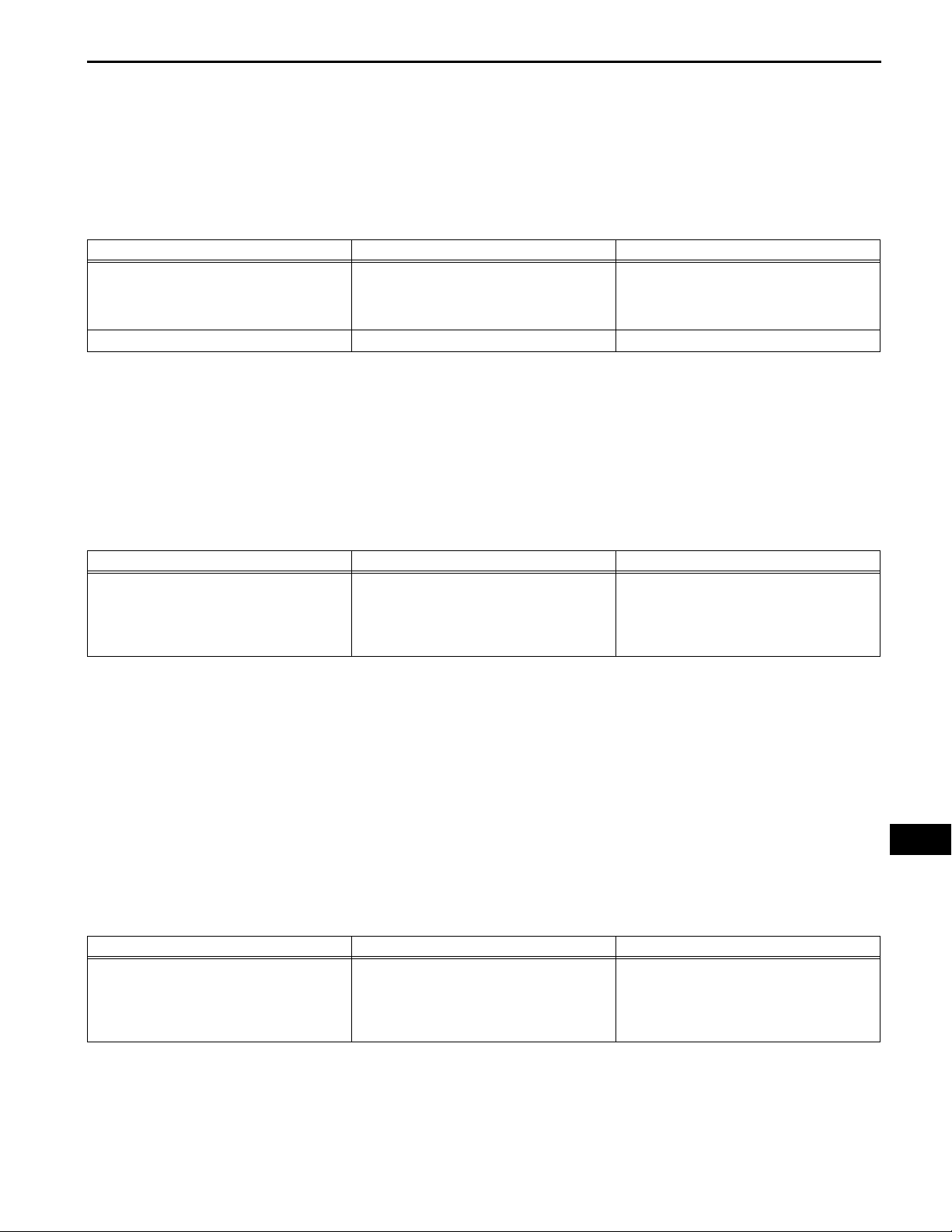

HOW TO PROCEED WITH

TROUBLESHOOTING

HINT:

• Use the following procedures to troubleshoot the lighting

system.

• *: Use the intelligent tester.

VEHICLE BROUGHT TO WORKSHOP

CUSTOMER PROBLEM ANALYSIS CHECK AND SYMPTOM CHECK

INSPECT BATTERY VOLTAGE

Standard voltage:

11 to 14 V

If the voltage is below 11 V, recharge or replace the battery

before proceeding.

NEXT

INSPECT CAN COMMUNICATION SYSTEM*

4

(a) Use the intelligent tester to check if the CAN

communication system is functioning normally.

Result

Result Proceed to

CAN communication system DTC is not output A

CAN communication system DTC is output B

LI

A

CHECK FOR DTC*

5

B

Go to step 8

Result

Result Proceed to

DTC is not output A

DTC is output B

B

A

Go to step 8

LIGHTING – LIGHTING SYSTEM

PROBLEM SYMPTOMS TABLE

6

Result

Result Proceed to

Fault is not listed in problem symptoms table A

Fault is listed in problem symptoms table B

LI–11

A

7

NEXT

8

NEXT

9

NEXT

B

OVERALL ANALYSIS AND TROUBLESHOOTING*

(a) Data List / Active Test (See page LI-21)

(b) Terminals of ECU (See page LI-16)

ADJUST, REPAIR OR REPLACE

CONFIRMATION TEST

Go to step 8

END

LI

LI–12

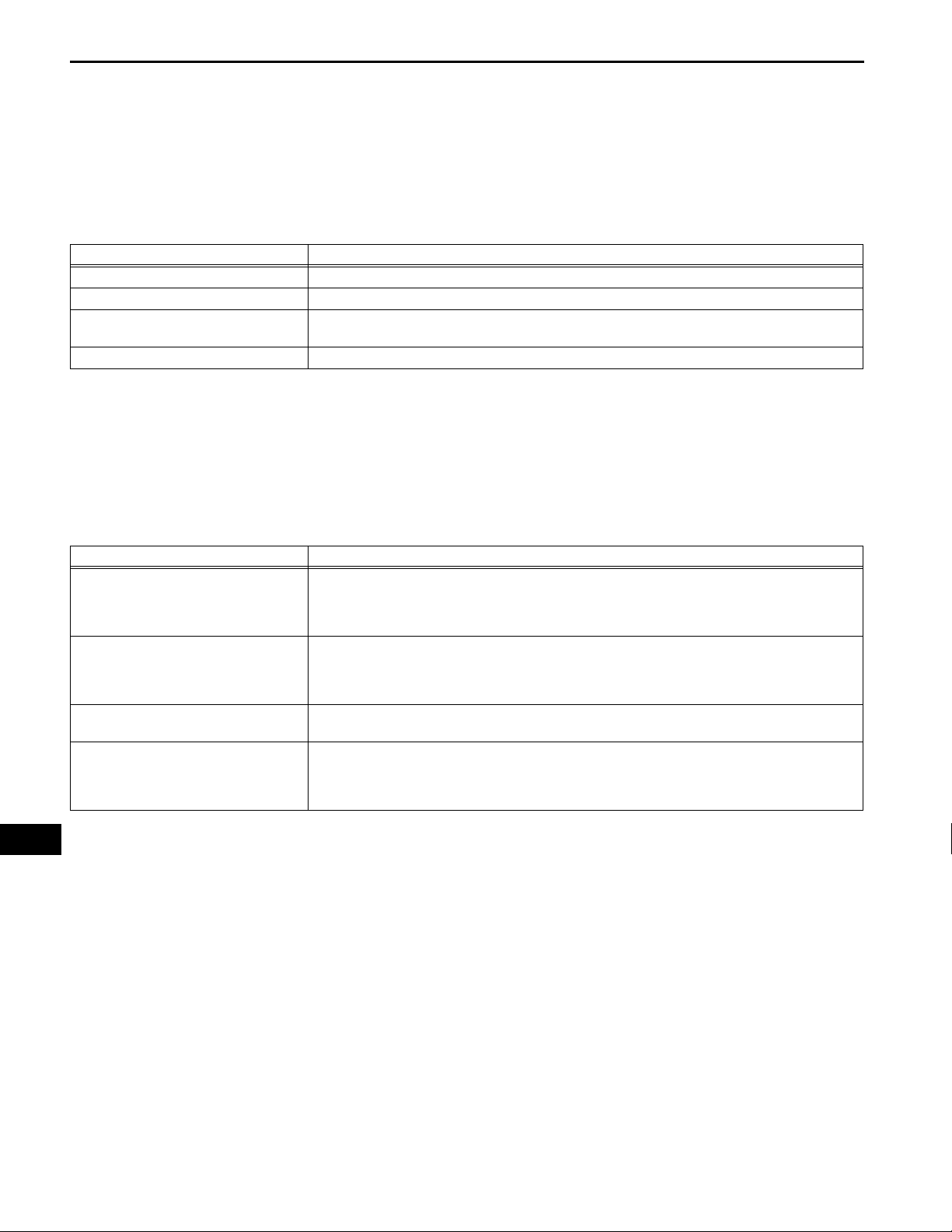

ILLUMINATED ENTRY:

Display Default Contents Setting

LIGHTING TIME 15 s

I/L ON / UNLOCK ON

I/L ON / ACC OFF ON

LIGHTING – LIGHTING SYSTEM

CUSTOMIZE PARAMETERS

HINT:

The followings are the possible items to be customized.

NOTICE:

• Before attempting to customize vehicle settings,

confirm whether it is possible to make the change that

the customer has requested.

• Be sure to record the current value before

customizing.

• In case of performing the troubleshooting, pay

attention because there is a possibility that the

function has been disabled by customizing. (Example:

In case of the symptom in which "The wireless

operation does not function", check that the wireless

operation has not been disabled by customizing, then

perform the troubleshooting.)

Changes the lighting time of the

interior light and ignition key

cylinder light.

Lights up the interior light and

ignition key cylinder light when a

door is unlocked.

Lights up the interior light and

ignition key cylinder light when

the ignition switch is turned from

on (ACC) to off

7.5 s / 15 s / 30 s

ON / OFF

ON / OFF

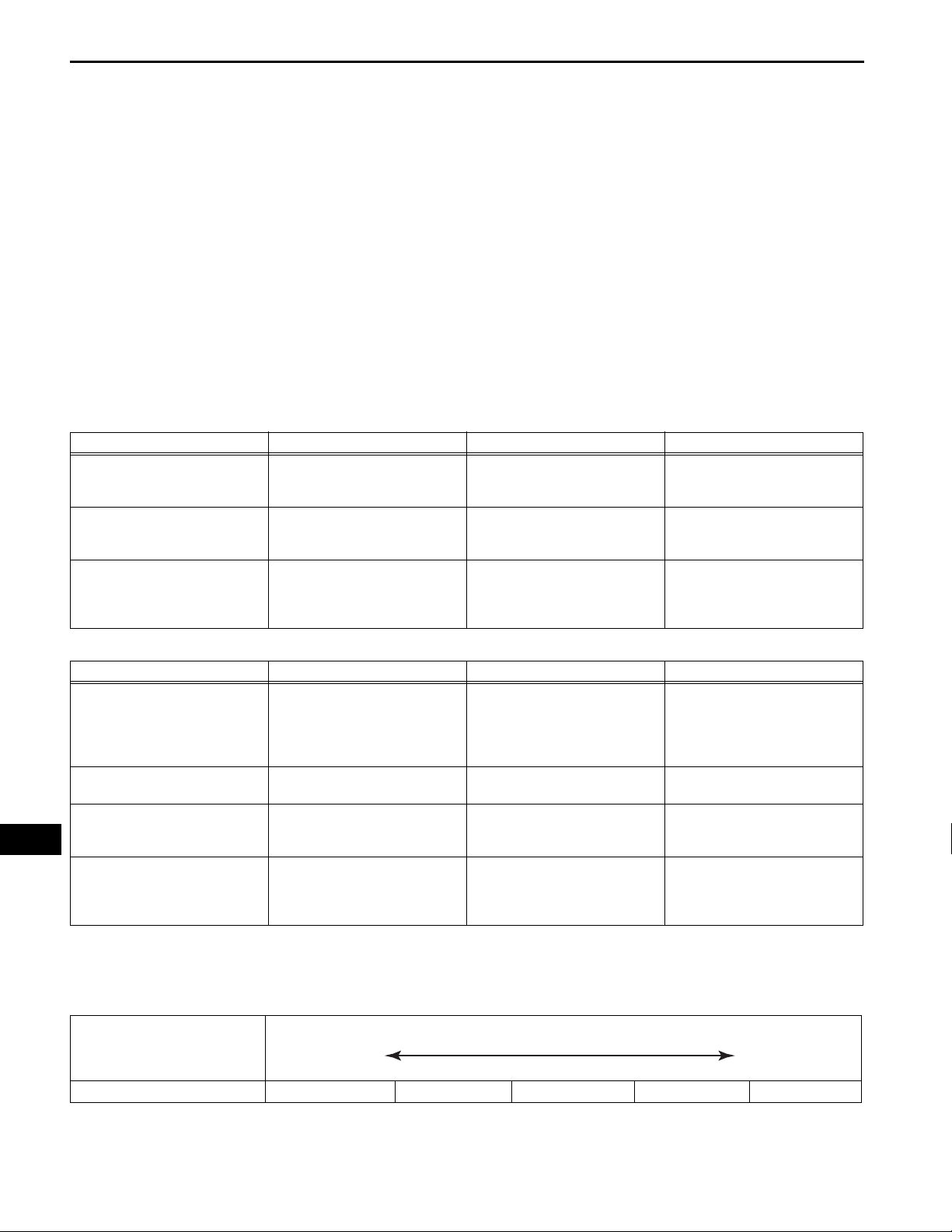

LIGHT CONTROL:

LIGHT OFF DELAY 30 s

DISP EX ON SEN NORMAL

LI

DISP EX OFF SEN NORMAL

Illustration *1

Ambient Brightness Level

Display Default Contents Setting

Keeps the headlights on for a

certain period of time after turning

OFF / 30 s / 60 s / 90 s

LIGHT 2 / LIGHT 1 / NORMAL /

DARK 1 / DARK 2

LIGHT 2 / LIGHT 1 / NORMAL /

DARK 1 / DARK 2

LIGHT 2 / LIGHT 1 / NORMAL /

DARK 1 / DARK 2

SENSITIVITY NORMAL

the ignition switch off and closing

all the doors with the headlights

on.

Adjusts the sensitivity of the

automatic light control system. *1

Changes the ambient brightness

level required to dim the clock

display illumination, etc. *1

Changes the ambient brightness

level required to cancel the

dimming of the clock display

illumination, etc.

HINT:

Sensitivity adjustment can hardly be confirmed. Check by

driving the customer's vehicle.

Dark Bright

Setting DARK2 DARK1 NORMAL LIGHT1 LIGHT2

LIGHTING – LIGHTING SYSTEM

1. Headlight system:

Symptom Suspected area See page

One side LO-beam headlight does not illuminate

Both left and right LO-beam headlights do not

illuminate

One side HI-beam headlight does not illuminate

Both left and right HI-beam headlights do not illuminate

"Flash" headlights do not illuminate

LO-beam headlights or HI-beam headlights do not go

off

LI–13

PROBLEM SYMPTOMS TABLE

1. H-LP RL fuse or H-LP LL fuse -

2. Bulb -

3. Harness or connector -

4. Power distributor (Engine room J/B) -

1. H-LP RL fuse and H-LP LL fuse -

2. Bulb -

3. Light control switch circuit LI-48

4. Headlight relay circuit LI-35

5. Main body ECU (Instrument panel J/B) -

1. H-LP RH fuse or H-LP LH fuse -

2. Bulb -

3. Harness or connector -

4. Power distributor (Engine room J/B) -

1. H-LP RH fuse and H-LP LH fuse -

2. Bulb -

3. Light control switch circuit LI-48

4. Headlight (HI-BEAM) circuit LI-39

5. Main body ECU (Instrument panel J/B) -

1. Light control switch circuit LI-48

2. Main body ECU (Instrument panel J/B) -

1. Headlight dimmer switch assembly LI-120

2. Power distributor (Engine room J/B) -

3. Harness or connector -

4. Main body ECU (Instrument panel J/B) -

2. Daytime running light system:

Symptom Suspected area See page

Day time running light system does not operate

3. Taillight system:

Symptom Suspected area See page

Front parking light does not illuminate

Rear taillight does not illuminate

License plate light does not illuminate

Front side marker light does not illuminate

Taillight system does not operate (Taillights, front side

marker lights, parking lights, and license plate lights do

not illuminate)

1. Light control switch circuit LI-48

2. Parking brake switch circuit LI-61

3. Power distributor (Engine room J/B) -

4. Main body ECU (Instrument panel J/B) -

5. ECM -

LI

1. Bulb -

2. Harness or connector -

1. Bulb -

2. Harness or connector -

1. Bulb -

2. Harness or connector -

1. Bulb -

2. Harness or connector -

1. TAIL fuse -

2. Taillight relay LI-141

3. Light control switch circuit LI-48

4. Taillight relay circuit LI-65

5. Main body ECU (Instrument panel J/B) -

LI–14

LIGHTING – LIGHTING SYSTEM

4. Stop light system:

Symptom Suspected area See page

Stop light system does not operate

One side stop light does not illuminate

Hi-mounted stop light does not illuminate

5. Front fog light system:

Symptom Suspected area See page

One side fog light does not illuminate

Both left and right fog lights do not illuminate (Taillight

system is normal)

1. Bulb -

2. Stop fuse -

3. Stop light switch LI-125

4. Harness or connector -

1. Bulb -

2. Harness or connector -

1. Bulb -

2. Harness or connector -

1. Bulb -

2. Harness or connector -

1. FR FOG fuse -

2. FR FOG relay LI-142

3. Light control switch circuit LI-48

4. Front fog light circuit LI-44

5. Main body ECU (Instrument panel J/B) -

6. Turn signal and hazard warning system:

Symptom Suspected area See page

Hazard warning lights do not operate (Turn signal

lights are normal)

Turn signal lights do not operate (Hazard warning

lights are normal)

"Hazard" and "Turn" do not operate

LI

Turn signal lights do not operate in one direction

Only one bulb does not operate

1. HAZ fuse -

2. Hazard warning signal switch LI-123

3. Clock assembly OT-4

4. Turn signal flasher assembly LI-138

5. Harness or connector -

1. GAUGE No. 1 fuse -

2. Headlight dimmer switch assembly (Turn signal switch) LI-120

3. Turn signal flasher assembly LI-138

4. Harness or connector -

1. HAZ fuse and GAUGE No. 1 fuse -

2. Bulb -

3. Turn signal flasher assembly LI-138

4. Hazard warning signal switch LI-123

5. Headlight dimmer switch assembly (Turn signal switch) LI-120

6. Clock assembly OT-4

7. Harness or connector -

1. Headlight dimmer switch assembly (Turn signal switch) LI-120

2. Turn signal flasher assembly LI-138

3. Harness or connector -

1. Bulb -

2. Harness or connector -

7. Buck-up light system:

Symptom Suspected area See page

One side back-up light does not illuminate

1. Bulb -

2. Harness or connector -

Symptom Suspected area See page

Both left and right back-up lights do not illuminate

8. Illuminated entry system:

Symptom Suspected area See page

Only interior light does not illuminate

Only ignition key cylinder light does not illuminate

Interior light and ignition key cylinder light do not

operate normally

LIGHTING – LIGHTING SYSTEM

1. Bulb -

2. GAUGE No. 1 fuse -

3. Buck-up light switch (for M/T) LI-127

4. Park/Neutral position switch (for U250E A/T) AX-129

5. Park/Neutral position switch (for U660E A/T) AX-175

6. Harness or connector -

1. Bulb -

2. Personal light assembly (with sliding roof) LI-105

3. Rear room light assembly (without sliding roof) LI-108

4. Harness or connector -

1. Transponder key amplifier (Ignition key cylinder light) LI-113

2. Harness or connector -

1. DOME fuse -

2. Personal light assembly LI-105

3. Rear room light assembly LI-108

4. Transponder key amplifier LI-113

5. Door courtesy switch circuit LI-52

6. Door lock position switch circuit LI-55

7. Ignition switch circuit LI-28

8. Interior light circuit LI-57

9. Main body ECU (Instrument panel J/B) -

LI–15

9. Vanity light system:

Symptom Suspected area See page

Vanity light does not illuminate

10. Luggage compartment light system:

Symptom Suspected area See page

Luggage compartment light does not illuminate

11. Glove box light system:

Symptom Suspected area See page

Glove box light does not illuminate

12. Door courtesy light system:

Symptom Suspected area See page

Door courtesy light does not illuminate

1. Bulb -

2. Vanity light assembly LI-116

3. Visor assembly (Vanity light switch) -

4. Harness or connector -

1. Luggage compartment light LI-111

2. Luggage compartment door lock assembly (Door courtesy

switch)

3. Harness or connector -

1. Bulb -

2. Glove box light assembly LI-115

3. Harness or connector -

1. Door courtesy light LI-109

2. Front door courtesy switch LI-129

3. Harness or connector -

LI-132

LI

LI–16

13. Personal light system:

Symptom Suspected area See page

Front personal lights do not illuminate

Rear personal lights do not illuminate

14. Automatic light control system:

Symptom Suspected area See page

Automatic light control system does not operate

normally

15. Light auto turn off system:

Symptom Suspected area See page

Light auto turn off system does not operate normally

LIGHTING – LIGHTING SYSTEM

1. Bulb -

2. Personal light assembly LI-105

3. Harness or connector -

1. Bulb -

2. Rear room light assembly LI-108

3. Harness or connector -

1. Light control switch circuit LI-48

2. Automatic light control sensor circuit LI-23

3. Main body ECU (Instrument panel J/B) -

1. Light control switch circuit LI-48

2. Door courtesy switch circuit LI-52

3. Main body ECU (Instrument panel J/B) -

16. Battery saving system:

Symptom Suspected area See page

Battery saving function does not operate

LI

1. Door courtesy switch circuit LI-52

2. Main body ECU (Instrument panel J/B) -

LIGHTING – LIGHTING SYSTEM

TERMINALS OF ECU

1. CHECK MAIN BODY ECU (INSTRUMENT PANEL J/B)

LI–17

Front Side:

IL IF

IMIK

IC ID

IB

IA

IR

IP

IJ

IE

IN

IO

Back Side:

E7

IG II IH

E6 E8 E9

(a) Disconnect the IA, ID, IF and IM J/B connectors.

(b) Measure the voltage and resistance between the

specified terminals of the wire harness side

connectors and body ground.

Standard voltage

Symbols Wiring Color Terminal Description Condition Specified Condition

IA-1 - Body ground B - Body ground Battery power supply Always 10 to 14 V

LI

E111961E05

LI–18

Symbols Wiring Color Terminal Description Condition Specified Condition

ALTB (ID-16) - Body

ground

Standard resistance

Symbols Wiring Color Terminal Description Condition Specified Condition

GND1 (IF-10) - Body

ground

GND2 (IM-9) - Body

ground

Standard resistance

Symbols Wiring Color Terminal Description Condition Specified Condition

CLTE (E6-18) - Body

ground

LIGHTING – LIGHTING SYSTEM

W - Body ground Generator power supply Always 10 to 14 V

W-B - Body ground Ground Always Below 1 Ω

W-B - Body ground Ground Always Below 1 Ω

If the result is not as specified, there may be a

malfunction on the wire harness side.

(c) Reconnect the IA, ID, IF, and IM J/B connectors.

(d) Measure the resistance and voltage between the

specified terminals of the J/B connectors and body

ground.

BR - Body ground

Automatic light control

ground

Always Below 1 Ω

Standard voltage

Symbols Wiring Color Terminal Description Condition Specified Condition

PKB (IC-14) - Body

ground (*3)

HRLY (ID-3) - Body

ground

DRL (ID-9) - Body

ground

HU (IG-5) - Body ground LG - Body ground

ILE (II-10) - Body ground

(*2)

LI

PKB (IM-2) - Body

ground (*4)

LCTY (IO-7) - Body

ground

LSR (IP-5) - Body ground

(*2)

LSWL (IP-5) - Body

ground (*2)

HEAD (E6-17) - Body

ground

L - Body ground

P - Body ground

V - Body ground

BR - Body ground

Y - Body ground

LG - Body ground

GR - Body ground

GR - Body ground

P - Body ground

Parking brake switch

input

Headlight relay drive

output

High beam headlights

drive output

Dimmer switch HIGH

input

Interior light and igniti on

key cylinder light drive

output

Parking brake switch

input

Rear left door courtesy

switch input

Rear left door lock

position switch input

Rear left door lock

position switch input

Light control switch

HEAD input

Parking brake switch ON Below 1 V

Parking brake switch

OFF

Light control switch in

HEAD

Light control switch not

in HEAD

Dimmer switch in HIGH

or HIGH FLASH

Dimmer switch in LOW 10 to 14 V

Dimmer switch in HIGH

or HIGH FLASH

Dimmer switch in LOW Below 1 V

Interior light and igni tion

key cylinder light ON

Interior light and igni tion

key cylinder light OFF

Parking brake switch ON Below 1 V

Parking brake switch

OFF (Released)

Rear left door open Below 1 V

Rear left door closed 10 to 14 V

Rear left door locked 10 to 14 V

Rear left door unlocked Below 1 V

Rear left door locked 10 to 14 V

Rear left door unlocked Below 1 V

Light control switch in

HEAD

Light control switch not

in HEAD

10 to 14 V

Below 1 V

10 to 14 V

Below 1 V

10 to 14 V

Below 1 V

10 to 14 V

10 to 14 V

Below 1 V

10 to 14 V

Symbols Wiring Color Terminal Description Condition Specified Condition

CLTS (E6-19) - Body

ground

CLTB (E6-20) - Body

ground

PCTY (E6-21) - Body

ground

LGCY (E6-25) - Body

ground

LSWP (E6-27) - Body

ground

FFOG (E6-28) - Body

ground

LSWR (E6-5) - Body

ground (*1)

RCTY (E6-5) - Body

ground (*2)

RCTY (E6-7) - Body

ground (*1)

HF (E7-13) - Body

ground

SSW2 (E7-16) - Body

ground (*1)

SSW1 (E7-17) - Body

ground (*1)

A (E7-21) - Body ground G - Body ground

ACCD (E7-22) - Body

ground (*1)

TAIL (E7-23) - Body

ground

DCTY (E7-24) - Body

ground

IG1D (E7-3) - Body

ground (*1)

G - Body ground

B - Body ground

Y - Body ground

W - Body ground

LG - Body ground

V - Body ground

V - Body ground

GR - Body ground

GR - Body ground

R - Body ground

V - Body ground Engine switch input

L - Body ground Engine switch input

W - Body ground

B - Body ground

L - Body ground

P - Body ground

LIGHTING – LIGHTING SYSTEM

Automatic light control

sensor signal input

Automatic light control

sensor power supply

output

Passenger side door

courtesy switch input

Luggage courtesy

switch input

Passenger side door

lock position switch

input

Front fog light switch

input

Rear right door lock

position switch input

Rear right door courtesy

switch input

Rear right door courtesy

switch input

Dimmer switch HIGH

FLASH signal input

Light control switch

AUTO signal input

Accessory relay drive

output

Light control switch

TAIL signal input

Driver side door

courtesy switch input

Ignition 1 relay drive

output

Ignition switch off Below 1 V

Automatic light control

system operates

Ignition switch off Below 1 V

Ignition switch on (IG)

and light control switch

in AUTO

Passenger side door

open

Passenger side door

closed

Luggage compartment

door open

Luggage compartment

door closed

Passenger side door

locked

Passenger side door

unlocked

Front fog light switch

ON

Front fog light switch

OFF

Rear right door locked 10 to 14 V

Rear right door

unlocked

Rear right door open Below 1 V

Rear right door closed 10 to 14 V

Rear right door open Below 1 V

Rear right door closed 10 to 14 V

Dimmer switch in HIGH

FLASH position

Dimmer switch not in

HIGH FLASH position

Engine switch not

pushed

Engine switch pushed Below 1 V

Engine switch not

pushed

Engine switch pushed Below 1 V

Light control switch in

AUTO

Light control switch not

in AUTO

Ignition switch on (ACC) Below 1 V

Ignition switch off 10 to 14 V

Light control switch in

TAIL or HEAD

Light control switch in

neither TAIL nor HEAD

Driver side door open Below 1 V

Driver side door closed 10 to 14 V

Ignition switch on (IG) Below 1 V

Ignition switch off 10 to 14 V

LI–19

Pulse generation

(See waveform 1)

10 to 14 V

Below 1 V

10 to 14 V

Below 1 V

10 to 14 V

10 to 14 V

Below 1 V

Below 1 V

10 to 14 V

Below 1 V

Below 1 V

10 to 14 V

10 to 14 V

10 to 14 V

LI

Below 1 V

10 to 14 V

Below 1 V

10 to 14 V

LI–20

Symbols Wiring Color Terminal Description Condition Specified Condition

FFGO (E7-4) - Body

ground

LSWD (E7-9) - Body

ground

CANH (E8-5) - Body

ground

CANL (E8-6) - Body

ground

R - Body ground

L - Body ground

R - Body ground

W - Body ground

LIGHTING – LIGHTING SYSTEM

Light control switch in

Front fog light relay

drive output

Driver side door lock

position switch input

Control system CAN

communication

Control system CAN

communication

HEAD and front fog light

switch ON

Front fog light switch

OFF

Driver side door locked 10 to 14 V

Driver side door

unlocked

Ignition switch on (IG) Pulse generation

Ignition switch off Below 1 V

Ignition switch on (IG) Pulse generation

Ignition switch off Below 1 V

If the result is not as specified, the main body ECU

(Instrument panel J/B) may have a malfunction.

HINT:

*1: with smart key system

*2: without smart key system

*3: Pedal type parking brake

*4: Lever type parking brake

Below 1 V

10 to 14 V

Below 1 V

LI

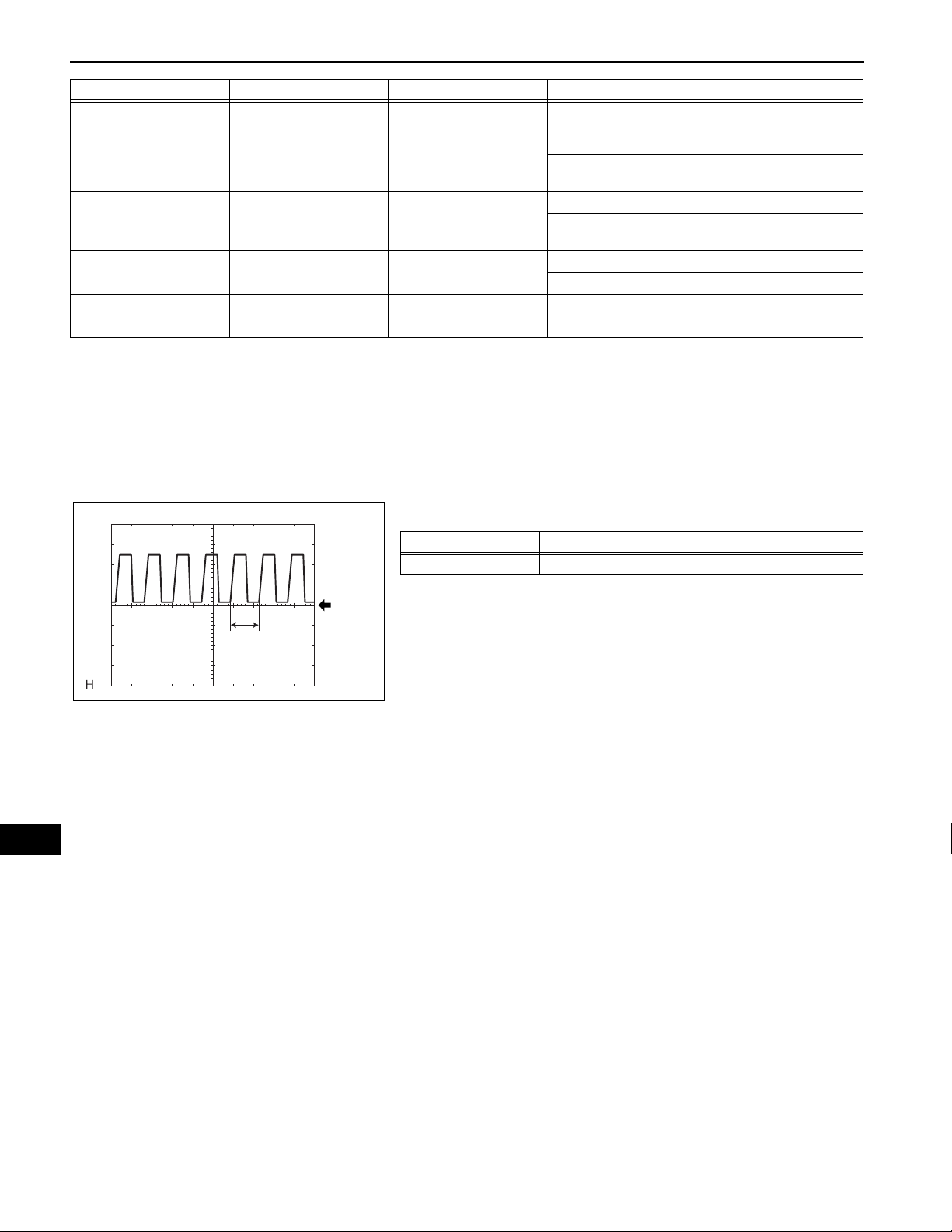

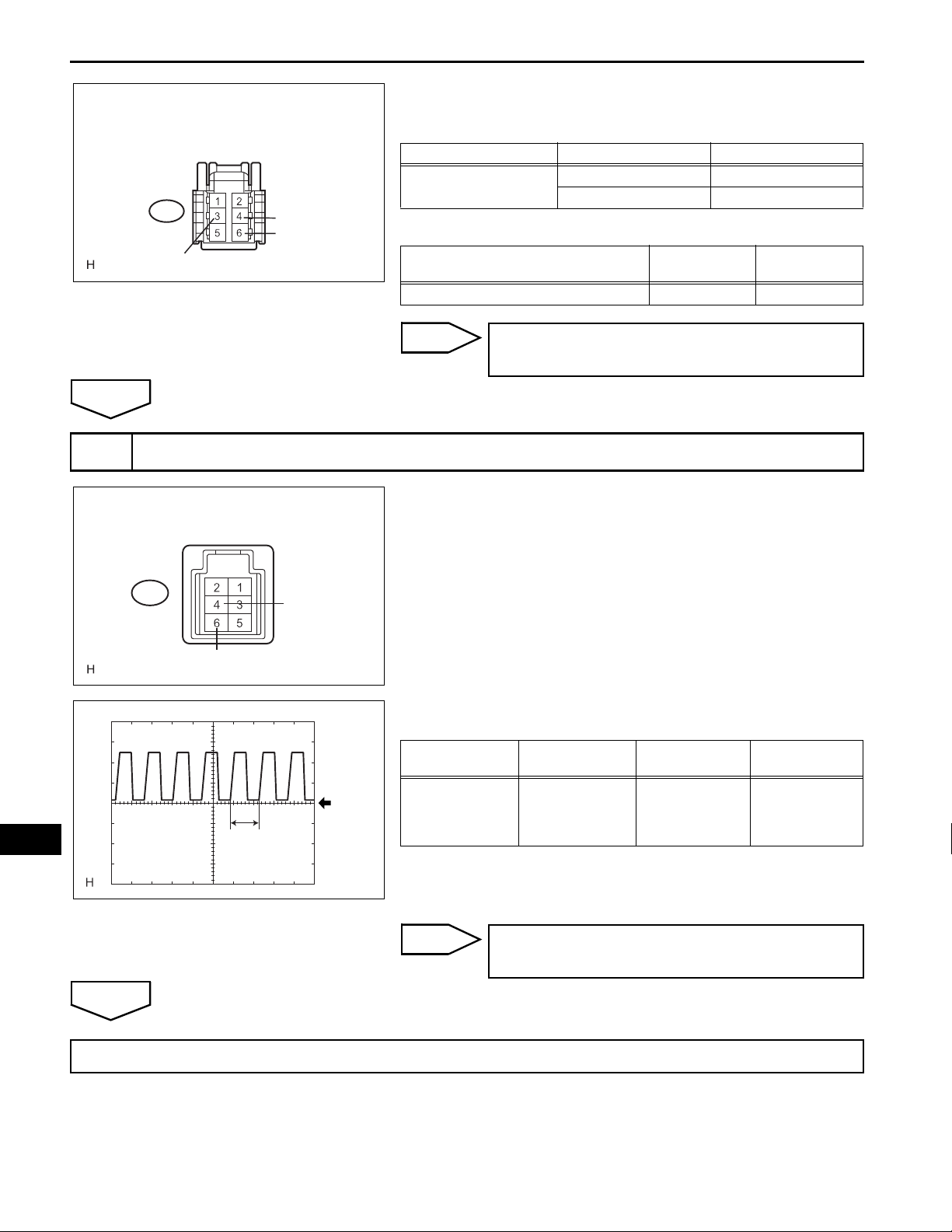

(1) Waveform 1

Item Contents

Tool setting 5 V/DIV., 5 ms./DIV.

A

GND

HINT:

If the ambient light becomes brighter, width A

becomes narrower.

B113714E01

CG

SG

CANH

SIL

LIGHTING – LIGHTING SYSTEM

DIAGNOSIS SYSTEM

1. DESCRIPTION

(a) Lighting system data and the Diagnostic Trouble

Codes (DTCs) can be read from the Data Link

Connector 3 (DLC3) of the vehicle. When the

system seems to be malfunctioning, use the

intelligent tester to check for malfunctions and

perform repairs.

2. CHECK DLC3

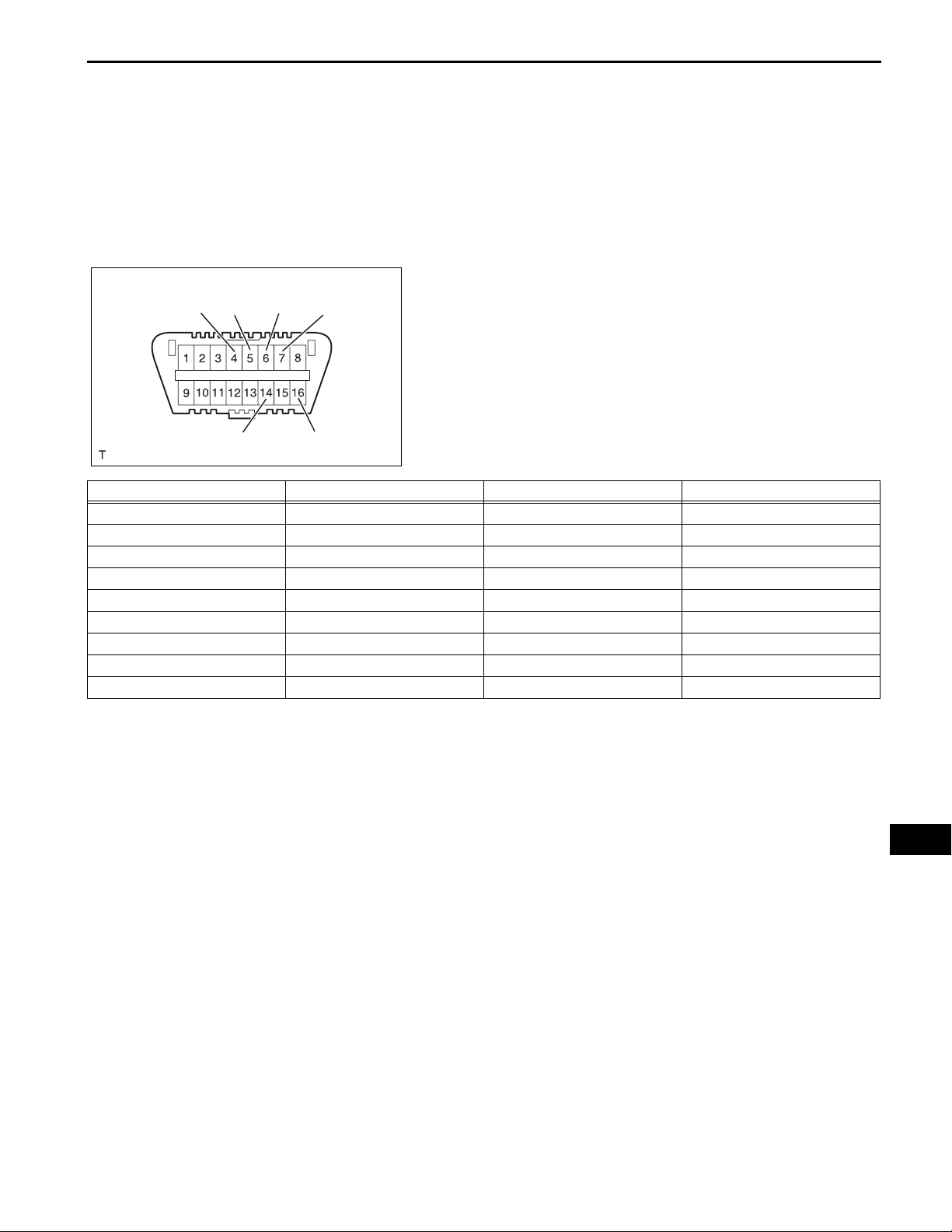

(a) The ECU uses ISO 15765-4 for communication.

The terminal arrangement of the DLC3 complies

with SAE J1962 and matches the ISO 15765-4

format.

LI–21

CANL

Symbols (Terminal No.) Terminal Description Condition Specified Condition

SIL (7) - SG (5) Bus "+" line During transmission Pulse generation

CG (4) - Body ground Chassis ground Always Below 1 Ω

SG (5) - Body ground Signal ground Always Below 1 Ω

BAT (16) - Body ground Battery positive Always 11 to 14 V

CANH (6) - CANL (14) CAN bus line Ignition switch off* 54 to 69 Ω

CANH (6) - CG (4) HIGH-level CAN bus line Ignition switch off* 200 Ω or higher

CANL (14) - CG (4) LOW-level CAN bus line Ignition switch off* 200 Ω or higher

CANH (6) - BAT (16) HIGH-level CAN bus line Ignition switch off* 6 kΩ or higher

CANL (14) - BAT (16) LOW-level CAN bus line Ignition switch off* 6 kΩ or higher

BAT

H100769E16

NOTICE:

*Before measuring the resistance, leave the

vehicle as is for at least 1minute and do not

operate the ignition switch, any other switches,

or the doors.

If the result is not as specified, the DLC3 may have

a malfunction. Repair or replace the harness and

connector.

LI

LI–22

LIGHTING – LIGHTING SYSTEM

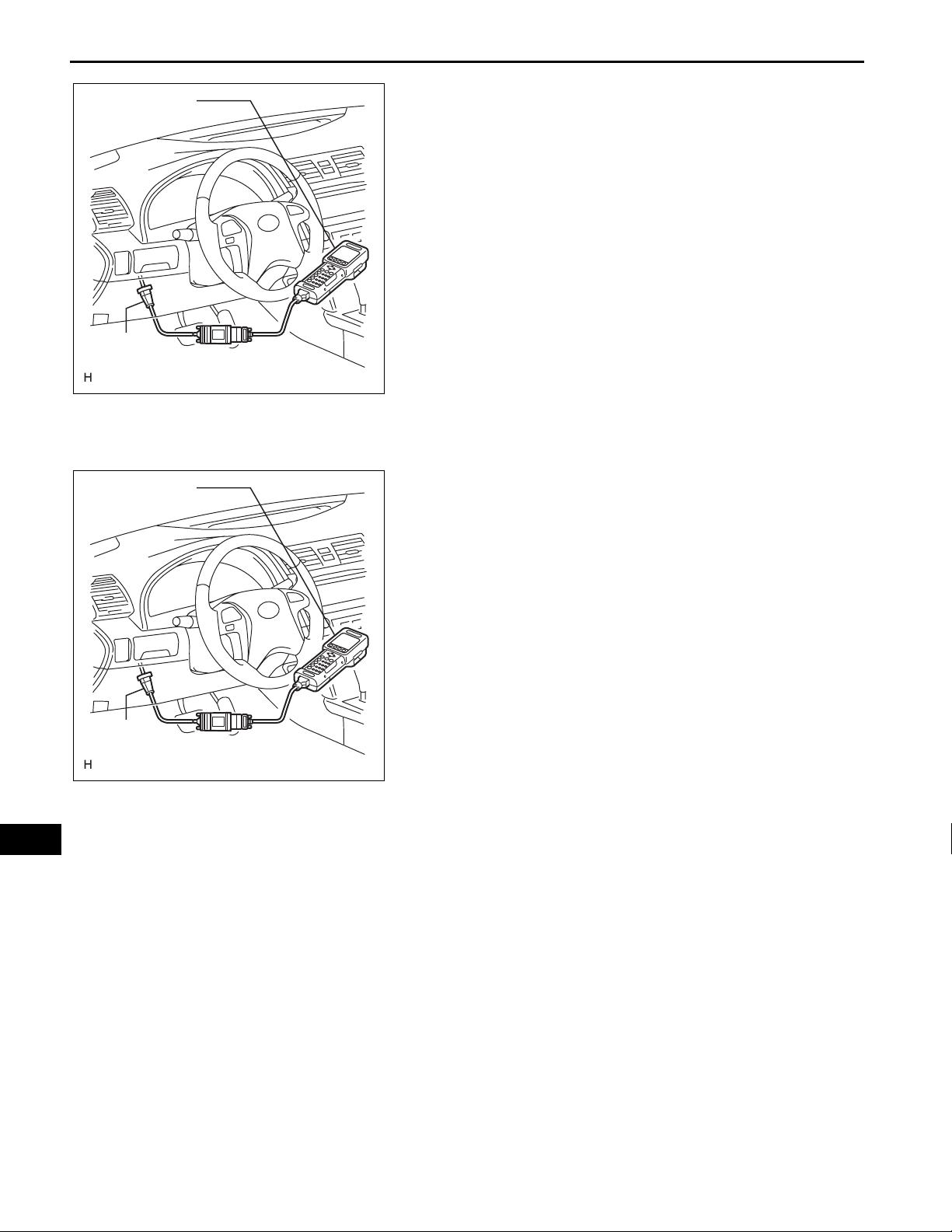

Intelligent Tester

DLC3

Intelligent Tester

DLC3

CAN VIM

CAN VIM

C131977E10

C131977E10

(b) Connect the cable of the intelligent tester to the

DLC3, turn the ignition switch on (IG) and attempt to

use the tester. If the display indicates that a

communication error has occurred, there is a

problem either with the vehicle or with the tester.

HINT:

• If communication is normal when the tester is

connected to another vehicle, inspect the DLC3

of the original vehicle.

• If communication is still not possible when the

tester is connected to another vehicle, the

problem may be in the tester itself. Consult the

Service Department listed in the tester's

instruction manual.

3. INSPECT BATTERY VOLTAGE

Standard voltage:

11 to 14 V

If the voltage is below 11 V, recharge or replace the

battery before proceeding.

DTC CHECK / CLEAR

1. CHECK DTC

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch on (IG).

(c) Read the DTCs by following the directions on the

tester screen.

HINT:

Please refer to the intelligent tester operator's

manual for further details.

2. CLEAR DTC

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch on (IG).

(c) Erase the DTCs by following the directions on the

tester screen.

HINT:

Please refer to the intelligent tester operator's

manual for further details.

LI

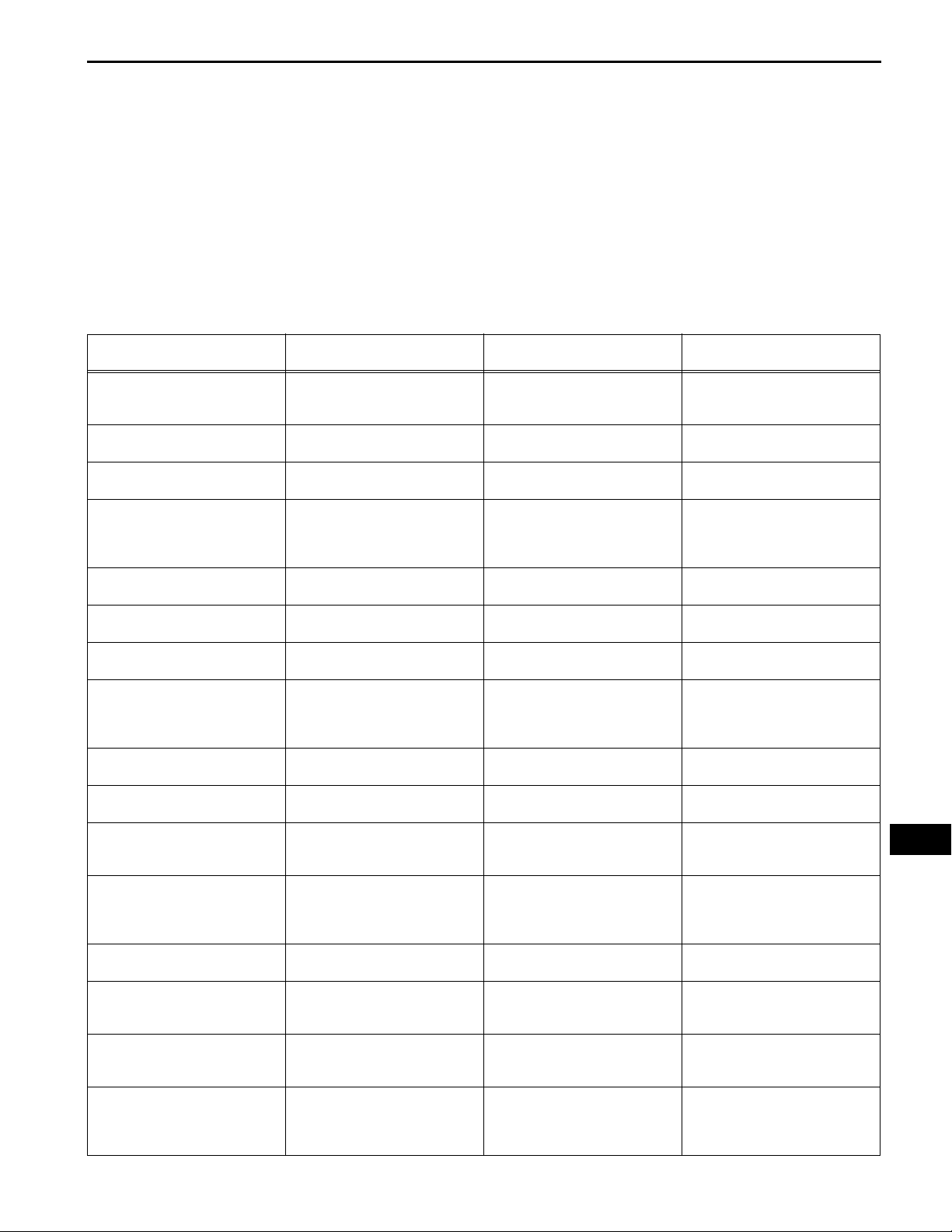

MAIN BODY (MAIN BODY ECU):

Item

ACC SW

IG SW

D DOR CTY SW

P DOR CTY SW

RR DOR CTY SW

RL DOR CTY SW

D LOCK POS SW

P LOCK POS SW

RR LOCK POS SW

(with Smart Key System)

RL. LOCK POS SW

(with Smart Key System)

DIMMER SW

HIGH FLASHER SW

F FOG LIGHT SW

AUTO LIGHT SW

HEAD LIGHT SW

TAIL LIGHT SW

Measurement Item / Display

Ignition switch or engine switch

ACC signal / ON or OFF

Ignition switch or engine switch

IG signal / ON or OFF

Driver side door courtesy switch

signal / ON or OFF

Passenger side door courtesy

switch signal / ON or OFF

Rear right door courtesy switch

signal / ON or OFF

Rear left door courtesy switch

signal / ON or OFF

Driver side door lock position

switch signal / ON or OFF

Passenger side door lock position

switch signal / ON or OFF

Rear right door lock position

switch signal / ON or OFF

Rear left door lock position switch

signal / ON or OFF

Dimmer switch HIGH signal / ON

or OFF

Dimmer switch HIGH FLASH

signal / ON or OFF

Fog light switch signal / ON or

OFF

Light control switch AUTO signal /

ON or OFF

Light control switch HEAD signal /

ON or OFF

Light control switch TAIL signal /

ON or OFF

LIGHTING – LIGHTING SYSTEM

DATA LIST / ACTIVE TEST

1. READ DATA LIST

HINT:

Using the intelligent tester DATA LIST allows switch,

actuator and other item values to be read without

removing any parts. Reading the DATA LIST early in

troubleshooting is one way to save time.

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch on (IG).

(c) Read the DATA LIST according to the display on the

tester.

(Range)

Normal Condition Diagnostic Note

ON: Ignition switch on (ACC or

IG)

OFF: Ignition switch off

ON: Ignition switch on (IG)

OFF: Ignition switch off

ON: Driver side door is open

OFF: Driver side door is closed

ON: Front passenger side door is

open

OFF: Front passenger side door

is closed

ON: Rear right door is open

OFF: Rear right door is closed

ON: Rear left door is open

OFF: Rear left door is closed

ON: Driver side door is unlocked

OFF: Driver side door is locked

ON: Front passenger side door is

unlocked

OFF: Front passenger side door

is locked

ON: Rear right door is unlocked

OFF: Rear right door is locked

ON: Rear left door is unlocked

OFF: Rear left door is locked

ON: Dimmer switch in HIGH or

HIGH FLASH

OFF: Dimmer switch in LOW

ON: Dimmer switch in HIGH

FLASH

OFF: Dimmer switch not in HIGH

FLASH

ON: Fog light switch ON

OFF: Fog light switch OFF

ON: Light control switch in AUTO

OFF: Light control switch not in

AUTO

ON: Light control switch in HEAD

OFF: Light control switch not in

HEAD

ON: Light control switch in TAIL or

HEAD

OFF: Light control switch not in

TAIL or HEAD

LI–23

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

LI

LI–24

LIGHTING – LIGHTING SYSTEM

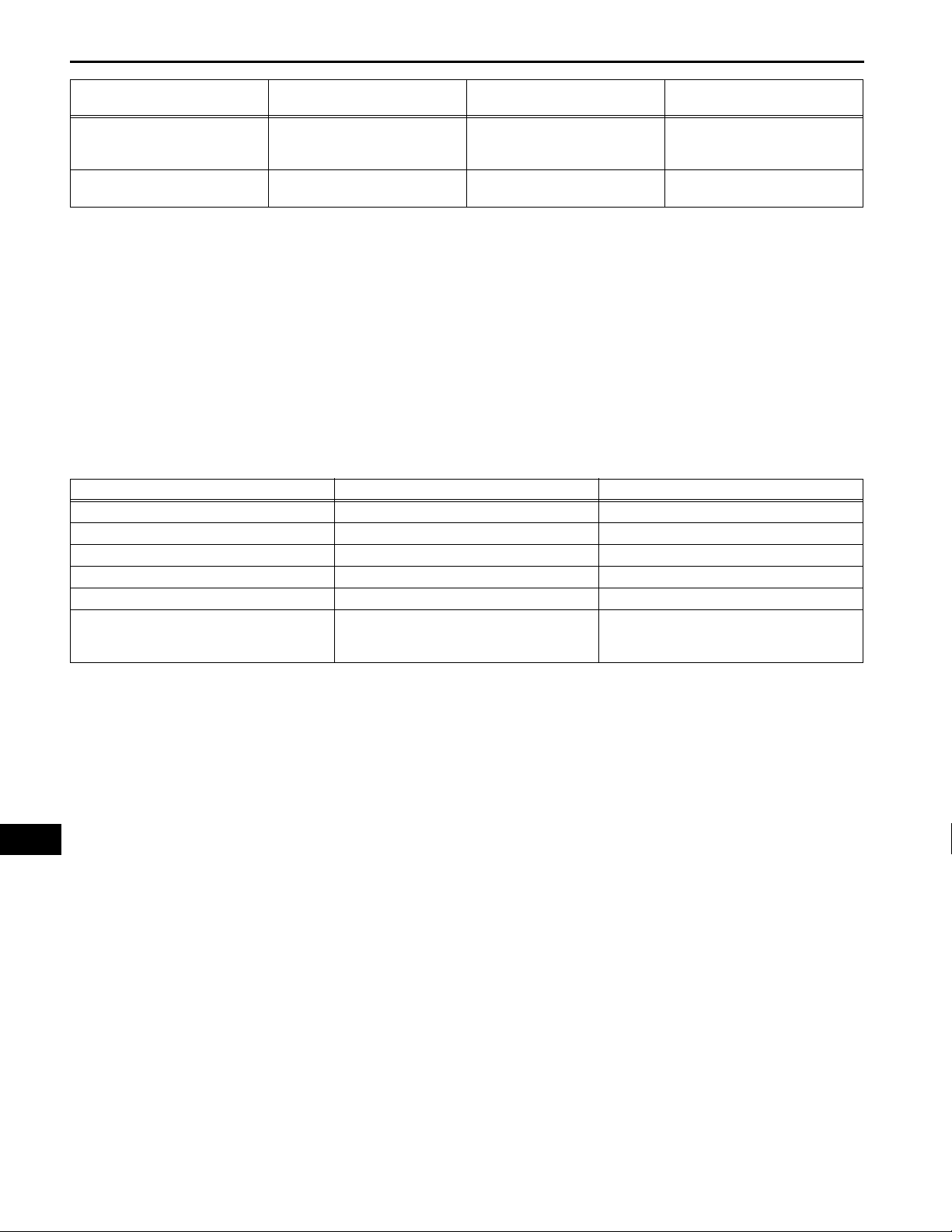

Item

ILLUMINATE RATE

PARKING BRAKE SW

Measurement Item / Display

Illumination rate information / 0

ms. to 99.99 ms.

Parking brake switch signal / ON

or OFF

MAIN BODY (MAIN BODY ECU):

Item Test Details Diagnostic Note

F FOG LIGHT RLY Front fog light relay ON / OFF -

HEAD LIGHT Headlight relay ON / OFF -

HEAD LIGHT (HI) High beam headlights ON / OFF -

TAIL LIGHT Taillight ON / OFF -

DIMMER SIG Dimmer signal ON / OFF -

ILLUMI OUTPUT

(Range)

Normal Condition Diagnostic Note

0.8 ms. to 22.0 ms. (Value is

output according to ambient

illuminance)

ON: Parking brake switch is ON

OFF: Parking brake switch is OFF

2. PERFORM ACTIVE TEST

HINT:

Performing the intelligent tester ACTIVE TEST allows a

relay, VSV, actuator, and other items to be operated

without removing any parts. Performing the ACTIVE

TEST early in troubleshooting is one way to save time.

The DATA LIST can be displayed during the ACTIVE

TEST.

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch on (IG).

(c) Perform the ACTIVE TEST according to the display

on the tester.

Interior light and ignition key cylinder light ON

/ OFF (Interior light switch in DOOR position

and all doors are closed)

-

-

-

LI

LIGHTING SYSTEM:

DTC No. Detection Item Suspected Area See page

B1244 Light Sensor Circuit Malfunction 1. Automatic light control sensor

LIGHTING – LIGHTING SYSTEM

DIAGNOSTIC TROUBLE CODE CHART

2. Harness or connector

3. Main body ECU (Instrument

panel J/B)

LI–25

LI-23

LI

LI–26

LIGHTING – LIGHTING SYSTEM

DTC B1244 Light Sensor Circuit Malfunction

DESCRIPTION

The automatic light control sensor detects ambient light, converts it into an elect rical signal, and output s it

to the main body ECU. The main body ECU turns on or off the headlights and taillights according to the

signal.

DTC No. DTC Detecting Condition Trouble Area

• Automatic light control sensor

• Harness or connector

• Main body ECU (Instrument panel J/B)

B1244

WIRING DIAGRAM

• Malfunction in automatic light control sensor

• Open or short in automatic light control sensor

circuit

E11

Automatic Light Control Sensor

CLTB

CLTS

CLTE

*1: Manual A/C *2: Automatic A/C

INSPECTION PROCEDURE

LI

3 (*1)

6 (*2)

4 (*1)

5 (*2)

6 (*1)

3 (*2)

E6

Main Body ECU

CLTB

20

CLTS

19

CLTE

18

E124321E04

READ VALUE OF INTELLIGENT TESTER

1

MAIN BODY (MAIN BODY ECU):

Item

ILLUMINATE RATE

Measurement Item / Display

Illumination rate information / 0

ms to 99.99 ms

(Range)

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch on (IG) and turn the intelligent

tester main switch on.

(c) Select the item below in the DATA LIST, and read the

display on the intelligent tester.

Normal Condition Diagnostic Note

0.8 ms to 22.0 ms (Value is output

according to ambient illuminance)

-

OK:

Normal condition listed above is displayed.

LIGHTING – LIGHTING SYSTEM

LI–27

OK

REPLACE INSTRUMENT PANEL JUNCTION

BLOCK ASSEMBLY

NG

CHECK VEHICLE CONDITION

2

Result

Vehicle Condition Proceed to

Manual Air Conditioning System A

Automatic Air Conditioning System B

B

Go to step 6

A

CHECK HARNESS AND CONNECTOR (MAIN BODY ECU - AUTOMATIC LIGHT CONTROL

3

SENSOR)

(a) Disconnect the E11 automatic light control sensor

Wire Harness Side:

connector.

(b) Disconnect the E6 main body ECU connector.

Automatic Light Control Sensor

(c) Measure the resistance according to the value(s) in the

table below.

Standard resistance

Tester Connection Condition

E6-18 (CLTE) - E11-6 (CLTE) Always Below 1 Ω

E6-19 (CLTS) - E11-4 (CLTS) Always Below 1 Ω

E6-20 (CLTB) - E11-3 (CLTB) Always Below 1 Ω

E6-18 (CLTE) - Body ground Always 10 kΩ or higher

E6-19 (CLTS) - Body ground Always 10 kΩ or higher

E6-20 (CLTB) - Body ground Always 10 kΩ or higher

E6

E11

CLTB

CLTS

CLTE

Main Body ECU

Specified

Condition

CLTE

NG

CLTB

CLTS

E121476E03

REPAIR OR REPLACE HARNESS OR

CONNECTOR

OK

INSPECT MAIN BODY ECU (INSTRUMENT PANEL JUNCTION BLOCK ASSEMBLY)

4

(a) Reconnect the main body ECU connector.

LI

LI–28

LIGHTING – LIGHTING SYSTEM

Wire Harness Side:

Automatic Light Control Sensor

E11

CLTB

OK

INSPECT AUTOMATIC LIGHT CONTROL SENSOR

5

Automatic Light Control Sensor

CLTS

CLTE

B109993E15

(b) Measure the voltage and resistance according to the

value(s) in the table below.

Standard voltage

Tester Connection Condition Specified Condition

E11-3 (CLTB) - E11-6

(CLTE)

Ignition switch off Below 1 V

Ignition switch on (IG) 10 to 14 V

Standard resistance

Tester Connection Condition

E11-6 (CLTE) - Body ground Always Below 1 Ω

NG

REPLACE INSTRUMENT PANEL JUNCTION

Specified

Condition

BLOCK ASSEMBLY

(a) Reconnect the automatic light control sensor connector.

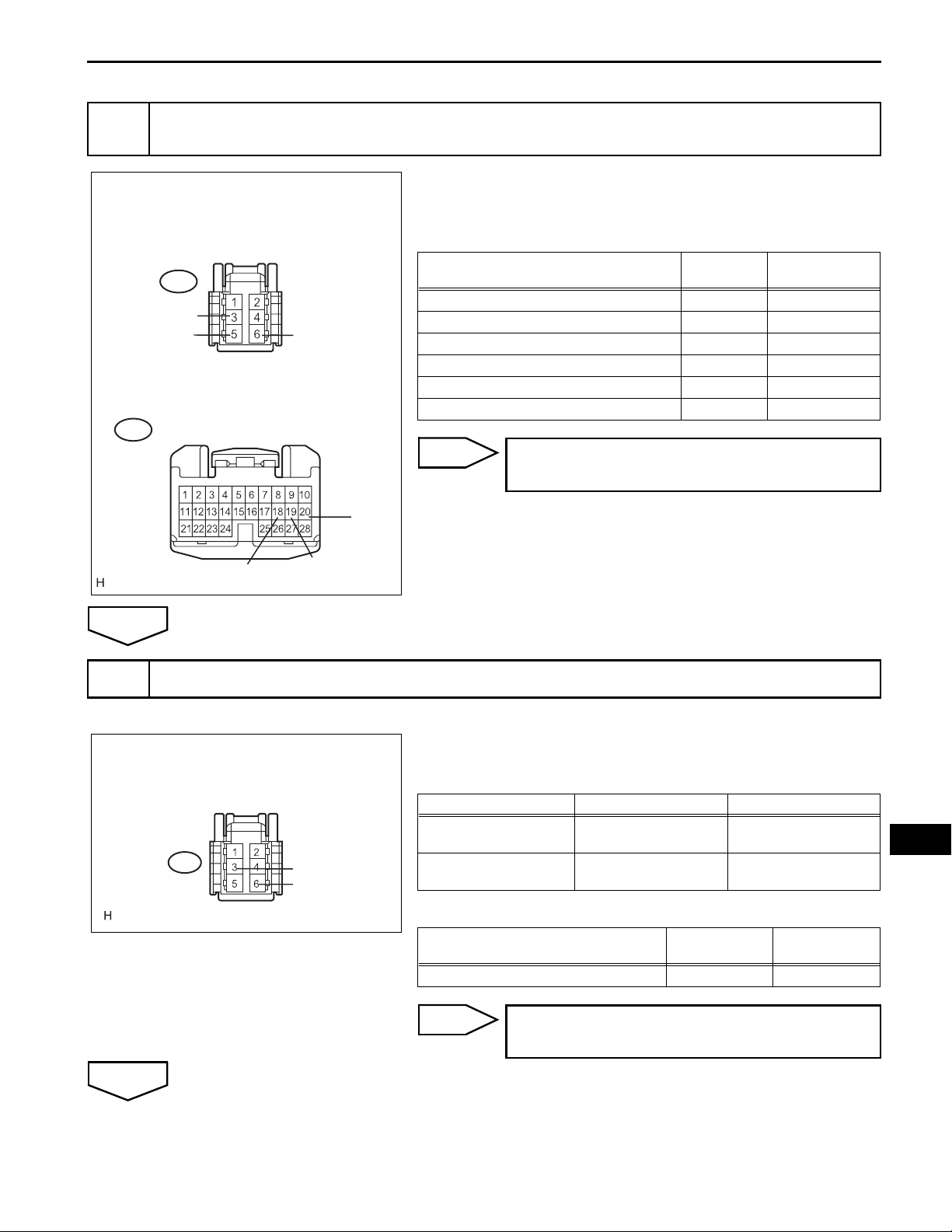

(b) Connect an oscilloscope to the automatic light control

sensor connector.

LI

OK

E11

CLTE

CLTS

E121468E03

(c) Check the waveform.

OK

Tester

Connection

A

GND

E11-6 (CLTE) -

E11-4 (CLTS)

Tool Setting Condition

Ignition switch

5 V/DIV., 5 ms./

DIV.

on (IG), light

control switch in

AUTO

Specified

Condition

Correct

waveform is as

shown

HINT:

B113714E01

If the ambient light becomes brighter, width A becomes

narrower.

NG

REPLACE AUTOMATIC LIGHT CONTROL

SENSOR

REPLACE INSTRUMENT PANEL JUNCTION BLOCK ASSEMBLY

LIGHTING – LIGHTING SYSTEM

CHECK HARNESS AND CONNECTOR (MAIN BODY ECU - AUTOMATIC LIGHT CONTROL

6

SENSOR)

(a) Disconnect the E11 automatic light control sensor

Wire Harness Side:

connector.

(b) Disconnect the E6 main body ECU connector.

Automatic Light Control Sensor

E11

CLTE

CLTS

Main Body ECU

E6

CLTB

Standard resistance

Tester Connection Condition

E6-18 (CLTE) - E11-3 (CLTE) Always Below 1 Ω

E6-19 (CLTS) - E11-5 (CLTS) Always Below 1 Ω

E6-20 (CLTB) - E11-6 (CLTB) Always Below 1 Ω

E6-18 (CLTE) - Body ground Always 10 kΩ or higher

E6-19 (CLTS) - Body ground Always 10 kΩ or higher

E6-20 (CLTB) - Body ground Always 10 kΩ or higher

NG

REPAIR OR REPLACE HARNESS OR

CONNECTOR

LI–29

Specified

Condition

CLTE

OK

INSPECT MAIN BODY ECU (INSTRUMENT PANEL JUNCTION BLOCK ASSEMBLY )

7

Wire Harness Side:

Automatic Light Control Sensor

E11

CLTS

CLTE

CLTB

CLTB

E121476E04

B109993E16

(a) Reconnect the main body ECU connector.

(b) Measure the voltage and resistance according to the

value(s) in the table below.

Standard voltage

Tester Connection Condition Specified Condition

E11-6 (CLTB) - E11-3

(CLTE)

E11-6 (CLTB) - E11-3

(CLTE)

Ignition switch off Below 1 V

Ignition switch on (IG) 10 to 14 V

Standard resistance

Tester Connection Condition

E11-3 (CLTE) - Body ground Always Below 1 Ω

Specified

Condition

LI

OK

NG

REPLACE INSTRUMENT PANEL JUNCTION

BLOCK ASSEMBLY

LI–30

8

LIGHTING – LIGHTING SYSTEM

INSPECT AUTOMATIC LIGHT CONTROL SENSOR

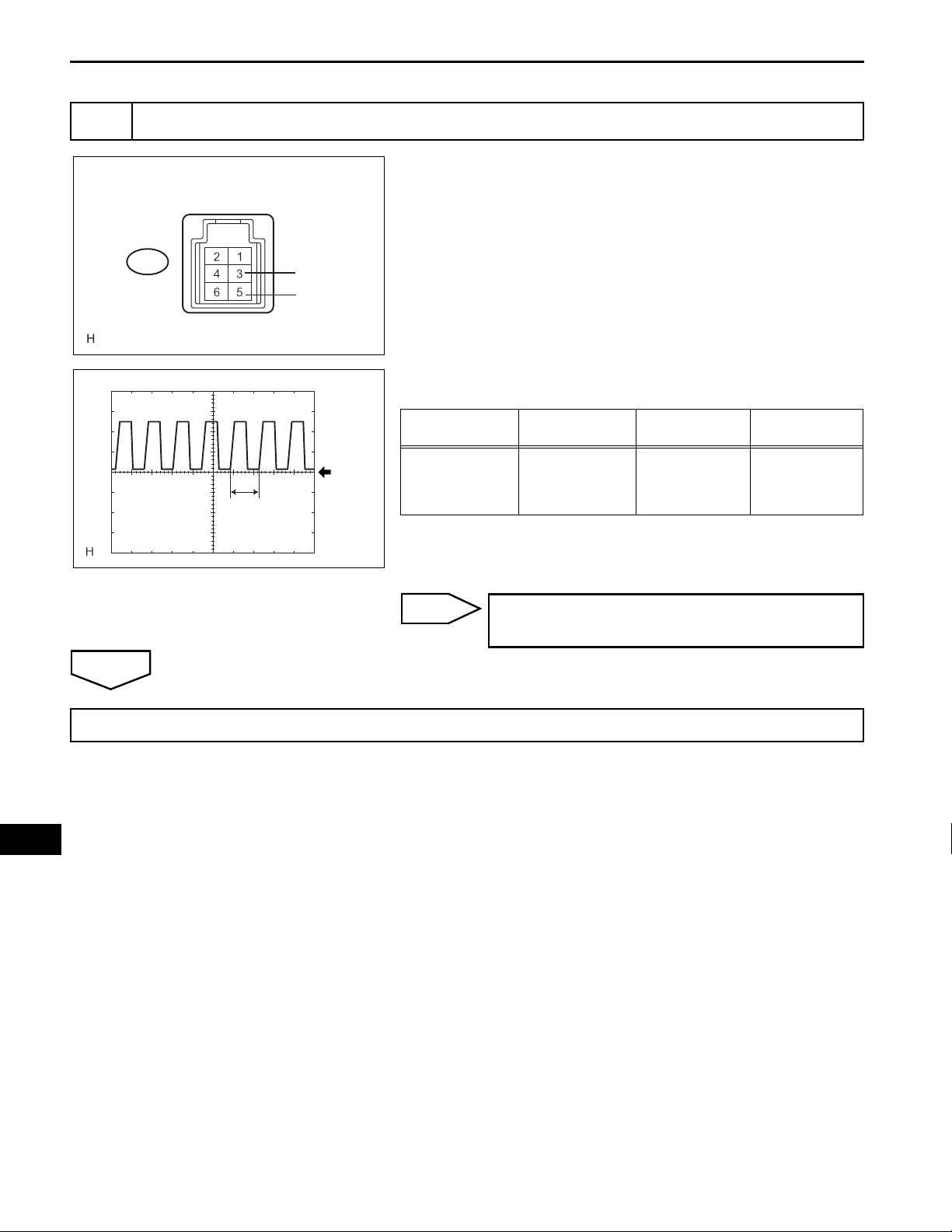

(a) Reconnect the automatic light control sensor connector.

Automatic Light Control Sensor

(b) Connect an oscilloscope to the automatic light control

sensor connector.

OK

E11

CLTE

CLTS

E121468E04

(c) Check the waveform.

OK

Tester

Connection

A

GND

E11-3 (CLTE) -

E11-5 (CLTS)

Tool Setting Condition

Ignition switch

5 V/DIV., 5 ms./

DIV.

on (IG), light

control switch in

AUTO

Specified

Condition

Correct

waveform is as

shown

HINT:

B113714E01

If the ambient light becomes brighter, width A becomes

narrower.

NG

REPLACE AUTOMATIC LIGHT CONTROL

SENSOR

REPLACE INSTRUMENT PANEL JUNCTION BLOCK ASSEMBLY

LI

LIGHTING – LIGHTING SYSTEM

LI–31

Ignition Switch Circuit

DESCRIPTION

This circuit detects the state of the ignition switch or engine switch, and sends it to the main body ECU.

WIRING DIAGRAM

without Smart Key System:

E23

Ignition Switch

ACC

2

IG1

1

ALT

AM1

Main Body ECU

Instrument Panel J/B

1

IA

3

II

4

4

II

9

II

10

IF

AM1

ACC

5

2

5

2

322

1

IG1

3

1

ECU-ACC

ECU IG No. 1

15

ACC

IG

FL MAIN

Battery

LI

E121497E02

LI–32

LIGHTING – LIGHTING SYSTEM

with Smart Key System:

ALT

Instrument Panel J/B

1

IA

3

II

10

IF

9

II

Main Body ECU

ACC

5

2

IG1

5

2

AM2

322

1

3

1

ECU-ACC

ECU-IG No. 1

6

E7

15

ACC

IG

AM1

FL MAIN

Battery

LI

INSPECTION PROCEDURE

E52 Engine SW

5

GND SS1

4

EOM

SS2

22

E7

ACCD

3

IG1D

E7

7

2

17

E7

16

E7

SSW1

SSW2

E121498E01

READ VALUE OF INTELLIGENT TESTER

1

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch on (IG) and turn the intelligent

tester main switch on.

MAIN BODY (MAIN BODY ECU):

Item

ACC SW

IG SW

Measurement Item / Display

Ignition switch or engine switch

ACC signal / ON or OFF

Ignition switch or engine switch

IG signal / ON or OFF

LIGHTING – LIGHTING SYSTEM

(c) Select the items below in the DATA LIST, and read the

display on the intelligent tester.

(Range)

Normal Condition Diagnostic Note

ON: Ignition switch on (IG or

ACC)

OFF: Ignition switch off

ON: Ignition switch on (IG)

OFF: Ignition switch off

OK:

Normal conditions listed above are displayed.

LI–33

-

-

NG

INSPECT ACC RELAY

2

3

5

2

OK

OK

PROCEED TO NEXT CIRCUIT INSPECTION

SHOWN IN PROBLEM SYMPTOMS TABLE

(a) Remove the ACC relay from the instrument panel J/B

3

assembly.

(b) Measure the resistance according to the value(s) in the

table below.

Standard resistance

Tester Connection Specified Condition

10 kΩ or higher

3 - 5

511

2

B087894E05

NG

REPLACE ACC RELAY

Below 1 Ω (When battery voltage is applied to

terminals 1 and 2)

INSPECT NO. 1 IGNITION RELAY

3

3

3

5

2

511

2

OK

B087894E05

(a) Remove the No. 1 ignition relay from the instrument

panel J/B assembly.

(b) Measure the resistance according to the value(s) in the

table below.

Standard resistance

Tester Connection Specified Condition

10 kΩ or higher

NG

3 - 5

REPLACE NO. 1 IGNITION RELAY

Below 1 Ω (When battery voltage is applied to

terminals 1 and 2)

LI

LI–34

4

LIGHTING – LIGHTING SYSTEM

CHECK HARNESS AND CONNECTOR (INSTRUMENT PANEL J/B ASSEMBLY - BATTERY

AND GROUND)

Wire Harness Side:

Instrument Panel J/B Assembly

Wire Harness Side:

Instrument Panel J/B Assembly

IA

E121505E01

IF

E121504E01

(a) Disconnect the IA instrument panel J/B assembly

connector.

(b) Measure the voltage according to the value(s) in the

table below.

Standard voltage

Tester Connection Condition Specified Condition

IA-1 - Body ground Always 10 to 14 V

(c) Disconnect the IF instrument panel J/B assembly

connector.

(d) Measure the resistance according to the value(s) in the

table below.

Standard resistance

Tester Connection Condition Specified Condition

IF-10 - Body ground Always Below 1 Ω

NG

REPAIR OR REPLACE HARNESS OR

CONNECTOR

OK

CHECK VEHICLE CONDITION

5

(a) Check the vehicle condition.

Result

Condition Proceed to

without Smart Key System A

with Smart Key System B

LI

B

Go to step 8

A

LIGHTING – LIGHTING SYSTEM

CHECK HARNESS AND CONNECTOR (INSTRUMENT PANEL J/B ASSEMBLY - IGNITION

6

SWITCH)

LI–35

Wire Harness Side:

Instrument Panel J/B Assembly

Ignition Switch

IG1

ACC

OK

II

E23

AM1

E121503E01

(a) Disconnect the E23 ignition switch connector.

(b) Disconnect the II instrument panel J/B assembly

connector.

(c) Measure the resistance according to the value(s) in the

table below.

Standard resistance

Tester Connection Condition Specified Condition

II-3 - E23-2 (ACC) Always Below 1 Ω

II-4 - E23-4 (AM1) Always Below 1 Ω

II-9 - E23-1 (IG1) Always Below 1 Ω

II-3 - Body ground Always 10 kΩ or higher

II-4 - Body ground Always 10 kΩ or higher

II-9 - Body ground Always 10 kΩ or higher

NG

REPAIR OR REPLACE HARNESS OR

CONNECTOR

INSPECT IGNITION SWITCH

7

(a) Inspect the ignition switch (See page ST-155)

OK:

Ignition switch is normal.

NG

OK

REPLACE INSTRUMENT PANEL J/B ASSEMBLY

REPLACE IGNITION SWITCH

LI

LI–36

8

LIGHTING – LIGHTING SYSTEM

CHECK HARNESS AND CONNECTOR (BATTERY - MAIN BODY ECU)

Wire Harness Side:

Main Body ECU

E7

OK

CHECK HARNESS AND CONNECTOR (INSTRUMENT PANEL J/B ASSEMBLY - MAIN

9

BODY ECU)

Wire Harness Side:

Instrument Panel J/B Assembly

Main Body ECU

AM1

II

E121506E01

(a) Disconnect the E7 main body ECU connector.

(b) Measure the voltage according to the value(s) in the

table below.

Standard voltage

Tester Connection Condition Specified Condition

E7-6 (AM1) - Body

ground

NG

REPAIR OR REPLACE HARNESS OR

Always 10 to 14 V

CONNECTOR

(a) Disconnect the E7 main body ECU connector.

(b) Disconnect the II instrument panel J/B assembly

connector.

(c) Measure the resistance according to the value(s) in the

table below.

Standard resistance

Tester Connection Condition Specified Condition

II-3 - E7-22 (ACCD) Always Below 1 Ω

II-9 - E7-3 (IG1D) Always Below 1 Ω

II-3 - Body ground Always 10 kΩ or higher

II-9 - Body ground Always 10 kΩ or higher

LI

OK

E7

E121484E02

NG

REPAIR OR REPLACE HARNESS OR

CONNECTOR

LIGHTING – LIGHTING SYSTEM

LI–37

10

CHECK HARNESS AND CONNECTOR (ENGINE SWITCH - MAIN BODY ECU AND BODY

GROUND)

Wire Harness Side:

Engine Switch

SS2

Main Body ECU

SS1

E52

E7

SSW1

(a) Disconnect the E52 engine switch connector.

(b) Disconnect the E7 main body ECU connector.

(c) Measure the resistance according to the value(s) in the

table below.

Standard resistance

Tester Connection Condition Specified Condition

E52-7 (SS1) - E7-17 (SSW1) Always Below 1 Ω

E52-2 (SS2) - E7-16 (SSW2) Always Below 1 Ω

E52-5 (GND) - Body ground Always 10 kΩ or higher

E52-4 (EOM) - Body ground Always 10 kΩ or higher

NG

REPAIR OR REPLACE HARNESS OR

CONNECTOR

SSW2

E121502E01

OK

11

INSPECT ENGINE SWITCH

(a) Inspect the engine switch (See page ST-153).

OK:

Engine switch is normal.

NG

OK

REPLACE INSTRUMENT PANEL J/B ASSEMBLY

REPLACE ENGINE SWITCH

LI

LI–38

LIGHTING – LIGHTING SYSTEM

Headlight Relay Circuit

DESCRIPTION

The main body ECU receives a light control switch HEAD signal from the headlight dimmer switch

assembly, and turns the low beam headlights on. The headlight relay is installed in the power distributor

(engine room J/B assembly).

WIRING DIAGRAM

Main Body ECU

Engine Room J/B

1

1G

FL MAIN

H-LP (LL)

H-LP (RL)

H-LP (LL)

H-LP (RL)

A49

Headlight (RH Low)

12

A45

Headlight (LH Low)

9

1D

4

1B

5

1B

Instrument Panel J/B

3

ID

HRLY

8

LI

Battery

INSPECTION PROCEDURE

PERFORM ACTIVE TEST BY INTELLIGENT TESTER

1

12

E121488E01

(a) Connect the intelligent tester to the DLC3.

MAIN BODY (MAIN BODY ECU):

Item Test Details Diagnostic Note

HEAD RELAY Headlight Relay ON / OFF -

LIGHTING – LIGHTING SYSTEM

(b) Turn the ignition switch on (IG) and turn the intelligent

tester main switch on.

(c) Select the item below in the ACTIVE TEST and then

check that the relay operates.

OK:

Headlight relay operates. (Low beam headlights

illuminate.)

LI–39

OK

PROCEED TO NEXT CIRCUIT INSPECTION

SHOWN IN PROBLEM SYMPTOMS TABLE

NG

INSPECT INSTRUMENT PANEL JUNCTION BLOCK ASSEMBLY

2

(a) Measure the voltage according to the value(s) in the

Instrument Panel J/B Assembly

table below.

Standard voltage

ID

HRLY

E121528E01

Tester Connection Condition Specified Condition

ID-3 (HRLY) - Body

ground

OK

Go to step 6

Light control switch

OFF → HEAD

NG

CHECK HARNESS AND CONNECTOR (BATTERY - ENGINE ROOM J/B ASSEMBLY)

3

10 to 14 V → Below 1 V

Wire Harness Side:

Engine Room

J/B Assembly

OK

INSPECT ENGINE ROOM J/B BLOCK ASSEMBLY

4

(a) Disconnect the 1G engine room J/B assembly connector .

(b) Measure the voltage according to the value(s) in the

table below.

Standard voltage

1

1G

B074501E17

Tester Connector Condition Specified Condition

1G - Body ground Always 10 to 14 V

NG

REPAIR OR REPLACE HARNESS OR

CONNECTOR

LI

(a) Reconnect the 1G engine room J/B assembly connector.

LI–40

Engine Room J/B Assembly

1D

LIGHTING – LIGHTING SYSTEM

(b) Disconnect the 1D engine room J/B assembly connector.

(c) Measure the voltage according to the value(s) in the

table below.

Standard voltage

Tester Connection Condition Specified Condition

1D-9 - Body ground Always 10 to 14 V

OK

CHECK HARNESS AND CONNECTOR (ENGINE ROOM J/B ASSEMBLY - INSTRUMENT

5

PANEL J/B ASSEMBLY)

Wire Harness Side:

Instrument Panel J/B Assembly

HRLY

OK

E121531E01

ID

E121479E03

NG

REPLACE ENGINE ROOM JUNCTION

BLOCK ASSEMBLY (POWER DISTRIBUTOR)

(a) Reconnect the 1D engine room J/B assembly connector.

(b) Disconnect the ID instrument panel J/B assembly

connector.

(c) Measure the voltage according to the value(s) in the

table below.

Standard voltage

Tester Connection Condition Specified Condition

ID-3 (HRLY) - Body

ground

NG

REPAIR OR REPLACE HARNESS OR

Always 10 to 14 V

CONNECTOR

REPLACE INSTRUMENT PANEL JUNCTION BLOCK ASSEMBLY

LI

LIGHTING – LIGHTING SYSTEM

INSPECT ENGINE ROOM JUNCTION BLOCK ASSEMBLY

6

LI–41

Power Distributer (Engine Room J/B)

H-LP (RL)

Terminal

H-LP (LL)

Terminal

OK

E121533E01

(a) Remove the H-LP (RL) fuse and H-LP (LL) fuse from the

engine room J/B assembly.

(b) Measure the voltage between the loading slot of each

fuse and body ground.

Standard voltage

Tester Connection Condition Specified Condition

H-LP (RL) Terminal -

Body ground

H-LP (LL) Terminal -

Body ground

NG

REPLACE ENGINE ROOM JUNCTION

Light control switch in

HEAD

Light control switch in

HEAD

10 to 14 V

10 to 14 V

BLOCK ASSEMBLY (POWER DISTRIBUTOR)

REPAIR OR REPLACE HARNESS OR CONNECTOR (FUSE - BODY GROUND)

LI

LI–42

LIGHTING – LIGHTING SYSTEM

Headlight (HI-BEAM) Circuit

DESCRIPTION

The main body ECU receives dimmer switch HIGH signal and light control switch HEAD signal from the

headlight dimmer switch assembly, and turns the high beam headlights on.

HINT:

When a short circuit occurs between the power distributor (engine room J/B assembly) and high beam

headlight, the power distributor stops the DRL relay operation (Fail-safe function).

WIRING DIAGRAM

Light Control Circuit

DRL

H-LP (LH)

H-LP (RH)

8

1D

9

1D

11

1E

2

1B

3

1B

1

1G

Main Body ECU

Instrument Panel J/BPower Distributor (Engine Room J/B)

9

ID

3

ID

11

8

DRL

HRLY

LI

FL MAIN

Battery

A29

Headlight (RH High)

12

A8

Headlight (LH High)

1

2

E121490E01

INSPECTION PROCEDURE

PERFORM ACTIVE TEST BY INTELLIGENT TESTER

1

MAIN BODY (MAIN BODY ECU):

Item Test Details Diagnostic Note

HEAD LIGHT (HI) High beam headlights ON / OFF -

LIGHTING – LIGHTING SYSTEM

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch on (IG) and turn the intelligent

tester main switch on.

(c) Select the item below in the ACTIVE TEST and then

check that the relay operates.

OK:

Relay operates. (High beam headlights illuminate.)

LI–43

OK

PROCEED TO NEXT CIRCUIT INSPECTION

SHOWN IN PROBLEM SYMPTOMS TABLE

NG

INSPECT INSTRUMENT PANEL JUNCTION BLOCK ASSEMBLY

2

(a) Measure the voltage according to the value(s) in the

Instrument Panel J/B Assembly

table below.

Standard voltage

ID

HRLY DRL

E121528E02

Tester Connection Condition Specified Condition

ID-3 (HRLY) - Body

ground

ID-9 (DRL) - Body

ground

OK

Go to step 6

Light control switch

OFF → HEAD

Light control switch in

HEAD, dimmer switch

LOW → HIGH

10 to 14 V → Below 1 V

10 to 14 V → Below 1 V

NG

CHECK HARNESS AND CONNECTOR (ENGINE ROOM J/B ASSEMBLY - BATTERY AND

3

BODY GROUND)

LI

Wire Harness Side:

Engine Room

J/B Assembly

(a) Disconnect the 1G engine room J/B assembly connector .

(b) Measure the voltage according to the value(s) in the

table below.

Standard voltage

1

1G

B074501E17

Tester Connection Condition Specified Condition

1G-1 - Body ground Always 10 to 14 V

LI–44

LIGHTING – LIGHTING SYSTEM

Wire Harness Side:

Engine Room J/B Assembly

OK

INSPECT ENGINE ROOM JUNCTION BLOCK ASSEMBLY

4

Engine Room J/B Assembly

1D

1E

E121481E01

(c) Disconnect the 1E engine room J/B assembly connector.

(d) Measure the resistance according to the value(s) in the

table below.

Standard resistance

Tester Connection Condition Specified Condition

1E-11 - Body ground Always Below 1 Ω

NG

REPAIR OR REPLACE HARNESS OR

CONNECTOR

(a) Reconnect the 1G and 1E engine room J/B assembly

connectors.

(b) Disconnect the 1D engine room J/B assembly connector.

(c) Measure the voltage according to the value(s) in the

table below.

Standard voltage

Tester Connection Condition Specified Condition

1D-8 - Body ground Always 10 to 14 V

1D-9 - Body ground Always 10 to 14 V

LI

OK

CHECK HARNESS AND CONNECTOR (ENGINE ROOM J/B ASSEMBLY - INSTRUMENT

5

PANEL J/B ASSEMBLY)

Wire Harness Side:

Instrument Panel J/B Assembly

HRLY

DRL

E121531E01

ID

E121479E02

NG

REPLACE ENGINE ROOM JUNCTION

BLOCK ASSEMBLY (POWER DISTRIBUTOR)

(a) Reconnect the 1D engine room J/B assembly connector.

(b) Disconnect the ID instrument panel J/B connector.

(c) Measure the voltage according to the value(s) in the

table below.

Standard voltage

Tester Connection Condition Specified Condition

ID-3 (DRL) - Body

ground

ID-9 (HRLY) - Body

ground

NG

REPAIR OR REPLACE HARNESS OR

Always 10 to 14 V

Always 10 to 14 V

CONNECTOR

OK

REPLACE INSTRUMENT PANEL JUNCTION BLOCK ASSEMBLY

LIGHTING – LIGHTING SYSTEM

CHECK HARNESS AND CONNECTOR (SHORT IN RELAY-DRIVEN CIRCUIT)

6

LI–45

Power Distributor (Engine Room J/B)

H-LP(RH)

H-LP(LH)

NG

E121471E01

(a) Remove the H-LP (RH) fuse from the engine room J/B

assembly.

(b) Turn the light control switch to the HEAD position and

turn the dimmer switch to the HIGH position.

(c) Check if the high beam headlight LH illuminates.

(d) Turn the dimmer switch to the LOW position.

(e) Install the H-LP (RH) fuse and remove the H-LP (LH)

fuse.

(f) Turn the dimmer switch to the HIGH position.

(g) Check if the high beam headlight RH illuminates.

OK:

Either high beam headlight LH or RH illuminates.

OK

REPAIR OR REPLACE HARNESS OR

CONNECTOR (SHORT CIRCUIT BETWEEN

FUSE AND BULB)

INSPECT ENGINE ROOM JUNCTION BLOCK ASSEMBLY

7

H-LP (LH)

Terminal

H-LP (RH)

Terminal

E121532E01

(a) Remove the H-LP (RH) fuse and H-LP (LH) fuse from

the engine room J/B assembly.

(b) Measure the voltage between the loading slot of each

fuse and body ground.

Standard voltage

Tester Connection Condition Specified Condition

H-LP (RH) Terminal -

Body ground

H-LP (LH) Terminal -

Body ground

NG

REPLACE ENGINE ROOM JUNCTION

Light control switch in

HEAD and dimmer

switch in HIGH

Light control switch in

HEAD and dimmer

switch in HIGH

10 to 14 V

10 to 14 V

BLOCK ASSEMBLY (POWER DISTRIBUTOR)

LI

LI–46

OK

REP AIR OR REPLACE HARNESS OR CONNECTOR (OPEN CIRCUIT BETWEEN FUSE AND BODY

GROUND)

LIGHTING – LIGHTING SYSTEM

LI

LIGHTING – LIGHTING SYSTEM

Light Control Switch Circuit

DESCRIPTION

This circuit detects the condition of the headlight dimmer switch assembly.

LI–51

LI

LI–52

WIRING DIAGRAM

E21

Headlight Dimmer Switch Assembly

Fog SW

OFF

ON

LIGHTING – LIGHTING SYSTEM

LFG BFG

Instrument Panel J/B

5

IG

4

Main Body ECU

13

HF

E7

HU

13

28

E6

FFOG

LI

11

17

3

16

Dimmer

SW

Light

Control

SW

HF HL HU ED

Low

High

Flash

DRL-OFF (USA)

OFF (*1)

Auto

Ta il

Head

THAEL

18

20

19

23

E7

17

E6

21

E7 A

TAIL

HEAD

12

*1: Except USA

E121491E02

INSPECTION PROCEDURE

READ VALUE OF INTELLIGENT TESTER

1

MAIN BODY (MAIN BODY ECU):

Item

DIMMER SW

HIGH FLASHER SW

F FOG LIGHT SW

AUTO LIGHT SW

HEAD LIGHT SW

TAIL LIGHT SW

Measurement Item / Display

Dimmer switch HIGH signal / ON

or OFF

Dimmer switch FLASH signal /

ON or OFF

Front fog light switch signal / ON

or OFF

Light control switch AUTO signal /

ON or OFF

Light control switch HEAD signal /

ON or OFF

Light control switch TAIL signal /

ON or OFF

LIGHTING – LIGHTING SYSTEM

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch on (IG) and turn the intelligent

tester main switch on.

(c) Select the items below in the DATA LIST, and read the

display on the intelligent tester.

(Range)

Normal Condition Diagnostic Note

ON: Dimmer switch in HIGH or

FLASH

OFF: Dimmer switch in neither

HIGH nor FLASH

ON: Dimmer switch in FLASH

OFF: Dimmer switch not in

FLASH

ON: Fog light switch ON

OFF: Fog light switch OFF

ON: Light control switch in AUTO

OFF: Light control switch not in

AUTO

ON: Light control switch in HEAD

OFF: Light control switch not in

HEAD

ON: Light control switch in TAIL or

HEAD

OFF: Light control switch in

neither TAIL nor HEAD

LI–53

-

-

-

-

-

-

OK:

Normal conditions listed above are displayed.

OK

NG

INSPECT HEADLIGHT DIMMER SWITCH ASSEMBLY

2

(a) Inspect the headlight dimmer switch assembly (See

page LI-120).

OK:

Headlight dimmer switch assembly is normal.

NG

OK

PROCEED TO NEXT CIRCUIT INSPECTION

SHOWN IN PROBLEM SYMPTOMS TABLE

LI

REPLACE HEADLIGHT DIMMER SWITCH

ASSEMBLY

LI–54

CHECK HARNESS AND CONNECTOR (INSTRUMENT PANEL J/B ASSEMBLY - SWITCH

3

ASSEMBLY)

Wire Harness Side:

Headlight Dimmer Switch Assembly

BFG

T

LIGHTING – LIGHTING SYSTEM

(a) Disconnect the E21 headlight dimmer switch assembly

connector.

(b) Disconnect the E6 and E7 main body ECU connectors.

(c) Disconnect the IG instrument panel J/B connector.

(d) Measure the resistance according to the value(s) in the

table below.

Standard resistance

LI

LFG

HU

HF

EL

HL HF

A

Main Body ECU

TAIL

A

Main Body ECU

HEAD

E21

H

E7

E6

FFOG

Tester Connection Condition Specified Condition

E21-3 (LFG) - E21-16

(HL)

E21-4 (BFG) - E6-28

(FFOG)

E21-11 (HU) - IG-5 (HU) Always Below 1 Ω

E21-17 (HF) - E7-13 (HF) Always Below 1 Ω

E21-18 (T) - E7-23

(TAIL)

E21-19 (A) - E7-21 (A) Always Below 1 Ω

E21-20 (H) - E6-17

(HEAD)

E21-3 (LFG) - Body

ground

E21-4 (BFG) - Body

ground

E21-11 (HU) - Body

ground

E21-17 (HF) - Body

ground

E21-18 (T) - Body

ground

E21-19 (A) - Body

ground

E21-20 (H) - Body

ground

E21-12 (EL) - Body

ground

Always Below 1 Ω

Always Below 1 Ω

Always Below 1 Ω

Always Below 1 Ω

Always 10 kΩ or higher

Always 10 kΩ or higher

Always 10 kΩ or higher

Always 10 kΩ or higher

Always 10 kΩ or higher

Always 10 kΩ or higher

Always 10 kΩ or higher

Always Below 1 Ω

Instrument Panel J/B Assembly

NG

REPAIR OR REPLACE HARNESS OR

CONNECTOR

HU

IG

E121507E02

OK

REPLACE INSTRUMENT PANEL JUNCTION BLOCK ASSEMBLY

LIGHTING – LIGHTING SYSTEM

LI–47

Front Fog Light Circuit

DESCRIPTION

The main body ECU controls the FOG relay when a signal is received from the headlight dimmer switch

assembly.

WIRING DIAGRAM

Main Body ECU

Instrument Panel Junction Block

TRLY

TAIL

7

3

IL

4

IL

1

IA

ALT

FL MAIN

TAIL

FR FOG

2

3

FOG

1

5

1

5

8

2

3

II

5

ID

1

IC

A1

Fog Light (Front LH)

12

A34

Fog Light (Front RH)

12

4

E7

FFGO

LI

Battery

INSPECTION PROCEDURE

PERFORM ACTIVE TEST BY INTELLIGENT TESTER

1

E121495E02

(a) Connect the intelligent tester to the DLC3.

LI–48

MAIN BODY (MAIN BODY ECU):

Item Test Details Diagnostic Note

F FOG LIGHT RLY Front fog light relay ON / OFF -

LIGHTING – LIGHTING SYSTEM

(b) Turn the ignition switch on (IG) and turn the intelligent

tester main switch on.

(c) Select the item below in the ACTIVE TEST and then

check that the relay operates.

OK:

Front fog light relay operates. (Front fog lights

come on.)

LI

3

2

NG

INSPECT FUSE (FR FOG)

2

OK

INSPECT FOG LIGHT RELAY

3

1

5

1

2

5

3

B060778E87

OK

PROCEED TO NEXT CIRCUIT INSPECTION

SHOWN IN PROBLEM SYMPTOMS TABLE

(a) Remove the FR FOG fuse from the instrument panel J/B

assembly.

(b) Measure the resistance of the fuse.

Standard resistance:

Below 1 Ω

NG

REPLACE FUSE

(a) Remove the front fog light relay from the instrument

panel J/B assembly.

(b) Measure the resistance according to the value(s) in the

table below.

Standard resistance

Tester Connection Specified Condition

10 kΩ or higher

3 - 5

Below 1 Ω (When battery voltage is applied to

terminals 1 and 2)

OK

NG

REPLACE FOG LIGHT RELAY

LIGHTING – LIGHTING SYSTEM

INSPECT INSTRUMENT PANEL JUNCTION BLOCK ASSEMBLY

4

(a) Measure the voltage according to the value(s) in the

Instrument Panel J/B Assembly

table below.

Standard voltage

ID

IC

Tester Connection Condition Specified Condition

IC-1 - Body ground

ID-5 - Body ground

E121539E01

Light control switch in

HEAD, front fog light

switch OFF → ON

Light control switch in

HEAD, front fog light

switch OFF → ON

LI–49

Below 1 V → 10 to 14 V

Below 1 V → 10 to 14 V

OK

REPAIR OR REPLACE HARNESS OR

CONNECTOR (INSTRUMENT PANEL J/B

ASSEMBLY - BODY GROUND)

NG

INSPECT INSTRUMENT PANEL JUNCTION BLOCK ASSEMBLY

5

(a) Measure the voltage according to the value(s) in the

Instrument Panel J/B Assembly

table below.

Standard voltage

IL

E121527E01

Tester Connection Condition Specified Condition

IL-3 - Body ground

NG

REPLACE INSTRUMENT PANEL JUNCTION

Light control switch

OFF → TAIL

Below 1 V → 10 to 14 V

BLOCK ASSEMBLY

OK

CHECK HARNESS AND CONNECTOR (BETWEEN CONNECTOR IL-3 AND CONNECTOR

6

IL-4)

LI

Instrument Panel J/B Assembly

OK

IL

E121527E01

(a) Measure the voltage according to the value(s) in the

table below.

Standard voltage

Tester Connection Condition Specified Condition

IL-4 - Body ground

NG

REPAIR OR REPLACE HARNESS OR

Light control switch

OFF → TAIL

Below 1 V → 10 to 14 V

CONNECTOR

LI–50

7

LIGHTING – LIGHTING SYSTEM

INSPECT INSTRUMENT PANEL JUNCTION BLOCK ASSEMBLY

(a) Disconnect the II instrument panel J/B assembly

Instrument Panel J/B Assembly

connector.

(b) Measure the voltage according to the value(s) in the

II

table below.

Standard voltage

Tester Connection Condition Specified Condition

II-8 - Body ground

Light control switch

OFF → TAIL

Below 1 V → 10 to 14 V

OK

CHECK HARNESS AND CONNECTOR (BODY ECU - INSTRUMENT PANEL JUNCTION

8

BLOCK ASSEMBLY)

Wire Harness Side:

Instrument Panel J/B Assembly

Main Body ECU

II

E121526E01

NG

REPLACE INSTRUMENT PANEL JUNCTION

BLOCK ASSEMBLY

(a) Disconnect the E7 main body ECU connector.

(b) Measure the resistance according to the value(s) in the

table below.

Standard resistance

Tester Connection Condition Specified Condition

E7-4 - II-8 Always Below 1 Ω

NG

REPAIR OR REPLACE HARNESS OR

CONNECTOR

FFGO

LI

E7

E121484E01

OK

REPLACE INSTRUMENT PANEL JUNCTION BLOCK ASSEMBLY

LIGHTING – LIGHTING SYSTEM

Door Courtesy Switch Circuit

DESCRIPTION

The main body ECU detects the condition of the door courtesy switches.

WIRING DIAGRAM

LI–55

*2: with Smart Key System*1: without Smart Key System

Instrument Panel J/B

7

IO

11 11

M6

Door Courtesy

Switch (Driver

Side)

O6

Door Courtesy

Switch (Front

Passenger Side)

O10

Door Courtesy

Switch (Rear RH)

N13

Door Courtesy

Switch (Rear LH)

7 (*2)

5 (*1)

Main Body ECU

24

DCTY

E7

21

E6

PCTY

RCTY

E6

LCTY

17

C

INSPECTION PROCEDURE

READ VALUE OF INTELLIGENT TESTER

1

MAIN BODY (MAIN BODY ECU):

Item

D DOR CTY SW

P DOR CTY SW

RR DOR CTY SW

Measurement Item / Display

Driver side door courtesy switch

signal / ON or OFF

Passenger side door courtesy

switch signal / ON or OFF

Rear right door courtesy switch

signal / ON or OFF

(Range)

B110597E05

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch on (IG) and turn the intelligent

tester main switch on.

(c) Select the items below in the DATA LIST, and read the

display on the intelligent tester.

Normal Condition Diagnostic Note

ON: Driver side door is open

OFF: Driver side door is closed

ON: Passenger side door is open

OFF: Passenger side door is

closed

ON: Rear right door is open

OFF: Rear right door is closed

-

-

-

LI

LI–56

LIGHTING – LIGHTING SYSTEM

Item

RL DOR CTY SW

Measurement Item / Display

Rear left door courtesy switch

signal / ON or OFF

NG

INSPECT DOOR COURTESY SWITCH